3M 2178-XSB User Manual

Displayed below is the user manual for 2178-XSB by 3M which is a product in the Cable Organizers category. This manual has pages.

Related Manuals

July 2010

78-8135-0094-5-K

3M™ Fiber Optic Splice Closure

2178-XSB/XSB-FR & 2178-XLB/XLB-FR

3M™ Cable Addition Kit

2181-XB/XB-FR

Instructions

3

3

78-8135-0094-5-K

1.0 General

The 3M™ Fiber Optic Splice Closure 2178-XSB has

been developed to accommodate up to 48 single fusion

splices, and 144 mass fusion splices. The closure has

two 1" ports and one 1.4" port in the center.

The 2178-XSB splice closure can accommodate two

3M™ Fiber Optic Splice Trays 2532. The 2532 splice

tray can accommodate single fusion, single mechanical

or 12-ribbon fiber.

The 3M™ Fiber Optic Splice Closure 2178-XLB has

been developed to accommodate up to 96 single fusion

splices, and 288 mass fusion splices. The closure has

two 1" ports and one 1.4" port in the center.

The 2178-XLB splice closure can accommodate four

3M™ Fiber Optic Splice Trays 2532. The 2532 splice

tray can accommodate single fusion, single mechanical

or 12-ribbon fiber.

Length

14.56"

(370 mm)

Width

10.10"

(257 mm)

2178-XSB

Height

4.62"

(117 mm)

2178-XLB

Height

5.75"

(146 mm)

2181

Adapter

adds

2.05"

(52 mm)

2.0 Kit Contents

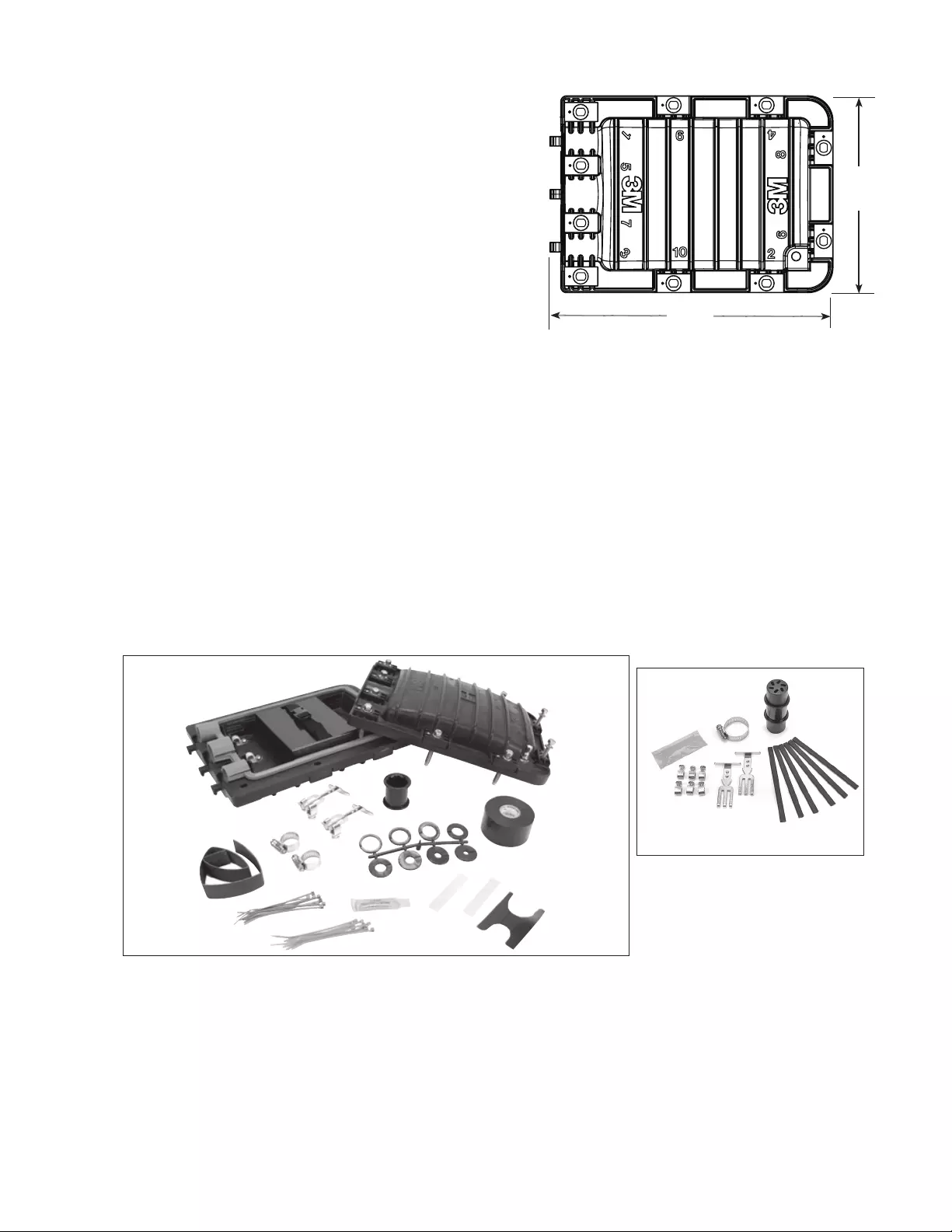

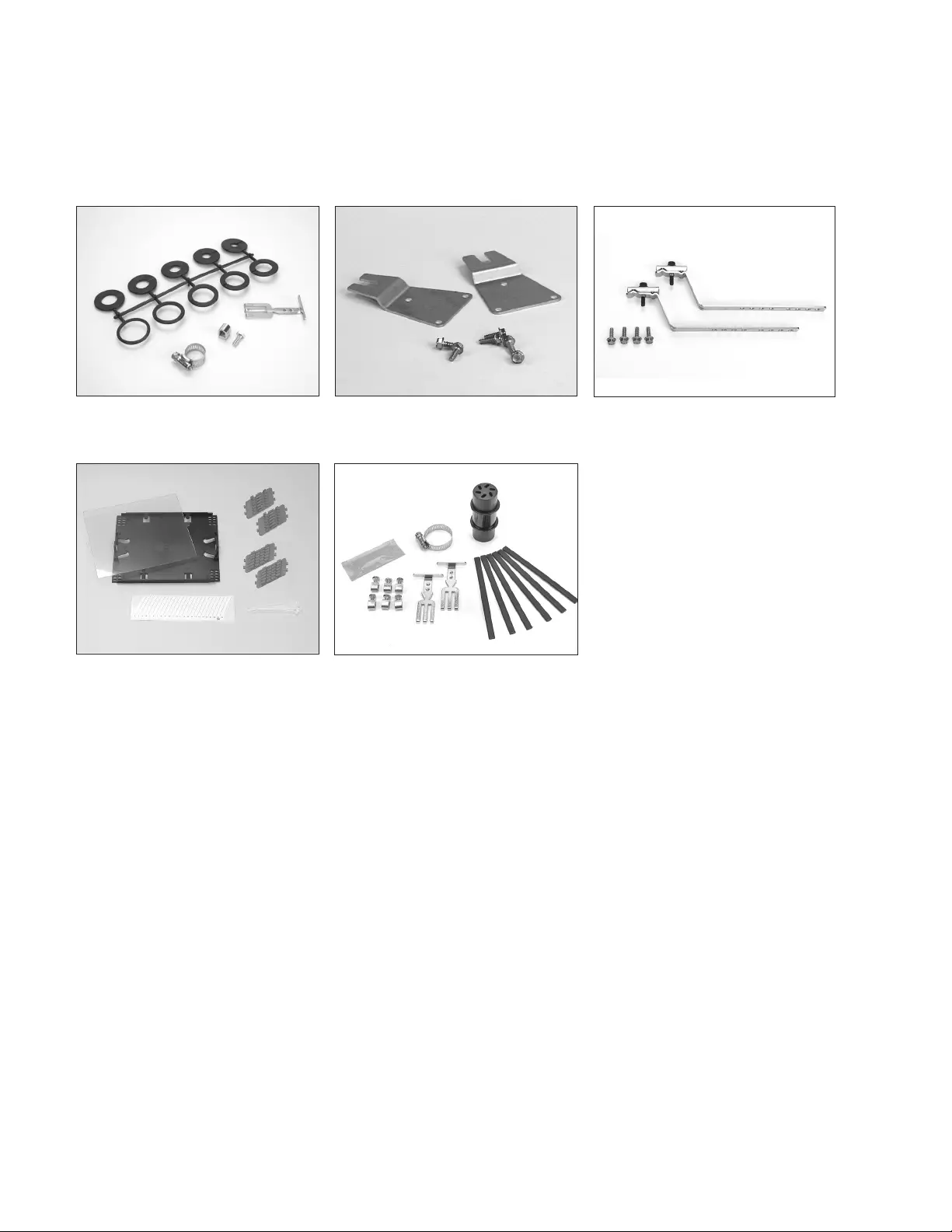

2.1 3M™ Fiber Optic Splice Closure 2178-XSB/XSB-FR Kit Contents

3M™ Multiport Grommet included

in certain kits only.

C.

A.

M.

B.

K.

L.

G.

F.

E.

I.

N.

H.

J.

D.

A. 1 - 2178-XSB closure body with bolts

B. 2 - Sheath retention inserts

C. 1 - 3M™ Multiport Grommet (certain kits only)

D. 4 - 1" Washer trees

E. 1 - 1.4" Plug

F. 8 - Cable ties (blue)

G. 8 - Cable ties (green)

H. 2 - 3M™ Reclosable Dual Lock™ Fasteners

I. 1 - Roll Scotch® Linerless Rubber Splicing

Tape 130C

J. 1 - Packet of silicone lubricant

K. 2 - 1" Hose clamps

L. 1 - Sheath scuff

M. 1 - Tray support with strap

N. 1 - Tape collar gauge

O. 1 - Transition tube-tie-down. Bracket not shown.

478-8135-0094-5-K

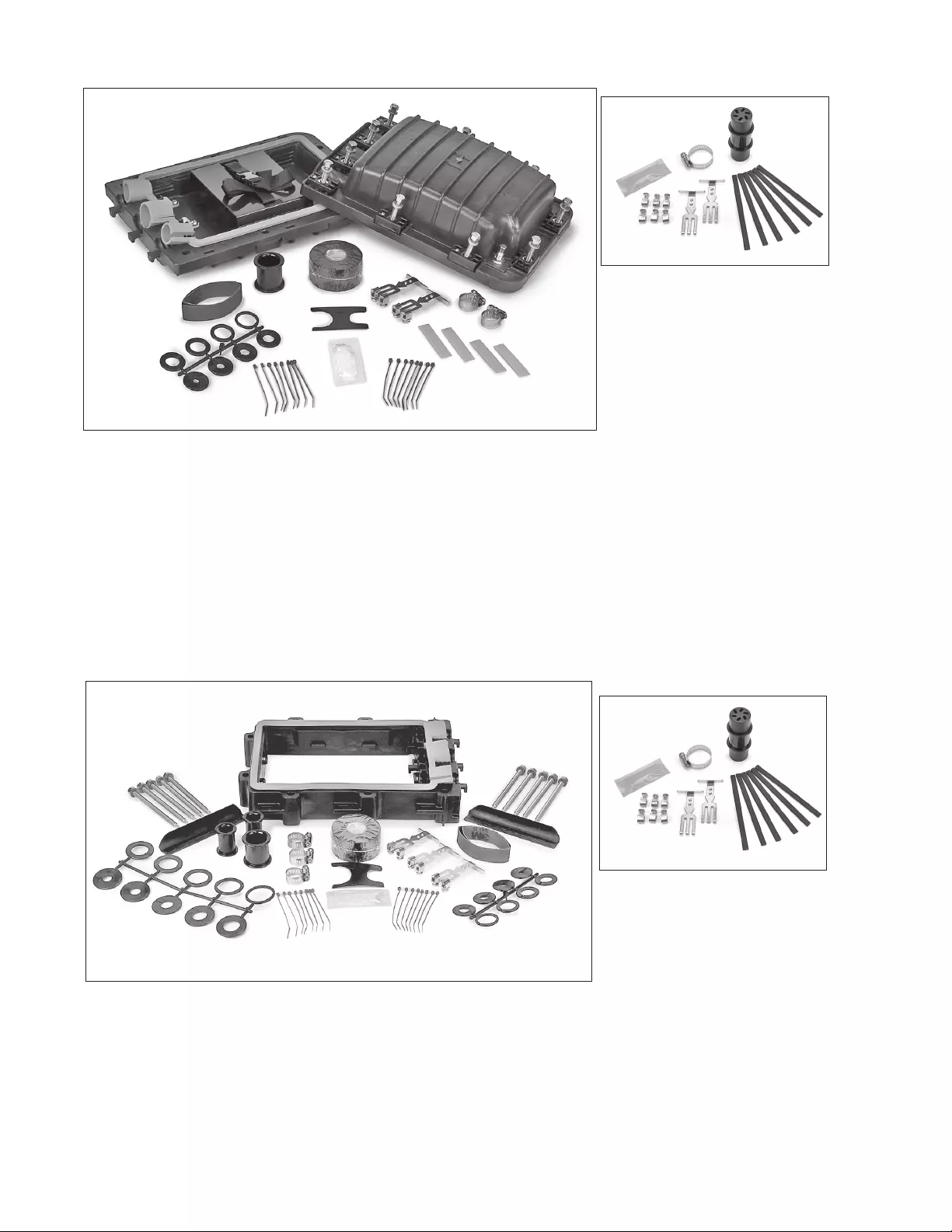

2.2 3M™ Fiber Optic Splice Closure 2178-XLB/XLB-FR Kit Contents

A.

M.

B.

K.

L.

G.

F.

E.

I.

N.

H.

J.

D.

3M™ Multiport Grommet included

in certain kits only.

C.

A. 1 - 2178-XLB closure body with bolts

B. 2 - Sheath retention inserts

C. 1 - 3M™ Multiport Grommet (certain kits only)

D. 4 - 1" Washer trees

E. 1 - 1.4" Plug

F. 8 - Cable ties (blue)

G. 8 - Cable ties (green)

H. 2 - 3M™ Reclosable Dual Lock™ Fasteners

I. 1 - Roll Scotch® Linerless Rubber Splicing

Tape 130C

J. 1 - Packet of silicone lubricant

K. 2 - 1" Hose clamps

L. 1 - Sheath scuff

M. 1 - Tray support with strap

N. 1 - Tape collar gauge

O. 1 - Transition tube-tie-down. Bracket not shown.

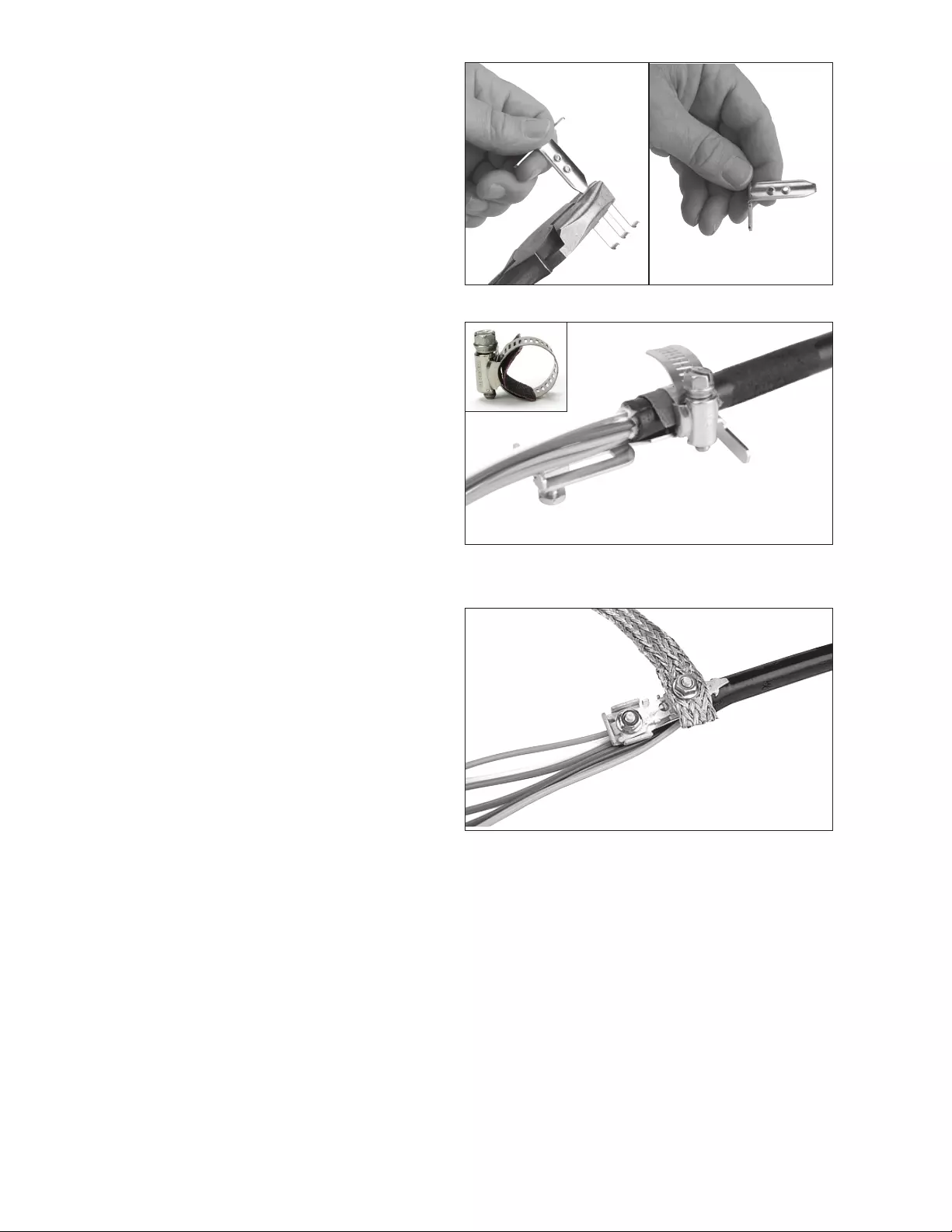

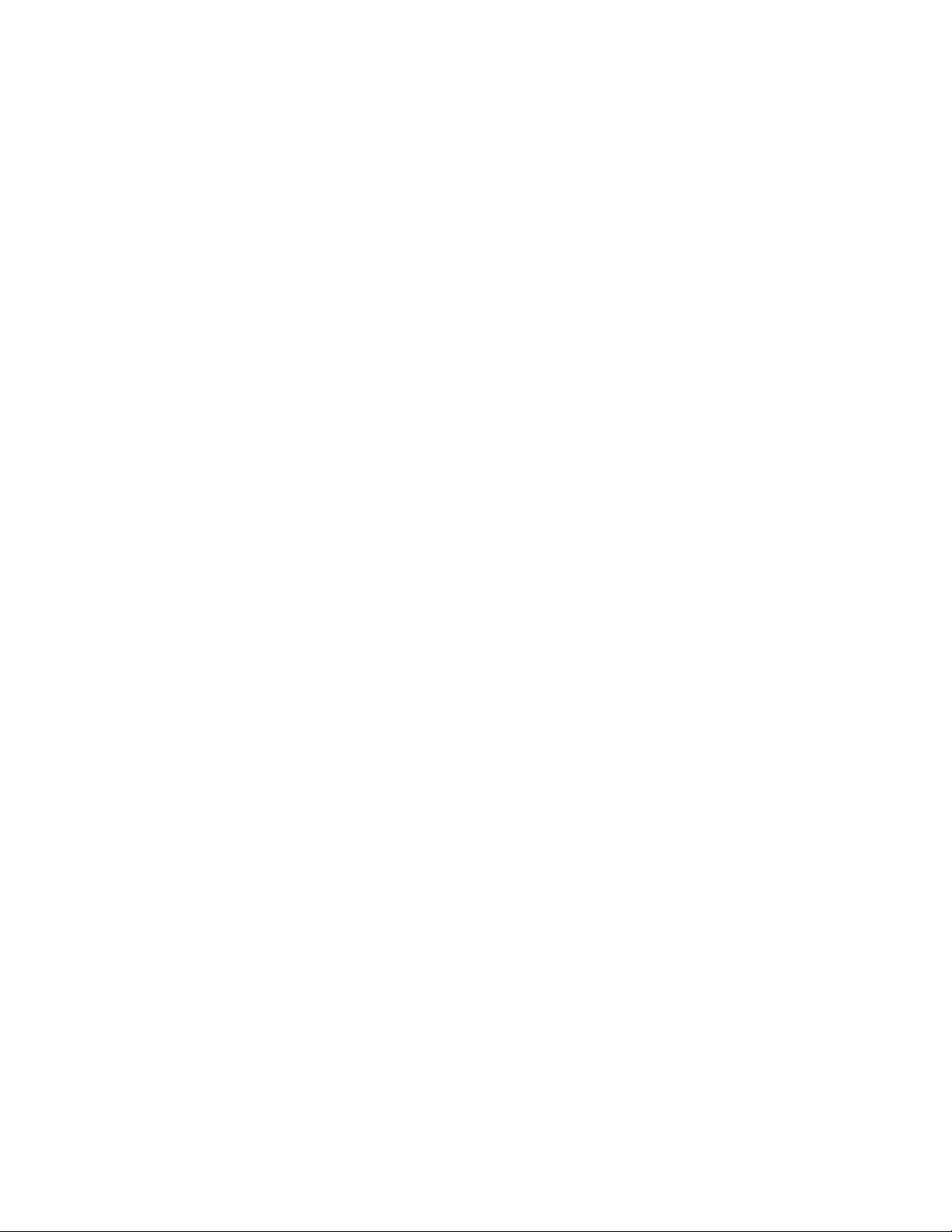

2.3 3M™ Fiber Optic Splice Closure Adapter 2181-XB/XB-FR Kit Contents

3M™ Multiport Grommet included

in certain kits only.

C.

A.

M. M.

O.

B.

K. L.

G.F.

E.

I.

N.

H. J. D.

A. 1 - 2181-XB adapter with gasket

B. 3 - Sheath retention inserts

C. 1 - 3M™ Multiport Grommet (certain kits only)

D. 4 - 1" Washer trees

E. 1 - 1.4" Plug

F. 8 - Cable ties (blue)

G. 8 - Cable ties (green)

H. 2 - 1.4" Washer trees

I. 1 - Roll Scotch® Linerless Rubber Tape 130-C

J. 1 - Packet of silicone lubricant

K. 3 - 1" Hose clamps

L. 1 - Sheath scuff

M. 10 - Bolts

N. 1 - Tape collar gauge

O. 2 - 1" Plugs

5

78-8135-0094-5-K

2.4 Additional materials required:

3M™ Fiber Optic Splice Tray 2532

To branch splice in the center port, order 3M™ 1.4" Cable Branch Port Kit, part no. 80-6113-1460-2.

For armored sheath cable, use 3M™ Scotchlok™ Shield Bond Connector 4460-D/FO.

Note: Closure can handle two trays.

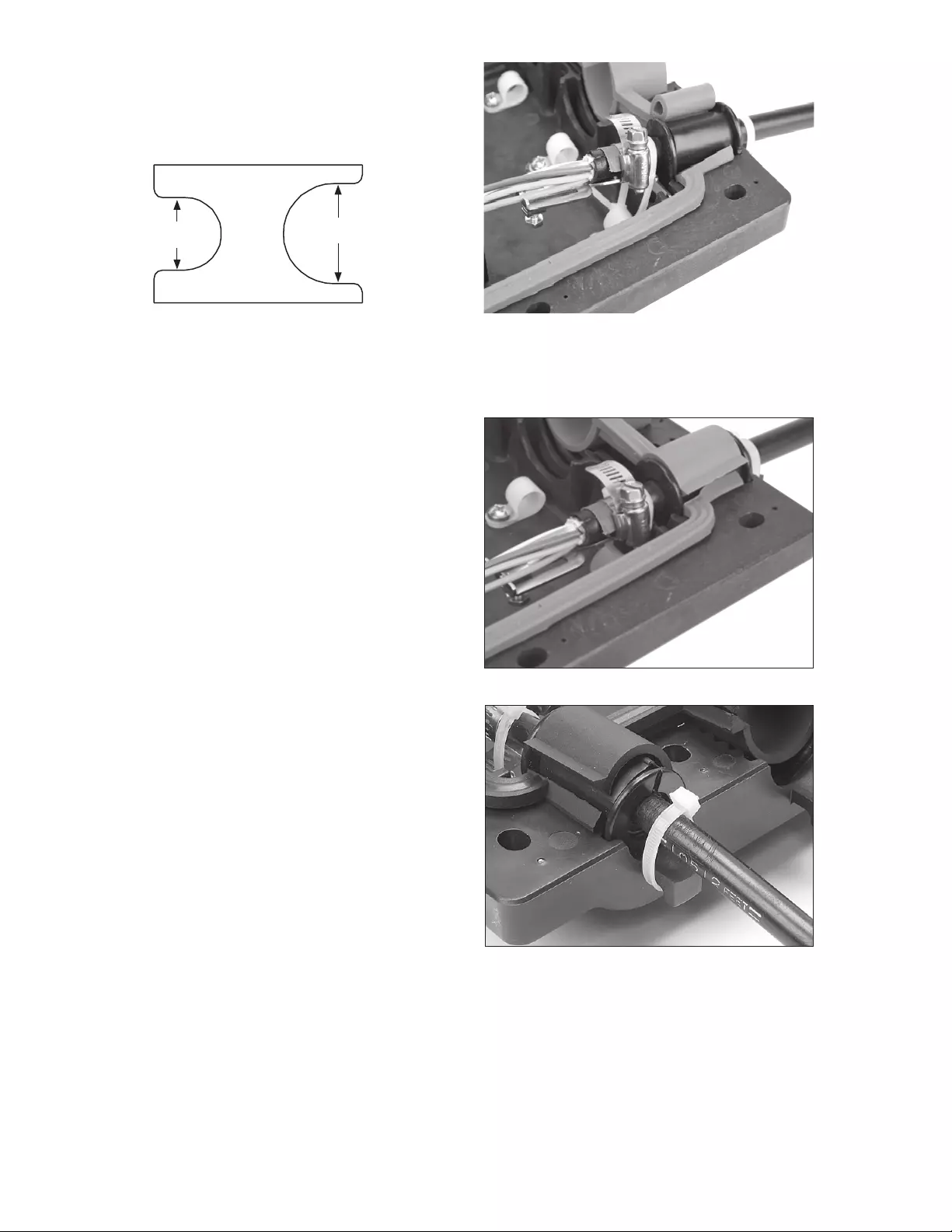

3.0 Cable Preparation

3.1 Determine amount of cable needed for storage

and splicing. The closure can store 8' (2.4 m)

of buffer tube fiber.

3.2 Remove sheath and clean fiber per company

practice.

3.3 Scuff 6" (150 mm) of cable sheath, starting at

end of sheath.

Figure 1

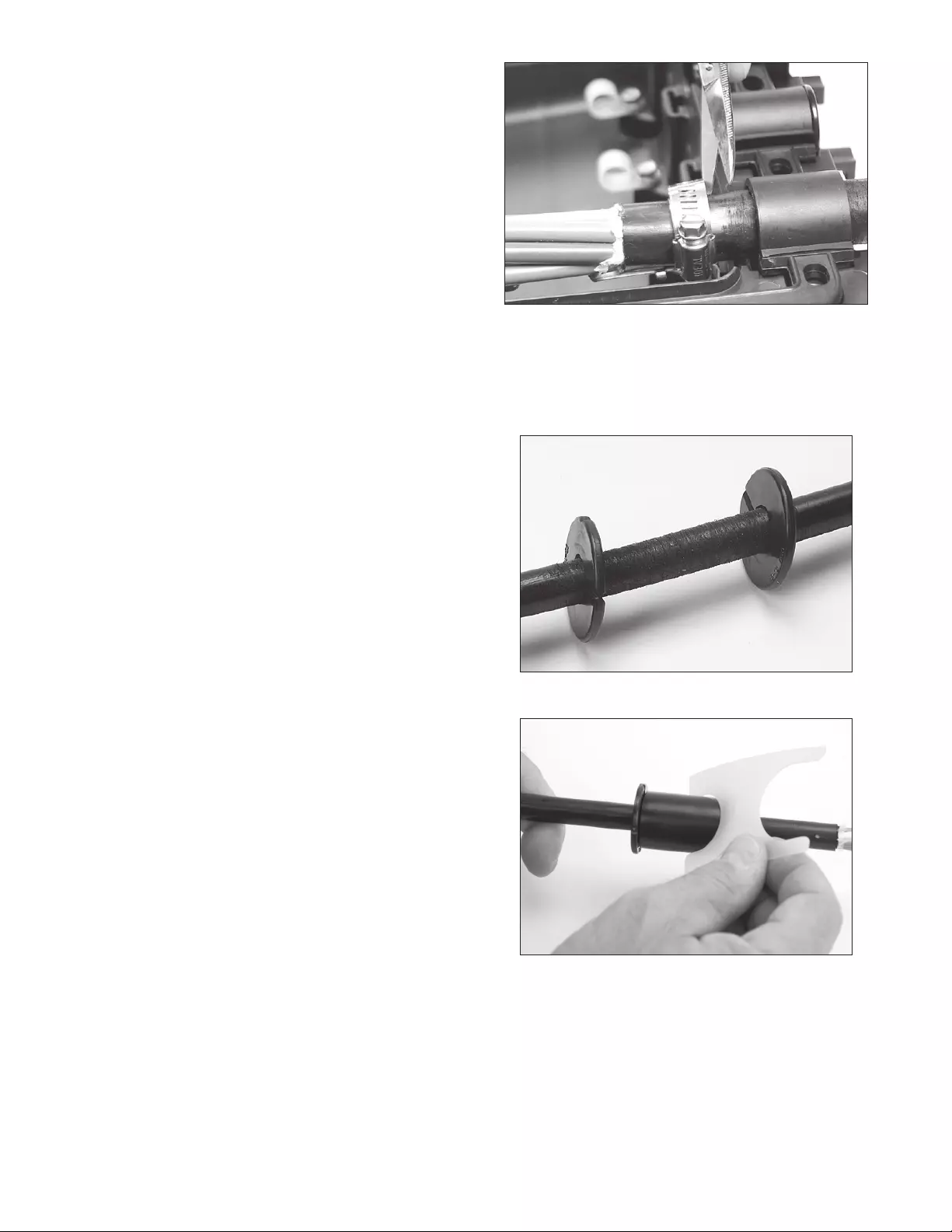

3.4 Secure the strength members.

3.4.1 If cable has central strength member,

assemble strength member clamp

onto strain relief bracket as shown

in Figure 2. Mark and cut the central

strength member at end of strength

member clamp.

Figure 2

3.4.2 If cable has dual strength members,

assemble strength member clamp

onto strain relief bracket as shown in

Figure 3.

Figure 3

678-8135-0094-5-K

3.4.3 If securing the strength members

is not required, the front half of

the sheath retention inserts can be

removed as shown in Figure 4.

3.4.4 Slide central strength member under

retention lug and tighten bolt to 40

in-lbs ± 5 in-lbs (4.6 N•m ± 0.6 N•m).

Figure 4

3.4.5 Cut a small length of the unused

sheath scuff and place it grit side

inward inside of the hose clamp.

Note: The cut piece of sheath scuff should wrap at

least halfway around the cable sheath, but not

completely around the cable.

Place cable retention clamp and sheath

scuff onto the cable so that hose

clamp will be 1" (25 mm) from end of

sheath.

3.4.6 Install hose clamp and tighten to

40 in-lbs ± 5 in-lbs

(4.6 N•m ± 0.6 N•m).

Figure 5

3.5 For armored cables (Figure 6), use 3M™

Scotchlok™ Shield Bond Connector

4460-D/FO Kit.

Figure 6

7

78-8135-0094-5-K

3.6 Place retention clamp into place in the closure

and mark location of gasket edges on cable.

This will be the area of the tape collar.

3.7 Determine the diameter of the scuffed area

of the cable and choose two (2) appropriately

sized washers for each cable. Washer inner

diameters should be as close to the diameter of

the cable as possible.

3.7.1 If diameter of cable is close to either

end of the marked washer diameter

range, try both sizes and choose the

snuggest fit available.

3.7.2 For example, if the cable diameter

measures 1.12", try both the 1.0–1.1

and 1.1–1.2 marked washers. Select

the washer with the snuggest fit

around the cable diameter, allowing

the washer to close at the split.

Figure 7

3.8 Place washers onto cable on either side of the

area marked for tape collar build up. Washers

may be split if necessary to ease installation.

Figure 8

3.9 Using the supplied Scotch® Linerless Rubber

Splicing Tape 130C, build up the collars to the

appropriate diameter from approximately 1.5”

(40 mm) from sheath opening.

Figure 9

878-8135-0094-5-K

3.9.1 Collars should be built up to 1.45"

diameter for large port and 1.05"

diameter for the smaller port. Use the

tape collar gauge provided in kit to

measure for required diameter.

1.05"

end

1.45"

end

Figure 10

3.10 Thinly coat all surfaces of cable ports and tape

collar with silicone lubricant and insert into

gasket at the proper port. Insert cable retention

clamp into slot at same time and push down

until cable is in proper alignment.

Note: Ensure that washers are properly seated in the

grooves of the case on either side of the gasket.

Note: Carefully follow health and safety

environmental instructions as given on Material

Safety Data Sheet for the silicone lubricant.

Figure 11

3.11 Using two (2) black cable ties, retain cables in

ports by placing ties both inside and outside

the base.

Note: White cable ties are shown for clarity.

Figure 12

9

78-8135-0094-5-K

3.12 For ribbon transition to tray applications,

secure the transition tube to the bracket

mounted in base.

Figure 13

3.13 When tray support and tray are in place,

mount the other end of the transition tube to

the tray.

Figure 14

4.0 Drop Cable Preparation

4.1 Determine how many drop cables will be

passing through the 3M™ Multiport Grommet.

4.2 Remove sheath on drops exposing buffer tubes

to a length required per company practice.

4.3 Insert drops into multiport grommet first and

then insert blank plugs last.

Note: A small amount of lubricant provided in kit may

be placed on blank plugs and cable to allow

for ease of installation into multiport grommet.

An additional method to ease installation is to

take sheath scuff supplied in closure kits, and

slightly sand the leading edge of the drop cable

and blank plugs.

Figure 15

10 78-8135-0094-5-K

4.4 Grease approximately 2" (50 mm) of cable drop

jacket.

4.5 Place a small amount of lubricant on the gasket

inside diameter in the area where it seals with

the 3M™ Multiport Grommet.

Note: Carefully follow health and safety environmental

instructions as given on Material Safety Data

Sheet for the silicone lubricant.

Figure 16

4.6 Insert drop 1"–2" (25 mm—50 mm) into

multiport grommet and then pull back out.

4.7 Insert drop the entire length of multiport

grommet.

4.8 Repeat steps 4.3–4.7 for the blank plugs as well.

Note: Leave future ports orientated to top of closure

for ease of future installations of drop.

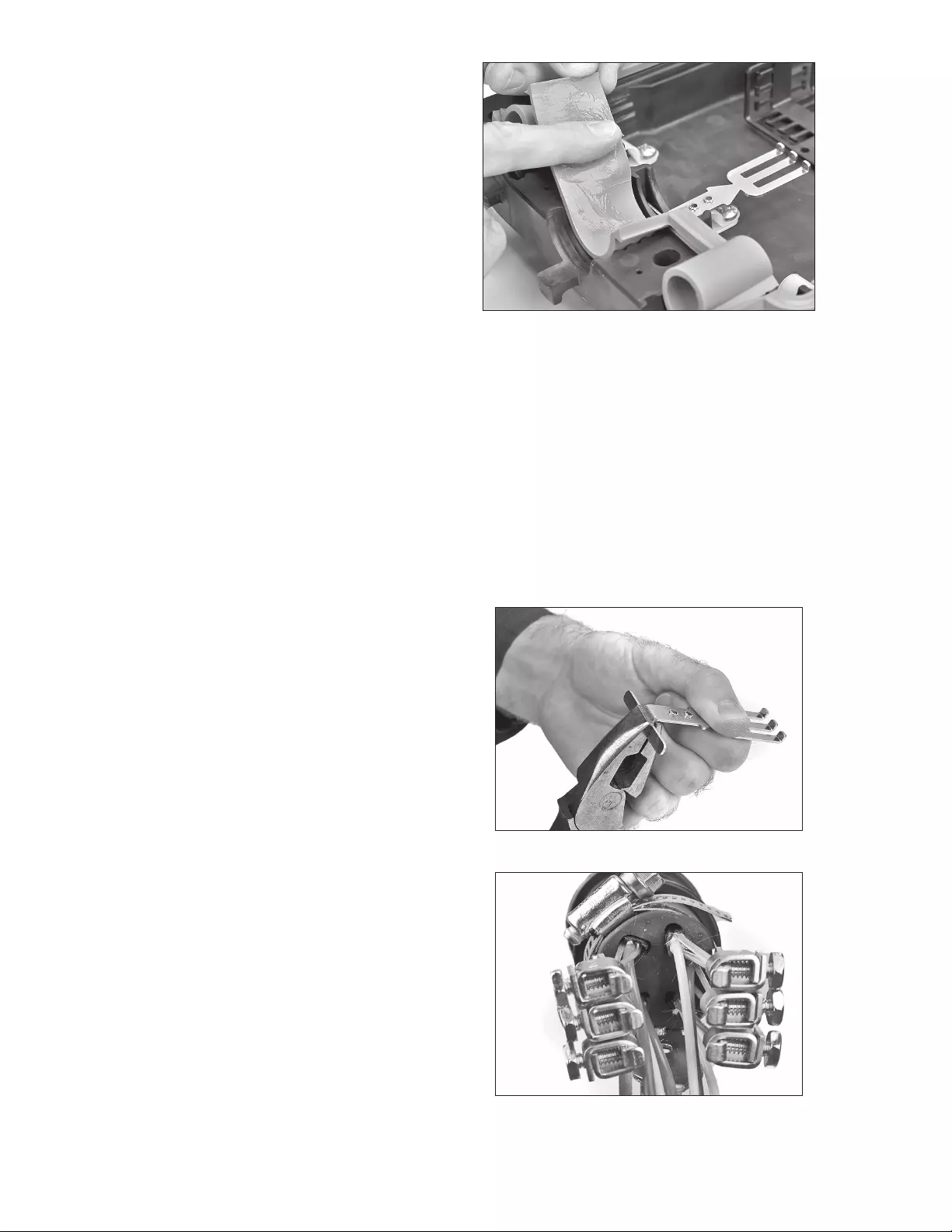

5.0 3M™ Multiport Grommet 6-Port (1.4") Installation

5.1 Break off the tab feature as shown on both cable

strain relief brackets.

Figure 17

5.2 Place cable strain relief brackets on either side

of the grommet, with three drops on either side

as shown. Insert cable strength members into

small K-connectors.

Figure 18

11

78-8135-0094-5-K

5.3 Secure cable strain relief brackets and the

strain relief bracket from the closure to the

grommet with the hose clamp as shown.

Tighten the hose clamp to 40 in.-lbs. ± 5 in.-lbs.

(4.6 N•m ± 0.6 N•m).

Note: Ensure that extruded retention feature of strain

relief has sufficient contact with surface of

grommet.

Figure 19

5.4 Tighten the six K-connector nuts to

40 in.-lbs. ± 5 in.-lbs. (4.6 N•m ± 0.6 N•m)

each.

Figure 20

5.5 Place cable strain relief and the 3M™ Multiport

Grommet assembly into closure.

5.6 Place cable ties around multiport grommet

assembly inside and out as shown.

Note: White cable ties are shown for clarity.

5.7 Follow closure instruction for all other

preparation leading up to and including sealing

closure.

3M™ Fiber Optic Splice Closure 2178 XSB

3M™ Fiber Optic Splice Closure 2178 XLB

12 78-8135-0094-5-K

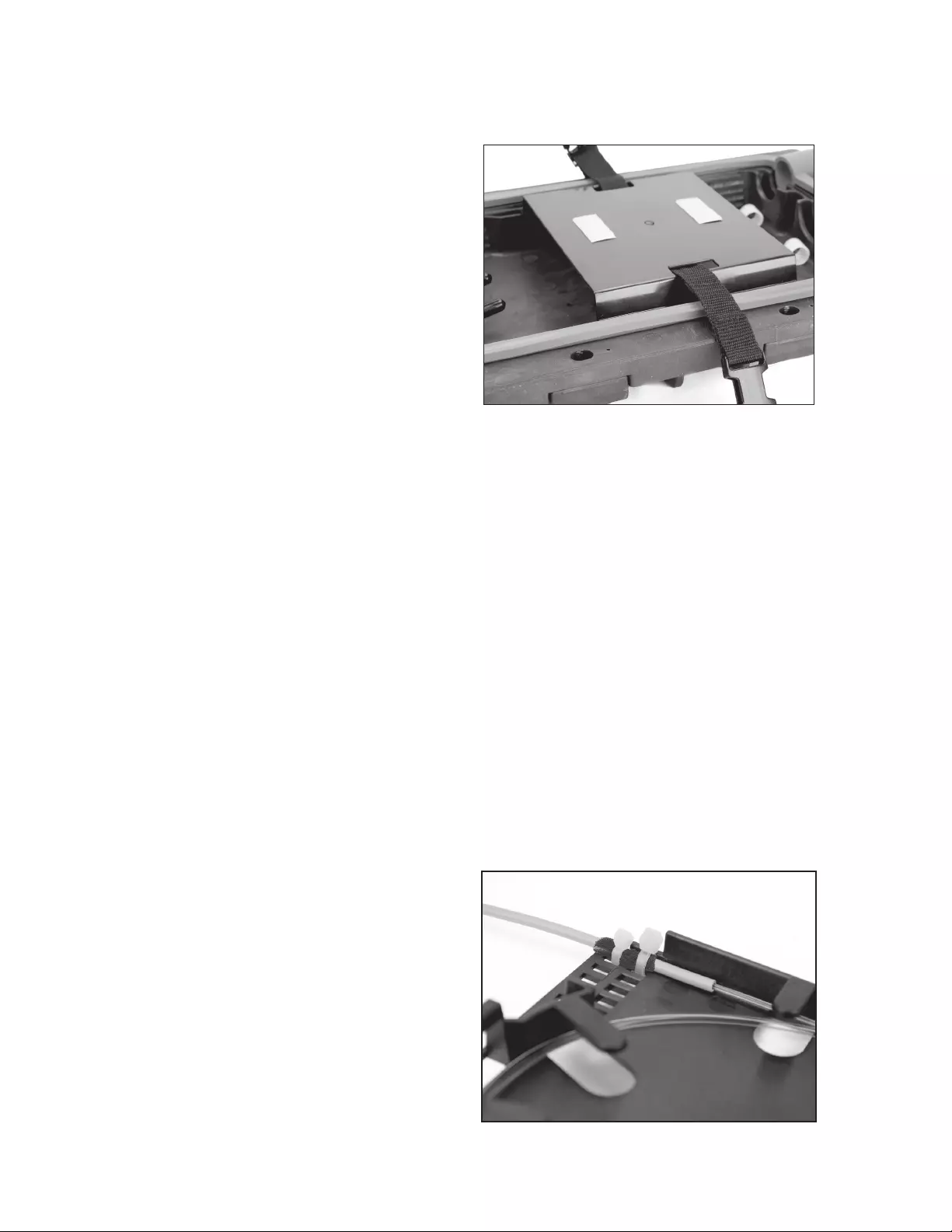

6.0 Tray Installation and Splicing

6.1 Once cables have been anchored, place tray

support in position and tighten two (2) screws.

6.2 Cut two 3M™ Reclosable Dual Lock™

Fasteners in half. Remove liner from two

pieces of fastener and place on tray support as

shown. Mate second two pieces of fastener to

the attached pieces. Remove liner from back

of top pieces and attach first tray.

Figure 21

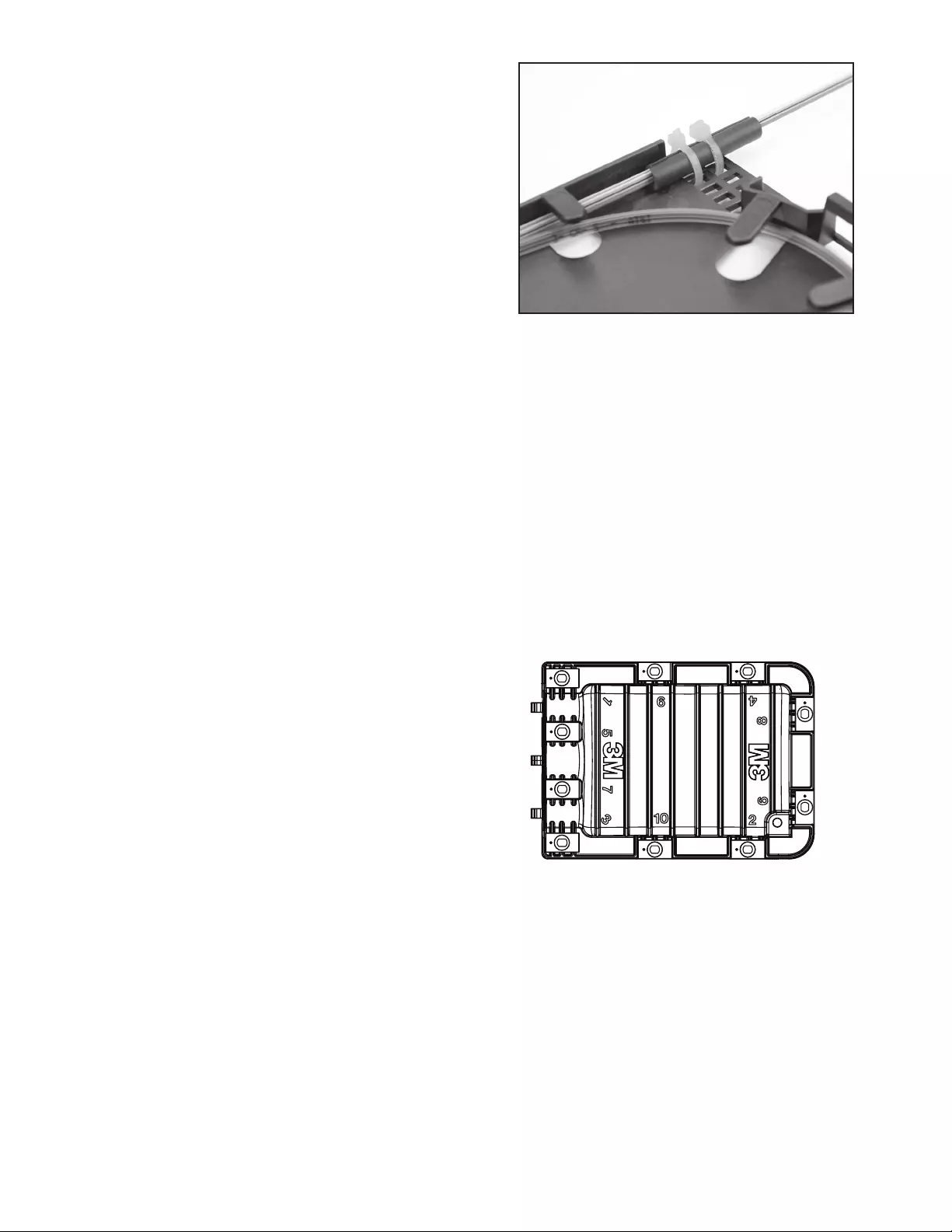

7.0 Fiber Management Inside Tray

7.1 Select appropriate splice holder based on type

of splicing to be performed

7.2 Remove adhesive backing and position splice

holders on tray.

Note: Positioning of splice holders should be such

that a minimum of 1.5" (40 mm) bend radius is

maintained for each fiber to be spliced.

Note: In a dirty environment an alcohol wipe may be

used to clean tray surface for better adhesion.

Note: Carefully follow safety, health and environmental

information given on product label or the

Material Safety Data Sheet for the cleaner.

7.3 Route buffer tube or ribbon to desired tray

corner.

Note: Do not exceed minimum 1.5" (40 mm) bend

radius during routing process.

7.4 Secure loose buffer tube to tray using the

supplied cable ties.

Figure 22

13

78-8135-0094-5-K

7.5 Place ribbon fiber into 1"–1.5" (25 mm–40 mm)

of ribbon retention grommet (cut segments

as needed from supplied length) and secure

assembly into tray using supplied cable ties. Be

sure to use two cable ties per each buffer tube.

(A maximum of six ribbons can be loaded into

each retention grommet segment.)

Note: Do NOT use pliers to tighten cable ties to tray.

Cable ties should be hand tightened such that

ribbon or buffer tube are immobilized. Over

tightening can cause damage to buffer tube or

ribbon.

Figure 23

7.6 Splice per company practice and place sleeves

into splice holders.

8.0 Splice Closure Assembly

8.1 Thinly coat all gasket surfaces with a light

application of silicone lubricant to aid in

gasket sealing.

Note: Carefully follow health and safety

environmental instructions as given on Material

Safety Data Sheet for the silicone lubricant.

8.2 Place cover on base and hand start bolts 1,

5, 7, and 3 in that order first. All others can

be started in any order. Using tightening

sequence, torque all bolts to 240 in-lbs.

TORQUING SEQUENCE

8.3 Closure should be flash tested by pressurizing

closure to a maximum of 5 PSI. Check for

leaks and then

8.4 On future opening and closing of closure, if

leaks are detected, torque bolts or re-tape cable

ports as needed.

14 78-8135-0094-5-K

9.0 Opening Splice Closure

9.1 To re-enter splice closure, open bolt positions

5, 7, 1 and 3 in seqence. All other bolt

positions can be opened randomly.

10.0 Closure Accessories

15

78-8135-0094-5-K

3M, Scotchlok and Dual Lock are trademarks of 3M Company. Scotch is a registered trademark of 3M Company.

Important Notice

All statements, technical information, and recommendations related to 3M’s products are based on information believed

to be reliable, but the accuracy or completeness is not guaranteed. Before using this product, you must evaluate it and

determine if it is suitable for your intended application. You assume all risks and liability associated with such use.

Any statements related to the product which are not contained in 3M’s current publications, or any contrary statements

contained on your purchase order shall have no force or effect unless expressly agreed upon, in writing, by an authorized

officer of 3M.

Warranty; Limited Remedy; Limited Liability.

This product will be free from defects in material and manufacture for a period of one (1) year from the time of purchase.

3M MAKES NO OTHER WARRANTIES INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. If this product is defective within the warranty period stated above, your exclusive

remedy shall be, at 3M’s option, to replace or repair the 3M product or refund the purchase price of the 3M product. Except

where prohibited by law, 3M will not be liable for any indirect, special, incidental or consequential loss or damage arising

from this 3M product, regardless of the legal theory asserted.

3

Communication Markets Division

6801 River Place Blvd.

Austin, TX 78726-9000

1-800-426-8688

www.3MTelecommunications.com

Please Recycle. Printed in USA.

© 3M 2010. All Rights Reserved.

78-8135-0094-5-K