3M 2178-XL User Manual

Displayed below is the user manual for 2178-XL by 3M which is a product in the Cable Organizers category. This manual has pages.

Related Manuals

3M™ Fiber Optic Splice Closure

2178-XL & 2178-XL/FR

3M™ Cable Addition Kit 2181-XL and 2181-XL/FR

Instructions

July 2010

78-8130-5055-2-L 3

78-8130-5055-2-L

2

1.0 Contents

1.0 General..........................................................................................................................................3

2.0 KitContents..................................................................................................................................3

3.0 CablePreparation..........................................................................................................................4

4.0 DropCablePreparation.................................................................................................................8

5.0 TrayInstallationandSplicing..................................................................................................... 11

6.0 SpliceClosureAssembly............................................................................................................12

7.0 3M™CableAdditionKit2181-XLand2181-XL/FR.................................................................12

8.0 ClosureAccessories....................................................................................................................13

378-8130-5055-2-L

1.0 General

1.1 The3M™FiberOpticSpliceClosure2178-XLandFlameRetardantSpliceClosure2178-XL/FRhavebeen

developedtoaccommodateupto576singlefusionsplicesand1728massfusionsplices.Theclosureshave

two1.0"portsandtwo1.4"portsoneachend.Newlargertrayshavebeendeveloped,providingmoreroom

forribbonfibersandsplices.

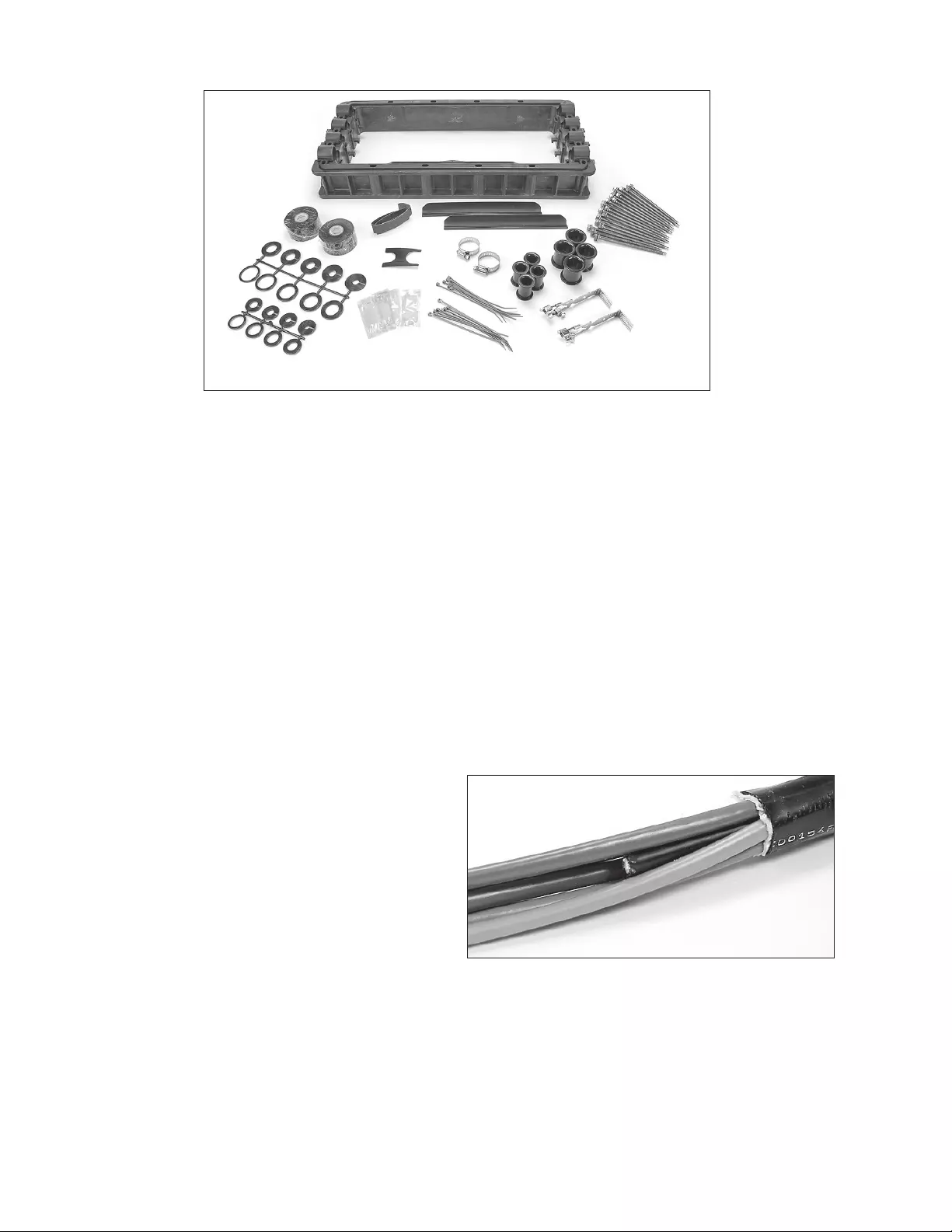

2.0 Kit Contents

Visually inspect all components. If any component is missing or appears damaged, do not install.

Call customer service at 1-800-426-8688 for a replacement product.

2.1 3M™FiberOpticSpliceClosure2178-XLand2178-XL/FRkitcontents:

an

c

d

g

ip

k

o

j

b

m

e

f

l

q

h

a) 1-2178-XLclosurebodywithbolts

b) 4-Strainrelief/strengthmemberbrackets

c) 4-1.4"washertrees

d) 4-1"washertrees

e) 4-1.4"plugs

f) 4-1"plugs

g) 8-Cableties(blue)

h) 8-Cableties(green)

i) 4-3M™DualLock™Fasteners

j) 2-RollsScotch®LinerlessRubberSplicing

Tape130C

k) 4-Packetsofsiliconelubricant

l) 4-1.5"hoseclamps

m) 1-Sheathscuff

n) 1-Traysupportwithstraps

o) 2-3M™SpliceTrays2527withinserts

p) 1-Tapecollargauge

q) 8-K-connectors&screws

78-8130-5055-2-L

4

2.2 3M™CableAdditionKit2181-XLand2181-XL/FRKitContents

a

l

n

b

j

k

f

e

d

h

m

g

i

c

o

a) 1-2181-XLand2181-XL/FRadapterwithgasket

b) 2-Sheathretentioninserts

c) 4-1"washertrees

d) 4-1.4"plug

e) 8-Cableties(blue)

f) 8-Cableties(green)

g) 4-1.4"washertrees

h) 2-RollScotch®LinerlessRubberSplicing

Tape130C

i) 4-Packetofsiliconelubricant

j) 2-1"hoseclamps

k) 1-Sheathscuff

l) 18-Bolts

m) 1-Tapecollargauge

n) 4-1"plugs

o) Slackstorageretainers

2.3 Additionalmaterialsrequired:

Forarmoredsheathcable,use3M™Scotchlok™ShieldBondConnector4460-D/DS.Tobranchsplicein

unusedports,order3M™CableStrainRelief/StrengthMenberBracket2178-XL-XSB-SR-SMC,partno.

80-6113-2343-9.

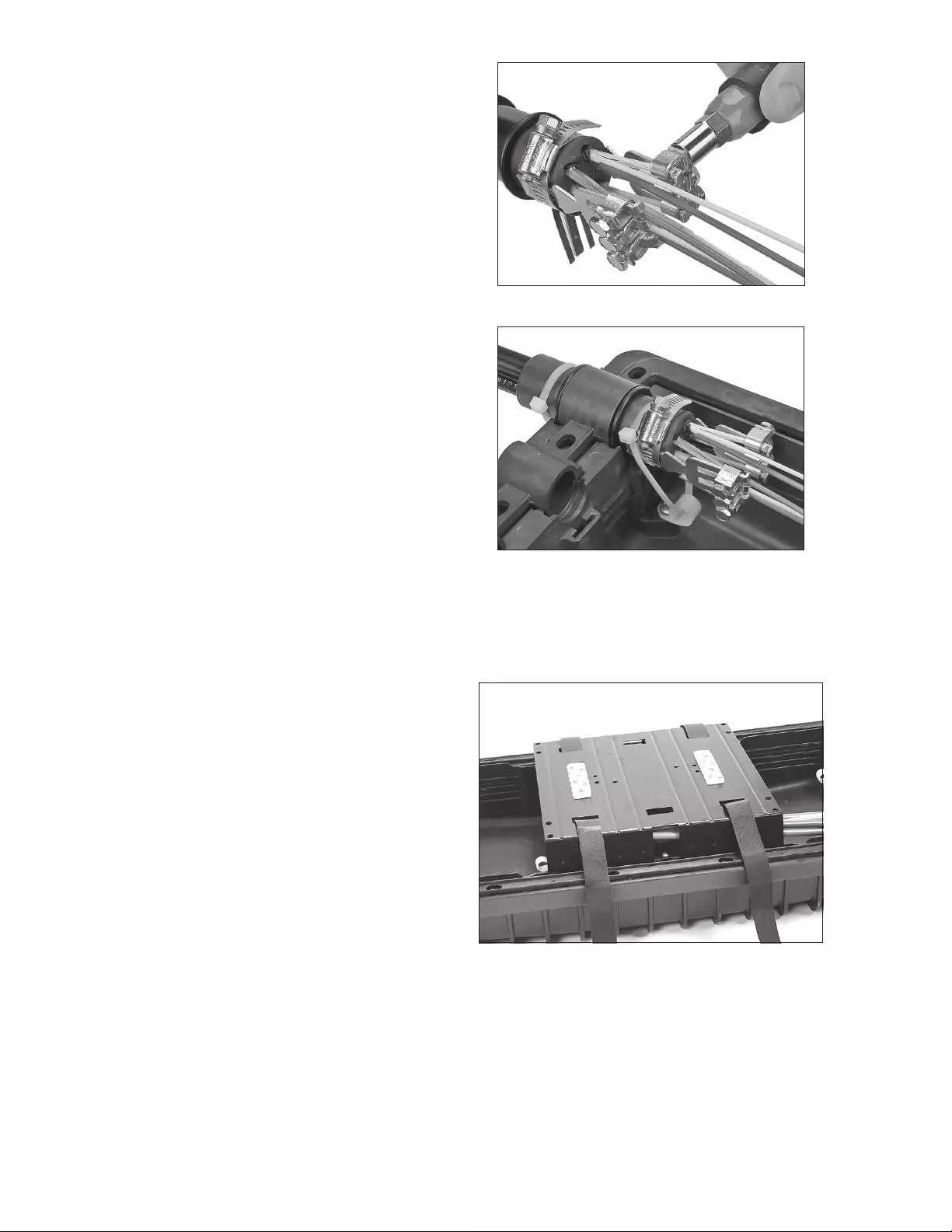

3.0 Cable Preparation

3.1 Determineamountofcableneededforstorage

andsplicing.

3.2 Removesheathandcleanfiberpercompany

practice.

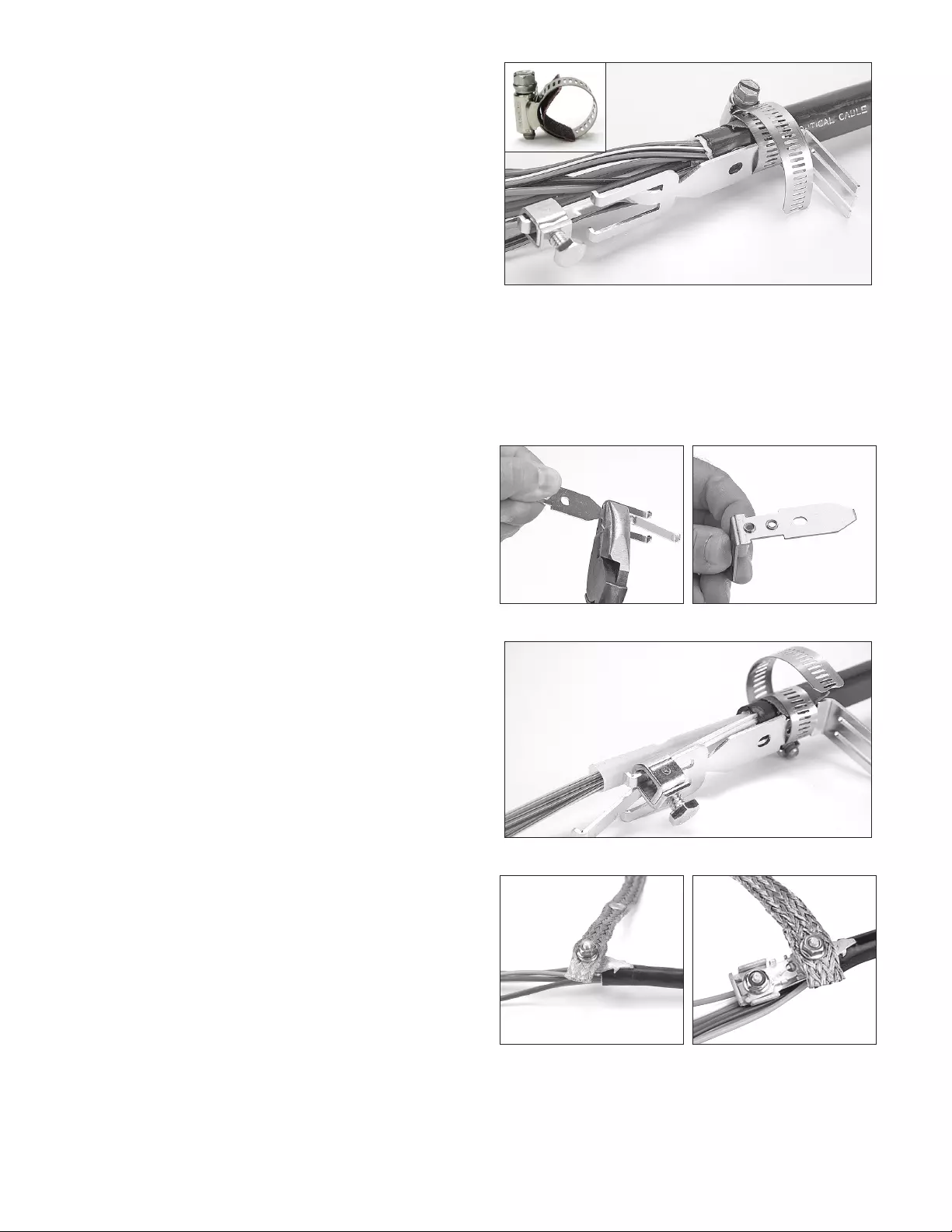

3.3 Scuff6"ofcablesheath,startingatendofsheath.

Figure 1

578-8130-5055-2-L

3.4 Cutasmalllengthoftheunusedsheathscuffand

placeitgritsideinwardinsideofthehoseclamp.

Note: The cut piece of sheath scuff should wrap at

least halfway around the cable sheath, but not

completely around the cable.

3.4.1 Placecableretentionclamponcablesothat

hoseclampwillbe1"(25mm)fromend

ofsheath.

3.4.2 Ifcablehascentralstrengthmember,

assemblestrengthmemberclampontostrain

reliefbracketasshowninFigure2.Mark

andcutthecentralstrengthmemberatend

ofstrengthmemberclamp.Slidecentral

strengthmemberunderretentionlugand

tightenboltto40in-lbs±5in-lbs(4.6N•m

±0.6N•m).Installhoseclampandtighten

to40in-lbs±5in-lbs(4.6N•m±0.6N•m).

Figure 2

3.4.3 Ifcablehasnocentralstrengthmember,

breakoffthethreeprongsusingpliersand

useonlythestrainreliefbracketasshown

inFigure3.

Figure 3

3.4.4 Installhoseclampandtighten.

Figure 4

3.4.5 Forarmoredcables(Figure5),use3M™

Scotchlok™ShieldBondConnector

4460-Dor4460-DS.

Figure5

78-8130-5055-2-L

6

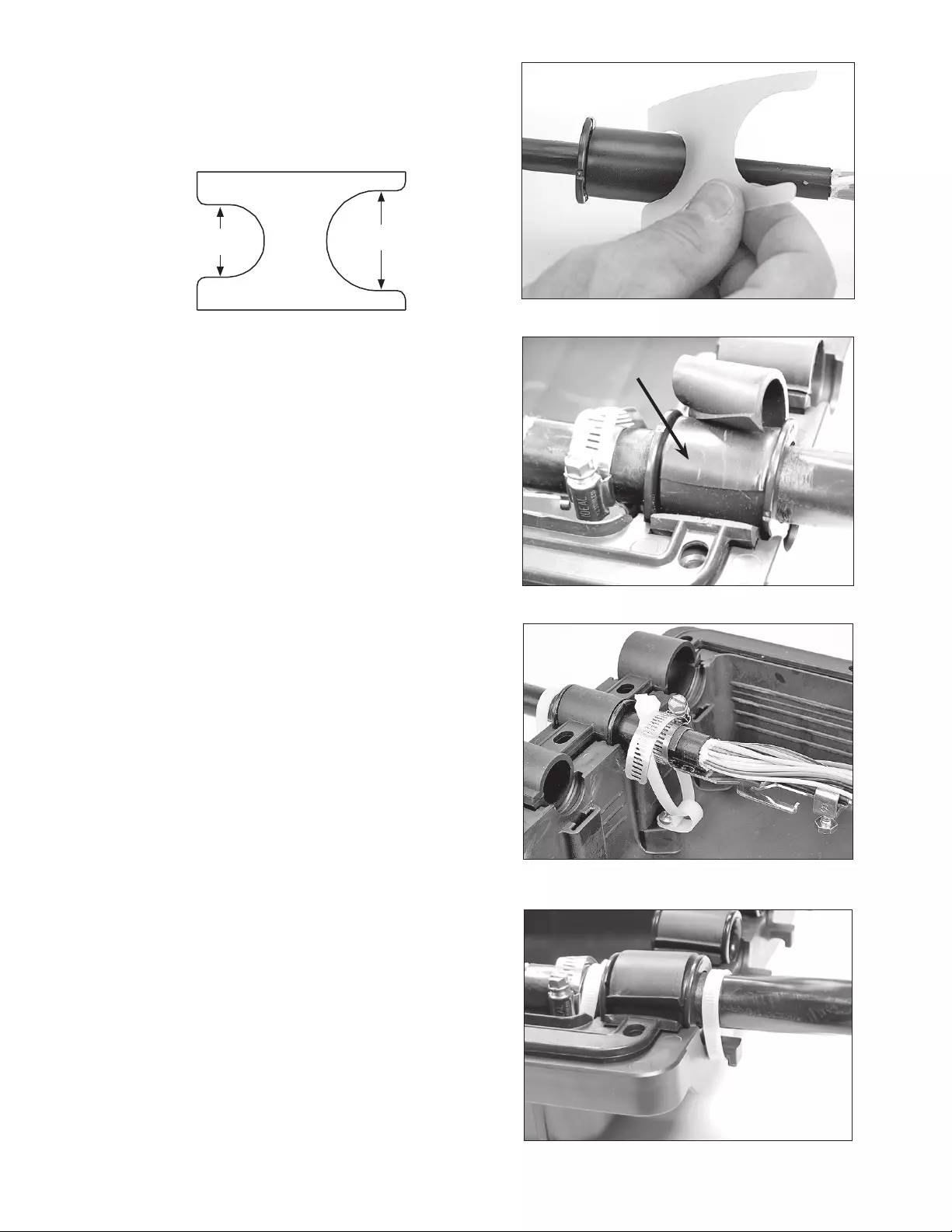

3.5 Placeretentionclampintoplaceintheclosureand

marklocationofgasketedgesoncable.Thiswill

betheareaofthetapecollar,asshowninFigure6.

3.6 Determinethediameterofthescuffedareaof

thecableandchoosetwo(2)appropriatelysized

washersforeachcable.Washerinnerdiameters

shouldbeasclosetothediameterofthecableas

possible.Washersmaybesplitandplacedonto

cable.

3.6.1 Ifdiameterofcableisclosetoeitherendof

themarkedwasherdiameterrangetryboth

sizesandchoosethesnuggestfitavailable.

Forexample,ifcablediametermeasures

1.12,”tryboththe1.0-1.1and1.1-1.2

markedwashers.Selectthewasherwith

thesnuggestfitaroundthecablediameter,

allowingthewashertocloseatthesplit.

Figure 6

3.7 Splitwashersandplaceontocableoneithersideof

theareamarkedfortapecollarbuildup,asshown

inFigure7.

Figure 7

3.8 UsingthesuppliedScotch®LinerlessRubber

SplicingTape130C,buildupthecollarstothe

appropriatediameter.

3.8.1 Stretchtapeslightlytofitbetweenmarked

collarareaasbestaspossible.

Figure 8

778-8130-5055-2-L

3.8.2 Collarsshouldbebuiltupto1.45"diameter

forlargeportand1.05"diameterforthe

smallerport.Usethetapecollargauge

providedinkittomeasureforrequired

diameter.

1.05"end 1.45"end

Figure 9

3.9 Coattapecollarwithsiliconelubricantandinsert

intogasketattheproperport.Insertcableretention

clampintoslotatsametimeandpushdownuntil

cableisinproperalignment.

Note: Insure that washers are properly seated in the

grooves of the case on either side of the gasket.

Note: Carefully follow health and safety

environmental instructions as given on Material

Safety Data Sheet for the silicone lubricant.

Scotch® Linerless

Rubber Splicing Tape 130C

Figure 10

3.10 Usingtwo(2)blackcableties,retaincablesin

portsbyplacingtiesbothinsideandoutsidethe

baseasshowninFigure11and12.(Whitecable

tiesusedforpictureclarityonly.)

Figure 11

Figure 12

78-8130-5055-2-L

8

4.0 Drop Cable Preparation

4.1 Determinehowmanydropcableswillbepassing

through3M™MultiportGrommet.

4.2 Removesheathondropsexposingbuffertubestoa

lengthrequiredpercompanypractice.

4.3 Insertdropsintomultiportgrommetfirstandthen

insertblankplugslast.

Note: A small amount of lubricant provided in kit may

be placed on blank plugs and cable to allow for

ease of installation into multiport grommet.

An additional method to ease installation is to

take sheath scuff supplied in closure kits, and

slightly sand the leading edge of the drop cable

and blank plugs.

4.4 Greaseapproximately2"ofcabledropjacket.

4.5 Insertdrop1"–2"intomultiportgrommetandthen

pullbackout.

4.6 Insertdroptheentirelengthofmultiportgrommet.

4.7 Repeatsteps4.3–4.6fortheblankplugsaswell.

Note: Leave future ports orientated to top of closure

for ease of future installations of drop.

Figure 13

4.8 Placeasmallamountoflubricantonthegasket

insidediameterintheareawhereitsealswith

multiportgrommet.

Note: Carefully follow health and safety environmental

instructions as given on Material Safety Data

Sheet for the silicone lubricant.

Figure 14

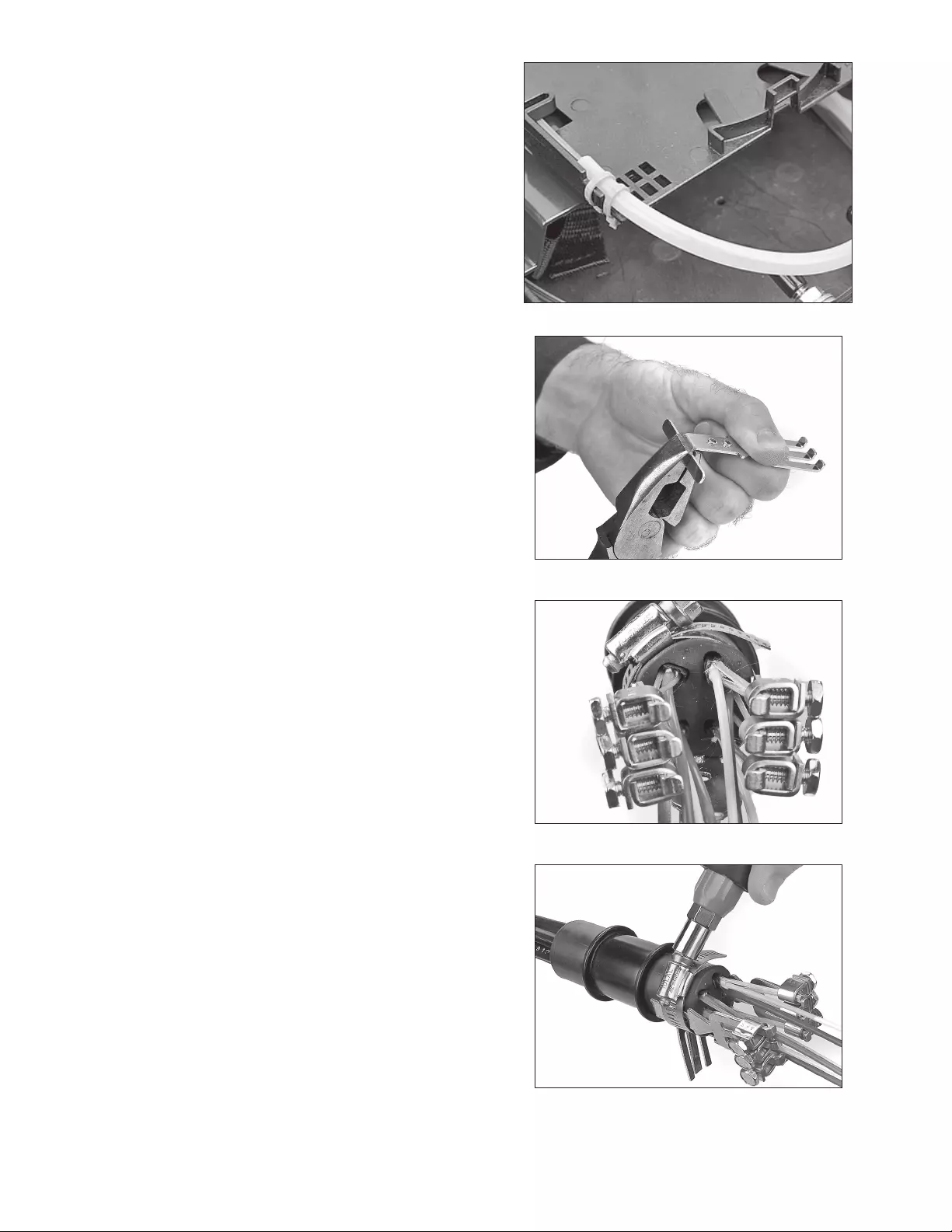

4.9 Forribbontransitiontotrayapplications,secure

thetransitiontubetothebracketmountedinbase.

Figure 15

978-8130-5055-2-L

4.10 Whentraysupportandtrayareinplace,mount

theotherendofthetransitiontubetothetray.

Figure 16

4.11 Breakoffthetabfeatureasshownonbothcable

strainreliefbrackets.

Figure 17

4.12 Placecablestrainreliefbracketsoneithersideof

thegrommet,withthreedropsoneithersideas

shown.Insertcablestrengthmembersintosmall

K-connectors.

Figure 18

4.13 Securecablestrainreliefbracketsandthestrain

reliefbracketfromtheclosuretothegrommetwith

thehoseclampasshown.Tightenthehoseclamp

to40in.-lbs.±5in.-lbs.(4.6N•m±0.6N•m).

Note: Ensure that extruded retention feature of strain

relief has sufficient contact with surface of

grommet.

Figure 19

78-8130-5055-2-L

10

4.14 TightenthesixK-connectornutsto

40in.-lbs.±5in.-lbs.(4.6N•m±0.6N•m)each.

Figure 20

4.15 Placecablestrainreliefand3M™Multiport

Grommetassemblyintoclosure.

4.16 Placecabletiesaroundmultiportgrommet

assemblyinsideandoutasshowninFigure21.

Note: White cable ties are shown for clarity.

4.17 Followclosureinstructionforallotherpreparation

leadinguptoandincludingsealingclosure.

Figure 21

5.0 Tray Installation and Splicing

5.1 Oncecableshavebeenanchored,placetraysupport

inpositionandtightentwo(2)screws.

5.2 Removeliner.Placetwopiecesof3M™DualLock™

Fastenerontraysupport,asshown.Matesecond

twopiecesoffastenertotheattachedpieces.

Removelinerfrombackoftoppiecesandattach

firsttray.(SeeFigure22)

Figure 22

1178-8130-5055-2-L

5.3 Routethefibersintothetray.Securebuffertube

withcabletie.(SeeFigure23)

5.4 Splicepercompanypractice.

Figure 23

6.0 Splice Closure Assembly

6.1 Coatallgasketsurfaceswithalightapplicationof

siliconelubricanttoaidingasketsealing.

Note: Carefully follow health and safety

environmental instructions as given on Material

Safety Data Sheet for the silicone lubricant.

6.2 Placecoveronbaseandhand start all bolts.

Usingtighteningsequence(Figure28),torque

allboltsto240in-lbs.Torque -FR Closures to

50 in./lbs.

6.3 Closuremaybeflashtestedbypressurizingclosure

toamaximumof10PSI.Checkforleaksandthen

release air pressure.

Figure 24

7.0 3M™ Cable Addition Kit 2181-XL/XLFR

7.1 Followsteps3.0–4.0topreparecables.

7.2 Thetraysupportcanbeinstalledineitherthe3M™

FiberOpticSpliceClosure2178-XLor2178-XL/

FRorthe2181adapter.Installthetraysupport

ontothedesiredlevelbyplacingitintotheslots

ontheclosurebaseoradapterandtighteningthe

screwsuntilsnug.

7.3 Installthe2181adapterbetweenthehalvesofthe

2178closureusingthelongerboltsincludedwith

theadapter.Followstep6.0forassembly.

78-8130-5055-2-L

12

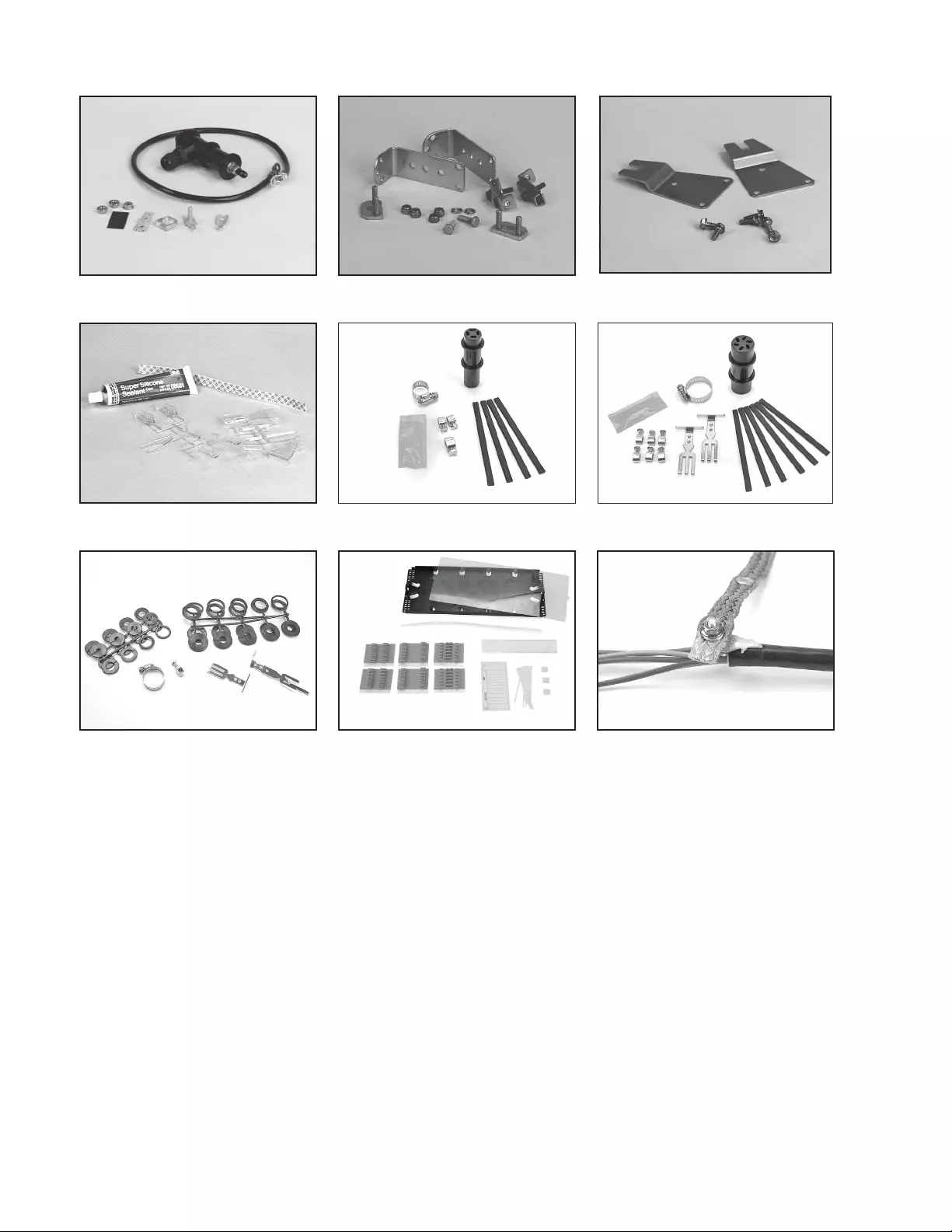

8.0 Closure Accessories

3M™ External Ground Isolation Kit 2178-EGI 3M™ Universal Aerial Hanger Kit 2183-UHB

3M™ Wall Mount Bracket 2198

3M™ Cable Fanout Kit 2519 and 2519-X 3M™ 4-Port Grommet 2178-4PGA 3M™ 6-Port Grommet 2178-6PGA

3M™ Cable Branch Port Kit 2178-XL-XSB 3M™ Fiber Optic Splice Tray 2543 3M™ Scotchlok™ Shield Bond Connector

Assembly 4460-D/FO

1378-8130-5055-2-L

3M, Dual Lock and Scotchlok are trademarks of 3M Company.

Scotch is a registered trademark of 3M Company.

Important Notice

All statements, technical information, and recommendations related to 3M’s products are based on information believed to be reliable,

but the accuracy or completeness is not guaranteed. Before using this product, you must evaluate it and determine if it is suitable for

your intended application. You assume all risks and liability associated with such use. Any statements related to the product which are not

contained in 3M’s current publications, or any contrary statements contained on your purchase order shall have no force or effect unless

expressly agreed upon, in writing, by an authorized officer of 3M.

Warranty; Limited Remedy; Limited Liability.

This product will be free from defects in material and manufacture for a period of one (1) year from the time of purchase. 3M MAKES NO

OTHER WARRANTIES INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. If this product is defective within the warranty period stated above, your exclusive remedy shall be, at 3M’s option,

to replace or repair the 3M product or refund the purchase price of the 3M product. Except where prohibited by law, 3M will not be

liable for any indirect, special, incidental or consequential loss or damage arising from this 3M product, regardless of the

legal theory asserted.

3

Communication Markets Division

6801 River Place Blvd.

Austin, TX 78726-9000

1-800-426-8688

www.3MTelecommunications.com

Please Recycle. Printed in USA.

© 3M 2010. All Rights Reserved.

78-8130-5055-2-L