3M 80610872675 User Manual

Displayed below is the user manual for 80610872675 by 3M which is a product in the Electrical Tapes category. This manual has pages.

Related Manuals

Tech Brief

CTI: The Comparative

Tracking Index Test

The Comparative Tracking Index

(CTI) is the maximum voltage,

measured in volts, at which a

material withstands 50 drops

of contaminated water without

tracking. Tracking is dened as the

formation of conductive paths

due to electrical stress, humidity,

and contamination.

The CTI test provides an

accelerated simulation of

conditions of surface discharges

and possible resulting tracking

and failure (typically a “short”)

in equipment using insulating

materials. This test also provides

a means to compare insulating

materials performances under wet

and contaminated conditions.

CTI requirements became

important to manufacturers after

the publication of the Underwriters

Laboratories document UL 1950

in March 1992. UL 1950 is the UL

Standard for Safety titled

“Information Technology

Equipment including Electrical

Business Equipment.” Section

2.9 of this document outlines

requirements for Creepage

Distance, which is the shortest

path between two conductive parts

measured along the surface of

the insulation.

Depending on the CTI of the insulating material used, the minimum

creepage distance required will vary. The higher the CTI value, the lower the

minimum creepage distance required. In practice, the higher the CTI of the

insulating material used, the closer two conductive parts can be. The result

is often a smaller part, increasingly desirable in technology and

industry today. These values would be of particular interest to design

engineers who must comply with UL requirements.

The original test method referred to in UL 1950 was IEC Publication 112. This

method requires a 3-mm thick sample*, subjected to a voltage, while one

drop of test electrolyte solution (0.1% ammonium chloride) falls every 30

seconds onto the sample surface. The test continues until either 50 drops

fall or tracking occurs. Failure results if tracking occurs before 50 drops fall,

generating enough amps to trip the tester’s built-in over-current relay. If the

*In order to meet the 3-mm thickness requirement, the electrical tapes must be carefully stacked

one layer upon another until the thickness is achieved.

sample burns the test is inconclusive

and should be repeated using a thicker

sample. The maximum test voltage is

600 volts; if failure occurs voltage is

typically decreased by 25 volts and the

test repeated until a voltage is reached

that the sample can pass.

The passing voltage must be repeated

for a total of ve test sites on the

sample. The sample must, in addition,

also pass 100 drops at 25 volts less than

the original passing voltage.

When all conditions are met, a

Material Group is determined for the

insulating material based upon the

passing voltage for the 50-drop test.

Both the backing and adhesive

sides of tapes are tested. Prior to

2008, the lower of the two voltage

levels determined the Material

Group assigned.

Material Groups are identied in UL

1950, Section 2.9:

(a) Material Group I 600 </= CTI

(b) Material Group II 400 </= CTI < 600

(c) Material Group IIIa 175 </= CTI < 400

(d) Material Group IIIb 100 </= CTI < 175

UL revised the requirements and references for Material Group

Classications after 2008, eliminating the Material Group IIIb rating.

The current notes regarding CTI Material Groups state the following in

the Online Certications Directory:

(a) Material Group I May be marked “Comparative Tracking Index (CTI) equal to

or greater than 600V, PLC=0, UL840 Material Group I, when

tested to IEC60112 on both sides of tape.

(b) Material Group II May be marked “Comparative Tracking Index (CTI) ) equal to

or greater than 400V but less than 600V, PLC=1, UL840

Material Group II, when tested to IEC60112 on both sides

of tape.

(c) Material Group IIIa May be marked “Comparative Tracking Index (CTI) equal to

or greater than 175V but less than 400V, PLC=2 or 3, UL840

Material Group IIIa, when tested to IEC60112 on both sides

of tape.

(d) Material Group IIIa May be marked “Comparative Tracking Index (CTI) 325(275)

on Adhesive side, UL840, Material Group IIIa and/or CTI 225

on Film Side, Material Group IIIa or equivalent when tested to

IEC60112, 4th Edition (2003).

UL Standard 840 Standard for Insulation Coordination Including Clearances

and Creepage Distances for Electrical Equipment. UL 746A is

referenced in UL840.

UL Standard 746A Standard for Polymeric Materials - Short Term Property

Evaluations.

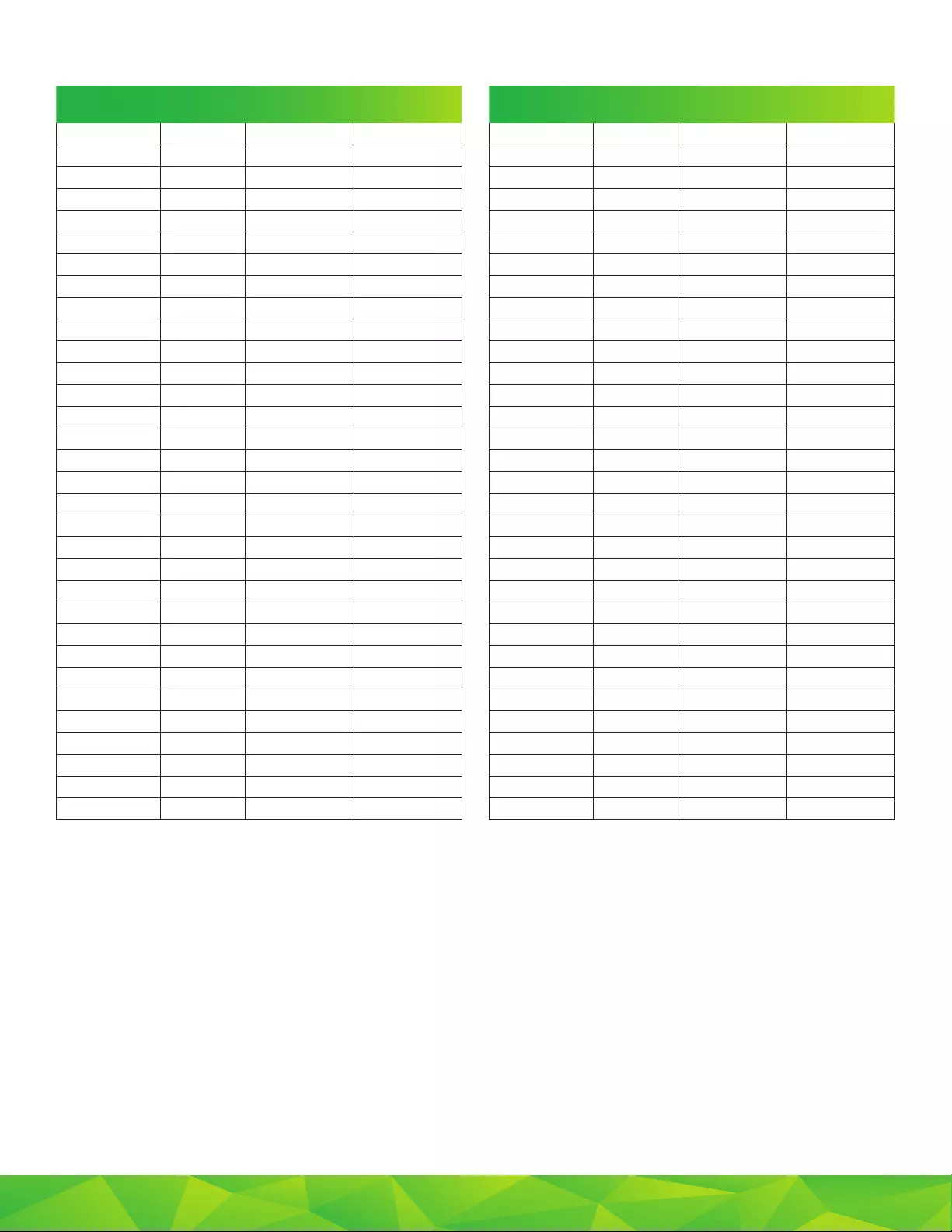

The 3M Electrical Markets Division (EMD) Laboratory tested and

determined a CTI value for more than 50 Electrical Insulating Tapes from

3M. Underwriters Laboratory has tested 37 insulating and conductive tapes

from 3M to verify results. CTI testing at UL is optional.

UL added Material Groups assigned to the tapes tested at UL to the UL

Online Certications Directory. To see these references, go to

www.ul.com, then click on Online Certications Directory, and enter

E17385 into the search cell for UL File Number. Click on the link provided

there to nd a list of all EMD UL-Recognized tapes; CTI values are

indicated by subscripts (a, b, c, or d). Of the tapes tested, 3M qualied

34 for Material Group I rating, and UL qualied 24 of those, verifying

3M procedure and method.

3M™ Tape CTI Value

Material

Group (3M)

Material

Group (UL)

1600 I

5600 I

Super 10 600 I

11 600 I

12 600 I

16 600 I

Super 20 600 I

27 600 I

28 600 I

44 600 I

44D 600 I

44T-A 600 I

46 475 II

54 600 I

55 600 I

56 600 I

57 600 I

58 600 I

60 600 I

61 600 I

62 600 I

63 600 I

69 600 I

74 600 I

75 600 I

79 600 I

90 600 I

92 150 IIIb

MR94 600 I

MR94B IIIa

1205 125 IIIb

1276 600 I

3M™ Tape CTI Value

Material

Group (3M)

Material

Group (UL)

1291 600 I

1298 II

1312 600 I

1318B-1 200 IIIa

1318B-2 200 IIIa

1318W-1 450 II

1318W-2 450 II

1318Y-1 I

1318Y-2 600 I

44HT 600 I I

1318 Clear 600 I

1318-MW 600 I

1339 600 I

1350B-1 IIIa

1350B-2 IIIa

1350W-1 IIIa

1350W-2 IIIa

1350Y-1 II

1350Y-2 IIIa

1350F-B-1 IIIa

1350F-B-2 IIIa

1350F-W-1 IIIa

1350F-W-2 IIIa

1350F-Y-1 II

1350F-Y-2 IIIa

1350T-1 II

1351T-1 600 I

1351-1 600 I

1351-2 600 I

1554 600 I

1098-1 550 II

1098 Black 600 I

The following table shows results for current 3M OEM Electrical Insulating Tapes:

3M is a trademark of 3M company.

All other trademarks used herein are the property of their respective owners.

Electrical Markets Division

6801 River Place Blvd.

Austin, TX 78726-9000 USA

Phone 800-676-8381

Fax 800-828-9329

Web www.3M.com/oem

3M is a trademark of 3M Company.

Important Notice

All statements, technical information, and recommendations related to 3M’s products are based on information believed to be reliable, but the accu-

racy or completeness is not guaranteed. Before using this product, you must evaluate it and determine if it is suitable for your intended application.

You assume all risks and liability associated with such use. Any statements related to the product which are not contained in 3M’s current publications,

or any contrary statements contained on your purchase order shall have no force or eect unless expressly agreed upon, in writing, by an authorized

ocer of 3M.

Warranty; Limited Remedy; Limited Liability.

3M’s product warranty is stated in its Product Literature available upon request. 3M MAKES NO OTHER WARRANTIES INCLUDING, BUT NOT

LIMITED TO, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. If this product is defective within

the warranty period stated above, your exclusive remedy shall be, at 3M’s option, to replace or repair the 3M product or refund the purchase price of

the 3M product. Except where prohibited by law, 3M will not be liable for any direct, indirect, special, incidental or consequential loss or damage

arising from this 3M product, regardless of the legal theory asserted.

© 3M 2016. All rights reserved.