3M 4991 User Manual

Displayed below is the user manual for 4991 by 3M which is a product in the Mounting Tapes & Labels category. This manual has pages.

Related Manuals

1

3M Industrial Adhesives and Tapes | October 2017 Edition

Solutions for

your assembly

challenges.

3M Industrial Adhesives and Tapes

Design & Production Guide | October 2017

289

3M Industrial Adhesives and Tapes

1

chance to do it right

100,000

patents

Do it responsibly.

• Sustainability is a natural extension of 3M’s corporate values.

• We developed the rst water-based contact adhesive

ever — more than 40 years ago.

• We have a wide selection of Low VOC products that help

contribute to LEED® credits and are GREENGUARD™ Certied.

Do it boldly.

• 3M has been a world leader in bonding technology

for decades and we have the patents to prove it.

• Quality, consistency and reliability—the attributes

you look for in a bonding solution—help drive our

quest for new innovations.

88,667

employees

Do it together.

• No matter what you need to bond, you can count on 3M’s

expertise, technologies and 88,667 dedicated employees to

help you nd solutions.

• From wood, metal, foil, insulation, foam, fabric and panel

lamination to specialty high performance and multipurpose

materials of every kind, solutions are one call away.

5,000+

adhesive and tape SKUs

Do it your way.

• 3M systems are built around your

manufacturing processes, not the

other way around.

• Whether it’s structural or non-structural

adhesives, bonding tapes or reclosable

fasteners, 3M solutions ensure speed,

convenience and ease of use.

Finding your

3M Adhesive

& Tape

Assembly Solutions

290

1

3M Industrial Adhesives and Tapes | October 2017 Edition

Table of Contents

Adhesives and Tapes Overview ...................................................................... 2

Considerations for Selecting 3M™ Adhesives and Tapes ........................... 3

Assembly Solutions ...........................................................................4–16

Adhesives and Sealants

3M™ Scotch-Weld™ Structural Adhesives ............................................ 18–35

3M™ Scotch-Weld™ PUR Adhesive Systems ...................................... 36–38

3M™ Scotch-Weld™ Instant Adhesives ................................................ 38–40

3M™ Scotch-Weld™ Anaerobic Adhesives ........................................... 41–42

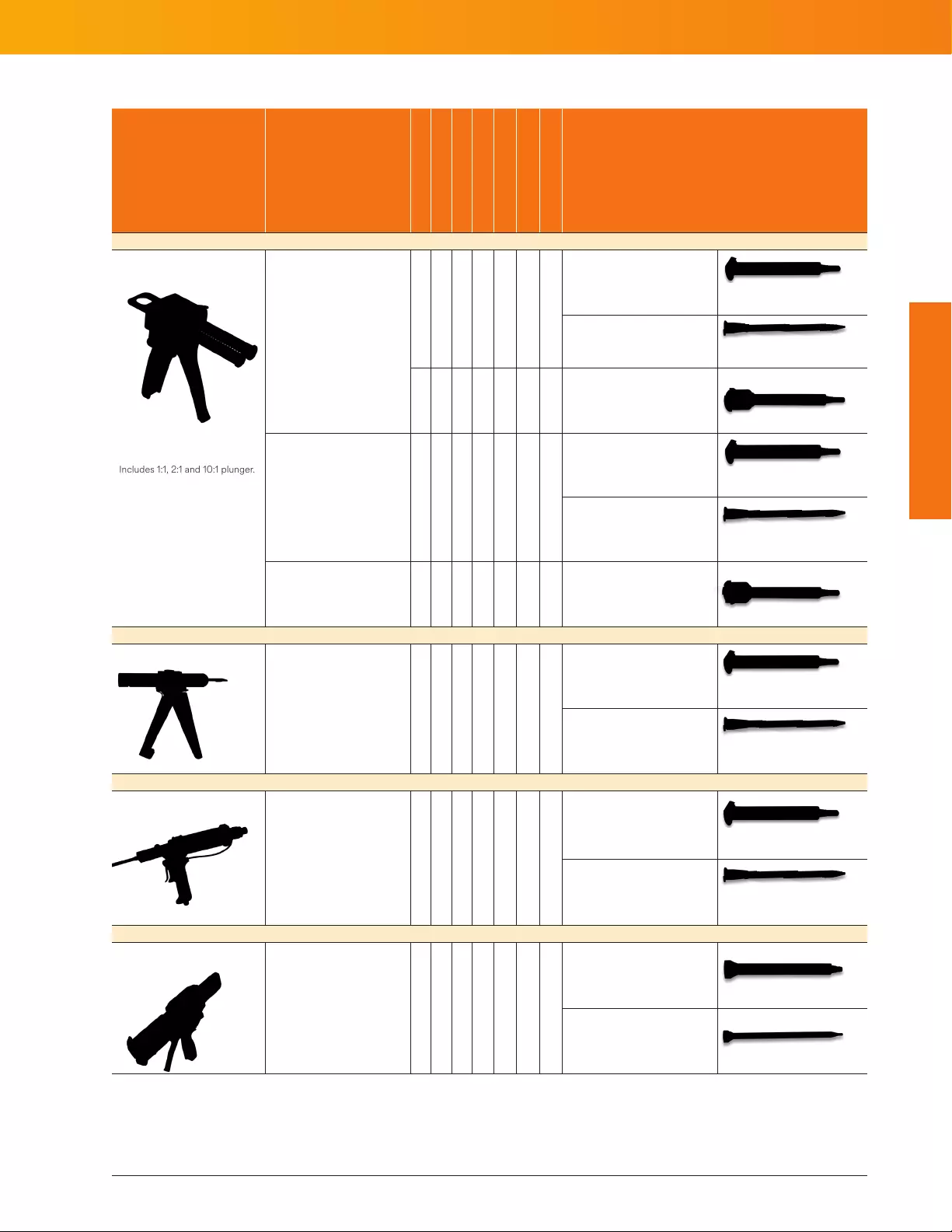

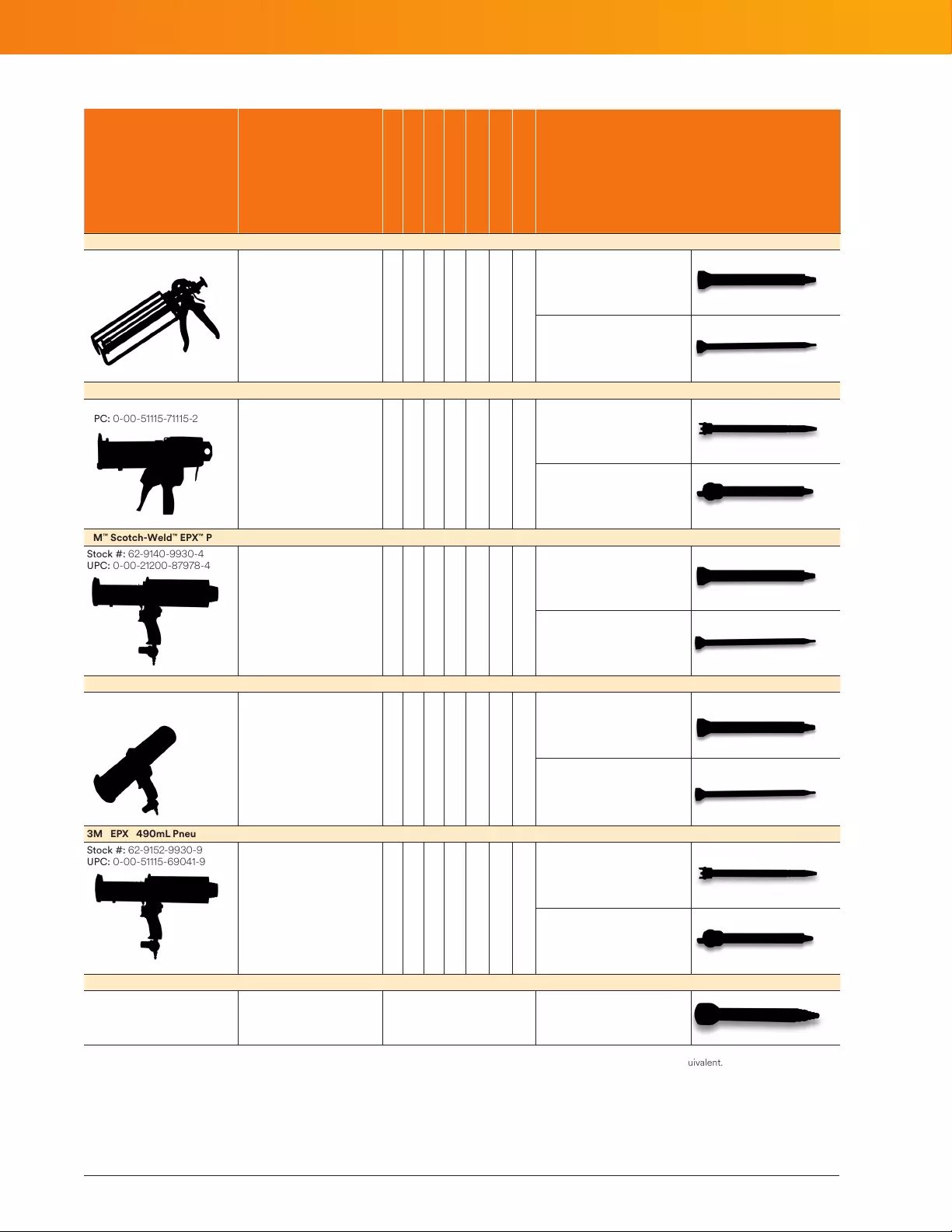

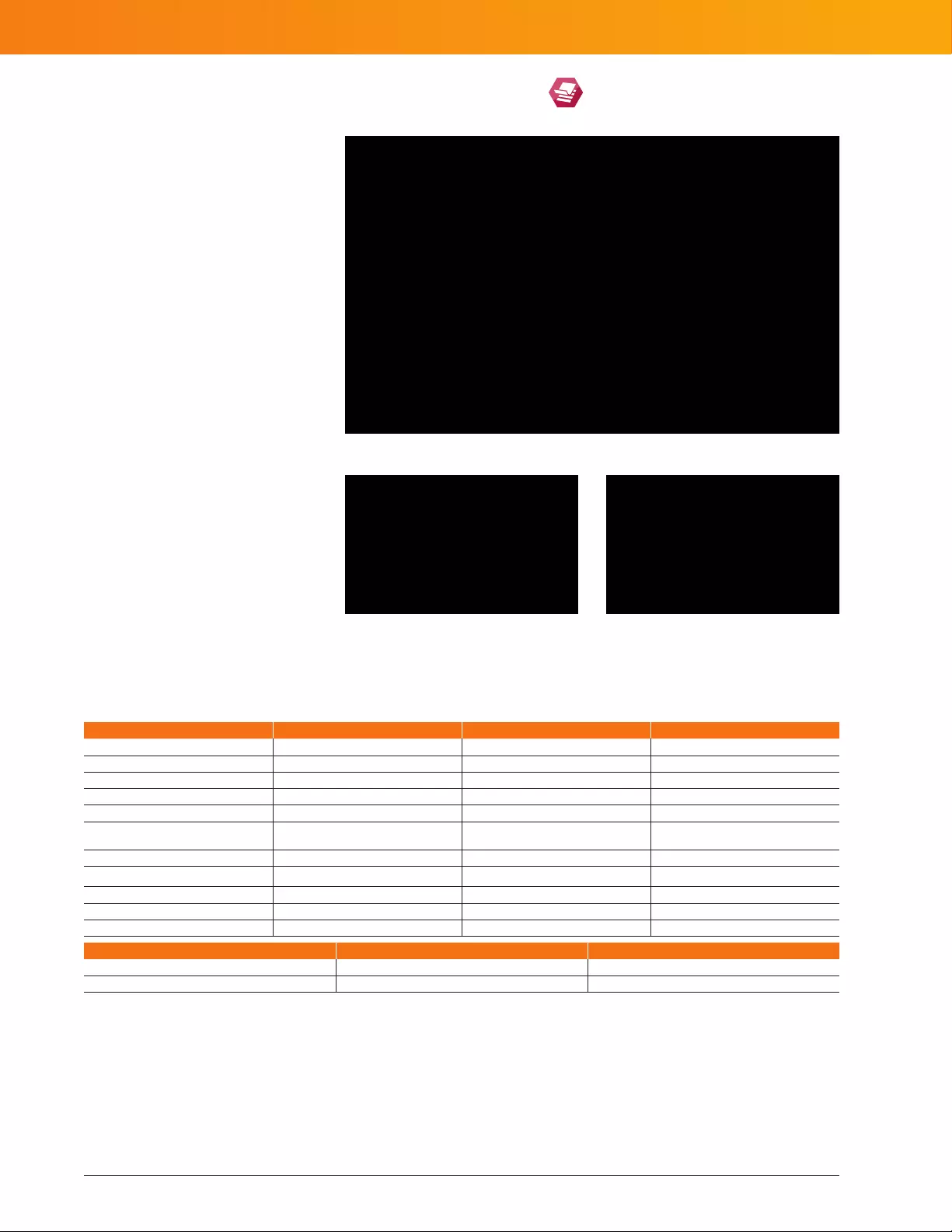

3M™ Scotch-Weld™ EPX™ Applicators and Nozzles .......................... 43–44

3M™ Concrete Repair .....................................................................................45

3M™ Hot Melt Spray Adhesives .................................................................... 46

3M™ Hot Melt Adhesives, Applicators and Accessories ....................47–51

3M™ Solvent and Water Based Adhesives .............................52–56, 60-63

3M™ Cleaners and Lubricants .......................................................................57

3M™ Cylinder Spray Adhesives ............................................................ 58–59

3M™ Adhesive Sealants ..........................................................................64–66

Bonding Tapes

3M™ VHB™ Tapes and Primers ............................................................... 68–75

3M™ Extreme Sealing Tapes .......................................................................... 76

3M™ Double Coated Foam Tapes ..........................................................77–78

3M™ Double Coated Tapes ..................................................................... 79–81

3M™ Removable/Repositionable Tapes ......................................................82

3M™ Adhesive Transfer Tapes ............................................................... 83–87

Scotch® ATG Adhesive Transfer Tapes ........................................................88

3M™ Extended Liner Tapes ............................................................................89

Specialty Technologies

3M™ Dual Lock™ Reclosable Fasteners................................................ 92–93

3M™ Hook and Loop Reclosable Fasteners ........................................ 94–95

3M™ Single Coated Foam Tapes ...................................................................96

3M™ Converter Markets Center ................................................................... 97

Numerical Index .................................................................................... 98–100

Product Name Index .............................................................................101–104

7

8

9

3M™ Adhesives and Tapes

for design, assembly and production.

3M Industrial Adhesives and Tapes | 3M.com/Assemblysolutions

2

3M Industrial Adhesives and Tapes

3M™ VHB™ Tapes 3M™ Contact and

Spray Adhesives

3M™ Scotch-Weld™

Gasket Makers

3M™ Scotch-Weld™

Structural Adhesives

3M™ Adhesive

Sealants

3M™ Double

Coated Tapes

3M™ Scotch-Weld™

Instant Adhesives

3M™ Extreme

Sealing Tapes

3M™ Scotch-Weld™

PUR Adhesives

3M™ Hot Melt

Adhesives

3M™ Scotch-Weld™

Retaining Compound

3M™ Adhesive

Transfer Tapes

3M™ Reclosable

Fasteners

3M™ Scotch-Weld™

Threadlockers

3M™ Adhesives and Tapes Product Family

Build strong, durable products:

• From repositionable to permanent,

3M has an adhesive or tape that can

be readily matched to the substrate

and stress characteristics needed

in the joint.

Improve appearance and aesthetics:

• 3M adhesives and tapes are

generally hidden between the

bonded substrates, oering nearly

invisible fastening.

• Surfaces stay smooth and clean

for a more attractive appearance

and less surface renishing.

Lower production and material costs:

• Reduce process steps such as weld

grinding and sealing individual

penetrations from screws, nuts

and bolts.

• Use thinner, lighter or less expensive

materials that cannot be welded or

fastened traditionally.

• Potentially lower capital investment.

Many adhesives and tapes do not

require major capital to use.

• Manage labor costs. Many tape

and adhesive technologies require

little operator training.

Build products with a continuous

bond line:

• Adhesives and tapes uniformly

distribute stress along the entire

joint. Nuts, bolts and other fasteners

concentrate stress at a point which

can decrease physical properties

of the substrates being assembled.

• Bond and seal simultaneously.

Many 3M adhesives and tapes will

provide a strong bond, but are also

an eective seal against dirt, dust,

water and other environmental

conditions.

• Good fatigue resistance. If your

parts are subject to vibration or

other movement, the viscoelastic

nature of 3M adhesives and tapes

will impart exibility to a joint or

bonded area.

Wider material selection

for assemblies:

• Lighter and thinner materials can be

used. Welding and fastening weaken

substrates and require a minimum

thickness to retain integrity.

• Bond dissimilar materials. 3M

adhesives and tapes bond to a wide

range of substrates from metals,

wood, glass, plastics and ceramics.

This includes “hard to bond,” low

surface energy materials.

• Prevent galvanic corrosion. 3M

adhesives and tapes can provide

a lm barrier to reduce or prevent

bimetallic corrosion that can occur

when joining to dierent types

of metals.

Mechanical Fastener 10 3M™ VHB™ Tape 10

What can 3M™ Adhesives and Tapes do for your

product and process?

With uniform stress distribution of adhesives and tapes, lighter, thinner materials can be used

without concerns about distortion, splitting, or crazing at the mechanically fastened site.

Elimination of holes in metal also reduces the chances for rust and corrosion.

VS

8

11

12

13

14

15

16

17

18

19

20

21

22

23

3

3M Industrial Adhesives and Tapes | October 2017 Edition

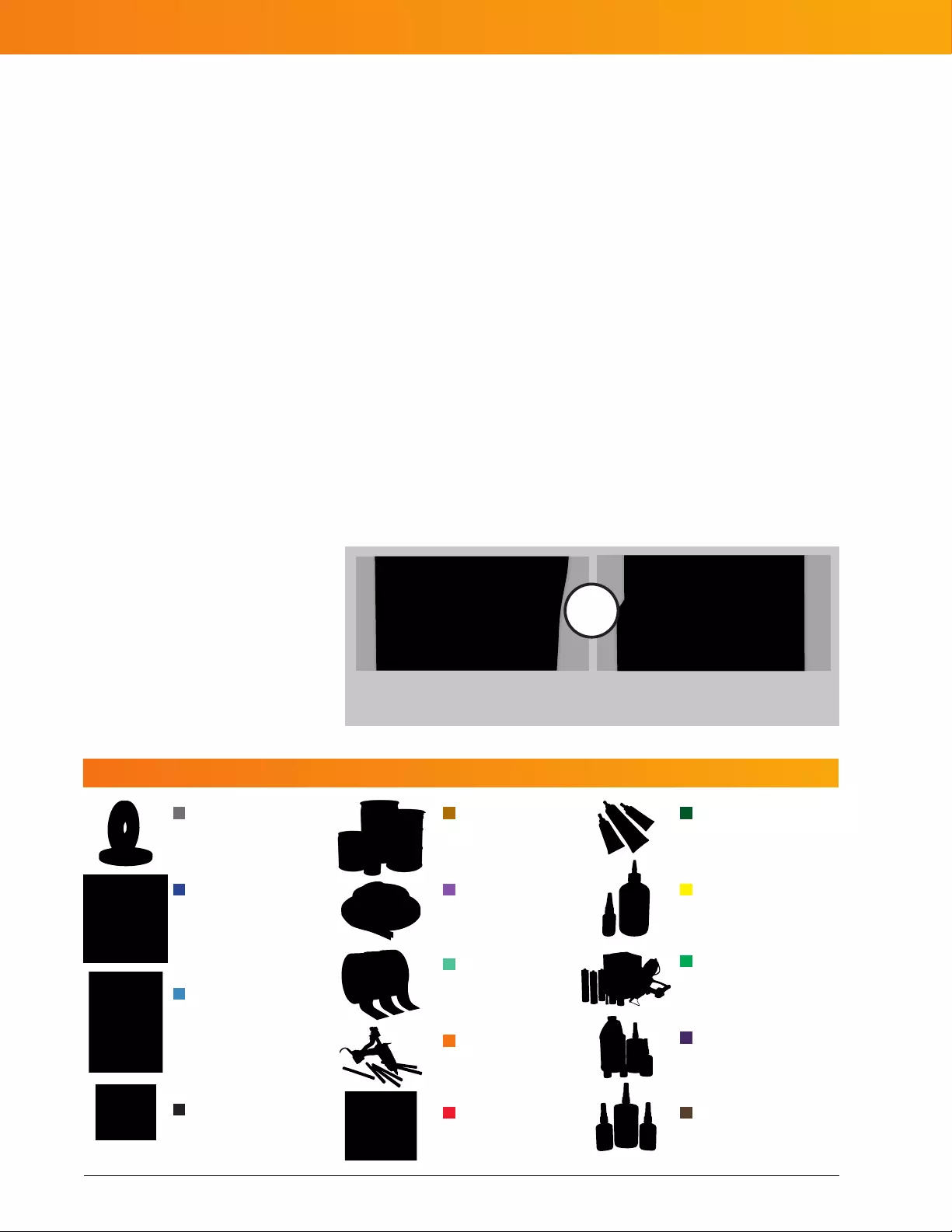

Panel to Frame/

Stiener to Panel

pg 4

Small Joint

Assembly

pg 6

Mounting and

Trim Attachment

pg 10

Potting and

Encapsulating

pg 14

Sealing

pg 14

Gasket Attachment

pg 12

Large Surface

Lamination

pg 8

Assembly Solutions

are made up of these

common applications:

Considerations when selecting

3M™ Adhesives and Tapes for

your product and process.

Assembly

What type of assembly is required? (Refer to 7

common assembly types in the right hand column.)

What are the overall performance needs of the

assembly (exibility, high peel strength, etc.)?

Substrate

What are the materials that are being bonded

together? (Refer to the substrate selectors for

each assembly type on pages 4–15.)

Consider the surface condition texture of

each material.

Process

What is the current assembly and manufacturing

process?

Does the solution need to t into the current process/

equipment or can the process/equipment change?

What are the various process steps and how

quickly will the assembly be moved to each step?

At any time, might the assembly bond need to be

repositioned? If so, why and when?

Are there any environmental, regulatory or

workplace safety restrictions?

End-Use

How and where is the nal product used?

Will the assembly be exposed to harsh

environmental conditions (UV, chemicals, high

humidity, very high or low temperatures, etc.)?

Cost

Where can improvements be made in the

assembly process (labor, reduction of

process steps, materials, workow, etc.)?

291

292

292

292

292

292

292

292

292

292

292

292

A

S

P

E

C

3M Industrial Adhesives and Tapes | 3M.com/Assemblysolutions

4

3M Industrial Adhesives and Tapes

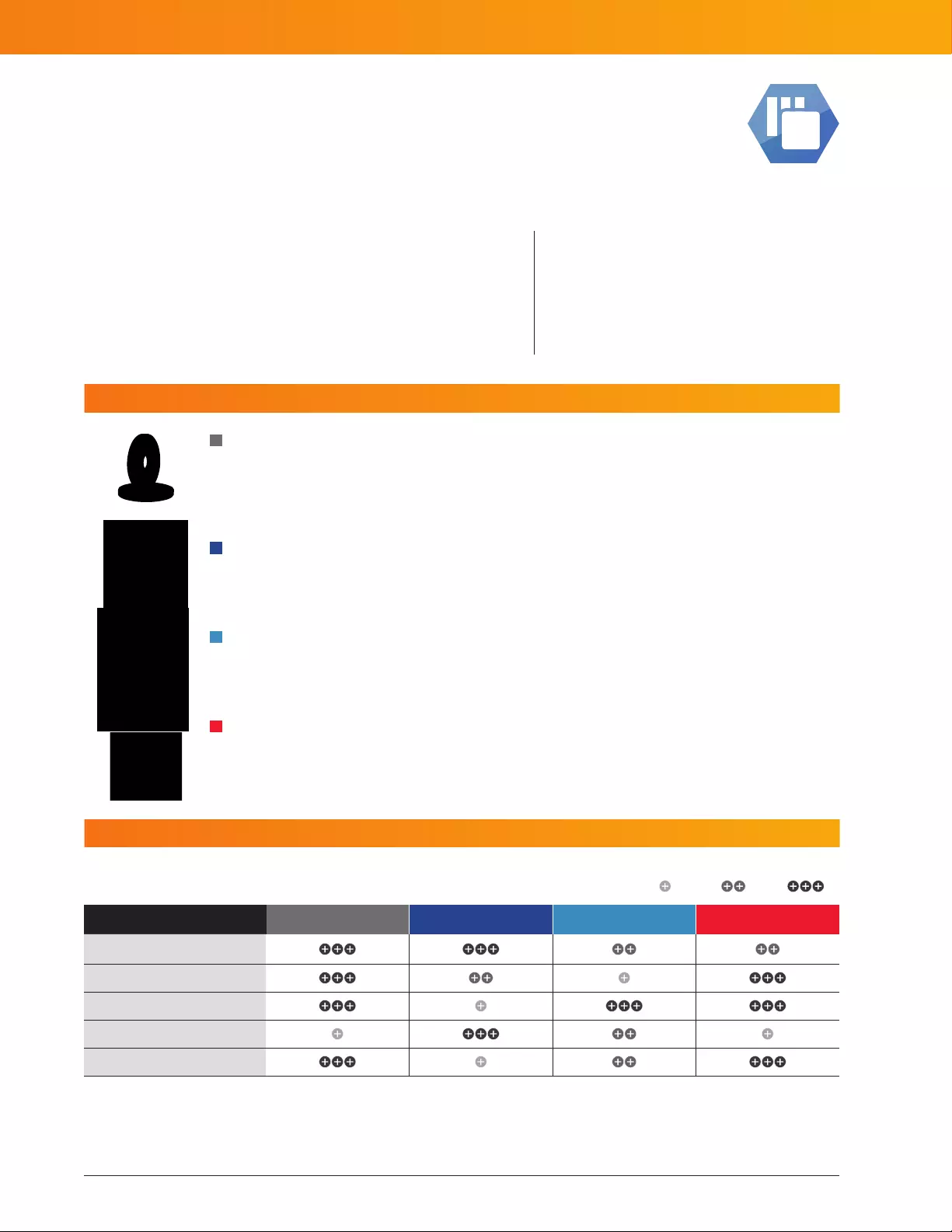

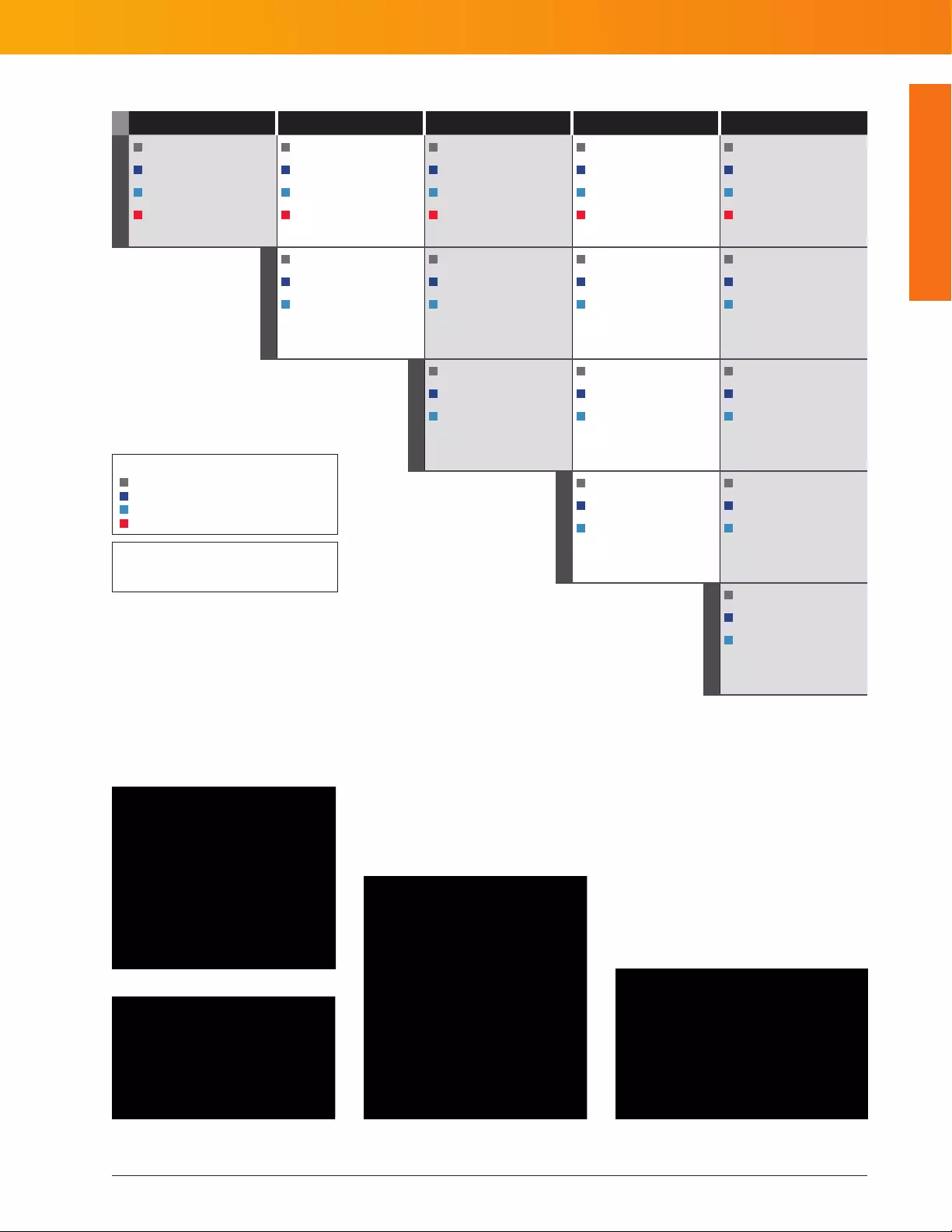

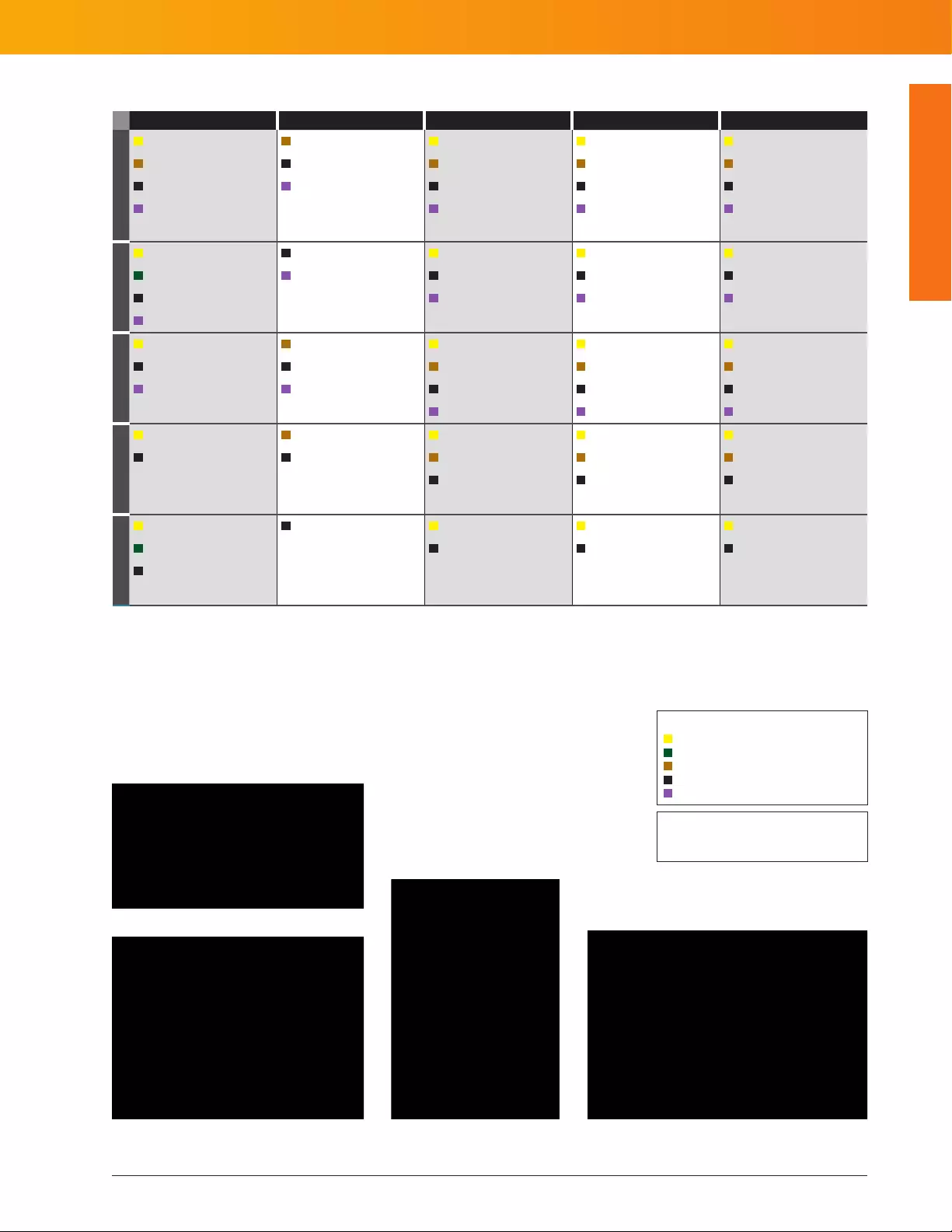

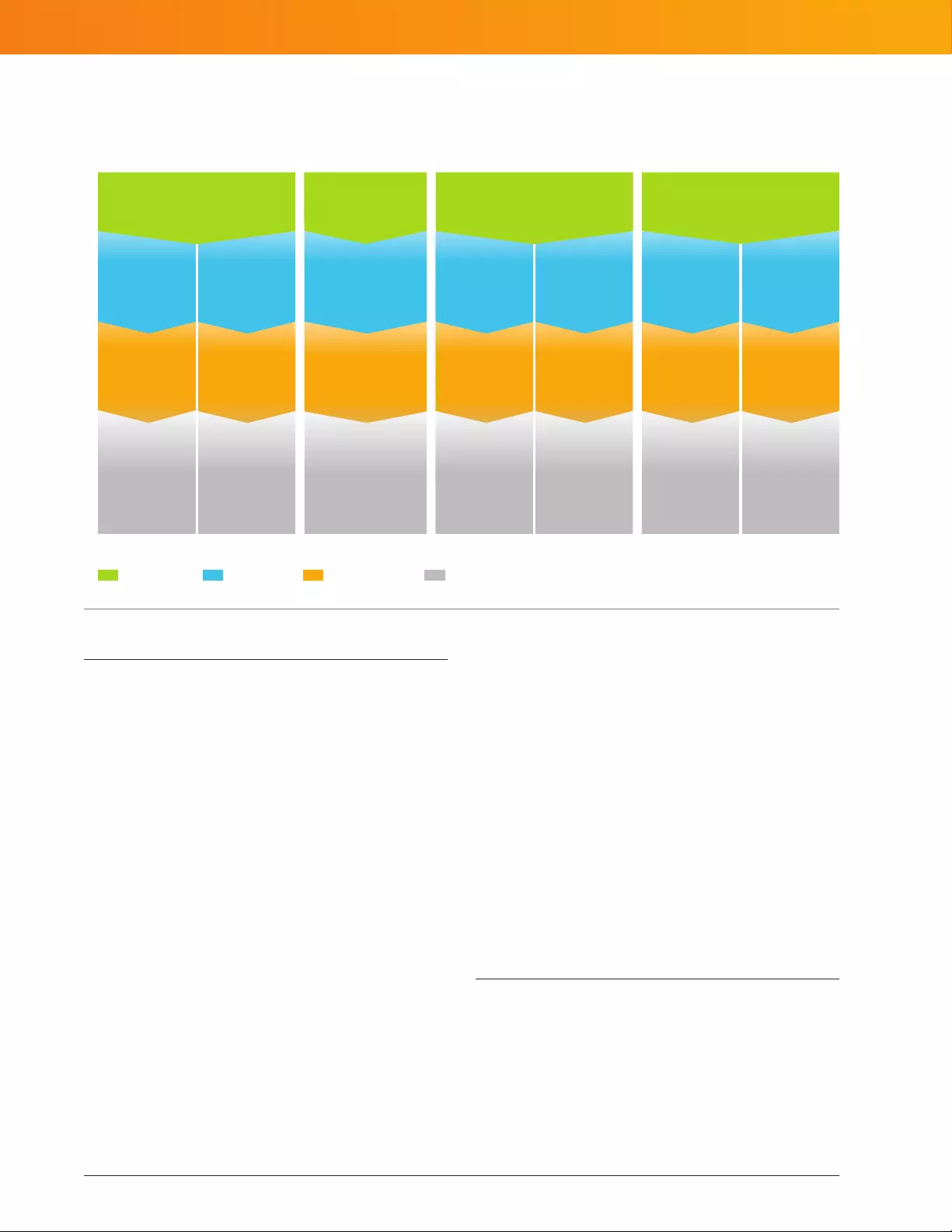

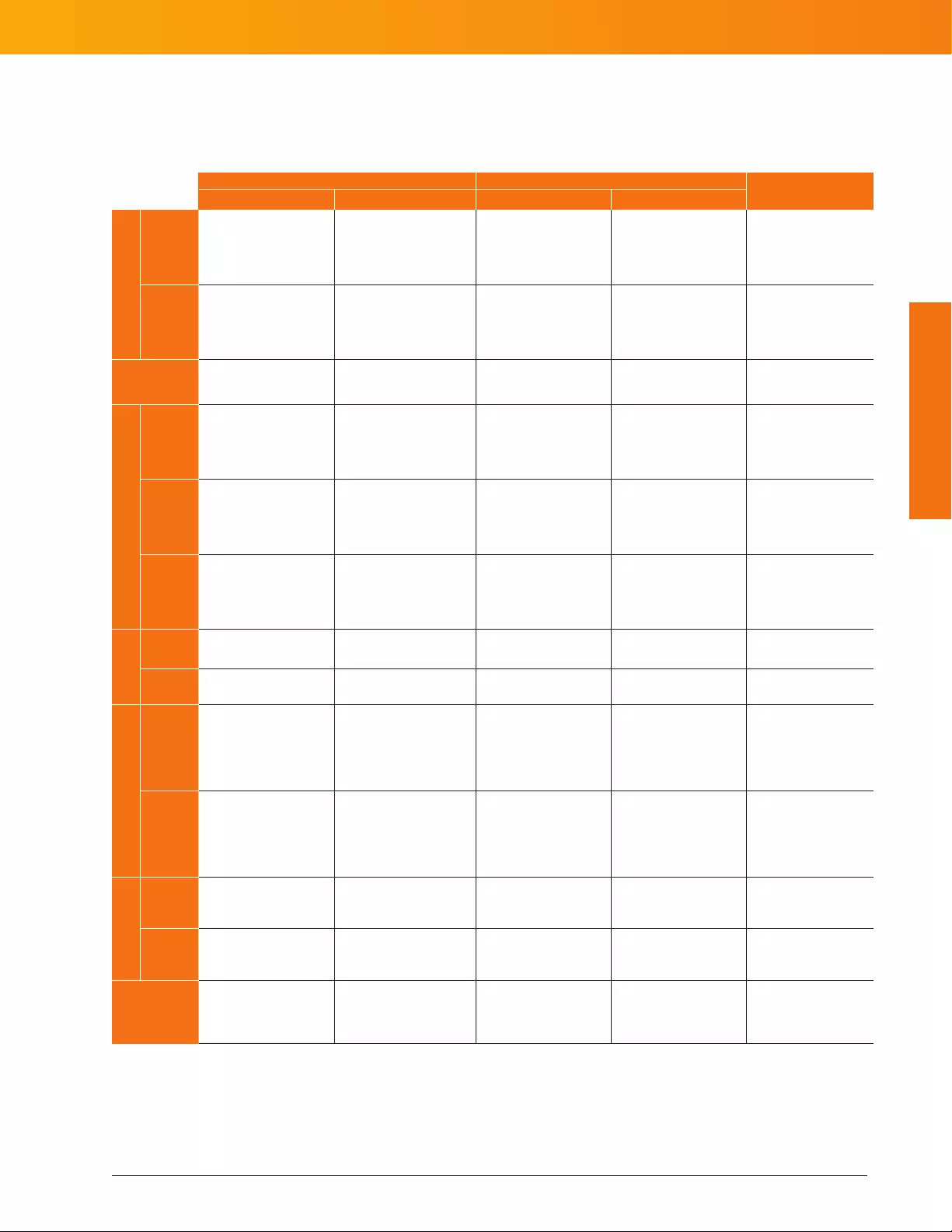

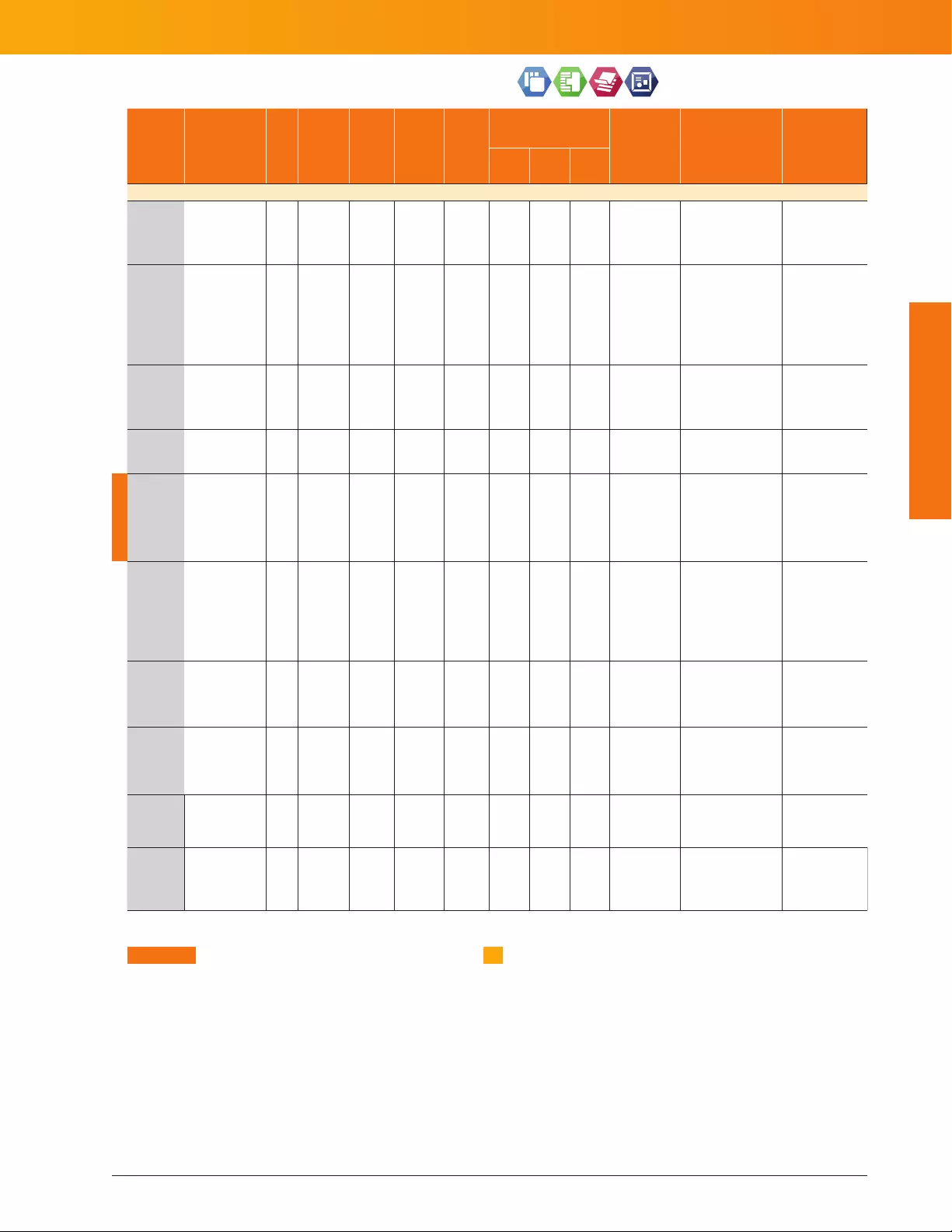

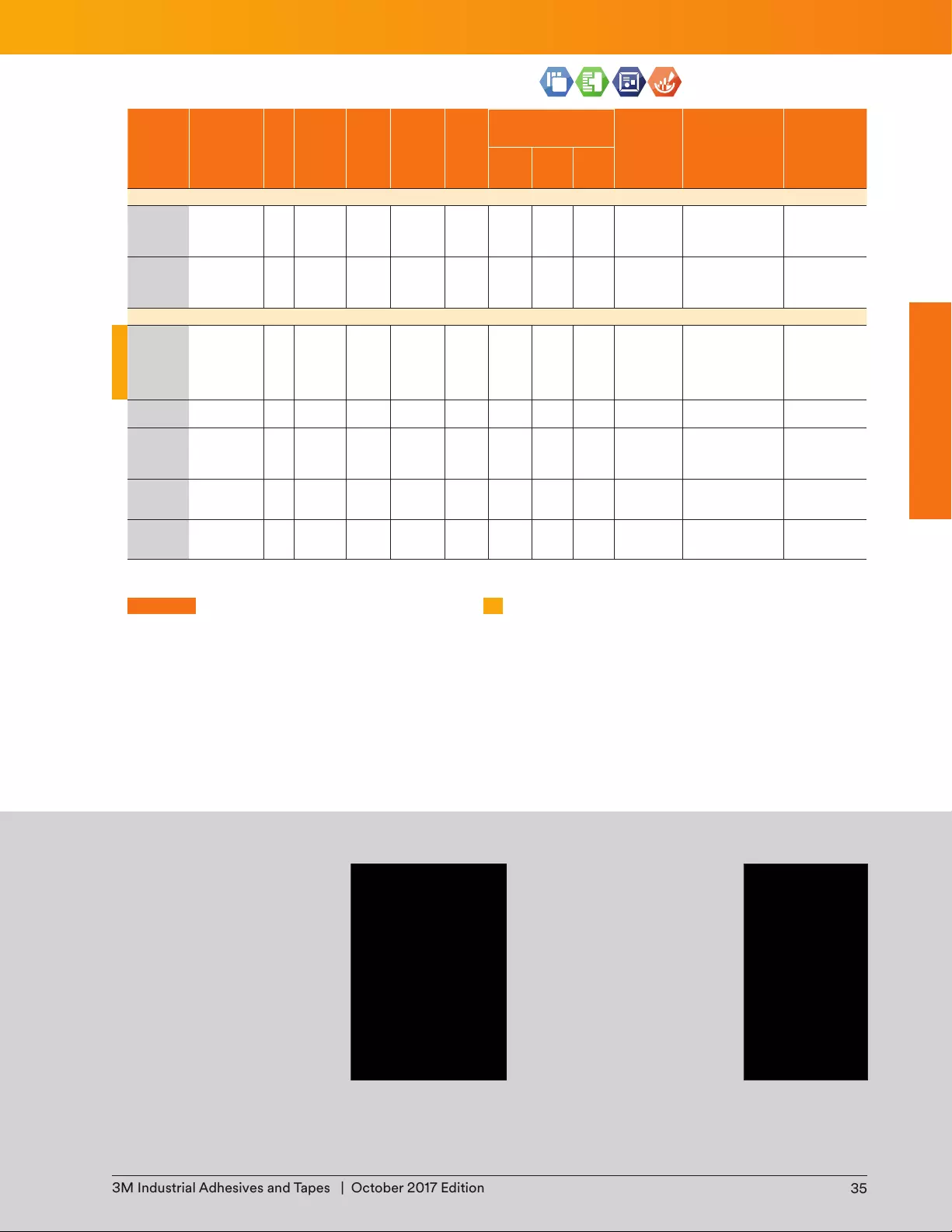

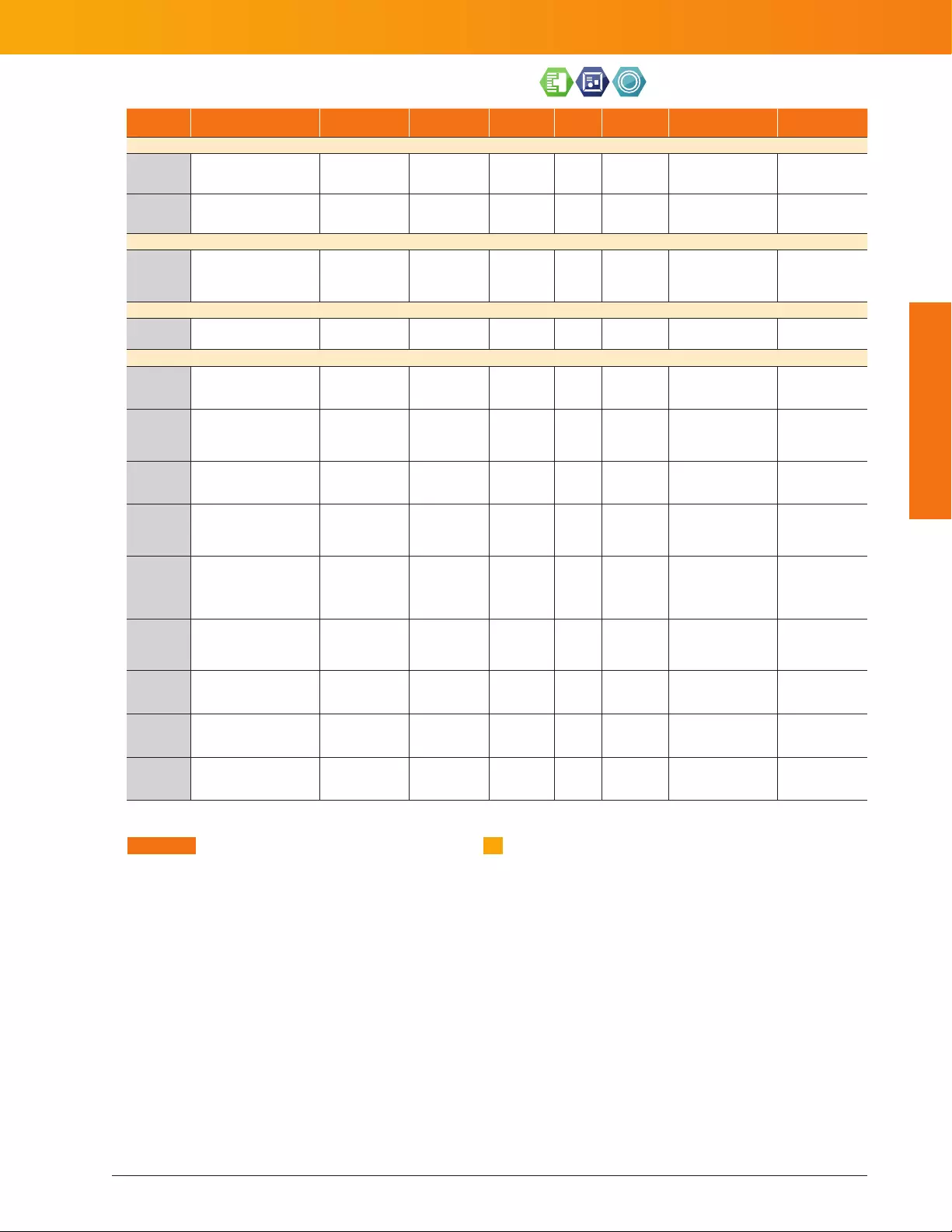

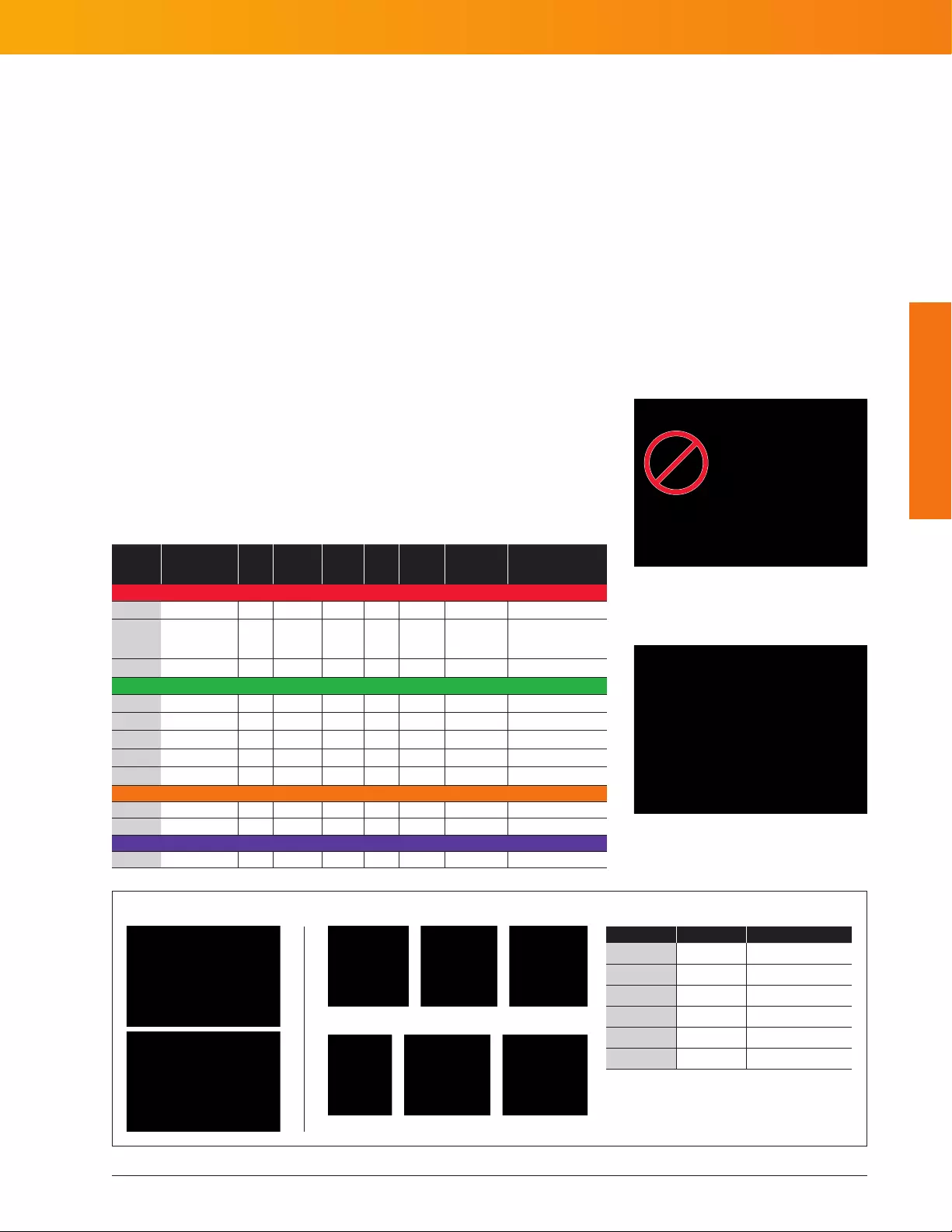

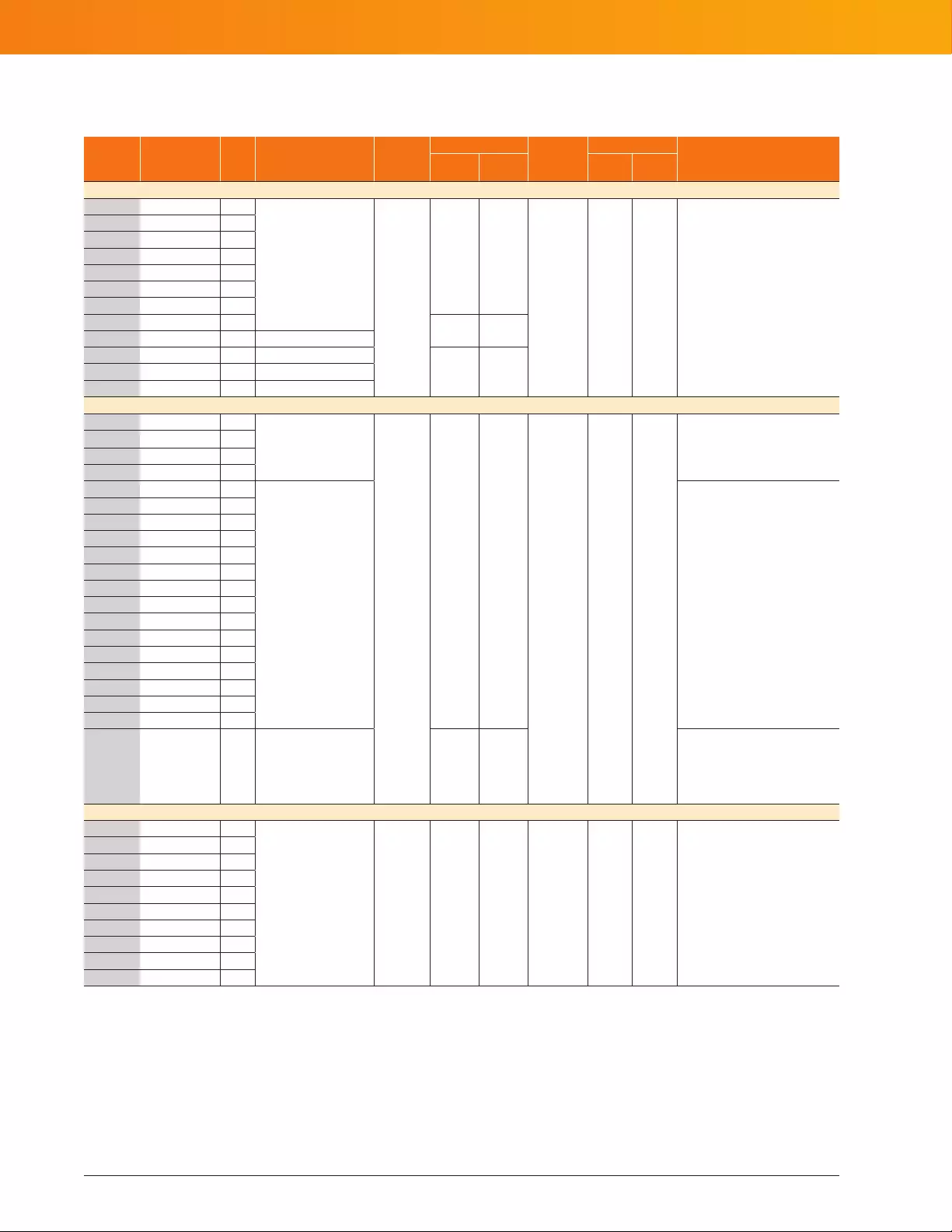

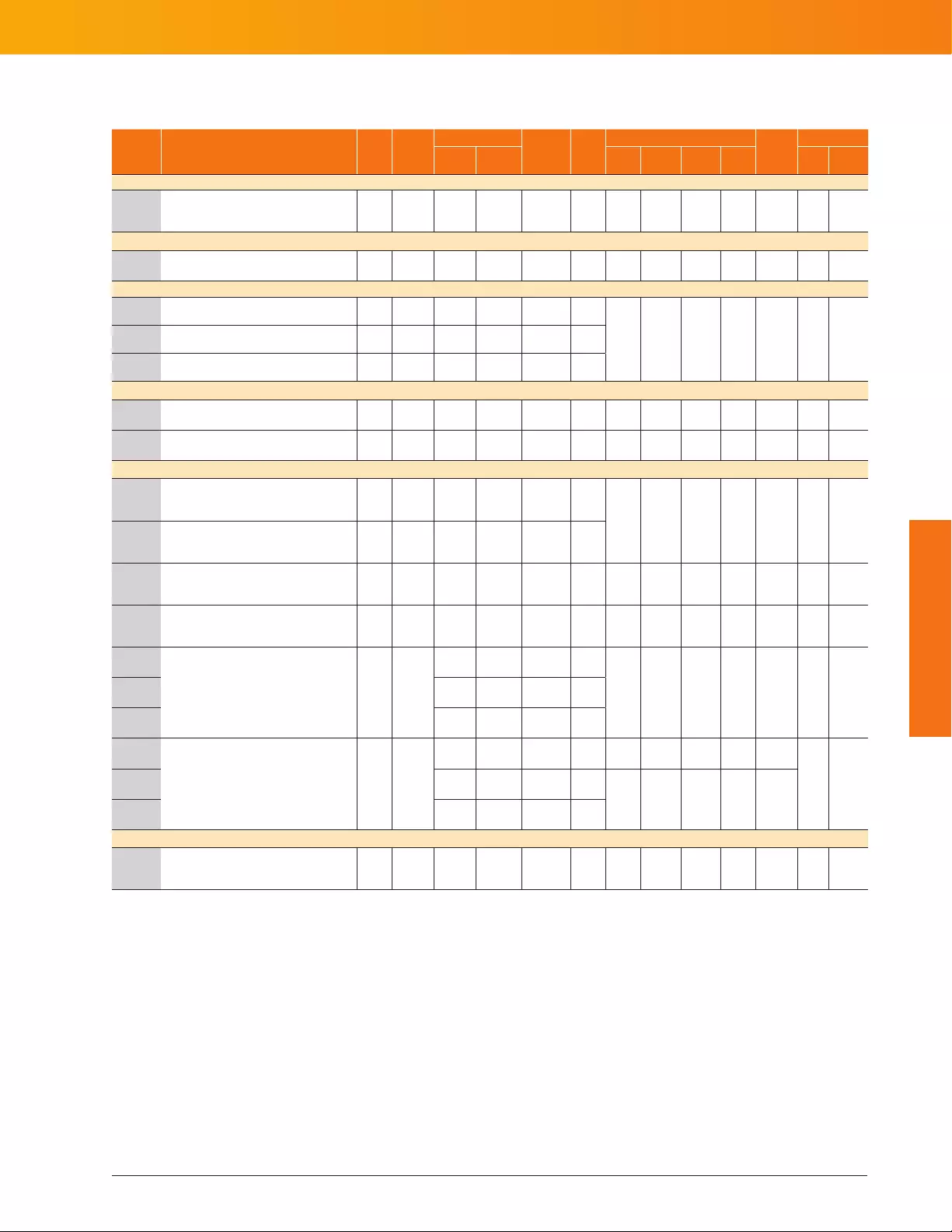

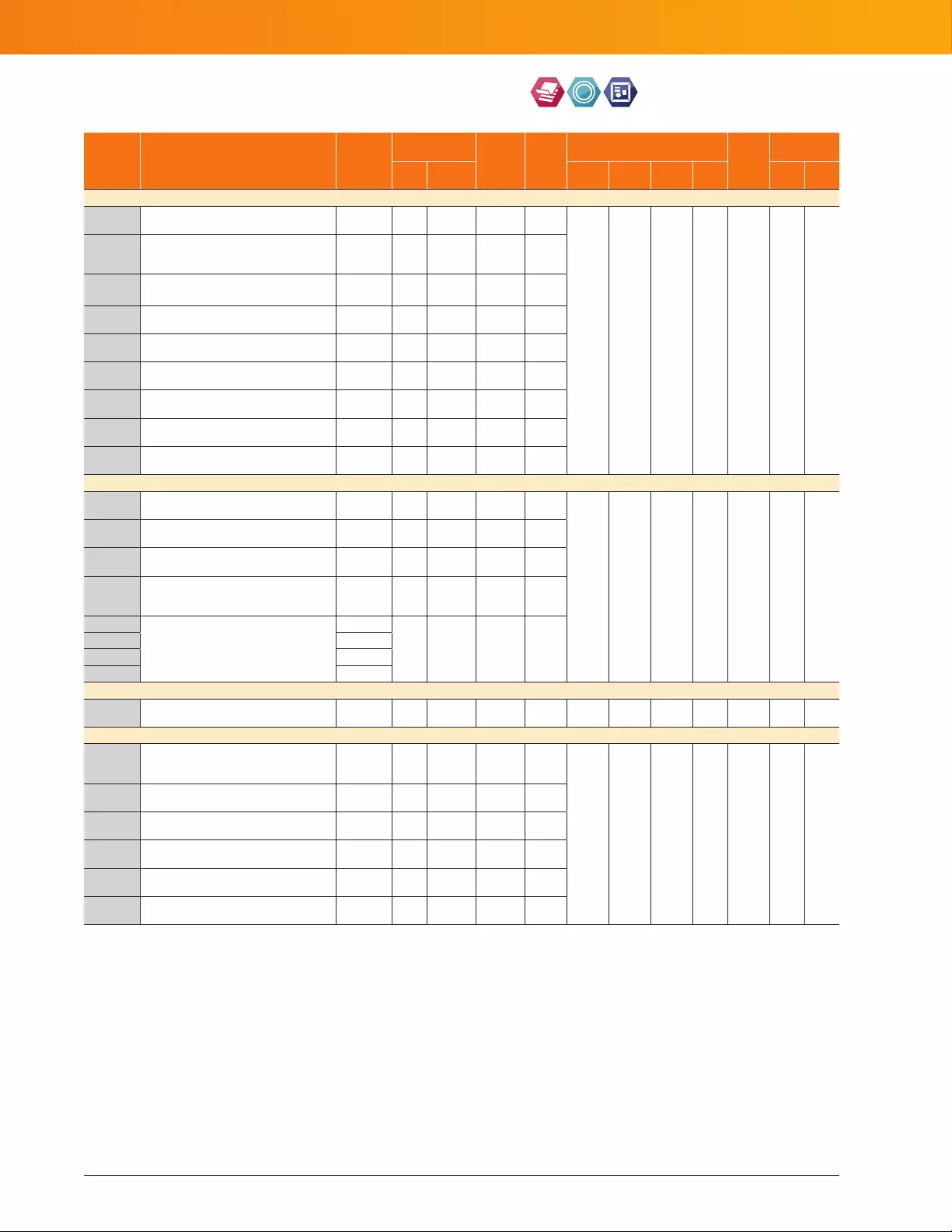

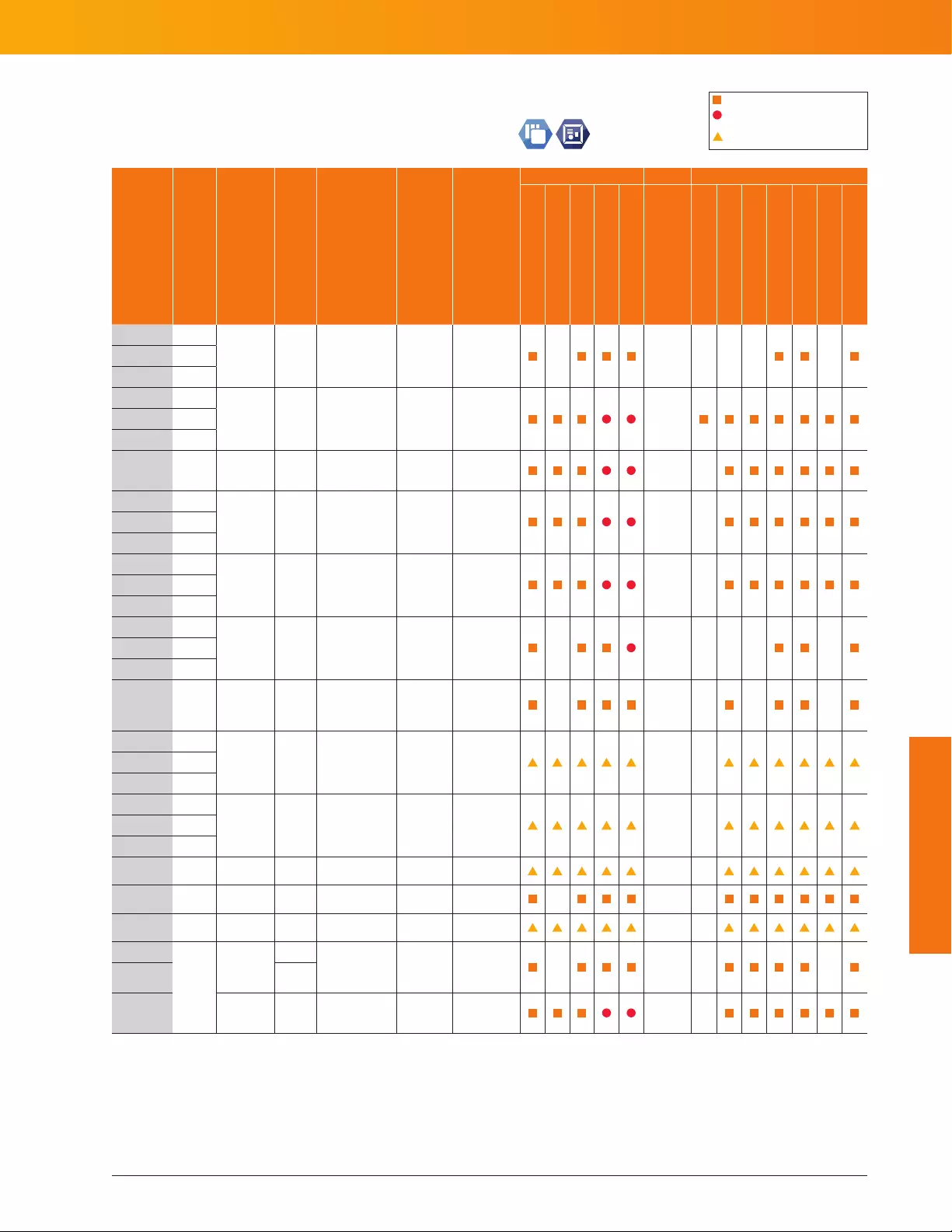

Performance Factors for Panel to Frame/Stiener to Panel Assemblies

All 3M technologies in the table below are commonly used in panel applications.

Use the table below as a relative comparison of product performance.

Attribute 3M™ VHB™ Tapes

3M™ Scotch-Weld™

Structural Adhesives 3M™ Adhesive Sealants 3M™ Reclosable Fasteners

Number of Steps to Apply and

Ease of Application

Rate of Strength Build

Flexibility and Joint Expansion

Holding Power

Repair/Removal After Cure

What are Panel to Frame Assemblies?

What are Stiener to Panel Assemblies?

Panels are used in multiple markets, such as transportation,

metalworking and construction.

Panel to Frame: Decorative or load bearing panel that is applied

to a rigid frame or support. Examples include trailer panels,

elevator walls and sign boxes.

Stiener to Panel: Stieners are applied to panels to give extra

support and rigidity. Examples include trailer wall panels, trac

signs and large metal enclosures.

Possible Adhesive or Tape Requirements:

• Dead load holding strength

• Flexibility for dynamic loads and thermal

expansion mismatch

• Fill a gap or variation in t from end to end

• Provide a water seal

3M™ VHB™ Tapes (pg 68–75)

These high-strength bonding tapes are a proven alternative to screws, rivets, welds and other

mechanical fasteners. 3M™ VHB™ Tape oers instant strength, a high ultimate bond and seals

simultaneously. 3M™ VHB™ Tape’s viscoelasticity allows relative movement of parts for thermal

expansion/contraction. Best for at to at applications with a consistent bondline thickness.

3M™ Scotch-Weld™ Structural Adhesives (pg 18–36)

Acrylic, epoxy and urethane structural adhesives that hold over 1,000 psi in overlap shear strength.

Best suited for thinner bondlines, irregular shapes and textured surfaces where load-bearing

strength is needed. Provides the highest load-bearing strength and environmental resistance.

3M™ Adhesive Sealants (pg 47–51)

Acrylic, polyurethane, nitrile and hybrid one-component adhesive technologies with outstanding

sealing properties. These products are capable of lling larger and irregular gaps including rough

substrates. Highly exible formulations allow for relative movement for thermal expansion/contraction.

3M™ Reclosable Fasteners (pg 92–95)

3M™ Dual Lock™ and 3M™ Hook and Loop Reclosable Fasteners for strong yet easily removable

fastening solutions. These products are ideal to allow access for servicing or replacement of a

panel. Generally backed with 3M™ VHB™ Tape or other 3M adhesive technologies.

8

12

18

11

292

Best 3M Solutions for Panel to Frame/Stiener to Panel Assemblies

Good = Better = Best =

5

3M Industrial Adhesives and Tapes | October 2017 Edition

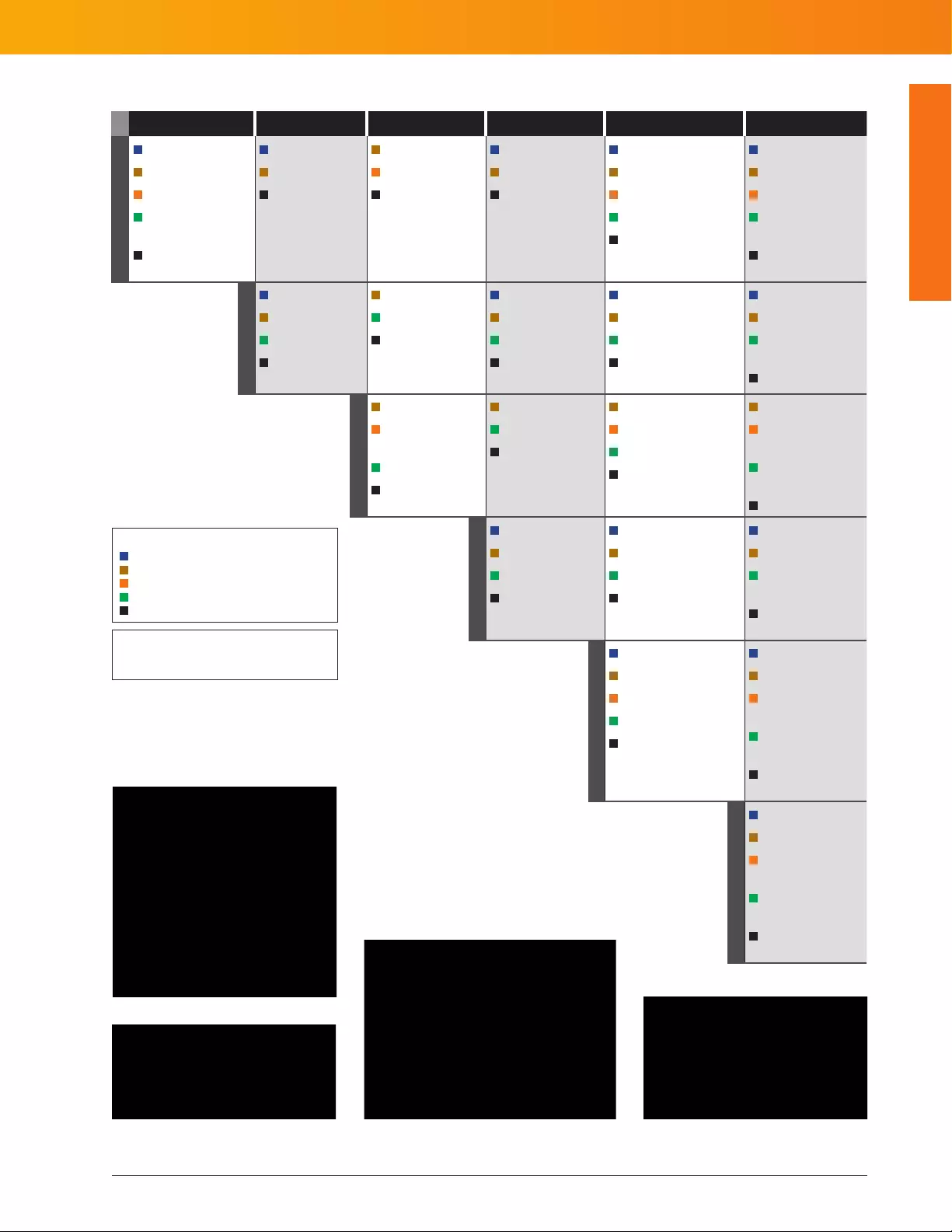

Panel to Frame/Stiener to Panel Assembly Solutions

+

Metals

(Aluminum, Steel, Stainless, Galvanized)

Paints (Powder Coat,

Painted Metal, Composite Panel) Glass

Plastics: HSE, MSE

(ABS, Acrylic, Polycarbonate, Nylon)

Plastics: LSE

(Polypropylene, Polyethylene)

Metals

4941, RP45, 5952

LSB60NS

*550FC + AC61

SJ3550/51/52,

SJ3571/72

*4941, *RP45, 5952

LSB60NS

*550FC + AC61

SJ3540/41/42,

SJ3526N/27N

*4941, *RP45, *5952

LSB60NS

*590, *560, *760

SJ3560/61/62,

SJ3571/72

*4941, *RP45, 5952

LSB60NS

*560, *760

SJ3550/51/52,

SJ3571/72

*4941, *RP45, *5952

DP8010 Blue

*560, *760

SJ3540/41/42,

SJ3526N/27N

*4941, *RP45, 5952

DP8810NS

*550, *560, *760

*4941, *RP45, *5952

LSB60NS

*590, *560, *760

*4941, *RP45, 5952

DP8810NS

*560, *760

*4941, *RP45, *5952

DP8010 Blue

*560, *760

*4941, *RP45, *5952

DP460

*590

*4941, *RP45, 5952

DP100 Plus Clear

*560, *760

*4941, *RP45, *5952

DP8010 Blue

* 560, *760

*4941, *RP45, 5952

DP8405NS

*560, *760

*4941, *RP45, *5952

DP8010 Blue

*560, *760

*4941, *RP45, *5952

DP8010 Blue

*560, *760

Plastics: LSE

Plastics: HSE, MSE

Glass

Paints

Key

3M™ VHB™ Tapes

3M™ Scotch-Weld™ Structural Adhesives

3M™ Adhesive Sealants

3M™ Reclosable Fasteners

* Primers may also be required in some

cases. See specic product pages for

primer details.

For 3M™ VHB™ Tape applications in the Commercial Vehicle

market, refer to page 72 for a selection of products.

Assembly Solutions

27

26

28

29

29

This guide lists products that are commonly used for this specic application. It is important that the customer evaluates these suggested products in their specic application.

3M Industrial Adhesives and Tapes | 3M.com/Assemblysolutions

6

3M Industrial Adhesives and Tapes

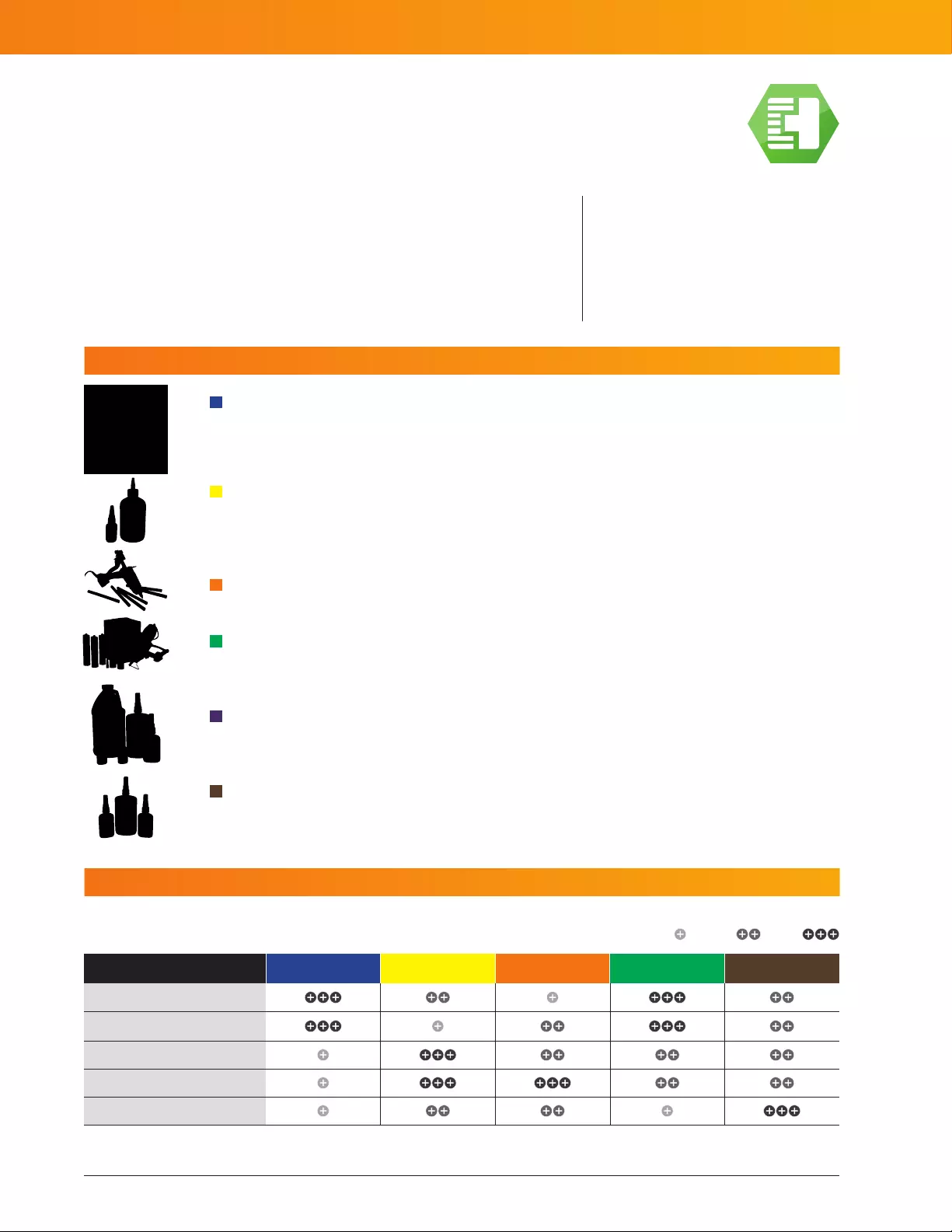

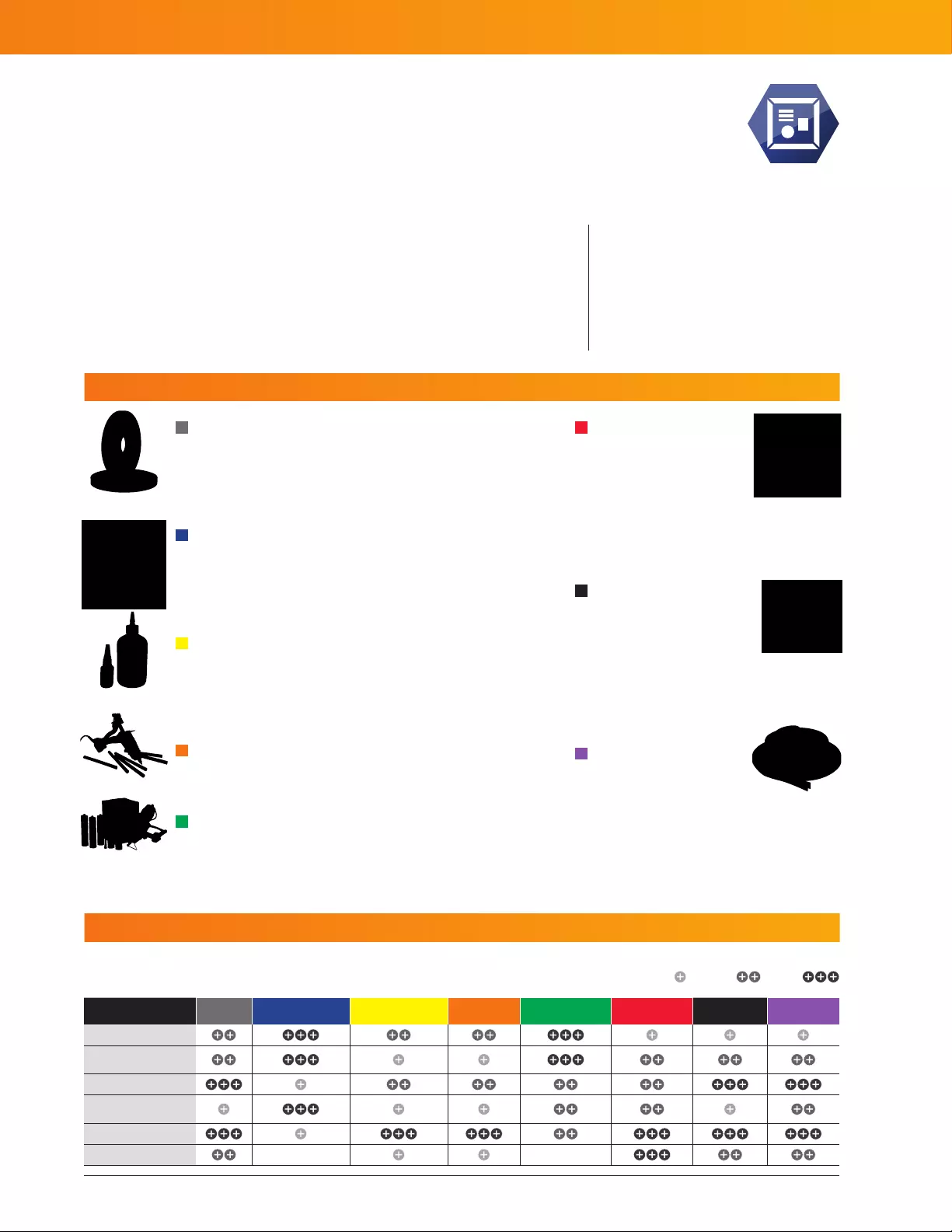

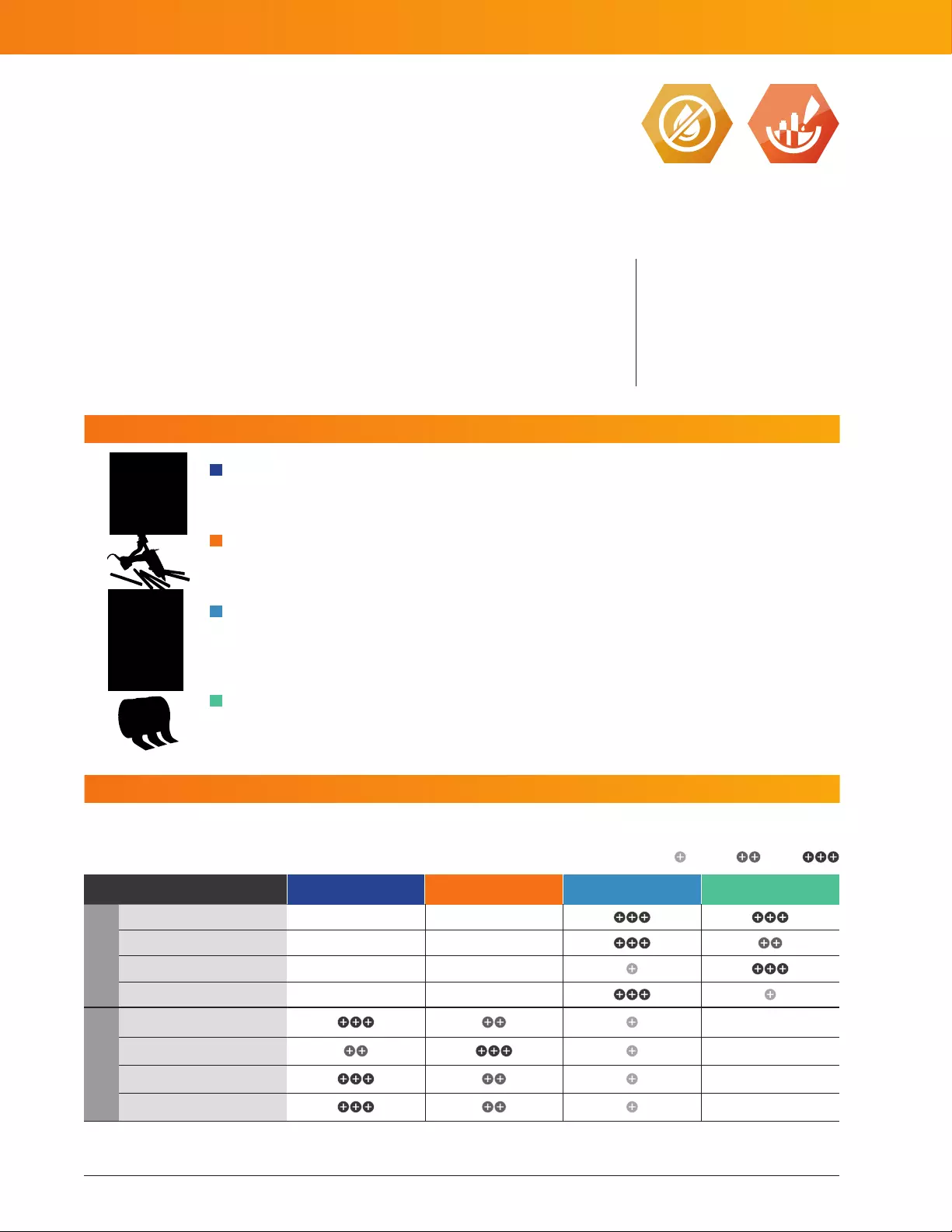

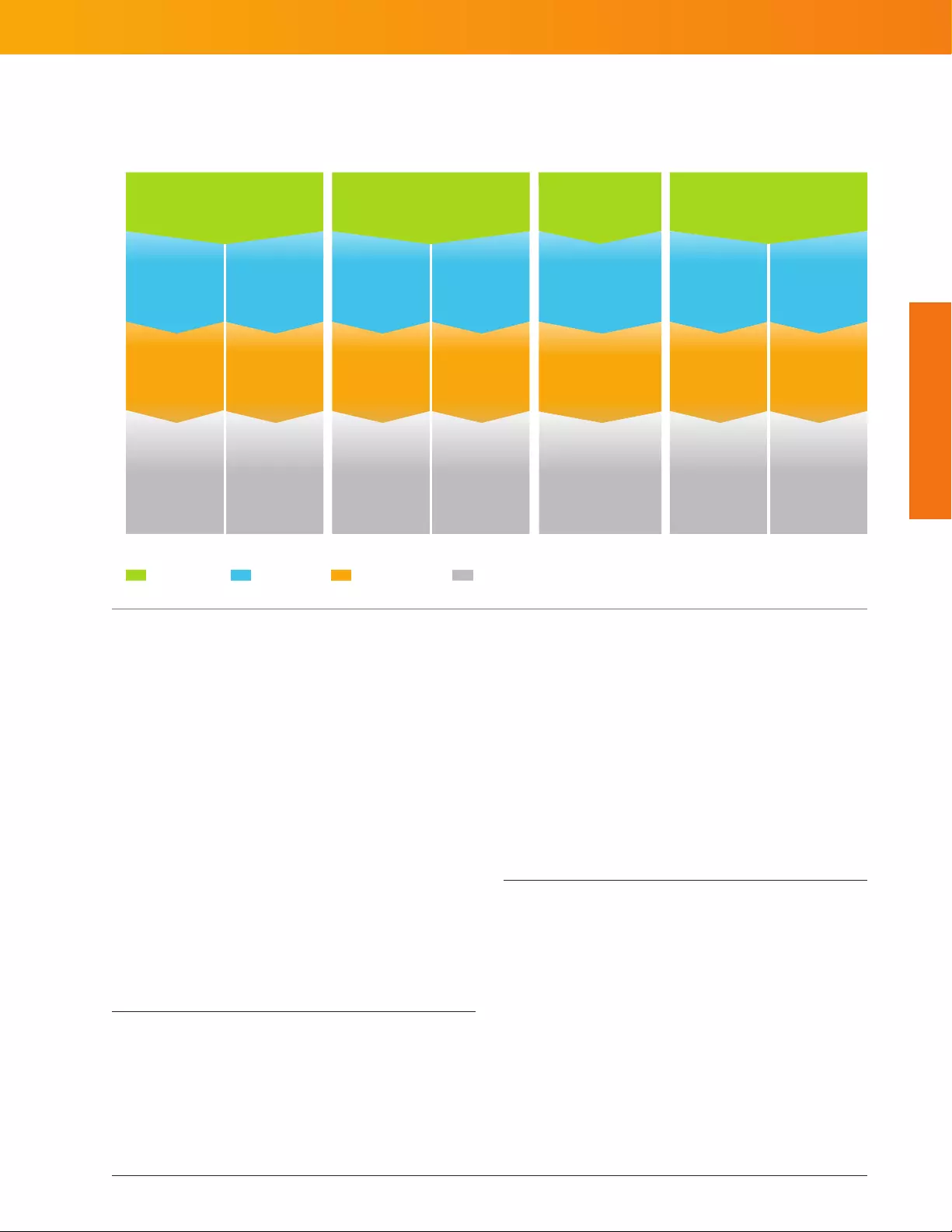

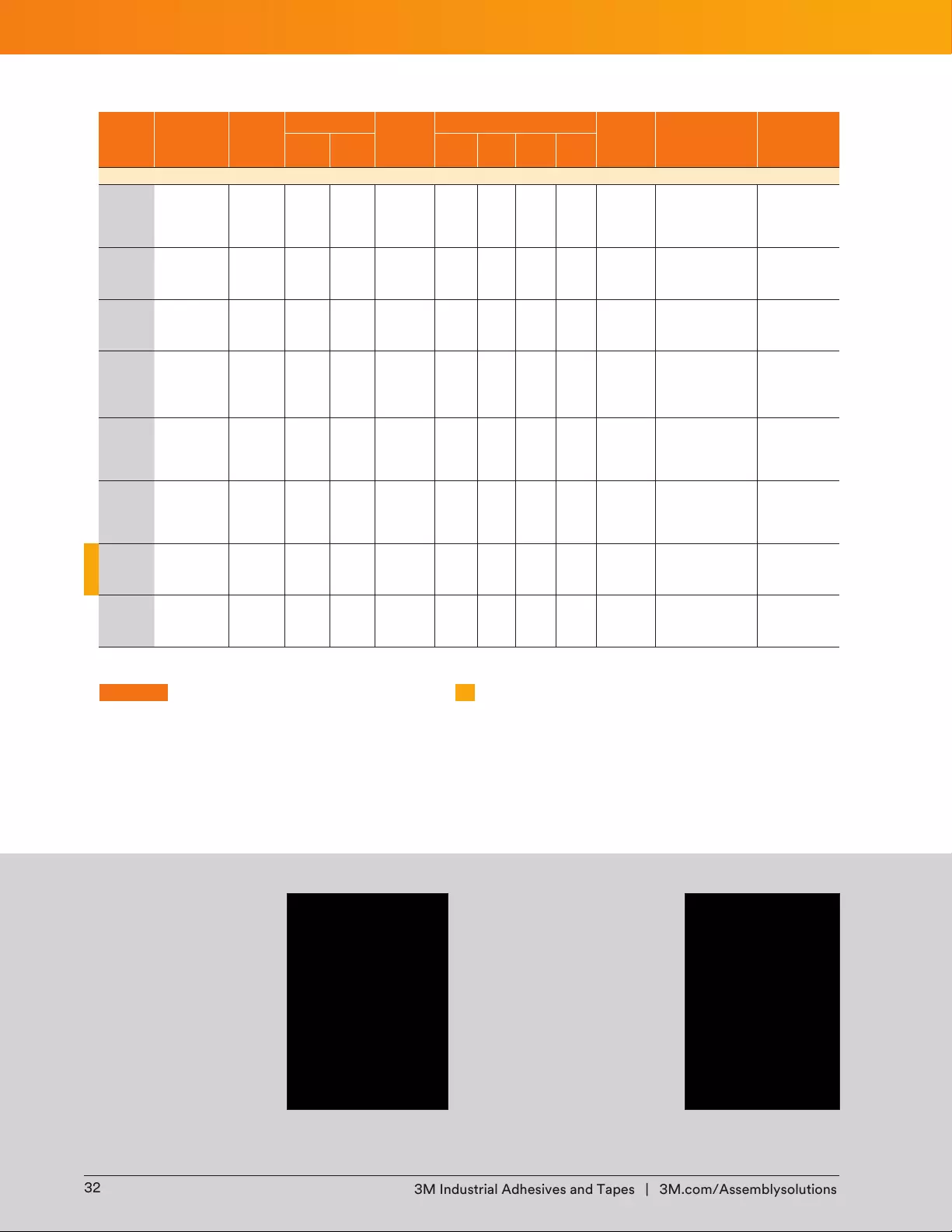

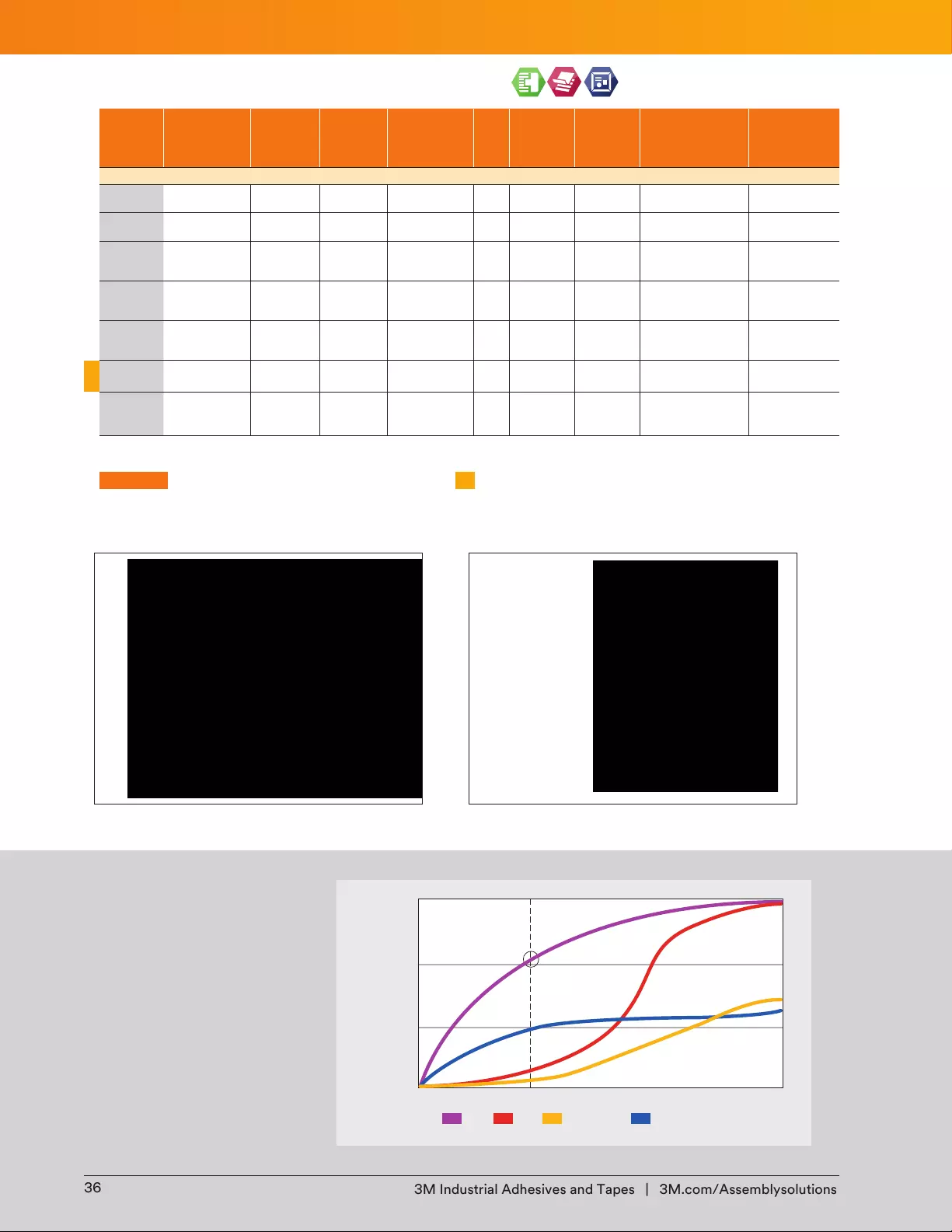

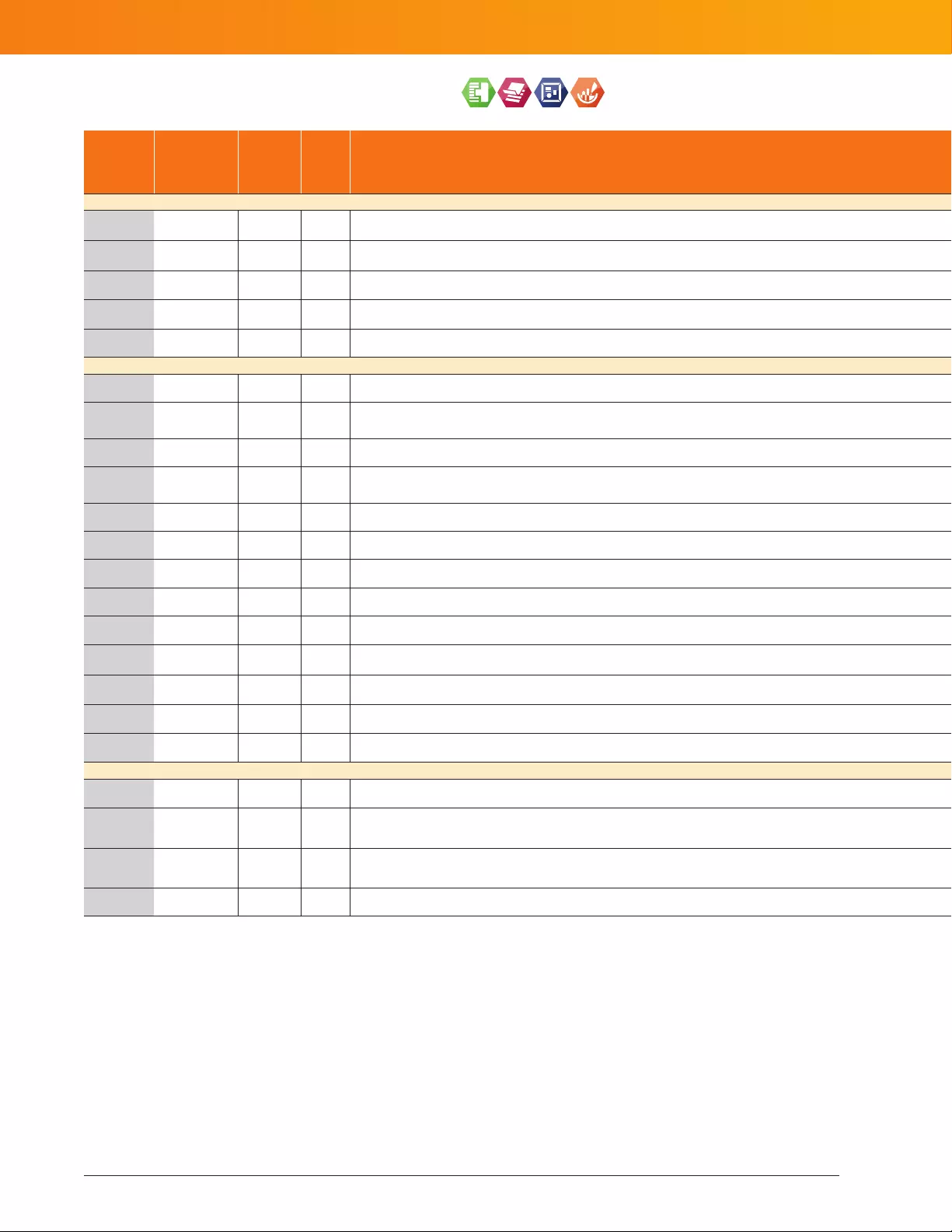

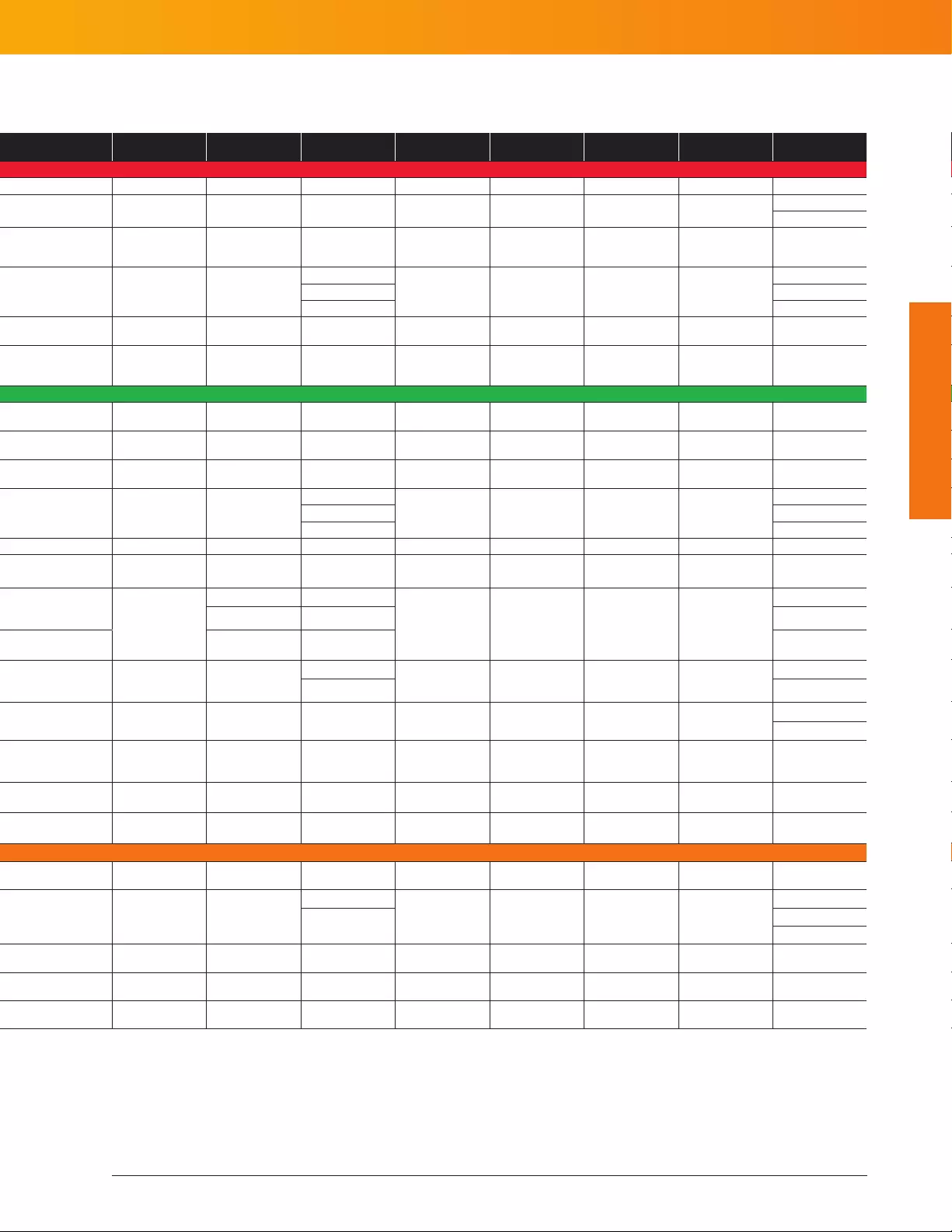

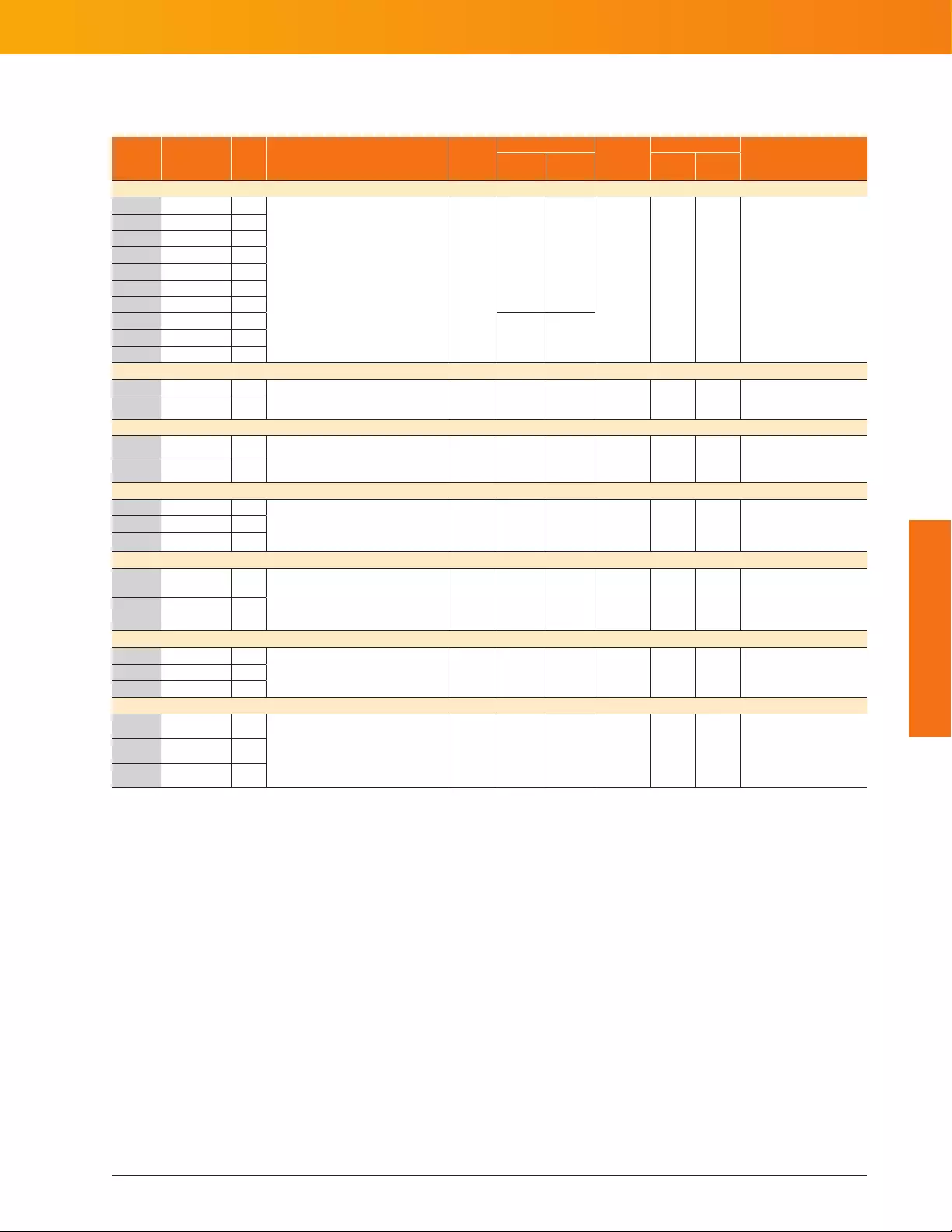

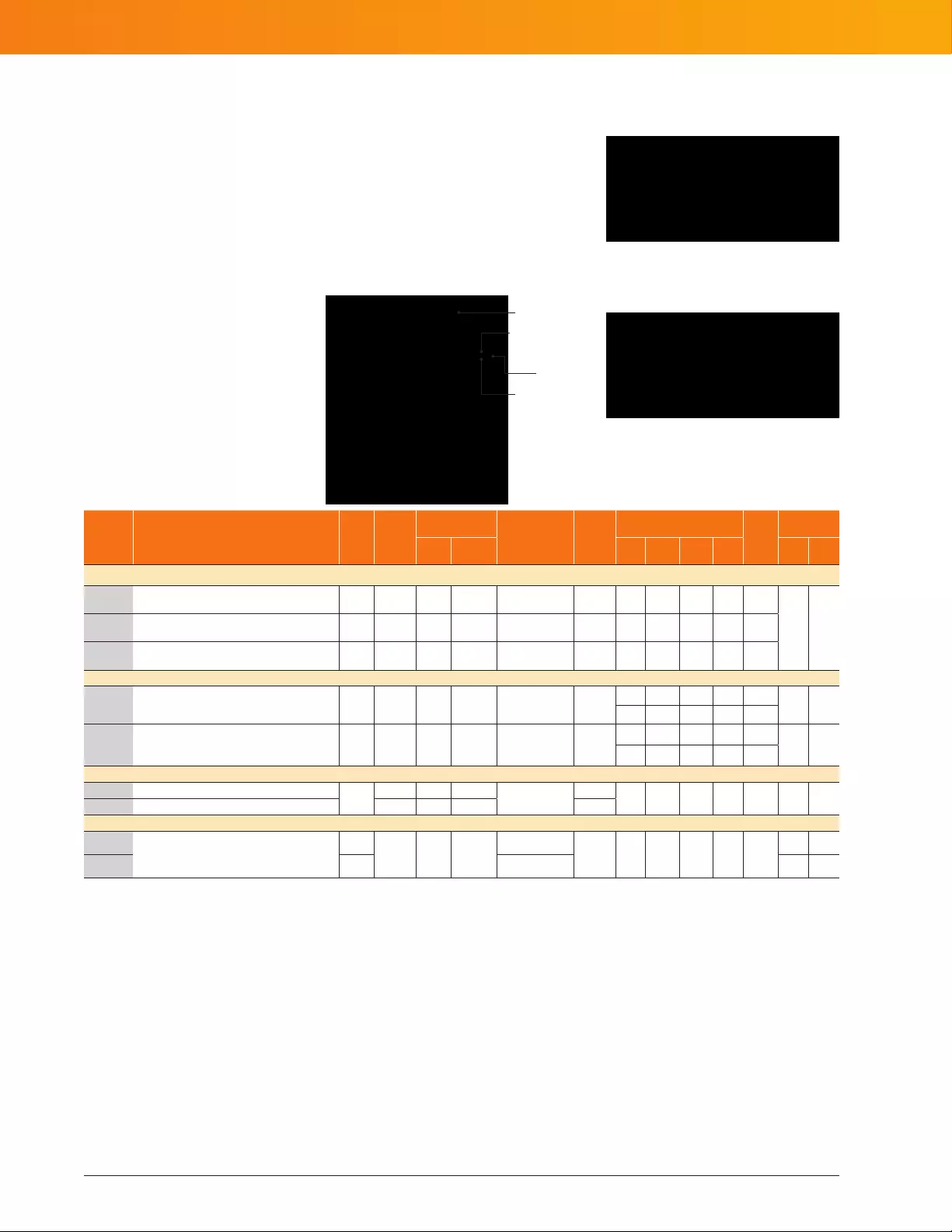

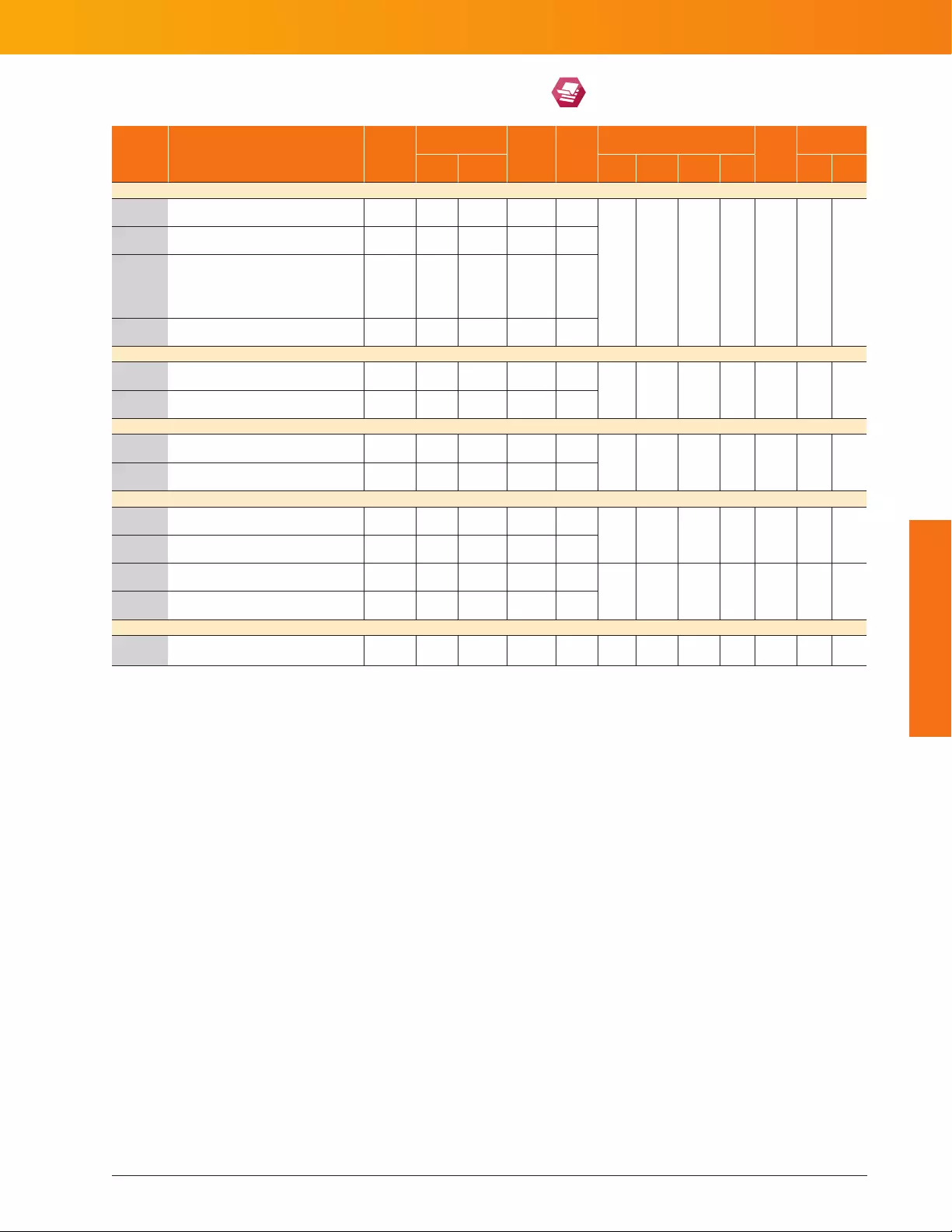

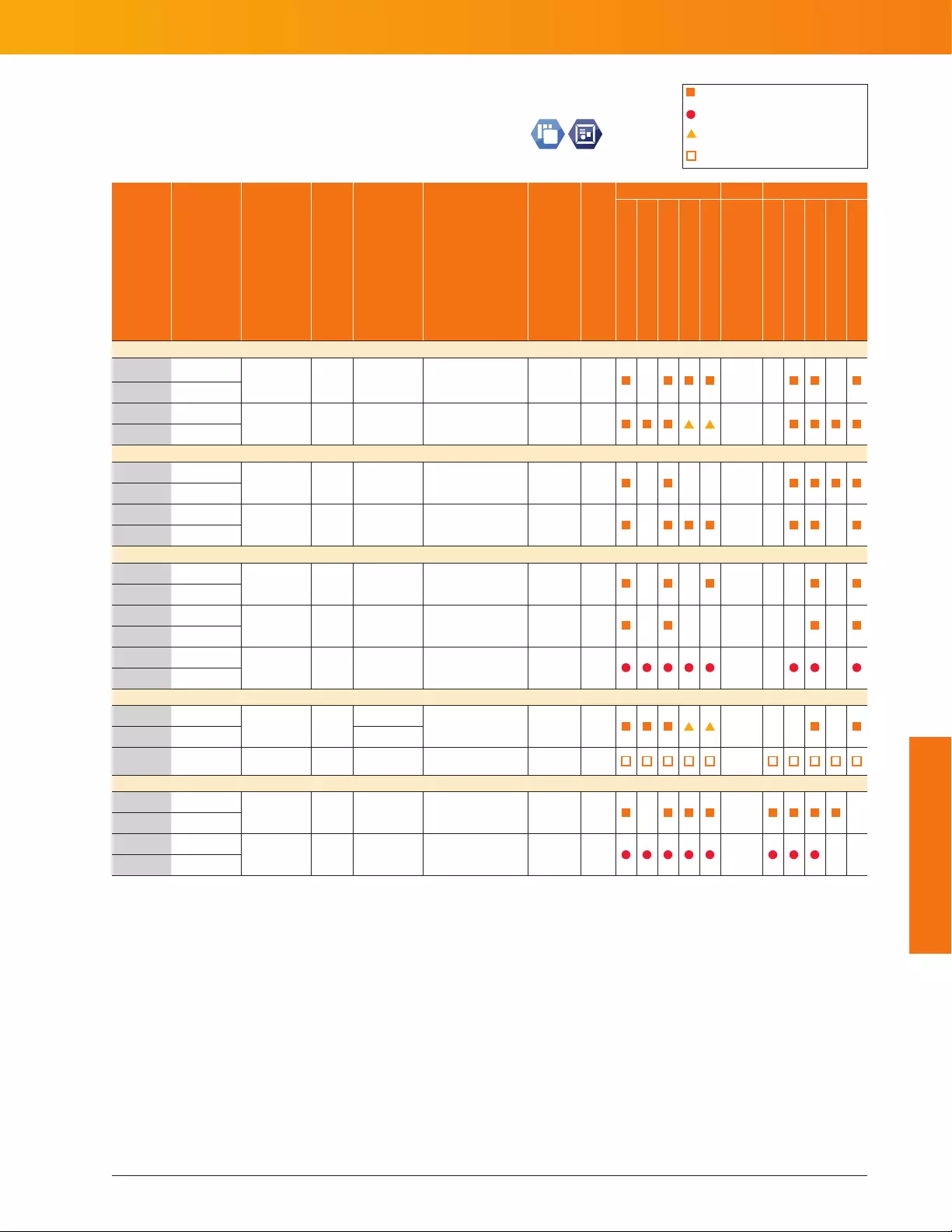

Performance Factors for Small Joint Assemblies

All 3M technologies in the table below are commonly used in small joint applications.

Use the table below as a relative comparison of product performance.

Attribute

3M™ Scotch-Weld™

Structural Adhesives

3M™ Scotch-Weld™

Instant Adhesives

3M™ Hot Melt

Adhesives

3M™ Scotch-Weld™

PUR Adhesives

3M™ Scotch-Weld™

Threadlockers

Shear and Peel Strength

Temperature and

Solvent Resistance

Aesthetics

Rate of Strength Build

Rework

Small Joint: Small joints are typically irregularly shaped but only a few

inches of overlap area. They may be insertion joints or overlap joints,

or some combination. Examples include sporting goods (e.g., golf

club heads to shaft), plastic casings, lens mounting for instrumentation,

mortise and tenon furniture joints, thread locking or shaft retailing,

magnet bonding and jewelry making.

Possible Adhesive or

Tape Requirements:

• Low viscosity for tight tting parts

• Vibration resistance

• Very high strength

• Bond dissimilar materials

3M™ Scotch-Weld™ Structural Adhesives (pg 18–36)

Acrylic, epoxy and urethane structural adhesives that hold over 1000 psi in overlap shear strength.

Best choice for highest strength, fatigue and environmental resistance especially for metal

to metal bonds.

3M™ Scotch-Weld™ Instant Adhesives (pg 38–40)

One part solvent-free adhesive that reaches handling strength in 5–10 seconds. Best for small

bondlines (<10cm2). Commonly used on rubbers and plastics. Very tight bondlines are achievable

with near instant strength.

3M™ Hot Melt Adhesives (pg 47–51)

100% solid, thermoplastic resins that reach bond strength in seconds. Best for wood and plastic.

3M™ Scotch-Weld™ PUR Adhesives (pg 36–38)

One component, hot applied thermosetting adhesive with immediate strength and holding power.

Final cured strength over 1,000 psi. Best for wood and plastic.

3M™ Scotch-Weld™ Retaining Compounds (pg 42)

One-part anaerobic adhesives cure between metal surfaces. Permanent and removable grades

are available.

3M™ Scotch-Weld™ Threadlockers (pg 42)

One-part anaerobic adhesives cure between metal surfaces. Permanent and removable grades

are available.

17

20

21

22

23

11

What are Small Joint Assemblies?

Small joint assemblies exist in multiple markets, such as sporting goods,

electronics, furniture, motors and electrical. 292

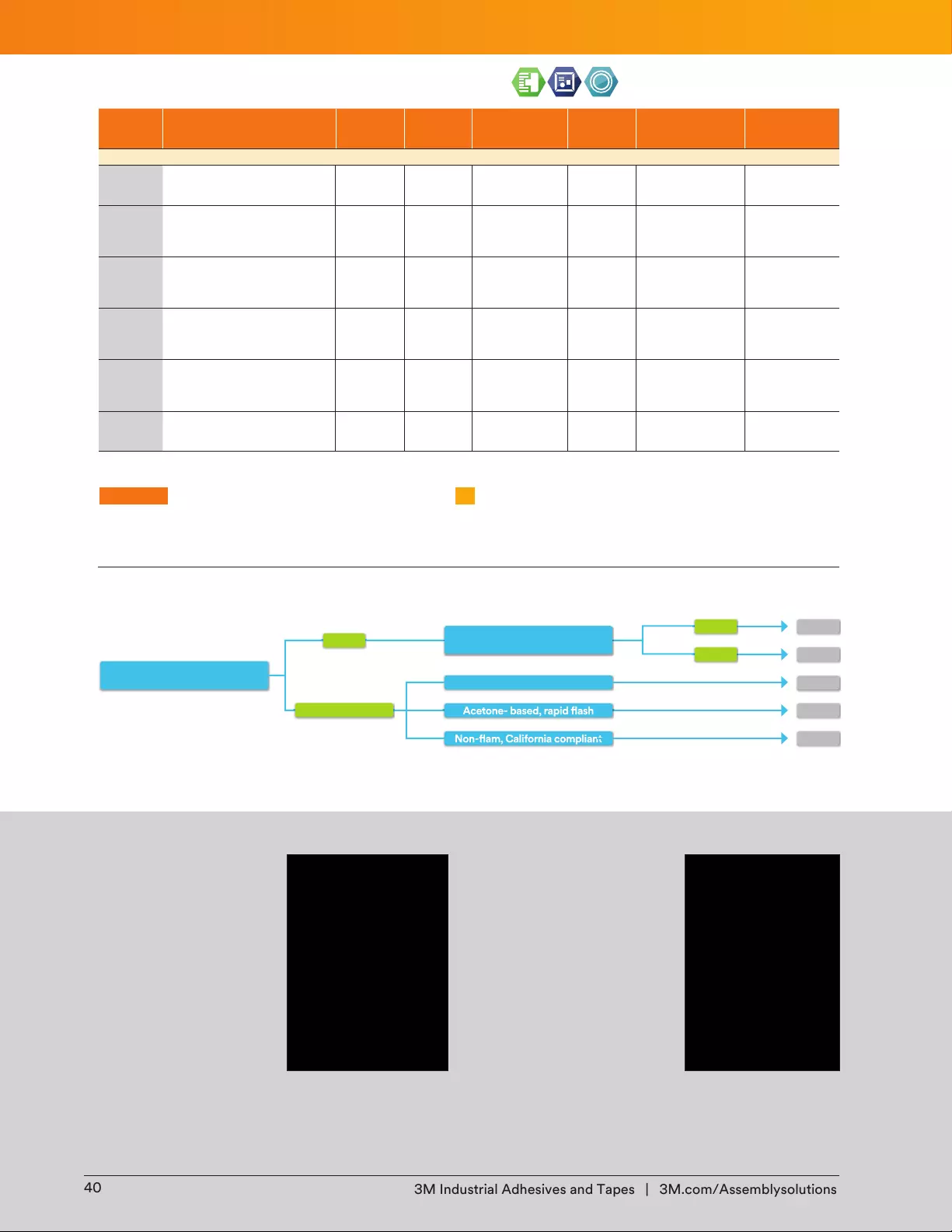

Good = Better = Best =

Best 3M Solutions for Small Joint Assemblies

7

3M Industrial Adhesives and Tapes | October 2017 Edition

Small Joint Assembly Solutions

+

Metal

(Unpainted)

Metal

(Painted) Glass, Ceramic, Stones Rubber, Elastomers

Plastics: HSE, MSE

(ABS, Acrylic,

Polycarbonate, Nylon)

Plastics: LSE

(Polypropylene,

Polyethylene) Wood

Metal (Unpainted)

DP420NS

3747, 3789

RT09

TL62

DP8805NS

3747, 3764

DP420NS

3747, 3789

2216

DP8805NS

3764, 3747

TE040,

EZ250150

DP8010 Blue

3748, 3764

TE040,

EZ250150

DP100 Plus

3792

EZ25150

DP8805NS

PR100

3747, 3764

DP100 Plus

PR100

3764, 3792

DP620NS

*PR100

DP8805NS

PR100

3748, 3764

TE040,

EZ250150

DP8010 Blue

*PR100

3748, 3764

TE040,

EZ250150

DP620NS

SI100

3764, 3792

EZ25150

DP100 Plus

PR100

3792

DP100 Plus

*PR100

DP100 Plus

PR100

3748, 3764

DP8010 Blue

*PR100

3748, 3764

DP420NS

SI100

3792

EZ250120,

EZ250150

*PR100

DP620NS

*PR100

*PR100

DP604NS

*SI100

DP8405NS,

DP8805NS

PR100

3748, 3764

EZ250150

DP8010 Blue

*PR100

3748, 3764

DP620NS

SI100

3764, 3792

EZ250150

DP8010 Blue

*PR100

3748, 3764

DP8010NS

*SI100

3764, 3792

EZ250150

DP100

SI100

3792

EZ250120,

EZ250060

Metal (Painted)

Glass, Ceramic, Stones

Rubber, Elastomers

Plastics: HSE, MSE

Plastics: LSE

Wood

Key

3M™ Scotch-Weld™ Structural Adhesives

3M™ Scotch-Weld™ Instant Adhesives

3M™ Hot Melt Adhesives

3M™ Scotch-Weld™ PUR Adhesives

3M™ Scotch-Weld™ Retaining Compounds

3M™ Scotch-Weld™ Threadlockers

* Primers may also be required in some cases.

See specic product pages for primer details.

30 3231

Assembly Solutions

This guide lists products that are commonly used for this specic application. It is important that the customer evaluates these suggested products in their specic application.

3M Industrial Adhesives and Tapes | 3M.com/Assemblysolutions

8

3M Industrial Adhesives and Tapes

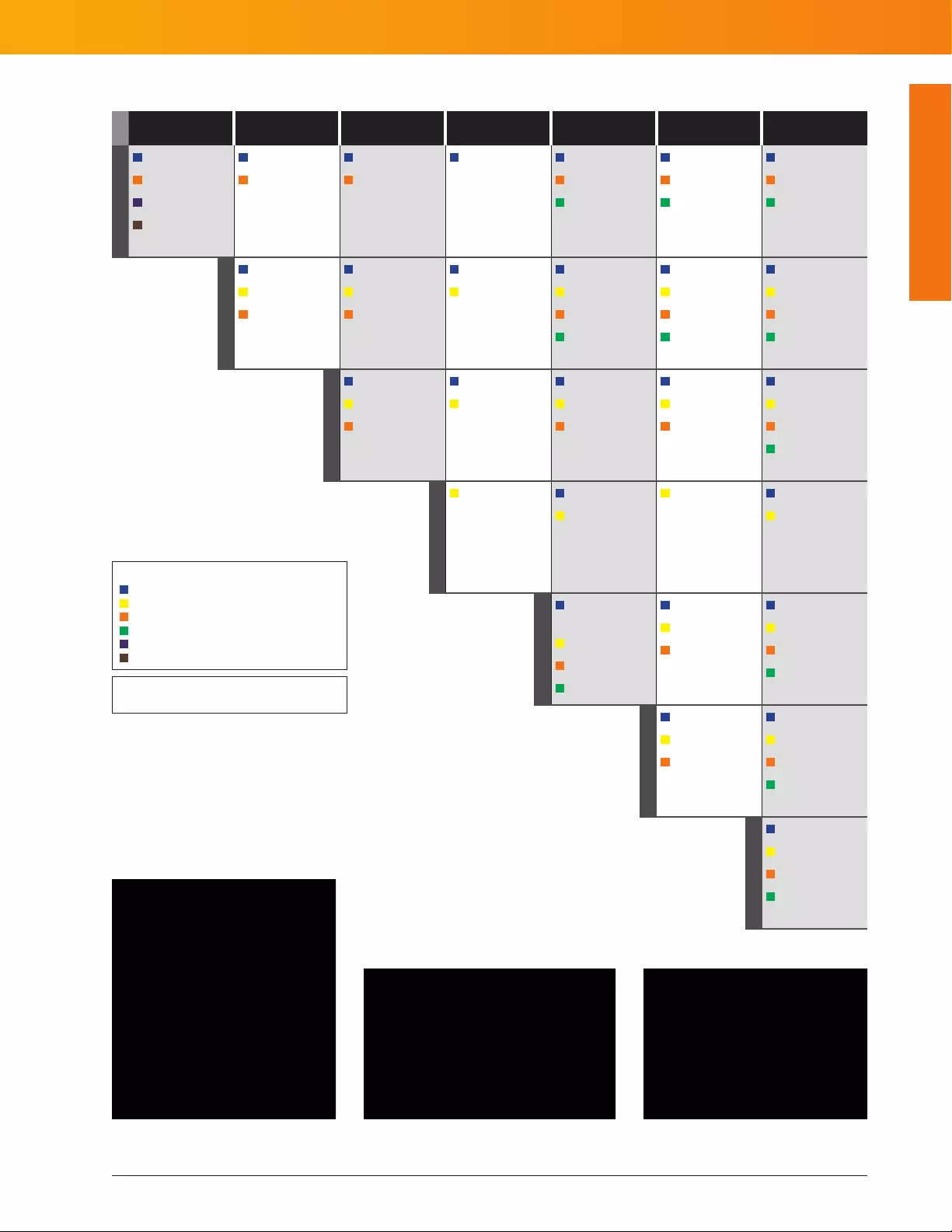

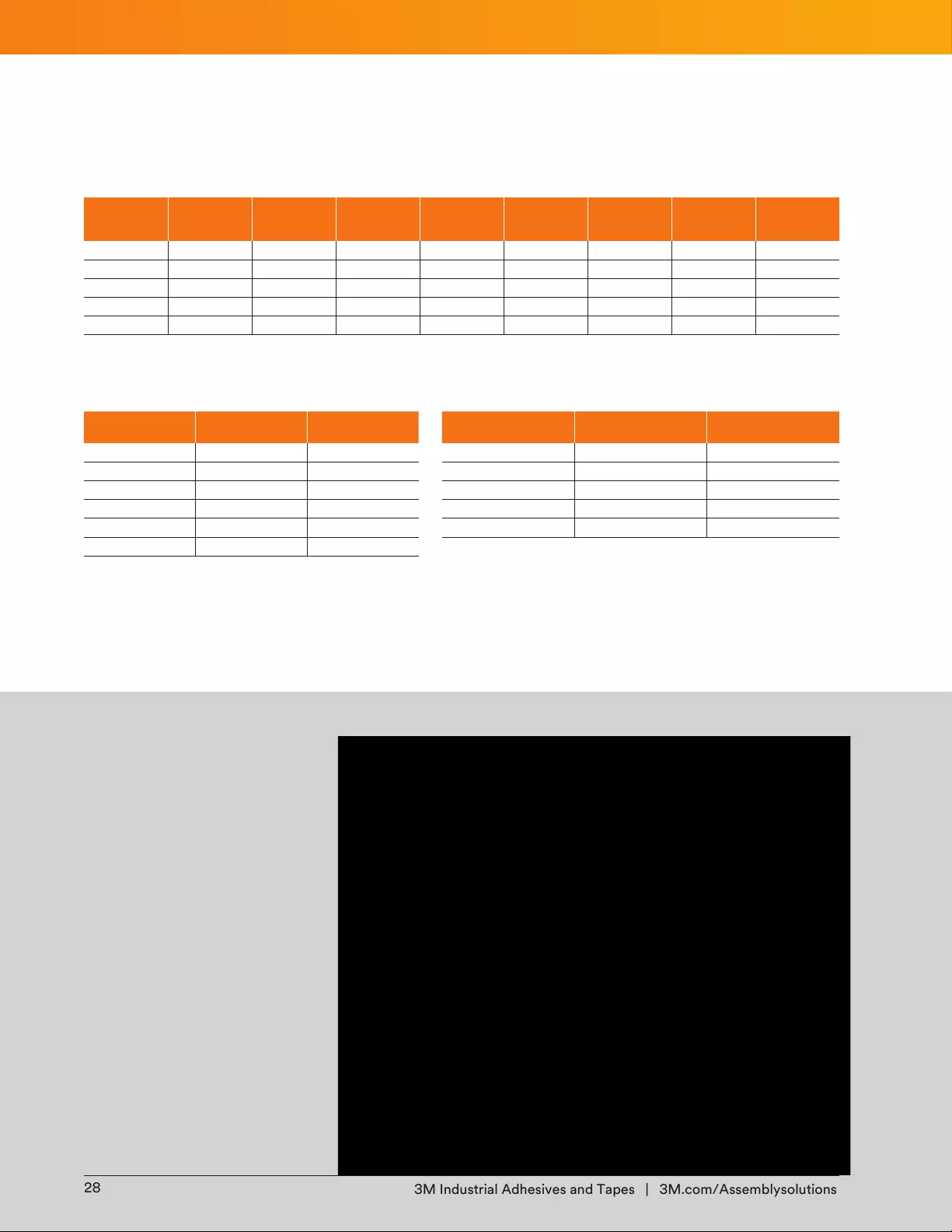

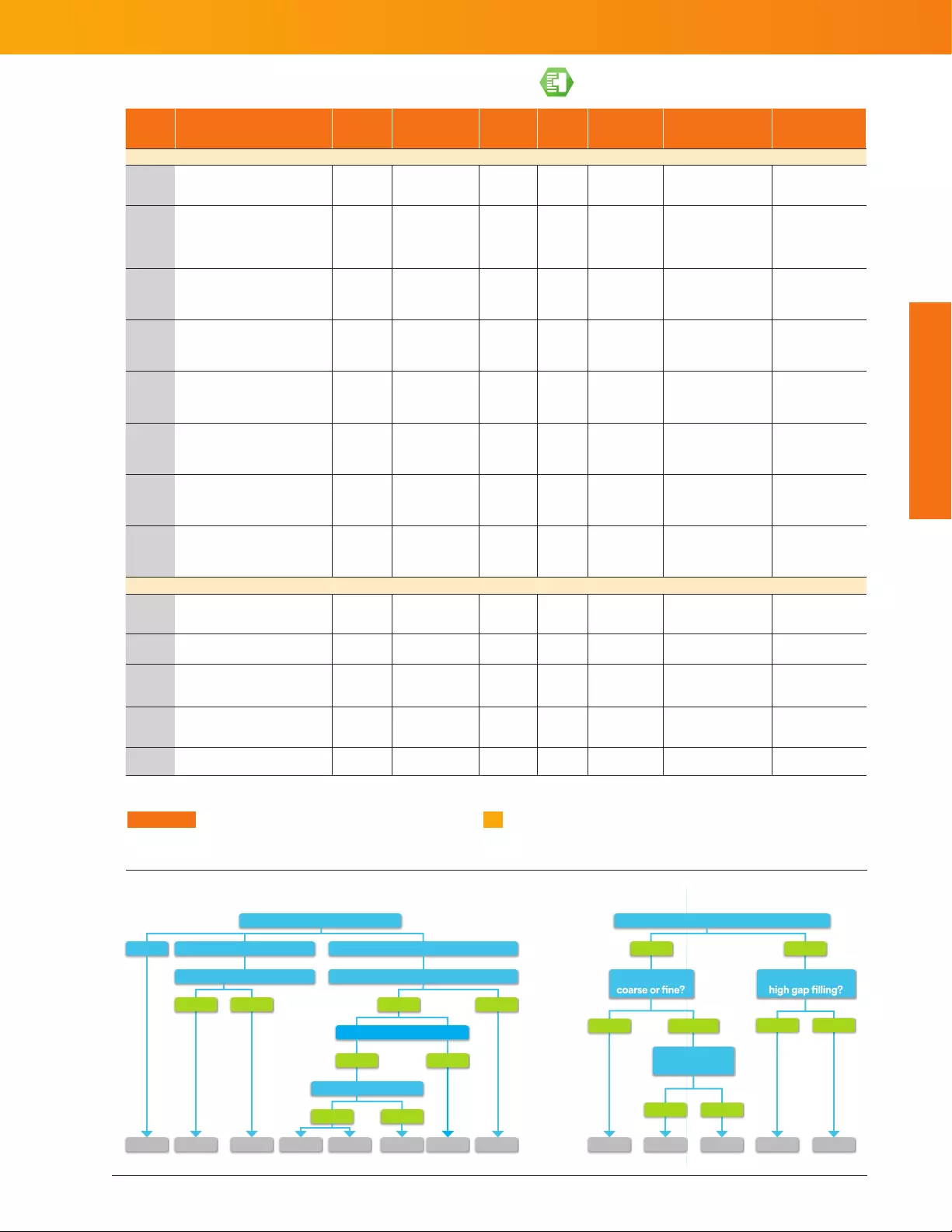

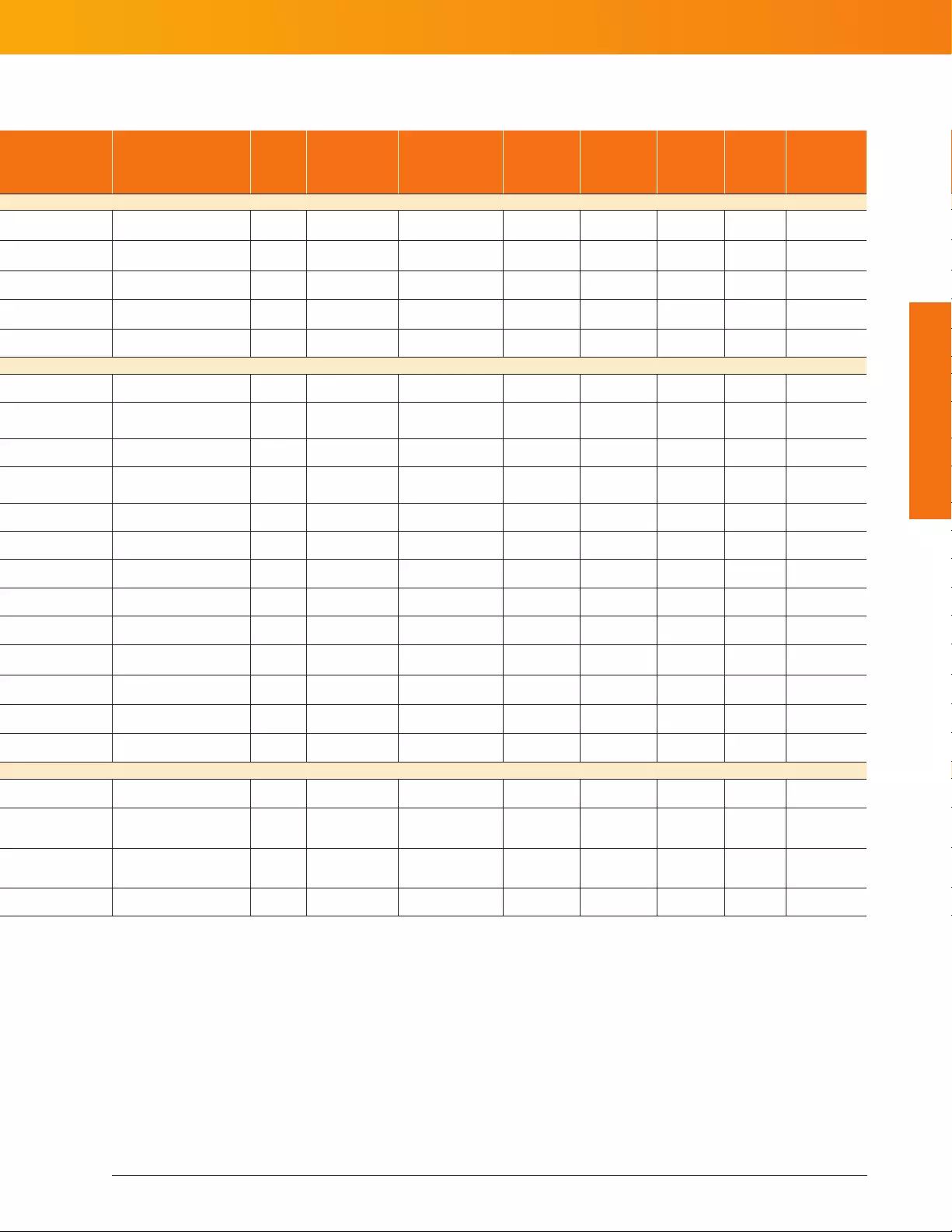

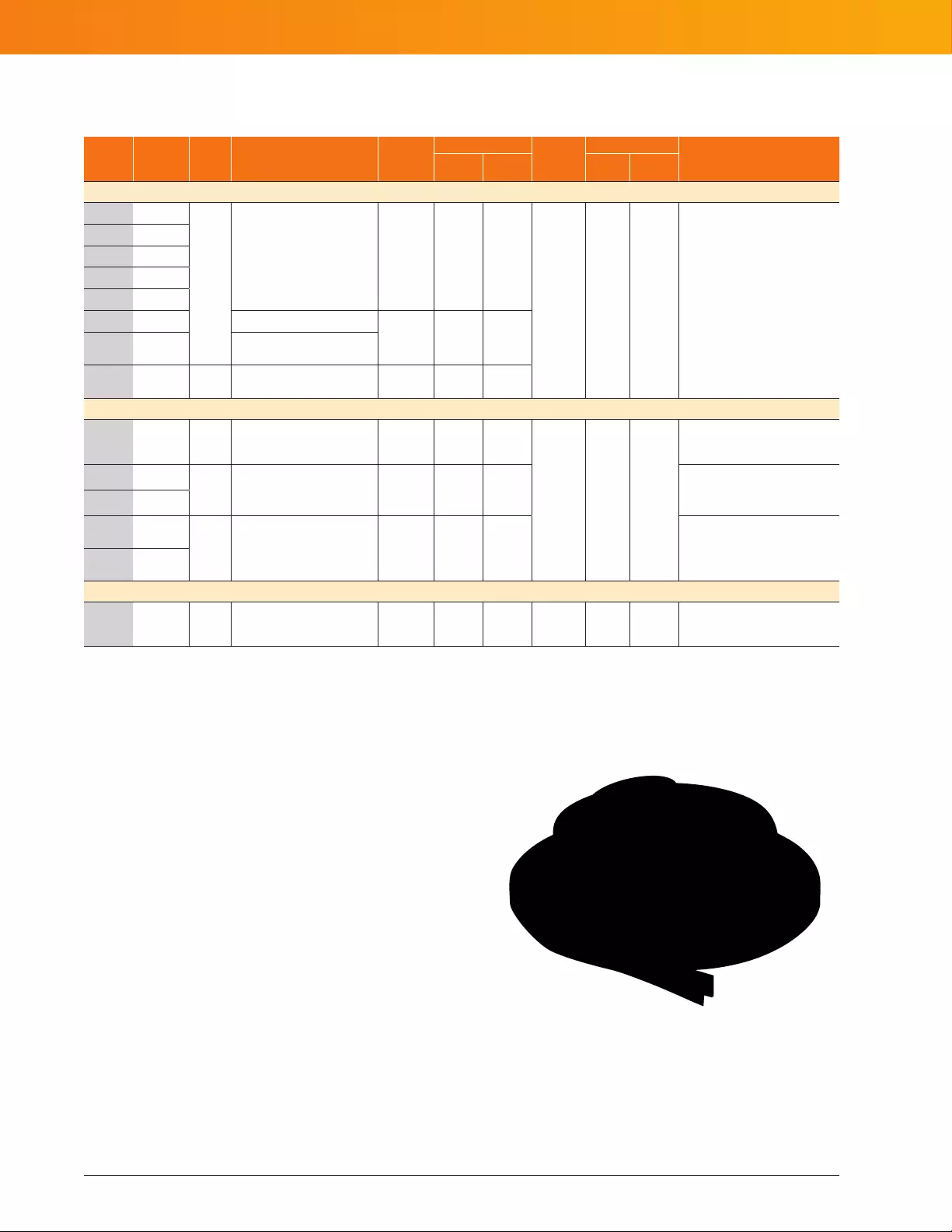

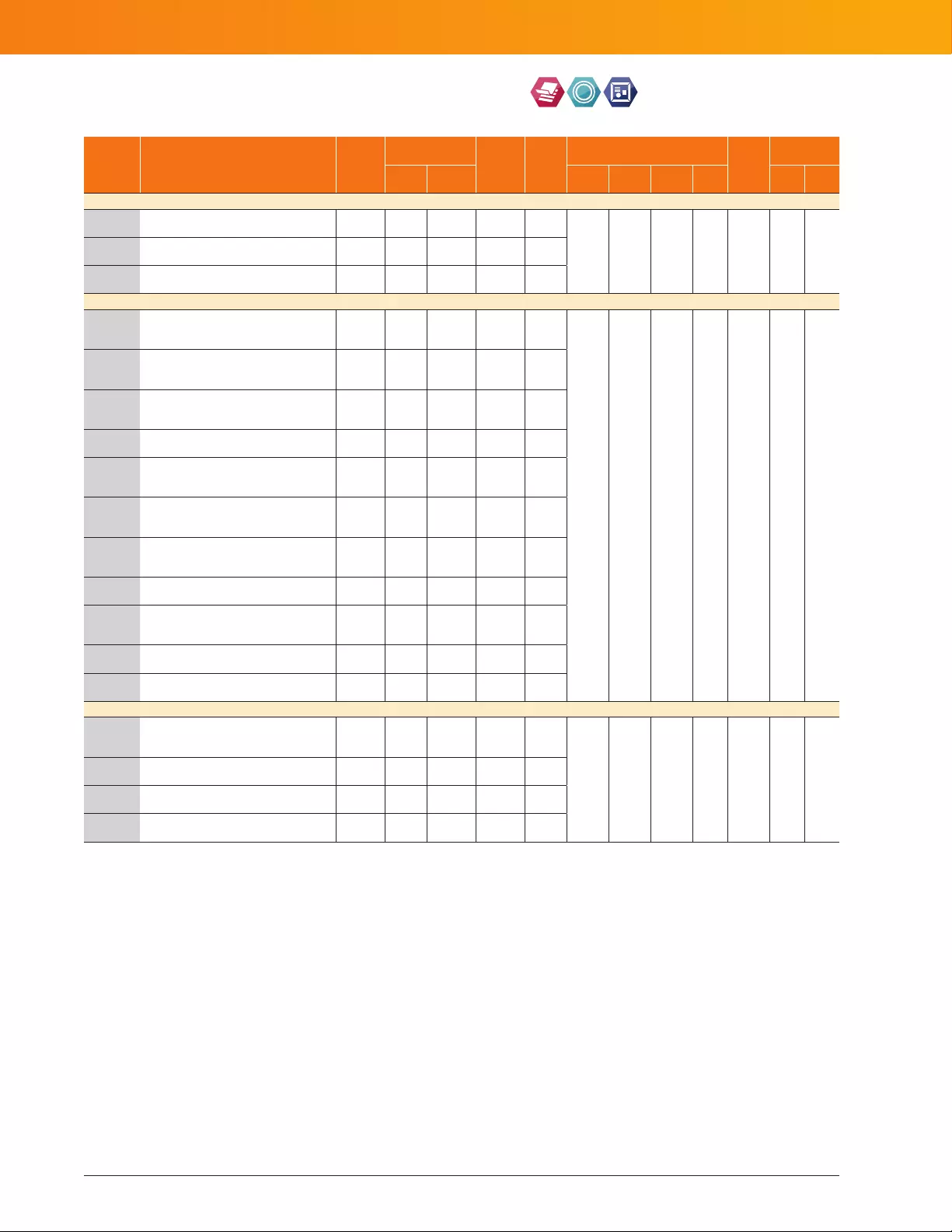

All 3M technologies in the table below are commonly used in large surface bonding

applications. Use the table below as a relative comparison of product performance.

Attribute

3M™ Scotch-Weld™

Structural Adhesives

3M™ Contact and

Spray Adhesives

3M™ Hot Melt

Adhesives

3M™ Scotch-Weld™

PUR Adhesives

3M™ Adhesive

Transfer Tapes

Shear and Peel Strength

Temperature and

Solvent Resistance

Aesthetics and Read Through

Speed and Convenience

of Application

Rate of Strength Build

3M™ Scotch-Weld™ Structural Adhesives (pg 18–36)

Acrylic, epoxy and urethane structural adhesives that hold over 1,000 psi in overlap shear strength.

Best suited for applications where high load-bearing strength is required.

3M™ Contact and Spray Adhesives (pg 58–59)

Solvent and water based adhesives that can be sprayed, brushed or roll applied. Very fast and

easy coverage of large areas including irregular and mildly textured shapes. Bonds the widest

range of substrates.

3M™ Hot Melt Adhesives (pg 47–51)

100% solid, low VOC thermoplastic resins that reach bond strength in seconds. Long open-time

formulations can be spray applied. Bonds irregular shapes and textured surfaces.

3M™ Scotch-Weld™ PUR Adhesives (pg 36–38)

One component, hot applied thermosetting adhesive with immediate strength and holding power.

Final cured strength over 1,000 psi. Long open-time formulations can be spray applied.

3M™ Adhesive Transfer Tapes (pg 83–87)

A pressure sensitive adhesive on a liner. Can be laminated onto a surface by hand or by automation.

Instant adhesion with no mess or waste and very thin bondlines.

13

14

17

21

11

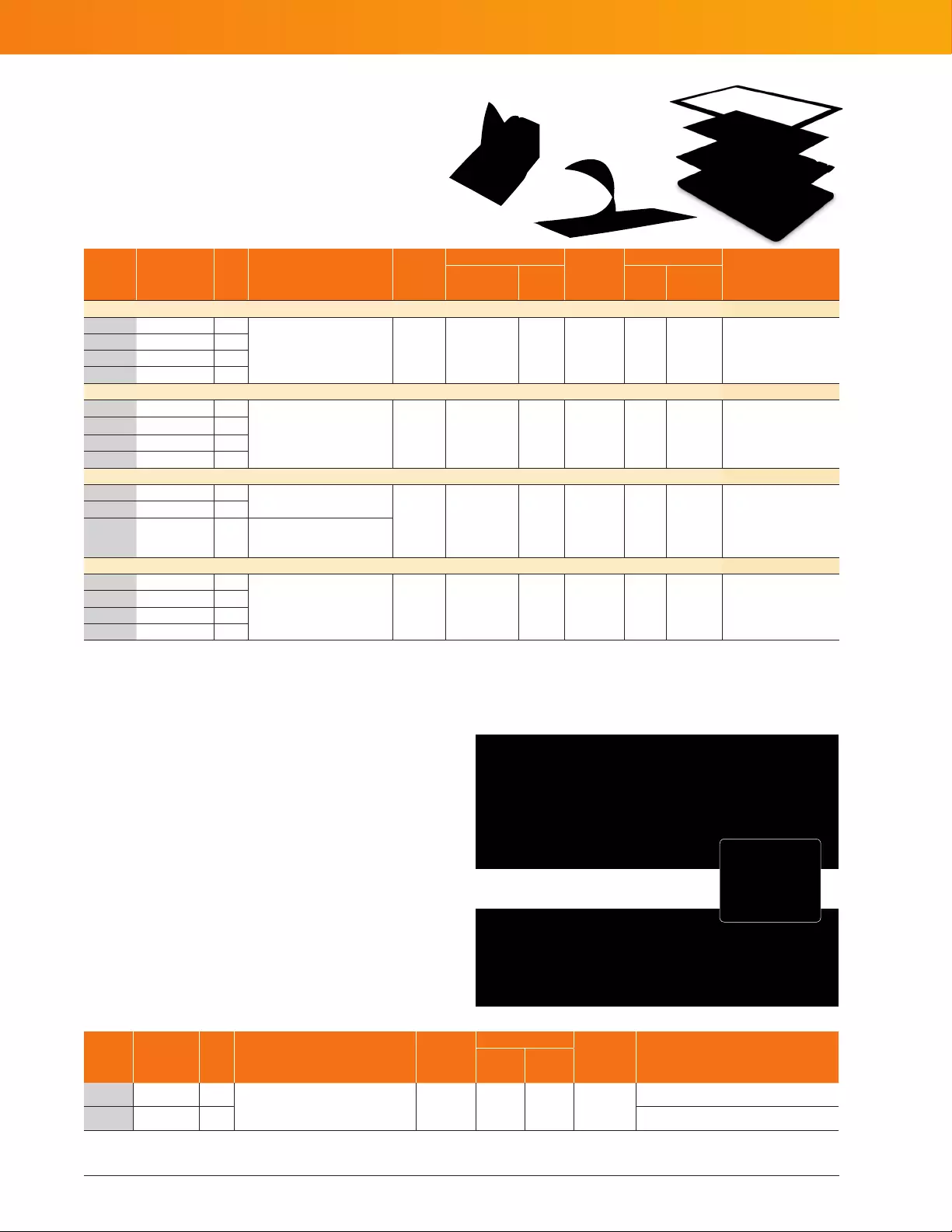

What are Large Surface

Lamination Assemblies?

Large surface bonds and laminations exist in multiple markets,

such as transportation, appliance, furniture and construction.

Large Surface Lamination: Two surfaces (substrates) of similar size,

either rigid or exible, are bonded or laminated together where a

majority of the surface is covered by the adhesive or tape in order

to create the bond. Examples include high pressure laminate

to tabletops, fabric to foam for furniture, veneers on wood

and exible transportation ooring.

Possible Adhesive or Tape Requirements:

• Cover full surface

• Flexible when dry; not sti

• Allow for positioning parts

• Bonds quickly/little or no xturing

Performance Factors for Large Surface Lamination Assemblies

Best 3M Solutions for Large Surface Lamination Assemblies

Good = Better = Best =

292

9

3M Industrial Adhesives and Tapes | October 2017 Edition

Large Surface Lamination Assembly Solutions

+

Metals, Paints, Glass

Rubber

(EPDM, Santoprene®)

Foam and Cloth

(Urethane, Fabrics) Plasticized Vinyl

Plastics (ABS, Acrylic,

Polycarbonate, Nylon) Wood

Metals, Paints, Glass

LSB60

94 CA, 1357

6111/6111HT

TS230,

TS115HGS

F9473PC,

9485PC

2216

1300, 847

*468MP, 950

74, 100NF

6111/6111HT

6035PC, 950

2216

4491, 1000NF

F9467U,

F9465PC

2216

94 CA, 4475

6111/6111HT, 6116

TS230, TS115

468MP, 9472LE

2216

94 CA, 1357

6111/6111HT

TS230,

TS115HGS

6035PC,

468MP

2216

4799

TS230

*468MP, 950

4799

TS230, TS115

6035PC, 950

2216

4799

TS230, TS115

*F9467U,

F9465PC

2216

4799

TS230, TS115

*468MP, 9472LE

2216

4799

TS230,

TS115HGS

*468MP, 950

74, 100NF

6111/6111HT,

6116

TS230, TS115

6035PC, 950

4491, 1000NF

TS230, TS115

950, F9465PC

77, 74

6111/6111HT, 6116

TS230, TS115

950, 6035PC

77, 1000NF

6111/6111HT,

6116

TS230,

TS115HGS

950, 6035PC

2216

4491, 1300

TS230, TS115

F9467U,

F9465PC

2216

4491, 1300

TS230, TS115

F9467U, F9465PC

2216

4491, 1000NF

TS230,

TS115HGS

F9467U,

F9465PC

2216

94 CA, 4475

6111/6111HT, 6116

TS230, TS115

9472LE, 468MP

2216

94 CA, 4475

6111/6111HT,

6116

TS230,

TS115HGS

9472LE,

468MP

2216

94 CA, 30NF

6111/6111HT,

6116

TS230,

TS115HGS

6035PC,

468MP

Rubber

Foam and Cloth

Plasticized Vinyl

Wood

Plastics

Key

3M™ Scotch-Weld™ Structural Adhesives

3M™ Contact and Spray Adhesives

3M™ Hot Melt Adhesives

3M™ Scotch-Weld™ PUR Adhesives

3M™ Adhesive Transfer Tapes

* Primers may also be required in some

cases. See specic product pages for

primer details.

33

34

35 36

Assembly Solutions

This guide lists products that are commonly used for this specic application. It is important that the customer evaluates these suggested products in their specic application.

3M Industrial Adhesives and Tapes | 3M.com/Assemblysolutions

10

3M Industrial Adhesives and Tapes

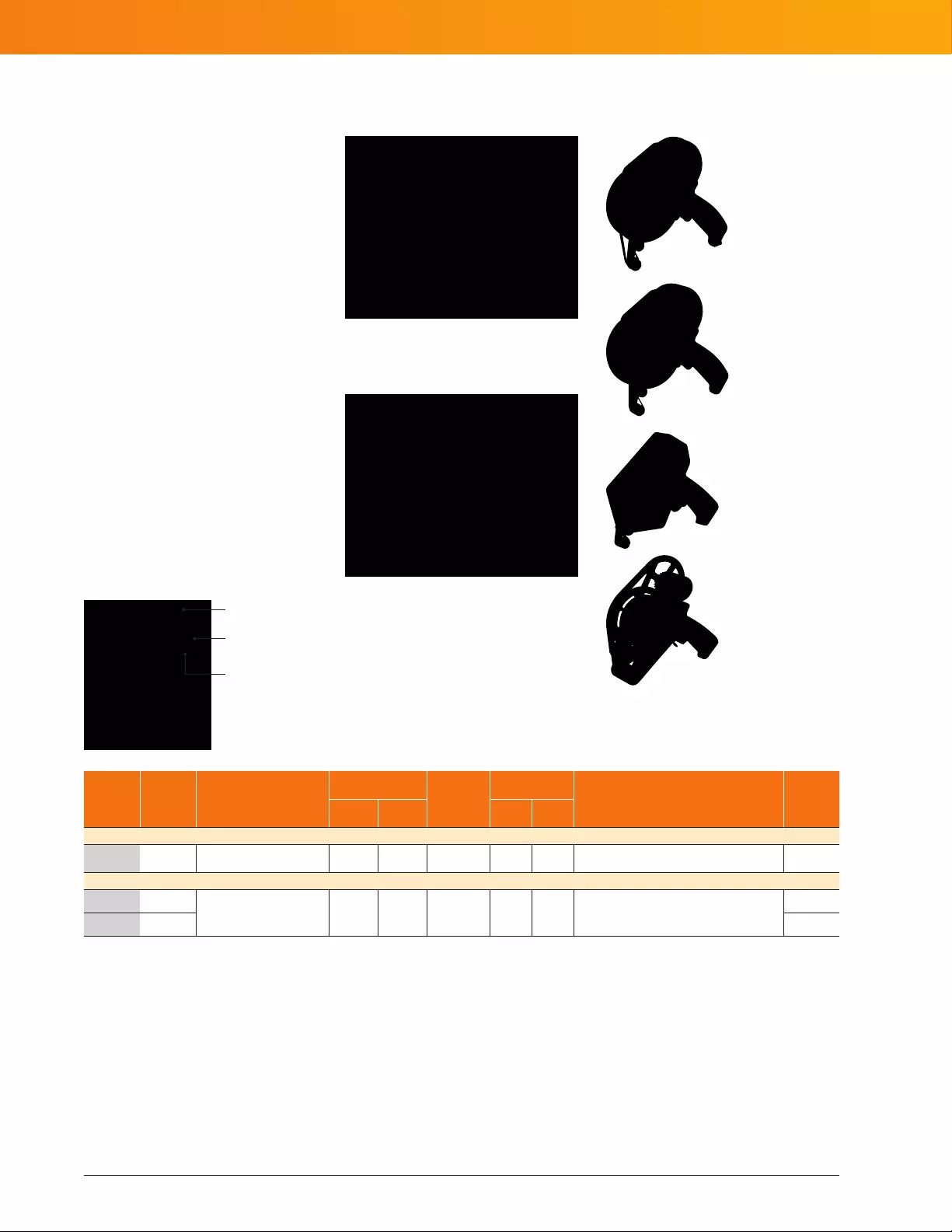

What are Mounting and

Trim Attachment Assemblies?

Mounting and trim attachment exists in multiple markets, such as

transportation, appliance, furniture, construction and architecture.

3M™ VHB™ Tapes (pg 68–75)

High-strength bonding tapes that are a proven alternative

to screws, rivets, welds and other mechanical fasteners.

Can pre-apply to trim for production exibility. Ideal for

dissimilar substrates.

3M™ Scotch-Weld™ Structural Adhesives (pg 18–36)

Acrylic, epoxy and urethane structural adhesives that hold

over 1,000 psi in overlap shear strength. Use for heavy dead-

loads with smaller joint areas (Example: brackets on heavy

panels, poorly matched parts with high spring-back forces).

3M™ Scotch-Weld™ Instant Adhesives (pg 38–40)

One part solvent-free cyanoacrylate (CA) adhesive that

reaches handling strength in 5–30 seconds. Best for small

very tight bondlines (<10cm2). Commonly used on rubbers

and plastics.

3M™ Hot Melt Adhesives (pg 47–51)

100% solid, thermoplastic resins that reach bond strength

in seconds. Best for wood and plastic.

3M™ Scotch-Weld™ PUR Adhesives (pg 36–38)

One component, hot applied thermosetting adhesive with

immediate strength and holding power. Final cured strength

over 1,000 psi. Best for wood and plastic.

Mounting: Applying an object to a surface. Generally, static loads are

prevalent and the mounted item is smaller than the surface to which it is

bonded. Examples include small signs, mirrors and white boards,

and panel-over-panel with partial adhesive coverage.

Trim: Decoration or identication added to a surface. Examples include

nameplates, edge banding, bezels, rosettes and muntin bars.

Possible Adhesive or

Tape Requirements:

• Dead load holding strength

• Aesthetics

• Removability

• Fast bonding/little or no xturing

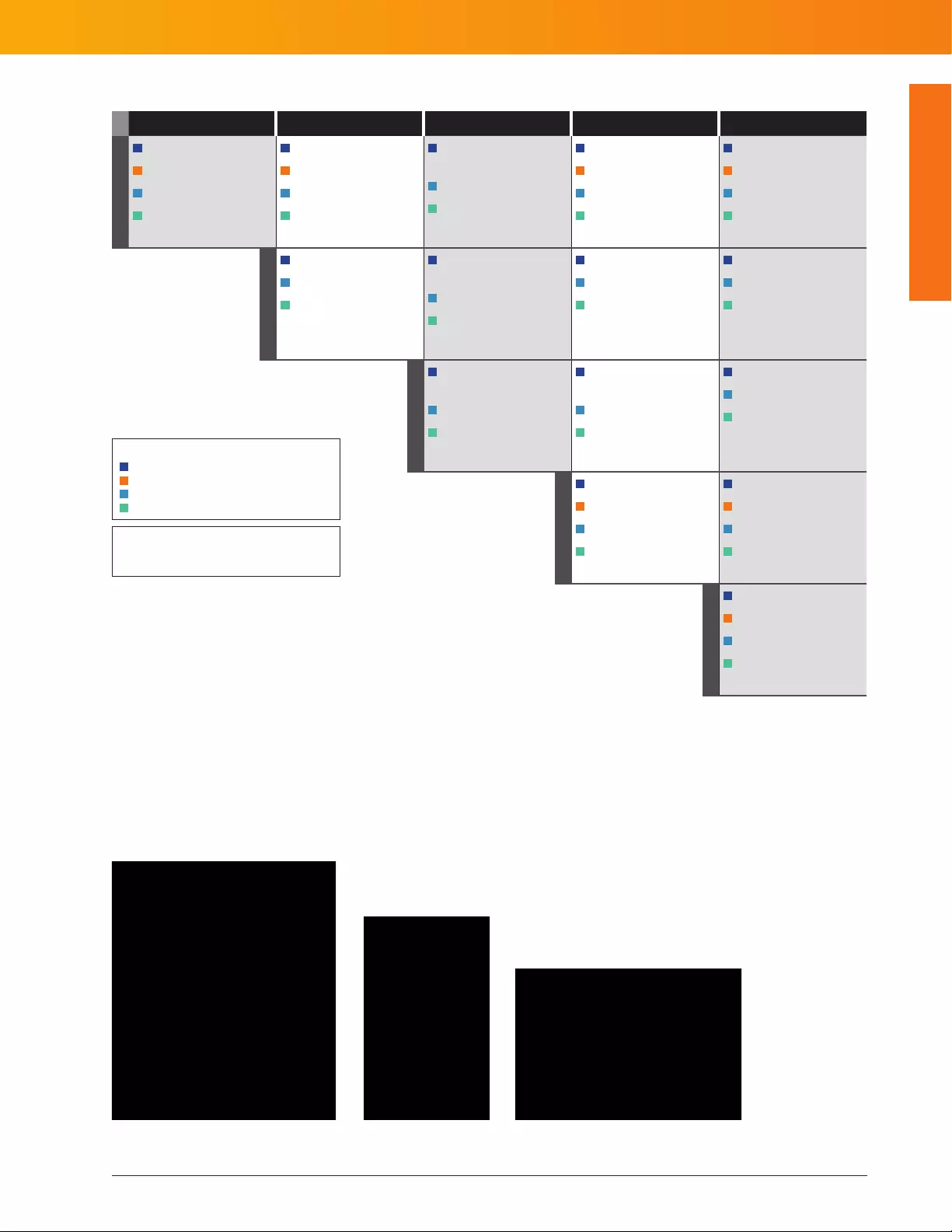

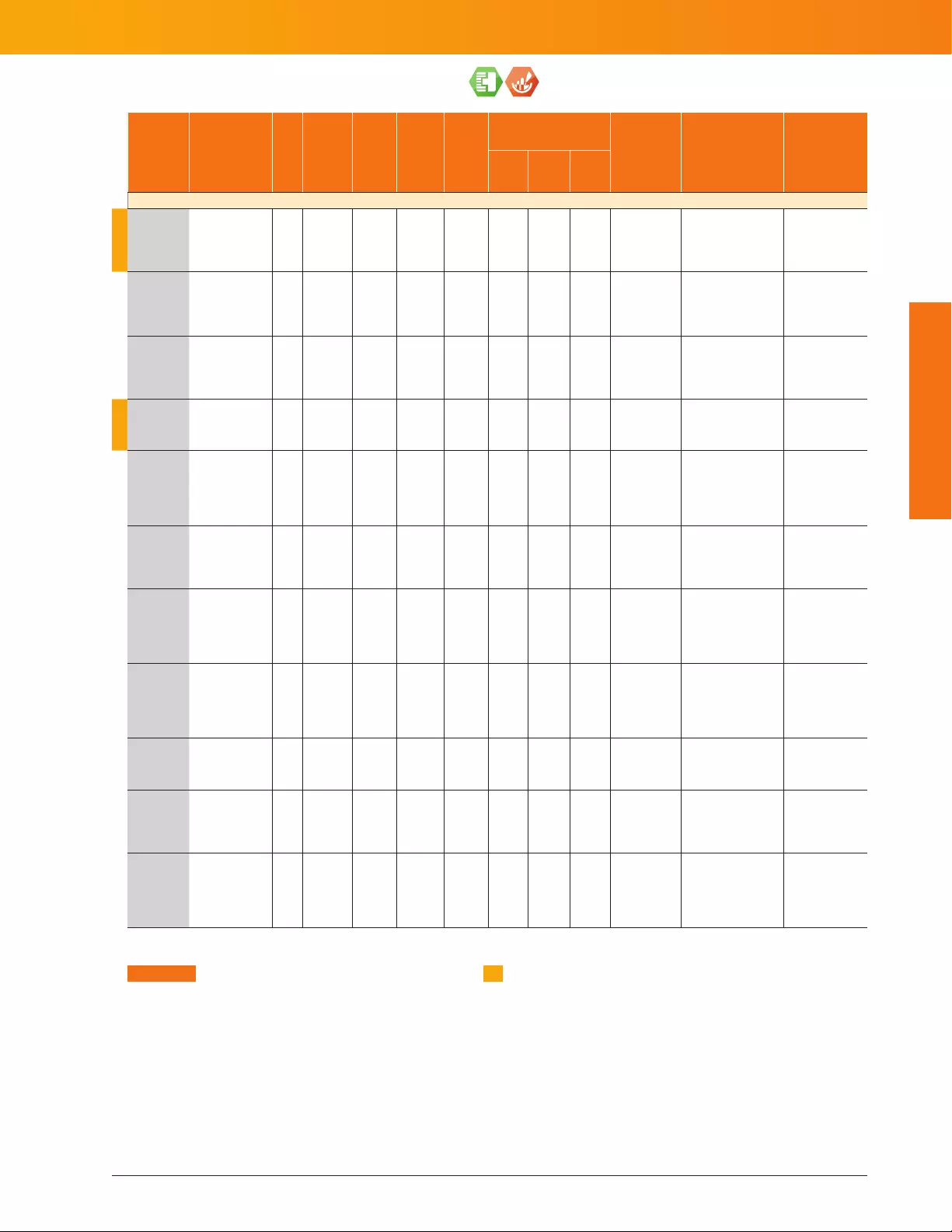

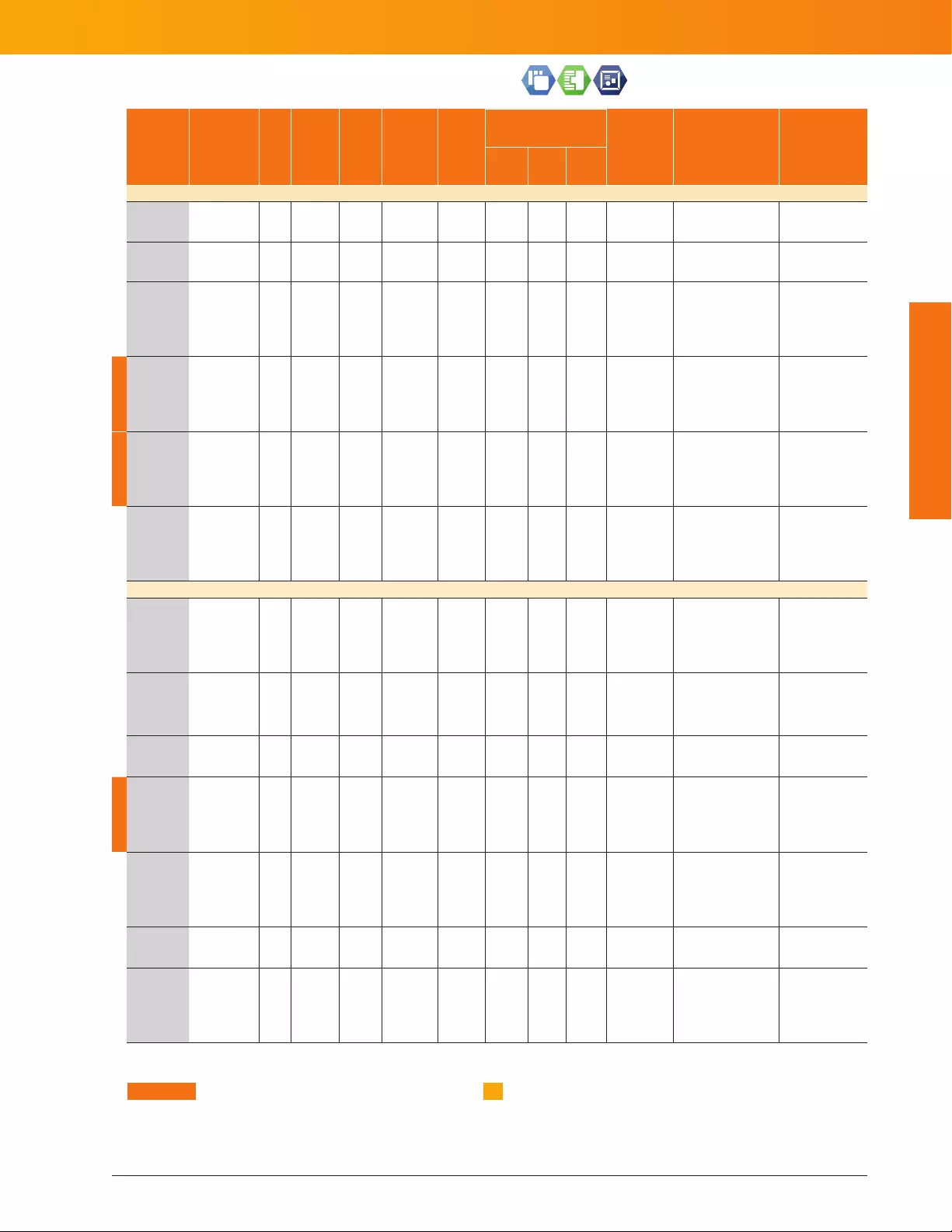

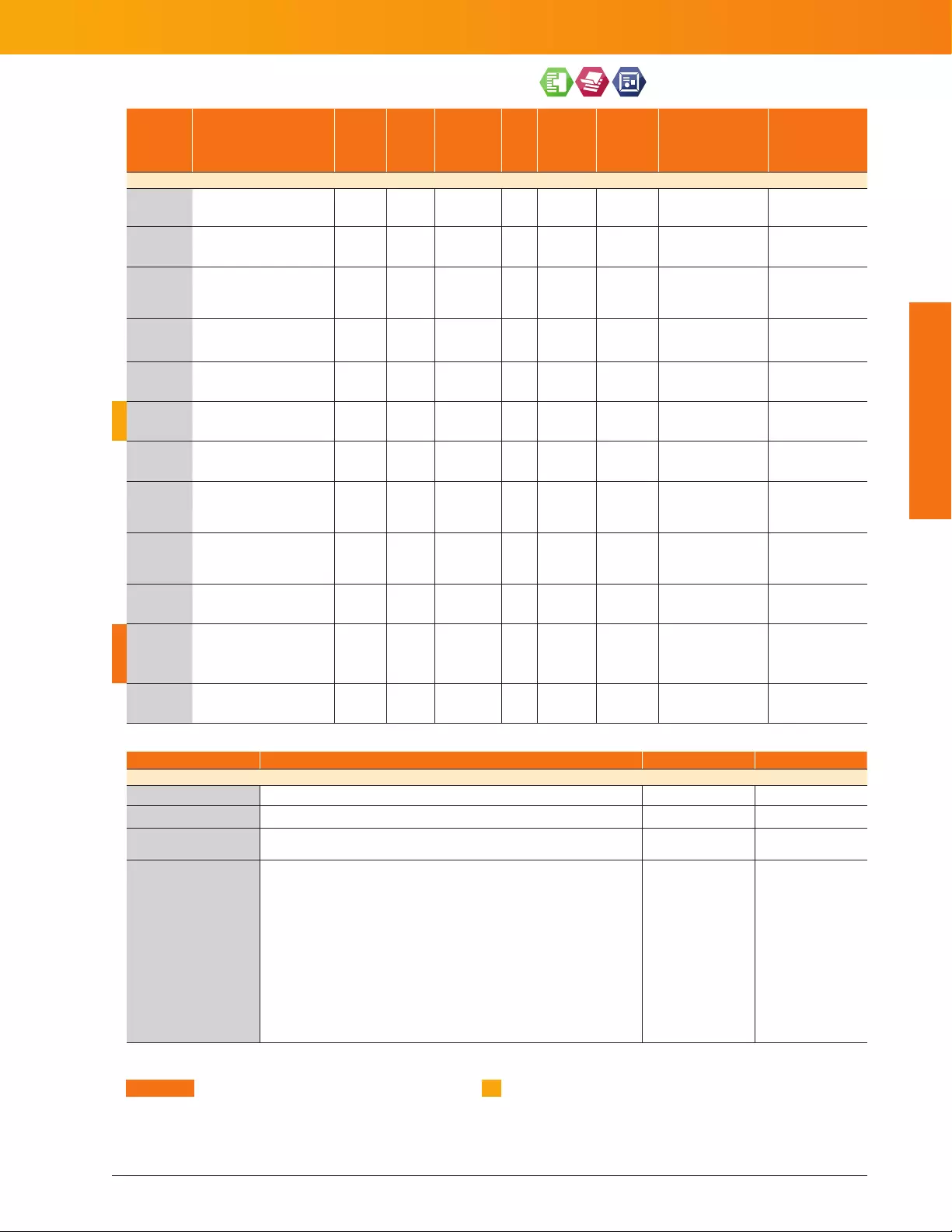

All 3M technologies in the table below are commonly used in mounting and trim attachment

applications. Use the table below as a relative comparison of product performance.

Attribute

3M™ VHB™

Tapes

3M™ Scotch-Weld™

Structural Adhesive

3M™ Scotch-Weld™

Instant Adhesive

3M™ Hot Melt

Adhesives

3M™ Scotch-Weld™

PUR Adhesives

3M™ Reclosable

Fasteners

3M™ Adhesive

Transfer Tapes

3M™ Double

Coated Tapes

Shear and Peel Strength

Temperature and

Solvent Resistance

Aesthetics

Repositionability

During Application

Rate of Strength Build

Removable After Cure N/A N/A

8

17

3M™ Reclosable Fasteners

(pg 92–95)

3M™ Dual Lock™ and 3M™

Hook and Loop Reclosable

Fasteners for strong yet easily removable

fastening solutions. These products are

ideal for quick mounting, trim or sign

installation and change out.

3M™ Adhesive Transfer

Tapes (pg 83–87)

A pressure sensitive adhesive

on a liner. Can be laminated

onto a surface by hand or by automation.

Can be pre-applied to trim. Provides very

thin, aesthetic bondlines. Special

formulations for LSE plastics.

3M™ Double Coated

Tapes (pg 77–80)

A paper, lm or tissue carrier with

pressure sensitive adhesive on both sides.

Can be laminated onto a surface by hand

or by automation. Can be pre-applied to

trim. Provides very thin, aesthetic bond-

lines. Special formulations for LSE plastics.

20

21

11

13

15

18

Performance Factors for Mounting and Trim Attachment Assemblies

Best 3M Solutions for Mounting and Trim Attachment Assemblies

Good = Better = Best =

292

11

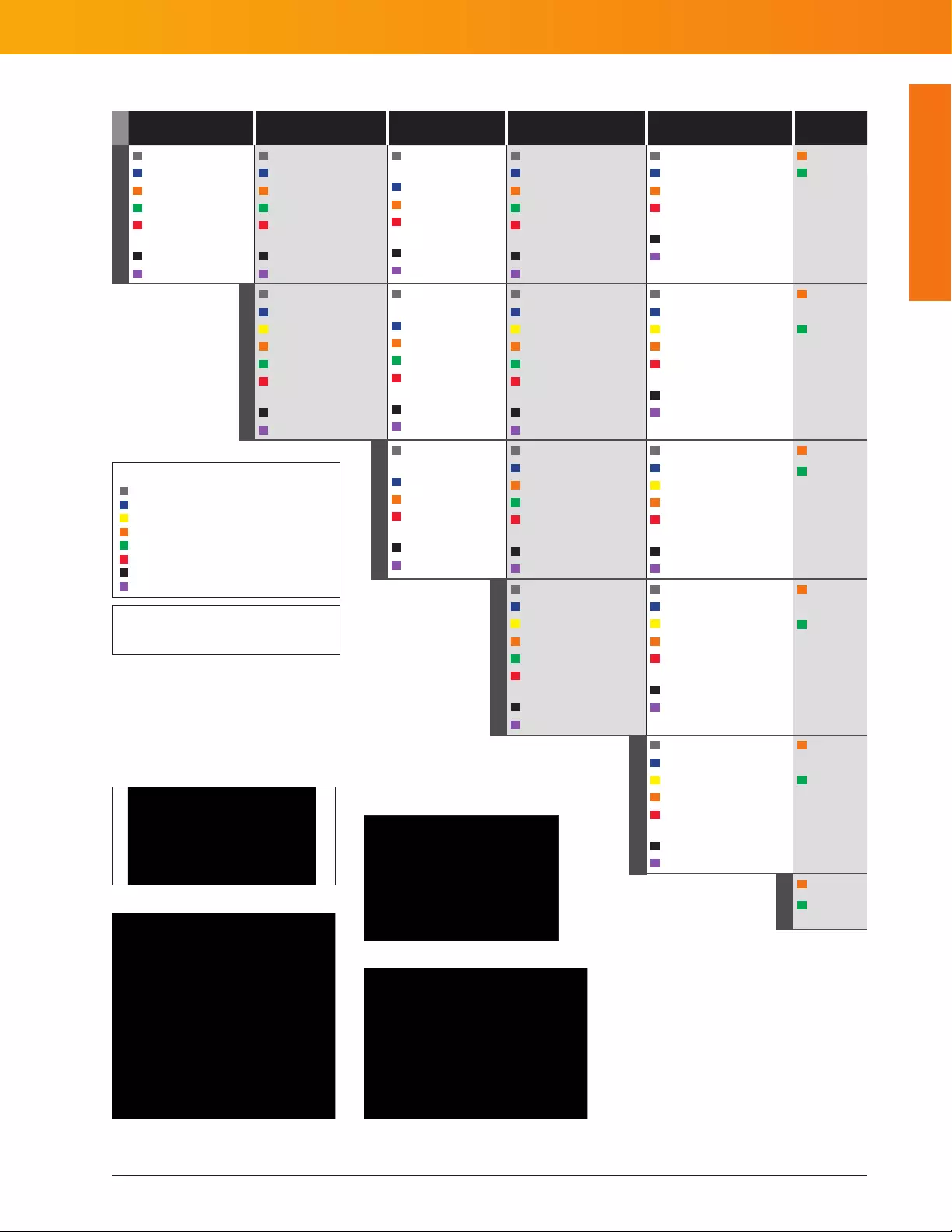

3M Industrial Adhesives and Tapes | October 2017 Edition

+

Metals (Aluminum, Steel,

Stainless, Galvanized)

Paints (Powder Coat,

Painted Metal, Composite Panel,

Sealed or Painted Wood) Glass

Plastics: HSE, MSE

(ABS, Acrylic,

Polycarbonate, Nylon)

Plastics: LSE

(Polypropylene, Polyethylene) Wood

Metals

4941, 5952, RP45

DP8805NS

3789, 3747

TE040, EZ250150

SJ3550/51/52,

SJ3571/72

468MP, F9473PC

9500PC

*4941, 5952, *RP45

DP8810NS

3764, 3747

TE040, EZ250150

SJ3540/41/42,

SJ3526N/27N

9472LE, 9485PC

9500PC

*4941, *5952,

*RP45

DP420NS

3789, 3747

SJ3560/61/62,

SJ3571/72

468MP, F9473PC

9500PC

*4941, 5952, *RP45

DP8805NS

3764, 3747

TE040, EZ250150

SJ3550/51/52,

SJ3571/72

468MP, 9472LE

9500PC

*4941, *5952, *RP45

DP8010 Blue

3764, 3747

SJ3540/41/42,

SJ3526N/27N

9472LE, 9485PC

9500PC

3792

EZ250150

*4941, 5952, *RP45

DP8810NS

PR100

3764, 3792

EZ250150

SJ3540/41/42,

SJ3526N/27N

9472LE, 468MP

9832, 9500PC

*4941, *5952,

*RP45

DP420NS

3764, 3792

EZ250150

SJ3560/61/62,

SJ3571/72

9472LE, 468MP

9832, 9500PC

*4941, 5952, *RP45

DP8410NS

PR100

3747, 3792

EZ250150

SJ3550/51/52,

SJ3571/72

468MP, 9472LE

9832, 9500PC

*4941, *5952, *RP45

DP8010 Blue

* PR100

3748, 3764

SJ3540/41/42,

SJ3526N/27N

9472LE, 9485PC

9832, 9500PC

3764,

3792

EZ25150

*4941, *5952,

*RP45

DP100 Plus Clear

3792

SJ3560/61/62,

SJ3571/72

468MP, F9473PC

9500PC

*4941, 5952, *RP45

DP100 Plus

3748, 3792

EZ250150

SJ3550/51/52,

SJ3571/72

468MP, 9485PC

9500PC

*4941, *5952, *RP45

DP8010 Blue

* PR100

3748, 3764

SJ3540/41/42,

SJ3526N/27N

9472LE, 9485PC

9500PC

3792

EZ250120,

EZ250150

*4941, 5952, *RP45

DP8405NS

PR100

3748, 3792

EZ250150, EZ250030

SJ3550/51/52,

SJ3571/72

468MP, 9472LE

9500PC, 9832

*4941, *5952, *RP45

DP8010 Blue

* PR100

3748, 3764

SJ3540/41/42,

SJ3526N/27N

9472LE, 9485PC

9500PC, 9832

3764,

3792

EZ250150

*4941, *5952, *RP45

DP8010 Blue

* PR100

3748, 3764

SJ3540/41/42,

SJ3526N/27N

9472LE, 9485PC

9500PC

3764,

3792

EZ250150

3792

EZ250120,

EZ250060

Paints

Plastics: HSE, MSE

Plastics: LSE

Wood

Glass

Key

3M™ VHB™ Tapes

3M™ Scotch-Weld™ Structural Adhesives

3M™ Scotch-Weld™ Instant Adhesives

3M™ Hot Melt Adhesives

3M™ Scotch-Weld™ PUR Adhesives

3M™ Reclosable Fasteners

3M™ Adhesive Transfer Tapes

3M™ Double Coated Tapes

* Primers may also be required in some

cases. See specic product pages for

primer details.

For 3M™ VHB™ Tape applications

in the Window and Door market,

refer to page 70 for a selection

of products.

3

37

Assembly Solutions

Mounting and Trim Attachment Assembly Solutions

This guide lists products that are commonly used for this specic application. It is important that the customer evaluates these suggested products in their specic application.

38 39

3M Industrial Adhesives and Tapes | 3M.com/Assemblysolutions

12

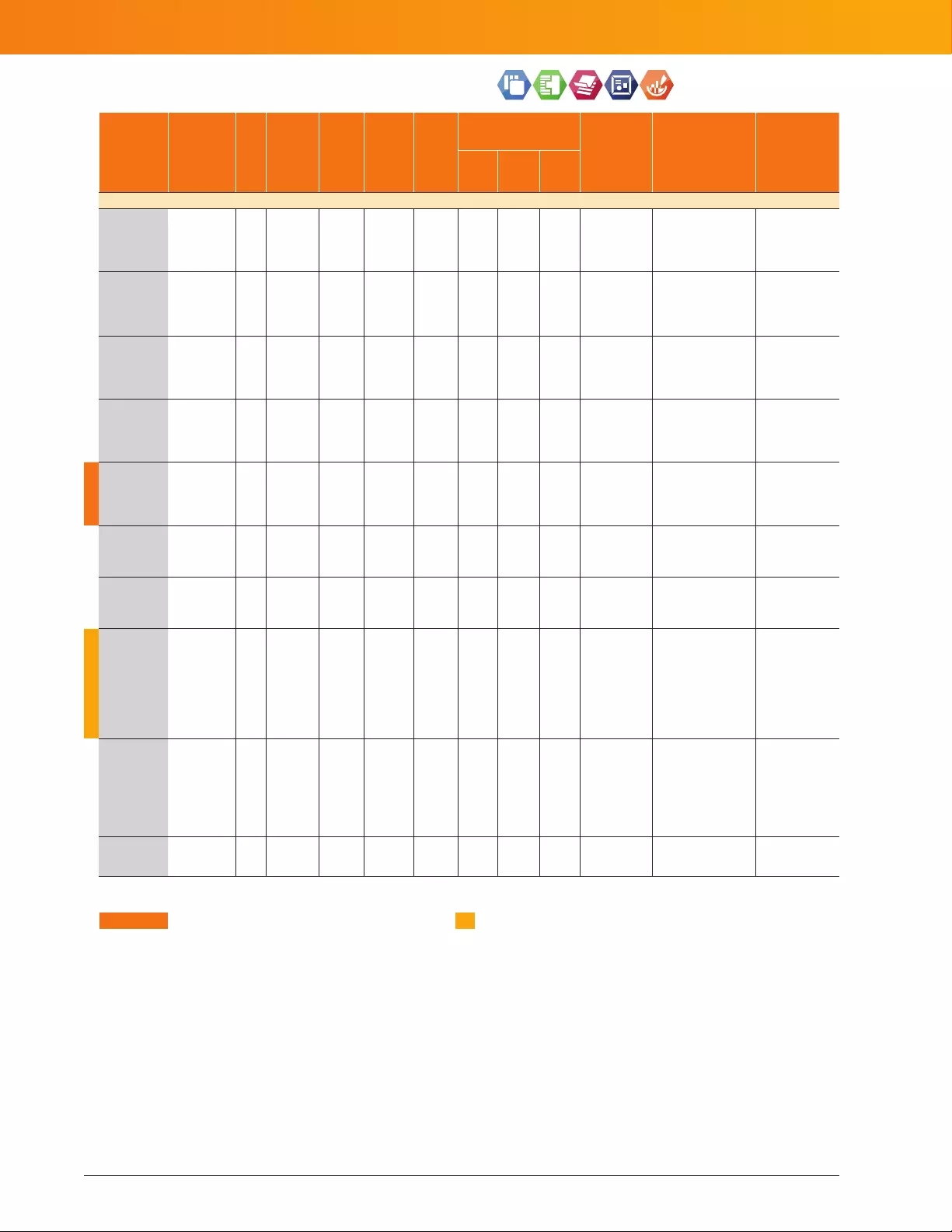

3M Industrial Adhesives and Tapes

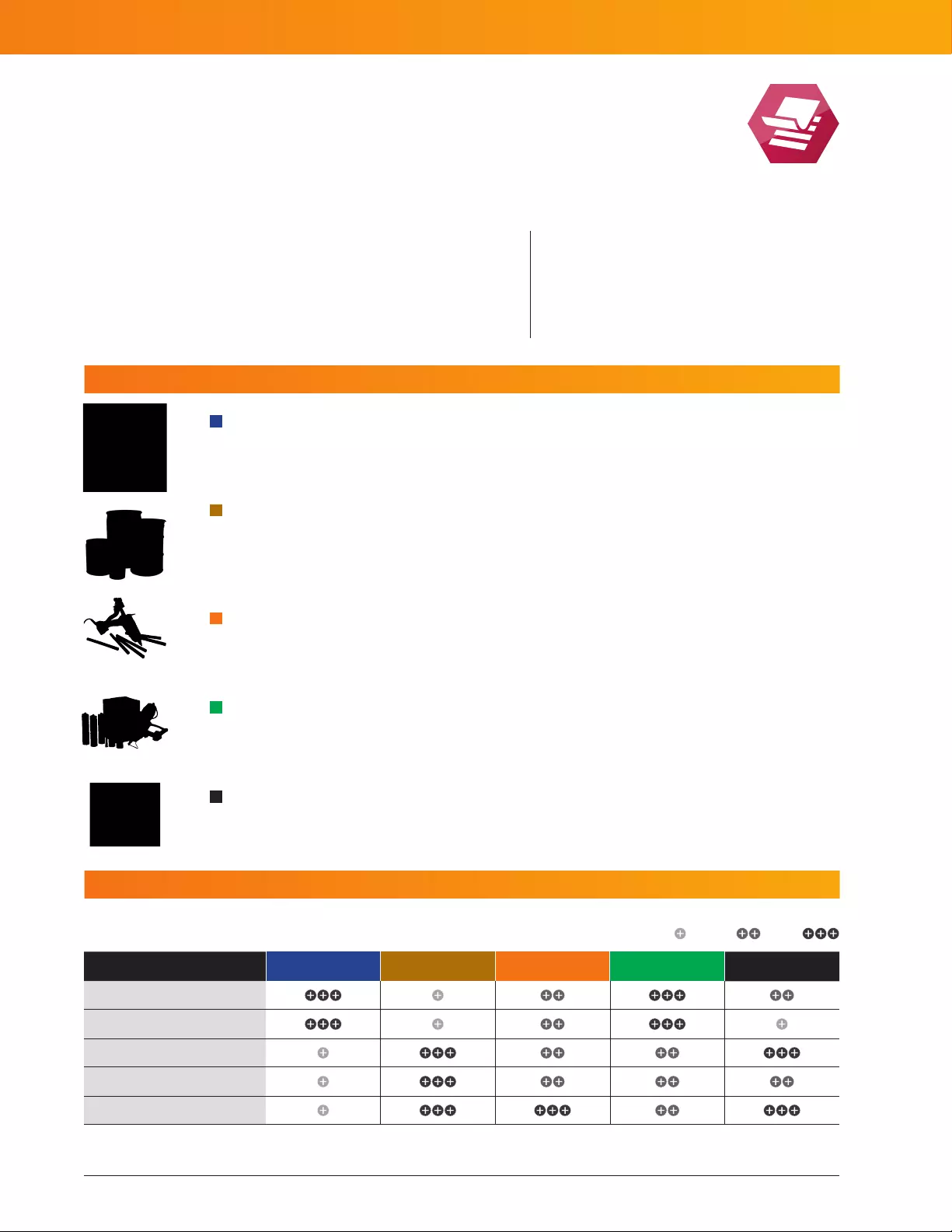

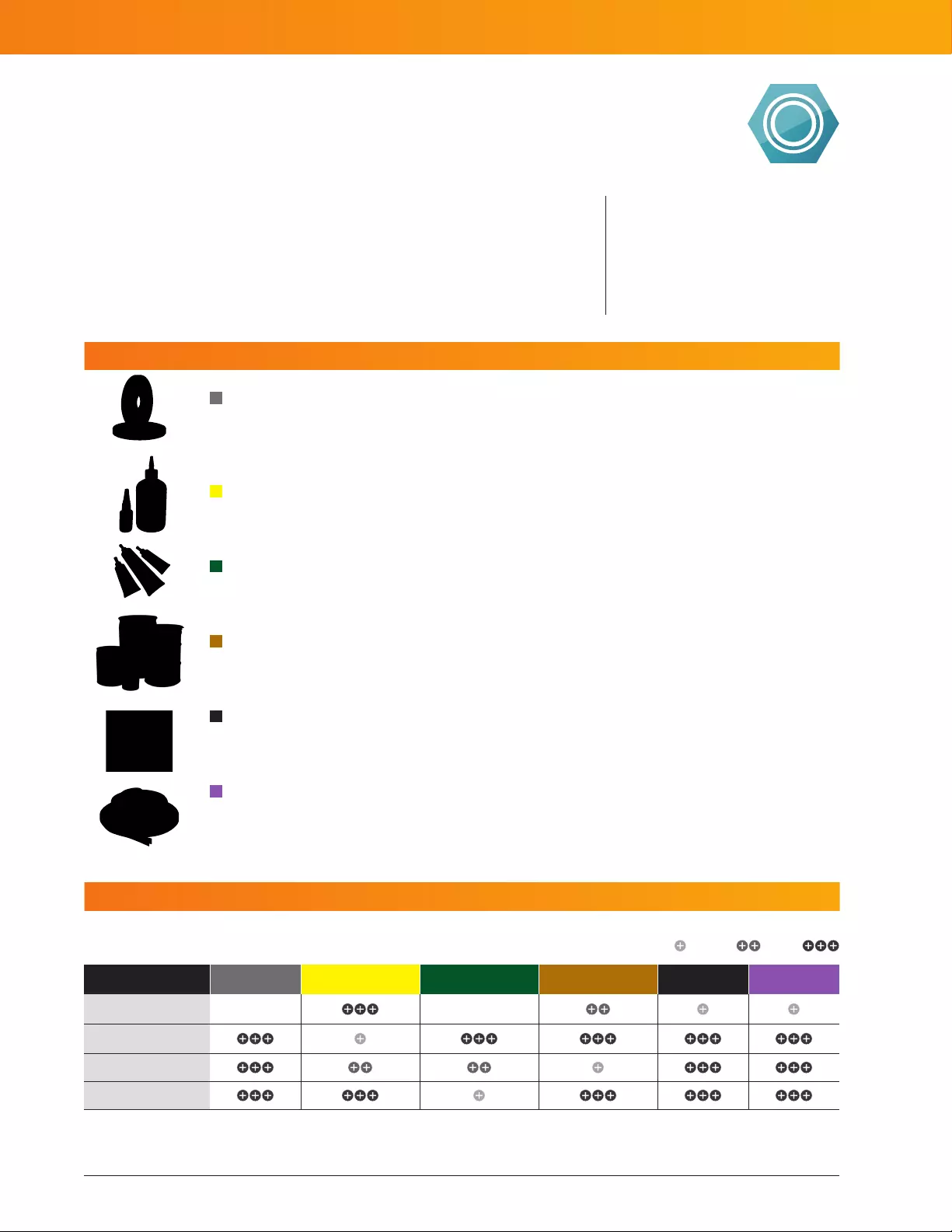

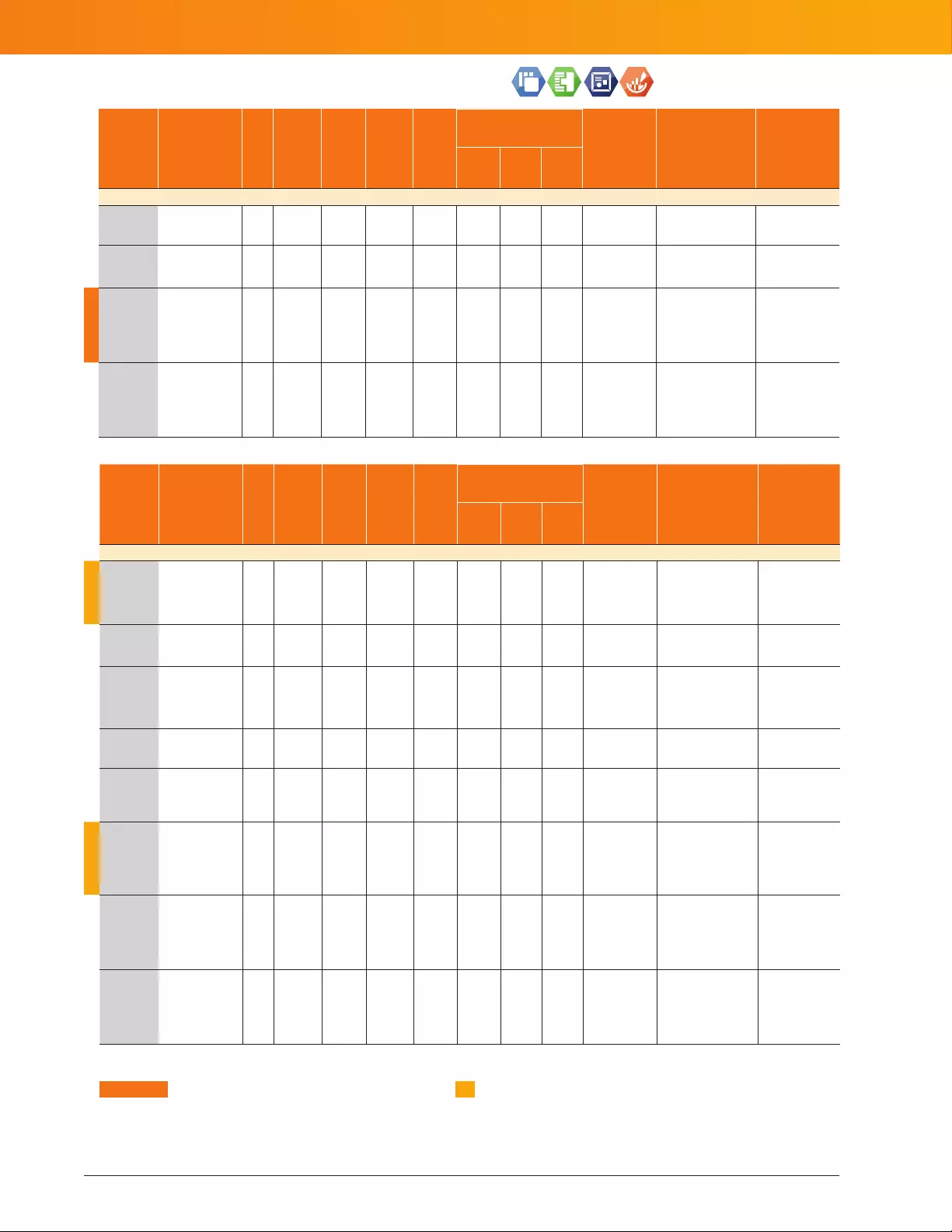

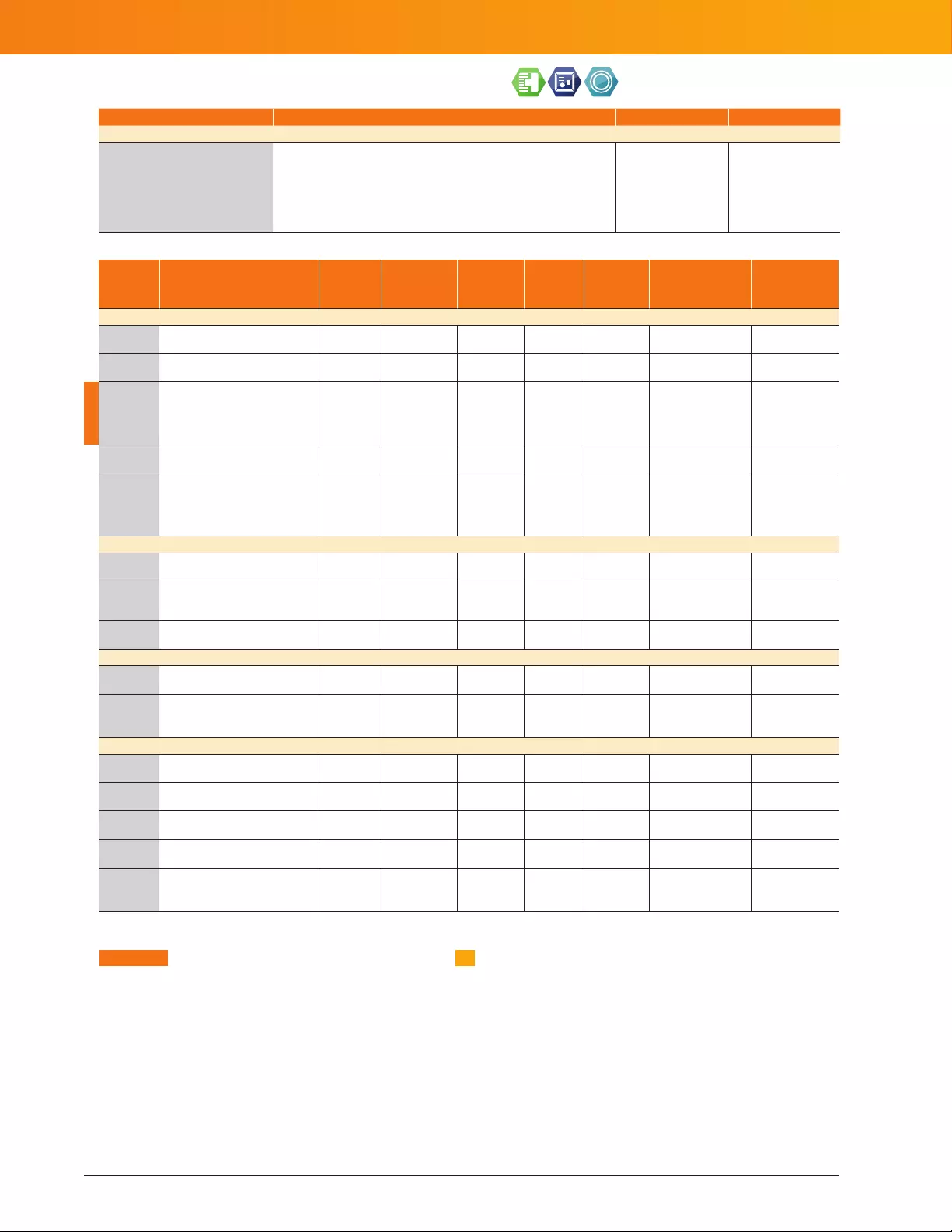

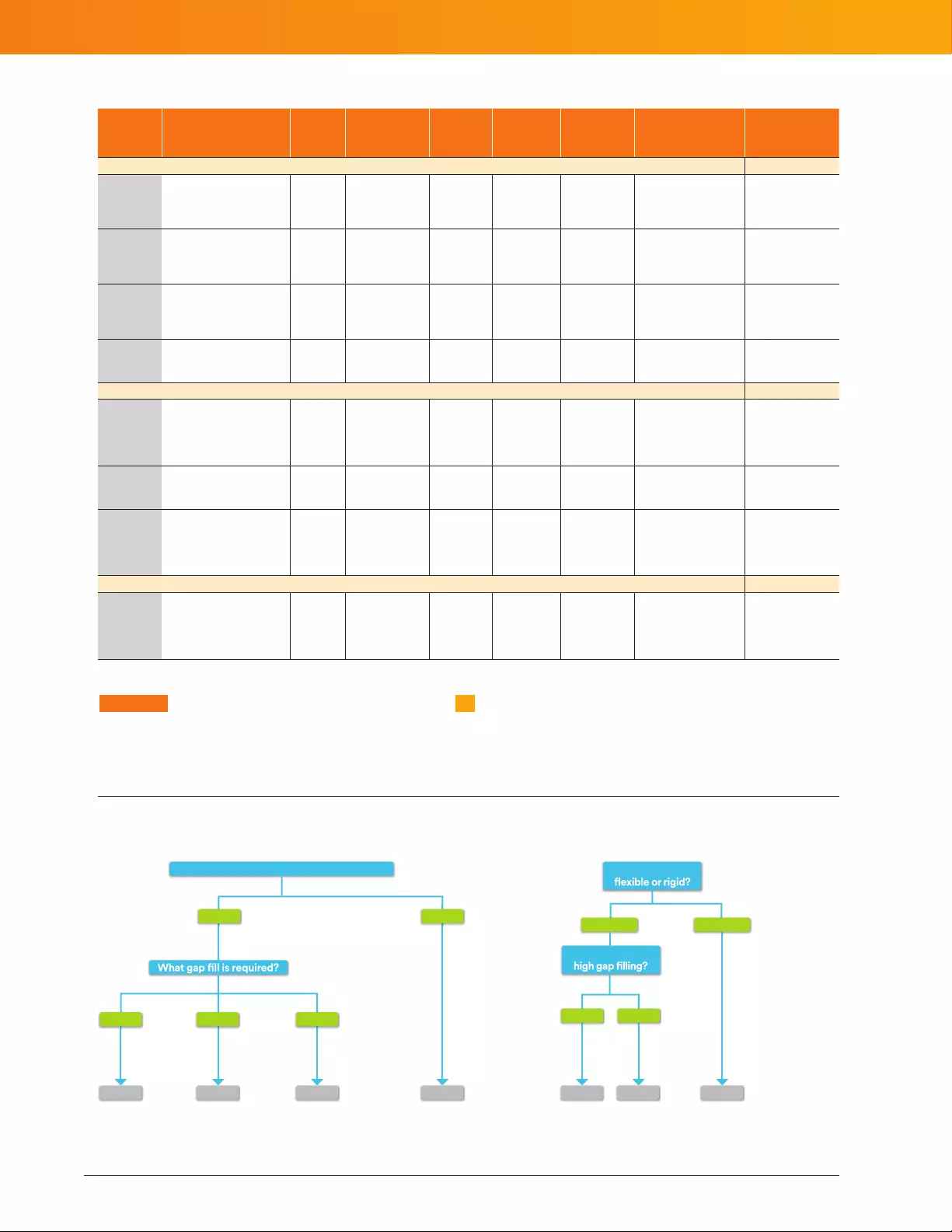

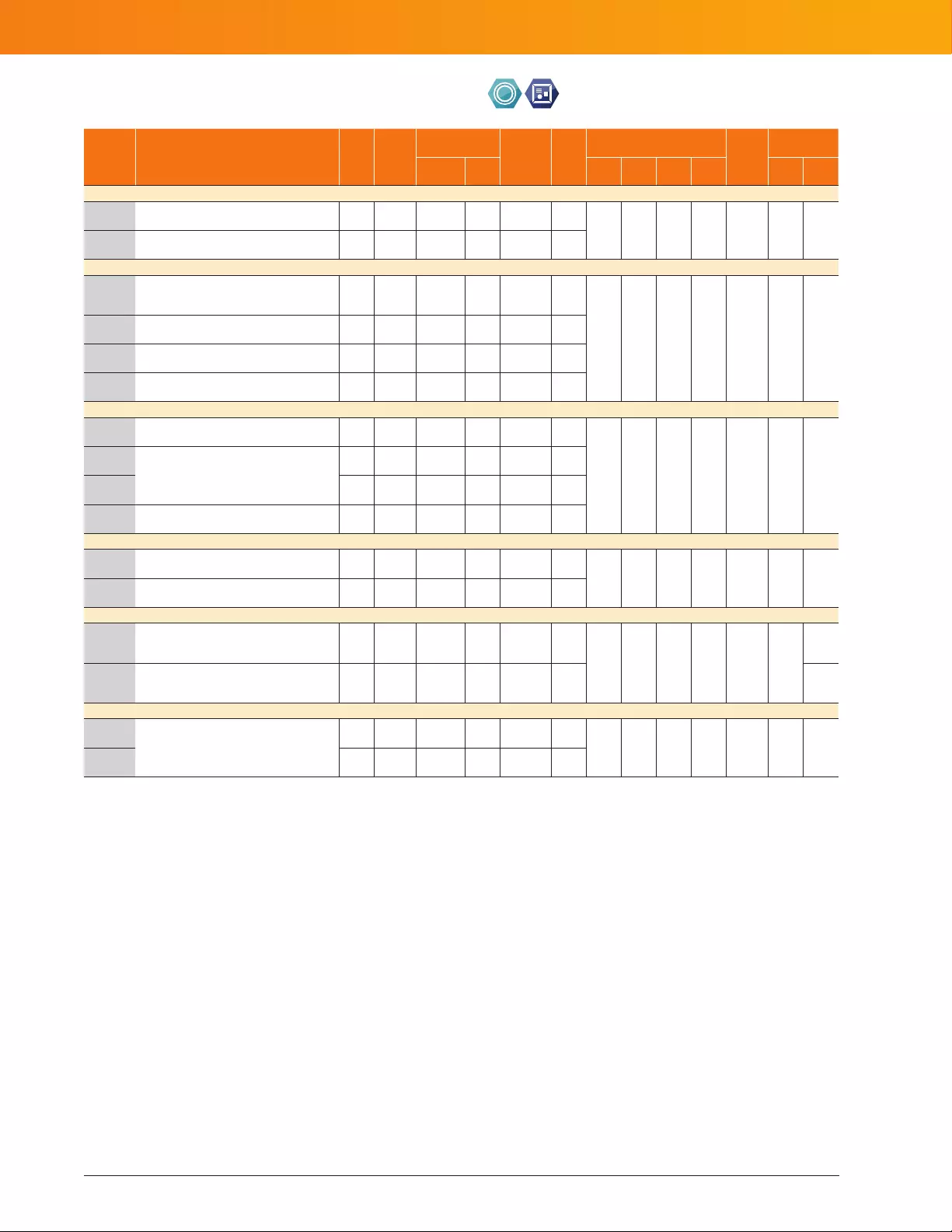

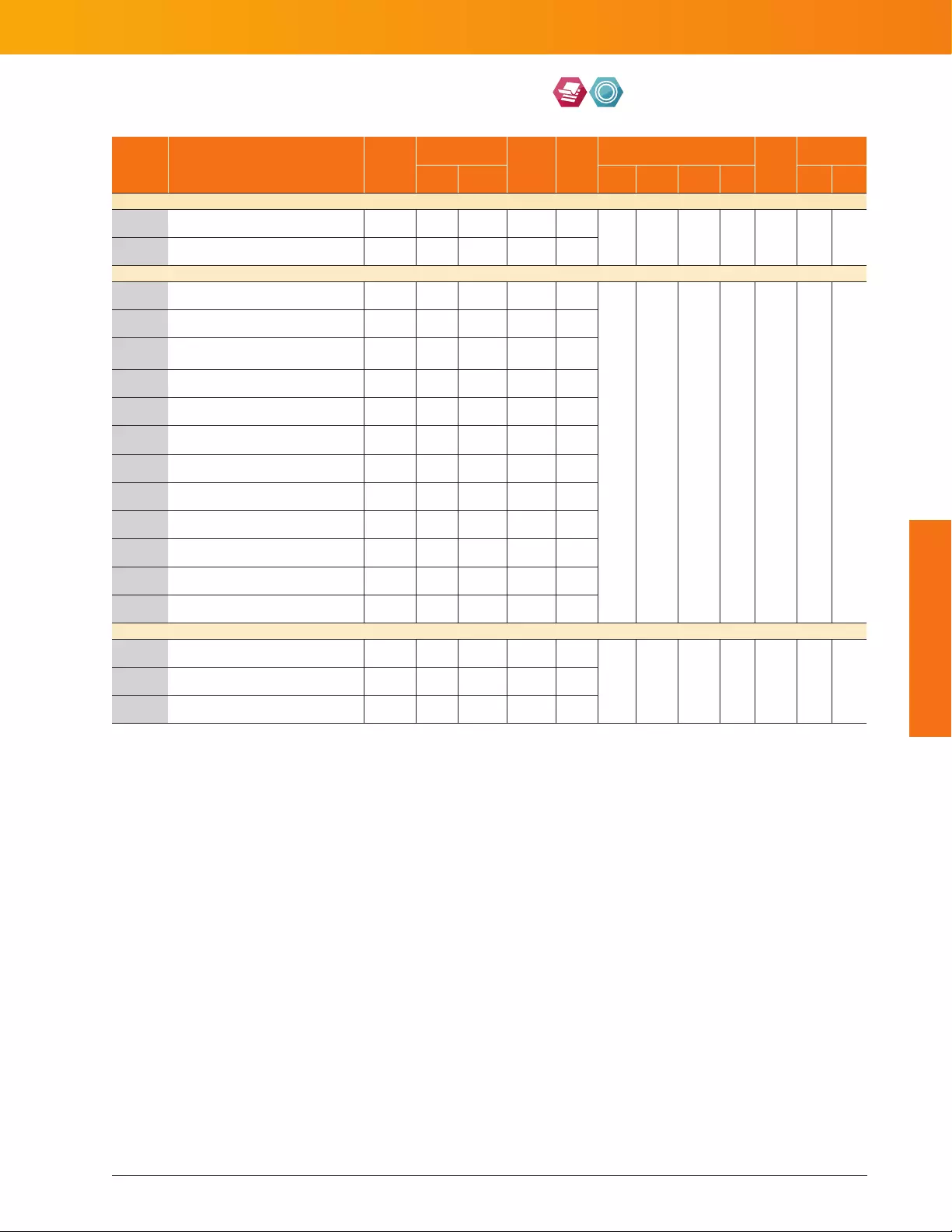

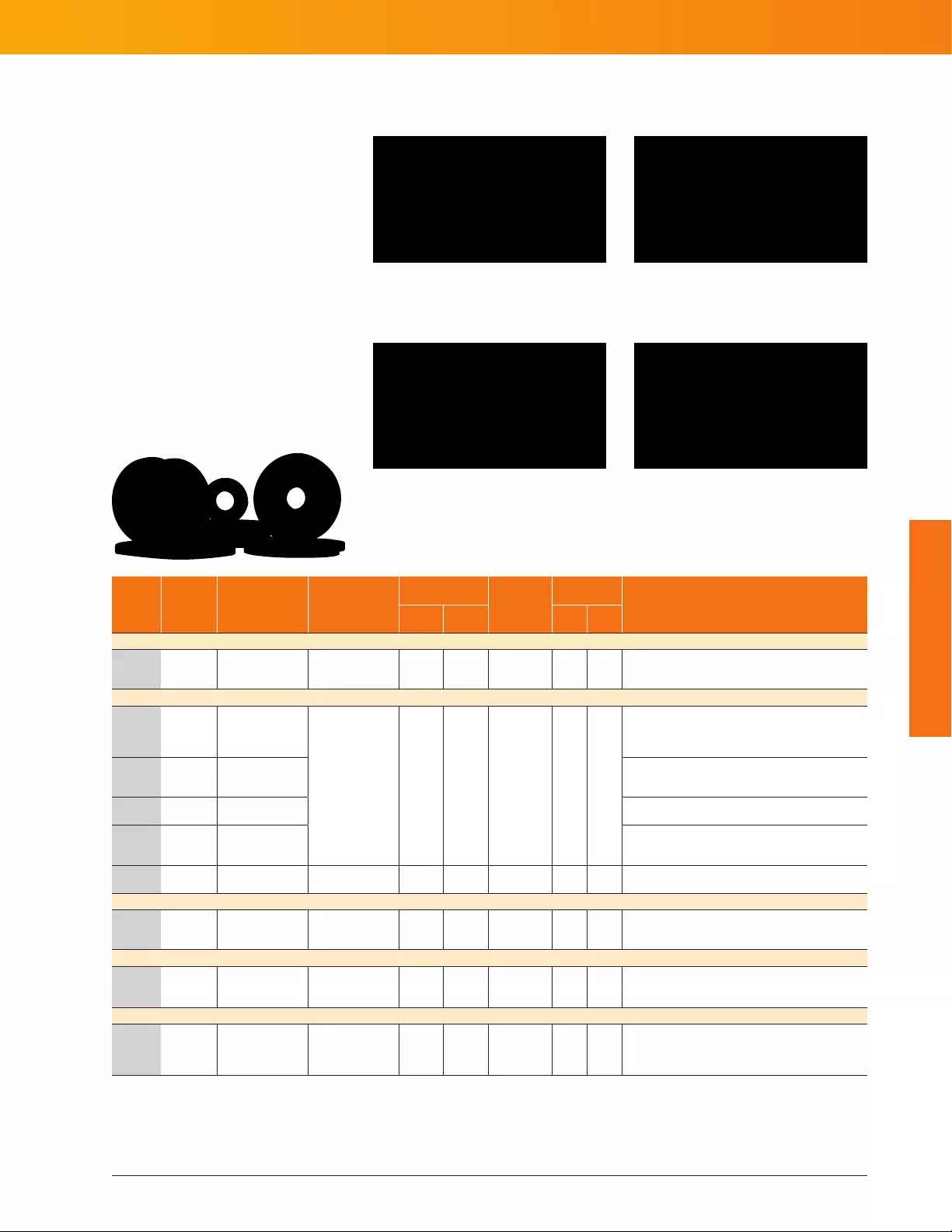

All 3M technologies in the table below are commonly used in gasket attachment

applications. Use the table below as a relative comparison of product performance.

Attribute

3M™ VHB™

Tapes

3M™ Scotch-Weld™

Instant Adhesives

3M™ Scotch-Weld™

Gasket Makers

3M™ Contact and

Spray Adhesives

3M™ Adhesive

Transfer Tapes

3M™ Double

Coated Tapes

High Strength and

Rubber Bonding N/A N/A

Temperature and

Solvent Resistance

Ease of Application

Rate of Strength Build

What are Gasket Attachment Assemblies?

Gaskets are used in multiple markets, such as electronics, transportation,

uid handling equipment and appliance.

Gasketing: Attachment of a substrate typically, foam, rubber or paper that

acts as an interface or seal between two surfaces. 3M oers solutions for

attaching preformed gaskets, and also solutions which can replace gaskets or

bond and seal simultaneously. Examples include air and liquid lters, uid

handling equipment, heat exchangers and ball joints.

Possible Adhesive or

Tape Requirements:

• Easy and fast to apply gaskets

• Resist uids

• High adhesion to foams

and rubber

3M™ VHB™ Tapes (pg 62–69)

High-strength bonding tapes that can be die-cut into a variety of shapes to replace rubber

or foam gaskets, providing an instant, simple solution. Their closed-cell construction provides

a watertight barrier between at parts.

3M™ Scotch-Weld™ Instant Adhesives (pg 29)

One part solvent-free cyanoacrylate (CA) adhesive that reaches handling strength in 5–30

seconds. Best for small very tight bondlines (<10cm2). Commonly used on rubbers and plastics.

3M™ Scotch-Weld™ Gasket Makers (pg 33)

One-part anaerobic adhesives can be applied as a curing liquid gasket between complex metal

shapes, replacing pre-formed gaskets.

3M™ Contact and Spray Adhesives (pg 54–57)

Solvent and water based adhesives can be sprayed, brushed or roll applied. Very fast, easy

and economical coverage of multiple substrates, irregular shapes and mild textures.

3M™ Adhesive Transfer Tapes (pg 78–81)

Can be pre-applied to gasketing material which is then die-cut to provide parts. These products

provide instant adhesion to at, untextured substrates.

3M™ Double Coated Tapes (pg 71–76)

Can be pre-applied to gasketing material which is then die-cut to provide parts. These products

provide instant adhesion.

8

13

14

15

19

20

Performance Factors for Gasket Assemblies

Best 3M Solutions for Gasket Assemblies

Good = Better = Best =

292

13

3M Industrial Adhesives and Tapes | October 2017 Edition

+

Metal Glass Paint Plastics: HSE Plastics: LSE

Rubber (EPDM, Santoprene®)

*PR100

4799

*468MP, 950

9832

4799

*468MP, 950

9832

*PR100

4799

*468MP, 950

9832

*PR100

4799

*468MP, 950

9832

* PR100

4799

*9472LE, 950

9832

Silicone Gaskets

*PR100

GM18 replace gasket

91022

9731, 96042

91022

9731, 96042

*PR100

91022

9731, 96042

*PR100

91022

9731, 96042

*PR100

91022

9731, 96042

Neoprene

*PR100

6035PC, 950

9832

1300

6035PC, 950

9832

*PR100

1300

6035PC, 950

9832

*PR100

1300

6035PC, 950

9832

*PR100

90

6035PC, 950

9832

Nylon

PR100

9472LE

1099

9472LE

PR100

1099

9472LE

PR100

1099

9472LE

*PR100

90

9472LE

PTFE

*PR100

GM18 replace gasket

950

9472LE *PR100

9472LE

* PR100

9472LE

*PR100

9472LE

3M™ VHB™ Tape can replace gaskets on many substrates listed in the chart.

3M™ Scotch-Weld™ Gasket Makers are suitable to replace gaskets in metal to metal applications.

Key

3M™ Scotch-Weld™ Instant Adhesives

3M™ Scotch-Weld™ Gasket Makers

3M™ Contact and Spray Adhesives

3M™ Adhesive Transfer Tapes

3M™ Double Coated Tapes

* Primers may also be required in some

cases. See specic product pages for

primer details.

40

41 42 43

Assembly Solutions

Gasket Attachment Assembly Solutions

This guide lists products that are commonly used for this specic application. It is important that the customer evaluates these suggested products in their specic application.

3M Industrial Adhesives and Tapes | 3M.com/Assemblysolutions

14

3M Industrial Adhesives and Tapes

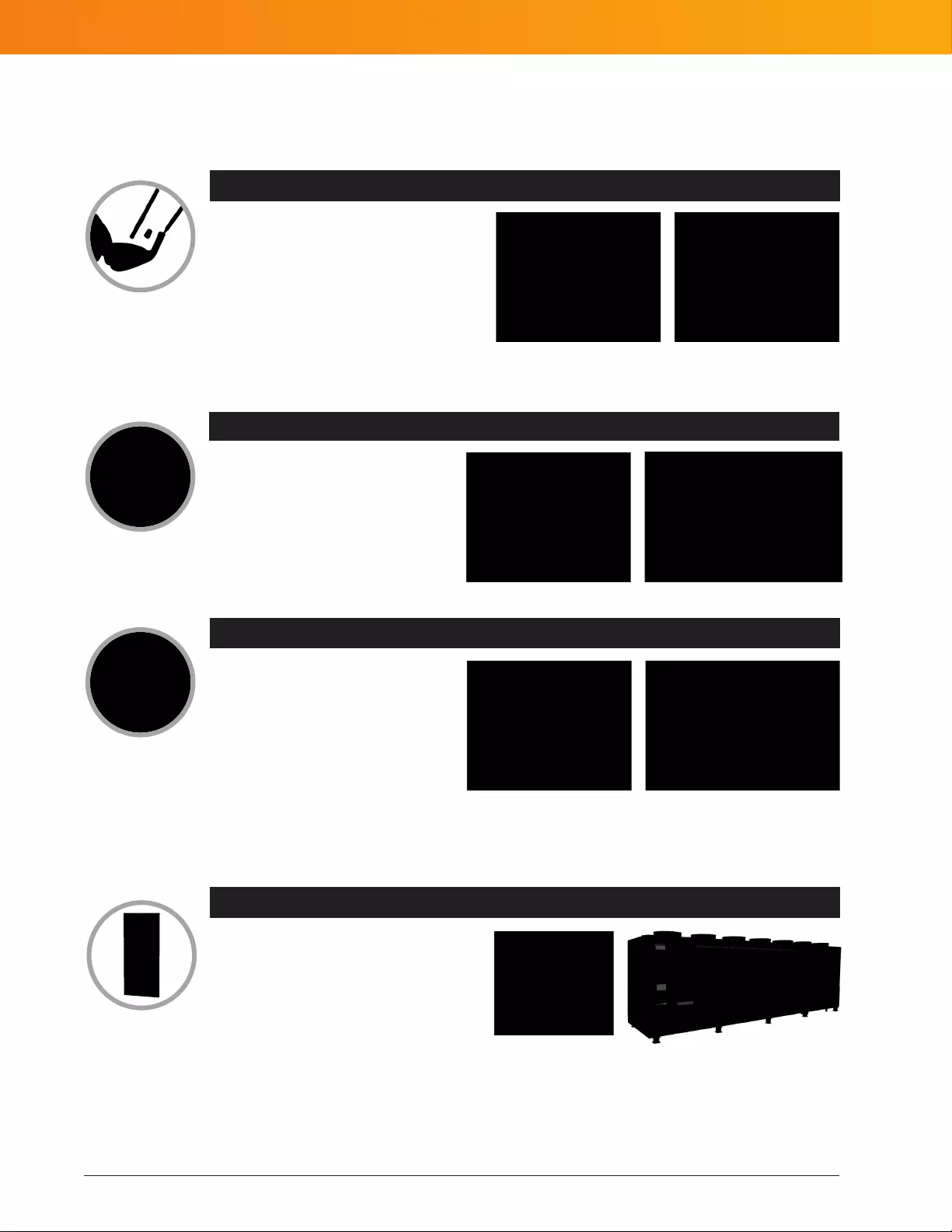

All 3M technologies in the table below are commonly used in sealing, potting

and encapsulation applications. Use the table below as a relative comparison

of product performance.

Attribute

3M™ Scotch-Weld™

Structural Adhesives

3M™ Hot Melt

Adhesives

3M™ Adhesive

Sealants

3M™ Extreme

Sealing Tapes

Sealing

Flexibility N/A N/A

Ease of Application N/A N/A

Time to Paint (or handle part) N/A N/A

Immediate Rework N/A N/A

Potting and

Encapsulating

Temperature and

Solvent Resistance N/A

Time to Paint (or handle part) N/A

Flowability* N/A

Adhesion to Substrates N/A

* 3M™ Scotch-Weld™ Structural Adhesives and 3M™ Hot Melt Adhesives are used for potting and encapsulating where their ow and conformability allow them to ll into, or dome

over, complex shapes. 3M™ Adhesive Sealants are thick and can be dispensed into wide vertical or horizontal gaps, as well as over seams. 3M™ Extreme Sealing Tape seals over

seams and narrow gaps but does not ow into gaps. It can conform over low prole objects such as rivet heads.

What is Sealing of Assemblies?

What is Potting and Encapsulating

of Assemblies?

Sealing and potting exists in multiple markets, such as transportation,

metalworking, electronics, electrical, construction and MRO.

Sealing: Tape or sealant is applied over a seam to prevent uid ingress or uid

egress. Examples include roof seams on vehicles, seams on metal enclosures

and pipe sealing.

Potting and Encapsulating: Adhesive ows over and around a component or lls

in a chamber to protect components therein. Examples include heavy duty

electrical cords and connectors, electronics in plastic cases, circuit boards

and concrete repair.

Possible Adhesive or

Tape Requirements:

• Highly elongating/exible

• Fast cure for painting

• Durability

3M™ Scotch-Weld™ Structural Adhesives (pg 18–35)

Acrylic, epoxy and urethane structural adhesives are available in a variety of cure times and

ow proles for potting and encapsulation. Available in both rigid and exible formulations.

3M™ Hot Melt Adhesives (pg 44–45)

Extrudable, 100% solid, thermoplastic resins designed for potting and encapsulating electrical

components.

3M™ Adhesive Sealants (pg 58–59)

Acrylic, polyurethane and nitrile and hybrid are one component sealing technologies. Can

be extruded in any shape on a substrate and are non-sag to ll gaps. Some formulations

can be painted wet.

3M™ Extreme Sealing Tapes (pg 70)

Provides instant sealing and paint-ability when applied over seams or gaps. Conformable

over rivets.

12

16

17

11

Performance Factors for Sealing, Potting and Encapsulating

Best 3M Solutions for Sealing, Potting and Encapsulating

Good = Better = Best =

292292

15

3M Industrial Adhesives and Tapes | October 2017 Edition

+

Metals (Aluminum, Steel,

Stainless, Galvanized)

Paints (Powder Coat,

Painted Metal, Composite Panel) Glass

Plastics: HSE, MSE (ABS, Acrylic,

Polycarbonate, Nylon)

Plastics: LSE

(Polypropylene, Polyethylene)

Metals

2216, DP270

3797, 3748 VO

*540, *740

4411B, 4411N, 4411G

2216, DP604NS

3797, 3748 VO

*540, *740

4411B, 4411N, 4411G

DP125 Gray,

DP100 Plus Clear

*540, *740

4411B, 4411N, 4411G

2216, DP604NS

3797, 3748 VO

*540, *740

4411B, 4411N, 4411G

DP8010 Blue

3797, 3748 VO

*540, *740

*4411B, *4411N,

*4411G

2216, DP604NS

*540, *740

4411B, 4411N, 4411G

DP125 Gray,

DP100 Plus Clear

*540, *740

4411B, 4411N, 4411G

2216, DP604NS

*540, *740

4411B, 4411N, 4411G

DP8010 Blue

*540, *740

*4411B, *4411N,

*4411G

DP125 Gray,

DP100 Plus Clear

*540, *740

4411B, 4411N, 4411G

DP125 Gray,

DP100 Plus Clear

*540, *740

4411B, 4411N, 4411G

DP8010 Blue

*540, *740

*4411B, *4411N,

*4411G

2216, DP604NS

3797, 3748 VO

*540, *740

4411B, 4411N, 4411G

DP8010 Blue

3797, 3748 VO

*540, *740

*4411B, *4411N,

*4411G

DP8010 Blue

3797, 3748 VO

*540, *740

*4411B, *4411N,

*4411G

Paints

Glass

Plastics: HSE, MSE

Plastics: LSE

Key

3M™ Scotch-Weld™ Structural Adhesives

3M™ Hot Melt Adhesives

3M™ Adhesive Sealants

3M™ Extreme Sealing Tapes

* Primers may also be required in some

cases. See specic product pages for

primer details.

44 45 46

Assembly Solutions

This guide lists products that are commonly used for this specic application. It is important that the customer evaluates these suggested products in their specic application.

Sealing, Potting and Encapsulating Assembly Solutions

3M Industrial Adhesives and Tapes | 3M.com/Assemblysolutions16

3M Industrial Adhesives and Tapes

Substrates and Adhesion – A Surface Phenomenon,

So Know Surfaces Well.

Adhesive attaches to the surfaces of two substrates,

unlike a process that fuses the substrates into a unied

whole such as welding or solvent activation of plastics.

When selecting a 3M adhesive or tape, surface condition

must be considered: roughness, smoothness, porosity,

coated, uncoated, cleanliness, exibility size of part and

surface energy of part.

Adhesive paste, for example, ows readily into a rough

surface for improved eective adhesion. Flexible materials

such as paper or thin gauge metal can be bonded with

thin adhesive transfer tape. Large rigid parts with smooth

clean surfaces can be bonded with a variety of 3M product

ranging from double-coated foam tapes to two-part

structural adhesives. Some plastics have plasticizers

which migrate to the surface and degrade the bond over

time, so plasticizer-resistant adhesive or tape is essential.

If the surface has been powder coat painted, the coating

is the bonding surface rather than the substrate, and you

would want to consider a 3M tape or adhesive developed

specically for the surface.

Surface energy ranges from high to low. To illustrate

the concept of surface energy, think of water on an

unwaxed hood of a car. The unwaxed hood has high

surface energy and the water on the hood ows into

puddles. In comparison, a waxed hood has low surface

energy and the water beads up rather than ow out.

Similar to water, adhesive on a high surface energy

ows and “wets out” the surface. “Wetting out” is

required to form a strong bond.

As a rule of thumb, the higher the surface energy,

the greater the strength of the adhesion.

Specially formulated adhesives are available for low

surface energy surfaces. The following illustrations

and surface rankings give an idea of the relative

surface energy.

Regardless of surface energy, the substrate must be

unied, dry and clean to maximize adhesive contact.

Metal Surfaces (High Surface Energy) High Surface Energy Plastics (HSE) Low Surface Energy Plastics (LSE)

mJ/m2Surfaces

1103 Copper

840 Aluminum

753 Zinc

526 Tin

458 Lead

700 –1100 Stainless Steel

250 –500 Glass Porcelain

mJ/m2Surfaces

50 Polyimide

Industrial Film

47 Phenolic

46 Nylon

45 Alkyd Enamel

43 Polyester

43 Epoxy Paint

43 Polyurethane

Paint

mJ/m2Surfaces

42 ABS

42 Polycarbonate

39 PVC Rigid

38 Modied PPE

Resin

38 Acrylic

mJ/m2Surfaces

37 PVA

36 Polystyrene

36 Acetal

33 EVA

31 Polyethylene

29 Polypropylene

28 Polyvinyl Fluoride Film

18 PTFE

Broad

Range Powder Coated Paints

Note: These values are provided as a guide. Formulation modications can substantially alter surface energies.

Surface Energy Chart

295 295 295

Adhesives and Sealants

17

3M Industrial Adhesives and Tapes | October 2017 Edition

Powerful Adhesive and Sealant Solutions

3M oers a wide range of innovative adhesives and sealants

designed for industrial markets. High quality, precision

formulations with proven performance provide reliable,

long-term durability for a variety of applications, indoors

and out.

Adhesives and Sealants

The best formulas

deliver the best

performance.

293

3M Industrial Adhesives and Tapes | 3M.com/Assemblysolutions

18

3M Industrial Adhesives and Tapes

In today’s world, successful new

products demand advancements

in design, manufacturing processes

and end-use performance. Industrial

engineering and design professionals

around the world depend on 3M™

Scotch-Weld™ Structural Adhesives

to help them design beyond the

limits of mechanical fasteners to

create next generation products.

Trusted innovations

from aerospace to

With over 60 years of experience developing

innovative structural adhesives for aerospace,

automotive and hundreds of other industries,

3M delivers the solutions you can trust.

Our advanced formulations create durable

bonds, even on challenging materials or in

extreme conditions.

3M global service

and support

3M supports our customers with the testing,

technology, and training needed to create

better products. Our world-wide support

sta has the experience you can rely on

for everything from structural adhesive

selection to process improvement.

Leverage 3M’s proven selection of structural

adhesives, deep industry expertise, and

technical support to your advantage.

Design with Condence. Build to Last.

Design with

Confidence.

Build to

Last.

296

Adhesives and Sealants

19

3M Industrial Adhesives and Tapes | October 2017 Edition

Freedom of Design: Join composites to metal, build

with hard-to-bond plastics, and use thinner, lighter

weight materials.

Improve Aesthetics: Improve product appearance with

invisible joints and smoother bond lines, reduce weight

and noise, enhance corrosion and fatigue resistance,

and more.

Strong, Flexible Bonds: Adhesives bond and seal

simultaneously, eliminate stress concentration and

absorb shock and vibration for durable bonds.

Increased Durability: Resist chemicals, environment,

galvanic corrosion, fatigue, and material separation

along edges or corners.

Accurate and Easy: Dispense by hand or with automated

equipment, and choose from a wide range of viscosities

Enhance Productivity: Reduce labor and material

costs, build faster with minimal surface prep and match

cure rates to your process needs.

Advancing design, process and performance

The benets of designing and building products with 3M™ Scotch-Weld™ Structural Adhesives

help drive product success. Eliminating mechanical fasteners provides a wide range of benets

for all stages of product development.

Design Solutions

Performance Optimization

297

298

299

3M Industrial Adhesives and Tapes | 3M.com/Assemblysolutions

20

3M Industrial Adhesives and Tapes

Simplifying Adhesive Decisions for Your Application

The following questions will help you narrow adhesive choices to a few possibilities

for evaluation.

Q: What materials will be bonded?

A: Structural adhesives

work by adhering to

the top surface of the

bonded parts, so it’s

important to know

the exact material and

condition on those

surfaces. For metals,

will the adhesive be

applied to bare metal,

or will there be a paint

or coating on the surface? For plastics, exactly which

base resin? Could there be residual release agents

on the surfaces used for mold release?

Q: What is the preferred cure speed?

A: The chosen structural

adhesive must have

enough work life

(open time, pot life)

to allow proper mixing

and application of

the adhesive and

assembling of the

bonded parts. Smaller

assemblies or shorter

cycle time production

processes may be able to use a faster curing

adhesive with a work life of only ve minutes or

less, while larger assemblies that require alignment

and clamping will probably need a work life of

20 minutes or more.

Q: What surface preparation will be required?

A: Structural adhesives

generally prefer clean,

rough, dry surfaces for

highest bond strength.

This typically means

either light abrasion

and solvent cleaning of

the surface, or solvent

cleaning followed by

chemical etching or

applying a primer.

Adhesion tests should be performed to determine the

adequate surface preparation for a specic application.

Q: What types of joints are best for

structural adhesives?

A: Joint designs that put

the adhesive bond

under shear, tension,

or compression forces

will provide the highest

strength. Designs that

tend to apply peel or

cleavage forces to the

adhesive, where the

applied stresses are

not distributed over

the entire bond area, will have lower bond strength,

but the bond may still be sucient for the needs

of the application. In addition, optimum bond line

thickness typically ranges from 0.005" to 0.020".

The adhesive qualication process should always

include testing of prototype assemblies to ensure

the adhesive will provide enough performance.

Q: How are structural adhesives used and applied?

A: Structural adhesives

come in many forms,

including low viscosity

liquids and non-sag

pastes, one- and

two-component

formulations, short and

long work lives, and

various package sizes

and shapes. Most

two-part structural

adhesives are available in both bulk containers and

convenient, easy-to-use cartridge mixing systems.

Q: What are the general characteristics of the

dierent types of structural adhesives?

A: All structural

adhesives provide at

least 1,000 psi of

overlap shear strength

to aluminum, but the

dierent adhesive

chemistries have

various properties.

300

303

301

304

302

305

Adhesives and Sealants

21

3M Industrial Adhesives and Tapes | October 2017 Edition

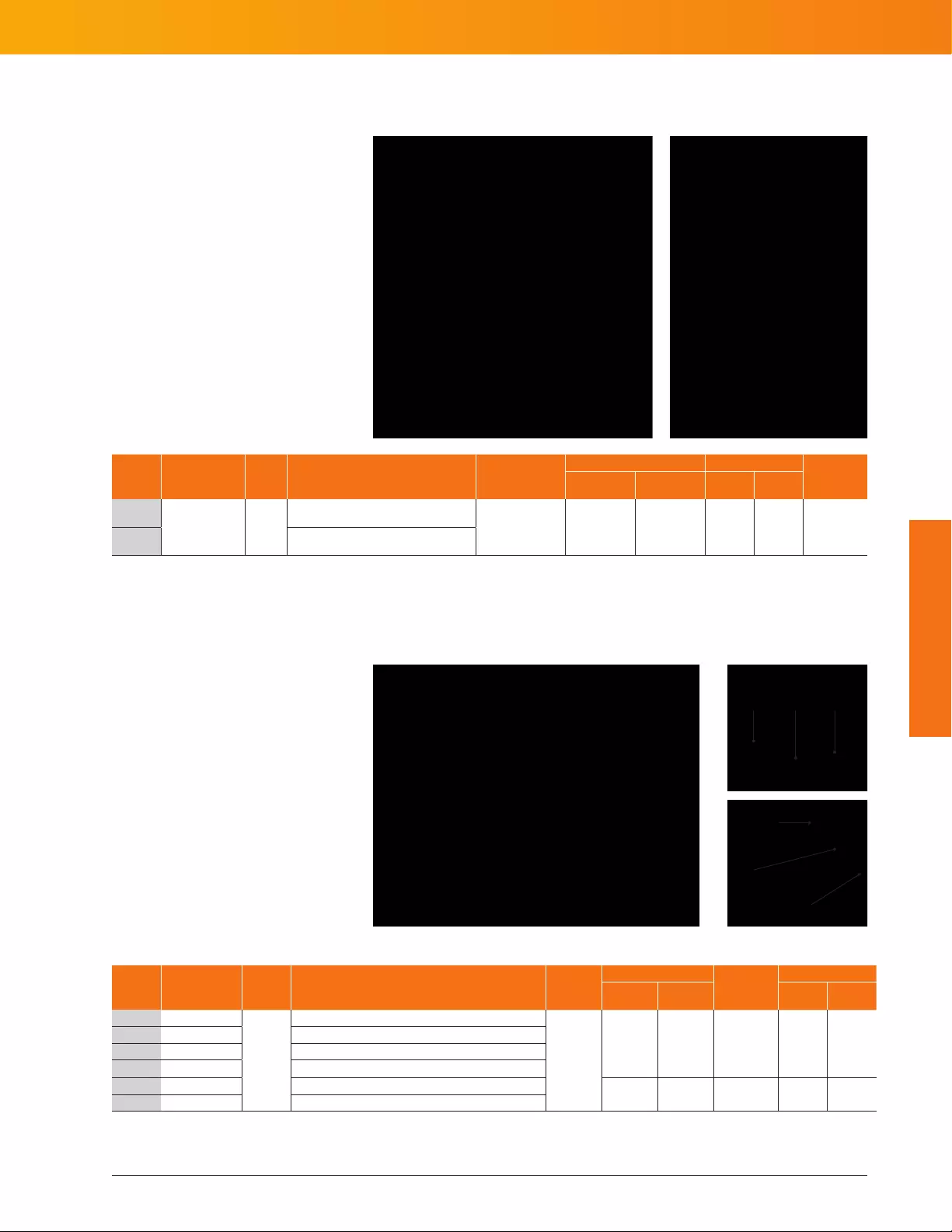

Shear

Peel

Shear is pull directed across the adhesive, forcing the

substrates to slide over each other.

Tensile is pull exerted equally over the entire joint. Pull direction

is straight and away from the adhesive bond.

Tensile

Shear

Cleavage is pull concentrated at one edge of the joint, exerting

a prying force on the bond. The other edge of the joint is

theoretically under zero stress.

Cleavage

Peel is concentrated along a thin line at the edge of the bond

Peel

Epoxy adhesives come in both two-part adhesives (that

cure upon mixing the two components) and one-part

adhesives (that cure with temperature). They generally have

the highest strength and overall performance. They also

provide the best resistance to high temperatures, solvents

and outdoor weathering. They adhere well to metals, woods

some plastics and rubbers. Epoxy adhesives usually require

clean, abraded surfaces to obtain maximum bond strength.

Acrylic adhesives are two-part adhesives that provide

excellent bond strength and durability, although slightly

lower than epoxy adhesives. However, they have several

features that make them easier to use in many applications

faster cure speed, higher tolerance for oily or unprepared

bonding surfaces and the ability to bond a wide variety

of materials, including nearly all plastics. Newer acrylic

adhesive formulations are room temperature stable with

a long shelf life, and some have much lower odor than

regular acrylic adhesives.

Urethane adhesives are two-part adhesives that are

excellent impact resistance and good adhesion to most

plastics. They also bond well to woods, concrete and rubbers,

but they tend to have reduced resistance to solvents and

high temperatures. Uncured adhesive components are

sensitive to moisture.

Cyanoacrylate adhesives (instant adhesives) are one-

component, lower viscosity liquids that cure extremely quickly

with just contact pressure and surface moisture. They adhere

well, with thin bond lines, to plastics, metals and rubbers. With

the use of primers, they can also adhere to low surface energy

strength and impact resistance compared to other structural

adhesives. They are generally used for applications such as

gasket bonding and smaller assemblies.

Anaerobic adhesives are one-part adhesives that cure

on active metal surfaces when oxygen gets excluded from

the bond line. These products keep your factory running

bond well to glass, plastics or rubbers, and are primarily

used for applications such as locking threads and sealing

pipe connections.

PUR adhesives (Polyurethane-reactive adhesives) are

one-part adhesives that apply like a hot melt, but cure with

ambient moisture for near structural strength bonds. Fast

set times and build strength over the next 24–48 hours

can reach as much as 1,000 psi in overlap shear strength.

and most solvents. Most commonly used in bonds where

at least one substrate contains or transmits moisture

(such as wood or plastic).

337

338

339

340

3M Industrial Adhesives and Tapes | 3M.com/Assemblysolutions

22

3M Industrial Adhesives and Tapes

Key markets and applications for

3M™ Scotch-Weld™ Structural Adhesives.

Signage

• One adhesive to bond all

of your substrates

• Strong formulations and thin

bond lines

• Weather resistance

• UL recognition

Key Products

DP8805NS, DP8405NS, DP100 Plus

Sporting Goods

• Excellent impact resistance of high

stressed bonds

• High strength for small joints

• High strength bonding of rubber,

composites and metals to each other

Key Products

DP420NS Black, DP8810NS, PR100, TS230

Metalworking

• High strength and durability

• Reduced surface preparation

before bonding, and no grinding

after bonding

• Save weight and improve appearance

with adhesives instead of welds or rivets

Key Products

DP420NS Black, DP8407NS, DP8410NS

35 68

66

Specialty Vehicle

• Weight reduction

• High strength

• Vibration and fatigue resistance

Key Products

DP8410NS, LSB60NS, TL42

3

73

74

76

75

72

77

78 79

Adhesives and Sealants

23

3M Industrial Adhesives and Tapes | October 2017 Edition

Electronics

• Excellent impact resistance of high

stressed bonds

• High strength for small joints

• High strength bonding of rubber,

composites and metals to each other

Key Products

DP420NS Black, DP8810NS, PR100, TS230

Appliance

• Simplify operations by bonding

after powdercoating

• Eliminate the challenge of bonding

• Noise damping

• Reduce complexity-bond and

seal glass to metal in one step

Key Products

DP125 Gray, DP8810NS, TS230, TL42

61

62

59

63

45

64

65

Plastic, Composite & Rubber

• Bonding of low surface energy

plastics without priming

• Impact resistant composite

bonding

Key Products

DP8010 Blue, DP420NS,

DP6310NS, TS230, PR100

Aerospace

• Available in UL94 or FST

compliant options

Key Products

2216 Gray, DP100FR, DP640

58

60

69

70

71

3M Industrial Adhesives and Tapes | 3M.com/Assemblysolutions

24

3M Industrial Adhesives and Tapes

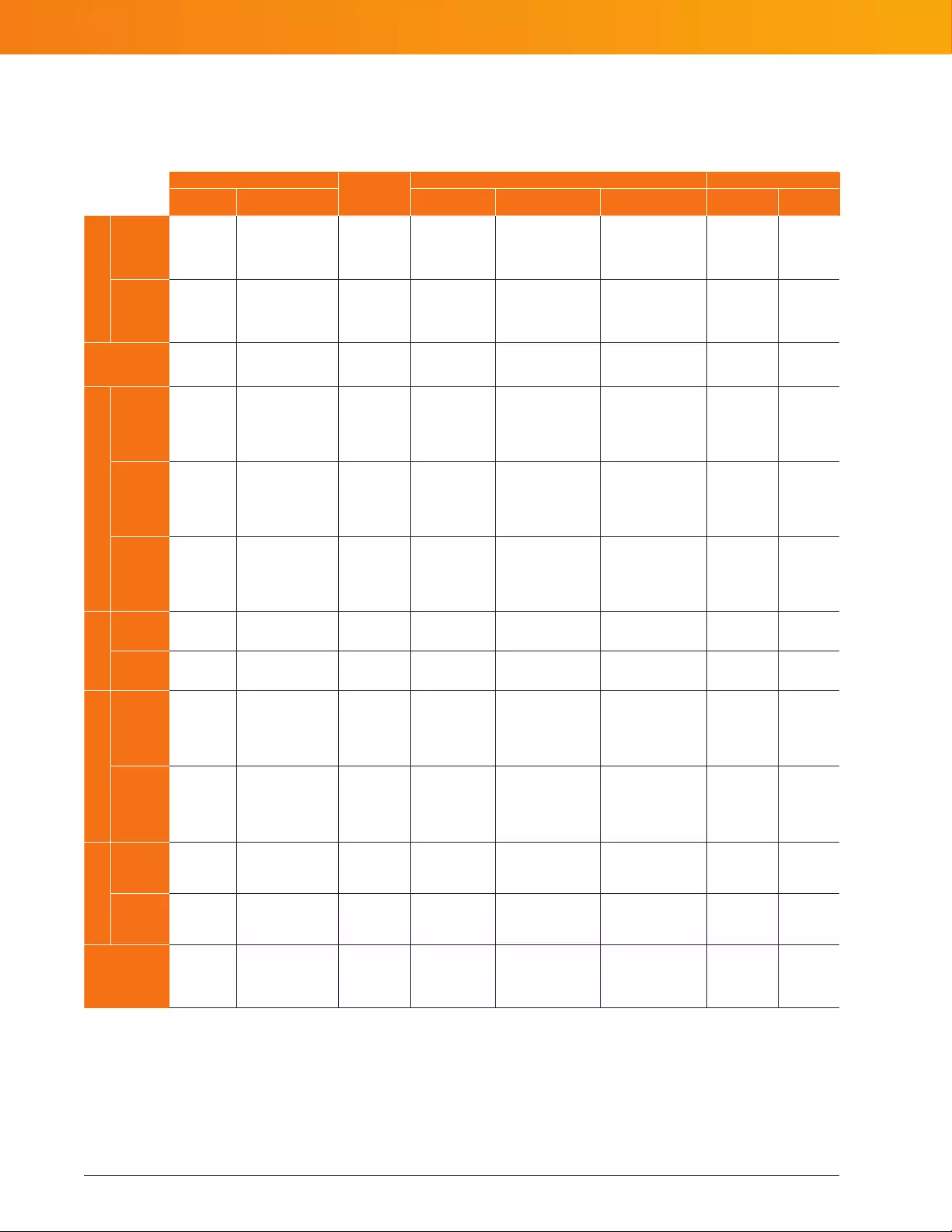

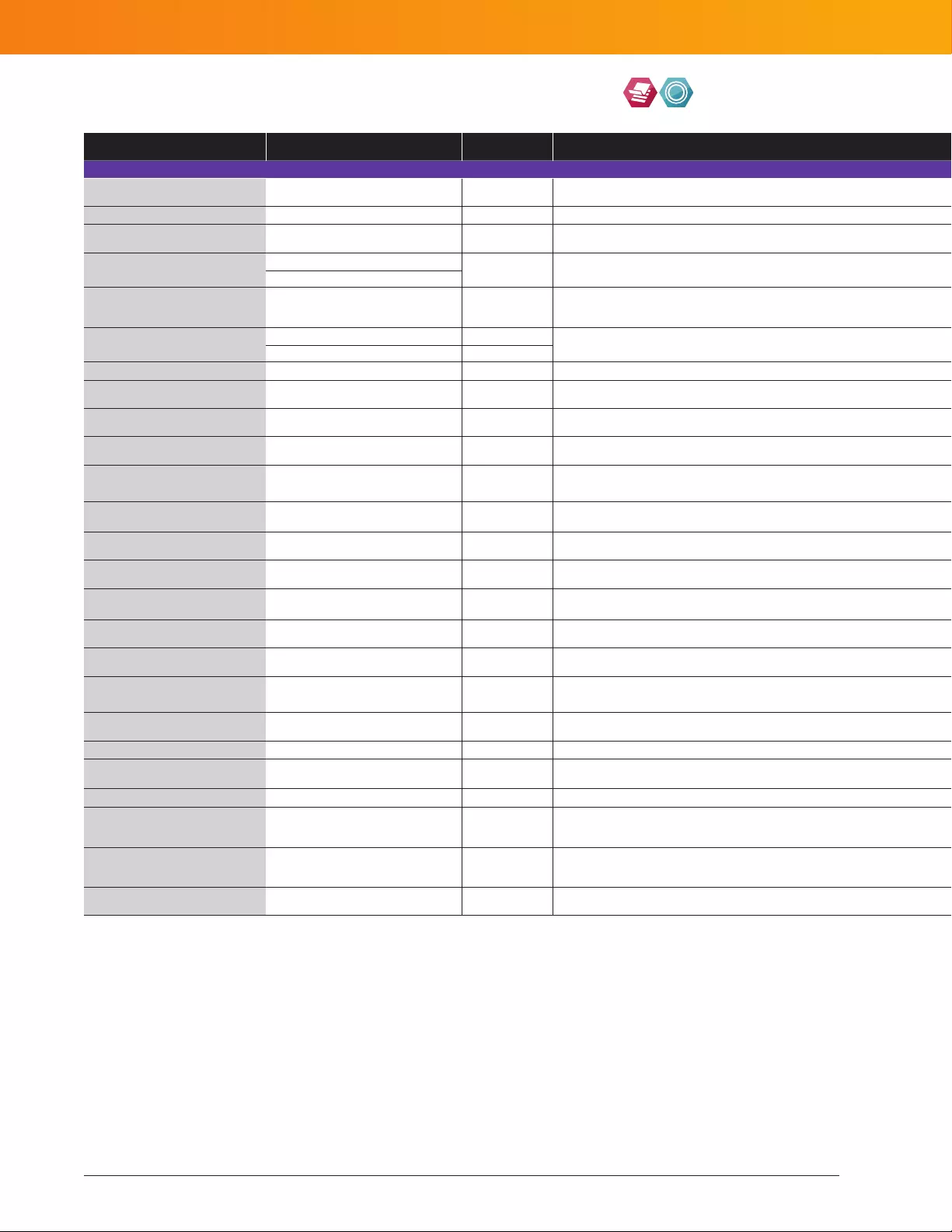

3M™ Scotch-Weld™ Adhesives Selector Guide

Step 1: Select Most Dicult Substrate Step 2: Determine Key Attribute Step 3: Select Product Family

Structural Adhesive Families

Rigid Epoxy Adhesives: Higher tensile strength at lower

elongations for greater long-term holding power. Mostly

used for rigid substrates (metals) with high static loads.

Flexible Epoxy Adhesives: Lower tensile strength at

higher elongations for greater capability to withstand

strength and higher adhesion to most plastics.

Toughened Epoxy Adhesives: Higher tensile strength

dynamic stresses. They have long-term holding power,

higher peel strength, and exceptional higher resistance

against shock, vibration and impact loads. Lower adhesion

to most thermoplastics.

Heat-cured Epoxy Adhesives: One-component, rigid

adhesives with outstanding strength at elevated tempera-

tures. These adhesives require a thermal cure, typically

around 250–350°F (120–180°C) for 40–60 minutes.

MMA Acrylic Adhesives: Provides greater adhesion to

a wide variety of materials including most plastics and

paint systems, are tolerant of many surface

contaminations. High impact resistance for metal bonds.

Low Odor Acrylic Adhesives: Less odor than typical

acrylic adhesives and faster rate of strength build than

most two-part structural adhesives. Excellent adhesion

to a variety of materials, including plastics and paint

systems. They provide high impact resistance for plastic

LSE Acrylic Adhesives: Outstanding adhesion to

and TPO without surface treatment.

Semi-rigid Urethane Adhesives: Higher tensile

modulus and lower elongation capability, with greater

long-term holding power.

Flexible Urethane Adhesives: Lower tensile modulus

and higher elongation capability. Excellent adhesion to

most plastics.

Instant Adhesive Families

Plastic & Rubber (PR) Instant Adhesives: Bond to the

widest variety of materials, have an extremely fast cure

speed, and come in a wide range of viscosity.

Surface Insensitive (SI) Instant Adhesives: Cure even

on acidic surfaces (such as wood, paper, leather, and

traditional instant adhesives.

SUBSTRATE ATTRIBUTE KEY PRODUCT PRODUCT FAMILIES

PRODUCT FAMILIES KEY PRODUCTS ATTRIBUTE SUBSTRATE

PR100

• Plastic & Rubber CA

• Flexible Epoxy

Rubber

Polyolens &

low surface

energy

materials

General

purpose

DP8010

Blue

DP8805NS

Green

• LSE Acrylic

• Plastic &

Rubber CA

• Low Odor Acrylic

• MMA Acrylic

• Flexible Epoxy

• Flexible Urethane

• Plastic PUR

• Plastic &

Rubber CA

Plastics/Paints/Coatings

Aluminum and

Stainless Steel

All other

metals

DP8407NS

• MMA Acrylic

• Low Odor Acrylic

DP8410NS

Oily Metals

High

temperature

strength

and solvent

resistance

General

purpose

2214

Regular

Gray

DP420NS

Black

DP420NS

•

Heat-cured

Epoxy

•

Toughened

Epoxy

•

Toughened

Epoxy

•

MMA Acrylic

•

Low Odor

Acrylic

• Plastic PUR

•

Toughened CA

Metals

*See chart in back of guide for more details.

Adhesives and Sealants

25

3M Industrial Adhesives and Tapes | October 2017 Edition

Outdoor

variable

temperature

Indoor constant

temperature

DP125 Gray DP420NS

Black

•

Flexible

Epoxy

•

Flexible

Urethane

•

Toughened

Epoxy

•

Flexible Epoxy

•

Semi-rigid

Urethane

•

Flexible

Urethane

• Plastic PUR

Concrete/Stone/

Ceramics/Glass

Step 1: Select Most Dicult Substrate Step 2: Determine Key Attribute Step 3: Select Product Family

Low Odor (LO) Instant Adhesives: Provide a

an improved appearance.

General Purpose (EC) Instant Adhesives: Slightly less

expensive products that have lower strength and impact

resistance compared to traditional instant adhesives.

Super Fast (SF) Instant Adhesives: Provide the fastest

rate of cure speed for most applications.

Rubber Toughened (RT) Instant Adhesives: Can

be used for applications that require improved impact

bonding two rigid materials together.

Metal (MC) Instant Adhesives: Provide improved

performance on metal substrates.

Engineered Grade (EG) Instant Adhesives: Provide

excellent overall performance for most applications.

Anaerobic Adhesive Families

Threadlockers (TL): Hold screws and other threaded

fasteners in place to prevent loosening from shock,

adhesives replace lock washers and nylon-insert nuts.

Retaining Compounds (RT): Bond and seal non-threaded

and set screws.

Pipe Sealants (PS): Provide a pressure seal on threaded

and pastes.

Gasket Makers (GM): Fill voids between metal parts to

o-rings and pre-formed gaskets.

PUR Adhesive Families

Wood PUR: Higher shear strength at lower elongations

for long term holding power. Mostly used for rigid wood

substrates and some plastics.

Plastic PUR: Higher impact strength, elongation and

of bonded parts. Higher adhesion to most plastics,

glass and aluminum.

SUBSTRATE ATTRIBUTE KEY PRODUCT PRODUCT FAMILIES

KEY PRODUCTS PRODUCT FAMILIESSUBSTRATE ATTRIBUTE

PRODUCT FAMILIES KEY PRODUCTS ATTRIBUTE SUBSTRATE

TE100

•

Wood PUR

•

Rigid Epoxy

•

Flexible Epoxy

•

Semi-rigid Urethane

•

Surface Insensitive CA

Wood

Epoxy-based Fiberglass/

SMC

DP6310NS

DP420NS

Black

DP8410NS

Green

•

Toughened Epoxy

•

Flexible Epoxy

•

Toughened CA

•

MMA Acrylic

•

Low Odor Acrylic

•

Toughened Epoxy

• Plastic PUR

•

Toughened CA

Composites

Outdoor

variable

temperature

Indoor

constant

temperature

DP270

•

Rigid Epoxy

•

Flexible

Epoxy

•

Toughened

Epoxy

• Plastic PUR

•

Flexible Epoxy

2216 Gray

Electronics Potting

*See chart in back of guide for more details.

3M Industrial Adhesives and Tapes | 3M.com/Assemblysolutions

26

3M Industrial Adhesives and Tapes

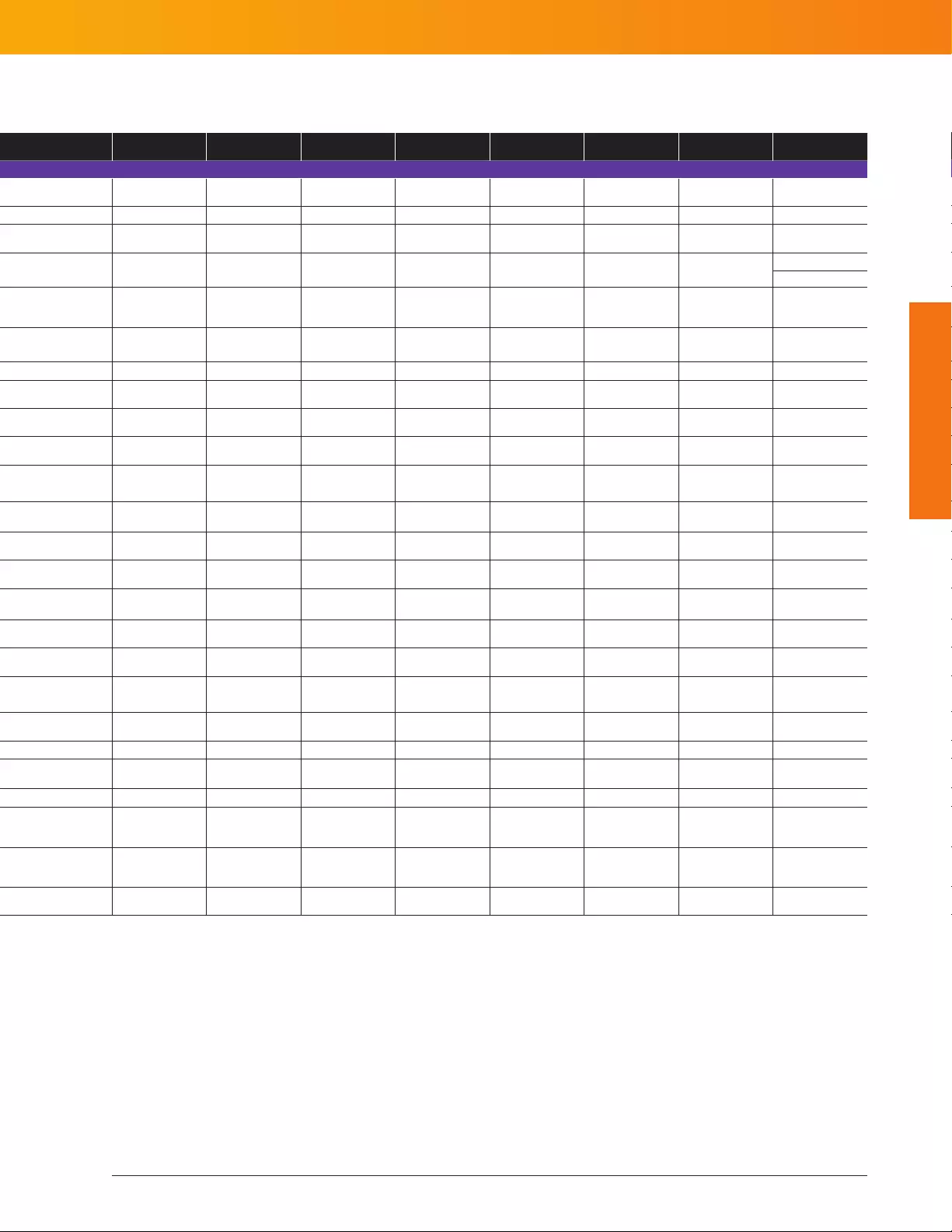

Substrate Selector

Step 1: Select Substrate Step 2: Determine Key Attribute Step 3: Select Product

Bold = Best In Class Product Light = Suggested Alternate Product

* = With Primer

Plastic/Paints/Coatings

Rubber

Metals Oily Metals

Low Surface

Energy

General

Purpose

Temperature

and

Solvent Resistant

Stainless Steel &

Aluminum

Other

Metals

Stainless Steel

& Aluminum

Other

Metals

Plastic/Paints/Coatings

Low

Surface

Energy

LSE Acrylic*

Plastic &

Rubber CA

LSE Acrylic*

Plastic & Rubber CA

Plastic &

Rubber CA*

N/A LSE Acrylic LSE Acrylic LSE Acrylic LSE Acrylic

General

Purpose

LSE Acrylic*

Plastic &

Rubber CA

LO Acrylic

MMA Acrylic

Plastic PUR

Flexible Epoxy

Plastic & Rubber CA

Plastic &

Rubber CA*

Plastic PUR

Toughened

Epoxy

Flexible Epoxy

LO Acrylic

MMA Acrylic

Flexible Epoxy

Plastic PUR

Plastic & Rubber CA

DP8407NS

Toughened Epoxy

Flexible Epoxy

Plastic PUR

Plastic & Rubber CA

LO Acrylic

MMA Acrylic

DP8407NS

Rubber

Plastic &

Rubber CA*

Plastic &

Rubber CA*

Plastic PUR

Plastic &

Rubber CA*

N/A Flexible Epoxy

Plastic PUR

Flexible Epoxy

Plastic PUR

N/A N/A

Metals

Temperature

and Solvent

Resistant

N/A Toughened Epoxy

Flexible Epoxy

N/A Toughened

Epoxy

Flexible Epoxy

Toughened Epoxy

Flexible Epoxy

One-part

Heat-cured Epoxy

Toughened Epoxy

Heat-cured

Epoxy

Heat-cured

Epoxy

Stainless

Steel &

Aluminum

LSE Acrylic LO Acrylic

MMA Acrylic

Flexible Epoxy

Plastic PUR

Plastic & Rubber CA

Plastic &

Rubber CA*

Plastic PUR

Toughened

Epoxy

Flexible Epoxy

LO Acrylic

MMA Acrylic

Toughened Epoxy

Flexible Epoxy

Rigid Epoxy

Toughened CA

Heat-cured Epoxy

Toughened Epoxy

LO Acrylic

MMA Acrylic

DP8407NS

Heat-cured

Epoxy

Other

Metals

LSE Acrylic DP8407NS

Toughened Epoxy

Flexible Epoxy

Plastic PUR

Plastic & Rubber CA

Plastic &

Rubber CA*

Plastic PUR

Heat-cured

Epoxy

Toughened Epoxy

Heat-cured Epoxy

Toughened Epoxy

Toughened Epoxy

Flexible Epoxy

Heat-cured Epoxy

DP810

DP8407NS

Heat-cured

Epoxy

DP8407NS

Heat-cured

Epoxy

Oily Metals

Stainless

Steel &

Aluminum

LSE Acrylic LO Acrylic

MMA Acrylic

N/A Heat-cured

Epoxy

LO Acrylic

MMA Acrylic

DP8407NS

Heat-cured Epoxy

LO Acrylic

MMA Acrylic

DP8407NS

Other

Metals

LSE Acrylic DP8407NS N/A Heat-cured

Epoxy

DP8407NS

Heat-cured Epoxy

DP8407NS

Heat-cured Epoxy

DP8407NS DP8407NS

Heat-cured

Epoxy

Composites

Fiberglass/

SMC

LSE Acrylic

Toughened

CA*

Semi-rigid Urethane

MMA Acrylic

LO Acrylic

Flexible Urethane

Plastic PUR

Toughened CA

Plastic &

Rubber CA*

Plastic PUR

Toughened

Epoxy

Flexible Epoxy

Plastic PUR

Semi-rigid Urethane

MMA Acrylic

LO Acrylic

Toughened Epoxy

Plastic PUR

Toughened CA

Semi-rigid Urethane

Toughened Epoxy

Flexible Epoxy

Plastic PUR

MMA Acrylic

LO Acrylic

DP8407NS

Epoxy LSE Acrylic

Toughened

CA*

Semi-rigid Urethane

MMA Acrylic

Flexible Epoxy

Toughened Epoxy

Plastic PUR

Toughened CA

Plastic &

Rubber CA*

Plastic PUR

Toughened

Epoxy

Flexible Epoxy

Plastic PUR

Semi-rigid Urethane

Toughened Epoxy

MMA Acrylic

LO Acrylic

Plastic PUR

Toughened CA

Toughened Epoxy

Flexible Epoxy

Heat-cured Epoxy

Plastic PUR

MMA Acrylic

LO Acrylic

Heat-cured

Epoxy

Heat-cured

Epoxy

Concrete/Stone/

Ceramics/Glass

Indoor LSE Acrylic Flexible Epoxy

Rigid Urethane

Flexible Urethane

Plastic PUR

Flexible Epoxy

Plastic PUR

Toughened

Epoxy

Flexible Epoxy

Toughened

Epoxy

Flexible Epoxy

Toughened Epoxy

Heat-cured Epoxy

N/A N/A

Outdoor LSE Acrylic Flexible Epoxy

Flexible Urethane

Plastic PUR

Flexible Epoxy

Plastic PUR

Flexible Epoxy Flexible Epoxy Flexible Epoxy N/A N/A

Wood

LSE Acrylic

Surface

Insensitive

CA*

Wood PUR

Flexible Epoxy

Rigid Urethane

Surface

Insensitive CA

Plastic PUR

Surface

Insensitive CA*

Toughened

Epoxy

Plastic PUR

Flexible Epoxy

Plastic PUR

Toughened Epoxy

Rigid Epoxy

Flexible Epoxy

Surface Insensitive CA

Plastic PUR

Toughened Epoxy

N/A N/A

Adhesives and Sealants

27

3M Industrial Adhesives and Tapes | October 2017 Edition

Substrate Selector (cont.)

Step 1: Select Substrate Step 2: Determine Key Attribute Step 3: Select Product

Bold = Best In Class Product Light = Suggested Alternate Product

* = With Primer

Composites Concrete/Stone/Ceramics/Glass

WoodFiberglass/SMC Epoxy Indoor Outdoor

Plastic/Paints/Coatings

Low

Surface

Energy

LSE Acrylic

Toughened CA*

LSE Acrylic

Toughened CA*

LSE Acrylic LSE Acrylic LSE Acrylic

Surface Insensitive CA*

General

Purpose

Semi-rigid Urethane

MMA Acrylic

LO Acrylic Flexible

Urethane

Plastic PUR

Toughened CA

Semi-rigid Urethane

MMA Acrylic

Flexible Epoxy

Toughened Epoxy

Plastic PUR

Toughened CA

Flexible Epoxy

Rigid Urethane

Flexible Urethane

Plastic PUR

Flexible Epoxy

Flexible Urethane

Plastic PUR

Wood PUR

Flexible Epoxy

Rigid Urethane

Surface Insensitive CA

Rubber

Plastic & Rubber CA*

Plastic PUR

Plastic & Rubber CA*

Plastic PUR

Flexible Epoxy

Plastic PUR

Flexible Epoxy

Plastic PUR

Surface Insensitive CA*

Plastic PUR

Flexible Epoxy

Metals

Temperature

and Solvent

Resistant

Toughened Epoxy

Flexible Epoxy

Plastic PUR

Toughened Epoxy

Flexible Epoxy

Plastic PUR

Toughened Epoxy

Flexible Epoxy

Flexible Epoxy Toughened Epoxy

Plastic PUR

Flexible Epoxy

Stainless

Steel &

Aluminum

Semi-rigid Urethane

MMA Acrylic

LO Acrylic

Toughened Epoxy

Plastic PUR

Toughened CA

Semi-rigid Urethane

Toughened Epoxy

MMA Acrylic

LO Acrylic

Plastic PUR

Toughened CA

Toughened Epoxy

Flexible Epoxy

Flexible Epoxy Plastic PUR

Toughened Epoxy

Rigid Epoxy

Flexible Epoxy

Surface Insensitive CA

Other

Metals

Semi-rigid Urethane

Toughened Epoxy

Flexible Epoxy

Plastic PUR

Toughened Epoxy

Flexible Epoxy

Heat-cured Epoxy

Plastic PUR

Toughened Epoxy

Heat-cured Epoxy

Flexible Epoxy Plastic PUR

Toughened Epoxy

Oily Metals

Stainless

Steel &

Aluminum

MMA Acrylic

LO Acrylic

MMA Acrylic

LO Acrylic

Heat-cured Epoxy

N/A N/A N/A

Other

Metals

DP8407NS Heat-cured Epoxy N/A N/A N/A

Composites

Fiberglass/

SMC

Semi-rigid Urethane

MMA Acrylic

LO Acrylic

Toughened Epoxy

Flexible Epoxy

Plastic PUR

Toughened CA

Semi-rigid Urethane

Toughened Epoxy

Flexible Epoxy

Plastic PUR

Toughened CA

Semi-rigid Urethane

Toughened Epoxy

Flexible Epoxy

Plastic PUR

Semi-rigid Urethane

Flexible Epoxy

Flexible Urethane

Plastic PUR

Semi-rigid Urethane

Toughened Epoxy

Rigid Urethane

Flexible Epoxy

Plastic PUR

Epoxy Semi-rigid Urethane

Toughened Epoxy

Flexible Epoxy

Plastic PUR

Toughened CA

Toughened Epoxy

Flexible Epoxy

Plastic PUR

Toughened CA

Semi-rigid Urethane

Toughened Epoxy

Flexible Epoxy

Plastic PUR

Semi-rigid Urethane

Flexible Epoxy

Plastic PUR

Semi-rigid Urethane

Toughened Epoxy

Flexible Epoxy

Plastic PUR

Concrete/Stone/

Ceramics/Glass

Indoor Semi-rigid Urethane

Toughened Epoxy

Flexible Epoxy

Plastic PUR

Semi-rigid Urethane

Toughened Epoxy

Flexible Epoxy

Plastic PUR

Toughened Epoxy

Flexible Epoxy

Rigid Urethane

Flexible Urethane

Flexible Epoxy

Flexible Urethane

Flexible Epoxy

Plastic PUR

Flexible Urethane

Outdoor Semi-rigid Urethane

Flexible Epoxy

Flexible Urethane

Plastic PUR

Semi-rigid Urethane

Flexible Epoxy

Plastic PUR

Flexible Epoxy

Flexible Urethane

Flexible Epoxy

Flexible Urethane

Flexible Epoxy

Plastic PUR

Flexible Urethane

Wood

Semi-rigid Urethane

Toughened Epoxy

Rigid Urethane

Flexible Epoxy

Plastic PUR

Semi-rigid Urethane

Toughened Epoxy

Flexible Epoxy

Plastic PUR

Flexible Epoxy

Plastic PUR

Flexible Urethane

Flexible Epoxy

Plastic PUR

Flexible Urethane

Wood PUR

Rigid Epoxy

Toughened Epoxy

Rigid Urethane

Surface Insensitive CA

3M Industrial Adhesives and Tapes | 3M.com/Assemblysolutions

28

3M Industrial Adhesives and Tapes

3M™ Scotch-Weld™ Low Odor

and MMA Acrylic Adhesives

3M’s Low Odor and MMA Acrylic Adhesives

are designed for all of your sign application

needs. They provide excellent impact strength,

high peel strength and greatly extended shelf

life compared to ordinary structural adhesives.

With high structural strength, fast cure and

choice for the sign industry. DP8805NS,

DP8810NS, DP8825NS, DP8405NS,

DP8407NS, DP8410NS and DP8425NS.

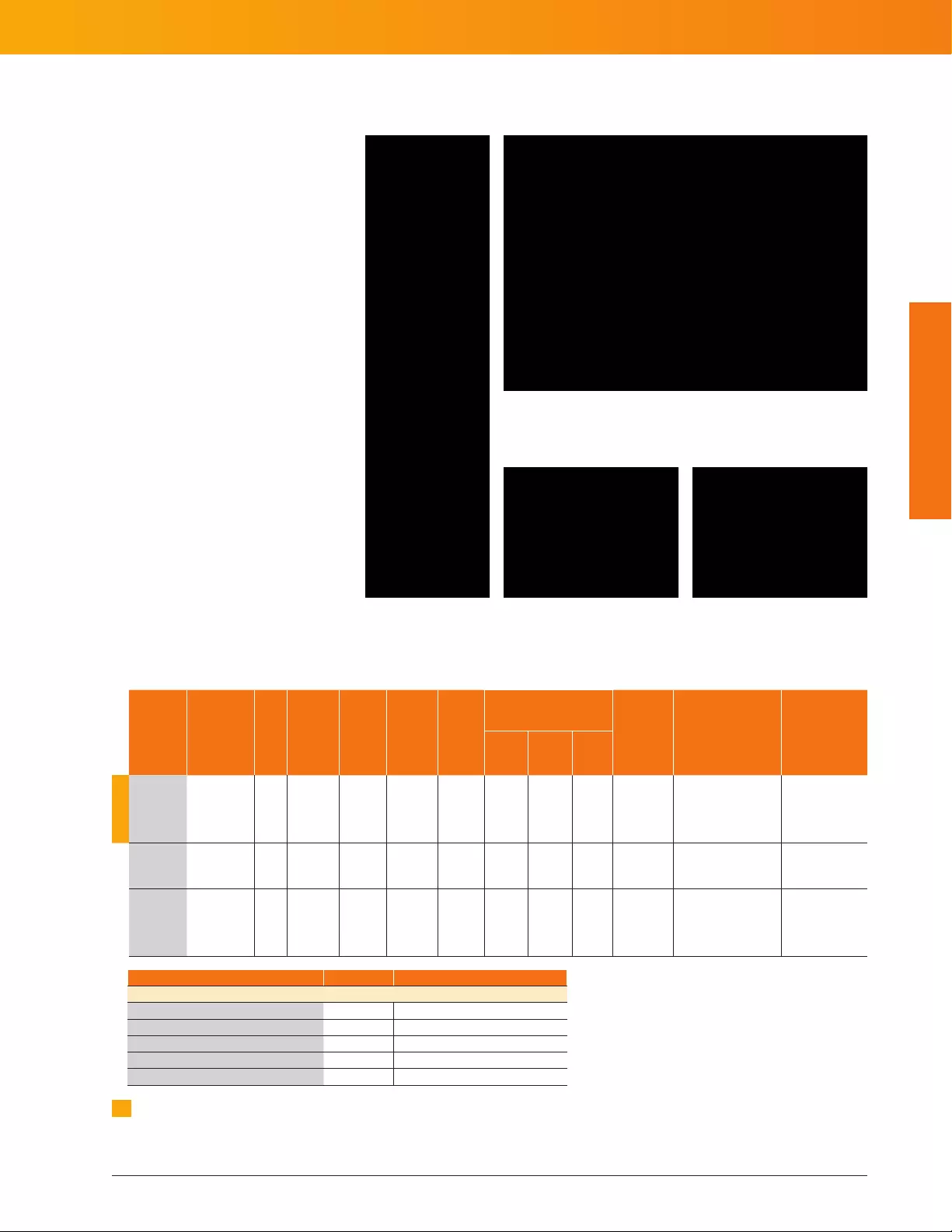

Approximate Coverages for 3M™ Scotch-Weld™ Adhesives in Duo-Pak Cartridges

Bead Size