3M 4251 User Manual

Displayed below is the user manual for 4251 by 3M which is a product in the Dust Masks category. This manual has pages.

Related Manuals

3M™ 4000 Series

Reusable Half Face Masks

Product Description

The 3M™ 4000 Series Reusable Half Face Masks are a range

of ready-to-use, maintenance-free half face masks, designed

for eective and comfortable protection against many gases,

vapours and combination particulate hazards found throughout

industry. Utilizing unique filter technology allows a very low-profile

for undisturbed view to make your work life more comfortable.

Key Features

• Disposable,maintenancefreehalfmask.

• Soft,texturedfacesealtoprovideamorecomfortabletto

the face.

• Lightweightandwellbalancedtoensurecomfortduringlong

periods of work.

• Twininhalationvalvesandlarge,bondedcarbonlters

to reduce breathing resistance, complimented by a low

resistanceparabolicexhalationvalvetoreduceheatbuild-up.

• Lowproledesignallowsforbetterperipheralvisionand

compatibility with 3M™ Eyewear range.

• Easytouseasnoneedforassembly,maintenanceorrecord

keeping.

• Easyandsecurettingofneckstrapandadjustmentofhead

cradle.

• Optionaloversprayguardprolongsthelifeoftheparticulate

filter when paint spraying.

• Maximumproductweightof320grams.

Applications

The 3M™ 4000 Series Reusable Half Face Masks come in a

variety of dierent product options:

• 3M™4251(FFA1P2RD)providesprotectionagainstorganic

vapours(goodwarningpropertiesandb.pt.>65°C),upto

10xThresholdLimitValue(TLV)or1000partspermillion

(ppm),whicheverislower,and12xTLVforparticulates.

• 3M™4255(FFA2P3RD)providesprotectionagainstorganic

vapours(goodwarningpropertiesandb.pt.>65°C),upto

10xTLVor5000ppm,whicheverislowerand50xTLVfor

particulates.

• 3M™4277(FFABE1P3RD)providesprotectionagainst

organicvapours(goodwarningpropertiesandb.pt.>65°C),

inorganicandacidgasesupto10xTLVor1000ppm,

whicheverislowerand50xTLVforparticulates.

• 3M™4279(FFABEK1P3RD)providesprotectionagainst

organicvapours(goodwarningpropertiesandb.pt.>65°C),

inorganicandacidgasesandammonia,upto10xTLVor

1000ppm,whicheverislowerand50xTLVforparticulates.

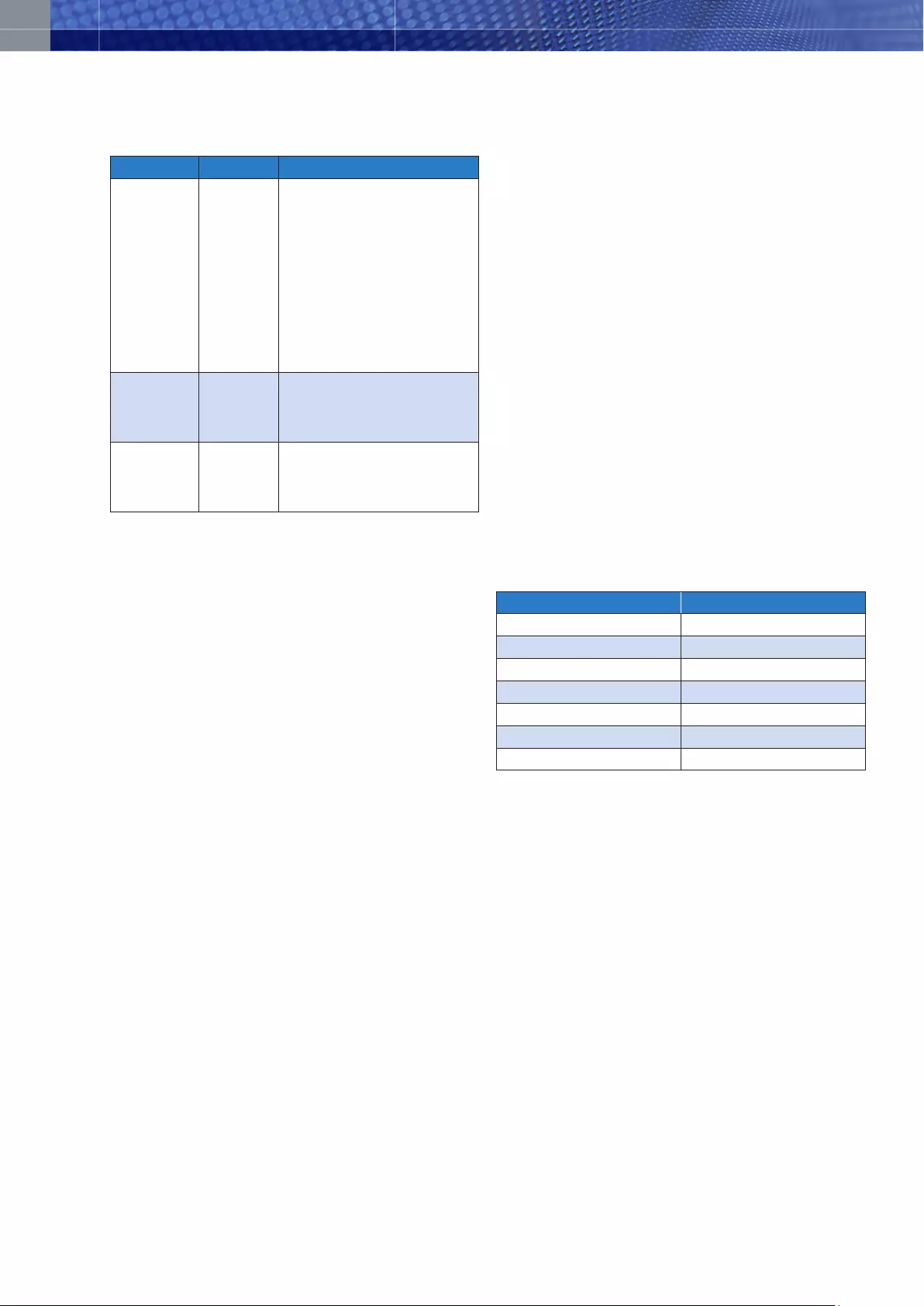

Datasheet

Technical

Filter Table

Filter Hazard Industry

4251

(FFA1P2 R D)

4255

(FFA2P3 R D)

Organic Vapours

and Particulates

• Anywhere conventional paints are used.

(non-Isocyanates, subject to usage

conditions)

• Vehicle manufacture

• Plant equipment manufacture

• Shoe treatment and tanneries

• Domestic appliance manufacture

• Aircraft manufacture and refurbishment

• Boat building

• Machinery manufacture

• Chemical manufacture and handling

• Ink and dye manufacture and usage

• Adhesive manufacture and laboratories

• Paint and varnish manufacture

• Manufacture and use of resins

4277

(FFABE1P3 R D)

Organic Vapours,

Inorganic Gases,

Acid Gases and

Particulates

As 4251 but also:

• Electrolytic processes

• Acid cleaning

• Metal pickling

• Metal etching

4279

(FFABEK1P3 R D)

Organic Vapours,

Inorganic and

Acid Gases, plus

Ammonia and

Particulates

As 4277 but also:

• Manufacture and maintenance of

refrigeration equipment

• Agrochemicals

Standards and Approval

The 3M™ 4000 Series Respirators meet the performance

requirementsoftheEuropeanStandardEN405:2001+A1:2009

for valved filtering half-mask respirators for gases, vapours and

particulate combinations.

The 3M™ 4000 Series Respirators have met the requirements

oftheEuropeanCommunityDirective89/686/EEC(Personal

ProtectiveEquipmentDirective)andarethusCEmarked.

CerticationunderArticle10,ECType-Examination,hasbeen

issuedfortheseproductsbyINSPECInternationalLimited,56

LeslieHoughWay,Salford,GreaterManchesterM66AJ,UK

(NotiedBodynumber0194).CerticationunderArticle11,EC

qualitycontrol,hasbeenissuedbyBSIProductServices(Notied

Bodynumber0086).

Cleaning and Storage

If the respirator is to be used for more than one shift it should

be cleaned at the end of each shift and stored between shifts

in the original packaging. To clean the respirator, the faceseal

should be wiped with a cloth moistened in warm soapy water

(thewatertemperatureshouldbebelow40°C)anddriedatroom

temperature.TheproductMUSTNOTbeimmersedinwater

duringcleaning.Alternatively,facesealmaybecleanedusingthe

3M™105FaceSealCleaner.Alwayscheckthattheproducthas

notexceededtheusebydatebeforeuse.

RespiratoryProtectionisonlyeectiveifitiscorrectlyselected,

ttedandwornthroughoutthetimewhenthewearerisexposed

to respiratory contaminants.

3M oers advice on the selection of products, and training in the

correct fitting and usage.

For more information on 3M products and services please call the

3M Health & Safety Helpline.

Materials

Component Material

Facemask Thermoplastic elastomer

Head Harness Polypropylene

Head Strap Polypropylene/cotton

Inhalation Valve Polyisoprene

Exhalation Valve Silicone Rubber

Gas and Vapour Filter Body Activated Carbon

Particulate Filter Element Polypropylene

Use Limitation

Thisrespiratordoesnotsupplyoxygen.Donotusein

atmospherescontaininglessthan19.5%*oxygen.

1. Donotuseforrespiratoryprotectionagainstatmospheric

contaminants that have poor warning properties or are

unknownorimmediatelydangeroustolifeandhealth(IDLH)

or against contaminants which generate high heats of reaction

with chemical filters.

2. Donotmisuse,alter,modifyorrepairthisproduct.

3. Donotusewithbeardsorotherfacialhairthatpreventdirect

contact between face and edge of the respirator.

4. Donotusewithunknownconcentrationsofcontaminants.

5. Donotuseforescapepurposes.

6. Leavetheworkareaimmediatelyandchecktheintegrityof

the respirator and replace face mask if:

- Damagehasoccurredorisapparent.

- Breathingbecomesdicultorincreasedbreathing

resistance occurs.

- Dizzinessorotherdistressoccurs.

- You taste or smell the contaminant or an irritation occurs.

7. Storethisdeviceinasealedcontainerawayfrom

contaminated areas when not in use.

8. Usestrictlyinaccordancewithrespiratorandlteruser

instruction leaflet.

9. Incaseofintendeduseinexplosiveatmospheres,contact3M

technical service.

*3Mdefinitionminimum19.5%byvolumeoxygen

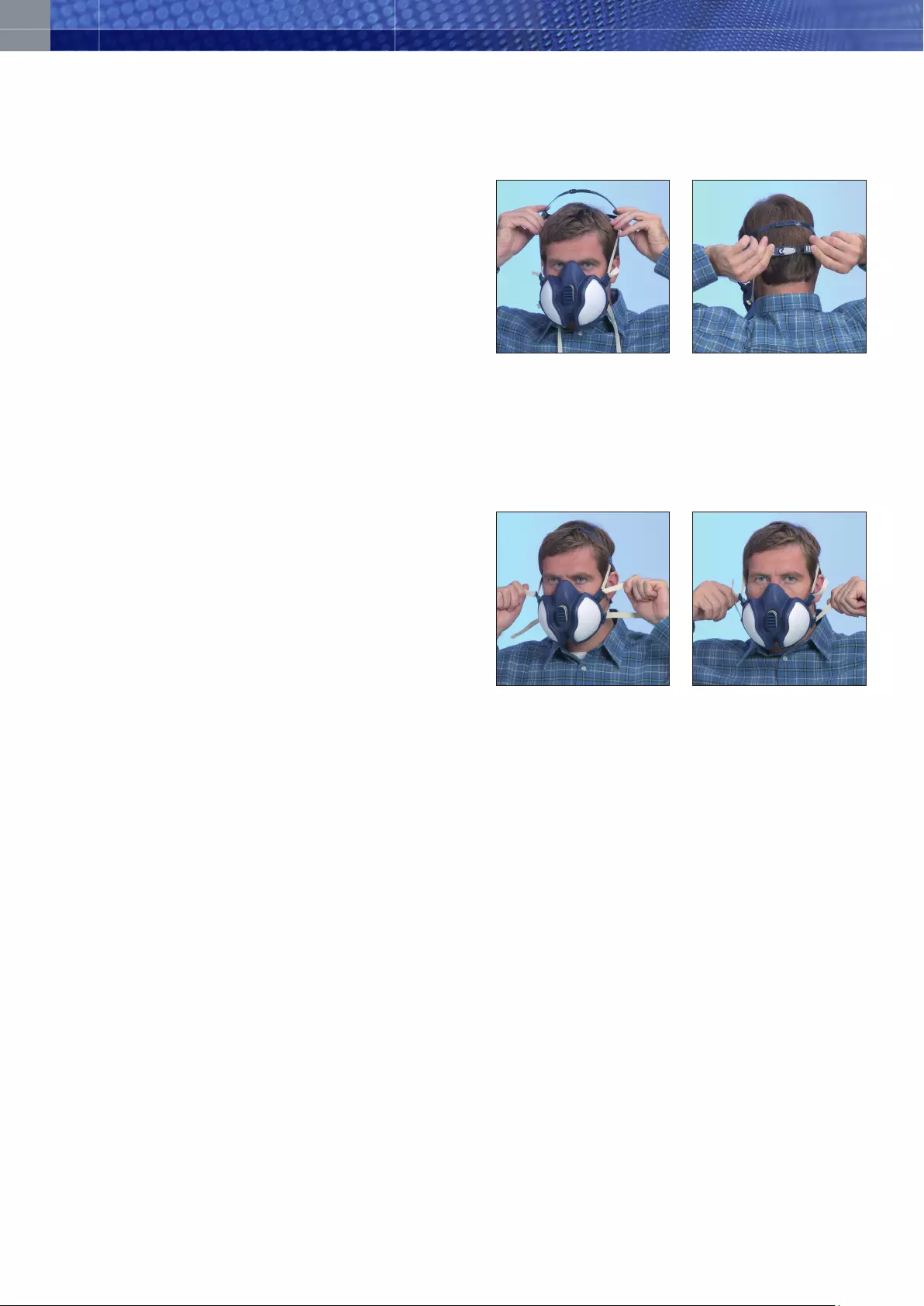

Fitting Instructions

Beforeassigninganyrespiratortobeworninacontaminated

area, we recommend that a qualitative or quantitative fit check be

performed before entering the workplace.

Fitting instructions must be followed each time the respirator is

worn.

1. Assemble/adjustheadcradlebyfeedingtheperforatedstrip

through the buckle and pressing down on the stud at the

required length. Repeat for second strip.

2. Placetherespiratorovertheface,ttingitcomfortablyon

bridge of the nose, then pull the head harness over the crown

of the head.

3. Ifnecessaryremovetherespiratorandreadjustthehead

cradletoacomfortabletandrepeatstep2.

4. Take a bottom strap in each hand, place them at the back of

the neck and hook the straps together

5. Tightenthetopheadharnessrstbypullingontheendsto

achieve a comfortable and secure fit. Tighten bottom straps in

a similar manner. Strap tension may be decreased by pushing

out on back side of buckles.

6. (Whereapplicable)Aftertighteningtheheadharness(see5),

slide the 4 plastic

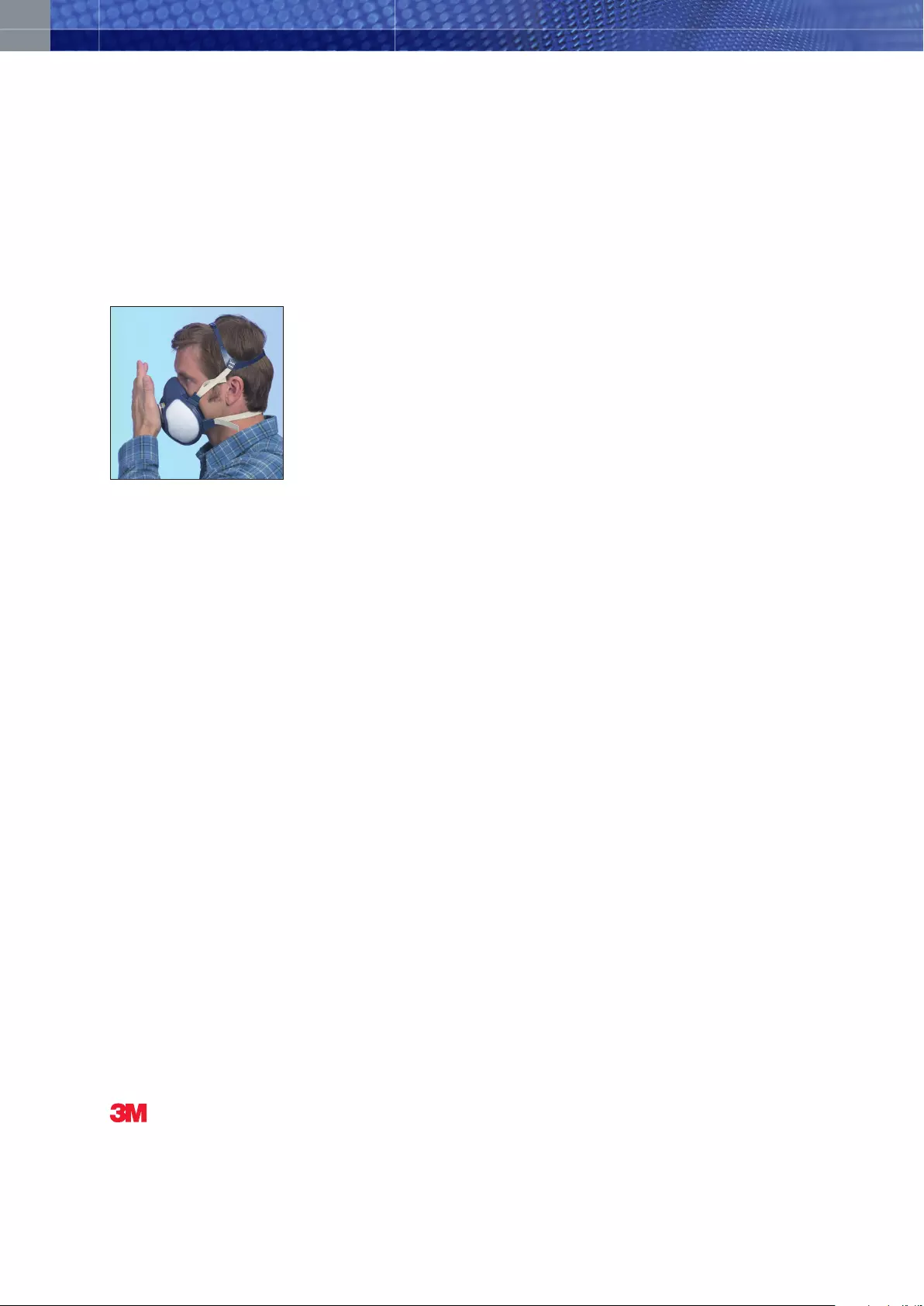

Fit Check

Performapositivepressuretcheckeachtimetherespiratoris

donned.

PositivepressureFaceFitcheck

Fitting instructions must be followed each time the respirator is

worn.

1. Placethepalmofthehandovertheexhalationvalvecoverand

exhalegently.

2. Iftherespiratorbulgesslightlyandnoairleakagebetween

the face and the respirator is detected, a proper fit has been

achieved.

3. If air leakage is detected, re-position the respirator on the

faceand/orreadjustthetensionofthestraptoeliminatethe

leakage.

4. Repeat the above face fit check

5. Ifyoucannotachieveapropert,donotenterthe

contaminated area. See your supervisor

Important Notice

3M does not accept liability of any kind, be it direct or

consequential(including,butnotlimitedto,lossofprofits,

businessand/orgoodwill)arisingfromrelianceuponany

information herein provided by 3M. The user is responsible for

determining the suitability of the products for their intended

use.Nothinginthisstatementwillbedeemedtoexcludeor

restrict3M’sliabilityfordeathorpersonalinjuryarisingfromits

negligence.

EU_Master_01

3M is a trademark of 3M company.

Pleaserecycle.©3M2013.

Allrightsreserved.

16755

3M Personal Safety Division

EMEA Region

3MCentre,

CainRoad,Bracknell

BerkshireRG128HT

UnitedKingdom

Tel:+44(0)1344858000

www.3M.eu/safety