Table of Contents

- Contents

- Figures

- Tables

- Preface

- Chapter 1

- Chapter 2

- Overview of the Ethernet Line Cards

- Chapter 3

- Chapter 4

- Chapter 5

- Chapter 6

- Chapter 7

- Chapter 8

- Installing the Transceivers and Cabling the Ports

- Guidelines to Cabling the Twisted Pair Ports on AT-SBx31GP24, AT- SBx31GT24, and AT-SBx31GT40 Line Cards

- Guidelines to Installing SFP, SFP+, CSFP, and XFP Transceivers

- Installing SFP Transceivers in the AT-SBx31GS24 Line Card

- Installing SFP and CSFP Transceivers in the AT-SBx31GC40 Line Card

- Installing SFP+ Transceivers in the AT-SBx31XS6 Line Card

- Installing AT-SP10TW Cables in the AT-SBx31XS6 Line Card

- Installing XFP Transceivers in the AT-SBx31XZ4 Line Card

- Cabling the NET MGMT Port on the AT-SBx31CFC Card

- Installing the Transceivers and Cabling the Ports

- Chapter 9

- Powering On the Chassis

- Verifying the Installation

- Powering On the AT-SBxPWRSYS1 or AT-SBxPWRSYS2 AC System Power Supply

- Powering on the AT-SBxPWRPOE1 AC PoE Power Supply

- Powering On the AT-SBxPWRSYS1 DC System Power Supply

- Choosing a Method for Attaching the Grounding Wire

- Connecting the Grounding Wire with the Grounding Terminal

- Connecting the Grounding Wire with Bare Wire

- Choosing a Method for Attaching the Power Wires

- Connecting the DC Power Wires with the Straight Terminals

- Connecting the DC Power Wires with the Right Angle Terminals

- Connecting Bare DC Power Wires

- Monitoring the Initialization Process

- Powering On the Chassis

- Chapter 10

- Chapter 11

- Troubleshooting

- AT-SBxPWRSYS1, AT-SBxPWRSYS2, or AT-SBxPWRPOE1 AC Power Supply

- AT-SBxPWRSYS1 DC System Power Supply

- Ethernet Line Cards

- Twisted Pair Ports

- Power Over Ethernet

- Fiber Optic Transceivers

- AT-SBx31CFC Controller Fabric Card

- AT-SBxFAN12 Fan Module

- Local (Out-of-Band) Management Session

- Power Supply Interfaces (Opto-couplers)

- Troubleshooting

- Chapter 12

- Appendix A

Allied Telesis AT-SBX31GS24 User Manual

Displayed below is the user manual for AT-SBX31GS24 by Allied Telesis which is a product in the Network Switch Modules category. This manual has pages.

Related Manuals

613-002222 Rev. A

SwitchBlade x3112

Access Edge Chassis Switch

AT-SBx31CFC

Controller Fabric Card (R17.2.1)

AT-SBx3112 Chassis

AT-SBx31GT24 Line Card

AT-SBx31GT40 Line Card

AT-SBx31GP24 PoE Line Card

AT-SBx31GS24 SFP Line Card

AT-SBx31GC40 SFP CSFP BiDi Line Card

AT-SBx31XZ4 XFP Line Card

AT-SBx31XS6 SFP+ Line Card

AT-SBxPWRSYS1 and AT-SBxPWRSYS2 System Power Supplies

AT-SBxPWRPOE1 PoE Power Supply

Installation Guide

Copyright © 2015 Allied Telesis, Inc.

All rights reserved. No part of this publication may be reproduced without prior written permission from Allied Telesis,

Inc.

Allied Telesis and the Allied Telesis logo are trademarks of Allied Telesis, Incorporated. All other product names,

company names, logos or other designations mentioned herein are trademarks or registered trademarks of their respective

owners.

Allied Telesis, Inc. reserves the right to make changes in specifications and other information contained in this document

without prior written notice. The information provided herein is subject to change without notice. In no event shall Allied

Telesis, Inc. be liable for any incidental, special, indirect, or consequential damages whatsoever, including but not limited

to lost profits, arising out of or rel ated to this manual or the information contained herein, even if Allied Telesis, Inc. has

been advised of, known, or should have known, the possibilit y of such damages.

3

Electrical Safety and Emissions Standards

This product meets the following standards.

EMI/RFI Emissions: FCC Class A, EN55022 Class A, EN61000-3-2, EN61000-3-3, CISPR Class A,

VCCI Class A, AS/NZS Class A

Immunity: EN55024

Electrical Safety: EN60950-1 (TUV), UL 60950-1 (CULUS), EN60825

Safety Agency Approvals: CULUS, TUV, C-TICK, CE

U.S. Federal Communications Commission

Radiated Energy

Note: This equipment has been tested and found to comply with the limits for a Class A digital device pursuant to Part 15

of FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with this instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a resid ential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense.

Note: Modifications or changes not expressly approved of by the manufacturer or the FCC, can void your right to operate

this equipment.

Industry Canad a

This Class A digital apparatus complies with Canadia n ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

European Union Restriction of the Use of Certain Hazardous Substances

(RoHS) in Electrical and Electronic Equipment

This Allied Telesis RoHS-compliant product conforms to the European Union Restriction of the Use of Certain Hazardous

Substances (RoHS) in Electrical and Electronic Equipment. Allied Telesis ensures RoHS conformance by requiring

supplier Declarations of Conformity, monitoring incoming materials, and maintaining manufacturing process controls.

Warning: In a domestic environment this product may cause radio interference in

which case the user may be required to take adequate measures.

Laser Safety EN60825

5

Preface ............................................................................................................................................................15

Safety Symbols Used in this Document ...........................................................................................................16

Contacting Allied Telesis ..................................................................................................................................17

Chapter 1: Overview of the Chassis and Power Supplies .........................................................................19

AT-SBx3112 Chassis .......................................................................................................................................20

Slots for the Ethernet Line and Controller Cards..............................................................................................23

Power Supplies and Power Supply Slots .........................................................................................................24

LEDs ..........................................................................................................................................................26

AT-SBxFAN12 Module .....................................................................................................................................29

LED ............................................................................................................................................................29

Power Supply Interfaces (Opto-couplers).........................................................................................................30

LED ............................................................................................................................................................30

Chapter 2: Overview of the Ethernet Line Cards ........................................................................................31

Ethernet Line Cards... ................ ... .... ... ... ... .... ... ... ... ................ .... ... ... ... .... ... ... ... ... .... .........................................32

AT-SBx31GT24 Line Card................................................................................................................................33

LEDs ..........................................................................................................................................................33

AT-SBx31GT40 Line Card................................................................................................................................35

LEDs ..........................................................................................................................................................36

AT-SBx31GP24 PoE Line Card........................................................................................................................38

LEDs ..........................................................................................................................................................39

AT-SBx31GS24 SFP Line Card .......................................................................................................................41

LEDs ..........................................................................................................................................................41

AT-SBx31GC40 Line Card ...............................................................................................................................43

Port Numbers................ ... ... ................ .... ... ... ... ... .... ... ................ ... .... ... ... ... ... ................. ............................44

LEDs ..........................................................................................................................................................46

AT-SBx31XZ4 XFP Line Card..........................................................................................................................49

LEDs ..........................................................................................................................................................49

AT-SBx31XS6 SFP+ Line Card........................................................................................................................51

LEDs ..........................................................................................................................................................51

10/100/1000Base-T Twisted Pair Ports............................................................................................................53

Connector Type...... ... .... ................ ... ... .... ... ................ ... ... .... ... ... ................ ... .... ... ... ...................................53

Speed.........................................................................................................................................................53

Duplex Mode............. .... ... ... ... .... ... ................ ... ... .... ... ... ... .... ................ ... ... ... .... ... ... ...................................53

Maximum Distance.....................................................................................................................................54

Cable Requirements ..................................................................................................................................54

Automatic MDIX Detection......................... ... ... ... .... ... ... ... .... ... ... ... .... ... ................ ... ... .... ... ... ... ...................55

Straight-through or Crossover Cabling.......................................................................................................55

Port Pinouts............ ................ .... ... ... ... ................ .... ... ... ... .... ................ ... ... ... .... .........................................56

Power over Ethernet on the AT-SBx31GP24 Line Card...................................................................................57

Powered Device Classes ...........................................................................................................................57

Power Budgeting........................................................................................................................................58

PoE Wiring .................................................................................................................................................58

Contents

Contents

6

Chapter 3: Overview of the AT-SBx31CFC Controller Fabric Card .......................................................... 61

Controller Fabric Cards for the AT-SBx3112 Chassis...................................................................................... 62

Hardware Components on the AT-SBx31CFC Card........................................................................................ 64

Guidelines........................................................................................................................................................ 66

Dual Controller Cards ...... ... ... .... ... ... ................ .... ... ... ... ... .... ... ... ... ................. ... ... ... ... .... ... ............................... 68

SYS Status LEDs............................................................................................................................................. 69

eco-friendly Button ........................................................................................................................................... 70

SBx Linecard Status LEDs.................. .... ... ... ... ................ .... ... ... ... .... ... ... ... .... ................ ... ... ... ......................... 71

Console (RS-232) Port..................................................................................................................................... 72

NET MGMT Port .............................................................................................................................................. 73

NET MGMT Port LED................................................................................................................................ 75

SD Card Slot .................................................................................................................................................... 76

SD Status LED .......................................................................................................................................... 76

Reset Button .................................................................................................................................................... 78

Chapter 4: Safety Precautions and Site Preparation ................................................................................. 81

Reviewing Safety Precautions ......................................................................................................................... 82

Selecting a Site for the SwitchBlade x3112 ..................................................................................................... 86

Installation Tools and Material ......................................................................................................................... 88

Chapter 5: Installing the Chassis in an Equipment Rack .......................................................................... 89

Required Tools and Material............................................................................................................................ 90

Preparing the Equipment Rack ........................................................................................................................ 91

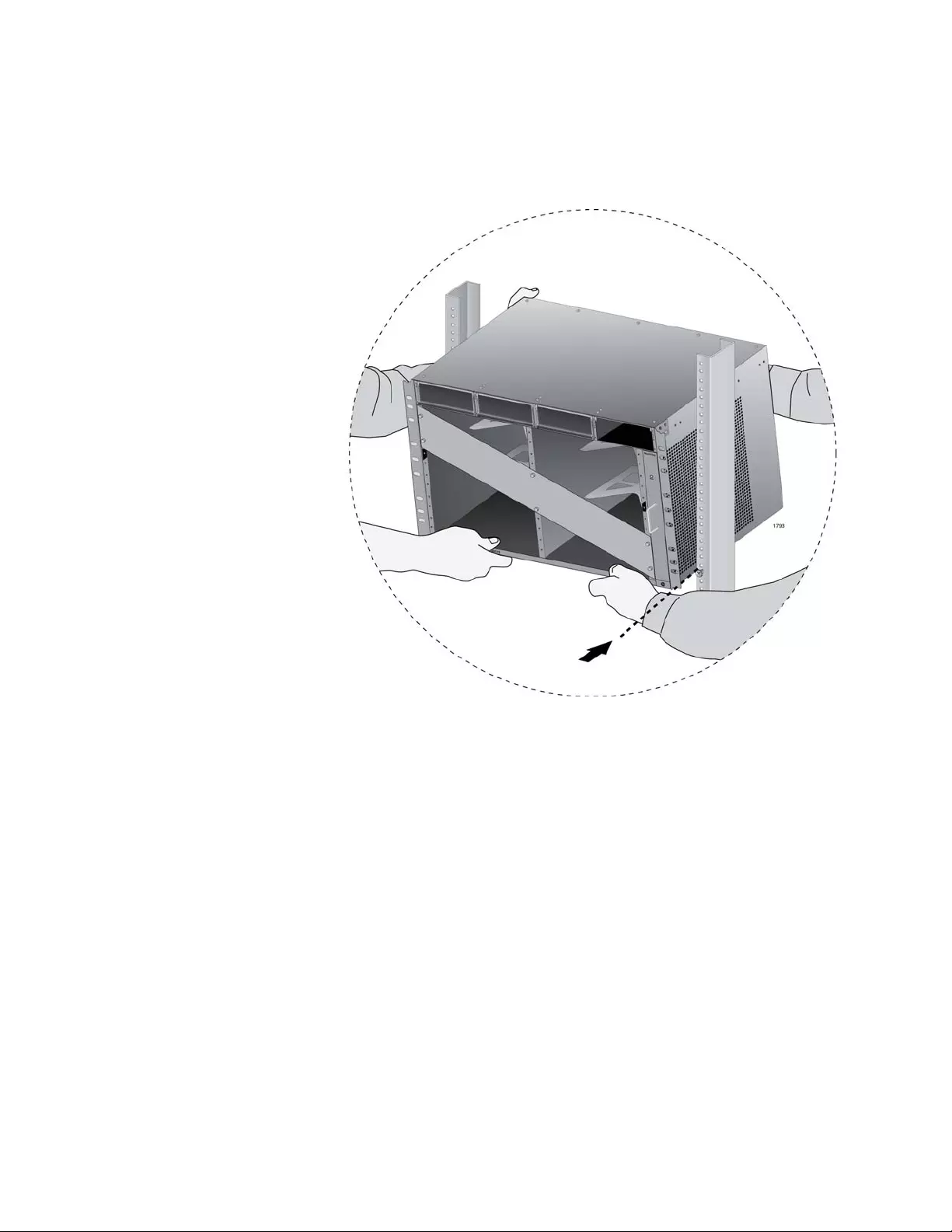

Unpacking the AT-SBx3112 Chassis............................................................................................................... 94

Adjusting the Equipment Rack Brackets.......................................................................................................... 96

Installing the AT-SBx3112 Chassis in the Equipment Rack............................................................................. 98

Removing the Shipping Brace ....................................................................................................................... 101

Installing the Chassis Grounding Lug ............................................................................................................ 102

Chapter 6: Installing the Power Supplies ....... ... ... ................ ... .... ... ... ... .... ... ... ... ................ .... ... ... ............. 105

Protecting Against Electrostatic Discharge (ESD) ......................................................................................... 106

Installing the AT-SBxPWRSYS1 or AT-SBxPWRSYS2 AC System Power Supply....................................... 107

Installing the AT-SBxPWRPOE1 AC Power Supply ...................................................................................... 113

Installing the AT-SBxPWRSYS1 DC System Power Supply.......................................................................... 119

Chapter 7: Installing the AT-SBx31CFC Card and Ethernet Line Cards ................................................ 127

Guidelines to Handling the Controller and Line Cards................................................................................... 128

Installing the AT-SBx31CFC Controller Fabric Card...................................................................................... 130

Installing the Ethernet Line Cards.................................................................................................................. 136

Installing the Blank Slot Covers ..................................................................................................................... 140

Chapter 8: Installing the Transceivers and Cabling the Ports ................................................................ 143

Guidelines to Cabling the Twisted Pair Ports on AT-SBx31GP24, AT-SBx31GT24, and AT-SBx31GT40

Line Cards...................................................................................................................................................... 144

Connecting Cables to the AT-SBx31GT40 Line Card ............................................................................. 145

Guidelines to Installing SFP, SFP+, CSFP, and XFP Transceivers............................................................... 147

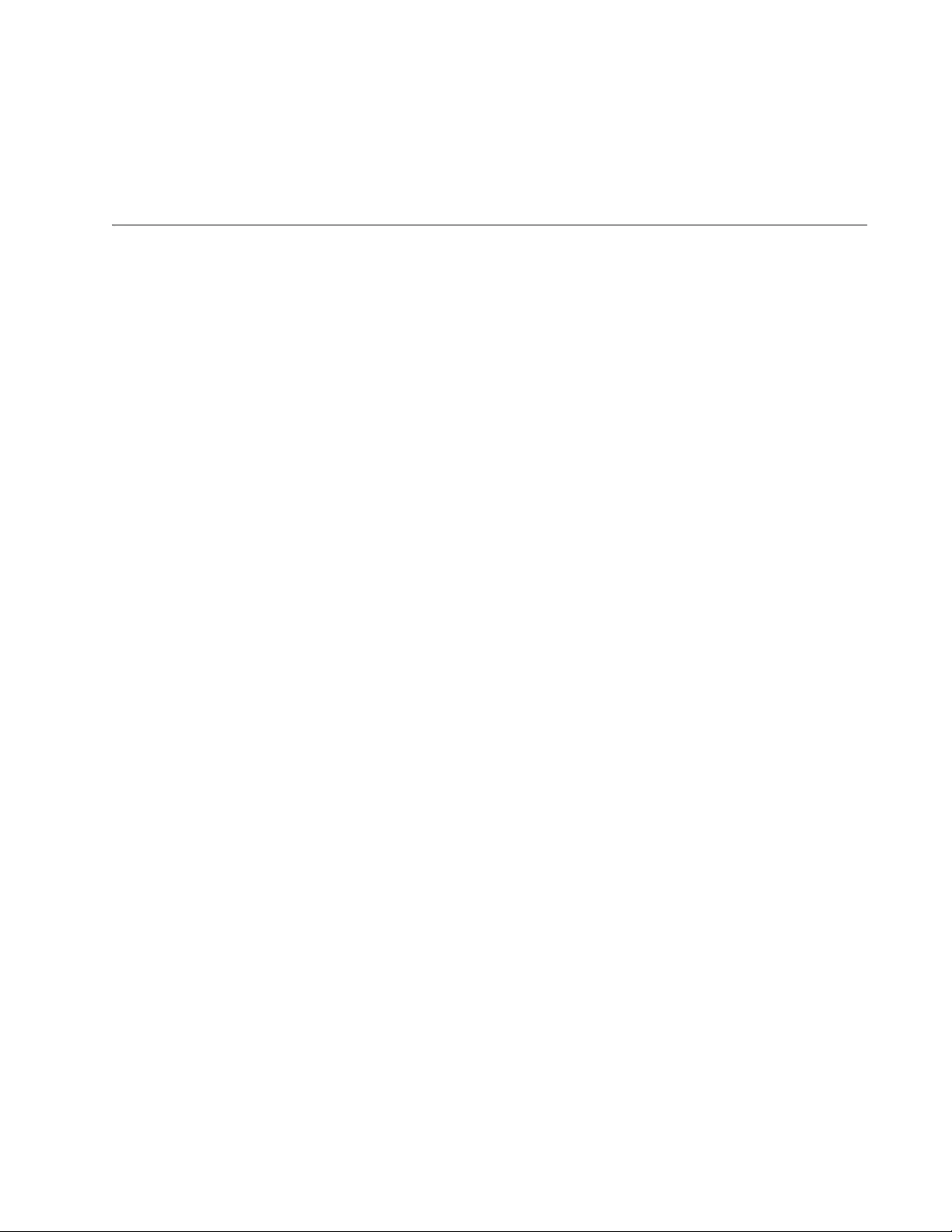

Installing SFP Transceivers in the AT-SBx31GS24 Line Card .................. .... ... ... ... ... .... ... ... ... .... ... ... ... .......... 148

Installing SFP and CSFP Transceivers in the AT-SBx31GC40 Line Card..................................................... 151

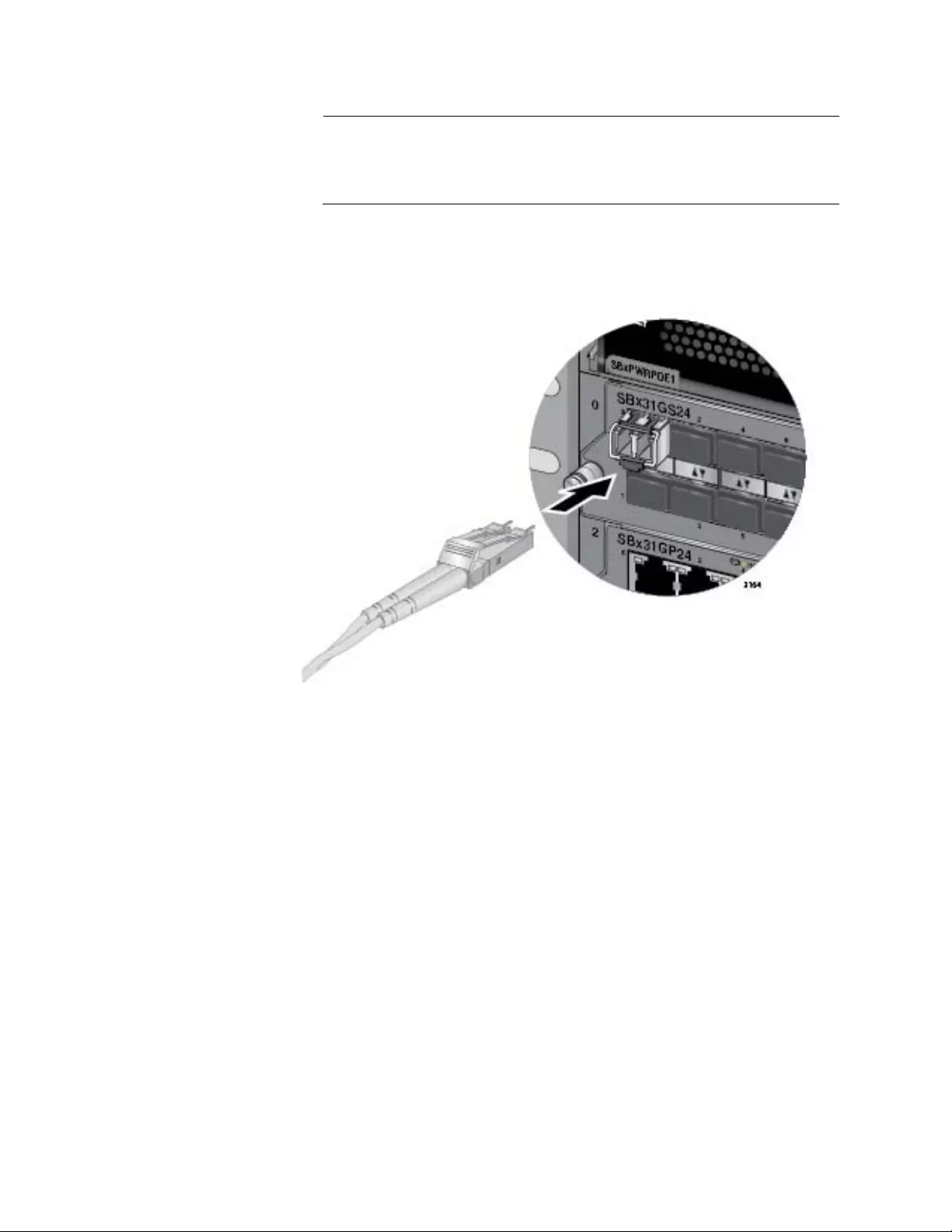

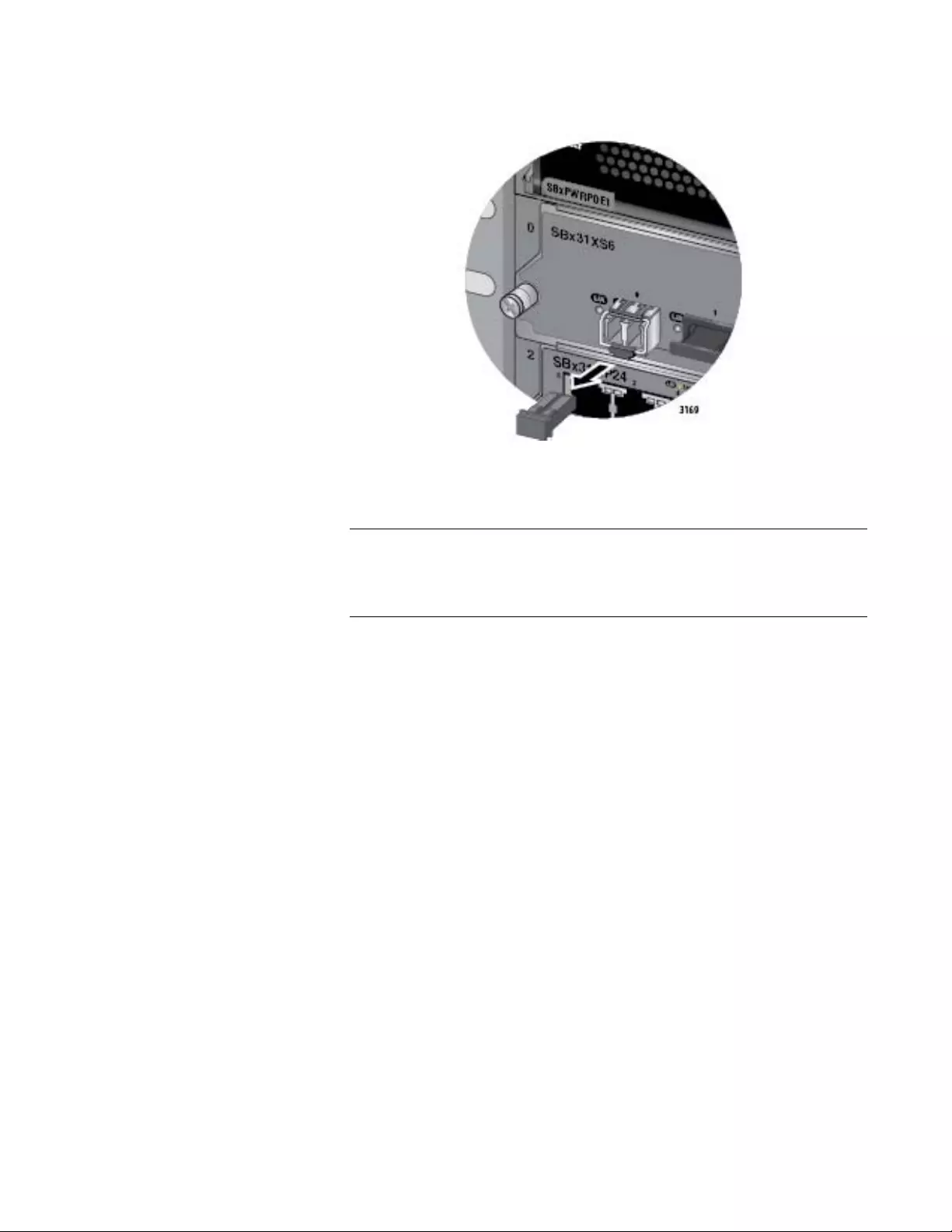

Installing SFP+ Transceivers in the AT-SBx31XS6 Line Card.......................................................................155

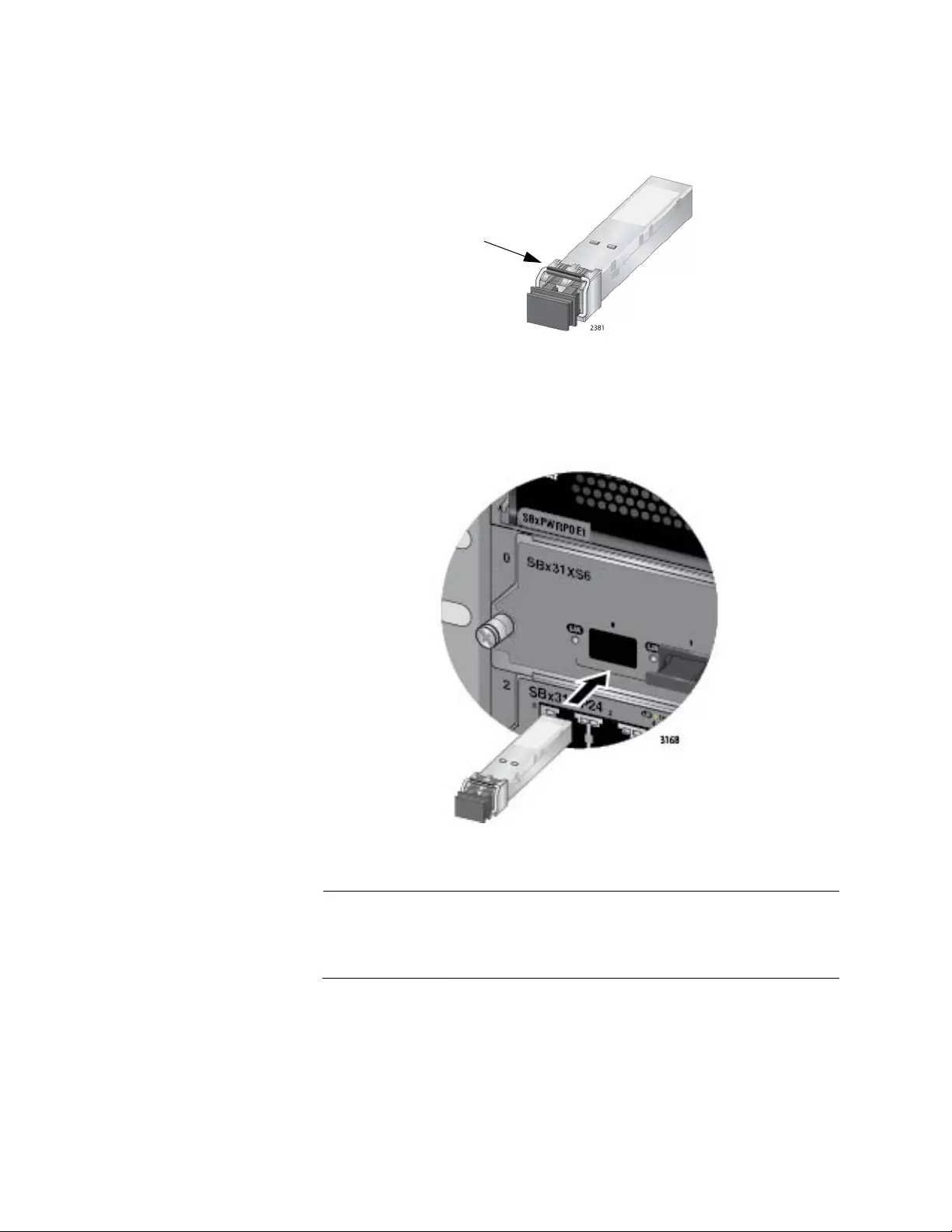

Installing AT-SP10TW Cables in the AT-SBx31XS6 Line Card..................................................................... 159

Installing XFP Transceivers in the AT-SBx31XZ4 Line Card......................................................................... 161

Cabling the NET MGMT Port on the AT-SBx31CFC Card............................................................................. 165

Chapter 9: Powering On the Chassis ........................................................................................................ 167

Verifying the Installation................................................................................................................................. 168

Powering On the AT-SBxPWRSYS1 or AT-SBxPWRSYS2 AC System Power Supply................................ 169

Powering on the AT-SBxPWRPOE1 AC PoE Power Supply......................................................................... 172

Powering On the AT-SBxPWRSYS1 DC System Power Supply................................................................... 175

SwitchBlade x3112 Chassis Switch and AT-SBx31CFC Card Installation Guide

7

Choosing a Method for Attaching the Grounding Wire.............................................................................177

Connecting the Grounding Wire with the Grounding Terminal...... ...........................................................177

Connecting the Grounding Wire with Bare Wire ......................................................................................180

Choosing a Method for Attaching the Power Wires .................................................................................181

Connecting the DC Power Wires with the Straight Terminals..................................................................182

Connecting the DC Power Wires with the Right Angle Terminals............................................................190

Connecting Bare DC Power Wires............. ... ... ................ .... ... ... ... .... ... ... ... ... .... ... ... ... .... ..........................196

Monitoring the Initialization Process....... ... .... .................................................................................................200

Using the LEDs to Monitor the Initialization Process ...............................................................................201

Using the Console Port to Monitor the Initializ ation Proc ess ...................................................................202

Chapter 10: Verifying the Hardware Operations of the Chassis .............................................................205

Using the LEDs to Verify the Chassis........ .... ... ... ... ... .... ... ................ ... .... ... ... ... ... .... ... ... .................................206

Using Local Management to Verify the Chassis.............................................................................................208

Starting a Local Management Session ....................................................................................................208

Entering the Management Software Commands .....................................................................................209

Chapter 11: Troubleshooting .....................................................................................................................213

AT-SBxPWRSYS1, AT-SBxPWRSYS2, or AT-SBxPWRPOE1 AC Power Supply. ... ... ... .... ... ... ... ... .... ... ... ... .214

AT-SBxPWRSYS1 DC System Power Supply ...............................................................................................216

Ethernet Line Cards... ................ ... .... ... ... ... .... ... ... ... ................ .... ... ... ... .... ... ... ... ... .... .......................................218

Twisted Pair Ports ..........................................................................................................................................220

Power Over Ethernet......................................................................................................................................222

Fiber Optic Transceivers ........ ... ... .... ... ... ... .... ... ................ ... ... .... ... ... ... .... ... ... ................ ... .... ..........................224

AT-SBx31CFC Controller Fabric Card ...........................................................................................................226

AT-SBxFAN12 Fan Module............................................................................................................................228

Local (Out-of-Band) Management Session ....................................................................................................229

Power Supply Interfaces (Opto-couplers).......................................................................................................230

Chapter 12: Replacing Modules .................................................................................................................231

Replacing the AT-SBxPWRSYS1, AT-SBxPWRSYS2 AC, or AT-SBxPWRPOE1 Power Supply....... ..........232

Replacing the AT-SBxPWRSYS1 DC Power Supply .....................................................................................238

Replacing Ethernet Line Cards.. ... .... ................ ... ... ... .... ... ... ... .... ... ... ... .... ... ... ................ ... .... ... .......................250

Replacing the AT-SBx31CFC Controller Fabric Card ... .................................................................................253

Replacing the AT-SBxFAN12 Fan Module.... ... ... ... ........................................................................................256

Removing the AT-SBxFAN12 Fan Module ..............................................................................................256

Installing the New AT-SBxFAN12 Fan Module ........................................................................................259

Appendix A: Technical Specifications ......................................................................................................263

Physical Specifications...................................................................................................................................263

Environmental Specifications ........... ... ... ... .... ... ... ... ... .... ... ... ... ................. ... ... ... ... .... ... ... ... .... ... .......................265

Power Specifications ......................................................................................................................................266

Safety and Electromagnetic Emissions Certifications ....................................................................................269

Port Pinouts..... ................ .... ... ... ... .... ................ ... ... ... .... ................ ... ... .... ... ... .................................................270

Contents

8

9

Figures

Figure 1: AT-SBx3112 Chassis ....................................................................................................................... 20

Figure 2: Front View of the AT-SBx3112 Chassis........................................................................................... 21

Figure 3: Rear View of the AT-SBx3112 Chassis............................................................................................ 22

Figure 4: AT-SBx3112 Chassis with Line Cards, Controller Cards, and Power Supplies ............................... 22

Figure 5: Slots for the Ethernet Line and Controller Cards.............................................................................. 23

Figure 6: Power Supply Units.......................................................................................................................... 24

Figure 7: Power Supply Slots .......................................................................................................................... 25

Figure 8: AT-SBxFAN12 Module..................................................................................................................... 29

Figure 9: Power Supply Interfaces (Opto-couplers) ........................................................................................ 30

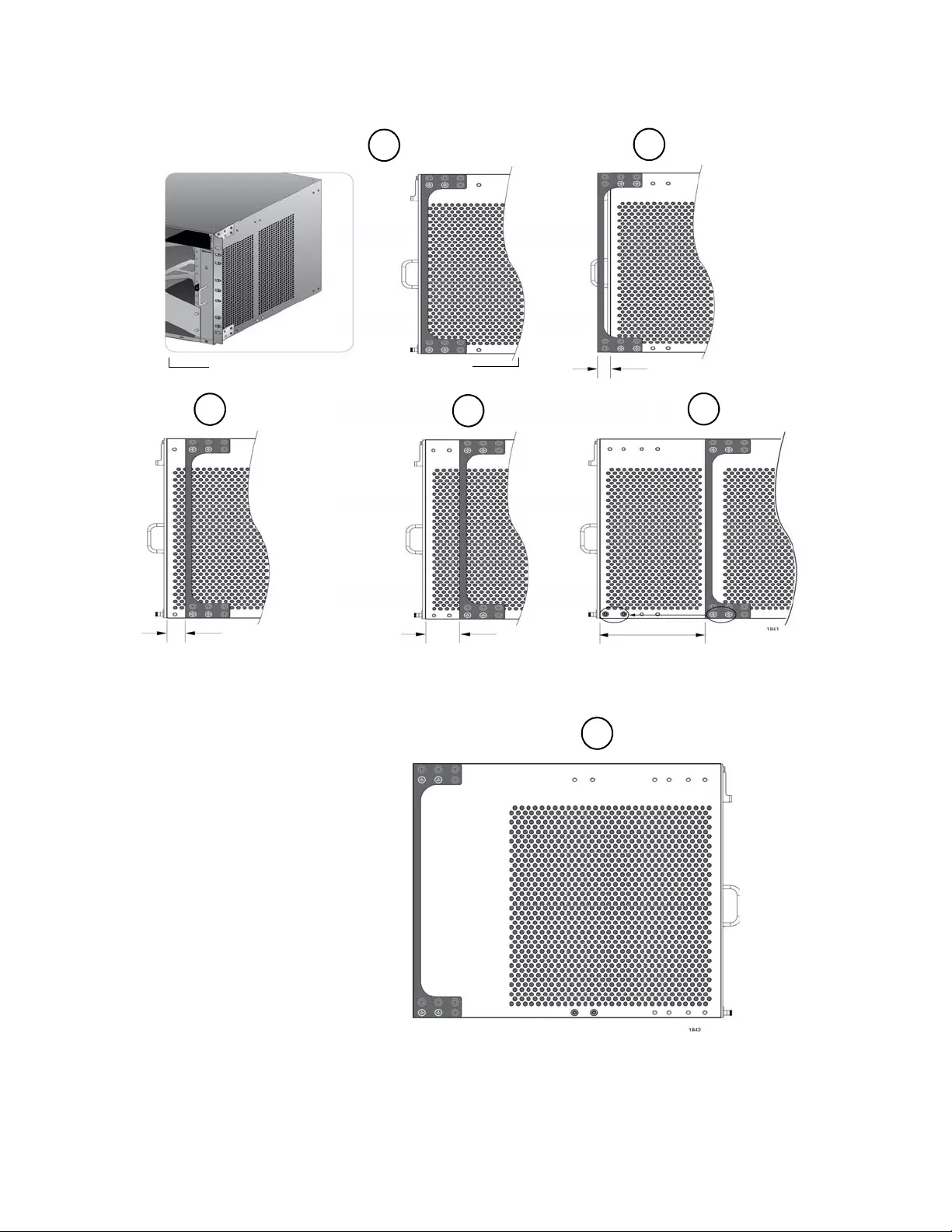

Figure 10: Ethernet Line Cards ....................................................................................................................... 32

Figure 11: AT-SBx31GT24 Line Card ............................................................................................................. 33

Figure 12: Port LEDs on the AT-SBx31GT24 Line Card................................................................................. 34

Figure 13: AT-SBx31GT40 Line Card ............................................................................................................. 35

Figure 14: Port LEDs on an RJ Point 5 Cable Connector for the AT-SBx31GT40 Line Card ......................... 36

Figure 15: Link/Activity LED on an RJ Point 5 Cable C onnector for the AT-SBx31GT40 Line Card............... 36

Figure 16: AT-SBx31GP24 PoE Line Card ..................................................................................................... 38

Figure 17: Port LEDs on the AT-SBx31GP24 PoE Line Card.......... ... .... ................ ... ... ... .... ... ................ ... ... .. 39

Figure 18: AT-SBx31GS24 SFP Line Card ..................................................................................................... 41

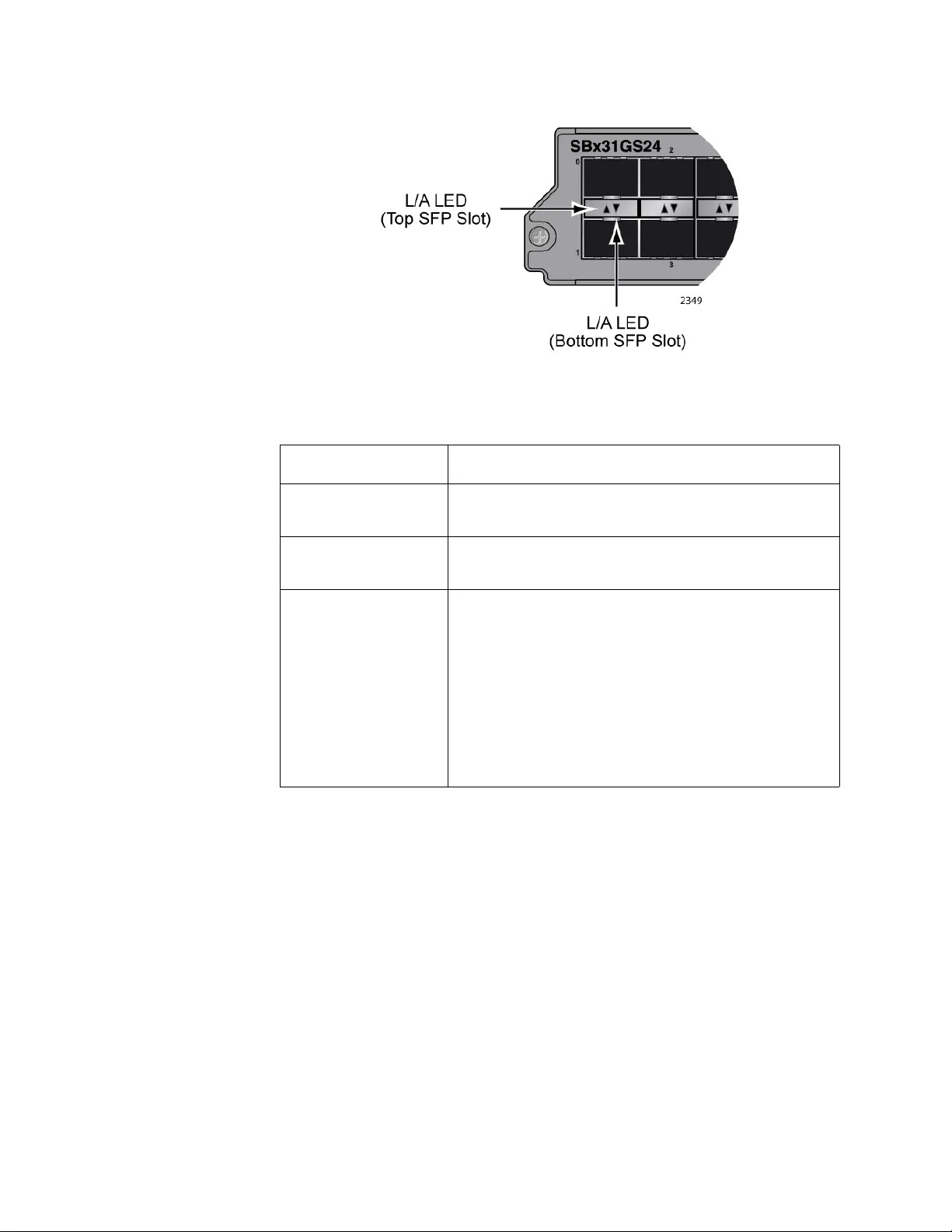

Figure 19: Port LEDs on the AT-SBx31GS24 SFP Line Card.................... ................ ... ... .... ... ................ ... ... .. 42

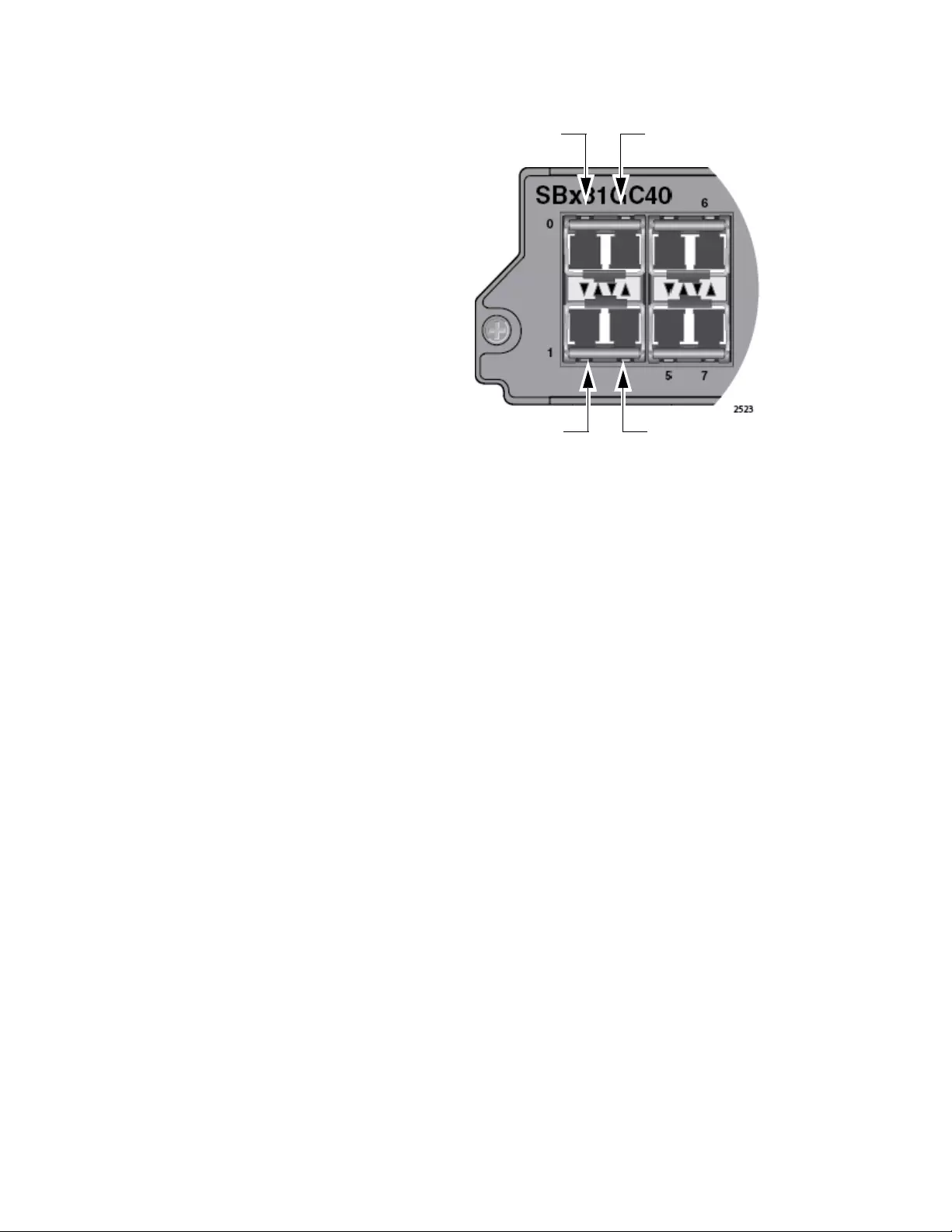

Figure 20: AT-SBx31GC40 Line Card............................................................................................................. 43

Figure 21: Port Numbers for Slots with CSFP Transceivers ...... ... ... ................ ... .... ... ... ... .... ... ... ... ... .... ... ... ..... 45

Figure 22: Port Numbers for Slots with Standard SFP Transceivers .............................................................. 46

Figure 23: LEDs for the AT-SBx31GC40 Line Card........................................................................................ 46

Figure 24: LEDs for the AT-SBx31GC40 Line Card, with CSFP Transceivers ... .... ... ... ... .... ... ... ... ... .... ... ... ... .. 47

Figure 25: LEDs for the AT-SBx31GC40 Line Card, with SFP Transceivers.................................................. 47

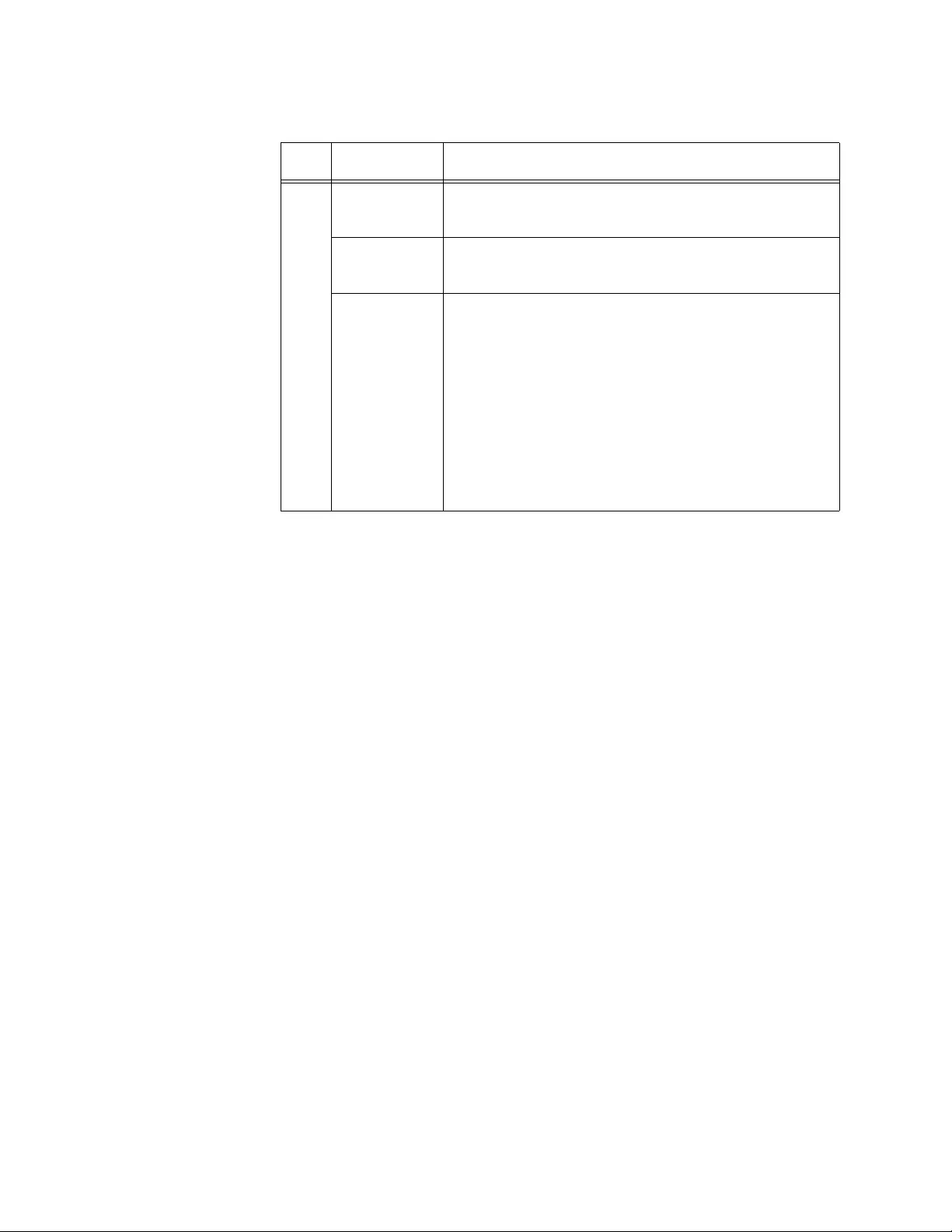

Figure 26: AT-SBx31XZ4 XFP Line Card........................................................................................................ 49

Figure 27: Transceiver Slot LEDs on the AT-SBx31XZ4 XFP Line Card........................................................ 50

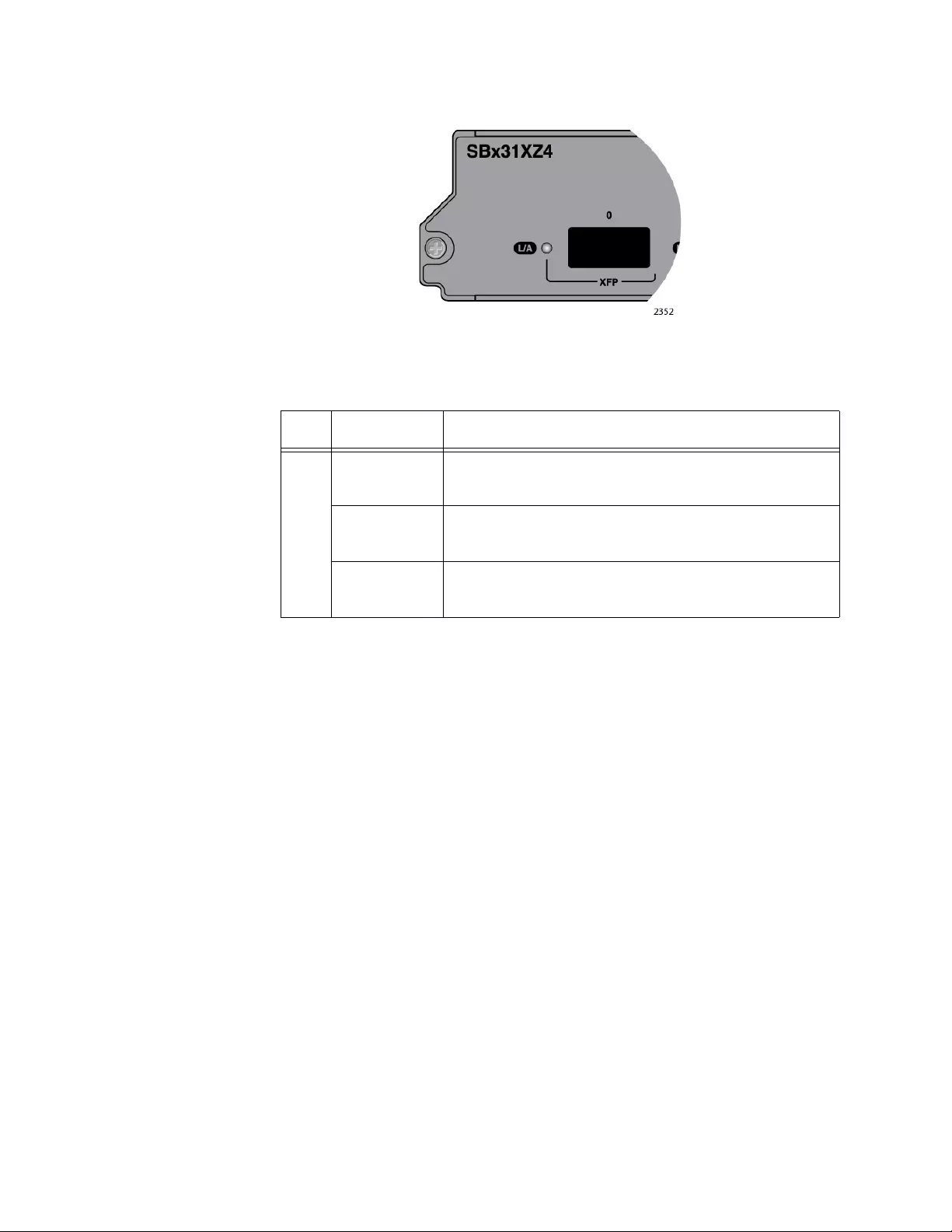

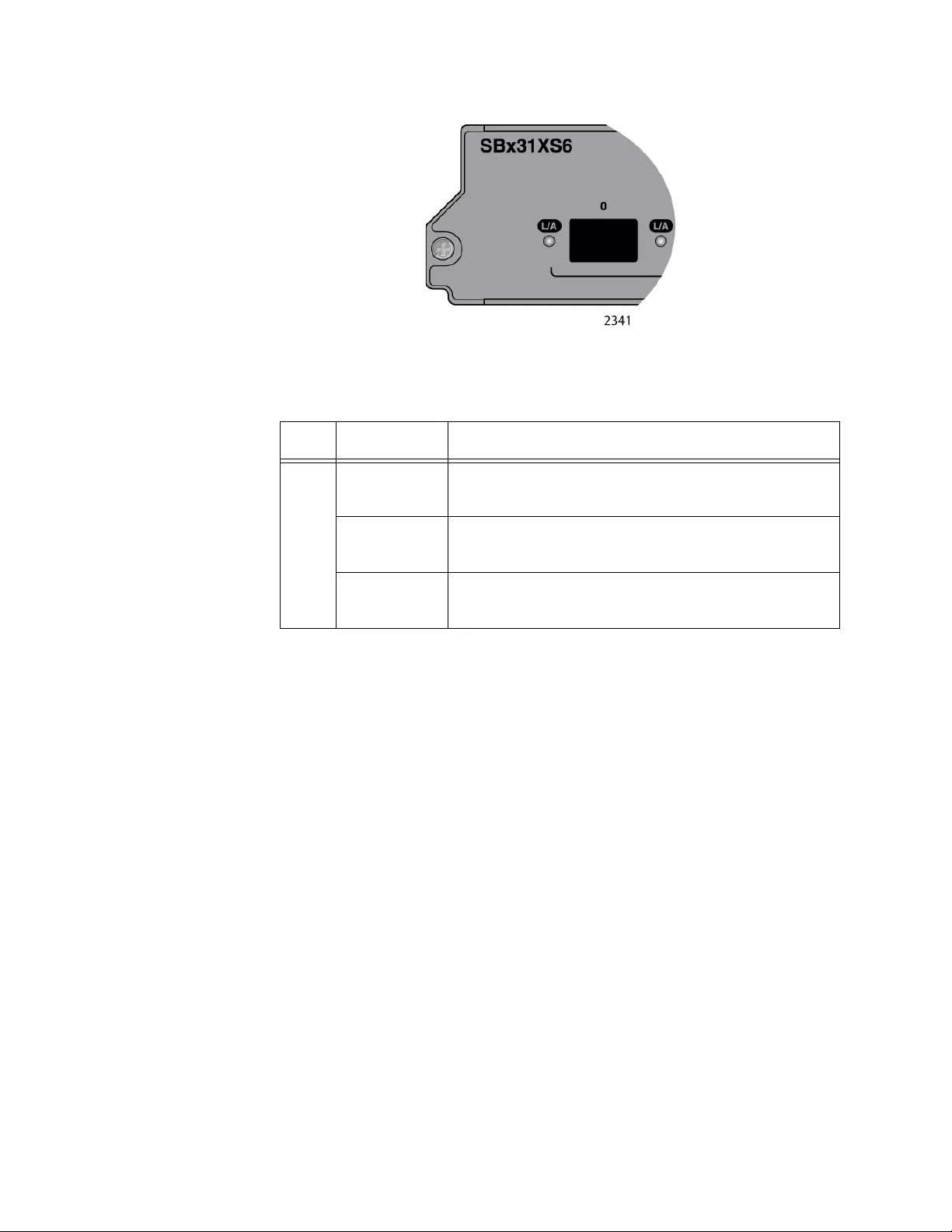

Figure 28: AT-SBx31XS6 Line Card................................................................................................................ 51

Figure 29: SFP+ Slot LEDs on the AT-SBx31XS6 Line Card.......................................................................... 52

Figure 30: Controller Fabric Cards for the AT-SBx3112 Chassis.. ... ... .... ... ... ... ... .... ... ... ... .... ... ... ... ... .... ... ........ 62

Figure 31: AT-SBx31CFC Controller Fabric Card ........................................................................................... 64

Figure 32: 100 - 125 VAC 125 V NEMA 5-20 Plug and Receptacle................................................................ 87

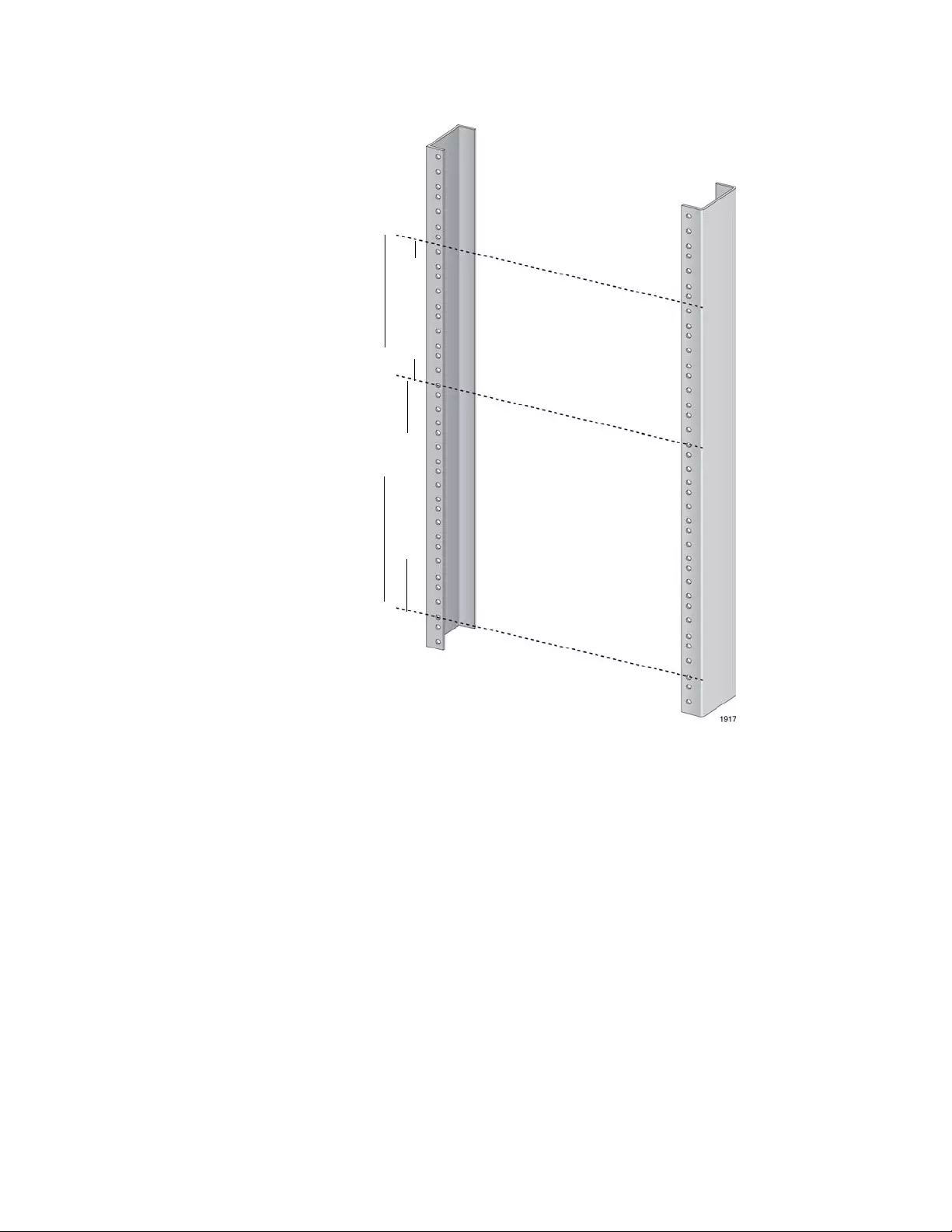

Figure 33: Reserving Vertical Rack Space.................... ... ... ... ................. ... ... ... ... .... ... ................ ... .................. 92

Figure 34: Rack Mounting Hole Locations....................................................................................................... 93

Figure 35: AT-SBx3112 Chassis Items ........................................................................................................... 94

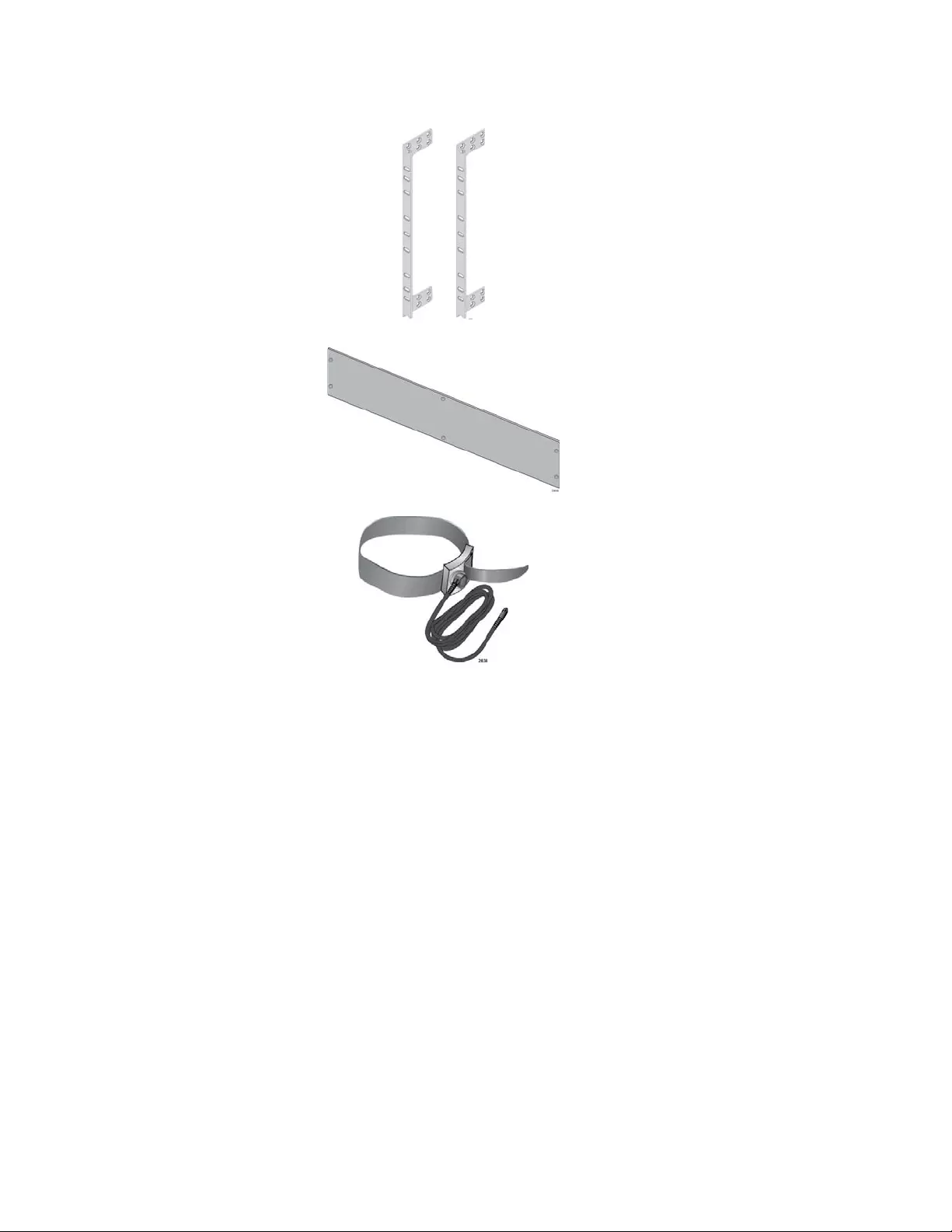

Figure 36: AT-SBx3112 Chassis Items (Continued)........................................................................................ 95

Figure 37: Rack Mounting Bracket Locations.................................................................................................. 97

Figure 38: Rack Bracket Locations for Reverse Position of Chassis .............................................................. 97

Figure 39: Lifting the AT-SBx3112 Chassis into the Equipment Rack ............................................................ 99

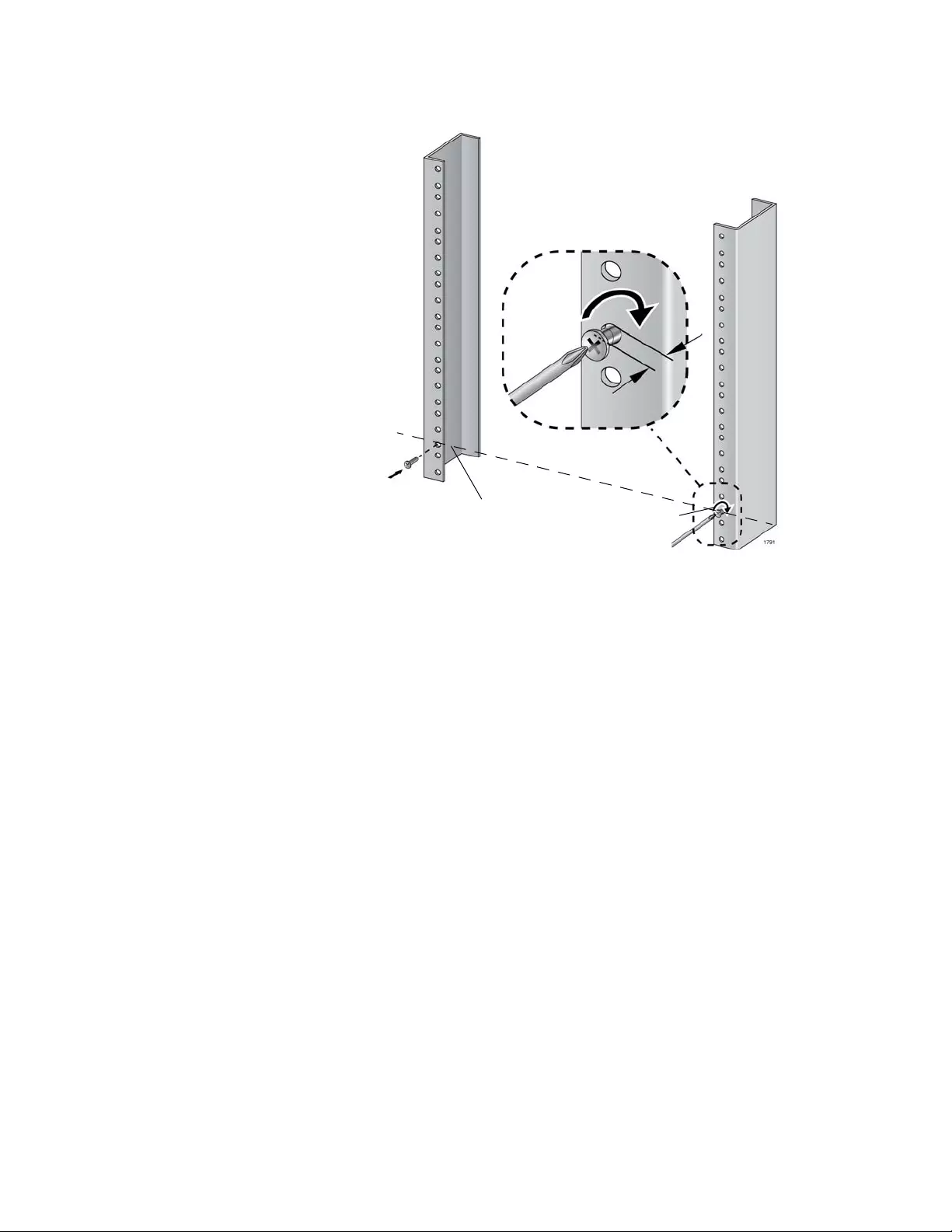

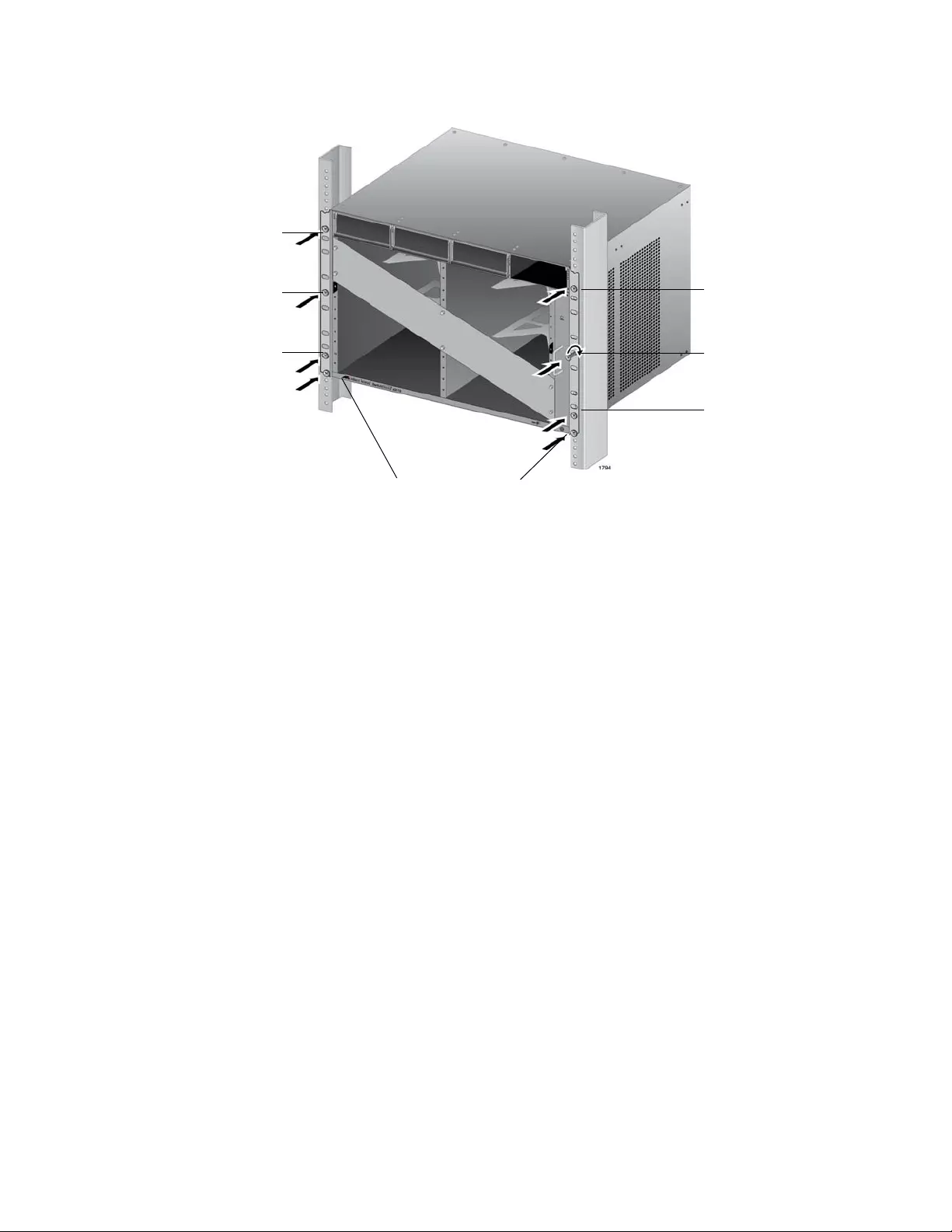

Figure 40: Installing the Rack Mount Screws ............ .... ... ... ... .... ... ................ ... ... .... ... ... ................ ... ............. 100

Figure 41: Removing the Shipping Brace...................................................................................................... 101

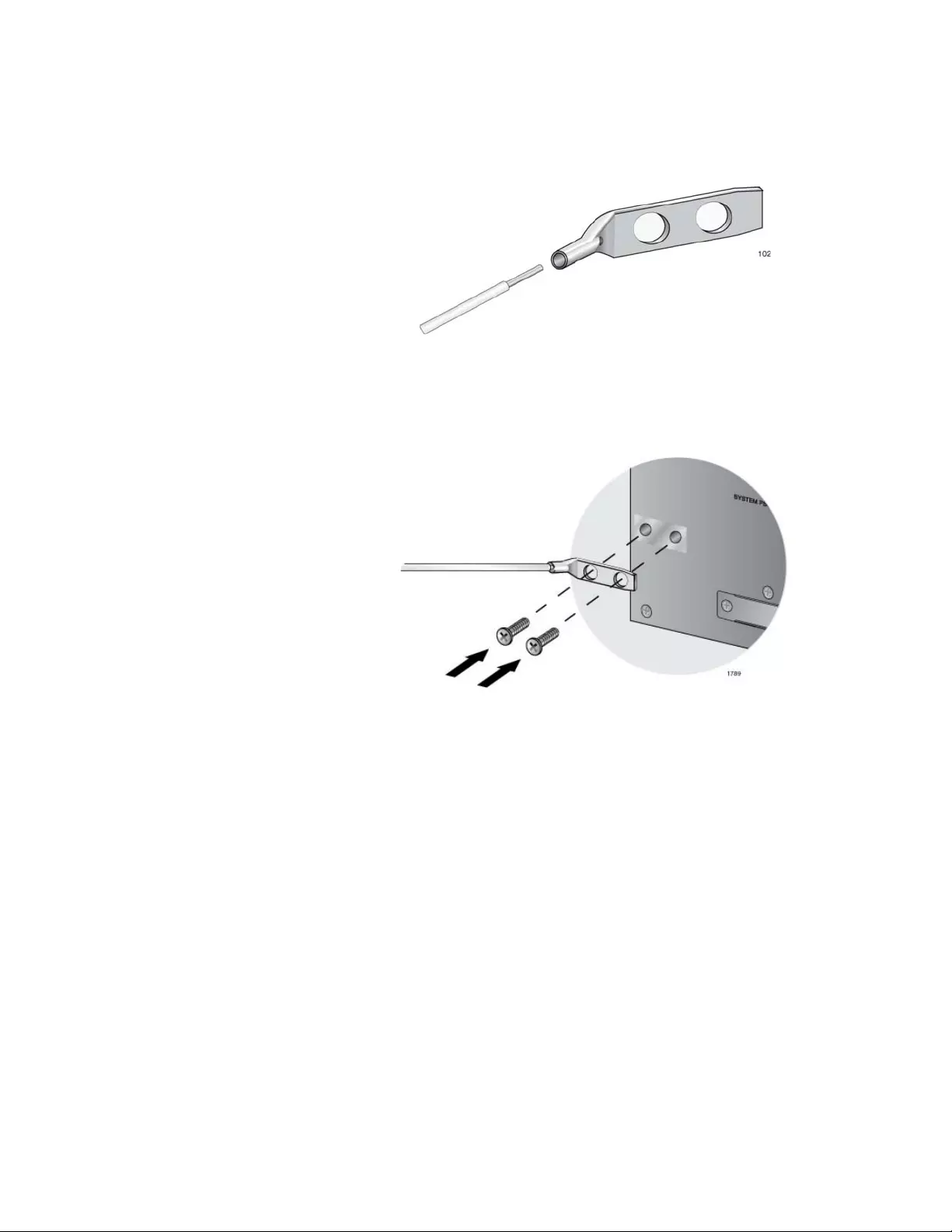

Figure 42: Stripping the Grounding Wire.......... ................ ... ... .... ... ... ... ................ .... ... ... ... .... ... ... ................... 102

Figure 43: Removing the Grounding Lug ...................................................................................................... 102

Figure 44: Attaching the Grounding Wire to the Grounding Lug ......... .... ... ... ... ... .... ... ... ................ ... .... ... ... ... 103

Figure 45: Installing the Grounding Lug and Wire......................................................................................... 103

List of Figures

10

Figure 46: ESD Socket and Wrist Strap......................................................................................................... 106

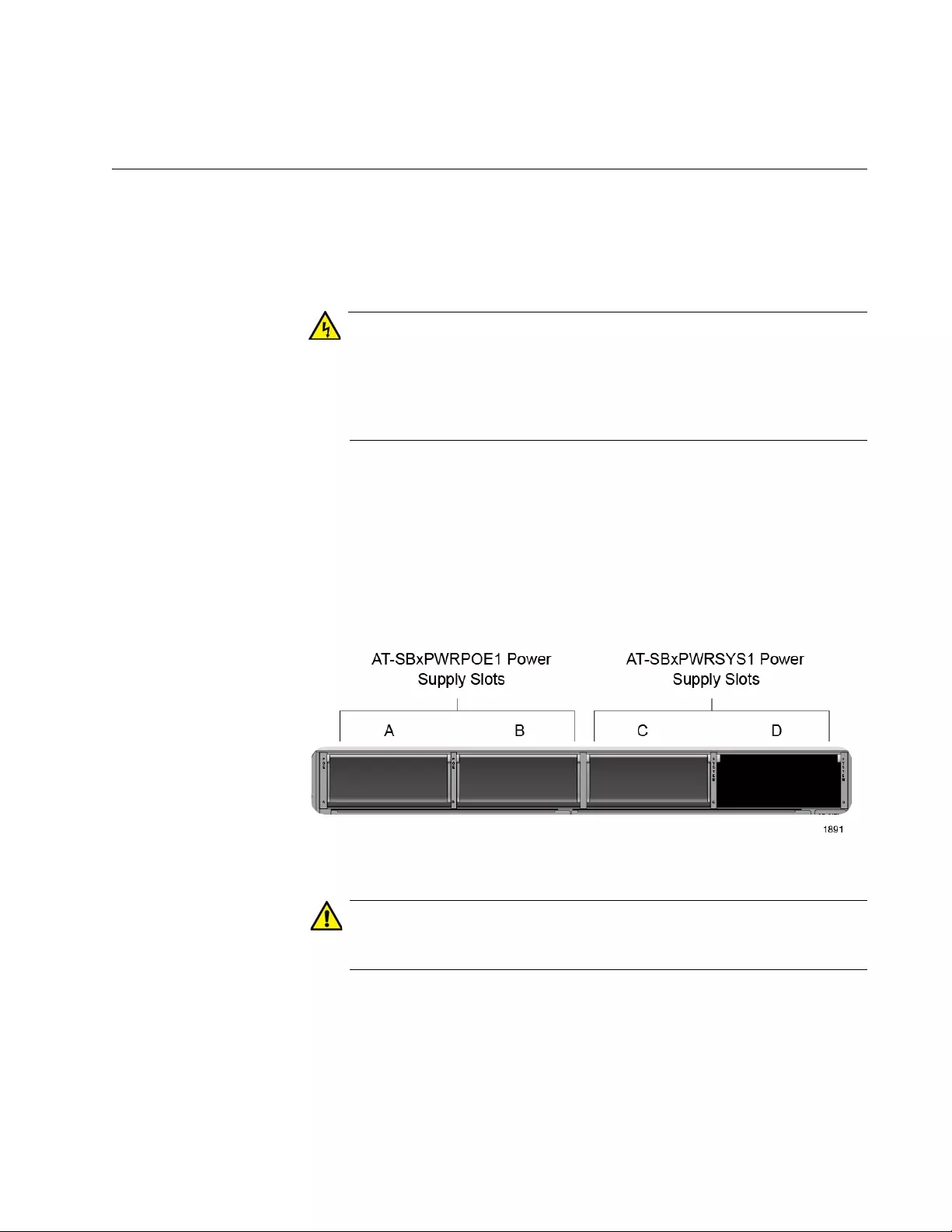

Figure 47: Power Supply Slots....................................................................................................................... 107

Figure 48: Removing the Blank Slot Cover from Power Supply Slot C.......................................................... 108

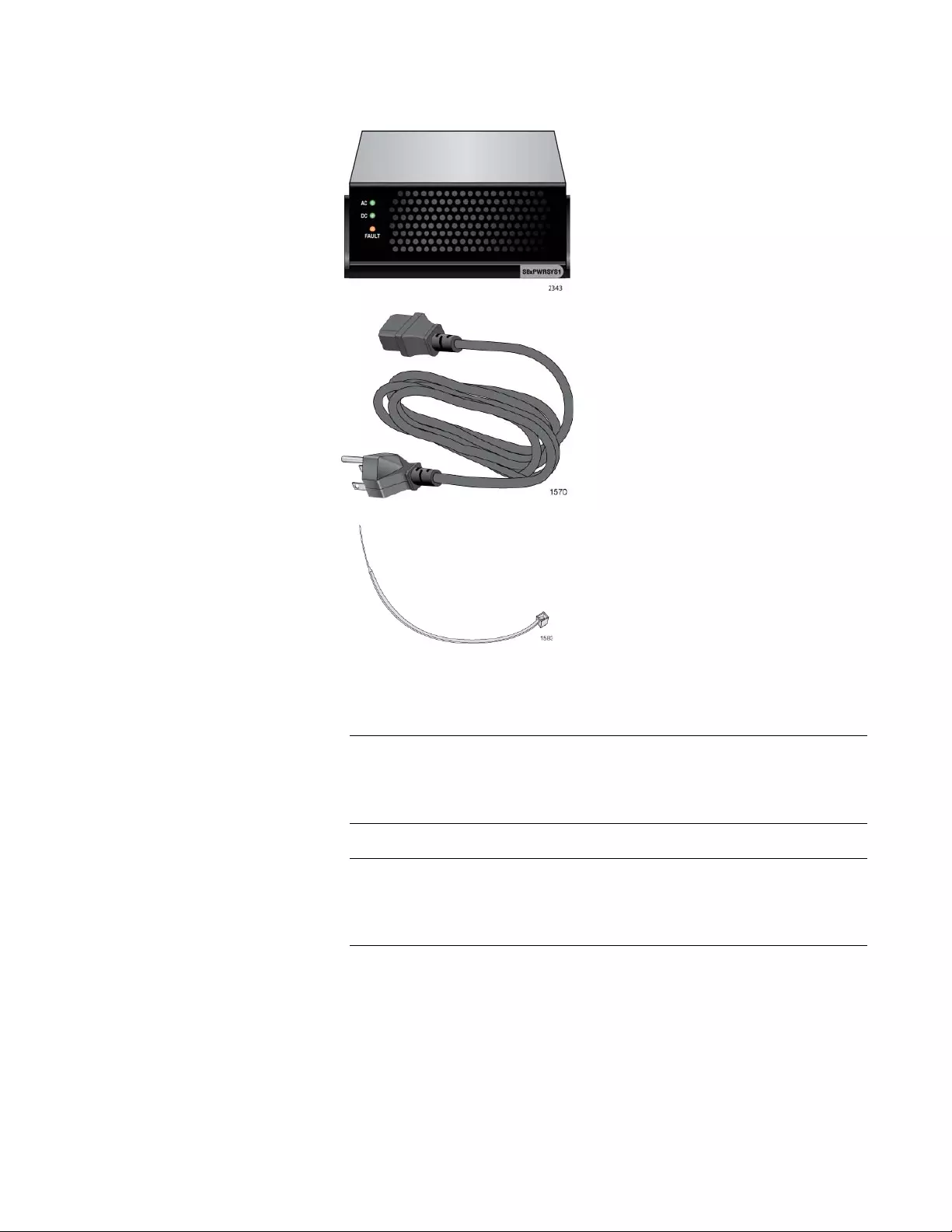

Figure 49: Items Included with the AT-SBxPWRSYS1 or AT-SBxPWRSYS2 AC System Power Supply..... 109

Figure 50: Raising the Handle on the Power Supply ..................................................................................... 110

Figure 51: Inserting the AT-SBxPWRSYS1 or AT-SBxPWRSYS2 AC Power Supply................................... 110

Figure 52: Lowering the Handle on the AT-SBxPWRSYS1 or AT-SBxPWRSYS2 AC Power Supply........... 111

Figure 53: Removing the Blank Slot Cover from Power Supply Slot A.......................................................... 114

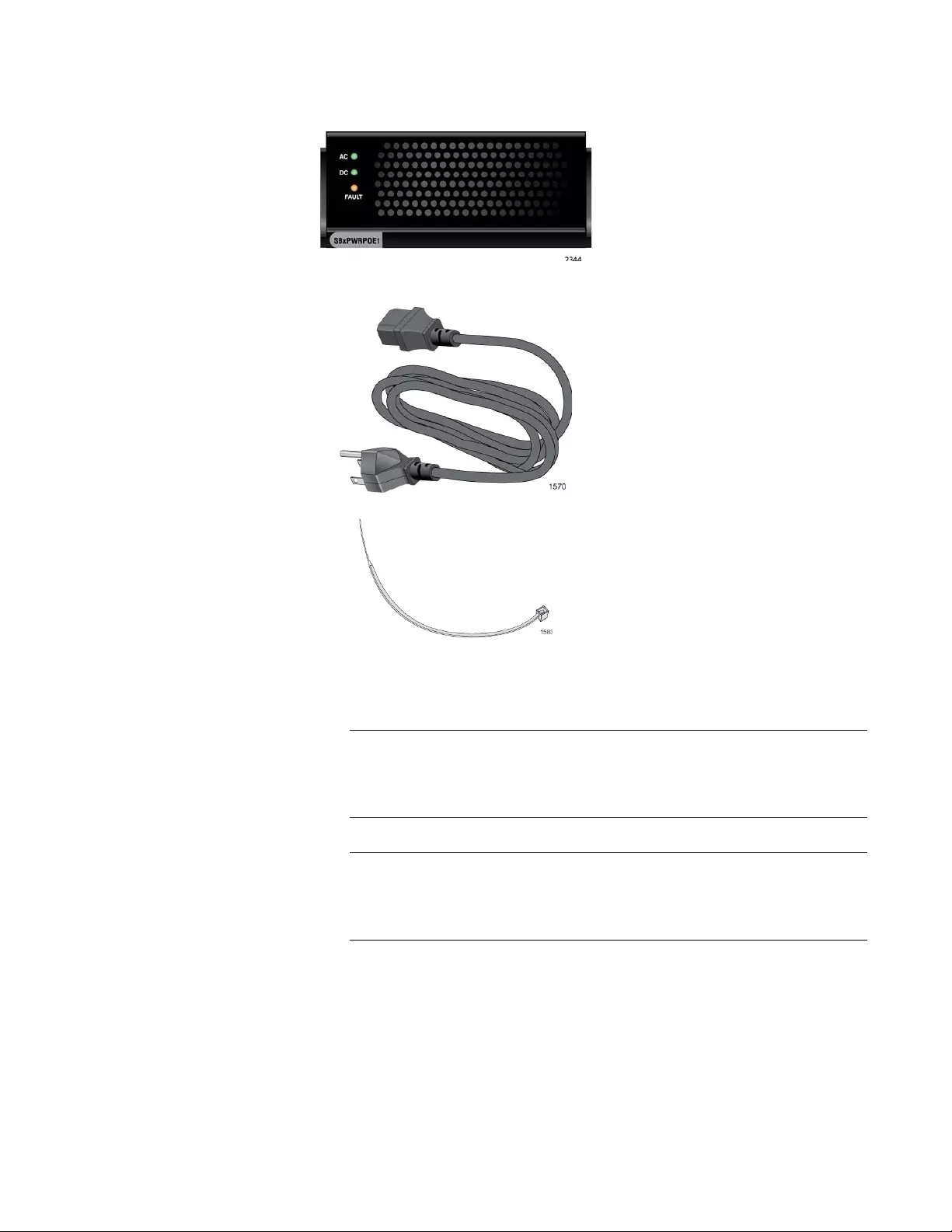

Figure 54: Items Included with the AT-SBxPWRPOE1 Power Supply Module.............................................. 115

Figure 55: Raising the Handle on the AT-SBxPWRPOE1 AC Power Supply................................................ 116

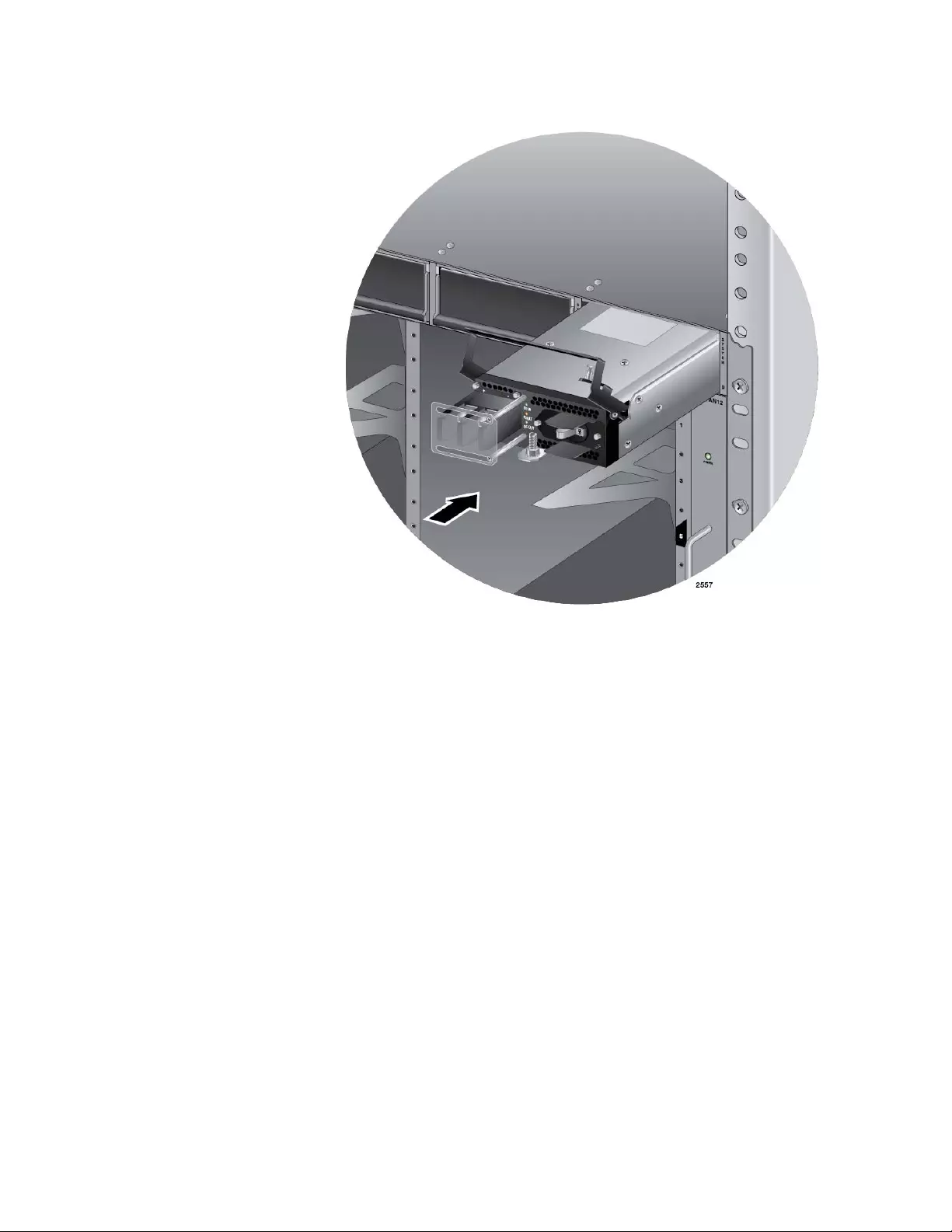

Figure 56: Inserting the AT-SBxPWRPOE1 AC Power Supply...................................................................... 116

Figure 57: Locking the Handle on the AT-SBxPWRPOE1 AC Power Supply................................................ 117

Figure 58: Removing the Blank Slot Cover from Power Supply Slot C.......................................................... 120

Figure 59: Items Included with the AT-SBxPWRSYS1 DC System Power Supply Module........................... 121

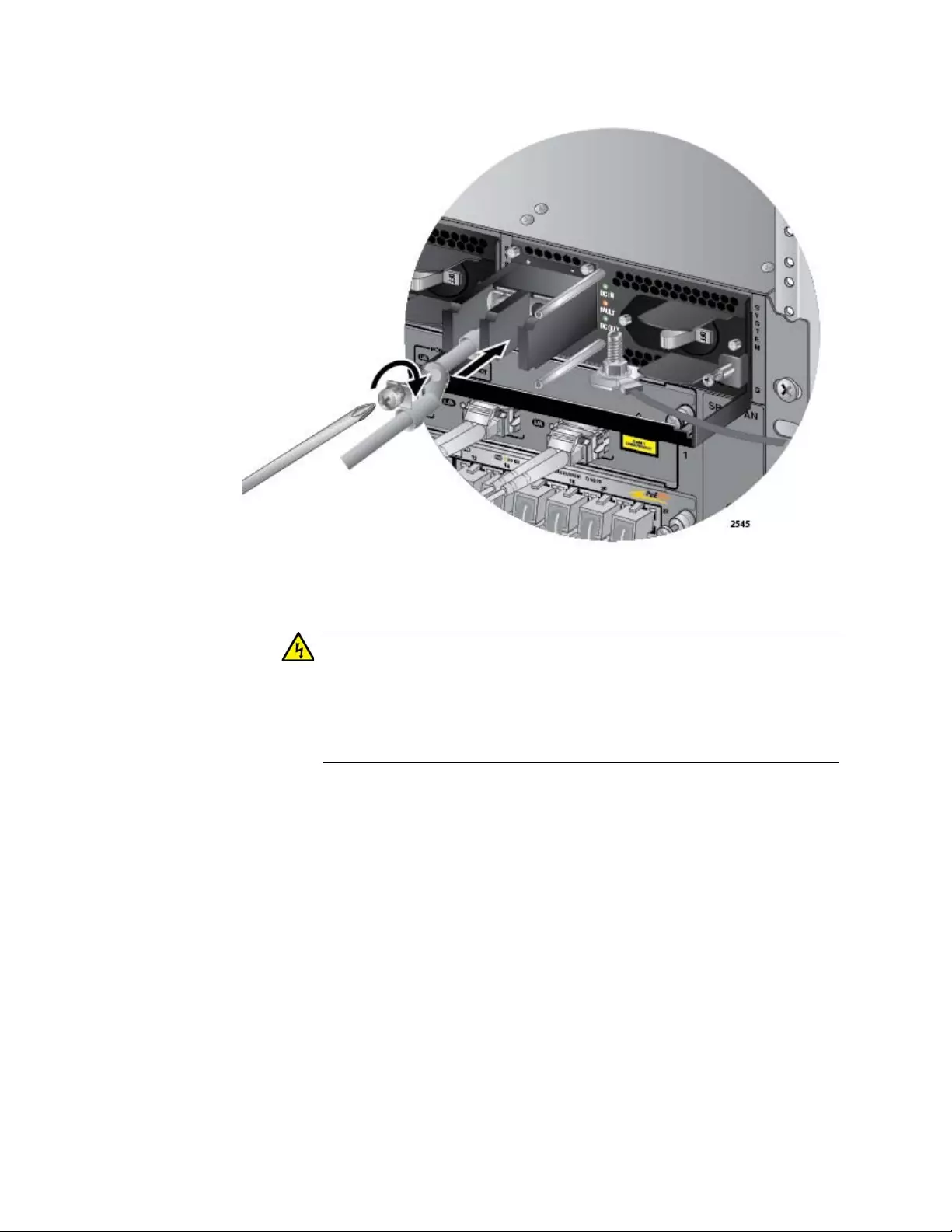

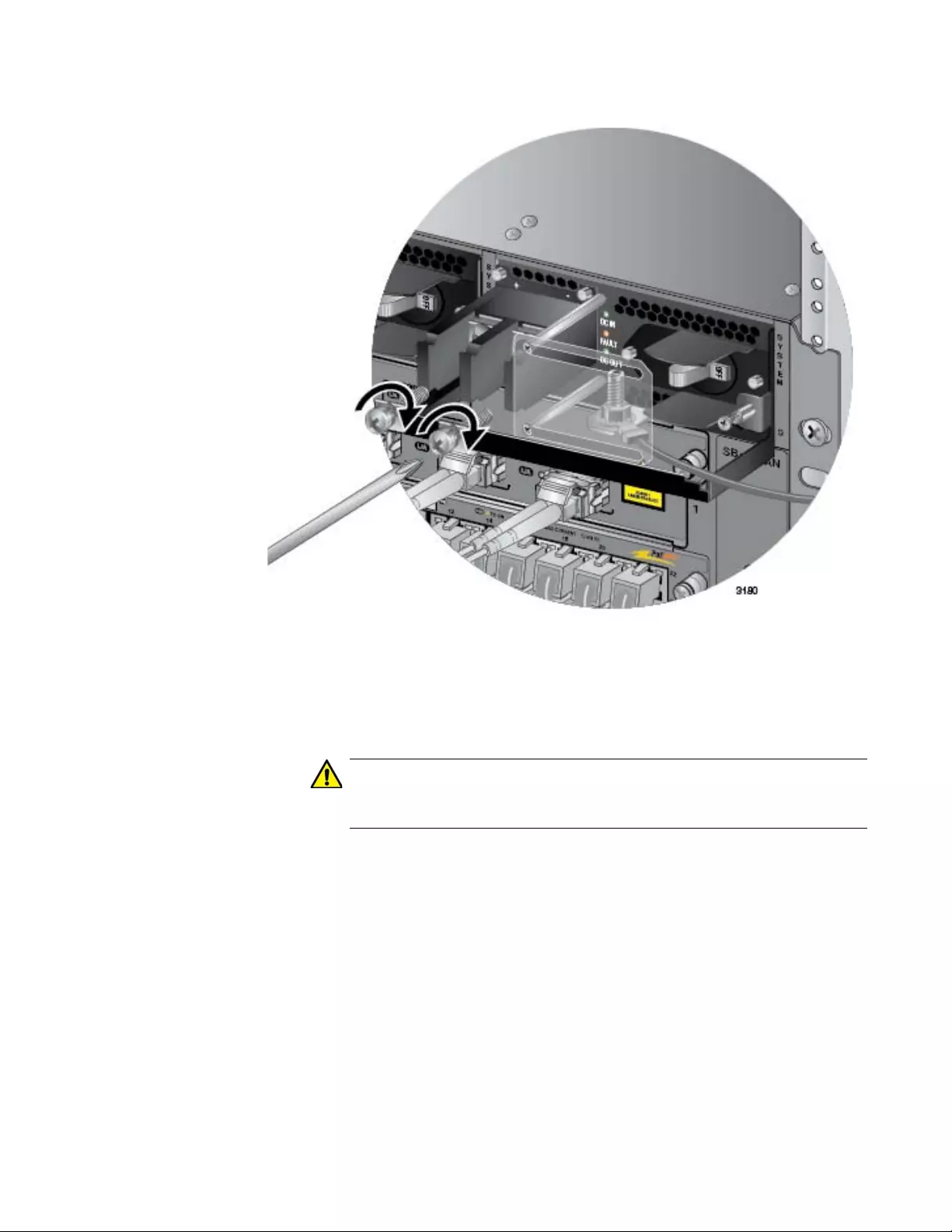

Figure 60: Loosening the Handle locking Screw on the AT-SBxPWRPOE1 DC System Power Supply....... 122

Figure 61: Raising the Handle on the AT-SBxPWRPOE1 DC System Power Supply................................... 122

Figure 62: Inserting the AT-SBxPWRSYS1 DC System Power Supply......................................................... 123

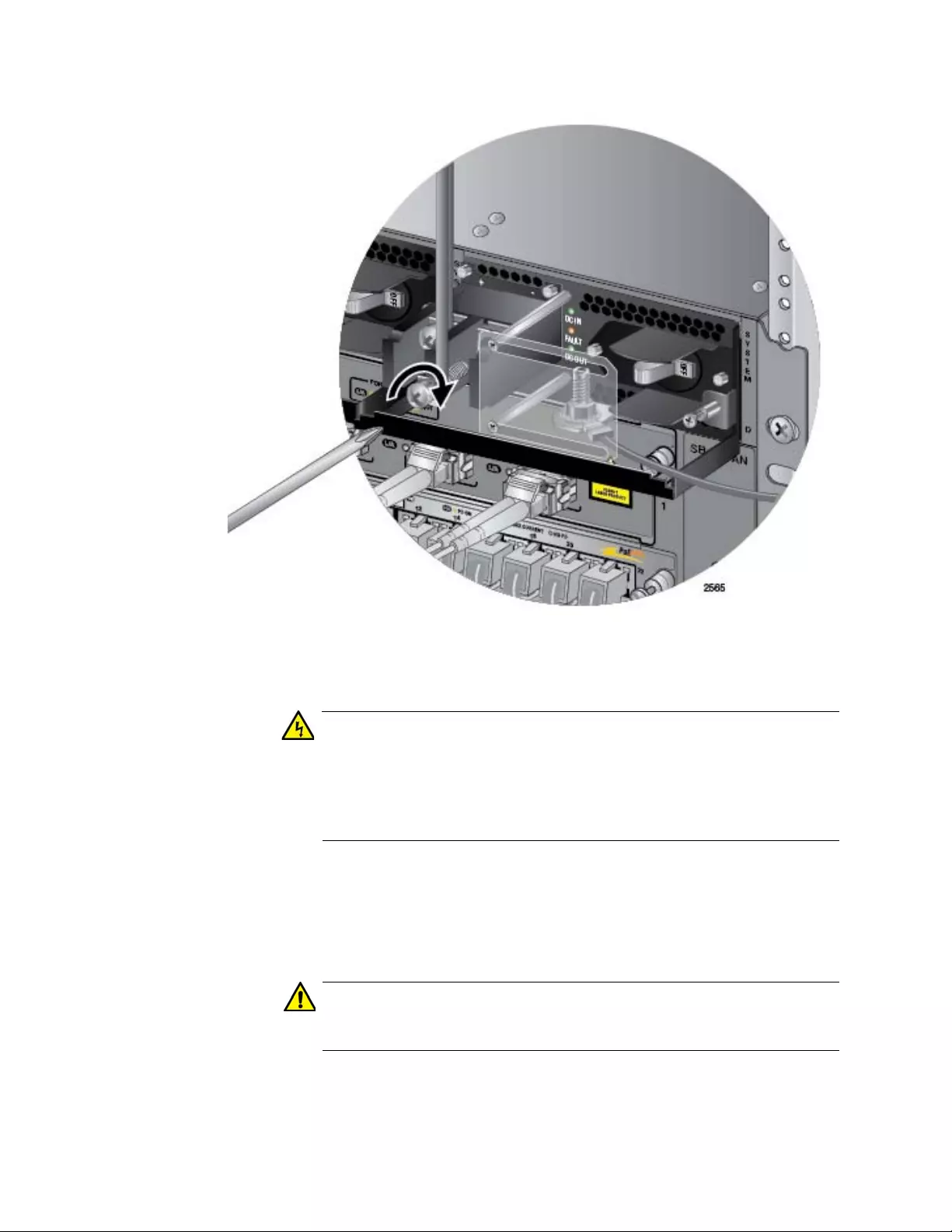

Figure 63: Locking the Handle on the AT-SBxPWRSYS1 DC System Power Supply................................... 124

Figure 64: Aligning a Card in a Slot ............................................................................................................... 129

Figure 65: Slots 4 and 5 for the AT-SBx31CFC Card .................................................................................... 130

Figure 66: Items Included with the AT-SB x31CFC Controller Fabric Card.................................................... 131

Figure 67: Removing the AT-SBx31CFC Controller Fabric Card from the Anti-static Bag ............................ 131

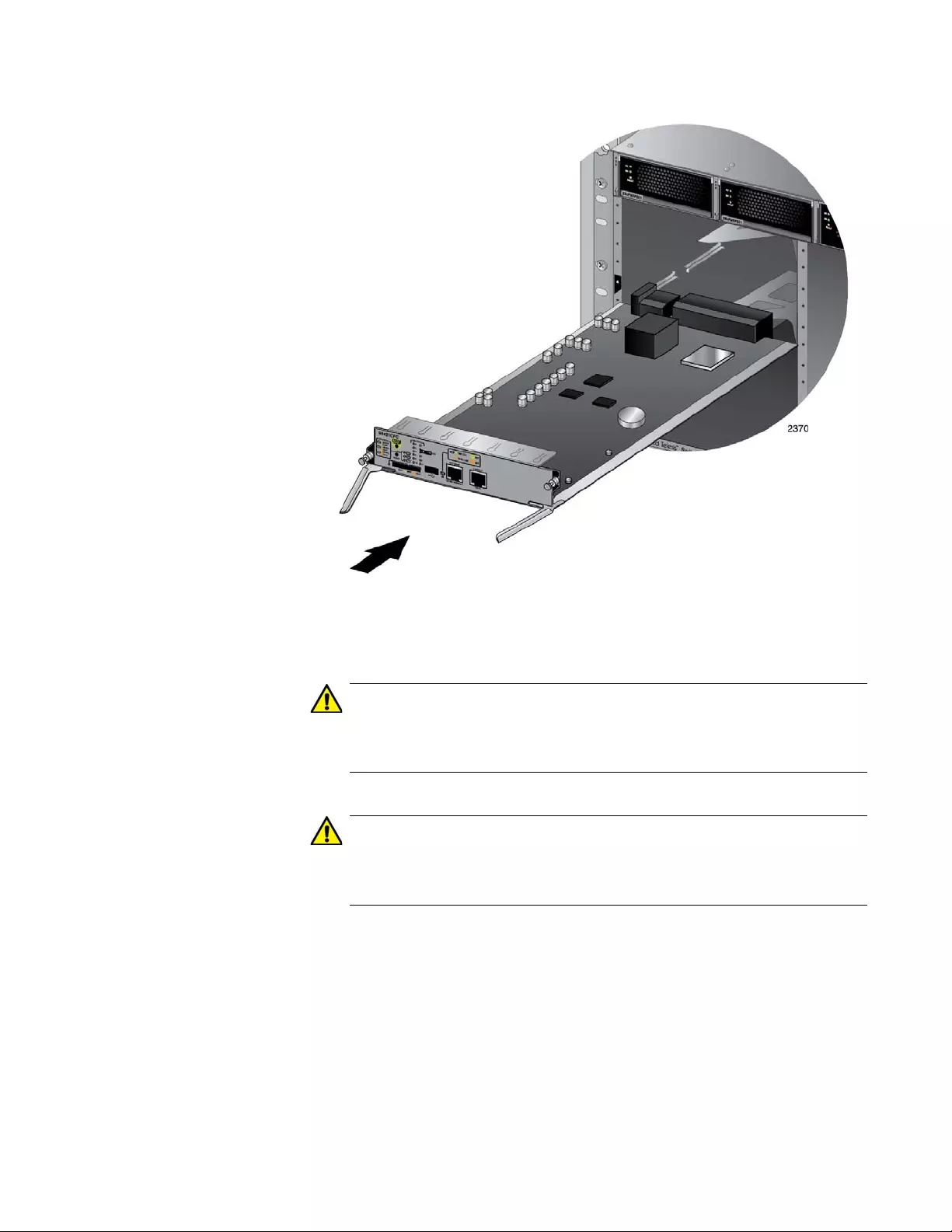

Figure 68: Opening the Locking Handles on the AT-SBx31CFC Controller Fabric Card............................... 132

Figure 69: Removing the Battery Insulator .................................................................................................... 132

Figure 70: Aligning the AT-SBx31CFC C ard in the Chass is Slot...... ... ... ... .... ... ... ................ ... .... ... ... ... ... .... ... 133

Figure 71: Closing the Locking Levers on the AT-SBx31CFC Controller Fabric Card...... ... ... .... ... ... ... ... .... ... 134

Figure 72: Tightening the Thumb Screws on the AT-SBx31CFC Card.......................................................... 135

Figure 73: Slots 0 to 3 and 6 to 11 for the Ethernet Line Cards..................................................................... 136

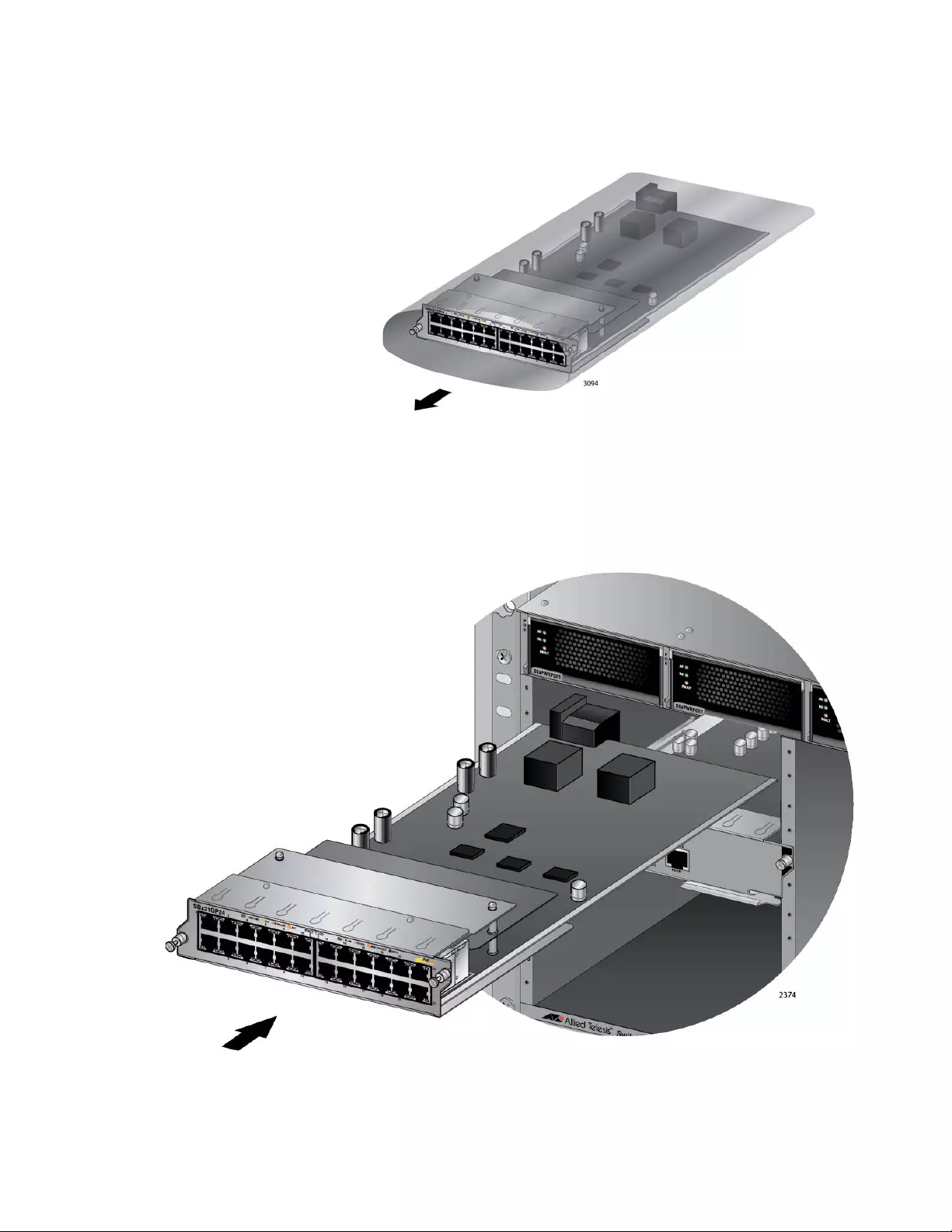

Figure 74: Removing an Ethernet Line Card from an Anti-static Bag ............................................................ 137

Figure 75: Aligning an Ethernet Line Card in a Chassis Slot ..... ... .... ... ... ... .... ... ................ ... ... .... ... ... ... ... ....... 137

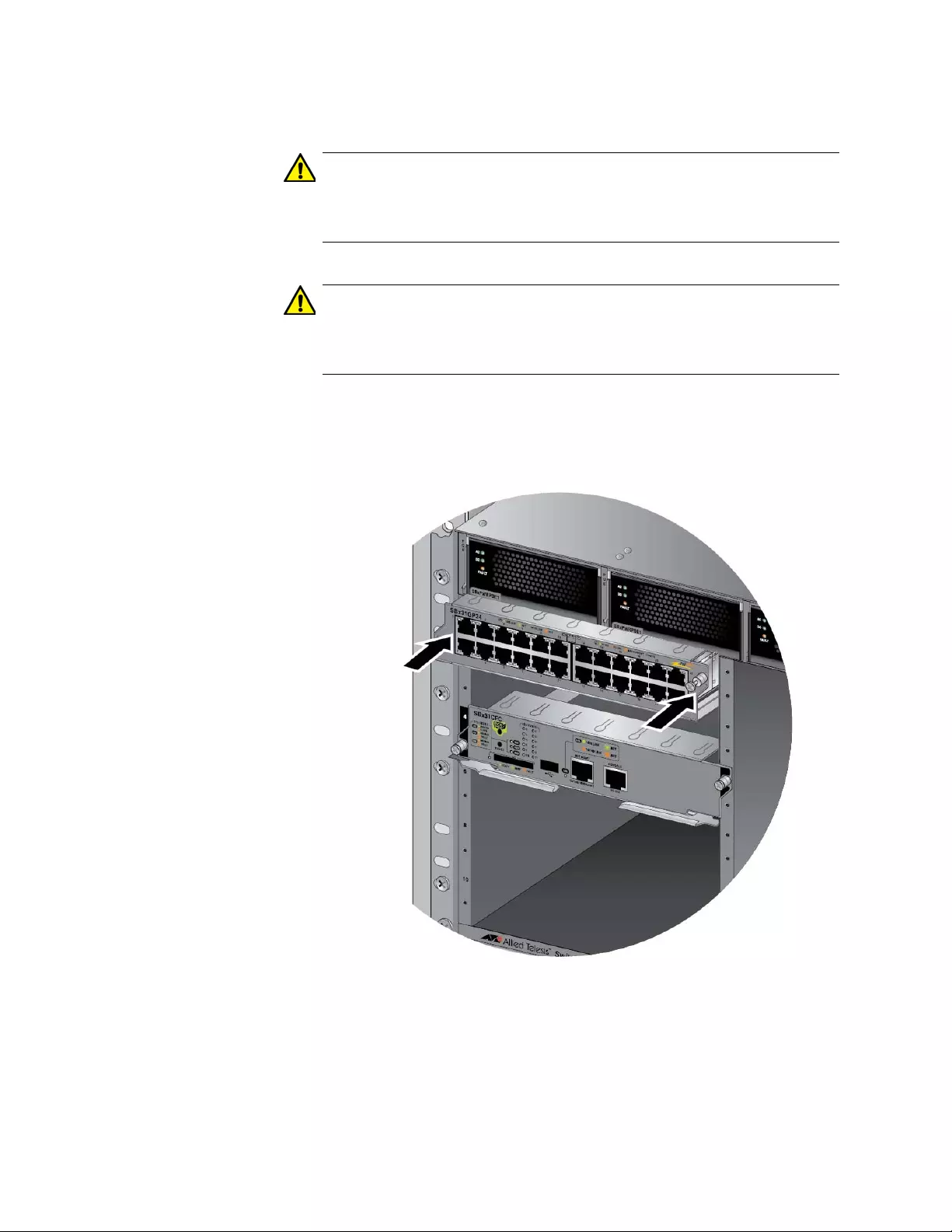

Figure 76: Seating an Ethernet Line Card on the Backplane Connector ....................................................... 138

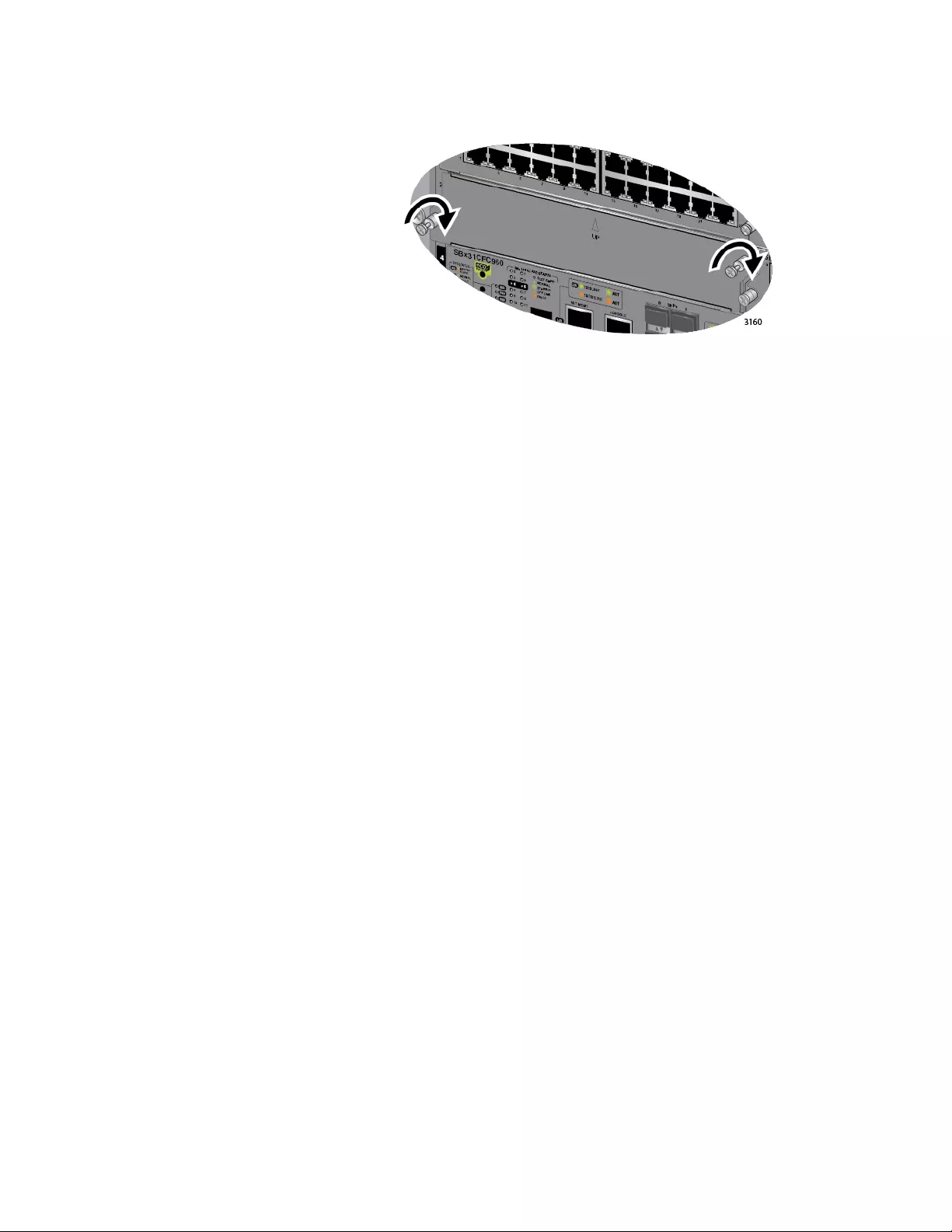

Figure 77: Tightening the Thumb Screws on an Ethernet Line Card............................................................. 139

Figure 78: Installing a Blank Slot Cover......................................................................................................... 140

Figure 79: Tightening the Thumbscrews on a Blank Slot Cover... .... ... ................ ... ... .... ... ................ ... ... .... ... 141

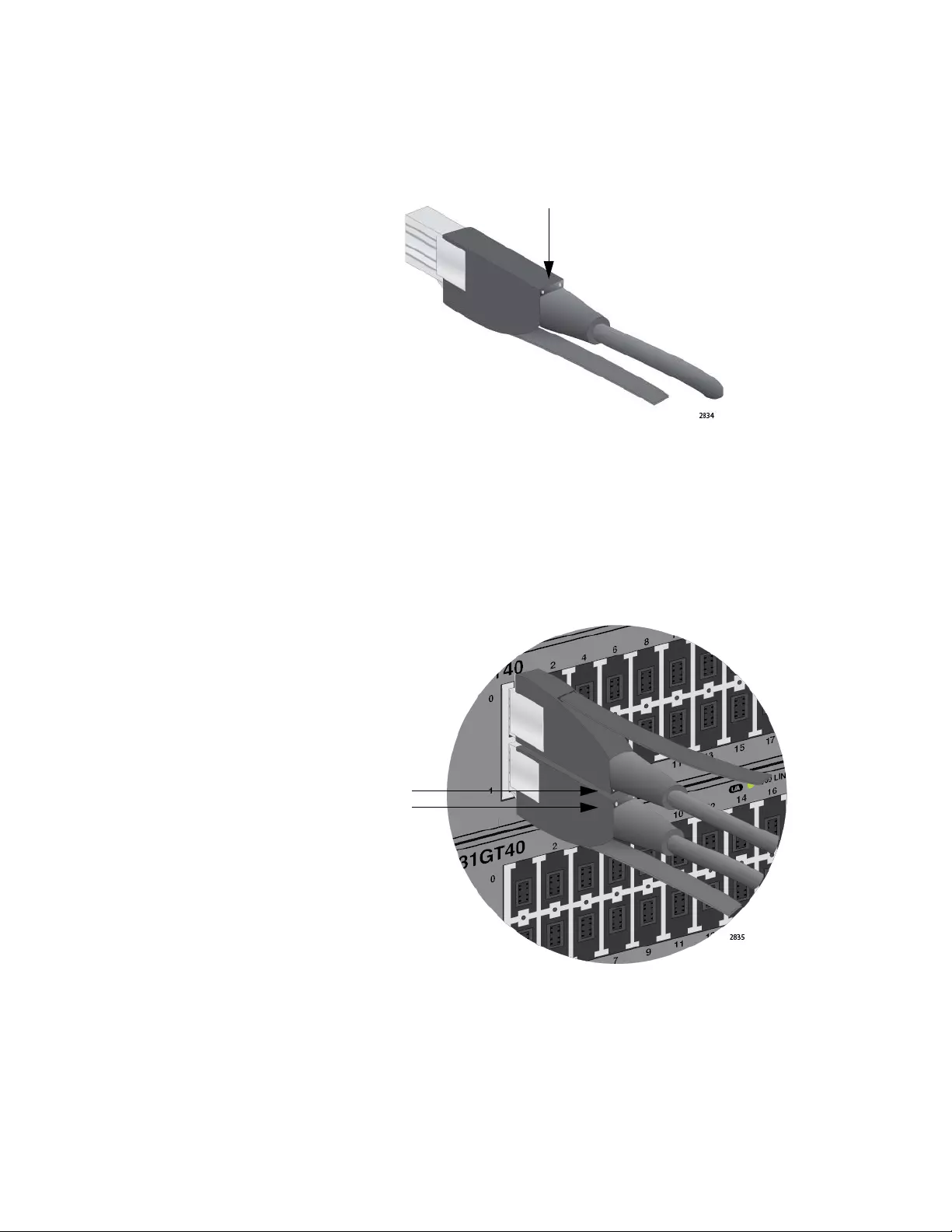

Figure 80: RJ Point 5 Cable Connector for AT-SBx31GT40 Line Card ......................................................... 145

Figure 81: Connecting Cables to Ports on the AT-SBx31GT40 Line Card .................................................... 146

Figure 82: Removing the Dust Cover from an SFP Slot in the AT-SBx31GS24 Line Card ........................... 148

Figure 83: Handle on SFP Transceiver.......................................................................................................... 148

Figure 84: Inserting an SFP Transceiver in the AT-SBx31GS24 Line Card .................................................. 149

Figure 85: Removing the Dust Cover from the SFP Transceiver in the AT-SBx31GS24 Line Card.... ... .... ... 149

Figure 86: Attaching a Fiber Optic Cable to an SFP Transceiver in the AT-SBx31GS24 Line Card ............. 150

Figure 87: Removing the Dust Cover from a Transceiver Slot on the AT-SBx31GC40 Line Card ................ 151

Figure 88: Labels on SFP and CSFP Transceivers ....................................................................................... 152

Figure 89: Inserting an SFP or a CSFP Transceiver...................................................................................... 152

Figure 90: Removing the Dust Cover from an SFP or a CSFP Transceiver.................................................. 153

Figure 91: Attaching a Fiber Optic Cable....................................................................................................... 154

Figure 92: Removing a Dust Cover From an SFP+ Slot in the AT-SBx31XS6 Line Card ............................. 155

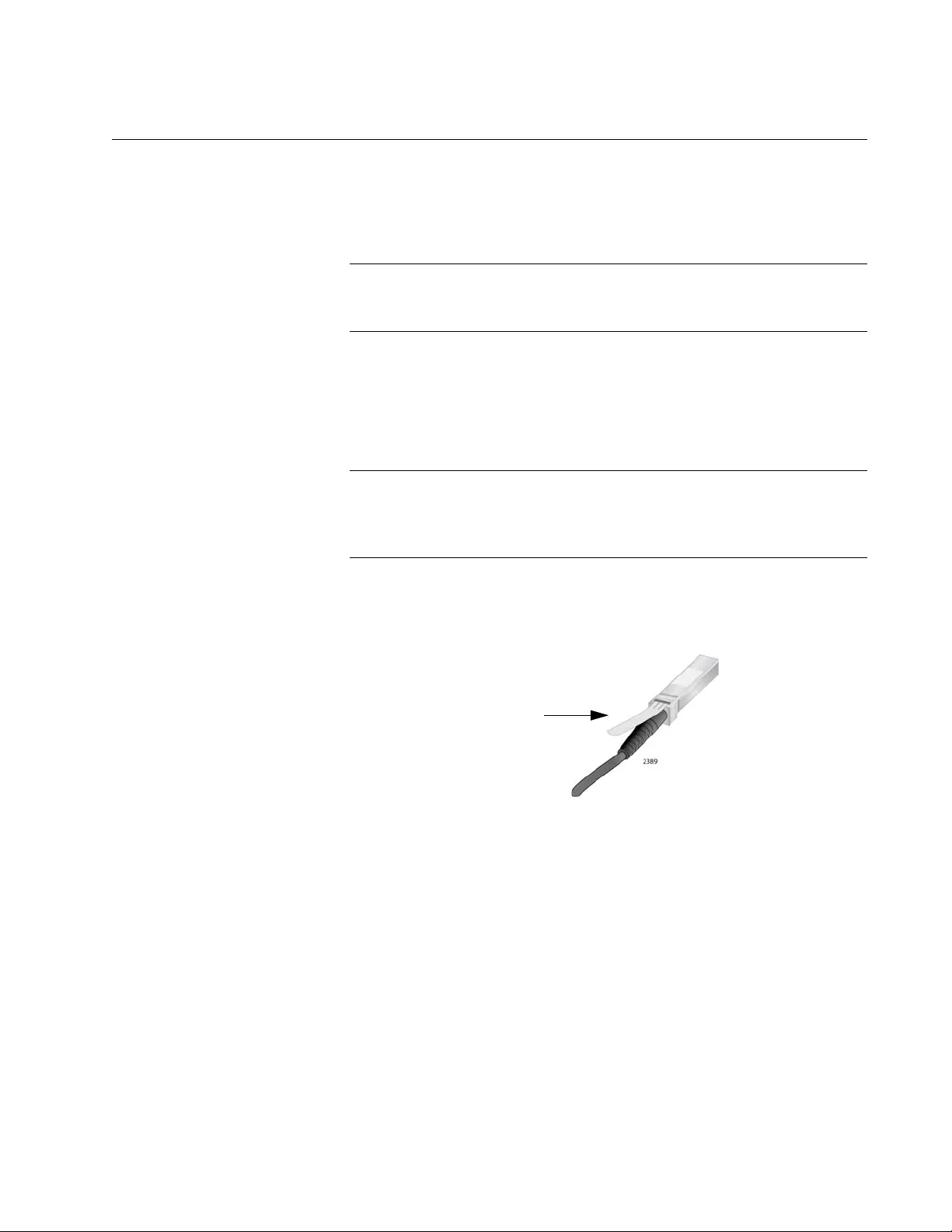

Figure 93: Handle on SFP+ Transceiver........................................................................................................ 156

Figure 94: Installing an SFP+ Transceiver in the AT-SBx31XS6 Line Card .................................................. 156

Figure 95: Removing the Dust Cover from an SFP+ Transceiver in the AT-SBx31XS6 Line Card............... 157

Figure 96: Attaching a Fiber Optic Cable to an SFP+ Transceiver in the AT-SBx31XS6 Line Card ............. 158

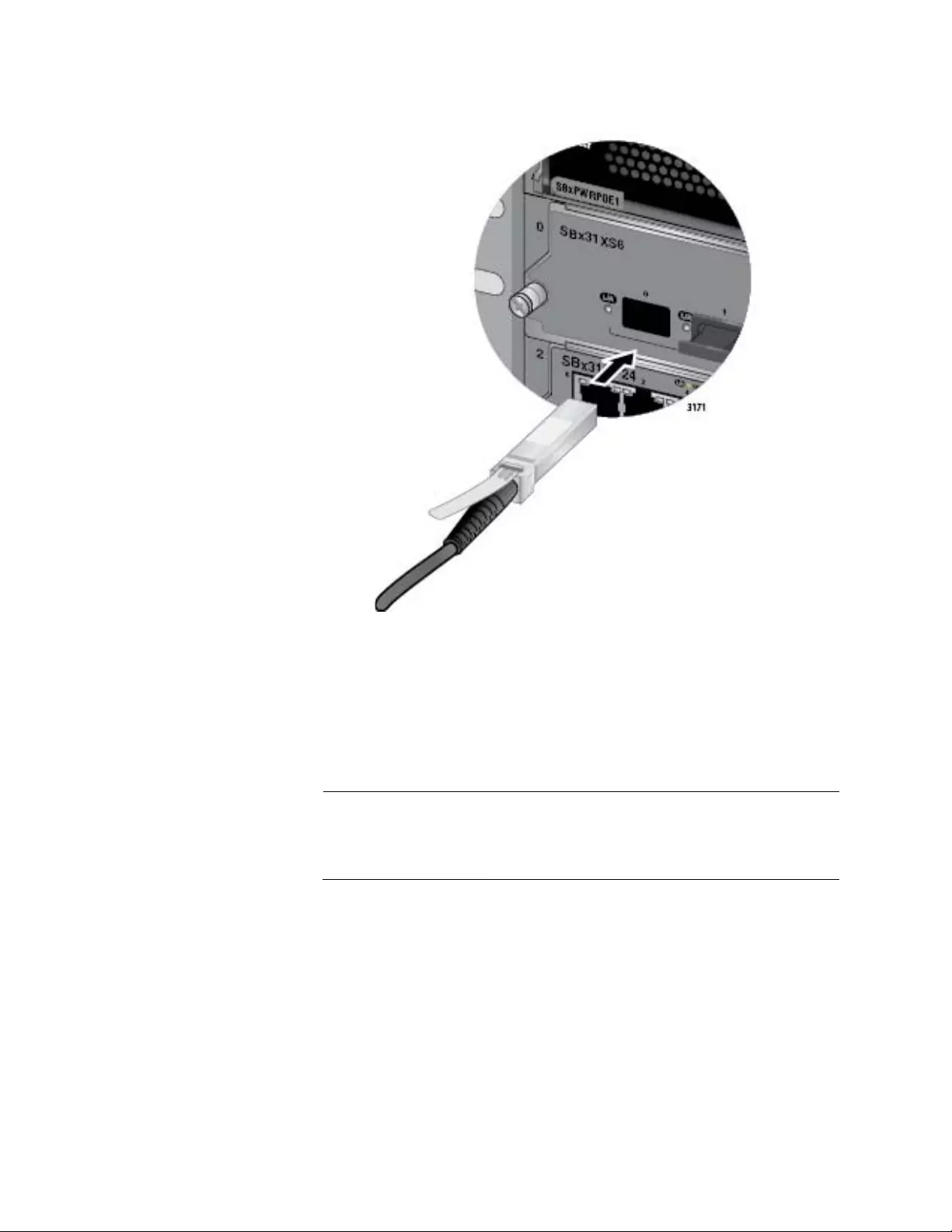

Figure 97: Release Tab on the AT-SBx31XS6 Line Card.............................................................................. 159

Figure 98: Installing the AT-SP10TW Cable in the AT-SBx31XS6 Line Card................................................ 160

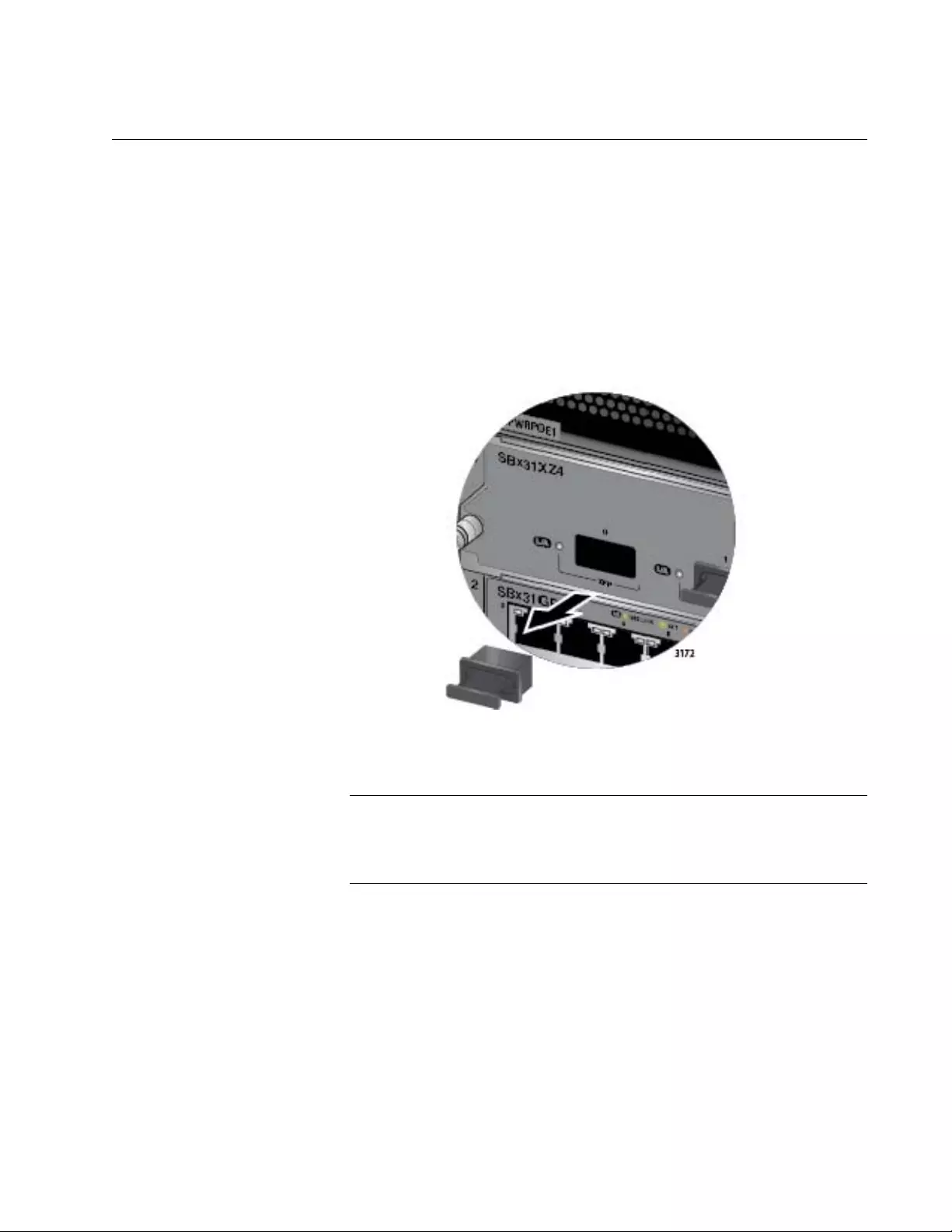

Figure 99: Removing the Dust Cover From an XFP Slot on the AT-SBx31XZ4 Line Card............................ 161

Figure 100: Handle on the XFP Transceiver.................................................................................................. 162

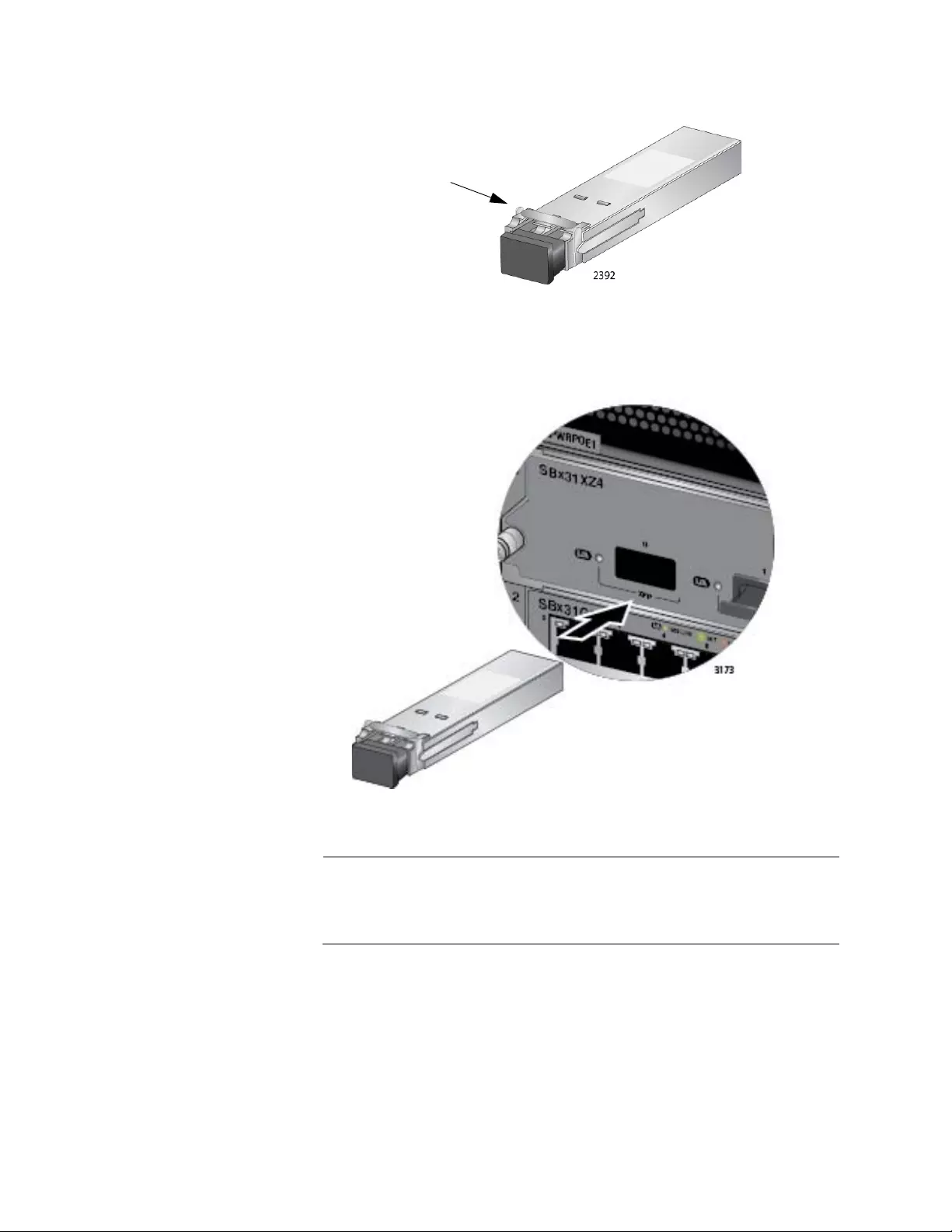

SwitchBlade x3112 Chassis Switch and AT-SBx31CFC Card Installation Guide

11

Figure 101: Installing an XFP Transceiver in the AT-SBx31XZ4 Line Card.................................................. 162

Figure 102: Removing the Protective Cover from an XFP Transceiver in the AT-SBx31XZ4 Line Card ...... 163

Figure 103: Attaching a Fiber Optic Cable to an XFP Transceiver in the AT-SBx31XZ4 Line Card ............. 164

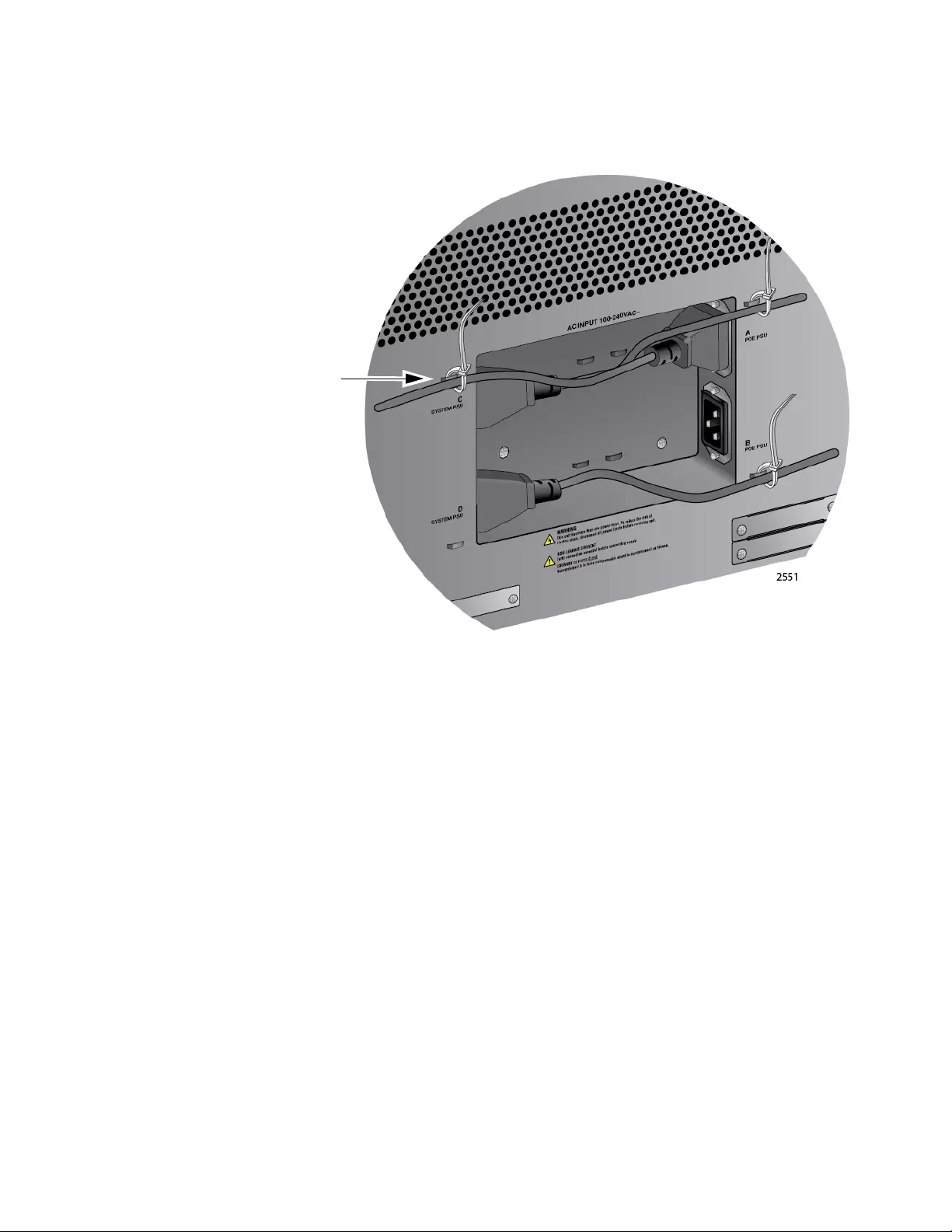

Figure 104: AC Sockets on the AT-SBx3112 Chassis Rear Panel ............................................................... 169

Figure 105: Connecting the AC Power Cord for the AT-SBxPWRSYS1 or AT-SBxPWRSYS2 AC System

Power Supply ................................................................................................................................................ 170

Figure 106: Securing the Power Cord for the AT-SBxPWRSYS1 or AT-SBxPWRSYS2 AC System Power

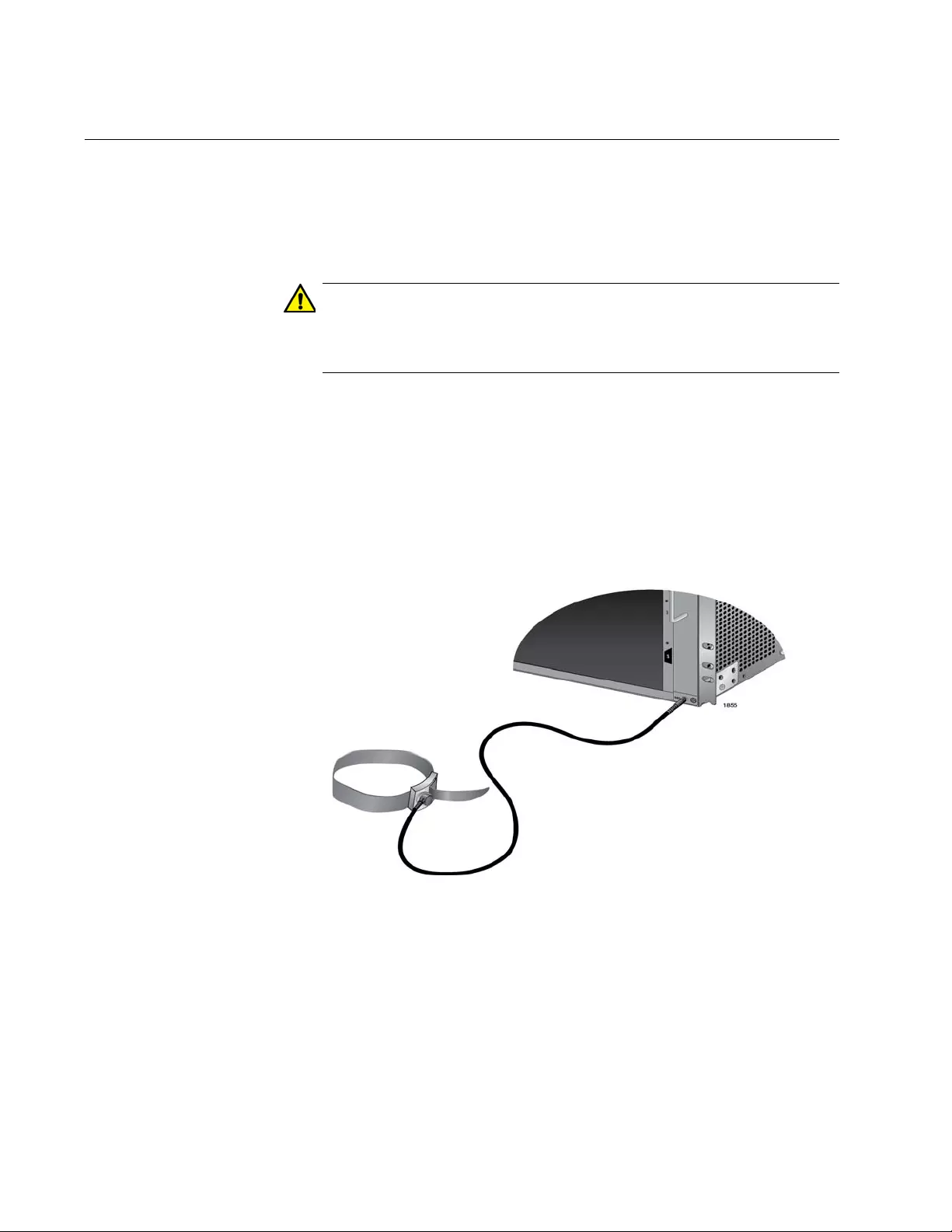

Supply to an Anchor ...................................................................................................................................... 171

Figure 107: Connecting the AC Power Cord for the AT-SBxPWRPOE1 Power Supply ............................... 172

Figure 108: Securing the Power Cord for the AT-SBxPWRPOE1 Power Supply to an Anchor.................... 173

Figure 109: Dress and Secure AC Power Cords........................................................................................... 174

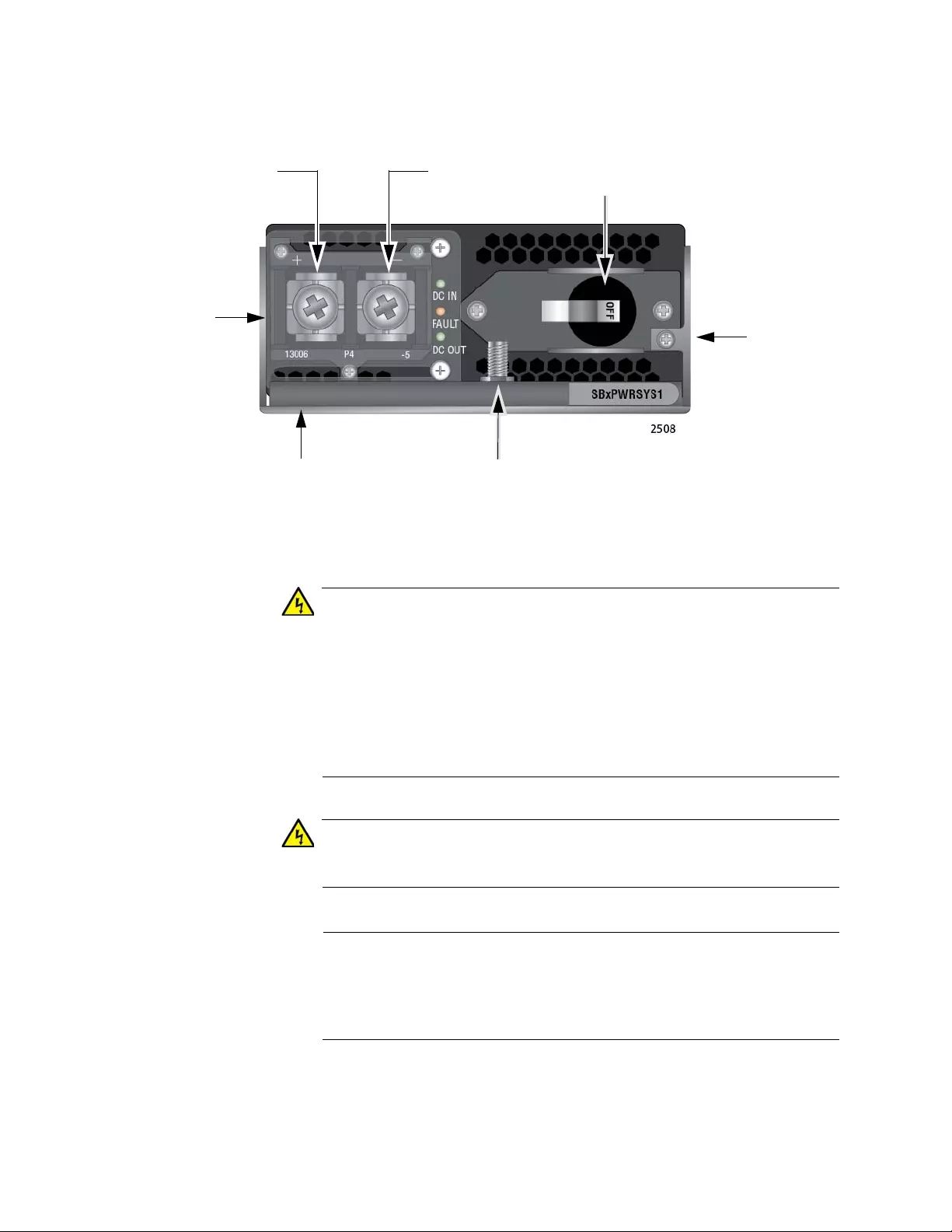

Figure 110: Components of the AT-SBxPWRSYS1 DC Power Supply......................................................... 176

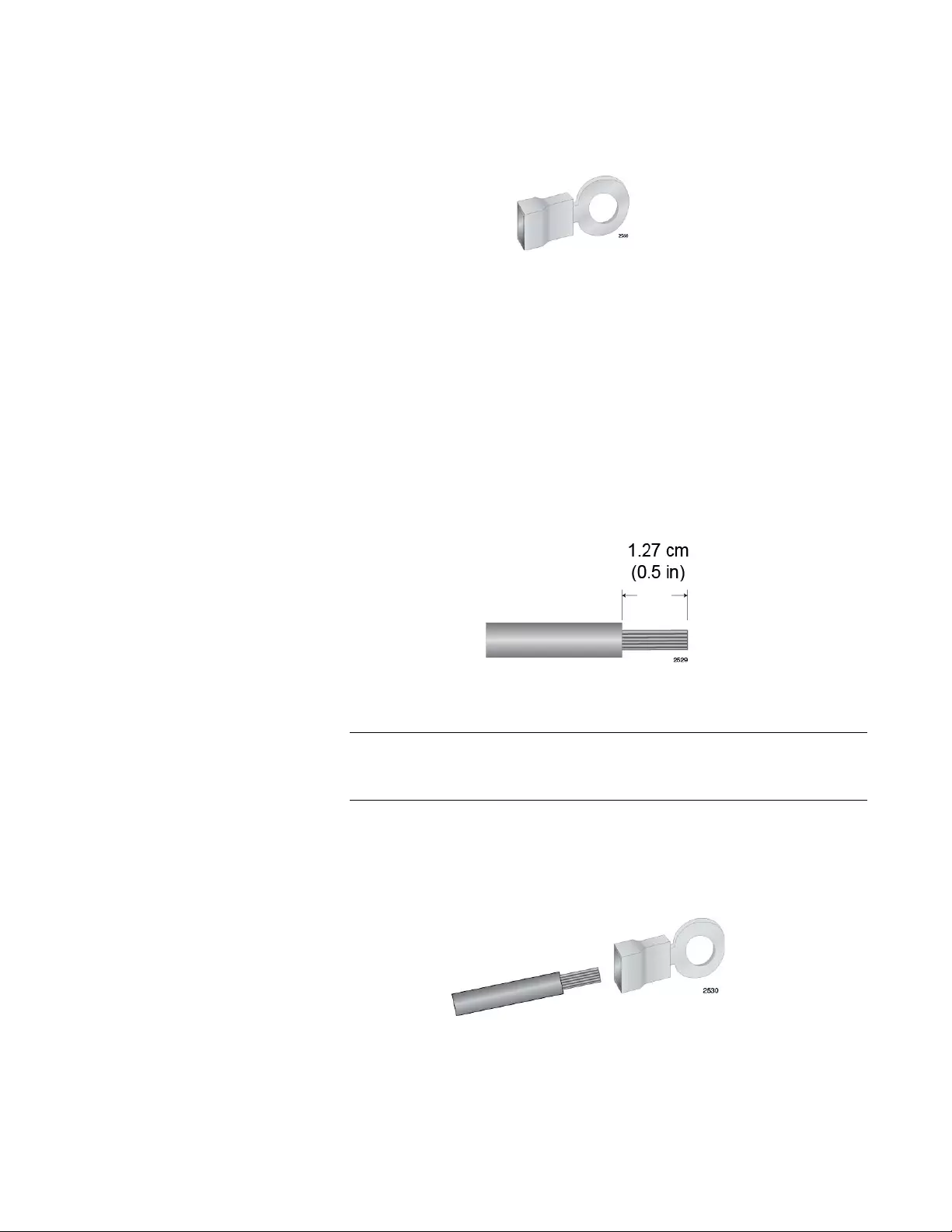

Figure 111: Grounding Wire Terminal ........................................................................................................... 177

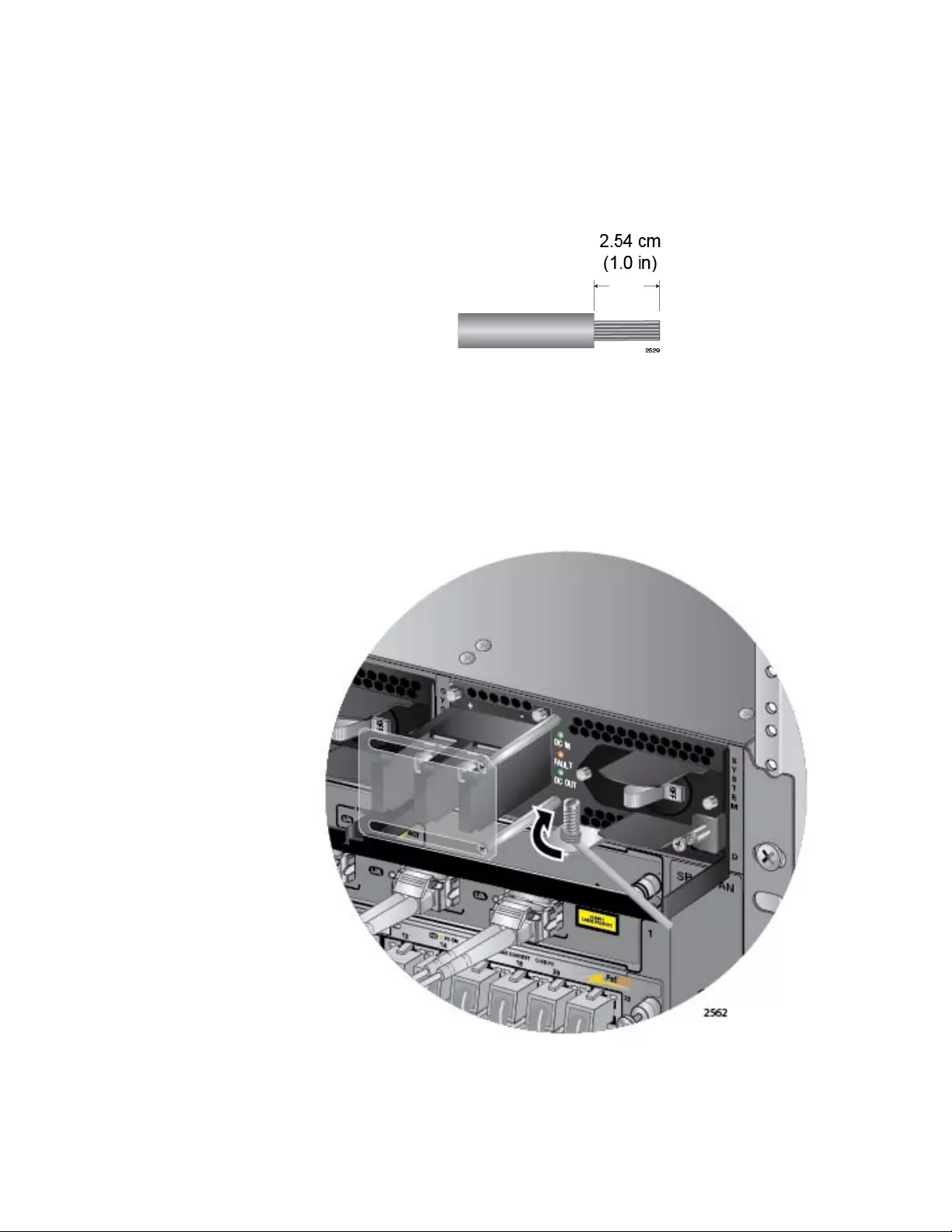

Figure 112: Stripping the Stranded Grounding Wire ..... ... ... ... .... ... ... ... .... ................ ... ... ... .... ... ... ................... 177

Figure 113: Attaching the Stranded Grounding Wire to the Gr ounding Termin al.......................................... 177

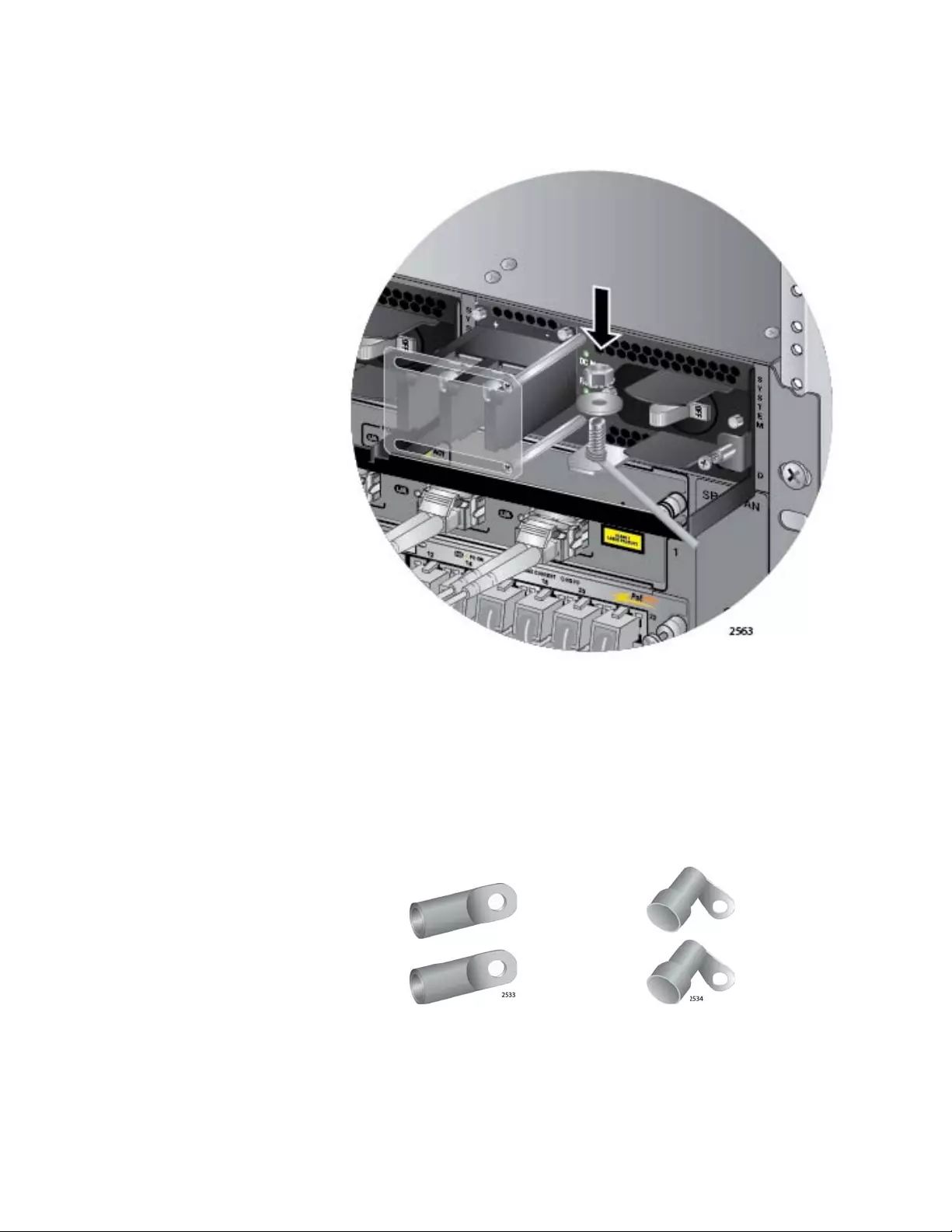

Figure 114: Removing the Nut and Washer from the Grounding Post.......................................................... 178

Figure 115: Installing the Grounding Wire..................................................................................................... 179

Figure 116: Stripping the solid or Stranded Grounding Wire............ ... .... ... ... ... ... .... ... ................ ... ... .... ... ...... 180

Figure 117: Attaching the Bare Grounding Wire to the Grounding Post........................................................ 180

Figure 118: Securing the Bare Grounding Wire to the Grounding Post ........................................................ 181

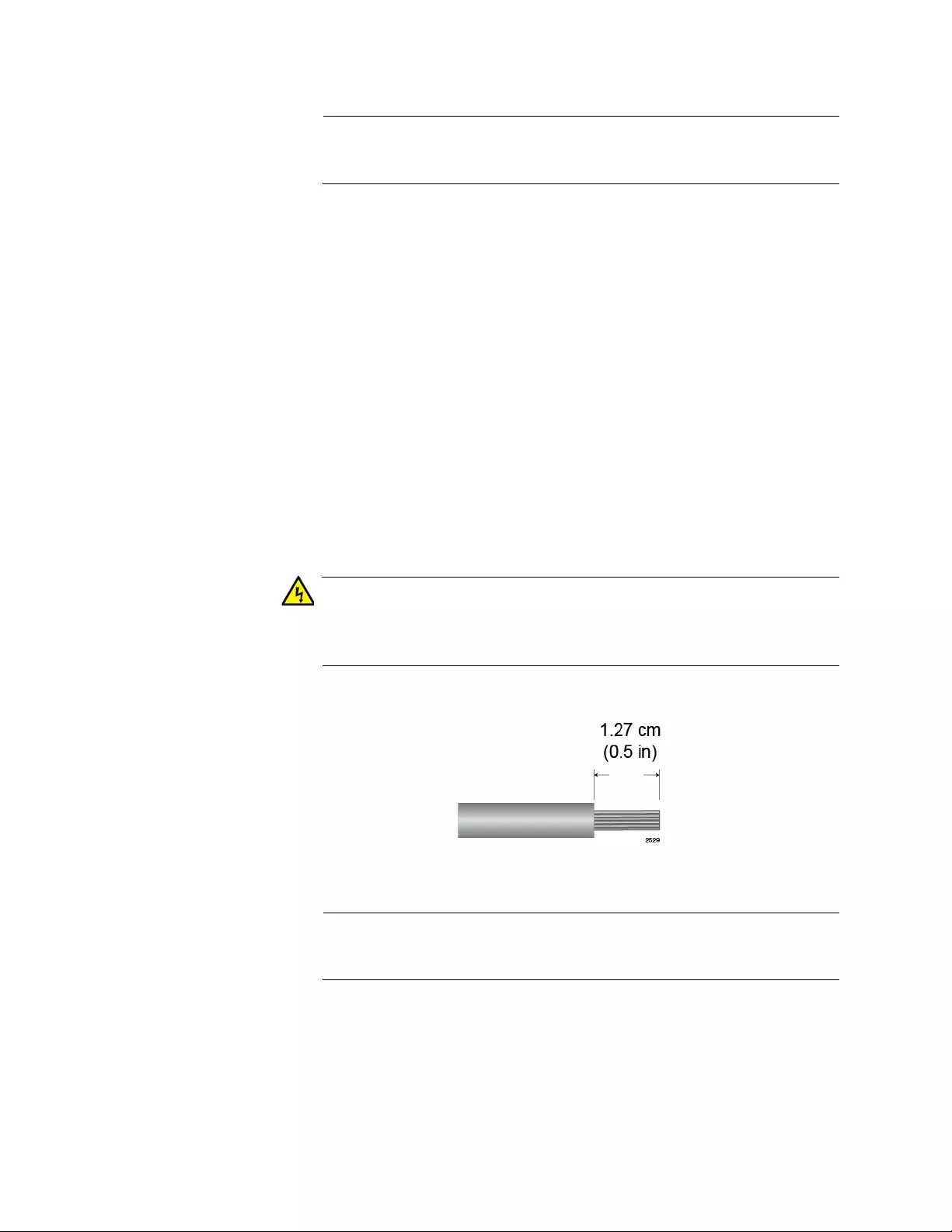

Figure 119: Power Wire Terminals................................................................................................................ 181

Figure 120: Stripping the Power Wires.......................................................................................................... 182

Figure 121: Attaching the Power Wires to the Power Terminal Lugs............................................................ 183

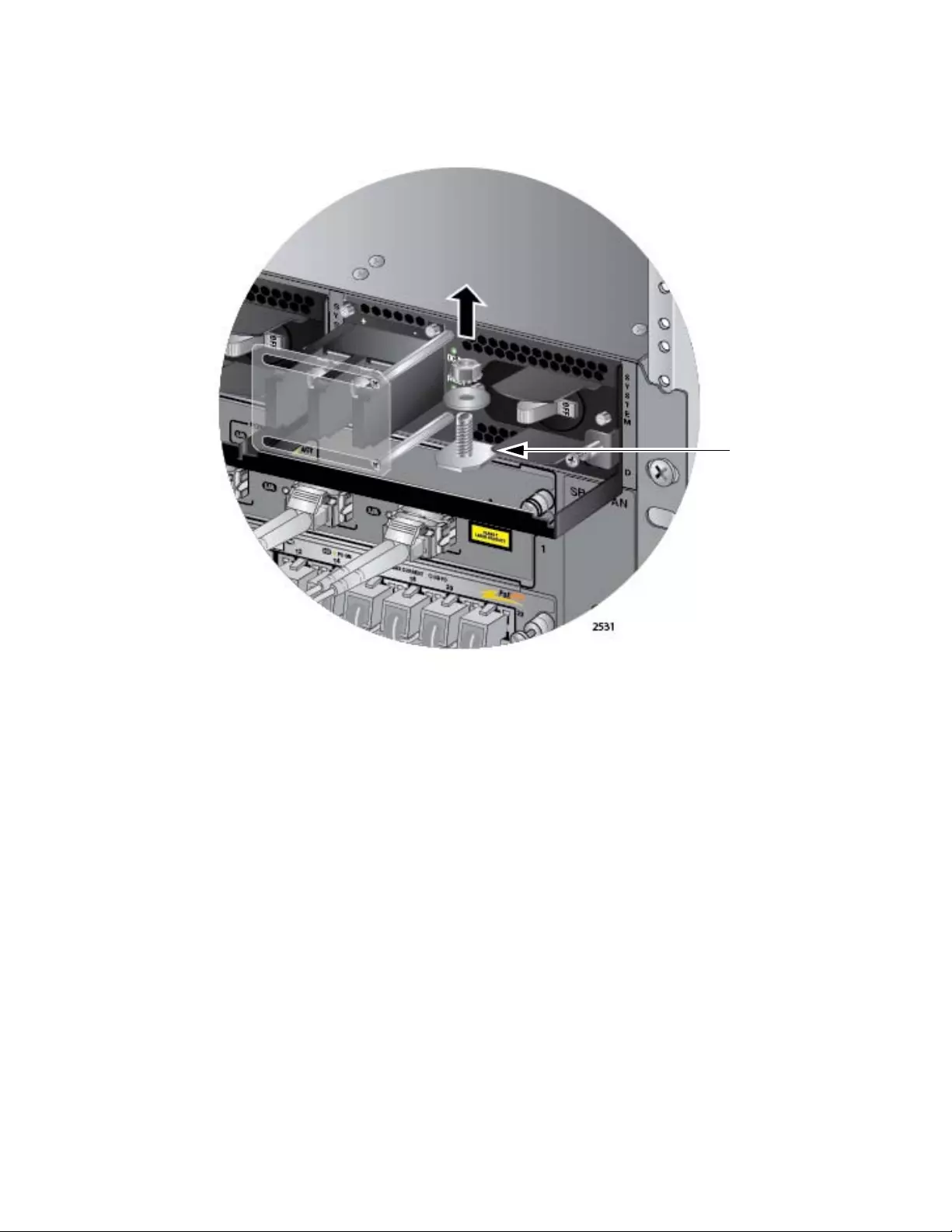

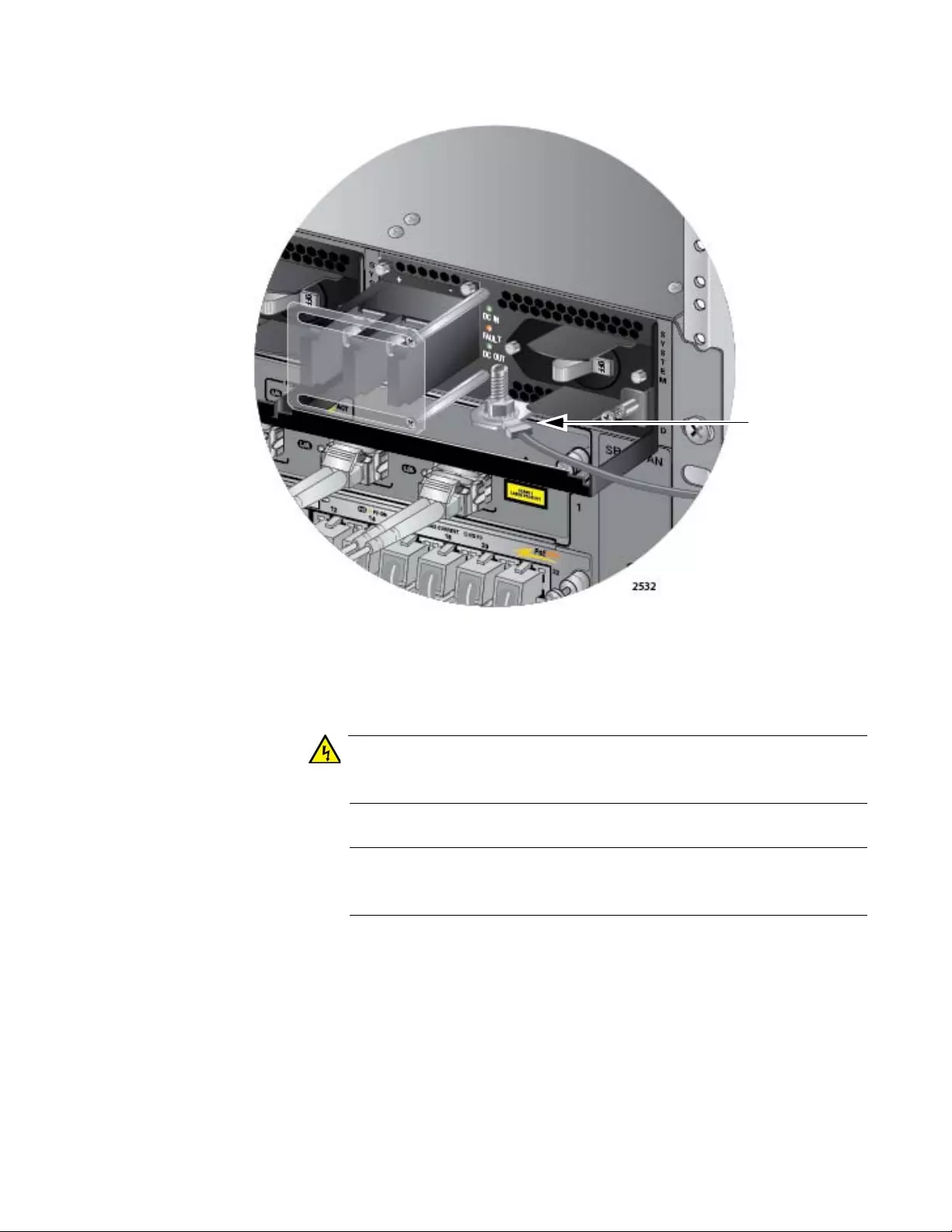

Figure 122: On/Off Switch On the AT-SBxPWRSYS1 DC Power Supply..................................................... 183

Figure 123: Opening the Plastic Cover.......................................................................................................... 184

Figure 124: Removing the Terminal Screws .... ... ... ... .... ................ ... ... .... ... ................ ... ... .... ... ... ................... 185

Figure 125: Connecting the Positive (+) Power Wire with a Straight Terminal.............................................. 186

Figure 126: Connecting the Negative (-) Power Wire with a Straight Terminal............................................. 187

Figure 127: Closing the Plastic Cover over the Terminal Connectors........................................................... 188

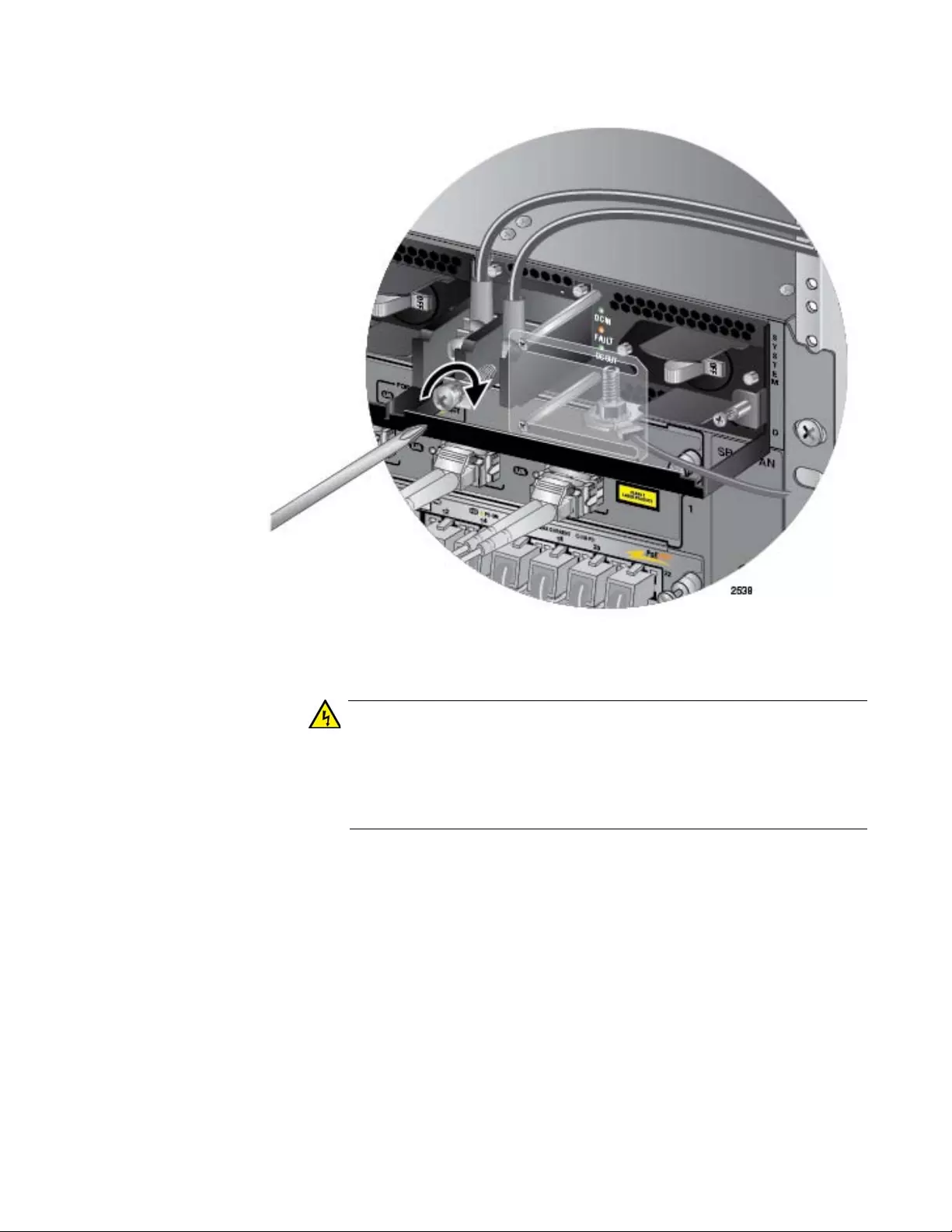

Figure 128: Tightening the Handle Locking Screw. ... .... ... ... ... .... ... ... ... .... ... ... ... ... .... ... ................ ... ... .... ......... 189

Figure 129: Stripping the Power Wires.......................................................................................................... 190

Figure 130: Attaching the Power Wires to the Right Angle Terminals........................................................... 190

Figure 131: Removing the Plastic Cover.......... ... ... ... .... ... ... ................ .... ... ... ................ ... .... ... ...................... 191

Figure 132: Removing the Terminal Screws .... ... ... ... .... ................ ... ... .... ... ................ ... ... .... ... ... ................... 192

Figure 133: Connecting the Positive (+) Power Wire with a Right Angle Terminal........................................ 193

Figure 134: Connecting the Negative (-) Power Wire with a Right Angle Terminal....................................... 194

Figure 135: Tightening the Handle Locking Screw. ... .... ... ... ... .... ... ... ... .... ... ... ... ... .... ... ................ ... ... .... ......... 195

Figure 136: Stripping Solid or Stranded DC Power Wires............................................................................. 196

Figure 137: Connecting the Positive Wire ..................................................................................................... 197

Figure 138: Connecting the Negative Lead Wire........................................................................................... 198

Figure 139: Switch Initialization Messages.................... ... ... ... .... ... ... ... .... ................ ... ... ... .... ... ... ... ................ 202

Figure 140: Switch Initialization Messages (Continued)... ... ... .... ... ... ... .... ... ... ... ... .... ... ... ... .... ... ... ... ... .... ......... 203

Figure 141: Connecting the Management Cable to the Console RS-232 Port.............................................. 208

Figure 142: SHOW PSU Command .............................................................................................................. 210

Figure 143: SHOW FANMODULE Command............................................................................................... 210

Figure 144: SHOW CARD Command ........................................................................................................... 211

Figure 145: Disconnecting the AC Power Cord from the AC Socket on the Back Panel .............................. 233

Figure 146: Lifting the Locking Handle on the Power Supply........................................................................ 234

Figure 147: Removing the Power Supply from the Chassis.......................................................................... 235

Figure 148: Installing a Blank Power Supply Slot Cover ............................................................................... 236

Figure 149: Lowering the Locking Handle on the Power Supply Slot Cover................................................. 237

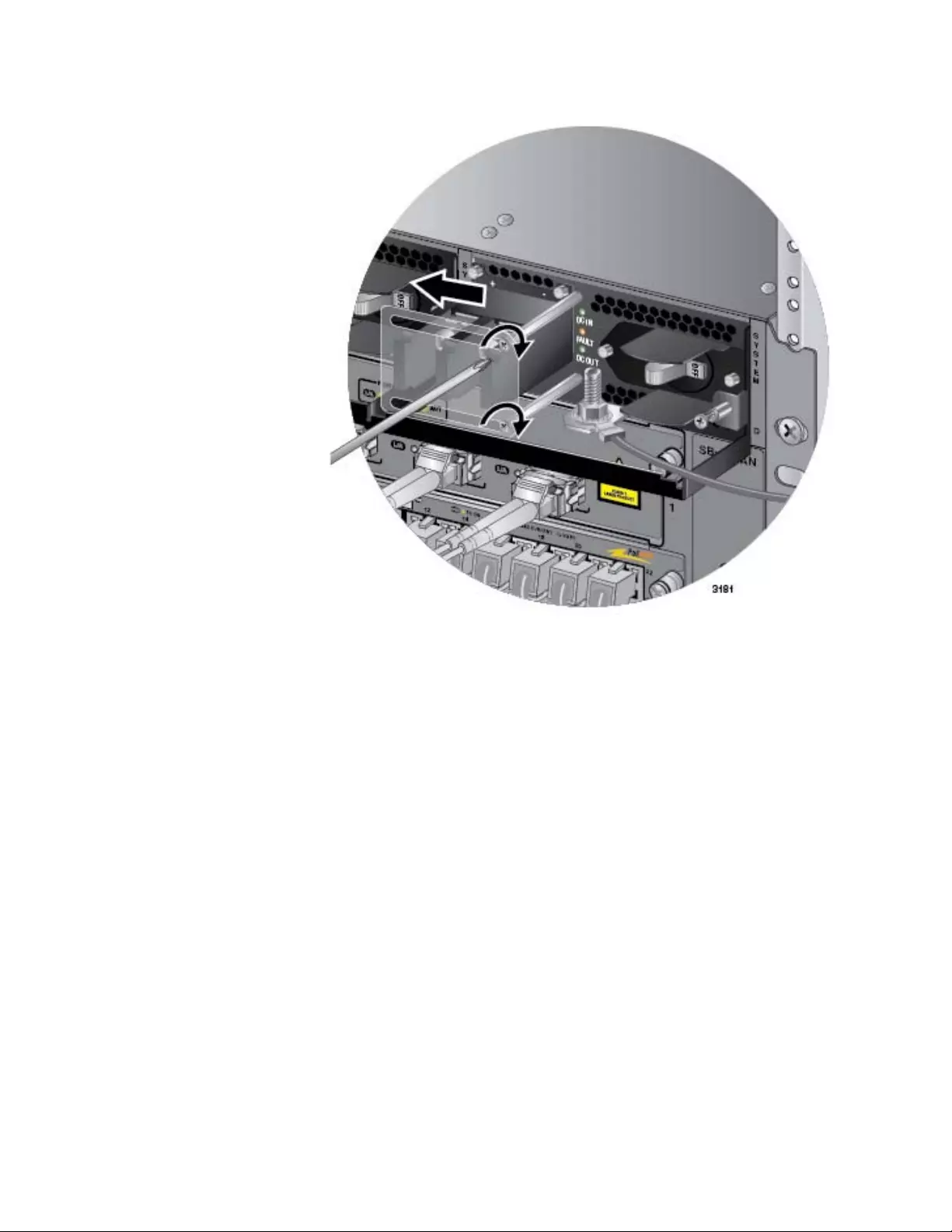

Figure 150: Loosening the Screw on the Locking Handle............................................................................. 239

Figure 151: Opening the Plastic Window on the Terminal Block...... ............................................................. 240

Figure 152: Removing the Negative Lead Wire............................................................................................. 241

Figure 153: Removing the Positive Lead Wire .............................................................................................. 242

List of Figures

12

Figure 154: Reinstalling the Screws on the Positive and Negative Terminals............................................... 243

Figure 155: Closing the Plastic Cover............................................................................................................ 244

Figure 156: Removing the Grounding Wire .. ... .... ... ... ................ ... .... ... ... ... ................ .... ... ... ... ....................... 245

Figure 157: Reinstalling the Nut and Washer on the Grounding Post ........................................................... 246

Figure 158: Lifting the Locking Handle and Removing the Power Supply ..................................................... 247

Figure 159: Installing a Blank Power Supply Slot Cover................................................................................ 248

Figure 160: Lowering the Locking Handle on the Power Supply Slot Cover........ ... ... .... ... ................ ... ... .... ... 249

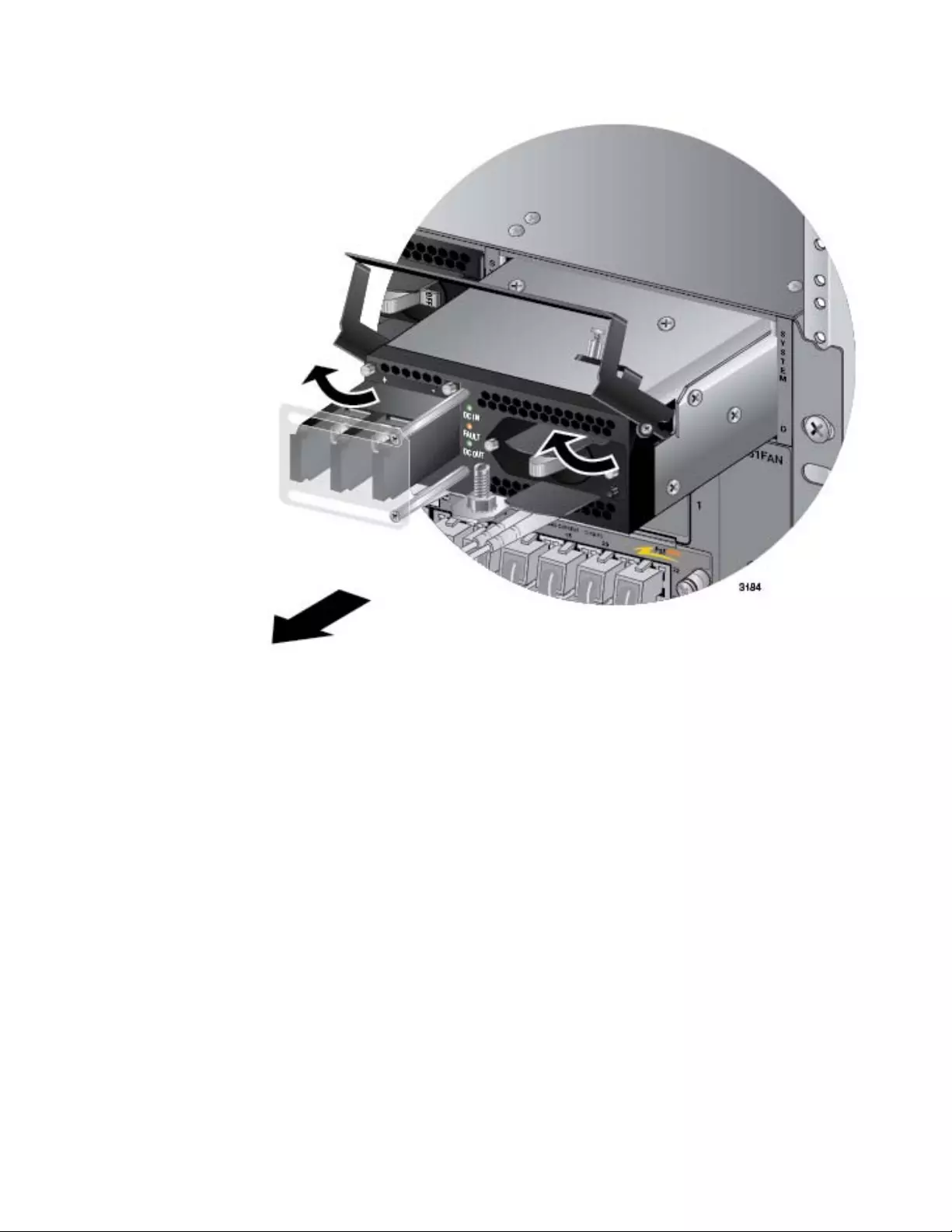

Figure 161: Loosening the Screw on the AT-SBxFAN12 Fan Module........................................................... 257

Figure 162: Loosening the AT-SBxFAN12 Fan Module from the Backplane Connector ............................... 257

Figure 163: Withdrawing the AT-SBxFAN12 Fan Module 25 mm (1 in.) from the Chassis ........................... 258

Figure 164: Removing the AT-SBxFAN12 Fan Module from the Chassis ..................................................... 259

Figure 165: Installing a New AT-SBxFAN12 Fan Module.............................................................................. 260

Figure 166: Securing the AT-SBxFAN12 Fan Module on the Backplane Connector..................................... 261

Figure 167: Tightening the Screw on the AT-SBxFAN12 Fan Module........................................................... 261

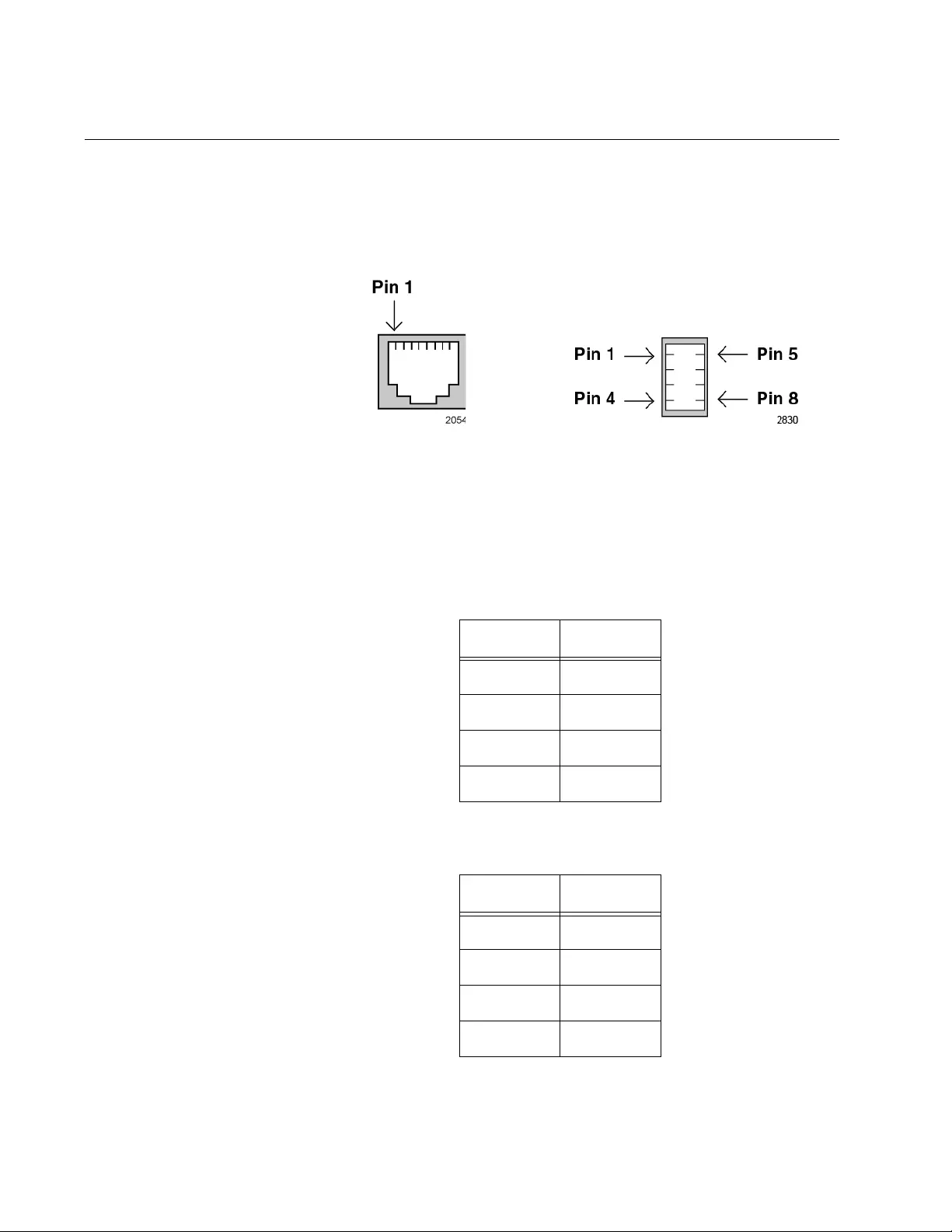

Figure 168: Pin Numbers for the RJ-45 and Point 5 Ports (Front View)........................................................ 270

13

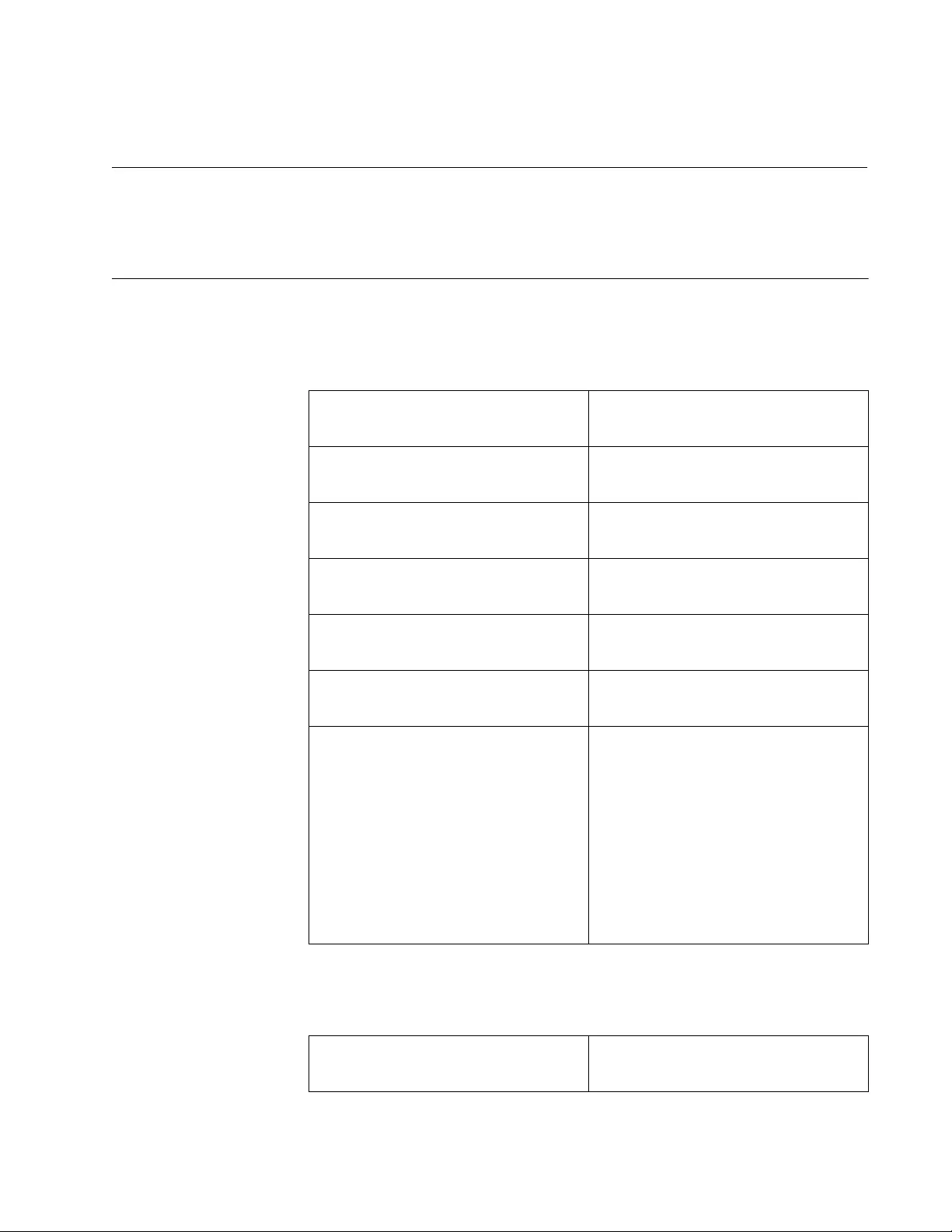

Table 1. LEDs on the AT-SBxPWRSYS1 and AT-SBxPWRSYS2 AC System Power Supplies .................... 27

Table 2. LEDs on the AT-SBxPWRSYS1 DC System Power Supply ............................................................ 27

Table 3. LEDs on the AT-SBxPWRPOE1 AC PoE Power Supply ................................................................. 28

Table 4. AT-SBxFAN12 Module LED ............................................................................................................. 29

Table 5. Power Supply Interface LED ............................................................................................................ 30

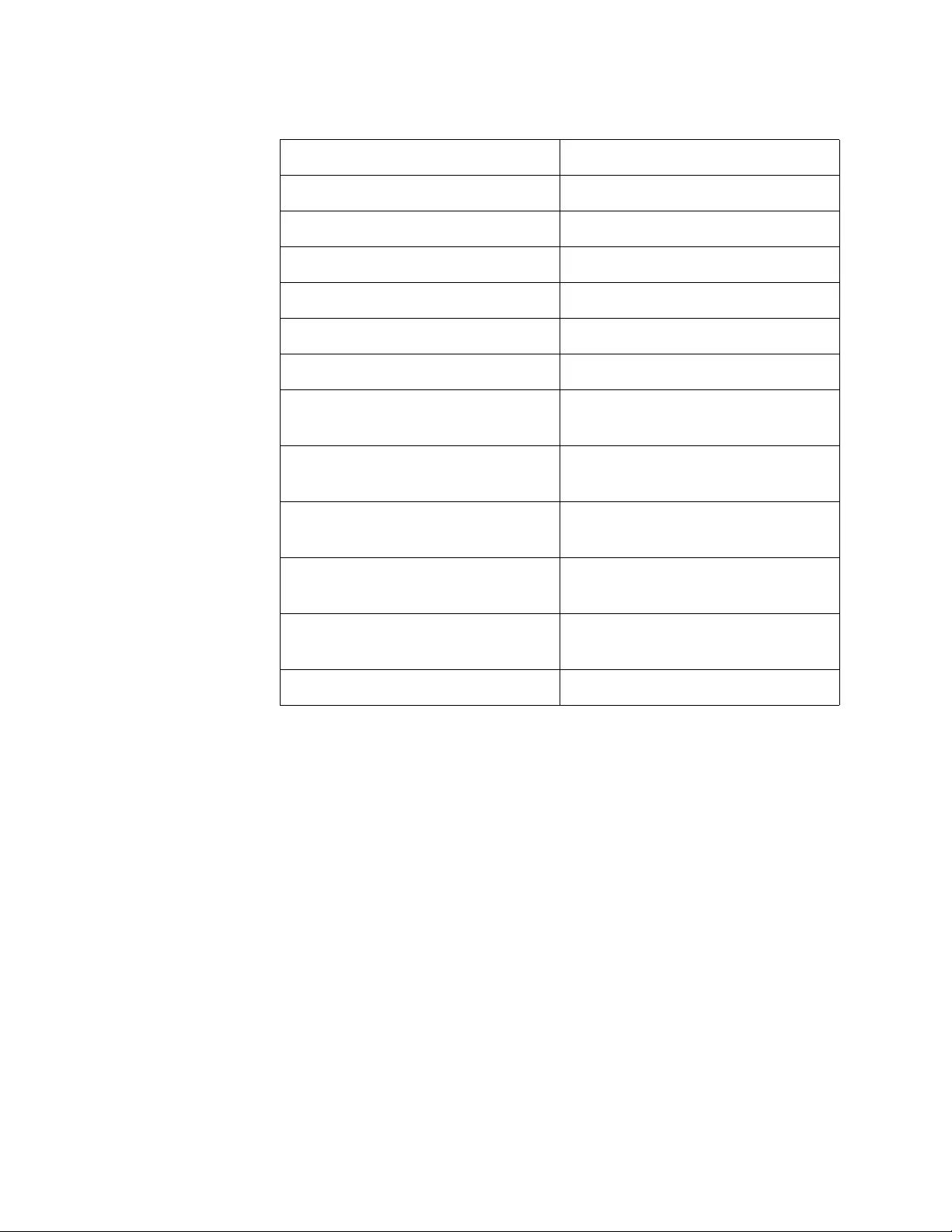

Table 6. Port LEDs on the AT-SBx31GT24 Line Card ................................................................................... 34

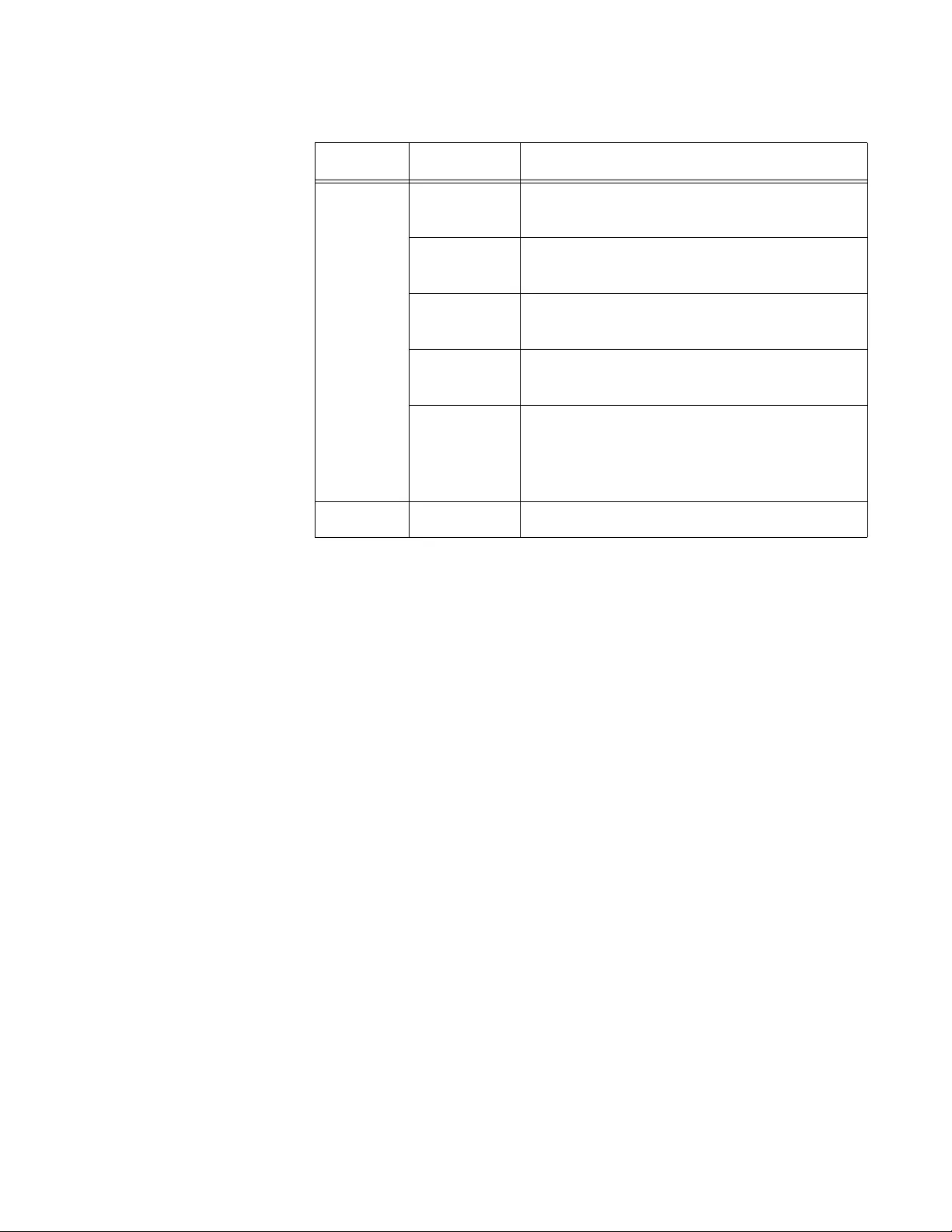

Table 7. Port LEDs for the AT-SBx31GT40 Line Card ................................................................................... 37

Table 8. Port LEDs on the AT-SBx31GP24 PoE Line Card ........................................................................... 39

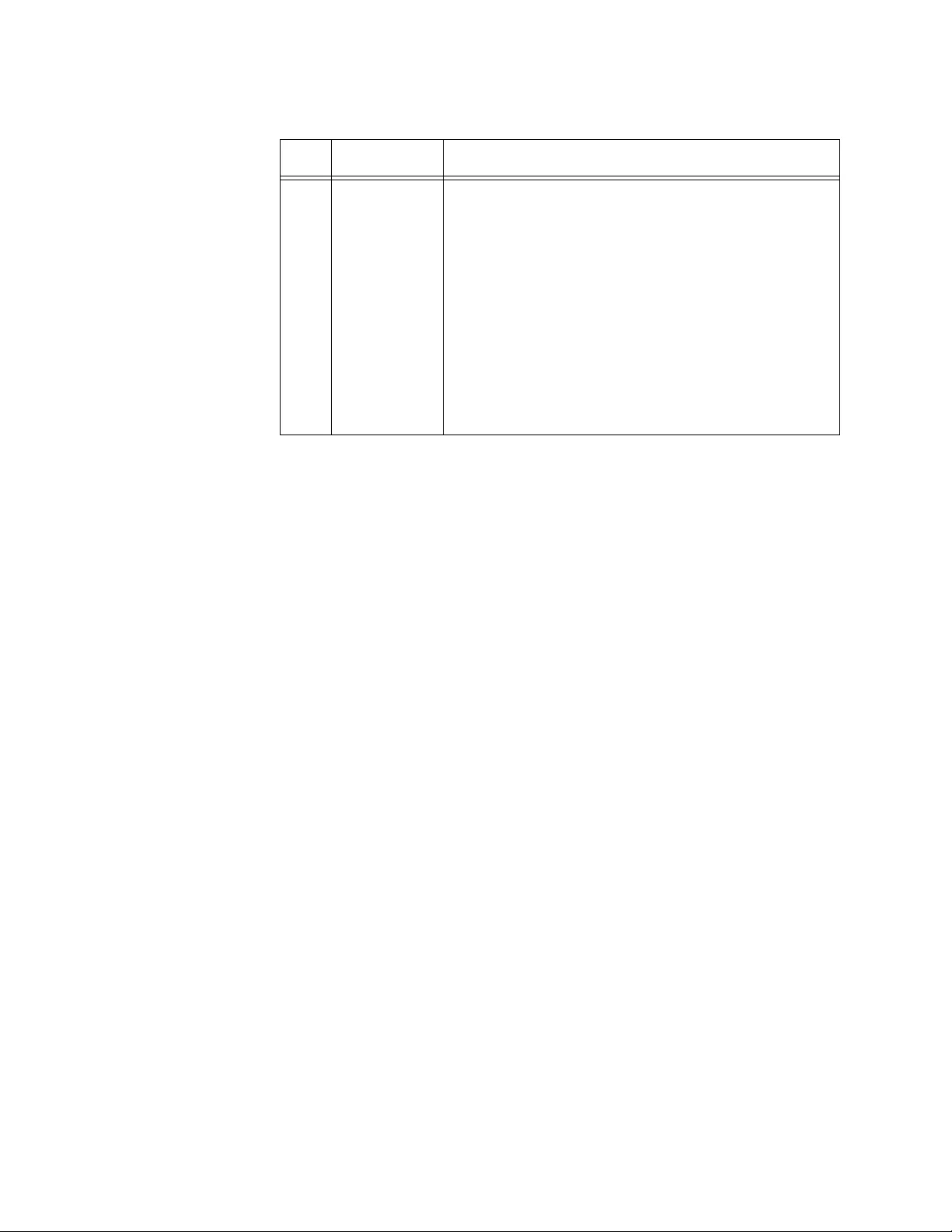

Table 9. Port LEDs on the AT-SBx31GS24 SFP Line Card ........................................................................... 42

Table 10. Transceiver Slot LEDs on the AT-SBx31GC40 Line Card .................... ... ... ... ....... ... ... ... .... ... ... ... ... 48

Table 11. Transceiver Slot LEDs on the AT-SBx31XZ4 XFP Line Card ........... .... ... ... ... .... ... ... ... ... .... ... ... ... ... 50

Table 12. SFP+ Slot LEDs on the AT-SBx31XS6 Line Card .......................................................................... 52

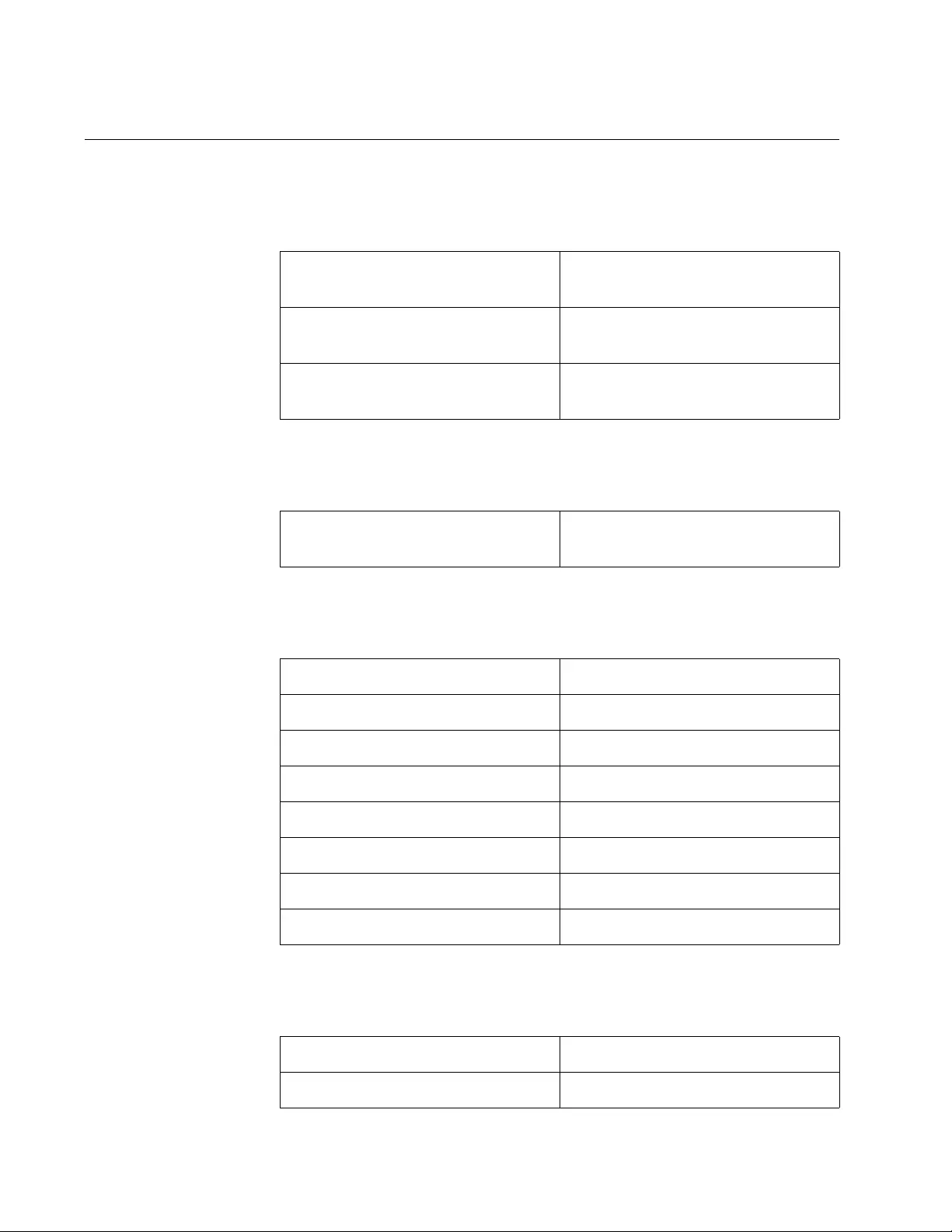

Table 13. Twisted Pair Cable for the AT-SBx31GT24 and AT-SBx31GT40 Line Cards ................................ 54

Table 14. Twisted Pair Cable for the AT-SBx31GP24 Line Card ...................................................................55

Table 15. IEEE802.3af and IEEE802.3at Powered Device Classes .............................................................. 57

Table 16. Maximum Number of Powered Devices .. .... ... ................ ... .... ... ... ... ... .... ................ ... ... ... .... ... ......... 58

Table 17. Differences Between the AT-SBx31CFC and AT-SBx31CFC960 Controller Fabric Cards ............ 62

Table 18. Components on the AT-SBx31CFC Controller Fabric Card ........................................................... 64

Table 19. SYS (System) Status LEDs ............................................................................................................ 69

Table 20. SBx Linecard Status LEDs ................ ... ... .... ... ... ... .... ... ... ... .... ... ... ... ... .... ... ... ... .... ... ... ... ................... 71

Table 21. Management Features Requiring Network Access ........................................................................73

Table 22. NET MGMT Port LED ........ ... ... ................ .... ... ... ... .... ... ... ... .... ... ... ... ... .... ................ ... ...................... 75

Table 23. SD Status LED .. ... ... ................ .... ... ... ... ... .... ... ... ... ................. ... ... ... ... .... ... ... ... .... ............................ 77

Table 24. Front Panel to Rack Rail Dimensions ............................................................................................. 96

Table 25. Switch Initialization Phases ............ ... ... ... .... ................ ... ... .... ... ... ... ... .... ... ... ... .... ... ... .................... 201

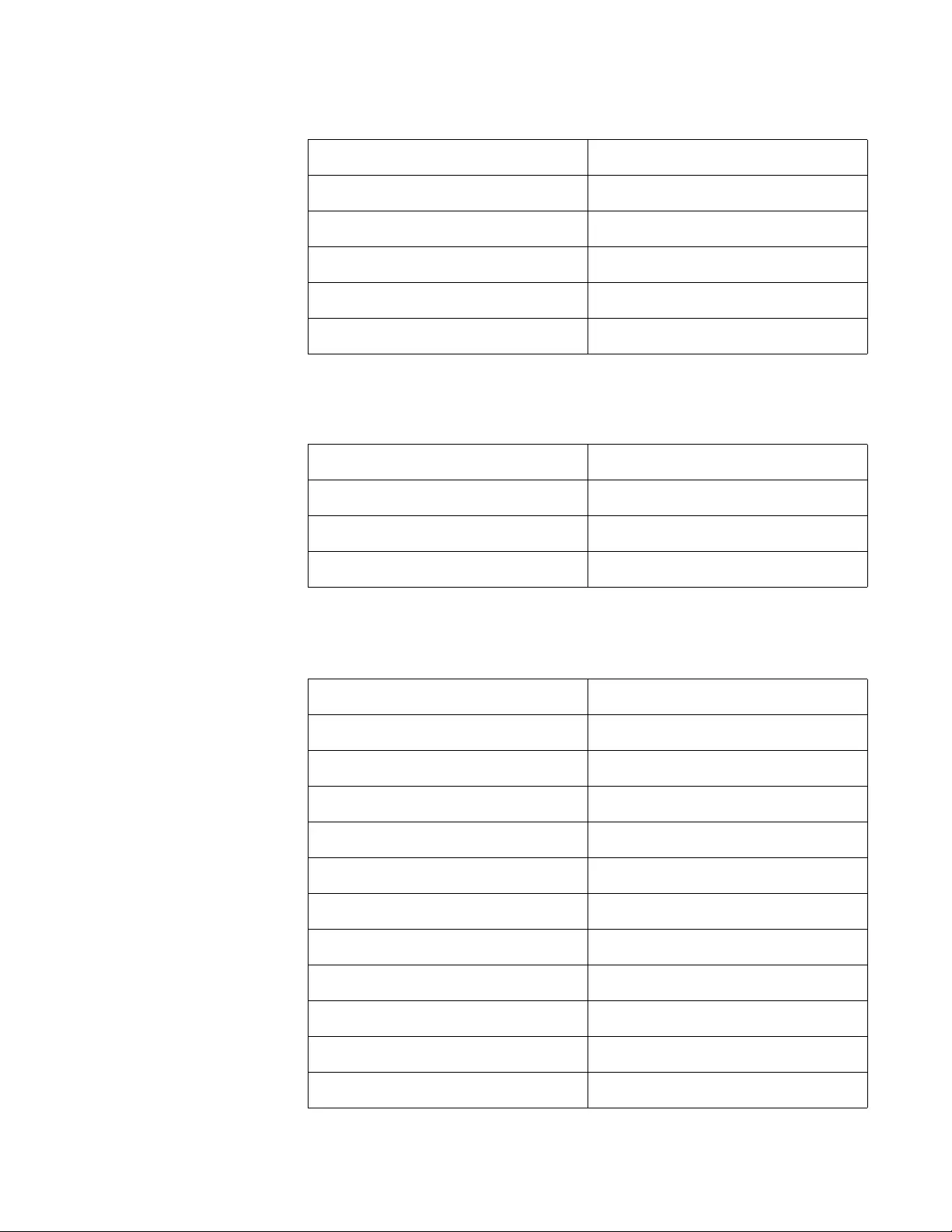

Table 26. Product Dimensions ................ .... ... ... ................ ... .... ... ... ... .... ... ... ... ................ .... ... ....................... 263

Table 27. Product Weights ...... ... .... ... ... ... .... ................ ... ... ... .... ... ... ................ ... .... ... ... ... .... .......................... 263

Table 28. Environmental Specifications ....................................................................................................... 265

Table 29. Acoustic Noise Test Components ........................ .... ... ... ... .... ... ... ... ... .... ... ... ... ................ .............. 265

Table 30. AC Voltage and Frequency Requirements ..... ... ... .... ... ... ... .... ... ... ... ... .... ... ... ... .... ... ... ... ... .... ... .. ..... 266

Table 31. DC Voltage Requirement ... ... ... .... ... .............................................................................................. 266

Table 32. Typical Power Savings in eco-friendly Mode ................................................................................ 266

Table 33. Maximum Power Consumption ..................................................................................................... 266

Table 34. Maximum Power Efficiency .......................................................................................................... 267

Table 35. Heat Dissipation ................... ... .... ... ... ... ... .... ... ... ................ .... ... ... ... ... .... ... ... ... .............................. 267

Table 36. Available Power Over Ethernet with One PoE Power Supply ...................................................... 268

Table 37. Available Power Over Ethernet with Two PoE Power Supplies ................................................... 268

Table 38. PoE Mode ............. ................ ... .... ... ... ... ... .... ... ... ................ .... ... ... ... ... .... ... ... ... .............................. 268

Table 39. Safety and Electromagnetic Emissions ........................................................................................ 269

Table 40. MDI Pin Signals (10Base-T or 100Base-TX) ................................................................................ 270

Table 41. MDI-X Pin Signals (10Base-T or 100Base-TX) ............................................................................ 270

Table 42. 1000Base-T Connector Pinouts ..................... ................ ... .... ... ... ... ... .... ... ... ... .... ... ... ... ... .............. 271

Tables

List of Tables

14

15

Preface

This guide contains the hardware installation instructions for the

SwitchBlade x3112 Chassis Switch. This preface contains the following

sections:

“Safety Symbols Used in this Document” on page 16

“Contacting Allied Telesis” on page 17

Note

This version of the installation guide ap plies to release 17.2.1 or later

of the management software for the AT-SBx31CFC Controller Fabric

Card. The latest release of the management software is available

from the Restricted Software Downloads web page on the Allied

Telesis web site, at www.alliedtelesis.com/support/software/

restricted.

Preface

16

Safety Symbols Used in this Document

This document uses the following conventions.

Note

Notes provide additional information.

Caution

Cautions inform you that performing or omitting a specific action

may result in equipment damage or loss of data.

Warning

Warnings inform you that performing or omitting a specific action

may result in bodily injury.

Warning

Laser warnings inform you that an eye or skin hazard exists due to

the presence of a Class 1 laser device.

Warning

Fan warnings inform you of danger from hazardous moving fan

blades.

SwitchBlade x3112 Chassis Switch and AT-SBx31CFC Card Installation Guide

17

Contacting Allied Telesis

If you need assistance with this product, you may contact Allied Telesis

technical support by going to the Support & Services section of the Allied

Telesis web site at www.alliedtelesis.com/support. You can find links for

the following services on this page:

24/7 Online Support — Enter our interactive support center to

search for answers to your product questions in our knowledge

database, to check support tickets, to learn about RMAs, and to

contact Allied Telesis technical experts.

USA and EMEA phone support — Select the phone number that

best fits your location and customer type.

Hardware warranty information — Learn about Allied Telesis

warranties and register your product online.

Replacement Services — Submit a Return Merchandise

Authorization (RMA) request via our interactive support center.

Documentation — View the most recent installation and user

guides, software release notes, white papers, and data sheets for

your products.

Software Downloads — Download the latest software releases for

your managed products.

For sales or corporate information, go to www.alliedtelesis.com/

purchase.

Preface

18

19

Chapter 1

Overview of the Chassis and Power

Supplies

This chapter contains an overview of the hardware components of the AT-

SBx3112 Chassis and power supplies. The sections in the chapter are

listed here:

“AT-SBx3112 Chassis” on page 20

“Slots for the Ethernet Line and Controller Cards” on page 23

“Power Supplies and Power Supply Slots” on page 24

“AT-SBxFAN12 Module” on page 29

“Power Supply Interfaces (Opto-couplers)” on page 30

Note

This version of the installation guide ap plies to release 17.2.1 or later

of the management software for the AT-SBx31CFC Controller Fabric

Card. The latest release of the management software is available

from the Restricted Software Downloads web page on the Allied

Telesis web site, at www.alliedtelesis.com/support/software/

restricted.

Chapter 1: Overview of the Chassis and Power Supplies

20

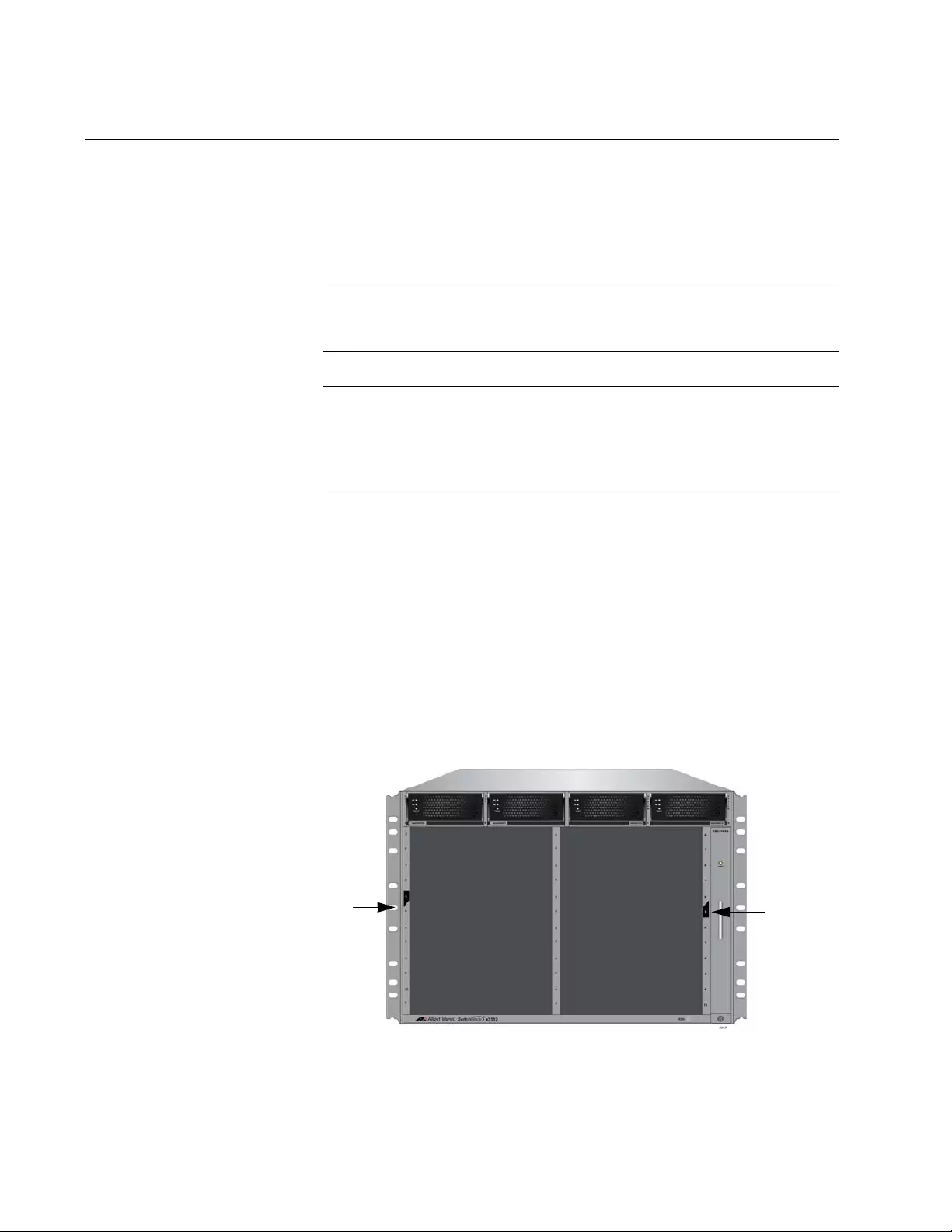

AT-SBx3112 Chassis

The SBx3112 product is a modular Gigabit and 10 Gigabit Ethernet

switch. The main components are the AT-SBx3112 Chassis, Ethernet line

cards, a controller card, a system power supply, a Power over Ethernet

Plus (PoE+) power supply, and a fan module.

The AT-SBx3112 Chassis is shown in Figure 1.

Figure 1. AT-SBx3112 Chassis

The chassis has slots for the following components:

Ten Ethernet line cards

Two AT-SBx31CFC Controller Fabric Cards

Two AC or DC system power supplies

Two Power over Ethernet Plus (PoE+) power supplies

One AT-SBxFAN12 Fan Module

The chassis components are identified in Figure 2 on page 21 and Figure

3 on page 22.

SwitchBlade x3112 Chassis Switch and AT-SBx31CFC Card Installation Guide

21

Figure 2. Front View of the AT-SBx3112 Chassis

Note

Do not remove the shipping brace from the front of the chassis until

after the unit is installed in the equipment rack. You might bend the

chassis and cause misalignment of the slots and card guides if you

lift the chassis into the equipment rack without the shipping brace.

Slots for Ethernet

Line Cards and

Controller Card

Slots for Ethernet

Line Cards and

Controller Card

PoE Power

Supply Slots System Power

Supply Slots

Shipping Brace AT-SBxFAN12

Module

ESD Wrist Strap

Plug

Chapter 1: Overview of the Chassis and Power Supplies

22

Figure 3. Rear View of the AT-SBx3112 Chassis

Figure 4 is an example of a fully populated chassis.

Figure 4. AT-SBx3112 Chassis with Line Cards, Controller Cards, and

Power Supplies

Grounding

Lug AC Power

Cord Sockets Power Supply

Interfaces

(Opto-couplers)

SwitchBlade x3112 Chassis Switch and AT-SBx31CFC Card Installation Guide

23

Slots for the Ethernet Line and Controller Cards

The chassis has slots for ten Ethernet line cards and two AT-SBx31CFC

Controller Fabric Cards. The functions of the slots, which are numbered

starting with 0, are predefined and may not be changed. Figure 5 identifies

the sl ots.

Figure 5. Slots for the Ethernet Line and Controller Cards

Slots 0 to 3 and 6 to 11 are for the Ethernet line cards. Each slot can

accommodate one card. You may install the cards in any order or variety

in the slots. For more information on the line cards, refer to Chapter 2,

“Overview of the Ethernet Line Cards” on page 31.

Slots 4 and 5 are for the AT-SBx31CFC Controller Fabric Card. Each slot

can accommodate one controller card. The chassis must have at least one

controller card. Installing two controller cards provides these benefits:

Management redundancy.

Higher backplane bandwidth for the Ethernet line cards.

For more information on the controller card, refer to Chapter 3, “Overview

of the AT-SBx31CFC Controller Fabric Card” on page 61.

Slot 0 - Line Card

Slot 2 - Line Card

Slot 4 - Controller Card

Slot 6 - Line Card

Slot 8 - Line Card

Slot 10 - Line Card

Slot 1 - Line Card

Slot 3 - Line Card

Slot 5 - Controller Card

Slot 7 - Line Card

Slot 9 - Line Card

Slot 11 - Line Card

Chapter 1: Overview of the Chassis and Power Supplies

24

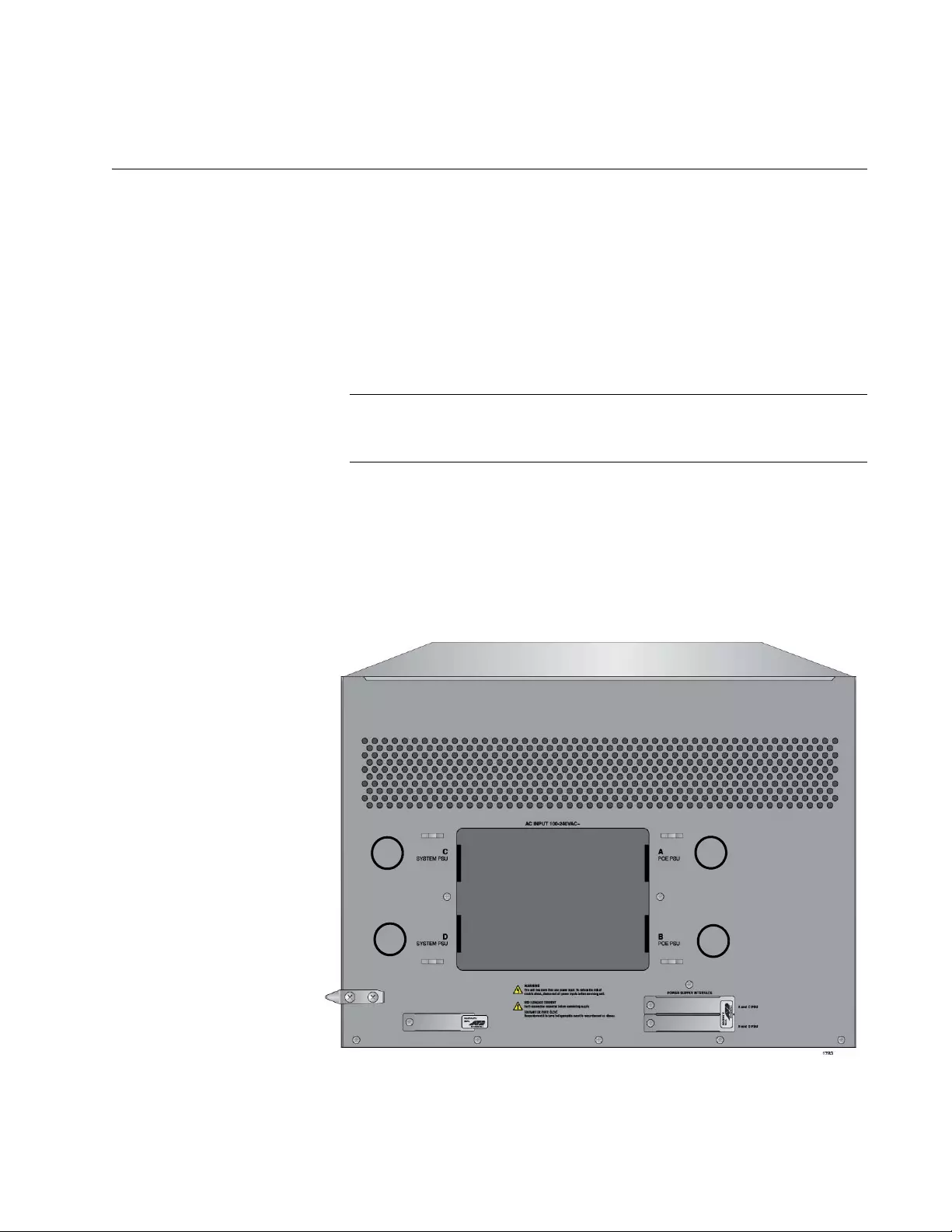

Power Supplies and Power Supply Slots

There are four power supplies for t he chassis. They are sh own in Figure 6.

Figure 6. Power Supply Units

Note

Allied Telesis is discontinuing the AT-SBxPWRSYS1 AC Power

Supply and replacing it with the AT-SBxPWRSYS2 AC Power

Supply.

The power supplies are installed in the four slots across the top of the front

of the chassis. The slots are labelled A to D. Refer to Figure 7 on page 25.

AT-SBxPWRSYS1 AC System Power

Supply for the Ethernet line cards, controller

cards, and fan module.

AT-SBxPWRPOE1 AC Power Supply with

1200 W PoE budget for the ports on the AT-

SBx31GP24 PoE Ethernet Line Card.

AT-SBxPWRSYS1 DC System Power

Supply for the Ethernet line cards, controller

cards, and fan module.

AT-SBxPWRSYS2 AC System Power

Supply for the Ethernet line cards, controller

cards, and fan module.

SwitchBlade x3112 Chassis Switch and AT-SBx31CFC Card Installation Guide

25

Figure 7. Power Supply Slots

Slots C and D are for system power supplies. The three system power

supplies are listed here:

AT-SBxPWRSYS1 AC Power Supply

AT-SBxPWRSYS2 AC Power Supply

AT-SBxPWRSYS1 DC Power Supply

System power supplies provide power for all of the chassis hardware

components, including the line cards, controller cards, and fan module.

The only component they do no t sup port is the PoE feature on the twisted

pair ports on the AT-SBx31GP24 Line Cards. Please review the following

items concerning the system power supplies:

The system power supplies are installed in slots C and D of the

chassis.

You may install either one or two system power supplies in the

chassis.

A single power supply can support a fully populated chassis.

Adding a second power supply adds power redundancy to the unit.

If you are installing only one system power supply, you may install

it in either slot C or D.

The AT-SBxPWRSYS1 AC and AT-SBxPWRSYS2 AC System

Power Supplies use the AC connectors on the back panel of the

chassis and are intended for AC environments.

The AT-SBxPWRSYS1 DC System Power Supply has DC power

connectors on its front panel and is intended for DC environments.

The system power supplies are hot swappable. You do not have to

power off the chassis to replace a power supply.

Slot A

Supply

PoE Power Slot B

Supply

PoE Power Slot C

Supply

System Power Slot D

Supply

System Power

Chapter 1: Overview of the Chassis and Power Supplies

26

The AT-SBxPWRSYS1 AC and AT-SBxPWRSYS2 AC System

Power Supplies are compatible and can be used in the same

chassis.

The AT-SBxPWRSYS2 AC System Power Supply was added to

the management software in R17.2.1. It will work with earlier

releases, but Allied Telesis recommends up datin g the so ftware on

controller cards that have earlier versions to the latest release to

ensure full compatibility.

Note

The AT-SBxPWRSYS1 DC System Power Supply is not compatible

with the other system and PoE power supplies and should not be

operated in the same chassis with other power supplies. You may,

however, operate the chassis for a short period of time with AC and

DC power supplies if you are converting it from one type of power

supply to another, such as from AC to DC.

Slots A and B are for the AT-SBxPWRPOE1 AC PoE Power Supply. This

module provides the PoE power for the twisted pair ports on the AT-

SBx31GP24 PoE Line Card. Please note the following items concerning

the PoE power supply:

PoE power supplies are installed in slots A and B of the chassis.

You may install either one or two PoE power supplies in the

chassis.

If you are installing only one power supply, you may install it in

either slot A or B.

A single PoE power supply provides up to 1,200 watts of power for

PoE. Two PoE power supplies provide up to 2,400 watts of power.

The PoE power supply is hot swappable. You do not have to power

off the chassis to replace it.

The total number of powered devices the chassis can support on

the ports on AT-SBx31GP24 PoE Line Cards depends on the

number of AT-SBxPWRPOE1 Power Supplies in the chassis and

the power requirements of the devic es. For instance, a chassis can

support 40 port s of Class 4, PoE+ (IEEE 802.3at) powere d devices

with one power supply or 80 ports with two power supplies. For

further information, refer to “Power Budgeting” on page 58.

Note

Power supplies are not included with the chassis and must be

purchased separately.

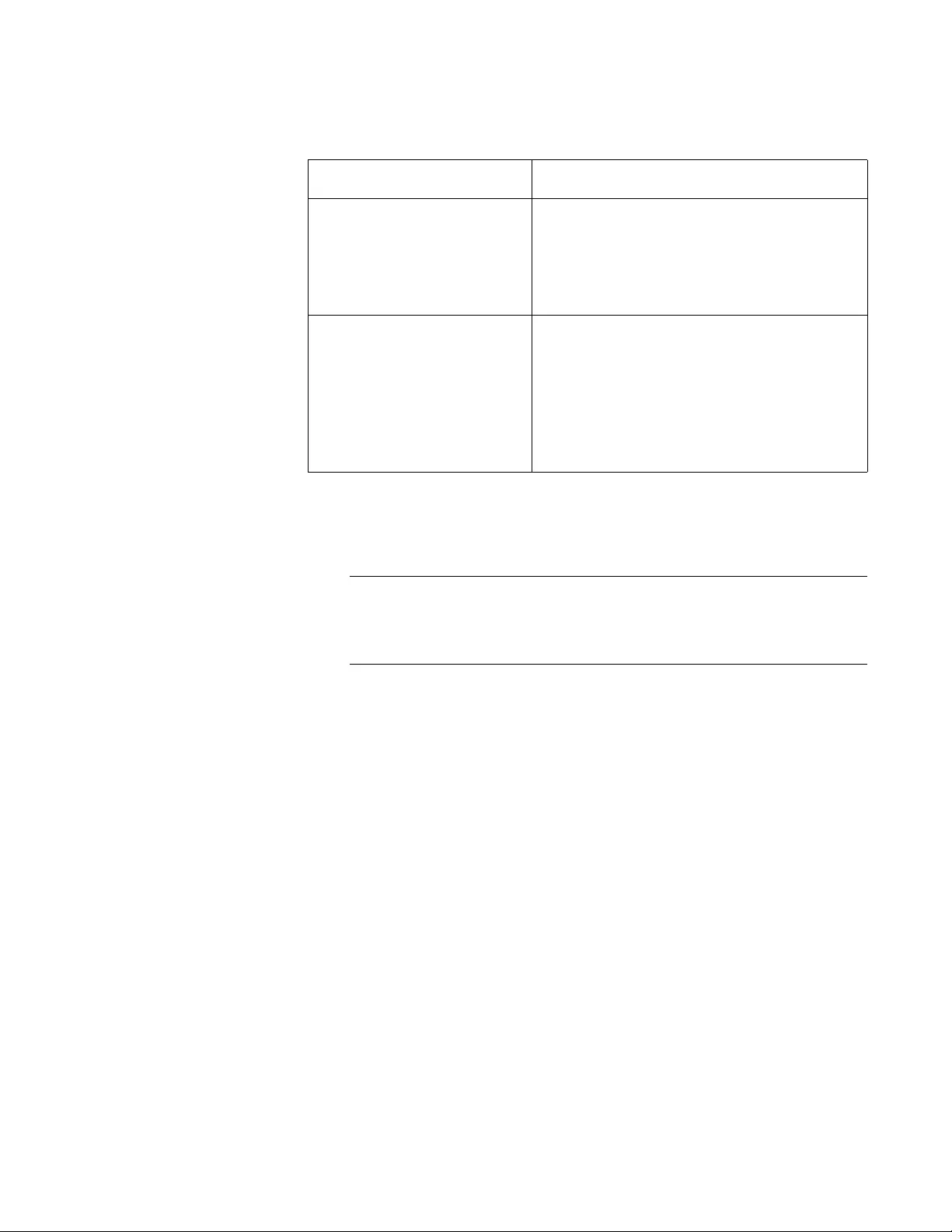

LEDs The LEDs on the AT-SBxPWRSYS1 and AT-SBxPWRSYS2 AC System

Power Supplies are described in Table 1 on page 27.

SwitchBlade x3112 Chassis Switch and AT-SBx31CFC Card Installation Guide

27

The LEDs on the AT-SBxPWRSYS1 DC System Power Supply are

described in Table 2.

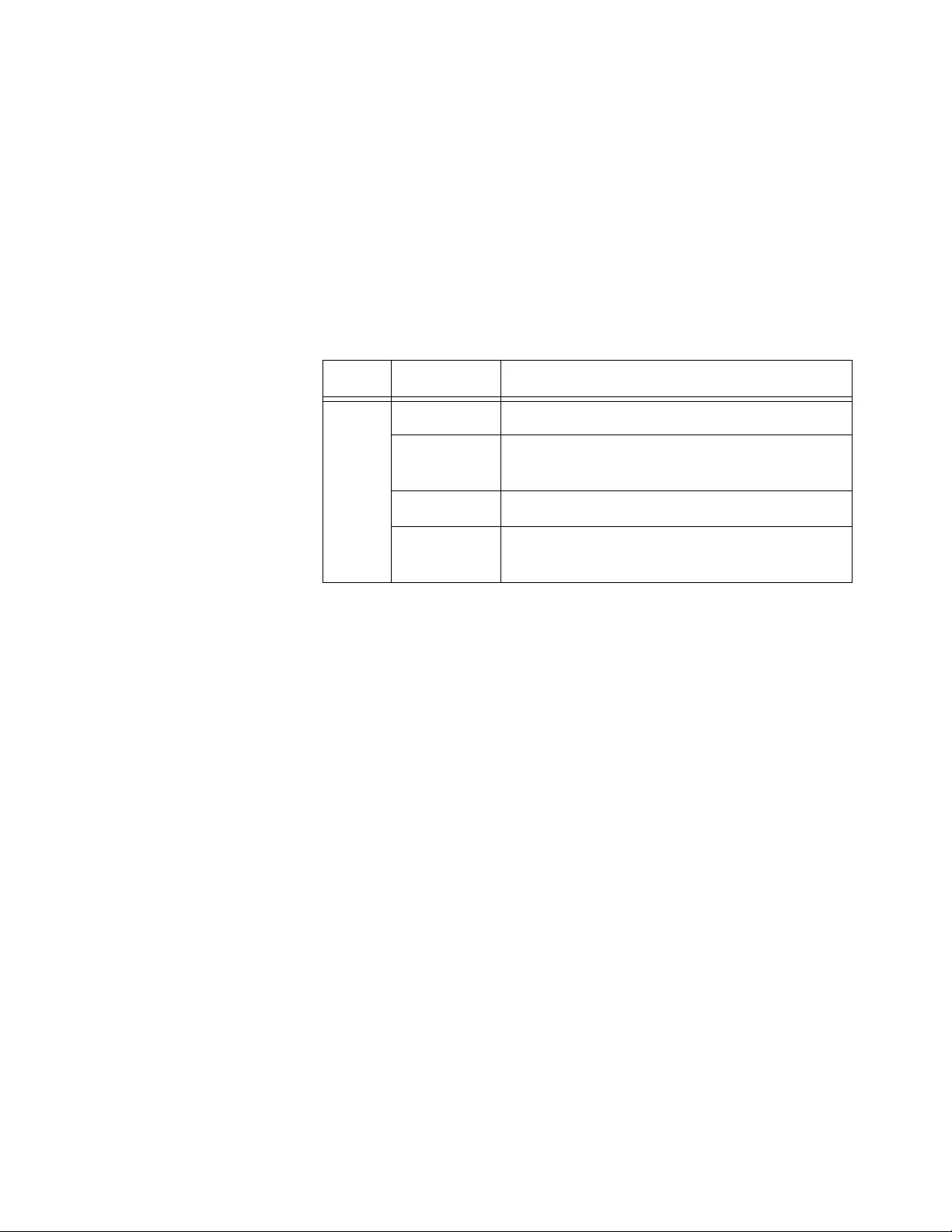

Table 1. LEDs on the AT-SBxPWRSYS1 and AT-SBxPWRSYS2 AC

System Power Supplies

LED State Description

AC

Solid Green The power supply is receiving AC power that is

within the normal operating range.

Off The power supply is not receiving power from the

AC power source.

DC

Solid Green The DC power that the module is providing to the

chassis components is within the normal

operating range.

Off The power supply is not generating DC power or

the power is outside the normal operating range.

Fault

Solid Amber The power supply has detected a fault condition,

such as an under-voltage or over-temperature

condition.

Off The power supply is operating normally or is

powered off.

Table 2. LEDs on the AT-SBxPWRSYS1 DC System Power Supply

LED State Description

DC

IN

Solid Green The power supply is receiving DC power that is

within the normal operating range.

Off The power supply is not receiving power from the

DC power source.

DC

OUT

Solid Green The DC power that the module is providing to the

chassis components is within the normal

operating range.

Off The power supply is not generating DC power or

the power is outside the normal operating range.

Fault

Solid Amber The power supply has detected a fault condition,

such as an under-voltage or over-temperature

condition.

Off The power supply is operating normally or is

powered off.

Chapter 1: Overview of the Chassis and Power Supplies

28

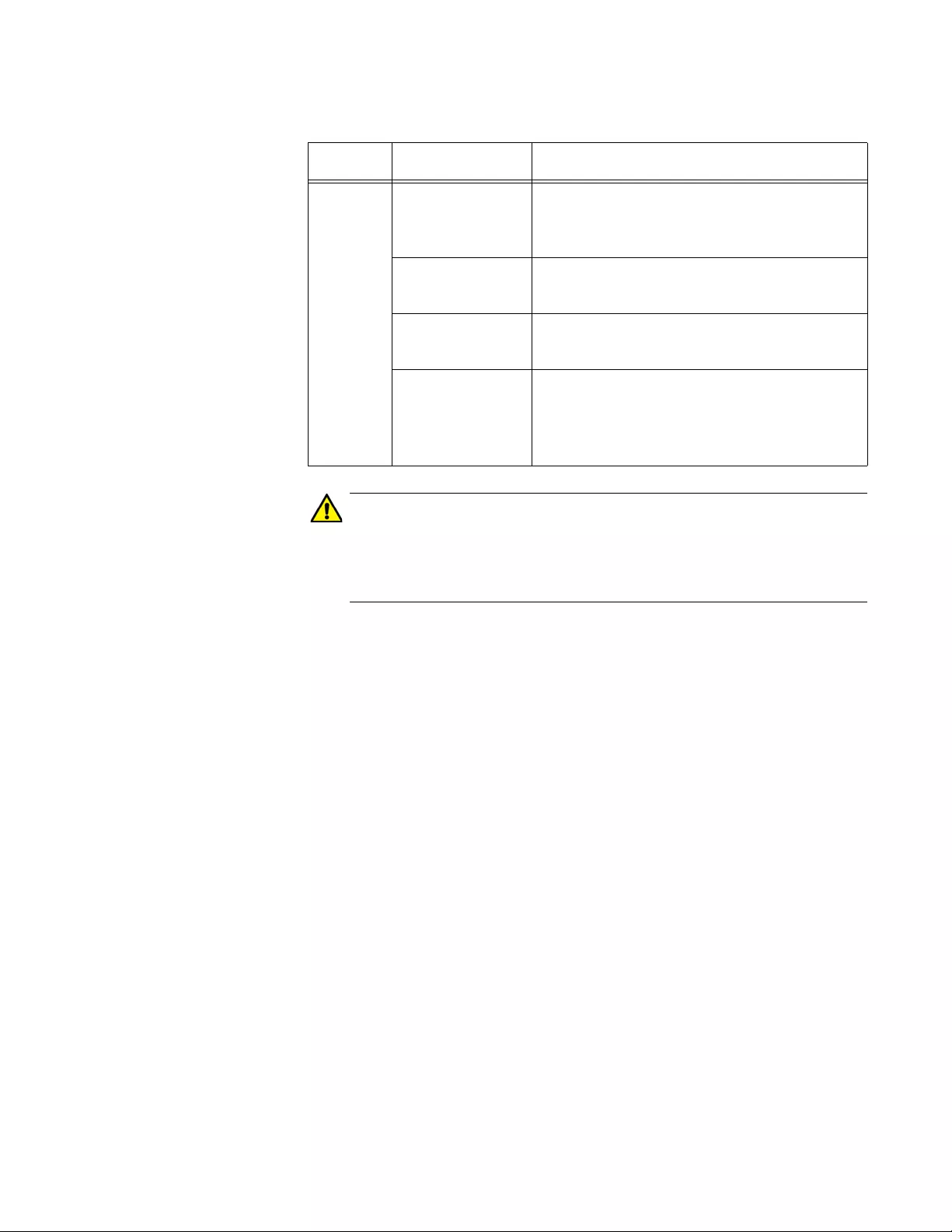

The LEDs on the AT-SBxPWRPOE1 AC PoE Power Supply are describe d

in Table 3.

Table 3. LEDs on the AT-SBxPWRPOE1 AC PoE Power Supply

LED State Description

AC

Solid Green The power supply is receiving AC power that is

within the normal operating range.

Off The power supply is not receiving power from the

AC power source.

DC

Solid Green The DC power provided by the module over the

backplane to the AT-SBx31GP24 PoE Line Cards

and the powered devices is within the normal

operating range.

Off The power supply is not providing any DC power

or the power is not within the normal operating

range.

Fault

Solid Amber The power supply has detected a fault condition,

such as an under-voltage or over-temperature

condition.

Off The power supply is operating normally or is

powered off.

SwitchBlade x3112 Chassis Switch and AT-SBx31CFC Card Installation Guide

29

AT-SBxFAN12 Module

The AT-SBxFAN12 Module is the cooling unit for the chassis. It is a field-

replaceable assembly that is factory installed and shipped with the AT-

SBx3112 Chassis.

The module is controlled by the AT-SBx31CFC Controller Fabric Card.

The fan speeds are automatically adjusted according to the internal

operating temperature of the switch. The fans are at their lowest speed

when the ambient temperature coming into the fan is a pproximately 20° C.

The fan speeds increase to provide ad ditional cooling as the ambient

temperature rises.

Figure 8. AT-SBxFAN12 Module

LED The POWER LED on the AT-SBxFAN12 Module is described in Table 4.

Table 4. AT-SBxFAN12 Module LED

LED State Description

Power Solid Green The AT-SBxFAN12 Module is receiving

power.

OFF The AT-SBxFAN12 Module is not receiving

power or has failed.

Chapter 1: Overview of the Chassis and Power Supplies

30

Power Supply Interfaces (Opto-couplers)

The chassis has two power supply interfaces, also referred to as opto-

couplers, in the lower right corner of the rear pane l. Refer to Fig ure 9. The

interfaces, labeled Power Supply Interface, are used by the active master

control card to obtain status information from the power supplies.

Figure 9. Power Supply Interfaces (Opto-couplers)

The active controller card uses the top interface to communicate with the

power supplies in slots A and C, and the bottom inte rface to communica te

with the power supplies in slots B and D.

The power supply interfaces are not hot swappable and should only be

serviced by an authorized service technician.

LED Each interface has one LED, labeled Power. The LED is described in

Table 5.

Table 5. Power Supply Interface LED

LED State Description

Power Solid Green The interface is operating normally.

Off The possible states of the LED are listed

here:

- The corresponding power supply slots of

the interface are empty.

- The power supplies in the power supply

slots are powered off or have failed.

- The power supplies in the power supply

slots are powered on and functioning

normally, but the power supply interf ace has

failed.

31

Chapter 2

Overview of the Ethernet Line Cards

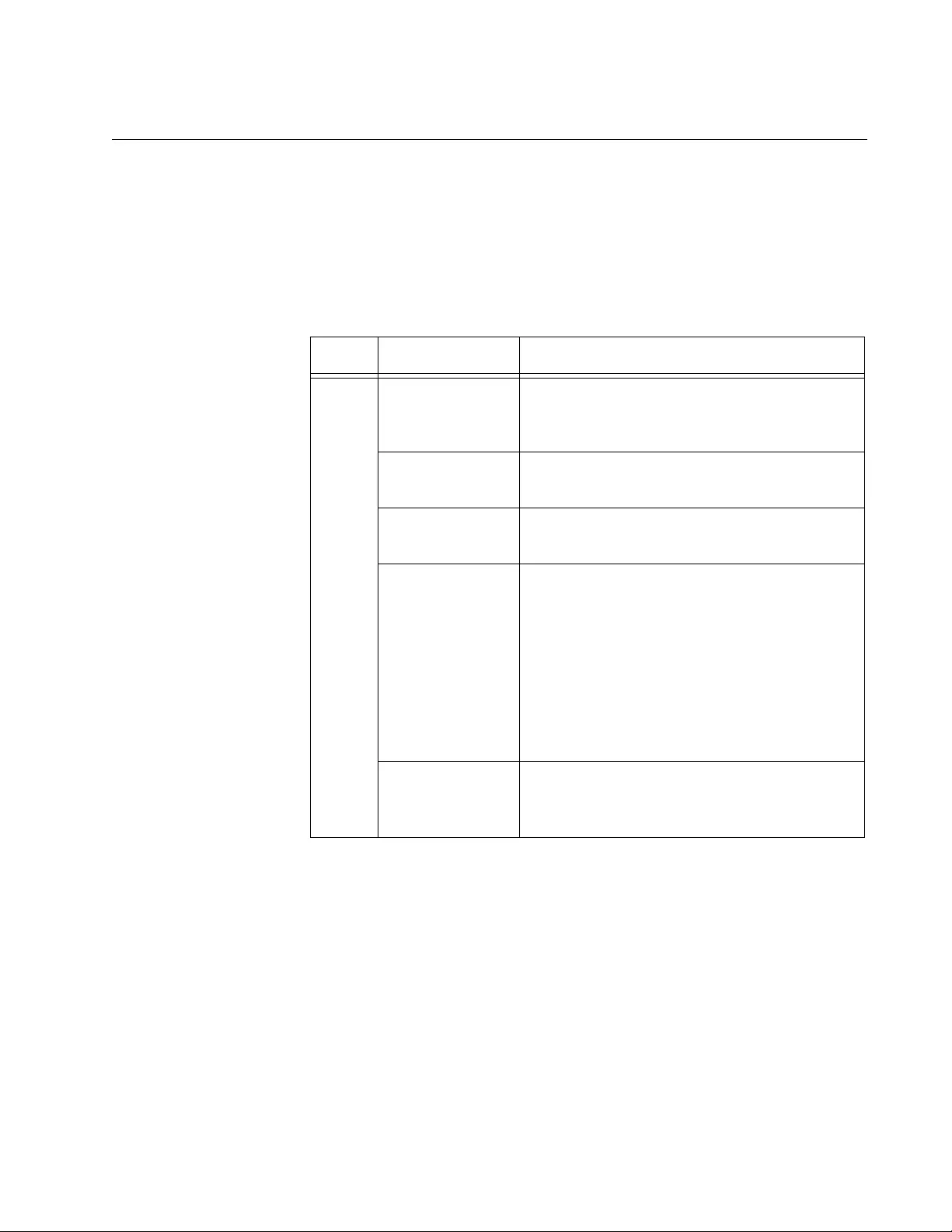

The sections in this chapter describe the Ethernet line cards for the AT-

SBx3112 Chassis:

“Ethernet Line Cards” on page 32

“AT-SBx31GT24 Line Card” on page 33

“AT-SBx31GT40 Line Card” on page 35

“AT-SBx31GP24 PoE Line Card” on page 38

“AT-SBx31GS24 SFP Line Card” on page 41

“AT-SBx31GC40 Line Card” on page 43

“AT-SBx31XZ4 XFP Line Card” on page 49

“AT-SBx31XS6 SFP+ Line Card” on page 51

“10/100/1000Base-T Twisted Pair Ports” on page 53

“Power over Ethernet on the AT-SBx31GP24 Line Card” on page 57

Chapter 2: Overview of the Ethernet Line Cards

32

Ethernet Line Cards

The Ethernet line cards are shown in Figure 10.

Figure 10. Ethernet Line Cards

AT-SBx31GT24 Ethernet Line Card with 24

10/100/1000Base-T twisted pair ports.

AT-SBx31GP24 Ethernet Line Card with 24

10/100/1000Base-T twisted pair ports, with

PoE+.

AT-SBx31GS24 Ethernet Line Card with 24

slots for 100 or 1000Mbps, fiber optic or

twisted pair SFP transceivers.

AT-SBx31GT40 Ethernet Line Card with 40

10/100/1000Base-T twisted pair ports, with

RJ point 5 connectors.

AT-SBx31XZ4 Ethernet Line Card with four

slots for 10Gbps, fiber optic XFP

transceivers.

AT-SBx31XS6 Ethernet Line Card with six

slots for 10Gbps, fiber optic SFP+

transceivers or Twinax direct connect

cables.

AT-SBx31GC40 Ethernet Line Card with 20

slots for 1000Mbps standard SFP or

compact SFP (CSFP) BiDi transceivers.

SwitchBlade x3112 Chassis Switch and AT-SBx31CFC Card Installation Guide

33

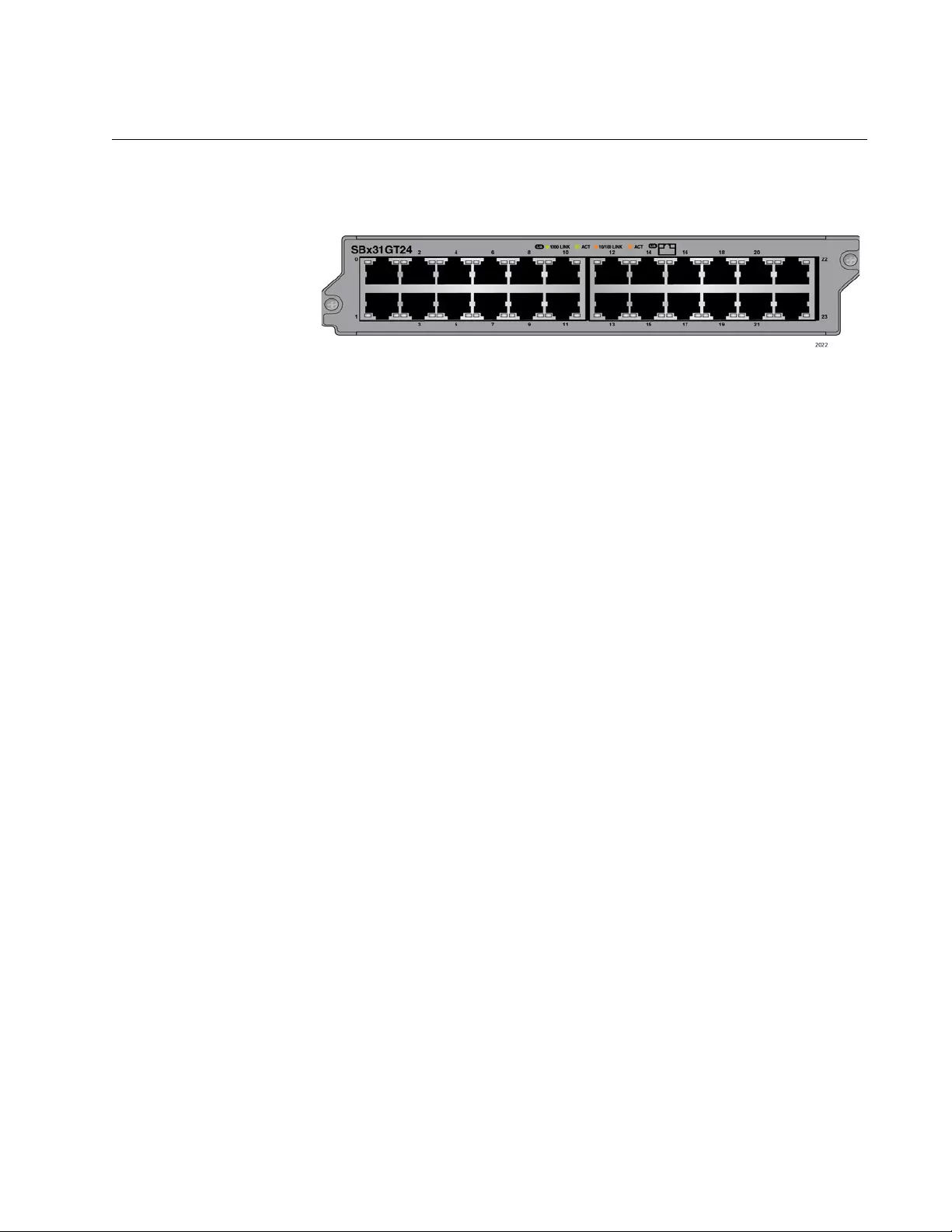

AT-SBx31GT24 Line Card

The AT-SBx31GT24 Line Card, shown in Figure 11, is a Gigabit Ethernet

switch.

Figure 11. AT-SBx31GT24 Line Card

Here are the main features of the line card:

24 10/100/1000Base-T ports

RJ-45 connectors

100 meters (328 feet) maximum operating distance per port

Auto-Negotiation for speed and duplex mode

Automatic MDIX detection for ports operating at 10/100Base-TX,

(Automatic MDIX detection does not apply to 1000Base-T

operation.)

Port Link/Activity (L/A) LEDs

16K entry MAC address table

12 Mb buffer memory

Jumbo frame support:

– 10240 octets for tagged and untagged traffic

between ports on the same line card

– 10232 octets for untagged traffic between ports on

different line cards

– 10236 octets for tagged traffic between ports on

different line cards

Non-blocking full-wire speed switching o n all packet sizes, with two

AT-SBx31CFC Controller Fabric Cards

Hot swappable

The cable requirements for the ports on the AT-SBx31GT24 Line Card are

listed in Table 13 on page 54.

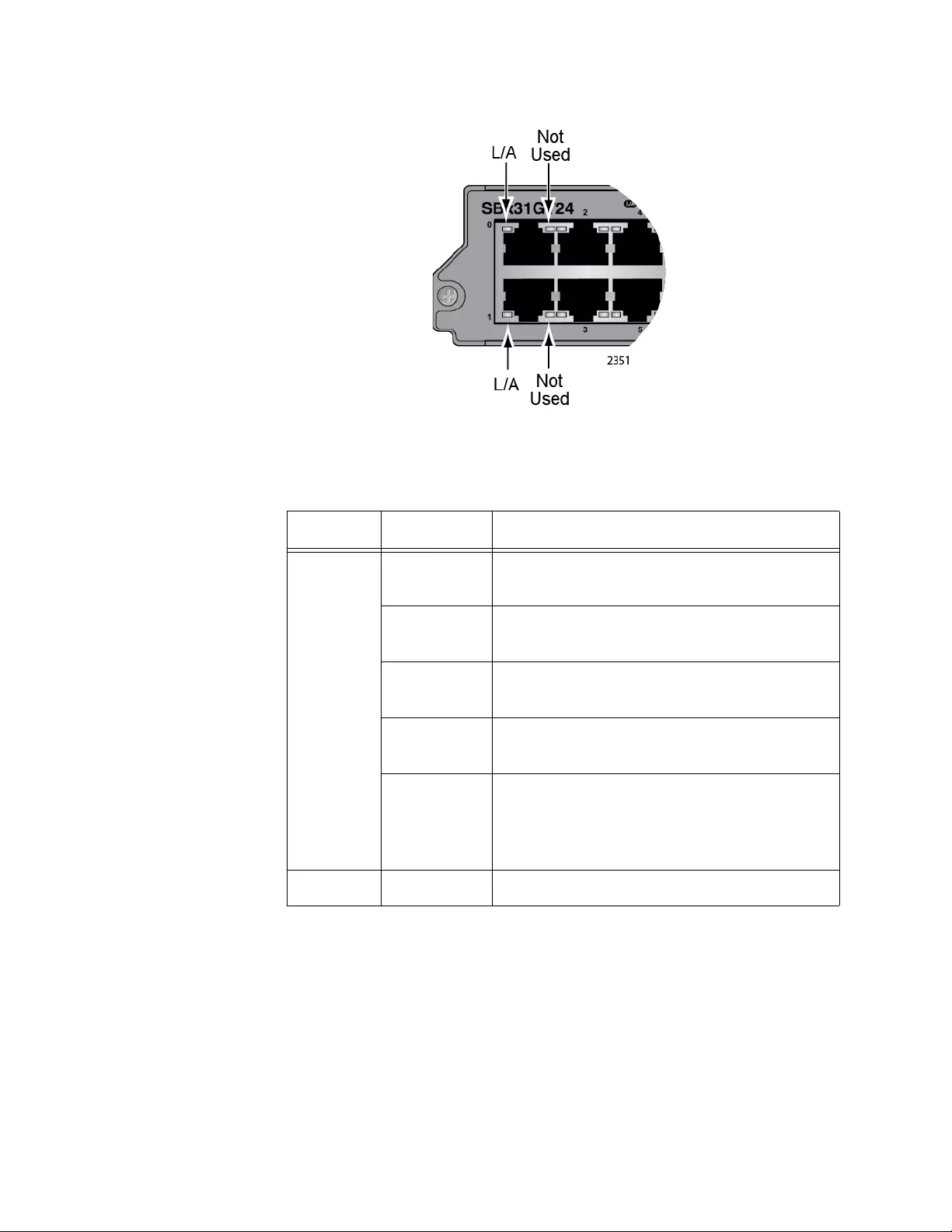

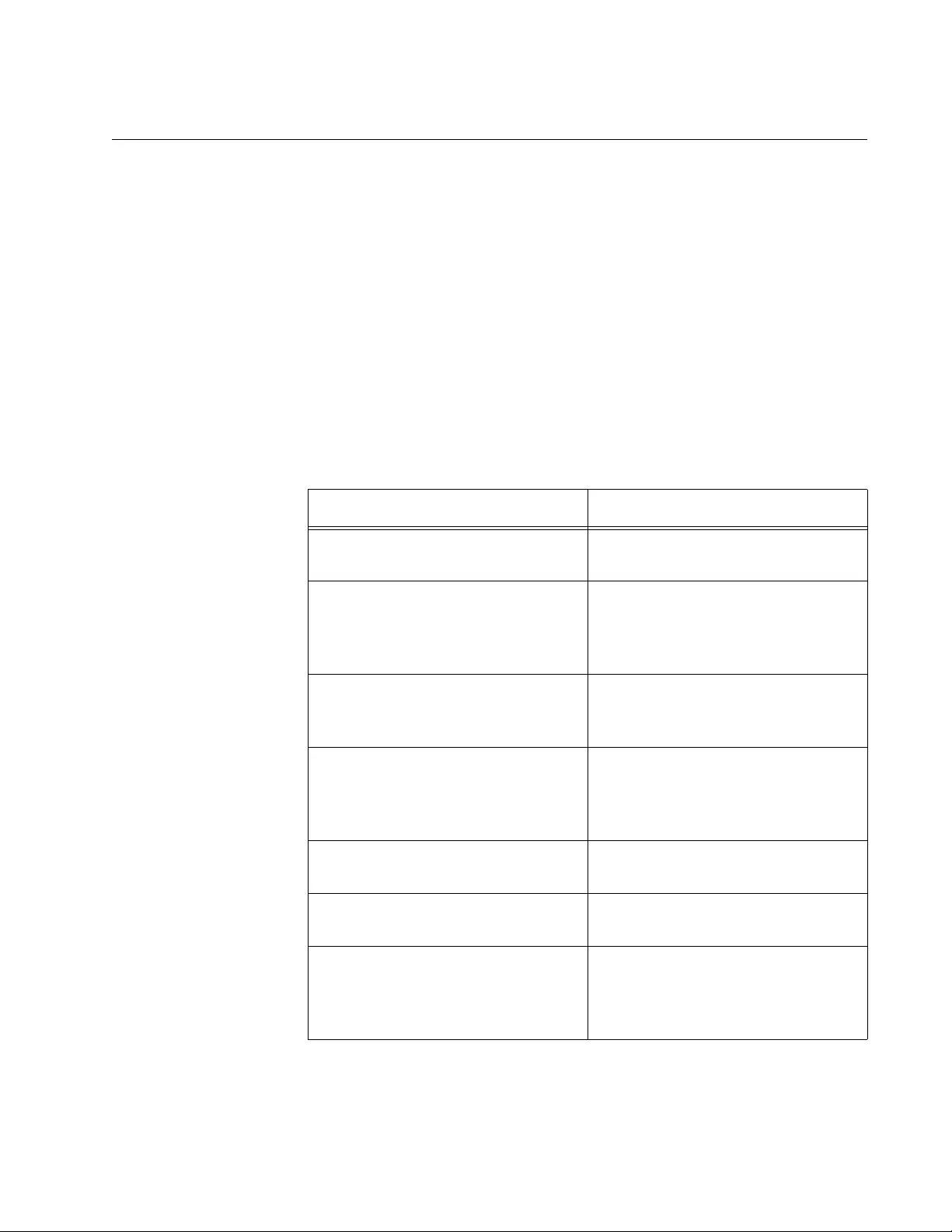

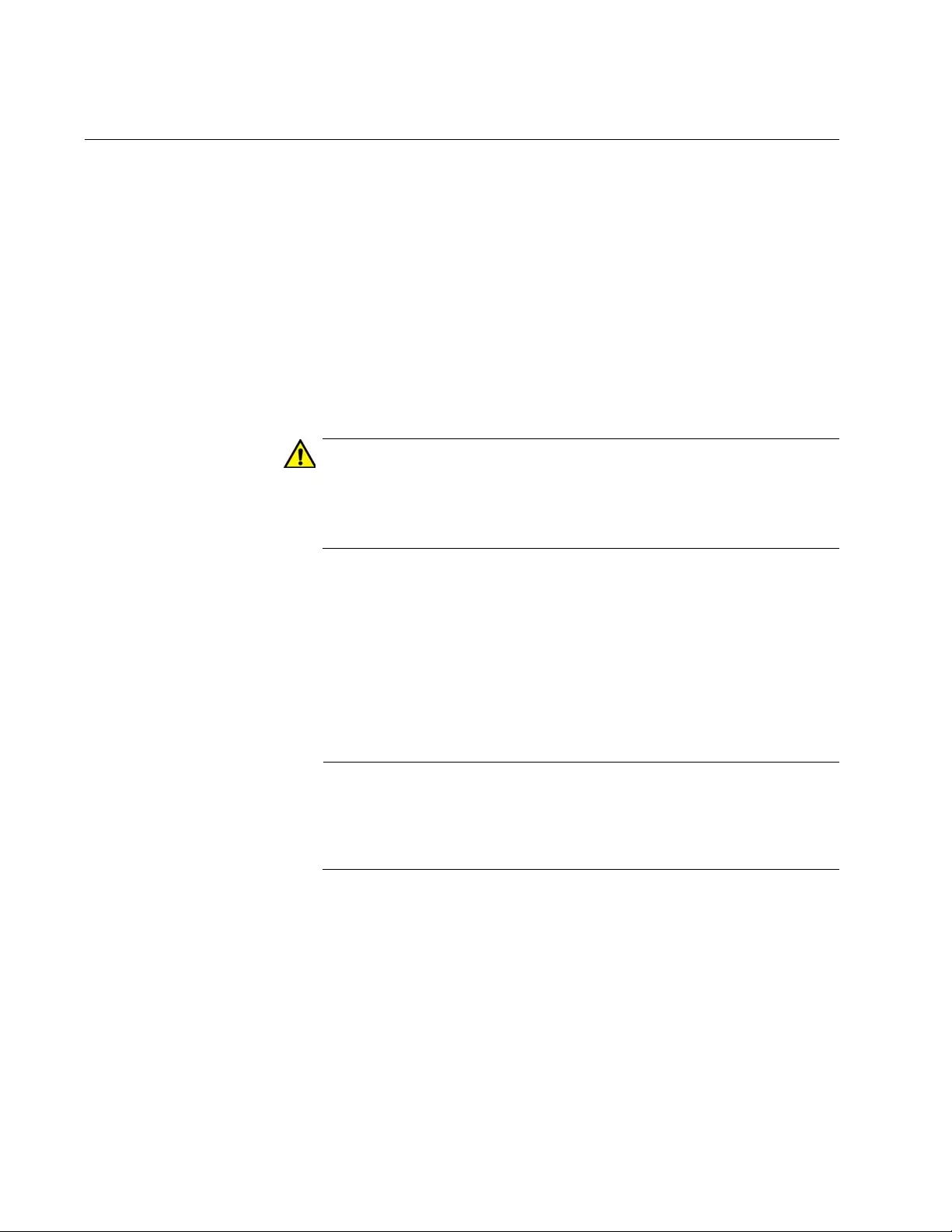

LEDs Each port on the AT-SBx31GT24 Line Card has two LEDs, but only one of

them is used. The LEDs are shown in Figure 12 on page 34 and describ ed

in Table 6 on page 34.

Chapter 2: Overview of the Ethernet Line Cards

34

Figure 12. Port LEDs on the AT-SBx31GT24 Line Card

Table 6. Port LEDs on the AT-SBx31GT24 Line Card

LED State Description

L/A

Solid Green The port has established an 1000 Mbps link

to a network device.

Flashing

Green The port is transmitting or receiving data at

1000 Mbps.

Solid Amber The port has established a 10 or 100 Mbps

link to a network device.

Flashing

Amber The port is transmitting or receiving data at

10 or 100.

Off The port has not established a link with

another network device or the LEDs are

turned off. To turn on the LEDs, use the

eco-friendly button on the controller card.

Right LED - This LED is not used.

SwitchBlade x3112 Chassis Switch and AT-SBx31CFC Card Installation Guide

35

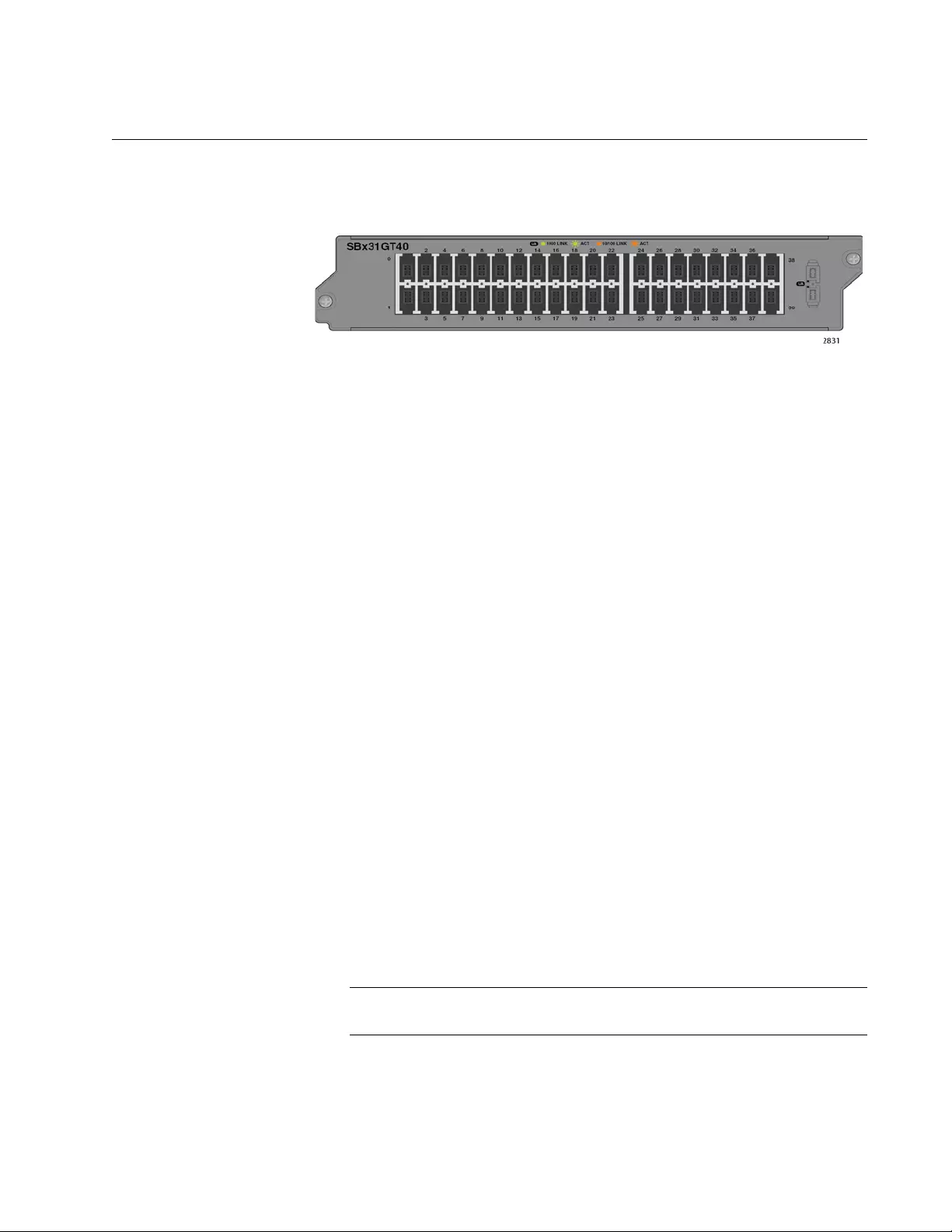

AT-SBx31GT40 Line Card

The AT-SBx31GT40 Line Card, shown in Figure 13, is a Gigabit Ethernet

switch.

Figure 13. AT-SBx31GT40 Line Card

Here are the main features of the line card:

40 10/100/1000Base-T ports

RJ point 5 connectors

100 meters (328 feet) maximum operating distance per port

Auto-Negotiation for speed

Full-duplex mode only

Automatic MDIX detection for ports operating at 10/100Base-TX,

(Automatic MDIX detection does not apply to 1000Base-T

operation.)

Port Link/Activity (L/A) LEDs

32K entry MAC address table

32 Mb buffer memory

Jumbo frame support:

– 10240 octets for tagged and untagged traffic

between ports on the same line card

– 10232 octets for untagged traffic between ports on

different line cards

– 10236 octets for tagged traffic between ports on

different line cards

Non-blocking full-wire speed switching o n all packet sizes, with two

AT-SBx31CFC Controller Fabric Cards

Hot swappable

Note

The ports on the line card do not support half-duplex operation.

The cable requirements for the ports on the AT-SBx31GT40 Line Card are

listed in Table 13 on page 54.

Chapter 2: Overview of the Ethernet Line Cards

36

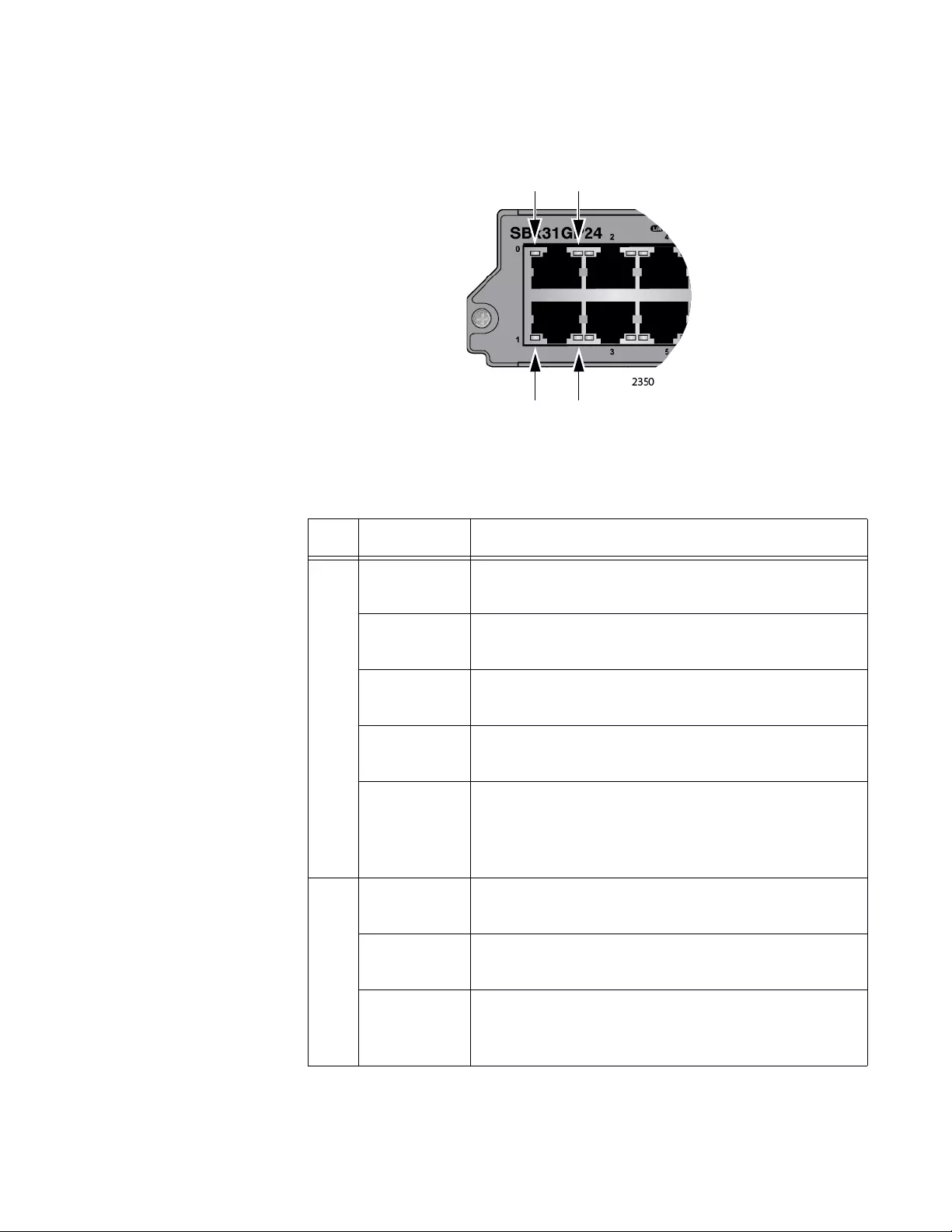

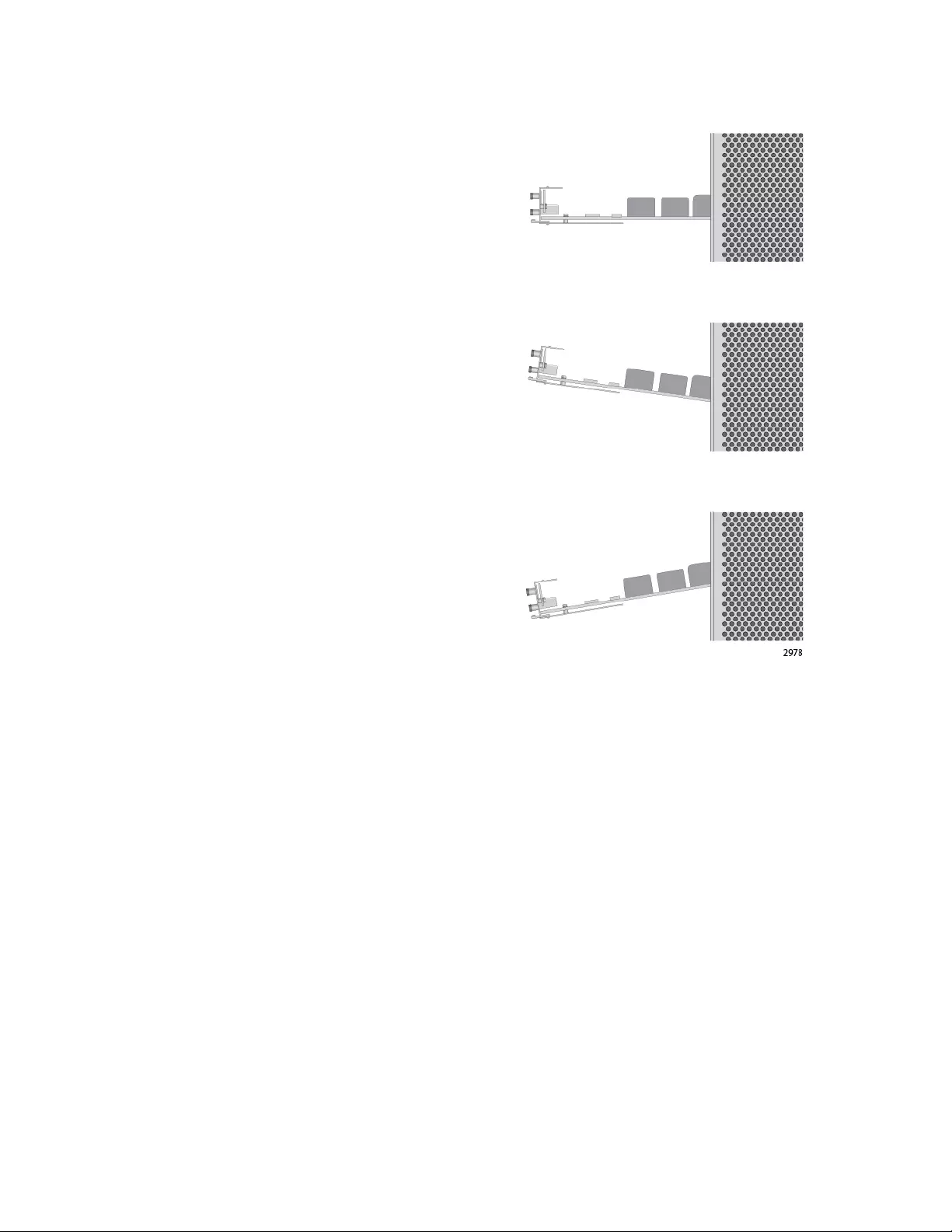

LEDs The LEDs for the ports on the AT-SBx31GT40 Line Ca rd are found on the