Table of Contents

APC ER1000R User Manual

Displayed below is the user manual for ER1000R by APC which is a product in the Power Cables category. This manual has pages.

Related Manuals

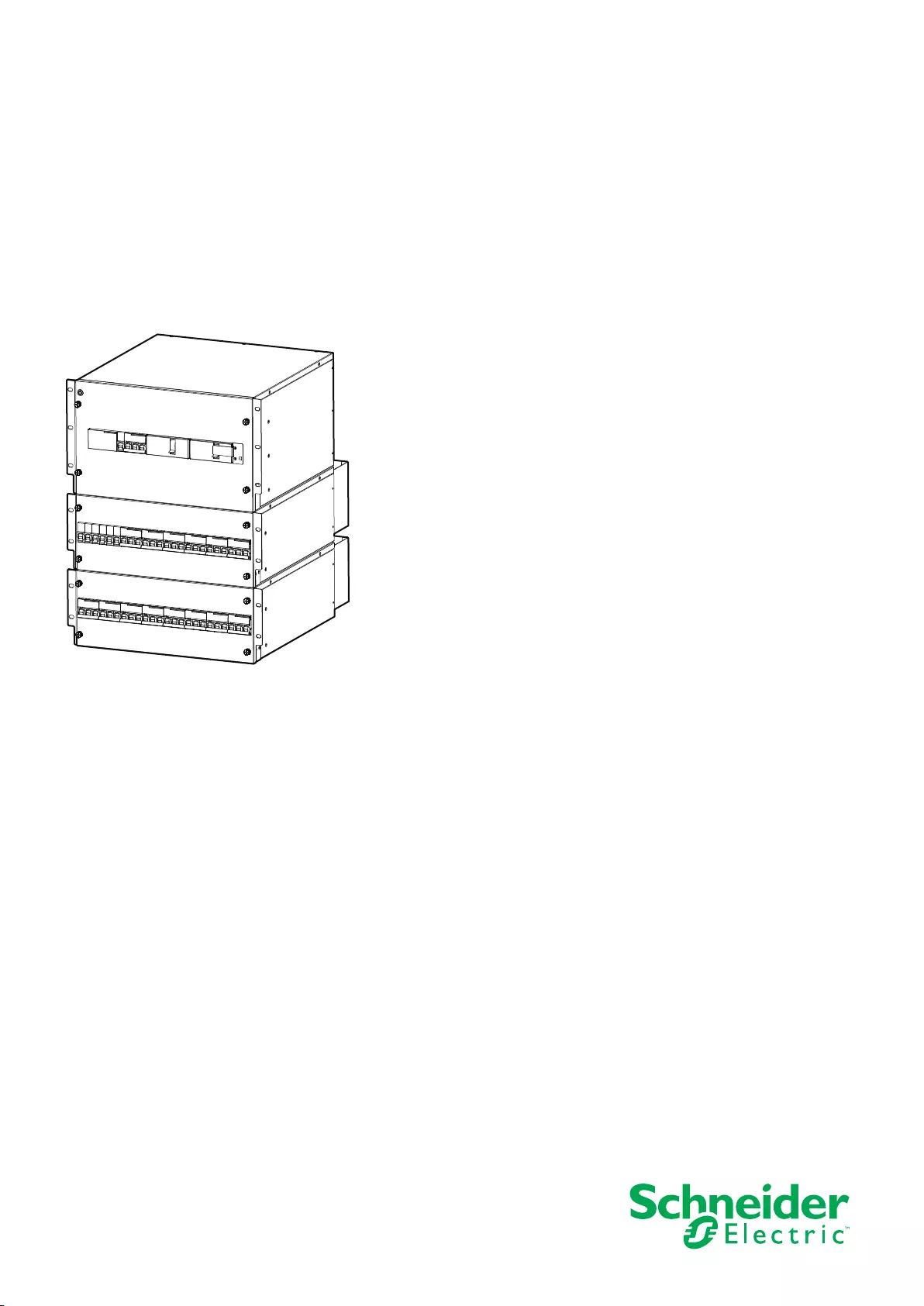

Rack Mounted Power Distribution Panels for

Row Data Centers

Installation

PDPMIB1N-40, PDPMIB2N-20, PDPUPS1N-40, PDPUPS2N-20, PDPPDU-40

990–91537

September 2021

www.se.com

Legal Information

The Schneider Electric brand and any trademarks of Schneider Electric SE and its

subsidiaries referred to in this guide are the property of Schneider Electric SE or its

subsidiaries. All other brands may be trademarks of their respective owners.

This guide and its content are protected under applicable copyright laws and

furnished for informational use only. No part of this guide may be reproduced or

transmitted in any form or by any means (electronic, mechanical, photocopying,

recording, or otherwise), for any purpose, without the prior written permission of

Schneider Electric.

Schneider Electric does not grant any right or license for commercial use of the guide

or its content, except for a non-exclusive and personal license to consult it on an "as

is" basis. Schneider Electric products and equipment should be installed, operated,

serviced, and maintained only by qualified personnel.

As standards, specifications, and designs change from time to time, information

contained in this guide may be subject to change without notice.

To the extent permitted by applicable law, no responsibility or liability is assumed by

Schneider Electric and its subsidiaries for any errors or omissions in the informational

content of this material or consequences arising out of or resulting from the use of the

information contained herein.

Table of Contents

General Information....................................................................................5

Safety........................................................................................................5

Receiving the Equipment ............................................................................6

Inventory.......................................................................................................7

Installation.................................................................................................. 11

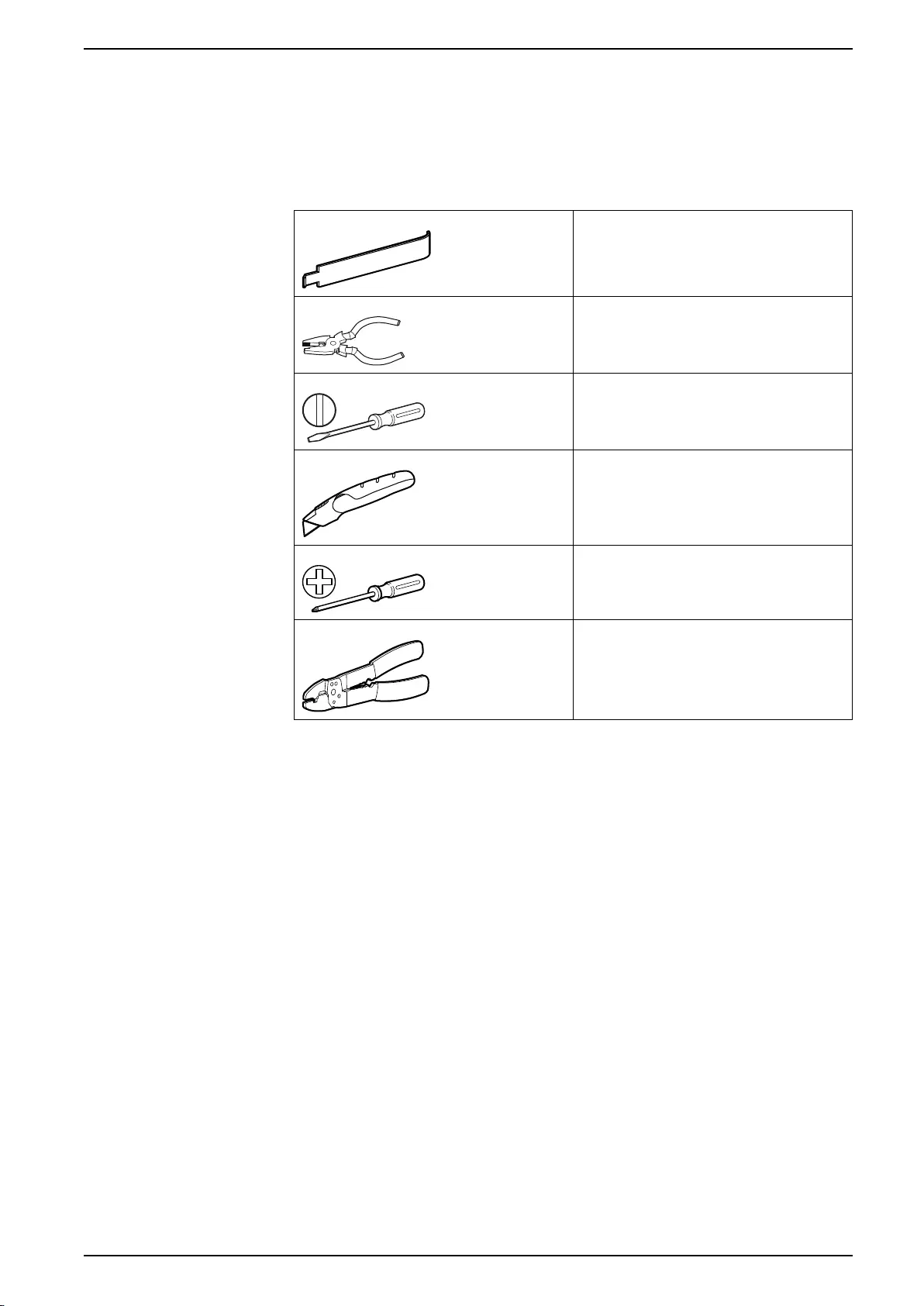

Tools Required ......................................................................................... 11

Installing Equipment .................................................................................12

Mounting Rails .........................................................................................13

Cable Access Panel..................................................................................14

System Components ................................................................................16

Configurations and Wiring .........................................................................19

Wiring Considerations...............................................................................24

Install the Safety Covers ...........................................................................26

System Startup..........................................................................................28

Maintenance Bypass Procedure ............................................................29

Troubleshooting ........................................................................................31

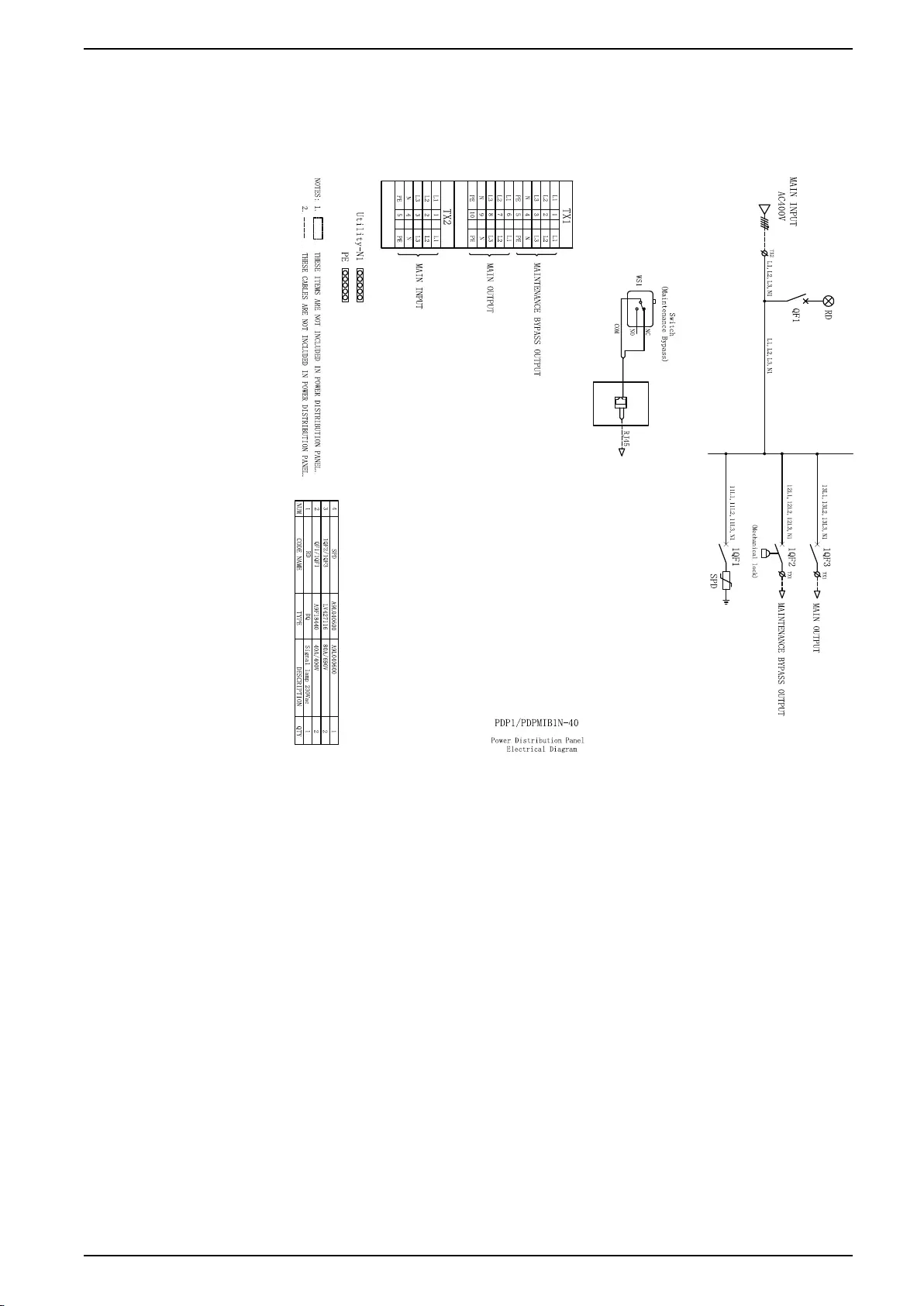

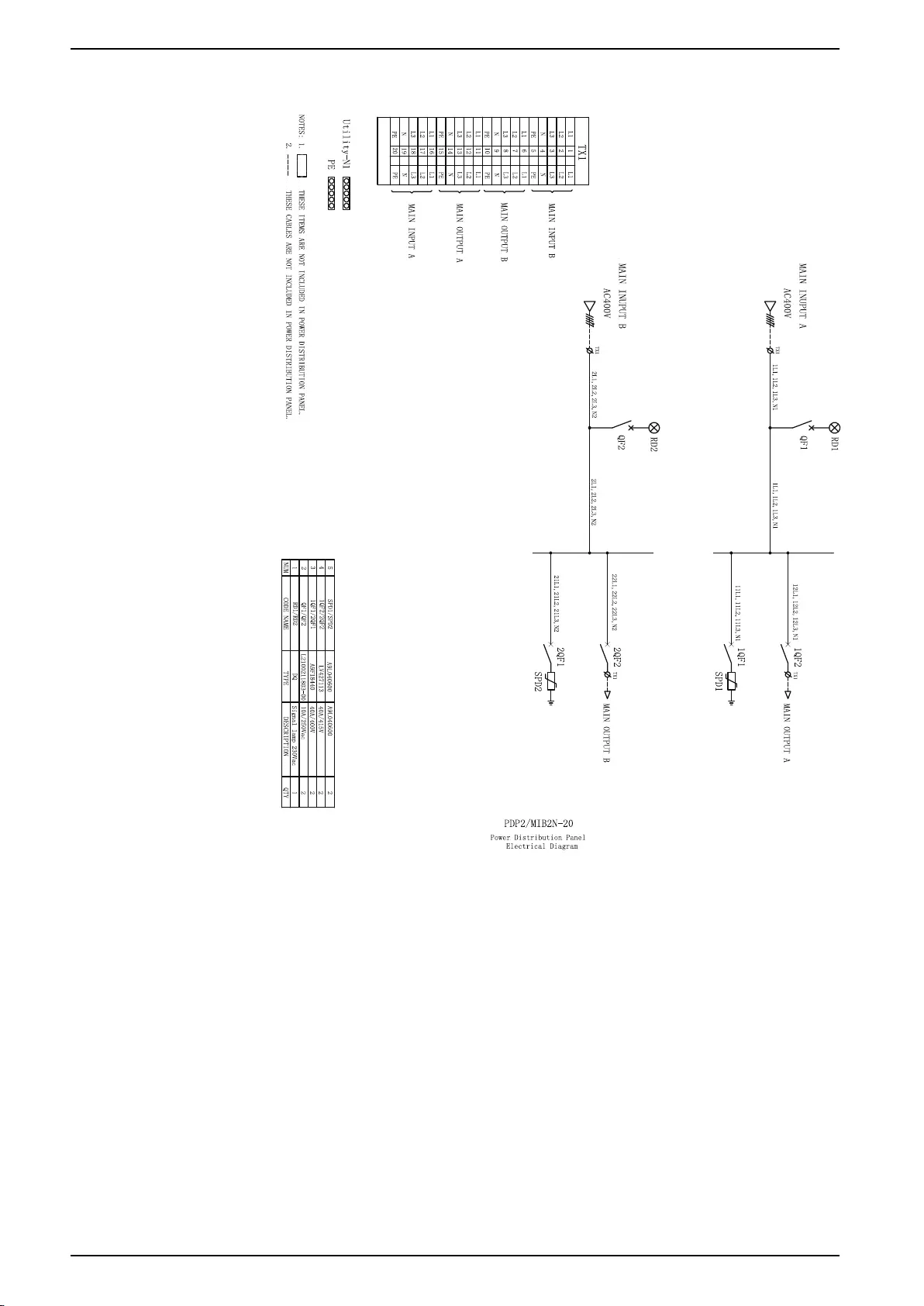

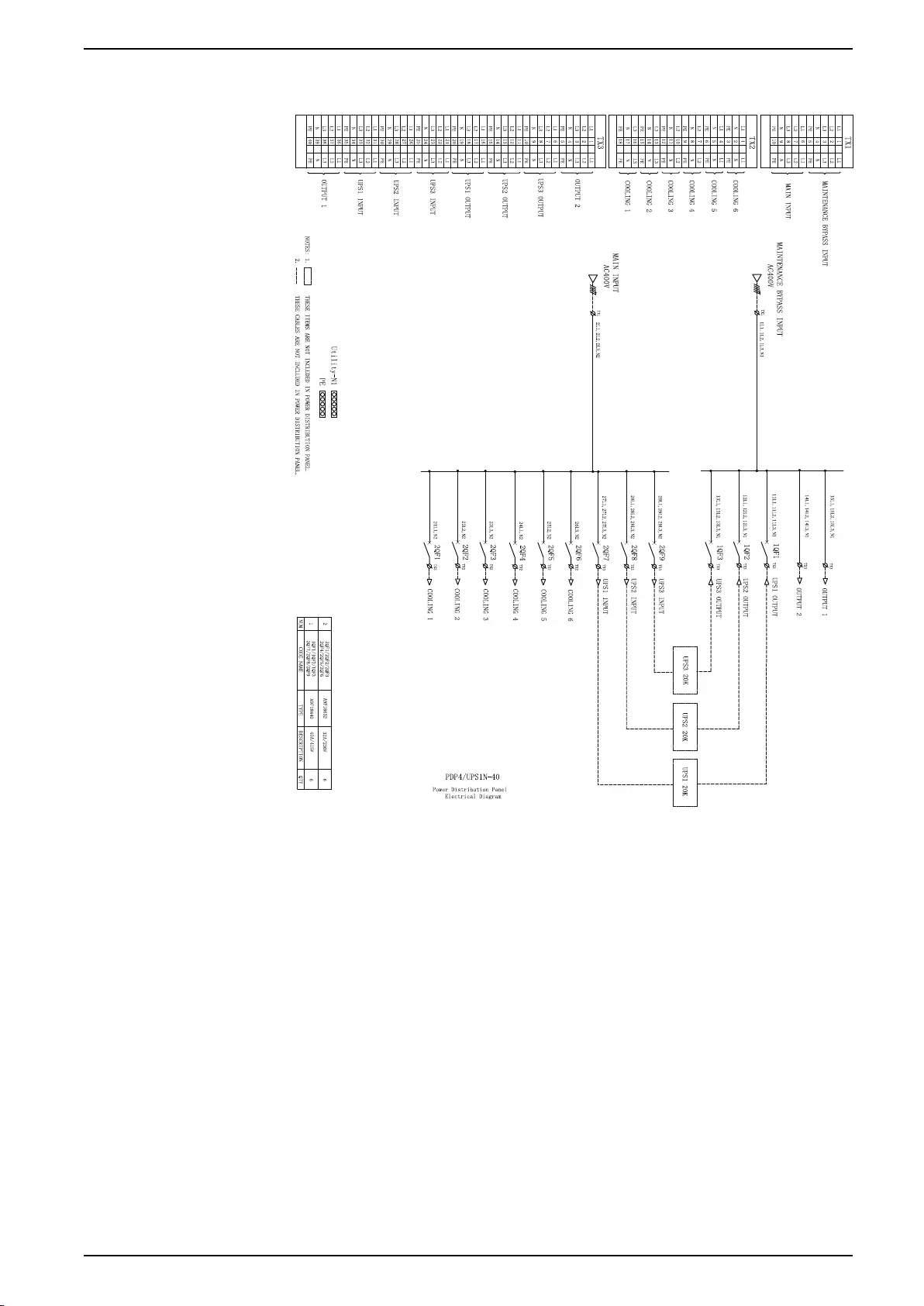

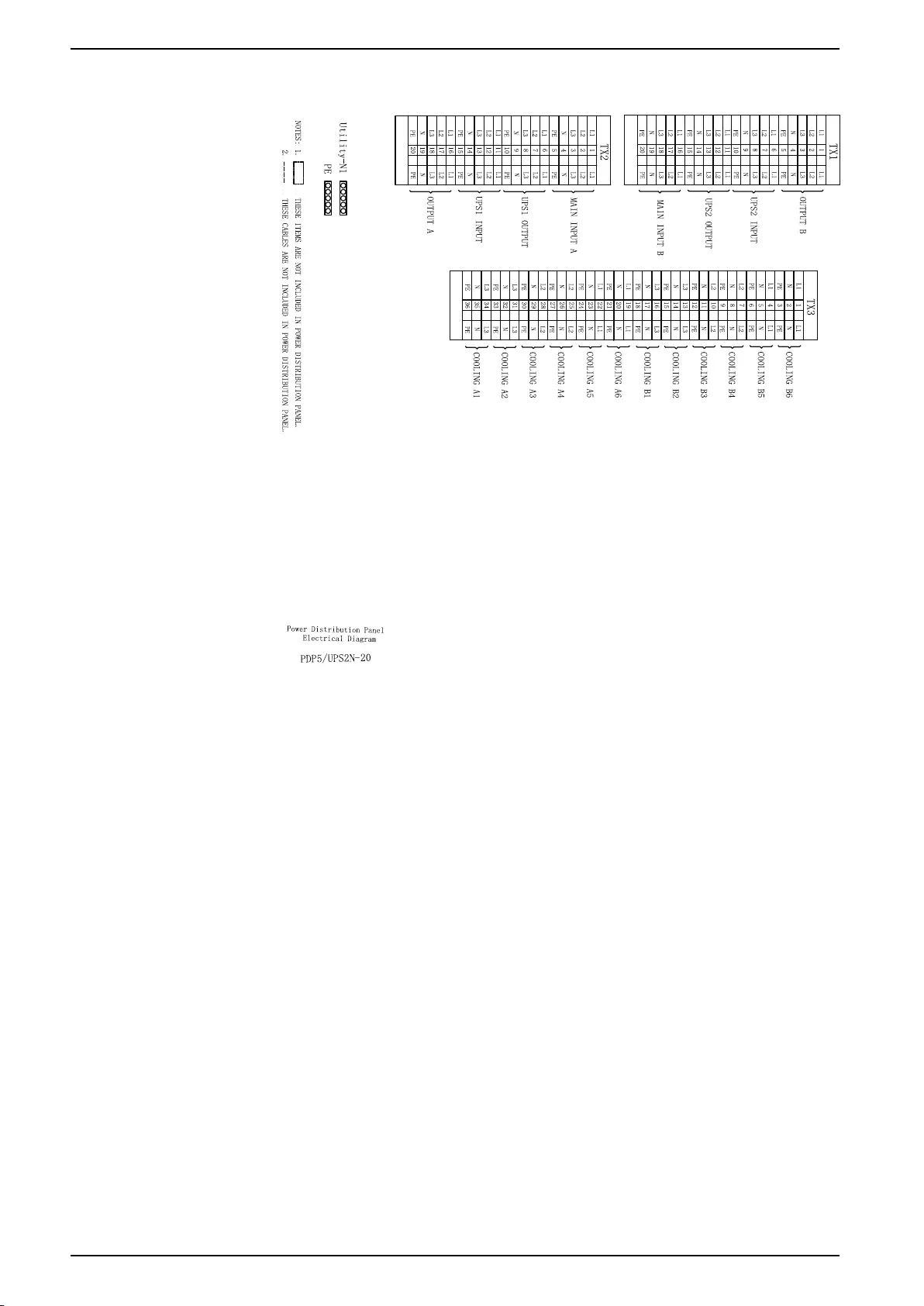

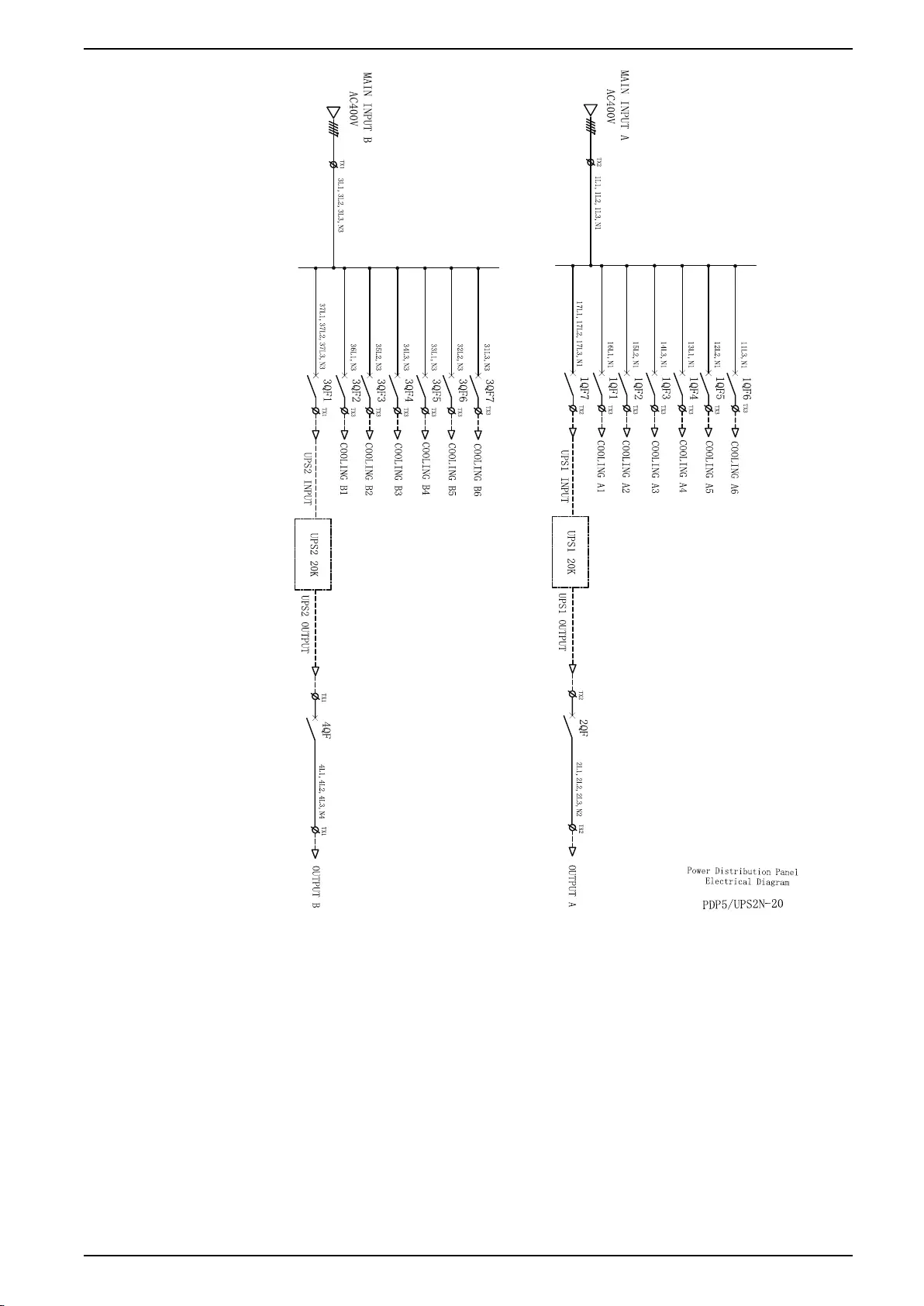

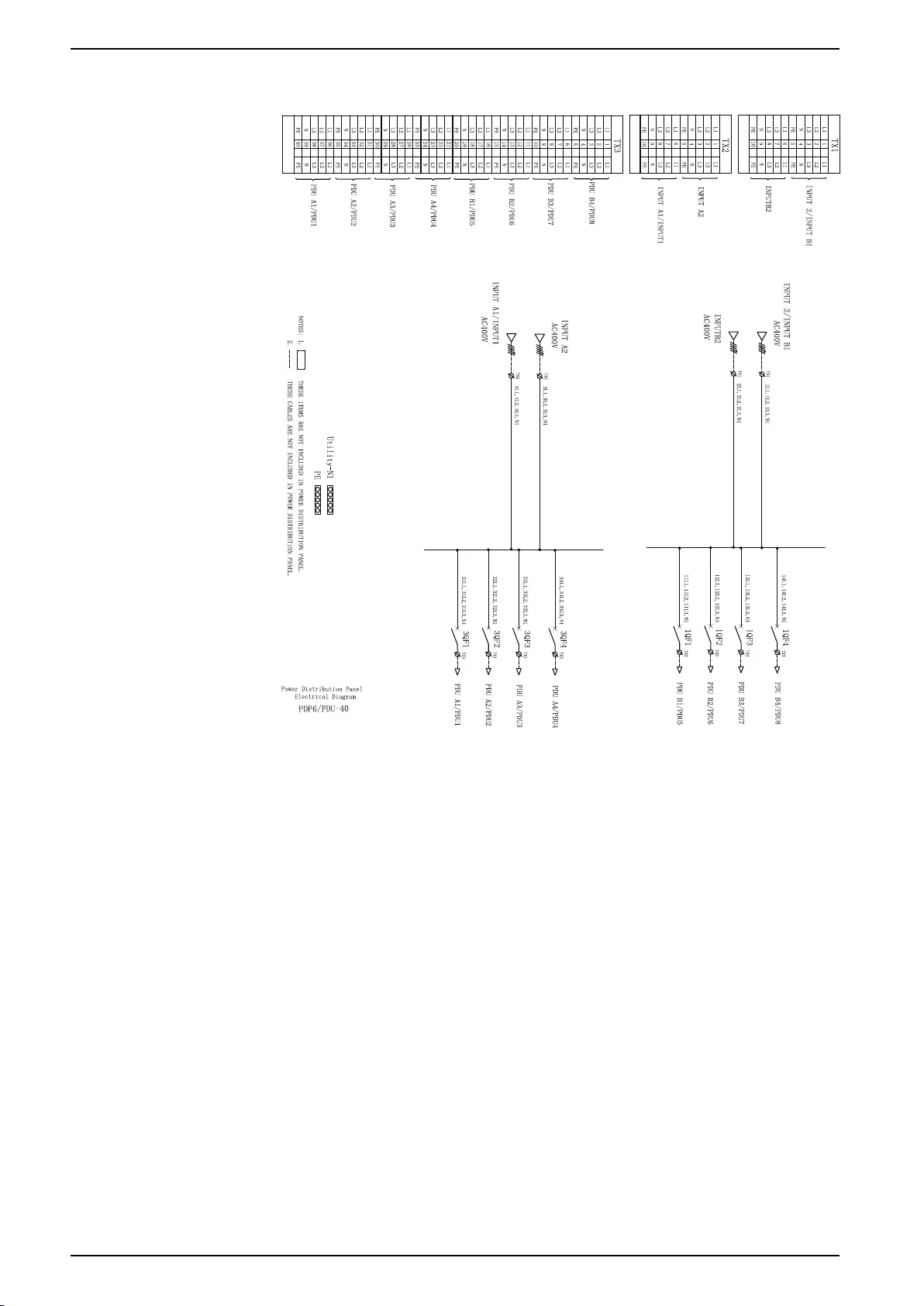

Power Distribution Panel Electrical Diagrams ......................................33

Specifications ............................................................................................39

Two-Year Factory Warranty.....................................................................41

990–91537 3

General Information

General Information

This manual provides instructions to install two configurations of the Power

Distribution Panels (PDP) for the Easy Rack PDP System Cabinet. Each of the

Maintenance Bypass Panels (MBP) and Power Distribution Panels (PDP) contain

Mechanical Circuit Breakers (MCBs) that facilitate the transfer of power from the

UPS to bypass operation to allow maintenance to be performed on the UPS.

PDPPDU-40 also houses 8-MCBs for distributing power to load. Read these

instructions carefully and observe all safety warnings and other precautions.

Should you require any installation/operation service, parts, accessories, or

maintenance, contact Schneider Electric Customer Support at www.se.com.

Safety

SAVE THESE INSTRUCTIONS

This manual contains important instructions that should be closely followed during

installation, maintenance, and operation of the system. Read all safety and

operating instructions before attempting to operate the system.

Adhere to all Warning labels on the unit, in this manual and in the attendant

manuals for the system. Follow all operating and user instructions.

This product is not intended for use with life support or other designated “critical”

devices. The maximum load must not exceed that shown on the rating label.

DANGER

HAZARD OF ARC FLASH AND ELECTRICAL SHOCK

• Remove incoming power to the system before performing any work.

Because of the UPS, live power exists within the equipment when power is

turned off. always use a properly rated voltage sensing device to confirm

there is no voltage in the system.

• Schneider Electric does NOT recommend performing maintenance to the

Maintenance Bypass Panel with Power Distribution while power is live.

Perform live maintenance at your own risk.

• Electrical equipment must be installed, operated, serviced, and maintained

only by qualified personnel.

• The system must be installed in accordance with the National Electrical

Code and all applicable local codes. This installation must comply with the

requirements of ANSI/NFPA 75 and NEC/ NFPA 79 Art. 645.

• Perform appropriate Lock Out/Tag Out procedures during equipment

installation and maintenance.

• Wear appropriate personal protective equipment (PPE) and follow safe

electrical work practices. See NFPA 70E and follow all local codes and

regulations.

• DO NOT remove the rear/side panels of the PDP, or any sheet metal not

designed to be removed.

Failure to follow these instructions will result in death or serious injury.

NOTICE

EQUIPMENT DAMAGE

• Follow all wiring instructions precisely.

• Do not use caustic detergents or abrasive materials to clean the sheet metal.

A damp, soft cloth is usually sufficient to remove dust or debris.

Failure to follow these instructions can result in equipment damage.

990–91537 5

General Information

Receiving the Equipment

Upon receipt of the equipment, inspect for obvious signs of external damage.

NOTE: A thorough internal inspection should be conducted only after the unit

has been positioned for installation and before making any electrical

connections.

Acceptable Environmental Requirements

Ambient Temperature:

-0° to 40°C

(32° to 104°F)

Relative Humidity:

0–95% Non-condensing

Altitude:

0–2000 m (0–6560 ft)

Storage Conditions:

NOTICE

HAZARD OF EQUIPMENT DAMAGE

• If the system will not be installed immediately, store the unit (covered) in an

indoor, temperature and humidity-controlled area, free of dirt, corrosive

elements or conductive contaminants.

• Leaving the equipment uncovered and exposed to the elements will cause

damage and void the factory warranty.

• Leaving the equipment uncovered and exposed to the elements will cause

damage and void the factory warranty. When possible, leave the equipment

on the pallet until you are ready to move it to its final location.

Failure to follow these instructions can result in equipment damage.

Unpacking the System Components

Save the shipping materials for later use or dispose of them appropriately.

CAUTION

HEAVY EQUIPMENT HAZARD

Use at least two people when unpacking, lifting, and assembling this equipment.

Failure to follow these instructions can result in injury or equipment

damage.

6 990–91537

Inventory

Inventory

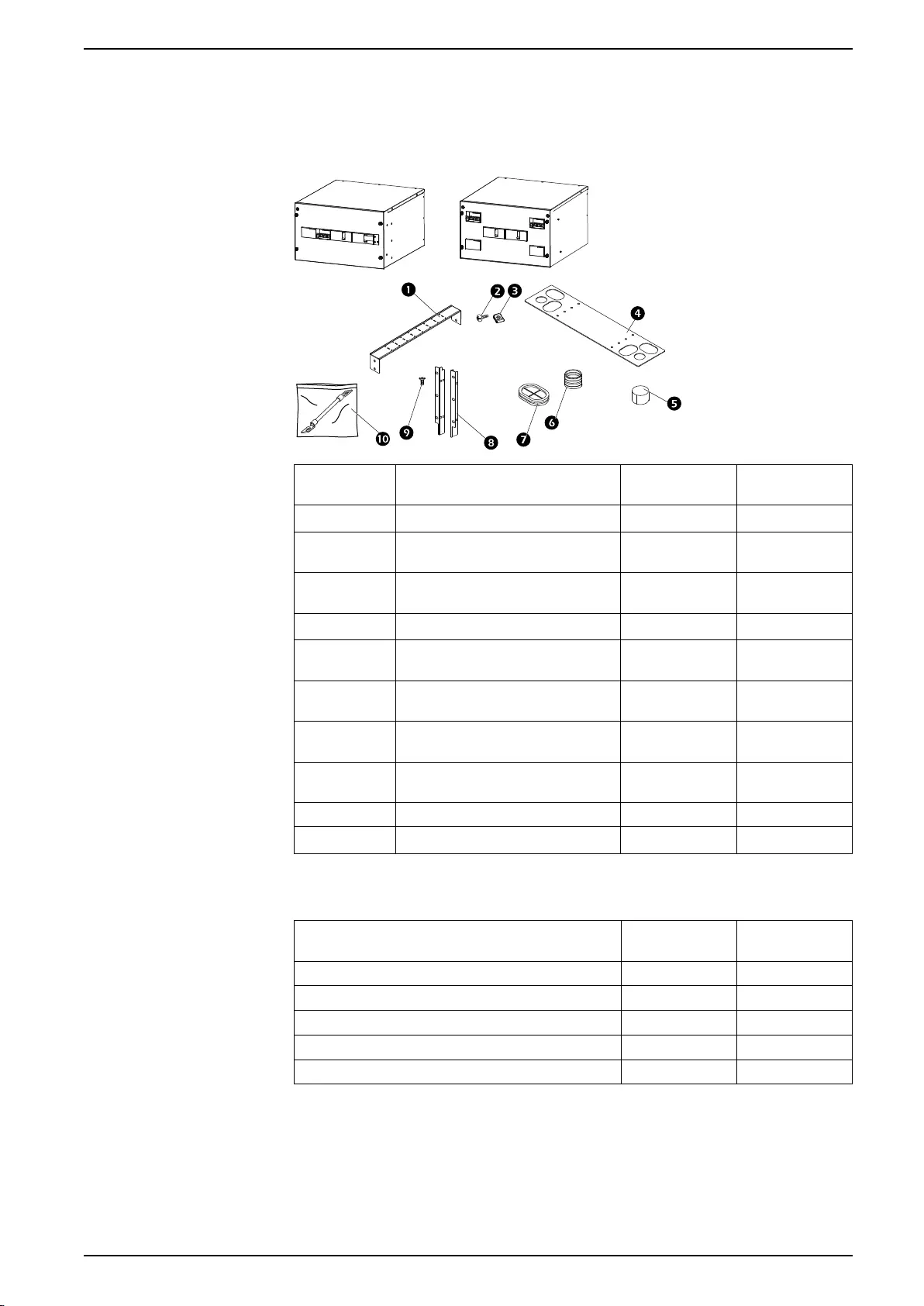

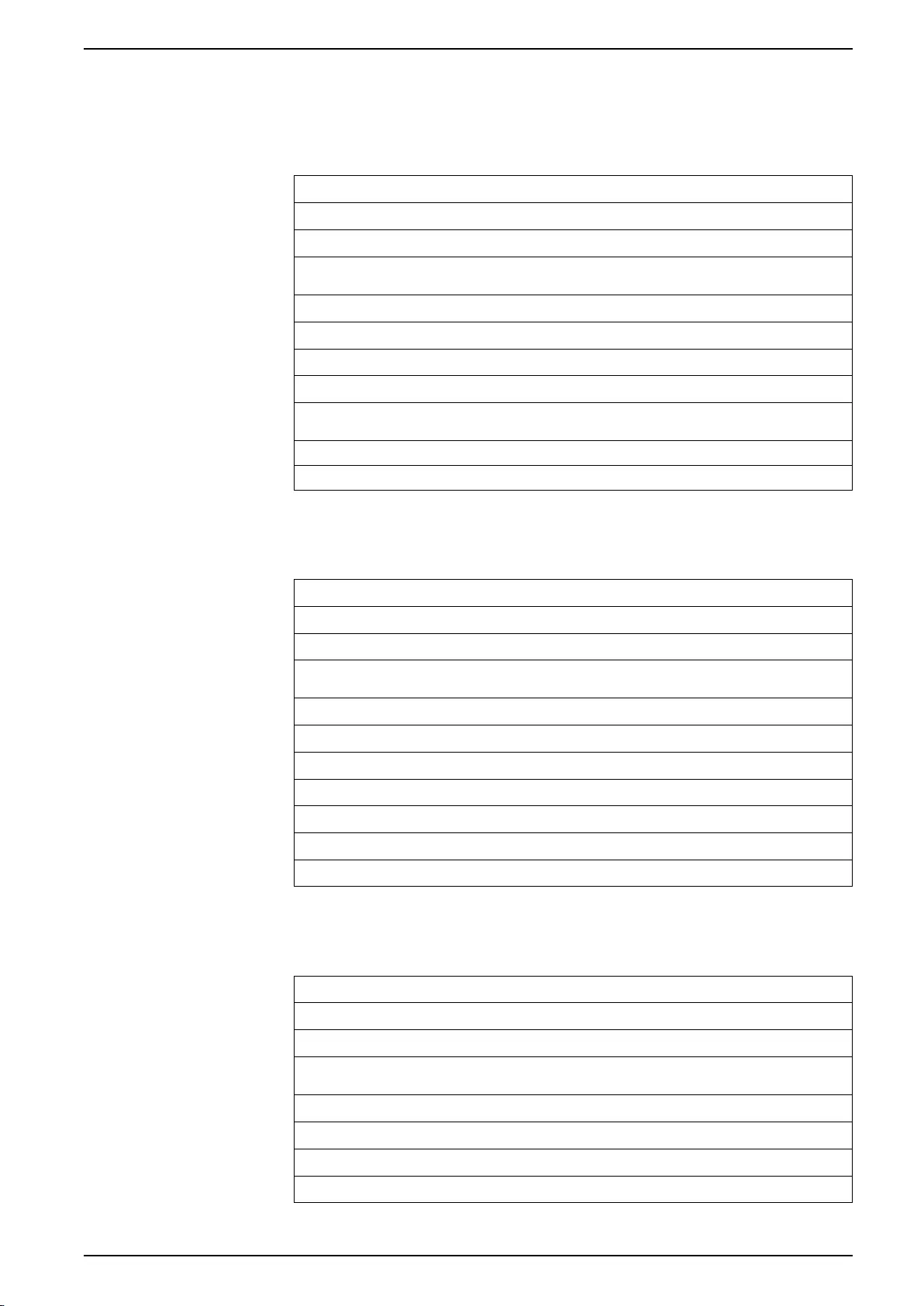

PDPMIB1N-40 or PDPMIB2N-20

OR

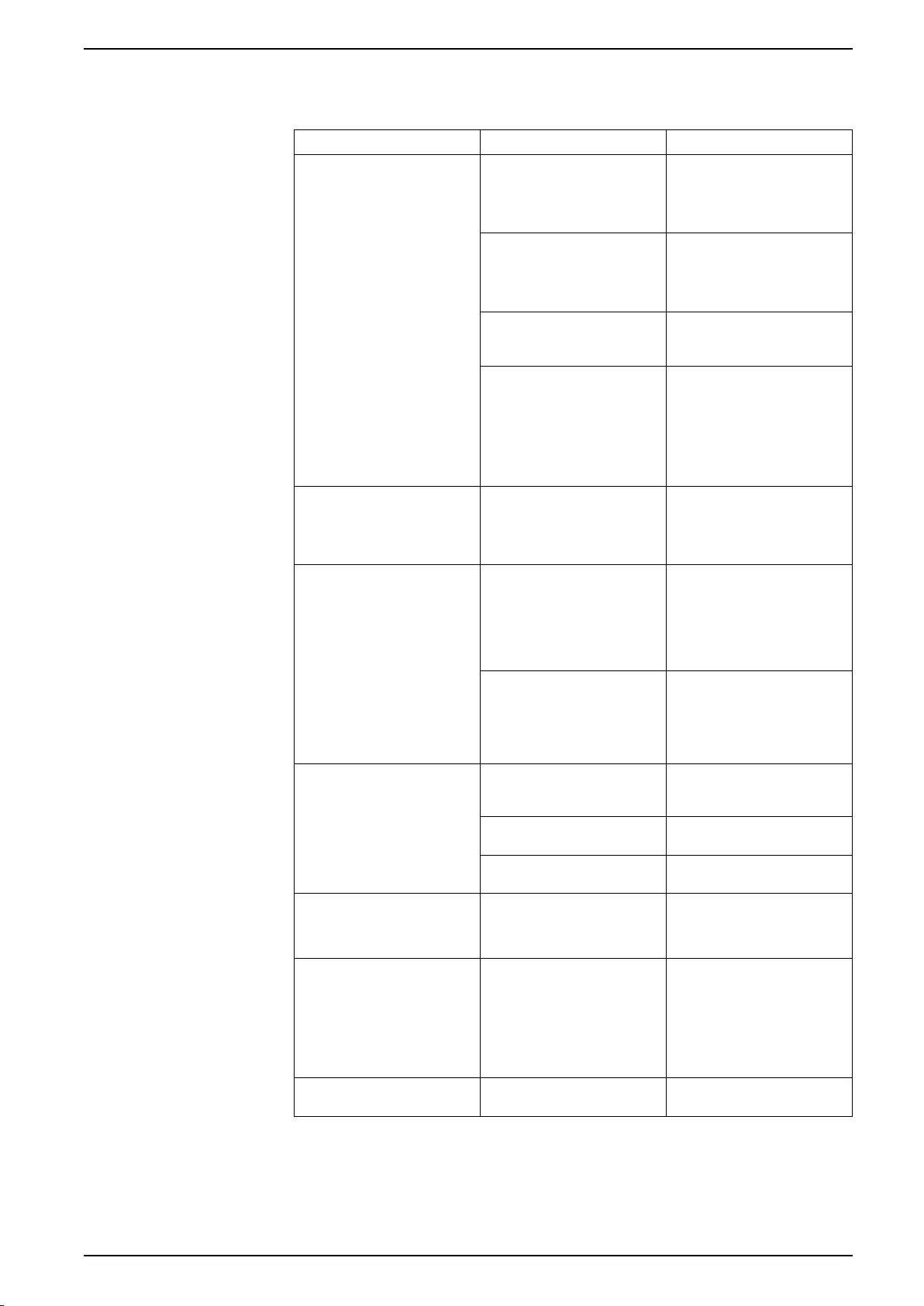

Item Description PDPMIB1N-40

Quantity

PDPMIB2N-20

Quantity

1 Cable manager 1 1

2 M6 x 12 Phillips pan head screw

(in accessory bag)

14 14

3 M6 Cage nut

(in accessory bag)

14 14

4 Top cable access panel 1 1

5Grommet cover

(in accessory bag)

2 2

6 Grommet

(in accessory bag)

1 2

7Cable Protector

(in accessory bag)

4 4

8 Mounting brackets 2

(1 Left, 1 Right)

2

(1 Left, 1 Right)

9 M4 x 8 Flat head screw 8 8

:Wire accessories bag 1 1

Contents of Wire accessories bag:

(not shown)

Description PDPMIB1N-40

Quantity

PDPMIB2N-20

Quantity

MBS WIRE 1 —

MAIN OP WIRE 1 set —

BYP OP WIRE 1 set —

MAIN OP A WIRE —1 set

MAIN OP B WIRE —1 set

990–91537 7

Inventory

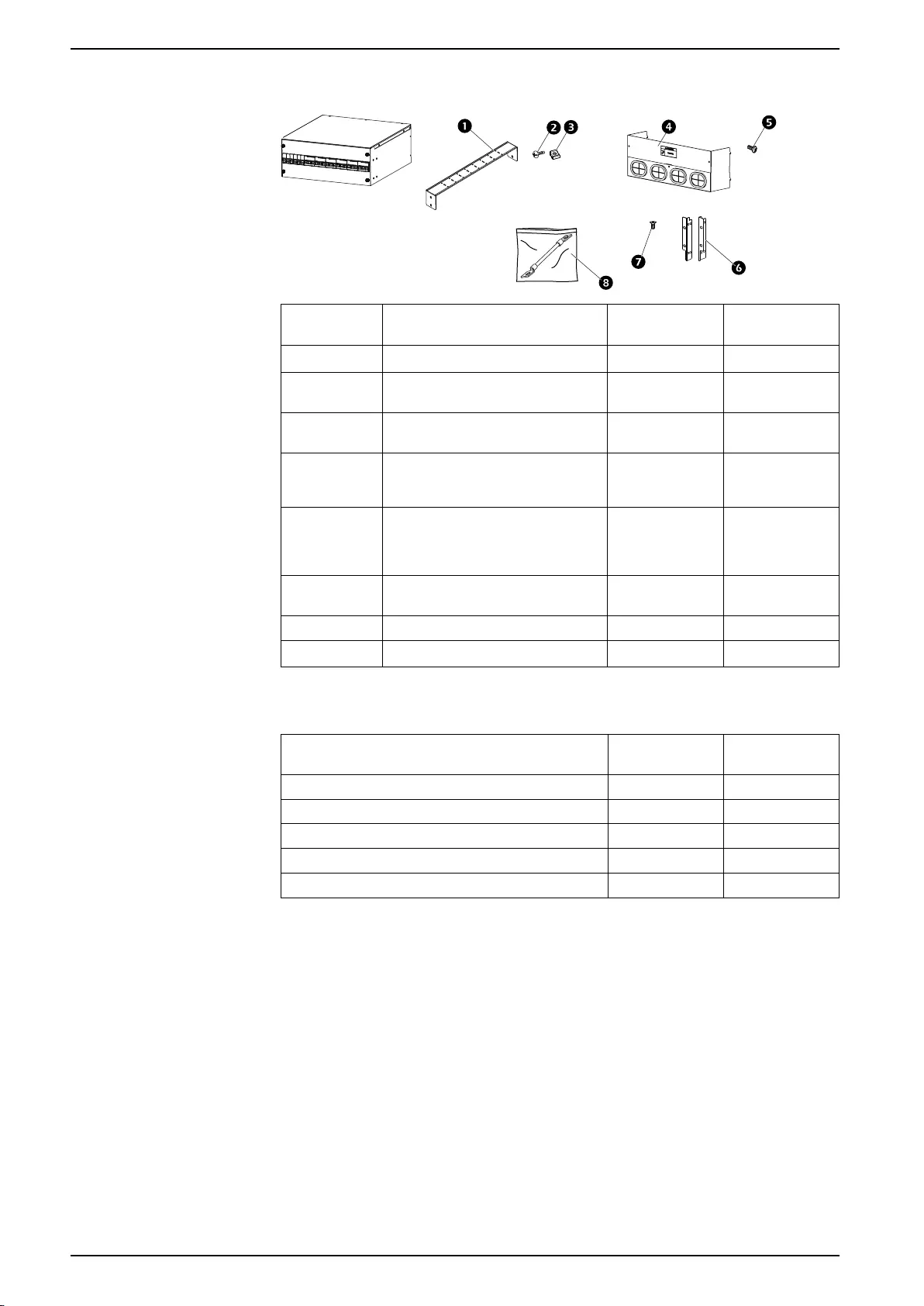

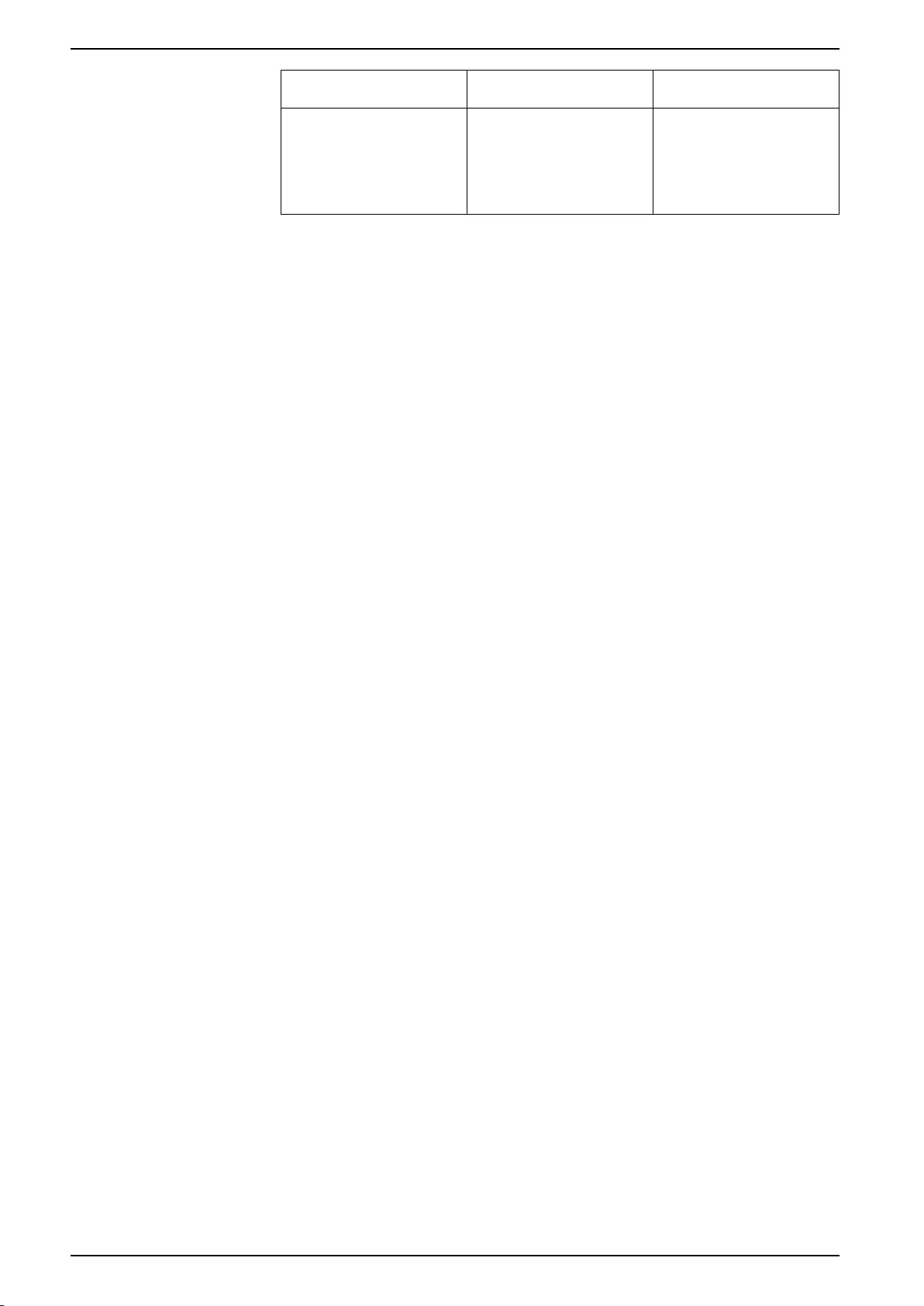

PDPUPS1N-40 or PDPUPS2N-20

Item Description PDPUPS1N-40

Quantity

PDPUPS2N-20

Quantity

1 Cable manager 1 1

2 M6 x 12 Phillips pan head screw

(in accessory bag)

8 8

3 M6 Cage nut

(in accessory bag)

8 8

4 Rear safety access panel (not

assembled)

(includes 4 cable protectors installed)

1 1

5 M4 x 8 Phillips pan head screw

(in accessory bag)

(for rear safety access panel

assembly)

2 2

6 Mounting brackets 2

(1 Left, 1 Right)

2

(1 Left, 1 Right)

7 M4 x 8 Flat head screw 8 8

8 Wire accessories bag 1 1

Contents of Wire accessories bag:

(not shown)

Description PDPUPS1N-40

Quantity

PDPUPS2N-20

Quantity

OP 1 WIRE 1 set —

OP 2 WIRE 1 set —

OP A WIRE —1 set

OP B WIRE —1 set

TERMINAL 35 25

8 990–91537

Inventory

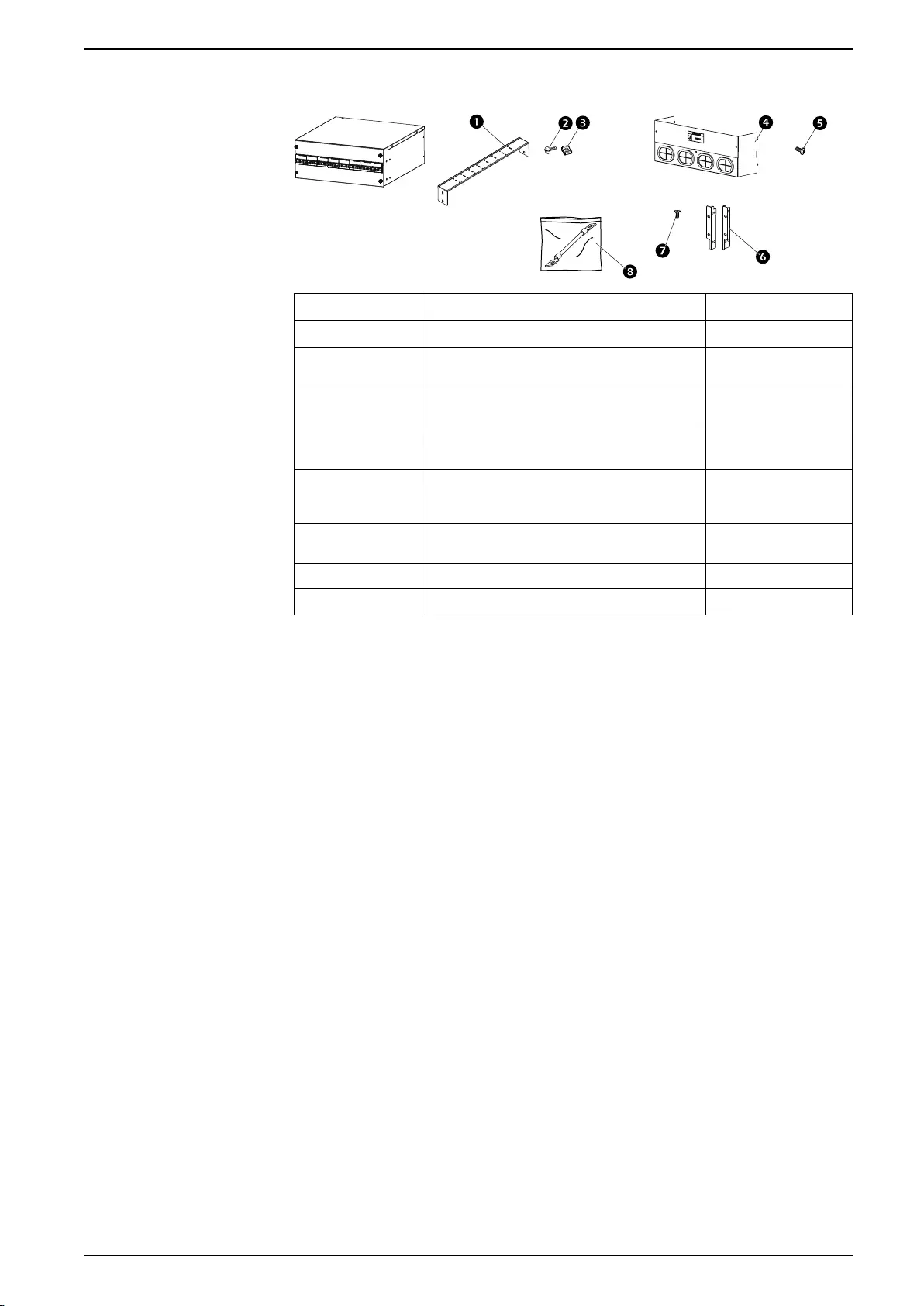

PDPPDU-40

Item Description Quantity

1 Cable manager 1

2 M6 x 12 Phillips pan head screw

(in accessory bag)

8

3 M6 Cage nut

(in accessory bag)

8

4 Rear safety access panel (not assembled)

(includes 4 cable protectors installed)

1

5 M4 x 8 Phillips pan head screw

(in accessory bag)

(for rear safety access panel assembly)

2

6 Mounting brackets 2

(1 Left, 1 Right)

7 M4 x 8 Flat head screw 8

8 Wire accessories bag 1

990–91537 9

Inventory

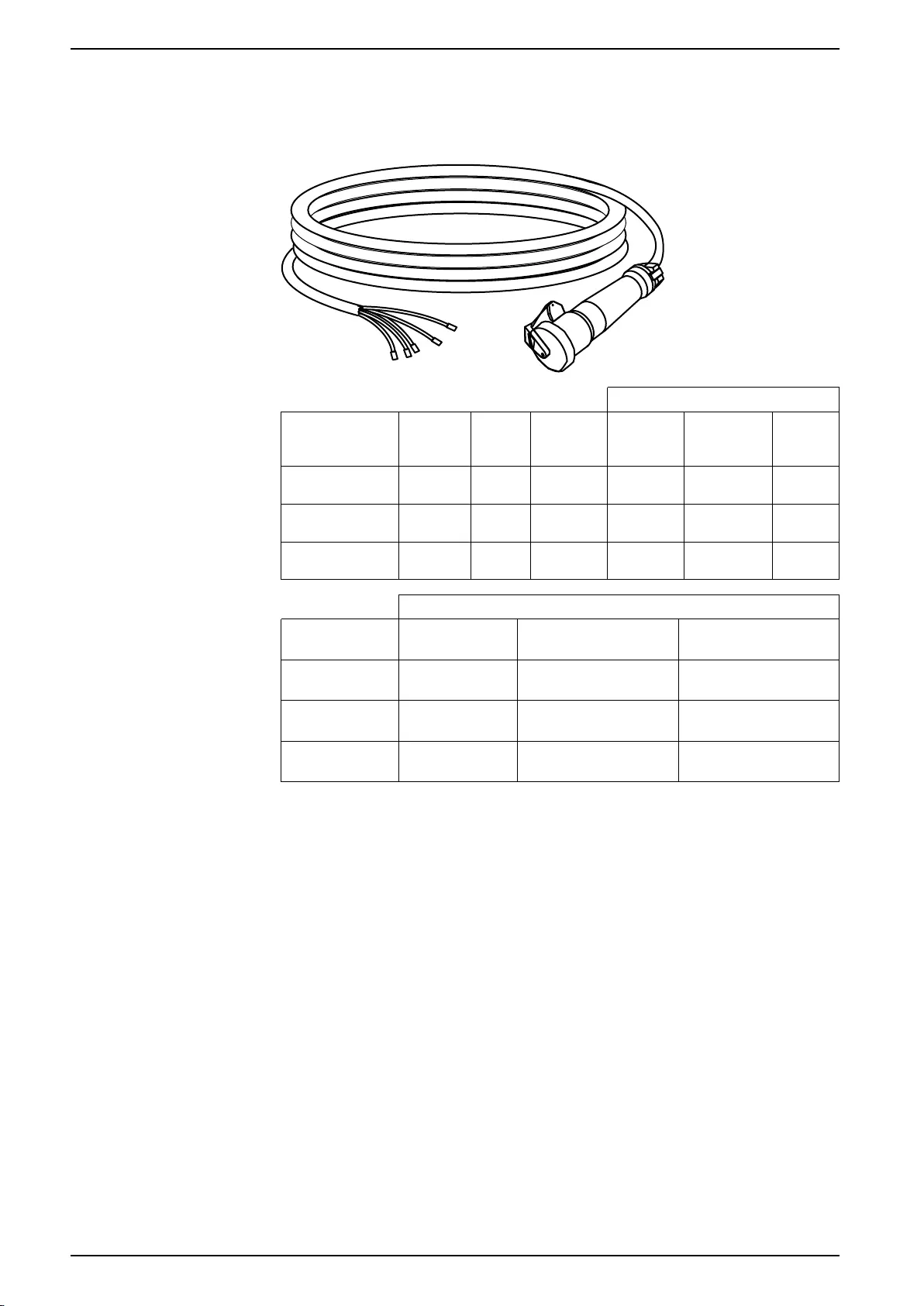

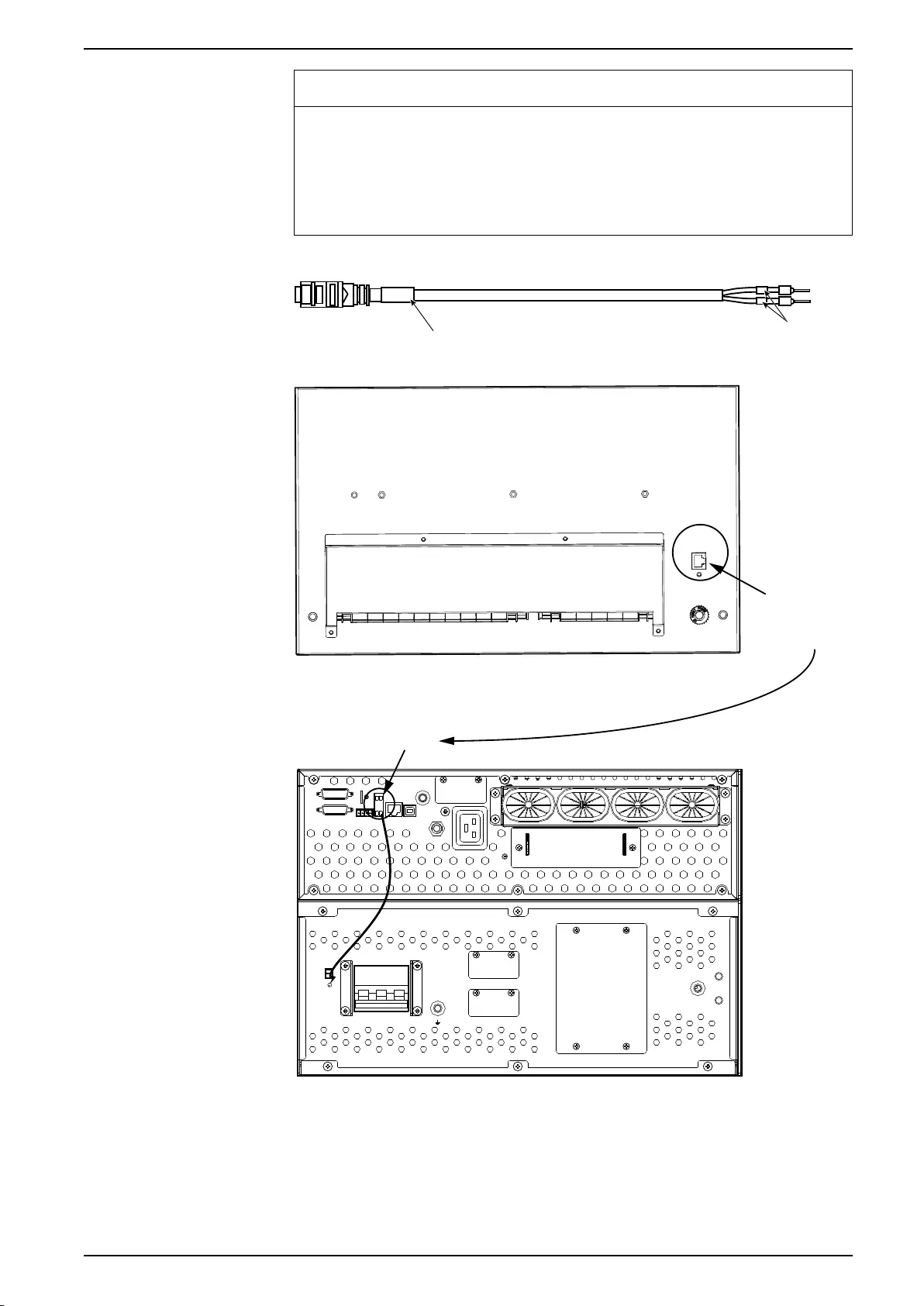

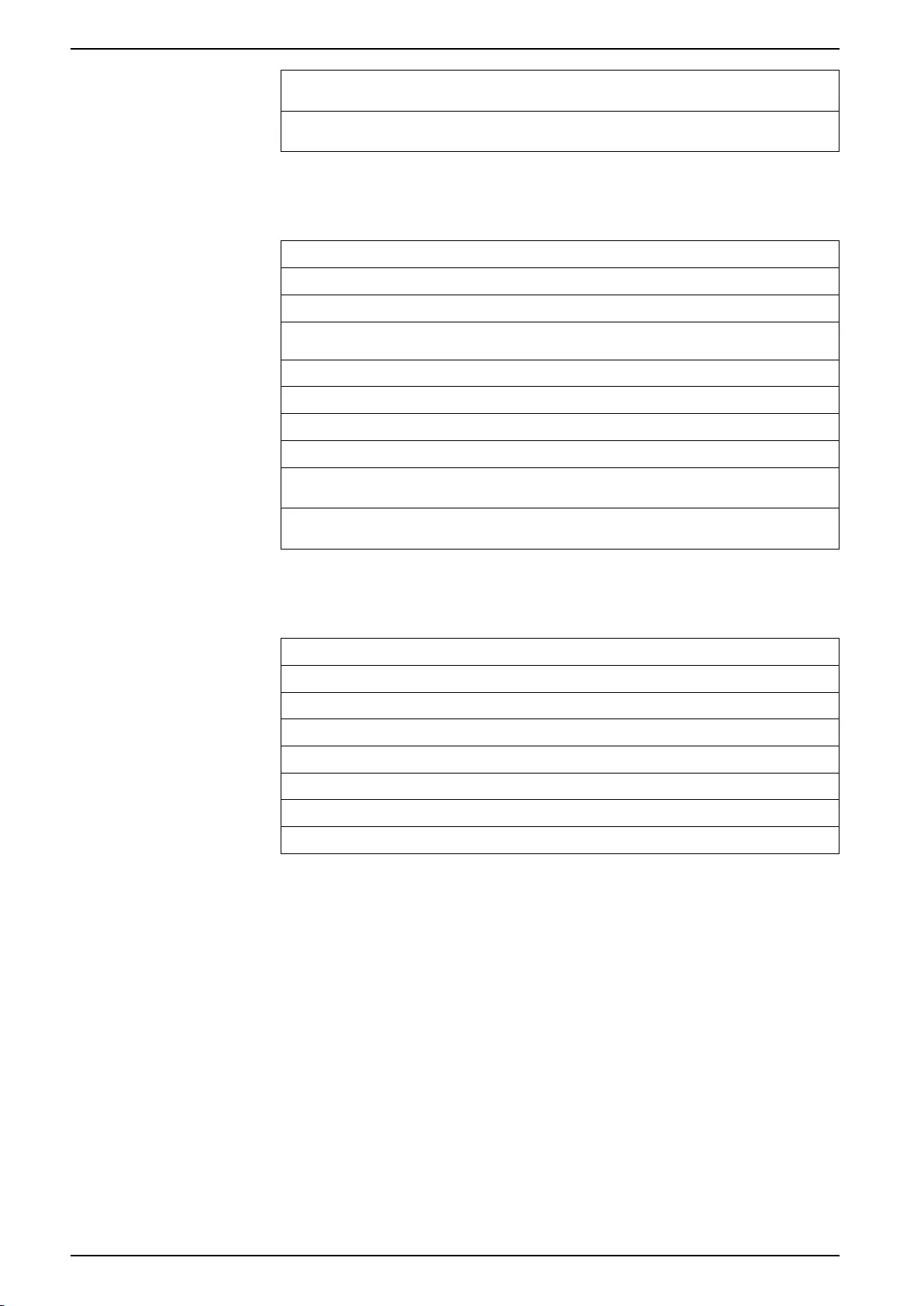

Power Cables

Power cables are required to connect the PDP system to other racks in the row.

Your configurator can determine which power cables are necessary for your row.

pdx1544a

Cable

SKU Applica-

tion

Cable

Length

(m)

Current

Rating (A)

Type Maximum

Tempera-

ture

Size

ER1000R 2–4 racks 5 25 H05VV-F

VDE

<70°C 2.5 mm²

ER1001R 5–6 racks 7 25 H05VV-F

VDE

<70°C 2.5 mm²

ER1002R 7–8 racks 9 25 H05VV-F

VDE

<70°C 2.5 mm²

continued Connector

SKU PDP Side

Terminal Type

Rack PDU Connector

Type

PDU Type

ER1000R CE040012 IEC309 16A

3P + N + E (Female)

EPDU1216B/

EPDU1216M

ER1001R CE040012 IEC309 16A

3P + N + E (Female)

EPDU1216B/

EPDU1216M

ER1002R CE040012 IEC309 16A

3P + N + E (Female)

EPDU1216B/

EPDU1216M

10 990–91537

Installation

Installing Equipment

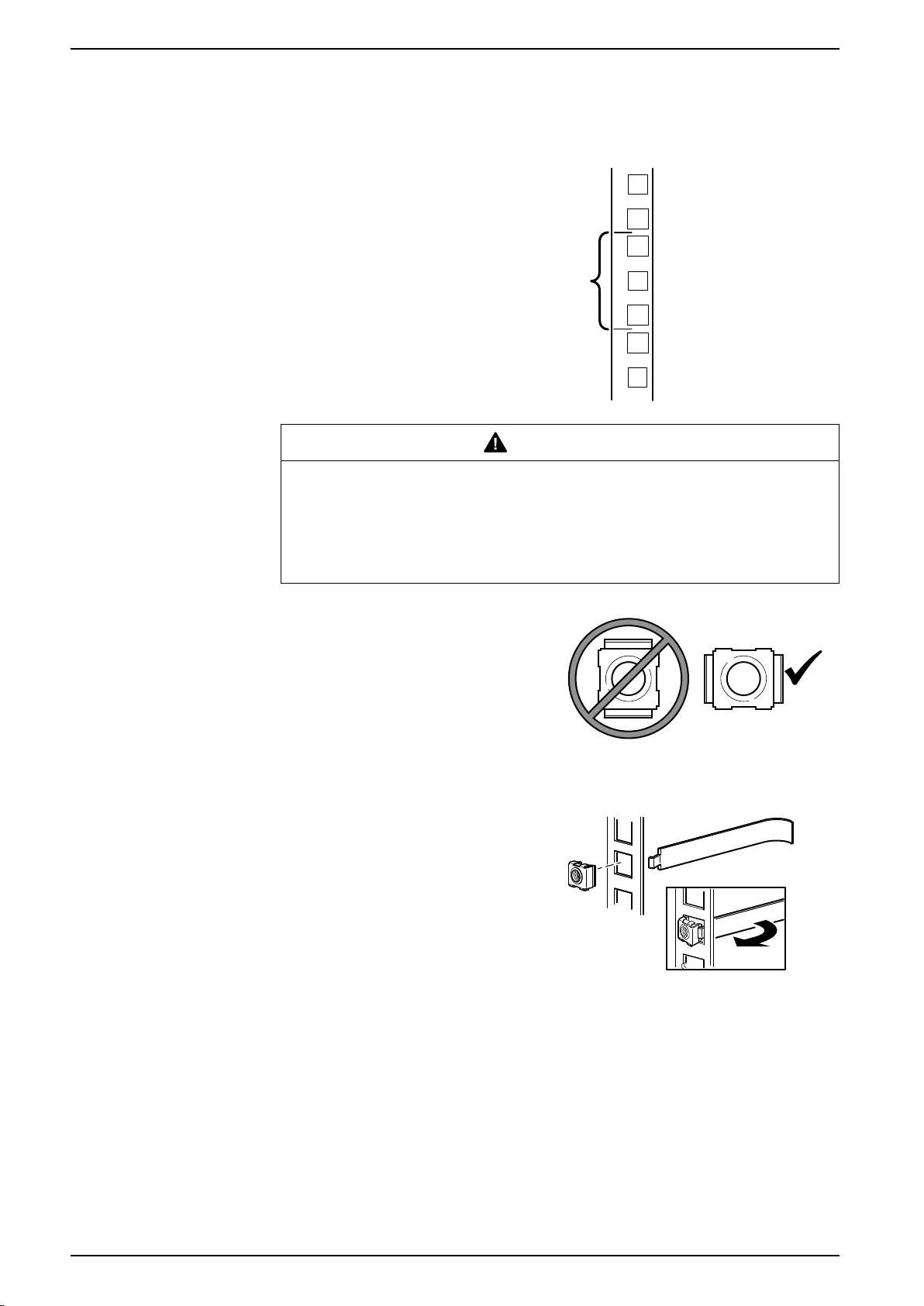

Using Cage Nuts:

• Locate the top and bottom U-space on the

vertical mounting rails. Every third hole on

the mounting rails is numbered to indicate

the middle of a U-space.

• Install the cage nuts on the interior of the

vertical mounting rail, then install the

equipment.

1U

7

6

5

ns0014a

CAUTION

FALLING EQUIPMENT HAZARD

Do NOT install cage nuts vertically with the tabs engaging the top and bottom of

the square hole.

Failure to follow these instructions can result in injury or equipment

damage.

• Install cage nuts horizontally, with the tabs

engaging the sides of the square hole.

• Install the cage nuts on the interior of the

vertical mounting rail.

ns1768a

Install a cage nut:

1. From the inside of the cabinet, insert the

cage nut into the square hole on the

vertical mounting flange.

2. Hook one of the tabs on the cage nut

through the far side of the hole.

3. Place the cage nut tool into the cage nut

from the other side of the vertical mounting

flange and pull to snap the cage nut into

position.

ns0086a

Remove a cage nut:

1. Remove any attached screw.

2. Grasp the cage nut and squeeze the tab sides. Push the cage nut

through the square hole in the vertical mounting flange to release it.

12 990–91537

Installation

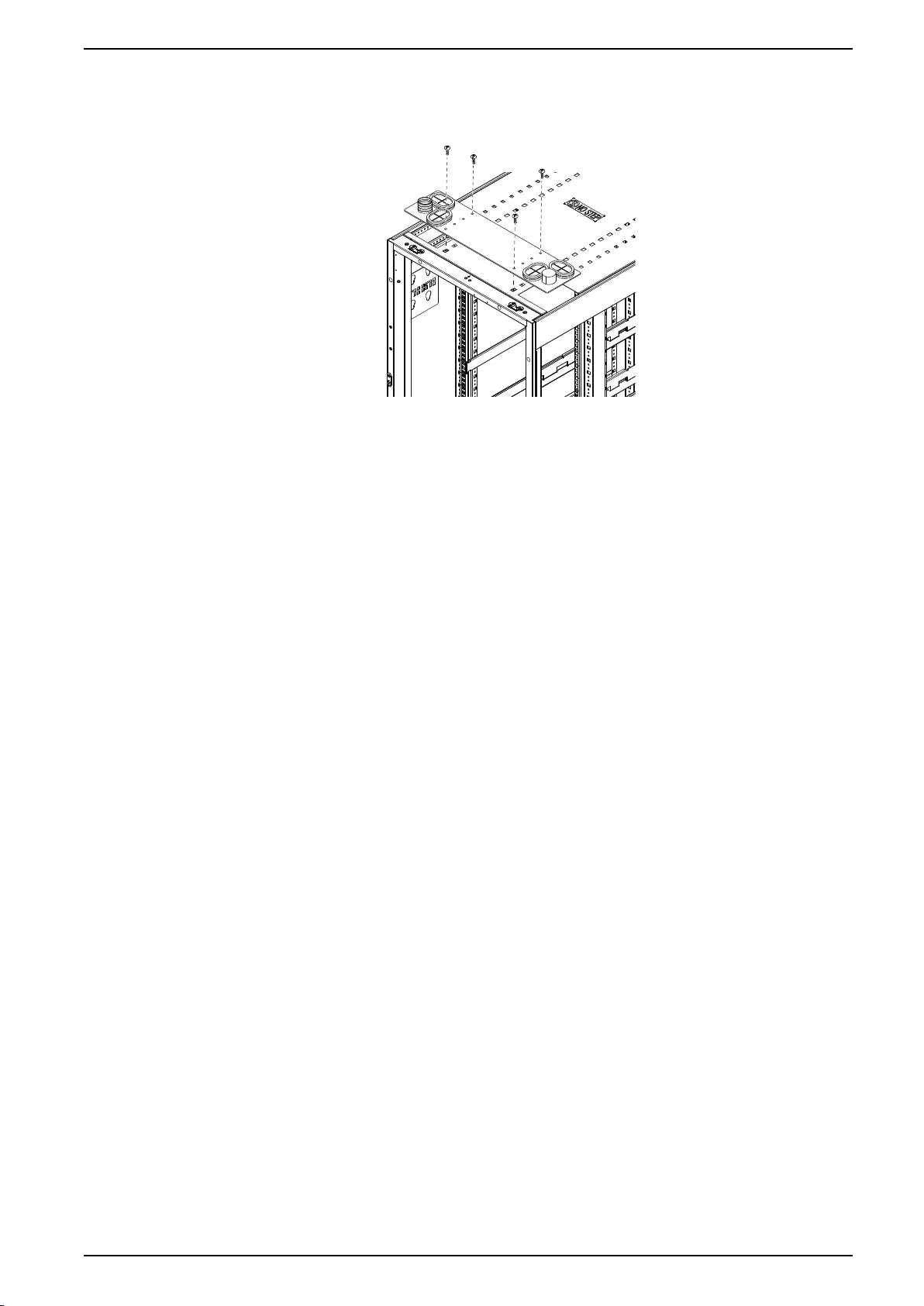

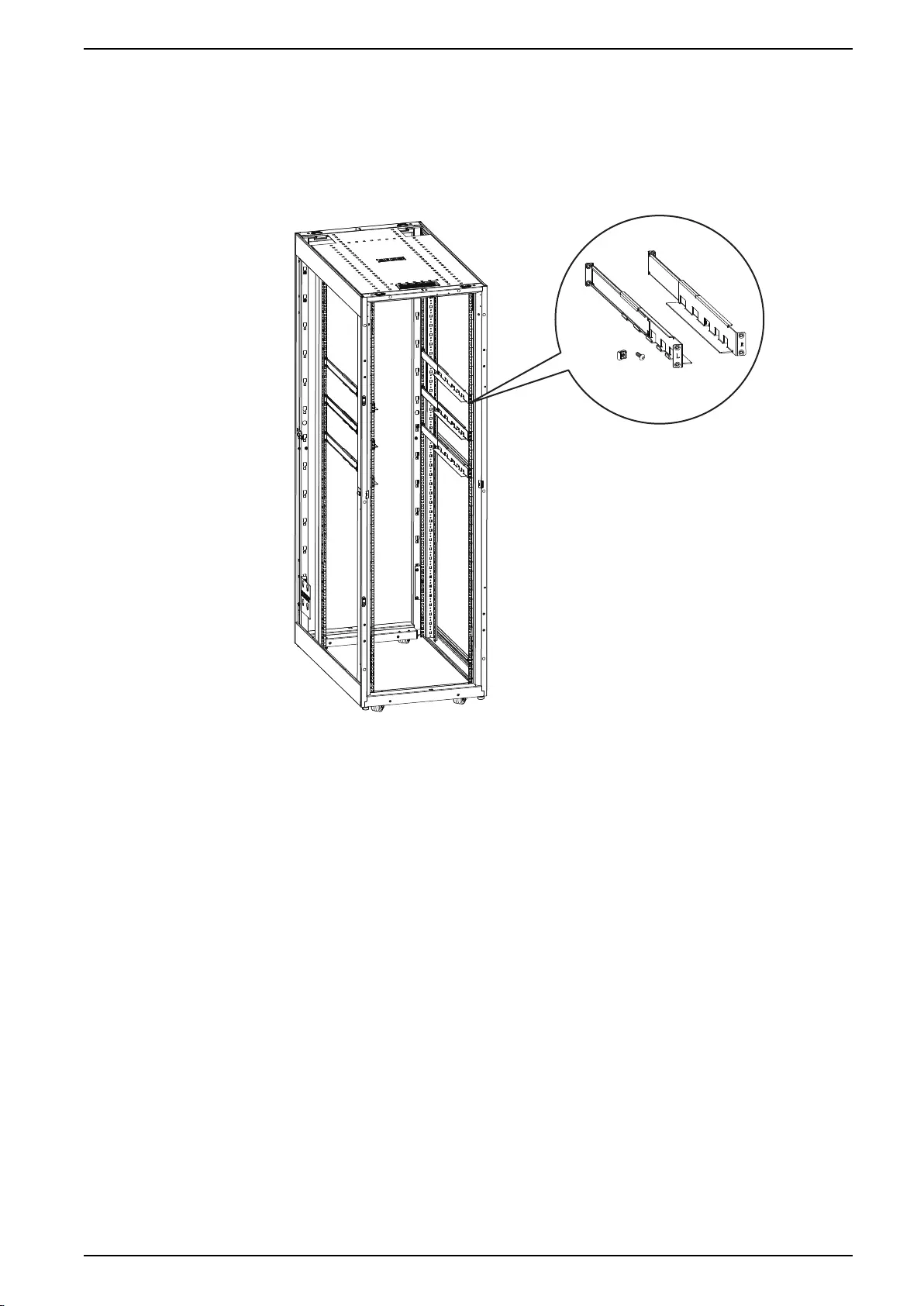

Mounting Rails

The PDP system is installed in an Easy Rack using Rail Kits SRVSRK1. The Rail

Kits include one rail for the Left side and one rail for the Right side of the rack. The

rails are clearly marked L and R. M6 cage nuts and M6 screws are included in the

kit. Position the rails in the Easy Rack at the U-spaces you have pre-determined

for this system.

ns3337a

The illustration above shows the Easy Rack with doors and side panels removed

for clarity.

990–91537 13

Installation

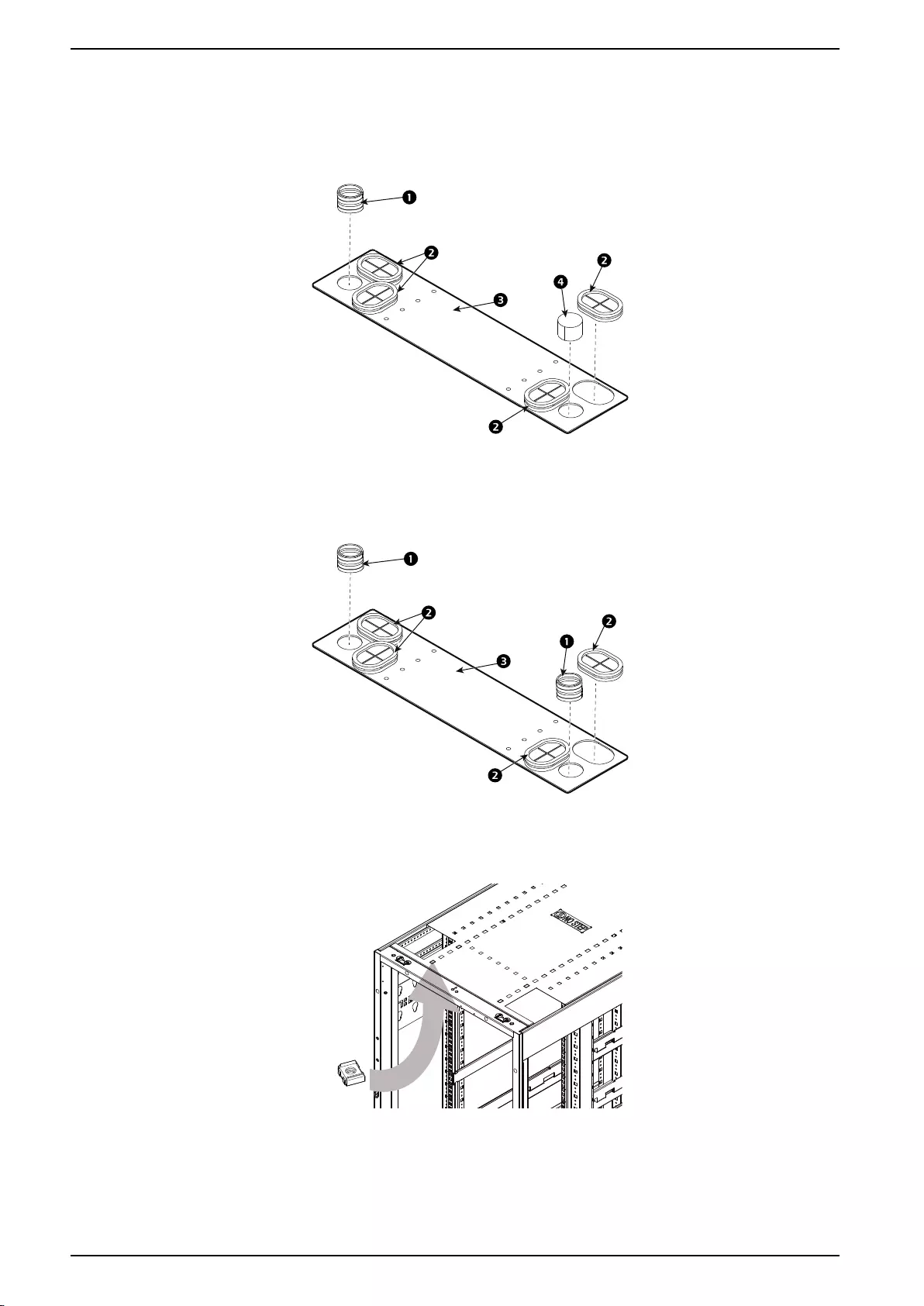

Cable Access Panel

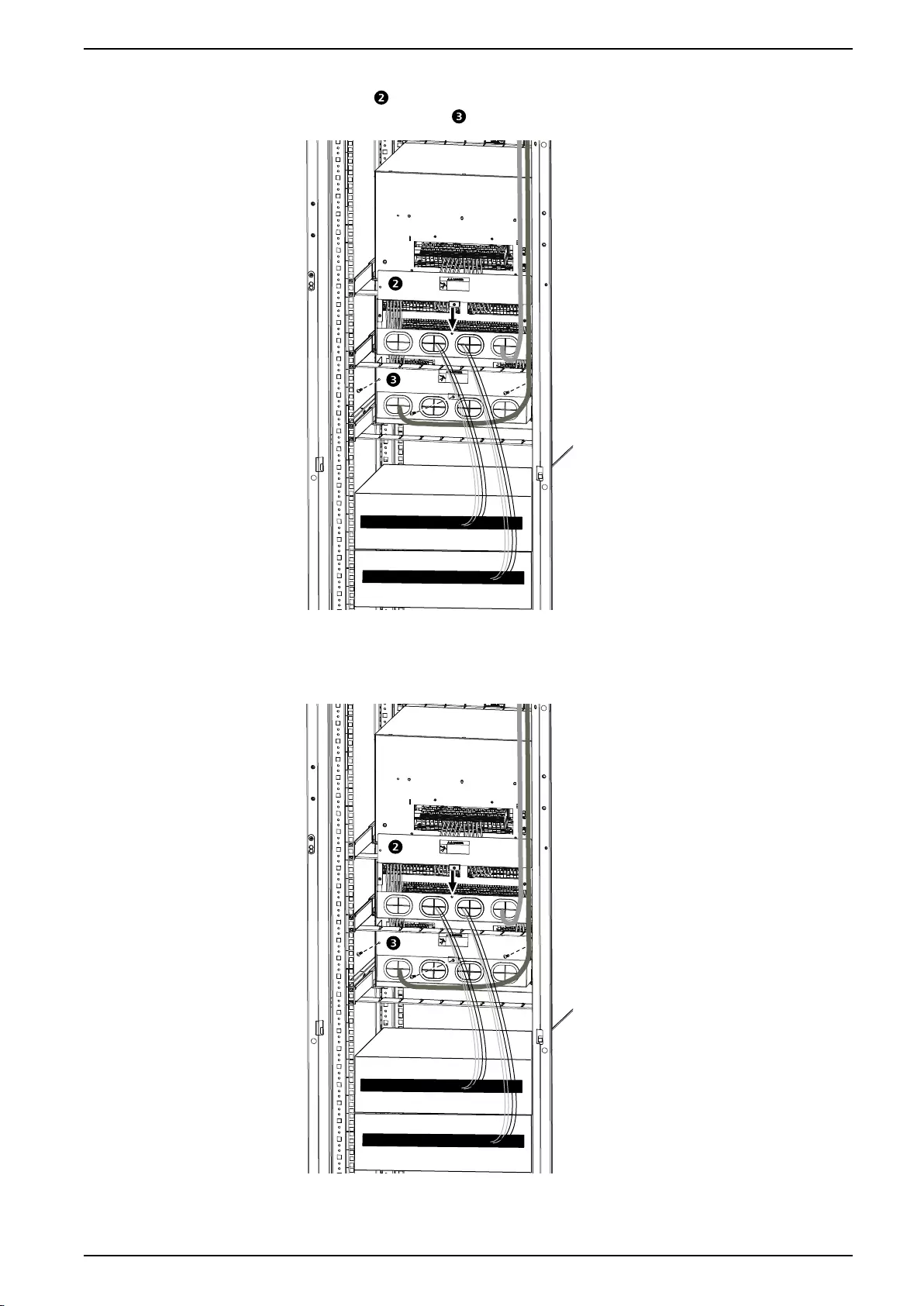

1. Install the cable protectors (2), grommet(s) (1), and grommet covers (4) as

required for your system’s configuration into the cable access panel (3).

1N Configuration:

pdx1532a

2N Configuration:

pdx1527a

2. Install four (4) cage nuts (from the hardware bag) to the roof of the Easy Rack

by inserting the cage nuts from inside the roof and pulling them through the

square holes to secure them. See the instructions in the Equipment

Installation section of this manual for more information.

ns3338a

14 990–91537

Installation

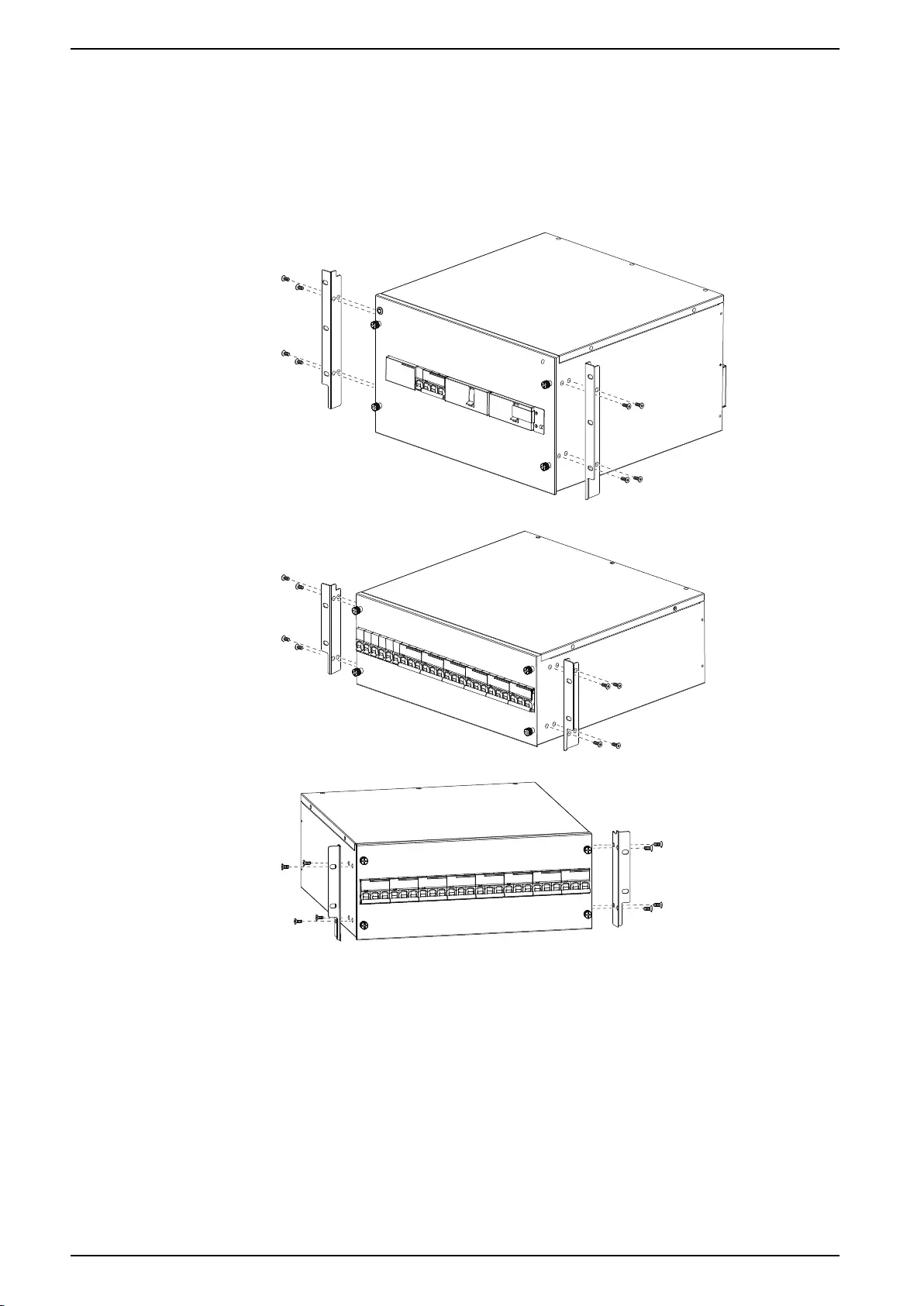

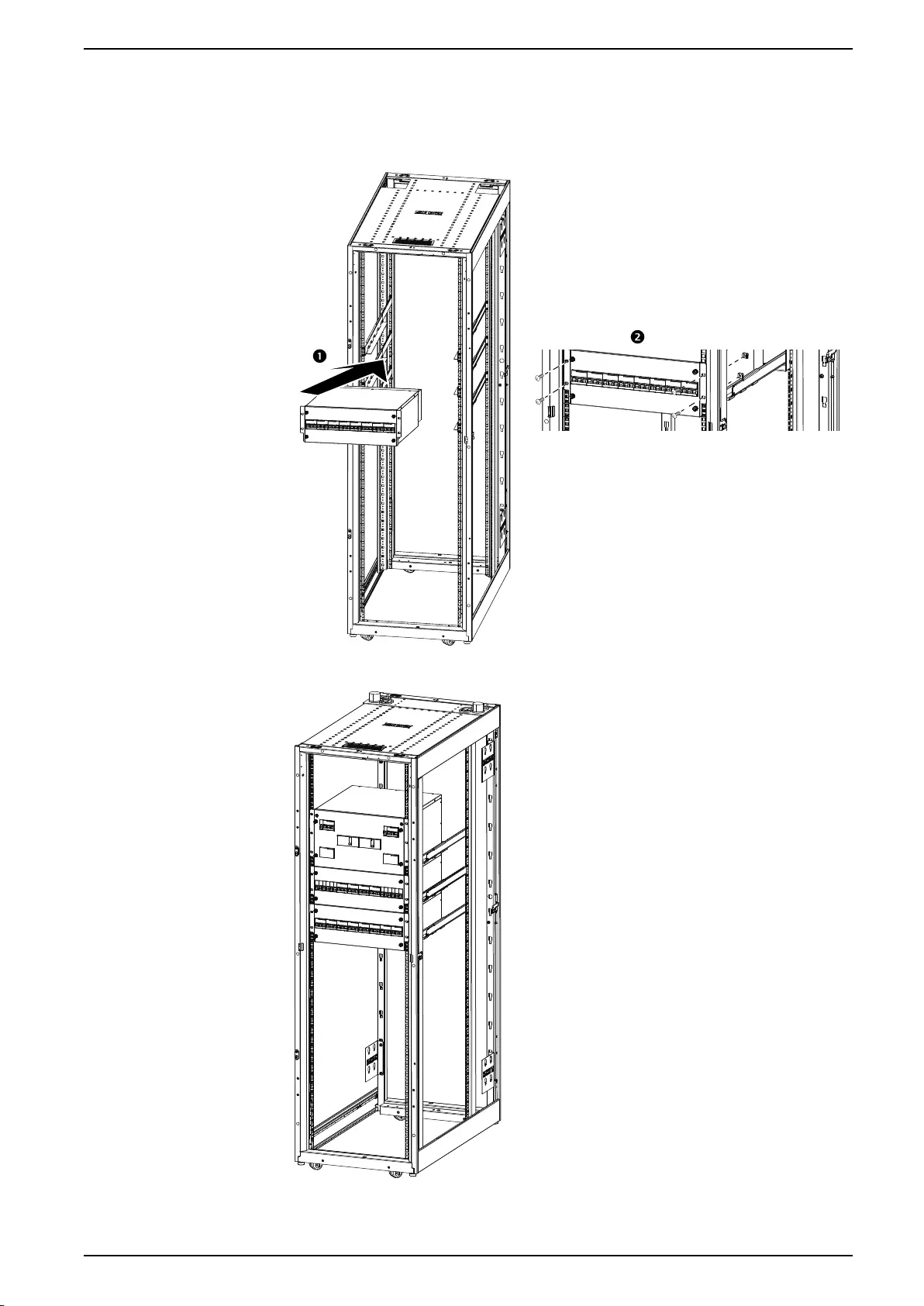

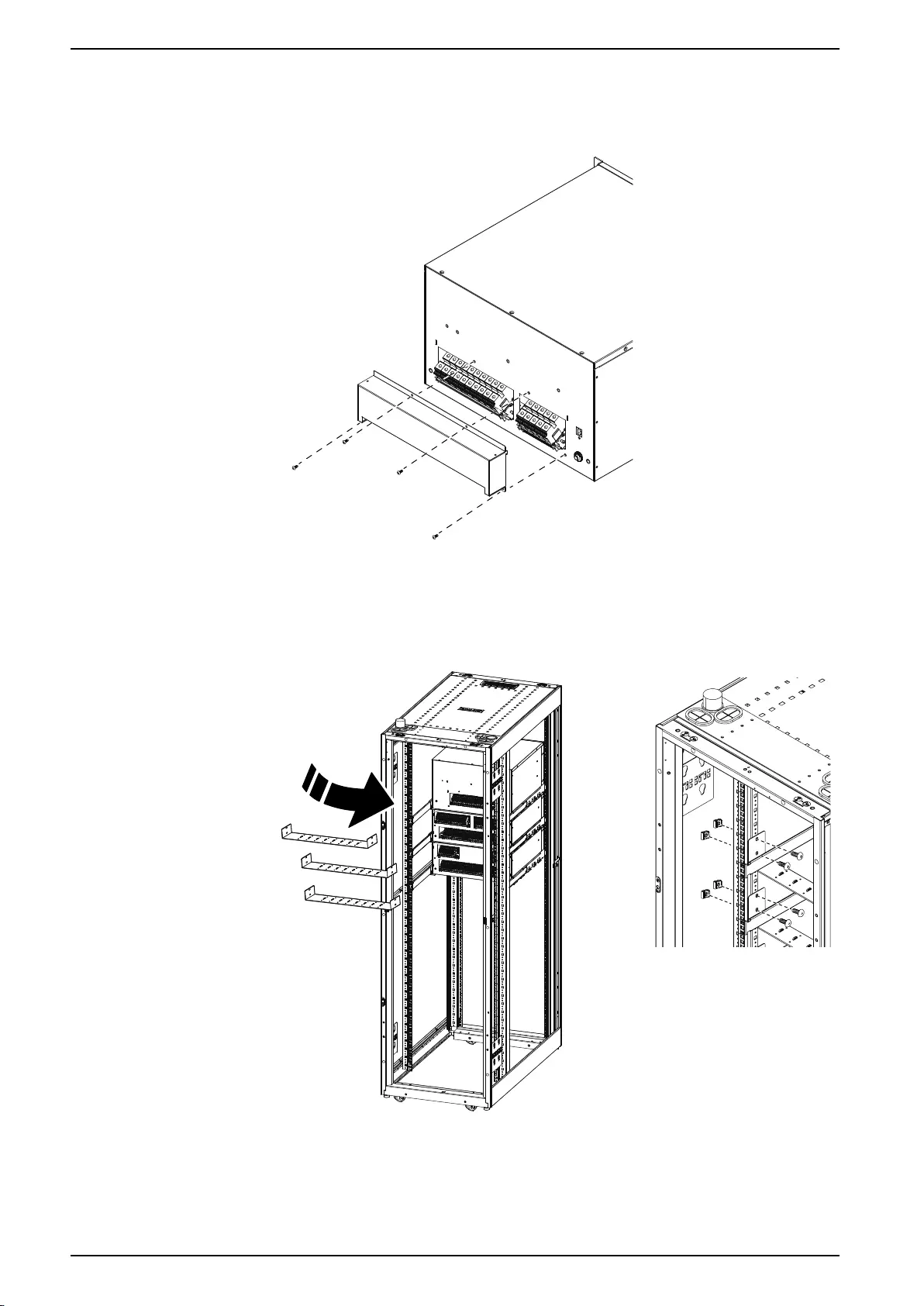

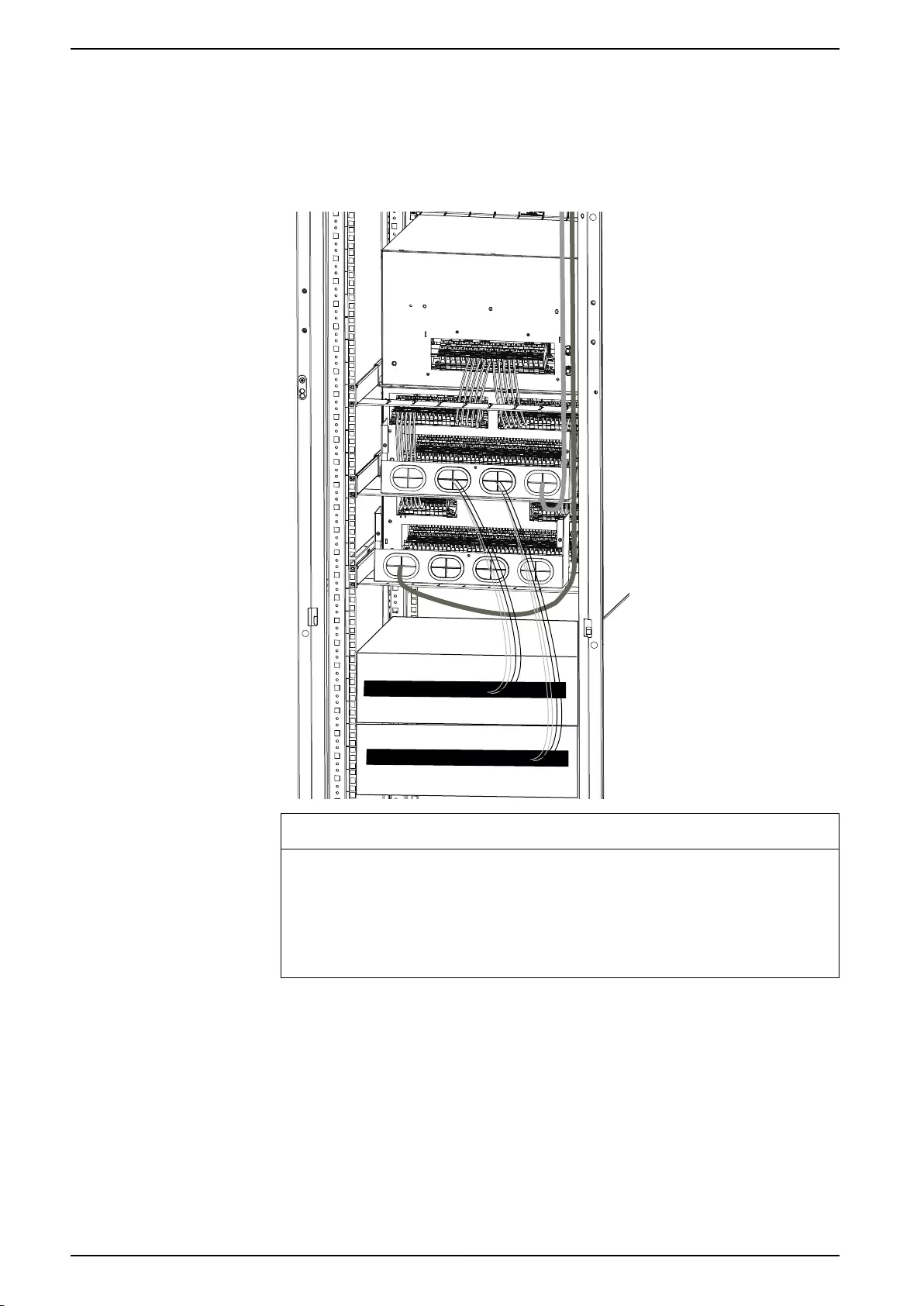

Install the System Components to the Rack

Install the system components on the rails intended for each starting with the

PDPPDU-40 in the lowest rack position. Use the M6 cage nuts and M6 screws

included in the hardware bag to secure each component to the Easy Rack.

pdx1543a

Install all three components of the PDP system in your rack.

pdx1545a

990–91537 17

Installation

Remove the Safety Cover from PDPMIB1N-40 or PDPMIB2N-20

To prepare for wiring the PDPs, remove the four (4) screws and lift the safety

cover from the back of PDPMIB1N-40 or PDPMIB2N-20.

pdx1514a

Install the Cable Managers

Use four (4) M6 cage nuts and four (4) M6 screws to install each cable manager to

the Vertical Mounting Flanges at the rear of the PDPs as shown in the illustration.

pdx1537a

18 990–91537

Installation

Configurations and Wiring

Complete wiring the PDP components using the wiring diagrams in the Power

Distribution Panel Electrical Diagrams Chapter in this manual.

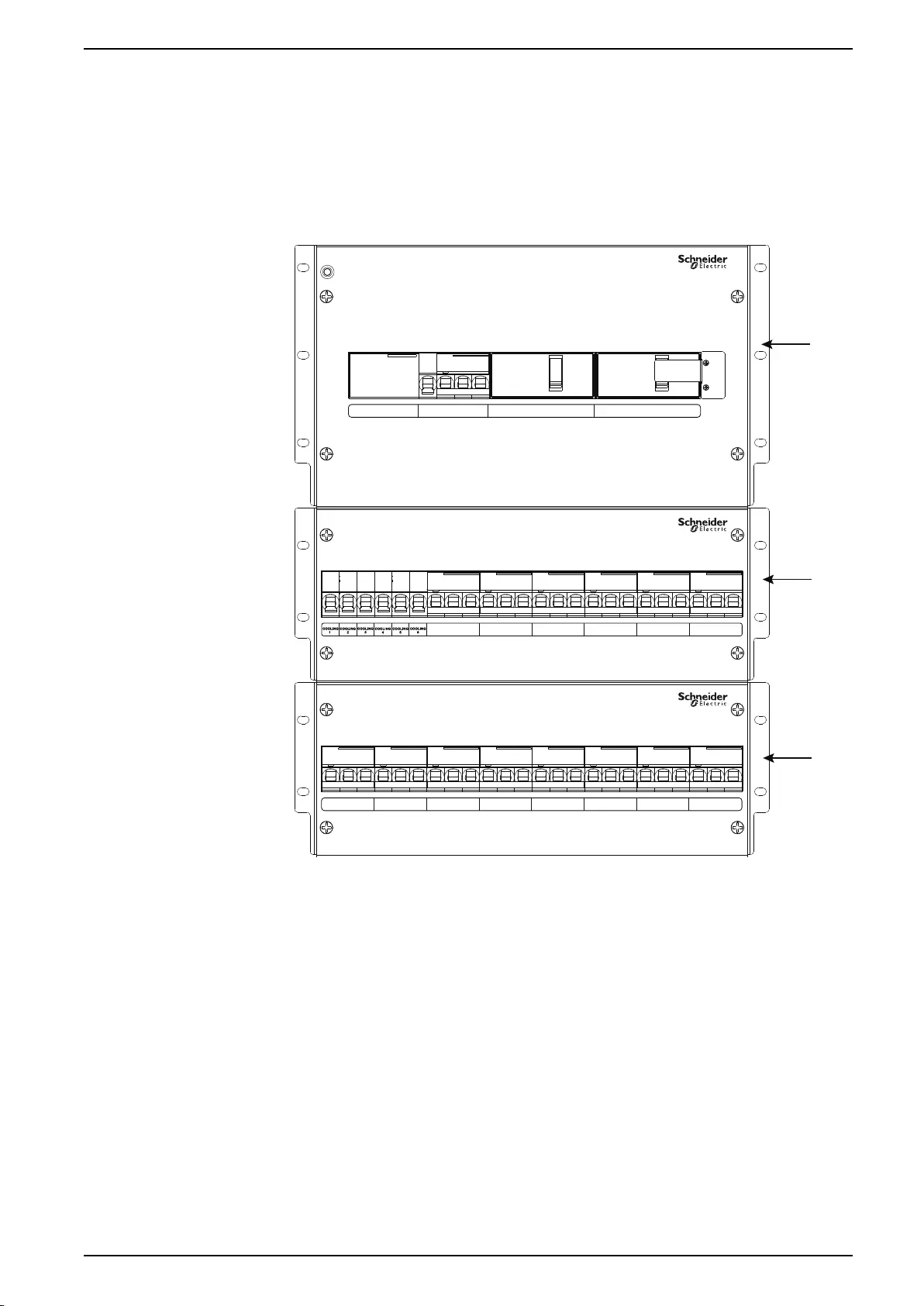

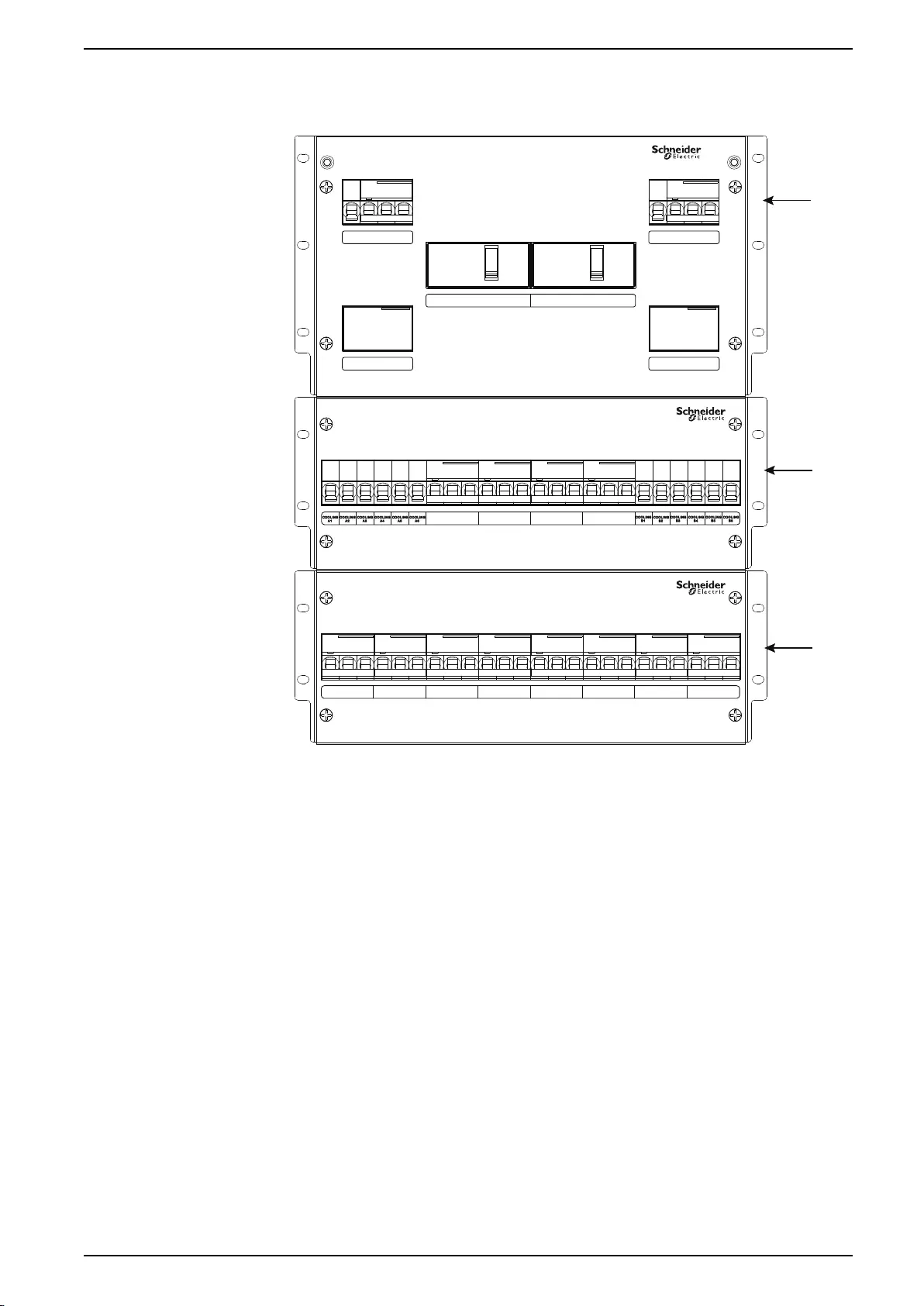

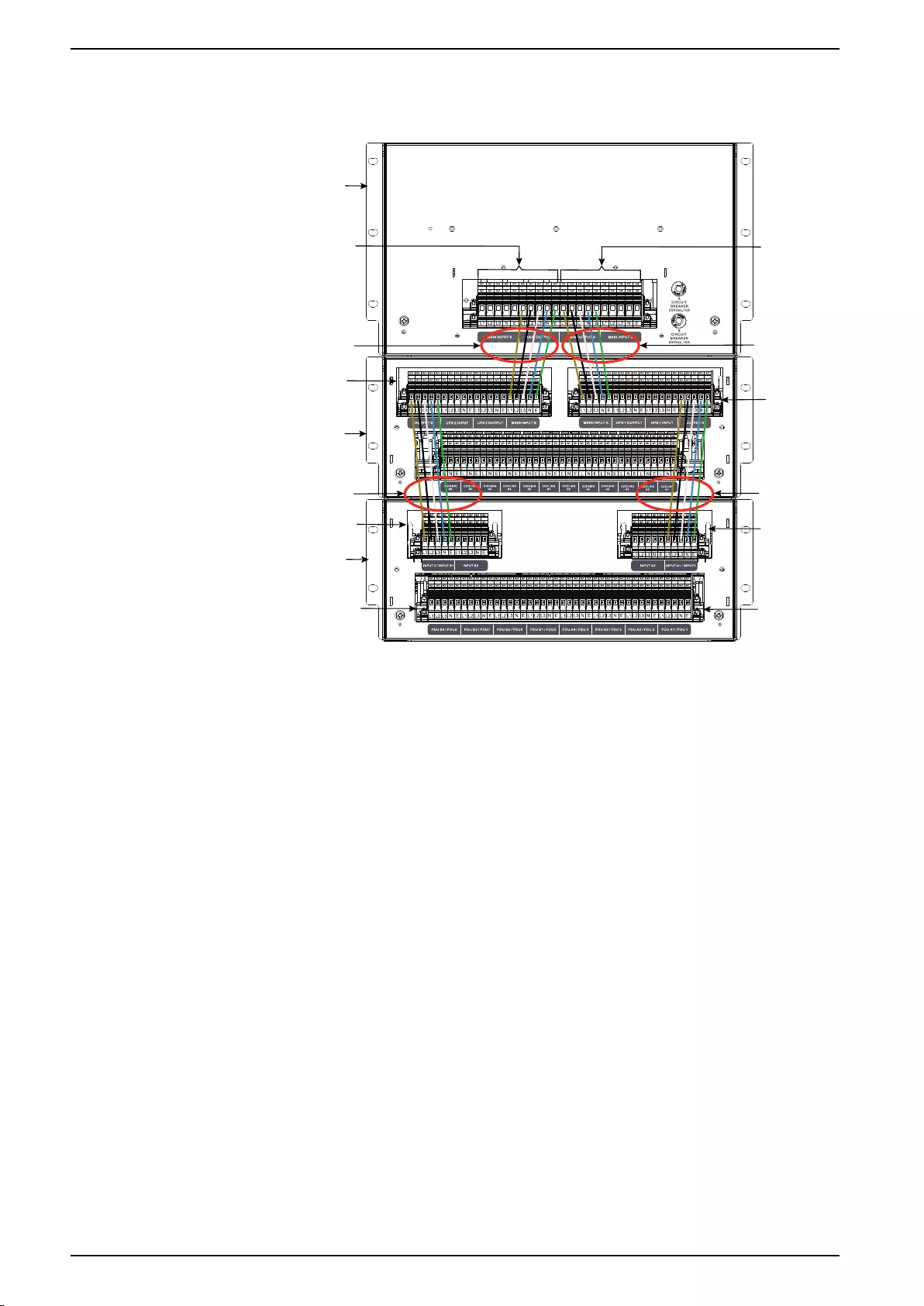

1N Configuration

Front View:

PDPMIB1N-40

PDPUPS1N-40

PDPPDU-40

pdx1500a

SPD SPD INPUT MAIN INPUT MAINTENANCE BYPASS

UPS 1

INPUT

POWER

UPS 2

INPUT

UPS 3

INPUT

UPS 1

OUTPUT

UPS 2

OUTPUT

UPS 3

OUTPUT

PDU A1 / PDU1 PDU A2 / PDU2 PDU A3 / PDU3 PDU A4 / PDU4 PDU B1 / PDU5 PDU B2 / PDU6 PDU B3 / PDU7 PDU B4 / PDU8

990–91537 19

Installation

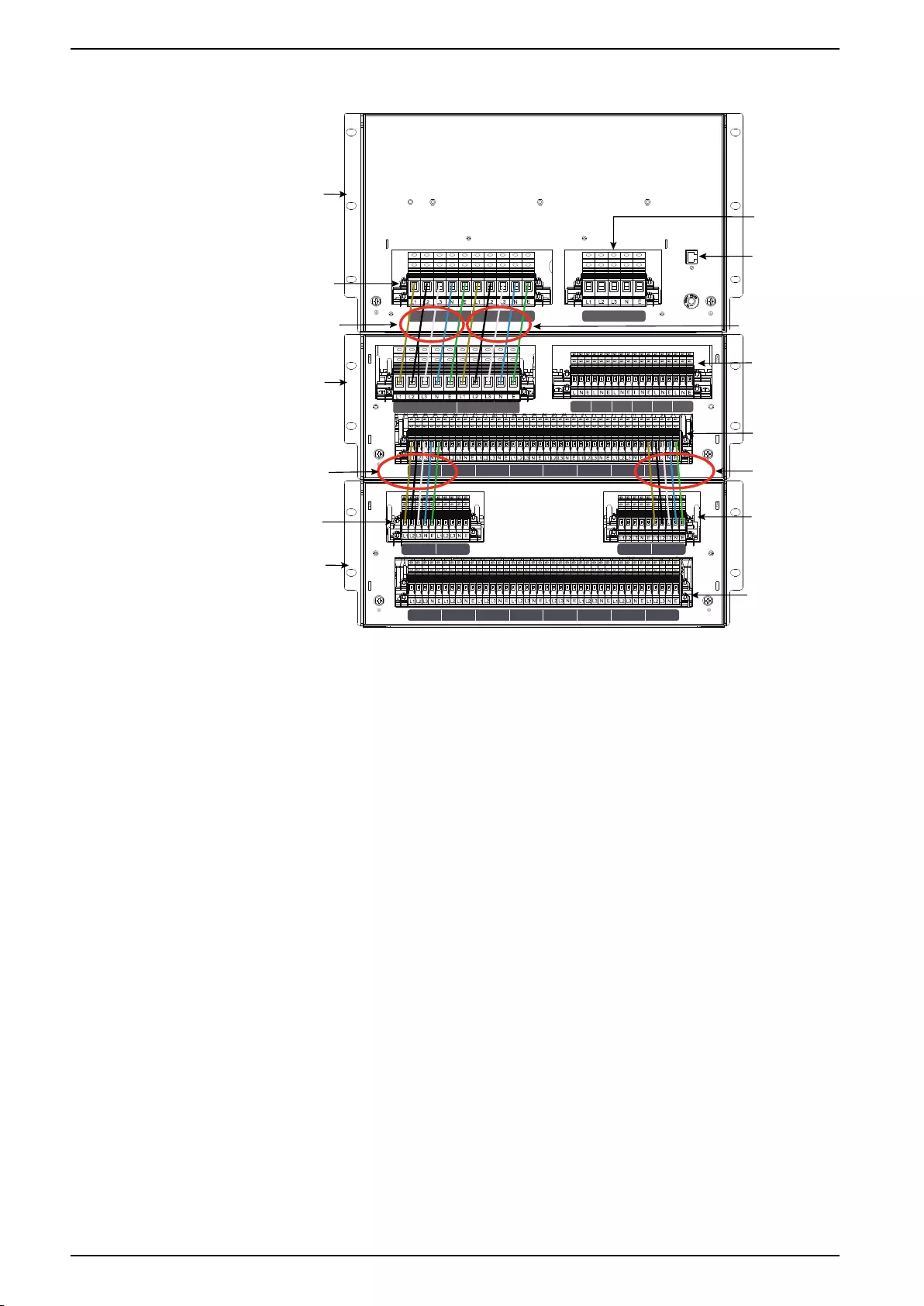

Rear View:

MAINTENANCE BYPASS OUTPUT MAIN OUTPUT

MAINTENANCE BYPASS INPUT MAIN INPUT

OUTPUT 2 UPS 3 OUTPUT UPS 2 OUTPUT UPS 1 OUTPUT UPS 3 INTPUT UPS 2 INPUT UPS 1 INPUT OUTPUT 1

COOLING

6

COOLING

5

COOLING

4

COOLING

3

COOLING

2

COOLING

1

INPUT A2 INPUT A1 / INPUT 1

PDU A1 / PDU1PDU A2 / PDU2PDU A3 / PDU3PDU A4 / PDU4PDU B1 / PDU5PDU B2 / PDU6PDU B3 / PDU7PDU B4 / PDU8

INPUT B2

INPUT 2 / INPUT B1

MAIN INPUT CIRCUIT

BREAKER

250 Vac, 10A

MBS

PORT

1N 40KW PDP ASSEMBLY & WIRING

PDPMIB1N-40

Main and Bypass

Breaker Output

Terminal

BYP OP WIRE

PDPUPS1N-40

OP 1 WIRE

PDU Input Terminals

3 Phase

PDPPDU-40

Utility Main Input Source

400 VAC, 3 Phase, 5 Wire

Bypass Breaker Sensor Output

Connect to UPS

MAIN OP WIRE

Indoor Row Cooling Terminals

1 Phase, 6 Units

Cooling6 - Cooling1

UPS Input/Output Terminals

3 Phase, 3 x Parallel Units

UPS Output (1-3) - UPS Input (1-3)

OP 2 WIRE

PDU Input Terminals

3 Phase

PDU Terminals

3 Phase, 8 Units

PDU8 - PDU1

pdx1506a

20 990–91537

Installation

2N Configuration

Front View:

PDPMIB2N-20

PDPUPS2N-20

PDPPDU-40

MAIN INPUT AMAIN INPUT A MAIN INPUT B

SPD A INPUT

POWER A

SPD B INPUT

POWER B

SPD A SPD B

UPS 2

INPUT

UPS 2

OUTPUT

UPS 1

OUTPUT

UPS 1

INPUT

PDU A1 / PDU1 PDU A2 / PDU2 PDU A3 / PDU3 PDU A4 / PDU4 PDU B1 / PDU5 PDU B2 / PDU6 PDU B3 / PDU7 PDU B4 / PDU8

990–91537 21

Installation

Rear View:

2N 20KW PDP ASSEMBLY & WIRING

PDPMIB2N-20

Utility Main Input Source B

400 VAC 3PH 5 Wire

MAIN OP B WIRE

PDPUPS2N-20

OP B WIRE

UPS B Input/Output Terminals

3 Phase, 1 Unit

UPS Output (2) - UPS Input (2)

PDPPDU-40

Utility Main Input Source A

400 VAC 3PH 5 Wire

2 PDU Output B Terminal

3 Phase

2N PDU Output B Terminals

3 Phase, 4 Units

PDUB4 - PDUB1

MAIN OP A WIRE

UPS A Input/Output Terminals

3 Phase, 1 Unit

UPS Output (1) - UPS Input (1)

OP A WIRE

2N PDU Input A Terminal

3 Phase

PDU Terminals

3 Phase, 4 Units

PDUA4 - PDUA1

pdx1507a

22 990–91537

Installation

Wiring Considerations

Wiring from the UPS should be installed through the cable protectors in the back

of the safety covers of the PDPUPS1N-40 or PDPUPS2N-20, and PDPPDU40. To

do this, place the bottom half of the safety covers on the cable managers. Do not

assemble the top half of the safety cover at this time. Do not attach the safety

covers at this time.

pdx1561a

NOTICE

• Recommended input cable size for PDPMIB1N-40 : 2AWG

• Recommended input cable size for PDPMIB2N-20: 6AWG

• Terminal accessories are provided to assemble UPS input and output

cables.

Failure to follow these instructions can result in equipment damage.

24 990–91537

Installation

NOTICE

• Recommended UPS Input and Output cable size is 10 mm² (not provided).

• Use the Accessory MBS Wire to make the connection from the MBS Port on

PDPMIB1N-40 to the UPS MBS Port on the UPS.

• Refer to the UPS Installation manual for complete instructions.

Failure to follow these instructions can result in equipment damage.

MBS Wire for PDPMIB1N-40

UPS MBS

PDP MBS

PDP and UPS MBS Ports

MBS

PORT

MBS

PORT

UPS

PORT

PDPMIB1N-40

UPS

pdx1567a

Maintenance

Bypass Breaker

Sensor Output

990–91537 25

Installation

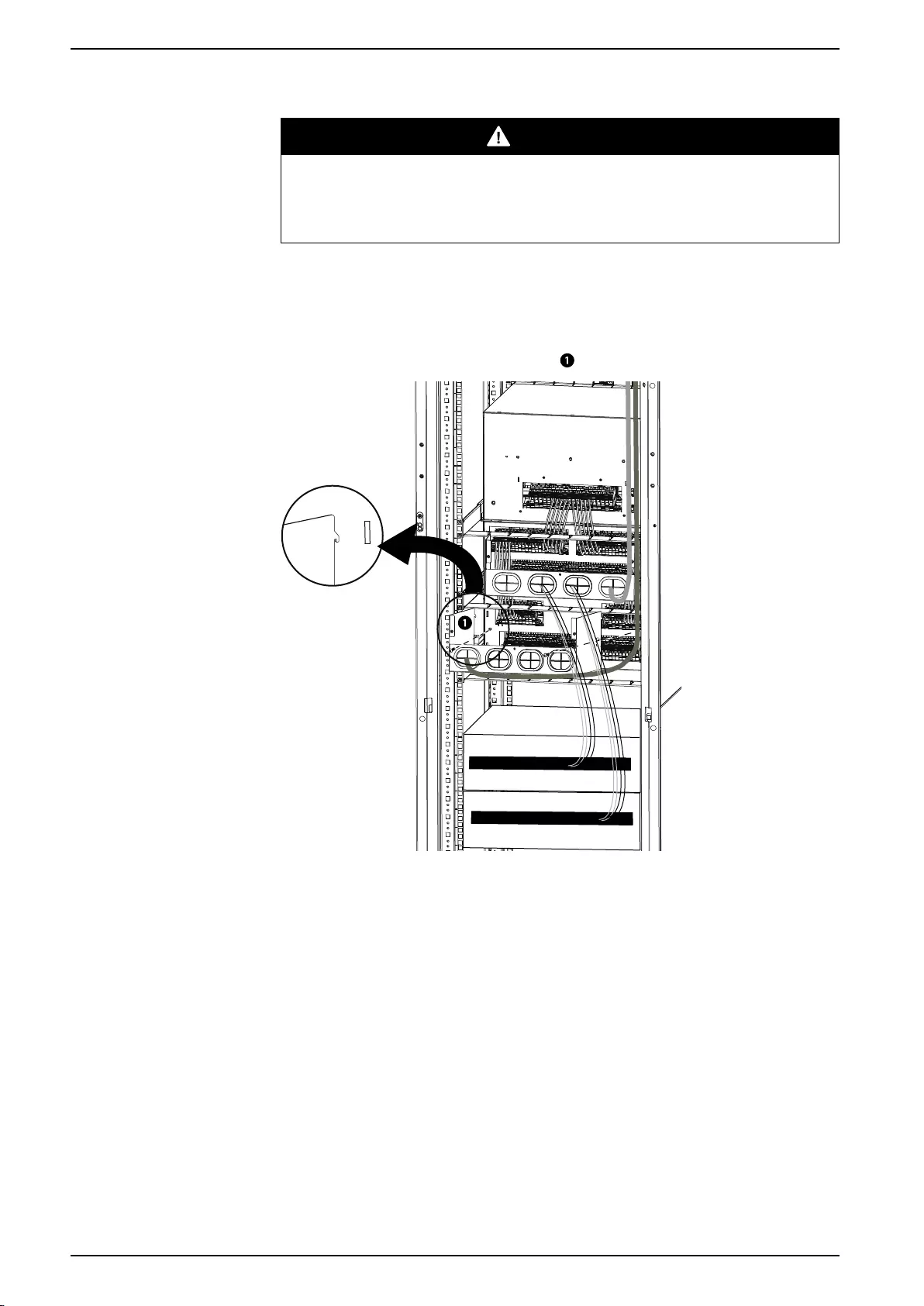

Install the Safety Covers

DANGER

SHOCK HAZARD

Do not operate this equipment with safety covers removed.

Failure to follow these instructions will result in death or serious injury.

All three safety covers must be installed to the rear of the PDPs.

The the bottom halves of the safety covers for PDPUPSN1–40, PDPUPSN2–20,

and PDPPDU-40 are attached to the back of the PDPs with 2 screws and tabs that

fit into slots in the back of the PDPs. See in the illustration below.

pdx1565a

26 990–91537

Installation

The top halves of the safety covers are now installed. Position the top half to the

bottom half . Use the three screws (provided) to attach the top half to the bottom

half of the safety cover .

pdx1562a

Install the safety cover to PDPMIB1N-40 or PDPMIB2N-20. Insert the tabs on the

safety covers into the slots in the back of the PDP then use the four (4) screws

(provided) to secure the safety cover to the rear of the PDP.

pdx1562a

990–91537 27

System Startup

System Startup

System Cabinet Preparations

1. Ensure the PDPs are properly installed in the rack. Refer to the installation

instructions.

2. Ensure the PDP power cables have been properly installed. See the wiring

and terminal allocation drawing.

3. Ensure the UPS and External Battery Packs have been properly installed in

the rack. Refer to the UPS installation manual for installation instructions.

4. Ensure the Cooling System is properly installed and cooling power input

cables are connected to the assigned power terminals. Refer to the wiring

and terminal allocation drawing.

5. Ensure the PDU cables have been properly installed to the assigned power

terminals. See the PDP wiring and terminal allocation drawing.

6. Connect the PDP Main Input Cable to the assigned terminals and the Main

Utility Distribution Panel. See the PDP wiring and terminal allocation drawing.

System Inspection

1. Check, measure, and confirm that the upstream mains voltage and frequency

are normal. Ensure there are no wiring errors or anomalies.

2. Check, measure, and confirm that the distribution cables of the UPS and PDP

are correctly connected.

3. Check that the air conditioner is charged with refrigerant.

4. Check that all the communication cables are connected correctly according to

the wiring diagram.

5. Check that the air conditioner pipes are properly connected and that there are

no leaks.

6. Verify that the power terminal connections are connected properly and the

screws are torqued to the correct rating.

Startup and Commissioning

1. Close the Main Utility Power Distribution Breaker. Check that the PDP1 light

is ON.

2. Close the UPS External Battery Circuit Breaker.

3. Close the UPS INPUT MCB. Power ON the UPS. Then, check that the UPS

output voltage and frequency is normal without any fault indicator.

4. Close all UPS OUTPUT MCBs. Close all PDU MCBs and verify all output

voltages are within normal operating range.

5. Close all Indoor and Outdoor Cooling MCBs and verify successful Cooling

System Start-up.

6. Verify Cooling Performance.

28 990–91537

Maintenance Bypass Procedure

Maintenance Bypass Procedure

1N Maintenance Bypass Procedure

This procedure is for the UPS system in the maintenance bypass-operating mode

(System is on External Maintenance Bypass) with 1N input wiring configuration.

1. Remove the cover on the Maintenance Bypass MCB. This will force the

UPS to automatically switch to operate in Static Bypass Mode. Check and

ensure that the UPS is operating in Static Bypass Mode.

2. Turn ON the Maintenance Bypass MCB.

3. Turn OFF the UPS INPUT MCB and UPS OUTPUT MCB.

4. Turn OFF the UPS and disconnect the Input and Output wiring in the PDP

rear panel.

5. Turn OFF all External Battery Pack Circuit Breakers.

6. Disconnect the UPS Battery Cable.

7. Allow a service engineer to replace or repair the UPS.

8. Install the UPS and connect the Input and Output wiring to the PDP rear

panel.

9. Install the UPS External Battery Pack Cable.

10. Verify that all wiring installations are connected properly.

11. Turn ON External Battery Pack MCB.

12. Turn ON the UPS INPUT MCB and Power ON the UPS.

13. Set the UPS to bypass mode. Follow the instructions in your UPS manual.

14. Turn ON the UPS OUTPUT MCB.

15. Turn OFF the Maintenance Bypass MCB and install the cover.

16. Turn ON the UPS and verify that the UPS operation and the Output voltage is

within normal operating range.

990–91537 29

Maintenance Bypass Procedure

2N Maintenance Bypass Procedure

This procedure is for placing the UPS system in the Maintenance Bypass-

Operating Mode (the System is on External Maintenance Bypass) in systems with

the 2N input wiring configuration.

1. Turn OFF the UPS INPUT MCB and the UPS OUTPUT MCB.

2. Turn OFF the UPS.

3. Turn OFF all External Battery Pack Circuit Breakers.

4. Disconnect the Input and Output wiring in the PDP rear panel.

5. Disconnect the UPS Battery Cable.

6. Allow a service engineer to repair or replace the UPS.

7. Install the UPS and connect the Input and Output wiring to the PDP rear

panel.

8. Install UPS External Battery Pack Cable.

9. Verify that all wiring installations are connected properly.

10. Turn ON the External Battery Pack MCB.

11. Turn ON the UPS INPUT MCB and Power ON the UPS.

12. Turn ON the UPS OUTPUT MCB.

13. Turn ON the UPS and verify the UPS operation and the Output Voltage is

within normal operating range.

30 990–91537

Troubleshooting

Troubleshooting

Problem Possible Cause Solution

Ambient high temperature

alarm

Cooling unit does not supply

cold air

Ensure no alarms are indicated

on the cooling unit’s Web UI or

display. If there are no alarms,

call the Schneider Electric

service hotline.

System overload Confirm that the actual load is

over the rated power. If an

overload situation exists, call

the Schneider Electric service

hotline.

The rack doors are not

properly closed, causing the

cooling leakage.

Check the rack doors and

confirm that all doors are

closed properly.

Excessively high external

ambient temperature.

Confirm the high-temperature

alarm threshold of the

temperature sensor is

reasonable and the ambient

temperature is exceeding the

threshold setting. Call the

Schneider Electric service

hotline.

Door sensor alarm The sealed doors of the rack

are not closed.

Close all the doors properly. If

closing the doors does not

eliminate the alarm call the

Schneider Electric service

hotline.

Interior light does not illuminate

when the door is opened.

The door sensor is out of

position to make contact.

Check that no cables or

equipment in the rack are

interfering with the door

sensor. If no interference is

detected, and the light is still

off, call the Schneider Electric

service hotline.

Power cable to the interior light

is disconnected or loose.

Ensure that the cable is

properly connected. If the

cable connection is secure and

the light is still off, call the

Schneider Electric service

hotline.

No power on the PDU Breaker The UPS is not turned on. Check the UPS display to

ensure the UPS is turned on. If

not, turn the UPS on.

The Main PDP1 and UPS MCB

is not closed.

Close the Main PDP1 and UPS

MCB.

Power cable connection to the

PDP is loose.

Secure the power cable

connection to the PDP.

Emergency door opening does

not activate during an

overtemperature protection

event.

Temperature sensor or door

sensor error.

Check the temperature and

door sensors. Replace the

sensors.

Emergency door power supply

or cable error.

Ensure the emergency door

power supply and cable

assembly are properly

connected and functioning

properly. If the power supply or

cable assembly are not

functioning, call the Schneider

Electric service hotline.

Cooling alarm Internal alarm event Call the Schneider Electric

service hotline.

990–91537 31

Troubleshooting

UPS alarm Internal alarm event Call the Schneider Electric

service hotline.

UPS overload alarm The load exceeds the

maximum power threshold

setting.

Check and confirm that the

actual total power load does

not exceed the threshold

setting. If the power load

exceeds the threshold setting,

call the Schneider Electric

service hotline.

32 990–91537

Specifications

Specifications

PDPMIB1N-40

AC Nominal Input Voltage 3ɸ 5–Wire 400 VAC

AC Input Voltage Range 380–415 VAC

Power Rating 40 kW

Maximum Input Breaker

Current

Input Voltage = 3ɸ 380 V 80 A

Input Frequency Range 50/60 Hz

Power Input Redundancy Single Input

System Load Redundancy N, N+1

Main Input Breaker 4 Poles 80 A

UPS Maintenance Bypass

Switch

4 Poles 80 A

SPD Breaker 4 Poles 40 A

SPD 3 Poles + N 40 A

PDPMIB2N-20

AC Nominal Input Voltage 3ɸ 5–Wire 400 VAC

AC Input Voltage Range 380–415 VAC

Power Rating 20 kW

Maximum Input Breaker

Current

40 A

Input Frequency Range 50/60 Hz

Power Input Redundancy Dual Input

System Load Redundancy N + N

Main Input Breaker Input 1 4 Poles 40 A

Main Input Breaker Input 2 4 Poles 40 A

SPD Breakers (Qty 2) 4 Poles 40 A

SPD (Qty 2) 3 Poles + N 40 A

PDPUPS1N-40

AC Nominal Input Voltage 3ɸ 5–Wire 400 VAC

AC Input Voltage Range 380–415 VAC

Power Rating 40 kW

Maximum Input Breaker

Current

80 A

Input Frequency Range 50/60 Hz

Power Input Redundancy Single Input

System Load Redundancy 1N, N+1

UPS Breakers (Qty 6) 3 Poles IN = 3, OUT = 3 40 A

990–91537 39

Specifications

1PH Indoor Cooling Breakers

(Qty 3)

1 Pole + N 32 A

1PH Indoor Cooling Breakers

(Qty 3)

1 Pole + N 32 A

PDPUPS2N-20

AC Nominal Input Voltage 3ɸ 5–Wire 400 VAC

AC Input Voltage Range 380–415 VAC

Power Rating 20 kW

Maximum Input Breaker

Current

40 A

Input Frequency Range 50/60 Hz

Power Input Redundancy Dual Input

System Load Redundancy N + N

UPS Breakers (Qty 4) 3 Poles IN = 2, OUT = 2 40 A

1PH Indoor Cooling Breakers

(Qty 6)

1 Pole + N 32 A

1PH Indoor Cooling Breakers

(Qty 6)

1 Pole + N 32 A

PDPPDU-40

AC Nominal Input Voltage 3ɸ 5–Wire 400 VAC

AC Input Voltage Range 380–415 VAC

Power Rating 40 kW

Maximum Input Current 80 A

Input Frequency Range 50/60 Hz

Power Input Redundancy Dual Input

System Load Redundancy N + N

PDU Breakers (Qty 8) 3 Poles 25 A

40 990–91537

Two-Year Factory Warranty

Two-Year Factory Warranty

for PDPMIB1N-40, PDPMIM2N-20, PDPUPS1N-40, PDPUPS2N-20, PDPPDU-40

The limited warranty provided by Schneider Electric in this Statement of Limited

Factory Warranty applies only to products you purchase for your commercial or

industrial use in the ordinary course of your business.

Terms of Warranty

Schneider Electric warrants its products to be free from defects in materials and

workmanship for a period of two years from the date of purchase. The obligation of

Schneider Electric under this warranty is limited to repairing or replacing, at its

sole discretion, any such defective products. This warranty does not apply to

equipment that has been damaged by accident, negligence or misapplication or

has been altered or modified in any way. Repair or replacement of a defective

product or part thereof does not extend the original warranty period. Any parts

furnished under this warranty may be new or factory-remanufactured.

Non-transferable warranty

This warranty extends only to the original purchaser who must have properly

registered the product. The product may be registered at the Schneider Electric

website, www.se.com.

Exclusions

Schneider Electric shall not be liable under the warranty if its testing and

examination disclose that the alleged defect in the product does not exist or was

caused by end user’s or any third person’s misuse, negligence, improper

installation or testing. Further, Schneider Electric shall not be liable under the

warranty for unauthorized attempts to repair or modify wrong or inadequate

electrical voltage or connection, inappropriate on-site operation conditions,

corrosive atmosphere, repair, installation, start-up by non-Schneider Electric

designated personnel, a change in location or operating use, exposure to the

elements, Acts of God, fire, theft, or installation contrary to Schneider Electric

recommendations or specifications or in any event if the Schneider Electric serial

number has been altered, defaced, or removed, or any other cause beyond the

range of the intended use.

THERE ARE NO WARRANTIES, EXPRESS OR IMPLIED, BY OPERATION OF

LAW OR OTHERWISE, OF PRODUCTS SOLD, SERVICED OR FURNISHED

UNDER THIS AGREEMENT OR IN CONNECTION HEREWITH. SCHNEIDER

ELECTRIC DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY,

SATISFACTION AND FITNESS FOR A PARTICULAR PURPOSE. SCHNEIDER

ELECTRIC EXPRESS WARRANTIES WILL NOT BE ENLARGED, DIMINISHED,

OR AFFECTED BY AND NO OBLIGATION OR LIABILITY WILL ARISE OUT OF,

SCHNEIDER ELECTRIC RENDERING OF TECHNICAL OR OTHER ADVICE OR

SERVICE IN CONNECTION WITH THE PRODUCTS. THE FOREGOING

WARRANTIES AND REMEDIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER

WARRANTIES AND REMEDIES. THE WARRANTIES SET FORTH ABOVE

CONSTITUTE SCHNEIDER ELECTRIC’S SOLE LIABILITY AND PURCHASER’S

EXCLUSIVE REMEDY FOR ANY BREACH OF SUCH WARRANTIES.

SCHNEIDER ELECTRIC WARRANTIES EXTEND ONLY TO PURCHASER AND

ARE NOT EXTENDED TO ANY THIRD PARTIES.

IN NO EVENT SHALL SCHNEIDER ELECTRIC, ITS OFFICERS, DIRECTORS,

AFFILIATES OR EMPLOYEES BE LIABLE FOR ANY FORM OF INDIRECT,

SPECIAL, CONSEQUENTIAL OR PUNITIVE DAMAGES, ARISING OUT OF THE

USE, SERVICE OR INSTALLATION, OF THE PRODUCTS, WHETHER SUCH

DAMAGES ARISE IN CONTRACT OR TORT, IRRESPECTIVE OF FAULT,

990–91537 41

Two-Year Factory Warranty

NEGLIGENCE OR STRICT LIABILITY OR WHETHER SCHNEIDER ELECTRIC

HAS BEEN ADVISED IN ADVANCE OF THE POSSIBILITY OF SUCH

DAMAGES. SPECIFICALLY, SCHNEIDER ELECTRIC IS NOT LIABLE FOR ANY

COSTS, SUCH AS LOST PROFITS OR REVENUE, LOSS OF EQUIPMENT,

LOSS OF USE OF EQUIPMENT, LOSS OF SOFTWARE, LOSS OF DATA,

COSTS OF SUBSTITUENTS, CLAIMS BY THIRD PARTIES, OR OTHERWISE.

NO SALESMAN, EMPLOYEE OR AGENT OF BY SCHNEIDER ELECTRIC IS

AUTHORIZED TO ADD TO OR VARY THE TERMS OF THIS WARRANTY.

WARRANTY TERMS MAY BE MODIFIED, IF AT ALL, ONLY IN WRITING

SIGNED BY A SCHNEIDER ELECTRIC OFFICER AND LEGAL DEPARTMENT.

Warranty claims

Customers with warranty claims issues may access the APC by Schneider

Electric customer support network through the Support page of the APC by

Schneider Electric website, www.apc.com/support. Select your country from the

country selection pull-down menu at the top of the Web page. Select the Support

tab to obtain contact information for customer support in your region.

42 990–91537

Schneider Electric

35 rue Joseph Monier

92500 Rueil Malmaison

France

+ 33 (0) 1 41 29 70 00

www.se.com

As standards, specifications, and design change from time to time,

please ask for confirmation of the information given in this publication.

© 2021 – Schneider Electric. All rights reserved.

990–91537