Table of Contents

- Important Safety Instructions — SAVE THESE INSTRUCTIONS

- Specifications

- Overview of Installation Kits

- Installation Procedure for Top Cable Entry

- Installation Procedure for Bottom Cable Entry

- Prepare the Maintenance Bypass Cabinet and the UPS for Cables

- Install the Seismic Anchoring (Option)

- Connect the Power Cables in a 10–80 kW Top Cable Entry System

- Connect the Power Cables in a 100–150 kW Top Cable Entry System

- Restrain the Cables

- Connect the Power Cables in a Bottom Cable Entry System

- Connect the Internal Power Cables

- Interconnect the UPS and the Maintenance Bypass Cabinet

- Connect the Signal Cables

- Final Installation

- Blank Page

- Blank Page

APC GVSBPSU80G User Manual

Displayed below is the user manual for GVSBPSU80G by APC which is a product in the UPS Accessories category. This manual has pages.

Related Manuals

Galaxy VS

Maintenance Bypass Cabinet

Installation

07/2018

www.schneider-electric.com

Legal Information

The Schneider Electric brand and any registered trademarks of Schneider Electric

Industries SAS referred to in this guide are the sole property of Schneider Electric

SA and its subsidiaries. They may not be used for any purpose without the owner's

permission, given in writing. This guide and its content are protected, within the

meaning of the French intellectual property code (Code de la propriété

intellectuelle français, referred to hereafter as "the Code"), under the laws of

copyright covering texts, drawings and models, as well as by trademark law. You

agree not to reproduce, other than for your own personal, noncommercial use as

defined in the Code, all or part of this guide on any medium whatsoever without

Schneider Electric's permission, given in writing. You also agree not to establish

any hypertext links to this guide or its content. Schneider Electric does not grant

any right or license for the personal and noncommercial use of the guide or its

content, except for a non-exclusive license to consult it on an "as is" basis, at your

own risk. All other rights are reserved.

Electrical equipment should be installed, operated, serviced, and maintained only

by qualified personnel. No responsibility is assumed by Schneider Electric for any

consequences arising out of the use of this material.

As standards, specifications, and designs change from time to time, please ask for

confirmation of the information given in this publication.

Maintenance Bypass Cabinet

Table of Contents

Important Safety Instructions — SAVE THESE

INSTRUCTIONS.........................................................................................5

FCC Statement ..........................................................................................6

Safety Precautions .....................................................................................6

Additional Safety Precautions After Installation........................................8

Electrical Safety .........................................................................................8

Battery Safety ............................................................................................9

Specifications ............................................................................................10

Maximum Input Short-Circuit Withstand......................................................10

Specifications for 480 V Systems ............................................................... 10

Trip Settings for 480 V.........................................................................10

Recommended Upstream Protection 480 V ..........................................10

Recommended Cable Sizes 480 V ....................................................... 11

Specifications for 208 V Systems ............................................................... 12

Trip Settings for 200/208/220 V ............................................................12

Recommended Upstream Protection 200/208/220 V .............................12

Recommended Cable Sizes 200/208/220 V ..........................................13

Specifications for 400 V Systems ............................................................... 14

Trip Settings for 400/415 V ..................................................................14

Recommended Upstream Protection 400/415 V ....................................14

Recommended Cable Sizes 400/415 V.................................................15

Recommended Bolt and Lug Sizes ............................................................16

Torque Specifications................................................................................16

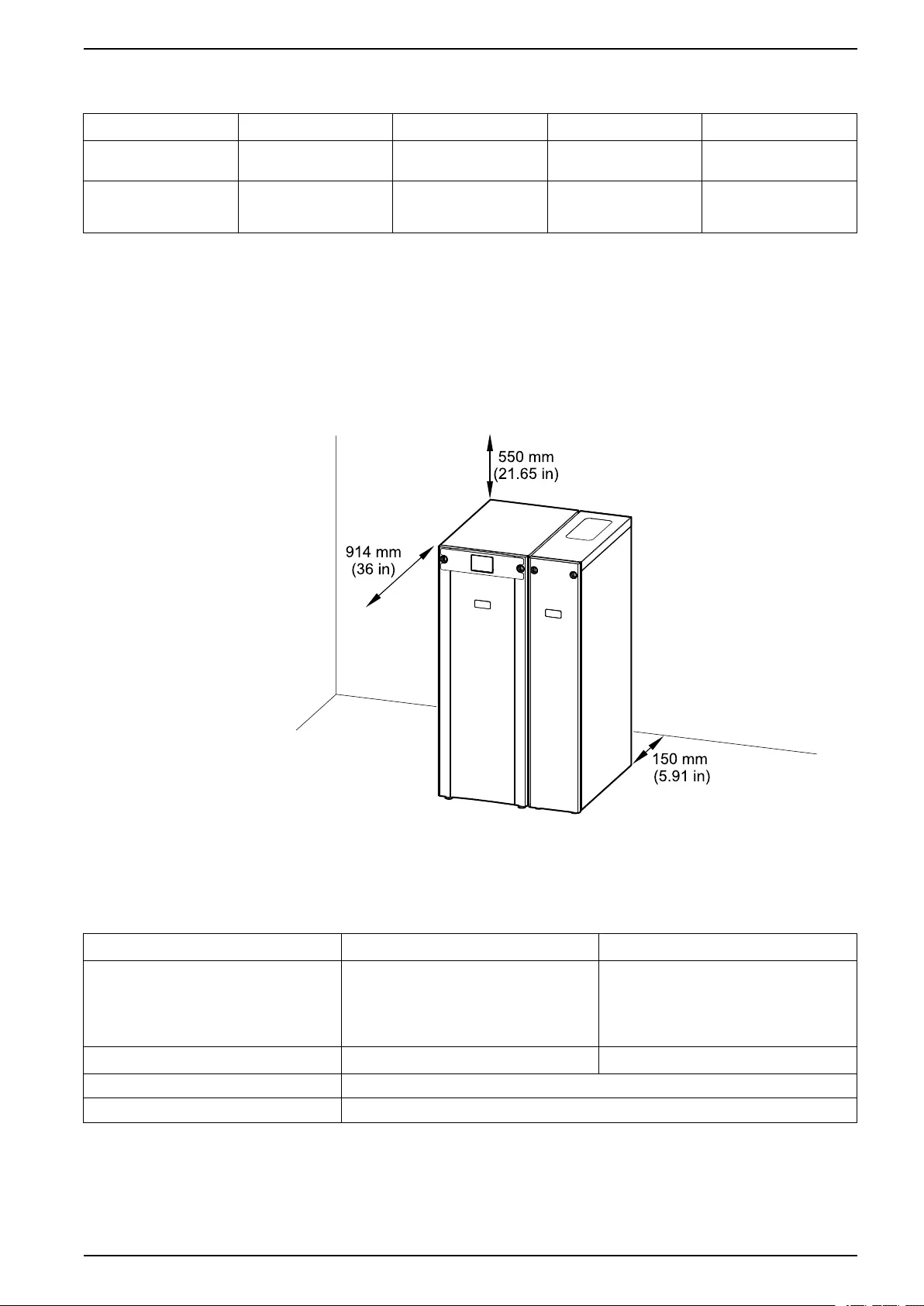

Maintenance Bypass Cabinet Weights and Dimensions...............................17

Clearance ................................................................................................17

Environment.............................................................................................17

System Overview .....................................................................................18

Overview of Installation Kits ....................................................................19

Optional Seismic Kit GVSOPT003 .............................................................21

Optional Kirk Key Kit GVSOPT004.............................................................22

Installation Procedure for Top Cable Entry ...........................................23

Installation Procedure for Bottom Cable Entry .....................................24

Prepare the Maintenance Bypass Cabinet and the UPS for

Cables.........................................................................................................25

Install the Seismic Anchoring (Option) ..................................................30

Connect the Power Cables in a 10–80 kW Top Cable Entry

System........................................................................................................32

Connect the Power Cables in a 100–150 kW Top Cable Entry

System........................................................................................................34

Restrain the Cables ..................................................................................36

Connect the Power Cables in a Bottom Cable Entry System.............38

Connect the Internal Power Cables .......................................................39

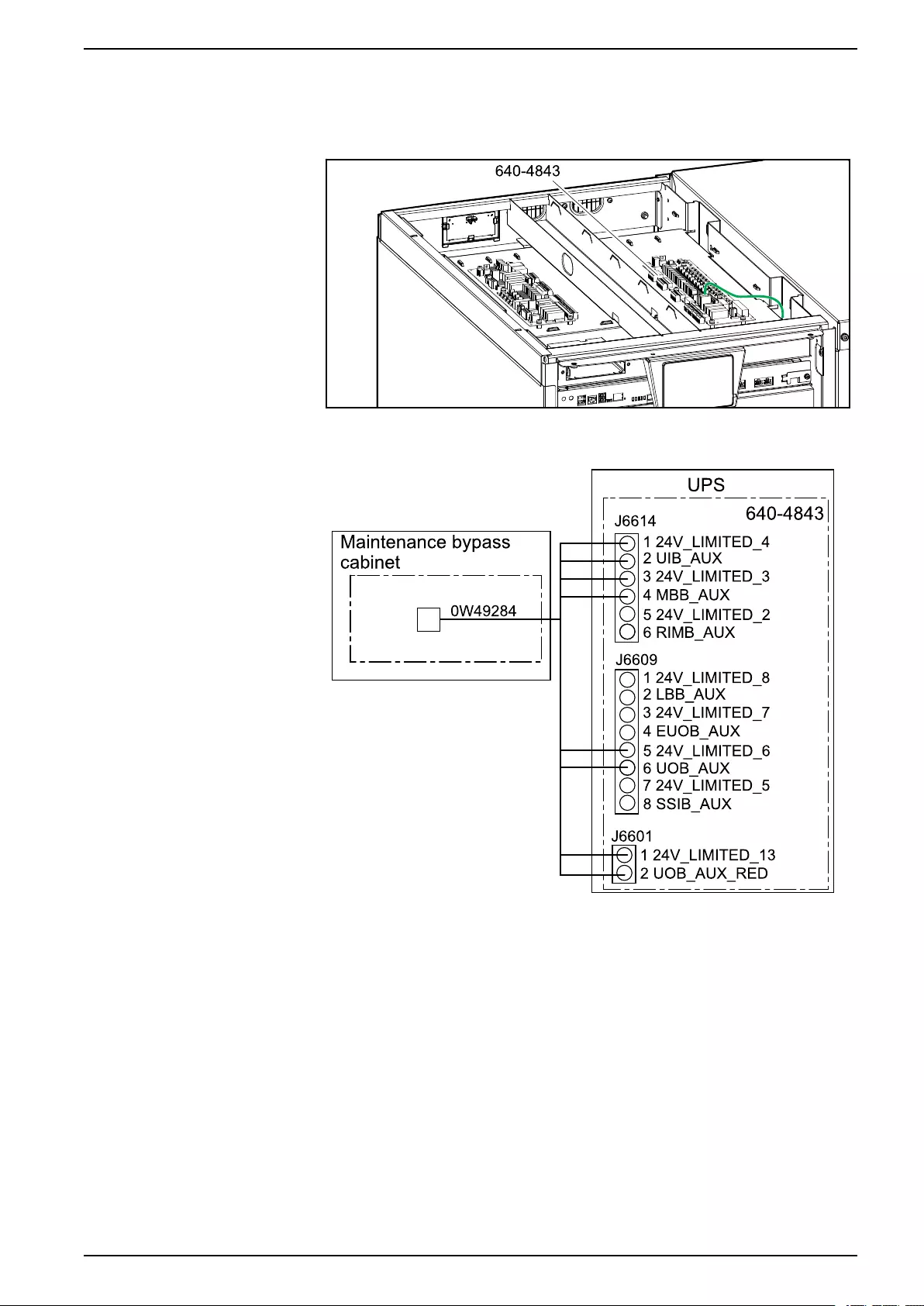

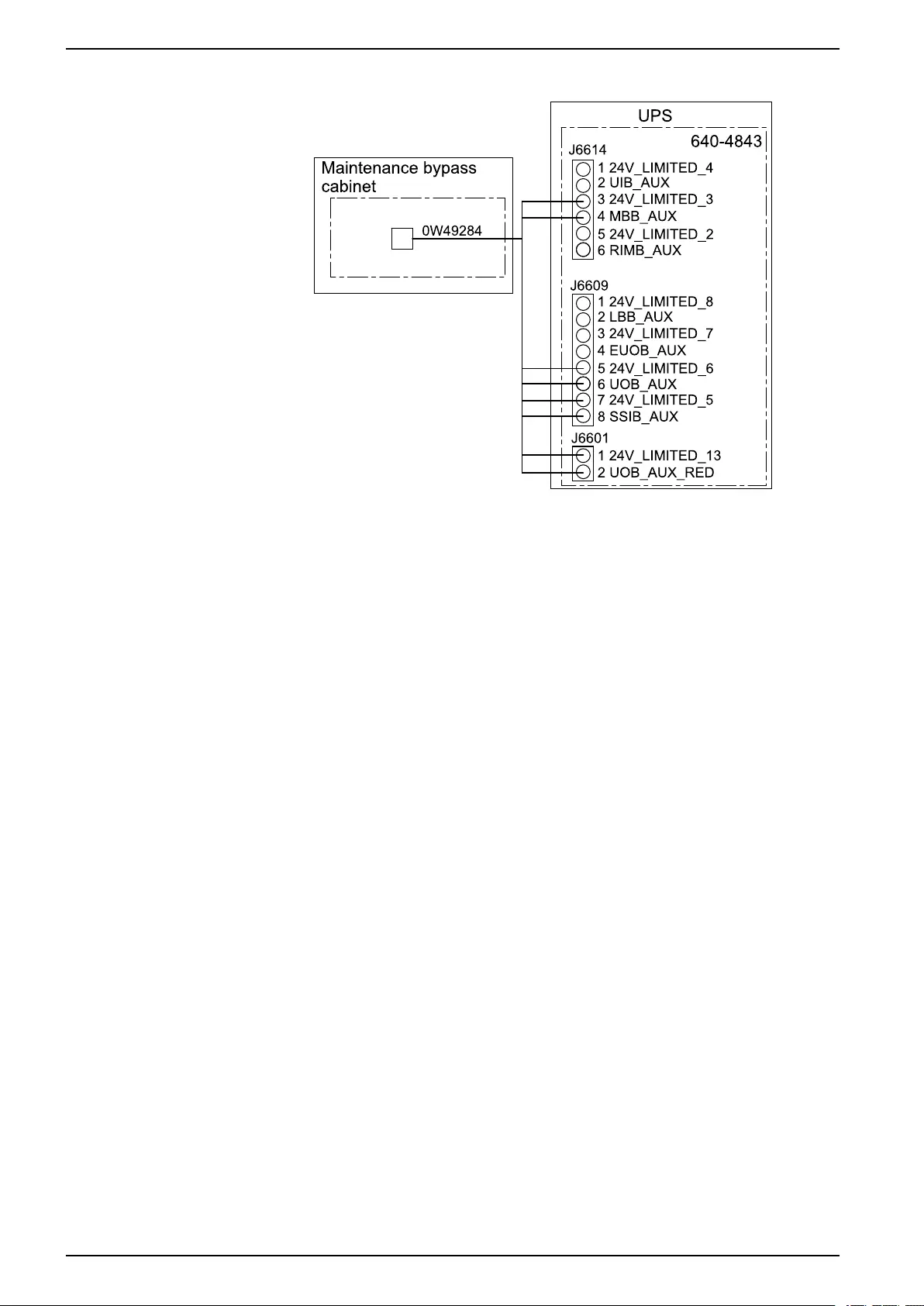

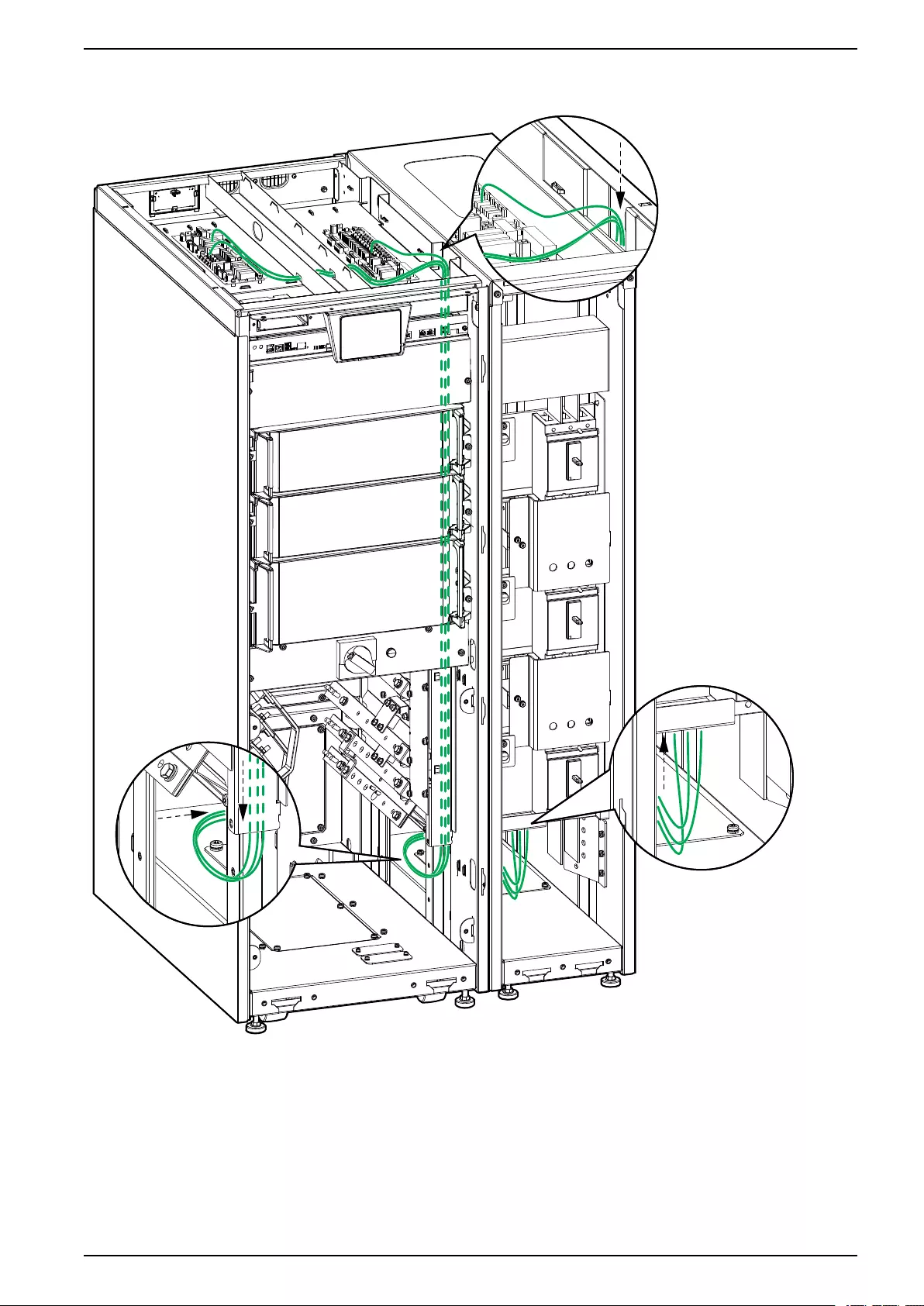

Interconnect the UPS and the Maintenance Bypass Cabinet ............42

Connect the Signal Cables......................................................................46

Final Installation ........................................................................................50

990-5909-001 3

Important Safety Instructions — SAVE THESE

INSTRUCTIONS Maintenance Bypass Cabinet

Important Safety Instructions — SAVE THESE

INSTRUCTIONS

Read these instructions carefully and look at the equipment to become familiar with

it before trying to install, operate, service or maintain it. The following safety

messages may appear throughout this manual or on the equipment to warn of

potential hazards or to call attention to information that clarifies or simplifies a

procedure.

The addition of this symbol to a “Danger” or “Warning” safety

message indicates that an electrical hazard exists which will result in

personal injury if the instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages with this symbol

to avoid possible injury or death.

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

Failure to follow these instructions will result in death or serious injury.

WARNING

WARNING indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

Failure to follow these instructions can result in injury or equipment

damage.

NOTICE

NOTICE is used to address practices not related to physical injury. The safety

alert symbol shall not be used with this type of safety message.

Failure to follow these instructions can result in equipment damage.

Please Note

Electrical equipment should only be installed, operated, serviced, and maintained

by qualified personnel. No responsibility is assumed by Schneider Electric for any

consequences arising out of the use of this material.

A qualified person is one who has skills and knowledge related to the construction,

installation, and operation of electrical equipment and has received safety training

to recognize and avoid the hazards involved.

990-5909-001 5

Maintenance Bypass Cabinet

Important Safety Instructions — SAVE THESE

INSTRUCTIONS

FCC Statement

NOTE: This equipment has been tested and found to comply with the limits for

a Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user

will be required to correct the interference at his own expense.

Any changes or modifications not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

Safety Precautions

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Read all instructions in the installation manual before installing or working on this

product.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Do not install the product until all construction work has been completed and the

installation room has been cleaned.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

The product must be installed according to the specifications and requirements

as defined by Schneider Electric. It concerns in particular the external and

internal protections (upstream breakers, battery breakers, cabling, etc.) and

environmental requirements. No responsibility is assumed by Schneider Electric

if these requirements are not respected.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

The UPS system must be installed according to local and national regulations.

Install the UPS according to:

• IEC 60364 (including 60364–4–41- protection against electric shock, 60364–

4–42 - protection against thermal effect, and 60364–4–43 - protection against

overcurrent), or

• NEC NFPA 70, or

• Canadian Electrical Code (C22.1, Part 1)

depending on which one of the standards apply in your local area.

Failure to follow these instructions will result in death or serious injury.

6 990-5909-001

Important Safety Instructions — SAVE THESE

INSTRUCTIONS Maintenance Bypass Cabinet

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Install the product in a temperature controlled indoor environment free of

conductive contaminants and humidity.

• Install the product on a non-flammable, level and solid surface (e.g. concrete)

that can support the weight of the system.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

The product is not designed for and must therefore not be installed in the

following unusual operating environments:

• Damaging fumes

• Explosive mixtures of dust or gases, corrosive gases, or conductive or radiant

heat from other sources

• Moisture, abrasive dust, steam or in an excessively damp environment

• Fungus, insects, vermin

• Salt-laden air or contaminated cooling refrigerant

• Pollution degree higher than 2 according to IEC 60664-1

• Exposure to abnormal vibrations, shocks, and tilting

• Exposure to direct sunlight, heat sources, or strong electromagnetic fields

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Do not drill or cut holes for cables or conduits with the gland plates installed and

do not drill or cut holes in close proximity to the UPS.

Failure to follow these instructions will result in death or serious injury.

WARNING

HAZARD OF ARC FLASH

Do not make mechanical changes to the product (including removal of cabinet

parts or drilling/cutting of holes) that are not described in the installation manual.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

NOTICE

RISK OF OVERHEATING

Respect the space requirements around the product and do not cover the

ventilation openings when the product is in operation.

Failure to follow these instructions can result in equipment damage.

990-5909-001 7

Maintenance Bypass Cabinet

Important Safety Instructions — SAVE THESE

INSTRUCTIONS

Additional Safety Precautions After Installation

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Do not install the UPS system until all construction work has been completed

and the installation room has been cleaned. If additional construction work is

needed in the installation room after this product has been installed, turn off the

product and cover the product with the protective packaging bag the product was

delivered in.

Failure to follow these instructions will result in death or serious injury.

Electrical Safety

This manual contains important safety instructions that should be followed during

the installation and maintenance of the UPS system.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Electrical equipment must be installed, operated, serviced, and maintained

only by qualified personnel.

• Apply appropriate personal protective equipment (PPE) and follow safe

electrical work practices.

• Disconnection devices for AC and DC must be provided by others, be readily

accessible, and the function of the disconnect device marked for its function.

• Turn off all power supplying the UPS system before working on or inside the

equipment.

• Before working on the UPS system, check for hazardous voltage between all

terminals including the protective earth.

• The UPS contains an internal energy source. Hazardous voltage can be

present even when disconnected from the mains supply. Before installing or

servicing the UPS system, ensure that the units are OFF and that mains and

batteries are disconnected. Wait five minutes before opening the UPS to

allow the capacitors to discharge.

• The UPS must be properly earthed/grounded and due to a high leakage

current, the earthing/grounding conductor must be connected first.

Failure to follow these instructions will result in death or serious injury.

When the UPS input is connected through external isolators that, when opened,

isolate the neutral or when the automatic backfeed isolation is provided external to

the equipment or is connected to an IT power distribution system, a label must be

fitted at the UPS input terminals, and on all primary power isolators installed

remotely from the UPS area and on external access points between such isolators

and the UPS, by the user, displaying the following text (or equivalent in a language

which is acceptable in the country in which the UPS system is installed):

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Risk of voltage backfeed. Before working on this circuit: Isolate the UPS and

check for hazardous voltage between all terminals including the protective earth.

Failure to follow these instructions will result in death or serious injury.

8 990-5909-001

Important Safety Instructions — SAVE THESE

INSTRUCTIONS Maintenance Bypass Cabinet

Battery Safety

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Battery circuit breakers must be installed according to the specifications and

requirements as defined by Schneider Electric.

• Servicing of batteries must only be performed or supervised by qualified

personnel knowledgeable of batteries and the required precautions. Keep

unqualified personnel away from batteries.

• Disconnect charging source prior to connecting or disconnecting battery

terminals.

• Do not dispose of batteries in a fire as they can explode.

• Do not open, alter, or mutilate batteries. Released electrolyte is harmful to the

skin and eyes. It may be toxic.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Batteries can present a risk of electric shock and high short-circuit current. The

following precautions must be observed when working on batteries

• Remove watches, rings, or other metal objects.

• Use tools with insulated handles.

• Wear protective glasses, gloves and boots.

• Do not lay tools or metal parts on top of batteries.

• Disconnect the charging source prior to connecting or disconnecting battery

terminals.

• Determine if the battery is inadvertently grounded. If inadvertently grounded,

remove source from ground. Contact with any part of a grounded battery can

result in electric shock. The likelihood of such shock can be reduced if such

grounds are removed during installation and maintenance (applicable to

equipment and remote battery supplies not having a grounded supply circuit).

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

When replacing batteries, always replace with the same type and number of

batteries or battery packs.

Failure to follow these instructions will result in death or serious injury.

NOTICE

RISK OF EQUIPMENT DAMAGE

• Wait until the system is ready to be powered up before installing batteries in

the system. The time duration from battery installation until the UPS system

is powered up must not exceed 72 hours or 3 days.

• Batteries must not be stored more than six months due to the requirement of

recharging. If the UPS system remains de-energized for a long period,

Schneider Electric recommends that you energize the UPS system for a

period of 24 hours at least once every month. This charges the batteries, thus

avoiding irreversible damage.

Failure to follow these instructions can result in equipment damage.

990-5909-001 9

Maintenance Bypass Cabinet Specifications

Specifications

Maximum Input Short-Circuit Withstand

The maximum input short-circuit withstand for the maintenance bypass cabinet is

Icw 65 kA RMS symmetrical.

Specifications for 480 V Systems

Trip Settings for 480 V

Rating (kW) Breaker Ir tr at 6 Ir1li (x In)1

Unit input breaker

UIB /

Static switch input

breaker SSIB

Maintenance

bypass breaker

MBB /

Unit output breaker

UOB

All breakers

20 HJF36150CU31X HJF36150CU31X 50 0.5 1.5

30 HJF36150CU31X HJF36150CU31X 50 0.5 1.5

40 HJF36150CU31X HJF36150CU31X 70 0.5 1.5

50 HJF36150CU31X HJF36150CU31X 80 0.5 1.5

60 HJF36150CU31X HJF36150CU31X 100 0.5 1.5

80 HJF36150CU31X HJF36150CU31X 125 0.5 1.5

100 LJF36400CU31X JJF36250CU31X 175 0.5 1.5

120 LJF36400CU31X JJF36250CU31X 200 0.5 1.5

150 LJF36400CU31X JJF36250CU31X 250 0.5 1.5

Recommended Upstream Protection 480 V

Rating 20 kW 30 kW 40 kW 50 kW

Input Bypass Input Bypass Input Bypass Input Bypass

Breaker HJF36100CU31X

Ir (A) 40 35 60 50 80 70 100 80

Tr at 6 Ir (A) 0.5

li (x In) (A) 1.5

Rating 60 kW 80 kW 100 kW 120 kW 150 kW

Input Bypass Input Bypass Input Bypass Input Bypass Input Bypass

Breaker HJ-

F36150-

CU31X

HJ-

F36100-

CU31X

JJ-

F36250-

CU31X

HJ-

F36150-

CU31X

JJF36250CU31X LJ-

F36400-

CU31X

JJ-

F36250-

CU31X

Ir (A) 125 100 175 125 200 175 250 200 300 250

Tr at 6 Ir (A) 0.5

li (x In) (A) 1.5

10 990-5909-001

1. tr and li must be set during installation. The default setting is marked on the breaker.

Specifications Maintenance Bypass Cabinet

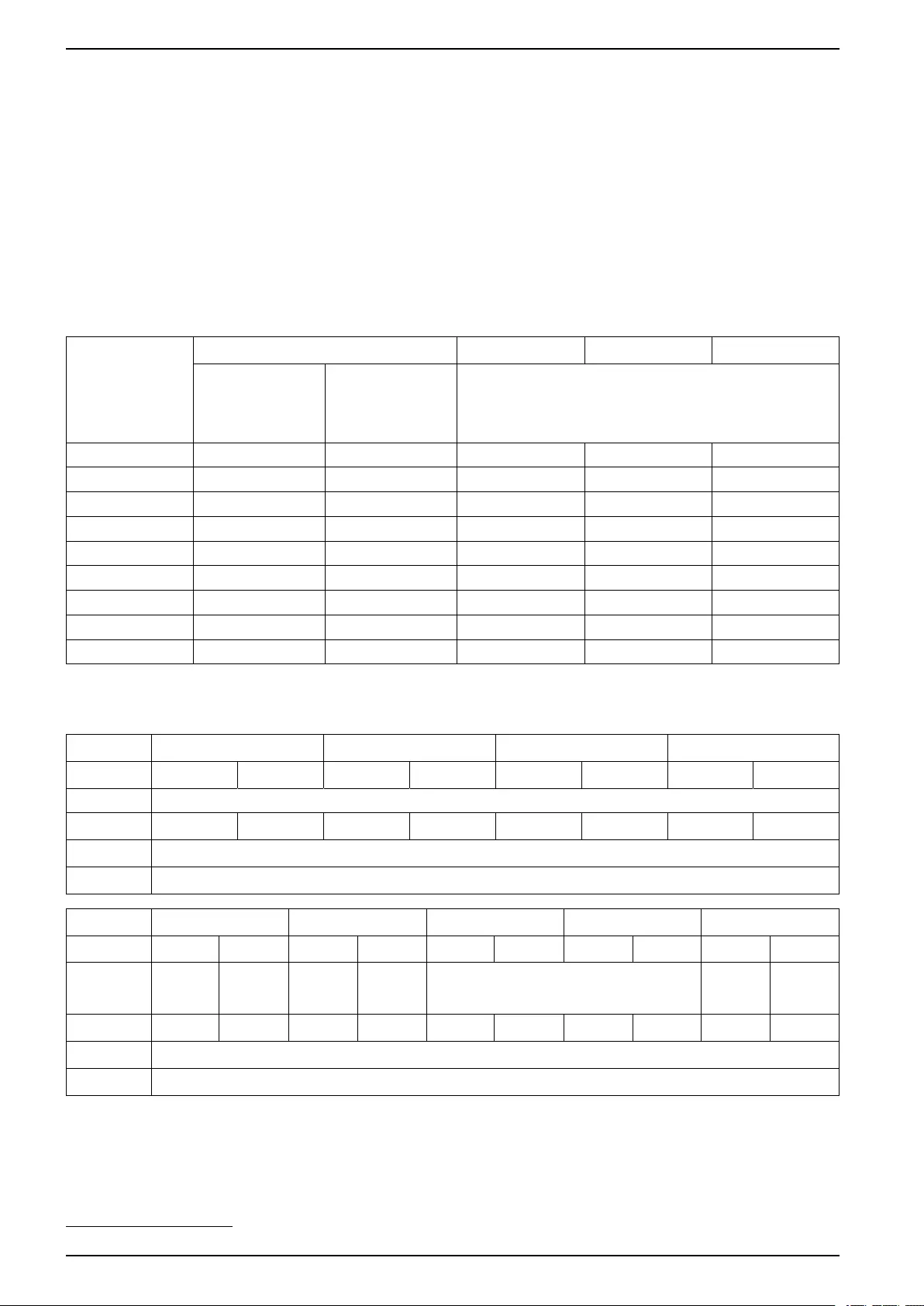

Recommended Cable Sizes 480 V

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

All wiring must comply with all applicable national and/or electrical codes. The

maximum allowable cable size is 4/0 AWG.

Failure to follow these instructions will result in death or serious injury.

NOTE: Overcurrent protection is to be provided by others.

Cable sizes in this manual are based on Table 310.15 (B)(16) of the National

Electrical Code (NEC) with the following assertions:

• 90 °C (194 °F) conductors (75 °C (167 °F) termination)

• An ambient temperature of 30 °C (86 °F)

• Use of copper conductors

If the ambient temperature is greater than 30 °C (86 °F), larger conductors are to

be selected in accordance with the correction factors of the NEC.

Equipment grounding conductors (PE in this manual) are sized in accordance with

NEC Article 250.122 and Table 250.122.

Copper 20 kW 30 kW 40 kW 50 kW 60 kW 80 kW 100 kW 120 kW 150 kW

Input Input phases (AWG/

kcmil)

8 6 4 3 1 2/0 2 x 1/0 2 x 1/0 2 x 1/0

Input PE (AWG/kcmil) 10 8 8 6 6 6 4 2 x 4 2 x 3

Bypass/

Output

Bypass/output phases

(AWG/kcmil)

10 8 6 4 3 1 2/0 2 x 1/0 2 x 1/0

Bypass PE/output PE

(AWG/kcmil)

10 10 8 8 8 6 6 2 x 6 2 x 4

Neutral (AWG/kcmil)26 4 2 1/0 2/0 2 x 1/0 2 x 1/0 4 x 1/0 4 x 1/0

DC DC +/- (AWG/kcmil) 43231/031/042/044/042 x 1/042 x 3/0 2 x 4/0

DC PE (AWG/kcmil) 8 6 6 6 6 4 4 3 2 x 2

NOTE: The DC cable sizes given here are recommendations — Always follow

the specific instructions in the battery solution documentation for DC +/- and

DC PE cable sizes.

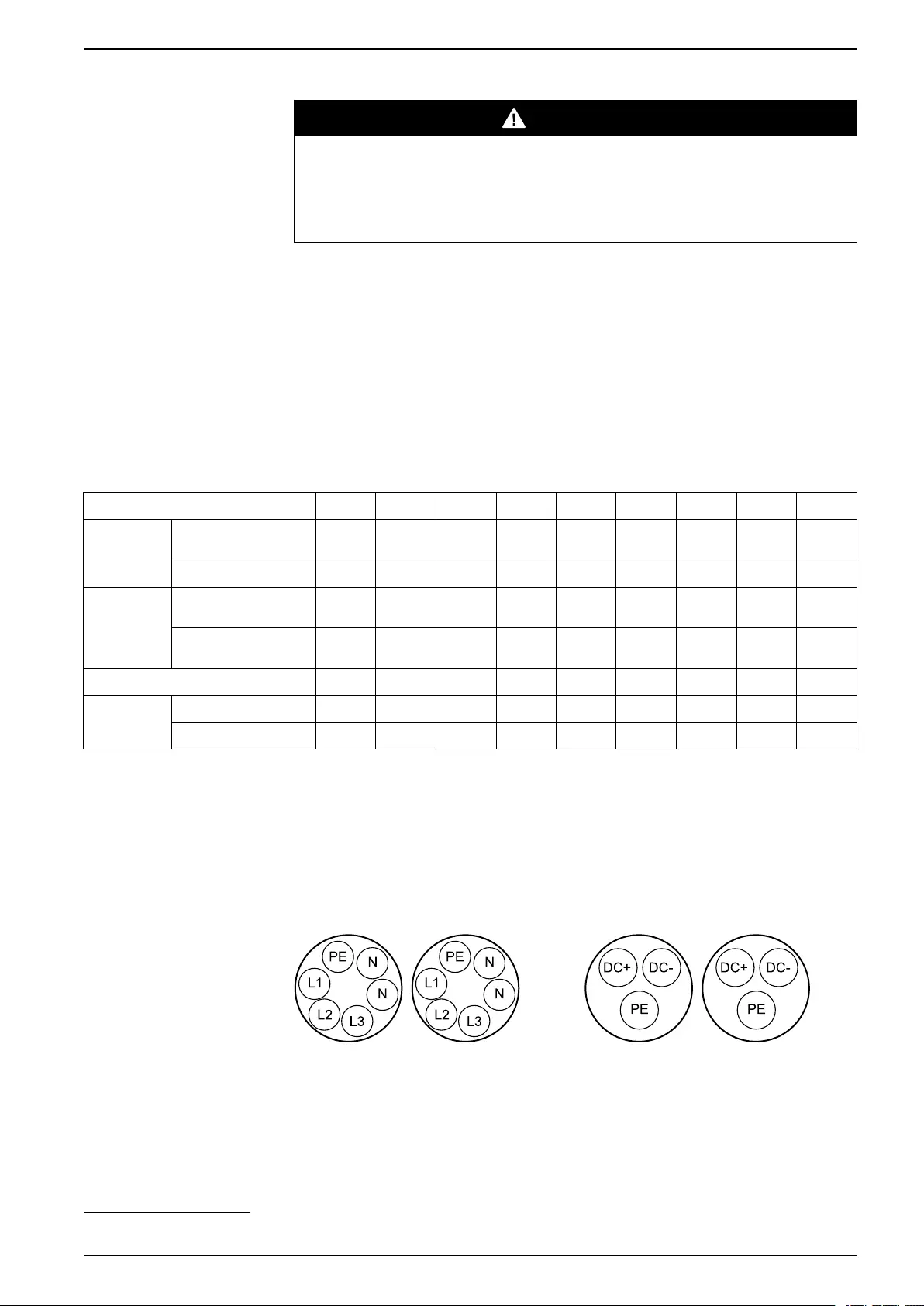

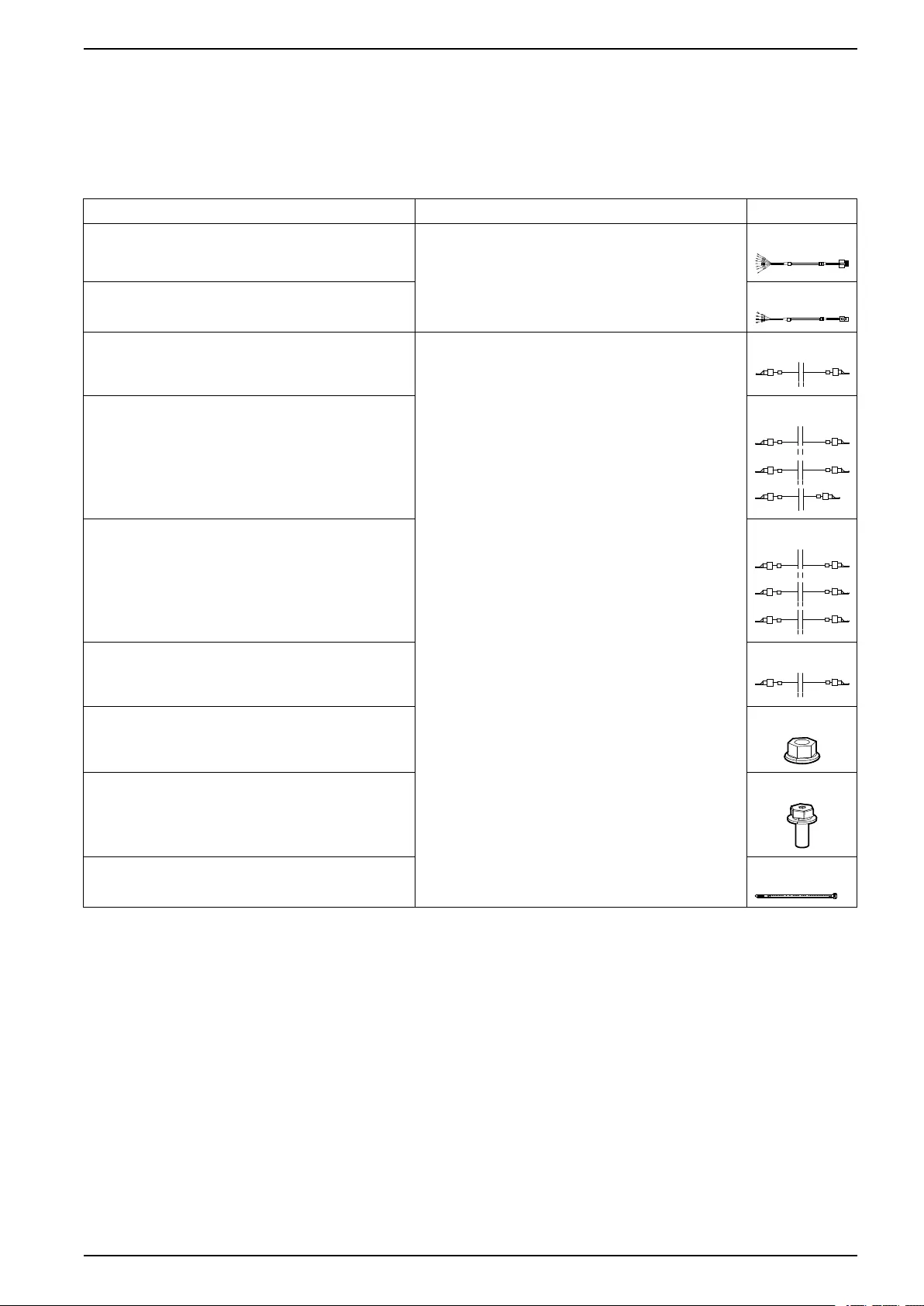

NOTE: For 120 kW, use two separate conduits for each of the input, bypass,

and output cable sets. Organize cables as illustrated in each conduit to avoid

eddy currents (heating).

NOTE: For 150 kW, use two separate conduits for each of the input, bypass,

output, and DC cable sets. Organize cables as illustrated in each conduit to

avoid eddy currents (heating).

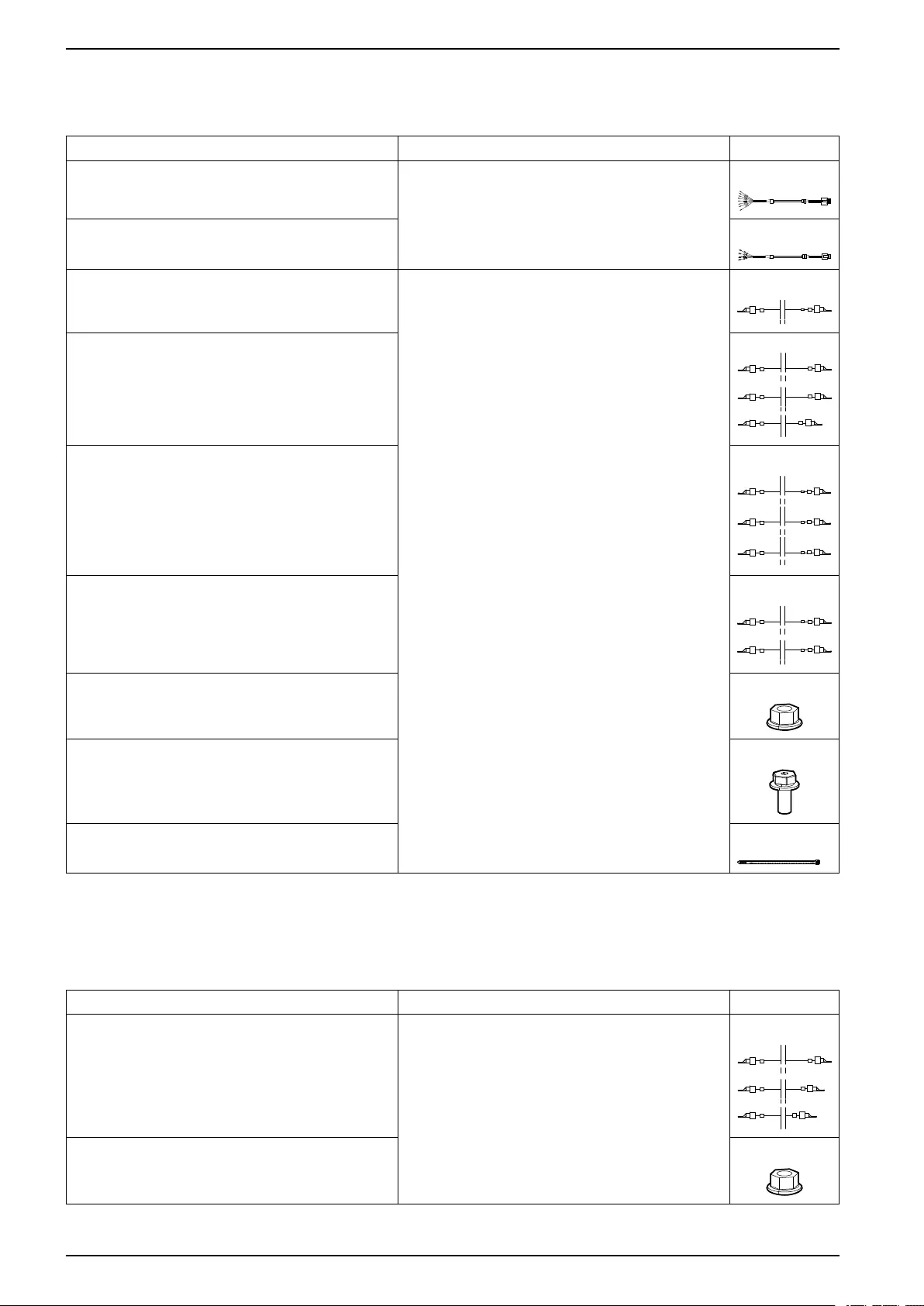

Cable Organization in Separate Conduits for Input/Bypass/Output and DC

990-5909-001 11

2. Neutral conductor is sized to handle 1.73 times phase current in case of high harmonic content from non-linear loads. If low or no

harmonic currents are expected, neutral conductor can be sized as phase conductor.

3. 20-40 kW: battery cables are sized according to 32 blocks.

4. 50 kW and higher: battery cables are sized according to 40 blocks.

Maintenance Bypass Cabinet Specifications

Specifications for 208 V Systems

Trip Settings for 200/208/220 V

Rating (kW) Breaker Ir tr at 6 Ir5li (x In)5

Unit input breaker

UIB /

Static switch input

breaker SSIB

Maintenance

bypass breaker

MBB /

Unit output breaker

UOB

Unit input

breaker UIB

Static switch

input breaker

SSIB /

Maintenance

bypass

breaker MBB /

Unit output

breaker UOB

All breakers

10 HJF36150CU31X HJF36150CU31X 50 50 0.5 1.5

15 HJF36150CU31X HJF36150CU31X 60 60 0.5 1.5

20 HJF36150CU31X HJF36150CU31X 80 80 0.5 1.5

25 HJF36150CU31X HJF36150CU31X 100 100 0.5 1.5

30 HJF36150CU31X HJF36150CU31X 125 110 0.5 1.5

40 HJF36150CU31X HJF36150CU31X 150 150 0.5 1.5

50 LJF36400CU31X JJF36250CU31X 200 200 0.5 1.5

60 LJF36400CU31X JJF36250CU31X 250 225 0.5 1.5

75 LJF36400CU31X JJF36250CU31X 300 250 0.5 1.5

Recommended Upstream Protection 200/208/220 V

Rating 10 kW 15 kW 20 kW 25 kW

Input Bypass Input Bypass Input Bypass Input Bypass

Breaker HJF36100CU31X HJF36150C-

U31X

HJF36100C-

U31X

Ir (A) 50 40 80 60 100 80 125 100

tr at 6 Ir (A) 0.5

li (x In) (A) 1.5

Rating 30 kW 40 kW 50 kW 60 kW 75 kW

Input Bypass Input Bypass Input Bypass Input Bypass Input Bypass

Breaker HJF36150CU31X JJ-

F36250-

CU31X

HJ-

F36150-

CU31X

JJF36250CU31X LJ-

F36400-

CU31X

JJ-

F36250-

CU31X

LJF36400CU31X

Ir (A) 150 110 200 150 250 200 300 225 350 300

tr at 6 Ir (A) 0.5

li (x In) (A) 1.5

12 990-5909-001

5. tr and li must be set during installation. The default setting is marked on the breaker.

Specifications Maintenance Bypass Cabinet

Recommended Cable Sizes 200/208/220 V

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

All wiring must comply with all applicable national and/or electrical codes. The

maximum allowable cable size is 4/0 AWG.

Failure to follow these instructions will result in death or serious injury.

NOTE: Overcurrent protection is to be provided by others.

Cable sizes in this manual are based on Table 310.15 (B)(16) of the National

Electrical Code (NEC) with the following assertions:

• 90 °C (194 °F) conductors (75 °C (167 °F) termination)

• An ambient temperature of 30 °C (86 °F)

• Use of copper conductors

If the ambient temperature is greater than 30 °C (86 °F), larger conductors are to

be selected in accordance with the correction factors of the NEC.

Equipment grounding conductors (PE in this manual) are sized in accordance with

NEC Article 250.122 and Table 250.122.

Copper 10 kW 15 kW 20 kW 25 kW 30 kW 40 kW 50 kW 60 kW 75 kW

Input Input phases (AWG/

kcmil)

8 4 3 2 1/0 2 x 1/0 2 x 1/0 2 x 1/0 2 x 2/0

Input PE (AWG/kcmil) 10 8 8 6 6 6 2 x 4 2 x 4 2 x 3

Bypass/

output

Bypass/output phases

(AWG/kcmil)

8 6 4 3 2 1/0 2 x 1/0 2 x 1/0 2 x 1/0

Bypass PE/output PE

(AWG/kcmil)

10 10 8 8 6 6 2 x 6 2 x 4 2 x 4

Neutral (AWG/kcmil)66 3 1 2/0 2 x 1/0 2 x 1/0 2 x 2/0 4 x 1/0 4 x 1/0

DC DC +/- (AWG/kcmil) 10 6 4 4 2 1/0 2/0 4/0 2 x 1/0

DC PE (AWG/kcmil) 10 10 8 8 6 6 6 4 4

NOTE: The DC cable sizes given here are recommendations — Always follow

the specific instructions in the battery solution documentation for DC +/- and

DC PE cable sizes.

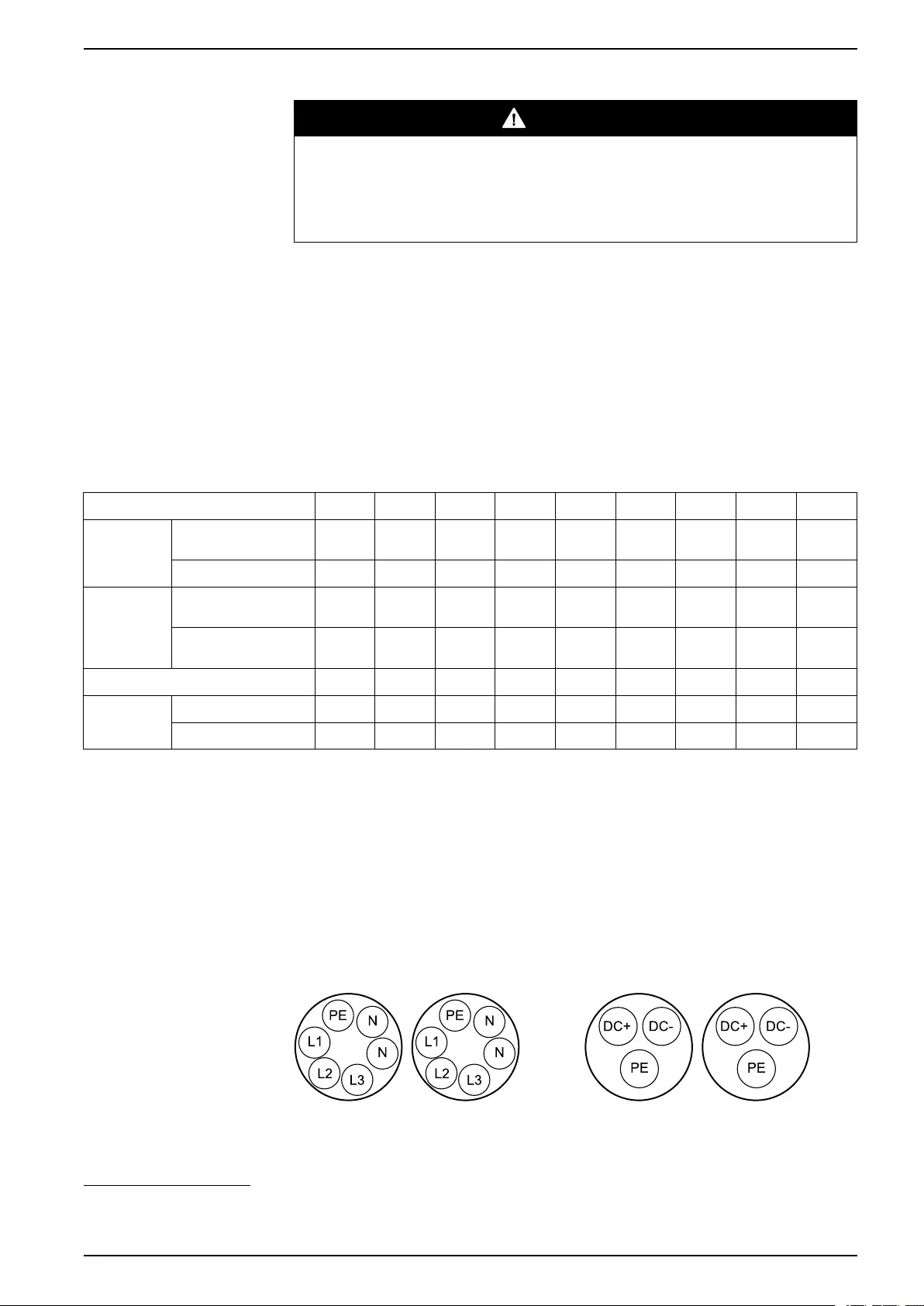

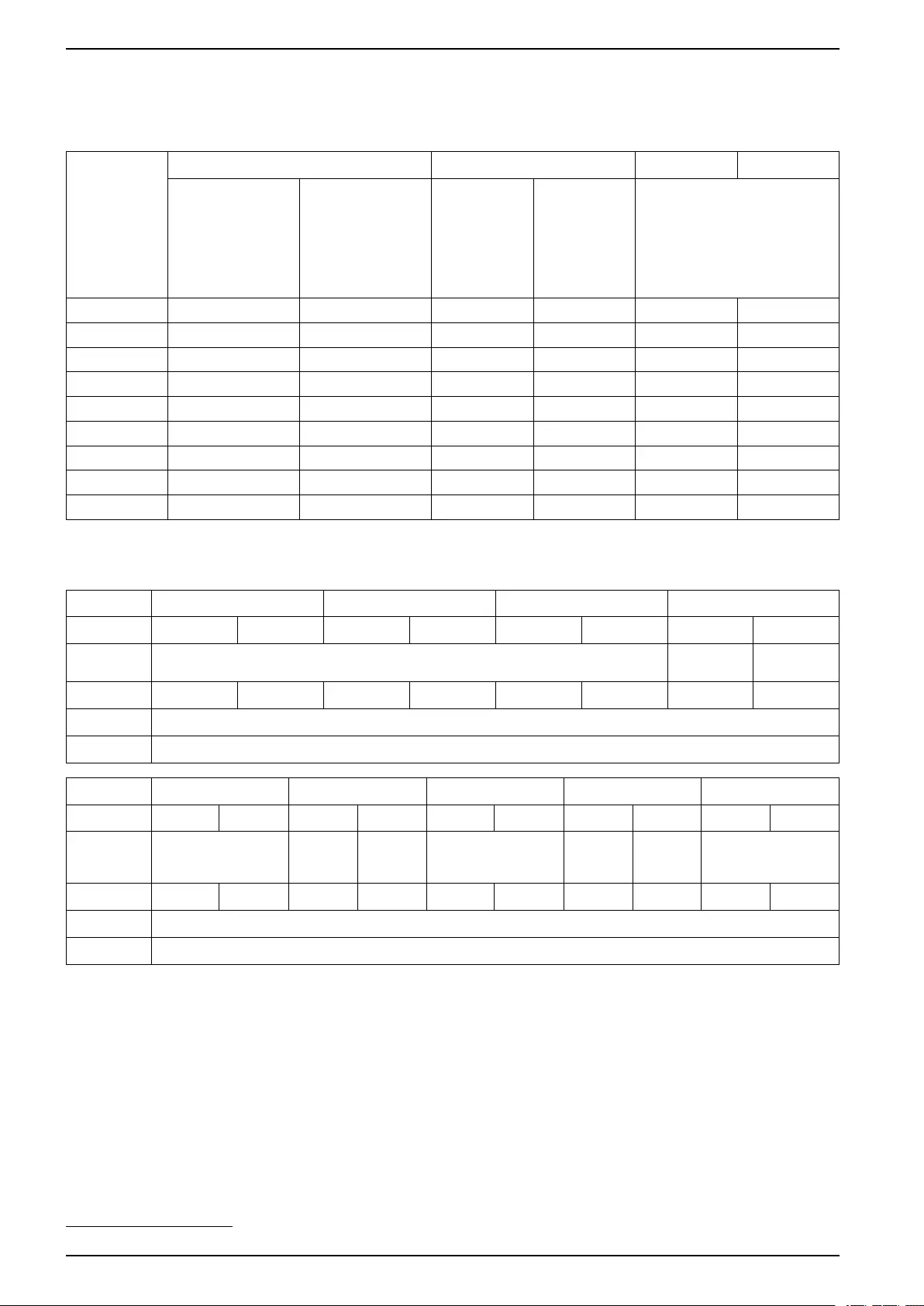

NOTE: For 50 kW, 60 kW, and 75 kW, use two separate conduits for each of

the input, bypass, and output cable sets. Organize cables as illustrated in each

conduit to avoid eddy currents (heating).

Cable Organization in Separate Conduits for Input/Bypass/Output and DC

990-5909-001 13

6. Neutral conductor is sized to handle 1.73 times phase current in case of high harmonic content from non-linear loads. If non or less

harmonic currents are expected, neutral conductor can be sized as phase conductor.

Maintenance Bypass Cabinet Specifications

Specifications for 400 V Systems

Trip Settings for 400/415 V

Rating (kW) Breaker Ir tr at 6 Ir7li (x In)7

Unit input breaker

UIB /

Static switch input

breaker SSIB

Maintenance

bypass breaker

MBB /

Unit output breaker

UOB

Unit input

breaker UIB

Static switch

input breaker

SSIB /

Maintenance

bypass

breaker MBB /

Unit output

breaker UOB

All breakers

20 HJF36150CU31X HJF36150CU31X 50 50 0.5 1.5

30 HJF36150CU31X HJF36150CU31X 60 60 0.5 1.5

40 HJF36150CU31X HJF36150CU31X 80 80 0.5 1.5

50 HJF36150CU31X HJF36150CU31X 100 100 0.5 1.5

60 HJF36150CU31X HJF36150CU31X 125 110 0.5 1.5

80 HJF36150CU31X HJF36150CU31X 150 150 0.5 1.5

100 LJF36400CU31X JJF36250CU31X 200 200 0.5 1.5

120 LJF36400CU31X JJF36250CU31X 225 225 0.5 1.5

150 LJF36400CU31X JJF36250CU31X 300 250 0.5 1.5

Recommended Upstream Protection 400/415 V

Rating 20 kW 30 kW 40 kW 50 kW

Input Bypass Input Bypass Input Bypass Input Bypass

Breaker HJF36100CU31X HJF36150C-

U31X

HJF36100C-

U31X

Ir (A) 50 40 70 60 100 80 125 100

Tr at 6 Ir (A) 0.5

li (x In) (A) 1.5

Rating 60 kW 80 kW 100 kW 120 kW 150 kW

Input Bypass Input Bypass Input Bypass Input Bypass Input Bypass

Breaker HJF36150CU31X JJ-

F36250-

CU31X

HJ-

F36150-

CU31X

JJF36250CU31X LJ-

F36400-

CU31X

JJ-

F36250-

CU31X

LJF36400CU31X

Ir (A) 150 110 200 150 250 200 300 225 350 300

Tr at 6 Ir (A) 0.5

li (x In) (A) 1.5

14 990-5909-001

7. tr and li must be set during installation. The default setting is marked on the breaker.

Specifications Maintenance Bypass Cabinet

Recommended Cable Sizes 400/415 V

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

All wiring must comply with all applicable national and/or electrical codes. The

maximum allowable cable size is 4/0 AWG.

Failure to follow these instructions will result in death or serious injury.

NOTE: Overcurrent protection is to be provided by others.

Cable sizes in this manual are based on Table 310.15 (B)(16) of the National

Electrical Code (NEC) with the following assertions:

• 90 °C (194 °F) conductors (75 °C (167 °F) termination)

• An ambient temperature of 30 °C (86 °F)

• Use of copper conductors

If the ambient temperature is greater than 30 °C (86 °F), larger conductors are to

be selected in accordance with the correction factors of the NEC.

Equipment grounding conductors (PE in this manual) are sized in accordance with

NEC Article 250.122 and Table 250.122.

Copper 20 kW 30 kW 40 kW 50 kW 60 kW 80 kW 100 kW 120 kW 150 kW

Input Input phases (AWG/

kcmil)

8 4 3 2 1/0 2 x 1/0 2 x 1/0 2 x 1/0 2 x 2/0

Input PE (AWG/kcmil) 10 8 8 6 6 6 2 x 4 2 x 4 2 x 3

Bypass/

output

Bypass/output phases

(AWG/kcmil)

8 6 4 3 2 1/0 2 x 1/0 2 x 1/0 2 x 1/0

Bypass PE/output PE

(AWG/kcmil)

10 10 8 8 6 6 2 x 6 2 x 4 2 x 4

Neutral (AWG/kcmil)86 3 1 2/0 2 x 1/0 2 x 1/0 2 x 2/0 4 x 1/0 4 x 1/0

DC DC +/- (AWG/kcmil) 4 2 1/0 1/0 2/0 4/0 2 x 1/0 2 x 3/0 2 x 4/0

DC PE (AWG/kcmil) 8 6 6 6 6 4 4 3 2 x 2

NOTE: The DC cable sizes given here are recommendations — Always follow

the specific instructions in the battery solution documentation for DC +/- and

DC PE cable sizes.

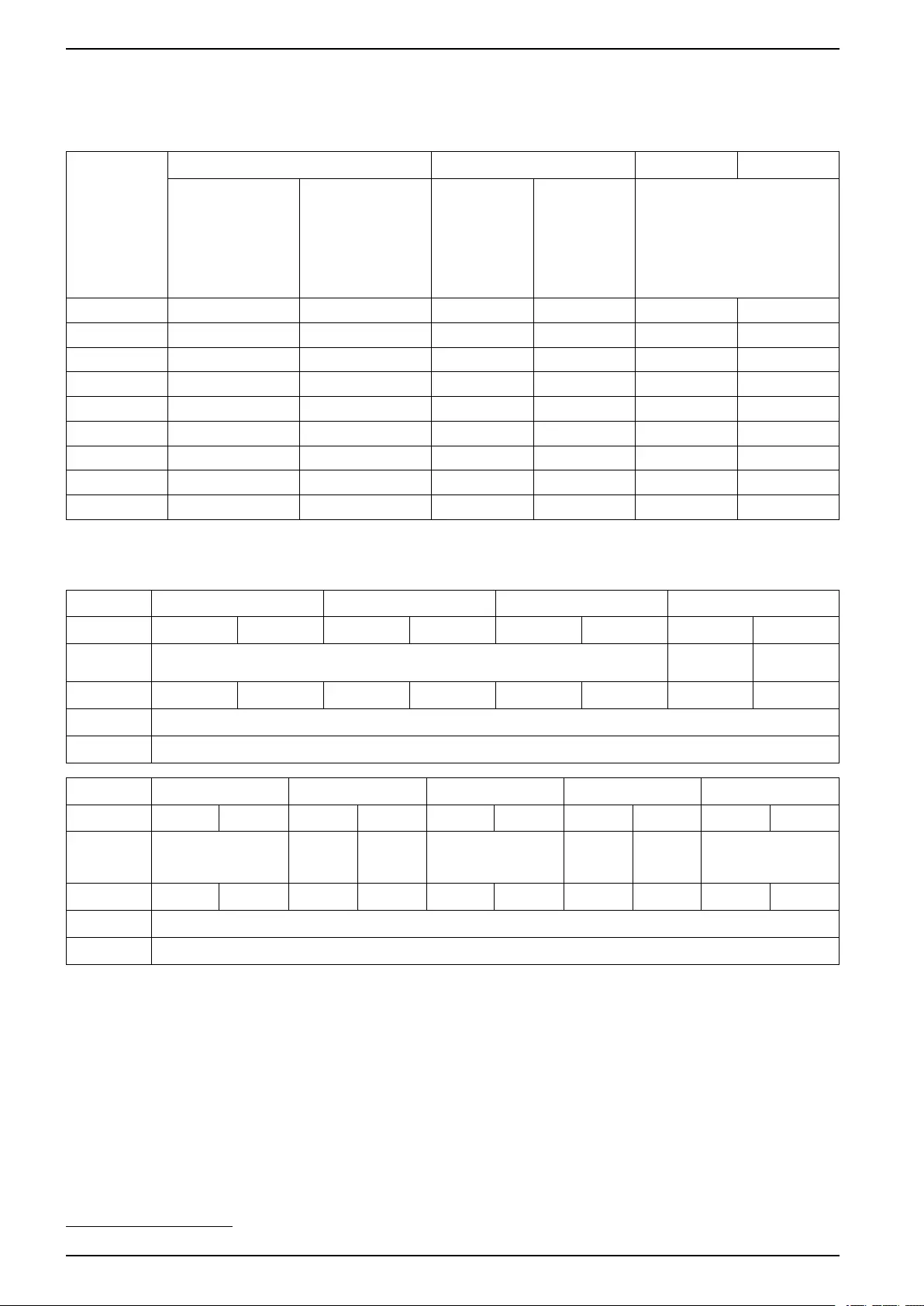

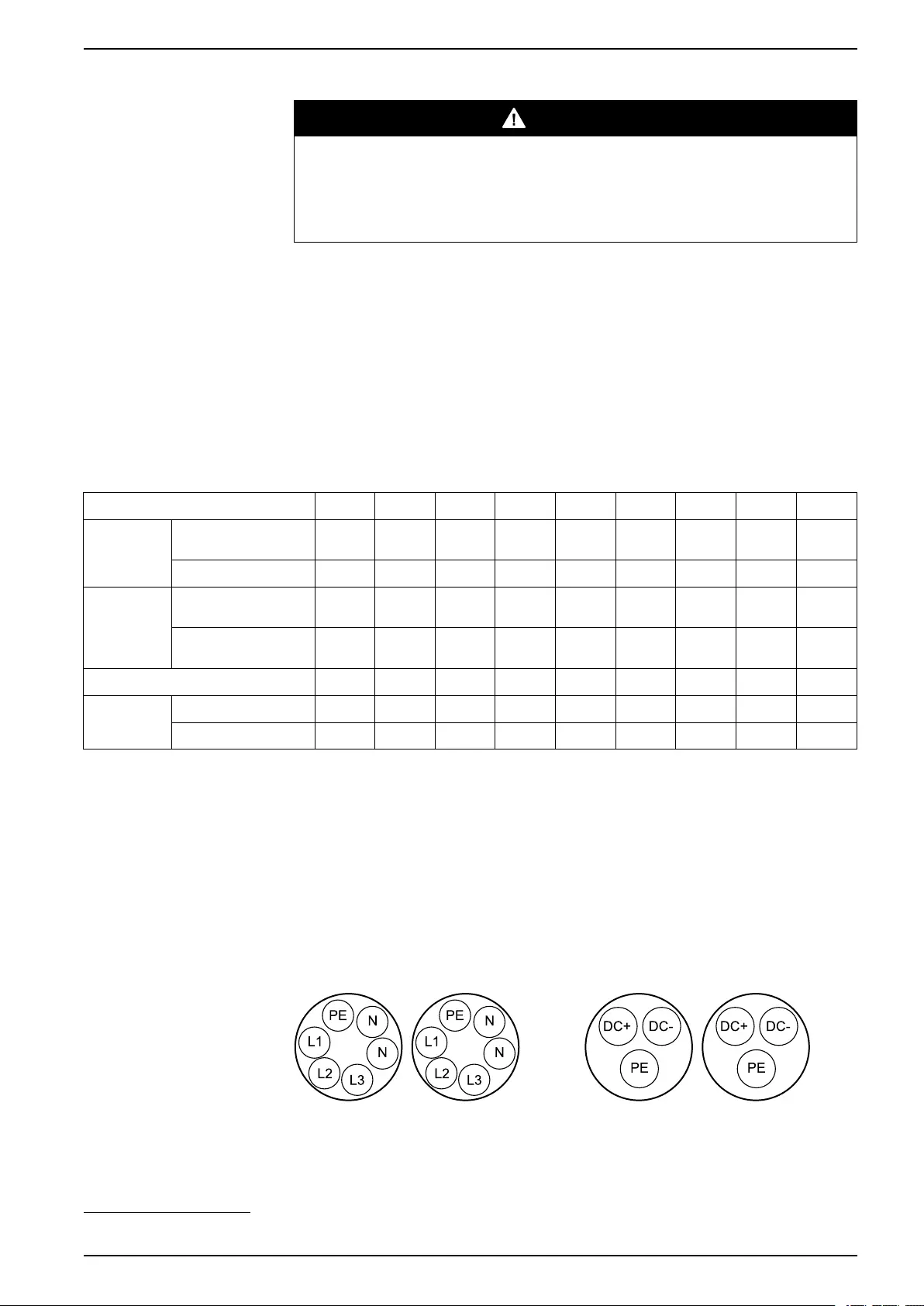

NOTE: For 100 and 120 kW , use two separate conduits for each of the input,

bypass, and output cable sets. Organize cables as illustrated in each conduit to

avoid eddy currents (heating).

NOTE: For 150 kW, use two separate conduits for each of the input, bypass,

output, and DC cable sets. Organize cables as illustrated in each conduit to

avoid eddy currents (heating).

Cable Organization in Separate Conduits for Input/Bypass/Output and DC

990-5909-001 15

8. Neutral conductor is sized to handle 1.73 times phase current in case of high harmonic content from non-linear loads. If non or less

harmonic currents are expected, neutral conductor can be sized as phase conductor.

Maintenance Bypass Cabinet Specifications

Recommended Bolt and Lug Sizes

NOTICE

RISK OF EQUIPMENT DAMAGE

Use only UL approved compression cable lugs.

Failure to follow these instructions can result in equipment damage.

Copper — One Hole Cable Lugs

Cable size Bolt size Cable lug type Crimping tool Die

10 AWG M8 x 35 mm LCA10-56-L NA NA

8 AWG M8 x 35 mm LCA8-56-L CT-720 CD-720-1 Red P21

6 AWG M8 x 35 mm LCA6-56-L CT-720 CD-720-1 Blue P24

4 AWG M8 x 35 mm LCA4-56-L CT-720 CD-720-1 Gray P29

3 AWG M8 x 35 mm LCA4-56-L CT-720 CD-720-1 Gray P29

2 AWG M8 x 35 mm LCA2-56-Q CT-720 CD-720-1 Brown P33

1 AWG M8 x 35 mm LCA1-56-E CT-720 CD-720-2 Green P37

1/0 AWG M8 x 35 mm LCA1/0-56-X CT-720 CD-720-2 Pink P42

2/0 AWG M8 x 35 mm LCA2/0-56-X CT-720 CD-720-2 Black P45

3/0 AWG M8 x 35 mm LCA3/0-56-X CT-720 CD-720-2 Orange P50

4/0 AWG M8 x 35 mm LCA4/0-56-X CT-720 CD-720-3 Purple P54

Copper — Two Hole Cable Lugs

Cable size Bolt size Cable lug type Crimping tool Die

6 AWG M10 x 35 mm LCC6-12-L CT-930 CD-920-6 Blue P24

4 AWG M10 x 35 mm

LCC4-12-L CT-930 CD-920-4 Gray P29

3 AWG M10 x 35 mm

2 AWG M10 x 35 mm LCC2-12-Q CT-930 CD-920-2 Brown P33

1 AWG M10 x 35 mm LCC1-12-E CT-930 CD-920-1 Green P37

1/0 AWG M10 x 35 mm LCC1/0-12-X CT-930 CD-920-1/0 Pink P42

2/0 AWG M10 x 35 mm LCC2/0-12-X CT-930 CD-920-2/0 Black P45

3/0 AWG M10 x 35 mm LCC3/0-12-X CT-930 CD-920-3/0 Orange P50

4/0 AWG M10 x 35 mm LCC4/0-12-X CT-930 CD-920-4/0 Purple P54

Torque Specifications

Bolt size Torque

M4 1.7 Nm (1.25 lb-ft)

M6 5 Nm (3.69 lb-ft)

M8 17.5 Nm (12.91 lb-ft)

M10 30 Nm (22 lb-ft)

16 990-5909-001

Specifications Maintenance Bypass Cabinet

Maintenance Bypass Cabinet Weights and Dimensions

Weight kg (lbs) Height mm (in) Width mm (in) Depth mm (in)

10–80 kW maintenance

bypass cabinet

110 (242.5) 1485 (58.47) 318 (12.52) 850 (33.46)

100–150 kW

maintenance bypass

cabinet

120 (264.6) 1485 (58.47) 318 (12.52) 850 (33.46)

Clearance

NOTE: Clearance dimensions are published for airflow and service access

only. Consult with the local safety codes and standards for additional

requirements in your local area.

Front View of the UPS and the Maintenance Bypass Cabinet

Environment

Operating Storage

Temperature 0 °C to 40 °C (32 °F to 104 °F ) -25 °C to 55 °C (-13 °F to 131 °F)

Relative humidity 0 – 95% non-condensing 0 – 95% non-condensing

Protection class IP20

Color RAL 9003 white

990-5909-001 17

Maintenance Bypass Cabinet Specifications

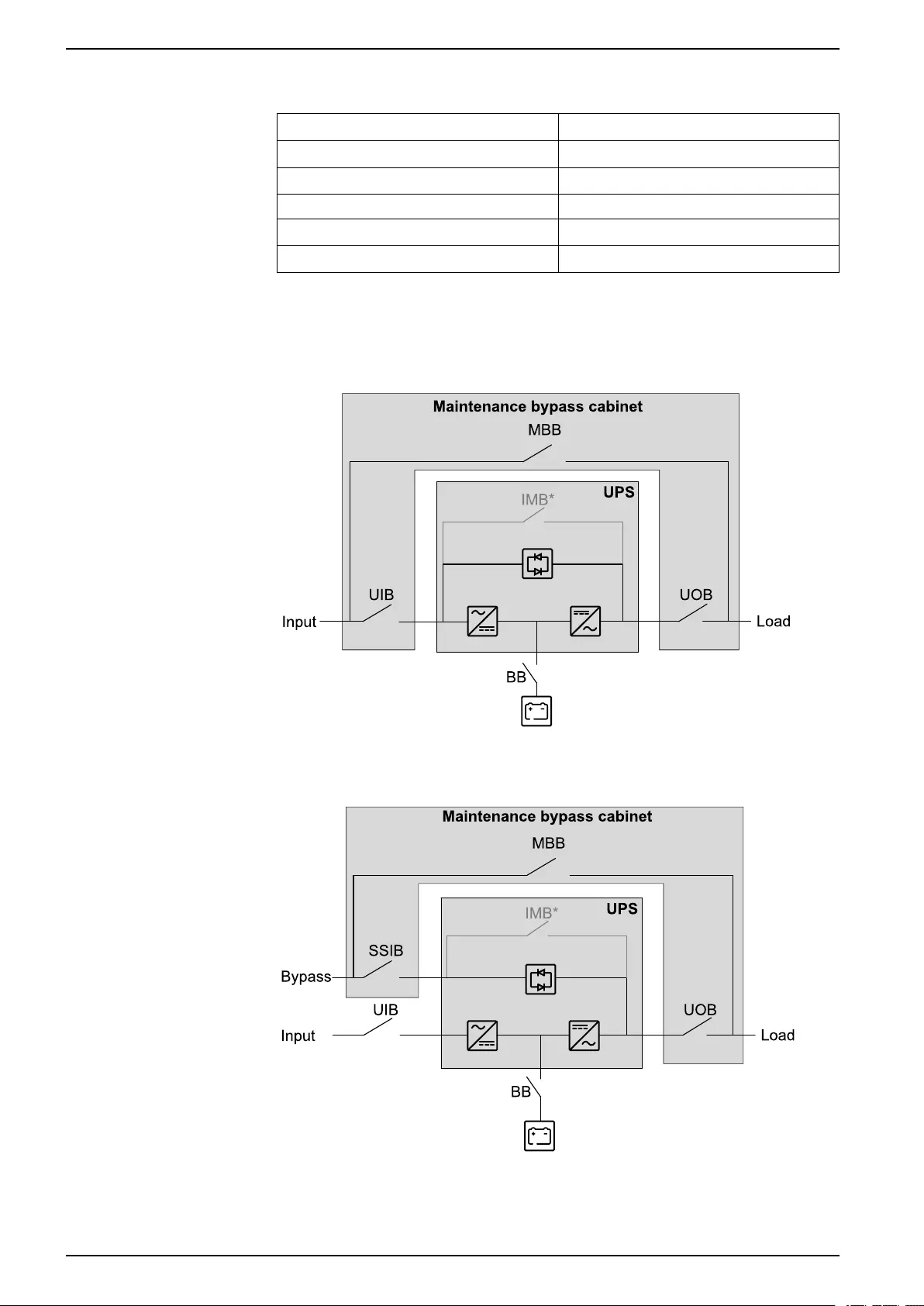

System Overview

UIB Unit input breaker

SSIB Static switch input breaker

MBB Maintenance bypass breaker

IMB Internal maintenance breaker

UOB Unit output breaker

BB Battery breaker

NOTE: The internal maintenance breaker IMB* in the UPS cannot be used with

a maintenance bypass cabinet and must be padlocked in the open position.

Single Mains UPS System

Dual Mains UPS System

18 990-5909-001

Overview of Installation Kits Maintenance Bypass Cabinet

Overview of Installation Kits

Installation Kit 0M-100265 for 10–80 kW Maintenance Bypass

Cabinet

Part Used in Number of units

0W49284 signal cable Connect the Signal Cables, page 46. 1

0W49283 signal cable 1

0W99053 UPS PE cable Connect the Power Cables in a 10–80 kW Top Cable

Entry System, page 32 or Connect the Power Cables in a

Bottom Cable Entry System, page 38.

1

0W99055 UPS output cables 1

0W99056 UPS input/UPS bypass cables 1

0W99054 UPS neutral cable 1

M8 nut with washer 10

M8 x 25 mm bolt with washer 10

Cable ties 10

990-5909-001 19

Maintenance Bypass Cabinet Overview of Installation Kits

Installation Kit 0M-100264 for 100–150 kW Maintenance Bypass

Cabinet

Part Used in Number of units

0W49284 signal cable Connect the Signal Cables, page 46. 1

0W49283 signal cable 1

0W99057 UPS PE cable Connect the Power Cables in a 100–150 kW Top Cable

Entry System, page 34, or Connect the Power Cables in a

Bottom Cable Entry System, page 38.

1

0W12375 UPS output cables

0W99058 UPS input/UPS bypass cables 1

0W99052 UPS neutral cable 1

M8 nut with washer 11

M8 x 25 mm bolt with washer 11

Cable ties 10

Installation Kit 0M-100247 for 100–150 kW Maintenance Bypass

Cabinet

Part Used in Number of units

0W49195 UPS input cables (for dual mains) Connect the Power Cables in a 100–150 kW Top Cable

Entry System, page 34.

1

M8 nut with washer 6

20 990-5909-001

Overview of Installation Kits Maintenance Bypass Cabinet

Part Used in Number of units

M8 x 25 mm bolt with washer 6

Cable ties 10

Installation Kit 0M-100250 for 100–150 kW Maintenance Bypass

Cabinet

Part Used in Number of units

0W49194 UPS DC-cables Connect the Power Cables in a 100–150 kW Top Cable

Entry System, page 34

1

M8 nut with washer 6

M8 x 25 mm bolt with washer 6

Cabel ties 10

Optional Seismic Kit GVSOPT003

Part Used in Number of units

Rear anchor Install the Seismic Anchoring (Option), page 30 and Final

Installation, page 50.

1

Front anchoring bracket 1

Rear anchoring bracket 1

M8 x 20 mm bolt 6

990-5909-001 21

Maintenance Bypass Cabinet Overview of Installation Kits

Optional Kirk Key Kit GVSOPT004

Part Used in Number of units

Support plate The optional kirk key kit will be installed by the Schneider

Electric representative during start-up of your system.

2

Flathead screw 8

Push-button 1

Top support plate 1

Electromechanical key interlock (SKRU) 1

Mechanical key interlock 2

Label 1

M6 nut with washer 2

0W12675 signal cable 1

0W49239 signal cable 1

22 990-5909-001

Installation Procedure for Top Cable Entry Maintenance Bypass Cabinet

Installation Procedure for Top Cable Entry

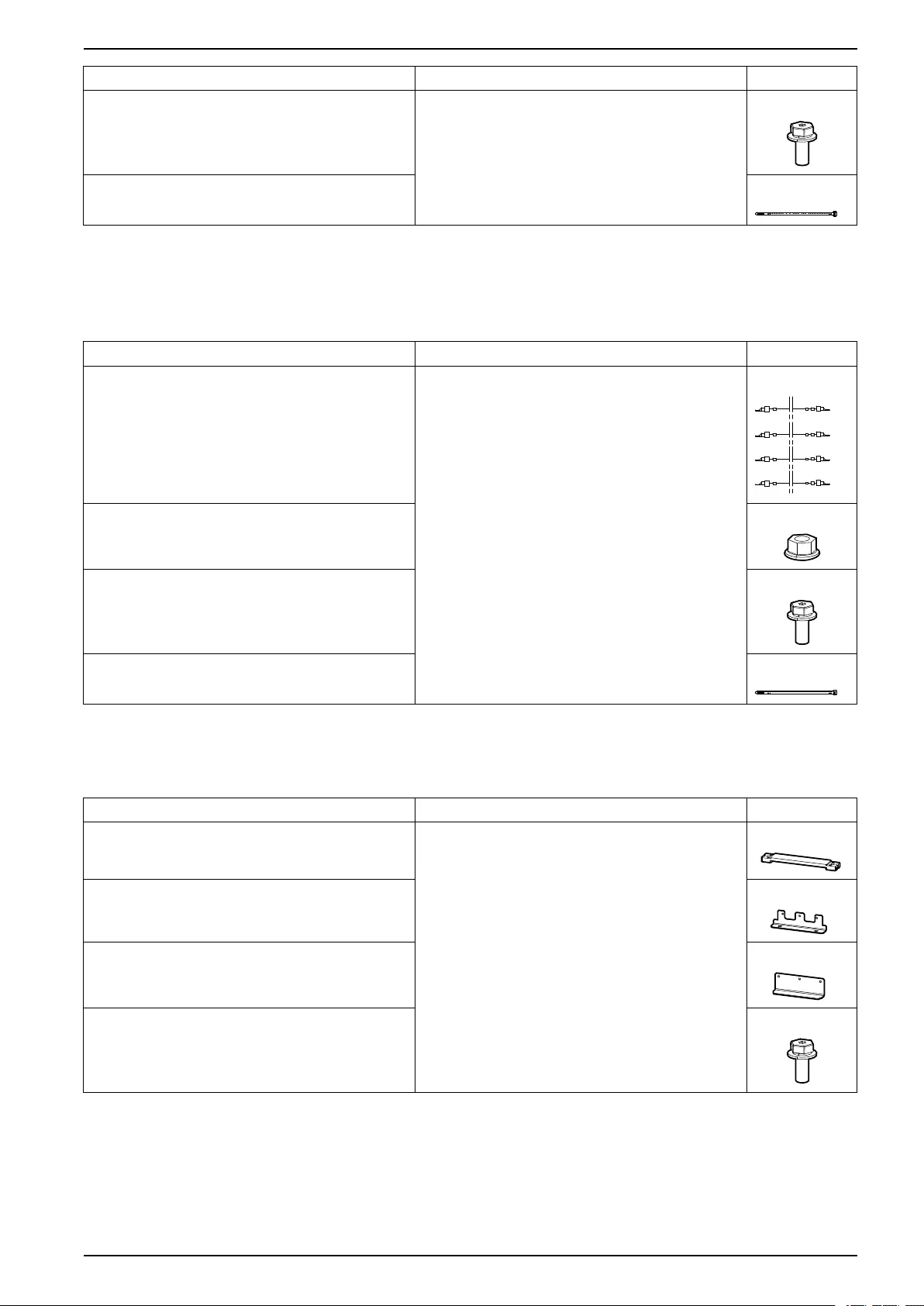

Single Mains Dual Mains

CAUTION

TIP HAZARD

Do not remove the transportation brackets from the maintenance bypass cabinet

until it is time to anchor it to the floor or interconnect it with the UPS.

Failure to follow these instructions can result in injury or equipment

damage.

1. Prepare the Maintenance Bypass Cabinet and the UPS for Cables, page 25.

2. Install the Seismic Anchoring (Option), page 30.

3. Perform one of the following:

–Connect the Power Cables in a 10–80 kW Top Cable Entry System, page

32, or

–Connect the Power Cables in a 100–150 kW Top Cable Entry System,

page 34.

4. Connect the Internal Power Cables, page 39.

5. Interconnect the UPS and the Maintenance Bypass Cabinet, page 42.

6. Connect the Signal Cables, page 46.

7. Final Installation, page 50.

8. Connect all power cables in the UPS – follow the UPS installation manual.

990-5909-001 23

Maintenance Bypass Cabinet Installation Procedure for Bottom Cable Entry

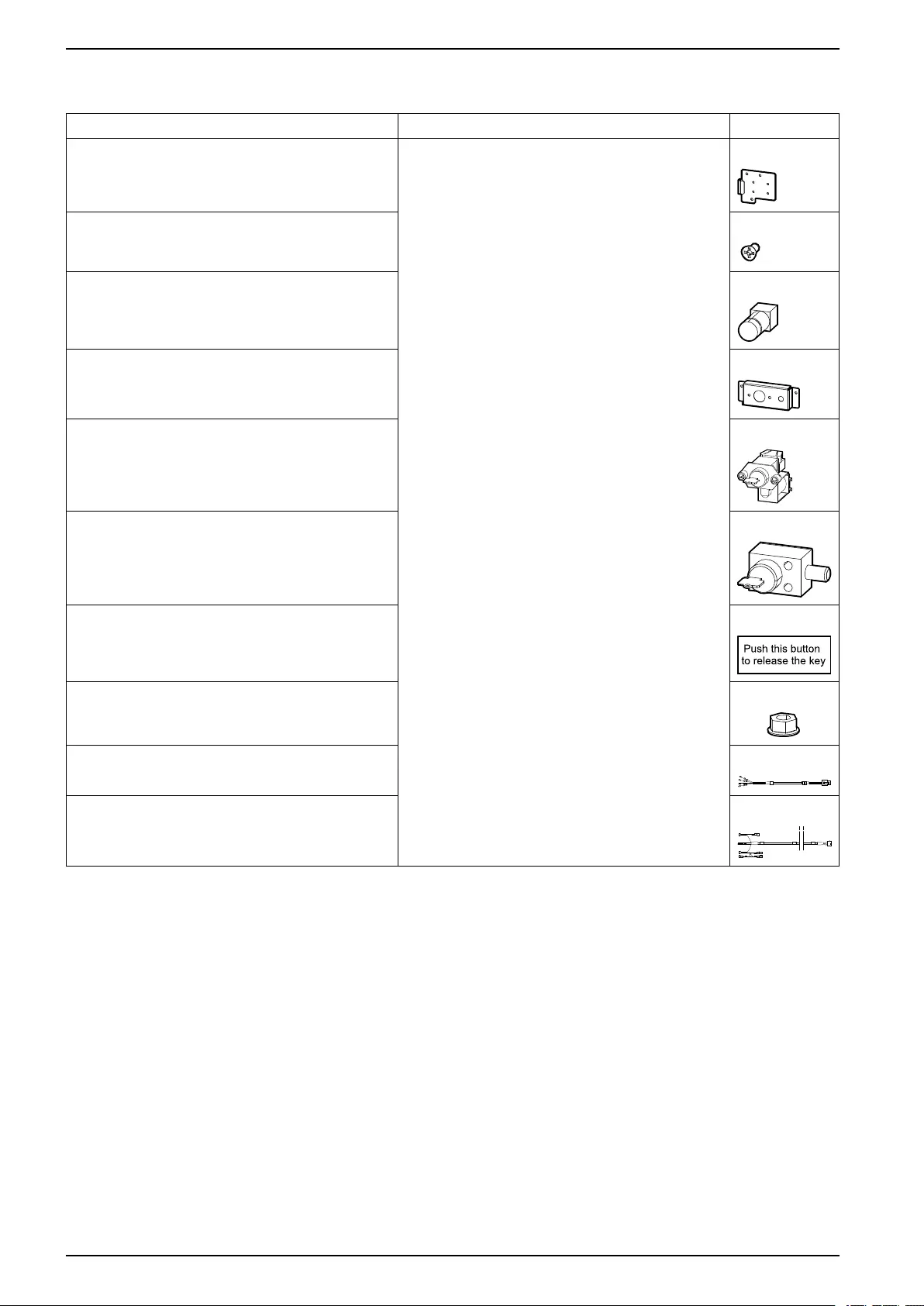

Installation Procedure for Bottom Cable Entry

Single Mains Dual Mains

CAUTION

TIP HAZARD

Do not remove the transportation brackets from the maintenance bypass cabinet

until it is time to anchor it to the floor or interconnect it with the UPS.

Failure to follow these instructions can result in injury or equipment

damage.

1. Prepare the Maintenance Bypass Cabinet and the UPS for Cables, page 25.

2. Install the Seismic Anchoring (Option), page 30.

3. Connect the Power Cables in a Bottom Cable Entry System, page 38.

4. Connect the Internal Power Cables, page 39.

5. Interconnect the UPS and the Maintenance Bypass Cabinet, page 42.

6. Connect the Signal Cables, page 46.

7. Final Installation, page 50.

8. Connect all power cables in the UPS – follow the UPS installation manual.

24 990-5909-001

Prepare the Maintenance Bypass Cabinet and the UPS for

Cables Maintenance Bypass Cabinet

Prepare the Maintenance Bypass Cabinet and the

UPS for Cables

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Do not drill or cut holes for power cables or conduits with the gland plate

installed and do not drill or cut holes in close proximity to the maintenance

bypass cabinet.

Failure to follow these instructions will result in death or serious injury.

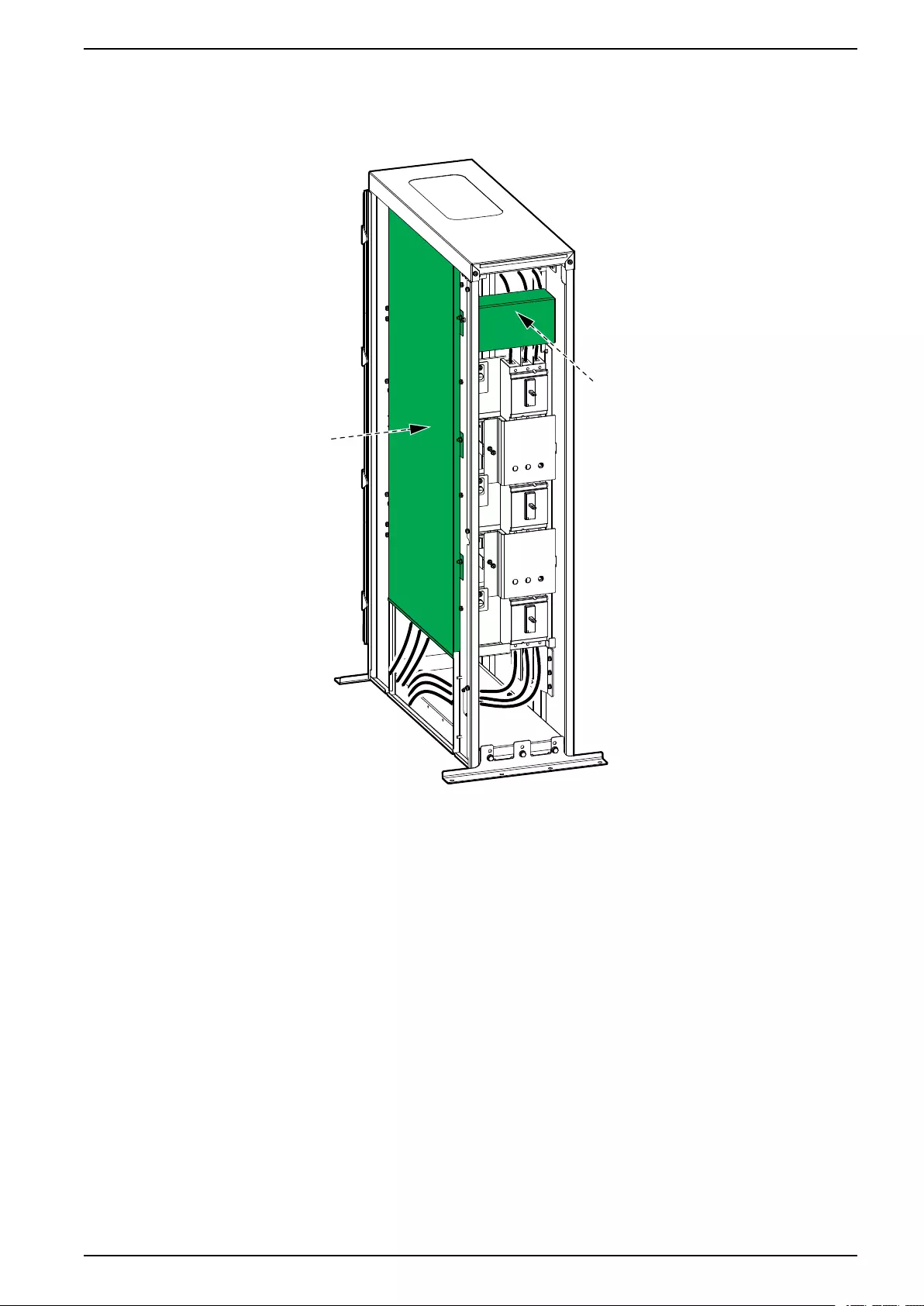

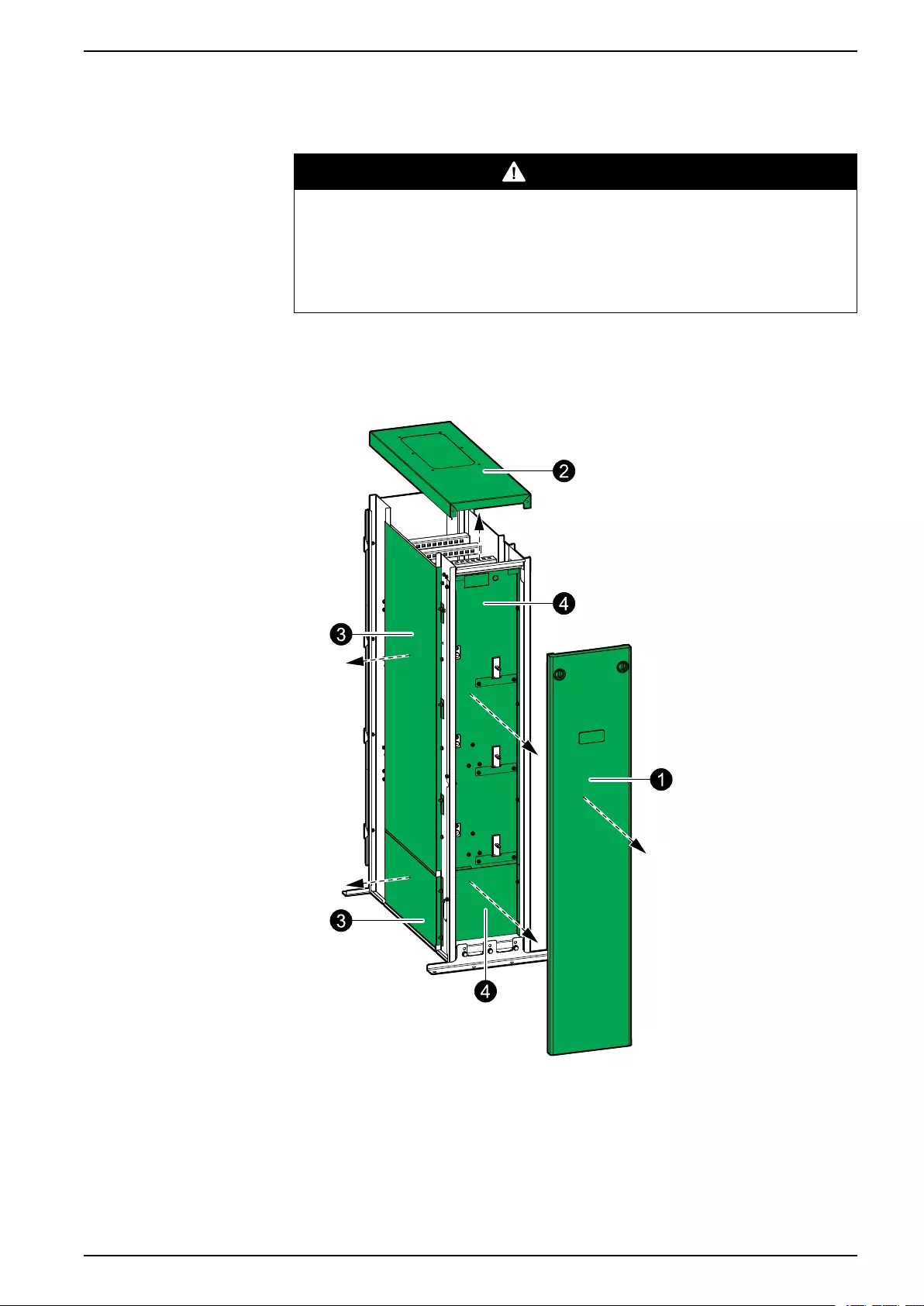

1. Remove the front panel from the maintenance bypass cabinet.

Front View of the Maintenance Bypass Cabinet

2. Remove the top cover from the maintenance bypass cabinet.

3. Remove the upper and lower left side plate from the maintenance bypass

cabinet. Save the upper left side plate for later.

4. Remove the lower and upper front plate from the maintenance bypass

cabinet.

990-5909-001 25

Maintenance Bypass Cabinet

Prepare the Maintenance Bypass Cabinet and the UPS for

Cables

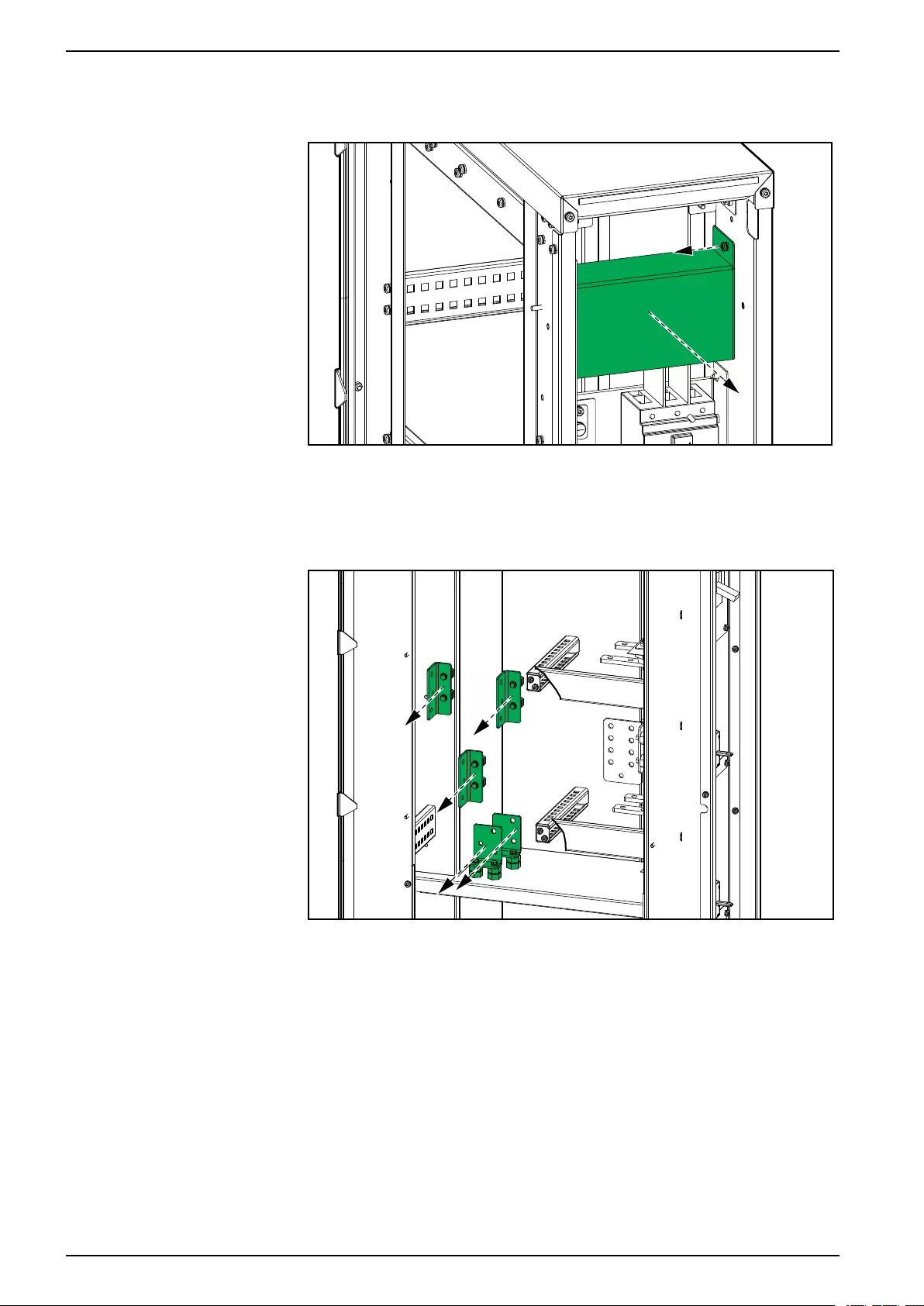

5. Remove the transparent plate above the top breaker.

Front View of the Maintenance Bypass Cabinet

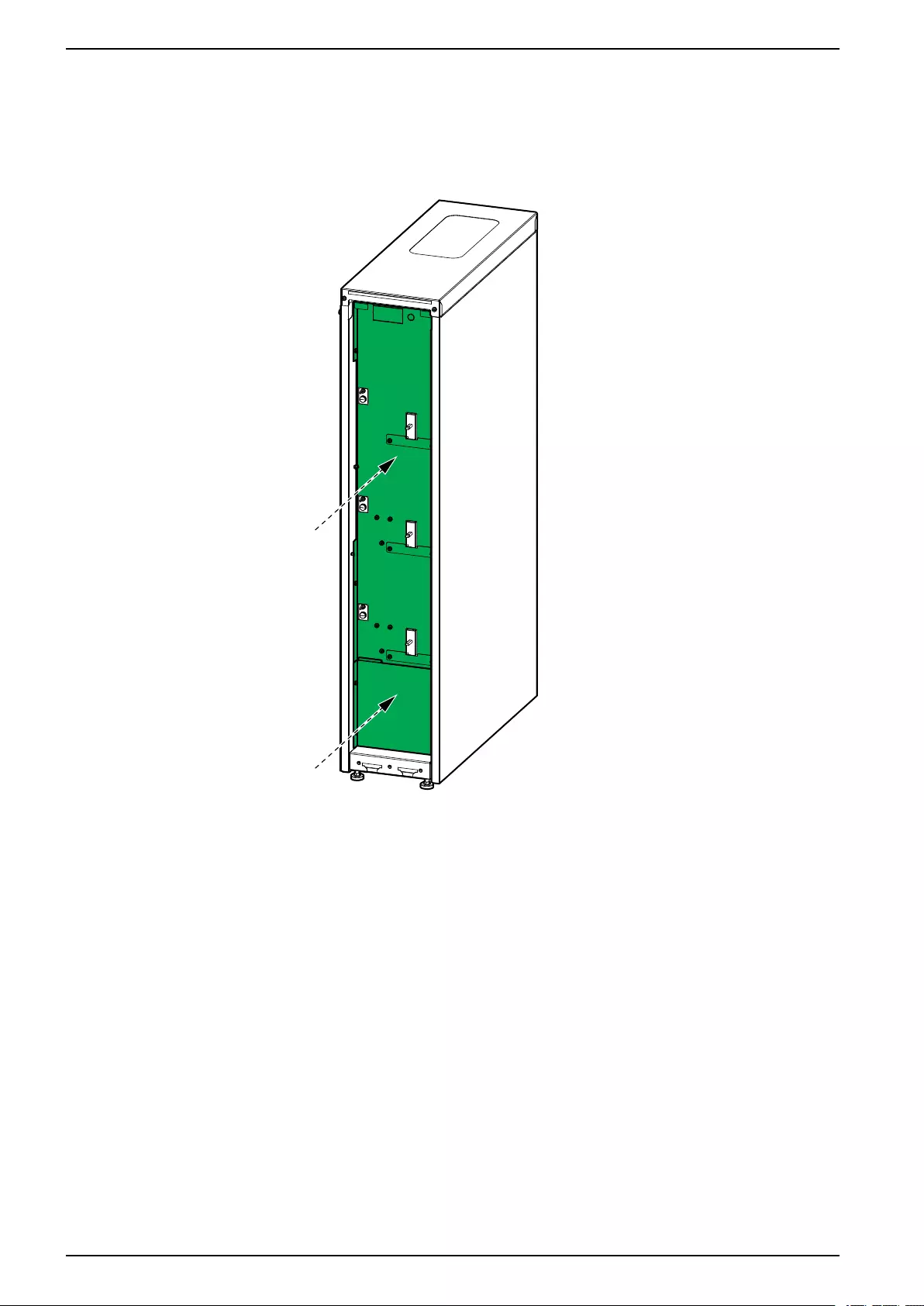

6. Only for bottom cable entry in 100–150 kW maintenance bypass cabinet:

Remove the indicated busbars and insulators in the maintenance bypass

cabinet for more cable routing space.

Left Side View of the 100–150 kW Maintenance Bypass Cabinet

26 990-5909-001

Prepare the Maintenance Bypass Cabinet and the UPS for

Cables Maintenance Bypass Cabinet

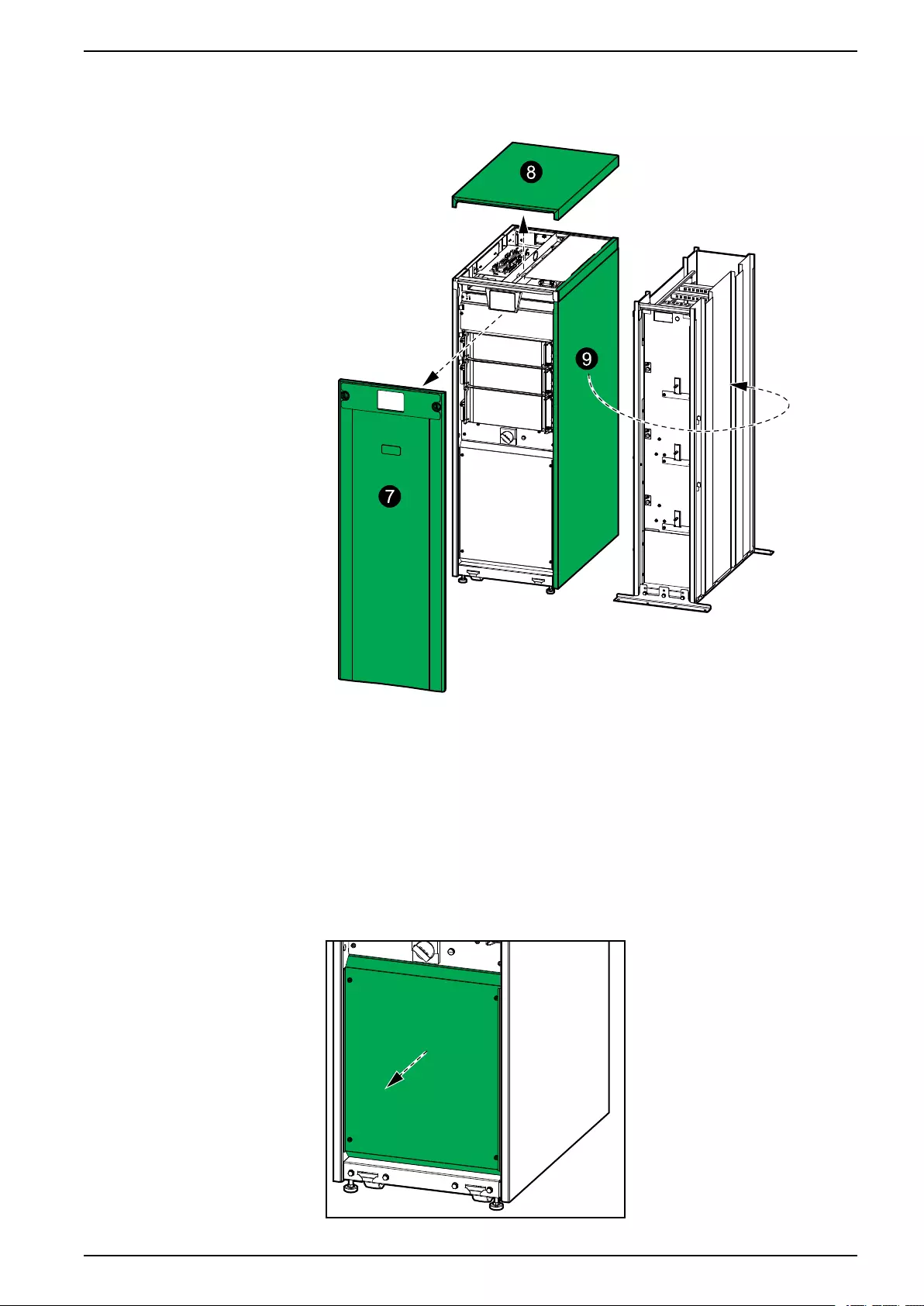

7. Remove the front panel from the UPS.

Front View of the UPS and the Maintenance Bypass Cabinet

8. Remove the top cover from the UPS:

a. Remove the screws and tilt the front of the top cover upwards.

b. Slide the top cover towards the rear to remove it. Taps in the rear of the

top cover must disconnect from the slots in the rear of the UPS.

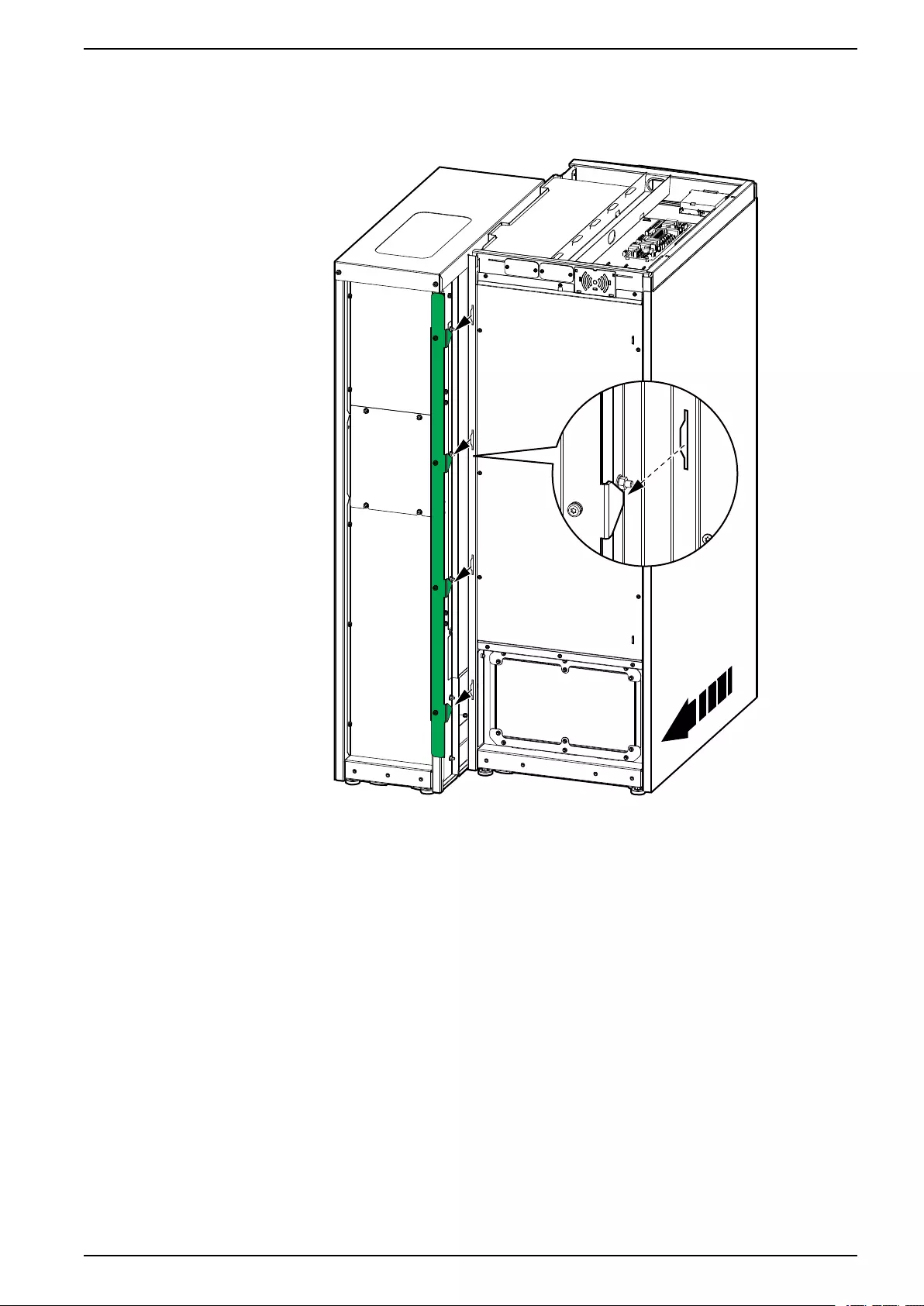

9. Remove the right side panel from the UPS and reinstall the side panel on the

right side of the maintenance bypass cabinet.

10. Remove the front plate from the UPS.

Front View of the UPS

990-5909-001 27

Maintenance Bypass Cabinet

Prepare the Maintenance Bypass Cabinet and the UPS for

Cables

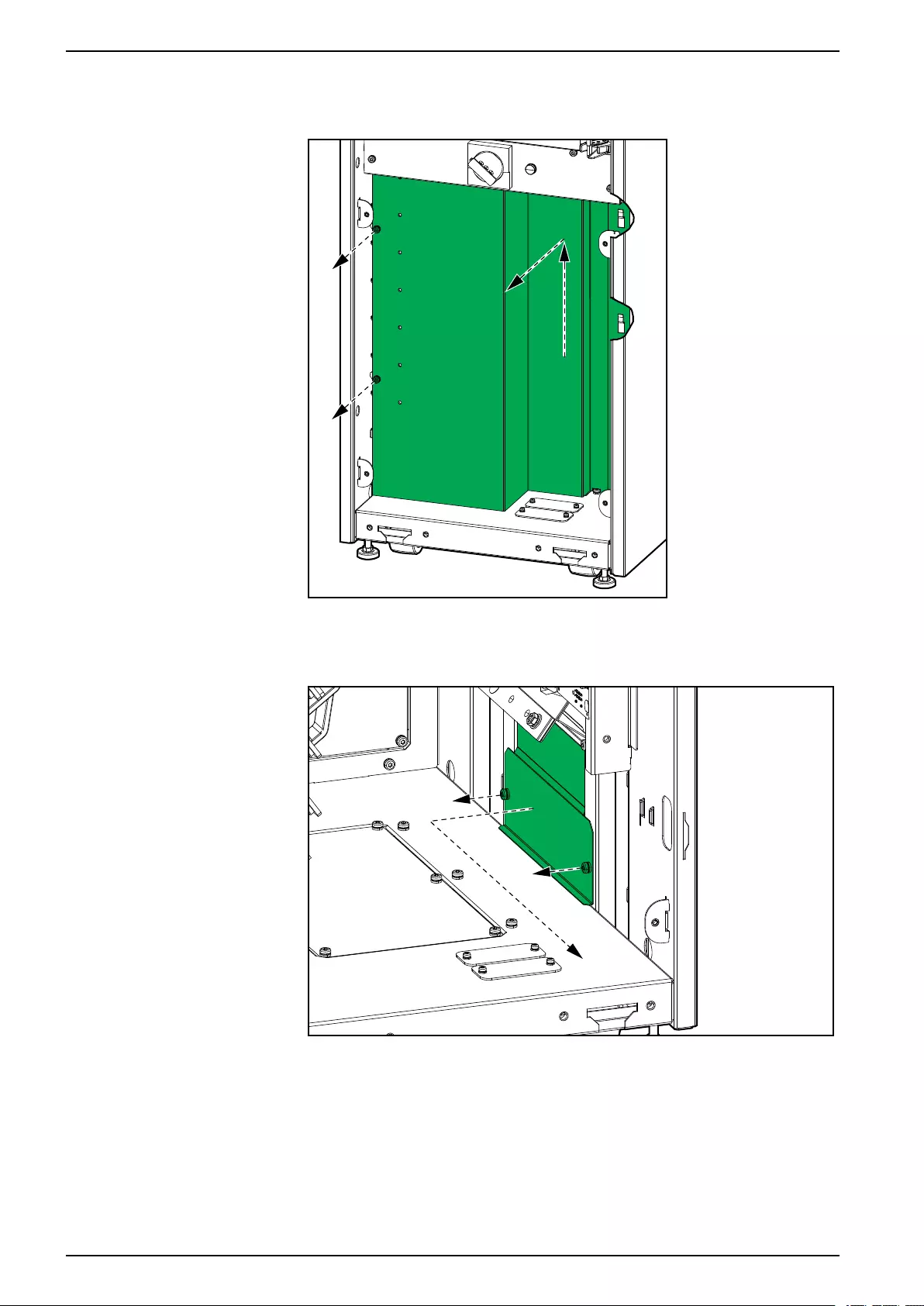

11. Remove the transparent plate from the UPS.

Front View of the UPS

12. Remove the lower right side plate from the UPS.

Front View of the UPS

13. Only for top cable entry system:

a. Remove the gland plate from the top cover of the maintenance bypass

cabinet.

b. Drill or punch holes for power cables or conduits in the gland plate.

Conduits are not provided.

c. Reinstall the gland plate in the top cover of the maintenance bypass

cabinet.

28 990-5909-001

Prepare the Maintenance Bypass Cabinet and the UPS for

Cables Maintenance Bypass Cabinet

14. Only for bottom cable entry system:

a. Remove the gland plate from the bottom of the maintenance bypass

cabinet.

b. Drill or punch holes for power cables or conduits in the gland plate.

Conduits are not provided.

c. Reinstall the gland plate in the bottom of the maintenance bypass cabinet

15. Reinstall the top cover on the maintenance bypass cabinet with four screws.

990-5909-001 29

Maintenance Bypass Cabinet Install the Seismic Anchoring (Option)

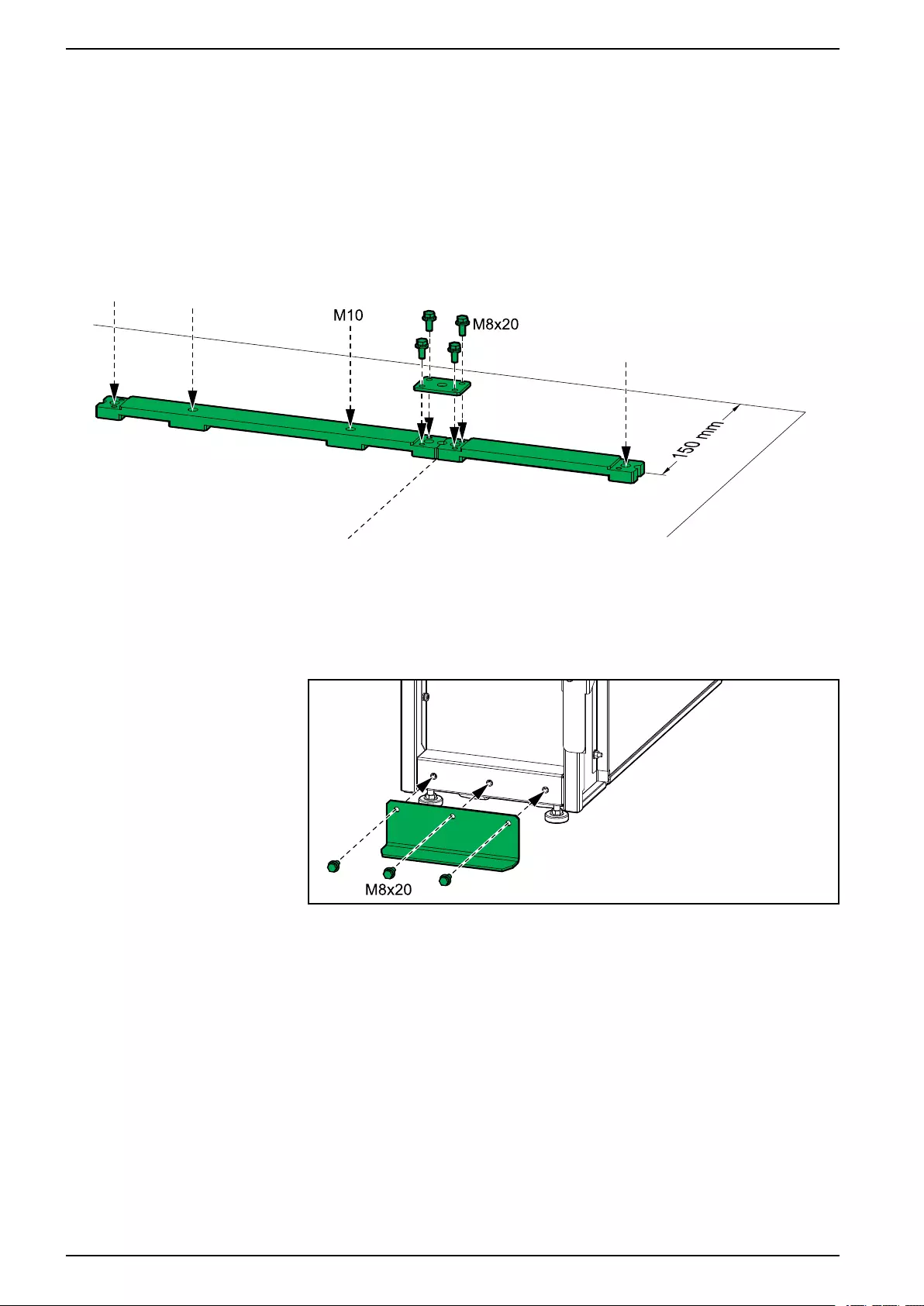

Install the Seismic Anchoring (Option)

Use the optional installation kits GVSOPT002 (shipped with the UPS) and

GVSOPT003 for this procedure.

1. Interconnect the rear anchors for the UPS (on the left) and the maintenance

bypass cabinet (on the right) with the interconnection plate and four M8 bolts

(provided).

2. Mount the rear anchor assembly to the floor with M10 expansion bolts (not

provided).

3. Remove the transportation brackets from the maintenance bypass cabinet.

4. Install the rear anchoring brackets on the UPS and the maintenance bypass

cabinet with the M8 bolts (provided).

Rear View of the Maintenance Bypass Cabinet

30 990-5909-001

Install the Seismic Anchoring (Option) Maintenance Bypass Cabinet

5. Push the maintenance bypass cabinet into position so the rear anchoring

bracket connects to the rear anchor. The front anchoring bracket is installed in

the final installation steps.

NOTE: Do not push the UPS into position yet.

Rear View of the Maintenance Bypass Cabinet

990-5909-001 31

Maintenance Bypass Cabinet

Connect the Power Cables in a 10–80 kW Top Cable Entry

System

Connect the Power Cables in a 10–80 kW Top Cable

Entry System

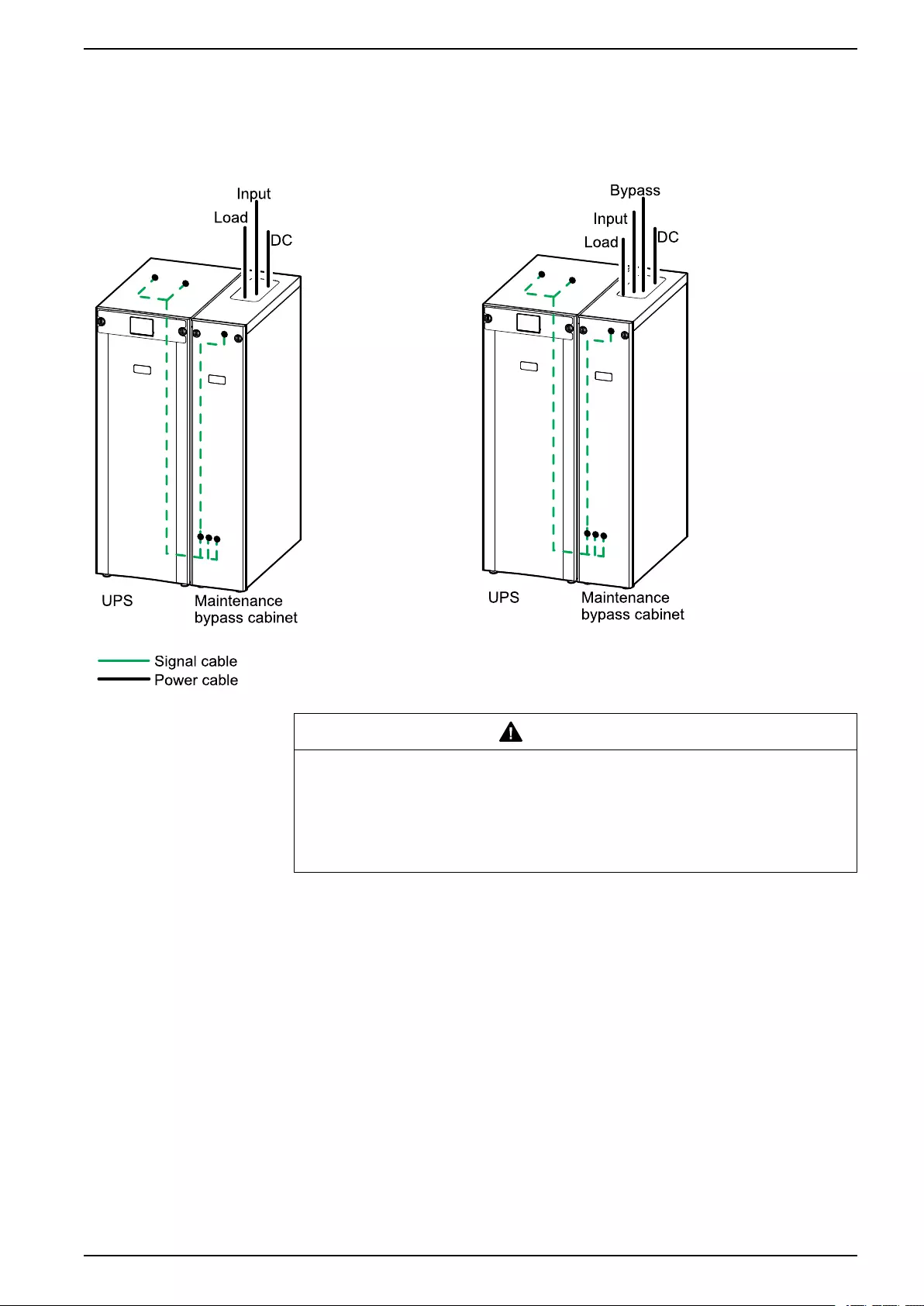

1. The power cables must be restrained with 3/8 nylon rope:

a. Tie the power cables to the beams with rope as illustrated. Make sure that

the rope holds the cables tightly in place. Note that L2 is routed under the

beam and L1 and L3 is routed over the beam in front of the busbars.

b. Tie the power cables together with rope as illustrated halfway between

the two beams. See Restrain the Cables, page 36 for restrain method.

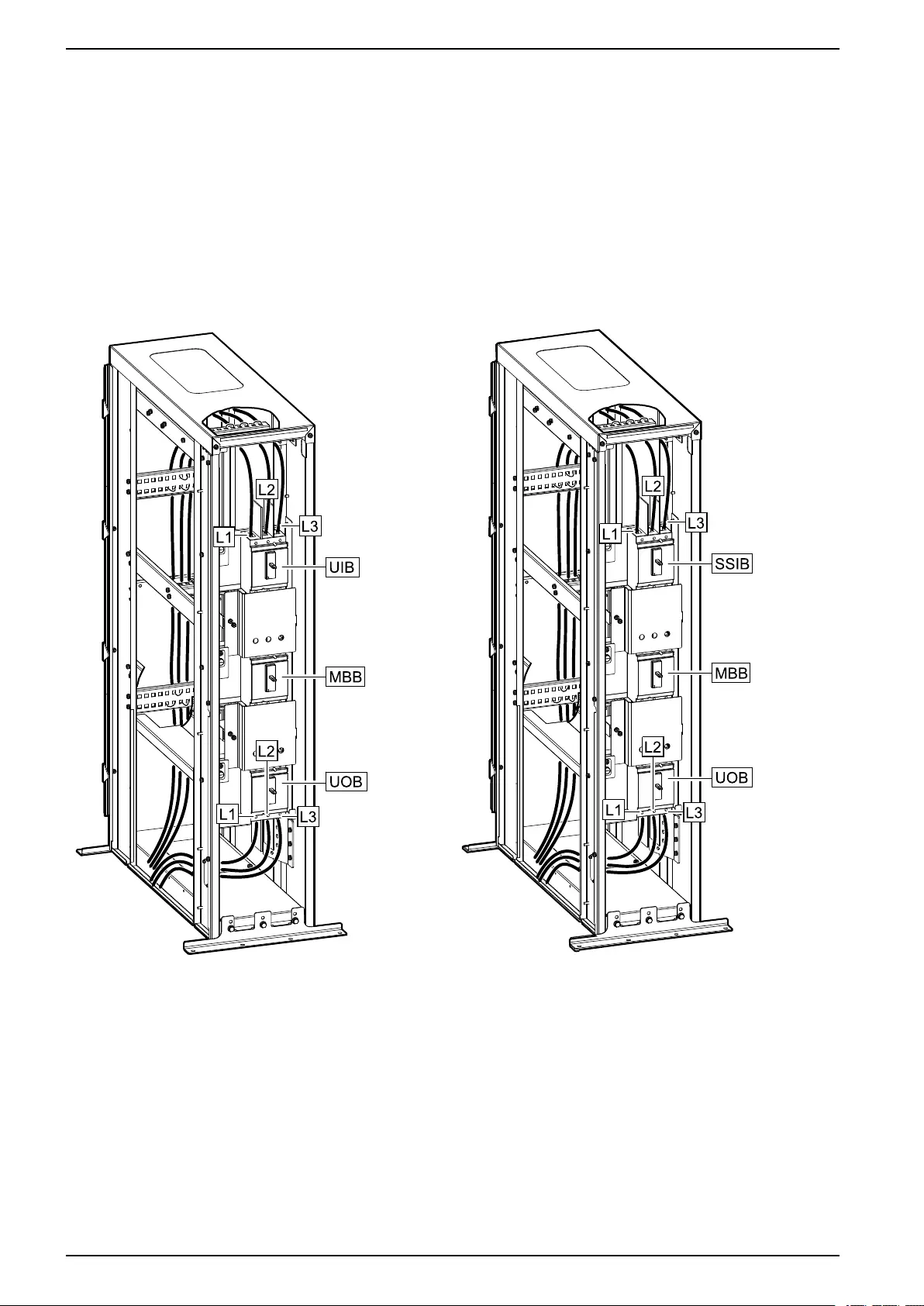

Left Side View of the Maintenance Bypass Cabinet

– Single Mains

Left Side View of the Maintenance Bypass Cabinet

– Dual Mains

2. Perform one of the following:

–Only for single mains system: Route the input cables and load cables

through the top of the maintenance bypass cabinet and connect to the

input busbars, the load busbars, and the PE-busbar.

–Only for dual mains system: Route the bypass cables and load cables

through the top of the maintenance bypass cabinet and connect to the

bypass busbars, the load busbars, and the PE-busbar.

32 990-5909-001

Connect the Power Cables in a 10–80 kW Top Cable Entry

System Maintenance Bypass Cabinet

3. Only for dual mains system: Route the input cables through the top of the

maintenance bypass cabinet and out through the left side of the maintenance

bypass cabinet.

4. Route the DC-cables through the top of the maintenance bypass cabinet and

out through the left side of the maintenance bypass cabinet.

990-5909-001 33

Maintenance Bypass Cabinet

Connect the Power Cables in a 100–150 kW Top Cable Entry

System

Connect the Power Cables in a 100–150 kW Top

Cable Entry System

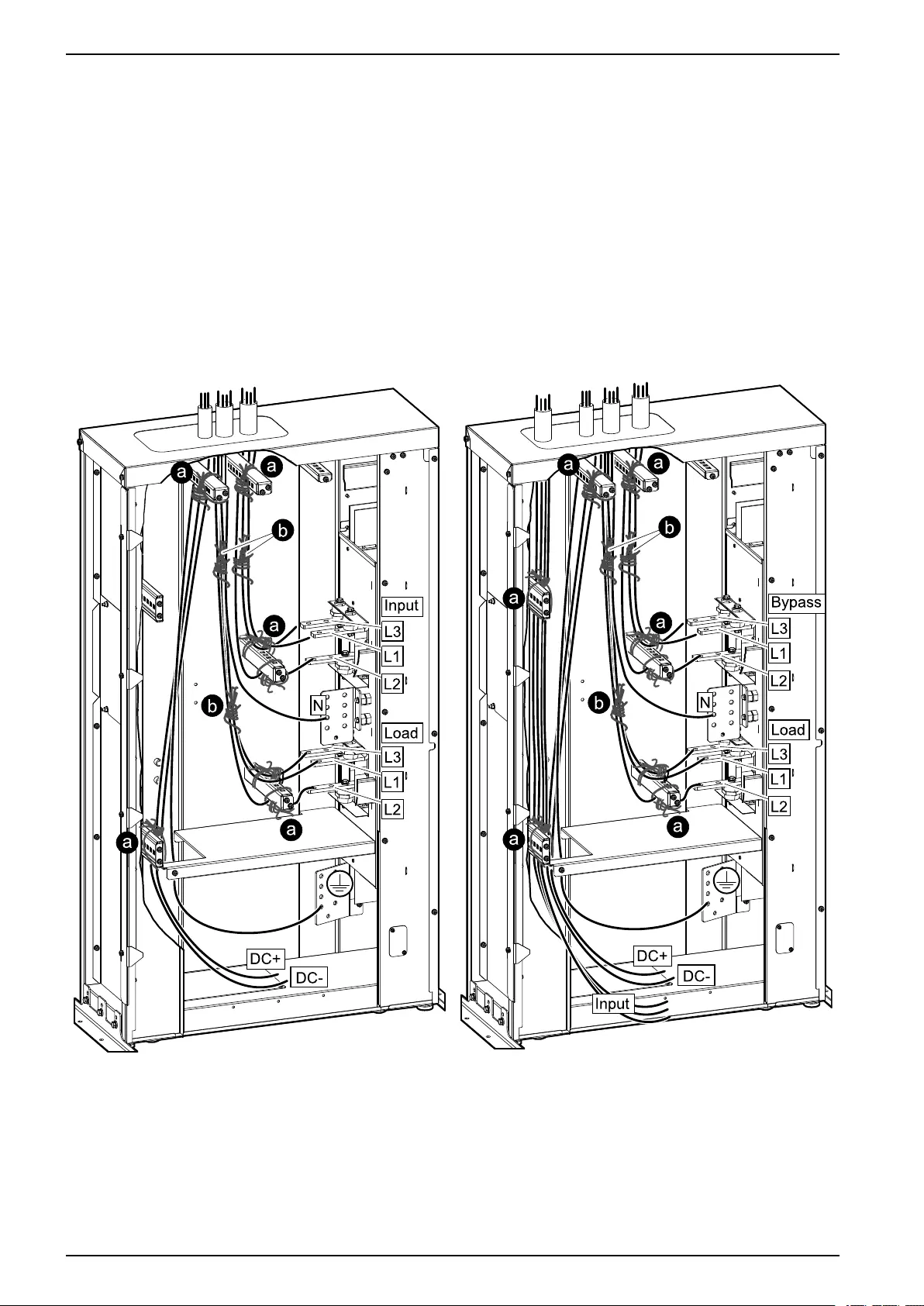

1. The power cables must be restrained with 3/8 nylon rope:

a. Tie the power cables to the beams with rope as illustrated. Make sure that

the rope holds the cables tightly in place. Note that L2 is routed under the

beam and L1 and L3 is routed over the beam in front of the busbars.

b. Tie the power cables together with rope as illustrated halfway between

the two beams. See Restrain the Cables, page 36 for restrain method.

Left Side View of the Maintenance Bypass Cabinet

– Single Mains

Left Side View of the Maintenance Bypass Cabinet

– Dual Mains

2. Perform one of the following:

–Only for single mains system: Route the input cables and the load

cables through the top of the maintenance bypass cabinet and connect to

the input busbars, the load busbars, and the PE-busbar.

–Only for dual mains system: Route the input cables, the bypass cables

and the load cables through the top of the maintenance bypass cabinet

and connect to the input busbars, the bypass busbars, the load busbars,

and the PE-busbar.

34 990-5909-001

Connect the Power Cables in a 100–150 kW Top Cable Entry

System Maintenance Bypass Cabinet

3. Route the DC-cables through the top of the maintenance bypass cabinet and

connect to the DC-busbars (DC+, DC–) and the PE-busbar.

4. Connect the provided UPS DC-cables to the DC-busbars (DC+, DC-) and

route the cables out through the left side of the maintenance bypass cabinet.

Fasten the cables to the beam with cable ties.

5. Only for dual mains system: Connect the provided UPS input cables to the

input busbars and route the cables out through the left side of the

maintenance bypass cabinet. Fasten the cables to the beam with cable ties.

Left Side View of the Maintenance Bypass Cabinet

990-5909-001 35

Maintenance Bypass Cabinet Restrain the Cables

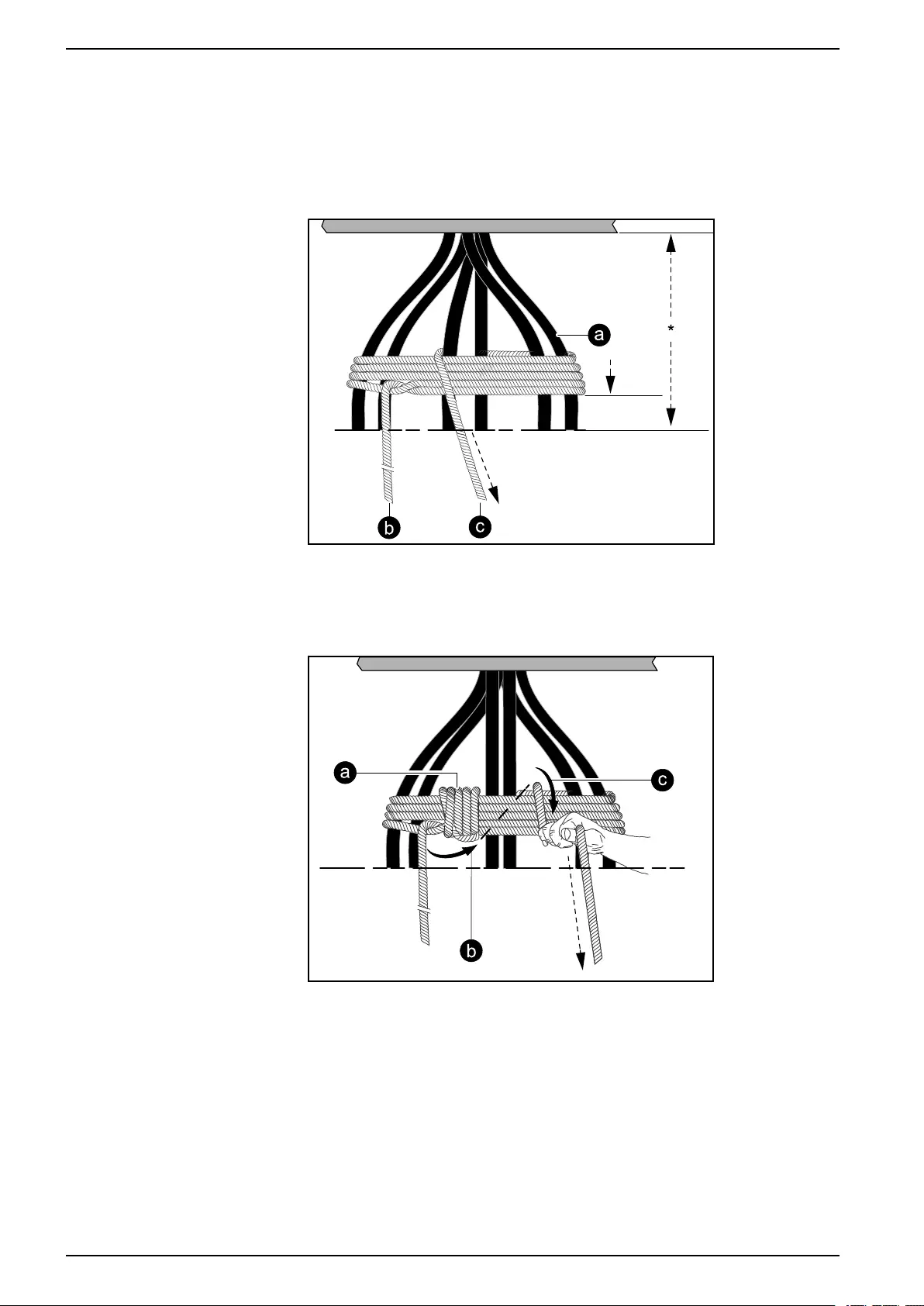

Restrain the Cables

Use 3/8 in nylon rope to restrain the cables.

1. Wrap the rope around the cables (a). Wrap the cables four times leaving 1 m

(3 ft) of excess rope at the first end (b). Pull rope (c) taut.

* Unsupported cable length.

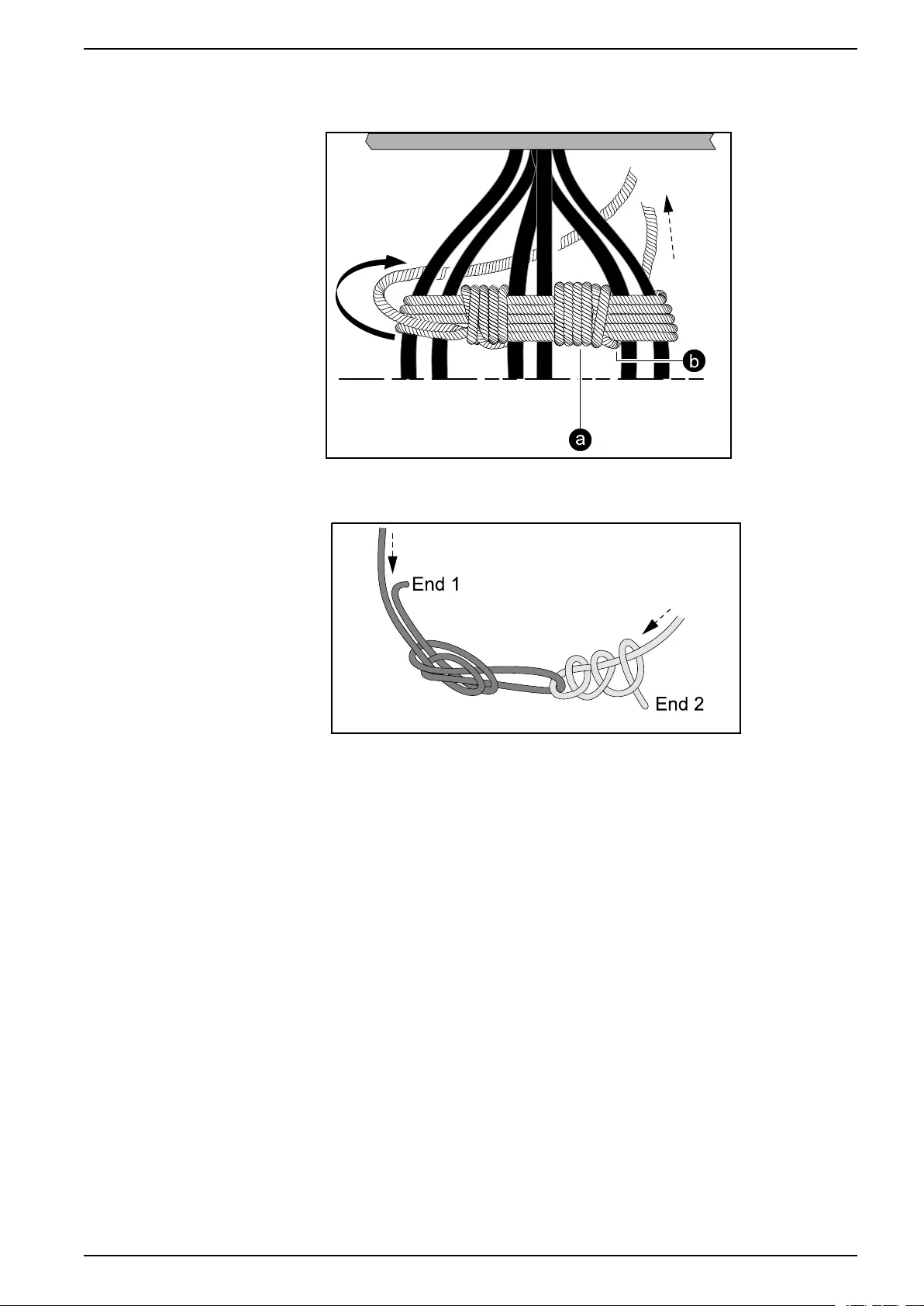

2. Wrap rope (a) several times until the space between the first two sets of

cables is completely filled. Weave final rope loop underneath the previous loop

(b). Bring rope (c) through the other open area and pull the rope taut.

36 990-5909-001

Restrain the Cables Maintenance Bypass Cabinet

3. Wrap rope (a) several times until the space between the second and the third

set of cables is completely filled. Wave the final rope loop (b) underneath the

previous loop as shown. Pull the rope taut.

4. Tie rope End 1 and End 2 together as shown. The rope must be taut. Cut off

excess rope and tape ends to prevent fraying.

5. Repeat the procedure where needed.

990-5909-001 37

Maintenance Bypass Cabinet Connect the Power Cables in a Bottom Cable Entry System

Connect the Power Cables in a Bottom Cable Entry

System

NOTE: DC-cables are routed through the bottom of the UPS. Follow the UPS

installation manual to install the DC-cables.

NOTE: Input cables in dual mains systems are routed through the bottom of

the UPS. Follow the UPS installation manual to install the input cables.

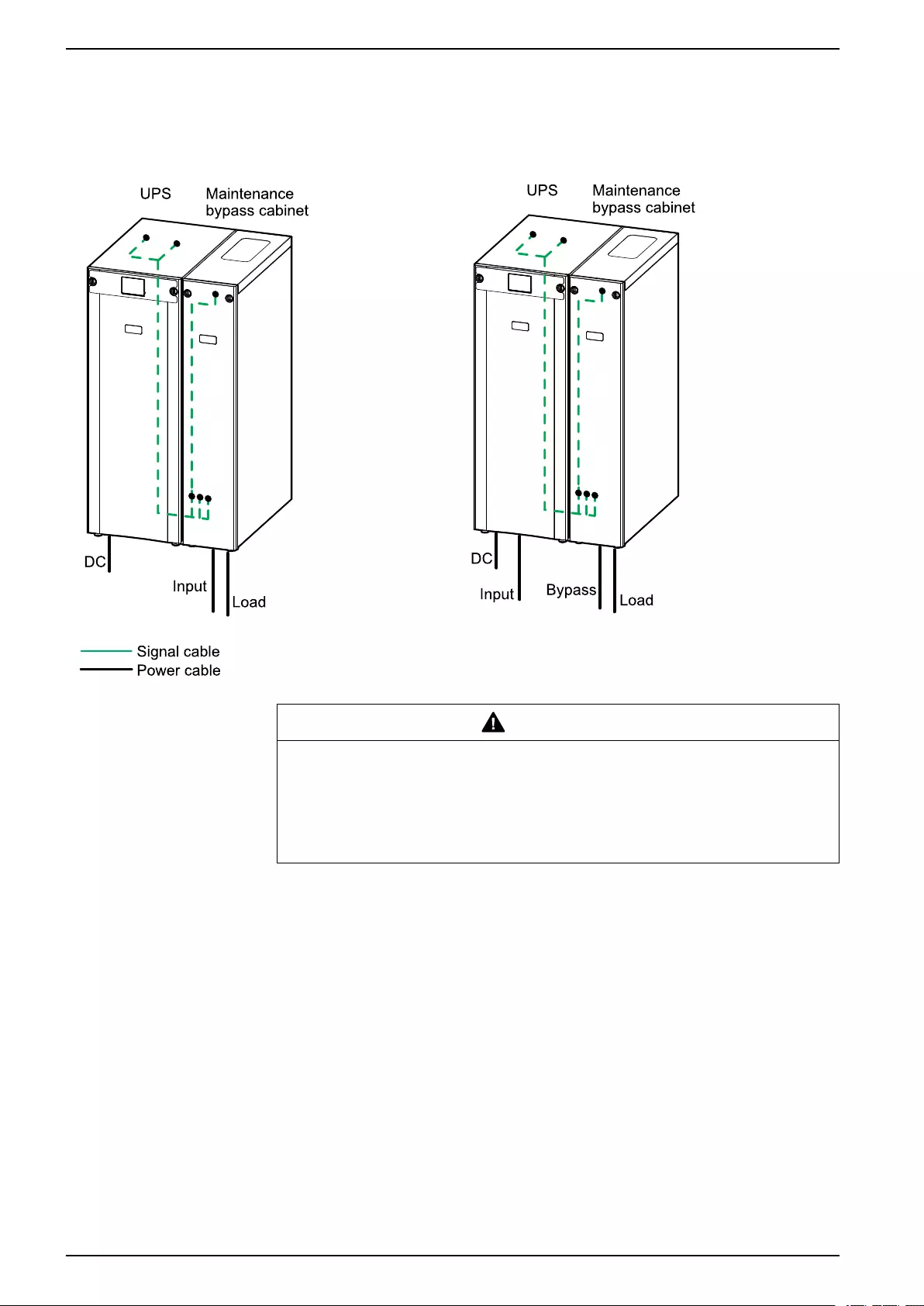

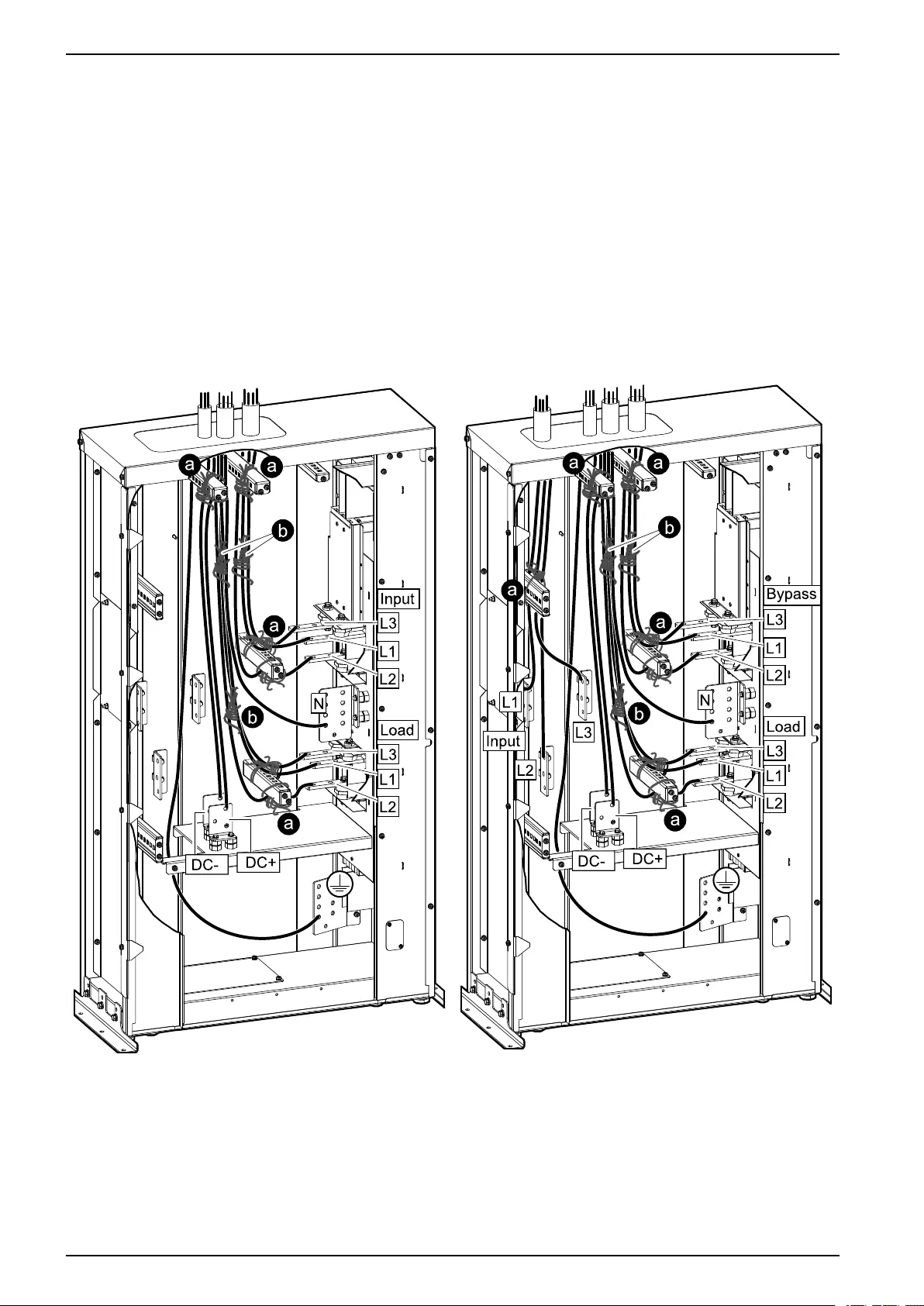

1. Perform one of the following:

–Only for single mains system: Route the input cables and the load

cables through the bottom of the maintenance bypass cabinet and connect

to the input busbars, the load busbars, and the PE-busbar.

–Only for dual mains system: Route the bypass cables and the load

cables through the bottom of the maintenance bypass cabinet and connect

to the bypass busbars, the load busbars, and the PE-busbar.

2. The power cables must be restrained with 3/8 nylon rope:

a. Tie the power cables to the beams with rope as illustrated. Make sure that

the rope holds the cables tightly in place. Note that L2 is routed under the

beam and L1 and L3 is routed over the beam in front of the busbars.

Left Side View of the Maintenance Bypass Cabinet

– Single Mains

Left Side View of the Maintenance Bypass Cabinet

– Dual Mains

38 990-5909-001

Connect the Internal Power Cables Maintenance Bypass Cabinet

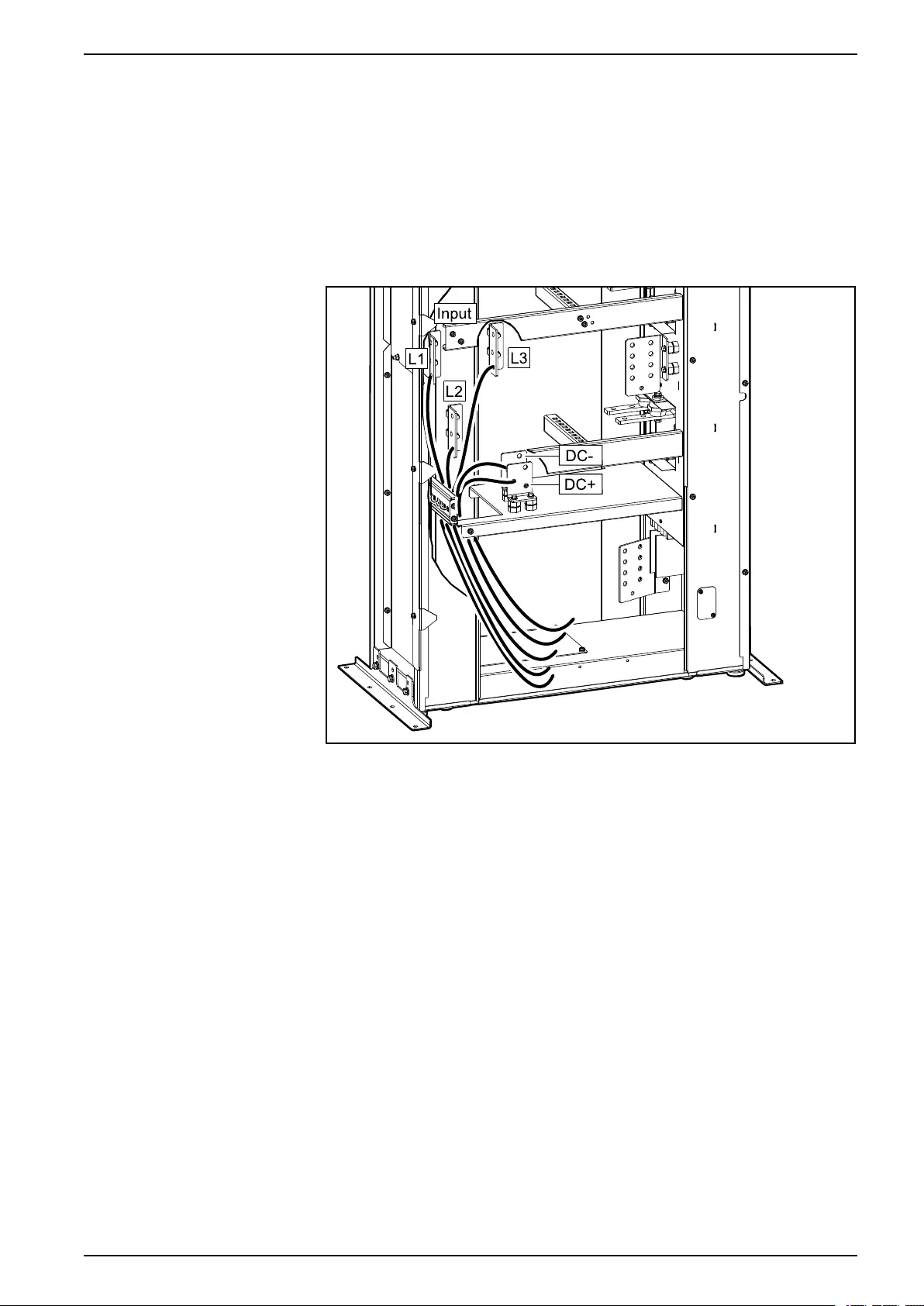

Connect the Internal Power Cables

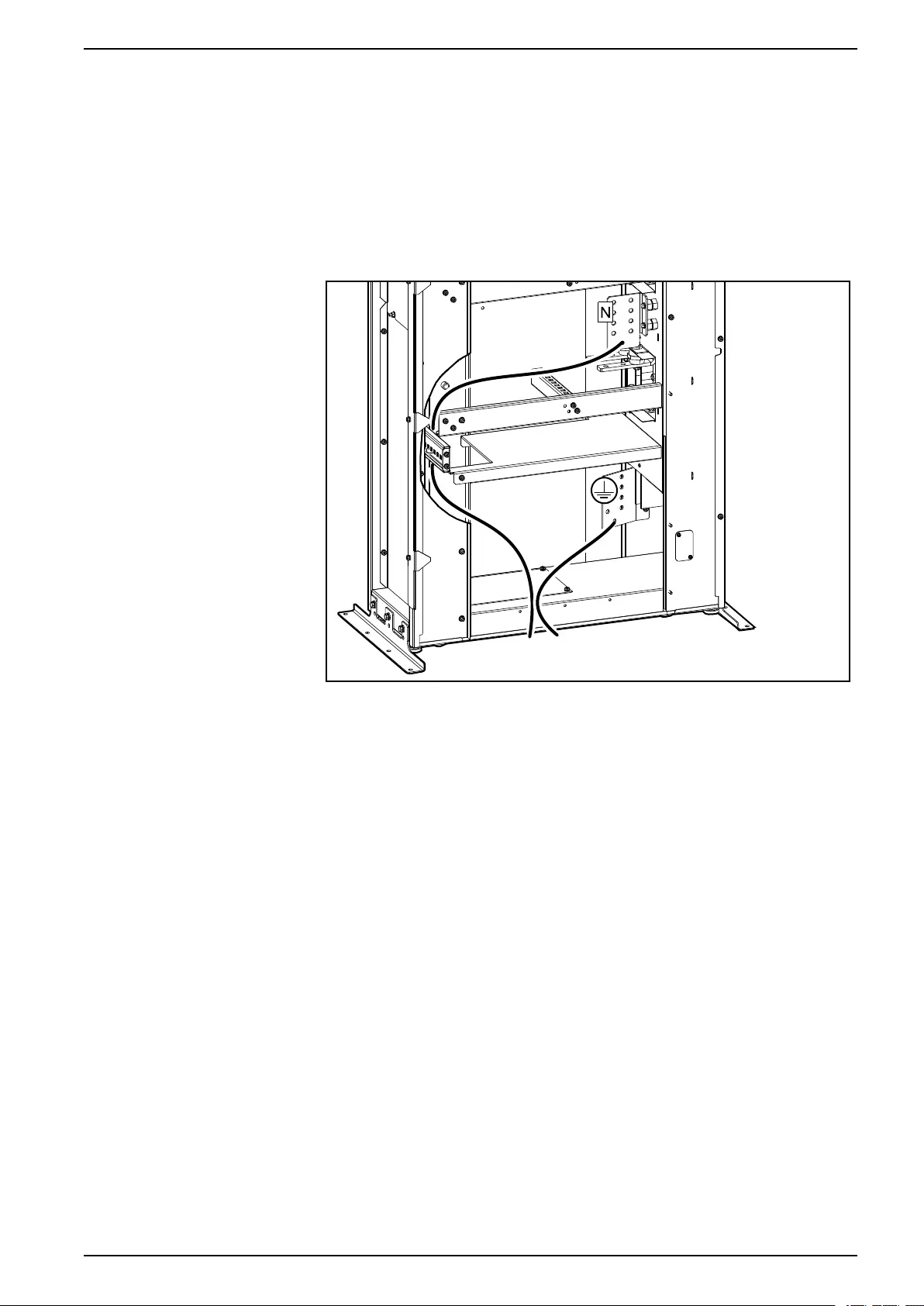

1. Connect the provided UPS PE cable to the PE busbar and route the cable out

through the left side of the maintenance bypass cabinet.

2. Connect the provided UPS N cable to the N busbar and route the cable out

through the left side of the maintenance bypass cabinet. Fasten the N cable to

the beam with a cable tie.

Left Side View of the Maintenance Bypass Cabinet

990-5909-001 39

Maintenance Bypass Cabinet Connect the Internal Power Cables

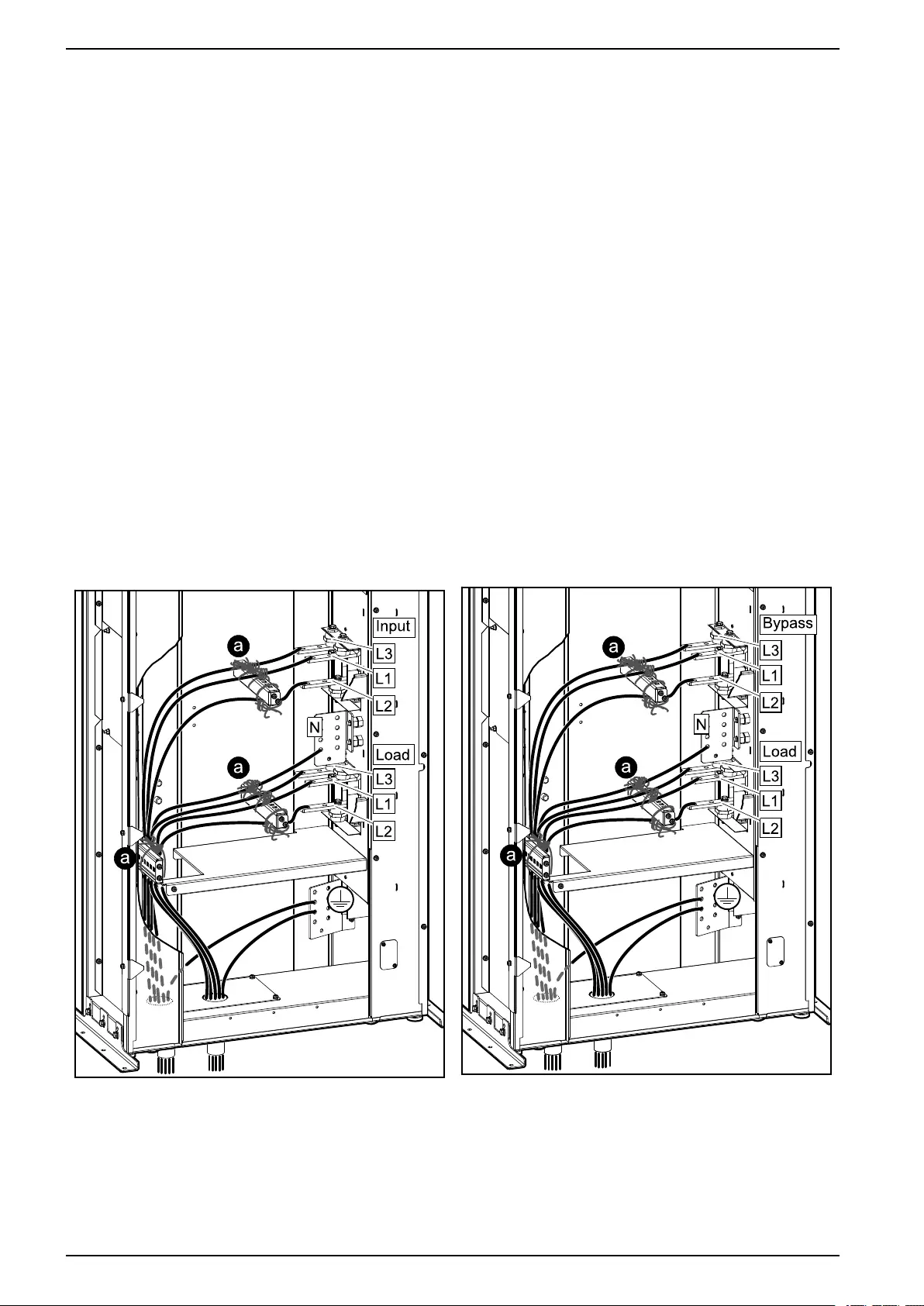

3. Perform one of the following:

–Only for single mains system: Connect the provided UPS input cables to

the unit input breaker UIB (L1, L2, L3) and route the cables out through the

left side of the maintenance bypass cabinet. Fasten the cables to the

beams with cable ties.

–Only for dual mains system: Connect the provided UPS bypass cables to

the static switch input breaker SSIB (L1, L2, L3) and route the cables out

through the left side of the maintenance bypass cabinet. Fasten the cables

to the beams with cable ties.

Front View of the Maintenance Bypass Cabinet –

Single Mains

Front View of the Maintenance Bypass Cabinet –

Dual Mains

4. Connect the provided UPS output cables to the unit output breaker UOB (L1,

L2, L3) and route the cables out through the left side of the maintenance

bypass cabinet.

40 990-5909-001

Maintenance Bypass Cabinet Interconnect the UPS and the Maintenance Bypass Cabinet

Interconnect the UPS and the Maintenance Bypass

Cabinet

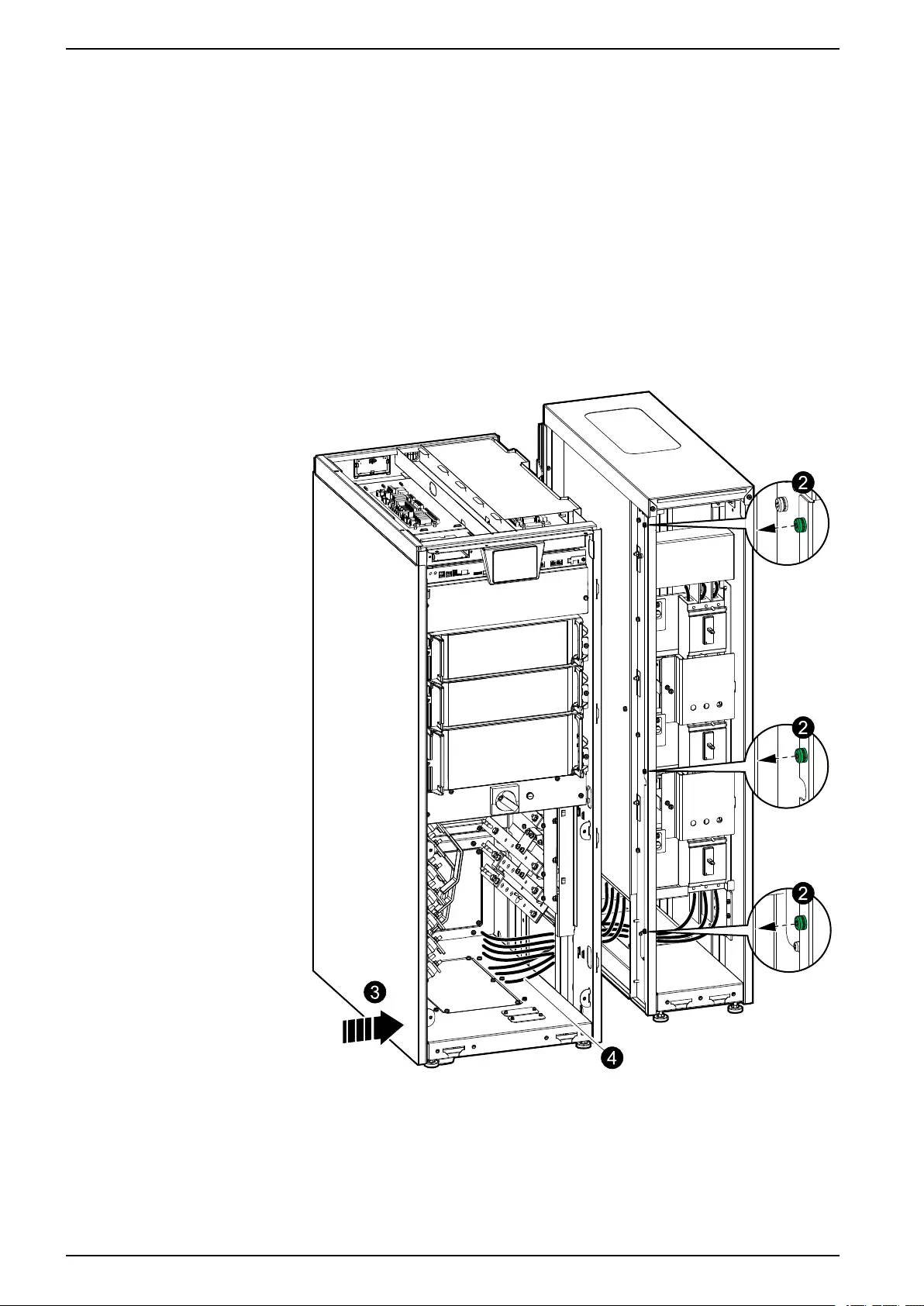

1. Remove the transportation brackets from the maintenance bypass cabinet, if

not already removed for seismic anchoring.

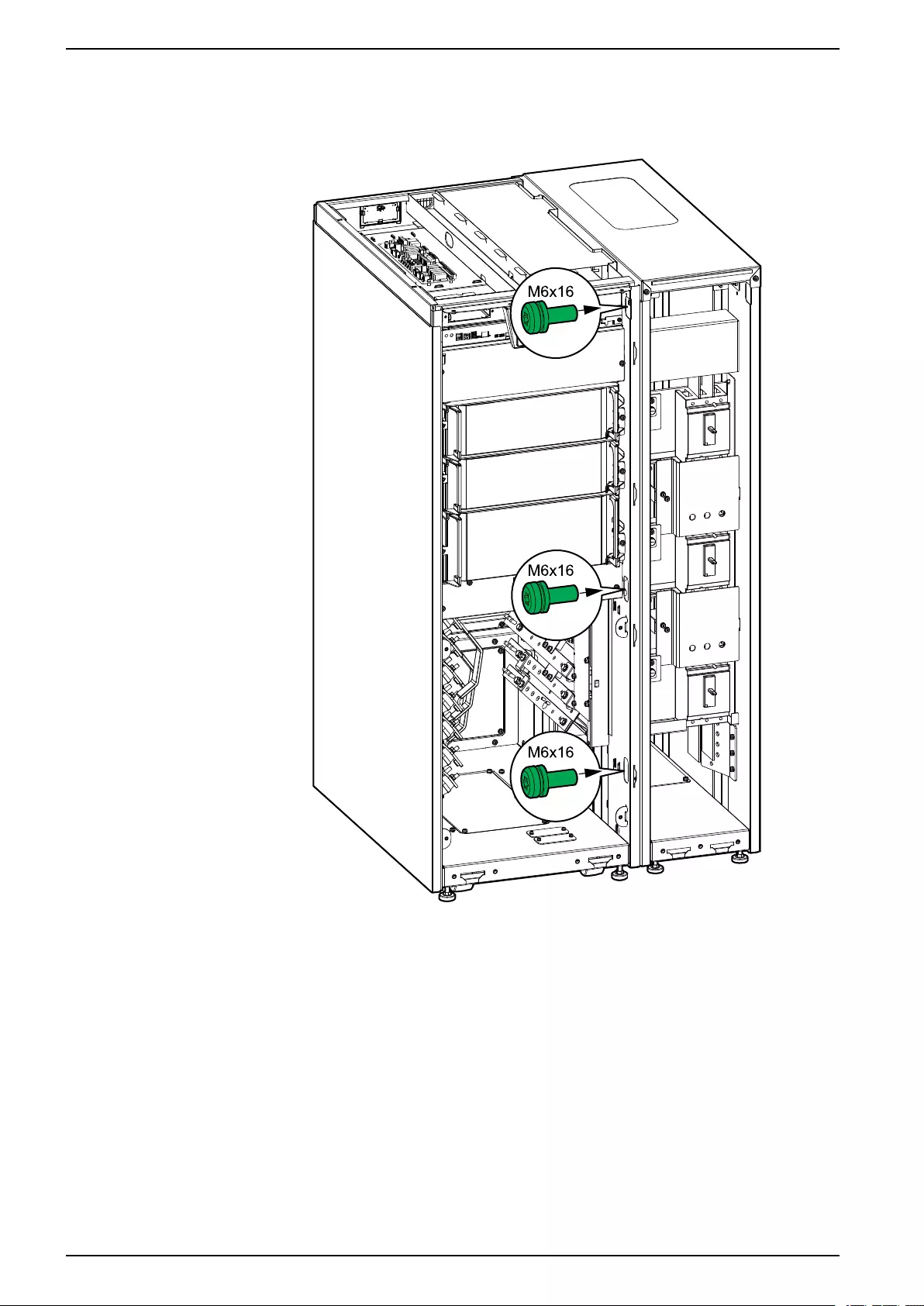

2. Remove the three M6 x 16 mm interconnection screws from the left side of the

maintenance bypass cabinet. Save for interconnection.

3. Position the UPS close to the maintenance bypass cabinet with a little free

space between the cabinets.

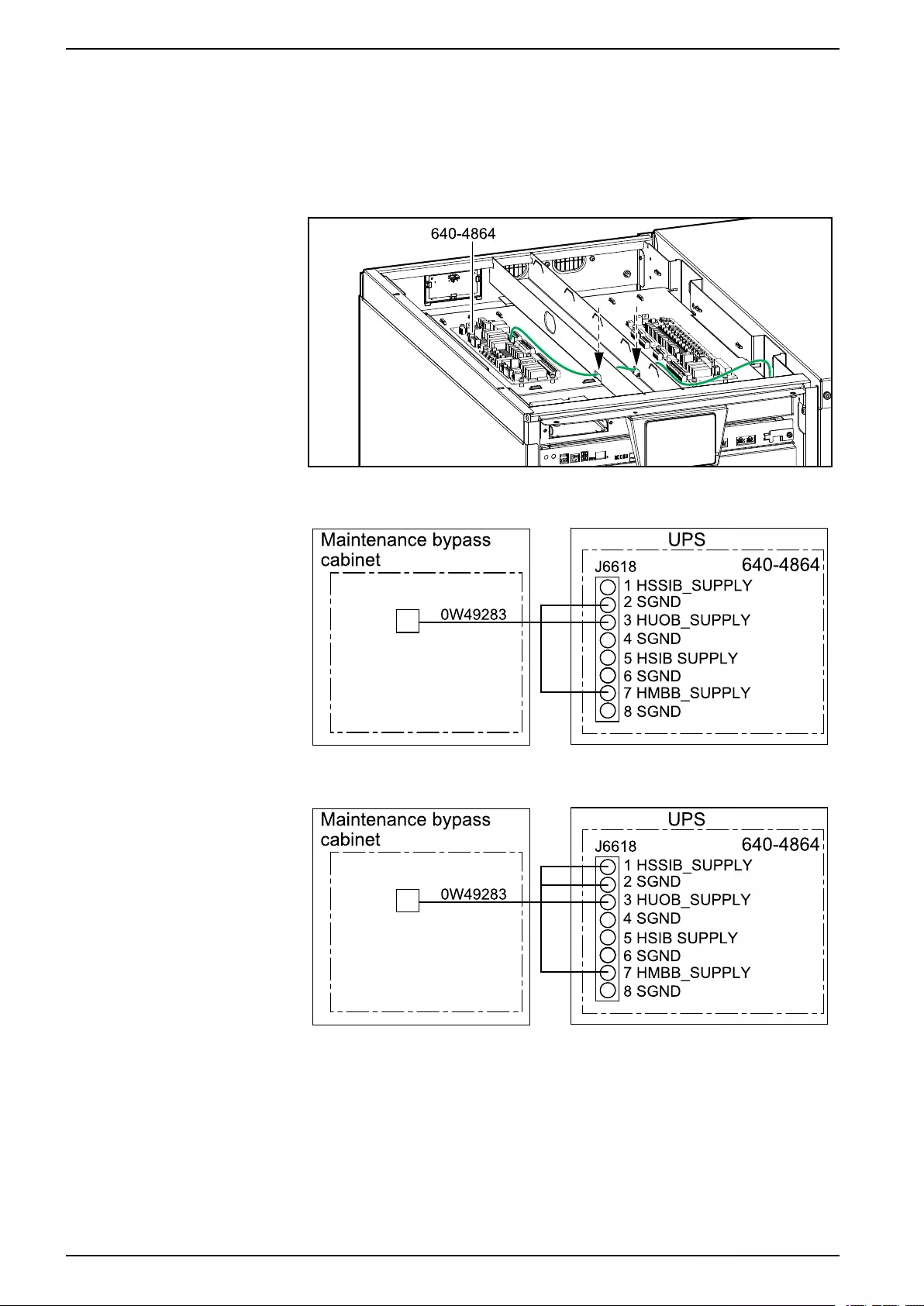

4. Route the internal power cables from the maintenance bypass cabinet into the

UPS.

Front View of the UPS and the Maintenance Bypass Cabinet

42 990-5909-001

Interconnect the UPS and the Maintenance Bypass Cabinet Maintenance Bypass Cabinet

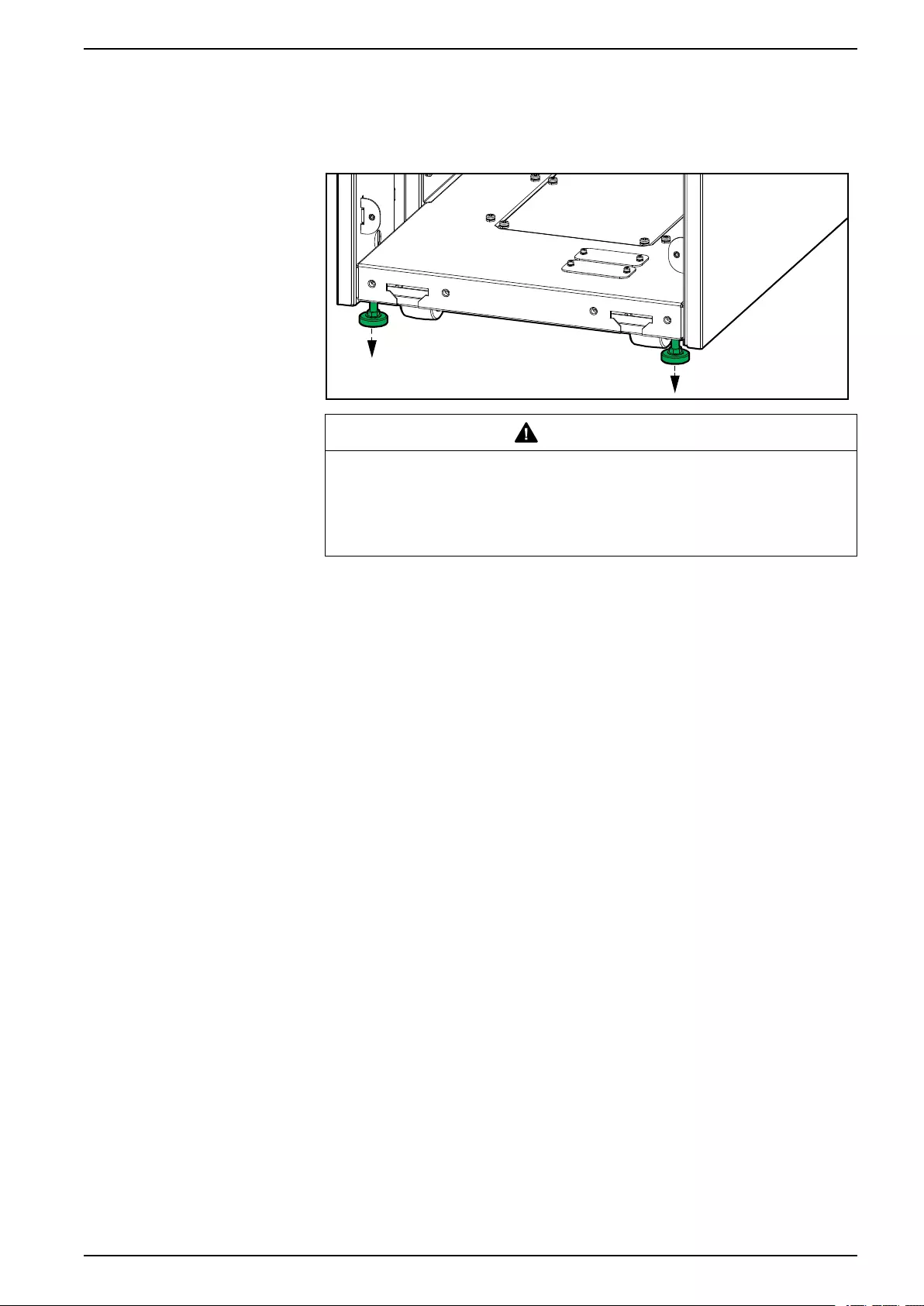

7. Lower the front and rear leveling feet on the UPS and the maintenance bypass

cabinet with a wrench until they connect with the floor. Use a bubble-leveler to

check that the UPS and maintenance bypass cabinet are level.

Front View of the UPS

CAUTION

TIP HAZARD

Do not move the cabinet after the leveling feet have been lowered.

Failure to follow these instructions can result in injury or equipment

damage.

990-5909-001 45

Final Installation Maintenance Bypass Cabinet

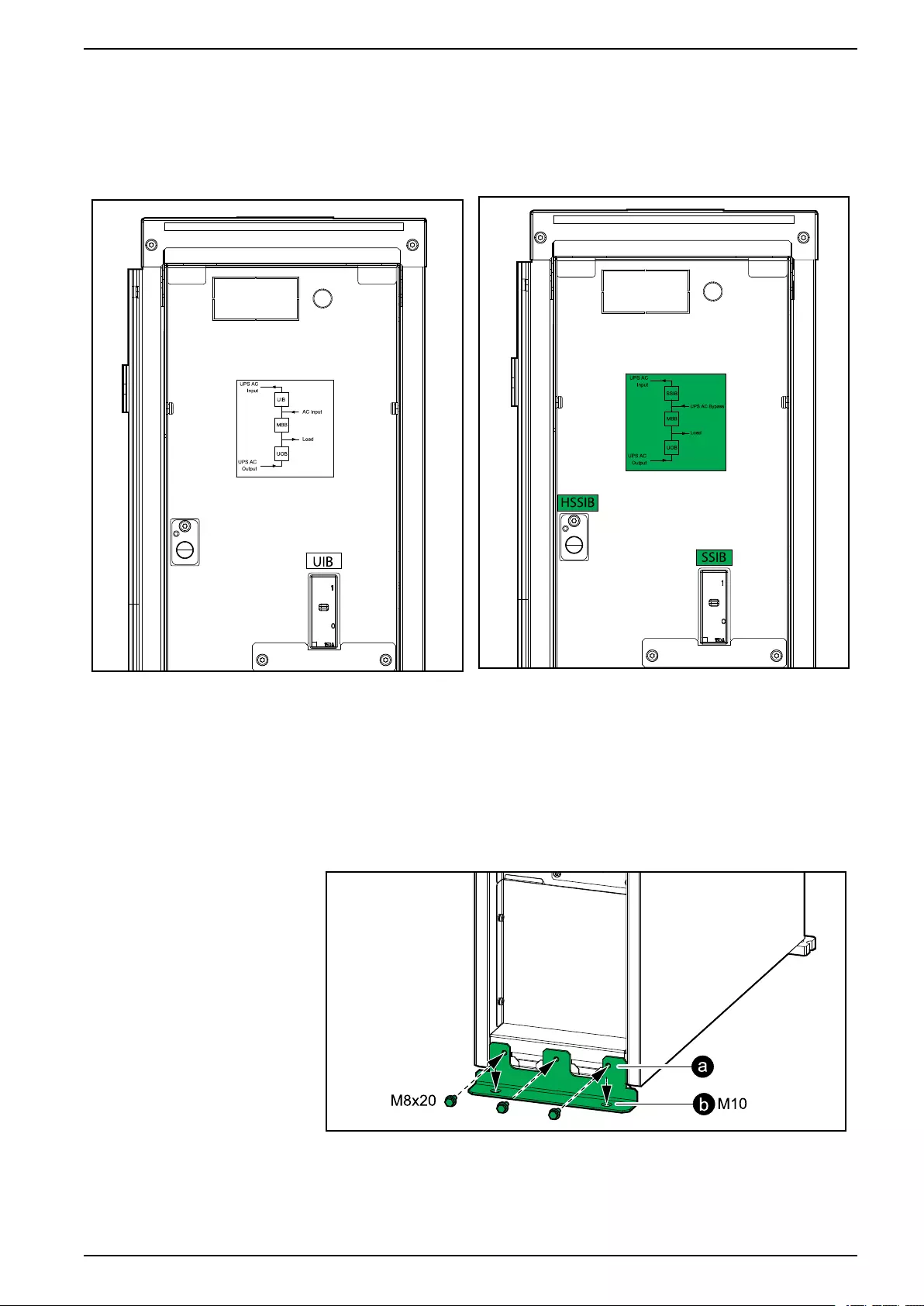

2. Only for dual mains: Add the labels SSIB, HSSIB, and the diagram label on

the upper front plate. The labels are provided with this manual.

Front View of the Maintenance Bypass Cabinet –

Single Mains

Front View of the Maintenance Bypass Cabinet –

Dual Mains

3. Only for seismic anchoring:

a. Install the seismic front anchoring bracket on the maintenance bypass

cabinet with the provided M8 bolts.

b. Mount the seismic front anchoring bracket on the maintenance bypass

cabinet to the floor with M10 expansion bolts (not provided).

Front View of the Maintenance Bypass Cabinet

990-5909-001 51

Maintenance Bypass Cabinet Final Installation

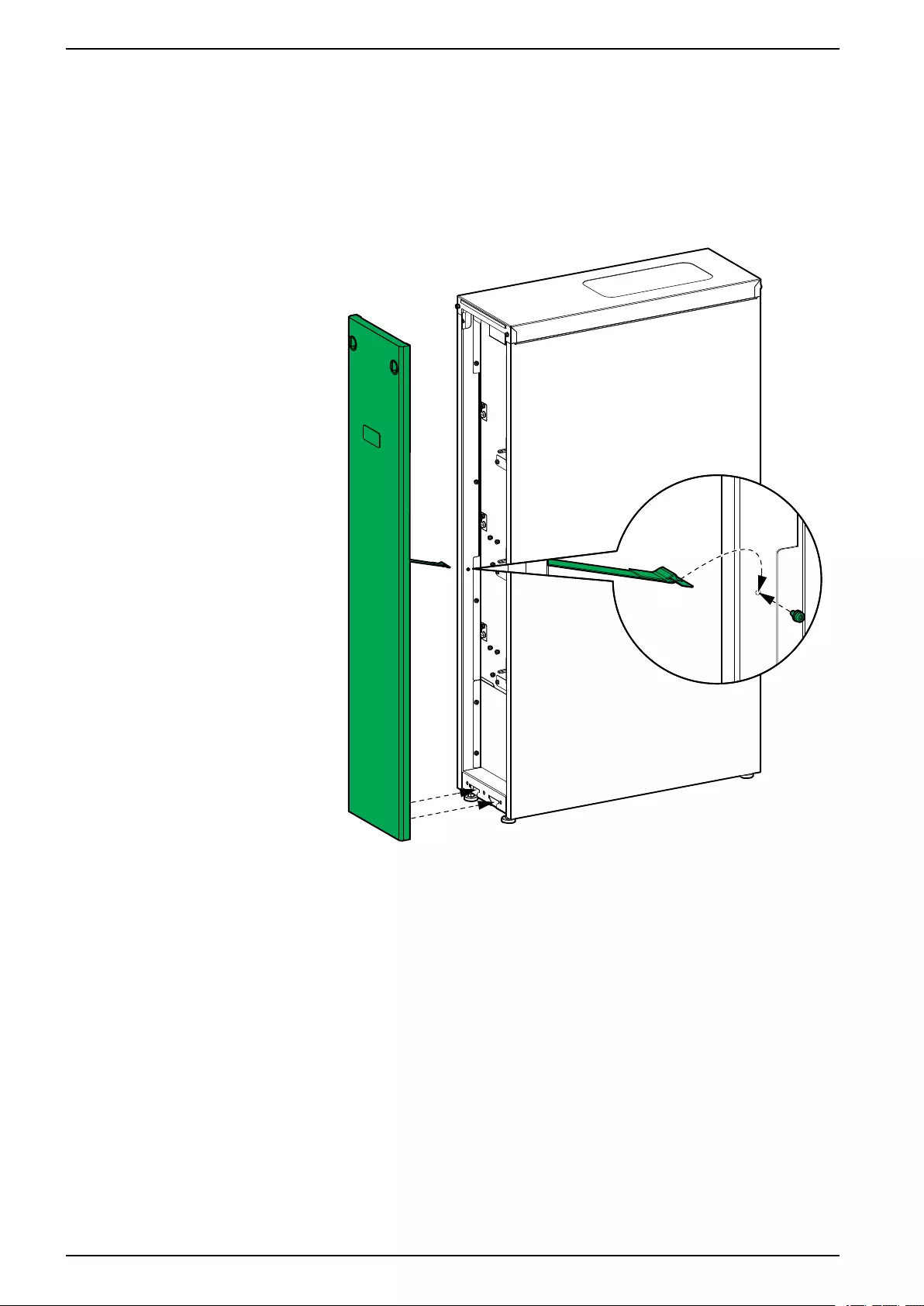

4. Reinstall the front panel on the maintenance bypass cabinet:

a. Insert the two taps in the bottom of the front panel in the maintenance

bypass cabinet at a tilted angle.

b. Reconnect the front panel strap to the maintenance bypass cabinet.

c. Close the front panel and lock with the two locking knobs.

Front Right View of the Maintenance Bypass Cabinet

5. Follow the UPS installation manual to connect the internal power cables in the

UPS.

52 990-5909-001

Schneider Electric

35 rue Joseph Monier

92500 Rueil Malmaison

France

+ 33 (0) 1 41 29 70 00

www.schneider-electric.com

As standards, specifications, and design change from time to time,

please ask for confirmation of the information given in this publication.

© 2018 – 2018 Schneider Electric. All rights reserved.

990-5909-001