Table of Contents

- Electrical Safety and Emissions Standards

- Contents

- Preface

- Chapter 1

- Chapter 2

- Chapter 3

- Chapter 4

- Appendix A

- Appendix B

Allied Telesis AT-IMC200TP/SC-980 User Manual

Displayed below is the user manual for AT-IMC200TP/SC-980 by Allied Telesis which is a product in the Network Media Converters category. This manual has pages.

Related Manuals

613-002626 Rev A

IMC2000/200 Series

Industrial Switching Media Converters

AT-IMC2000TP/SP

AT-IMC2000TP/SC

AT-IMC2000T/SP

AT-IMC2000T/SC

AT-IMC200TP/SC

AT-IMC200T/SC

Installation Guide

SFP

SYSTEM

1

2

3

SML

FORCE

100FD

REMOTE

PoE

CONTROL

OFF ON

AT-IMC2000

Industrial Media Converter

60W

PORT 1

PORT 2

SYSTEM

1

2

3

SML

NOT USED

FORCE

100FD

OFF ON

TX

RX

AT-IMC2000

Industrial Media Converter

PORT 1

PORT 2

SYSTEM

1

2

3

SML

NOT USED

FORCE

100FD

OFF ON

TX

RX

AT-IMC200

Industrial Media Converter

PORT 1

PORT 2

SYSTEM

1

2

3

OFF

TX

RX

AT-IMC2000

Industrial Media Converter

PORT 1

PORT 2

60W

ON SML

FORCE

100FD

REMOTE

PoE

CONTROL

SYSTEM

1

2

3

OFF

TX

RX

AT-IMC200

Industrial Media Converter

PORT 1

PORT 2

60W

ON SML

FORCE

100FD

REMOTE

PoE

CONTROL

PORT 1

SFP

SYSTEM

1

2

3

OFF

AT-IMC2000

Industrial Media Converter

PORT 2

ON

SML

NOT USED

FORCE

100FD

4533

Copyright 2018 Allied Telesis, Inc.

All rights reserved. No part of this publication may be reproduced without prior written permission from Allied Telesis, Inc.

Allied Telesis and the Allied Telesis logo are trademarks of Allied Telesis, Incorporated. All other product names, company names,

logos or other designations mentioned herein are trademarks or registered trademarks of their respective owners.

Allied Telesis, Inc. reserves the right to make changes in specifications and other information contained in this document without prior

written notice. The information provided herein is subject to change without notice. In no event shall Allied Telesis, Inc. be liable for

any incidental, special, indirect, or consequential damages whatsoever, including but not limited to lost profits, arising out of or related

to this manual or the information contained herein, even if Allied Telesis, Inc. has been advised of, known, or should have known, the

possibility of such damages.

3

Electrical Safety and Emissions

Standards

This section contains the following:

“US Federal Communications Commission”

“Industry Canada”

“Emissions, Immunity and Electrical Safety Standards” on page 4

“Translated Safety Statements” on page 4

US Federal Communications Commission

Radiated Energy

Note

This equipment has been tested and found to comply with the limits for a Class A digital device

pursuant to Part 15 of FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with this instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own

expense.

Note

Modifications or changes not expressly approved of by the manufacturer or the FCC, can void

your right to operate this equipment.

Industry Canada

Radiated Energy

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

4

Emissions, Immunity and Electrical Safety Standards

RFI Emissions FCC Class A, EN55032 Class A, CISPR 32 Class A, RCM, VCCI, FCC Part 15,

ICES

Warning

In a domestic environment this product may cause radio interference in which case the user

may be required to take adequate measures. E84

EMC (Immunity) EN55024, EN55035, EN61000-3-2, EN61000-3-3

Electrical Safety EN60950-1 (TUV), UL 60950-1 (CULUS)

Warning

Laser Safety: EN60825 L7

Translated Safety Statements

Important: The indicates that a translation of the safety statement is available in a PDF

document titled Translated Safety Statements on the Allied Telesis website at

www.alliedtelesis.com/support.

5

Contents

Preface............................................................................................................................................................... 7

Symbol Conventions .................................................................................................................................... 8

Contacting Allied Telesis.............................................................................................................................. 9

Chapter 1: Overview ..................................................................................................................................... 11

Description ................................................................................................................................................. 12

Key Features ....................................................................................................................................... 12

Auto MDI/MDI-X .................................................................................................................................. 13

DIP Switches ....................................................................................................................................... 14

DC Power ............................................................................................................................................ 14

Twisted-Pair Port ................................................................................................................................. 14

Auto-Negotiation or 100 Mbps Setting................................................................................................. 14

LEDs .......................................................................................................................................................... 16

Smart MissingLink™ (SML) ....................................................................................................................... 18

SML Example Scenarios ..................................................................................................................... 18

SML Example Scenarios with Two Connected Media Converters ...................................................... 19

Enabling SML ...................................................................................................................................... 20

Power over Ethernet (PoE) ........................................................................................................................ 21

Enabling Remote PoE Control............................................................................................................. 21

Chapter 2: Installation ................................................................................................................................... 23

Reviewing Safety Precautions ................................................................................................................... 24

Selecting a Site for the Media Converter ................................................................................................... 26

Planning the Installation ............................................................................................................................. 27

Cable Specifications for Copper Port .................................................................................................. 27

Speed/Duplex Combinations for AT-IMC2000 .................................................................................... 28

Speed/Duplex Combinations for AT-IMC200 ...................................................................................... 29

Unpacking the Media Converter................................................................................................................. 30

Installing the Media Converter ................................................................................................................... 32

Installing the Media Converter on a DIN Rail ............................................................................................. 33

Installing the Media Converter on a Wall ................................................................................................... 35

Installing the SFP Transceiver ................................................................................................................... 38

Chapter 3: Powering On the Media Converter .............................................................................................. 41

Wiring and Powering on the Media Converter ........................................................................................... 42

Chapter 4: Troubleshooting .......................................................................................................................... 45

Appendix A: Technical Specifications ............................................................................................................ 49

Physical Specifications............................................................................................................................... 49

Environmental Specifications ..................................................................................................................... 49

Power Specifications.................................................................................................................................. 50

RJ45 Connector and Port Pinouts.............................................................................................................. 50

Fiber-Optic Port Specifications................................................................................................................... 52

Appendix B: Cleaning Fiber-Optic Connectors .............................................................................................. 53

Introduction ................................................................................................................................................ 53

Using a Cartridge-Type Cleaner ................................................................................................................ 54

7

Preface

This guide contains the installation instructions for the following Industrial

Switching Media Converters.

AT-IMC2000TP/SP

AT-IMC2000TP/SC

AT-IMC2000T/SP

AT-IMC2000T/SC

AT-IMC200TP/SC

AT-IMC200T/SC

This preface contains the following sections:

“Symbol Conventions” on page 8

“Contacting Allied Telesis” on page 9

IMC2000/200 Series Media Converter Installation Guide

8

Symbol Conventions

This document uses the following conventions:

Note

Notes provide additional information.

Caution

Cautions inform you that performing or omitting a specific action

may result in equipment damage or loss of data.

Warning

Warnings inform you that performing or omitting a specific action

may result in bodily injury.

Warning

Laser warnings inform you that an eye and skin hazard exists due to

the presence of a Class 1 laser device.

Preface

9

Contacting Allied Telesis

If you need assistance with this product, you may contact Allied Telesis

technical support by going to the Support & Services section of the Allied

Telesis web site at www.alliedtelesis.com/support. You can find links for

the following services on this page:

24/7 Online Support - Enter our interactive support center to

search for answers to your questions in our knowledge database,

check support tickets, learn about Return Merchandise

Authorizations (RMAs), and contact Allied Telesis technical

experts.

USA and EMEA phone support - Select the phone number that

best fits your location and customer type.

Hardware warranty information - Learn about Allied Telesis

warranties and register your product online.

Replacement Services - Submit an RMA request via our interactive

support center.

Documentation - View the most recent installation guides, user

guides, software release notes, white papers and data sheets for

your product.

Software Updates - Download the latest software releases for your

product.

For sales or corporate contact information, go to www.alliedtelesis.com/

purchase and select your region.

IMC2000/200 Series Media Converter Installation Guide

10

IMC2000/200 Series Media Converter Installation Guide

12

Description

The IMC2000/200 series media converter extends the distance of your

network by interconnecting LAN devices that are physically separated by

large distances. In addition, this series models are industrial media

converters, which can be deployed outdoors and in hash environments.

Figure 1 shows the AT-IMC2000TP/SP model.

Figure 1. AT-IMC2000T/SP Media Converter

Key Features The IMC2000/200 series media converter has the following key features:

Tolerance to harsh industrial environments (See “Environmental

Specifications” on page 49)

DIN rail mountable

Wall mountable

Note

To install the media converter on the wall, you must obtain the

optional wall mounting kit separately.

DC power connector

IEEE 802.3u Auto-Negotiation compliant on the copper port

Auto-Negotiation or 100 Mbps full-duplex mode on the copper port

Auto MDI/MDI-X on the copper port (See “Auto MDI/MDI-X” on

page 13)

One SC or SFP fiber optics connector

Chapter 1: Overview

13

One twisted-pair port (See “Twisted-Pair Port” on page 14)

Far end fault on 100Mb fiber port

Power over Ethernet (PoE) (IEEE 802.3at 30watt)

Pre-standard 60watt PoE (LTPoE++)

10Kbyte Jumbo packets

Smart Missing LinkTM(SML) (See “Smart MissingLink™ (SML)” on

page 18)

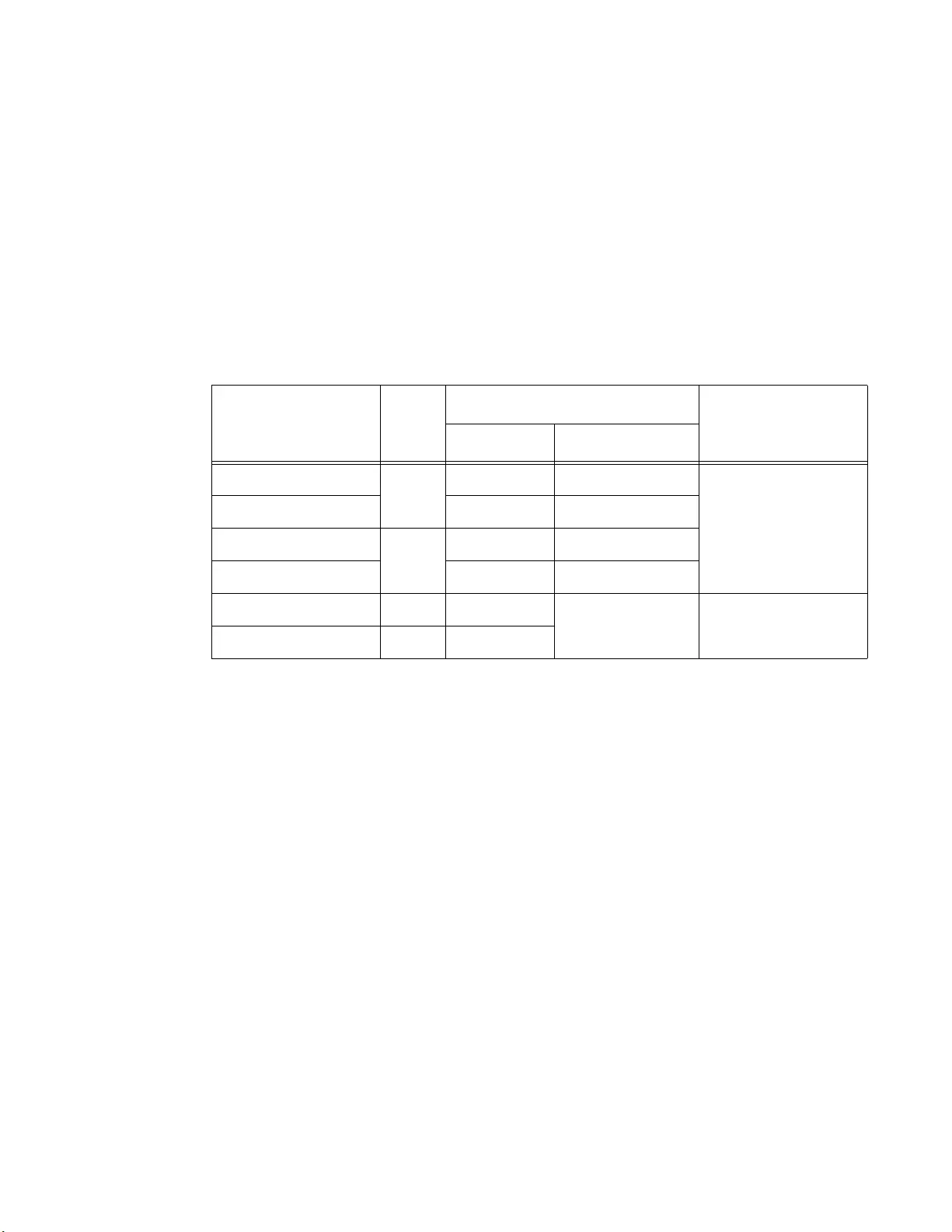

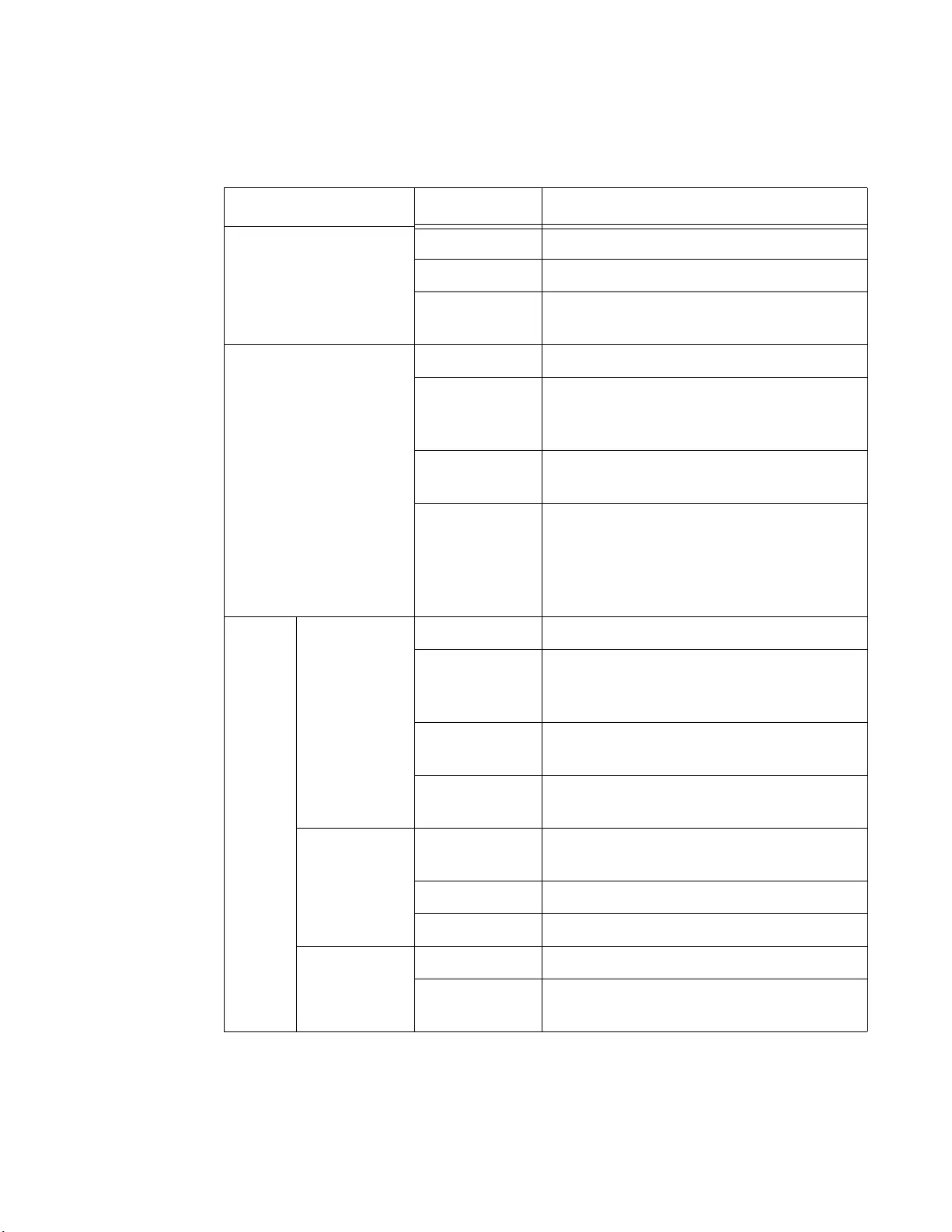

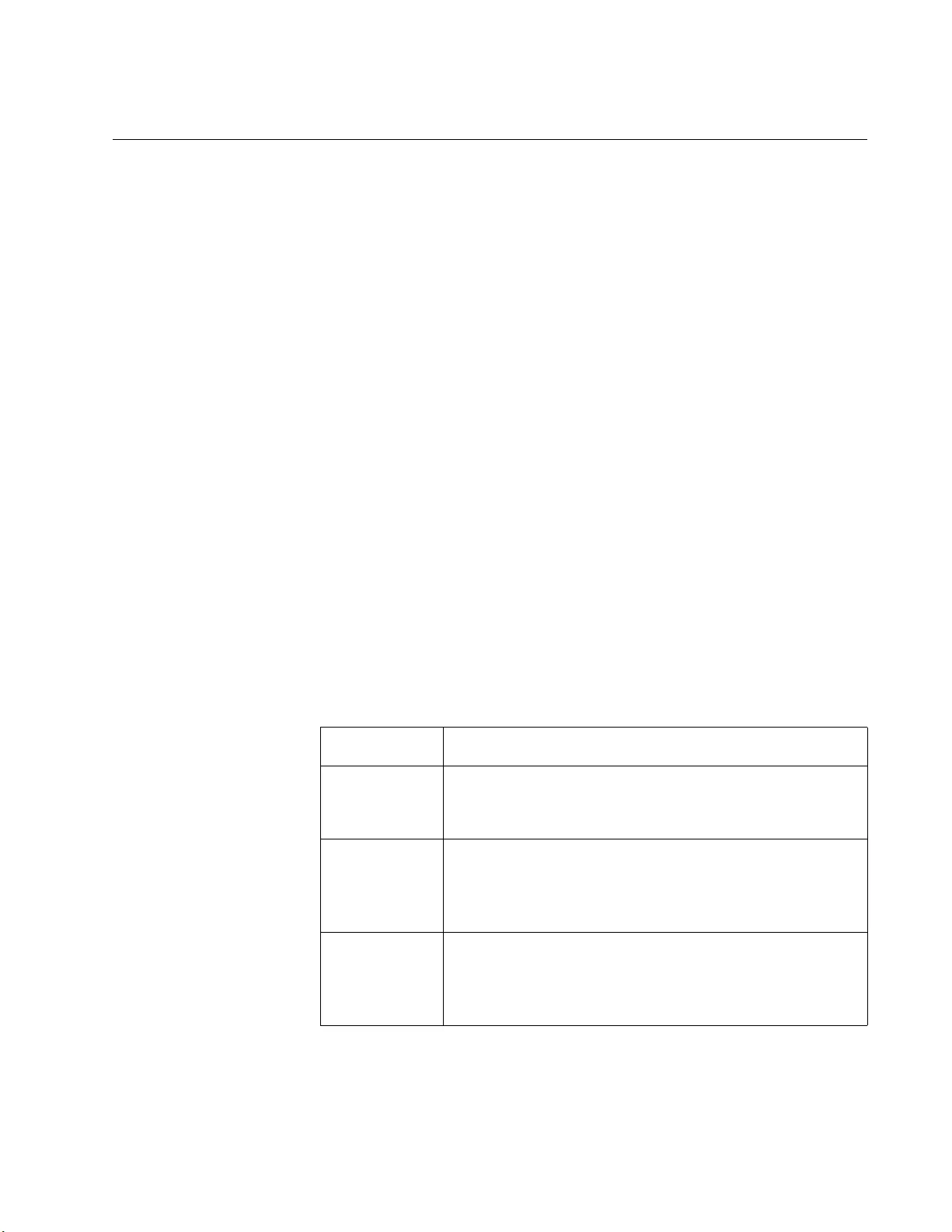

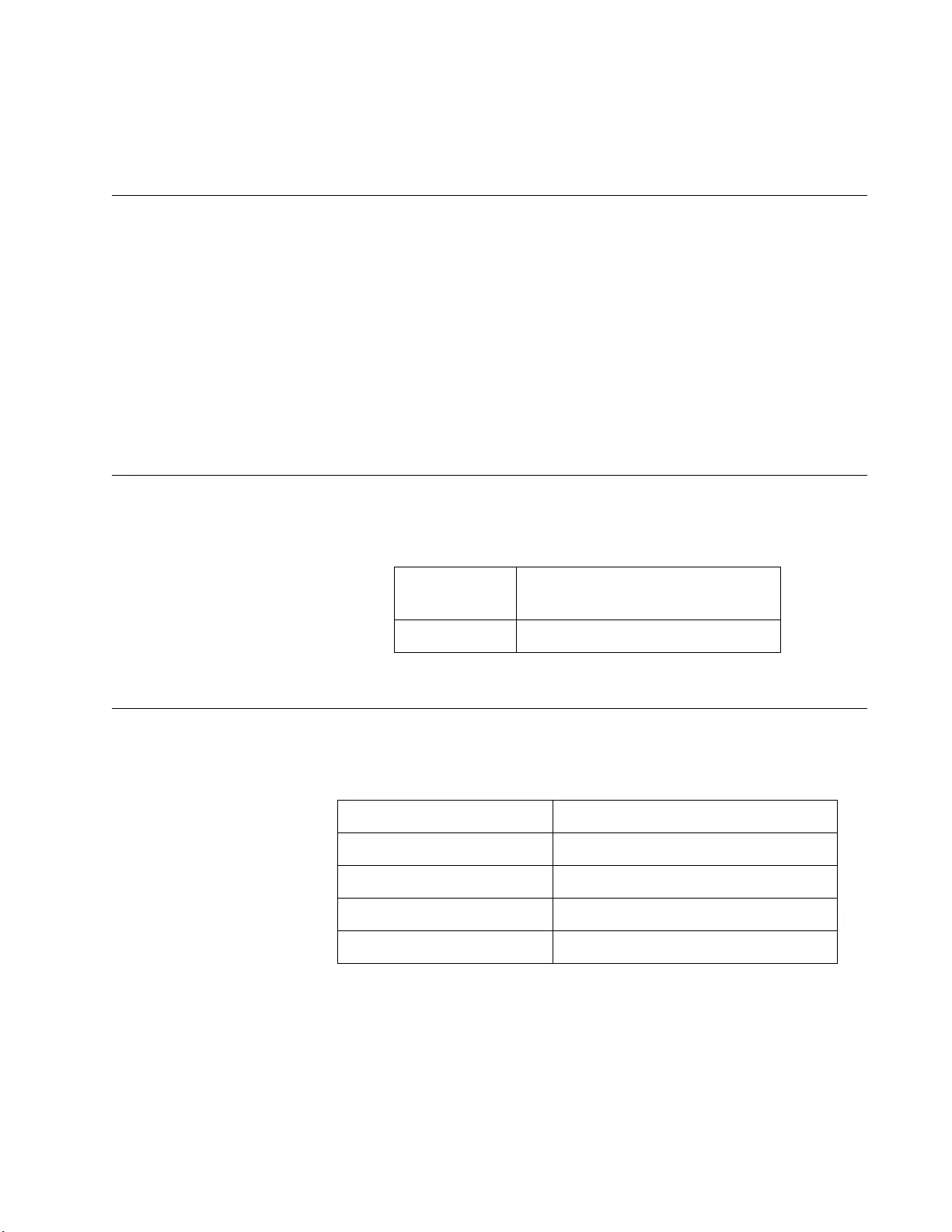

Table 1 shows the specifications of the ports and PoE for each model.

Auto MDI/

MDI-X

An RJ45 twisted-pair port on a 100 Mbps Ethernet network device can

have one of two possible wiring configurations: MDI or MDI-X. The RJ45

port on a PC, router, or bridge is typically wired as MDI, while the twisted-

pair port on a switch or hub is usually MDI-X.

The media converter features Auto MDI/MDI-X. The twisted-pair port

automatically determines the configuration of the port on the device to

which it is connected and then configures itself appropriately.

For example, if a port on a media converter is connected to a port on a

bridge, which is typically wired as MDI, the port on the media converter

automatically configures itself as MDI-X.

This feature allows you to use a straight-through cable when connecting

any type of device to the media converter, regardless of the wiring

configuration of the port on the device.

Table 1. Connecting Networks

Model PoE

Fiber-optic Port

Copper Port

Connector L1 Standard

AT-IMC2000TP/SP

60W

SFP 100/1000Base-X

10/100/1000Base-T

AT-IMC2000TP/SC SC 1000Base-SX

AT-IMC2000T/SP

n/a

SFP 100/1000Base-X

AT-IMC2000T/SC SC 1000Base-SX

AT-IMC200TP/SC 60W SC

100Base-FX 10/100/1000Base-T

AT-IMC200T/SC n/a SC

IMC2000/200 Series Media Converter Installation Guide

14

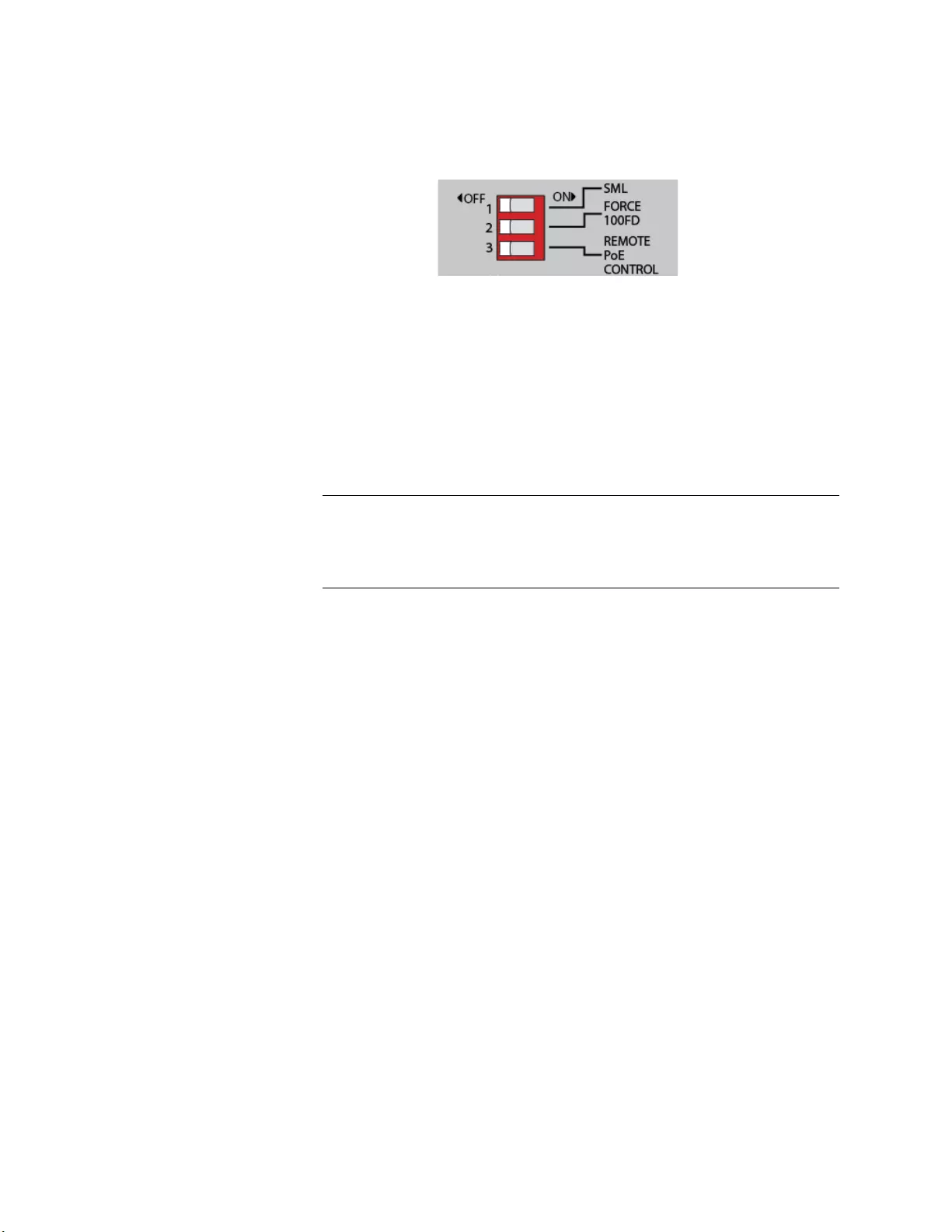

DIP Switches The media converter is equipped with the DIP switches. Figure 2 shows

the DIP switches on the media converter.

Figure 2. DIP Switches

To configure the media converter, use the following DIP switches:

SML - Turn on or off the SML feature.

FORCE 100FD - Select Auto Negotiation or set the port speed for

100Mbps in full-duplex mode.

REMOTE PoE CONTROL - Activate or deactivate remote PoE which

allows you to remotely power cycle your PoE device.

Note

The only AT-IMC2000TP/SP, AT-IMC2000TP/SC, and

AT-IMC200TP/SC models are equipped with the Remote PoE

Control DIP switch. DIP switch 3 is not used for the other models.

DC Power The IMC2000/200 series media converter is equipped with the DC power

connector.

Twisted-Pair Port The twisted-pair port features an eight-pin RJ45 connector that uses four

pins at 10 or 100 Mbps and all eight pins at 1000 Mbps. For the port

pinouts, see “RJ45 Connector and Port Pinouts” on page 50.

The port has a maximum operating distance of 100 m (328 feet). For

twisted-pair port cabling specifications, refer to Table 3 on page 27.

Auto-Negotiation

or 100 Mbps

Setting

You can set the twisted-pair port to 100 Mbps full-duplex mode or Auto-

Negotiation mode using the DIP switch See Figure 2 on page 14.

When this DIP switch is in the FORCE 100 F/D (up) position, the

twisted-pair port is forced to 100 Mbps full-duplex mode, and Auto

Negotiation is disabled

When in the AUTO NEG (down) position, the twisted-pair port

operates in Auto-Negotiation mode.

Chapter 1: Overview

15

Caution

100 Mbps full-duplex mode should not be used unless absolutely

necessary because forcing 100 Mbps full-duplex in most

applications is likely to cause a duplex mismatch, in turn, causing

poor network performance. 100 Mbps full-duplex mode should only

be used when the link partner is already forced to 100 Mbps full-

duplex operation, and Auto-Negotiation is disabled on the link

partner. In this specific case, using Auto Negotiation on the media

converter would result in a duplex mismatch.

IMC2000/200 Series Media Converter Installation Guide

16

LEDs

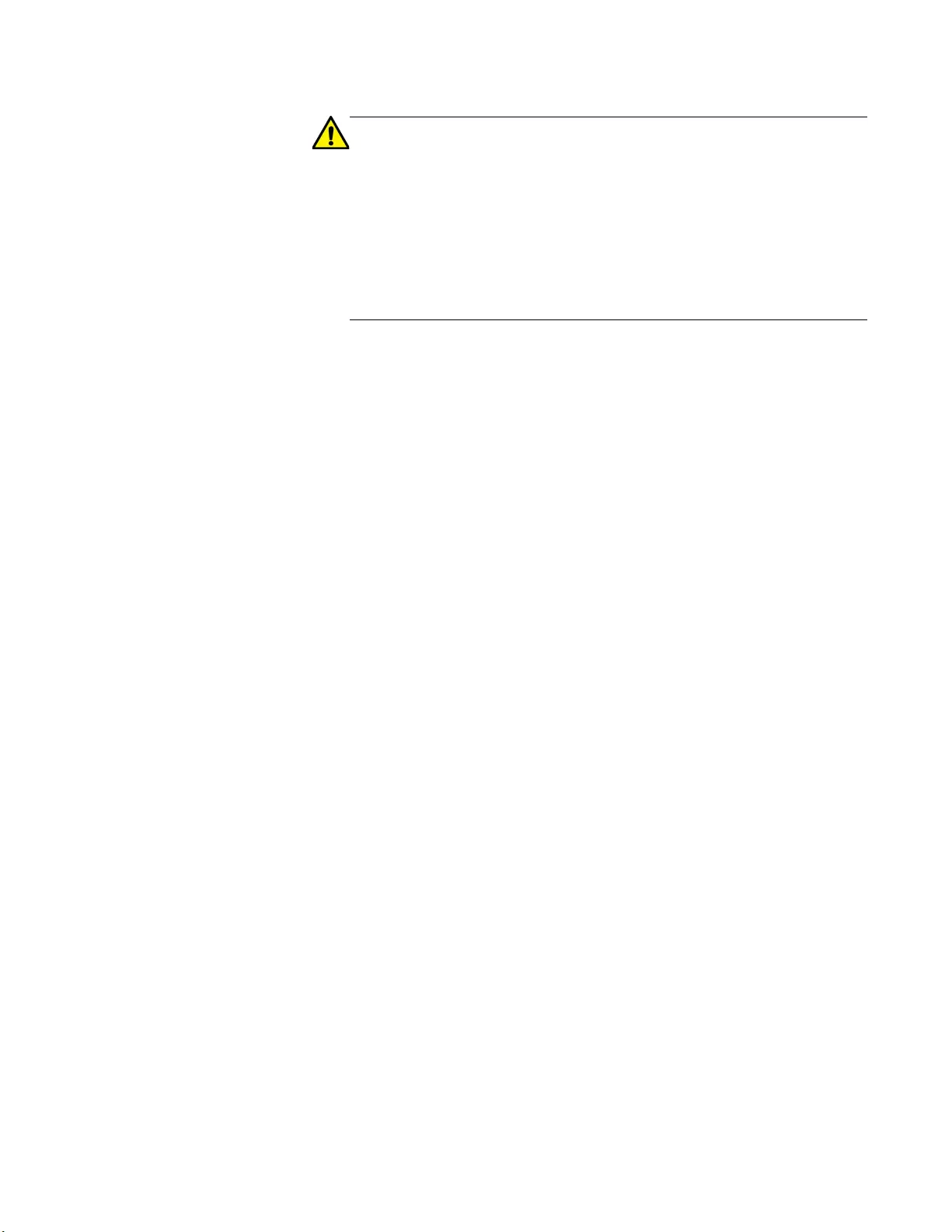

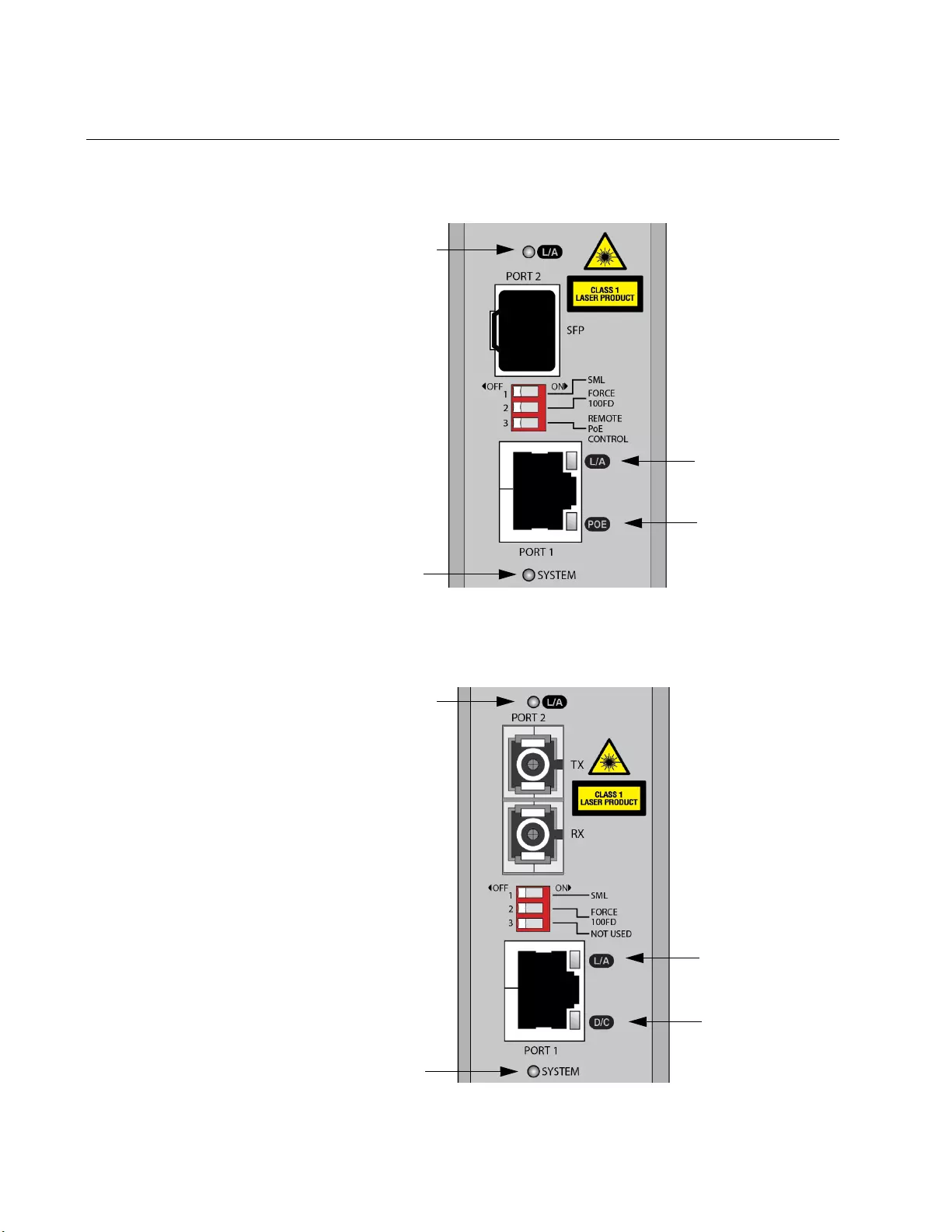

Figure 3 shows the LEDs on the AT-IMC2000TP/SP media converter.

Figure 3. LEDs on the AT-IMC2000TP/SP Media Converter

Figure 4 shows the LEDs on the AT-IMC2000T/SC media converter.

Figure 4. LEDs on the AT-IMC2000T/SC Media Converter

Copper Port PoE

Fiber Port

SYSTEM

Copper Port

Link Activity

Link Activity

Duplex Mode/

Fiber Port

SYSTEM

Copper Port

Link Activity

Link Activity

Collision Detection

Chapter 1: Overview

17

Table 2 describes the media converter’s LEDs.

Table 2. Media Converter LED Functional Descriptions

LED State Description

SYSTEM

Off The media converter is not operational.

Solid Green The media converter is operational.

Slow Blinking

Green

An error is present on the media

converter.

Fiber Port L/A

(Link/Activity)

Off The port has not established a link.

Solid Green The port has an established link to a

network device, but it is not transmitting

or receiving network packets.

Rapid Blinking

Green

The port is transmitting or receiving

network packets.

Slow Blinking

Green

SML is on and detects a failure on the

copper port or the remote fiber port when

operating in a back-to-back configuration

with another IMC2000/200 Series media

converter.

Copper

Port

L/A

(Link/Activity)

Off The port has not established a link.

Solid Green The port has an established link to a

network device, but it is not transmitting

or receiving network packets.

Rapid Blinking

Green

The port is transmitting or receiving

network packets.

Slow Blinking

Green

SML is on and detects a failure on the

link on the fiber port.

D/C

(Duplex

Mode and

Collisions)

Off The port is not operating or operating in

half-duplex mode.

Solid Green The port is operating in full-duplex mode.

Blinking Green Collisions are occurring on the port.

POE

Off There is no powered device detected.

Solid Green The end-node is a powered device and

the port is providing power to it.

IMC2000/200 Series Media Converter Installation Guide

18

Smart MissingLink™ (SML)

If one of the Ethernet connections to the media converter loses link, the

Smart MissingLink™ (SML) feature allows you to determine which port still

has a valid connection and which port requires troubleshooting. The value

to this type of network monitoring and fault notification is that you can

quickly determine which media converter port has failed and troubleshoot

the specific area where the problem is occurring.

When the media converter detects a loss of connection on one of the

ports, the port’s L/A LED is turned off. At the same time, the media

converter causes the opposite port’s L/A LED to blink while simultaneously

turning OFF that port’s Ethernet connection to its end node. This occurs

even though the properly operating port had a valid connection before the

failure occurred: The reason for this is so that its end node is notified that

the data path has been compromised, and immediate action is required.

For example, if the network connection to the media converter’s twisted-

pair port fails, the FIBER P2 L/A LED blinks slowly while its link is turned

OFF. The COPPER P2 L/A LED is turned OFF, indicating a failed

connection on the twisted-pair port. If the failure had started with the fiber-

optic cabling, then the COPPER P2 L/A LED would blink slowly, and the

FIBER P2 L/A LED would turn OFF.

SML Example

Scenarios

Following are example scenarios with one SML enabled media converter

connected between two end nodes.

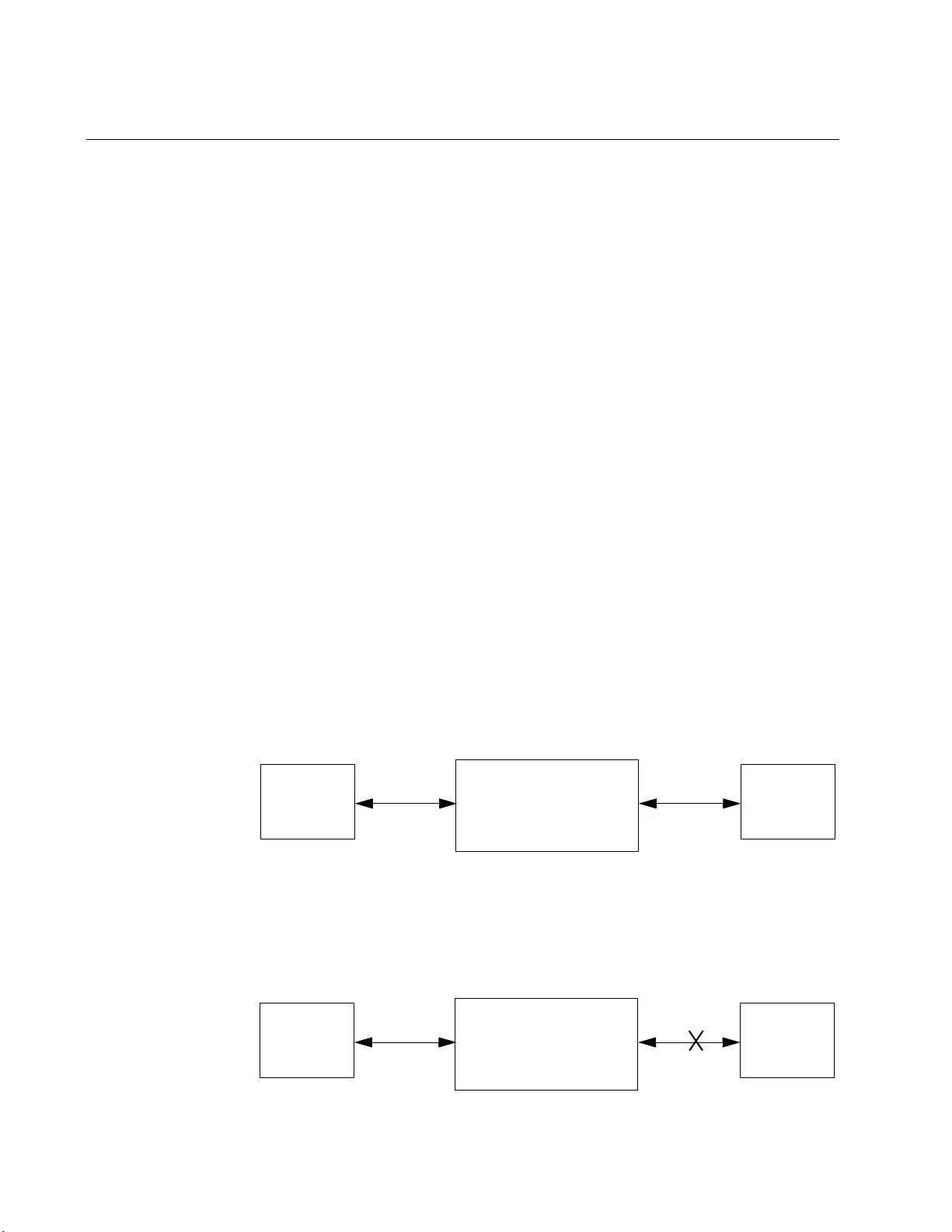

Figure 5 shows media converter and end node L/A LED behavior with

SML enabled under normal conditions.

Figure 5. SML in Normal Condition

Figure 6 shows media converter and end node L/A LED behavior with

SML enabled with a fiber connection down.

IMC2000/200

Copper L/A Fiber L/A

End Node Copper Cable Fiber Cable

Link LED On

End Node

Link LED On

LED On LED On

Media converter

IMC2000/200

Copper L/A Fiber L/A

End Node Copper Cable Fiber Cable

Link LED Off

End Node

Link LED Off

LED Blinking LED Off

Media converter

Chapter 1: Overview

19

Figure 6. SML with Fiber Connection Down

Figure 7 shows media converter and end node L/A LED behavior with

SML enabled with a copper connection down.

Figure 7. SML with Copper Connection Down

SML Example

Scenarios with

Two Connected

Media

Converters

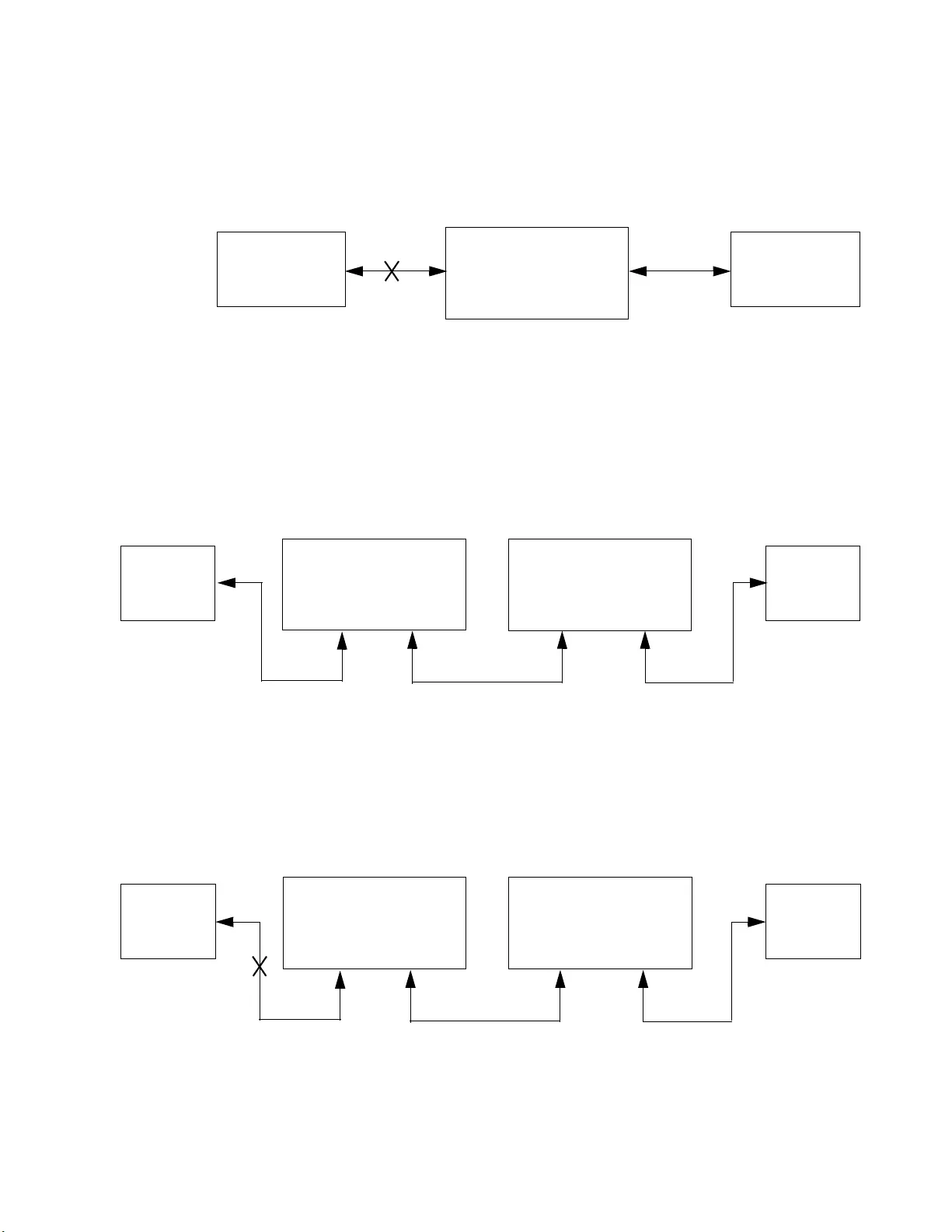

Following are example scenarios with two SML enabled media converters

connected back-to-back (bookend mode).

Figure 8 shows media converter and end node L/A LED behavior with

SML enabled under normal conditions.

Figure 8. SML in Normal Condition with Two Media Converters

Figure 9 shows media converter and end node L/A LED behavior with

SML enabled with a copper connection down between a media converter

and an end node.

Figure 9. SML with Copper Connection to End Node Down

IMC2000/200

Copper L/A Fiber L/A

End Node Copper Cable Fiber Cable

Link LED Off

End Node

Link LED Blinking

LED Off LED Blinking

Media converter

IMC2000/200

Fiber Cable

End Node

Link LED On

End Node

Link LED On

IMC2000/200

Copper L/A Fiber L/A

LED On LED On

Fiber L/A

LED On

Copper L/A

LED On

Copper Cable Copper Cable

Media converter Media converter

IMC2000/200

End Node

Link LED Off

End Node

Link LED Off

IMC2000/200

Copper L/A Fiber L/A

LED Off LED Blinking

Fiber L/A

LED Blinking

Copper L/A

LED Blinking

Fiber CableCopper Cable Copper Cable

Media converter Media converter

IMC2000/200 Series Media Converter Installation Guide

20

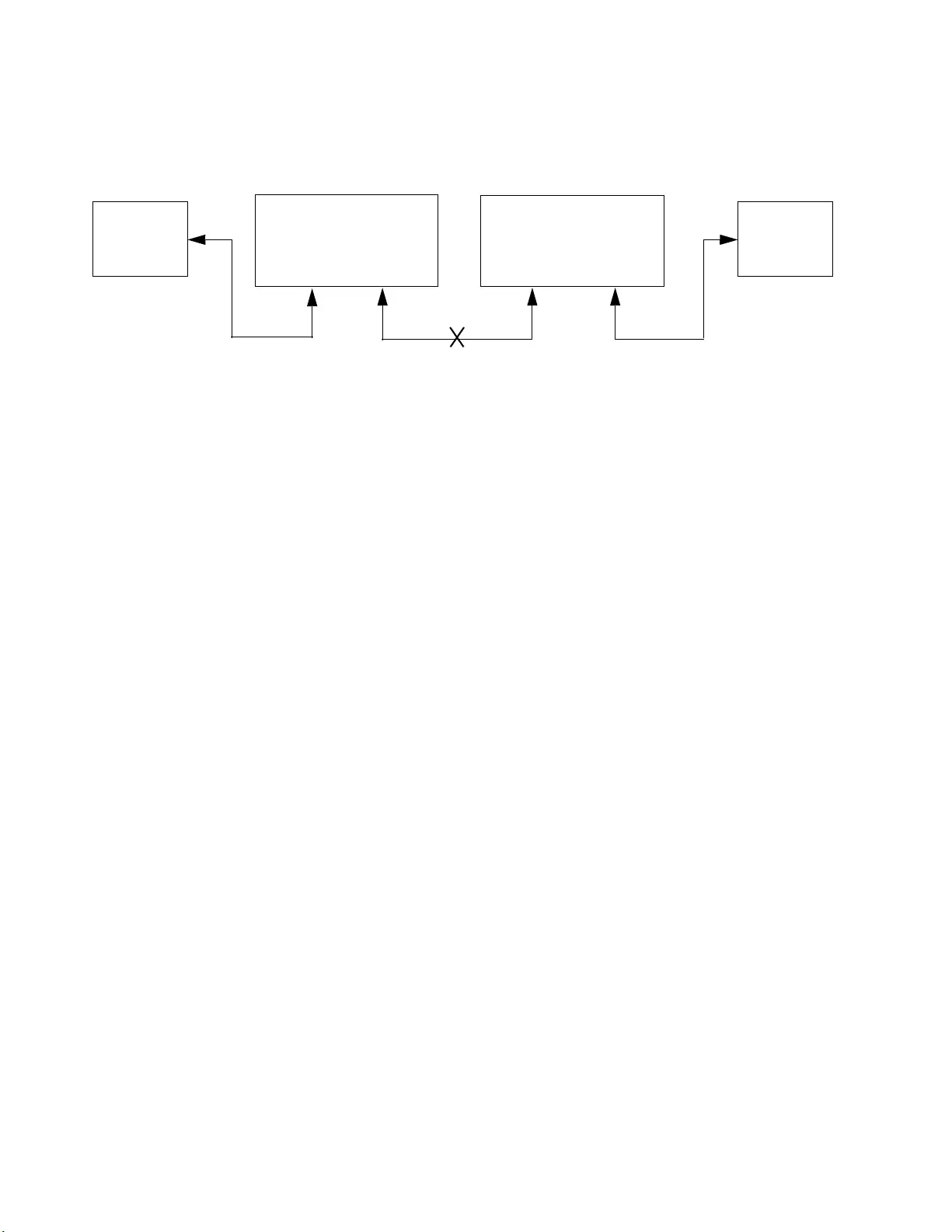

Figure 10 shows media converter and end node L/A LED behavior with

SML enabled with a fiber connection down between two media converters.

Figure 10. SML with Fiber Connection Between Media Converters Down

Enabling SML To enable SML on the unit, set the SML ON/OFF DIP switch 1 to the ON

position. See Figure 2 on page 14.

IMC2000/200

End Node

Link LED Off

End Node

Link LED Off

IMC2000/200

Copper L/A Fiber L/A

LED Blinking LED Off

Fiber L/A

LED Off

Copper L/A

LED Blinking

Fiber CableCopper Cable Copper Cable

Media converter Media converter

Chapter 1: Overview

21

Power over Ethernet (PoE)

Power over Ethernet (PoE) technology permits both power and data to be

transmitted over an Ethernet cable. Both PoE (EEE802.3af) and PoE+

(IEEE802.3at) are supported on the twisted-pair port of the media

converter. Powered device classes 0, 1, 2, 3, and 4 are supported.

Warning

To reduce the risk of electric shock, the PoE ports on this product

must not connect to cabling that is routed outside the building where

this device is located. E40

Enabling Remote

PoE Control

PoE is enabled on the media converter by default: the Remote PoE

Control DIP switch in the OFF position. See Figure 2 on page 14.

To enable PoE only when the fiber link is up, which allows you to remotely

power cycle your PoE device, set the REMOTE PoE CONTROL switch to

the ON position.

IMC2000/200 Series Media Converter Installation Guide

22

23

Chapter 2

Installation

This chapter contains the following sections:

“Reviewing Safety Precautions” on page 24

“Selecting a Site for the Media Converter” on page 26

“Planning the Installation” on page 27

“Unpacking the Media Converter” on page 30

“Installing the Media Converter” on page 32

“Installing the Media Converter on a DIN Rail” on page 33

“Installing the Media Converter on a DIN Rail” on page 33

“Installing the Media Converter on a Wall” on page 35

“Installing the SFP Transceiver” on page 38

IMC2000/200 Series Media Converter Installation Guide

24

Reviewing Safety Precautions

Review the following safety precautions before you begin to install the

chassis or any of its components.

Note

The indicates that a translation of the safety statement is

available in a PDF document titled Translated Safety Statements on

the Allied Telesis website at www.alliedtelesis.com/support.

Caution

Air vents must not be blocked and must have free access to the

room ambient air for cooling. E6

Note

All Countries: Install product in accordance with local and National

Electrical Codes. E8

Note

The power input must be provided from SELV source only, per

IEC60950. Do not connect to a centralized DC battery bank. E31

Warning

Operating Temperature. This product is designed for a maximum

ambient temperature of 75° degrees C. E57

Caution

Failing to pick up the ferrule tip when you reach the bottom of the

cleaning surface can result in static electricity that can damage the

fiber-optic cable. E82

Chapter 2: Installation

25

Warning

In a domestic environment this product may cause radio interference

in which case the user may be required to take adequate measures.

E84

Warning

An SFP transceiver can be damaged by static electricity. Be sure to

observe all standard electrostatic discharge (ESD) precautions,

such as wearing an antistatic wrist strap, to avoid damaging the

transceiver. E86

Warning

Do not stare into the laser beam. L2

Warning

Do not look directly at the fiber-optic cable ends or inspect the cable

ends with an optical lens. L6

Warning

Laser Safety: EN60825-1. L7

IMC2000/200 Series Media Converter Installation Guide

26

Selecting a Site for the Media Converter

Observe the following requirements when choosing a site for your media

converter:

If you are installing the media converter on a table, verify that the

table is level and secure.

The site should provide for easy access to the ports on the front of

the media converter. This will make it easier for you to connect and

disconnect cables, as well as view the media converter’s LEDs.

Air flow around the unit and through its vents on the side should

not be restricted so that the media converter can maintain

adequate cooling.

Do not place objects on top of the media converter.

Do not expose the media converter to moisture or water.

You should use dedicated power circuits or power conditioners to

supply reliable electrical power to the network devices.

Chapter 2: Installation

27

Planning the Installation

Be sure to observe the following guidelines when planning the installation

of your media converter.

On the AT-IMC2000 media converter, the end node connected to

the fiber connector on the media converter must operate at 1000

Mbps, except for the AT-IMC2000/SP when using a 100 Mbps SFP

module.

On the AT-IMC200 media converters, the end node connected to

the fiber connector on the media converter must operate at 100

Mbps.

The two end-nodes connected to the ports of the media converter

must operate with the same duplex mode, either half- or full-

duplex. The twisted-pair port on the media converter can operate in

either mode with Auto Negotiation enabled.

The media converter connects a copper unshielded twisted pair

(UTP) network cabling to a fiber optic cabling, which allows two

network devices, such as a network adapter card, repeater, switch,

media converter, router, camera, or access point, across long

distances.

The twisted-pair port has a maximum operating distance of 100

meters (328 feet).

Cable

Specifications for

Copper Port

Table 3 contains the cable specifications for the twisted-pair port.

Table 3. Twisted-Pair Port Cabling Specifications

Speed Type of Cable

10 Mbps Standard TIA/EIA 568-B-compliant Category 3 or

better shielded or unshielded cabling with 100 ohm

impedance and a frequency of 16 MHz.

100 Mbps Standard TIA/EIA 568-A-compliant Category 5 or TIA/

EIA 568-B-compliant Enhanced Category 5 (Cat 5e)

shielded or unshielded cabling with 100 ohm

impedance and a frequency of 100 MHz.

1000 Mbps Standard TIA/EIA 568-A-compliant Category 5 or TIA/

EIA 568-B-compliant Enhanced Category 5 (Cat 5e)

shielded or unshielded cabling with 100 ohm

impedance and a frequency of 100 MHz.

IMC2000/200 Series Media Converter Installation Guide

28

Speed/Duplex

Combinations for

AT-IMC2000

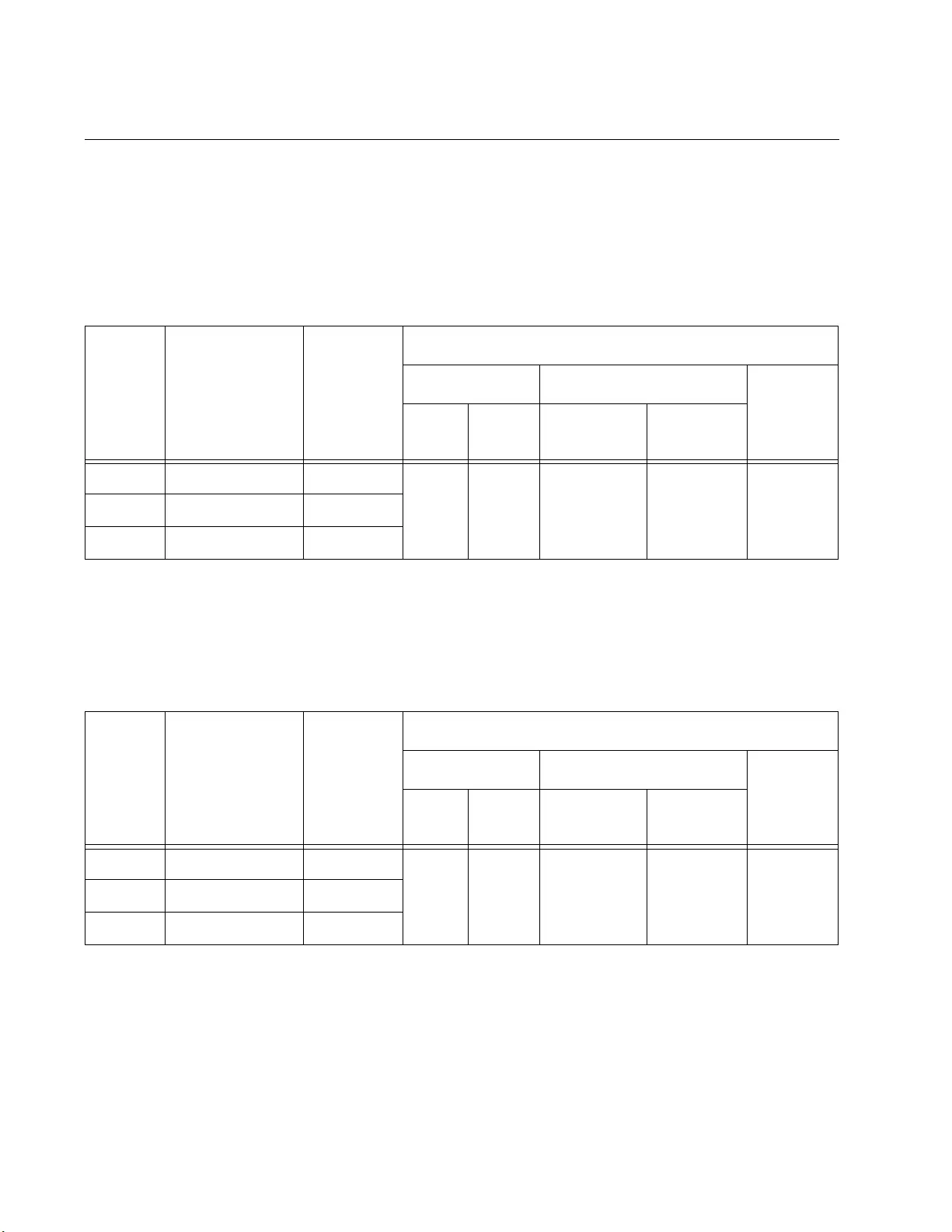

For speed/duplex interactions between the copper port on the

AT-IMC2000 and the copper link partner, see Table 4 for allowable speed/

duplex combinations.

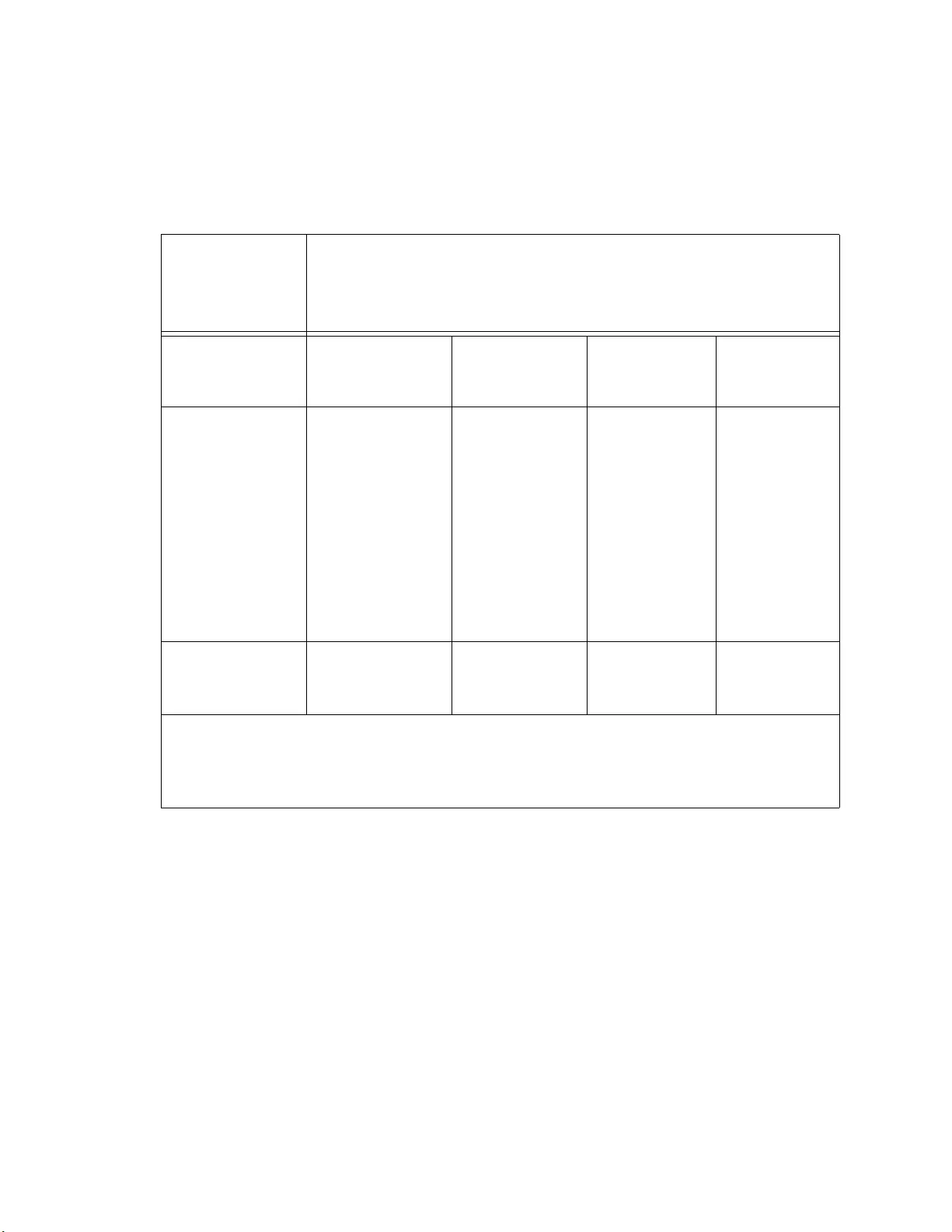

Table 4. Copper Connection Speed/Duplex and Resulting Speed - AT-IMC2000

AT-IMC2000

Copper Port

Speed/Duplex

Setting

Copper Link Partner Port Setting

Auto Negotiation 100Mbps

Force Full

Duplex

100Mbps

Force Half

Duplex

1000Mbps

Force Full

Duplex*

Auto Negotiation 1000Mbps full

duplex

connection for

Gigabit Link

Partners

100Mbps full

duplex

connection for

100Mbps Link

Partners

Duplex

mismatch – not

supported

100Mbps half

duplex

connection

1000Mbps

full duplex

connection

100Mbps Full

Duplex

Duplex

mismatch – not

supported

100Mbps full

duplex

connection

Duplex

mismatch –

not supported

No

connection

*Although 1000Mbps connections require Auto Negotiation, some switches allow the

option of only advertising 1000Mbps speed.

Note: The fiber port always runs at 1000Mbps full duplex.

Chapter 2: Installation

29

Speed/Duplex

Combinations for

AT-IMC200

For speed/duplex interactions between the copper port on the AT-IMC200

and the copper link partner, see Table 5 on page 29 for allowable speed/

duplex combinations.

Note

The twisted-pair port on the media converter features Auto MDI/

MDI-X when operating at 10, 100, or 1000 Mbps. The port is

configured as MDI or MDI-X when it is connected to an end node.

Consequently, you can use a straight-through twisted-pair cable

when connecting any type of network device to the twisted-pair port

on the media converter.

For the fiber-optic port specifications, refer to “Fiber-Optic Port

Specifications” on page 52.

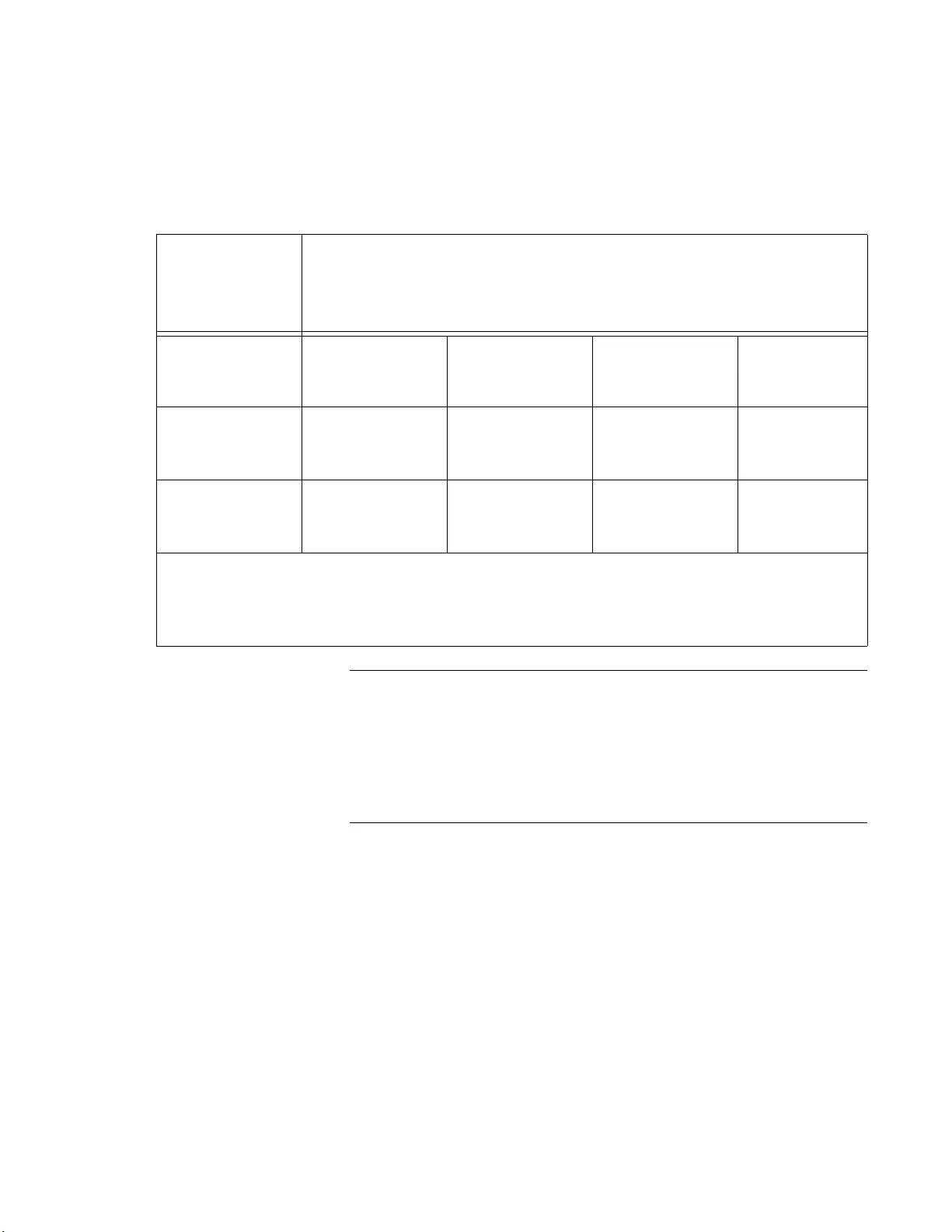

Table 5. Copper Connection Speed/Duplex and Resulting Speed - AT-IMC200

AT-IMC200

Copper Port

Speed/Duplex

Setting

Copper Link Partner Port Setting

Auto Negotiation 100Mbps Force

Full Duplex

100Mbps Force

Half Duplex

1000Mbps

Force Full

Duplex*

Auto Negotiation 100Mbps full

duplex

connection

Duplex

mismatch – not

supported

100Mbps half

duplex

connection

No connection

100Mbps Full

Duplex

Duplex

mismatch – not

supported

100Mbps full

duplex

connection

Duplex

mismatch – not

supported

No connection

*Although 1000Mbps connections require Auto Negotiation, some switches allow the option

of only advertising 1000Mbps speed.

Note: The fiber port always runs at 100Mbps full duplex.

IMC2000/200 Series Media Converter Installation Guide

30

Unpacking the Media Converter

To unpack the media converter, perform the following procedure:

1. Remove all of the components from the shipping package.

Note

Store the packaging material in a safe location. You must use the

original shipping material if you need to return the unit to Allied

Telesis.

2. Place the media converter on a level, secure surface.

3. Verify that the hardware components are included in your switch

package.Table 7 shows a list of the hardware components.

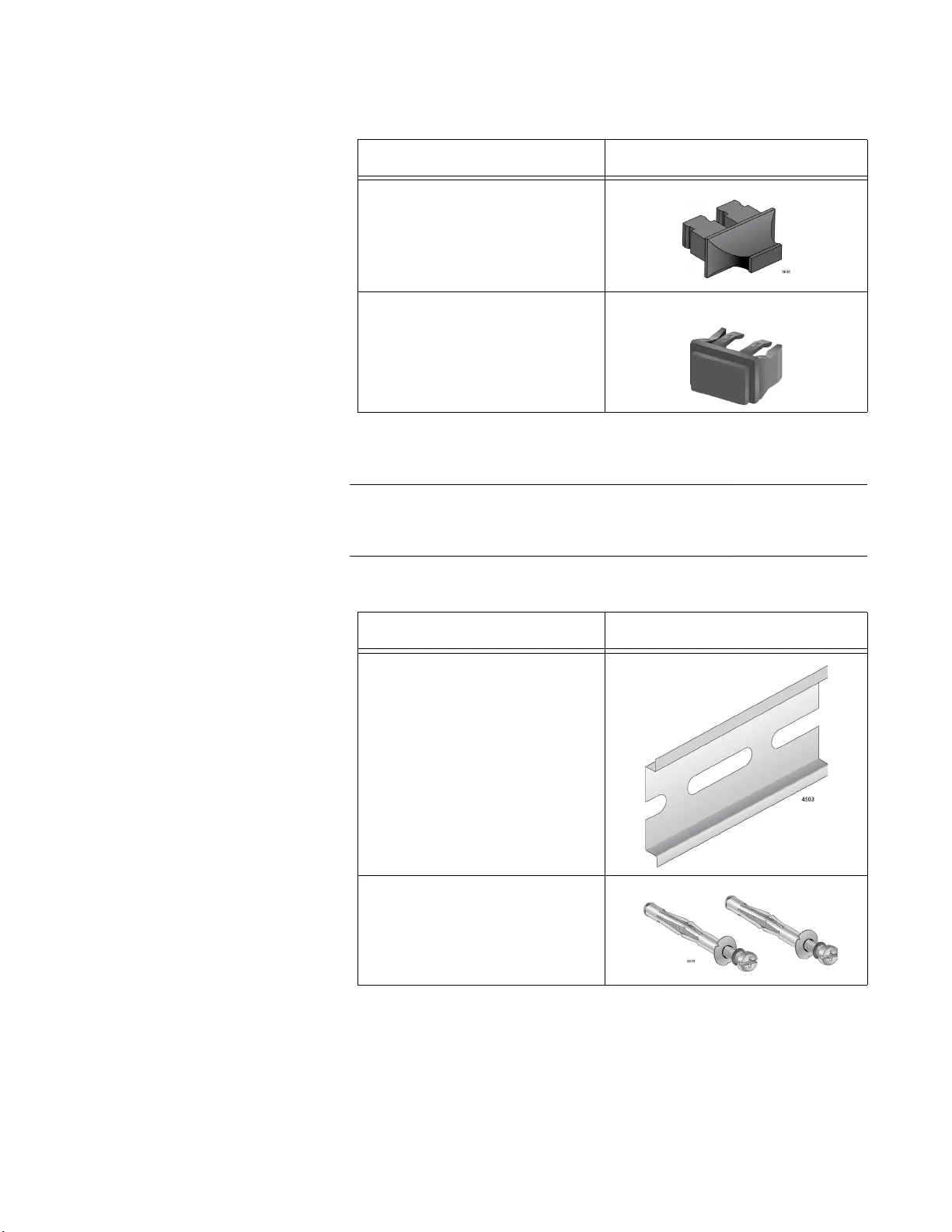

Table 6. Components in the Shipping Box

Component Illustration

One bracket for DIN rail

(Pre-installed)

Two screws for the bracket

(Pre-installed)

One 2-pin terminal block for

DC power

Chapter 2: Installation

31

4. Verify that the hardware components in the wall-mount kit. Table 7

shows a list of the hardware components.

Note

To install the media converter on the wall, you must purchase this

wall-mount kit separately.

One fiber port dust cover (pre-

installed)

For AT-IMC200xTP/SC and

AT-IMC200xT/SC models only

One SFP slot dust cover (pre-

installed)

For AT-IMC2000TP/SP and

AT-IMC2000T/SP models only

Table 7. Components in the Wall Mount Kit

Component Illustration

One piece of DIN rail for wall-

mount

Two sets of metal anchor and

screw for wall-mount

Table 6. Components in the Shipping Box

Component Illustration

IMC2000/200 Series Media Converter Installation Guide

32

Installing the Media Converter

You may install the media converter on a desktop, on a DIN rail, or on a

wall. Perform one of the following procedures:

To install the media converter on a DIN rail, see “Installing the

Media Converter on a DIN Rail” on page 33.

To install the media converter on a wall, see “Installing the Media

Converter on a Wall” on page 35.

Chapter 2: Installation

33

Installing the Media Converter on a DIN Rail

To install the media converter on a DIN rail, perform the following

procedure:

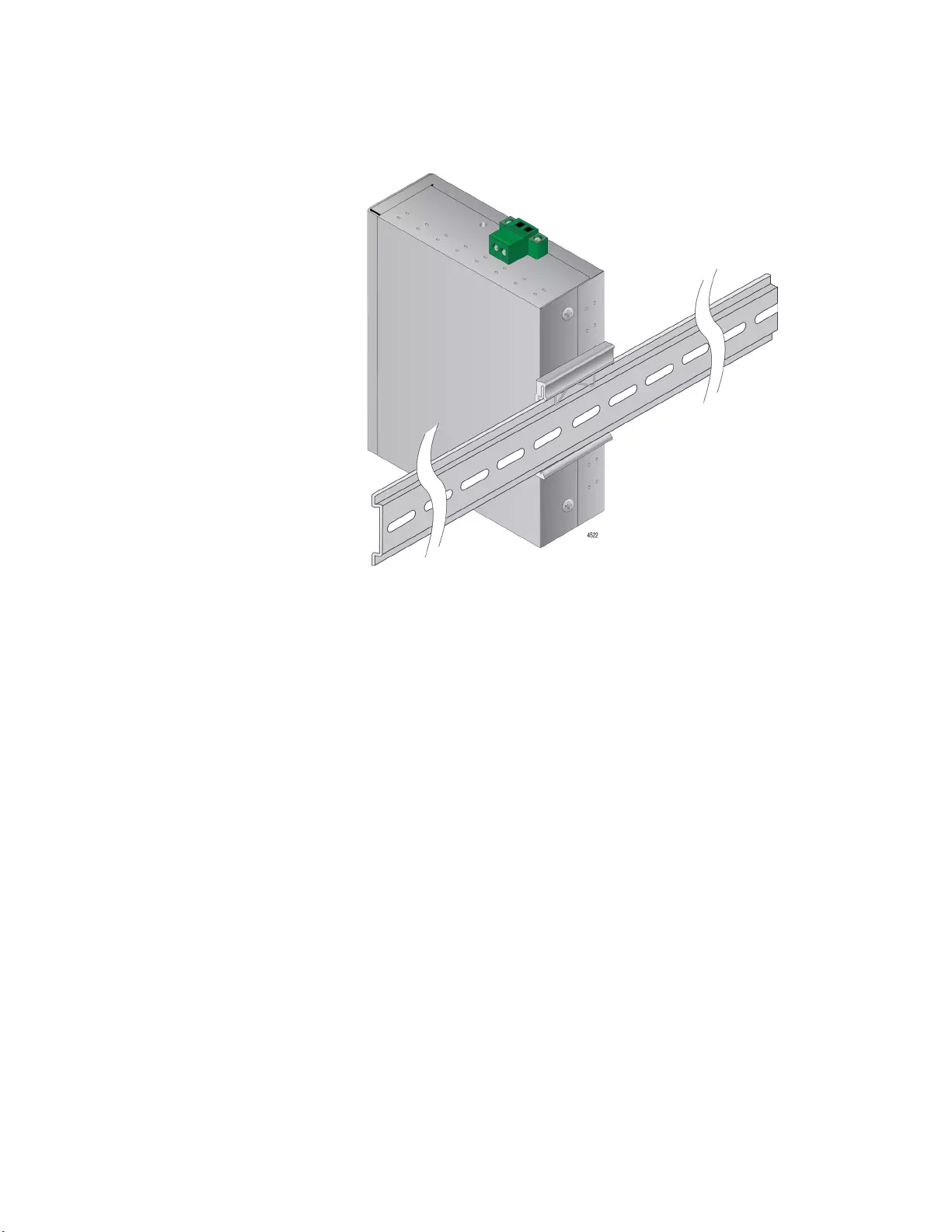

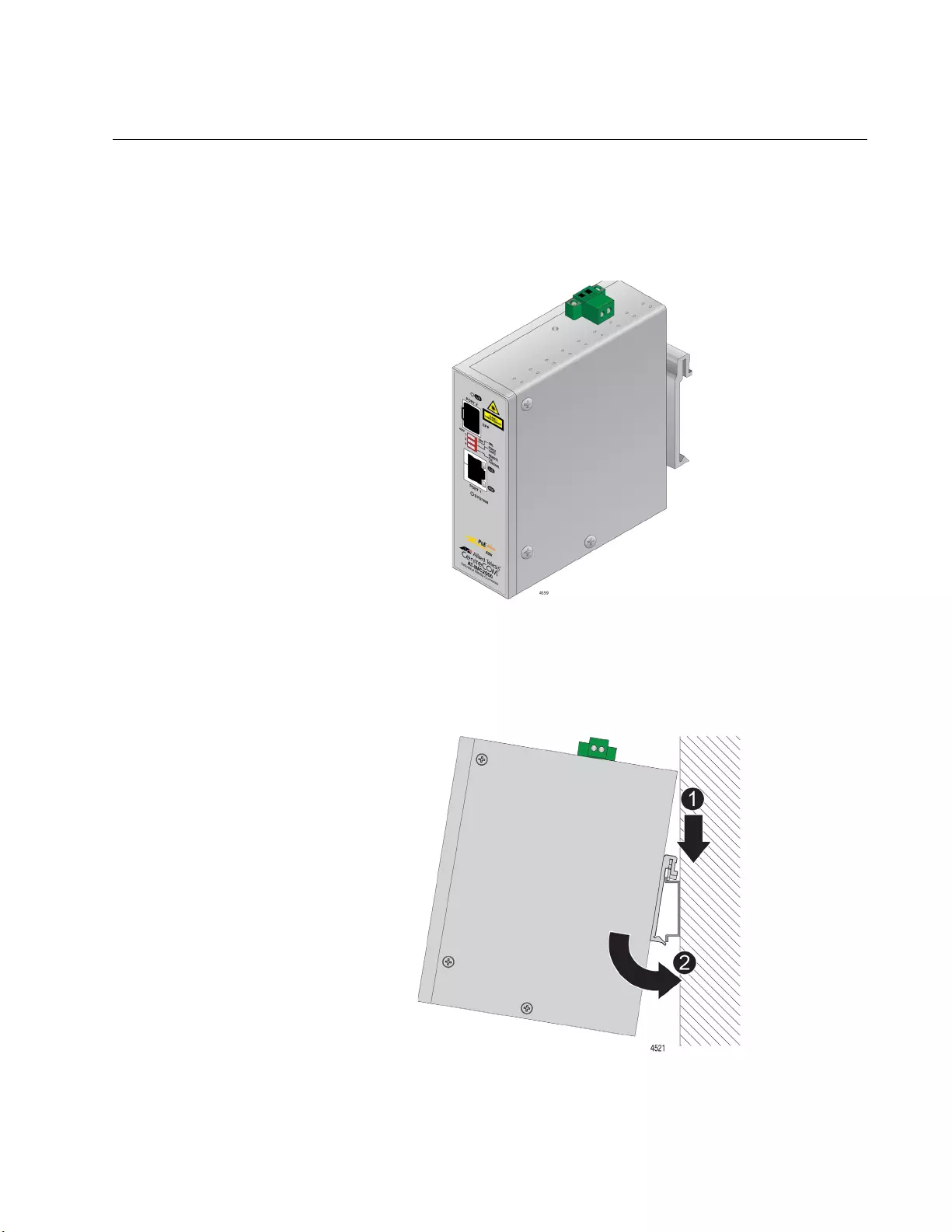

1. Take the media converter. See Figure 11.

Figure 11. The Media Converter with the Bracket Attached

2. Hook the top of the bracket on the upper side of the DIN rail and snap

down the media converter unit, as shown in Figure 12.

Figure 12. Hook the Bracket on the DIN Rail

Chapter 2: Installation

35

Installing the Media Converter on a Wall

To install the media converter on a wail, perform the following procedure:

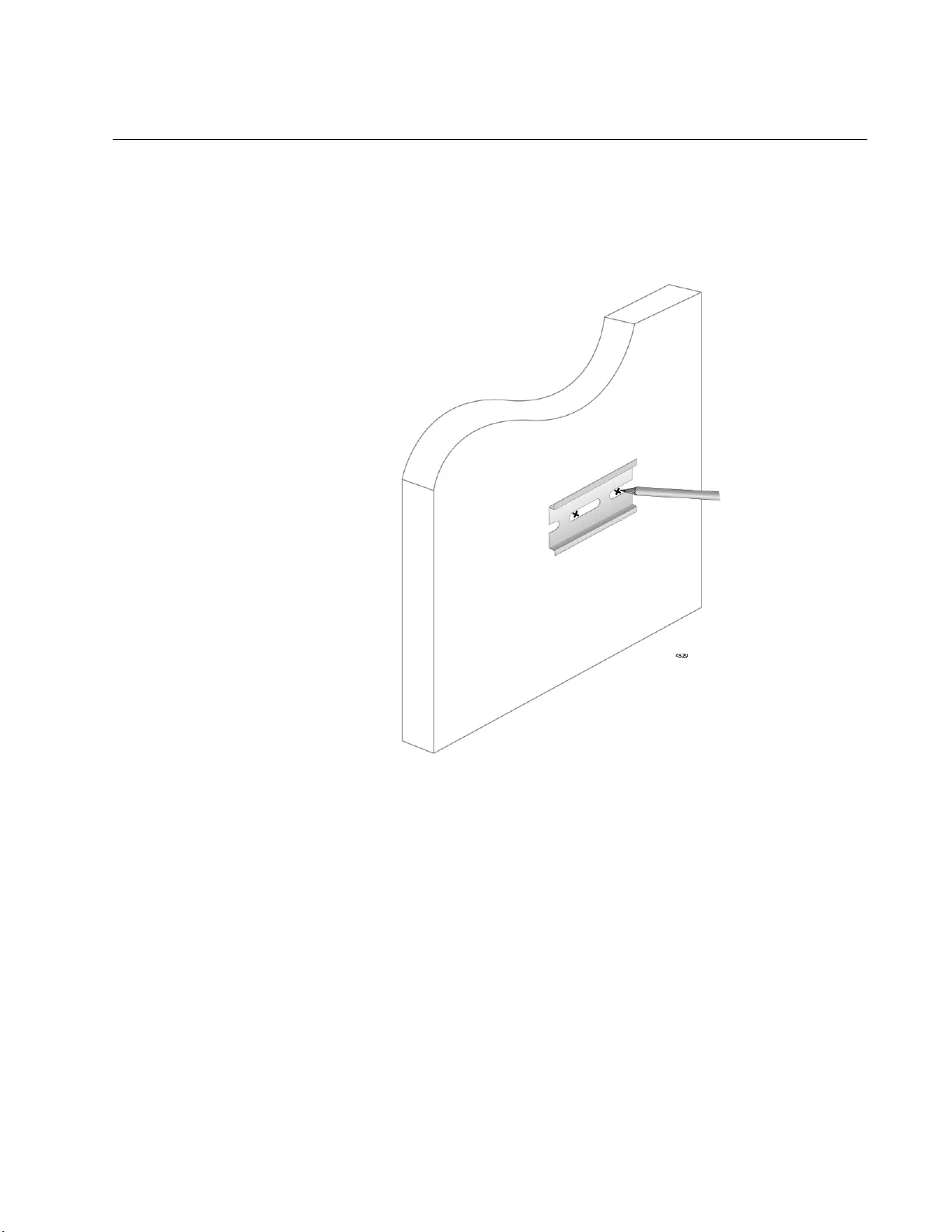

1. Use a pencil or pen to mark the wall with two screw locations in the

openings of your DIN rail. See Figure 14.

Figure 14. Marking the Wall for Screw Locations

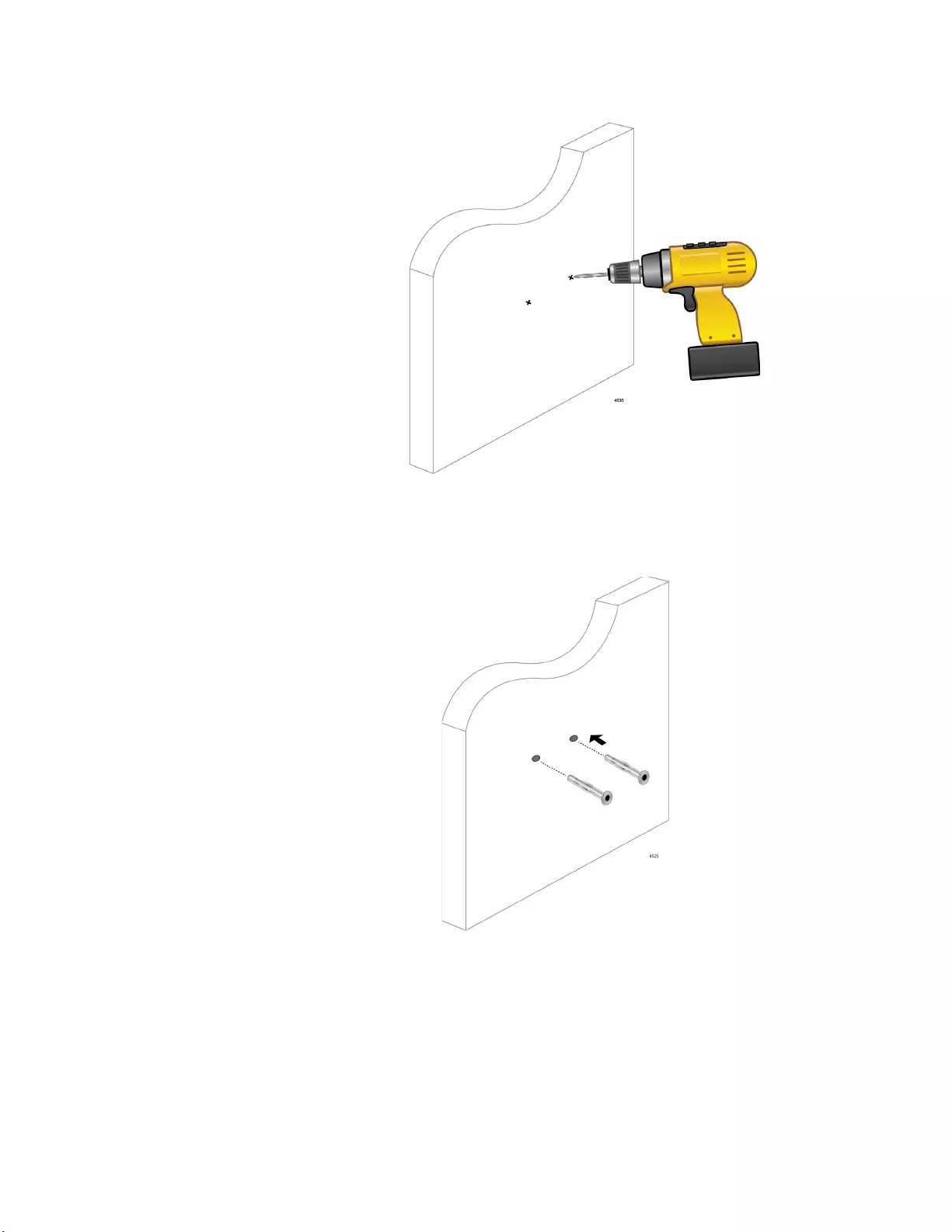

2. Pre-drill two 3/16-inch holes where you just marked. See Figure 15 on

page 36.

IMC2000/200 Series Media Converter Installation Guide

36

Figure 15. Pre-drilling the Holes on the Wall

3. Insert two metal anchors into the holes you drilled in Step 2.

Figure 16. Pre-drilling Holes

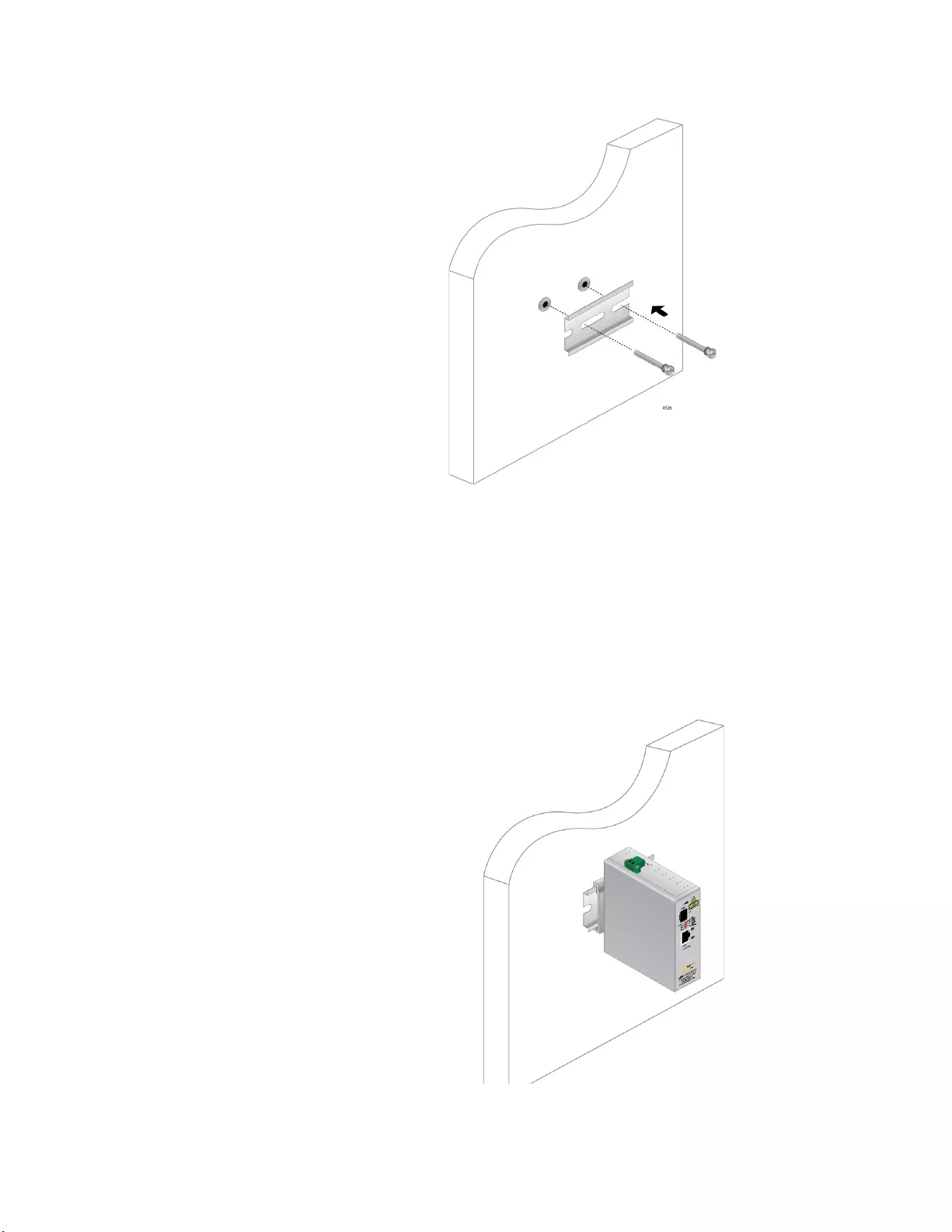

4. Align the openings in the piece of the DIN rail to the metal anchors on

the wall and insert the screws into the metal anchors. See Figure 17

on page 37.

Chapter 2: Installation

37

Figure 17. Installing the Piece of DIN Rail on the Wall

5. Tighten the screws to attach the piece of the DIN rail to the wall.

6. Hook the top of the bracket on the upper side of the piece of the DIN

rail and snap down the media converter unit, as shown in Figure 12 on

page 33.

7. Ensure that the media converter is installed securely to the wall. See

Figure 18.

Figure 18. Media Converter on the Wall

IMC2000/200 Series Media Converter Installation Guide

38

Installing the SFP Transceiver

To install an SFP transceiver, perform the following procedure:

Note

The transceiver can be hot-swapped; you do not need to power off

the media converter to install a transceiver. However, always

remove the cable before removing the transceiver.

Note

You should always install the transceiver before connecting the

fiber-optic cable to it.

1. Remove the transceiver from its shipping container and store the

packaging material in a safe location.

Warning

An SFP transceiver can be damaged by static electricity. Be sure to

observe all standard electrostatic discharge (ESD) precautions,

such as wearing an antistatic wrist strap, to avoid damaging the

transceiver. E86

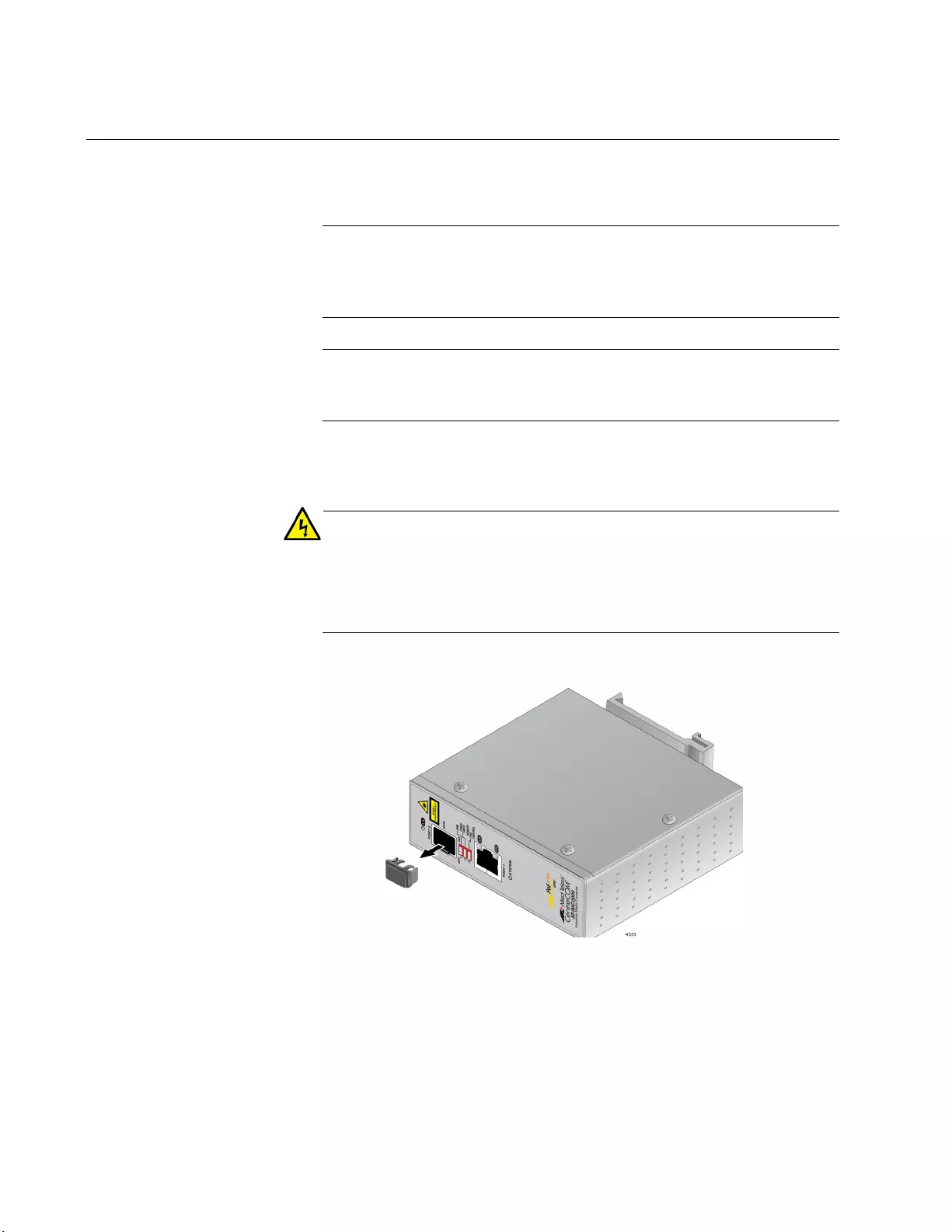

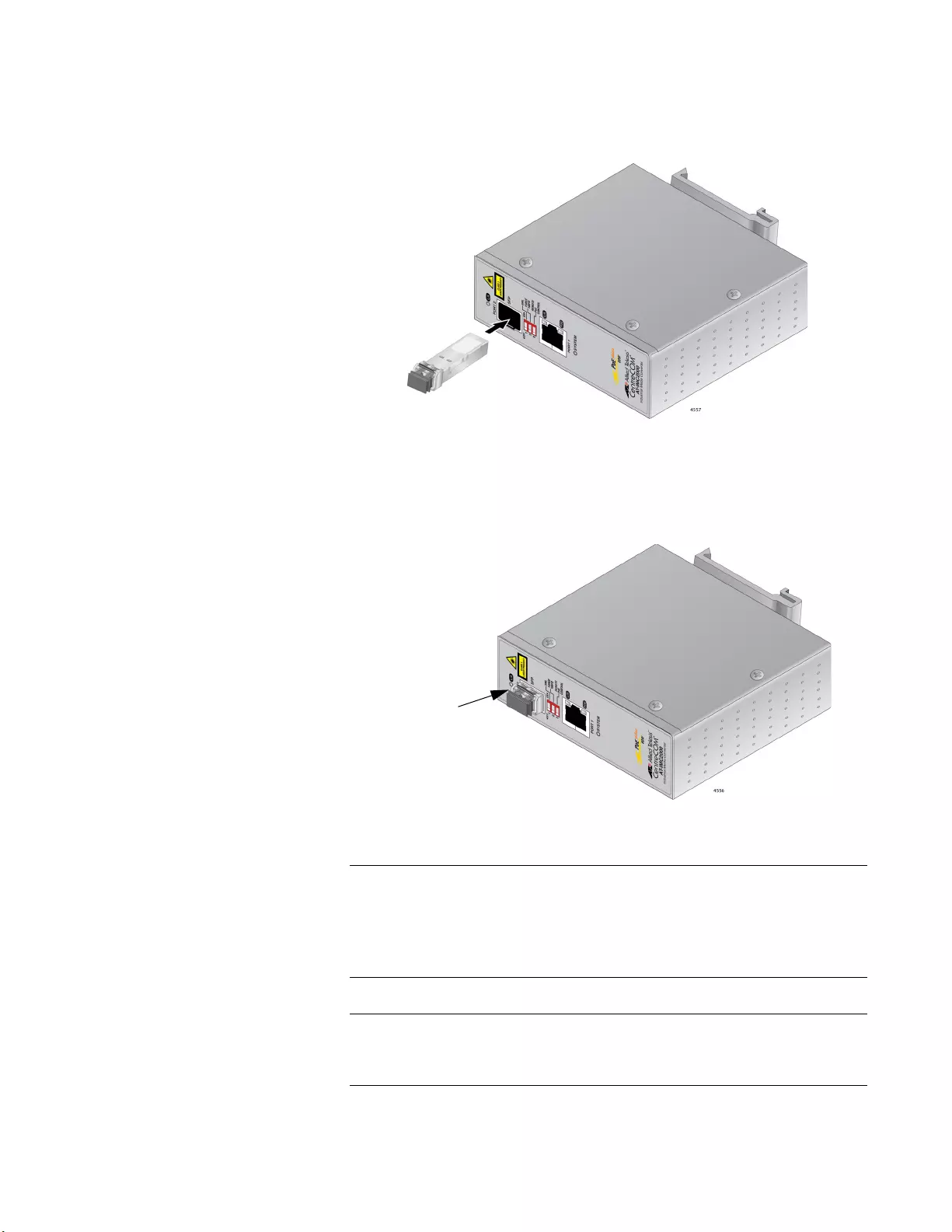

2. Remove the dust plug from the SFP slot. See Figure 19.

Figure 19. Removing the Dust Plug from an SFP Slot

3. Position the SFP transceiver with the label facing up.

Chapter 2: Installation

39

4. Slide the transceiver into the SFP slot until it clicks into place. See

Figure 20.

Figure 20. Inserting the SFP

5. Verify that the handle on the transceiver is in the upright position, as

shown in Figure 21. This secures the transceiver and prevents it from

being dislodged from the slot.

Figure 21. Positioning the SFP Handle in the Upright Position

Note

SFP transceivers are dust-sensitive. Always keep the plug in the

optical bores when a fiber-optic cable is not installed, or when

storing the SFP. When you do remove the plug, keep it for future

use.

Note

Unnecessary removal and insertion of an SFP can lead to premature

failure.

SFP Transceiver

Handle

IMC2000/200 Series Media Converter Installation Guide

40

For information on the cable specifications of the SFP, consult the

documentation shipped with the SFP.

IMC2000/200 Sereis Media Converter Installation Guide

42

Wiring and Powering on the Media Converter

To wire and power on the IMC2000/200 series media converter, perform

the following procedure:

Warning

Only trained and qualified personnel are allowed to install or to

replace this equipment. E14

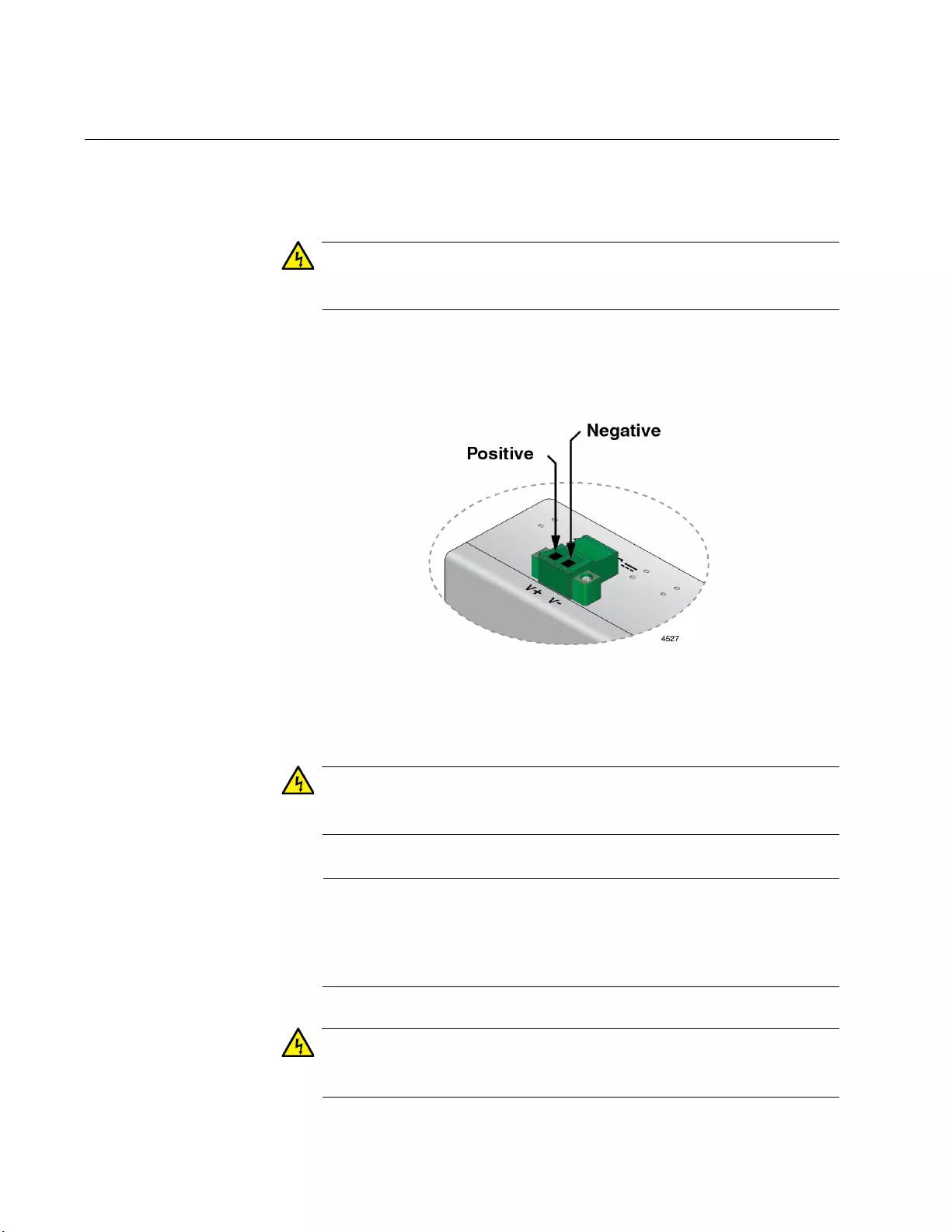

1. Identify the positive and negative terminals on the DC power supply

terminal block, as shown in Figure 22.

Figure 22. Locating the Terminals on the DC Terminal Block

2. Before you strip and attach the wires, review the following safety

precautions:

Warning

For centralized DC power connection, install only in a restricted

access area. E23

Note

A tray cable is required to connect the power source if the unit is

powered by centralized DC power. The tray cable must be a UL

listed Type TC tray cable and rated at 600 V and 90 degrees C, with

three conductors, minimum 14 AWG. E24

Warning

The source of the DC input shall be isolated from the AC power

source by reinforced insulation. E117

Chapter 3: Powering On the Media Converter

43

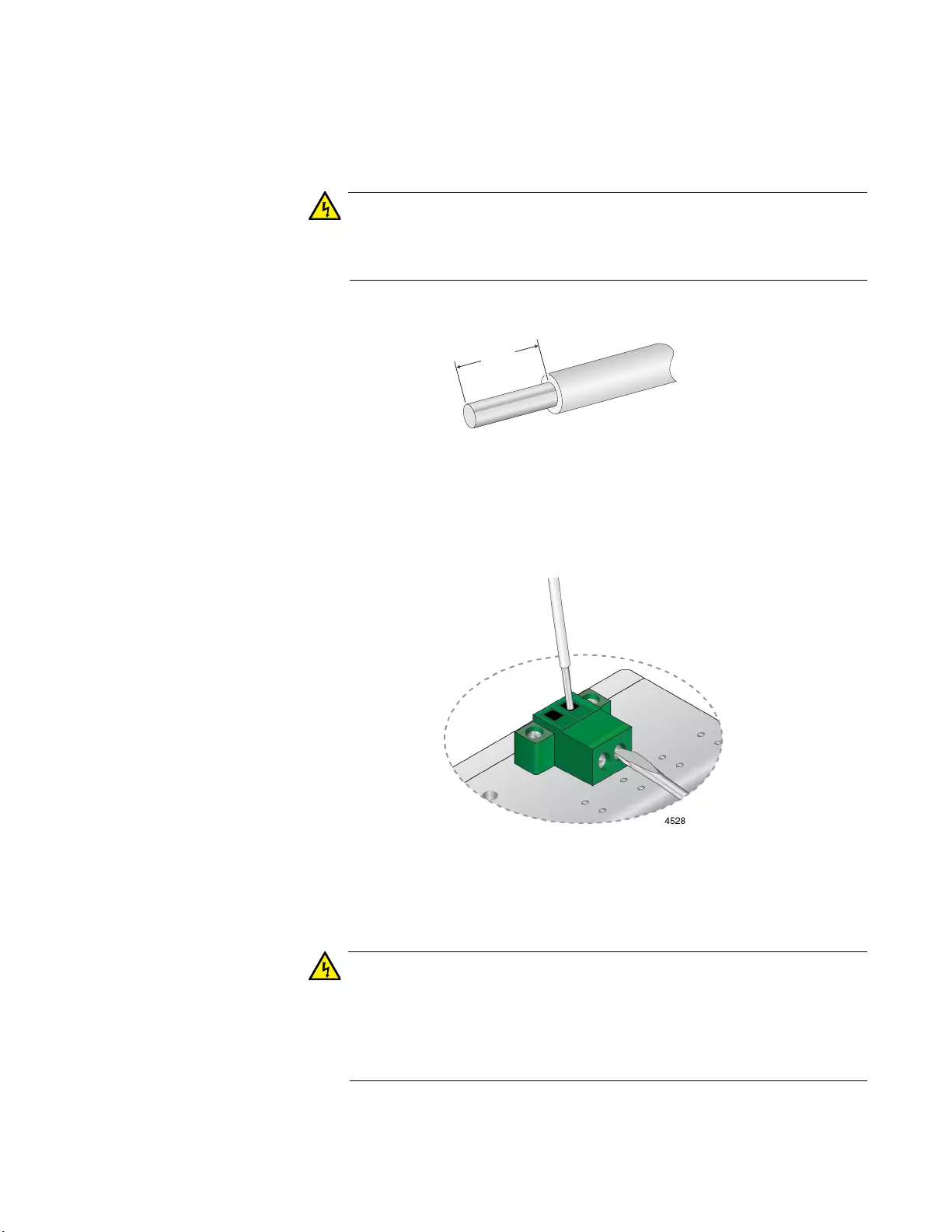

3. With a 14-gauge wire-stripping tool, strip the two wires in the tray cable

coming from the DC input power source to 8 millimeters ± 1 millimeters

(0.31 inches ± 0.039 inches), as shown in Figure 23.

Warning

Do not strip more than the recommended amount of wire. Stripping

more than the recommended amount can create a safety hazard by

leaving exposed wire on the terminal block after installation. E10

Figure 23. Stripped Wire

4. Connect the negative feed wire to the terminal marked V- (negative)

by inserting the wire into the terminal block and tightening the

connection with a flathead screwdriver. SeeFigure 24.

Figure 24. Connecting the Feed Wire

5. Connect the positive feed wire to the terminal block marked V+

(positive).

Warning

Check to see if there are any exposed copper strands coming from

the installed wire. When this installation is done correctly there

should be no exposed copper wire strands extending from the

terminal block. Any exposed wiring can conduct harmful levels of

electricity to persons touching the wires. E12

8mm ±1mm

(0.31in. ±0.039in.)

IMC2000/200 Sereis Media Converter Installation Guide

44

6. Secure the cables using multiple cable ties (not provided) to minimize

the chance of the connections being disturbed by casual contact with

the wiring.

Allied Telesis recommends that you use at least four cable ties 10

centimeters (4 inches) apart with the first one located within 15

centimeters (6 inches) of the terminal block.

7. Verify that the SYSTEM LED is green.

If it is not, refer to Chapter 4, “Troubleshooting” on page 45.

45

Chapter 4

Troubleshooting

This chapter contains information on how to troubleshoot the media

converter if a problem occurs.

Note

For further assistance, please contact Allied Telesis Technical

Support at www.alliedtelesis.com/support.

Problem 1: The SYSTEM LED on the media converter is off.

Solutions: The unit is not receiving power. Try the following:

Verify that the power cord is securely connected to the power

source and to the DC connector of the media converter.

Verify that the power outlet has power by connecting another

device to it.

Try using another power source.

Verify that the DC voltage from the power source is within the

required levels for the AT-IMC2000/200 series media converter.

Solution: An internal component on the unit is damaged or not working

properly. Try the following:

Power cycling the unit.

If power cycling does not clear the fault, return the unit to Allied

Telesis.

Problem 2: The SYSTEM LED on the media converter is blinking slowly.

Solution: An error is present on the unit. Try the following:

Power cycling the unit.

If it is an AT-IMC2000TP/SP or AT-IMC2000T/SP unit, a transmit fault may

be occurring on the SFP module, or the SFP module itself may be causing

some other errors. The media converter will try to clear this error, but if the

error persists, try the following:

Remove and re-seat the SFP module.

Try a different SFP module.

Verify the SFP module is the correct type for your application.

IMC2000/200 Series Media Converter Installation Guide

46

Problem 3: The twisted-pair port on the media converter is connected to

an end node, but the copper port’s L/A LED is off.

Solutions: The port is unable to establish a link to an end node. Try the

following:

Verify that the end node connected to the twisted-pair port is

powered on and is operating properly.

Verify that the twisted-pair cable is securely connected to the port

on the media converter channel and to the port on the remote end-

node.

Verify that the port is connected to the correct twisted-pair cable.

This is to eliminate the possibility that the port is connected to the

wrong end-node, such as a powered-off device.

Try connecting another end node to the twisted-pair port with a

different cable. If the twisted-pair port is able to establish a link,

then the problem is with the cable or the other end-node.

Verify that the twisted-pair cable does not exceed 100 meters (328

feet).

Verify that the end node connected to the media converter is

operating at the same speed.

Verify that you are using the appropriate category of twisted-pair

cable: Category 3 or better for 10 Mbps operation and Category 5

and Category 5E for 100 and 1000 Mbps operation.

Note

A 1000Base connection may require 5 to 10 seconds to establish a

link.

Problem 4: The FIBER port’s L/A LED for the fiber-optic port is off.

Solutions: The fiber-optic port on the transceiver is unable to establish a

link to an end node. Try the following:

Verify that the end node connected to the fiber-optic port is

operating properly.

Verify that the fiber-optic cable is securely connected to the port on

the media converter channel and to the port on the remote end-

node.

Verify that the end node connected to the media converter is

operating at the same speed.

Verify that the media converter’s transmitter port (TX) is connected

to the end node’s receiver port (RX) and that the media converter’s

receiver port (RX) is connected to the end node’s transmitter port

(TX).

Chapter 4: Troubleshooting

47

On the AT-IMC2000TP/SP or AT-IMC2000T/SP unit, check that

the SFP module is fully inserted in the slot.

On the AT-IMC2000TP/SP or AT-IMC2000T/SP unit, verify that the

operating specifications and wave lengths of the fiber-optic port on

the SFP transceiver and the remote end-node are compatible.

Verify that the correct type of fiber-optic cabling is being used.

Verify that the port is connected to the correct fiber-optic cable.

This is to eliminate the possibility that the port is connected to the

wrong remote end-node, such as a powered-off device.

Try connecting another end node to the fiber-optic port using a

different cable. If the port is able to establish a link, then the

problem is with the cable or with the other end node.

If the remote end-node is a management device, use its

management firmware to determine whether its port is enabled.

Test the attenuation on the fiber-optic cable with a fiber-optic tester

to determine whether the optical signal is too weak (sensitivity) or

too strong (maximum input power).

Problem 5: Network performance between the twisted-pair port on the

media converter and an end node is slow.

Solution: There might be a duplex mode mismatch between the port and

the end node. This occurs when a twisted-pair port using Auto Negotiation

is connected to a device with a fixed duplex mode of full duplex. If this is

the cause of the problem, adjust the duplex mode of the port on the end

node or on the media converter so that both ports are using the same

duplex mode.

IMC2000/200 Series Media Converter Installation Guide

48

49

Appendix A

Technical Specifications

Below are the technical specifications for the media converters. The

specification categories are as follows:

“Physical Specifications”

“Environmental Specifications”

“Power Specifications” on page 50

“RJ45 Connector and Port Pinouts” on page 50

“Fiber-Optic Port Specifications” on page 52

Physical Specifications

Environmental Specifications

Table 8. Physical Specifications

Dimensions

W x D x H

50.8 mm x 99.1 mm x 20.3 mm

(2.0 in x 3.9 in x 0.8 in)

Weight 0.2 kg (0.4 lb)

Table 9. Environmental Specifications

Operating Temperature -40°C to 75°C (-40°F to 167°F)

Storage Temperature -40°C to 85°C (-40°F to 185°F)

Operating Humidity 5% to 95% non-condensing

Storage Humidity 5% to 95% non-condensing

Operating Altitude Range Up to 2,000 m (6,561.7 ft)

IMC2000/200 Series Media Converter Installation Guide

50

Power Specifications

The following specifications apply to the DC power connector on the

media converter.

Table 10 shows power specifications for the AT-IMC2000TP/SP,AT-

IMC2000TP/SC, and AT-IMC200TP/SC models.

Table 11 shows power specifications for the AT-IMC2000T/SP,

AT-IMC2000T/SC, and AT-IMC200T/SC models.

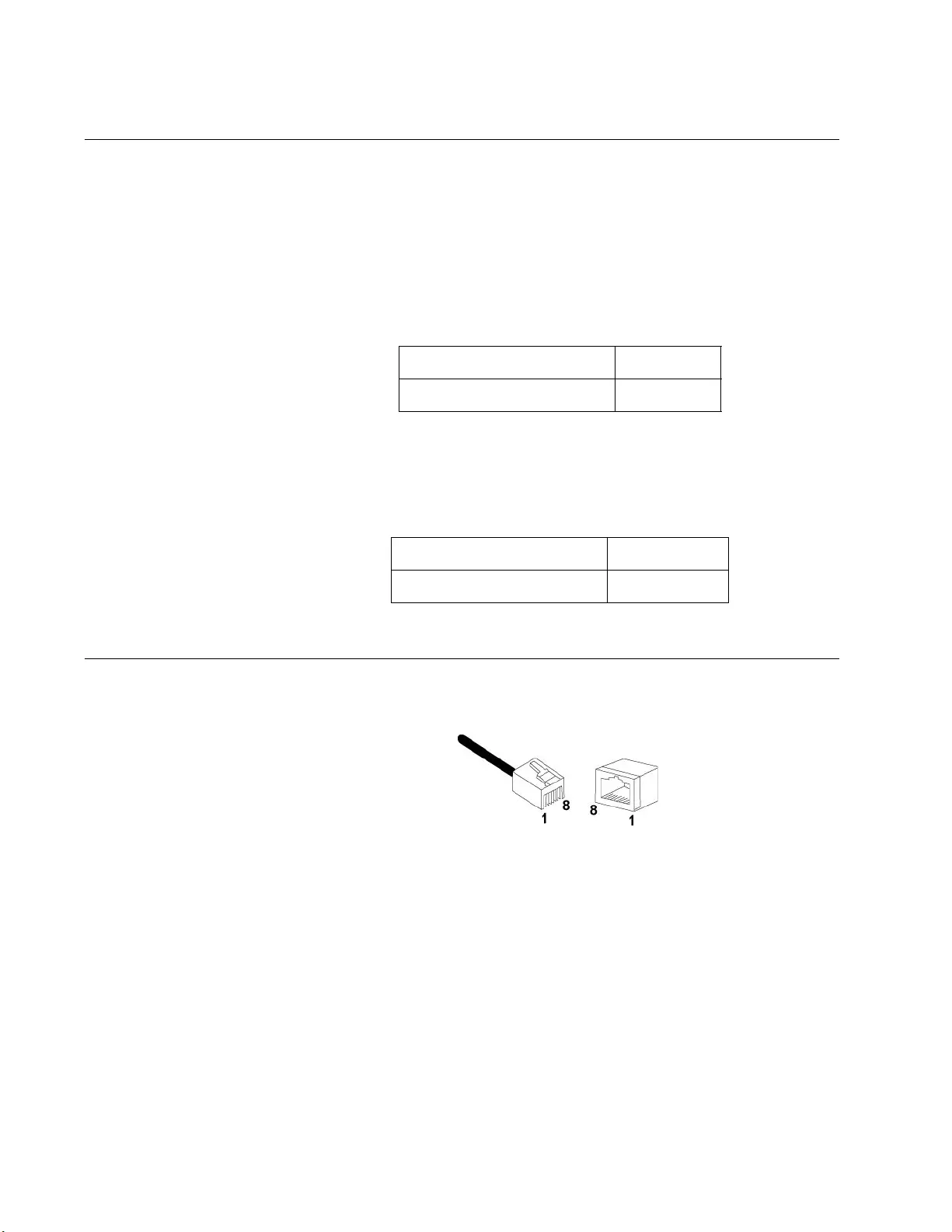

RJ45 Connector and Port Pinouts

Figure 25 illustrates the pin layout for the RJ45 connector and port.

Figure 25. RJ45 Connector and Port Pin Layout

Table 10. Power Specifications for the AT-IMC2000/200TP Models

Input supply voltage 48-60VDC

Input current 1.5A max

Table 11. Power Specifications for the AT-IMC2000/200T Models

Input supply voltage 12-60 VDC

Input current 200mA max

Appendix A: Technical Specifications

51

Table 12 lists the pin signals when a port is operating in the MDI

configuration at 10 or 100 Mbps.

Table 13 lists the pin signals when a port is operating in the MDI-X

configuration at 10 or 100 Mbps.

Table 14 lists the pin signals when a port is operating at 1000 Mbps.

Table 12. MDI Pin Signals (10 or 100 Mbps)

Pin Signal

1TX+

2TX-

3RX+

6RX-

Table 13. MDI-X Pin Signals (10 or 100 Mbps)

Pin Signal

1RX+

2RX-

3TX+

6TX-

Table 14. Pin Signals (1000 Mbps)

Pin Pair Signal

1 1 TX and RX+

2 1 TX and RX-

3 2 TX and RX+

4 3 TX and RX+

5 3 TX and RX-

6 2 TX and RX-

7 4 TX and RX+

8 4 TX and RX-

IMC2000/200 Series Media Converter Installation Guide

52

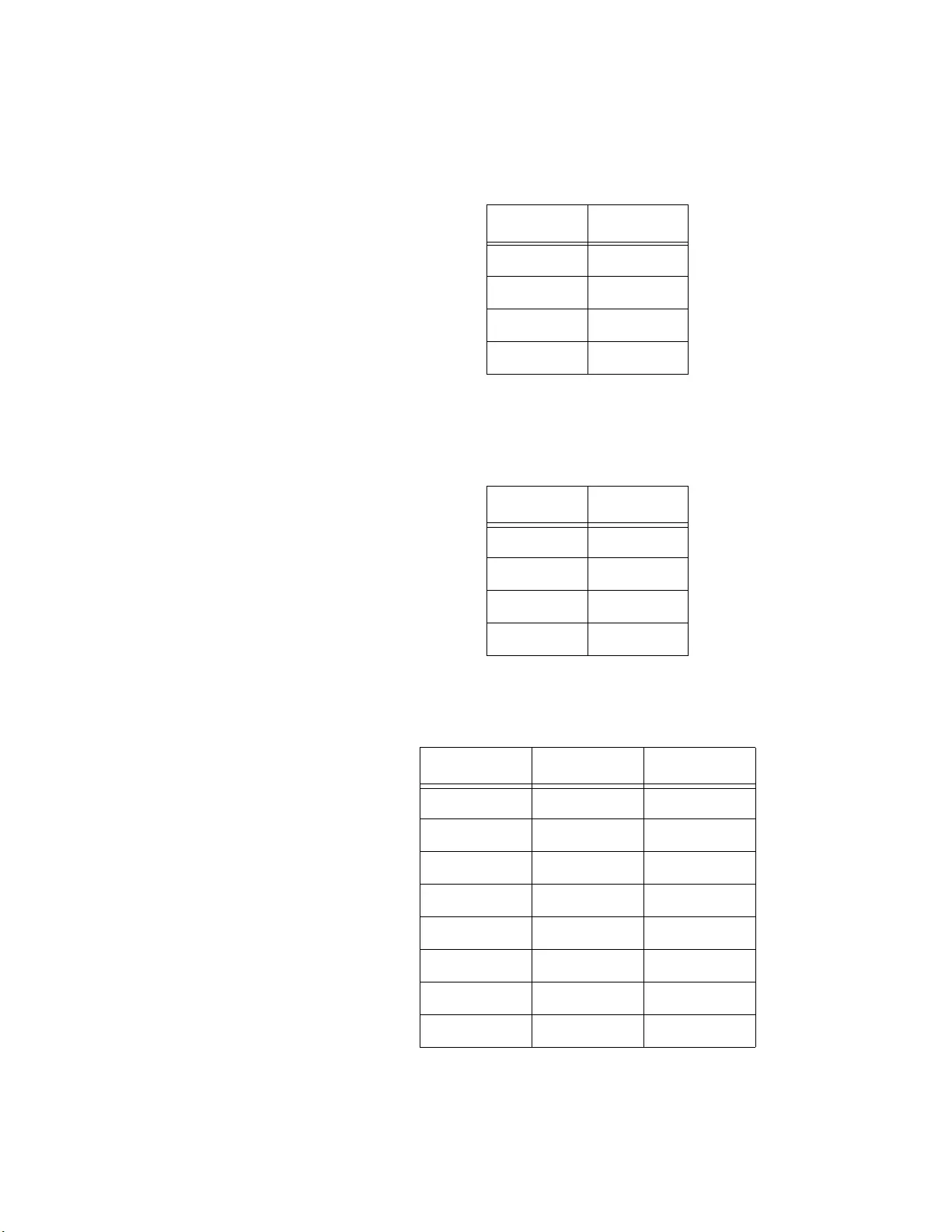

Fiber-Optic Port Specifications

The fiber type for the media converter is multimode.

Table 15 lists fiber-optic port specifications for the AT-IMC2000 media

converters.

Table 16 lists fiber-optic port specifications for the AT-IMC200 media

converters.

Table 15. AT-IMC2000 Fiber-Optic Port Specifications

Fiber

Optic

Cable

Cable

Diameter

(Core/Cladding)

Max

Distance1

Optical Parameters

Launch Power Receive Power Optical

Power

Budget

Min. Max. Min

(Sensitivity)

Max

(Overload)

FDDI 62.5/125 um 220 m

-9.5

dBm

-4.0

dBm -20 dBm -3 dBm 10.5

dBm

OM1 62.5/125 um 275 m

OM2 50/125 um 550 m

1. For reference only, actual distance is dependent on the specific attenuation of the cabling environment.

Table 16. AT-IMC200 Fiber-Optic Port Specifications

Fiber

Optic

Cable

Cable

Diameter

(Core/Cladding)

Max

Distance1

Optical Parameters

Launch Power Receive Power Optical

Power

Budget

Min. Max. Min

(Sensitivity)

Max

(Overload)

FDDI 62.5/125 um 2 km

-20

dBm

-14

dBm -32 dBm -3 dBm 12 dBmOM1 62.5/125 um 2 km

OM2 50/125 um 2 km

1. For reference only, actual distance is dependent on the specific attenuation of the cabling environment.

53

Appendix B

Cleaning Fiber-Optic Connectors

This appendix contains the following sections:

“Introduction”

“Using a Cartridge-Type Cleaner” on page 54

“Using a Swab” on page 56

This appendix describes how to clean fiber-optic connectors.

Introduction

The fiber-optic connector consists of a fiber-optic plug and its adapter. The

end of the fiber-optic cable is held in the core of the ferrule in the plug.

Light signals are transmitted through the core of the fiber. Even minor

smudges, or dirt, on the end face of the fiber (completely invisible to the

naked eye) can disrupt light transmission and lead to failure of the

component or of the entire system. Therefore, it is of utmost importance to

clean all fiber-optic connectors before use.

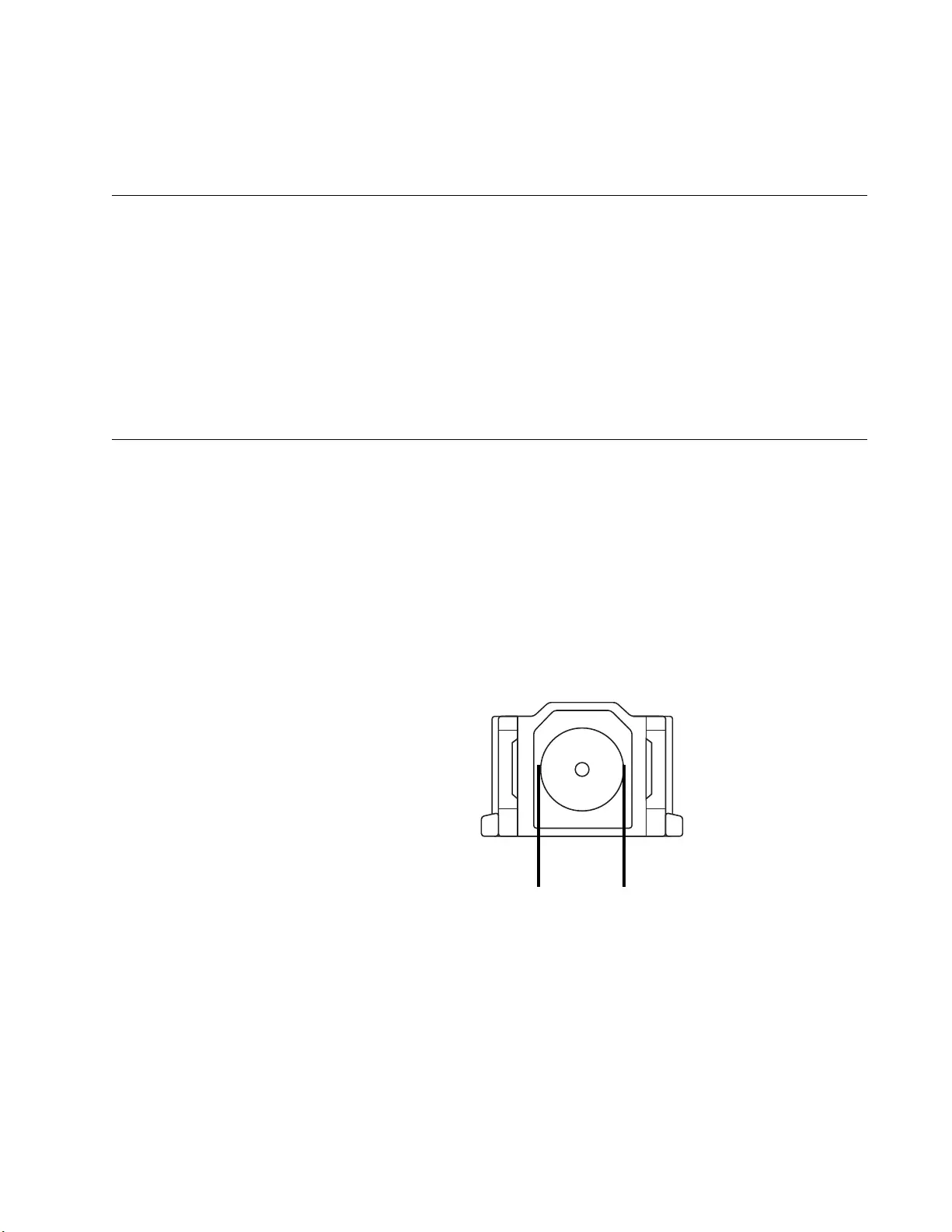

Figure 26 shows the ferrule in an SC connector.

Figure 26. Ferrule in an SC Connector Plug

177

Ferrule

IMC2000/200 Series Media Converter Installation Guide

54

The end face of an unclean and clean ferrule are shown in Figure 27.

Figure 27. Unclean and Clean Ferrule

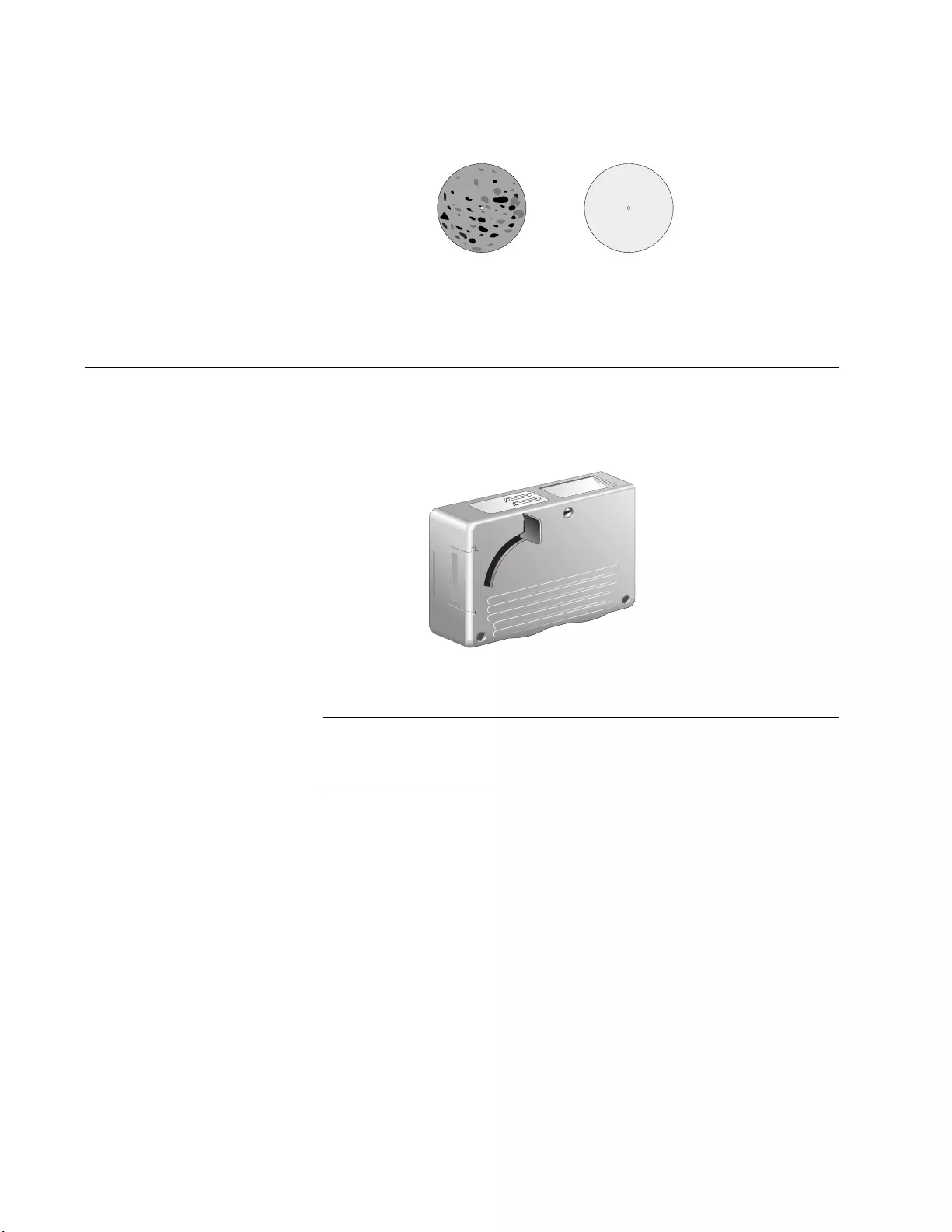

Using a Cartridge-Type Cleaner

Fiber-optic cartridge cleaners, shown in Figure 28, are available from

many vendors and are typically called “cartridge cleaners”.

Figure 28. Cartridge Cleaner

Note

Do not use compressed air or aerosol air to clean a fiber-optic

connector.

To clean a fiber-optic connector using a cartridge cleaner, perform the

following procedure.

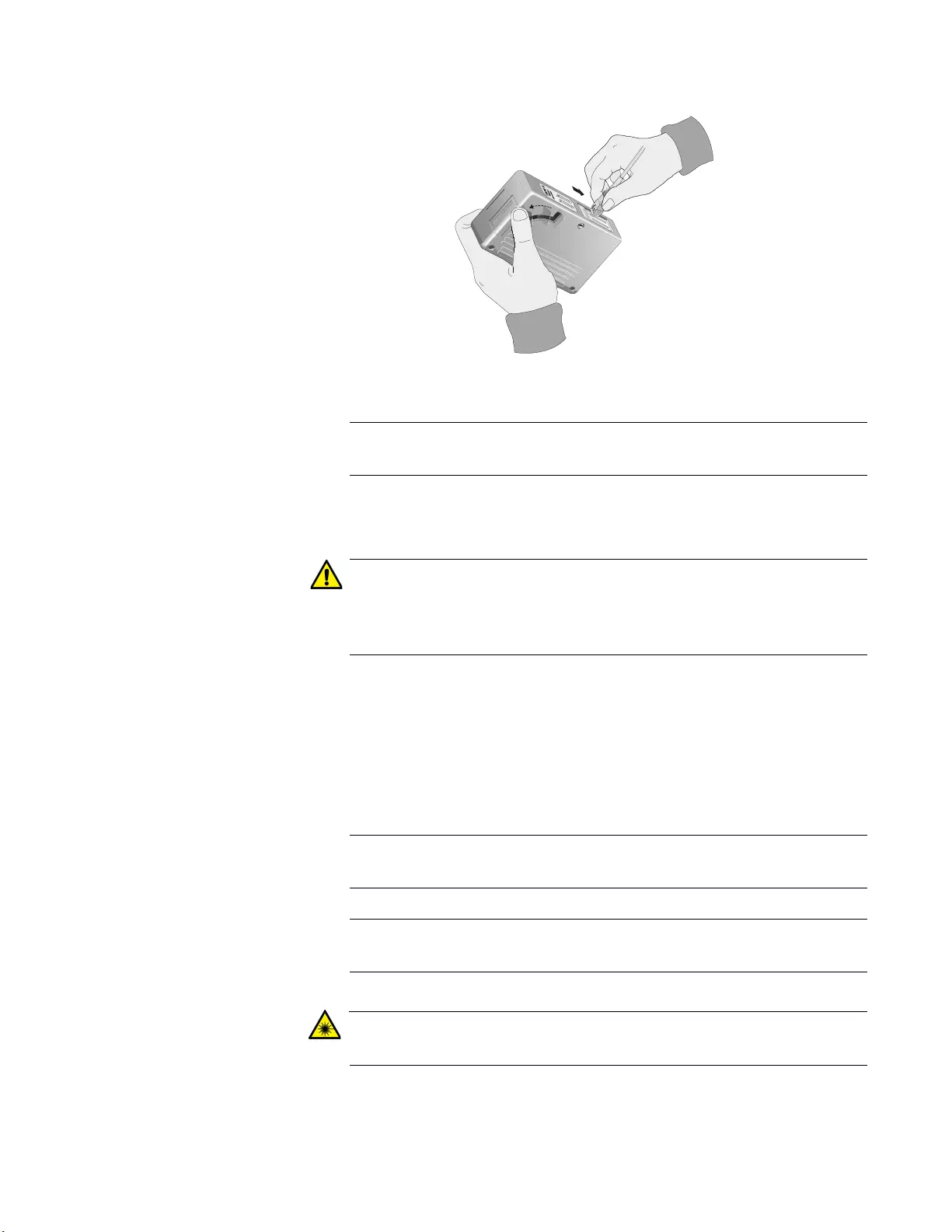

1. With one hand, hold the cartridge cleaner and push the lever on the

cleaning cartridge in the direction of the arrow to expose the cleaning

surface, as shown in Figure 29 on page 55.

2. Place the ferrule tip on the exposed cleaning surface and rub the

ferrule in a downward direction, as shown in Figure 29 on page 55.

156

Unclean Clean

TAPE A

Wiping

Direction

PUSH OPENPUSH OPEN

100

Appendix B: Cleaning Fiber-Optic Connectors

55

Figure 29. Rubbing the Ferrule Tip on the Cleaning Surface

Note

Rub the ferrule tip on the cleaning surface in one direction only.

3. When you reach the end of the cleaning surface, pick up the ferrule tip,

rotate and place it at the top, and rub downwards at least two times.

Caution

Failing to pick up the ferrule tip when you reach the bottom of the

cleaning surface can result in static electricity that can damage the

fiber-optic cable. E82

4. If desired, repeat Step 2 and Step 3.

5. If a fiber inspection scope is available, use the scope to inspect the

ferrule end face to make sure that it is clean.

6. Reconnect the cable to the port or protect the ferrule tip with a dust

cap.

Note

Always keep a dust cap on a fiber-optic cable when it is not in use.

Note

Do not touch the end face of the ferrule in the connector.

Warning

Do not stare into the laser beam. L2

102

IMC2000/200 Series Media Converter Installation Guide

56

Warning

Do not look directly at the fiber-optic cable ends or inspect the cable

ends with an optical lens. L6

Using a Swab

Specially treated swabs, or stick cleaners, are available for cleaning inside

connector adapters or hard-to-reach ferrule tips. These swabs, often

referred to as “lint-free” or “alcohol-free” swabs, shown in Figure 30, are

available from many vendors. Stick cleaners are available in both 2.5 mm

and 1.25 mm sizes for use on SC and MU connectors respectively.

Figure 30. Lint-Free and Alcohol-Free Swabs

Note

Never use a household cotton swab and alcohol to clean a fiber-

optic connector. This may leave a residue on the ferrule tip.

Note

Do not used compressed air or aerosol air to clean a fiber-optic

connector.

106

Appendix B: Cleaning Fiber-Optic Connectors

57

To clean a recessed ferrule using a swab, perform the following

procedure.

1. Insert the swab into the adapter as shown in Figure 31. Rub the ferrule

tip with the swab.

Figure 31. Cleaning a Recessed Ferrule

2. If desired, repeat Step 1.

3. If a fiber inspection scope is available, use the scope to inspect the

connector to make sure that it is clean and to check for scratches, pits,

or other problems that may affect performance.

Note

Always keep a dust cap on a fiber-optic cable when it is not in use.

Warning

Do not stare into the laser beam. L2

Warning

Do not look directly at the fiber-optic cable ends or inspect the cable

ends with an optical lens. L6

157

IMC2000/200 Series Media Converter Installation Guide

58