Table of Contents

- Important Safety Information

- Specifications

- UPS Product Overview

- Prepare for Installation

- Connect the UPS Power Cables

- Install Backfeed Protection

- Connect the UPS Signal Cables

- Install Battery Solution

- Battery Cabinet Product Overview

- Install a Galaxy 300 Battery Cabinet (G3HTBAT1, G3HTBAT2, and G3HTBAT3)

- Prepare Galaxy 300 Battery Cabinet (1300 mm) for Cables

- Connect Battery Cables from UPS to the Galaxy 300 Battery Cabinet (1300 mm)

- Connect External Battery Temperature (ATIZ) and External Battery Breaker Signal between the UPS and the Galaxy 300 Battery Cabinet (1300 mm)

- Connect Battery and Signal Cables from the Battery Cabinet (G3HTBAT1) to a Running UPS

- Install a Battery Cabinet (SYPBV96K160HB, G55TBATL10B, and G55TBAT2L7C)

- Connect the Deep Discharge Signal Cables Between the Battery Cabinet and the UPS

- Checklist after Installation

APC G3H10KHTT9X710 User Manual

Displayed below is the user manual for G3H10KHTT9X710 by APC which is a product in the Uninterruptible Power Supplies (UPSs) category. This manual has pages.

Related Manuals

Galaxy 300

10–40 kVA

Installation

Emergency Lighting

11/2015

www.schneider-electric.com

Legal Information

The Schneider Electric brand and any registered trademarks of Schneider Electric

Industries SAS referred to in this guide are the sole property of Schneider Electric

SA and its subsidiaries. They may not be used for any purpose without the owner's

permission, given in writing. This guide and its content are protected, within the

meaning of the French intellectual property code (Code de la propriété

intellectuelle français, referred to hereafter as "the Code"), under the laws of

copyright covering texts, drawings and models, as well as by trademark law. You

agree not to reproduce, other than for your own personal, noncommercial use as

defined in the Code, all or part of this guide on any medium whatsoever without

Schneider Electric's permission, given in writing. You also agree not to establish

any hypertext links to this guide or its content. Schneider Electric does not grant

any right or license for the personal and noncommercial use of the guide or its

content, except for a non-exclusive license to consult it on an "as is" basis, at your

own risk. All other rights are reserved.

Electrical equipment should be installed, operated, serviced, and maintained only

by qualified personnel. No responsibility is assumed by Schneider Electric for any

consequences arising out of the use of this material.

As standards, specifications, and designs change from time to time, please ask for

confirmation of the information given in this publication.

10–40 kVA

Table of Contents

Important Safety Information.....................................................................5

Safety Precautions .....................................................................................6

Electrical Safety....................................................................................8

Battery Safety.......................................................................................9

Specifications ............................................................................................ 11

AC Input Specifications ............................................................................. 11

3:3 and 3:1 UPS ................................................................................. 11

AC Output Specifications ..........................................................................12

3:3 UPS .............................................................................................12

3:1 UPS .............................................................................................12

Battery Specifications ...............................................................................13

Galaxy 300 Heat Dissipation .....................................................................13

3:3 UPS .............................................................................................13

3:1 UPS .............................................................................................13

Recommended Cable Sizes ......................................................................14

Overcurrent Protection..............................................................................14

Recommended Upstream Protection ....................................................14

Recommended Downstream Protection................................................15

Torque Specifications................................................................................15

UPS Product Overview ............................................................................16

Prepare for Installation.............................................................................24

Floor Anchoring........................................................................................24

Method 1: Unlimited Space Available....................................................24

Method 2: Limited Space Available.......................................................24

Prepare UPS for Cables............................................................................26

Connect the UPS Power Cables ............................................................27

Install Backfeed Protection......................................................................30

Install External Backfeed Protection ........................................................... 30

Connect the UPS Signal Cables.............................................................32

Connect the Signal Cables to the UPS .......................................................32

Connect the EPO Cable to the UPS ...........................................................34

Connect the Optional Signal Cables...........................................................36

Install Battery Solution .............................................................................37

Battery Cabinet Product Overview .............................................................38

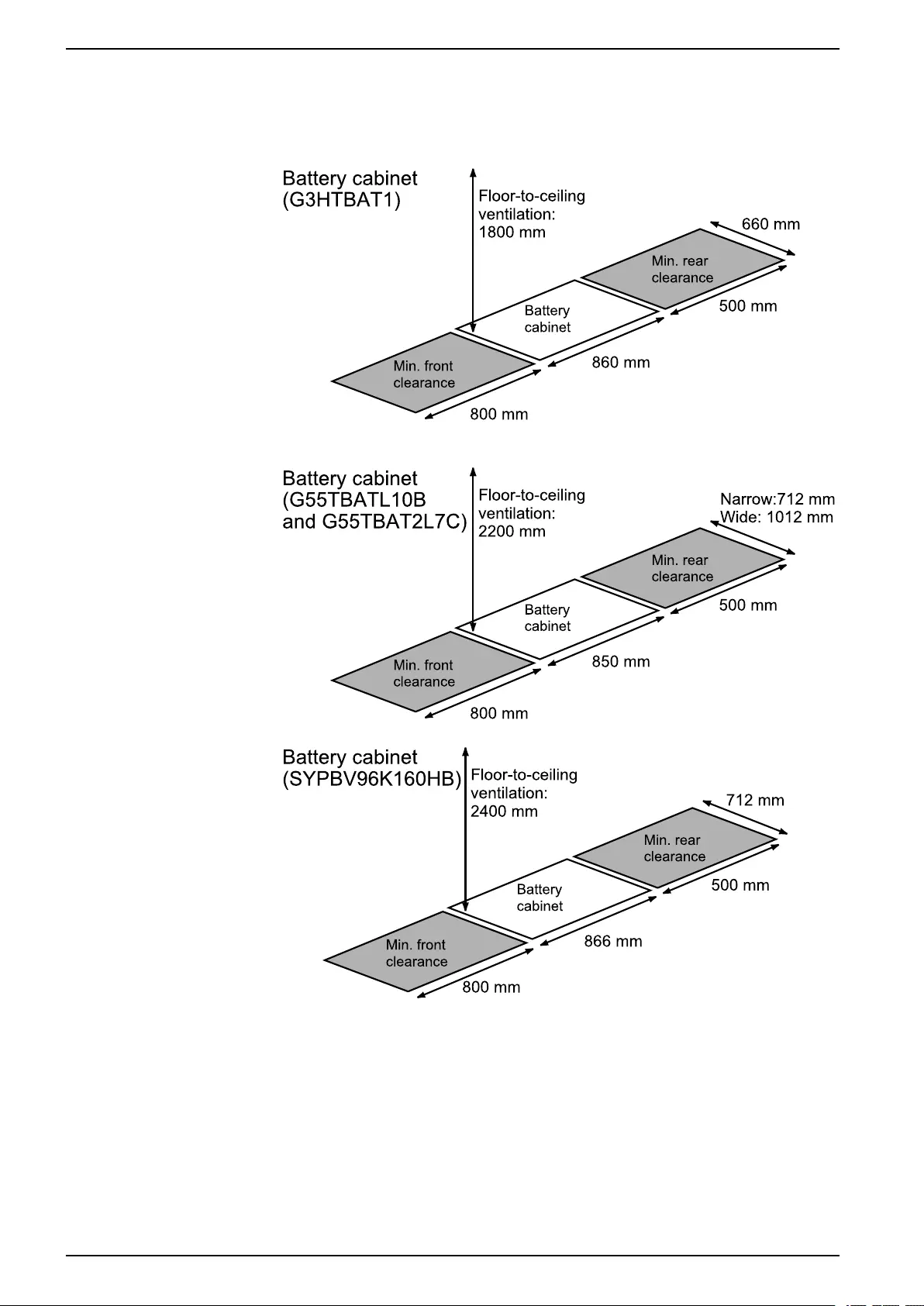

Battery Cabinet (G3HTBAT1)...............................................................38

Battery Cabinet (SYPBV96K160HB, G55TBATL10B and

G55TBAT2L7C) ..................................................................................38

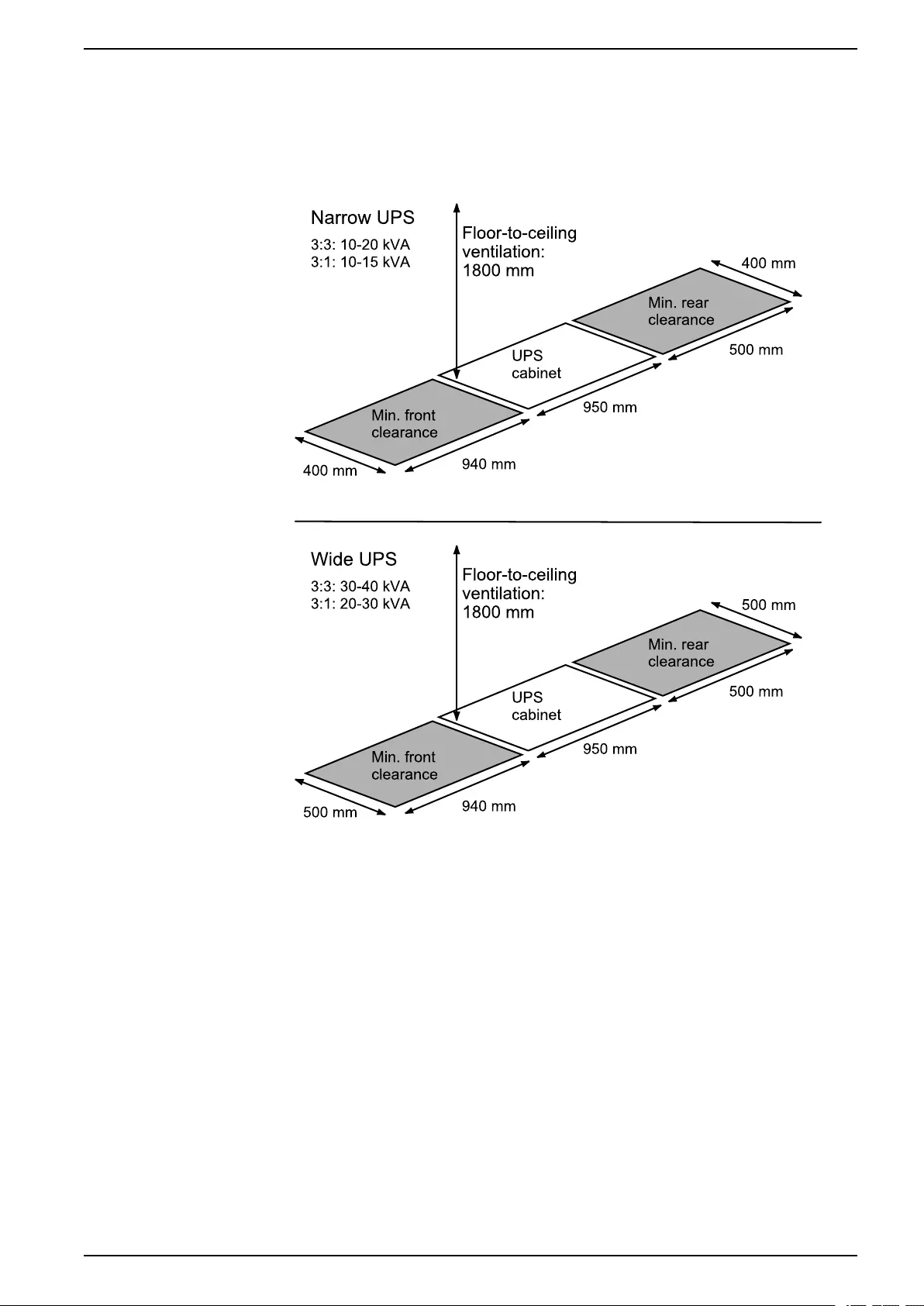

Battery Cabinet Clearance...................................................................40

Install a Galaxy 300 Battery Cabinet (G3HTBAT1, G3HTBAT2, and

G3HTBAT3) .............................................................................................41

Prepare Galaxy 300 Battery Cabinet (1300 mm) for Cables....................41

Connect Battery Cables from UPS to the Galaxy 300 Battery Cabinet

(1300 mm)..........................................................................................44

Connect External Battery Temperature (ATIZ) and External Battery

Breaker Signal between the UPS and the Galaxy 300 Battery Cabinet

(1300 mm)..........................................................................................44

990–9866–001 3

10–40 kVA

Connect Battery and Signal Cables from the Battery Cabinet

(G3HTBAT1) to a Running UPS ...........................................................46

Install a Battery Cabinet (SYPBV96K160HB, G55TBATL10B, and

G55TBAT2L7C)........................................................................................49

Remove Battery Protection on Batteries ...............................................49

Connect Battery Cables from the UPS to the Battery Cabinet

(SYPBV96K160HB, G55TBATL10B, or G55TBAT2L7C) ........................49

Connect Signal Cables Between the UPS and the Battery Cabinet

(SYPBV96K160HB, G55TBATL10B and G55TBAT2L7C) ......................50

Connect the Deep Discharge Signal Cables Between the Battery Cabinet

and the UPS.............................................................................................52

Checklist after Installation........................................................................53

4 990–9866–001

Important Safety Information 10–40 kVA

Important Safety Information

Read these instructions carefully and look at the equipment to become familiar with

it before trying to install, operate, service or maintain it. The following safety

messages may appear throughout this manual or on the equipment to warn of

potential hazards or to call attention to information that clarifies or simplifies a

procedure.

The addition of this symbol to a “Danger” or “Warning” safety

message indicates that an electrical hazard exists which will result in

personal injury if the instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages with this symbol

to avoid possible injury or death.

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

Failure to follow these instructions will result in death or serious injury.

WARNING

WARNING indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

Failure to follow these instructions can result in injury or equipment

damage.

NOTICE

NOTICE is used to address practices not related to physical injury. The safety

alert symbol shall not be used with this type of safety message.

Failure to follow these instructions can result in equipment damage.

Please Note

Electrical equipment should only be installed, operated, serviced, and maintained

by qualified personnel. No responsibility is assumed by Schneider Electric for any

consequences arising out of the use of this material.

A qualified person is one who has skills and knowledge related to the construction,

installation, and operation of electrical equipment and has received safety training

to recognize and avoid the hazards involved.

990–9866–001 5

10–40 kVA Important Safety Information

Safety Precautions

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

All safety instructions in this document must be read, understood and followed.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Read all instructions in the Installation Manual before installing or working on this

UPS system.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Do not install the UPS system until all construction work has been completed

and the installation room has been cleaned.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• The product must be installed according to the specifications and

requirements as defined by Schneider Electric. It concerns in particular the

external and internal protections (upstream breakers, battery breakers,

cabling, etc.) and environmental requirements. No responsibility is assumed

by Schneider Electric if these requirements are not respected.

• After the UPS system has been electrically wired, do not start up the system.

Startup must only be performed by Schneider Electric.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

The UPS System must be installed according to local and national regulations.

Install the UPS according to:

• IEC 60364 (including 60364–4–41- protection against electric shock, 60364–

4–42 - protection against thermal effect, and 60364–4–43 - protection against

overcurrent), or

• NEC NFPA 70, or

• Canadian Electrical Code (C22.1, Part 1)

depending on which one of the standards apply in your local area.

Failure to follow these instructions will result in death or serious injury.

6 990–9866–001

Important Safety Information 10–40 kVA

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Install the UPS system in a temperature controlled indoor environment free of

conductive contaminants and humidity.

• Install the UPS system on a non-flammable, level and solid surface (e.g.

concrete) that can support the weight of the system.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

The UPS is not designed for and must therefore not be installed in the following

unusual operating environments:

• Damaging fumes

• Explosive mixtures of dust or gases, corrosive gases, or conductive or radiant

heat from other sources

• Moisture, abrasive dust, steam or in an excessively damp environment

• Fungus, insects, vermin

• Salt-laden air or contaminated cooling refrigerant

• Pollution degree higher than 2 according to IEC 60664-1

• Exposure to abnormal vibrations, shocks, and tilting

• Exposure to direct sunlight, heat sources, or strong electromagnetic fields

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Do not drill or cut holes for cables or conduits with the gland plates installed and

do not drill or cut holes in close proximity to the UPS.

Failure to follow these instructions will result in death or serious injury.

WARNING

HAZARD OF ARC FLASH

Do not make mechanical changes to the product (including removal of cabinet

parts or drilling/cutting of holes) that are not described in the Installation Manual.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

WARNING

HAZARD OF OVERHEATING

Respect the space requirements around the UPS system and do not cover the

product’s ventilation openings when the UPS system is in operation.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

990–9866–001 7

10–40 kVA Important Safety Information

WARNING

HAZARD OF EQUIPMENT DAMAGE

Do not connect the UPS output to regenerative load systems including

photovoltaic systems and speed drives.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

Electrical Safety

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

• Electrical equipment must be installed, operated, serviced, and maintained

only by qualified personnel.

• The UPS system must be installed in a room with restricted access (qualified

personnel only).

• Apply appropriate personal protective equipment (PPE) and follow safe

electrical work practices.

• Turn off all power supplying the UPS system before working on or inside the

equipment.

• Before working on the UPS system, check for hazardous voltage between all

terminals including the protective earth.

• The UPS contains an internal energy source. Hazardous voltage can be

present even when disconnected from the utility/mains supply. Before

installing or servicing the UPS system, ensure that the units are OFF and that

utility/mains and batteries are disconnected. Wait five minutes before

opening the UPS to allow the capacitors to discharge.

• A disconnection device (e.g. disconnection circuit breaker or switch) must be

installed to enable isolation of the system from upstream power sources in

accordance with local regulations. This disconnection device must be easily

accessible and visible.

• The UPS must be properly earthed/grounded and due to a high leakage

current, the earthing/grounding conductor must be connected first.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

In systems where backfeed protection is not part of the standard design, an

automatic isolation device (backfeed protection option or other device meeting

the requirements of IEC/EN 62040–1 or UL1778 4th Edition – depending on

which of the two standards apply to your local area) must be installed to prevent

hazardous voltage or energy at the input terminals of the isolation device. The

device must open within 15 seconds after the upstream power supply fails and

must be rated according to the specifications.

Failure to follow these instructions will result in death or serious injury.

When the UPS input is connected through external isolators that, when opened,

isolate the neutral or when the automatic backfeed isolation is provided external to

the equipment or is connected to an IT power distribution system, a label must be

fitted at the UPS input terminals, and on all primary power isolators installed

remote from the UPS area and on external access points between such isolators

and the UPS, by the user, displaying the following text (or equivalent in a language

which is acceptable in the country in which the UPS system is installed):

8 990–9866–001

Important Safety Information 10–40 kVA

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Risk of Voltage Backfeed. Before working on this circuit: Isolate the UPS and

check for hazardous voltage between all terminals including the protective earth.

Failure to follow these instructions will result in death or serious injury.

Battery Safety

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Battery circuit breakers must be installed according to the specifications and

requirements as defined by Schneider Electric.

• Servicing of batteries must only be performed or supervised by qualified

personnel knowledgeable of batteries and the required precautions. Keep

unqualified personnel away from batteries.

• Disconnect charging source prior to connecting or disconnecting battery

terminals.

• Do not dispose of batteries in a fire as they can explode.

• Do not open, alter, or mutilate batteries. Released electrolyte is harmful to the

skin and eyes. It may be toxic.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Batteries can present a risk of electric shock and high short-circuit current. The

following precautions must be observed when working on batteries

• Remove watches, rings, or other metal objects.

• Use tools with insulated handles.

• Wear protective glasses, gloves and boots.

• Do not lay tools or metal parts on top of batteries.

• Disconnect the charging source prior to connecting or disconnecting battery

terminals.

• Determine if the battery is inadvertently grounded. If inadvertently grounded,

remove source from ground. Contact with any part of a grounded battery can

result in electric shock. The likelihood of such shock can be reduced if such

grounds are removed during installation and maintenance (applicable to

equipment and remote battery supplies not having a grounded supply circuit).

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

When replacing batteries, always replace with the same type and number of

batteries or battery packs.

Failure to follow these instructions will result in death or serious injury.

990–9866–001 9

10–40 kVA Important Safety Information

CAUTION

RISK OF EQUIPMENT DAMAGE

• Wait until the system is ready to be powered up before installing batteries in

the system. The time duration from battery installation until the UPS system

is powered up must not exceed 72 hours or 3 days.

• Batteries must not be stored more than six months due to the requirement of

recharging. If the UPS system remains de-energized for a long period, we

recommend that you energize the UPS system for a period of 24 hours at

least once every month. This charges the batteries, thus avoiding irreversible

damage.

Failure to follow these instructions can result in injury or equipment

damage.

10 990–9866–001

Specifications 10–40 kVA

Specifications

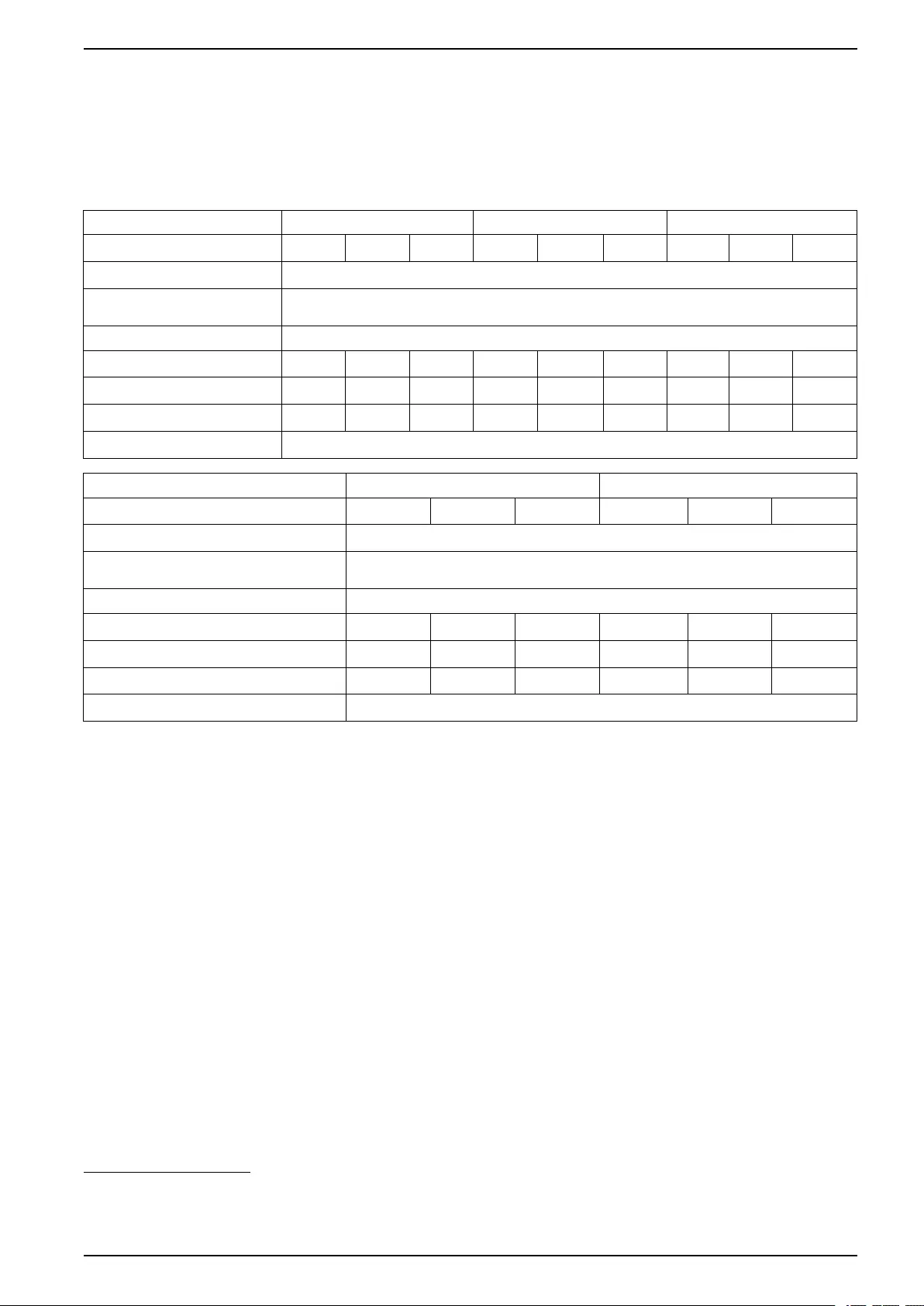

AC Input Specifications

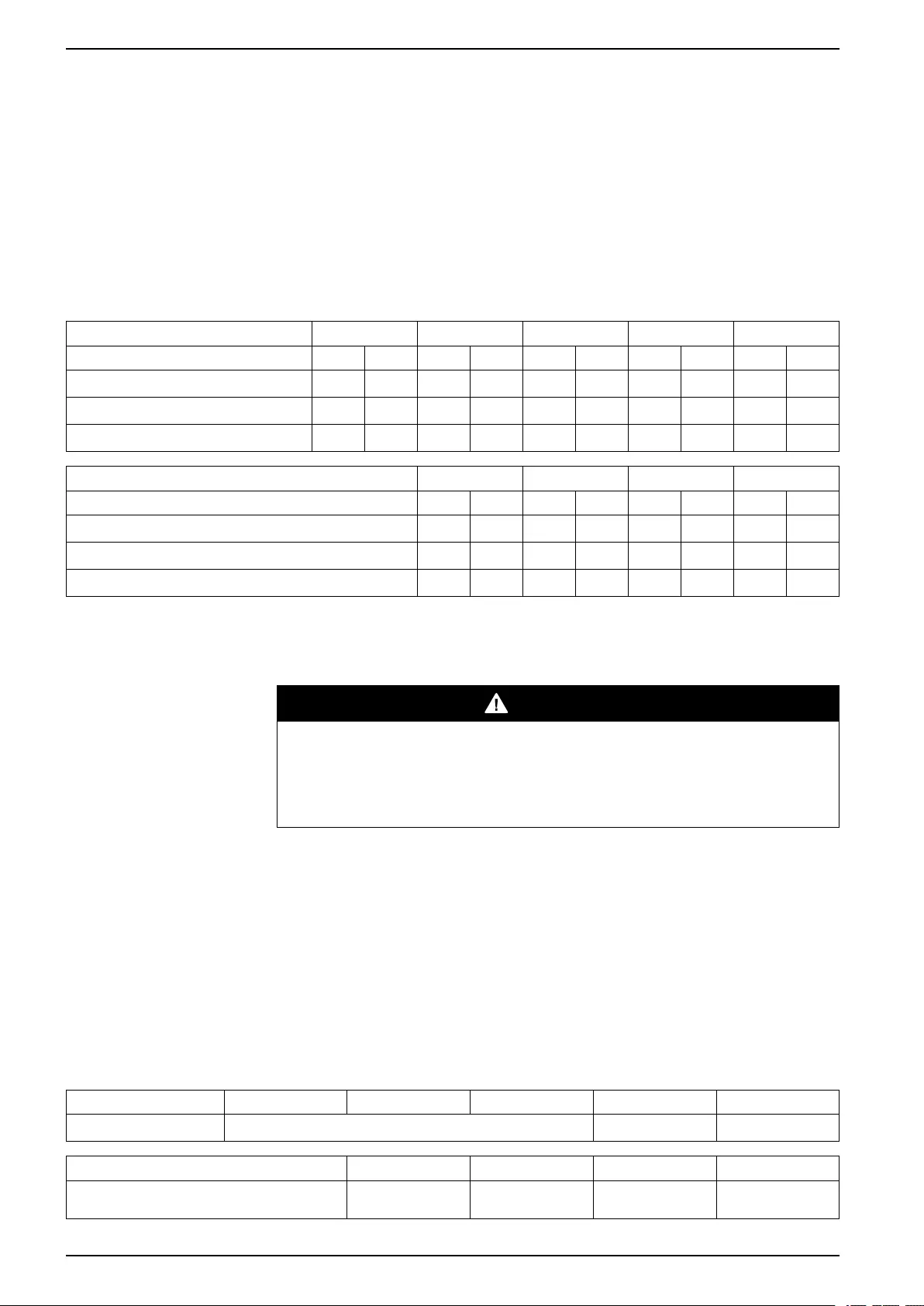

3:3 and 3:1 UPS

10 kVA 15 kVA 20 kVA

Voltage 380 400 415 380 400 415 380 400 415

Connection type 3PH + N + PE

Input frequency (Hz) 45–65

THDI < 9% at full load

Nom. input current (A)113 12.5 12 20 19 18 26 25 24

Max. input current (A)215.5 15 14.5 22.5 21.5 20.5 29 28 27

Input current limitation (A)317.5 17 16 25 24 22.5 32 31 30

Input power factor correction > 0.97 at load > 50%

30 kVA 40 kVA4

Voltage 380 400 415 380 400 415

Connection type 3PH + N + PE

Input frequency (Hz) 45–65

THDI < 9% at full load

Nom. input current (A)139.5 38 36 53 50 48

Max. input current (A)242 40.5 38.5 56 53 51

Input current limitation (A)347 45 42.5 61 59 56

Input power factor correction > 0.97 at load > 50%

990–9866–001 11

1. Input current based on rated load and batteries fully charged.

2. Input current based on full battery recharge, nominal voltage, and rated load.

3. Current limitation through electronic current limiting is based on full battery recharge and -15% input voltage.

4. Only available in 3:3 versions.

10–40 kVA Specifications

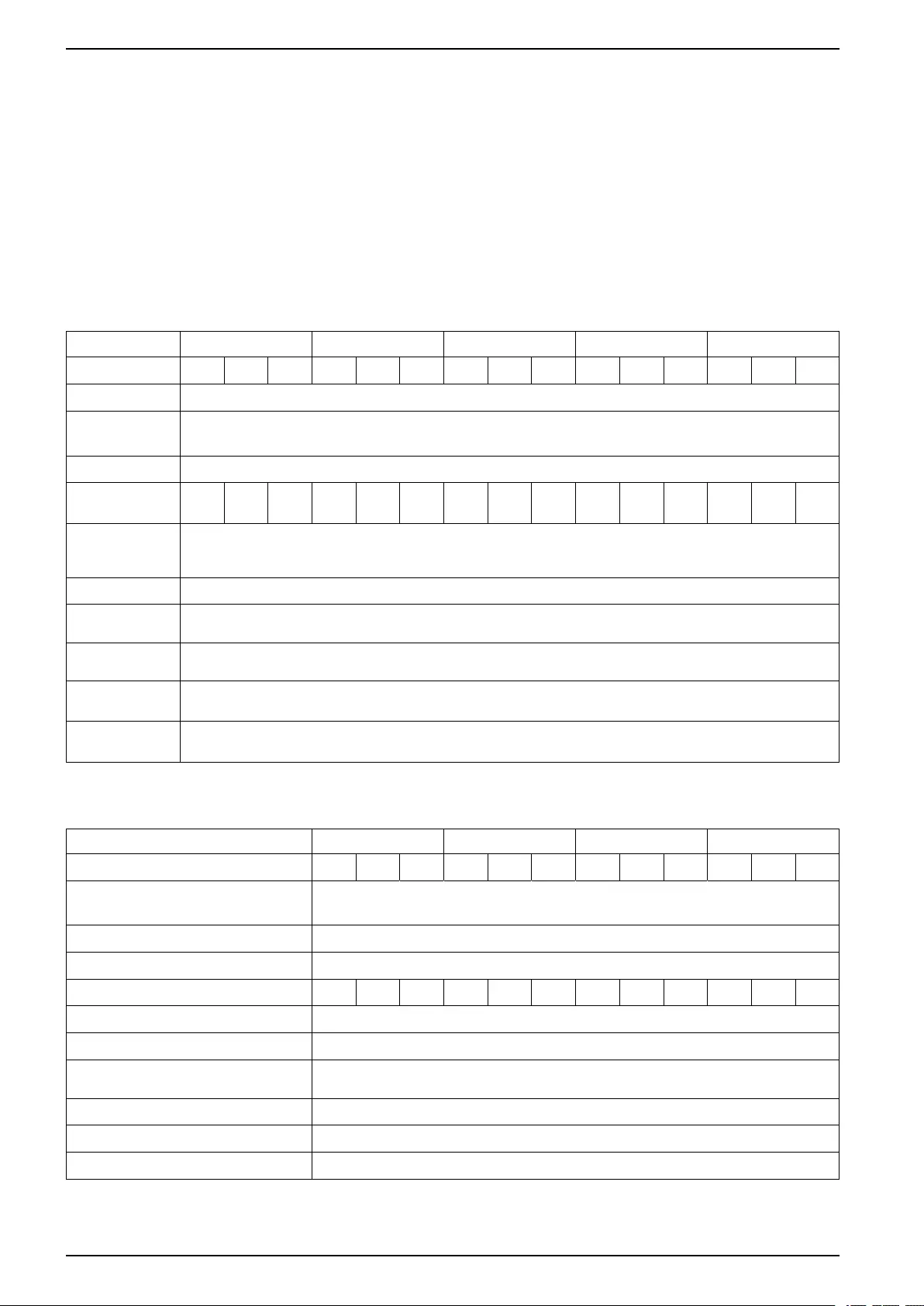

AC Output Specifications

3:3 UPS: 380, 400, 415 V (400 V 50 Hz is standard but 60 Hz is also possible).

Operation at 415 V/60 Hz is not allowed. For all other voltages or voltage

combinations, voltage-matching transformers are required.

3:1 UPS: 220, 230, 240 V (230 V is standard).

The operating voltage is set via the personalization procedures. The setting may

result in an overload if the output voltage is +3% and the current is at its rated level.

NOTE: In battery operation overload is not supported.

3:3 UPS

10 kVA 15 kVA 20 kVA 30 kVA 40 kVA

Voltage (V) 380 400 415 380 400 415 380 400 415 380 400 415 380 400 415

Connection type 3PH + N + PE

Output overload

capacity

<125% for 2 minutes

<150% for 10 seconds

Voltage tolerance ±2%

Nom. output

current (A)

15 14.5 14 23 22 21 30 29 27 45 43 41.5 60 58 55

Output frequency

(Hz)(sync to

mains)

50/60

Slew rate (Hz/s) Default: 2 Hz/s. Can be configured as 1 Hz/s.

THDU < 3.0% linear loads

< 5.0%. 100% unbalanced 100% non-linear loads

Output power

factor

From 0.5 leading to 0.5 lagging.

Dynamic load

response

±5%

Output voltage

regulation

±2%

3:1 UPS

10 kVA 15 kVA 20 kVA 30 kVA

Voltage (V) 220 230 240 220 230 240 220 230 240 220 230 240

Output overload capacity <125% for 2 minutes

<150% for 10 seconds

Connection type 1PH + N + PE

Voltage tolerance ±2%

Nom. output current (A) 45 43 42 68 65 62 90 87 83 136 130 125

Output frequency (Hz) (sync to mains) 50/60

Slew rate (Hz/Sec) Default: 2 Hz/s. Can be configured as 1 Hz/s.

THDU < 3.0% linear loads

< 5.0%. 100% non-linear loads

Output power factor From 0.5 leading to 0.5 lagging.

Dynamic load response ±5%

Output voltage regulation ±2%

12 990–9866–001

Specifications 10–40 kVA

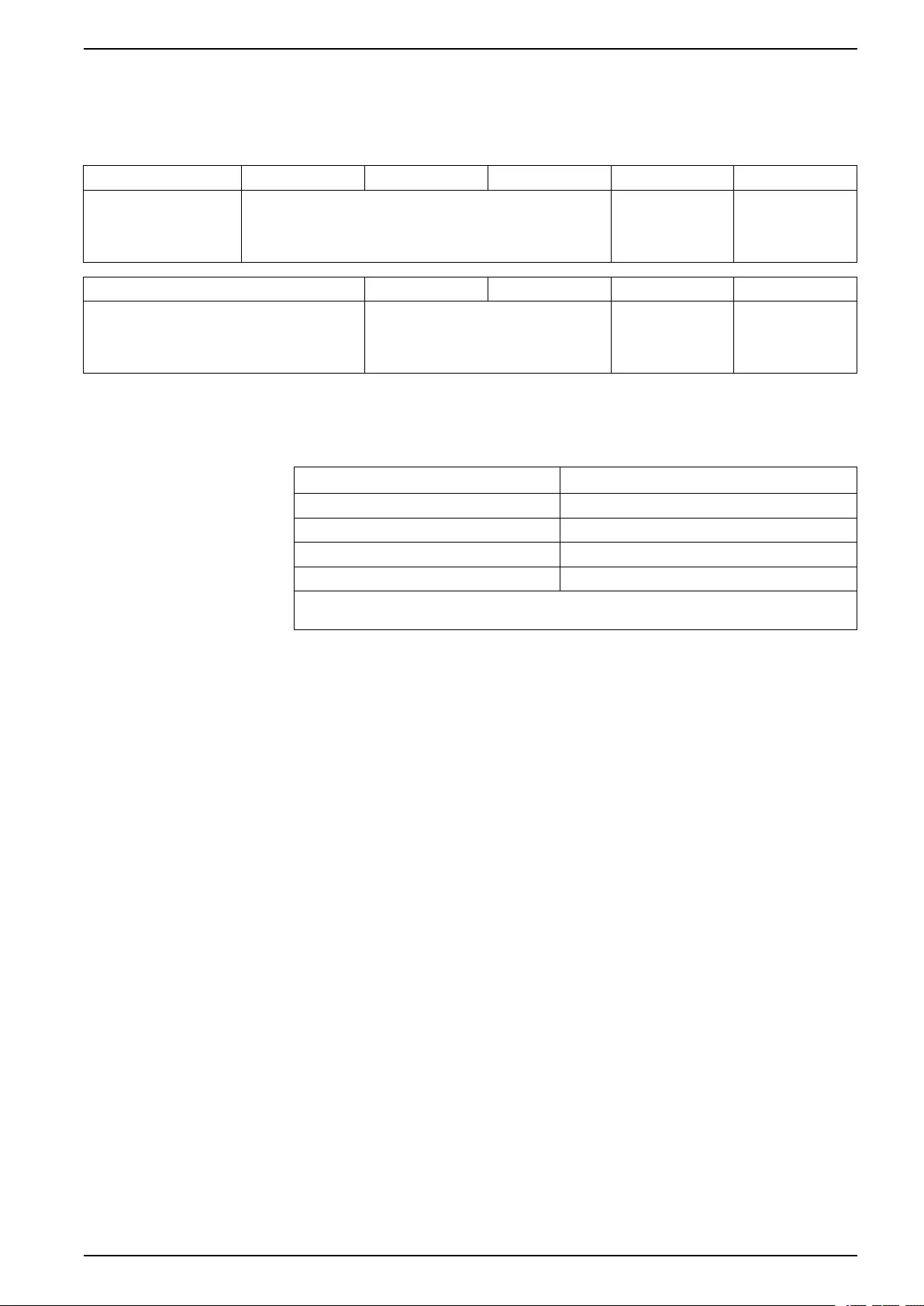

Battery Specifications

10 kVA 15 kVA 20 kVA 30 kVA 40 kVA

Type VRLA (Valve-Regulated Lead Acid) Battery

Nom. voltage (16

blocks/15 blocks)

(VDC)

± 192 / ±180

Float voltage (16

blocks/15 blocks)

(VDC)

± 218 / ±204

End of discharge

voltage (VDC) at

100% load

± 158 / ±148

Max. charging

power for UPS with

CLA charger (may

drop to lower values

at low AC input)5

3052 W 3052 W 3052 W 6104 W 6104 W

Typical recharge

time

CLA: (for external battery configuration)

24 hours - to 90% ±5% capacity after full discharge at min. Config.

Nom. voltage (V) 12 V/block

End voltage (V) 9.9 V/block (varies from 11.4 V to 9.9 V corresponding to load percentage from low to high)

INom discharge6(A)

(15 blocks)

25 37 50 74 99

IMax discharge7(A)

(15 blocks)

30 45 60 90 120

Galaxy 300 Heat Dissipation

3:3 UPS

Heat dissipation810 kVA 15 kVA 20 kVA

Load (%) 100 75 50 100 75 50 100 75 50

Heat dissipation (Watt) 656 514 420 937 712 514 1260 937 656

Heat dissipation830 kVA 40 kVA

Load (%) 100 75 50 100 75 50

Heat dissipation (Watt) 1804 1313 945 2479 1804 1195

3:1 UPS

Heat dissipation810 kVA 15 kVA

Load (%) 100 75 50 100 75 50

Heat dissipation (Watt) 707 577 463 1045 786 577

Heat dissipation820 kVA 30 kVA

Load (%) 100 75 50 100 75 50

Heat dissipation (Watt) 1212 888 612 1876 1417 1029

990–9866–001 13

5. UPS with CLA charger is to be used with external batteries ONLY.

6. Nominal battery discharge current based on rated load and nominal battery voltage.

7. Maximum battery discharge current based on rated load at the end of the discharge.

8. Batteries fully charged.

10–40 kVA Specifications

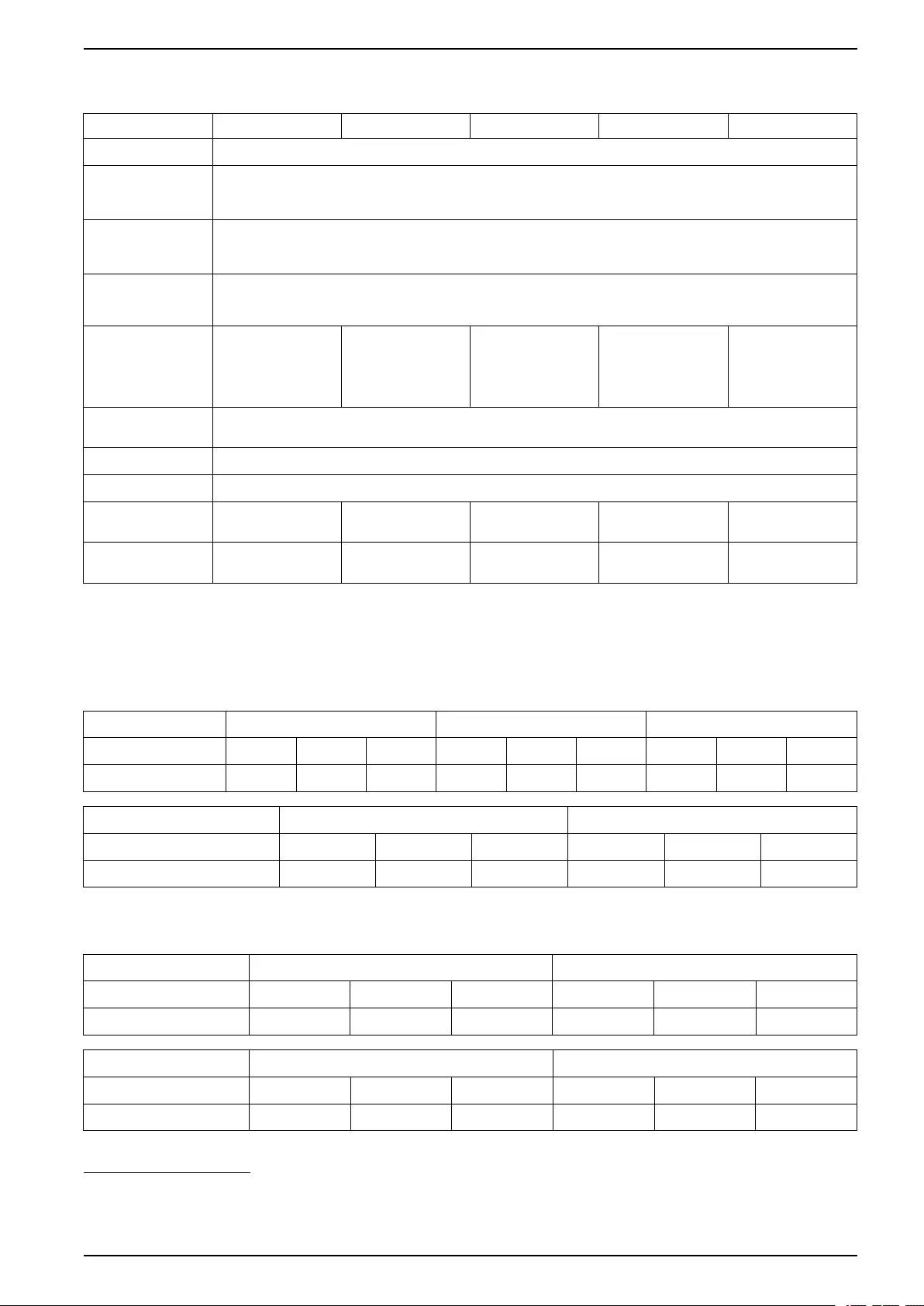

Recommended Cable Sizes

All wiring must comply with all applicable national and/or electrical codes. The

below specifications are recommendations only.

AC cable sizes are determined for:

- the TNS or IT system for copper, single-core cables, type U1000 R02V, 100 m

long with a line voltage drop <3%, installed on perforated cable trays, XLPE-type

insulation, single-layer trefoil formation, THDI between 15% and 33%, 35° C at 400

V, grouped in four touching cables.

Battery cable sizes are determined for:

- copper, single-core cables, type U1000 R02V, maximum length 25 m with a line

voltage drop <1%.

3:3 UPS 10 kVA 15 kVA 20 kVA 30 kVA 40 kVA

min max min max min max min max min max

Mains input (mm2) 10 35 10 35 10 35 16 35 25 35

AC output (mm2) 10 35 10 35 10 35 16 35 25 35

Battery input (mm2) 70° C 10 35 10 35 16 35 25 35 35 35

3:1 UPS 10 kVA 15 kVA 20 kVA 30 kVA

min max min max min max min max

Mains input (mm2) 16 35 25 35 35 90 70 90

AC output (mm2) 16 35 25 35 35 90 70 90

Battery input (mm2) 70° C 10 35 10 35 16 35 25 35

Overcurrent Protection

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

The recommended minimum residual current protection is 3A, provided the

conditions defined in IEC60364-4-41 are respected.

Failure to follow these instructions will result in death or serious injury.

NOTE: These protection systems ensure protection on all of the output circuits

connected to the unit. If the recommended downstream protection is not installed,

the result may be breaks in the supply of power longer than 20 milliseconds on all

the other output circuits.

NOTE: When the bypass source is within tolerance, the load is instantaneously

transferred to the bypass input and the upstream and downstream protection

devices ensures system protection.

NOTE: The short-circuit current of the installation must be less than the maximum

current of the downstream circuit breaker.

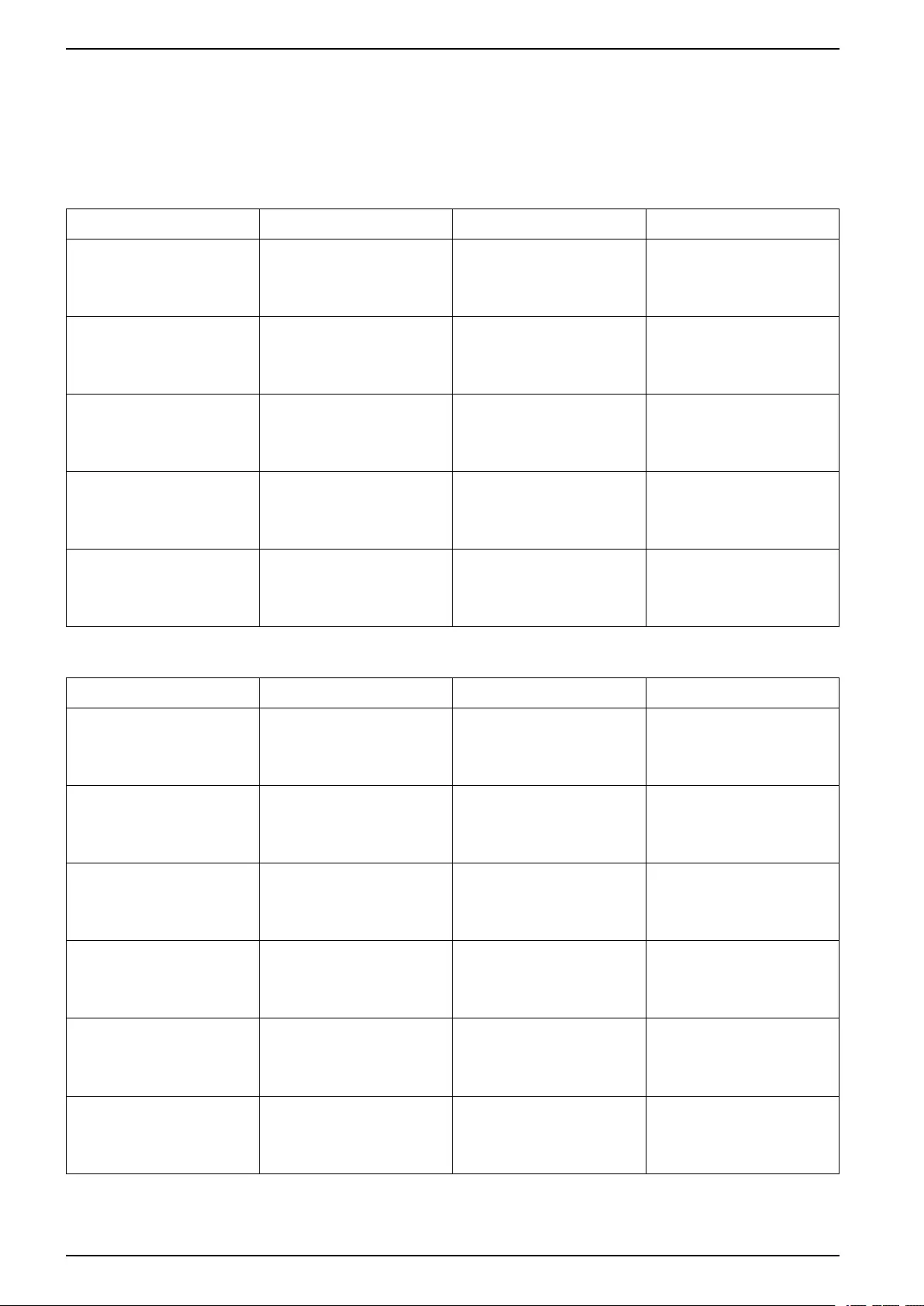

Recommended Upstream Protection

3:3 UPS 10 kVA 15 kVA 20 kVA 30 kVA 40 kVA

CB on input C65H-D-4P-63A/C60H-D-4P-63A C120H-D-4P-80A C120H-D-4P-125A

3:1 UPS 10 kVA 15 kVA 20 kVA 30 kVA

CB on input C65H-D-4P-63A/

C60H-D-4P-63A

C120H-D-4P-125A NSX250F TM200D

4P

NSX250F TM250D

4P

14 990–9866–001

Specifications 10–40 kVA

Recommended Downstream Protection

NOTE: The circuit breakers C65 and C60 are the same but applicable in different

regions. The C65 series must be used in China and the C60 series must be used in

all other countries.

3:3 UPS 10 kVA 15 kVA 20 kVA 30 kVA 40 kVA

Downstream CB C65N-B–4P-10A/C60N-B-4P-10A

C65N-B-4P-10A/C60N-C-4P-6A

C65N-B-4P-16A/

C60N-B-4P-16A

C65N-C-4P-10A/

C60N-C-4P-10A

C65N-B-4P-20A/

C60N-B-4P-20A

C65N-C-4P-10A/

C60N-C-4P-10A

3:1 UPS 10 kVA 15 kVA 20 kVA 30 kVA

Downstream CB C65N-B-2P-25A/C60N-B-2P-25A

C65N-C-2P-10A/C60N-C-2P-10A

C65N-B-2P-32A/

C60N-B-2P-32A

C65N-C-2P-16A/

C60N-C-2P-16A

C65N-B-2P-50A/

C60N-B-2P-50A

C65N-C-2P-25A/

C60N-C-2P-25A

Torque Specifications

Bolt size Torque

M3 1 Nm

M4 1.2 Nm – 2 Nm

M5 3.5 Nm – 4.5 Nm

M6 4.5 Nm – 6 Nm

For batteries: Use the torque recommended by Schneider Electric or by the third party battery

vendor.

990–9866–001 15

10–40 kVA UPS Product Overview

UPS Product Overview

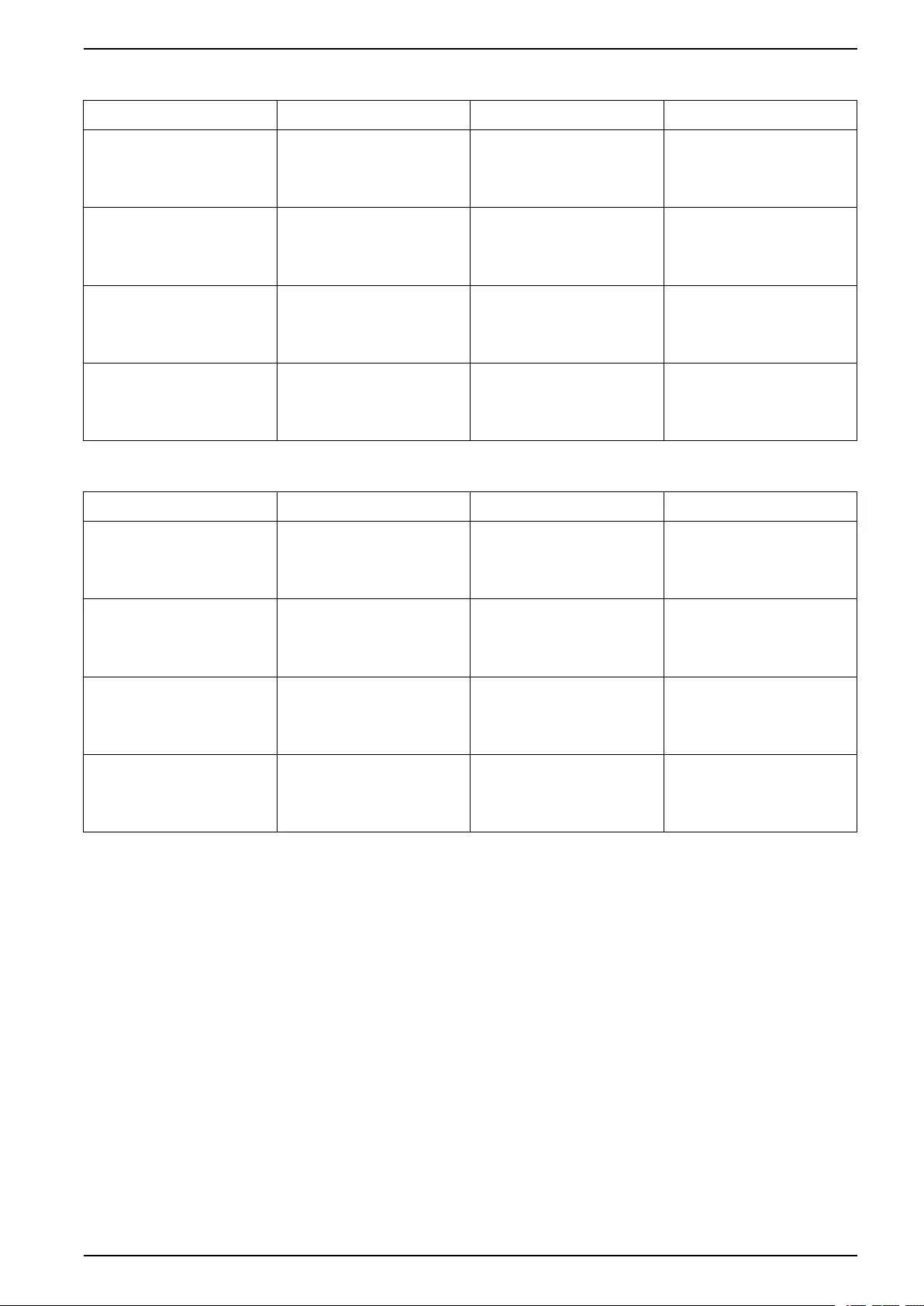

Emergency Lighting Model List

3:1 Input: Output Configuration with 60 Minutes Runtime

kVA kW Single PTO SKU Description

10 6.6 G3H10K3IM6X710 Emergency lighting

Galaxy 300 UPS 10 kVA

400 V 3:1 CLA TM 60

minutes

15 9.6 G3H15K3IM6X710 Emergency lighting

Galaxy 300 UPS 15 kVA

400 V 3:1 CLA TM 60

minutes

20 13.3 G3H20K3IM6X710 Emergency lighting

Galaxy 300 UPS 20 kVA

400 V 3:1 CLA TM 60

minutes

30 15.6 G3H303IM6AX710 Emergency lighting

Galaxy 300 UPS 30 kVA

400 V 3:1 CLA TM 60

minutes

30 20 G3H303IM6BX710 Emergency lighting

Galaxy 300 UPS 30 kVA

400 V 3:1 CLA TM 60

minutes

3:3 Input: Output Configuration with 60 Minutes Runtime

kVA kW Single PTO SKU Description

10 6.6 G3H10KHTT6X710 Emergency lighting

Galaxy 300 UPS 10 kVA

400 V 3:3 CLA TT 60

minutes

15 9.6 G3H15KHTT6X710 Emergency lighting

Galaxy 300 UPS 15 kVA

400 V 3:3 CLA TT 60

minutes

20 13.3 G3H20KHTT6X710 Emergency lighting

Galaxy 300 UPS 20 kVA

400 V 3:3 CLA TT 60

minutes

30 15.6 G3H30KHT6AX710 Emergency lighting

Galaxy 300 UPS 30 kVA

400 V 3:3 CLA TT 60

minutes

30 20 G3H30KHT6BX710 Emergency lighting

Galaxy 300 UPS 30 kVA

400 V 3:3 CLA TT 60

minutes

40 26.6 G3H40KHTT6X710 Emergency lighting

Galaxy 300 UPS 40 kVA

400 V 3:3 CLA TT 60

minutes

16 990–9866–001

UPS Product Overview 10–40 kVA

3:1 Input: Output Configuration with 90 Minutes Runtime

kVA kW Single PTO SKU Description

10 6.6 G3H10K3IM9X710 Emergency lighting

Galaxy 300 UPS 10 kVA

400 V 3:1 CLA TM 90

minutes

15 9.6 G3H15K3IM9X710 Emergency lighting

Galaxy 300 UPS 15 kVA

400 V 3:1 CLA TM 90

minutes

20 11.6 G3H20K3IM9X710 Emergency lighting

Galaxy 300 UPS 20 kVA

400 V 3:1 CLA TM 90

minutes

30 14.4 G3H30K3IM9X710 Emergency lighting

Galaxy 300 UPS 30 kVA

400 V 3:1 CLA TM 90

minutes

3:3 Input: Output Configuration with 90 Minutes Runtime

kVA kW Single PTO SKU Description

10 6.6 G3H10KHTT9X710 Emergency lighting

Galaxy 300 UPS 10 kVA

400 V 3:3 CLA TT 90

minutes

15 9.6 G3H15KHTT9X710 Emergency lighting

Galaxy 300 UPS 15 kVA

400 V 3:3 CLA TT 90

minutes

20 11.6 G3H20KHTT9X710 Emergency lighting

Galaxy 300 UPS 20 kVA

400 V 3:3 CLA TT 90

minutes

30 14.4 G3H30KHTT9X710 Emergency lighting

Galaxy 300 UPS 30 kVA

400 V 3:3 CLA TT 90

minutes

990–9866–001 17

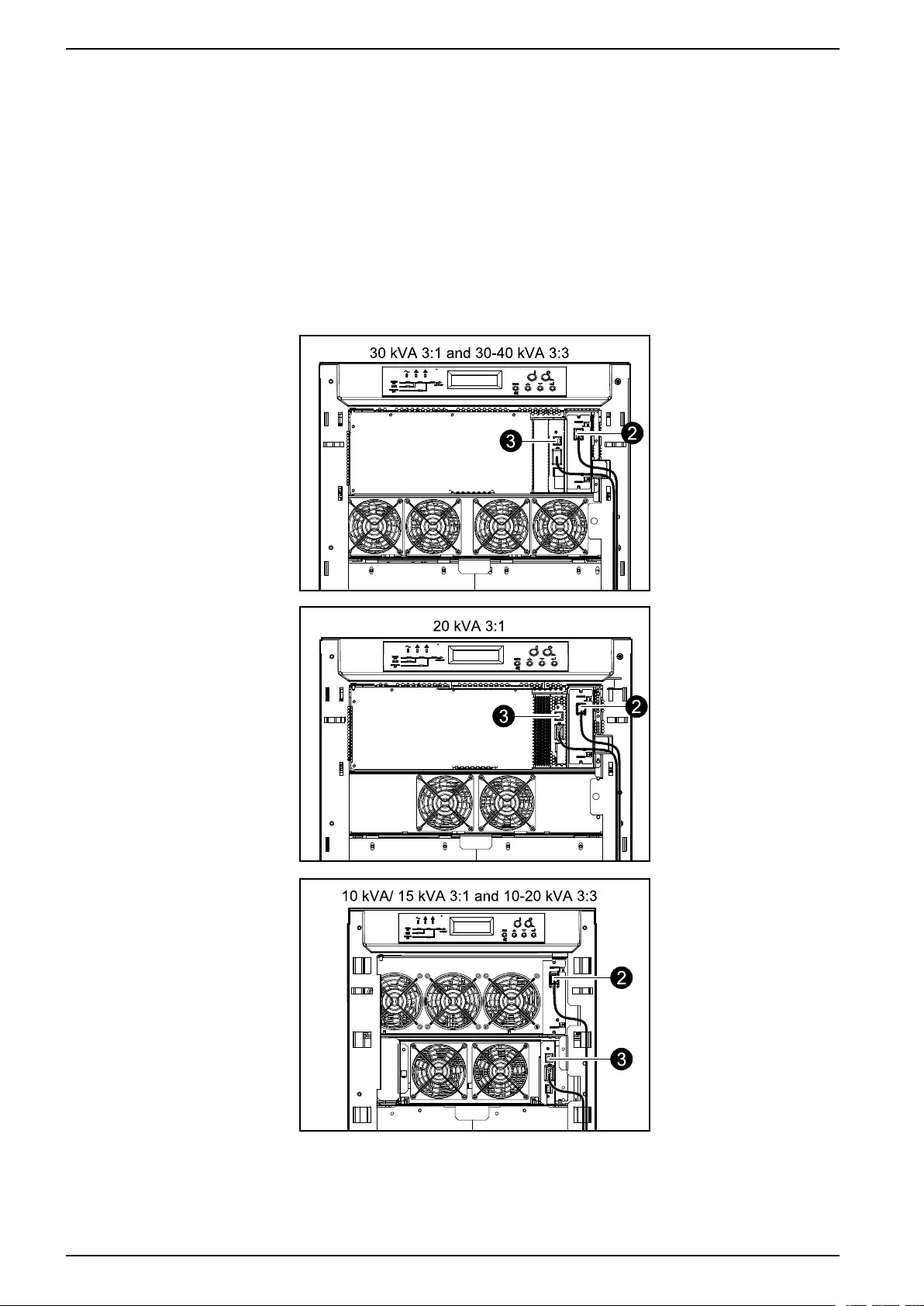

10–40 kVA UPS Product Overview

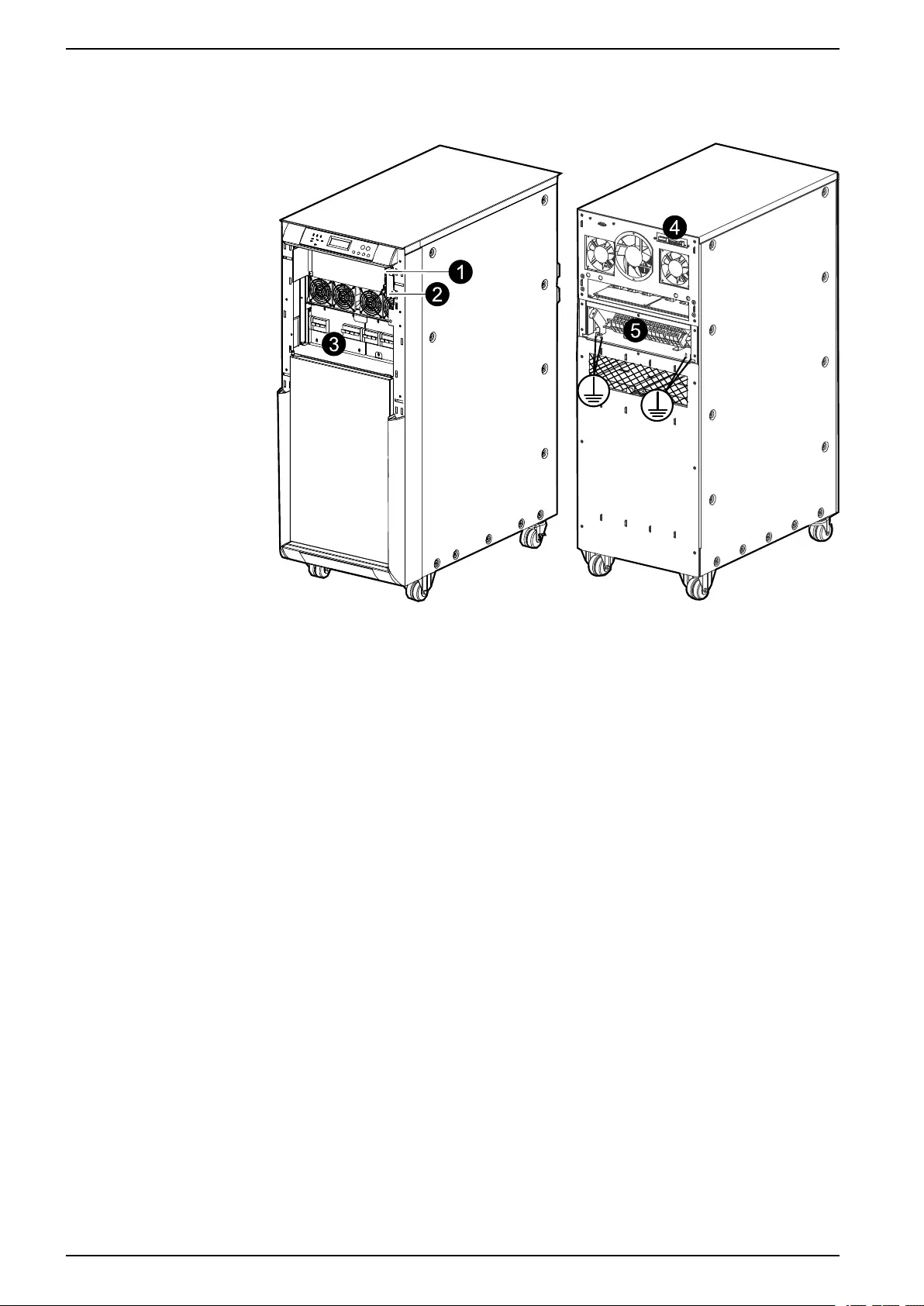

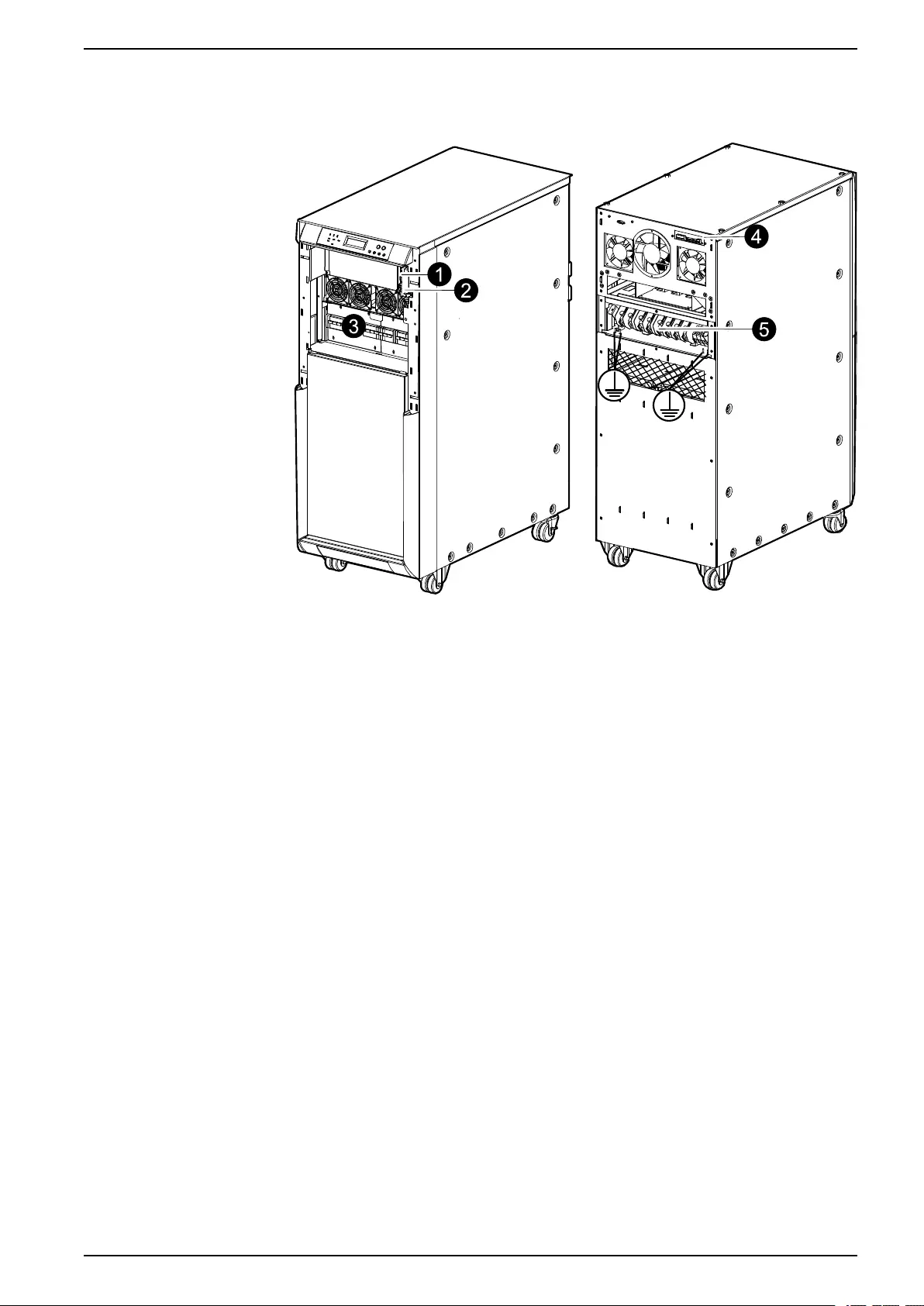

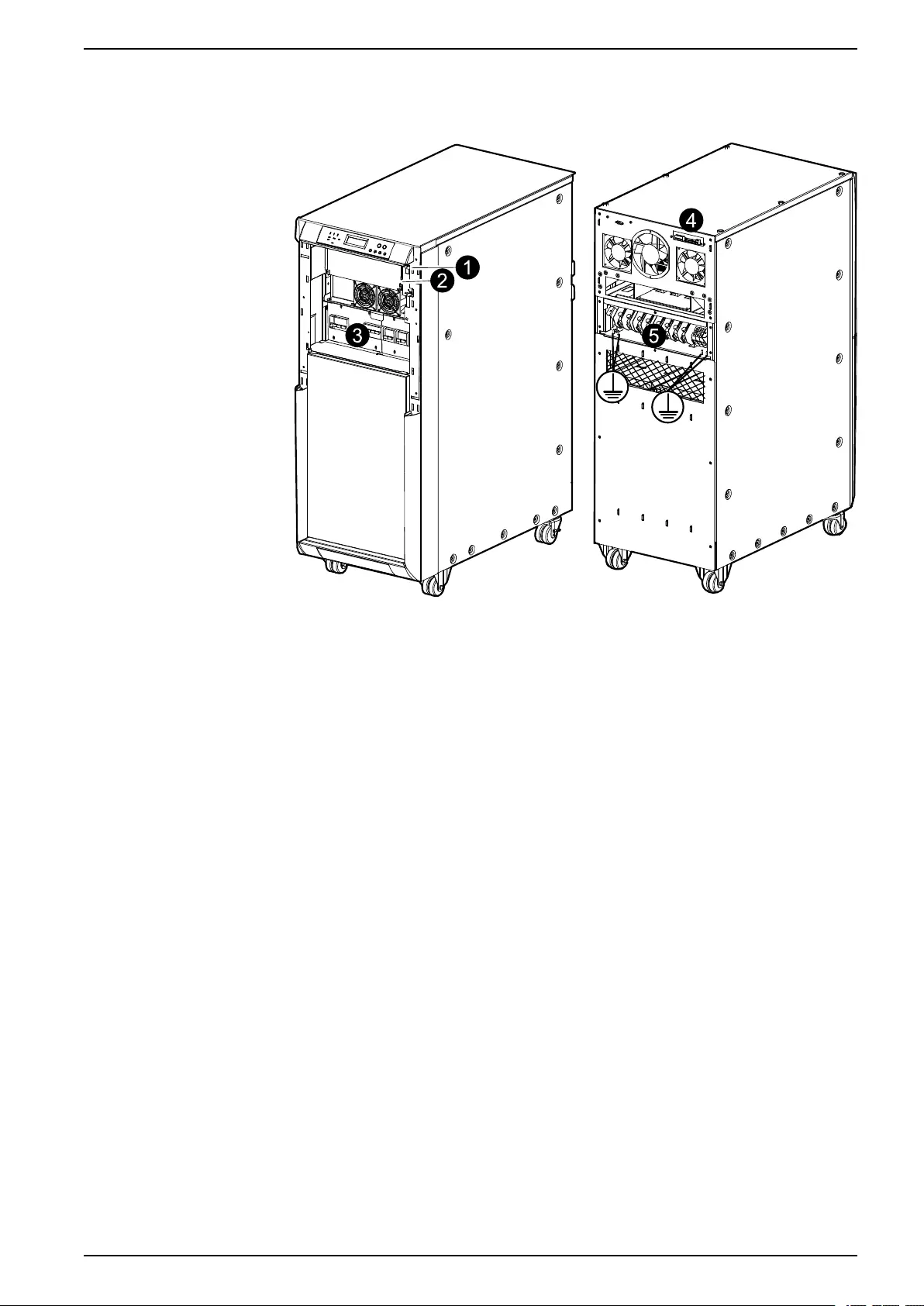

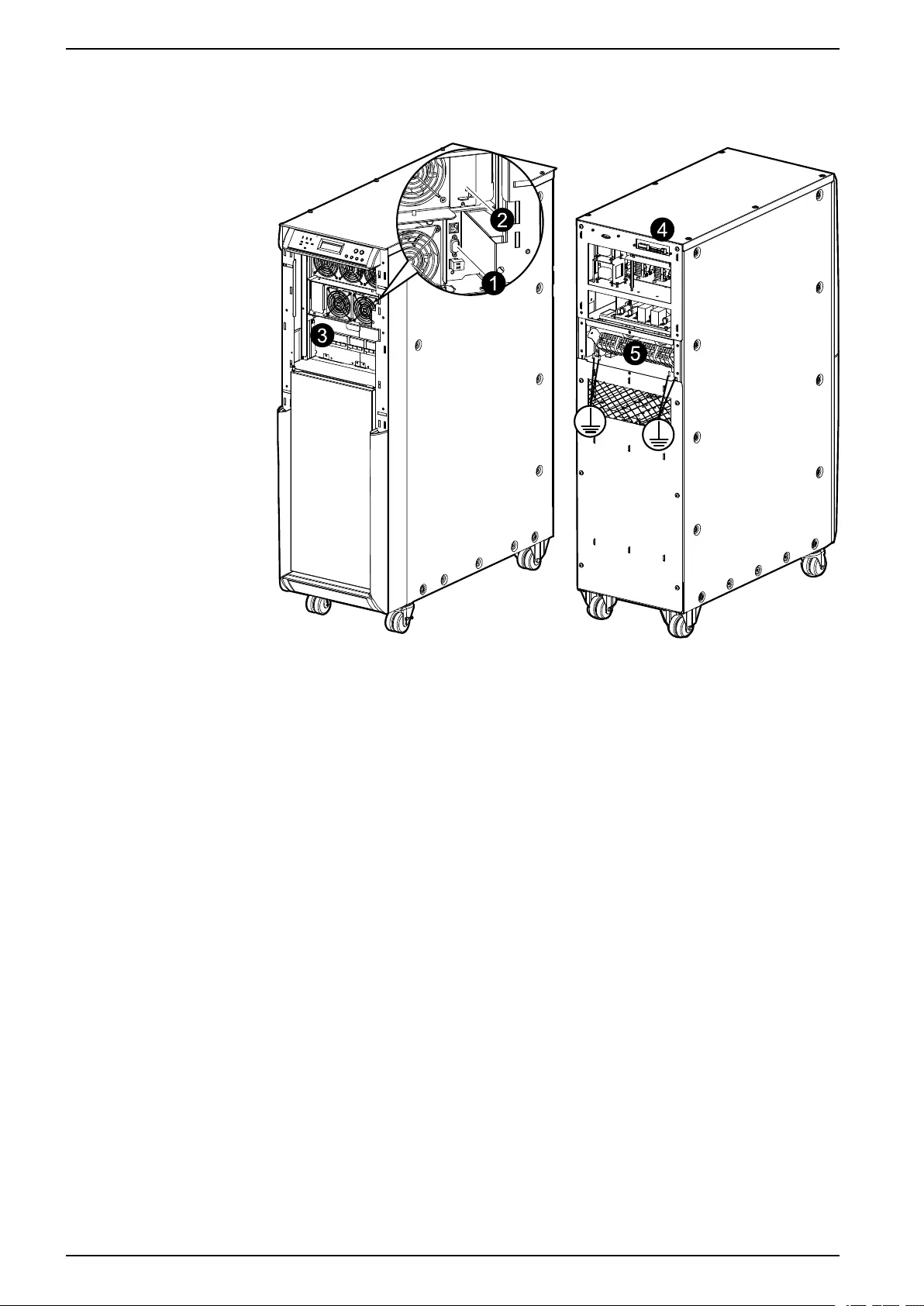

10/15/20 kVA 3:3

Front View and Rear View

1. Communication board (only for Schneider Electric Service)

2. Network management card

3. Breakers

4. Dry contact terminal, EPO, external battery breaker signal, and external battery

temperature (ATIZ)

5. Power terminals

20 990–9866–001

10–40 kVA Prepare for Installation

Prepare for Installation

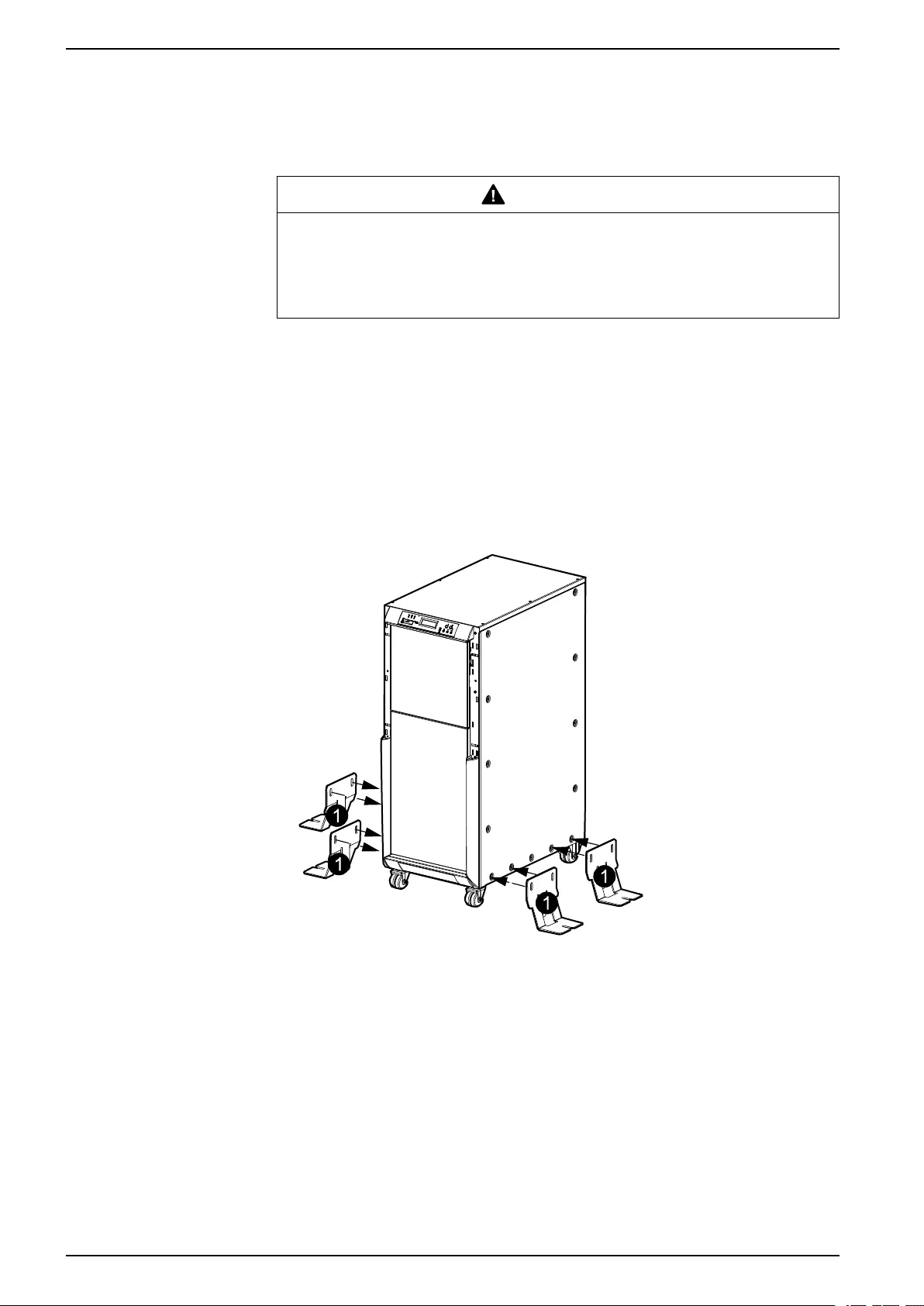

Floor Anchoring

CAUTION

HAZARD OF TILTING

The UPS must be anchored to the floor because it is top-heavy.

Failure to follow these instructions can result in injury or equipment

damage.

NOTE: The UPS system and battery cabinet must be installed on a non-

inflammable, level, and solid floor.

NOTE: The UPS can be anchored to the floor in two ways depending on the

available floor space.

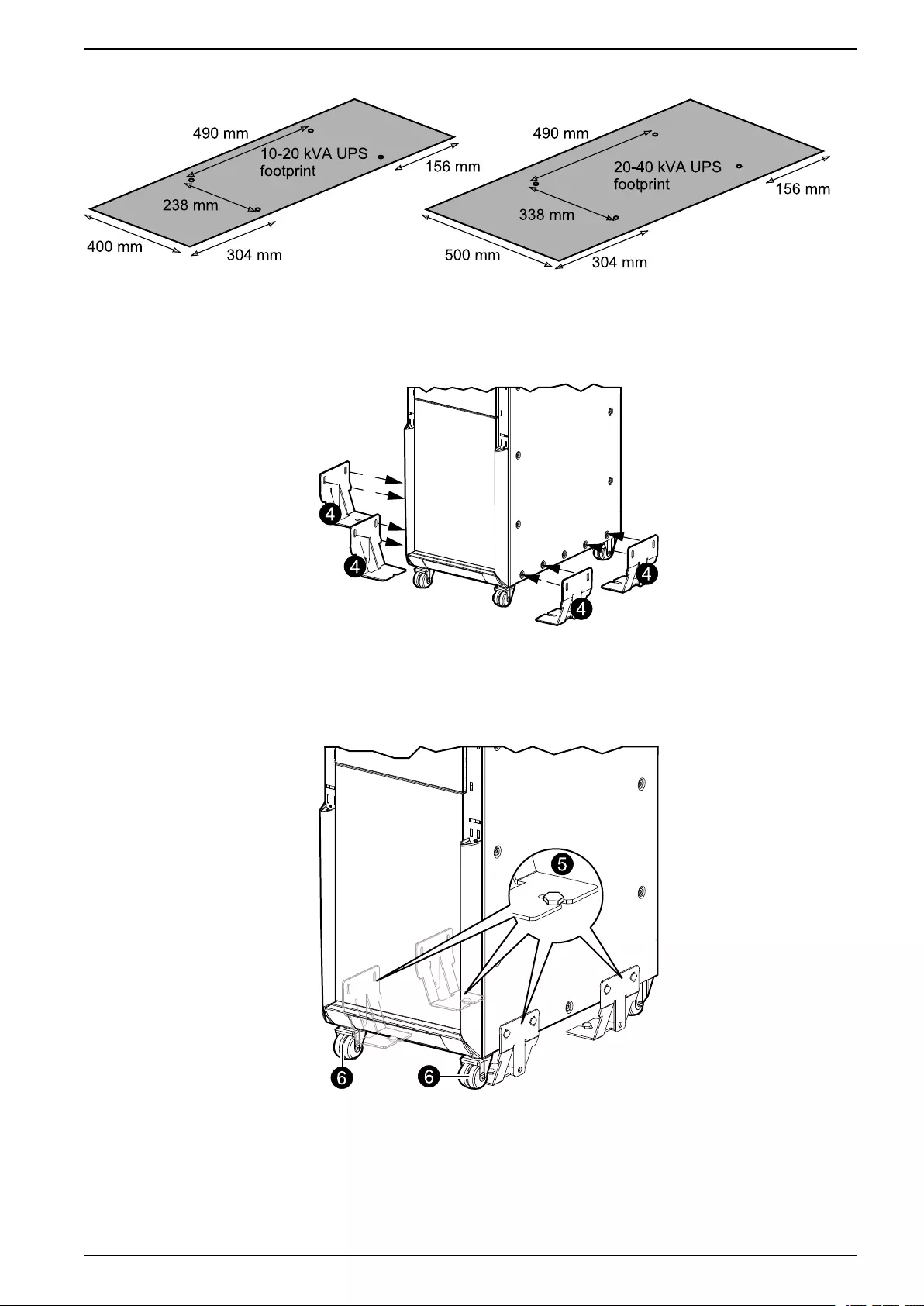

Method 1: Unlimited Space Available

1. Mount the four brackets on the UPS as shown.

Front View

Method 2: Limited Space Available

1. Drill four holes according to the UPS footprint (see illustration) and install four

M8 bolts into the floor for anchoring.

24 990–9866–001

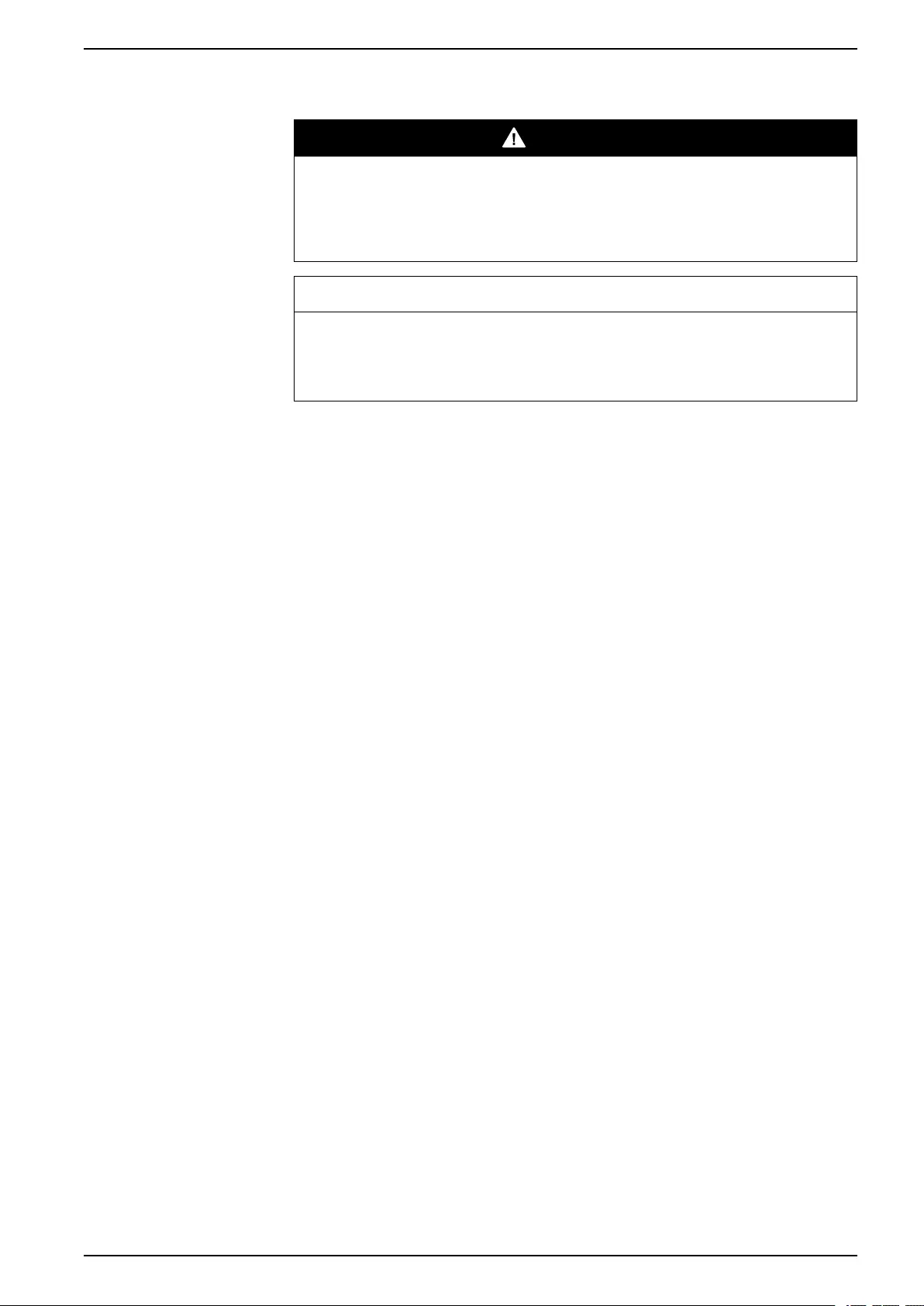

Connect the UPS Power Cables 10–40 kVA

Connect the UPS Power Cables

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

In frequency converter operation mode the maintenance bypass breaker (Q3BP)

and the static bypass breaker (QM2) must be in the OFF (opened) position.

Failure to follow these instructions will result in death or serious injury.

NOTICE

RISK OF ERRATIC SYSTEM OPERATION

If the neutral line connection is not reliable, the system will work abnormally.

Failure to follow these instructions can result in equipment damage.

NOTE: A padlock is available from Schneider Electric and is advisable to use

(padlock catalog number: 26970).

990–9866–001 27

10–40 kVA Connect the UPS Power Cables

Rear View of the UPS

1. Connect the PE-cables for input, for bypass, and for the load.

2. Connect the input cables (N, L1, L2, L3) to the input terminals starting with N.

3. Remove the cable(s) between the bypass and the input terminals.

4. Connect the cables from the load to the output terminals. 3:3 (N, L1, L2, L3), 3:1

(N and L1).

5. Connect the battery cables (BAT+, N, BAT-) to the battery terminals. The

battery cables will be connected to the external battery solution later.

28 990–9866–001

Connect the UPS Power Cables 10–40 kVA

6. Reinstall the plastic cover and the I/O sheet metal cover removed in Prepare

UPS for Cables, page 26.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

The I/O sheet metal cover must be fixed in the lowest position for safety

reasons.

Failure to follow these instructions will result in death or serious injury.

7. Bundle the input cables, the battery cables, and the output cables as three

separate groups of cables.

8. Attach all cables to the fixtures (shown below) with cable ties.

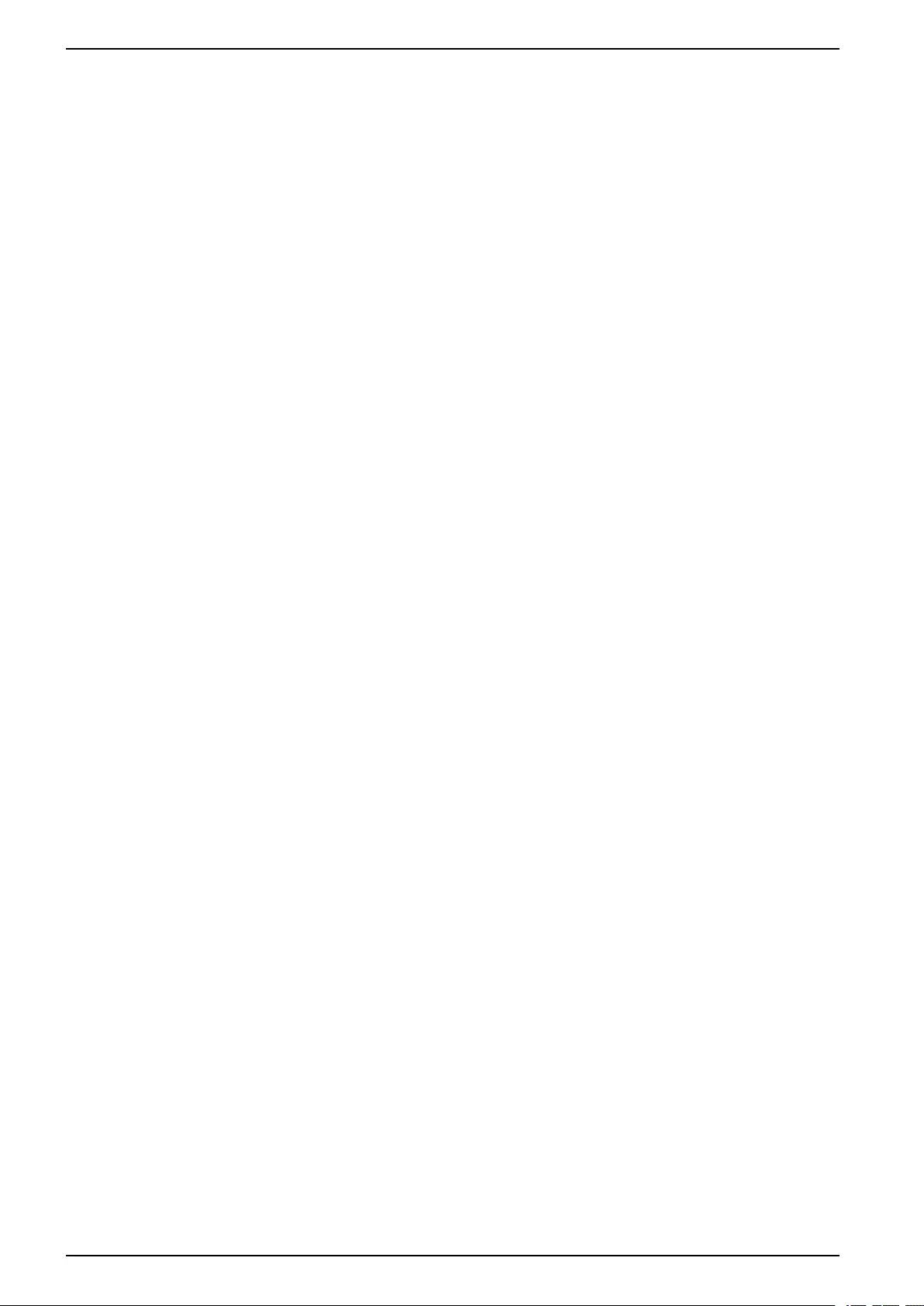

9. Schneider Electric recommends to install a padlock on the static bypass

breaker (QM2) and the maintenance bypass breaker (Q3BP) in the OFF

(opened) position.

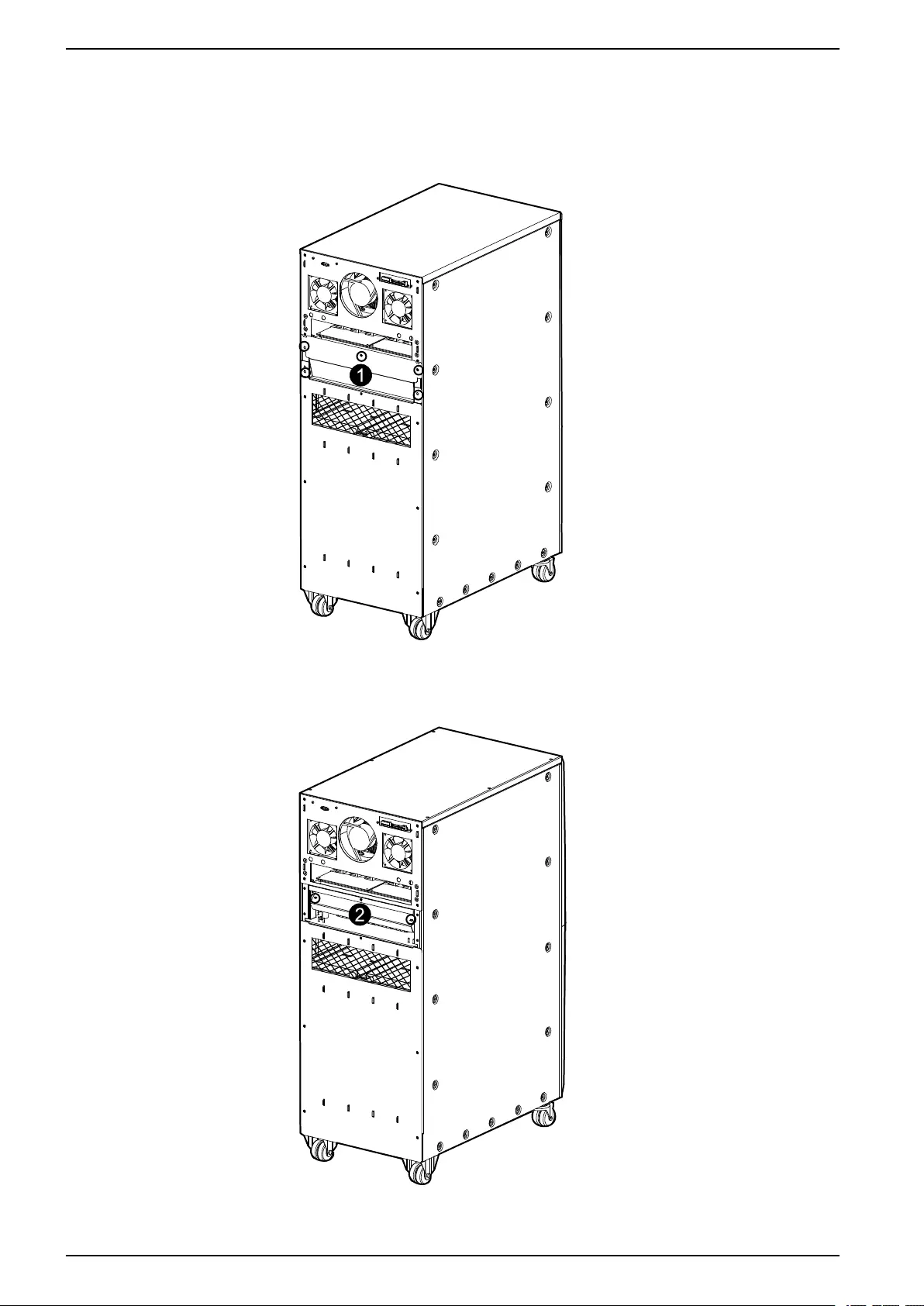

Front View of 3:3 30–40 kVA, and 3:1 20–30 kVA

Front View of 3:3 10–20 kVA, and 3:1 10–15 kVA

990–9866–001 29

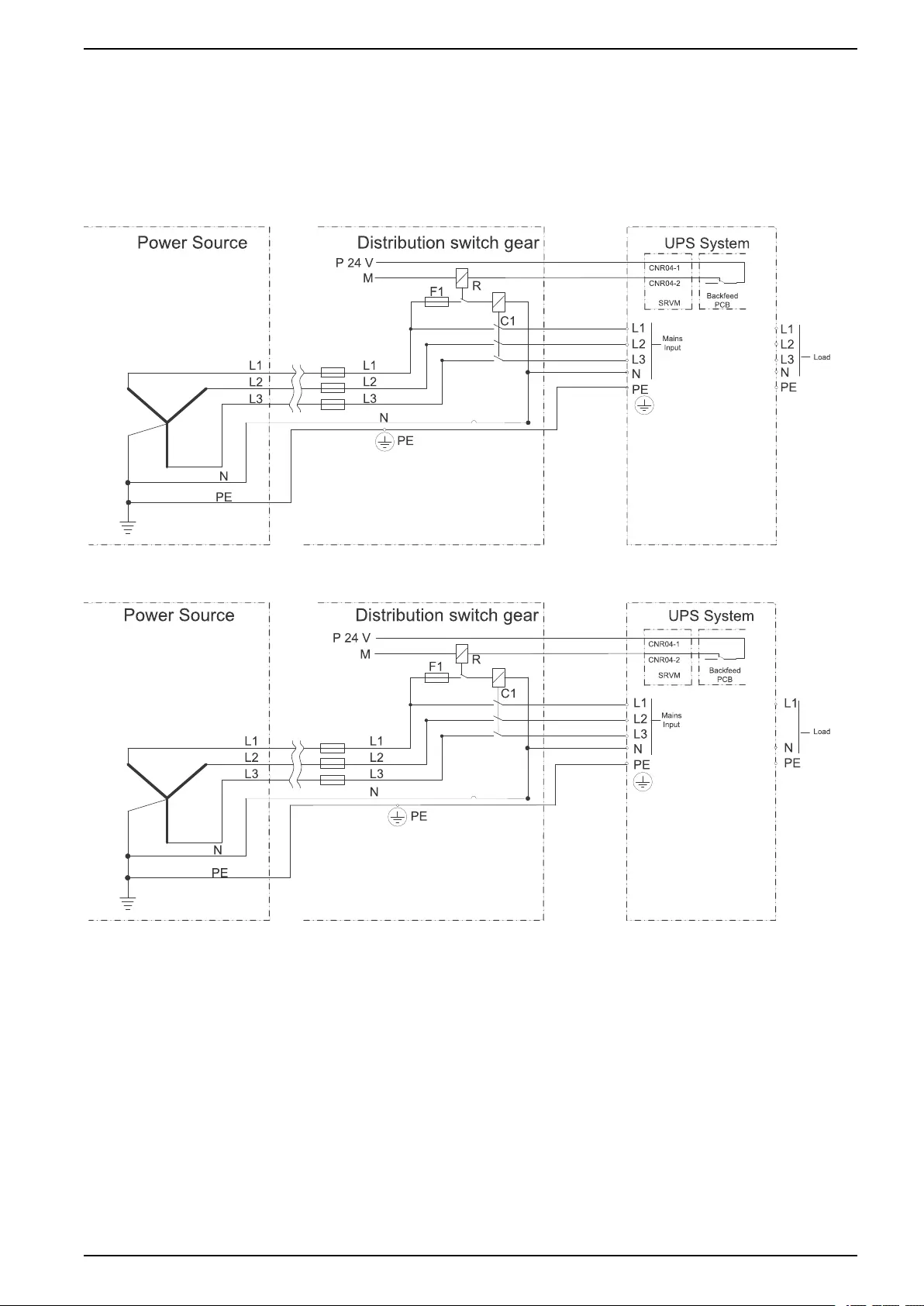

10–40 kVA Install Backfeed Protection

Install Backfeed Protection

NOTE: The presence of a backfeed on input mains is mandatory according to IEC

62040-1.

An additional external isolation device must be installed in the UPS system. A

magnetic contactor or a circuit breaker with UVR (Under Voltage Release)

functionality can be used for this purpose. In the shown examples, the isolation

device is a magnetic contactor (marked with a C1 for single feed configurations

and marked with a C1 and C2 for dual feed configurations).

The isolation device must be able to carry the UPS input current, check with the

relevant input current of the UPS specifications.

NOTE: The 24 V source should be generated from the input source in single mains

configurations and from the bypass source in dual mains configurations.

NOTE: The examples shown in the backfeed protection instructions are for TN

earthing systems. For other earthing systems, the external isolation device

schematics are similar; refer to Galaxy 300 Earthing Manual. In case of an IT

earthing system installation, where the upstream protection is a 4 pole device, the

external isolation device must also be 4 pole.

Connect the backfeed protection as instructed in Install External Backfeed

Protection, page 30.

Install External Backfeed Protection

1. Connect UPS backfeed dry contact CNR04-1 with an external +24 VDC supply

pole “+” (the UPS backfeed dry contact CNR04-1 CNR04-2 is connected later

with the other signal cables).

2. Connect UPS backfeed dry contact CNR04-2 with a terminal of the relay R coil.

3. Connect the other terminal of the relay R coil with +24 VDC supply pole “-”(M).

4. Serial-connect the fuse (F1), the auxiliary contact of relay R and the coil of C1

as shown in the illustration below.

5. Connect C1 (L1, L2, L3) to UPS input (L1, L2, L3) as the shown in the

illustration below.

6. Connect C1 (L1, L2, L3) to input feeding (L1, L2, L3) in customer’s distribution

switchgear as shown in the illustration below.

7. Connect UPS input (N), PE to input feeding (N), PE in customer’s distribution

switchgear.

30 990–9866–001

Install Backfeed Protection 10–40 kVA

8.

– For 3:3: Connect C1 (L1, L2, L3) with the input feeding (L1, L2, L3) in

distribution switchgear as shown in the illustration below.

– For 3:1: Connect C1 (L1, L2, L3) with the input feeding (L1, L2, L3) in

distribution switchgear as shown in the illustration below.

3:3 UPS and External Isolation Device

3:1 UPS and External Isolation Device

990–9866–001 31

10–40 kVA Connect the UPS Signal Cables

Connect the UPS Signal Cables

Connect the Signal Cables to the UPS

1. Open the front door.

2. Connect the shielded signal cables (optional) to the Network Management

Card. Refer to the Network Management Card documentation shipped with the

UPS.

3. Connect the UPS backfeed signal CNR04-1 CNR04-2.

Front View of the UPS

4. Run the cables through the slot (otherwise the door cannot close) and up along

the right side of the cabinet.

32 990–9866–001

Connect the UPS Signal Cables 10–40 kVA

5. Fasten the cables with cable ties.

Front View of the UPS

6. Close the upper front door by pushing the door in.

7. Install the two upper side covers with two hands by tipping the covers 10º. Then

push down the two clips on the covers (3 mm down) in the rectangular holes on

the front panel, and then push in the covers.

8. Install the two bottom side covers in the same way.

990–9866–001 33

10–40 kVA Connect the UPS Signal Cables

9. Connect the cables to your computer interface network.

Front View of the UPS

Connect the EPO Cable to the UPS

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

The cables must have a shielded layer, and the shielded layer must be

connected to grounding on both the UPS side and the customer side.

Failure to follow these instructions will result in death or serious injury.

NOTE: A jumper must be added if no EPO cable is connected.

34 990–9866–001

10–40 kVA Connect the UPS Signal Cables

Connect the Optional Signal Cables

1. Connect the dry connector with a shielded cable (cable not provided). The dry

contacts permit to monitor the UPS from external relay switches regarding

general alarms, battery mode, and low battery. Run the cables to an indication

instrument such as LEDs, etc.

Rear View of the UPS

Requirements for dry connector cables

Permissible voltage (VDC) 30

Permissible current (A) 1

Cable 4 x 0.93 mm², ø 6.6 ± 0.3 mm.

2. Connect the cable for the external battery temperature detection and the

external battery circuit breaker signal to signal ports 2 and 3.

NOTE: If the battery cabinet (G3HTBAT1) is used, one cable end is preinstalled

in this battery cabinet.

36 990–9866–001

Install Battery Solution 10–40 kVA

Install Battery Solution

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Make sure that the battery breaker is open before starting.

• Check the DC voltages with a DC voltage multimeter versus the battery

voltage before continuing.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK

The battery cabinet(s) and the UPS must be earthed.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

• Servicing of batteries must only be performed or supervised by qualified

personnel knowledgeable of batteries and the required precautions. Keep

unqualified personnel away from batteries.

• Disconnect charging source prior to connecting or disconnecting battery

terminals.

• Turn the battery circuit breakers OFF before connecting cables to the

terminals.

Failure to follow these instructions will result in death or serious injury.

Depending on your chosen solution, follow the appropriate steps in this chapter.

Solutions described:

•Battery cabinet (G3HTBAT1) – See Install a Galaxy 300 Battery Cabinet

(G3HTBAT1, G3HTBAT2, and G3HTBAT3), page 41.

•Battery cabinet (SYPBV96K160HB, G55TBATL10B and G55TBAT2L7C) –

See Install a Battery Cabinet (SYPBV96K160HB, G55TBATL10B, and

G55TBAT2L7C), page 49.

990–9866–001 37

10–40 kVA Install Battery Solution

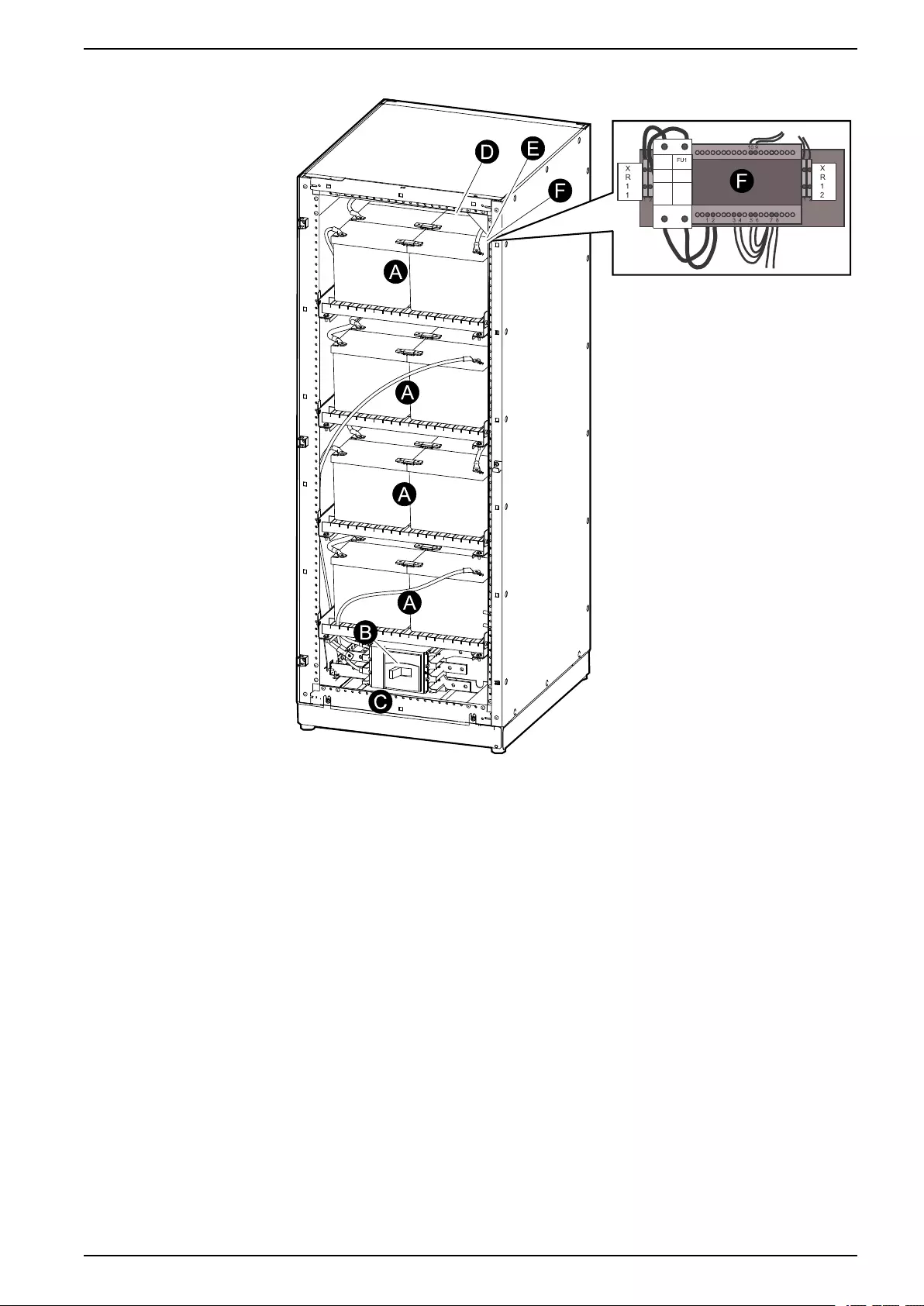

Battery Cabinet Product Overview

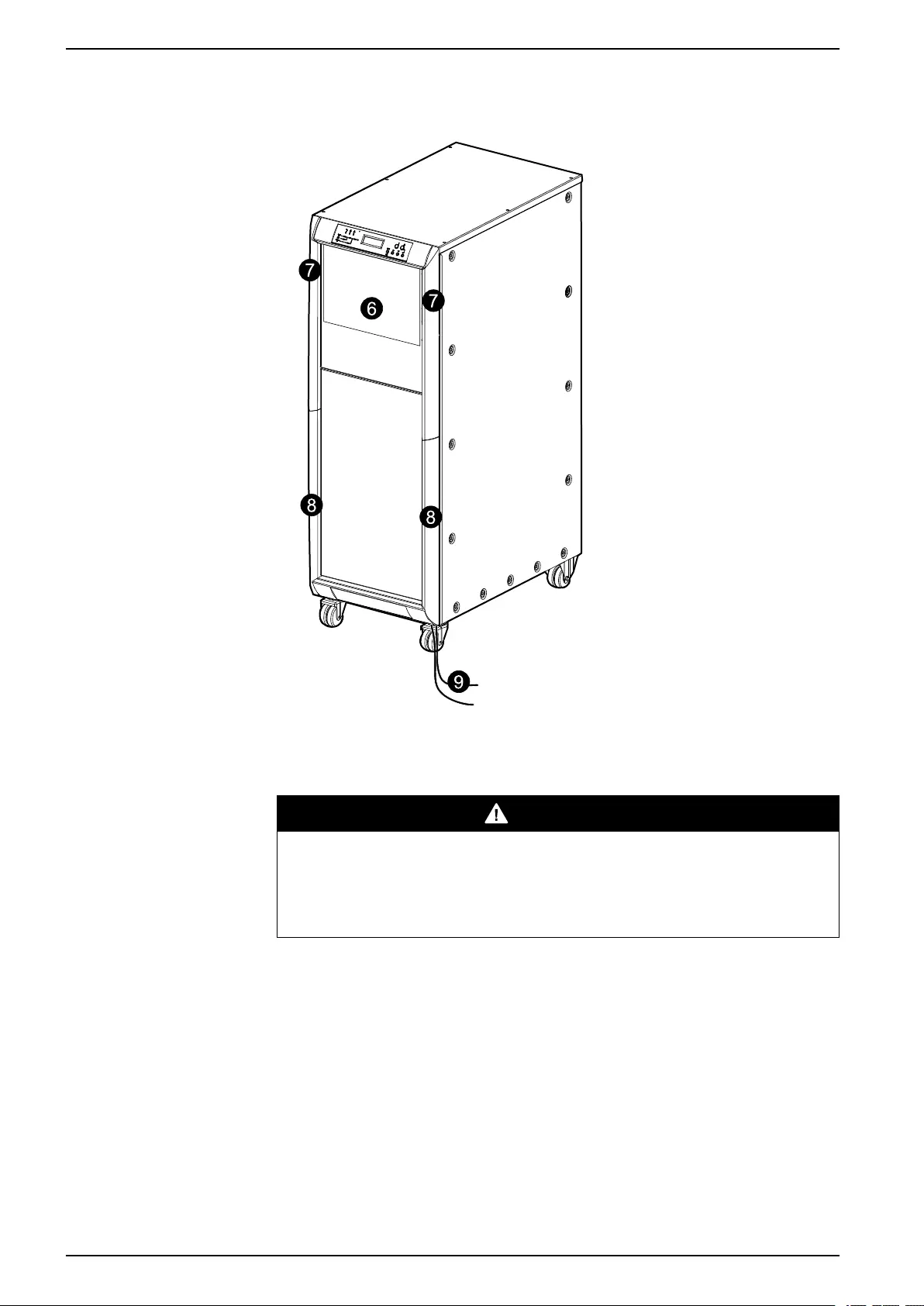

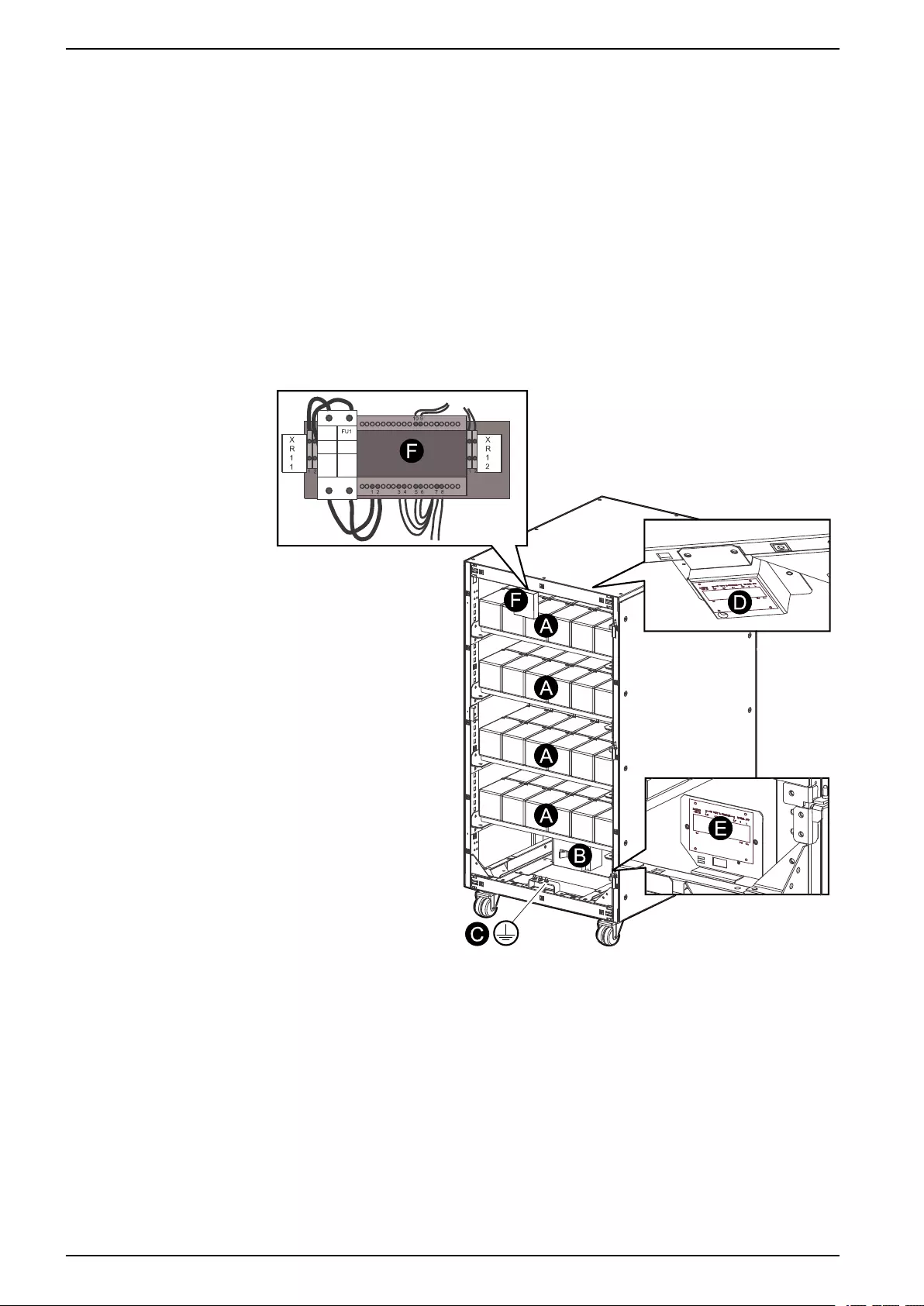

Battery Cabinet (G3HTBAT1)

A. Battery shelves

B. Battery circuit breaker

C. Ground cable connection (from the UPS)

D. Battery temperature sensor (ATIZ)

E. Connection terminal (for ATIZ, circuit breaker detection and power supply)

F. Deep discharge electronic card

G. Battery deep discharge alarm button on battery cabinet front door (not shown in

illustration)

Front View

Battery Cabinet (SYPBV96K160HB, G55TBATL10B and G55TBAT2L7C)

A. Battery shelves

B. Battery circuit breaker

C. Ground cable connection (from the UPS)

D. Battery temperature sensor (ATIZ board)

E. Cable terminal board (for ATIZ, circuit breaker detection and power supply)

F. Deep discharge electronic card

G. Battery deep discharge alarm button on battery cabinet front door (not shown in

illustration)

38 990–9866–001

Install Battery Solution 10–40 kVA

Install a Galaxy 300 Battery Cabinet (G3HTBAT1, G3HTBAT2, and

G3HTBAT3)

NOTE: The following procedure shows installing battery cabinet (G3HTBAT1).

Battery options G3HTBAT2 and G3HTBAT3 are installed in the same way as

battery option G3HTBAT1, but these options include two battery cabinets instead

of just one:

• One battery cabinet with batteries, battery breaker, temperature sensor, and

deep discharge alarm indicator, and

• One battery cabinet with only batteries

The two battery cabinets are interconnected with power cables (supplied).

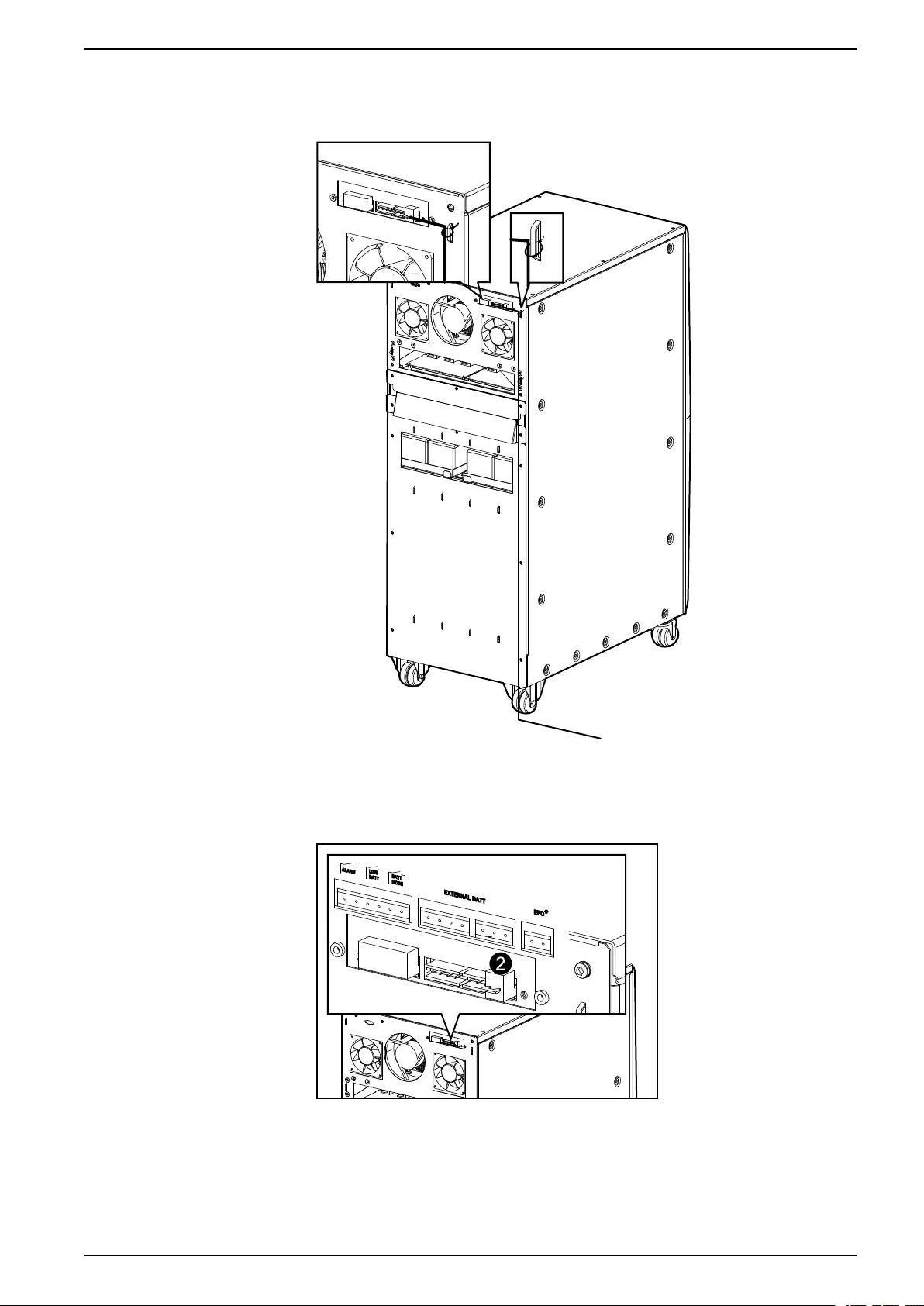

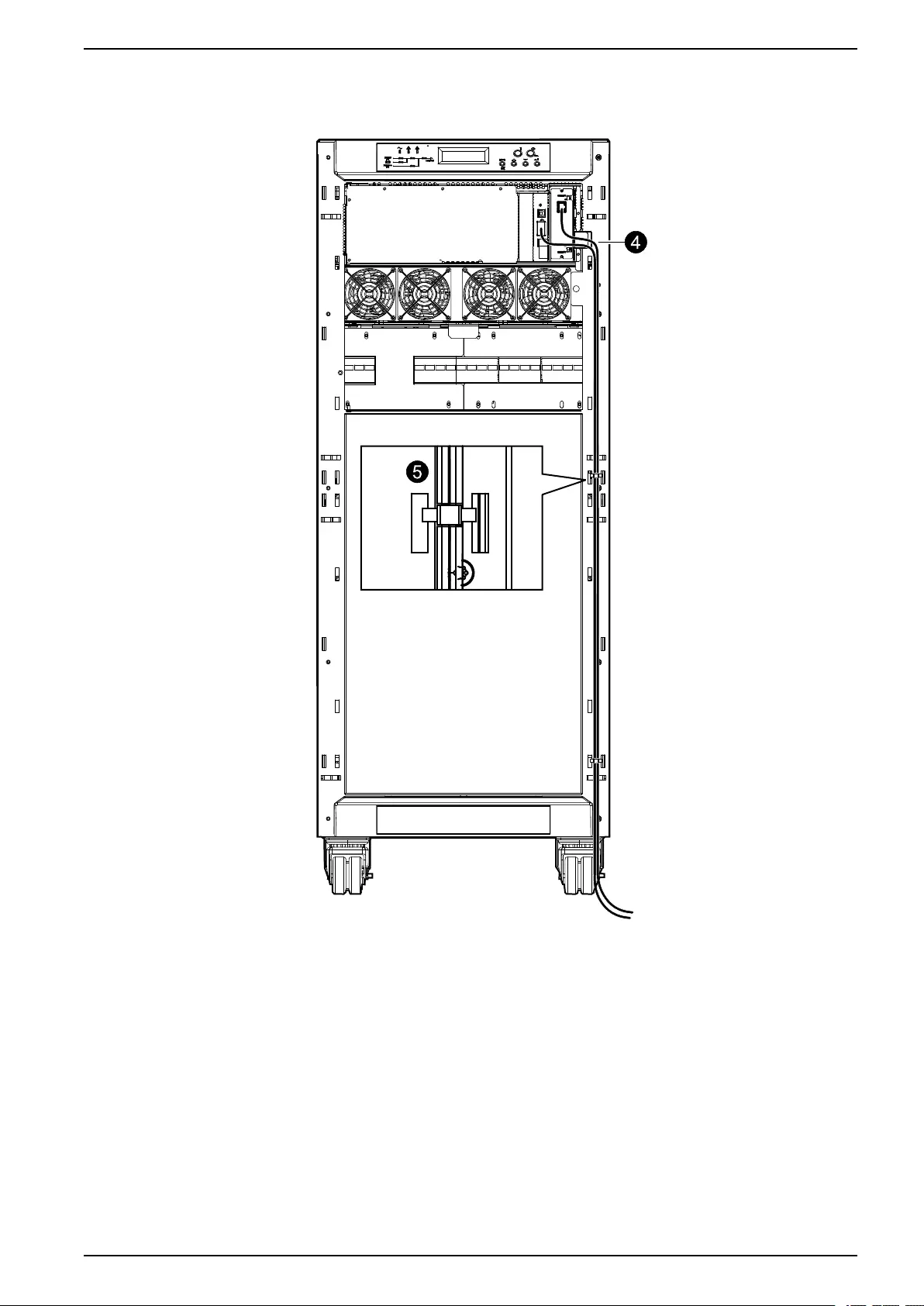

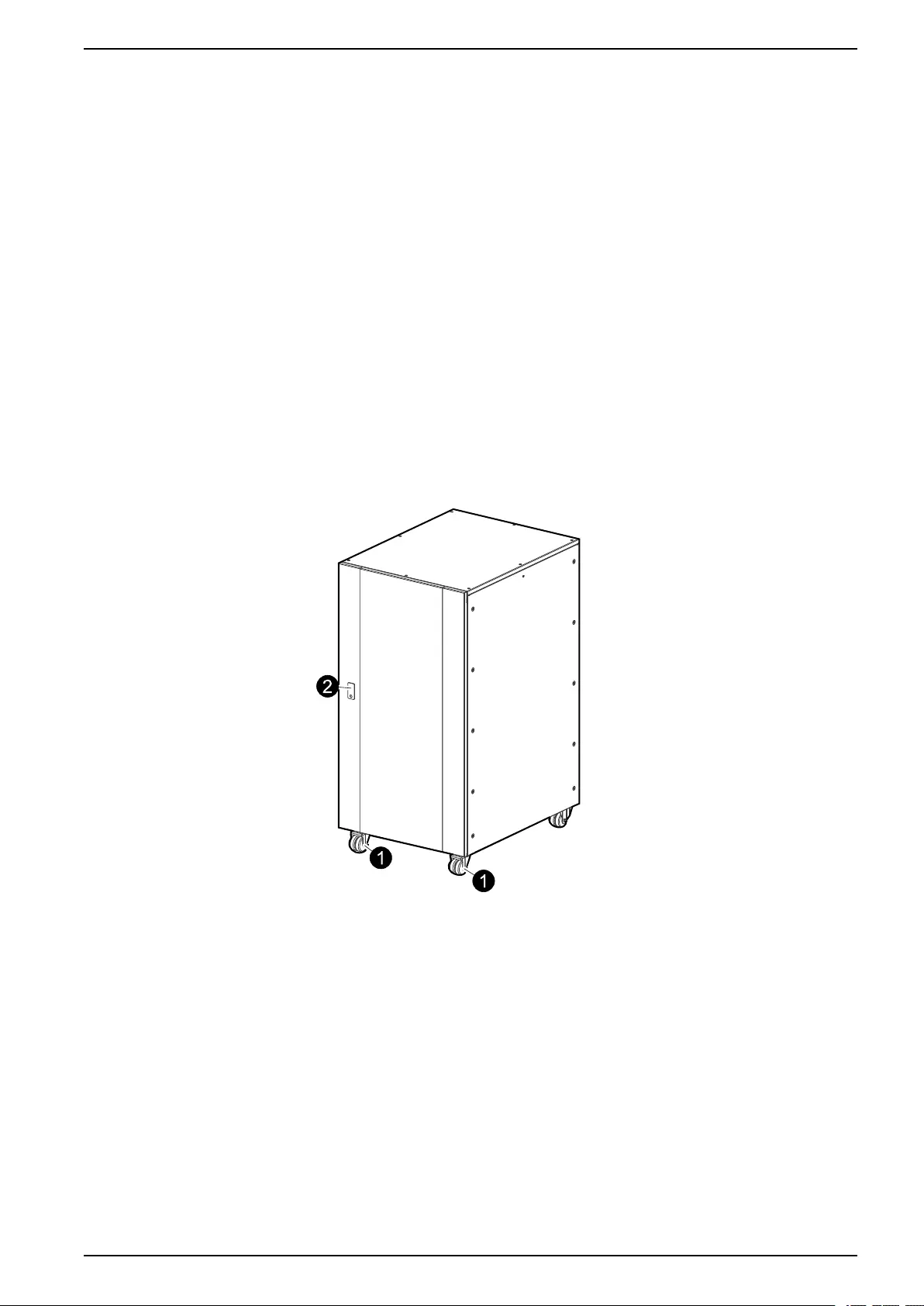

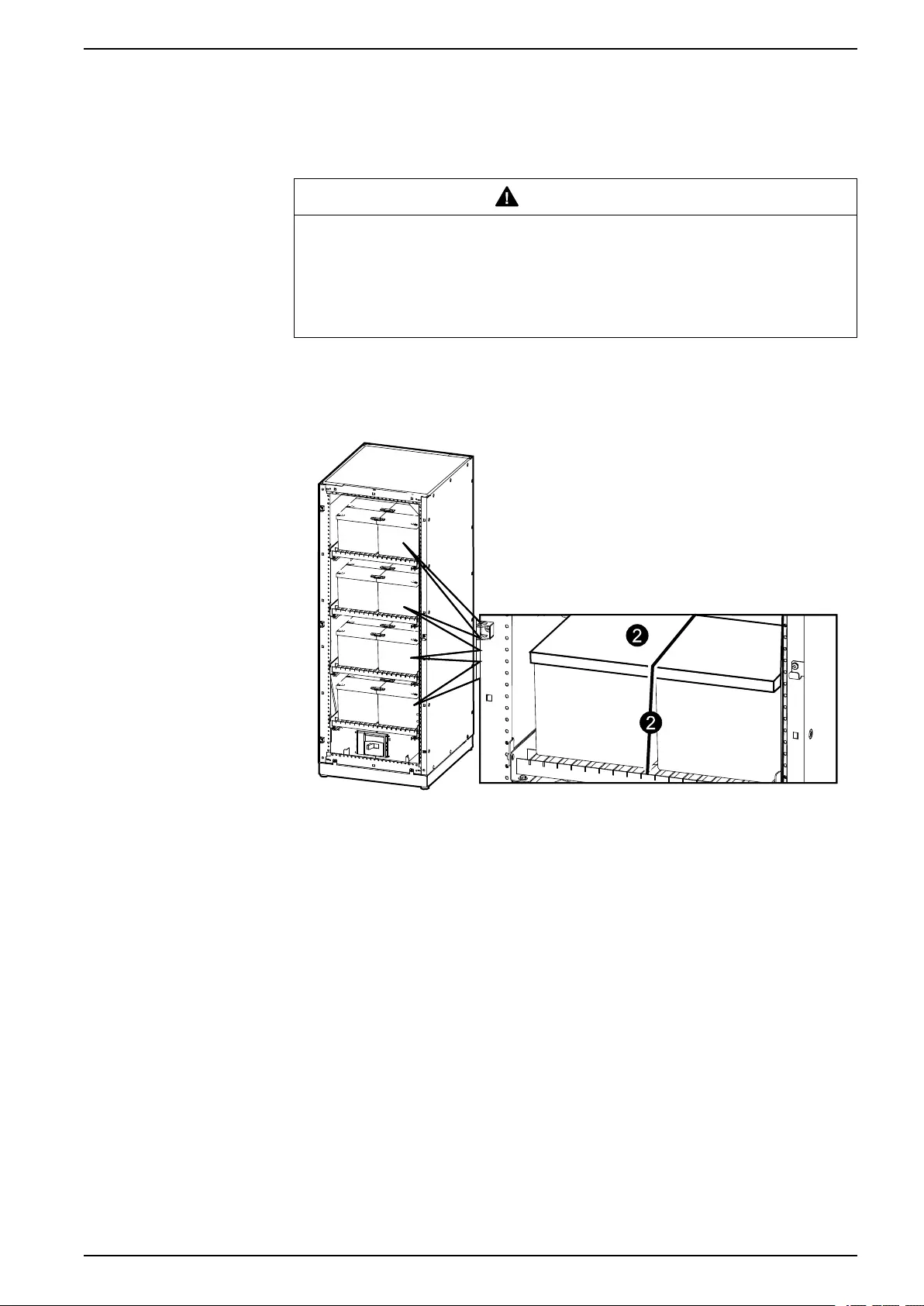

Prepare Galaxy 300 Battery Cabinet (1300 mm) for Cables

1. Lock the two front wheels by tightening the screws.

2. Open the unlocked front door.

NOTE: The key to the door can be found in the accessories package located in

the cabinet.

Front View

990–9866–001 41

10–40 kVA Install Battery Solution

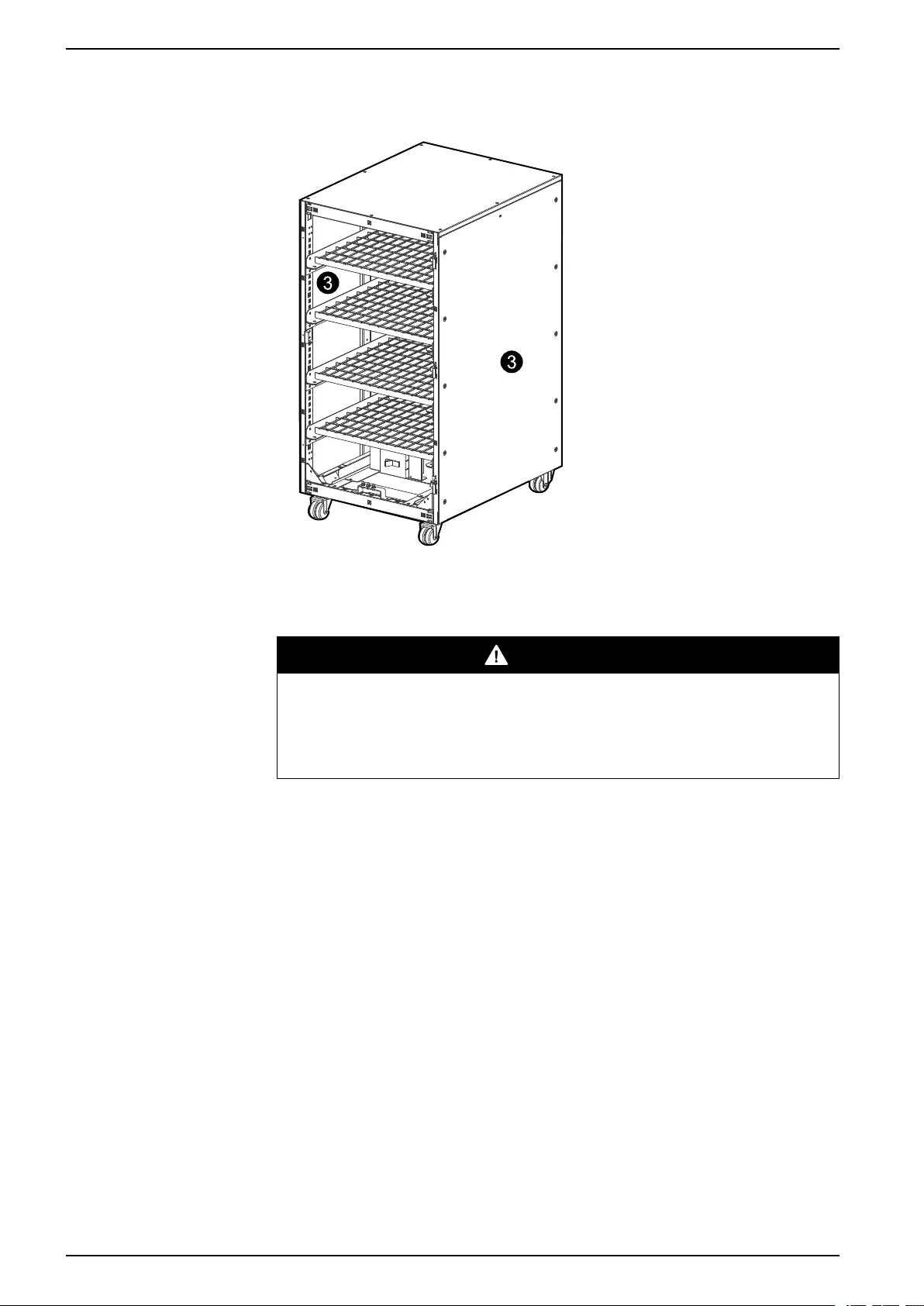

3. Remove both side panels.

Front View

Connect Internal Cables in Galaxy 300 Battery Cabinet (1300

mm) with Pre-Installed Batteries

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Remove all cardboard pieces, which are used to protect the batteries during

transport. Make sure that cables and copper busbars are separated.

Failure to follow these instructions will result in death or serious injury.

NOTE: A maximum of two battery cabinets can be connected to the UPS (one

battery cabinet with a circuit breaker plus one cabinet without a circuit breaker) by

a batch cable between the UPS and the circuit breaker in the battery cabinet.

42 990–9866–001

Install Battery Solution 10–40 kVA

1. Remove the left and right plastic cover from the battery breaker by removing the

four screws (two on each plastic cover).

Front View

2. Cut off the belts to remove the carton paper.

3. Run the cables inside each shelf and connect to the batteries.

4. Run the cables between the shelves.

5. Run the cables between the shelves and the circuit breaker.

NOTE: If the cables have more than one terminal, then the unconnected

terminals must be isolated with insulation tape before connecting the other

terminal.

Front View

990–9866–001 43

10–40 kVA Install Battery Solution

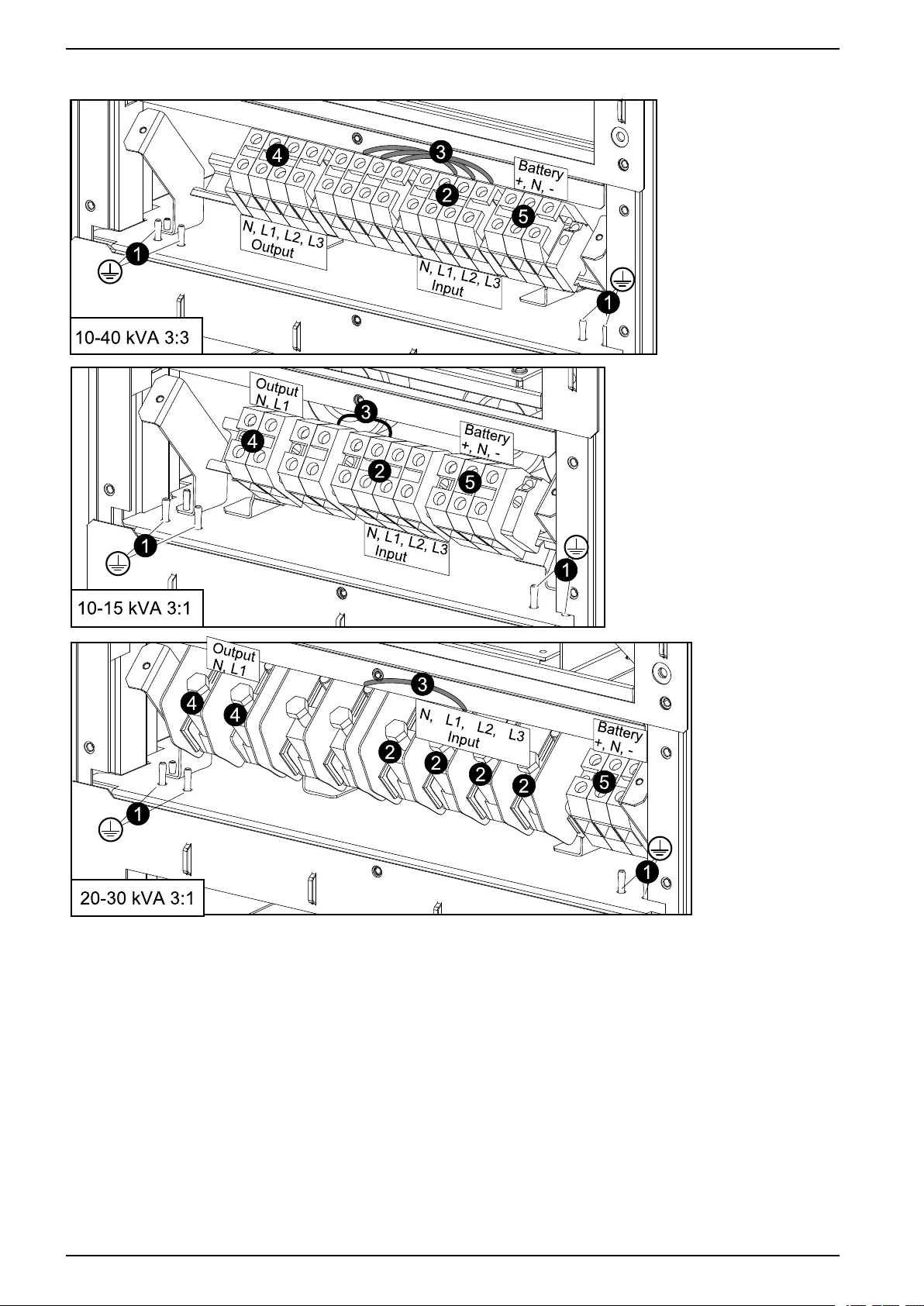

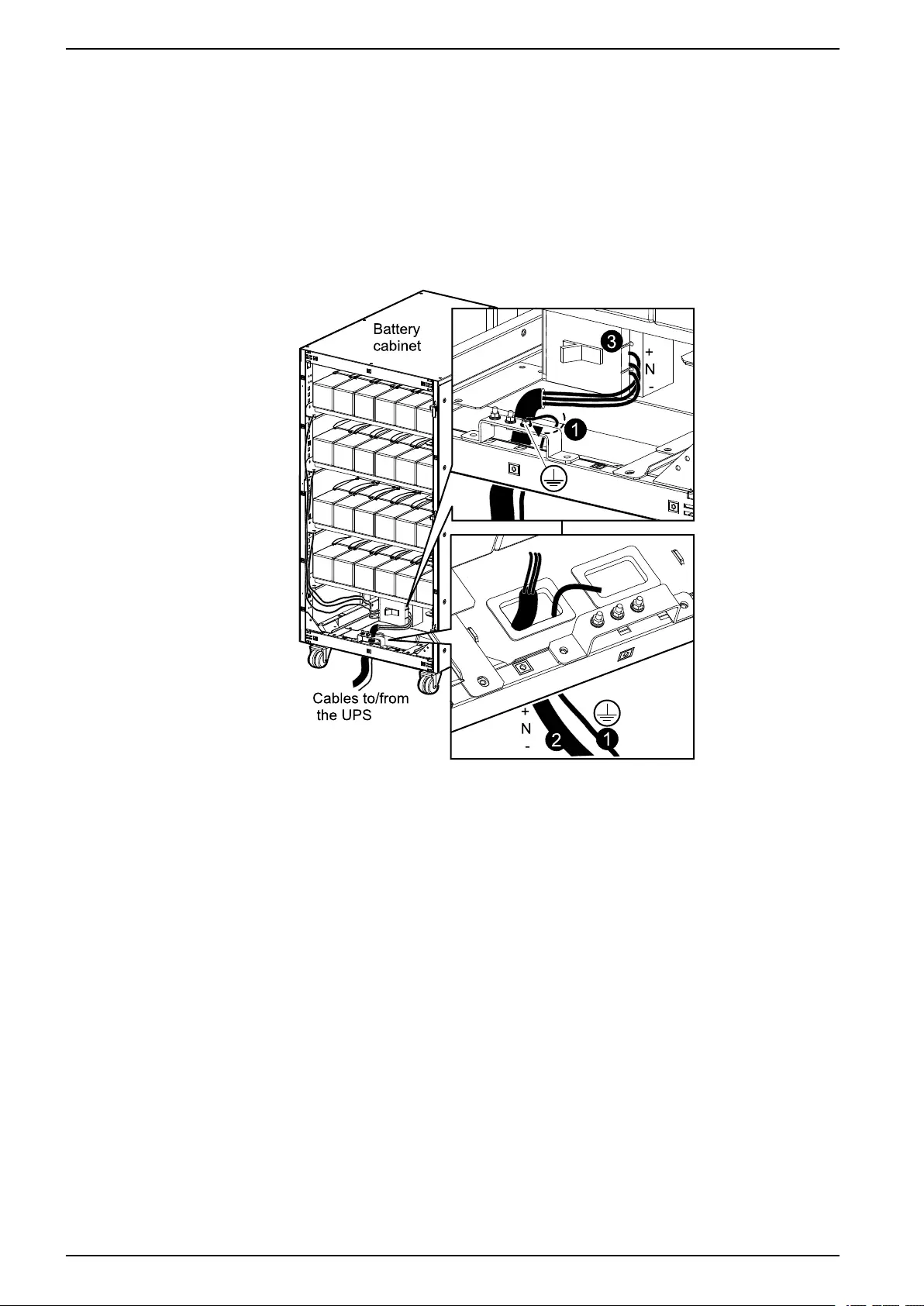

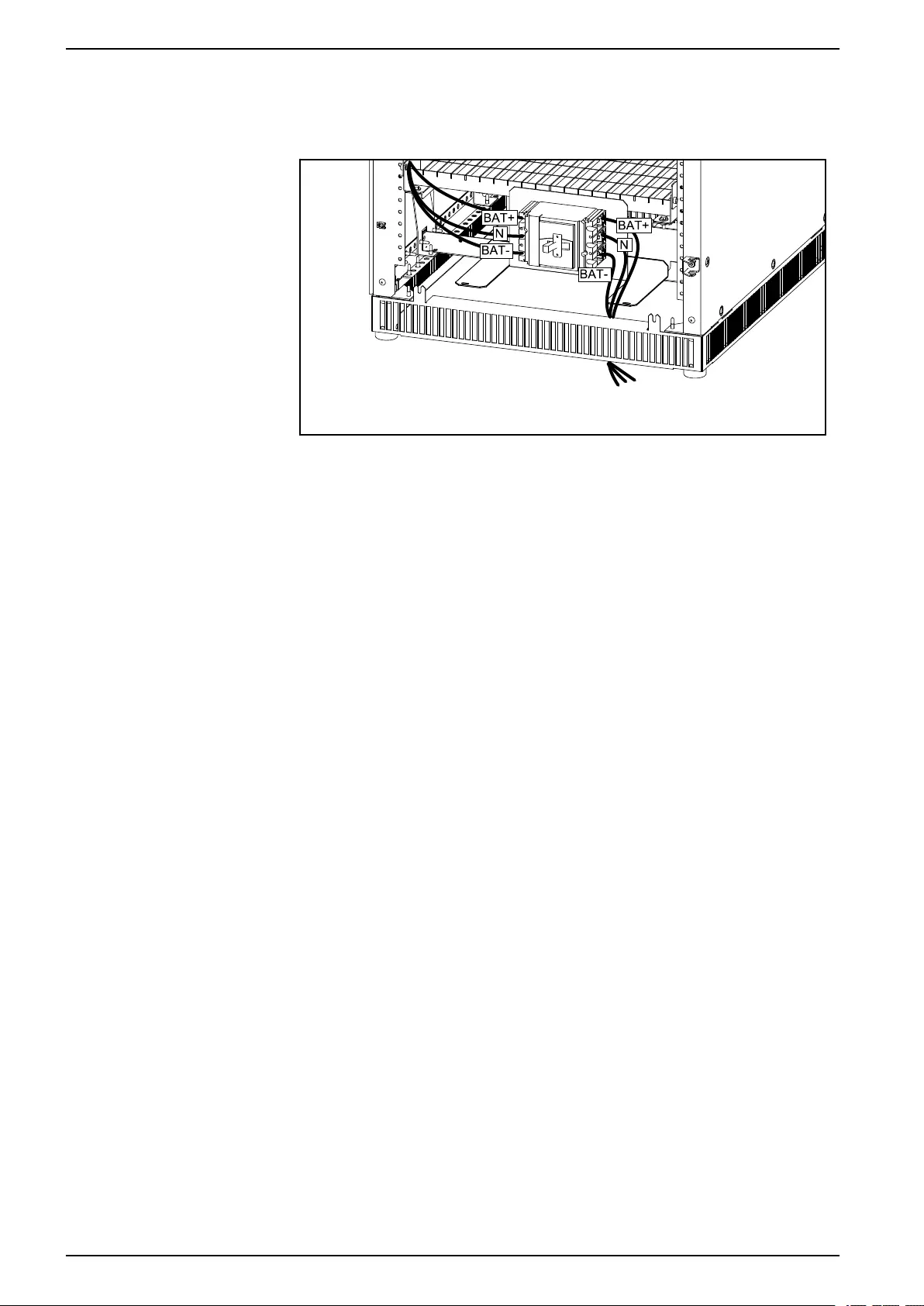

Connect Battery Cables from UPS to the Galaxy 300 Battery Cabinet (1300 mm)

1. Run the Protective Earth (PE) cable from the UPS up through the bottom front

hole of the battery cabinet and connect it to the busbar.

2. Run the battery cables (BAT+, N, and BAT-) from the UPS up through the

bottom front hole.

3. Attach the cables to the right side of the battery breaker.

4. Reinstall the side panels.

Front View

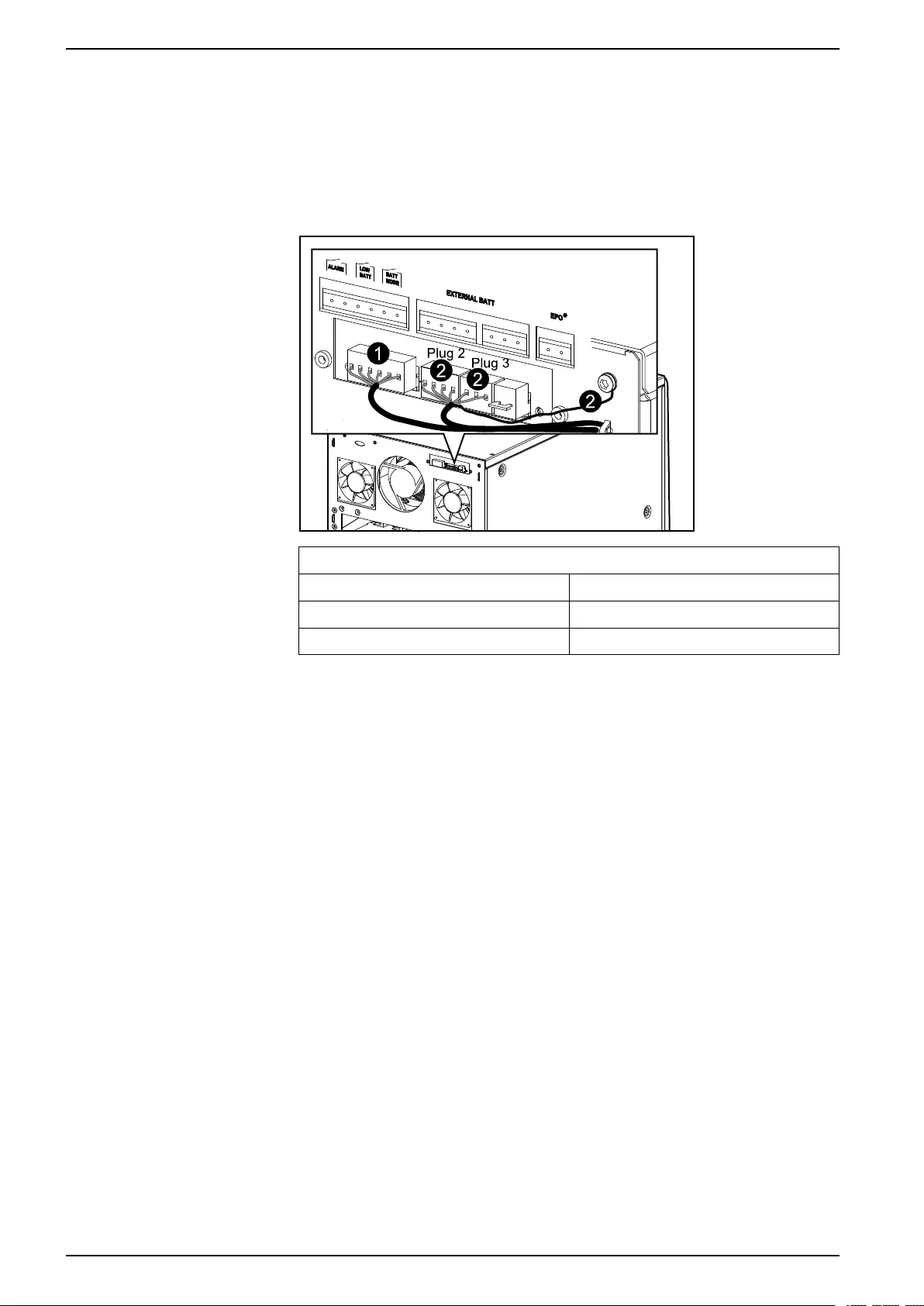

Connect External Battery Temperature (ATIZ) and External Battery Breaker Signal

between the UPS and the Galaxy 300 Battery Cabinet (1300 mm)

NOTE: The ATIZ cable is for the external battery temperature detection signal

(cable is pre-installed).

NOTE: The battery cable is for the external battery breaker signal (cable is pre-

installed).

NOTE: The connection of signal cables is only applicable between the UPS and

battery cabinet 1.

1. Run the combined battery breaker and ATIZ signal cable from the connection

terminal on the battery cabinet to the UPS.

2. Run the four cables from the connection terminal to the battery breaker on the

battery cabinet (see the below table for cable description).

44 990–9866–001

Install Battery Solution 10–40 kVA

3. Connect the combined battery breaker and ATIZ signal cable to the UPS as

shown and make sure to connect the cable with shielded layer to the screw on

the UPS.

Front View of Battery Cabinet (1300 mm)

Cable description

Cable color Cable label Description

Yellow QB OF-11 CB contact signal – to the auxiliary contact

(normally closed)

White QB OF-14 CB contact signal

Red QB OF-D4 +12 V power supply – to the coil terminal

Black QB OF-D1 -12 V power supply

Rear View of the UPS

NOTE: The cable(s) is routed the same way as the EPO cable.

990–9866–001 45

10–40 kVA Install Battery Solution

Connect Battery and Signal Cables from the Battery Cabinet (G3HTBAT1) to a Running

UPS

NOTE: A maximum of two battery cabinets can be connected to the UPS (one

battery cabinet with a circuit breaker plus one cabinet without a circuit breaker) by

a cable between the UPS and the circuit breaker in the battery cabinet.

NOTE: Before carrying out the below procedure, make sure that the UPS is

running in normal operation with no internal UPS alarms displayed. In normal

operation four breakers (QM1,QFB,QM2,QOP) must be in the ON (closed)

position and two breakers (Q3BP,QB) must be in the OFF (open) position.

1. Turn the UPS into maintenance bypass operation:

a. Press the Inverter OFF button for three seconds and then turn the input

breaker (QM1) to the OFF (open) position.

b. Turn the maintenance bypass breaker (Q3BP) to the ON (closed) position.

c. Turn the static bypass breaker (QM2) to the OFF (open) position.

d. Turn the output breaker (QOP) to the OFF (open) position.

2. Isolate the batteries by turning the UPS battery cabinet breaker (QFB) to the

OFF (open) position.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Check the DC voltages with a DC voltage multimeter versus the battery

voltage before continuing.

Failure to follow these instructions will result in death or serious injury.

3. Run a Protective Earth (PE) cable from the UPS up through the bottom front

hole of the battery cabinet and connect it to the busbar.

4. Run the battery cables (BAT+, N, and BAT-) from the UPS up through the

bottom front hole.

5. Attach the cables to the right side of the battery breaker.

46 990–9866–001

Install Battery Solution 10–40 kVA

6. Reinstall the side panels.

Front View of Battery Cabinet (G3HTBAT1)

7. Reinstall the plastic cover and the I/O sheet metal cover removed on the UPS –

these covers were removed while preparing the UPS for cables.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

The I/O sheet metal cover must be fixed in the lowest position for safety

reasons.

Failure to follow these instructions will result in death or serious injury.

990–9866–001 47

10–40 kVA Install Battery Solution

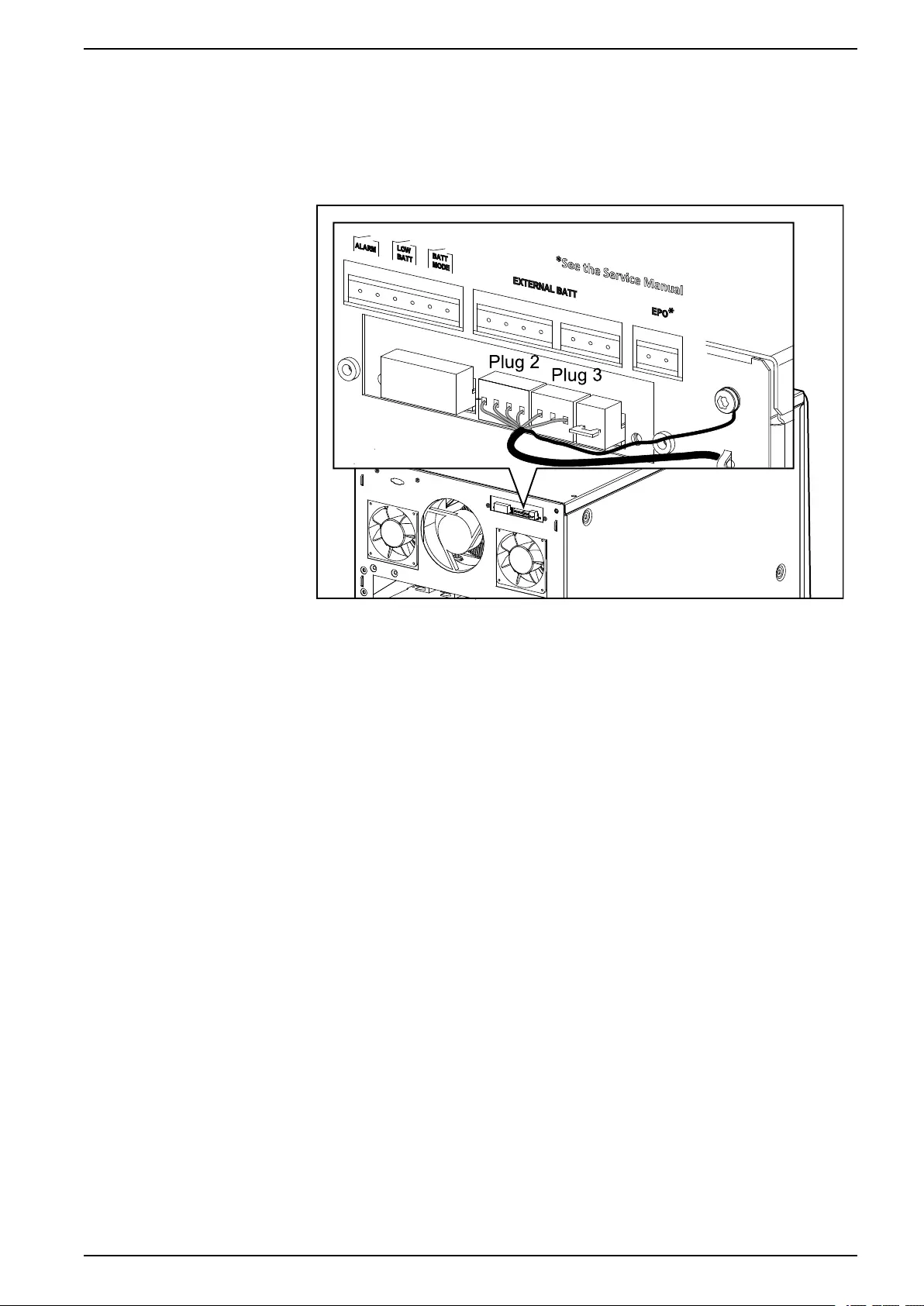

8. Connect the combined battery breaker and ATIZ signal cable to the UPS as

shown and make sure to connect the cable with shielded layer to the screw on

the UPS.

NOTE: See Connect External Battery Temperature (ATIZ) and External Battery

Breaker Signal between the UPS and the Galaxy 300 Battery Cabinet (1300

mm), page 44 for information on how to route the cable(s)

Rear View of the UPS

9. Turn the UPS back into normal operation:

a. Turn the output breaker (QOP) to the ON (closed) position.

b. Turn the static bypass breaker (QM2) to the ON (closed) position.

c. Wait a minute for the static bypass breaker LED and the output breaker LED

to turn green.

d. Turn the maintenance bypass breaker (Q3BP) to the OFF (open) position.

e. Turn the battery cabinet breaker (QFB) to the ON (closed) position.

f. Turn the input breaker (QM1) to the ON (closed) position.

g. When the soft start has finished, press the INVERTER ON button.

10.Check the LEDs to see if the UPS is running in normal operation:

• PFC LED: green

• INVERTER LED: green

• LOAD LED: green

• LOAD PROTECTED LED: green

• Other LEDs: OFF

48 990–9866–001

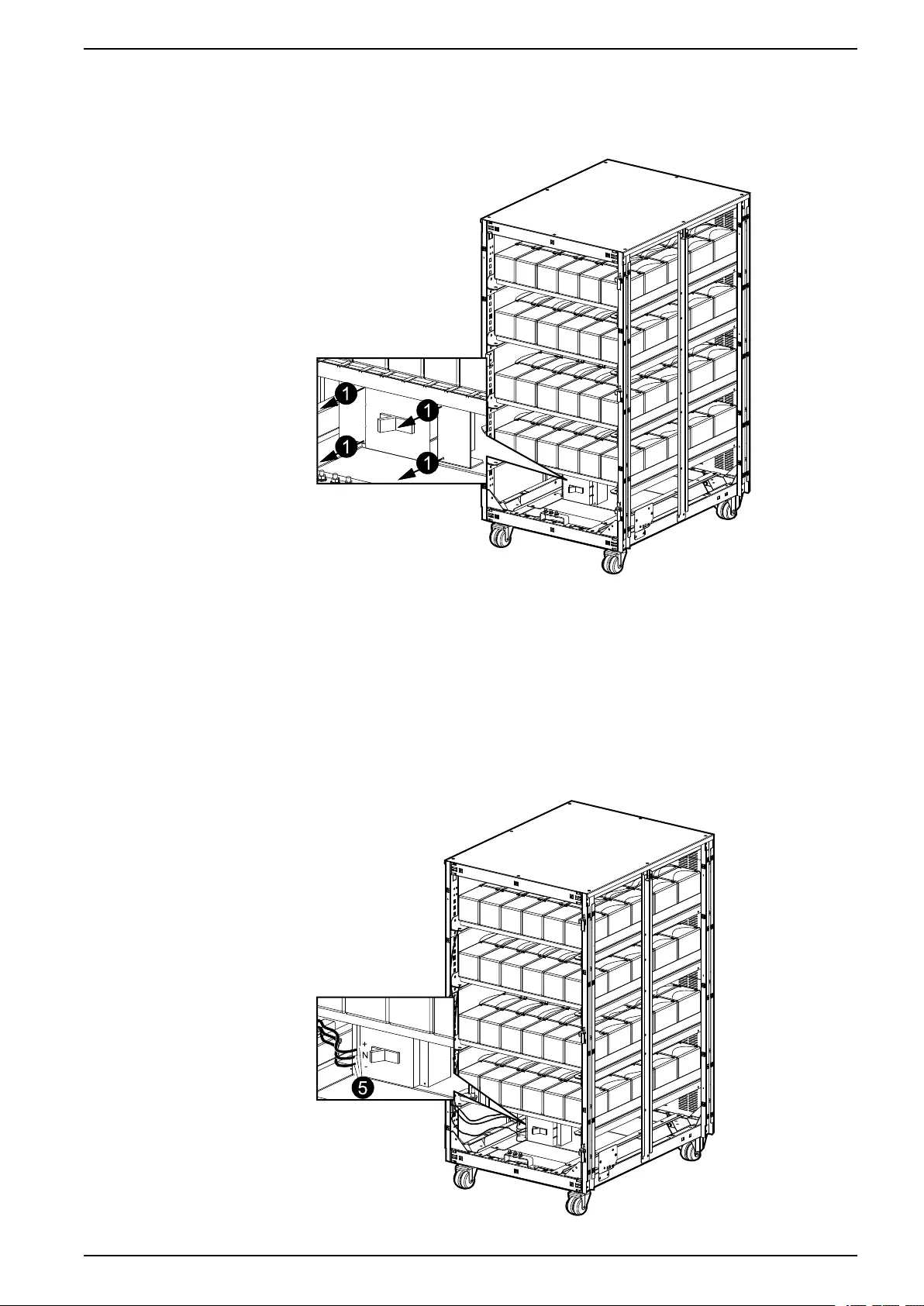

Install Battery Solution 10–40 kVA

Install a Battery Cabinet (SYPBV96K160HB, G55TBATL10B, and

G55TBAT2L7C)

Remove Battery Protection on Batteries

WARNING

HAZARD OF ELECTRIC SHOCK

Transportation straps and paperboard must be removed from the battery before

installation.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

1. Remove the cable and copper bar kit from the cabinet and save for battery

installation.

2. Remove the transportation straps and the paperboard from the batteries.

Connect Battery Cables from the UPS to the Battery Cabinet (SYPBV96K160HB,

G55TBATL10B, or G55TBAT2L7C)

1. Connect the Protective Earth (PE) cable between the battery cabinet(s) and the

UPS.

2. Interconnect the batteries on each shelf.

3. Interconnect all the battery shelves and then connect the battery cables (BAT+,

BAT-, N) from the overall battery assembly to the battery circuit breaker in the

battery cabinet as shown in the illustration.

4. If more than one battery cabinet is installed: Connect the BAT+, BAT-, and N

cables (not provided) between the battery cabinets in a daisy chain.

990–9866–001 49

10–40 kVA Install Battery Solution

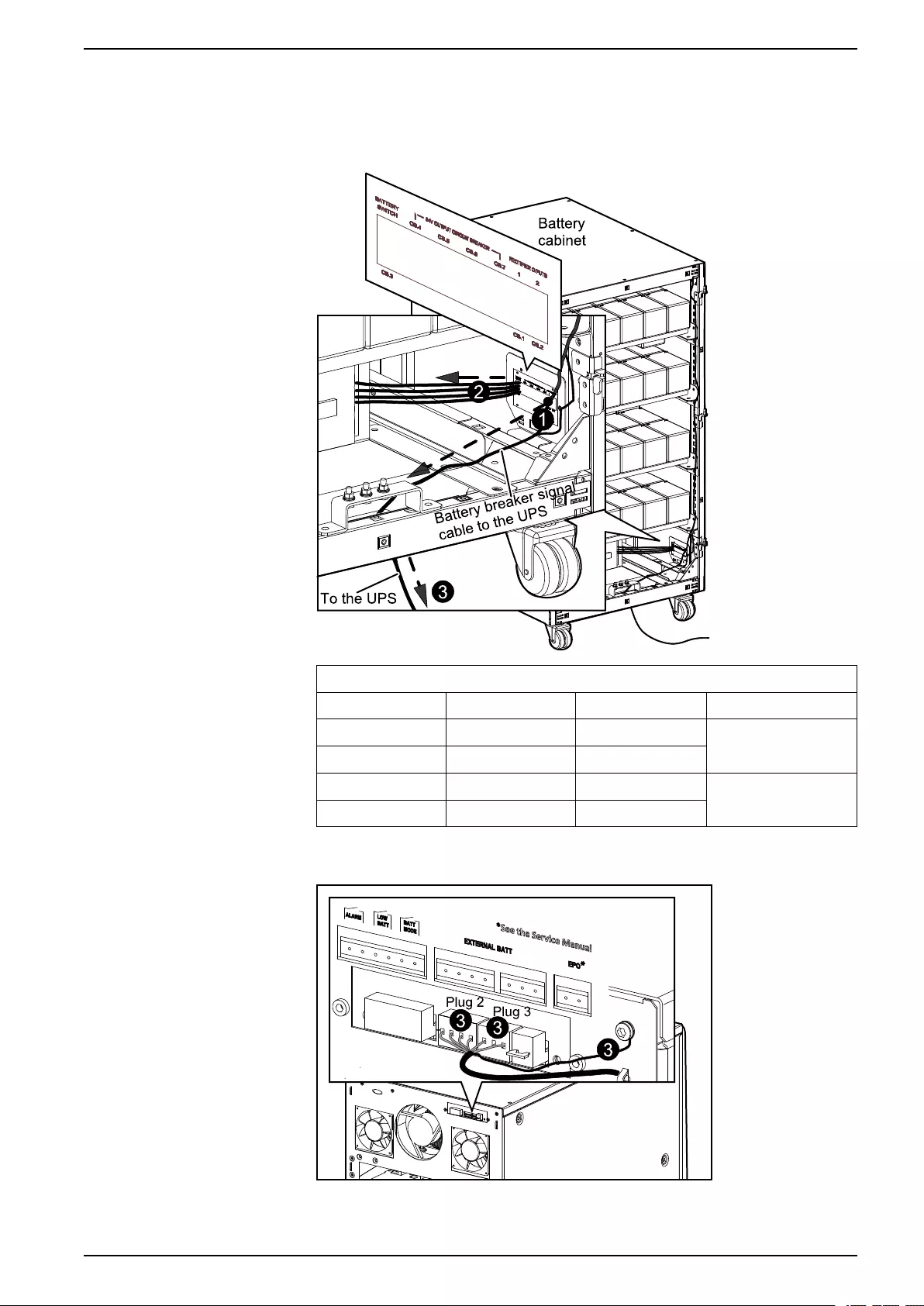

5. Connect the battery cables (BAT+, BAT-, N) from the UPS to the battery circuit

breaker in the battery cabinet that will be connected to the UPS.

Front View of the Battery Cabinet

Connect Signal Cables Between the UPS and the Battery Cabinet (SYPBV96K160HB,

G55TBATL10B and G55TBAT2L7C)

NOTE: The ATIZ cable is for the external battery temperature detection signal

(cable is preinstalled).

NOTE: The battery cable is for the external battery breaker signal (cable is

preinstalled).

NOTE: The connection of signal cables is only applicable between the UPS and

battery cabinet 1.

1. Run the combined battery breaker and ATIZ signal cable from the cable

terminal board in the battery cabinet to the UPS.

50 990–9866–001

10–40 kVA Install Battery Solution

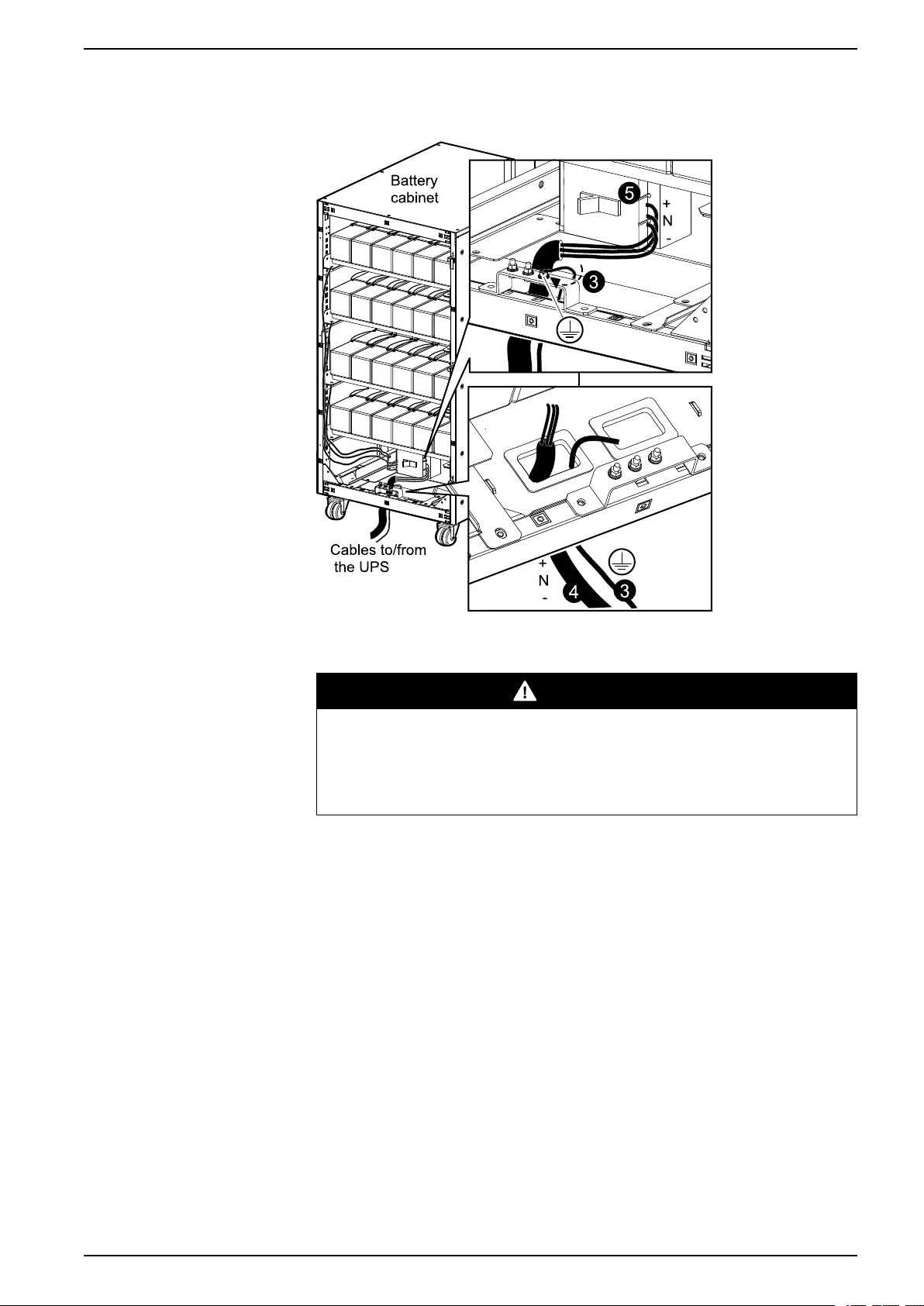

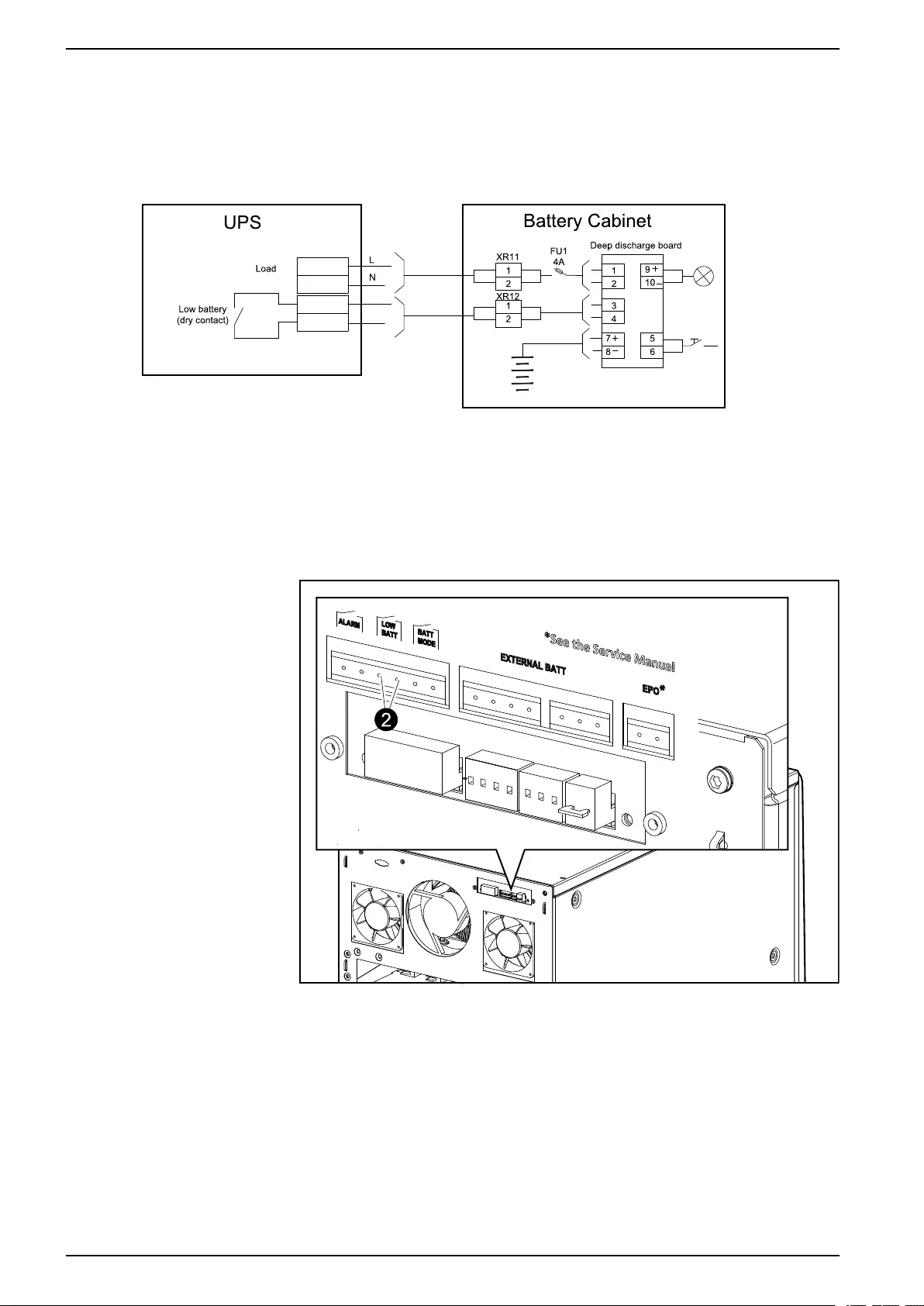

Connect the Deep Discharge Signal Cables Between the Battery

Cabinet and the UPS

NOTE: The deep discharge signal cables are connected in the same way on all

battery cabinet types. Refer to Battery Cabinet Product Overview, page 38 for

location of deep discharge board.

1. Connect signal cable from the deep discharge board XR11 terminals in the

battery cabinet to the input terminals (L1 and N) in the UPS cabinet.

2. Connect signal cable from the deep discharge board XR12 terminals in the

battery cabinet to the dry contact for LOW BATT in the rear of the UPS cabinet.

Rear View of the UPS

52 990–9866–001

Checklist after Installation 10–40 kVA

Checklist after Installation

UPS

• Check that the power wiring is torqued correctly.

• Check that the power wiring (for deep discharge card connections L1 and N) is

torqued correctly.

• Check that the auxiliary contact wiring (for deep discharge card) is torqued

correctly.

• Verify clockwise phase-rotation (L1, L2, L3) and make sure that a neutral

connection is present.

• Leave a wiring diagram on site for service personnel.

• Leave instruction manual for emergency lighting on site for service personnel.

• Reinstall all wiring access panels.

• Make sure that all battery breakers on the UPS unit are in the OFF (opened)

position.

Battery Solution

• Check that the power wiring is torqued as recommended by the battery vendor.

• If there are two battery cabinets, check that the power cable between two

battery cabinets is installed and torqued correctly.

• Check that the power wiring (for deep discharge card connections L1 and N)

are torqued correctly.

• Check that the auxiliary contact wiring (for deep discharge card) is torqued

correctly.

• Check that the battery voltage wiring (5 blocks of 12 V on deep discharge card)

is torqued correctly.

• Verify the polarity of battery cable connection (BAT+, N and BAT-).

• Leave a wiring diagram on site for service personnel.

• Reinstall all wiring access panels.

• Make sure that all battery breakers on the battery solution are in the OFF

(opened) position.

990–9866–001 53

Schneider Electric

35 rue Joseph Monier

92500 Rueil Malmaison

France

+ 33 (0) 1 41 29 70 00

www.schneider-electric.com

As standards, specifications, and design change from time to time,

please ask for confirmation of the information given in this publication.

© 2015 – 2015 Schneider Electric. All rights reserved.

990–9866–001