Whirlpool WDO 93F B K User Manual

Displayed below is the user manual for WDO 93F B K by Whirlpool which is a product in the Cooker Hoods category. This manual has pages.

Related Manuals

EN User and maintenance manual

EN3

IMPORTANT SAFETY INSTRUCTIONS

These instructions are also available on the website: docs.whirlpool.eu

YOUR SAFETY AND THAT OF OTHERS IS PARAMOUNT.

This manual and the appliance itself provide important safety warnings that must be read and heeded at all

times.

This is the safety warning symbol, which alerts users to potential hazards to themselves and others.

All safety messages are preceded by the warning symbol and the following words:

DANGER indicates a hazardous situation which, if not avoided, will cause

serious injury.

WARNING indicates a hazardous situation which, if not avoided, could cause

serious injury.

All safety messages indicate the nature of the potential hazard/warning and how to reduce the risk of injury,

harm and electric shock resulting from improper use of the appliance. Always comply with the following

instructions:

• Installation and maintenance must be carried out by a qualied technician, in compliance with the

manufacturer’s instructions and the local safety regulations. Do not repair or replace any part of the

appliance unless specically stated in the user manual.

• The appliance must be disconnected from the mains before carrying out any kind of installation work.

• It is compulsory to earth the appliance (however, it is not necessary for class II hoods identied by the

symbol on the specications label).

• The power cable must be long enough to connect the appliance to the power supply socket.

• Do not pull on the power cable to unplug the appliance.

• After installation, the electrical components must not be accessible to the user.

• Do not touch the appliance with wet hands and do not operate it when barefoot.

• This appliance may not be used by children (aged 8 and above), persons with any physical, sensory or

mental impairment, or persons lacking experience or knowledge of the appliance, unless they are

supervised or given instruction on how to use it safely and are made aware of the hazards its use might

entail. Children must not play with the appliance. Cleaning and user maintenance must not be carried out

by children unless they are under adult supervision.

• Do not repair or replace any part of the appliance unless specically recommended in the manual. Any

defective parts must be replaced with original spare parts. All other maintenance work must be carried

out by a qualied technician.

• Children must be supervised to ensure that they do not play with the appliance.

• When drilling holes into the wall or ceiling, take care not to damage any electrical wiring and/or

pipework.

• Ventilation ducts must always discharge exhaust air to the outside.

EN4

• Exhaust air must not be discharged through a ue used for extracting fumes produced by gas-burning or

any other fuel-burning appliances; it must have a separate outlet. All national exhaust air regulations

must be observed.

• If the hood is used at the same time as other appliances that use gas or other fuels, the negative pressure

of the room must not exceed 4Pa (4x10-5bar). Please ensure, therefore, that the room is adequately

ventilated.

• The manufacturer does not accept any liability for inappropriate use of the appliance or for incorrect

setting of the controls.

• Regular maintenance and cleaning ensure that the appliance works correctly and achieves optimum

performance. Regularly clean all stubborn surface dirt, to avoid a build-up of grease. Regularly remove

and then clean or replace the lters.

• Failure to observe the instructions for cleaning the hood and cleaning and replacing the lters may result

in a re.

• The extractor hood must never be opened without the grease lters tted and should be regularly

monitored.

• If three or more gas cooking zones are in use, the hood should be set at power setting 2 or higher. This

prevents the build-up of excess heat in the appliance.

• Wear protective gloves when carrying out any installation and maintenance work.

• This product is not suitable for outdoor use.

• When the hob is in use, accessible parts of the hood may become hot.

KEEP THESE INSTRUCTION

EN5

Declaration of Conformity

• This product has been designed, manufactured and marketed in compliance with:

-the ecodesign requirements of European Regulations n. 66/2014, n. 327/2011, n. 244/2009, n. 245/2009, n.1194/2012, n. 2015/1428;

The appliance's electrical safety can only be guaranteed if it is correctly connected to an approved earthing system.

Energy saving tips

• Switch on the hood at the lowest speed setting when you start cooking and allow it to run for a few minutes after you have nished cooking.

• Only increase the speed if there is a lot of smoke or steam and only use the "Boost" setting(s) in extreme situations.

• Replace the carbon lter(s) when necessary, to maintain ecient odour reduction.

• Clean the grease lter(s) when necessary, to maintain eciency.

• Use a pipe with the maximum diameter specied in this manual, to optimise eciency and reduce noise levels to a minimum.

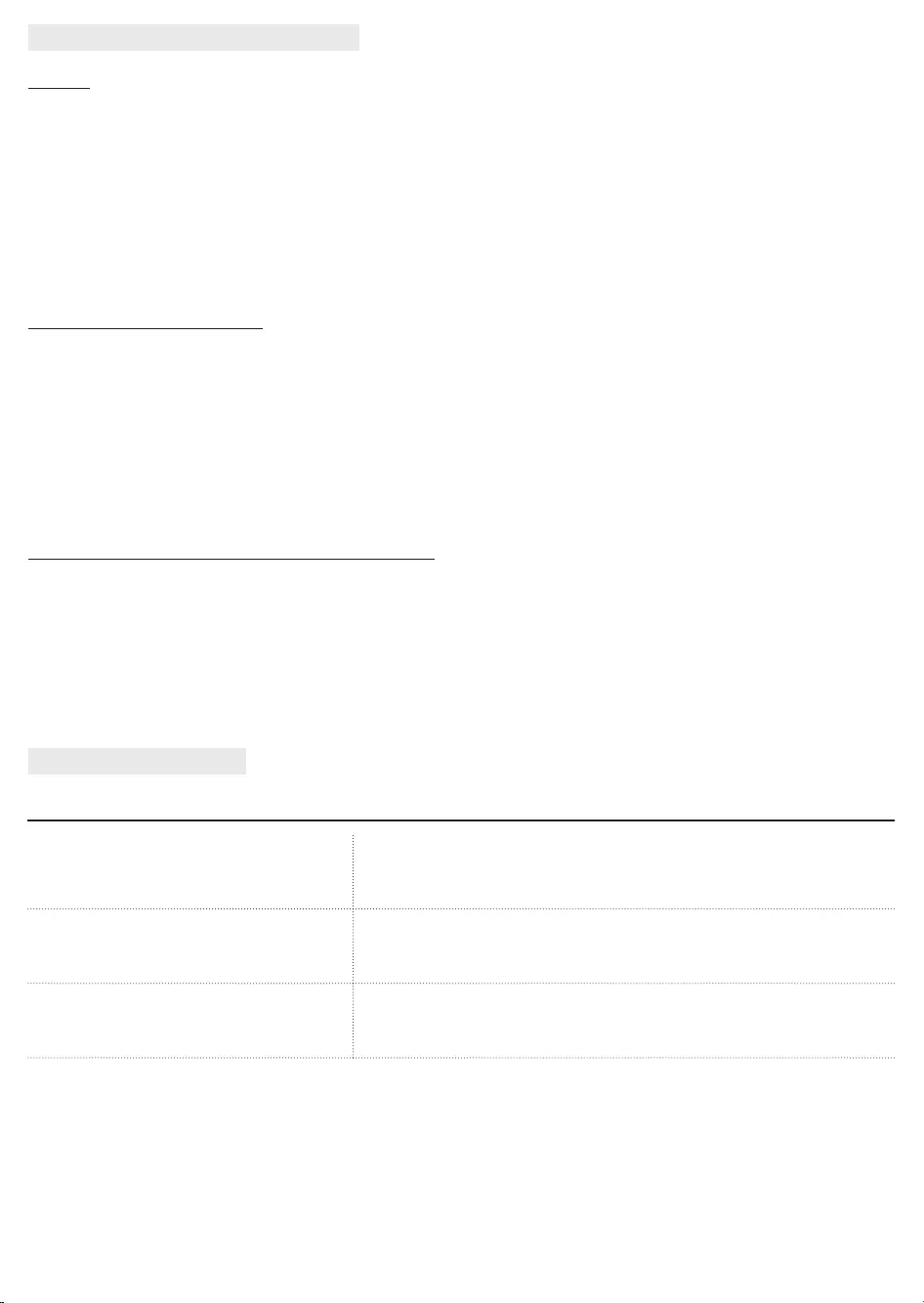

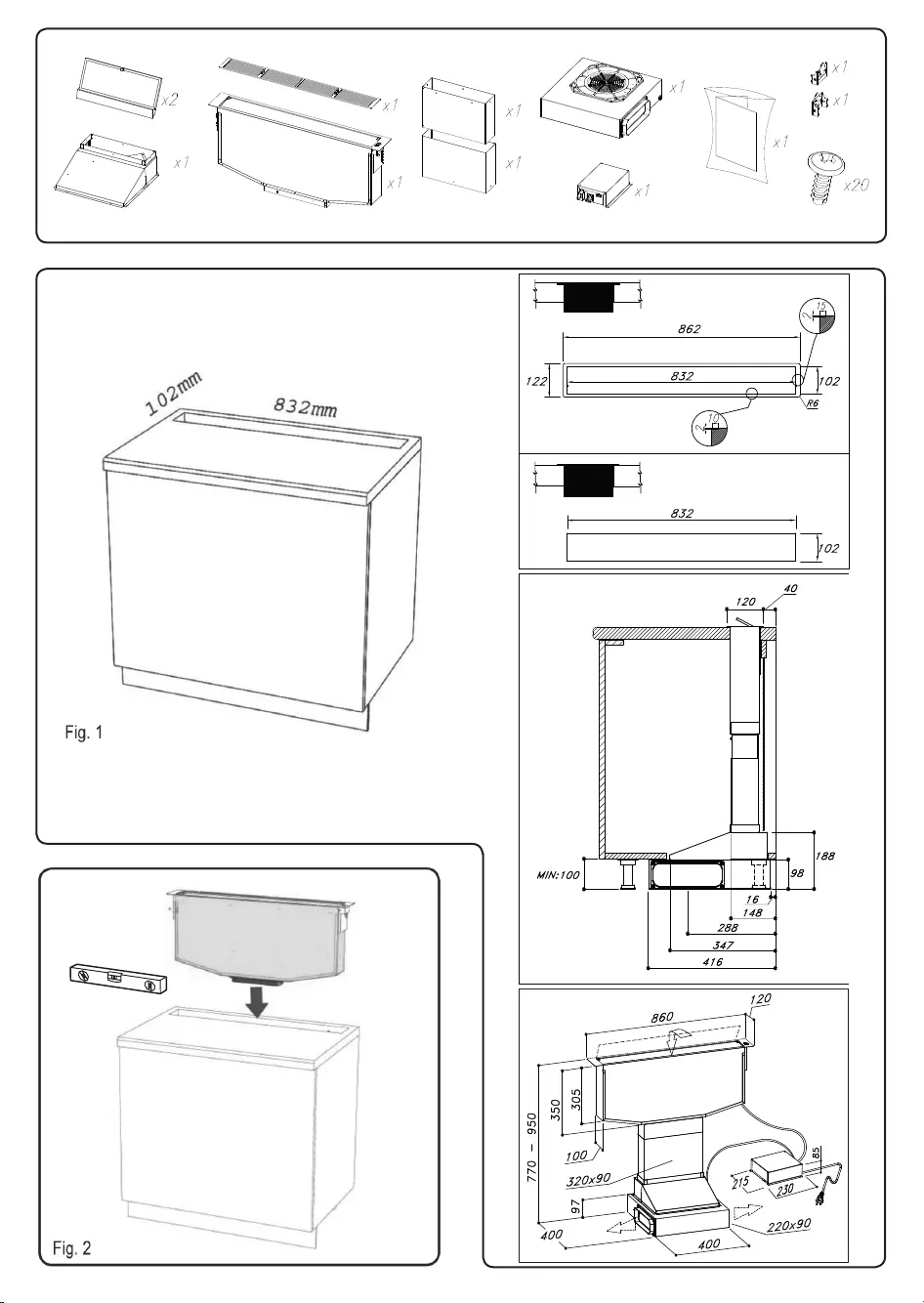

INSTALLATION

After unpacking the appliance, check that it has not been damaged in transit. In the event of problems, contact the dealer or your nearest After-sales Service. To

prevent any damage, only remove the appliance from its polystyrene base at the time of installation.

PREPARING FOR INSTALLATION

WARNING this appliance is heavy; the hood must be lifted and installed by two or more people.

The product must be installed in such a way as to ensure that the hood and electronic components are easily accessible should any maintenance operations need to

be carried out.

Position the metal box containing the electronic components at a distance of not less than 65 cm from the gas hob or in any case 65 cm from the hood suction point.

We recommend installing the metal box containing the electronic components at least 10 cm above oor level (e.g.: oven sides or hob).

Before installation, also check the minimum distances specied in the hob manual.

If the installation instructions for the hob specify a greater distance between the hob and the hood, this distance must be observed.

ELECTRICAL CONNECTION

Check that the voltage specied on the appliance identication plate is the same as the mains voltage.

This information is found on the inside of the hood, under the grease lter.

The power cable (type H05VV-F 3x0.75mm2) must only be replaced by an authorised electrician. Contact an authorised Service Centre.

If the hood is tted with an electric plug, connect the appliance to a socket which complies with current regulations and which is in an accessible location. If no plug

is tted (direct wiring to the mains), or if the socket is not in an accessible location, install a standardised two-pole circuit breaker that will allow complete isolation

from the mains in the event of category III overvoltage, in compliance with the wiring regulations.

If the cable is not tted with a plug, connect the wires according to the following table:

Mains voltage and

frequency Wire connection

220-240V – 50Hz

: yellow/green

N : blue

L : brown

GENERAL RECOMMENDATIONS

Before use

Remove any protective cardboard, transparent lm and adhesive labels from the accessories. Check whether the appliance has been damaged in transit.

During use

Do not place heavy items on the appliance as this may cause damage. Do not expose the appliance to atmospheric agents.

EN6

SAFEGUARDING THE ENVIRONMENT

Disposing of packaging material

The packaging material is 100% recyclable and is marked with the recycling symbol ( ). Do not dispose of the various packaging carelessly, but do so

responsibly and in full compliance with local authority regulations governing waste disposal.

Scrapping the product

-This appliance is marked in compliance with European Directive 2012/19/EU on Waste Electrical and Electronic Equipment (WEEE).

-By ensuring that this product is disposed of correctly, you will help prevent potentially negative consequences for the environment and human health.

-The symbol on the product or on the accompanying documentation indicates that it should not be treated as domestic waste but must be taken to an

appropriate collection centre for the recycling of electrical and electronic equipment.

Scrapping household appliances

• This appliance is manufactured using recyclable or reusable materials. Scrap the appliance in accordance with local regulations on waste disposal. Before

scrapping, cut o the power cable so that the appliance cannot be connected to the mains.

• For further information on the treatment, recovery and recycling of household appliances, contact the competent local authority, the domestic waste

collection service or the shop where you purchased the product.

AFTER-SALES SERVICE

Before calling the After-sales Service:

1. Check whether you can solve the problem yourself by following the suggestions given in the “Troubleshooting guide”.

2. Switch the appliance o and on again to see if the fault persists.

If the fault persists after carrying out the above checks, contact the nearest After-sales Service.

Always provide:

• A brief description of the fault;

• The type and exact model of the appliance;

• The Service number (the number after the word "SERVICE" on the identication plate), located on the inside of the appliance. The Service number is also stated

in the warranty booklet;

• Your full address;

• Your telephone number;

If any repairs are required, please contact an authorised After-sales Service Centre (to ensure that original spare parts are used and repairs are carried out correctly).

EN7

PRODUCT DESCRIPTION

FIRST TIME USE

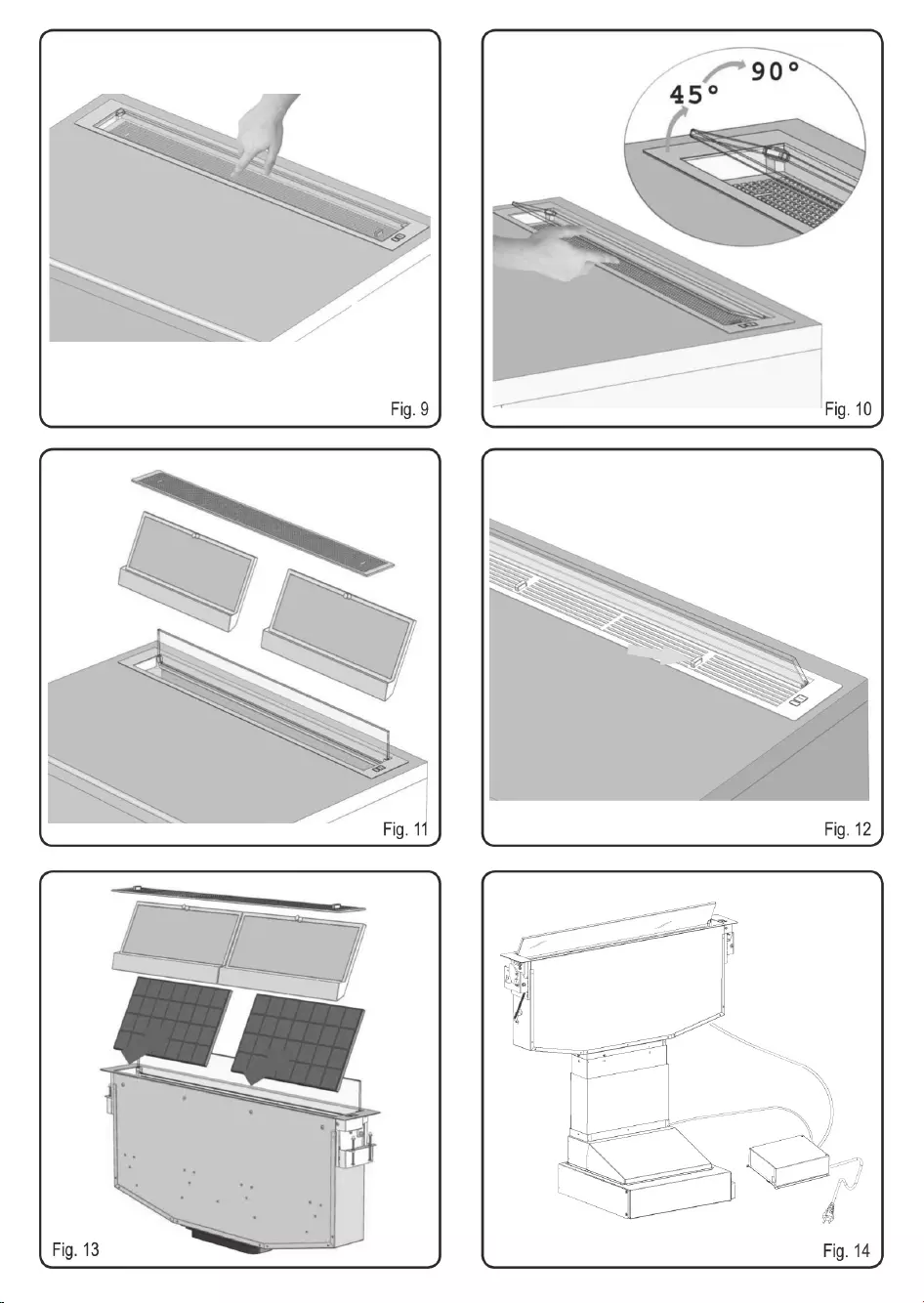

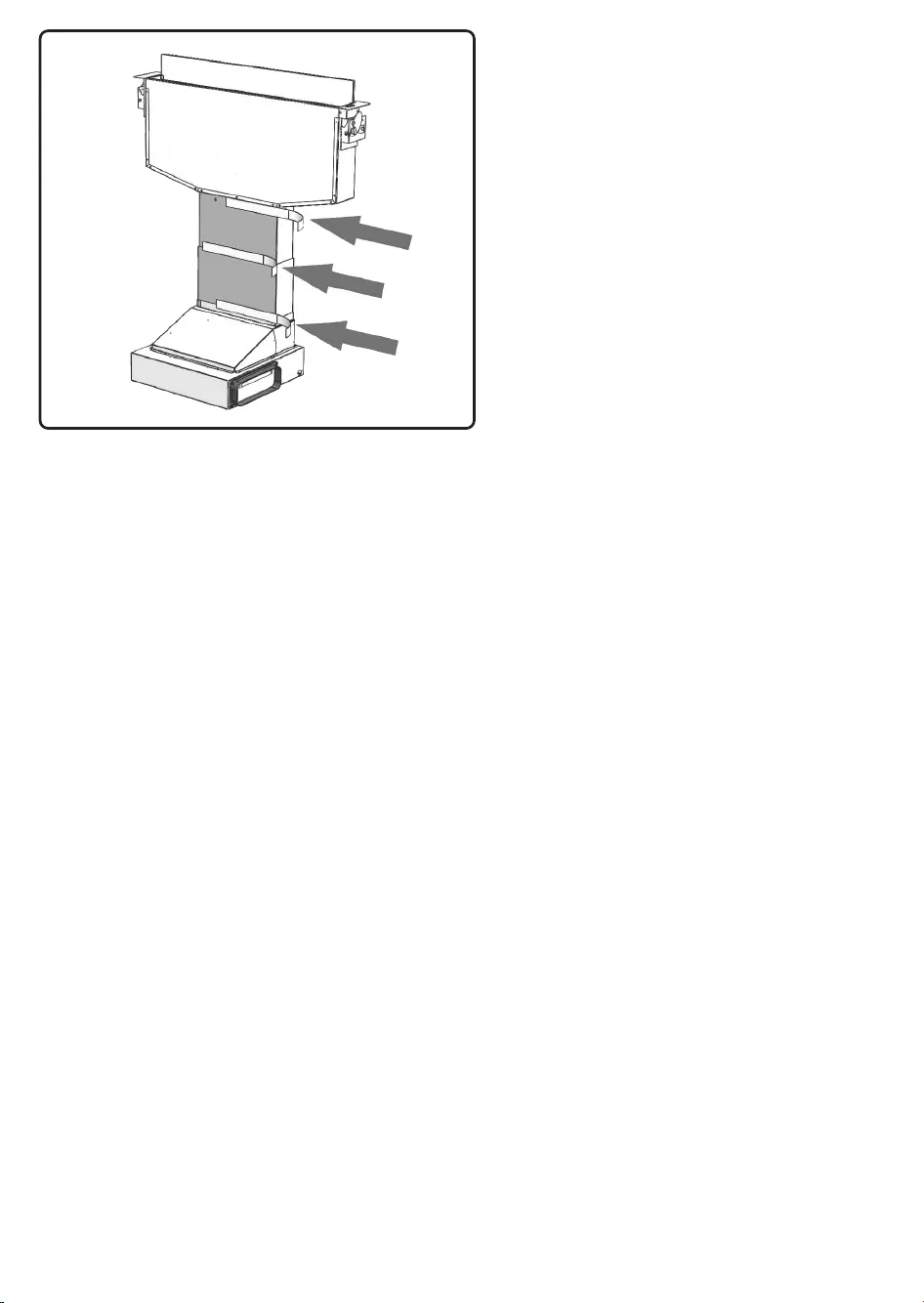

Once you have opened the glass pane, you will need to install the grease lters and the aesthetic grill. The grease lters are inserted as shown in g.11. Place them

inside the product and click them into place. The lters can be removed by following these steps in the reverse order.

To ensure that the product works as it should, open the glass pane as follows.

Push the front part of the pane down as indicated in g.9. This will release the pane and you will have an opening of around 2cm. You will need to turn the pane

until it is at a 45° or 90° opening angle depending on requirements (see gure10).

Once you have opened the glass pane, you can activate the extraction motor.

Air Vent (for the suction versions)

Connect the hood and discharge holes on the walls with a diameter equivalent to the air outlet (connection ange).

Using the tubes and discharge holes on walls with smaller dimensions will cause a diminution of the suction performance and a drastic increase in noise.

Any responsibility in the matter is therefore declined.

! Use a duct of the minimum indispensable length.

! Use a duct with as few elbows as possible (maximum elbow angle: 90°).

! Use an air outlet duct measuring 220 x 90mm, or with an equivalent cross-section, across its entire length.

! Avoid drastic changes in the duct cross-section.

! The company declines any responsibility whenever these regulations are not respected.

Filtering or ducting?

! Your cooker hood is ready to be used in suction version.

To use the hood in ltering version the special lter installation kit must be installed.

Check if the lter installation kit is furnished or must be bought separately.

Please note: If furnished, in certain cases, the additional activated carbon ltering system may be installed on the hood. Information about the conversion of the

hood from suction version to ltering version is present in the Manual “Safety Instructions & Installation”.

Ducting version

In this case the fumes are conveyed outside of the building by means of a special pipe.

ATTENTION! The exhausting pipe is not supplied and must be purchased apart. Diameter of the exhausting pipe must be equal to that of the connection ring.

ATTENTION! If the hood is supplied with active charcoal lter, then it must be removed.

Filter version

The aspirated air will be degreased and deodorised before being fed back into the room.

To use this version of the hood, you will need to purchase the lter installation kit containing long-life carbon lters (g. 13) and a selection of pipes for guiding the

air on one side of the unit.

EN8

CONTROL PANEL

T1. Timer ON/OFF button

T2. Decrease extraction speed (power)/OFF 1 button

T3. ON/increase extraction speed (power) button (1-2-3-intensive)

T3

L2 - L3

T2

L1

T1

T1. Timer ON/OFF button: Press to program automatic switch-o:

Speed 1: 20 minutes

Speed 2: 15 minutes

Speed 3: 10 minutes

Intensive speed: 5 minutes

T2. Decrease extraction speed (power) button

OFF 1: Press to gradually decrease the speed until the hood switches o.

OFF 2: Press and hold at any speed.

T3. ON/increase extraction speed (power) button (1-2-3-intensive).

Intensive speed runs for around 5 minutes and then speed 2 is applied automatically.

Filter saturation indicator

The hood indicates when the lters need servicing:

Grease lter (after approx. every 40hours of use): All the LEDs light up blue.

Activated carbon odour lter (after approx. every 160hours of use): All the LEDs light up blue; LEDs L2 and L3 ash.

Resetting the lter saturation

After servicing the lters, press and hold buttons T1 and T3. LEDs L1, L2 and L3 will ash blue briey before switching o.

Activating the active carbon odour lter saturation indicator.

This indicator is normally deactivated. To activate it, proceed as follows:

With the hood switched o, press and hold buttons T1 and T2 at the same time: L1 will switch on, followed by L2 and L3. Release the buttons. LEDs L2 and L3

will ash briey to show that the indicator has been activated.

To deactivate the carbon lter saturation LED: Repeat the steps described above. LEDs L1, L2 and L3 will switch on. Release the buttons. LEDs L2 and L3 will

switch o to show that the indicator has been deactivated.

EN9

CLEANING AND MAINTENANCE

CLEANING

• Do not use steam-cleaning equipment.

• Disconnect the appliance from the mains.

IMPORTANT: Do not use corrosive or abrasive detergents. If any such products unintentionally come into contact with the appliance, clean the appliance

immediately with a damp cloth. Do not use alcohol.

• Clean the surfaces with a damp cloth. If it is very dirty, add a few drops of washing-up detergent to the water. Finish o with a dry cloth.

IMPORTANT: Do not use abrasive sponges or metallic scrapers or scourers. Over time, these can ruin the enamel surfaces.

• Use detergents specically designed for cleaning the appliance and follow the manufacturer’s instructions.

IMPORTANT: Clean the lters at least once a month to remove oil and grease residue.

MAINTENANCE OF THE GREASE FILTERS

This must be cleaned once a month (or when the lter saturation indication system - if envisaged on the model in possession - indicates this necessity) using non

aggressive detergents, either by hand or in the dishwasher, which must be set to a low temperature and a short cycle.

When washed in a dishwasher, the grease lter may discolour slightly, but this does not aect its ltering capacity.

Open the extractor panel (turn upwards).

Please note: It is not necessary to remove the panel.

Pull out the handle to remove the lter.

Once the lter has been washed and left to dry, proceed in reverse order to ret the lter.

MAINTENANCE OF THE CHARCOAL FILTER (for ltration models only)

This lter retains the unpleasant odours produced during cooking.

The carbon lter can be cleaned every two months using hot water and a suitable detergent. It can also be cleaned in the dishwasher at 65 °C (running a full wash

cycle without anything else inside).

Carefully remove any excess water, then take the pad out of the plastic frame and place it in the oven for 10minutes at 100 °C to dry it completely.

Replace the pad every 3years, or sooner if it appears damaged.

Once you have removed the grease lters, you can insert the carbon lters (g.13) (not provided).

TROUBLESHOOTING

Problem Solutions

The appliance does not work. • Check the mains voltage and whether the appliance is connected to the power supply;

• Check that a speed has been selected;

• Switch the appliance o and on again to see if the fault persists.

The hood is not extracting air suciently. • Check that the air extraction speed is set to the desired level;

• Check that the lters are clean;

• Check the air vents for any obstructions.

The hood has turned o during normal functioning. • Check that the power has not been disconnected;

• Check that the omnipolar disconnection device has not tripped.

EN10

EN11

EN12

Fig. 15

400011307452

Ed. 10/18