Table of Contents

- Contents

- Figures

- Tables

- Preface

- Chapter 1

- Chapter 2

- Chapter 3

- Installing the Chassis

- Tools and Material

- Adjusting the Equipment Rack Brackets

- Installing the Chassis in an Equipment Rack

- Installing the Chassis Grounding Wire

- Installing AT-SBxPWRSYS2 AC Power Supplies

- Installing AT-SBxPWRSYS1-80 DC Power Supplies

- Installing Ethernet Line Cards

- Installing Blank Line Card Slot Covers

- Installing the Blank Power Supply Slot Cover

- Installing the Power Cord Retaining Clips

- Installing the Chassis

- Chapter 4

- Powering On the Chassis

- Verifying the Installation

- Powering On AT-SBxPWRSYS2 Power Supplies

- Powering On AT-SBxPWRSYS1-80 DC Power Supplies

- Choosing a Method for Attaching the Grounding Wire

- Connecting the Grounding Wire with the Grounding Terminal

- Connecting the Grounding Wire with Bare Wire

- Choosing a Method for Attaching the Power Wires

- Connecting the DC Power Wires with the Straight Terminals

- Connecting the DC Power Wires with the Right Angle Terminals

- Connecting Bare DC Power Wires

- Monitoring the Initialization Processes

- Verifying the Hardware Operations of the Chassis

- Powering On the Chassis

- Chapter 5

- Cabling the Networking Ports

- Cabling the 1Gbps or 10Gbps Ports on the AT-XEM2-12XT Line Card

- Guidelines to Handling SFP, SFP+, and QSFP+ Transceivers

- Installing 1GBase SFP or 10GBase SFP+ Transceivers in AT-XEM2- 12XS Line Cards

- Installing AT-SP10TW Direct Connect Twinax Cables in the AT- XEM2-12XS Switch

- Installing AT-QSFPSR4 or AT-QSFPLR4 Transceivers in QSFP+ Slots

- Installing AT-QSFPCU Cables in QSFP+ Slots

- Cabling the Networking Ports

- Chapter 6

- Chapter 7

- Appendix A

Allied Telesis AT-SBx908 GEN2 User Manual

Displayed below is the user manual for AT-SBx908 GEN2 by Allied Telesis which is a product in the Network Equipment Chassis category. This manual has pages.

Related Manuals

613-002443 Rev. A

AT-SBx908 Gen2 Switch

Advanced Layer 3+ Modular Switch

AlliedWare Plus™ v5.4.7A-1

AT-SBx908 Gen2 Chassis

AT-XEM2-12XT Ethernet Line Card

AT-XEM2-12XS Ethernet Line Card

AT-XEM2-4QS Ethernet Line Card

AT-FAN08 Fan Module

AT-SBxPWRSYS2 AC Power Supply

AT-SBxPWRSYS1-80 DC Power Supply

Installation Guide

Copyright © 2017 Allied Telesis, Inc.

All rights reserved. No part of this publication may be reproduced without prior written permission from Allied Telesis, Inc.

Allied Telesis, VCStack, and the Allied Telesis logo are trademarks of Allied Telesis, Incorpo rated. All other product names, company

names, logos or other designations mentioned herein are trademarks or registered trademarks of their respective owners.

Allied Telesis, Inc. reserves the right to make changes in specifications and other information contained in this document without prior

written notice. The information provided herein is subject to change without notice. In no event shall Allied Telesis, Inc. be liable for

any incidental, special, indirect, or consequential damages whatsoever, including but not limited to lost profits, arising out of or related

to this manual or the information contained herein, even if Allied Telesis, Inc . has been advised of, known, or should have known, the

possibility of such damages.

3

Electrical Safety and Emissions Standards

This product meets the following standards.

RFI Emissions: FCC Class A, CISPR 22 Class A, EN55032 Class A, VCCI Class A, ICES-003

Class A, RCM

EMC (Immunity): EN55024, EN61000-3-2, EN61000-3-3

Electrical Safety: UL 60950-1 (CULUS), EN60825-1 (TUV),

RoHS: RoHS6

U.S. Federal Communications Commission

Radiated Energy

Note: This equipment has been tested and found to comply with the limits for a Class A digital device pursuant to Part 15

of FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with this instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a resid ential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense.

Note: Modifications or changes not expressly approved of by the manufacturer or the FCC, can void your right to operate

this equipment.

Industry Canad a

This Class A digital apparatus complies with Canadia n ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

Warning: In a domestic environment this product may cause radio interference in which case

the user may be required to take adequate measures.

Laser Safety EN60825

5

Preface ...............................................................................................................................................................................13

Document Conventions .......................................................................................................................................................14

Contacting Allied Telesis .....................................................................................................................................................15

Chapter 1: Overview ........................................................................................................................................................ 17

Overview..............................................................................................................................................................................18

AT-SBx908 Gen2 Chassis.................... ... .............. ... .............. .............. .. .............. .............. ... ..............................................21

Ethernet Line Cards.............................................................................................................................................................22

AT-XEM2-12XT Line Card...................................................................................................................................................23

AT-XEM2-12XS Line Card...................................................................................................................................................25

AT-XEM2-4QS Line Card..................... ... ... .............. .. .............. ... .............. .............. ... .............. ...........................................26

Management Panel .............................................................................................................................................................27

USB Port ...................... .............. .............. ......................... .............. .......................... .... ...............................................27

NET MGMT Ethernet Management Port ......................................................................................................................28

Console (RS-232) Port.................................................................................................................................................29

Switch ID LED ..............................................................................................................................................................29

eco-friendly Button .......................................................................................................................................................30

Reset Button.................................................................................................................................................................30

Power Supplies....................................................................................................................................................................32

AT-FAN08 Units ..................................................................................................................................................................34

Specifying Ports in the Command Line Interface.................................................................................................................35

Chapter 2: Beginning the Installation ............................................................................................................................ 37

Reviewing Safety Precautions.............. ... ... .........................................................................................................................38

Choosing a Site for the Chassis ..........................................................................................................................................43

Unpacking the Chassis........................................................................................................................................................44

Unpacking AT-SBxPWRSYS2 AC Power Supplies.............................................................................................................49

Unpacking AT-SBxPWRSYS1-80 DC Power Supplies .......................................................................................................50

Chapter 3: Installing the Chassis ................................................................................................................................... 51

Tools and Material...............................................................................................................................................................52

Adjusting the Equipment Rack Brackets..............................................................................................................................53

Installing the Chassis in an Equipment Rack.......................................................................................................................57

Installing the Chassis Grounding Wire.................................................................................................................................58

Installing AT-SBxPWRSYS2 AC Power Supplies................................................................................................................61

Installing AT-SBxPWRSYS1-80 DC Power Supplies ..........................................................................................................65

Installing Ethernet Line Cards .............................................................................................................................................69

Installing Blank Lin e Card Slot Covers ................................................................................................................................73

Installing the Blank Power Supply Slot Cover......................................................................................................................75

Installing the Power Cord Retain ing Clips ...........................................................................................................................77

Chapter 4: Powering On the Chassis ............................................................................................................................. 79

Verifying the Installation .................... ... .............. ... .............. .............. ... .............. .............. ...................................................80

Powering On AT-SBxPWRSYS2 Power Supplies...............................................................................................................81

Powering On AT-SBxPWRSYS1-80 DC Power Supplies....................................................................................................84

Choosing a Method for Attaching the Grounding Wi re.................................................................................................86

Connecting the Grounding Wire with the Grounding Terminal.....................................................................................86

Connecting the Grounding Wire with Bare Wire...........................................................................................................91

Choosing a Method for Attaching the Power Wires......................................................................................................93

Connecting the DC Power Wires with the Straight Terminal s ......................................................................................93

Connecting the DC Power Wires with the Right Angle Terminals..............................................................................100

Contents

Contents

6

Connecting Bare DC Power Wires ............................................................................................................................ 107

Monitoring the Initializati on Processes.............................................................................................................................. 111

Verifying the Hardware Operations of the Chassis........................................................................................................... 114

Starting a Local Management Session...................................................................................................................... 114

Verifying the Chassis with the AlliedWare Plus Commands...................................................................................... 115

Chapter 5: Cab ling the Networking Ports .................................................................................................................... 117

Cabling the 1Gbps or 10Gbps Ports on the AT-XEM2-12XT Line Card.................................. .. ... .............. ... ........ ........... 118

Guidelines to Handling SFP, SFP+, and QSF P + Transceivers ........................................................................................ 119

Installing 1GBase SFP or 10GBase SFP+ Transceivers in AT-XEM2-12 XS Line Cards................................................. 120

Installing AT-SP10TW Direct Connect Twinax Cables in the AT-XEM2-12XS Switch ..................................................... 123

Installing AT-QSFPSR4 or AT-QSFPLR4 Transceivers in QSFP+ Slots ......................................................................... 125

Installing AT-QSFPCU Cables in QSFP+ Slots................................................................................................................ 126

Chapter 6: Replacing Modules ..................................................................................................................................... 129

Replacing AT-SBxPWRSYS2 AC Power Supplies........................................................................................................... 130

Replacing AT-SBxPWRSYS1-80 DC Power Supplies...................................................................................................... 134

Removing Ethernet Line Cards......................................................................................................................................... 145

Replacing AT-FAN08 Modules ............ ............................................................................................................................. 150

Removing AT-FAN08 Modules.................................................................................................................................. 150

Installing AT-FAN08 Modules.................................................................................................................................... 151

Chapter 7: Troubl e shooting .......................................................................................................................................... 155

Appendix A: Technical Specifications ......................................................................................................................... 159

Physical Specifications ..................................................................................................................................................... 160

Environmental Specifications............................................................................................................................................ 162

Power Specifications......................................................................................................................................................... 163

Certifications..................................................................................................................................................................... 165

Port Pinouts ........................... ......................... .............. .............. .............. .............. .......................................................... 166

7

Figure 1: Front Panel of the AT-SBx908 Gen2 Chassis.......................................................................................................21

Figure 2: Rear Panel of the AT-SBx908 Gen2 Chassis........................................................................................................21

Figure 3: AT-SBx908 Gen2 Ethernet Line Cards .................................................................................................................22

Figure 4: Management Panel ...............................................................................................................................................27

Figure 5: Switch ID LED .......................................................................................................................................................30

Figure 6: AT-SBxPWRSYS2 and AT-SBxPWRSYS1-80 Power Supplies ...........................................................................32

Figure 7: AT-FAN08 Module.................................................................................................................................................34

Figure 8: PORT Parameter in the Command Line Interface..... ... .............. ... ... .............. ... .............. .. ... .................................35

Figure 9: NEMA 5-20P Plug and Receptacle .......................................................................................................................43

Figure 10: AT-SBx908 Gen2 Switch Shipping Box.............. ... .. .............. ... ... .............. ... ... .............. .. ... .................................44

Figure 11: Lifting the Switch from the Shipping Box.............................................................................................................45

Figure 12: Removing the Switch from the Protective Shipping Bag. ....................................................................................45

Figure 13: Pre-installed Items on the Front and Side Panels ...............................................................................................46

Figure 14: Pre-installed Items on the Rear Panel.................................................................................................................47

Figure 15: Accessory Kit.......................................................................................................................................................48

Figure 16: Items in the Shipping Box for the AT-SBxPWRSYS2 AC Power Supply ............................................................49

Figure 17: Items in the Shipping Box for the AT-SBxPWRSYS1-80 DC Power Supply.......................................................50

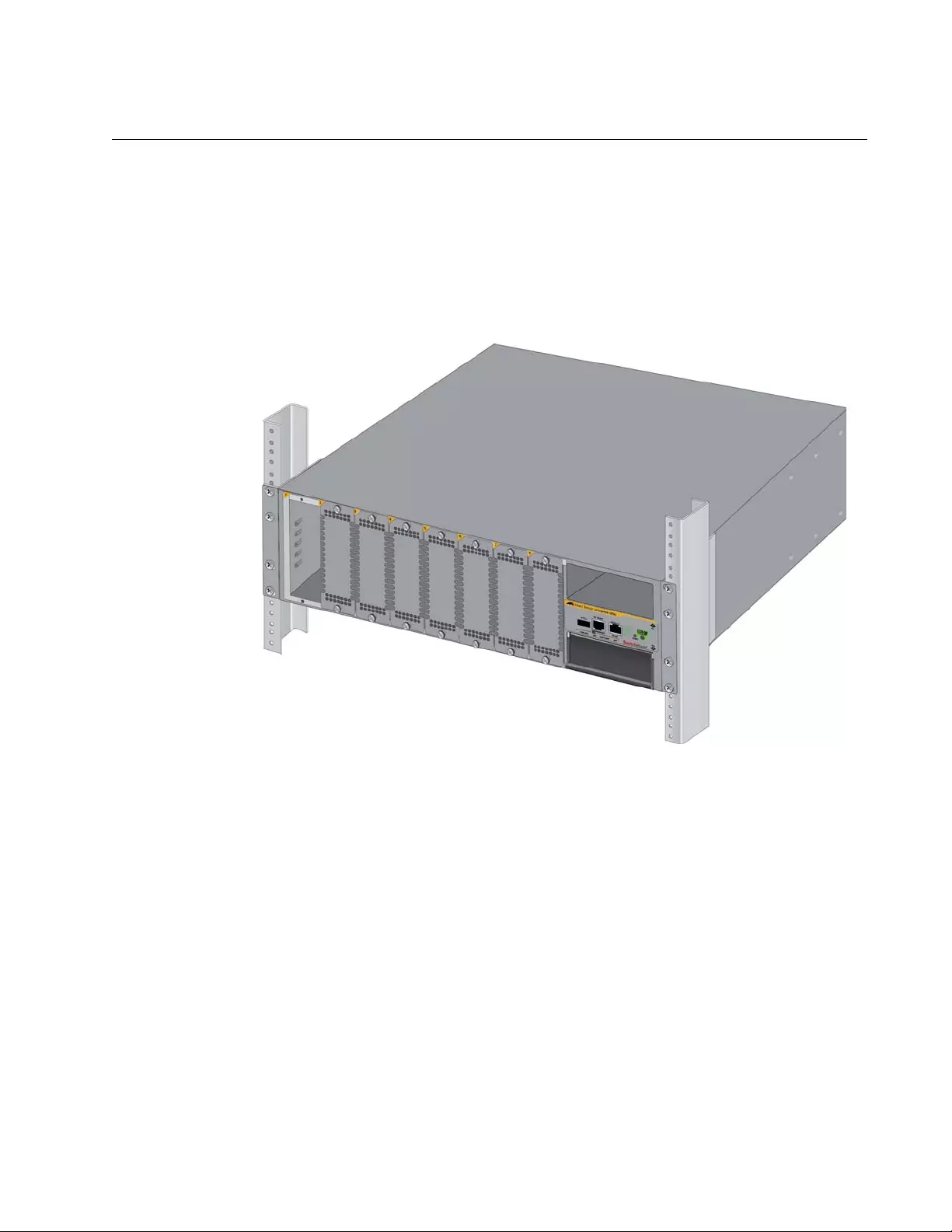

Figure 18: Chassis Orientations in the Equipmen t Rack ......................................................................................................53

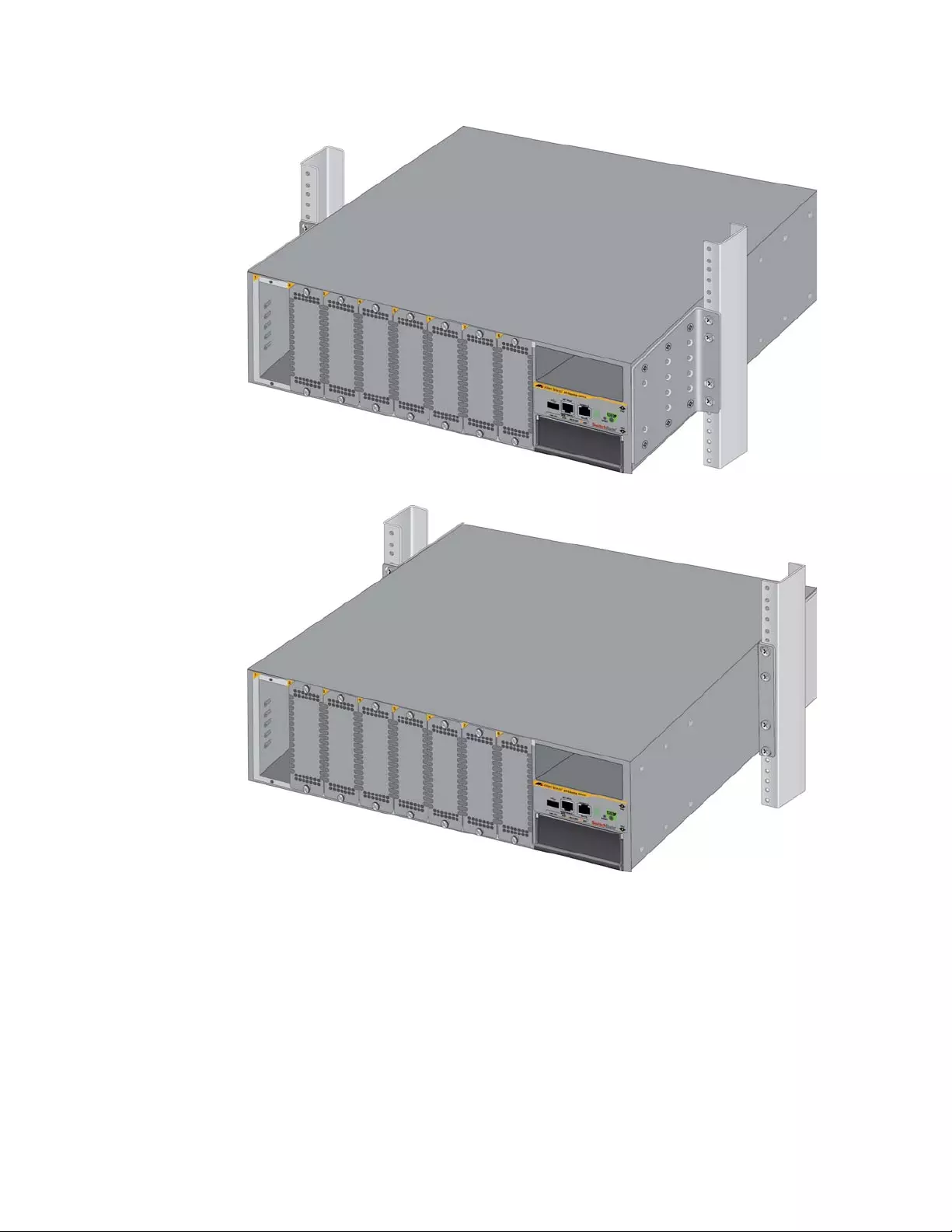

Figure 19: Chassis Orientations in the Equipment Rack (Continued) ..................................................................................54

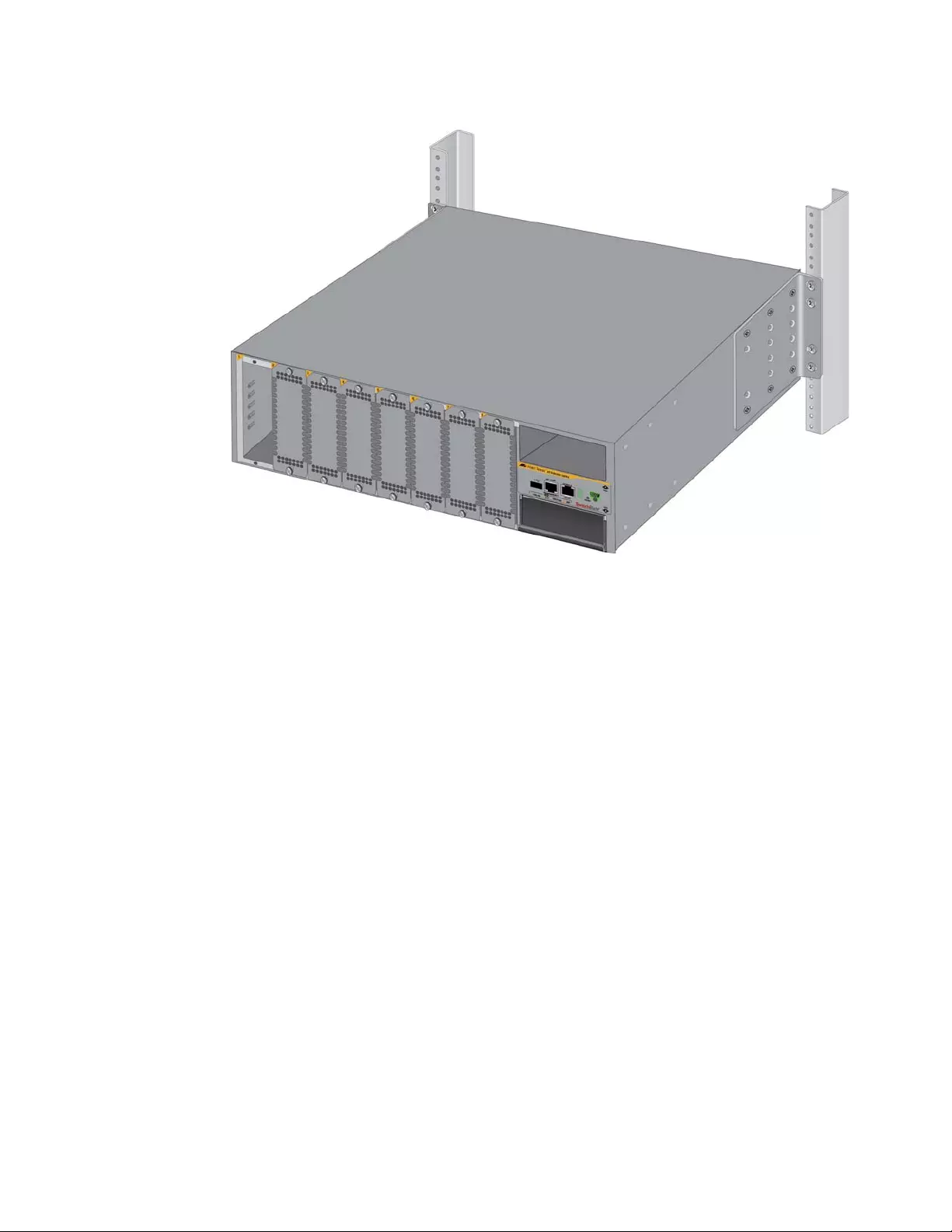

Figure 20: Chassis Orientations in the Equipment Rack (Continued) ..................................................................................55

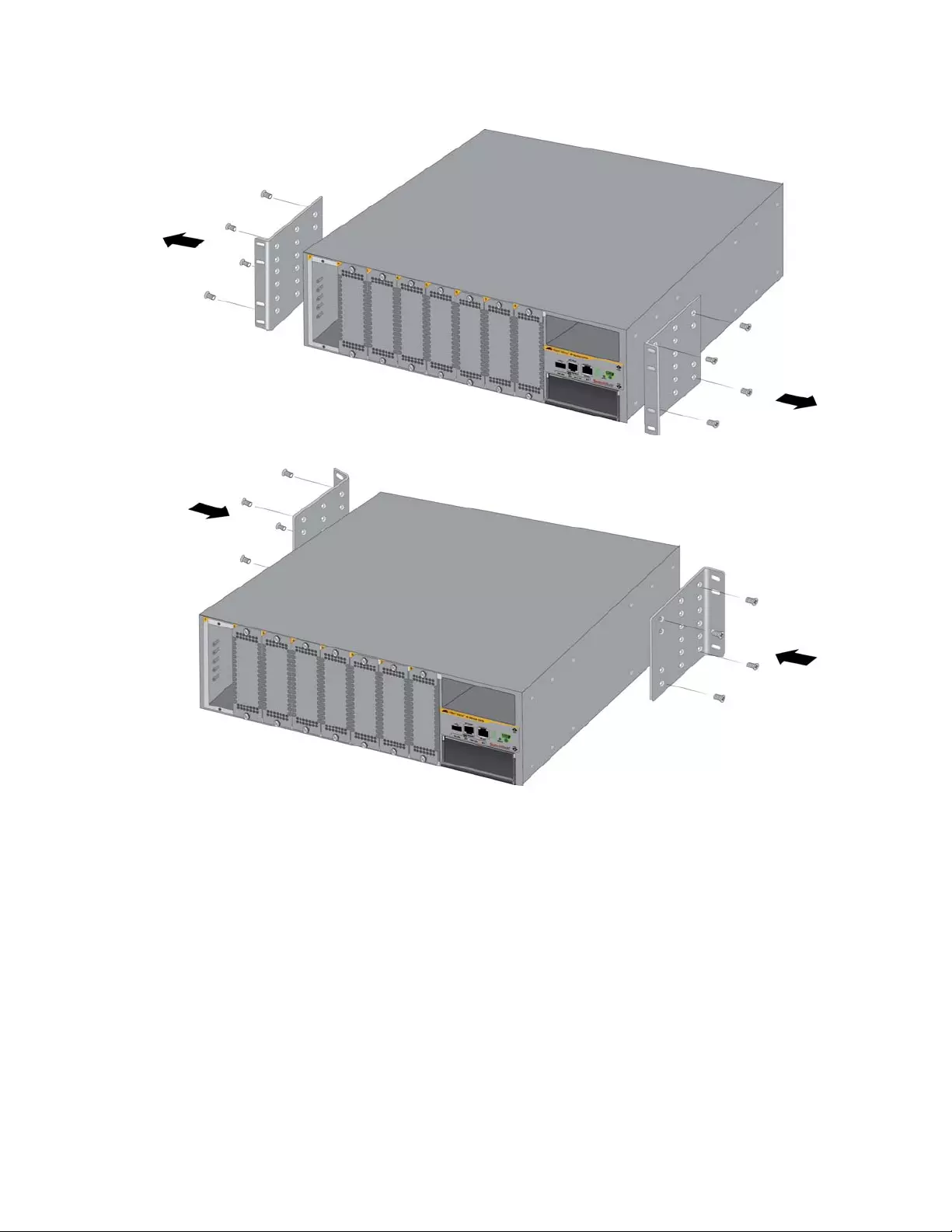

Figure 21: Example of Adjusting the Equipment Rack Brackets ..........................................................................................56

Figure 22: Securing the Chassis to the Equipment Rack .....................................................................................................57

Figure 23: Stripping the Grounding Wire..............................................................................................................................58

Figure 24: Removing the Grou nding Lug from the Chassis..................................................................................................59

Figure 25: Attaching the Grounding Wire to the Grounding Lug...........................................................................................59

Figure 26: Installing the Grounding Lug and Wire ................................................................................................................60

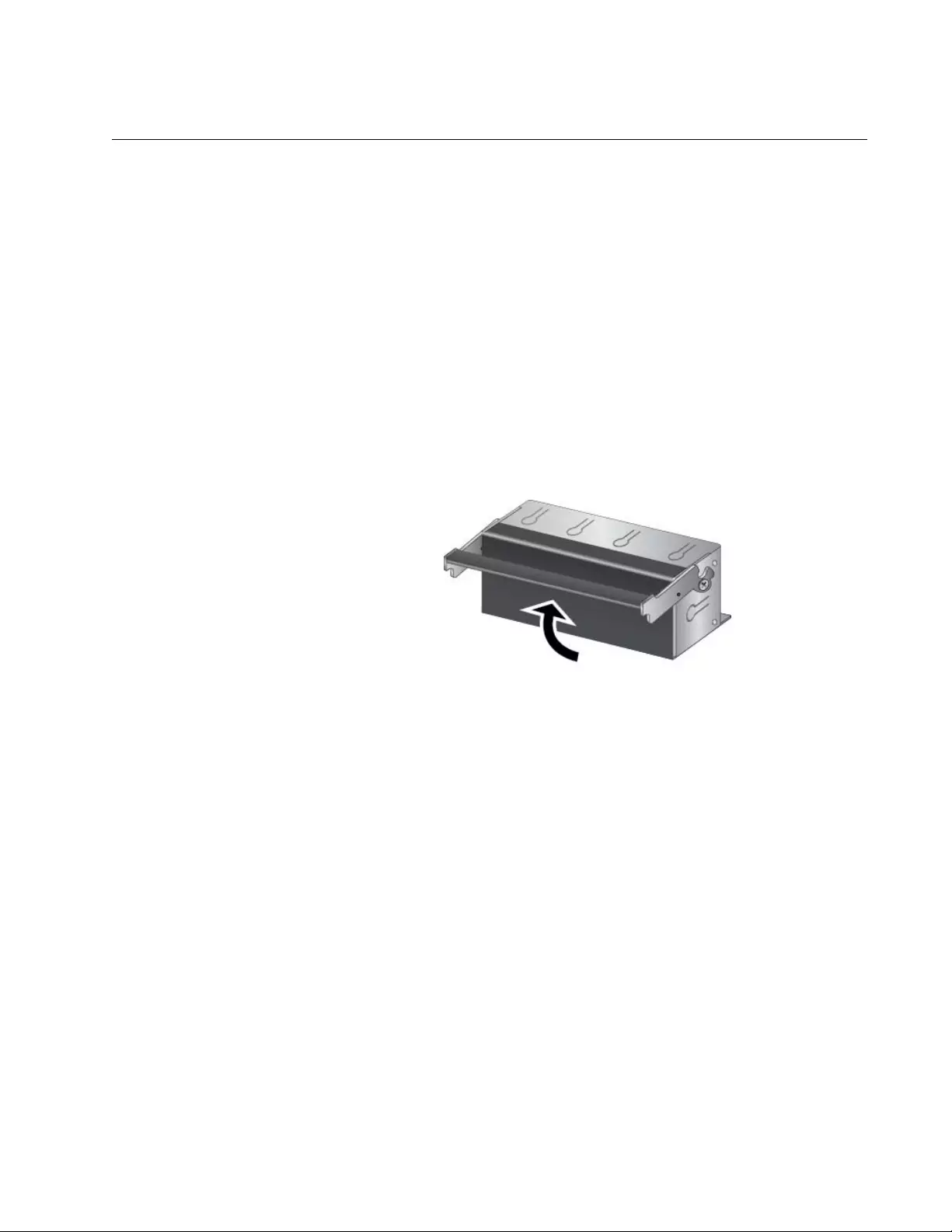

Figure 27: Removing the Blank Power Supply Panel from Power Supply Slot B.................................................................62

Figure 28: Lifting the Locking Handle on the AT-SBxPWRSYS2 Power Supply........ .............. .............. .............. ................62

Figure 29: Sliding the AT-SBxPWRSYS2 AC Power Supply into the Chassis.....................................................................63

Figure 30: Lowering the Locking Handle on the AT-SBxPWRSYS2 AC Power Supply........ ... ... .............. ... .............. ... .......64

Figure 31: On/Off Switch on the AT-SBxPWRSYS1-80 DC Power Supply..........................................................................66

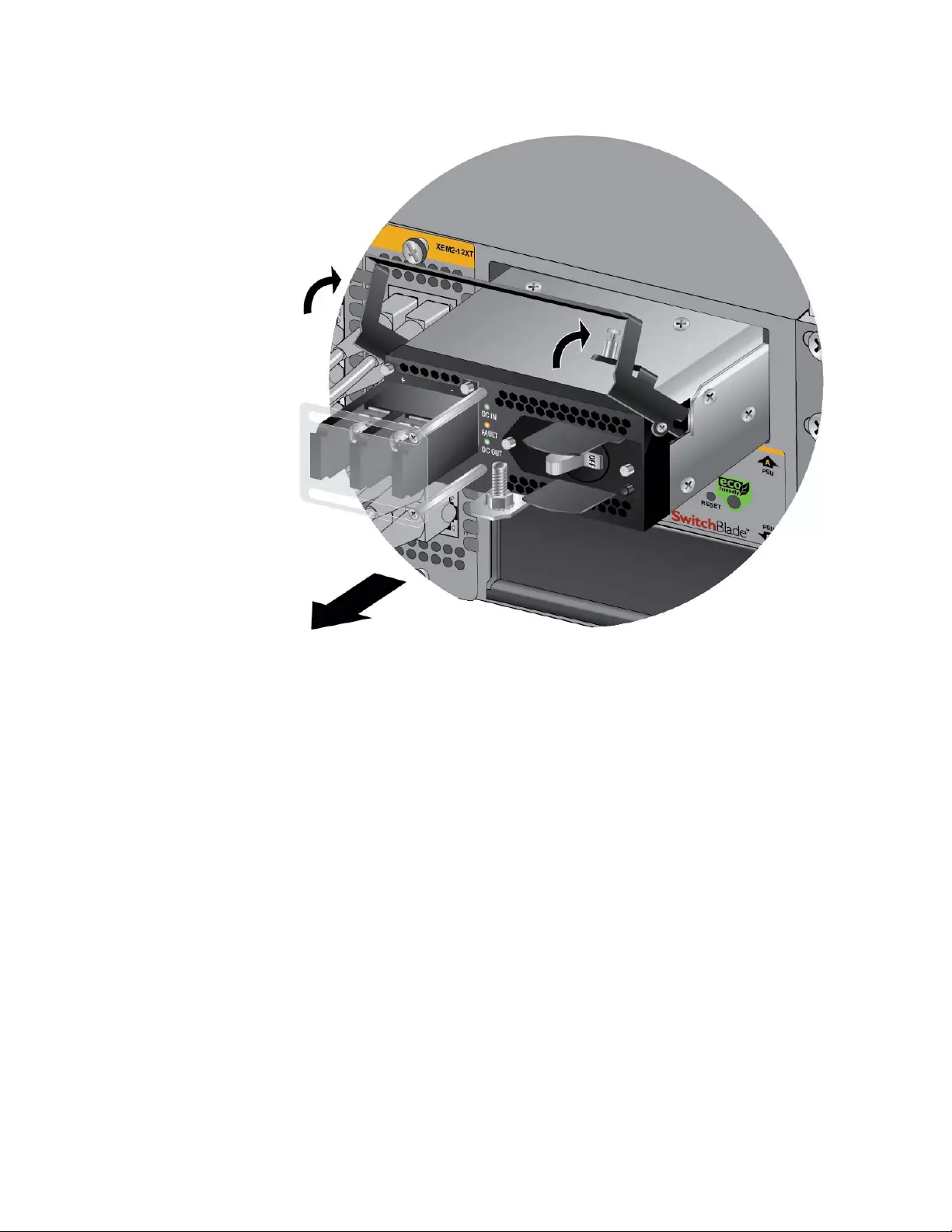

Figure 32: Loosening the Handle locking Screw on the AT-SBxPWRSYS1-80 DC Power Supply......................................66

Figure 33: Lifting the Locking Handle on the AT-SBxPWRSYS1-80 DC Power Supply.......................................................67

Figure 34: Inserting the AT-SBxPWRSYS1-80 DC Power Supply.......................................................................................67

Figure 35: Lowering the Locking Handle on the AT-SBxPWRSYS1-80 DC Power Supply..................................................68

Figure 36: Removing a Blank Line Card Cover ....................................................................................................................69

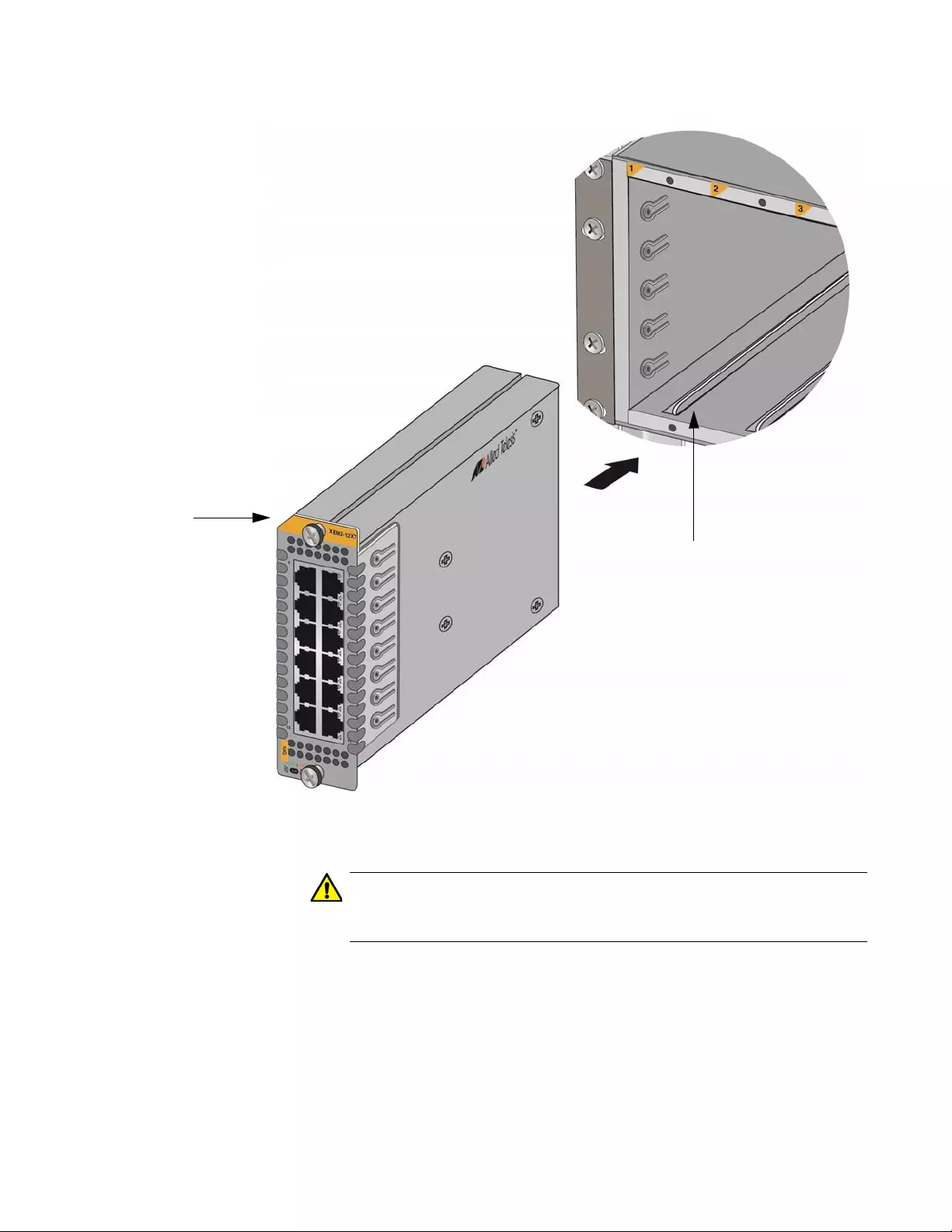

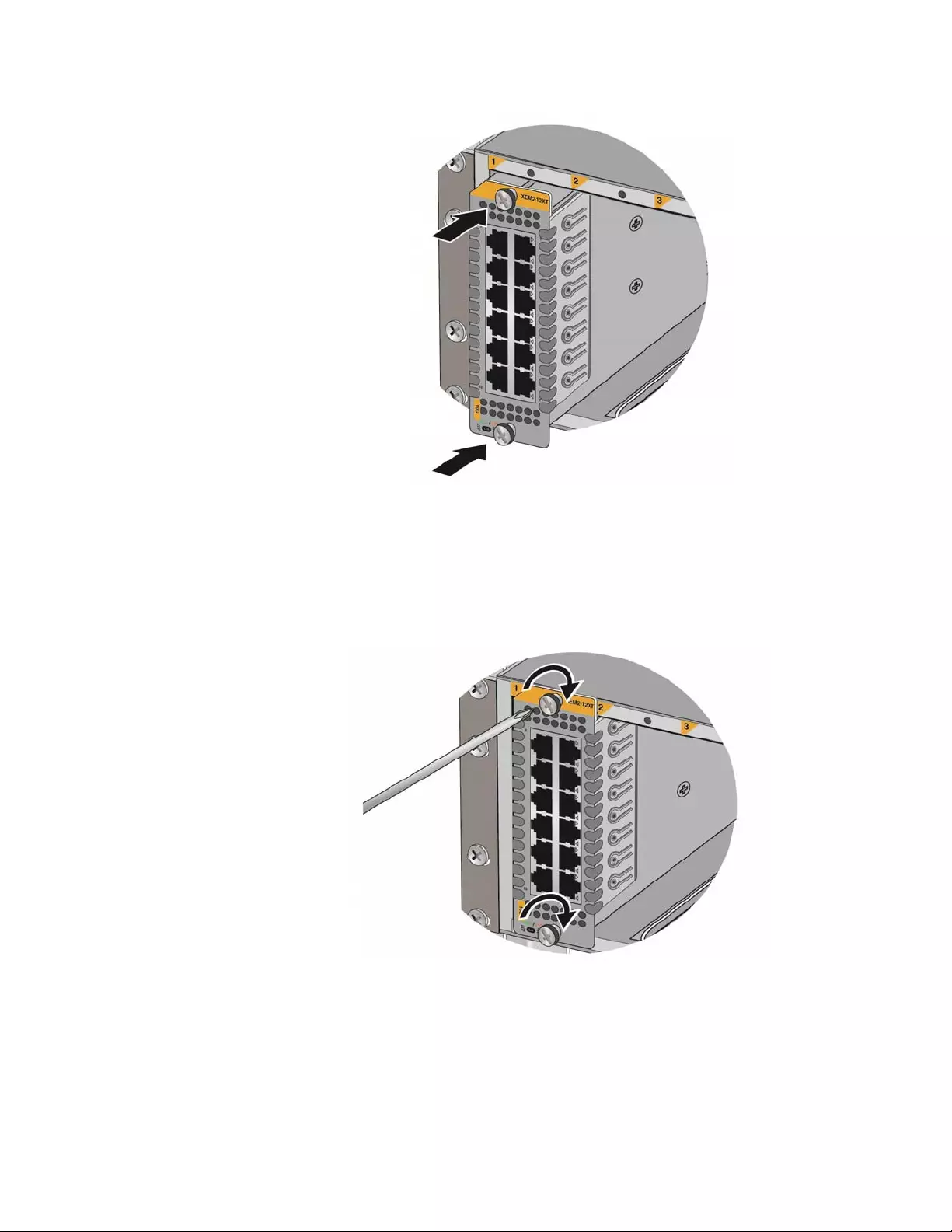

Figure 37: Removing the Ethernet Line Card from the Anti-static Bag.................................................................................70

Figure 38: Sliding the Ethernet Line Card into the Slot.........................................................................................................71

Figure 39: Seating an Ethernet Line Card in the Chassis.....................................................................................................72

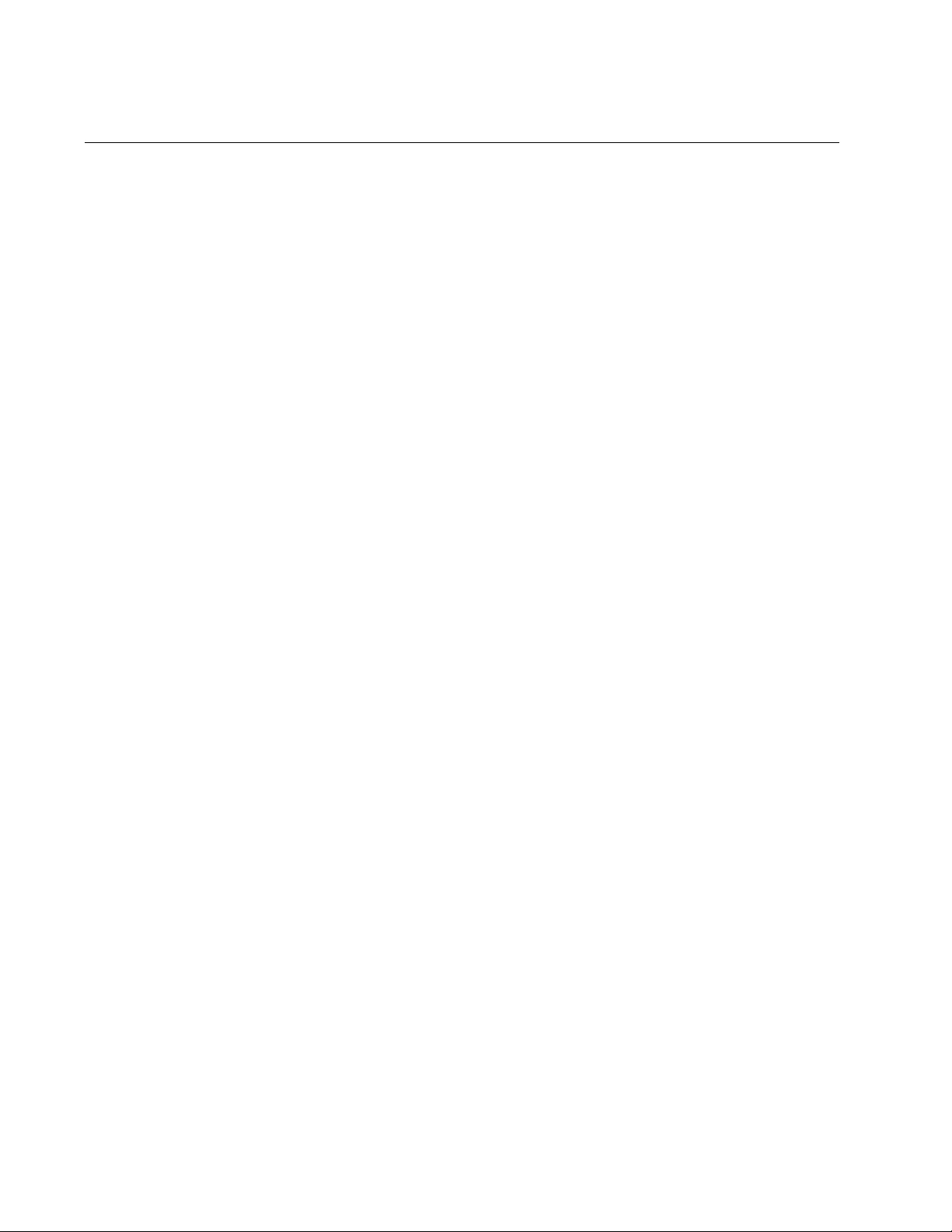

Figure 40: Tighteni ng the Two Captive Screws on the Ethernet Line Card ..........................................................................72

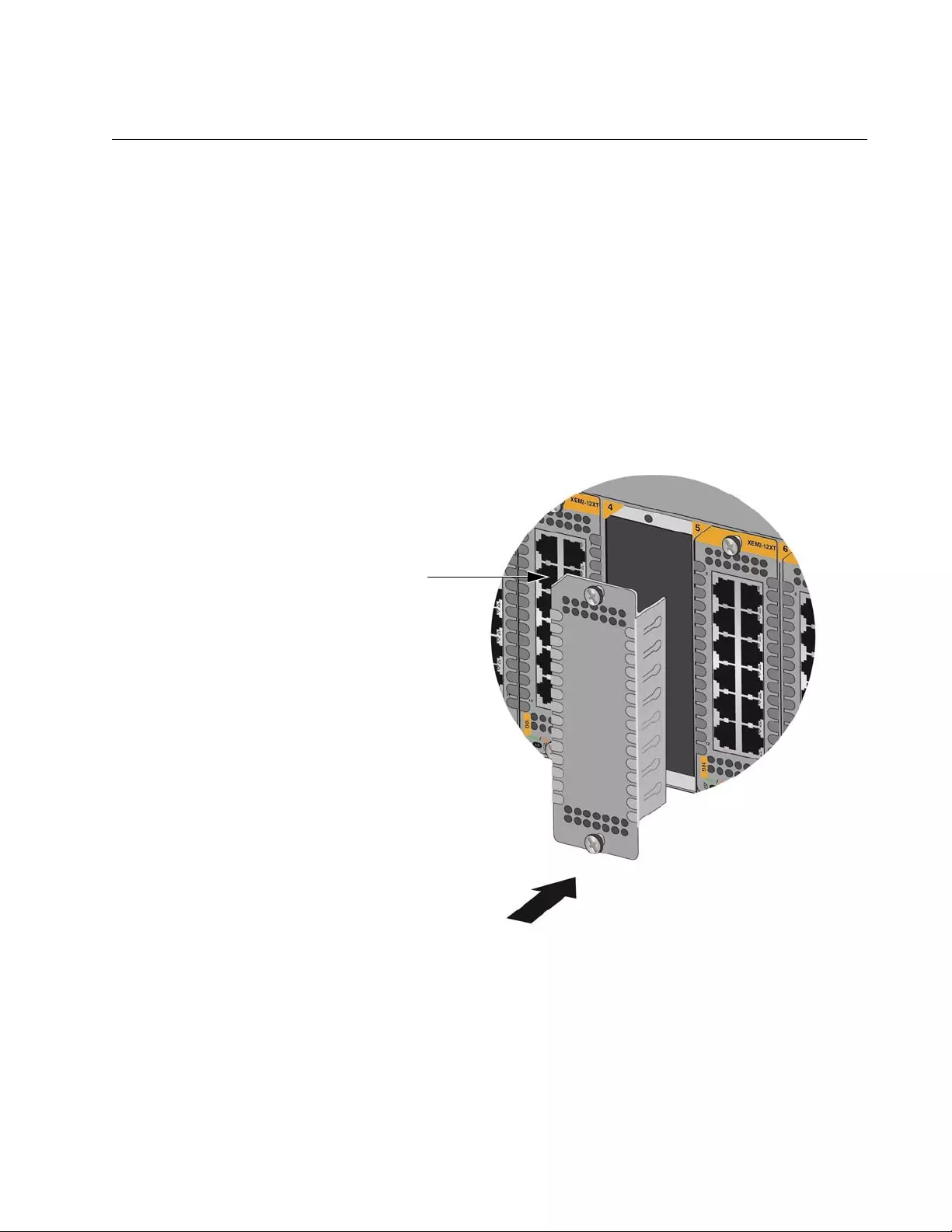

Figure 41: Installing a Blank Slot Cover................................................................................................................................73

Figure 42: Tightening the Captive Screws on a Blank Slot Cover. .......................................................................................74

Figure 43: Lifting the Locking Handle on the Blank Power Supply Slot Cover.....................................................................75

Figure 44: Aligning the Blank Power Supply Cover in the Slot.............................................................................................76

Figure 45: Lowering the Locking Handle on the Blank Power Supply Slot Cover ................................................................76

Figure 46: Installin g the Power Cord Retaining Clips ...........................................................................................................77

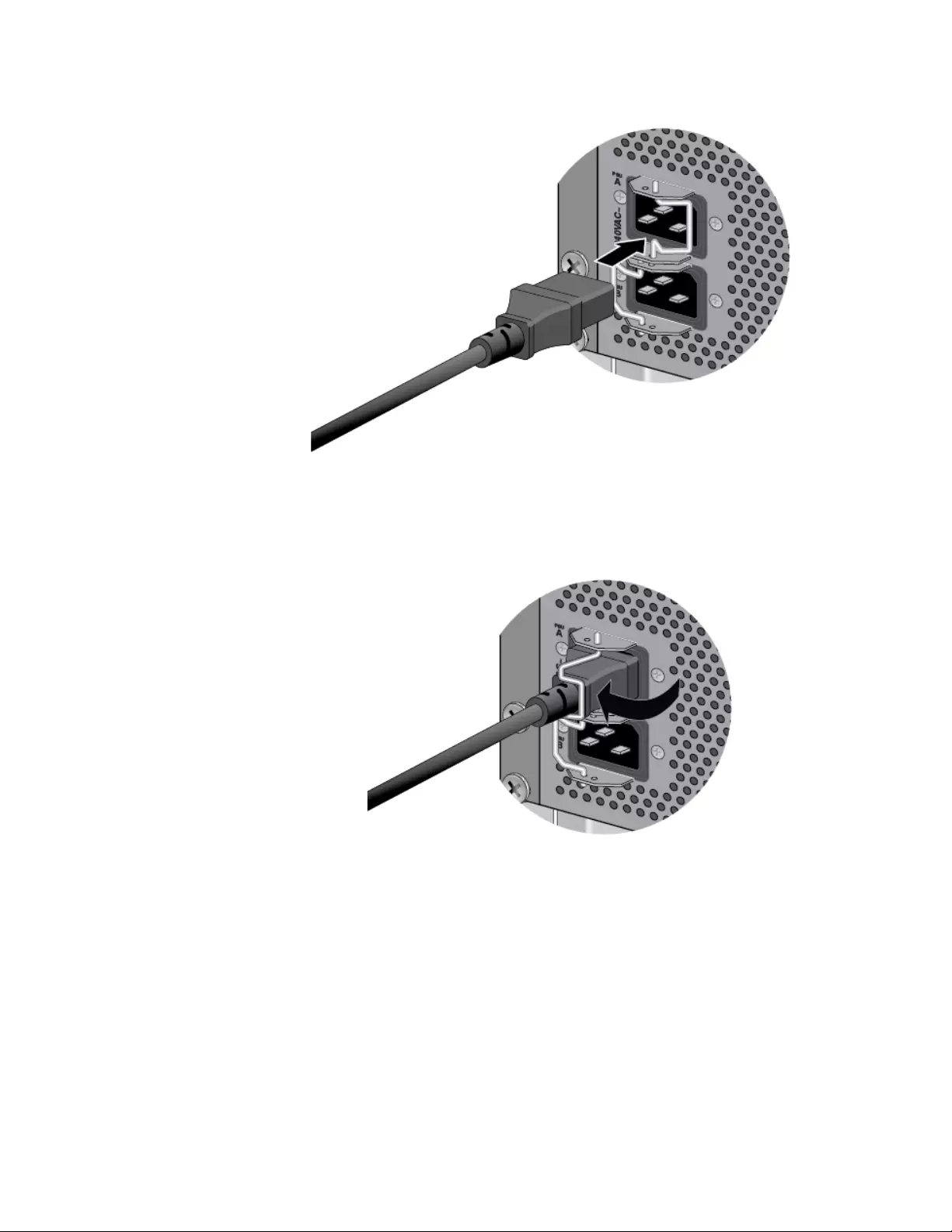

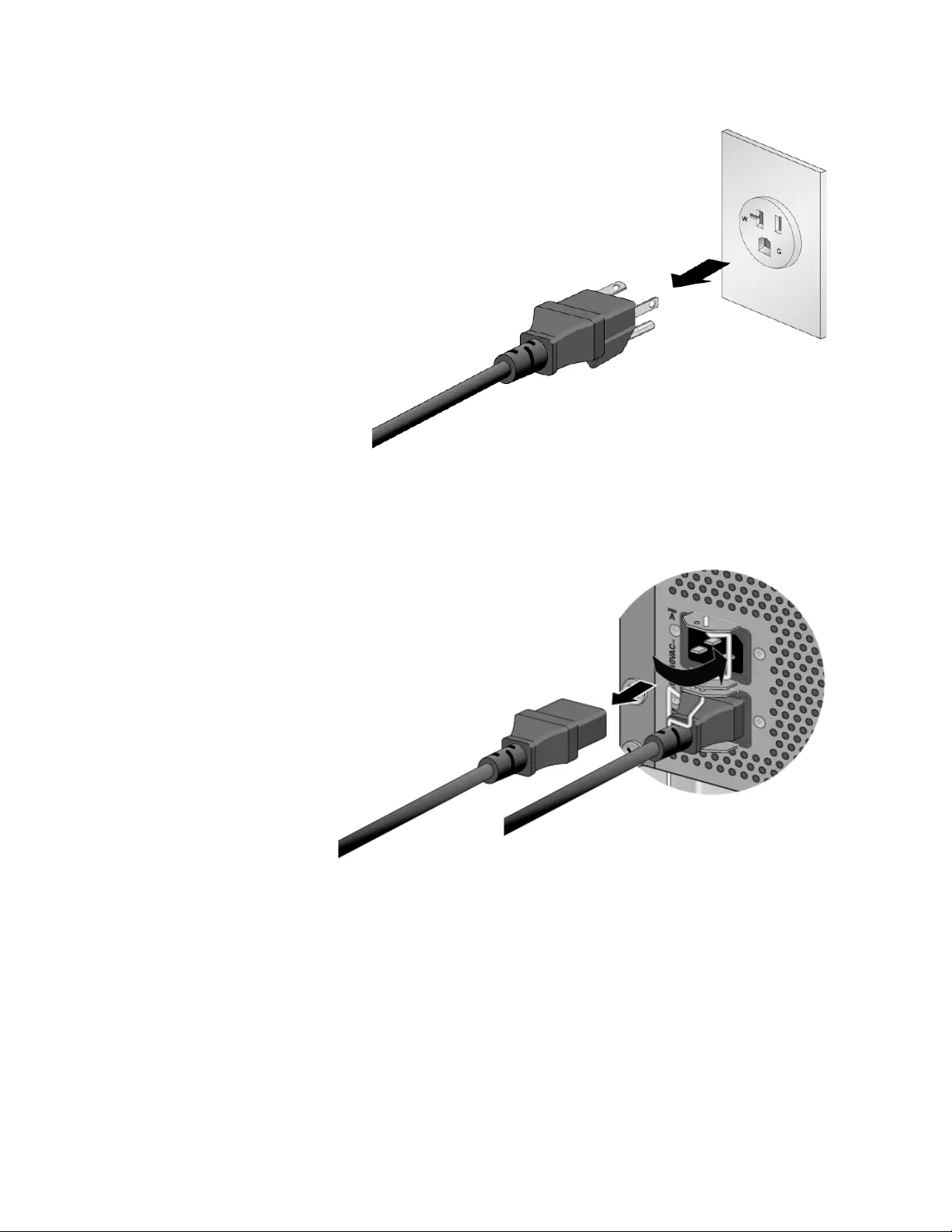

Figure 47: Connecting the AC Power Cord ..........................................................................................................................82

Figure 48: Securing the Power Cord with th e Retaining Clip................................................................................................82

Figure 49: Connecting the Power Cord to an AC Power Source..........................................................................................83

Figures

Figures

8

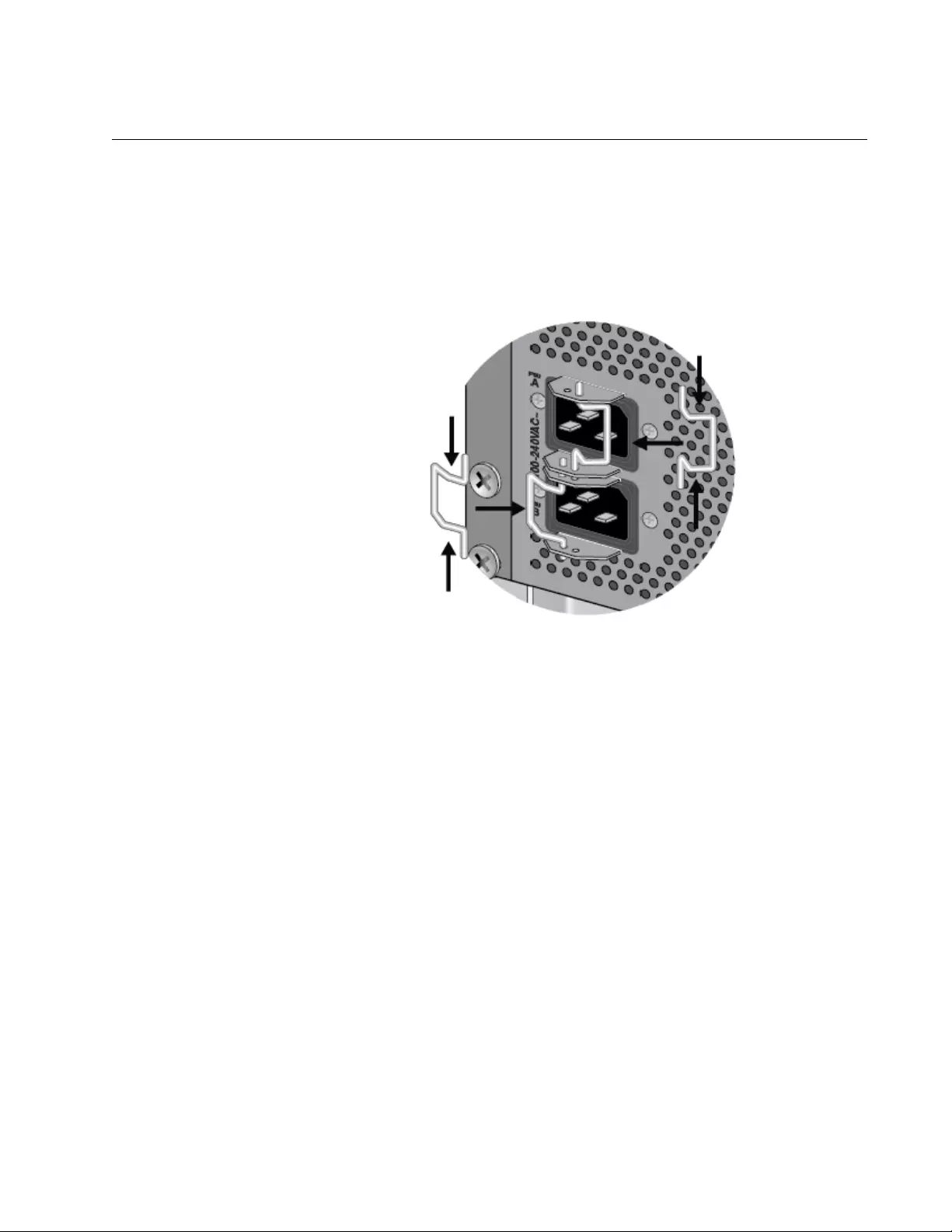

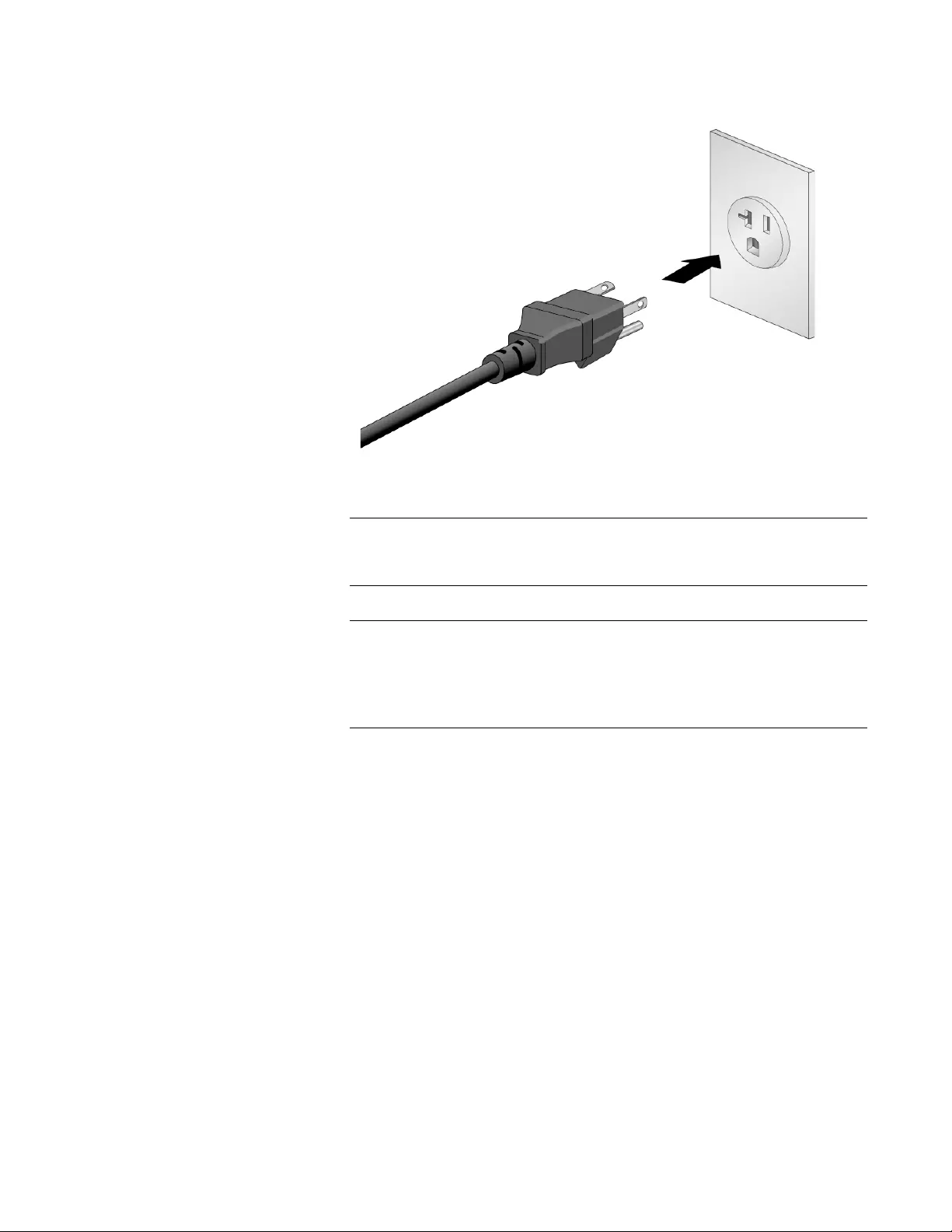

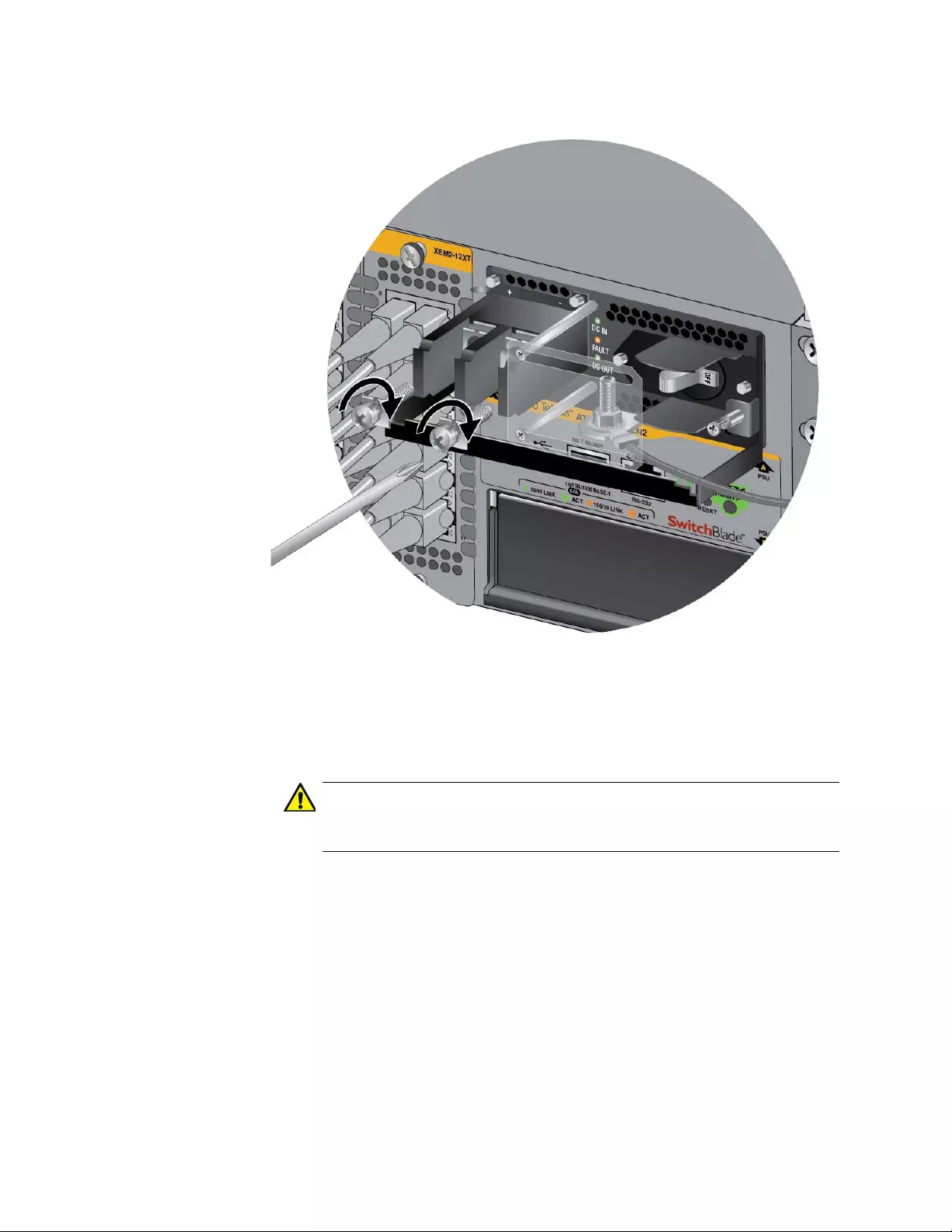

Figure 50: Components on the AT-SBxPWRSYS1-80 DC Power Supply............................................................................85

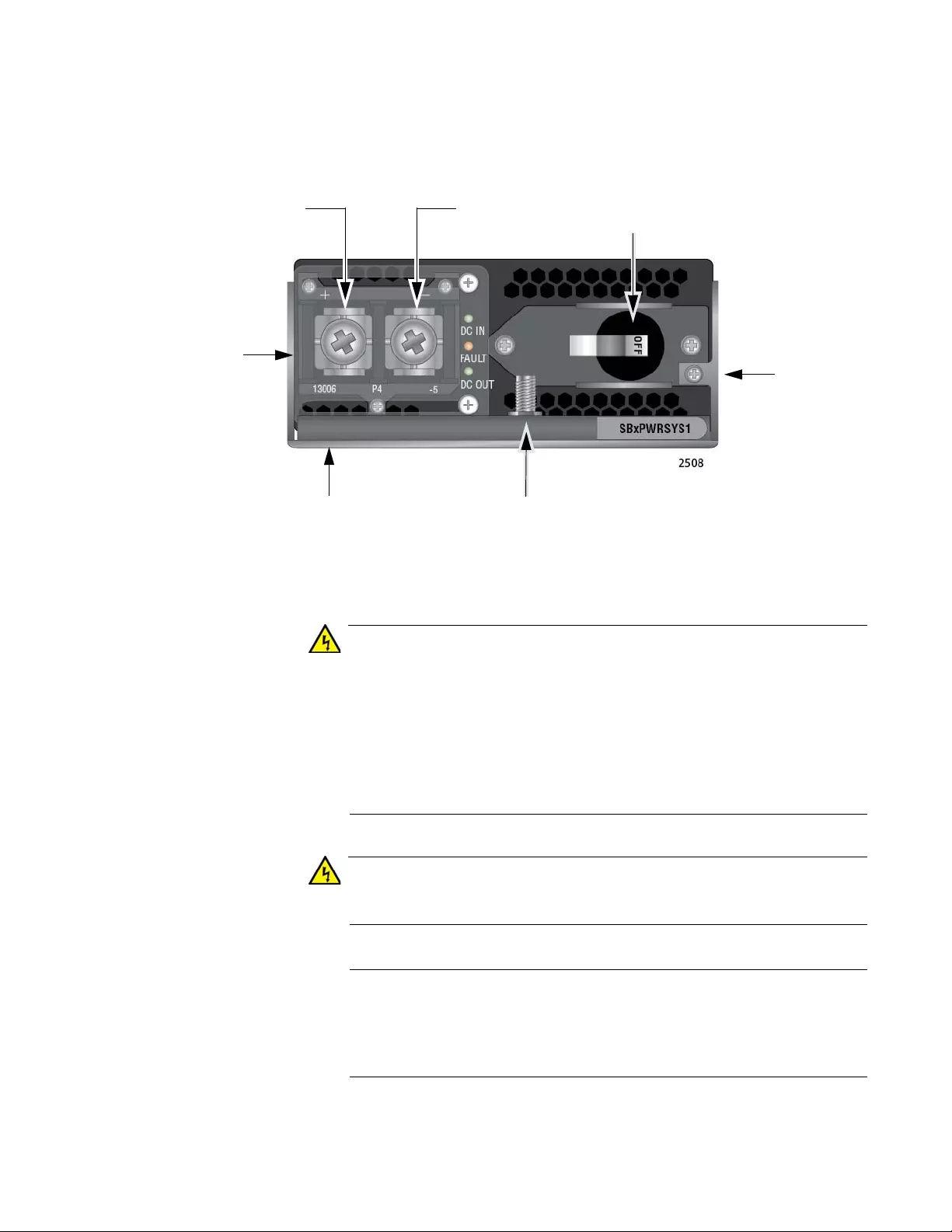

Figure 51: Grounding Wire Terminal.....................................................................................................................................86

Figure 52: Stripping the Stranded Grounding Wire...............................................................................................................86

Figure 53: Attaching the Stranded Grounding Wire to the Grounding Terminal ...................................................................86

Figure 54: On/Off Switch on the AT-SBxPWRSYS1-80 DC Power Supply..........................................................................87

Figure 55: Removing the Nut and Wash er from the Grounding Post ...................................................................................88

Figure 56: Attaching the Grounding Lug and Wire to the Grounding Post............................................................................89

Figure 57: Securing the Groundin g Wire ..............................................................................................................................90

Figure 58: Stripping the solid or Stranded Grounding Wire ..................................................................................................91

Figure 59: Attaching the Bare Grounding Wire to the Grounding Post.................................................................................91

Figure 60: Securing the Bare Grounding Wire to the Grounding Post..................................... .. .............. .............................92

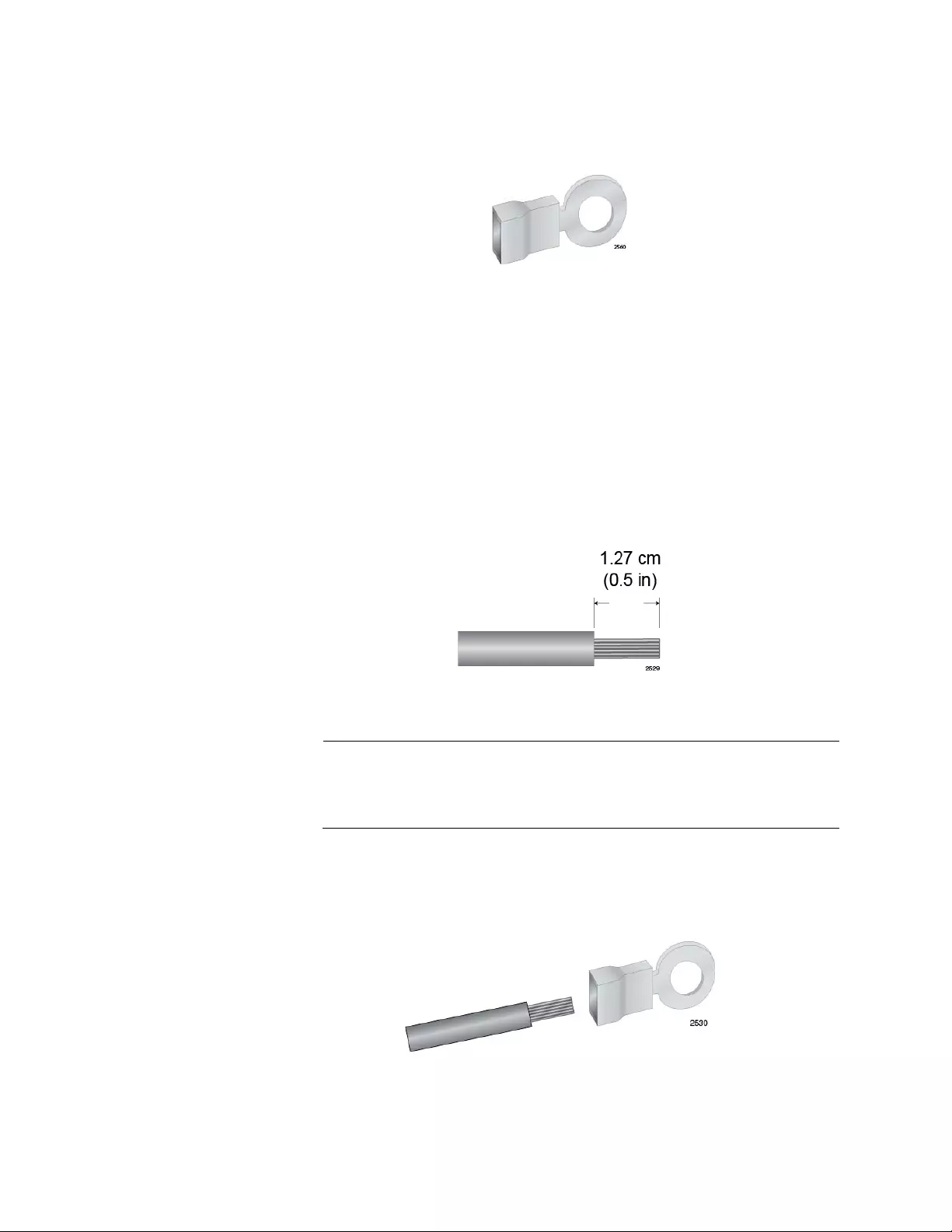

Figure 61: Power Wire Terminals .........................................................................................................................................93

Figure 62: Stripping the Power Wires...................................................................................................................................94

Figure 63: Attaching the Power Wires to the Straight Terminal Lugs ...................................................................................94

Figure 64: Opening the Plastic Cover...................................................................................................................................95

Figure 65: Removing the Terminal Screws...........................................................................................................................96

Figure 66: Connecting the Positive (+) Power W ire with a Straight Terminal............ .. .............. ... .............. ... .......................97

Figure 67: Connecting the Negative (-) Power Wire with a Straight Terminal ............. ... .............. ... .............. ... ....................98

Figure 68: Closing the Plastic Cover over the Terminal Connectors ....................................................................................99

Figure 69: Tightening the Handle Locking Screw...............................................................................................................100

Figure 70: Stripping the Power Wires.................................................................................................................................101

Figure 71: Attaching the Power Wires to the Right Angle Terminal Lugs...........................................................................101

Figure 72: Removing the Plastic Cover ..............................................................................................................................102

Figure 73: Removing the Terminal Screws.........................................................................................................................103

Figure 74: Connecting the Positive (+) Power W ire with a Right Angle Terminal...............................................................104

Figure 75: Connecting the Negative (-) Power Wire with a Right Angle Terminal ..............................................................105

Figure 76: Tightening the Handle Locking Screw...............................................................................................................106

Figure 77: Stripping Solid or Stranded DC Power Wires....................................................................................................107

Figure 78: Connecting the Positive Wire With Bare Wire ...................................................................................................108

Figure 79: Connecting the Negative Lea d Wire with Bare Wire..........................................................................................109

Figure 80: Switch Initialization Messages...........................................................................................................................111

Figure 81: Switch Initialization Messages (Continued ) .......................................................................................................112

Figure 82: Switch Initialization Messages (Continued ) .......................................................................................................113

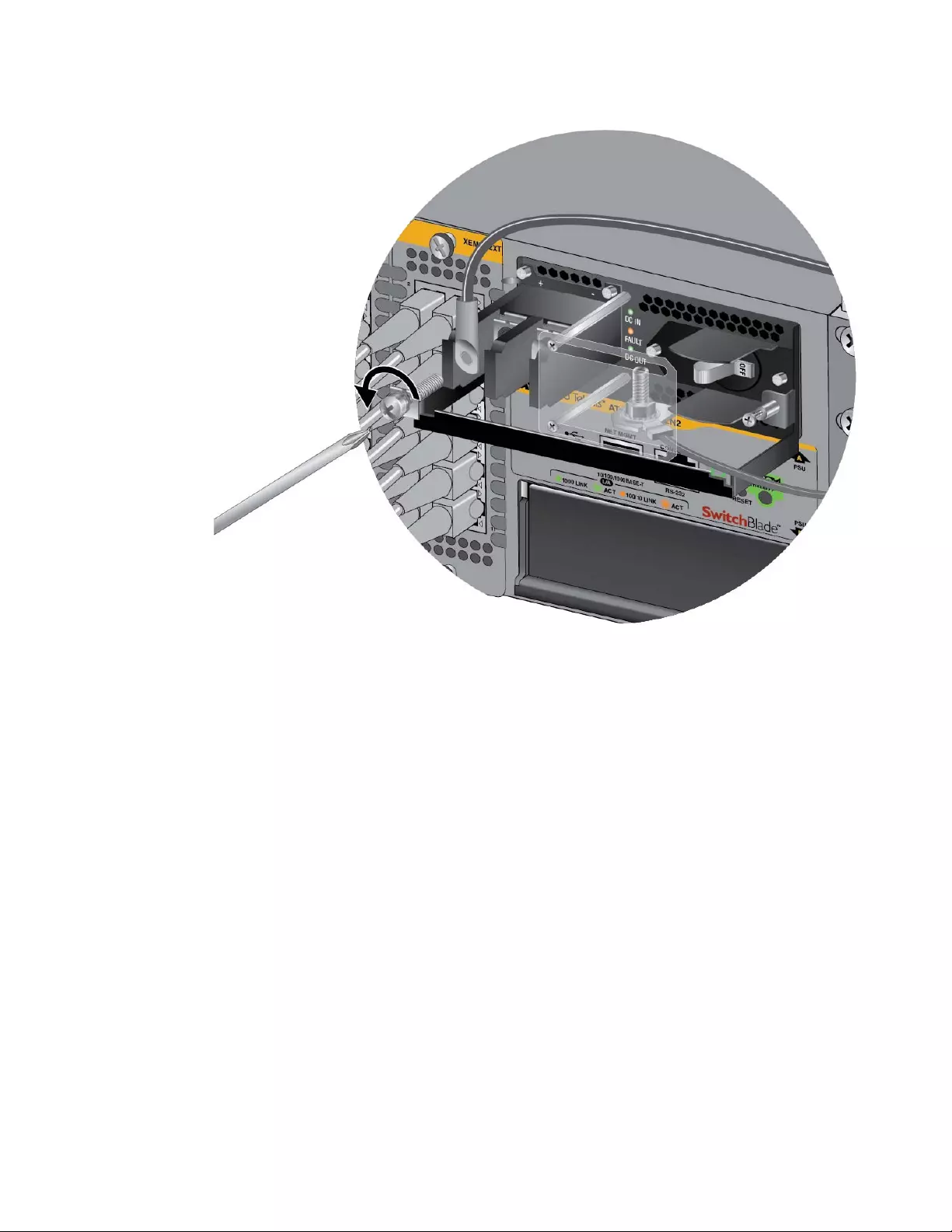

Figure 83: Connecting the Management Cable to the Console RS-232 Port ............ .............. .............. .. ............... ............114

Figure 84: SHOW CARD Command...................................................................................................................................116

Figure 85: Installing an SFP Transceiver............................................................................................................................120

Figure 86: Removing the Dust Cover from an SFP or SFP+ Transceiver ..........................................................................121

Figure 87: Positioning the SFP or SFP+ Handl e in the Upright Position ............................................................................121

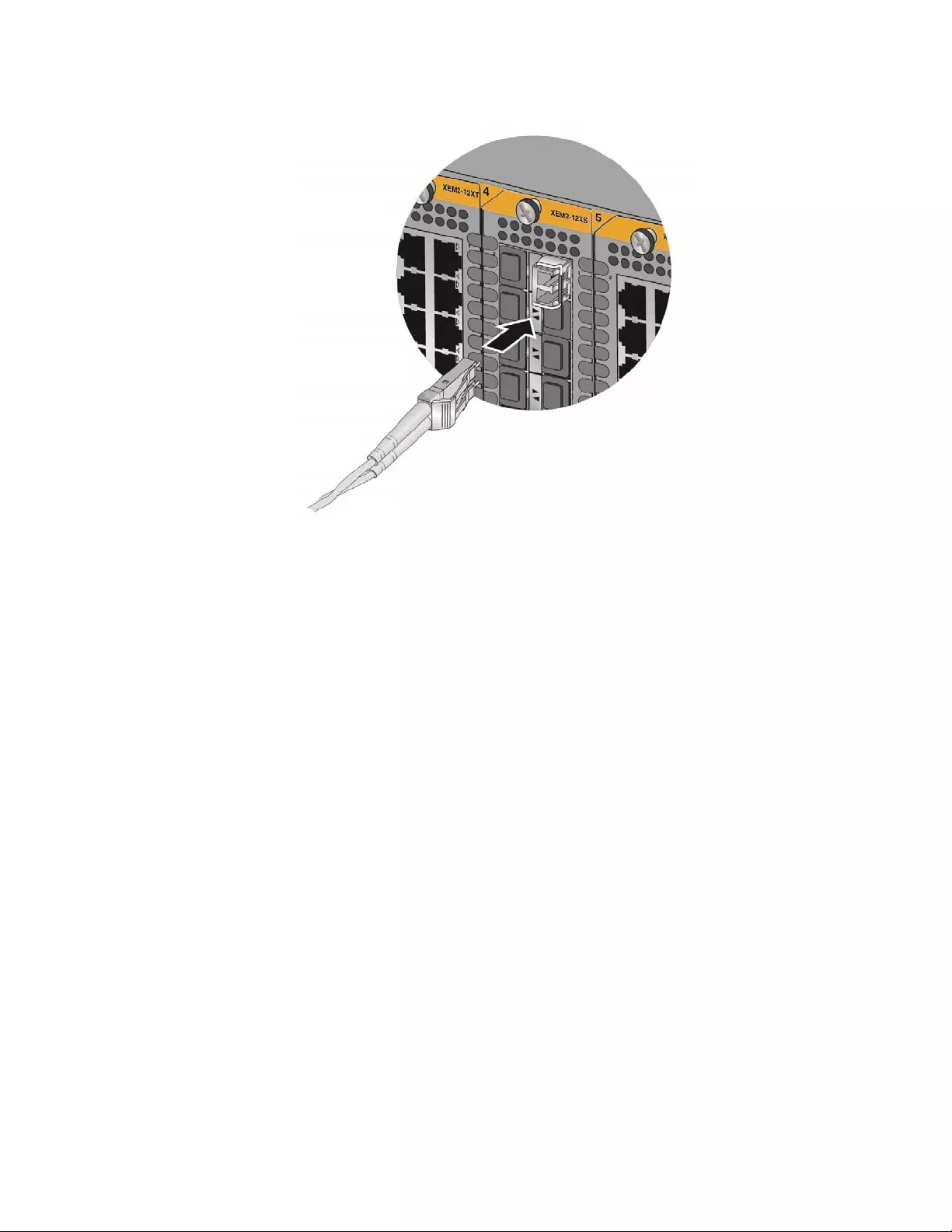

Figure 88: Connecting a Fiber Op tic Cable to an SFP or SFP+ Transceiver .............. ... ......................... ...........................122

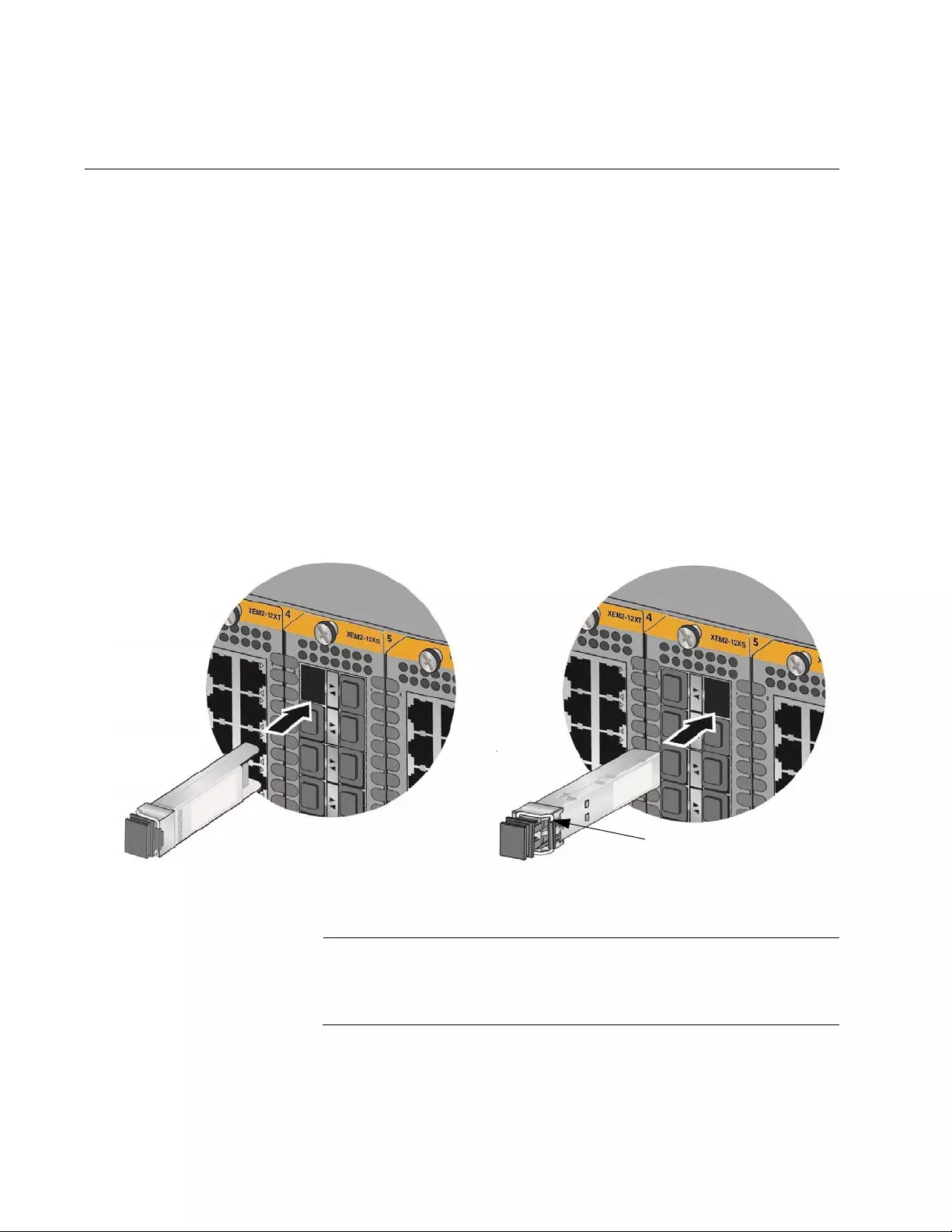

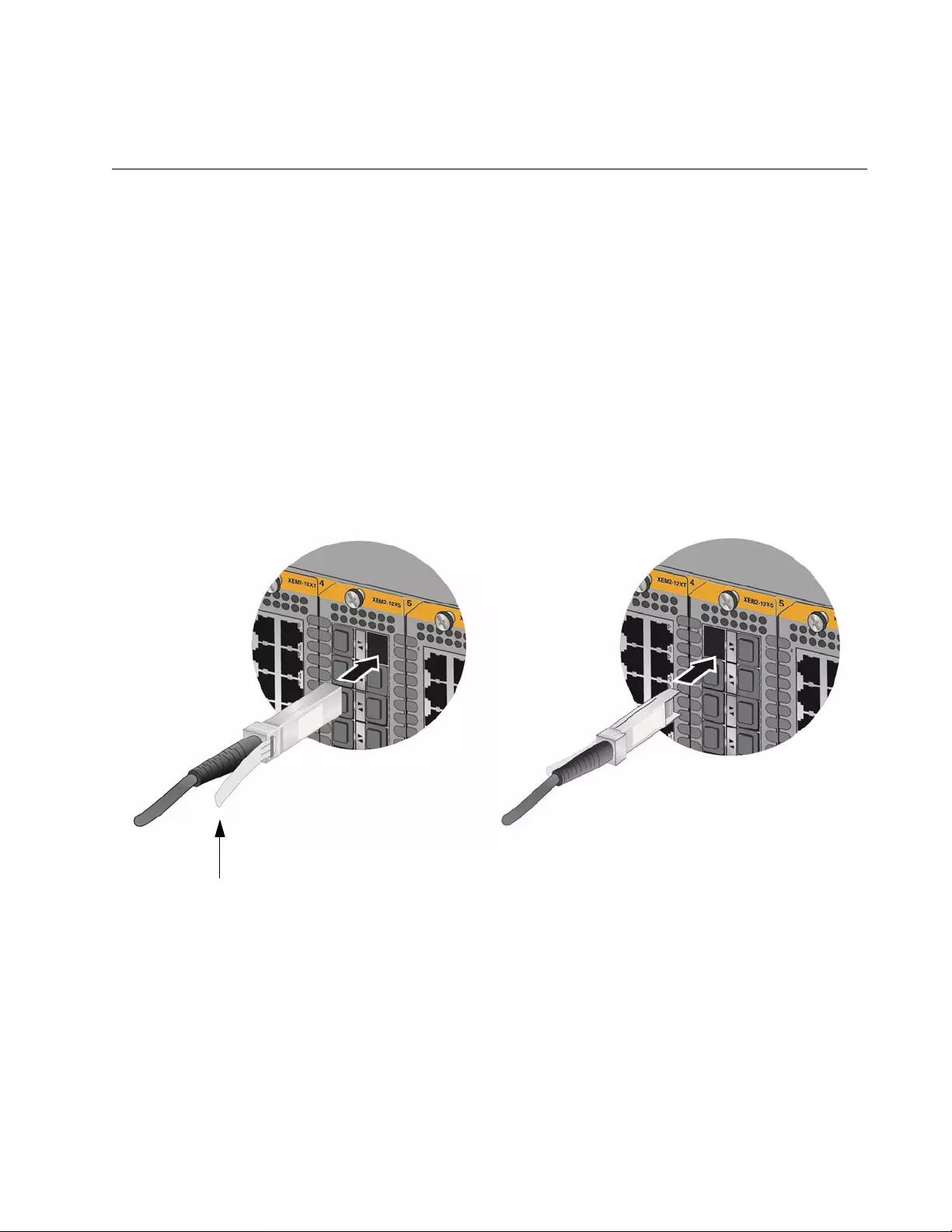

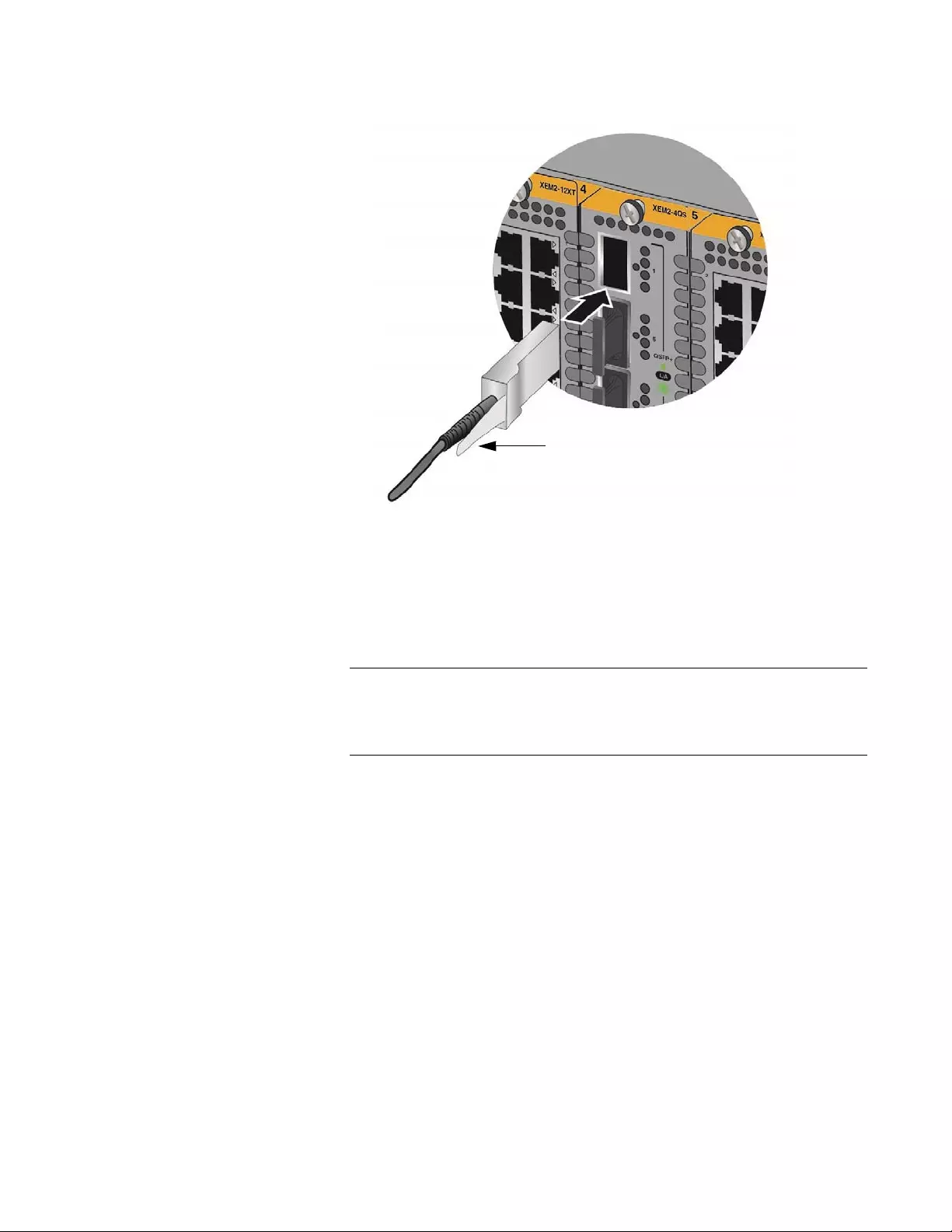

Figure 89: Installing AT-SP10TW Cables in the AT-XEM2-12XS Line Card ......................................................................123

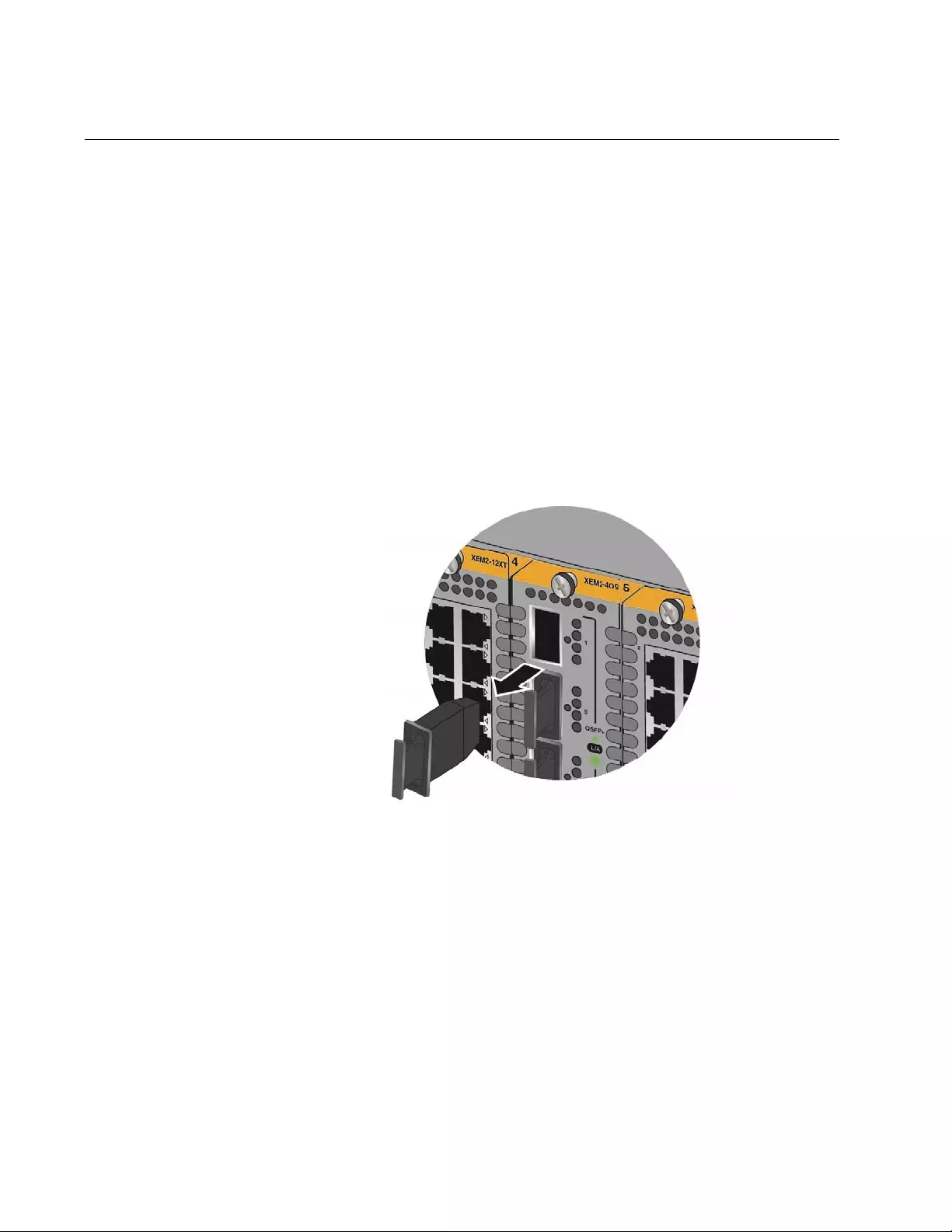

Figure 90: Removing the Dust Cover from a Slot on the AT-XEM2-4QS Line Card...........................................................126

Figure 91: Sliding the AT-QSFPCU Cable into the Slot... ...................................................................................................127

Figure 92: Disconnecting the AC Power Cord from the Power Source ............ ... .............. .............. .............. .....................131

Figure 93: Disconnecting the AC Power Cord from the Chassis ........................................................................................131

Figure 94: Lifting the Locking Handle on the AT-SBxPWRSYS2 AC Power Supply ..........................................................132

Figure 95: Removing the AT-SBxPWRSYS2 AC Power Supply ........................................................................................133

Figure 96: Loosening the Screw on the Locking Handle ....................................................................................................134

Figure 97: Opening the Plastic Window over the Terminal Block.......................................................................................135

Figure 98: Removing the Negative Lead Wire....................................................................................................................136

Figure 99: Removing the Po sitive Lead Wire from the Terminal Block...............................................................................137

Figure 100: Reinstalling the Screws on the Positive and Negative Te rminals....................................................................138

Figure 101: Closing the Plastic Cover.................................................................................................................................139

Figure 102: Removing the Gro unding Wire ........................................................................................................................140

Figure 103: Reinstalling the Nut and Washer on the Grounding Post ................................................................................141

Figure 104: Lifting the Locking Ha ndle and Removing the Power Suppl y..........................................................................142

Figure 105: Installing the Blank Powe r Supply Slot Cover..................................................................................................143

Figure 106: Lowering the Locking Handle on the Power Supply Slot Cover ......................................................................144

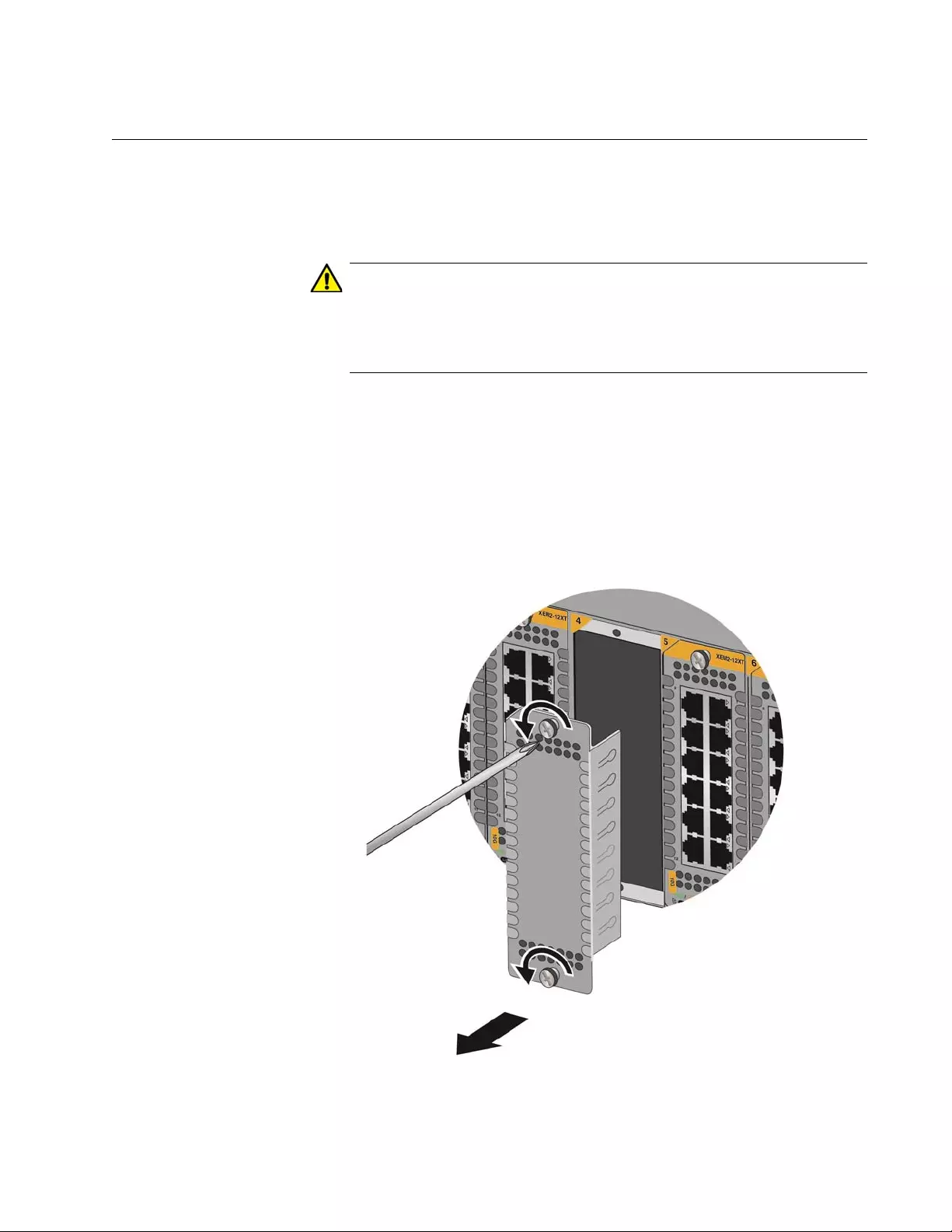

Figure 107: Loosening the Screws on the Ethernet Line Card...........................................................................................146

Figure 108: Disconnectin g an Eth ernet Line Card from the Chassis..................................................................................147

Figure 109: Sliding an Ethernet Line Card from the Chassis..............................................................................................148

AT-SBx908 Gen2 Switch Installation Guide

9

Figure 110: Placing the Ethernet Lin e Card in its Anti-static Bag.......................................................................................149

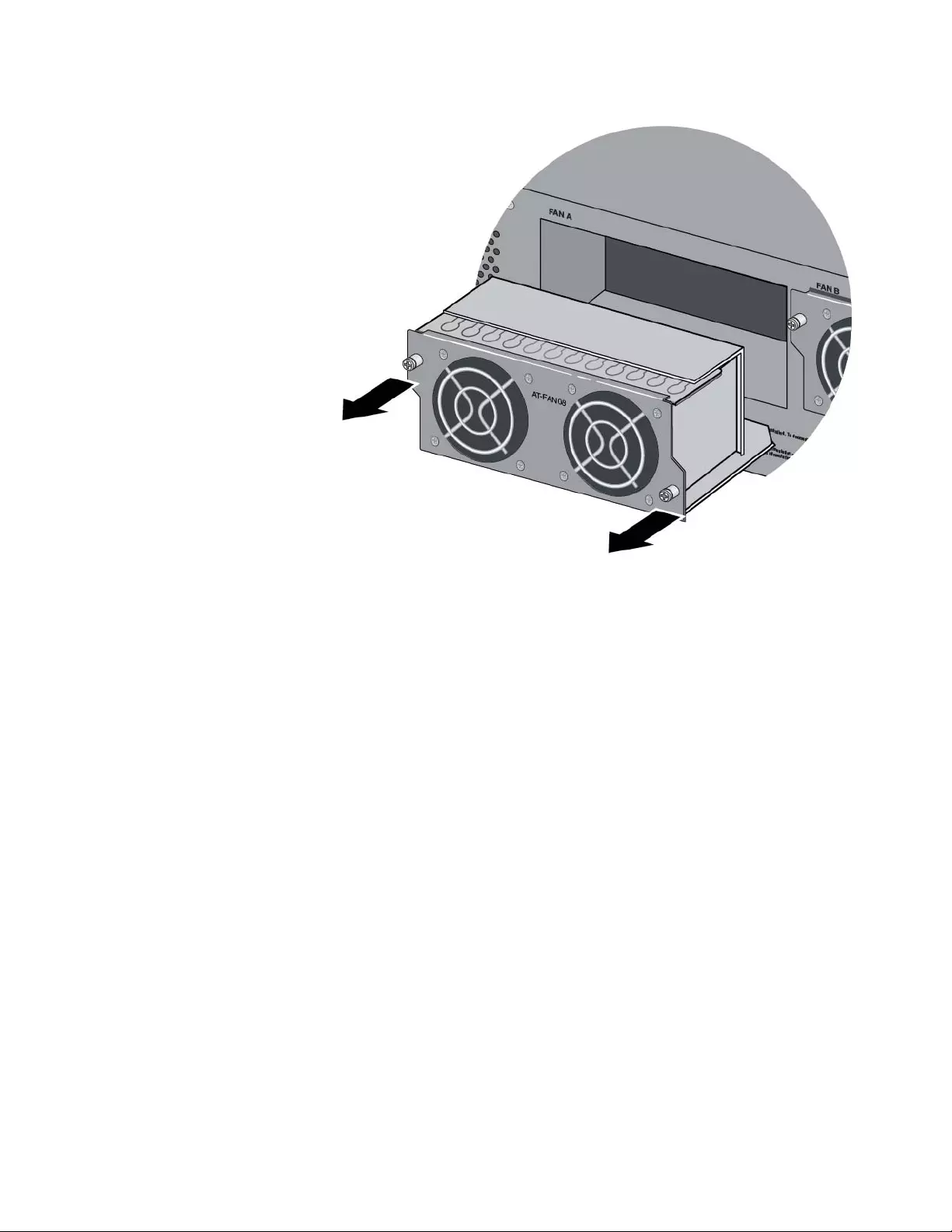

Figure 111: Loosening the Screws on the AT-FAN08 Module ...........................................................................................150

Figure 112: Disconnecting the AT-FAN08 Module from the Chassis .................................................................................151

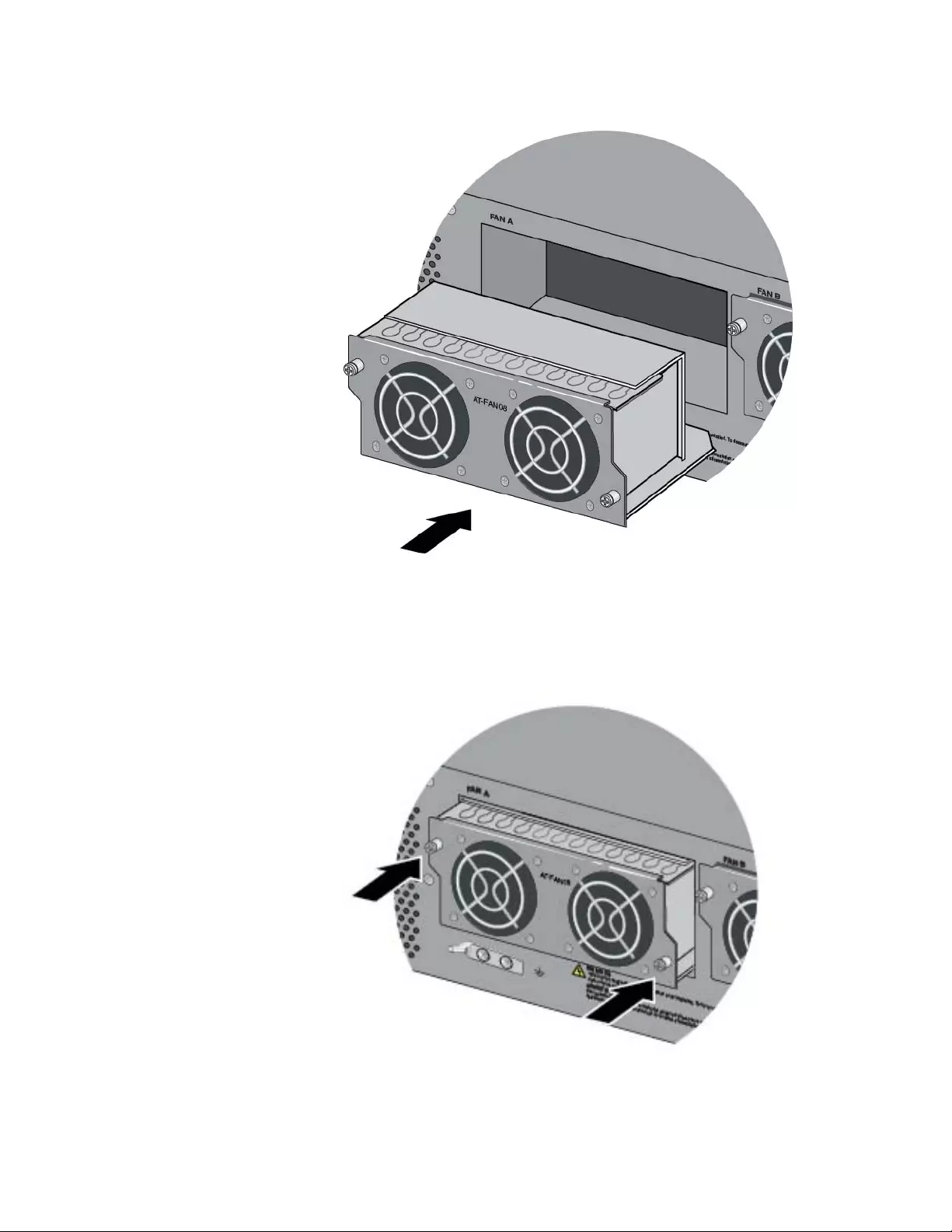

Figure 113: Aligning the AT-FAN08 Module in the Chassis Slot ........................................................................................152

Figure 114: Seating the AT-FAN08 Modul e on the Connector in the Chassis .................................... .............. ...... ...........152

Figure 115: Tightening the Two Captive Screws on the AT-FAN08 Module......................................................................153

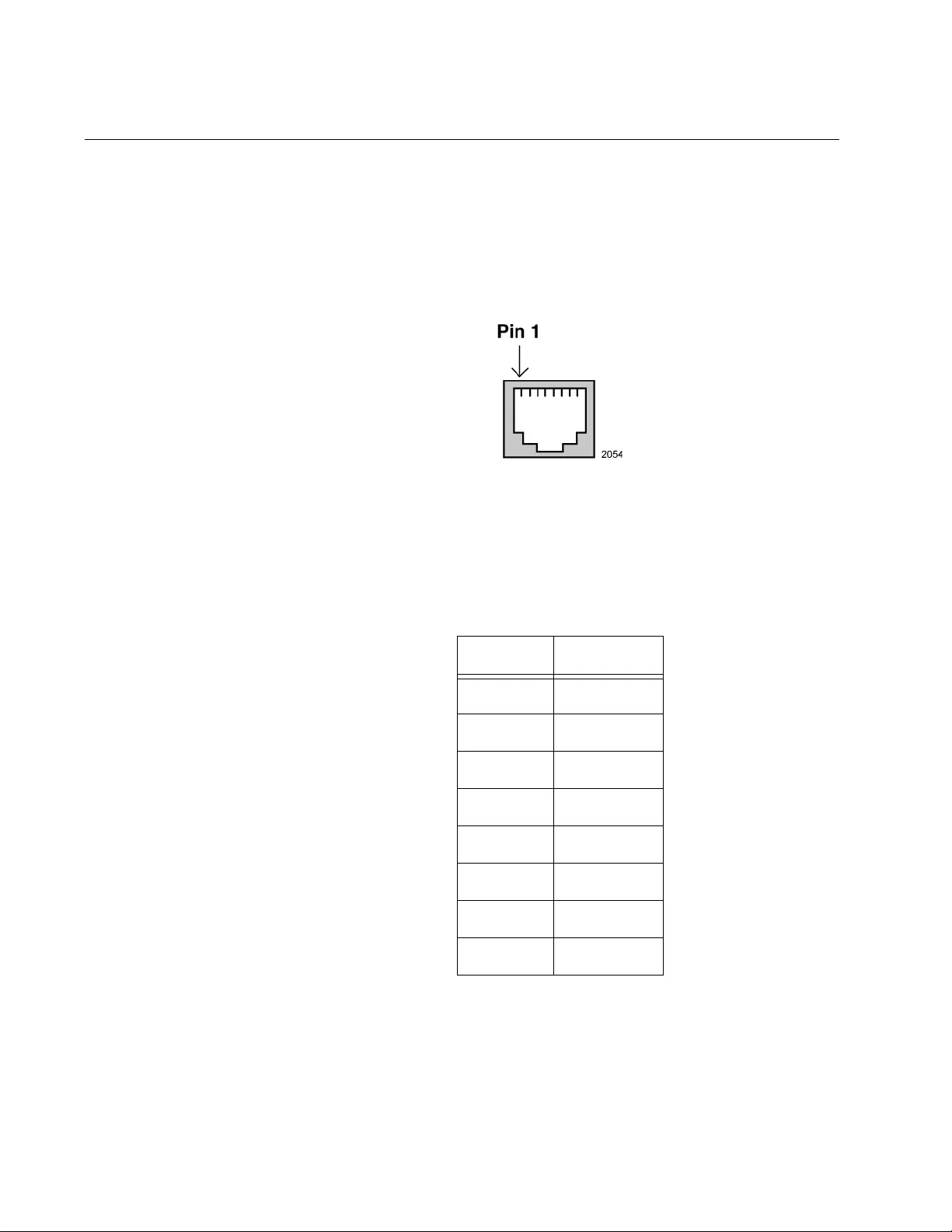

Figure 116: Pin Layout (Front View) of the 1Gbps or 10Gbps Ports on the AT-XEM2-12XT Line Card............................166

Figures

10

11

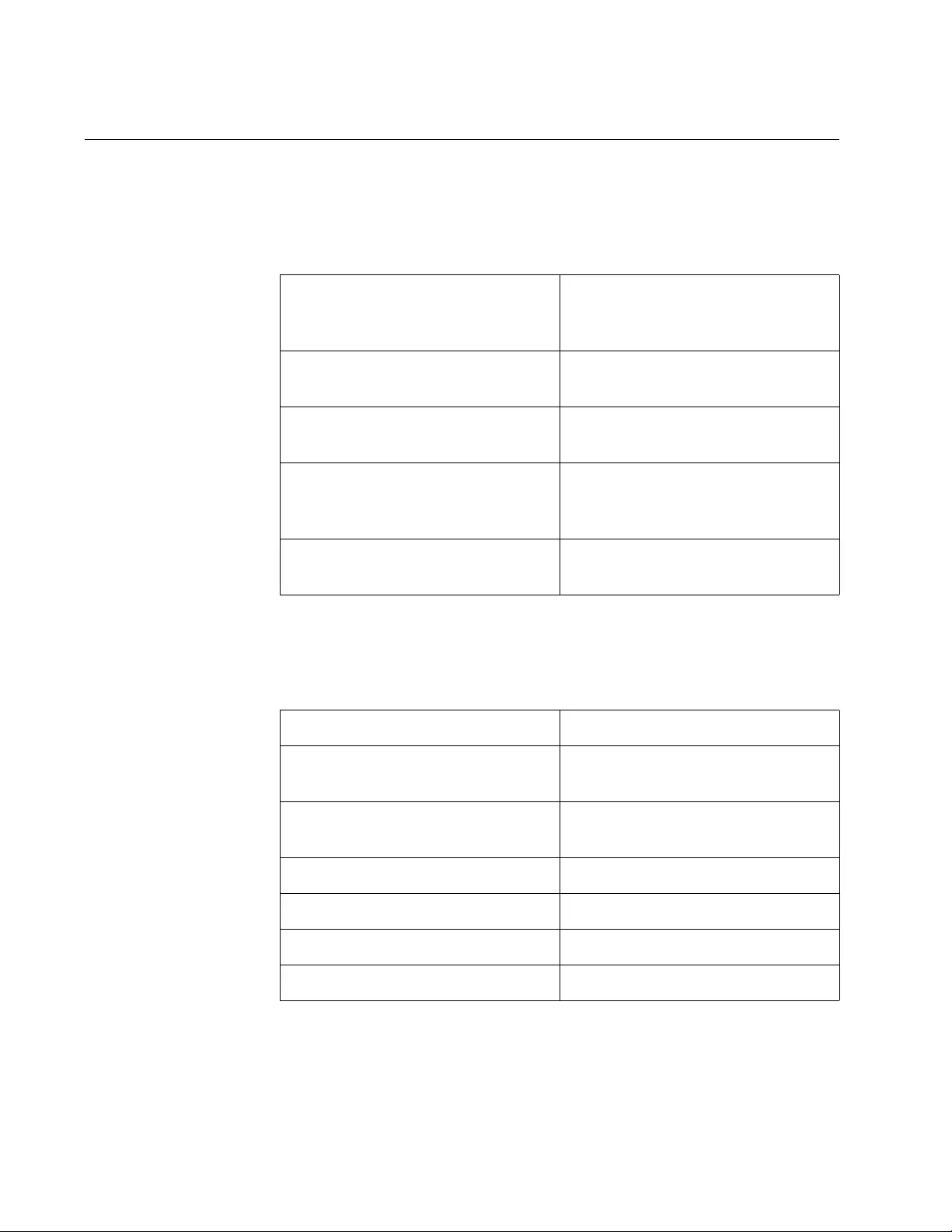

Tables

Table 1: Features of the AT-SBx908 Gen2 Chassis ............................................................................................................18

Table 2: Twisted Pair Ports on the AT-XEM2-12XT Line Ca rd ............................................................................................23

Table 3: Link and Activity LEDs on the AT-XEM2-12XT Line Card .....................................................................................23

Table 4: Link and Activity LEDs on the AT-XEM2-12XS Li ne Card ................................... .............. ............... .....................25

Table 5: Link and Activity Status LEDs for the AT-XEM2-4QS Line Card ...........................................................................26

Table 6: Twisted Pair Cable for the NET MGMT Port on the Management Panel ..............................................................28

Table 7: NET MGMT Port LED ............................................................................................................................................29

Table 8: PORT Parameter Format .......................................................................................................................................35

Table 9: Product Dimensions .............................................................................................................................................160

Table 10: Product Weights ................................................................................................................................................160

Table 11: Ventilation Requirements ...................................................................................................................................161

Table 12: Environmental Specifications .............................................................................................................................162

Table 13: AC Voltage and Frequency Requirements ........................................................................................................163

Table 14: DC Voltage Requirements .................................................................................................................................163

Table 15: Maximum Power Consumpti on (Watts) .............................................................................................................163

Table 16: Typical Power Savings in eco-friendly Mode (Watts) ........................................................................................163

Table 17: Maximum Power Supply Efficiency (Based on 100V Input Voltage) .................................................................164

Table 18: Heat Dissipation (British Thermal Units/Hour) ...................................................................................................164

Table 19: Product Certifications .........................................................................................................................................165

Table 20: Pin Signals for 1Gbps or 10Gbps ......................................................................................................................166

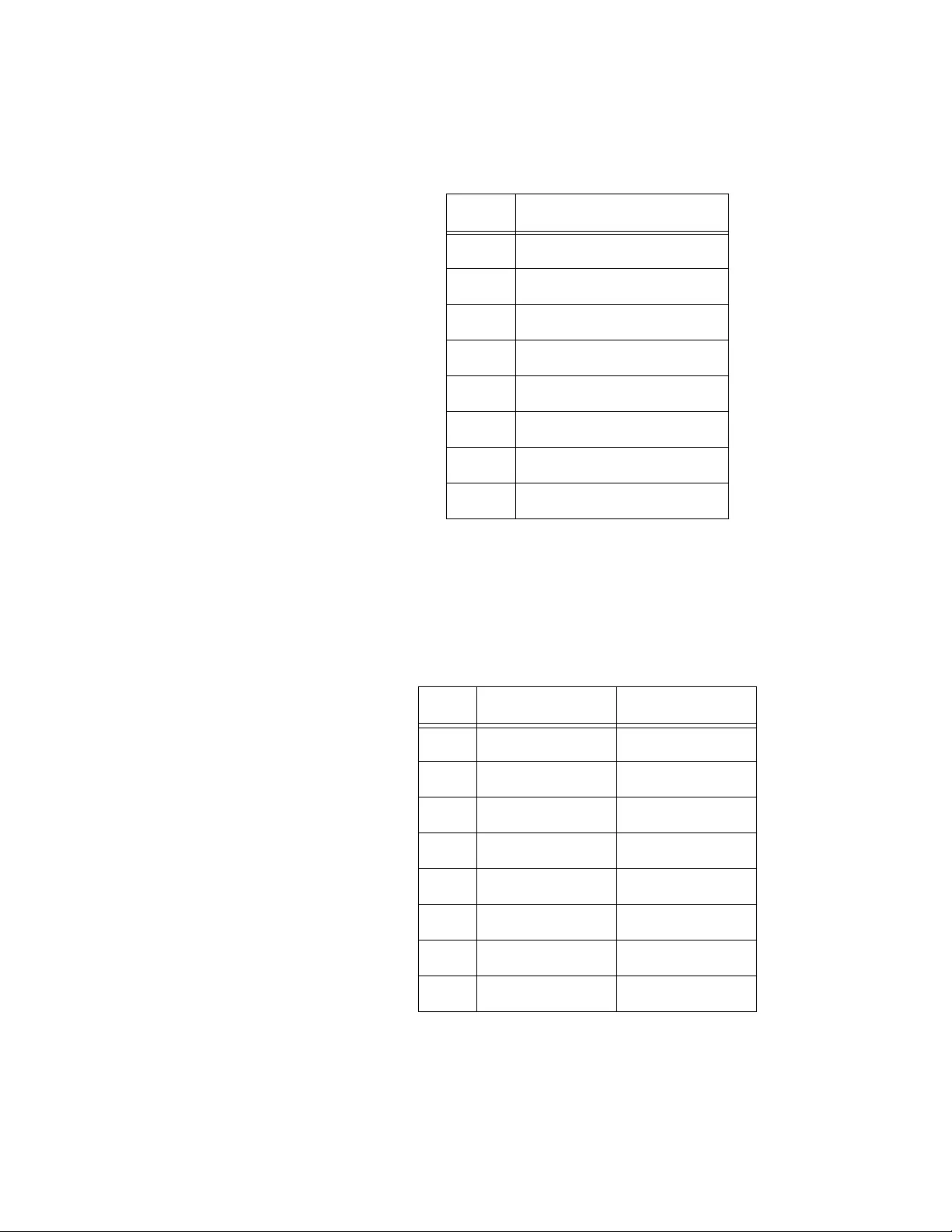

Table 21: RJ-45 Pin Signals for the Console Port on the Management Panel ..................................................................167

Table 22: RJ-45 Pin Signals for 10 or 100Mbps for the NET MGMT Port on the Management Panel ..............................167

Tables

12

Preface

14

Document Conventions

This document uses the following conventions:

Note

Notes provide additional information.

Caution

Cautions inform you that performing or omitting a specific action

may result in equipment damage or loss of data.

Warning

Warnings inform you that performing or omitting a specific action

may result in bodily injury.

AT-SBx908 Gen2 Switch Installation Guide

15

Contacting Allied Telesis

If you need assistance with this product, you may contact Allied Telesis

technical support by going to the Support & Services section of the Allied

Telesis web site at www.alliedtelesis.com/support. You can find links for

the following services on this page:

24/7 Online Support — Enter our interactive support center to

search for answers to your product questions in our knowledge

database, to check support tickets, to learn about RMAs, and to

contact Allied Telesis technical experts.

USA and EMEA phone support — Select the phone number that

best fits your location and customer type.

Hardware warranty information — Learn about Allied Telesis

warranties and register your product online.

Replacement Services — Submit a Return Merchandise

Authorization (RMA) request via our interactive support center.

Documentation — View the most recent installation and user

guides, software release notes, white papers, and data sheets for

your products.

Software Downloads — Download the latest software releases for

your managed products.

For sales or corporate information, go to www.alliedtelesis.com/

purchase and select your region.

Preface

16

17

Chapter 1

Overview

The chapter contains the following sections:

“Overview” on page 18

“AT-SBx908 Gen2 Chassis” on page 21

“Ethernet Line Cards” on p age 22

“AT-XEM2-12XT Line Card” on page 23

“AT-XEM2-12XS Line Card” on page 25

“AT-XEM2-4QS Line Card” on page 26

“Management Panel” on page 27

“Power Supplies” on page 32

“AT-FAN08 Units” on page 34

“Specifying Ports in the Command Line Interface” on page 35

Chapter 1: Overview

18

Overview

The AT-SBx908 Gen2 Chassis is an advanced Layer 3+ modular switch.

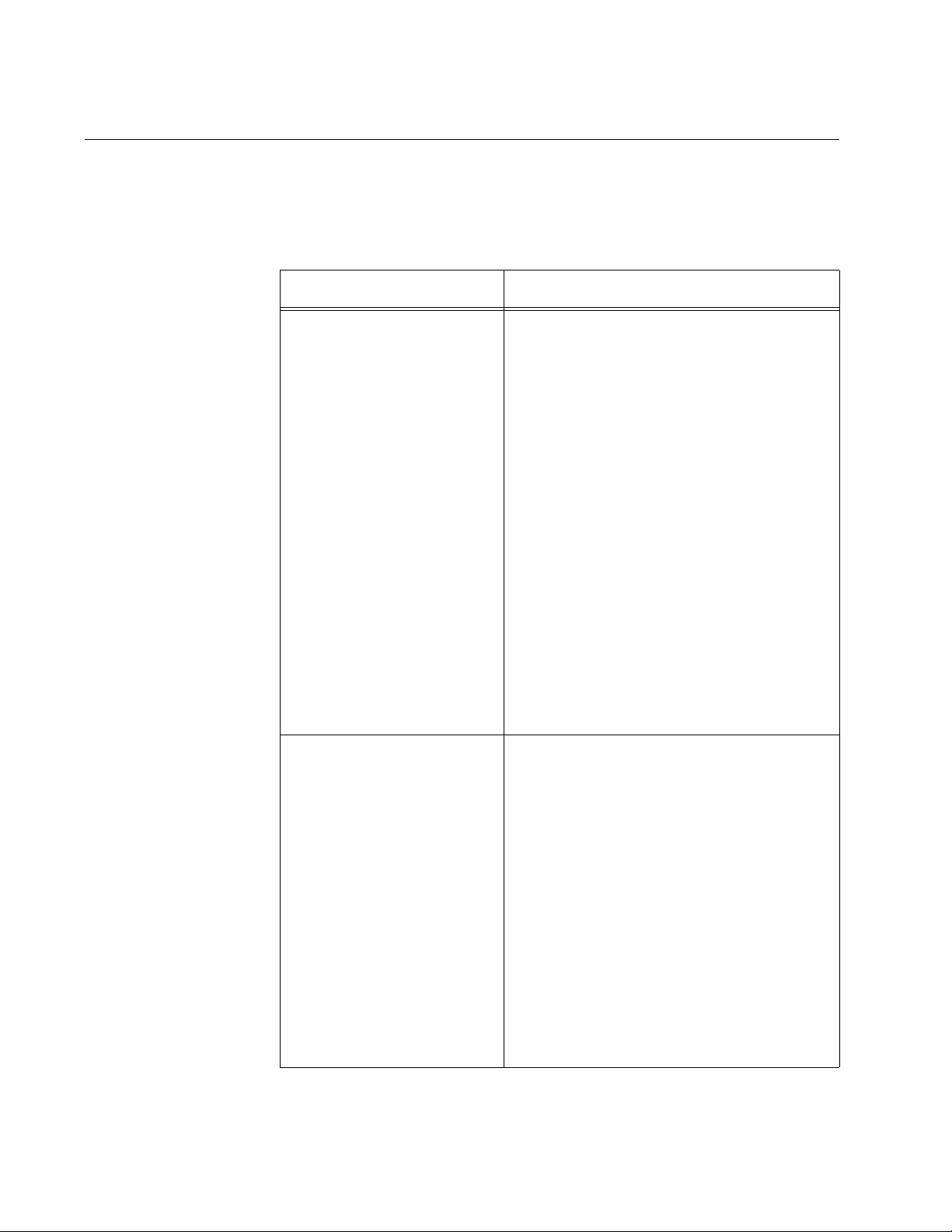

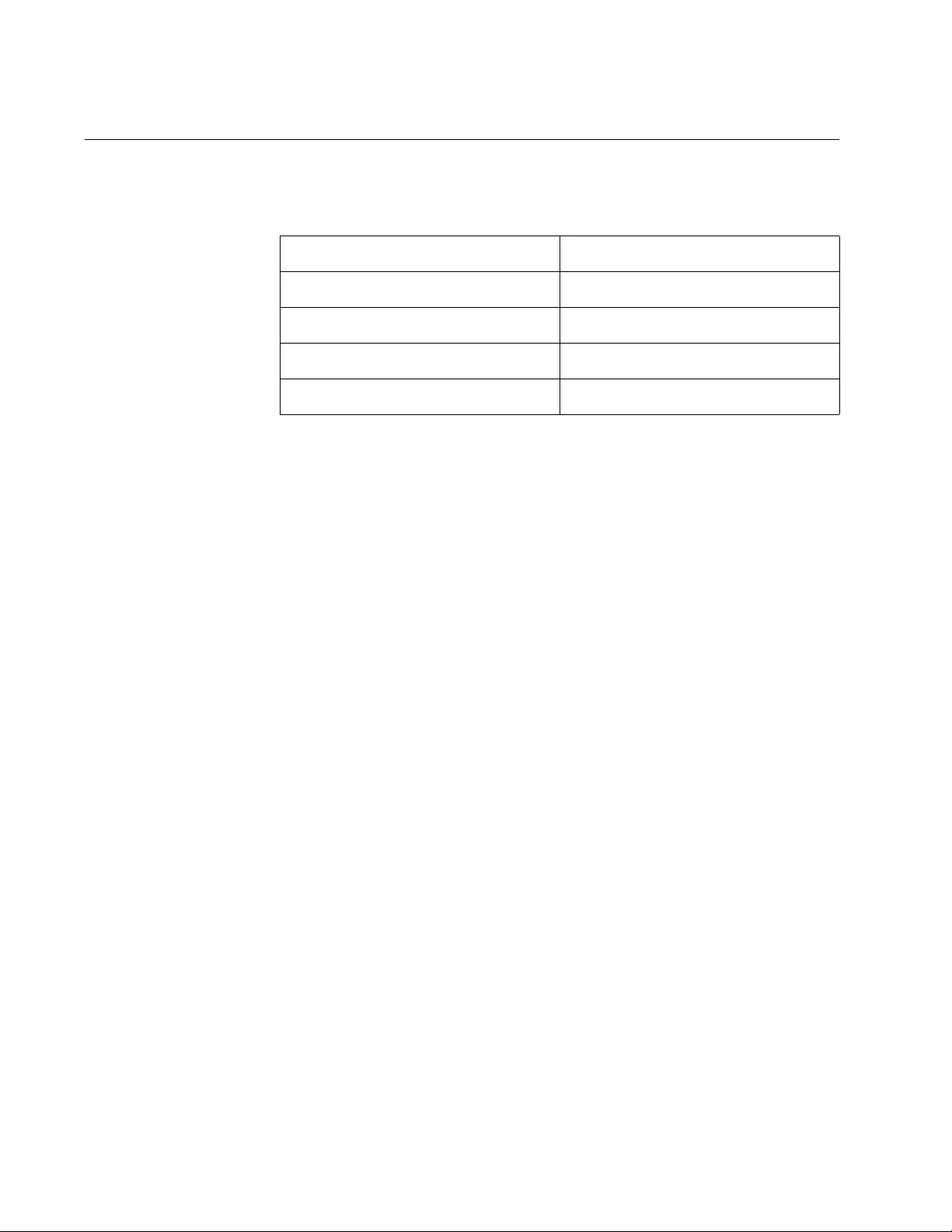

The main features are listed in Table 1.

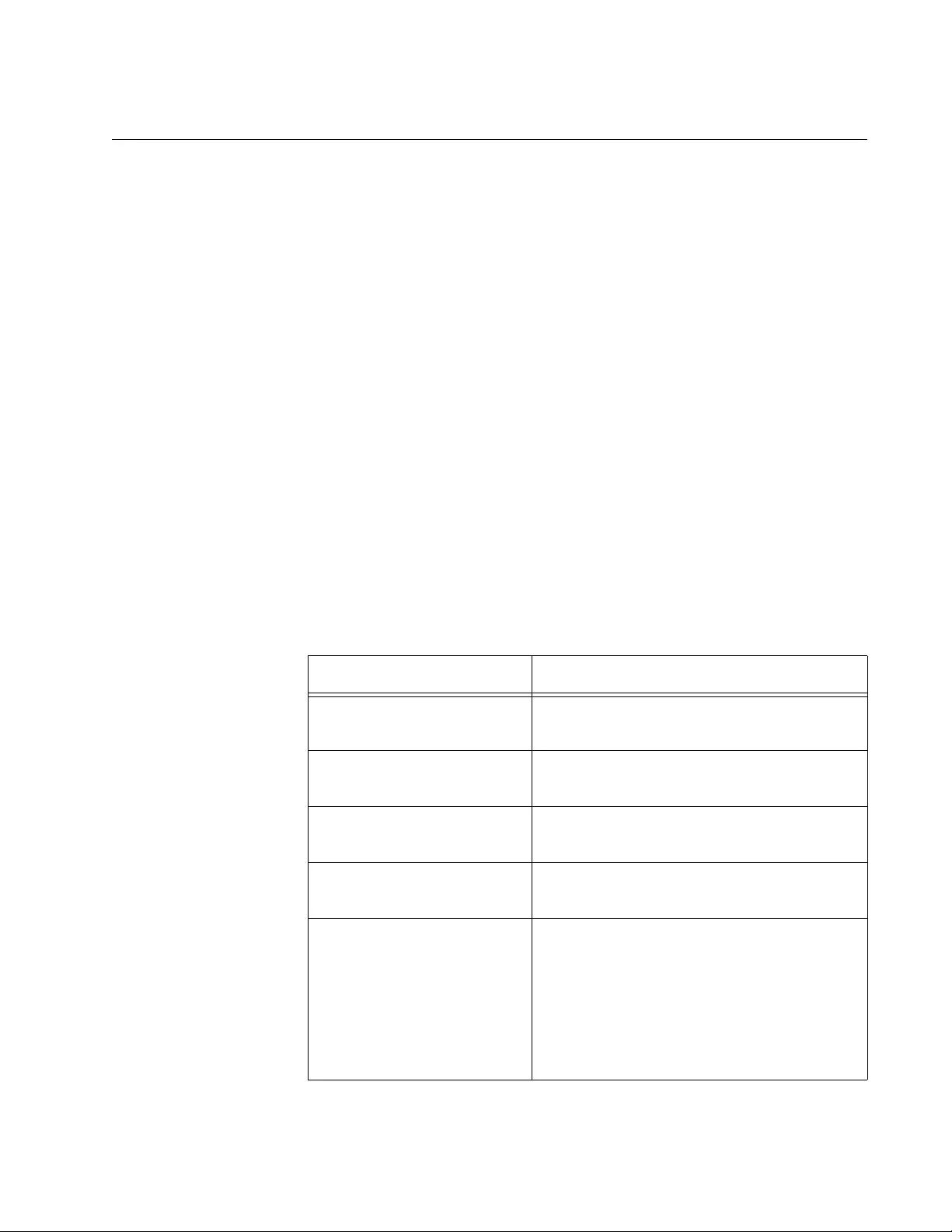

Table 1. Features of the AT-SBx908 Gen2 Chassis

Feature Description

AT-SBx908 Gen2 Chassis The chassis has the following hardware

features:

- The height is 3RU.

- There are eight slots for Ethernet line

cards.

- Each line card slot has 160Gbps

connectivity over the backplane.

- The unit supports two power supplies for

primary and redundant power.

- The chassis comes with two pre-installed

brackets for a standard 19-inch equipment

rack.

- The unit comes with two pre-installed fan

modules, providing front-to-back airflow.

- The line cards, power supplies, and fan

modules are hot-swappable.

Ethernet Line Cards The Ethernet line cards f or the chassis are

listed here:

- AT-XEM2-12XT Card features 12

1Gbps/10Gbps, twisted pair ports with RJ-

45 connectors.

- AT-XEM2-12XS Card features 12

transceiver slots for 1Gbps SFP or

10Gbps SFP+ transceivers.

- AT-XEM2-4QS Card features four

transceiver slots for 40Gbps QSFP+

transceivers.

Ethernet line cards are ordered

separately.

AT-x908 Gen2 Switch Installation Guide

19

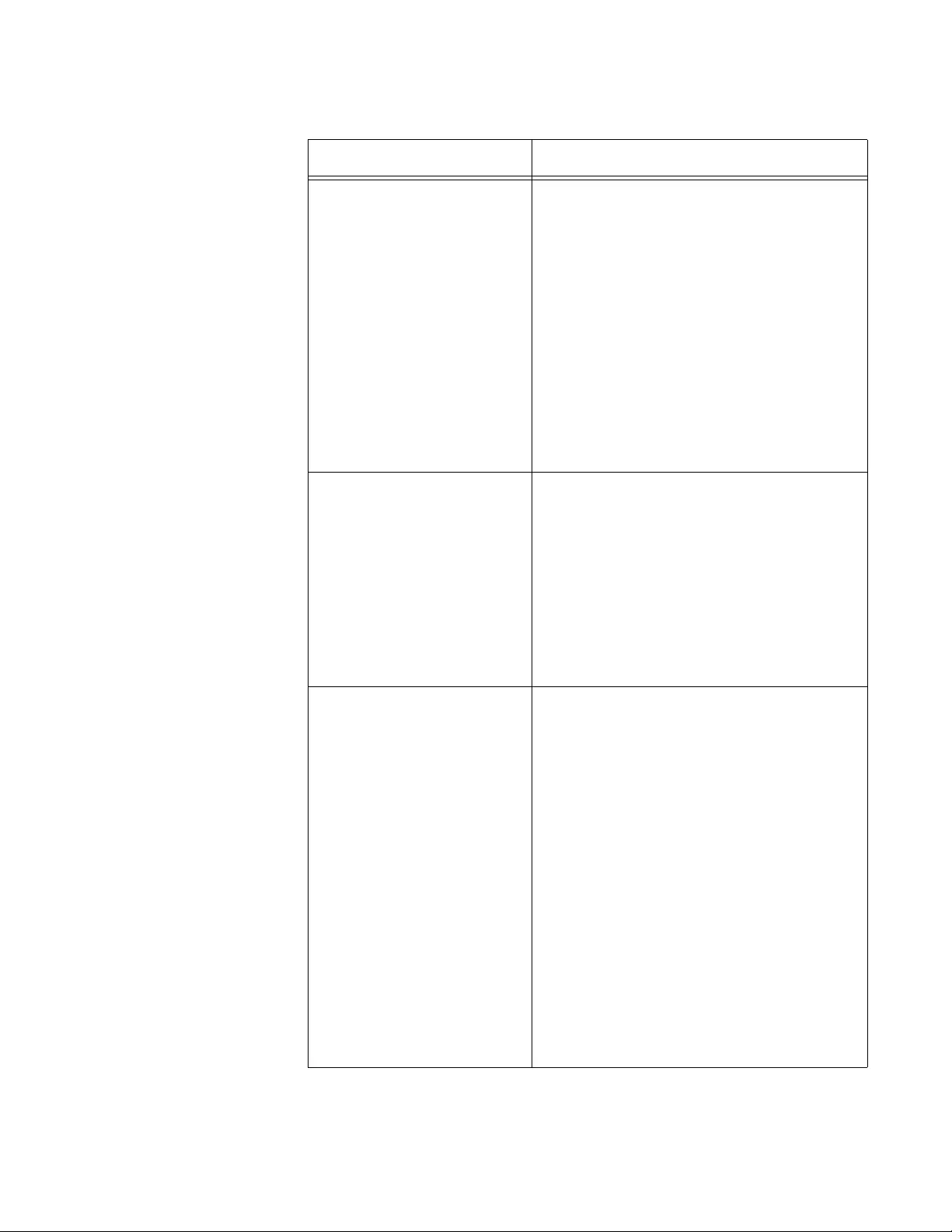

Management software and

interfaces

Here are the management software and

interfaces:

- AlliedWare Plus management software

- Command line interface, available lo cally

through the Console port or remotely o ver

the network.

- Web browser interface available

remotely over the network.

The AlliedWare Plus management

software comes pre-installed on the

chassis.

Management Methods You can manage the switch as follows:

- You can access the command line

interface locally through the Console port

or remotely using Telnet or Secure Shell.

- You can access the web browser

interface remotely using HTTP.

- You can also remotely manage the

switch with SNMPv1, v2c, or v3.

Management Panel The pre-installed management panel has

the following features:

- Console RS-232 port for local

management (no IP address required),

- USB 2.0 port for storing backup copies of

system configuration files, transferring

management software among units, and

other management functions.

- An eco-friendly button for turning off the

system LEDs to reduce power

consumption.

- Network management port for initial

configuration and maintenance access to

the chassis.

- Chassis reset button.

Table 1. Features of the AT-SBx908 Gen2 Chassis (Continued)

Feature Description

Chapter 1: Overview

20

Power Supplies The chassis can be powered by one or

two power supplies. A chassis with two

power supplies has power redundancy.

Power supplies are ordered separately

Table 1. Features of the AT-SBx908 Gen2 Chassis (Continued)

Feature Description

AT-x908 Gen2 Switch Installation Guide

21

AT-SBx908 Gen2 Chassis

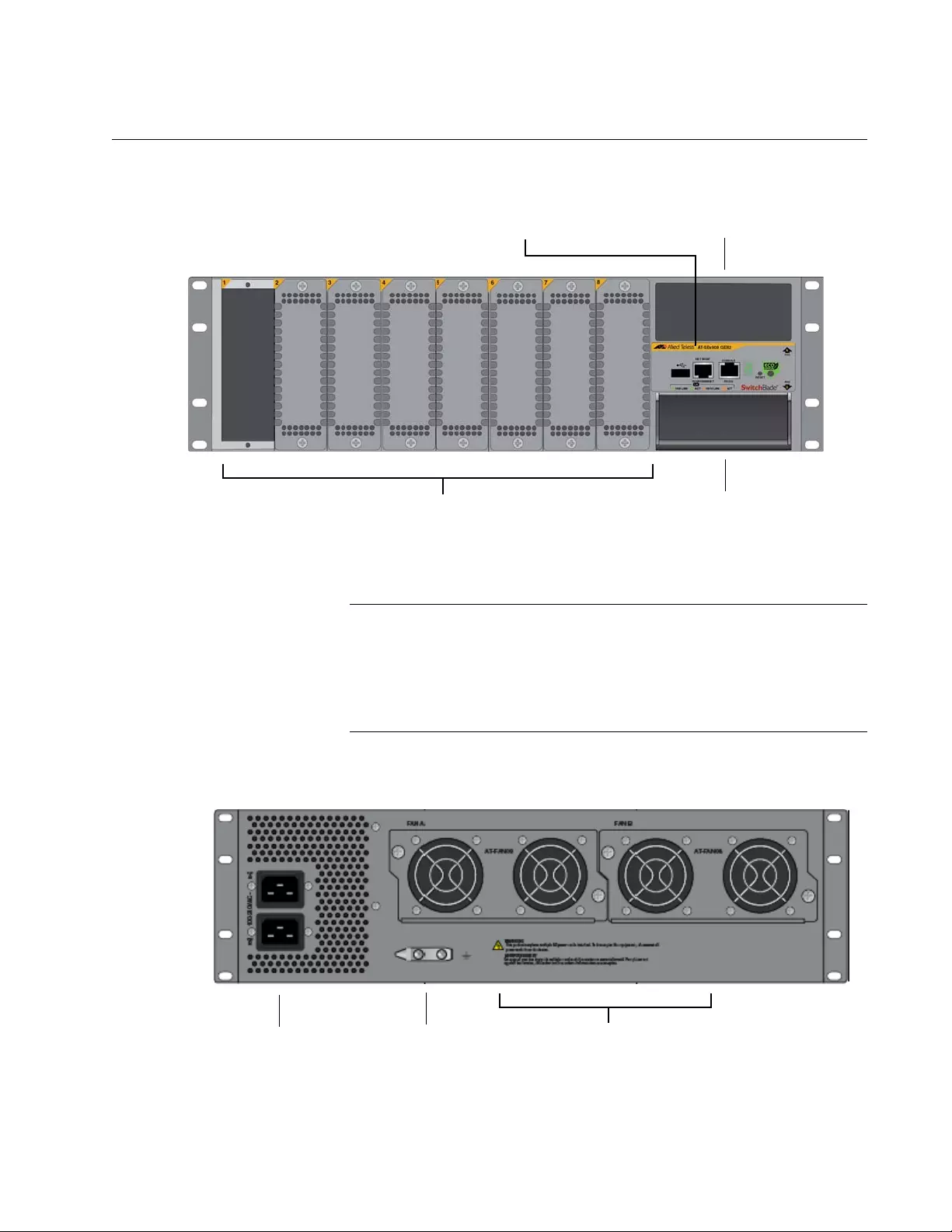

The front panel of the AT-SBx908 Gen2 Chassis is shown in Figure 1.

Figure 1. Front Panel of the AT-SBx908 Gen2 Chassis

Note

The switch comes with slot covers on line card slots 2 to 8. Do not

remove the slot covers until after the unit is installed in the

equipment rack. You might bend the chassis and cause

misalignment of the slots and card guides if you lift the chassis into

the equipment rack without the line card slot covers.

The rear panel is shown in Figure 2.

Figure 2. Rear Panel of the AT-SBx908 Gen2 Chassis

Eight Slots for Ethernet Line Cards

Power Supply Slot (PSU A)

Power Supply Slot (PSU B)

with Blank Cover

Management Panel

Ground Wire Lug

AC Input

Power Connectors

AT-FAN08 Fan Units

Chapter 1: Overview

22

Ethernet Line Cards

The AT-SBx908 Gen2 Ethernet line cards are shown in Figure 3.

Figure 3. AT-SBx908 Gen2 Ethernet Line Cards

AT-XEM2-12XT Line

Card with 12 1Gbps or

10Gbps ports with RJ-45

connectors.

AT-XEM2-12XS Line

Card with 12 slots for

1Gbps SFP or 10Gbps

SFP+ transceivers.

AT-XEM2-4QS Line

Card with four slots for

40Gbps QSFP+

transceivers.

AT-x908 Gen2 Switch Installation Guide

23

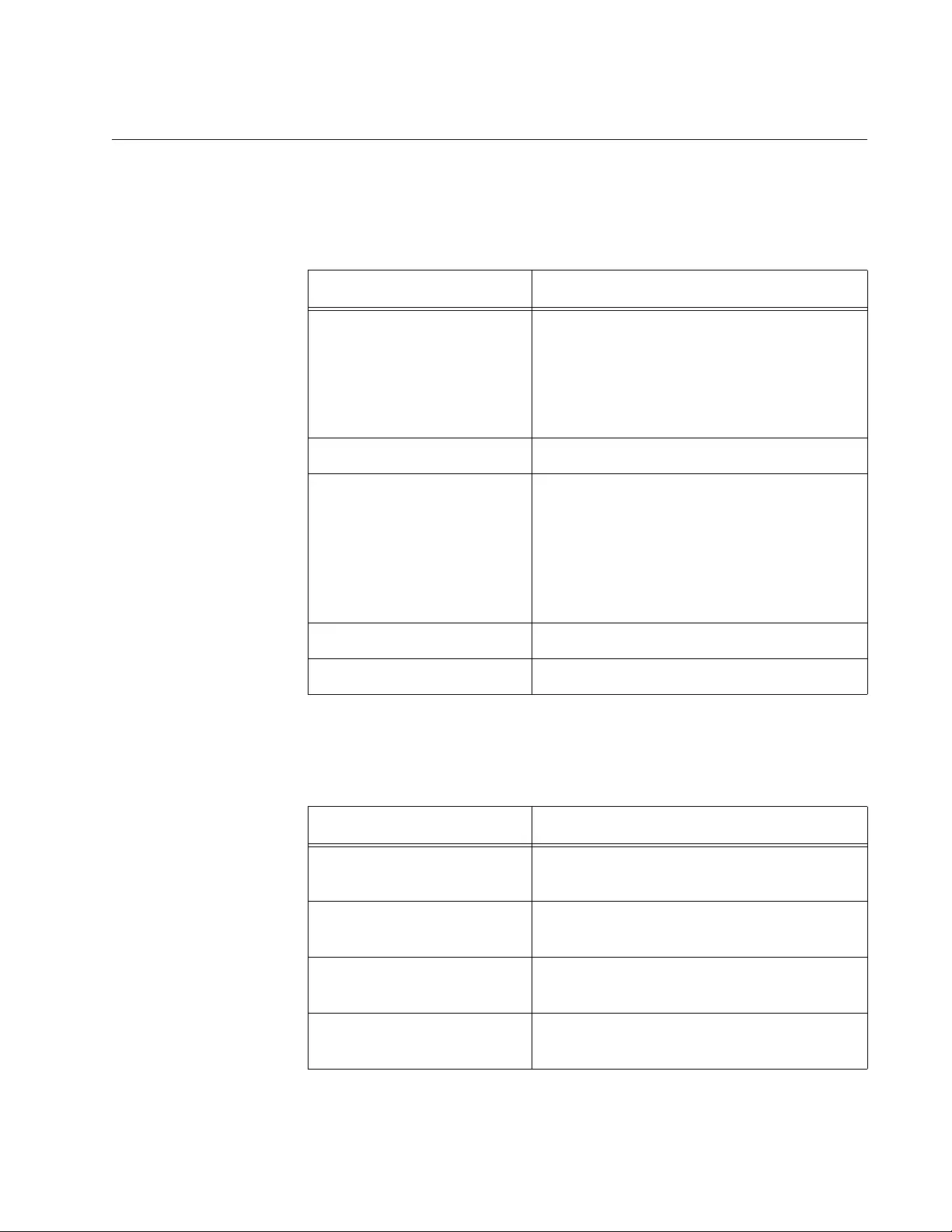

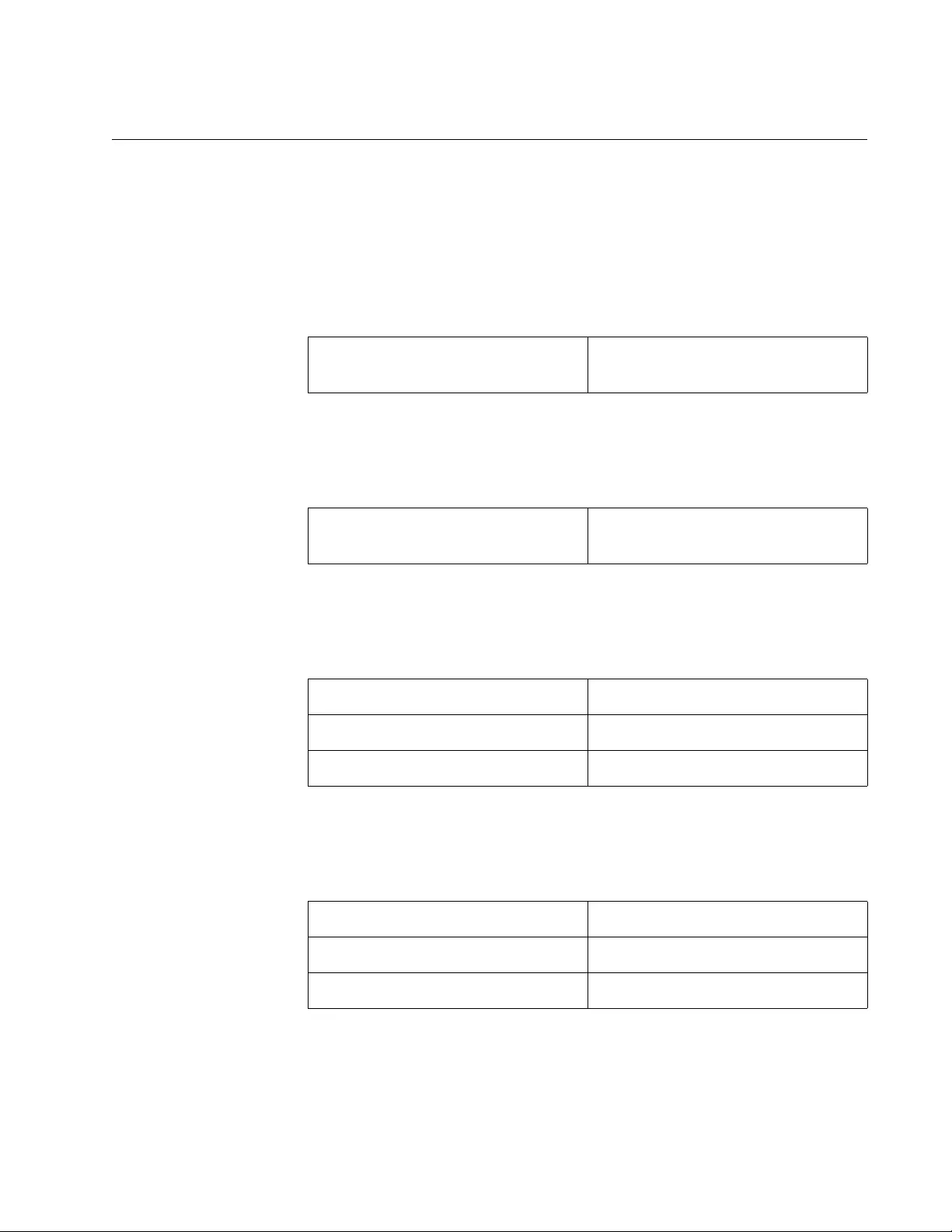

AT-XEM2-12XT Line Card

The AT-XEM2-12XT Card has 12 twisted pair ports with standard 8-pin

RJ-45 ports. The specifications of the ports are listed in Table 2.

Each port has a single LED that displays link and activity information. The

states of LEDs are described in Table 3.

Table 2. Twisted Pair Ports on the AT-XEM2-12XT Line Card

Specification Description

Port Speed The ports support 1Gbps or 10Gbps. The

ports do not support 10Mbps or 100Mbps.

You can set port speed with Auto-

Negotiation or manually. The default is

Auto-Negotiation.

Duplex Mode Full-duplex only

Cabling 1Gbps - Standard TIA/EIA 568-B-

compliant Category 6 shielded cabling or

better.

10Gbps -Standard TIA/EIA 568-C-

compliant Category 6a shielded ca bling or

better.

Maximum Distance 100 meters (328 feet)

Connector 8-pin RJ-45

Table 3. Link and Activity LEDs on the AT-XEM2-12XT Line Card

State Description

Solid Green The port has established a 10GBase link

to a network device.

Flashing Green The port is transmitting or receiving data

at 10GBase.

Solid Amber The port has established a 1GBase link to

a network device.

Flashing Amber The port is transmitting or receiving data

at 1GBase.

Chapter 1: Overview

24

Off Possible causes of this state are listed

here:

- The port has not established a link with

another network device.

- The LEDs are turned off. To turn on the

LEDs, use the eco-friendly button.

Table 3. Link and Activity LEDs on the AT-XEM2-12XT Line Card

State Description

AT-x908 Gen2 Switch Installation Guide

25

AT-XEM2-12XS Line Card

The AT-XEM2-12XS Card has twelve transceiver slots that support the

following types of 1Gbps SFP or 10Gbps SFP+ transceivers:

1Gbps SX or LX SFP transceivers

10Gbps SR or LR fiber optic transceivers

10Gbps AT-SP10TW direct connect twinax cables with SFP+

transceiver-style connectors

Guidelines about the SFP+ transceiver slots are listed here:

The card does not support 100Mbps transceivers.

The card supports full-duplex mode only.

You can set the port speeds with Auto-Negotiation or manually.

The default is Auto-Negotiation.

SFP or SFP+ transceivers must be purchased separately. For a list of

supported transceivers, refer to the AT-SBx908 Gen2 Series data sheet

on the Allied Telesis web site.

The slots have link and activity LEDs. The states of the LEDs are

described in Table 4.

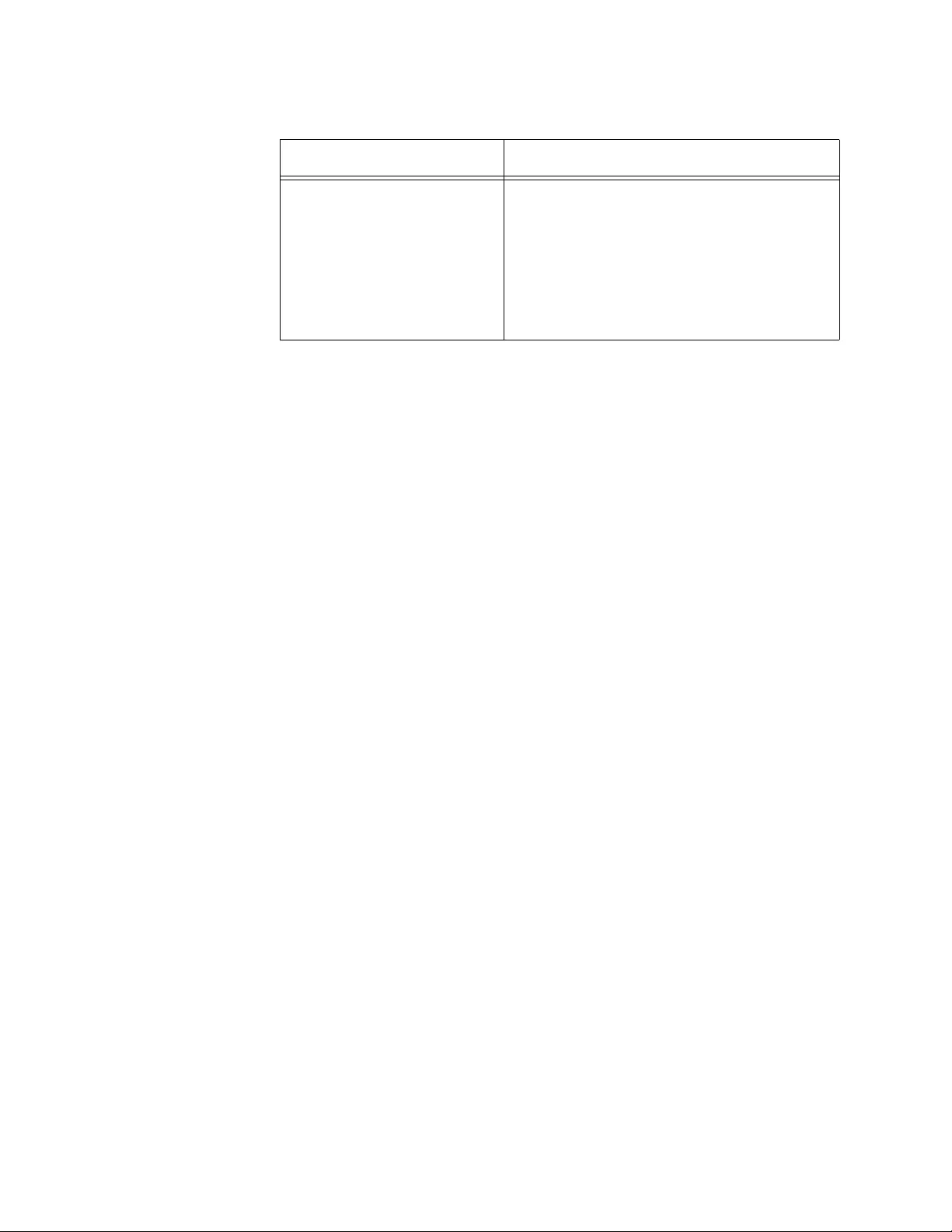

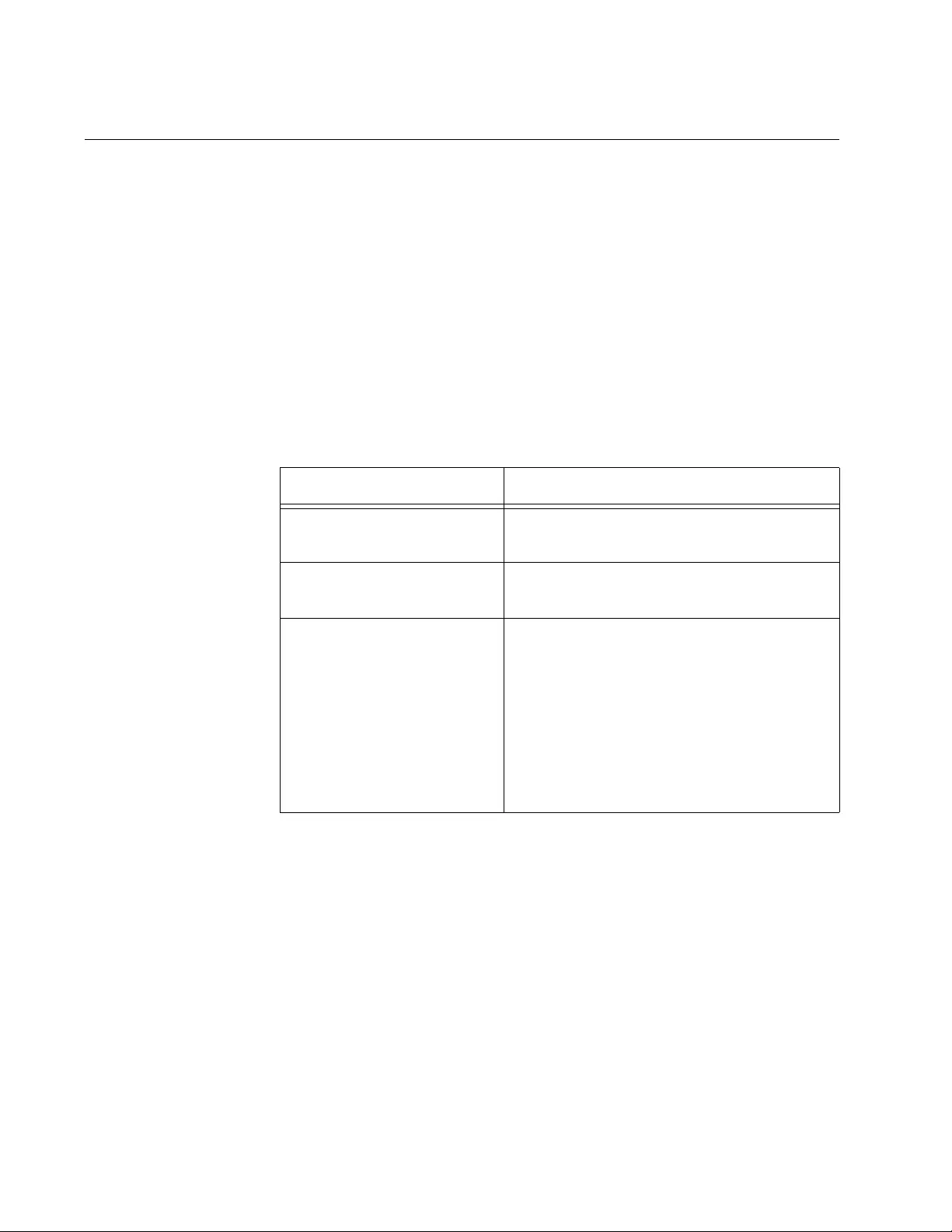

Table 4. Link and Activity LEDs on the AT-XEM2-12XS Line Card

State Description

Solid Green The transceiver in the slot has established

a 10GBase link to a network device.

Flashing Green The transceiver is transmitting or receiving

data at 10GBase.

Solid Amber The transceiver has established a 1GBase

link to a network device.

Flashing Amber The transceiver is transmitting or receiving

data at 1GBase.

Off Possible causes of this state are listed

here:

- The transceiver has not established a

link with another network device.

- The LEDs are turned off. To turn on the

LEDs, use the eco-friendly button.

Chapter 1: Overview

26

AT-XEM2-4QS Line Card

The AT-XEM2-4QS Line Card has four QSFP+ transceiver slots that

support the following types of 40Gbps transceivers:

AT-QSFPSR4 transceiver - Requires 12-strand OM4 fiber optic

cable and has a maximum operating distance of 150m (492 ft).

AT-QSFPLR4 transceiver - Requires single-mode fiber optic cable

and has an operating range of 2m (6.6 ft) to 10km (6.2 mi).

AT-QSFP1CU and AT-QSFP3CU direct connect cables in lengths

of 1 and 3 meters, respectively

The LED states for the QSFP+ transceiver slots on the AT-XEM2-4QS

Line Card are described in Table 5.

Table 5. Link and Activity Status LEDs for the AT-XEM2-4QS Line Card

State Description

Solid Green The transceiver has established a

40GBase link to a network device.

Flashing Green The transceiver is transmitting or receiving

data.

Off Possible causes of this state are listed

here:

- The slot is empty.

- The transceiver has not established a

link to a network device.

- The LEDs are turned off. To turn on the

LEDs, use the eco-friendly button.

AT-x908 Gen2 Switch Installation Guide

27

Management Panel

The components on the management panel are identified in Figure 4.

Figure 4. Management Panel

Note

The management panel is not field-replaceable.

USB Port You can use the USB port with a flash drive to perform the following

management functions:

Provide a centralized network backup location for Allied Telesis

Management Framework.

Store backup copies of configuration files.

Transfer configuration files between switches that are to have

similar configurations.

Store or transfer log files.

Store or transfer debug files (for example, the ou tput of the SHOW

TECH-SUPPORT command).

Boot the AlliedWare Plus operating system and master

configuration file from flash drive.

Using a flash drive with the switch is optional.

USB Slot NET MGMT

Port

CONSOLE

RS-232

Serial Port

Switch ID

LED

eco-friendly

Button

Reset Button

Chapter 1: Overview

28

NET MGMT

Ethernet

Management

Port

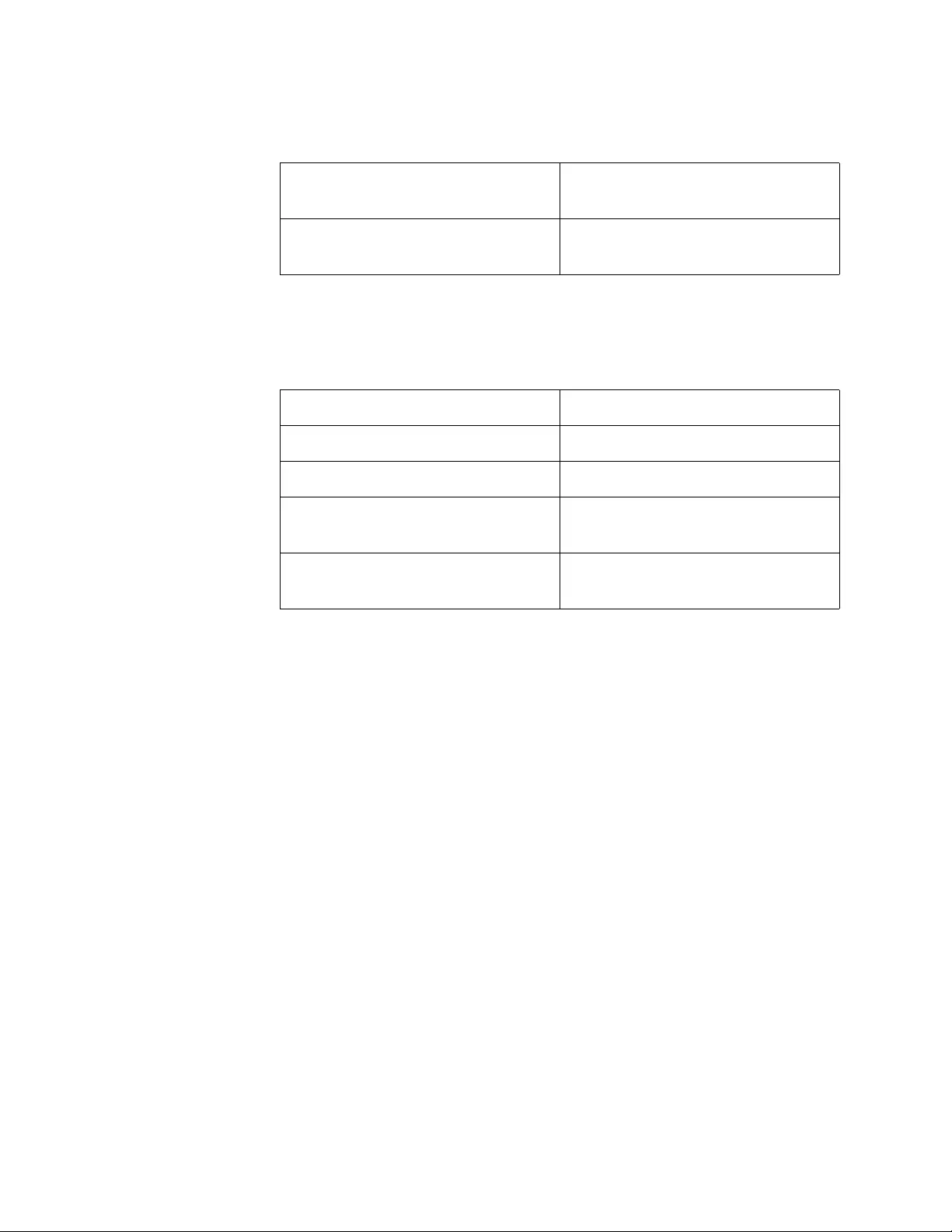

The switch uses the NET MGMT port as a separate routed eth0 interface.

The interface is not part of the switching matrix of the Ethernet line cards,

but the switch can route traffic in or out of the port from the line cards.

Here are the guidelines to using the port:

The port should only be used for initial configuration and

maintenance access to the chassis.

The NET MGMT port has a standard 8-pin RJ-45 connector and

operates at 10, 100, or 1000 Mbps in either half- or full-duplex

mode.

The default setting for the port is Auto-Negotiation, which sets the

speed and duplex mode automatically. You may disable Auto-

Negotiation and configure the port manually.

The wiring configuration of the NET MGMT port is set

automatically with automatic MDIX detection. You may disable

automatic MDIX detection and set the wiring configuration

manually.

The port is referred to as eth0 in the management software.

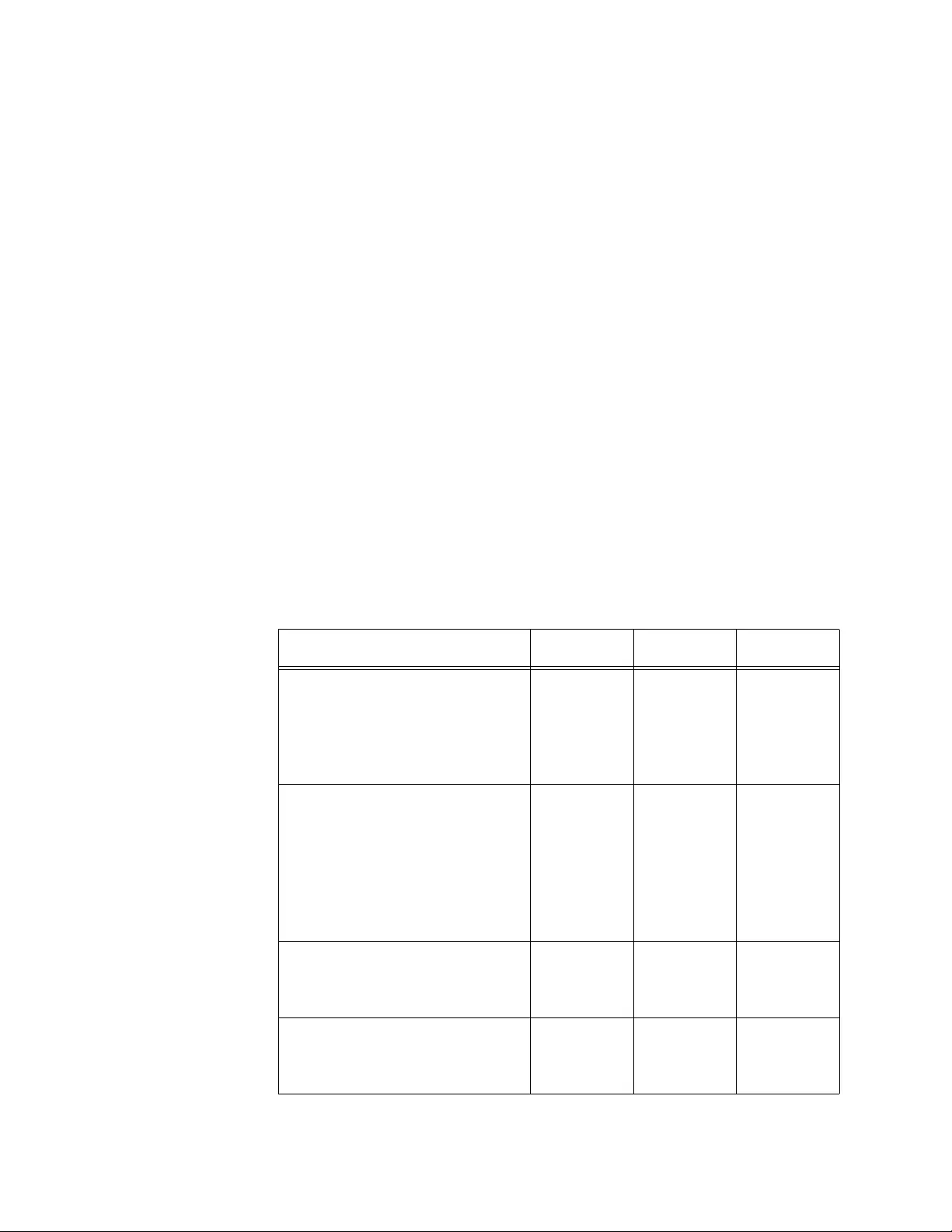

The cable requirements for the port are listed in Table 6.

Table 6. Twisted Pair Cable for the NET MGMT Port on the Management

Panel

Cable Type 10Mbps 100Mbps 1000Mbps

Standard TIA/EIA 568-B-

compliant Category 3 shielded

or unshielded cabling with 100

ohm impedance and a

frequency of 16 MHz.

Yes Yes No

Standard TIA/EIA 568-A-

compliant Category 5 or TIA/

EIA 568-B-compliant Enhanced

Category 5 (Cat 5e) shielded or

unshielded cabling with 100

ohm impedance and a

frequency of 100 MHz.

Yes Yes Yes

Standard TIA/EIA 568-B-

compliant Category 6 shielded

cabling.

Yes Yes Yes

Standard TIA/EIA 568-C-

compliant Category 6a shielded

cabling.

Yes Yes Yes

AT-x908 Gen2 Switch Installation Guide

29

For instructions on how to configure the NET MGMT port, refer to the

Software Reference for SwitchBlade x908 Gen2 Switch.

The Network Management (NET MGMT) port has one Status LED,

described in Table 7.

Console (RS-232)

Port You can use the Console Port to conduct local management sessions of

the switch. Local management sessions require a terminal or PC with a

terminal emulation program, and the management cable that comes with

the switch.

Local management sessions are not conducted over a network.

Consequently, the switch does not need an Internet Protocol (IP) address

for this type of management.

Because the switch does not come with a default IP address, your initial

management session must be a local management session. For

instructions on how to start a local mana gement session, refer to “Startin g

a Local Management Session” on page 114 or the Software Reference for

SwitchBlade x908 Gen2 Switch.

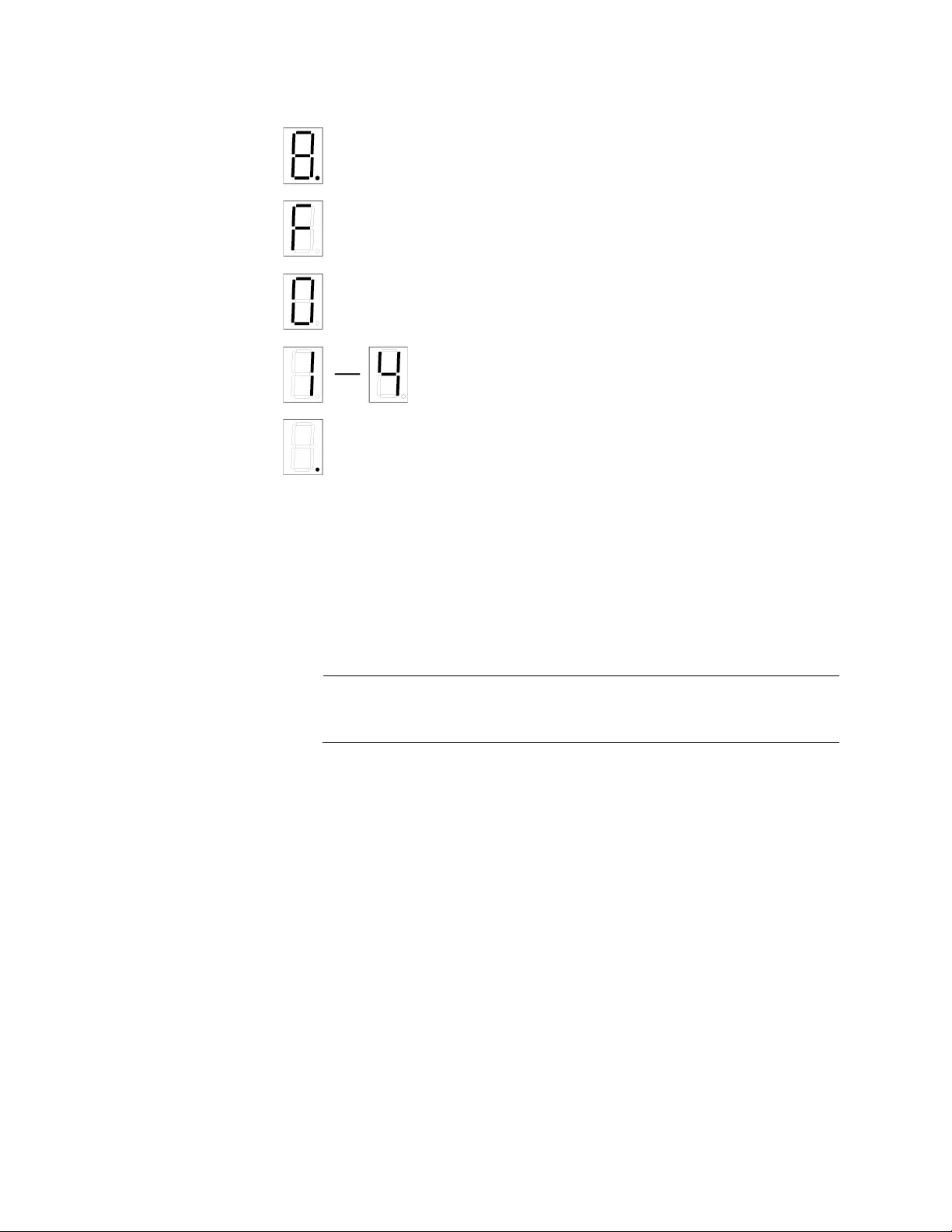

Switch ID LED The Switch ID LED, shown in Figure 4 on page 27, displays the ID number

of the switch. A stand-alone switch has the ID number 0. The states of the

LED when the switch is not oper ating in the low power mode are sho wn in

Figure 5 on page 30.

Table 7. NET MGMT Port LED

LED State Description

L/A

Solid Green The port has a valid 1000 Mbps link.

Flashing

Green The port is transmitting or receiving data at

1000 Mbps.

Solid Amber The port has a valid 10 or 100 Mbps link.

Flashing

Amber The port is transmitting or receiving data at

10 or 100 Mbps.

Off The port has not established a link to a

network device.

Chapter 1: Overview

30

Figure 5. Switch ID LED

The switch displays the letter “F” for fault on the ID LED if it detects one of

the following problems:

A cooling fan has failed.

The internal temperature of the switch has exceeded the normal

operating range and the switch may shut down.

Note

You can use the SHOW SYSTEM ENVIRONMENT command in the

command line interface to identify the source of the problem.

eco-friendly

Button You can use the eco-friendly button on the management panel to turn the

LEDs on or off. You may turn off the LEDs when you are not u sing them to

monitor the control and Ethernet line cards, to conserve electricity. When

the LEDs are off, the overall power consumption of the chassis is slightly

reduced by approximately 2 watts.

The button controls all of the port LEDs on the Ethernet line cards and

controller card, except for the L/A LED for the NET MGMT port. The but ton

does not control the LEDs on power supply systems.

Reset Button Pressing the Reset button resets all the Ethernet line ca rds in the chassis.

You might perform this function if the chassis and line cards are

experiencing a problem.

The chassis is booting up.

The chassis has encountered a fault condition.

The chassis is operating as a stand-alone unit, with the ID

number 1.

Reserved for future development.

The dot in the lower right corner flashes when the switch

accesses USB memory.

AT-x908 Gen2 Switch Installation Guide

31

Caution

The Ethernet line cards do not forward network traffic for about three

minutes while they initialize the AlliedWare Plus Operating System

and configure their parameter settings. Some network traffic ma y be

lost.

Note

To reset individual line cards in the chassis, use the REBOOT or

RELOAD command in the AlliedWare Plus operating system.

Chapter 1: Overview

32

Power Supplies

The power supply units for the chassis are the AT-SBxPWRSYS2 AC and

AT-SBxPWRSYS1-80 DC Power Supplies. Refer to Figure 6.

Figure 6. AT-SBxPWRSYS2 and AT-SBxPWRSYS1-80 Power Supplies

Here are the power supply guidelines:

The AT-SBxPWRSYS2 AC Power Supply uses the AC connectors

on the back panel of the switch and is intended for AC

environments.

The AT-SBxPWRSYS1-80 Power Supply has DC power

connectors on its front panel and is intended for DC environments.

AT-SBxPWRSYS2 AC

Power Supply

AT-SBxPWRSYS1-80 DC

Power Supply

AT-x908 Gen2 Switch Installation Guide

33

You can install either one or two power supplies in the chassis. A

single power supply can power a fully equipped chassis. Installing

two power supplies adds power redundancy. If a power supply fails

or loses power, the second power supply continues to power the

system, thus preventing a disruption to network operations.

The power supplies are installed in the PSU A and PSU B slots in

the front panel of the chassis. If you are installing only one power

supply, Allied Telesis recommends installing it in PSU A slot

because that slot does not come with a blank slot cover.

The switch does not come with power supplies. They must be

purchased separately.

The power supplies are field-replaceable and hot-swappable. You

do not have to power off the switch to replace them.

Caution

The AT-SBxPWRSYS2 and AT-SBxPWRSYS1-80 Power Supplies

are not compatible with each other. Do not install both types of

power supplies in the same chassis.

Chapter 1: Overview

34

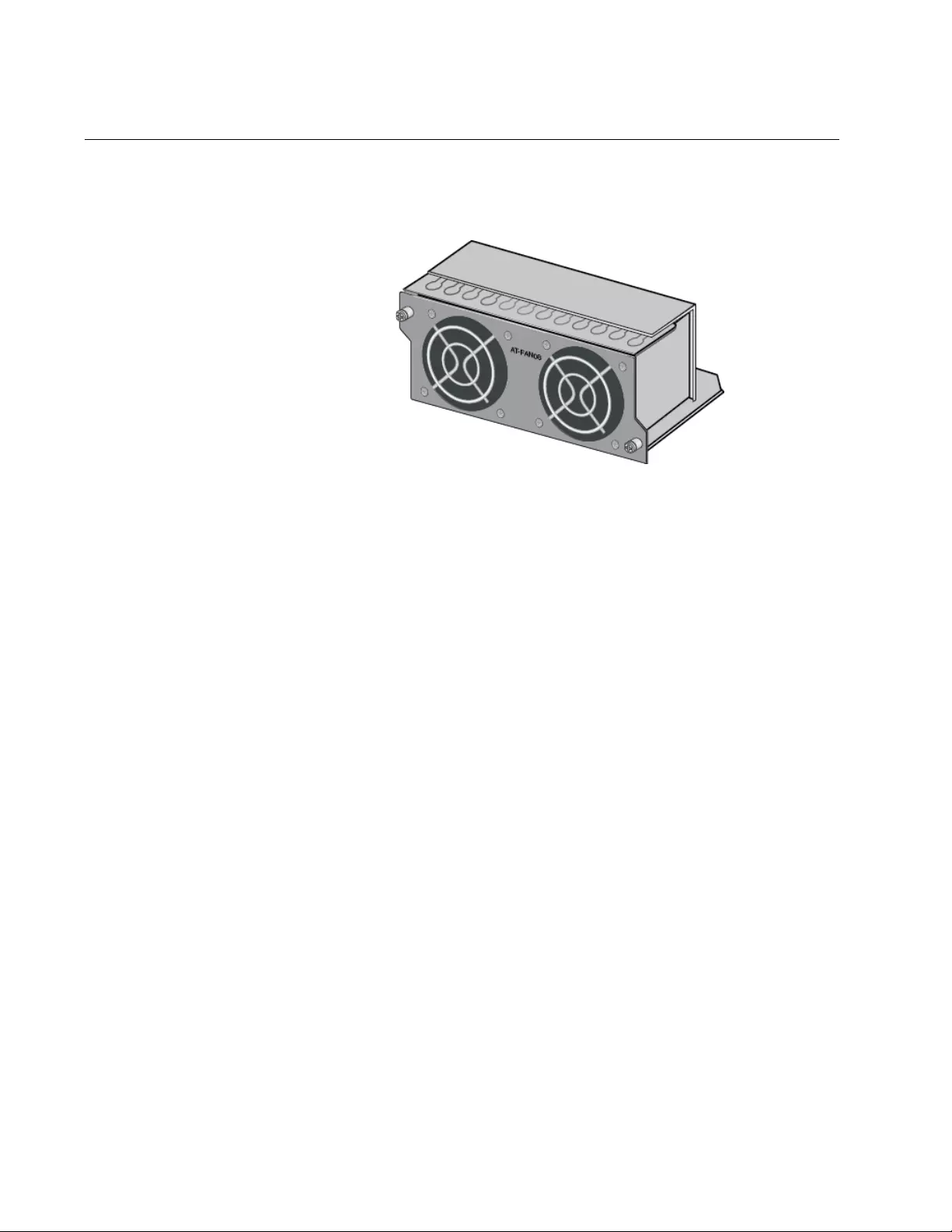

AT-FAN08 Units

The cooling unit for the chassis is the AT-FAN08 Fan module. Refer to

Figure 7.

Figure 7. AT-FAN08 Module

The chassis comes with two pre-installed fan modules in FAN A and FAN

B slots on the rear panel. The air flow is from the front to the back of the

chassis, with the fans drawing air out of the device.

The fan module has two fans. The switch automatically adjusts the speeds

of the fans, depending on its internal temperature.

The AT-FAN08 module is field-replaceable and hot-swappable. You do

not have to power off the switch to replace a fan module.

AT-x908 Gen2 Switch Installation Guide

35

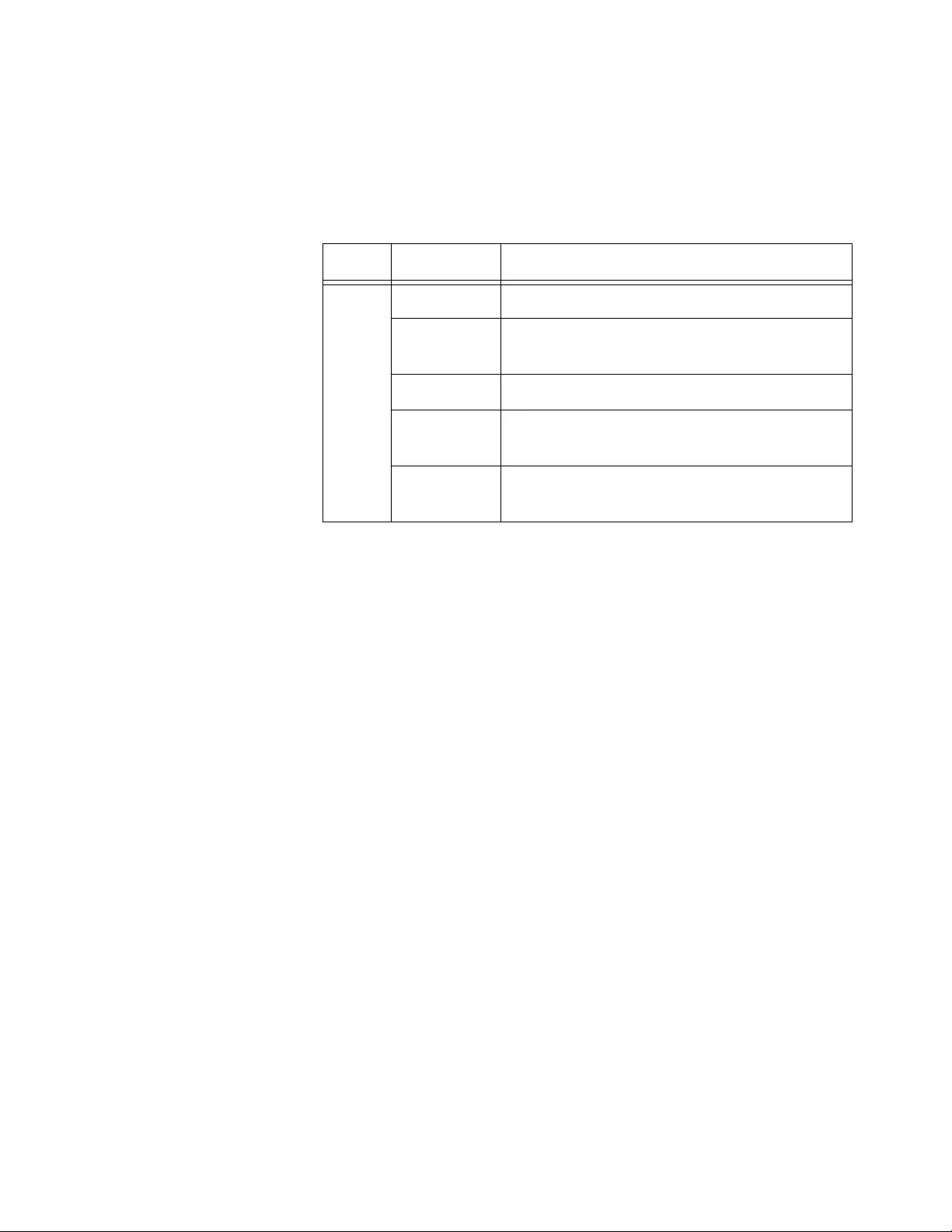

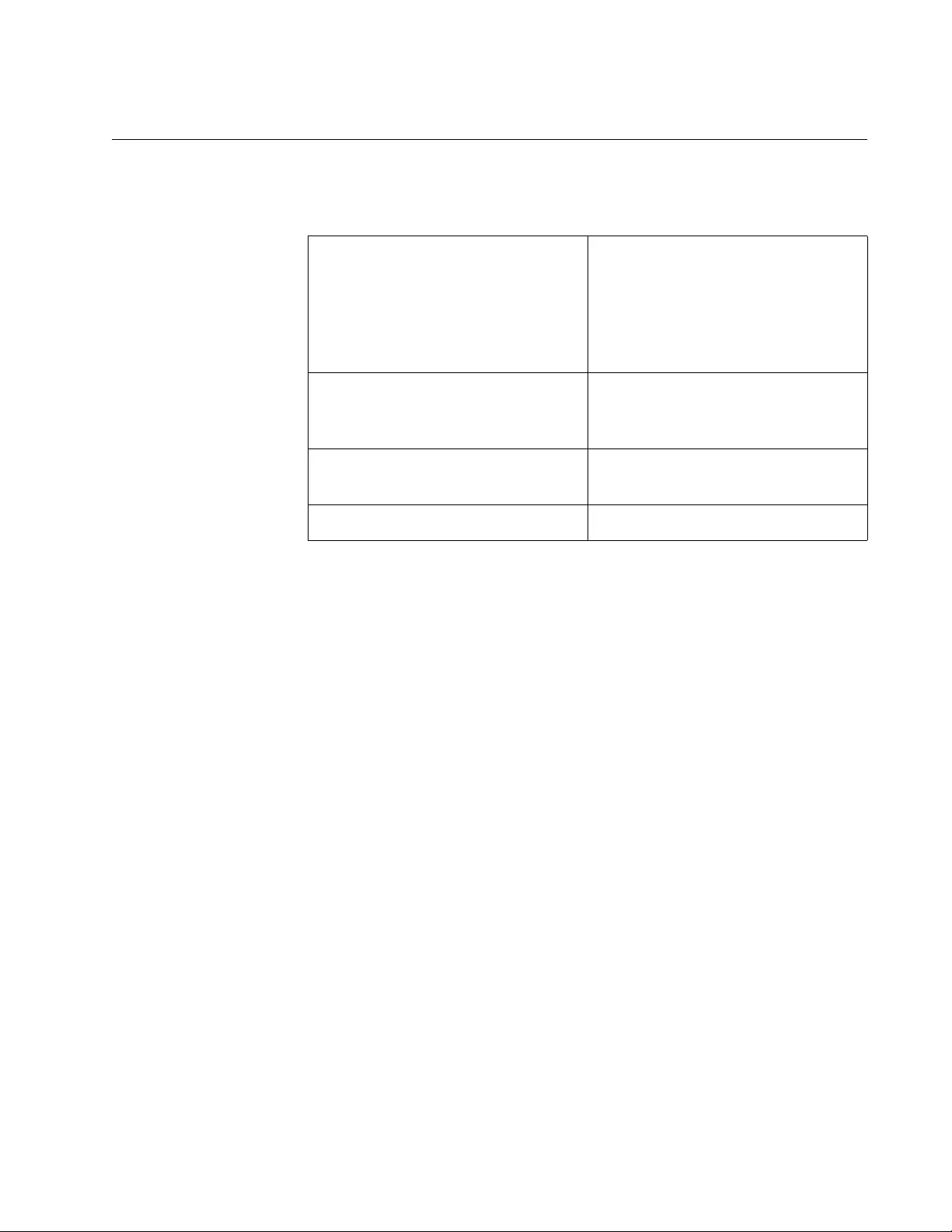

Specifying Ports in the Command Line Interface

The individual ports on the switches in a stack are specified in the

command line interface with the PORT parameter. The format of the

parameter is shown in Figure 8.

Figure 8. PORT Parameter in the Command Line Interface

The three parts of the PORT parameter are described in Table 8.

Here is an example of the PORT parameter on a switch in a stack. I t uses

the INTERFACE command to enter the Port Interface mode for ports 15

and 17 on the line card in slot 2:

awplus> enable

awplus# configure terminal

awplus(config)# interfac e po rt1 .2.15,port1. 2. 17

For instructions on the command line interface and the PORT parameter,

refer to the Software Reference for AT-SBx908 Gen2 Switch, AlliedWare

Plus Operating System.

Table 8. PORT Parameter Format

Number Description

Stack ID Number Designates the switch’s ID number. The

number is 1. To determine the ID number

of a switch, examine its Switch ID LED.

Slot Number Designates the slot number with the line

card whose ports you want to configure.

For the AT-SBx908 Gen2 Switch this value

can be 1 to 8.

Port Number Designates a port number on an AT-

SBx908 Gen2 Ethernet line card.

port1

.n.n

Slot Number

Port Number

Stack ID Number

Chapter 1: Overview

36

37

Chapter 2

Beginning the Installation

The chapter contains the following sections:

“Reviewing Safety Precautions” on page 38

“Choosing a Site for the Chassis” on page 43

“Unpacking the Chassis” on page 44

“Unpacking AT-SBxPWRSYS2 AC Power Supplies” on page 49

“Unpacking AT-SBxPWRSYS1-80 DC Power Supplies” on page 50

Chapter 2: Beginning the Installation

38

Reviewing Safety Precautions

Please review the following safety precautions before beginning the

installation procedure.

Note

Safety statements that have the symbol are translated into

multiple languages in the Transla ted Safety S tatement s document at

www.alliedtelesis.com/support.

Warning

Class 1 Laser product. L1

Warning

Laser Radiation.

Class 1M Laser product.

Warning

Do not stare into the laser beam. L2

Warning

Do not look directly at the fiber optic ends or inspect the cable ends

with an optical lens. L6

Warning

To prevent electric shock, do not remove the cover. No user-

serviceable parts inside. This unit contains hazardous voltages and

should only be opened by a trained and qualified technician. To

avoid the possibility of electric shock, disconnect electric power to

the product before connecting or disconnecting the LAN cables.

E1

Warning

Do not work on equipment or cables during periods of lightning

activity. E2

AT-SBx908 Gen2 Switch Installation Guide

39

Warning

Power cord is used as a disconnection device. To de-energize

equipment, disconnect the power cord. E3

Warning

Class I Equipment. This equipment must be earthed. The power

plug must be connected to a properly wired earth ground socket

outlet. An improperly wired socket outlet could place hazardous

voltages on accessible metal parts. E4

Note

Pluggable Equipment. The socket outlet shall be installed near the

equipment and shall be easily accessible. E5

Caution

Air vents must not be blocked and must have free access to the

room ambient air for cooling. E6

Warning

Operating Temperatures. This product is designed for a maximum

ambient temperature of 50° degrees C. E52

Note

All Countries: Install product in accordance with local and National

Electrical Codes. E8

Warning

When installing this equipment, always ensure that the frame ground

connection is installed first and disconnected last. E11

Warning

Only trained and qualified person nel are allowed to in st all or rep lace

this equipment. E14

Chapter 2: Beginning the Installation

40

Caution

Circuit Overloading: Consideration should be given to the

connection of the equipment to the supply circuit and the effect that

overloading of circuits might have on overcurrent protection and

supply wiring. Appropriate consideration of equipment nameplate

ratings should be used when addressing this concern. E21

Caution

Risk of explosion if battery is replaced by an incorrect type. Replace

only with the same or equivalent type recommended by the

manufacturer. Dispose of used batteries according to the

manufacturer’s instructions.

Attention: Le remplacement de la batterie par une batterie de type

incorrect peut provoquer un danger d’explosion. La remplacer

uniquement par une batterie du même type ou de type équivalent

recommandée par le constructeur. Les batteries doivent être

éliminées conformément aux instructions du constructeur. E22

Warning

Mounting of the equipment in the rack should be such that a

hazardous condition is not created due to uneven mechanical

loading. E25

Warning

The chassis may be heavy and awkward to lift. Allied Telesis

recommends that you get assistance when mounting the chassis in

an equipment rack. E28

Note

Use dedicated power circuits or power conditioners to supply

reliable electrical power to the device. E27

Warning

This unit might have more than one power cord. To reduce the risk

of electric shock, disconnect all power cords before servicing the

unit. E30

AT-SBx908 Gen2 Switch Installation Guide

41

Note

If installed in a closed or multi-unit rack assembly, the operating

ambient temperature of the rack environment may be greater than

the room ambient temperature. Therefore, consideration should be

given to installing the equipment in an environment compatible with

the manufacturer’s maximum rated ambient temperature (Tmra).

E35

Caution

Installation of the equipment in a rack should be such that the

amount of air flow required for saf e operation of the equipment is not

compromised. E36

Warning

Reliable earthing of rack-mounted equipment should be maint ained .

Particular attention should be given to supply connections other than

direct connections to the branch circuits (e.g., use of power strips ).

E37

Warning

This product may have multiple AC power cords installed. To de-

energize this equipment, disconnect all power cords from the device.

E41

Caution

An Energy Hazard exists insid e this equipment. Do not insert hands

or tools into open chassis slots or plugs. E44

Warning

This equipment shall be installed in a Restrict ed Access location.

E45

Caution

The unit does not contain serviceable components. Please return

damaged units for servicing. E42

Chapter 2: Beginning the Installation

42

Warning

The temperature of an operational SFP or SFP+ transceiver may

exceed 70° C (158° F). Exercise caution when removing or ha ndling

transceivers with unprotected hands. E43

Warning

The grounding lug on the rear panel of the chassis is for

supplemental grounding. The chassis must be supplied by a

grounded three wire AC source through the power supply cord.

AT-SBx908 Gen2 Switch Installation Guide

43

Choosing a Site for the Chassis

Observe these requirements when planning the installation of the chassis.

The AT-SBx908 Gen2 Chassis should be installed in a standard

19-inch equipment rack. It should n ot be installed on a table, d esk,

or wall.

Check that the equipment rack is safely secured so that it will not

tip over. Devices should be installed in the rack starting at the

bottom, with the heavier devices near the bottom of the rack.

The power outlet should be located near the chassis and be easily

accessible.

The site should allow for easy access to the ports on the front of

the switch, so that you can easily connect and disconnect cables,

and view the port LEDs.

The site should allow for adequate air flow around the unit and

through the cooling vents on the front and rear panels. (The

ventilation direction is from front to back, with the fans on the back

panel drawing the air out of the unit.)

The site should not expose the chassis to moisture or water.

The site should be a dust-free environment.

The site should include dedicated power circuits or power

conditioners to supply reliable electrical power to the network

devices.

Twisted pair cabling should not be exposed to sources of electrical

noise, such as radio transmitters, broadband amplifiers, power

lines, electric motors, or fluorescent fixtures.

Switch ports are suitable for intra-building connections, or where

non-exposed cabling is required.

Do not install the chassis in a wiring or utility box because it might

overheat and fail from inadequate airflow.

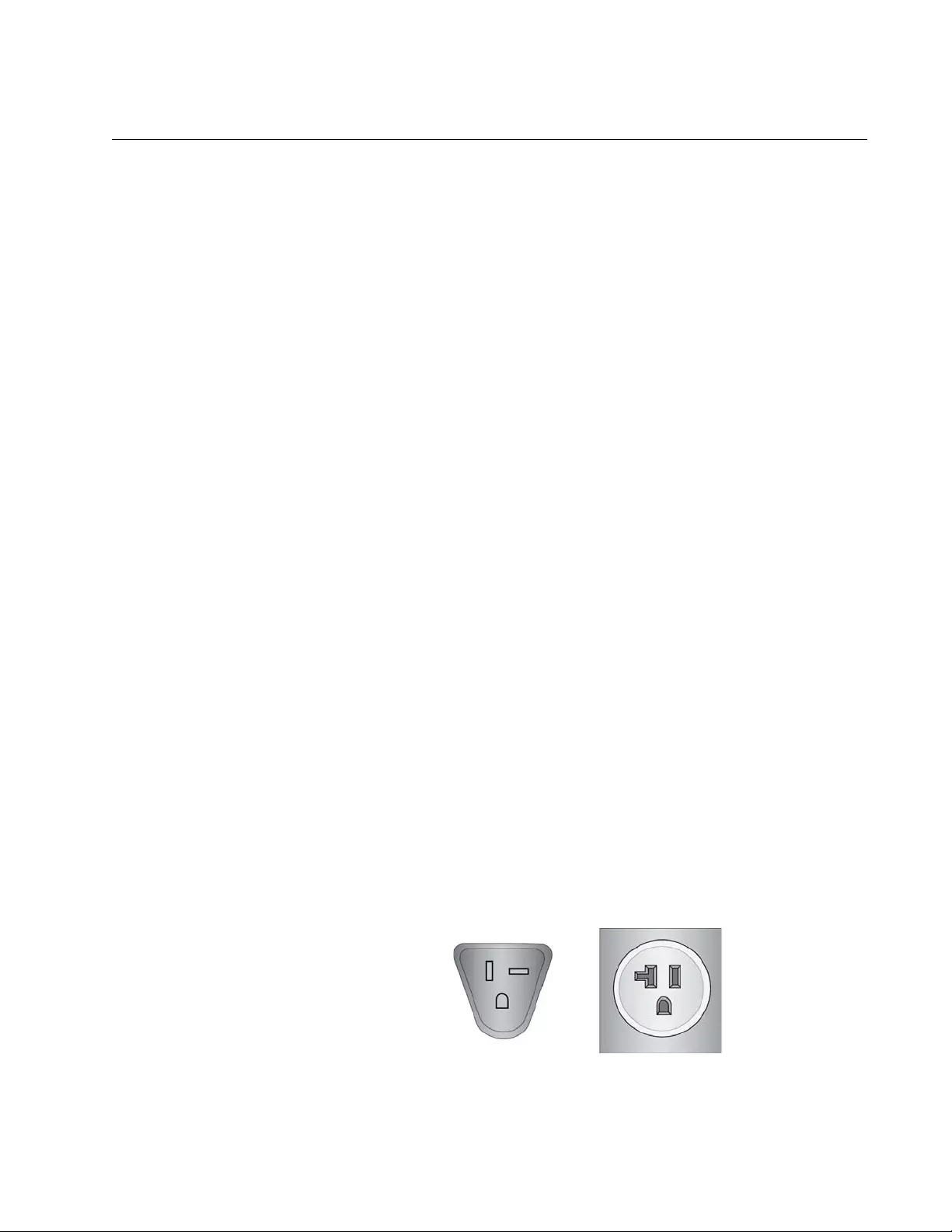

The power cords included with AT-SBxPWRSYS2 Power Supplies

for 100-125 VAC installations have 20 Amp, 125 V NEMA 5-20P

plugs that require NEMA 5-20R receptacles. Refer to Figure 9.

Figure 9. NEMA 5-20P Plug and Receptacle

Chapter 2: Beginning the Installation

44

Unpacking the Chassis

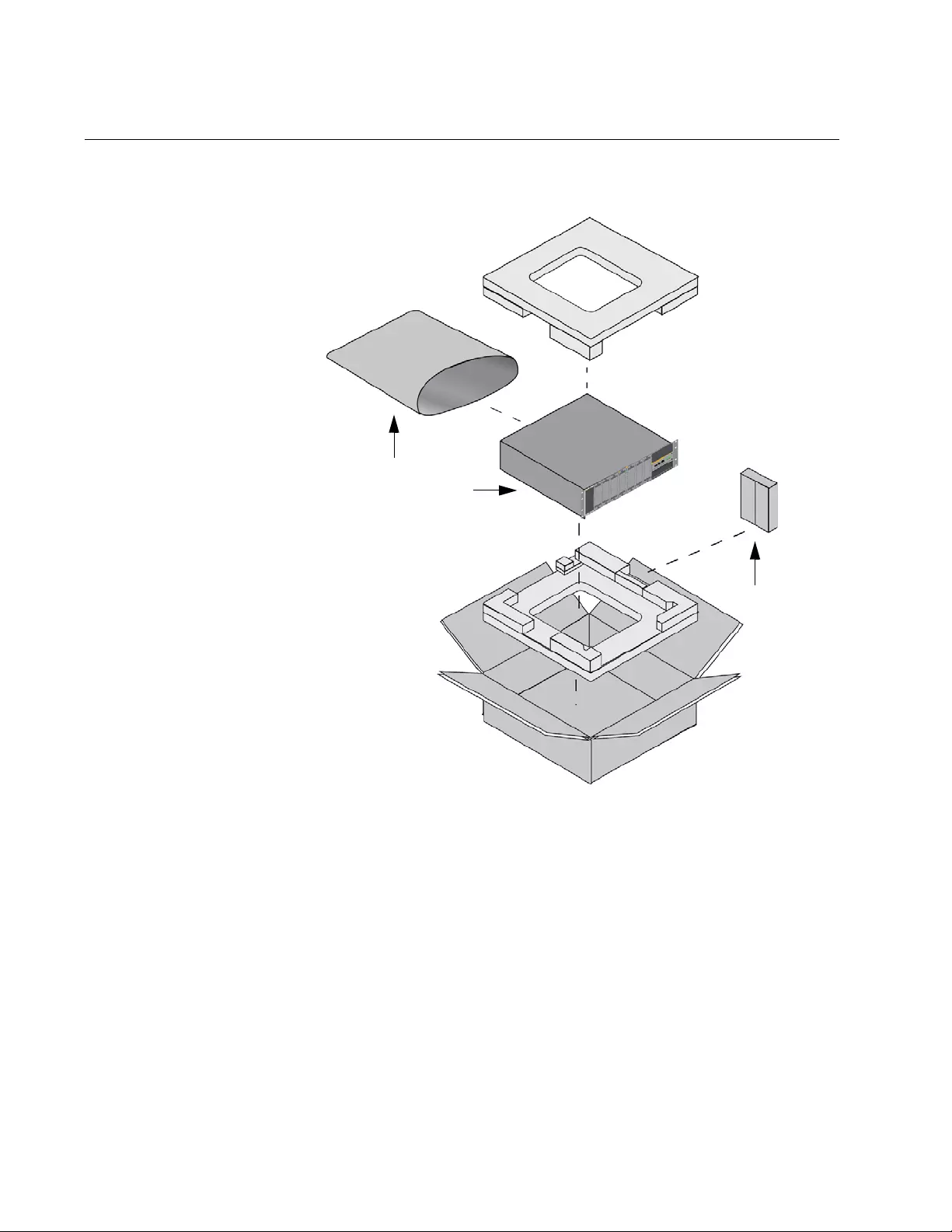

Figure 10 shows the shipping box for the switch.

Figure 10. AT-SBx908 Gen2 Switch Shipping Box

The items in the box are listed here:

A - Protective bag

B - AT-SBx908 Gen2 Switch

C - Accessory kit

To unpack the switch, perform the following procedure:

1. Lift the switch from the shipping box and place it on a level, secure

table. Refer to Figure 11 on page 45.

AB

C

AT-SBx908 Gen2 Switch Installation Guide

45

Warning

The switch is heavy. Get assistance lifting the device out of the

shipping box. You might injure yourself or damage the device if you

try lifting it without assistance.

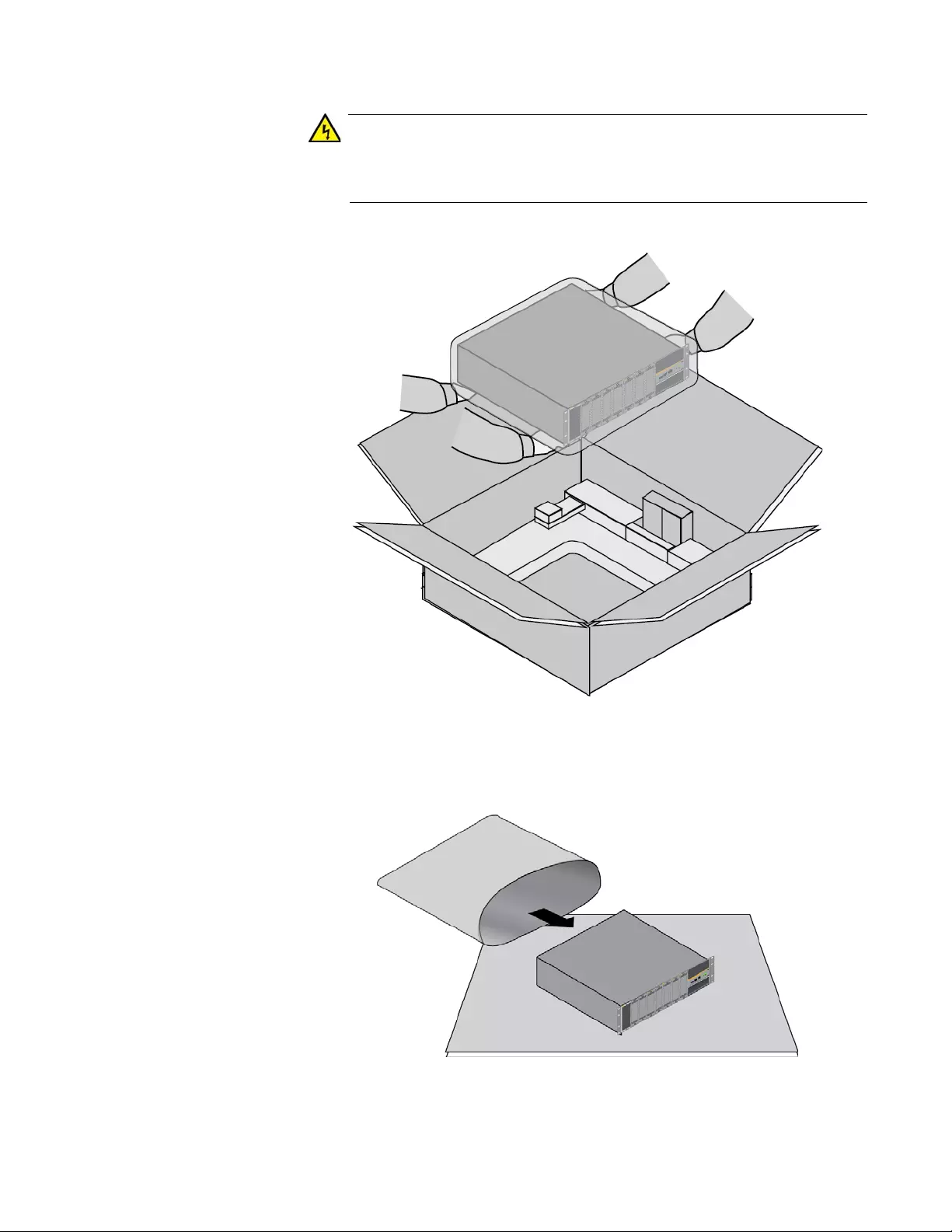

Figure 11. Lifting the Switch from the Shipping Box

2. Remove the switch from the protective shipping bag. Refer to

Figure 12.

Figure 12. Removing the Switch from the Protective Shipping Bag.

Chapter 2: Beginning the Installation

46

3. Visually inspect the front panel of the switch for the pre-installed

components identified in Figure 13.

Figure 13. Pre-installed Items on the Front and Side Panels

4. Visually inspect the rear panel for the pre-installed components

identified in Figure 14 on page 47.

2. Seven line card slot

covers

1. Two equipment rack

brackets 3. One blank panel in power

supply slot B

1 1

234

4. One management panel

(Not field replaceable.)

AT-SBx908 Gen2 Switch Installation Guide

47

Figure 14. Pre-installed Items on the Rear Panel

Note

You should retain the original packaging material in the event you

need to return the unit to Allied Telesis.

Note

The product does not come with power supplies. Power supplies

must be ordered separately.

5. Remove the accessory kit from the shipping box and verify its

components, listed in Figure 15 on page 48

2. Two AT-FAN08 Fan

Modules

1. One ground wire lug

2

12

Chapter 2: Beginning the Installation

48

Figure 15. Accessory Kit

If any item is missing or damaged, contact your Allied Telesis sales

representative for assistance.

6. After unpacking the switch, do one of the following:

To unpack the power supplies, go to “Unpacking AT-

SBxPWRSYS2 AC Power Supplies” on page 49 or “Unpacking AT-

SBxPWRSYS1-80 DC Power Supplies” on page 50.

Otherwise, go to Chapter 3, “Installing the Chassis” on page 51.

One 2 m (6.6 ft) local management

cable with RJ-45 (8P8C) and DB-9 (D-

sub 9-pin) connectors.

Two power cord retaining clips

AT-SBx908 Gen2 Switch Installation Guide

49

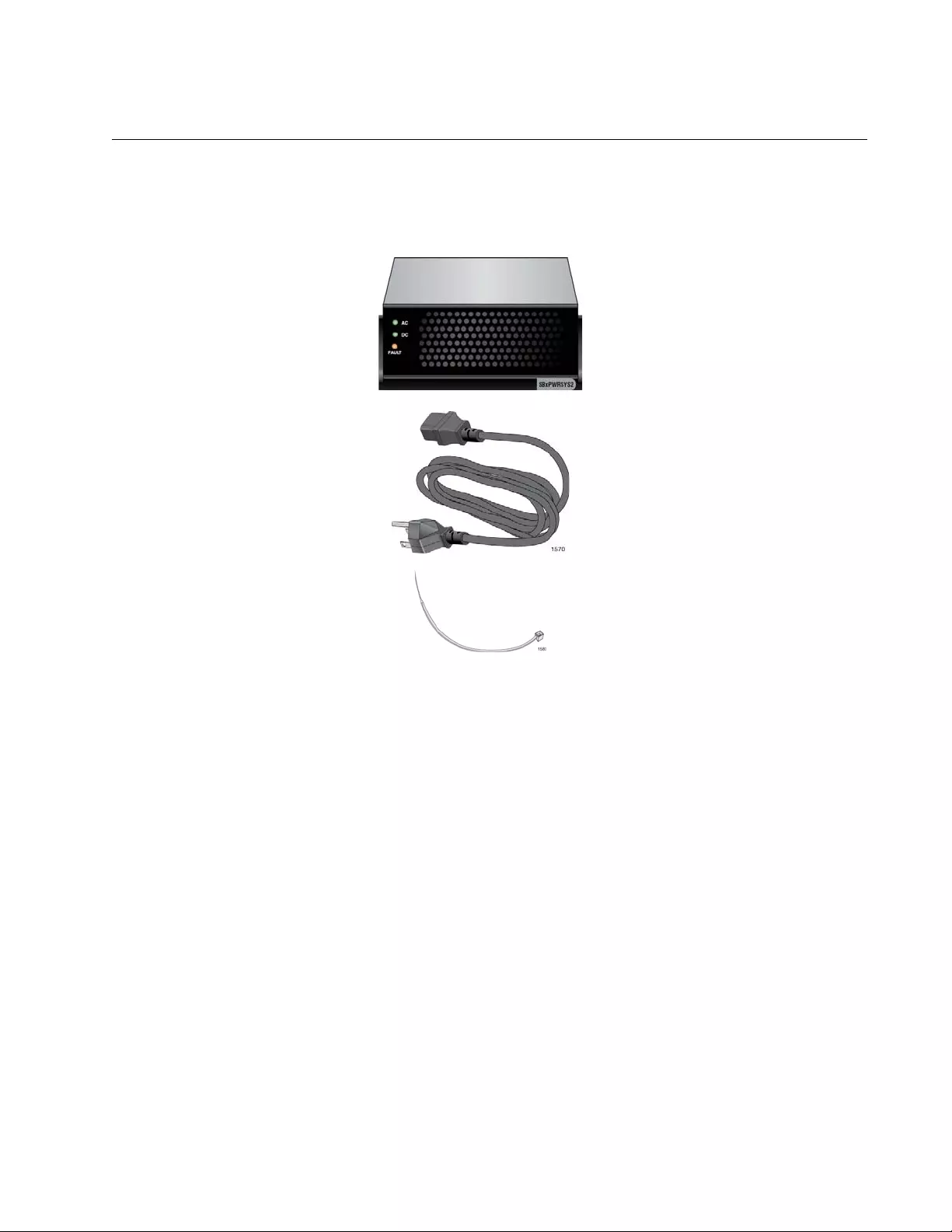

Unpacking AT-SBxPWRSYS2 AC Power Supplies

The AT-SBxPWRSYS2 AC Power Supply shipping box should include the

items in Figure 16.

Figure 16. Items in the Shipping Box for the AT-SBxPWRSYS2 AC Po wer

Supply

The tie wrap included with the power supply is not used with the AT-

SBx908 Gen2 chassis.

If any item is missing or damaged, contact your Allied Telesis sales

representative for assistance.

After unpacking the chassis and power supplies, go to Chapter 3,

“Installing the Chassis” on page 51.

One AT-SBxPWRSYS2

Power Supply

One regional AC power

supply cord

One tie wrap

Chapter 2: Beginning the Installation

50

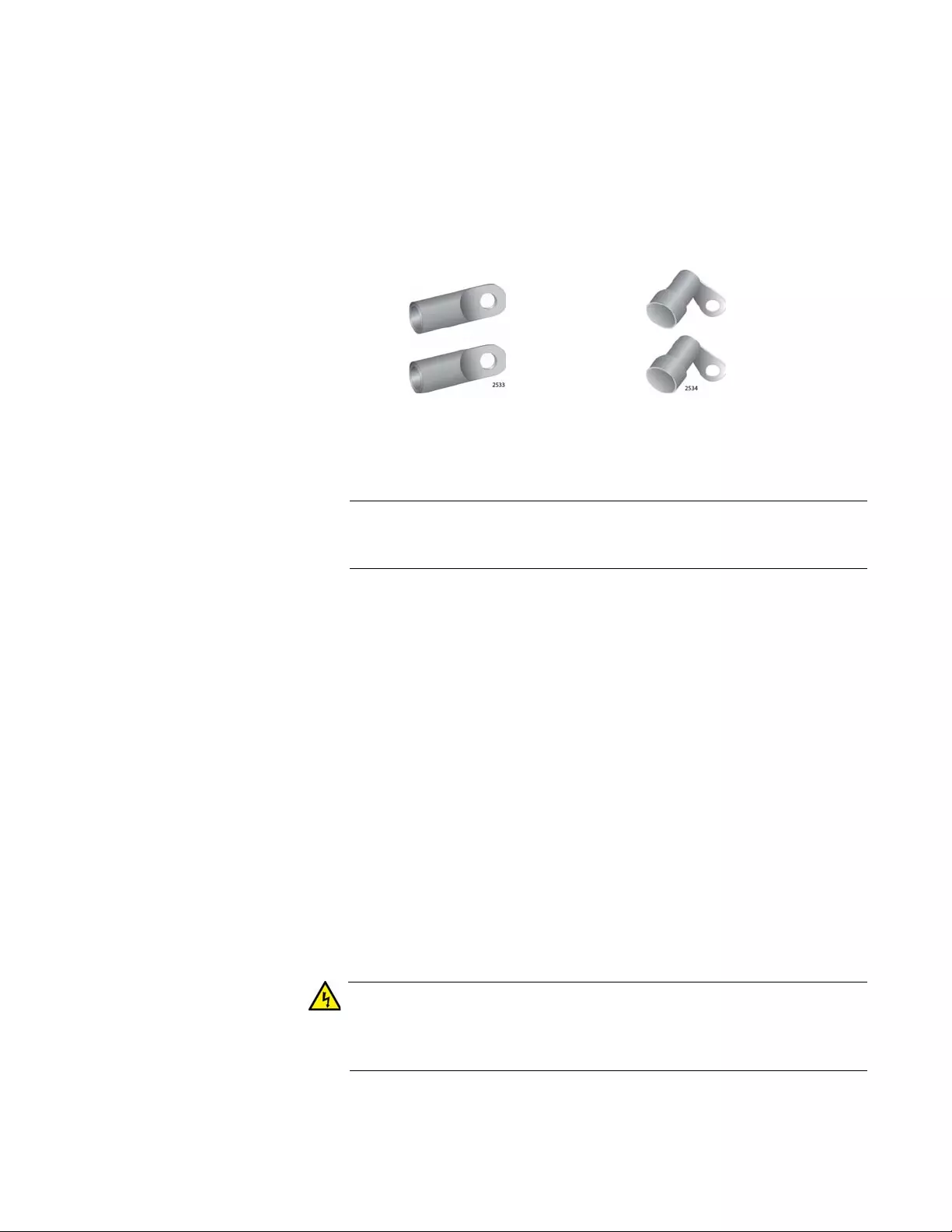

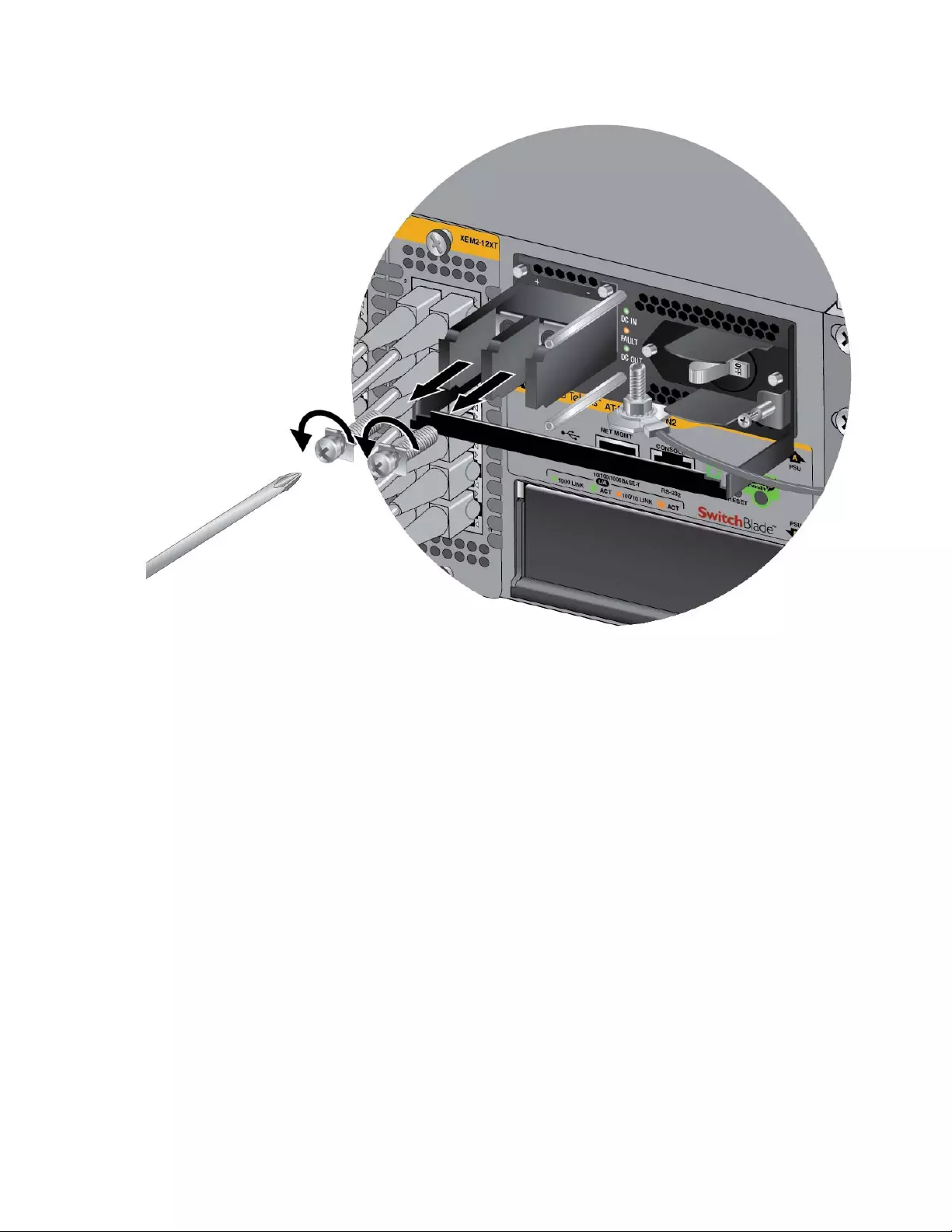

Unpacking AT-SBxPWRSYS1-80 DC Power Supplies

The shipping box for the AT-SBxPWRSYS1-80 DC Power Supply should

include the items in Figure 17.

Figure 17. Items in the Shipping Box for the AT-SBxPWRSYS1-80 DC

Power Supply

If any item is missing or damaged, contact your Allied Telesis sales

representative for assistance.

After unpacking the chassis and power supplies, go to Chapter 3,

“Installing the Chassis” on page 51.

One AT-SBxPWRSYS1-80

DC Power Supply

Two straight power wire

ring lugs

Two right angle power wire

ring lugs

One grounding wire ring

lug

51

Chapter 3

Installing the Chassis

The procedures in this chapter explain how to install the chassis in a

standard 19-inch equipment rack. The procedures are listed here:

“Tools and Material” on page 52

“Adjusting the Equipment Rack Brackets” on page 53

“Installing the Chassis in an Equipment Rack” on page 57

“Installing the Chassis Grounding Wire” on page 58

“Installing AT-SBxPWRSYS2 AC Power Supplies” on page 61

“Installing AT-SBxPWRSYS1-80 DC Power Supplies” on page 65

“Installing Ethernet Line Cards” on page 69

“Installing Blank Line Card Slot Covers” on page 73

“Installing the Blank Power Supply Slot Cover” on page 75

“Installing the Power Cord Retaining Clips” on page 77

Chapter 3: Installing the Chassis

52

Tools and Material

You need to provide the following tools and material to install the chassis:

#2 Phillips-head screwdriver

Eight screws for a standard 19-inch equipment rack

10 AWG stranded grounding wire

Wire insulation stripper

Crimping tool

AT-SBx908 Gen2 Switch Installation Guide

53

Adjusting the Equipment Rack Brackets

The chassis comes with two pre-installed equipment rack brackets. The

default positions of the brackets align th e front of the chassis with the fro nt

of the equipment rack. You can re-position the brackets on the sid es of the

chassis to have the device extend in front of the rack. Figure 18 here and

Figure 19 on page 54 and Figure 20 on page 55 show the various bracke t

and chassis orientations. The first illustration in Figure 18 shows the

default positions of the brackets.

Figure 18. Chassis Orientations in the Equipment Rack

Chapter 3: Installing the Chassis

54

Figure 19. Chassis Orientations in the Equipment Rack (Continued)

AT-SBx908 Gen2 Switch Installation Guide

55

Figure 20. Chassis Orientations in the Equipment Rack (Continued)

To change the positions of the brackets, use a #2 phillips-head

screwdriver to remove them from their default positions and secure them

to the new locations. An example is shown in Figure 21 on page 56.

Chapter 3: Installing the Chassis

56

Figure 21. Example of Adjusting the Equipment Rack Brackets

AT-SBx908 Gen2 Switch Installation Guide

57

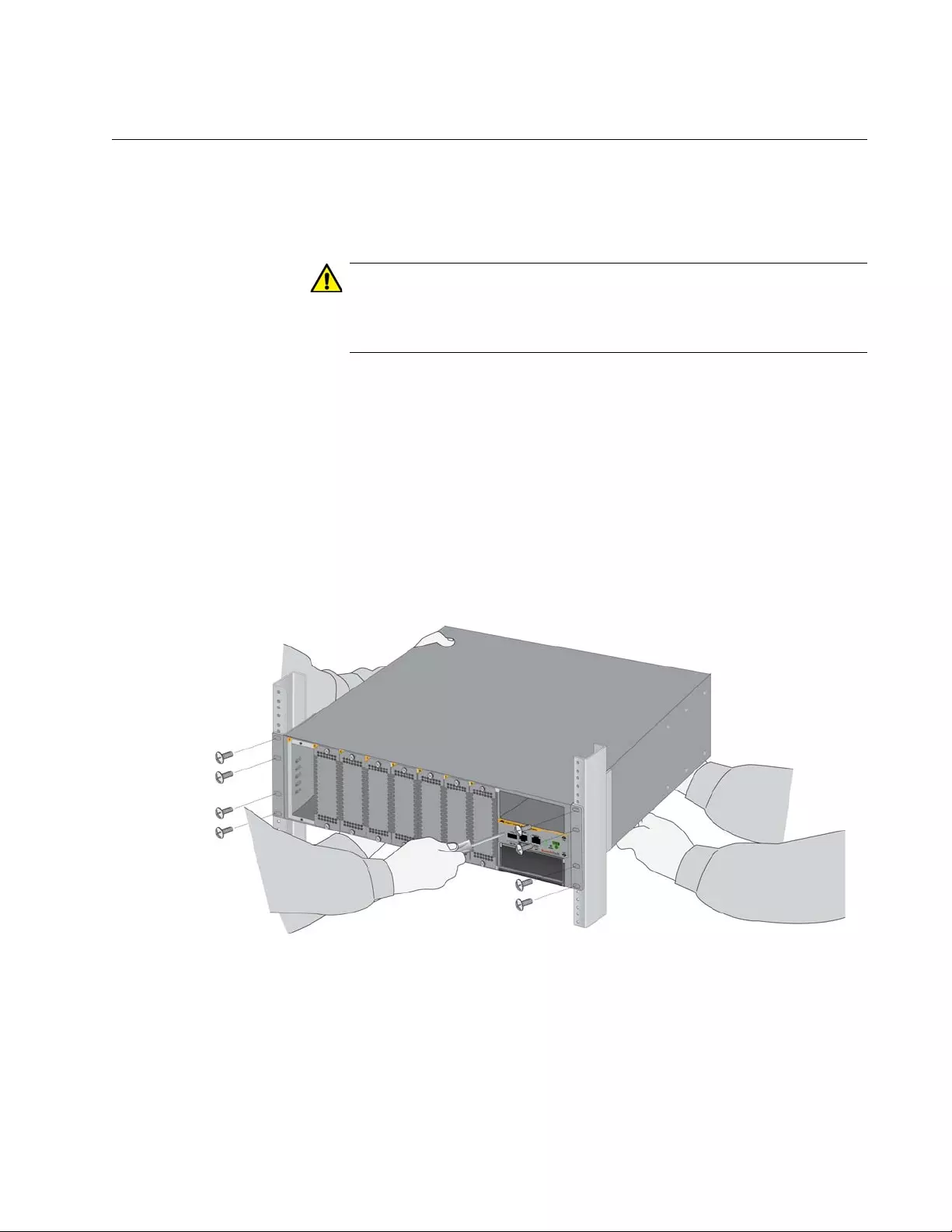

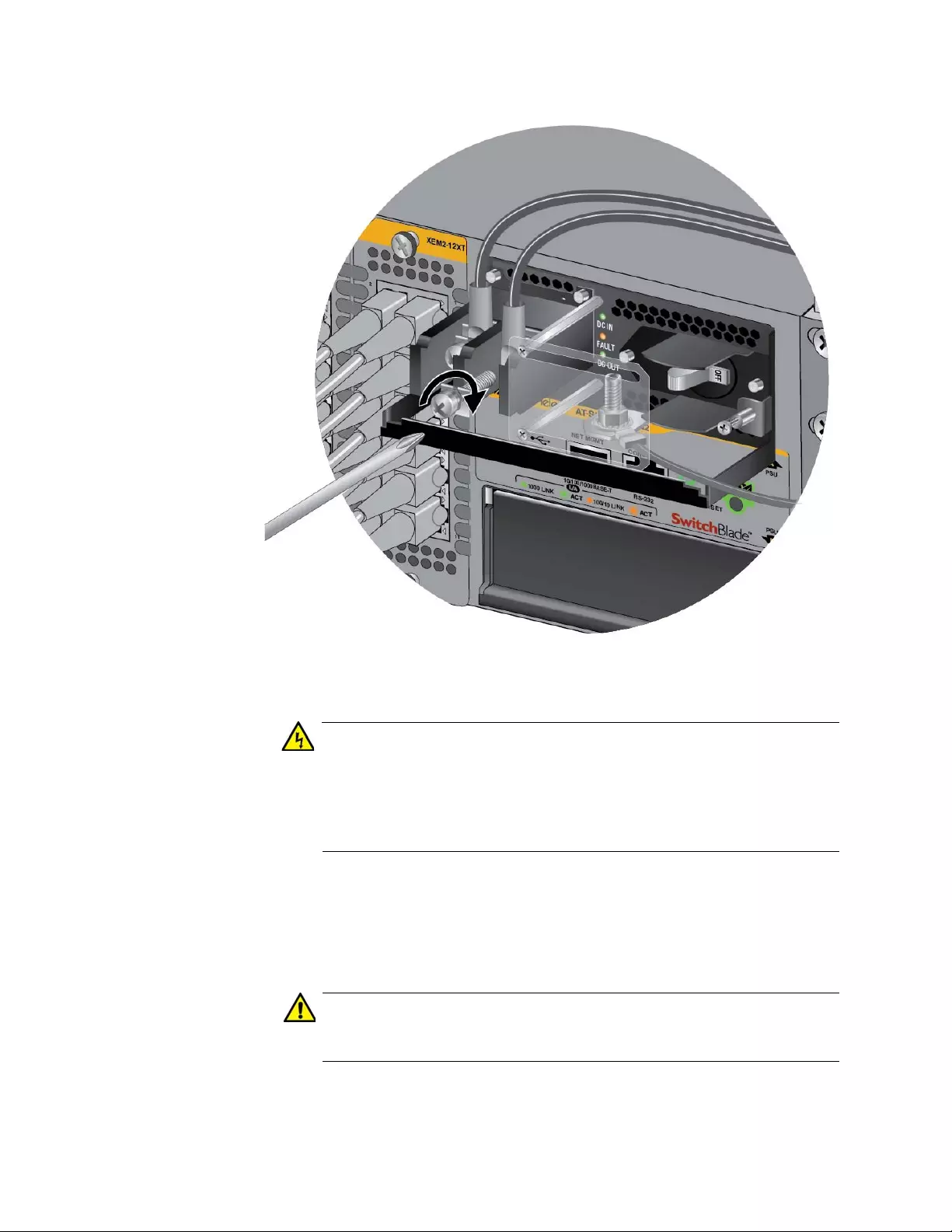

Installing the Chassis in an Equipment Rack

This chassis is designed to be installed in a standard 19-inch equipment

rack. Please review the installation guidelines in “Choosing a Site for the

Chassis” on page 43 before installing the chassis.

Caution

The chassis may be heavy and awkward to lift. Allied Telesis

recommends that you get assistance when mounting the chassis in

an equipment rack. E28

To install the chassis, perform the following procedure:

1. Place the chassis on a level, secure surface.

2. If you want to reposition the brackets from their pre-installe d positions,

remove them using a #2 Phillips-hea d screwdriver and secur e them in

their new position. Refer to Figure 21 on page 56 for an example.

3. Have two other people hold the chassis in the equipment rack at the

desired location while you secure it using eight standard equipment

rack screws (not provided). Refer to Figure 22.

Figure 22. Securing the Chassis to the Equipment Rack

4. Go to “Installing the Chassis Grounding Wire” on page 58.

Chapter 3: Installing the Chassis

58

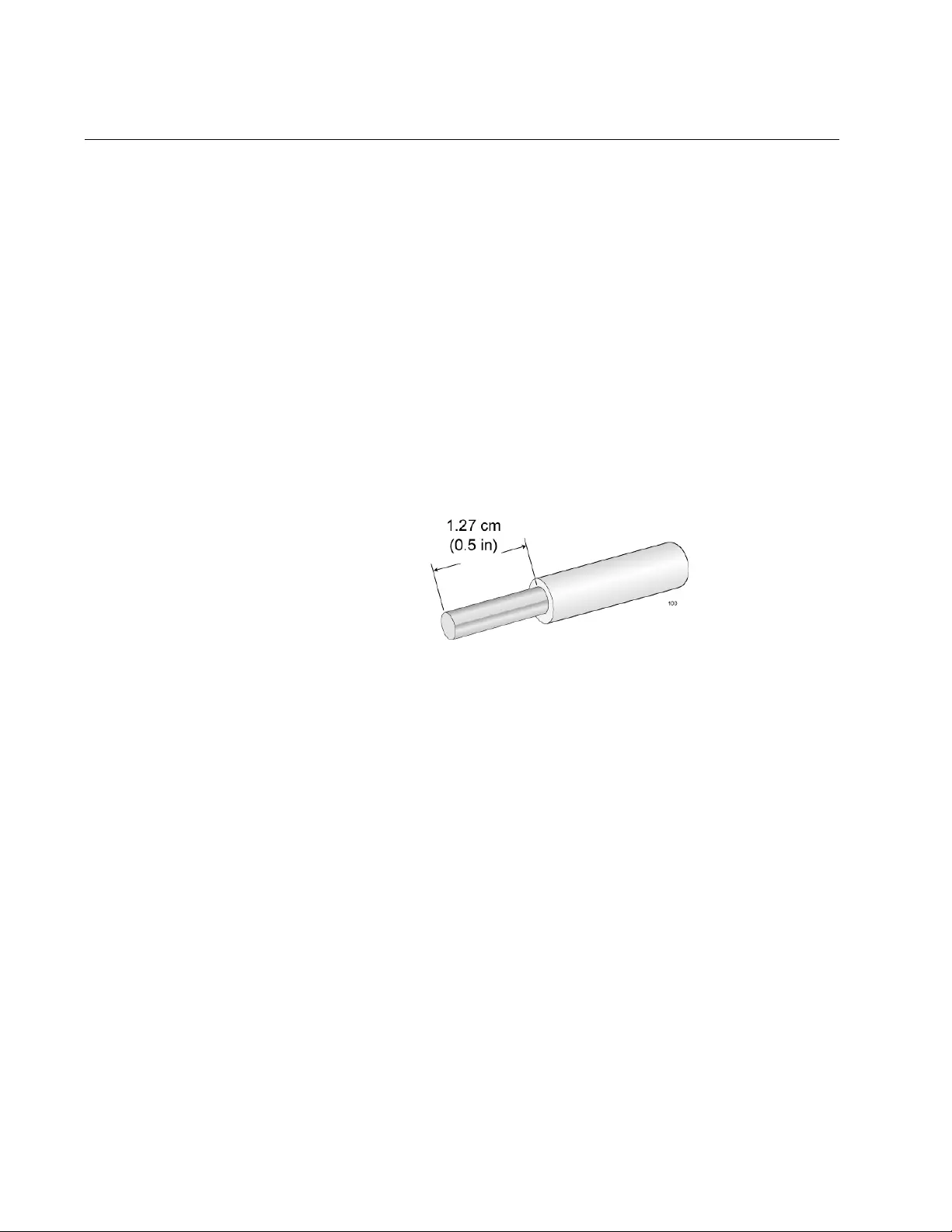

Installing the Chassis Grounding Wire

This procedure explains how to connect a grounding wire to the chassis.

The chassis requires a permanent connection for the line cards and power

supplies to a good earth ground. The procedure requires the following

items:

Grounding lug (pre-installed on the rear panel of the chassis)

#2 Phillips-head screwdriver (not provided)

Crimping tool (not provided)

10 AWG stranded grounding wire (not provided)

To connect the chassis to an earth ground, perform the following

procedure:

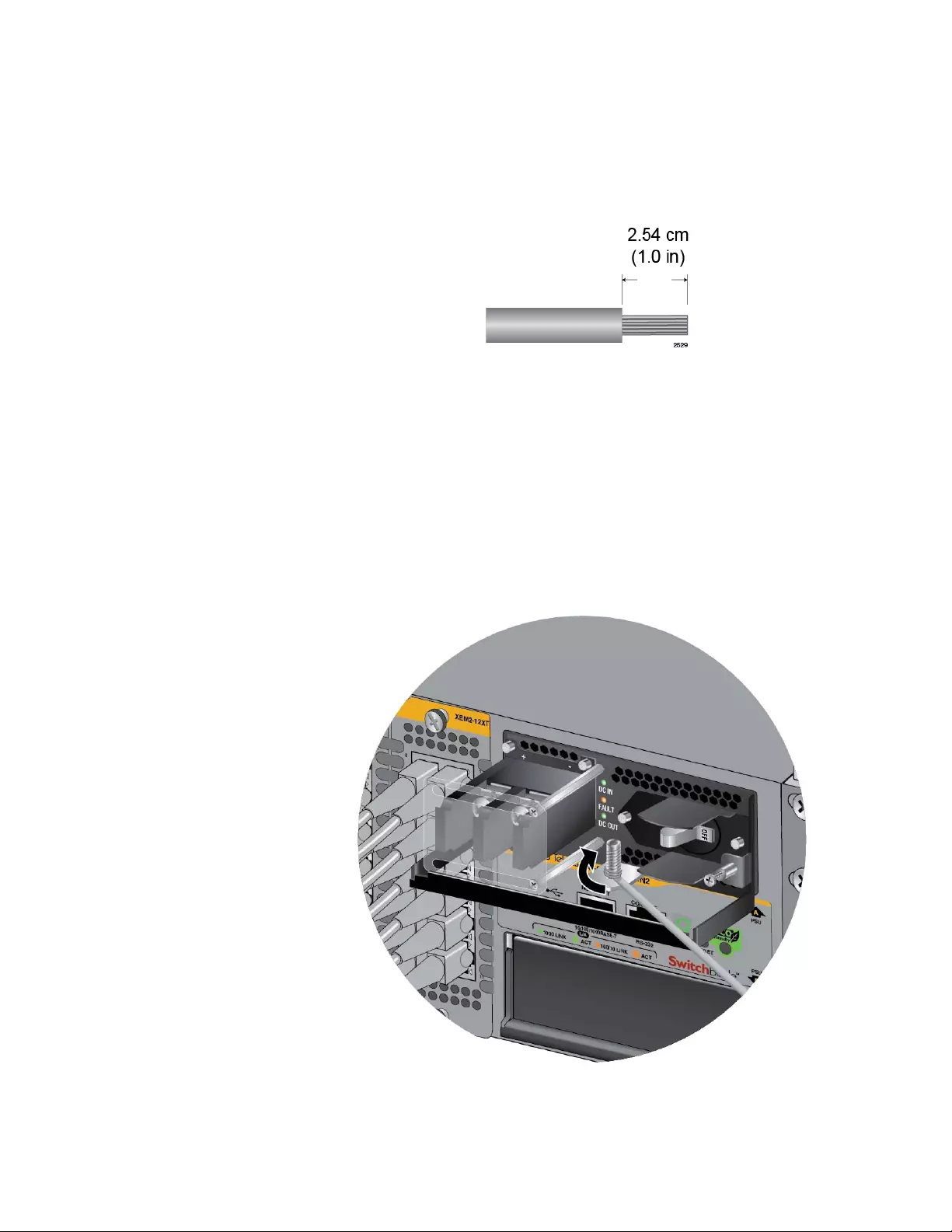

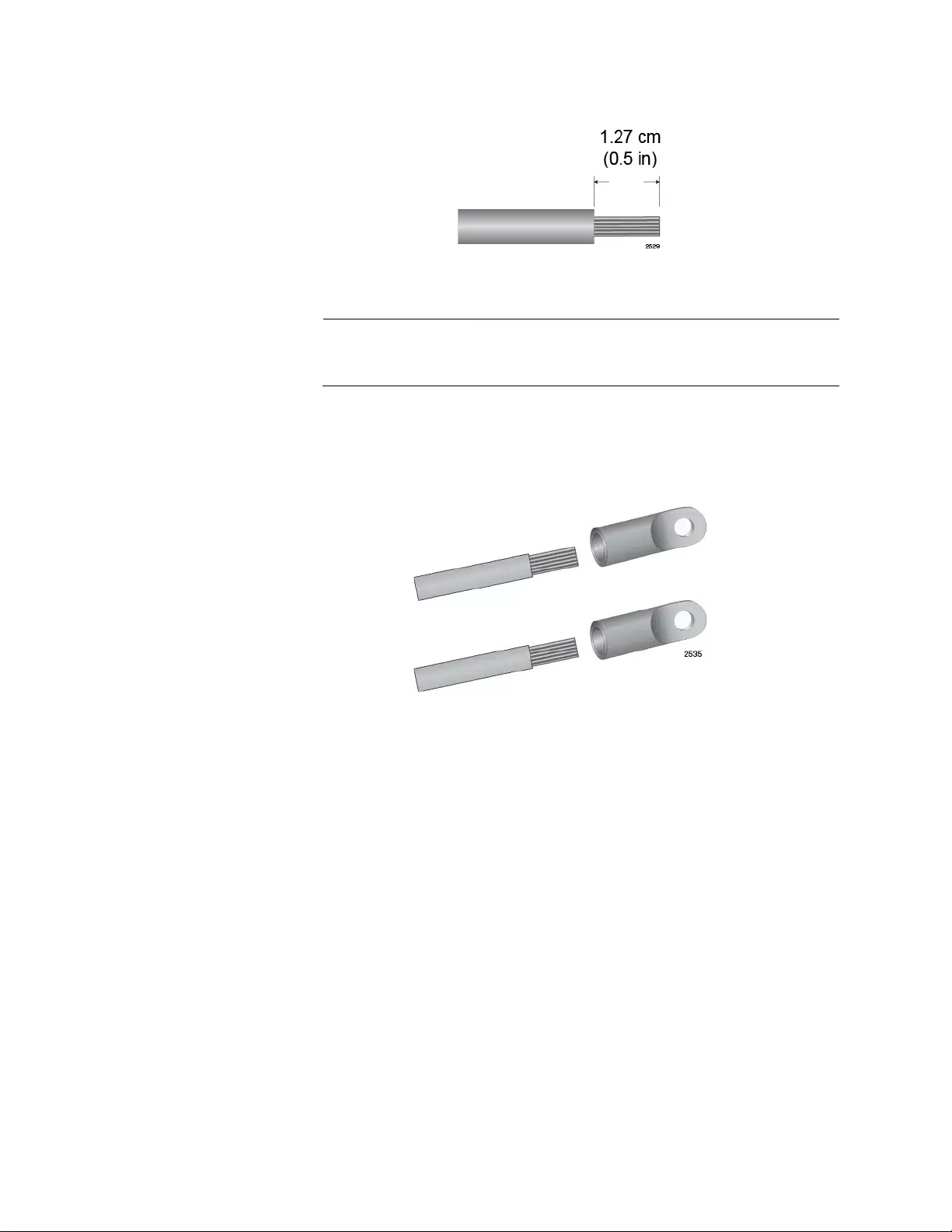

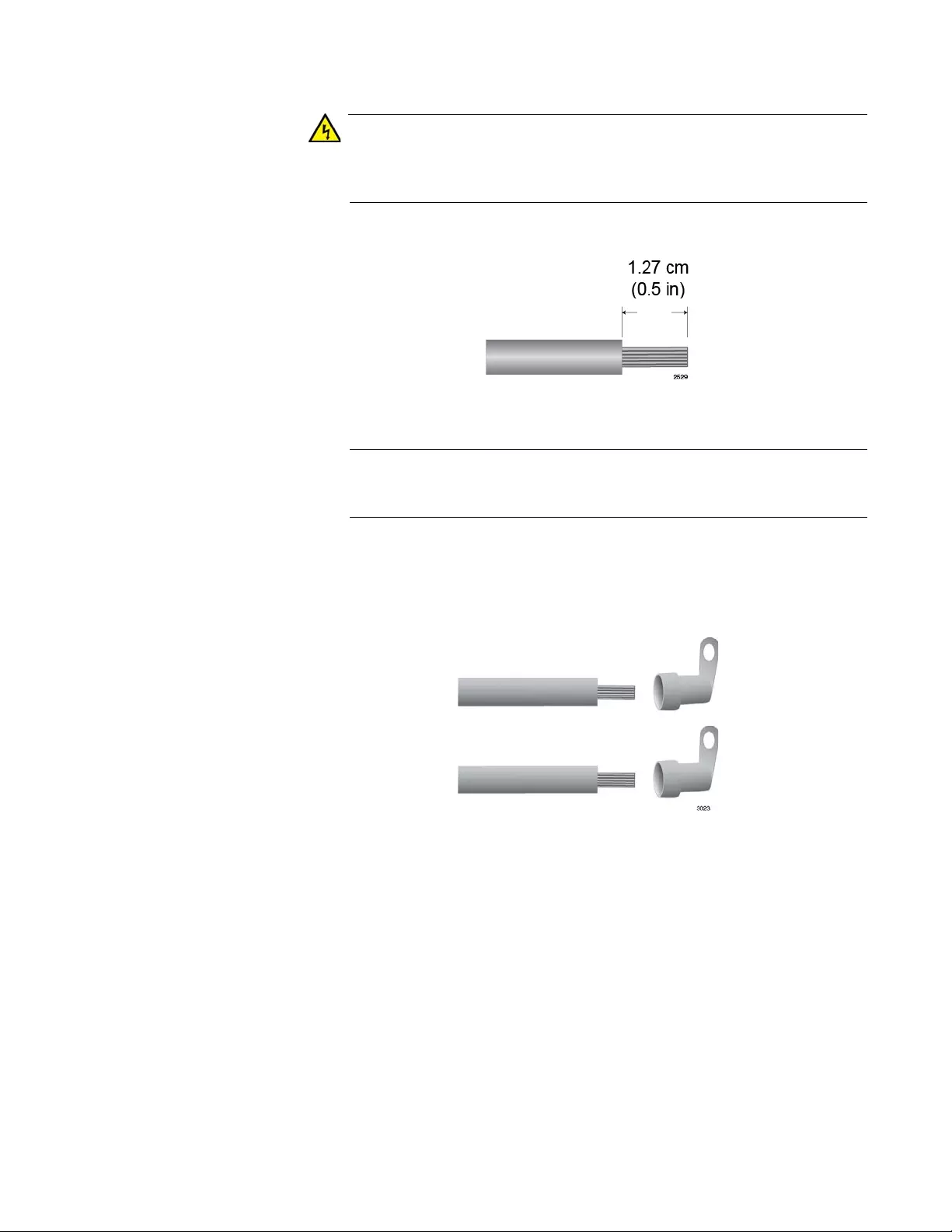

1. Prepare an adequate length of stranded grounding wire (10 AWG) for

the ground connection by stripping it as shown in Figure 23.

Figure 23. Stripping the Grounding Wire

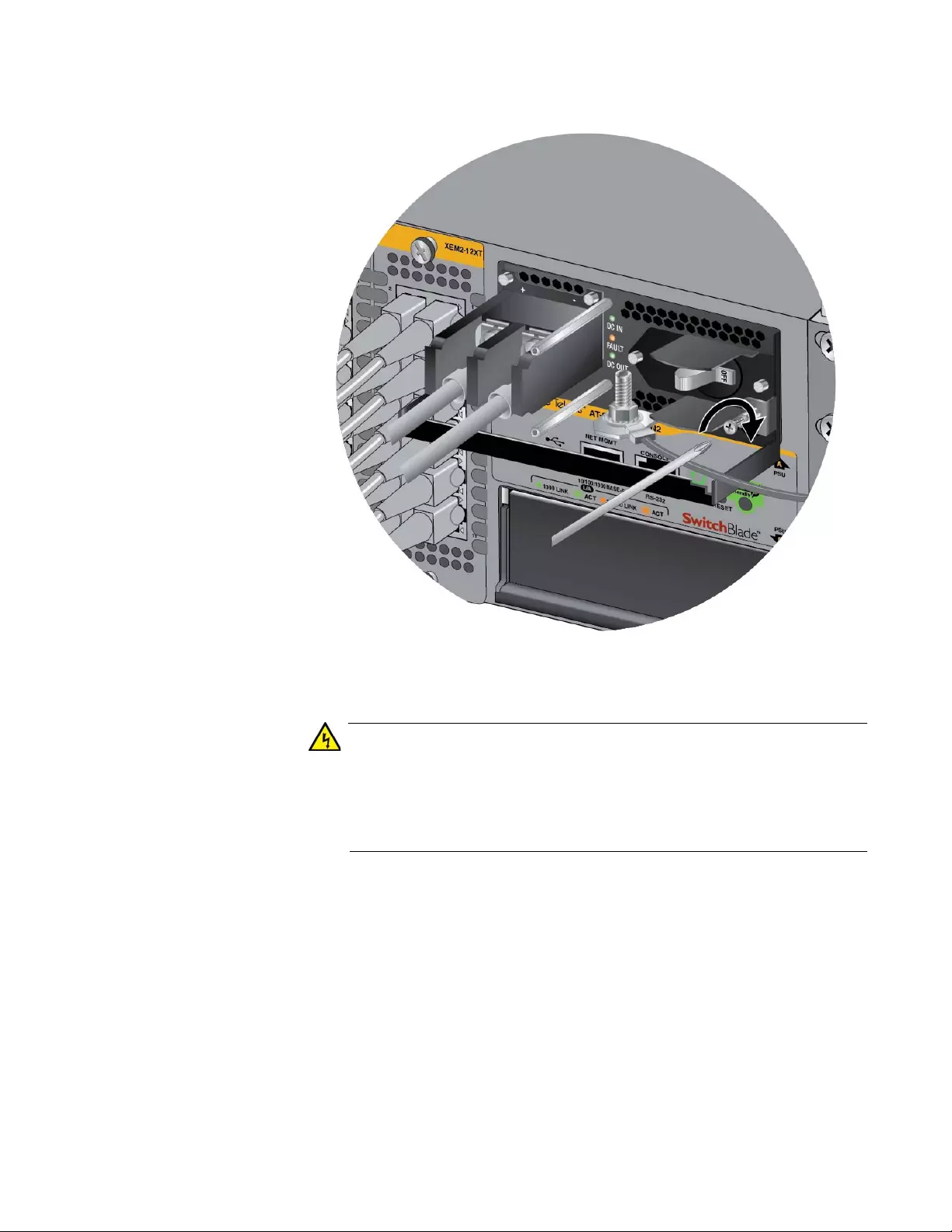

2. Use a #2 Phillips-head screwdriver to remove the two screws that

secure the grounding lug to the rear panel of the chassis. Refer to

Figure 24 on page 59.

AT-SBx908 Gen2 Switch Installation Guide

59

Figure 24. Removing the Grounding Lug from the Chassis

3. Insert one end of the grounding wire into the grounding lug, as shown

in Figure 25, and use a crimping tool to secure the wire to the

grounding lug.

Figure 25. Attaching the Grounding Wire to the Grounding Lug