Table of Contents

- Galaxy VX

- Important Safety Instructions — SAVE THESE INSTRUCTIONS

- Specifications for 380, 400, 415, and 440 V Systems

- Specifications for 480 V Systems

- Specifications

- Overview of Configurations

- Overview of Supplied Installation Kits

- Installation Procedure

- Mechanical Installation

- Connect the Power Cables

- Prepare the I/O Cabinet for Power Cables in Top Cable Entry Systems

- Prepare the I/O Cabinet for Power Cables in Bottom Cable Entry Systems

- Install the Single Utility/Mains Installation Kit 0H-9161

- Connect the Power Cables in a 380 V, 400 V, 415, and 440 V System

- Connect the Power Cables in a 480 V System

- Mount the Front Anchoring Brackets

- Connect the Signal Cables

- Prepare for Signal Cables

- Connect the Signal Cables between the I/O Cabinet and the Power Cabinets

- Connect the Signal Cables between the I/O Cabinet and the Switchgear

- Connect the Signal Cables for Battery Solutions

- Connect the Emergency Power Off (EPO)

- Connect External Synchronization

- Connect Equipment to Input Contacts and Output Relays

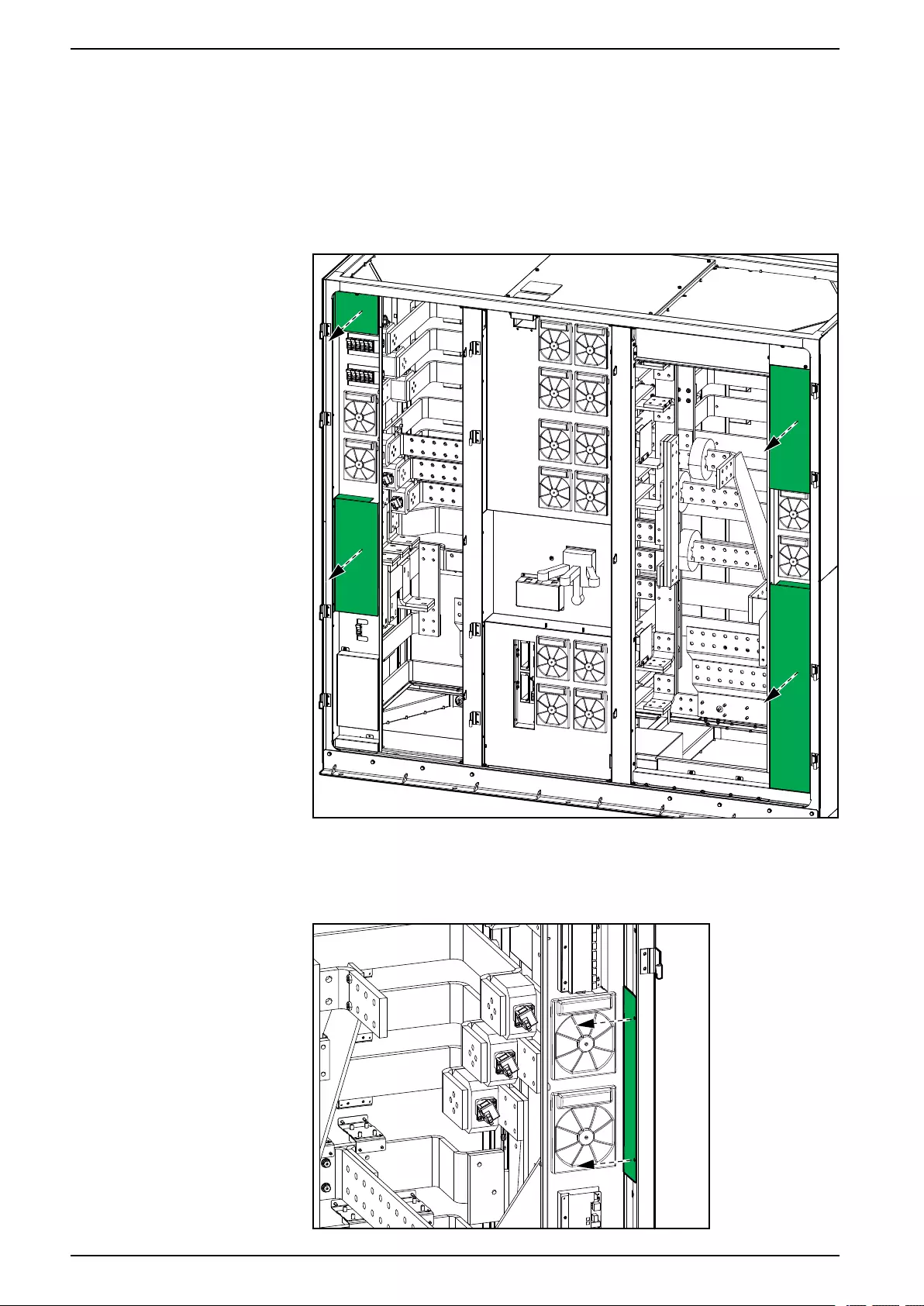

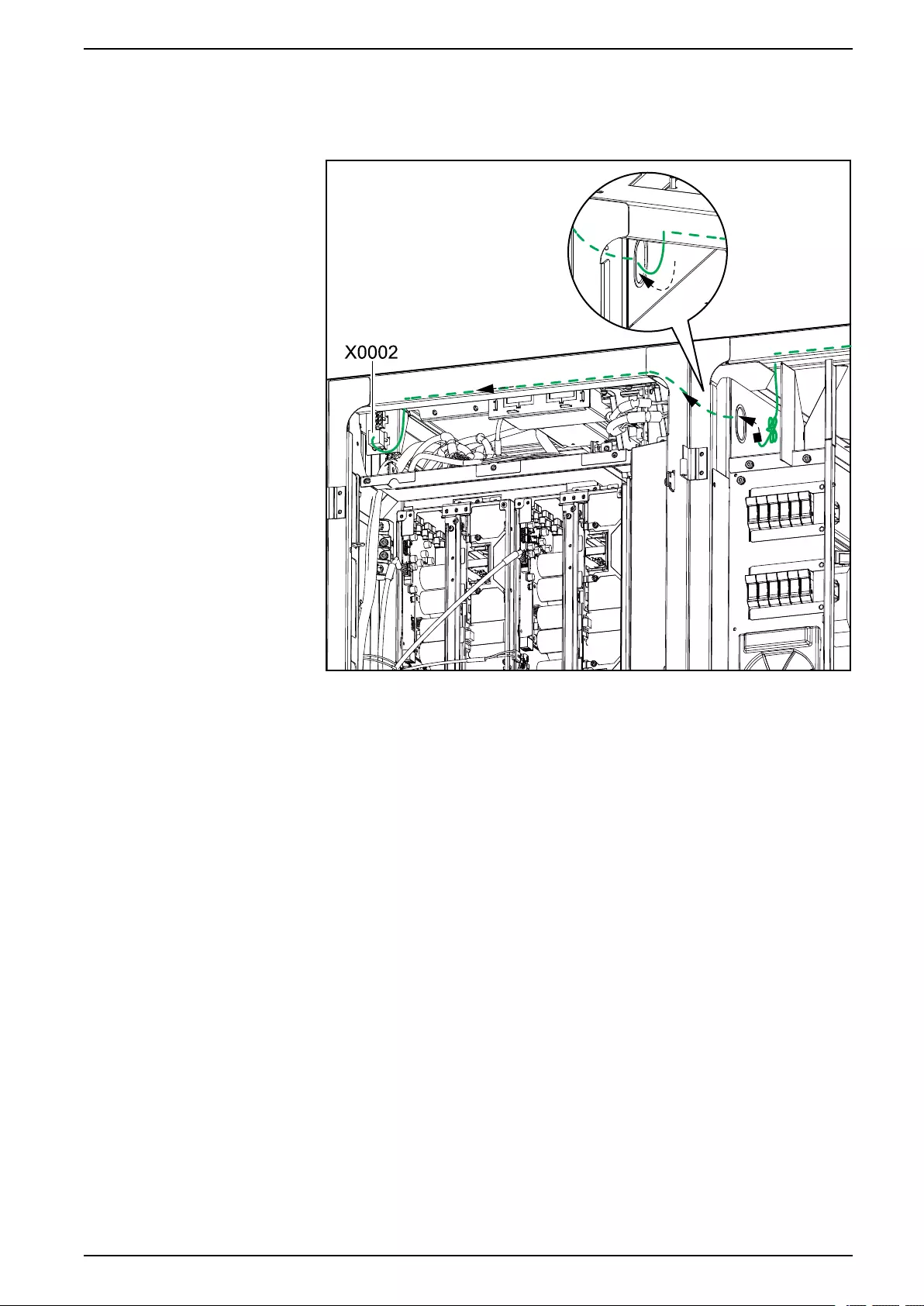

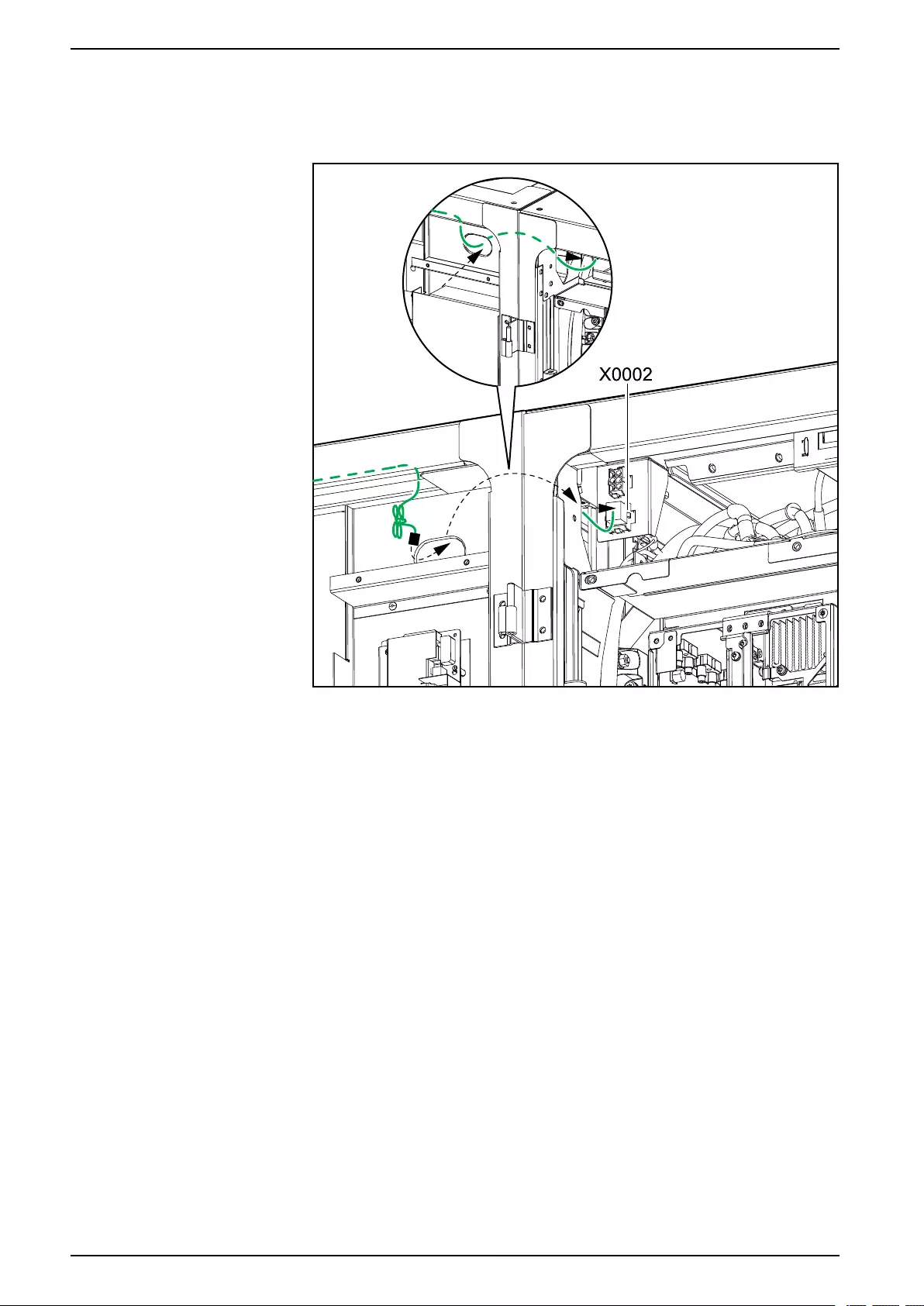

- Connect the PBUS Cables between Parallel UPS Units

- External Communication

- Final Mechanical Assembly

- Tom side

- Tom side

APC GVX1250K1500HS User Manual

Displayed below is the user manual for GVX1250K1500HS by APC which is a product in the Uninterruptible Power Supplies (UPSs) category. This manual has pages.

Related Manuals

Galaxy VX

UPS with 1500 kW I/O Cabinet

Installation

380 V, 400 V, 415 V, 440 V, and 480 V

1100 kW/kVA and 1100 kW/kVA N+1

500 kW/kVA, 750 kW/kVA, and 1000 kW/kVA Expandable to 1250 kW/kVA, 1250 kW/kVA,

1250 kW/kVA, 1250 kW/kVA N+1

500 kW/kVA, 750 kW/kVA, 1000 kW/kVA, and 1250 kW/kVA Expandable to 1500 kW/kVA,

1500 kW/kVA, 1500 kW/kVA N+1

10/2019

www.schneider-electric.com

Legal Information

The Schneider Electric brand and any trademarks of Schneider Electric SE and its

subsidiaries referred to in this guide are the property of Schneider Electric SE or its

subsidiaries. All other brands may be trademarks of their respective owners.

This guide and its content are protected under applicable copyright laws and

furnished for informational use only. No part of this guide may be reproduced or

transmitted in any form or by any means (electronic, mechanical, photocopying,

recording, or otherwise), for any purpose, without the prior written permission of

Schneider Electric.

Schneider Electric does not grant any right or license for commercial use of the guide

or its content, except for a non-exclusive and personal license to consult it on an "as

is" basis. Schneider Electric products and equipment should be installed, operated,

serviced, and maintained only by qualified personnel.

As standards, specifications, and designs change from time to time, information

contained in this guide may be subject to change without notice.

To the extent permitted by applicable law, no responsibility or liability is assumed by

Schneider Electric and its subsidiaries for any errors or omissions in the informational

content of this material or consequences arising out of or resulting from the use of the

information contained herein.

UPS with 1500 kW I/O Cabinet

Table of Contents

Important Safety Instructions — SAVE THESE

INSTRUCTIONS.........................................................................................5

FCC Statement ..........................................................................................6

Electromagnetic Compatibility .....................................................................6

Safety Precautions .....................................................................................6

Electrical Safety....................................................................................8

Battery Safety.......................................................................................9

Specifications for 380, 400, 415, and 440 V Systems......................... 11

Specifications for 500 kW UPS .................................................................. 11

Specifications for 750 kW UPS ..................................................................13

Specifications for 1000 kW UPS ................................................................15

Specifications for 1100 kW UPS.................................................................17

Specifications for 1250 kW UPS ................................................................19

Specifications for 1500 kW UPS ................................................................21

Recommended Upstream Protection and Cable Sizes.................................23

Specifications for 480 V Systems ...........................................................25

Input Specifications ..................................................................................25

Bypass Specifications...............................................................................25

Output Specifications................................................................................26

Battery Specifications ...............................................................................26

Recommended Breaker and Cable Sizes ...................................................27

Recommended Bolt and Lug Sizes for Copper Cables.................................28

Recommended Bolt and Lug Sizes for Aluminium Cables ............................28

Heat Dissipation .......................................................................................28

Specifications ............................................................................................30

Torque Specifications................................................................................30

Environment.............................................................................................30

Weights and Dimensions for UPSs with 1500 kW I/O Cabinet ......................31

Clearance for UPSs with 1500 kW I/O Cabinet............................................31

Guidance for Organizing Battery Cables.....................................................31

Overview of Configurations .....................................................................33

Overview of UPSs with 1500 kW I/O Cabinet – Single Utility/Mains...............33

Overview of UPSs with 1500 kW I/O Cabinet – Dual Utility/Mains .................34

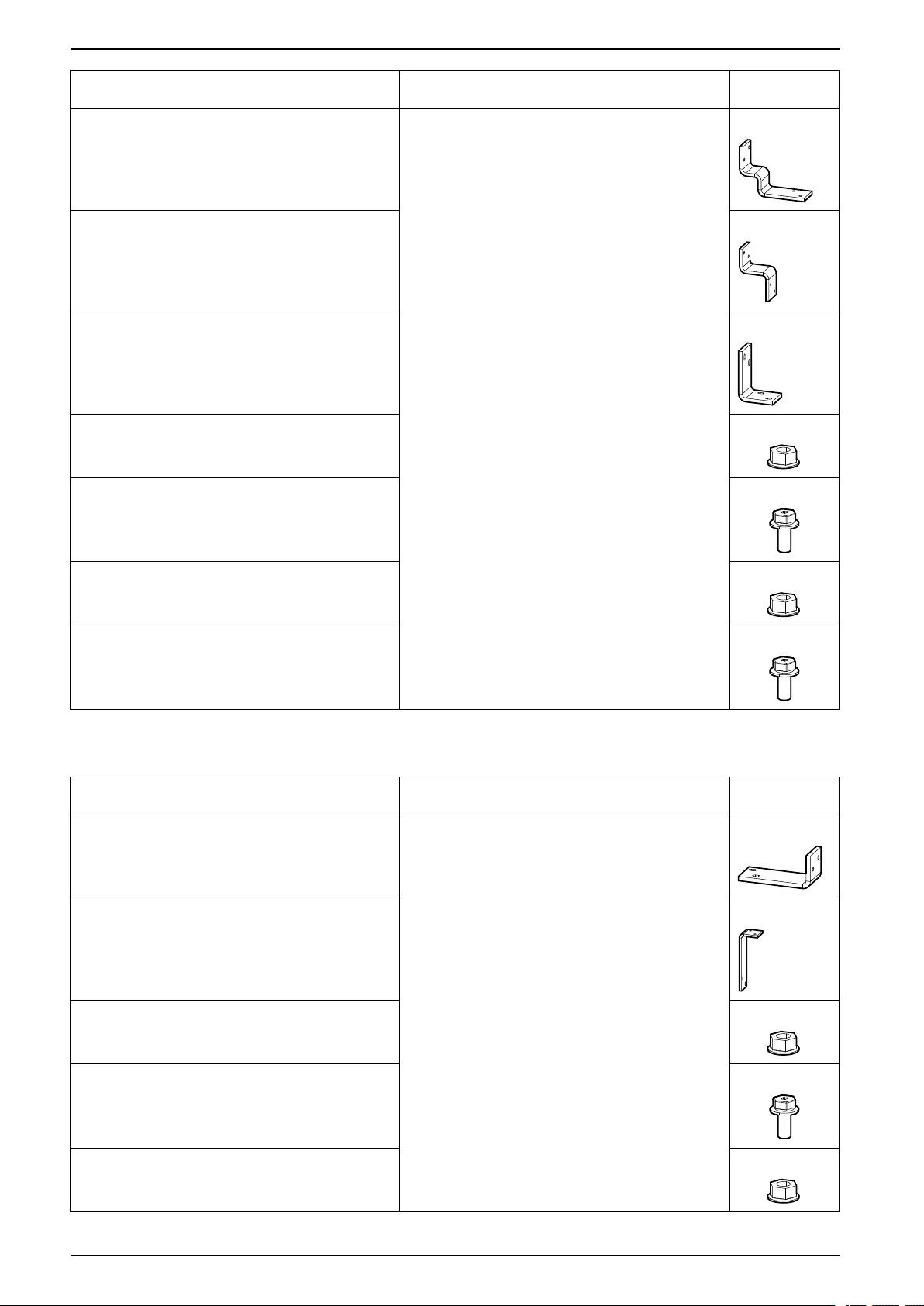

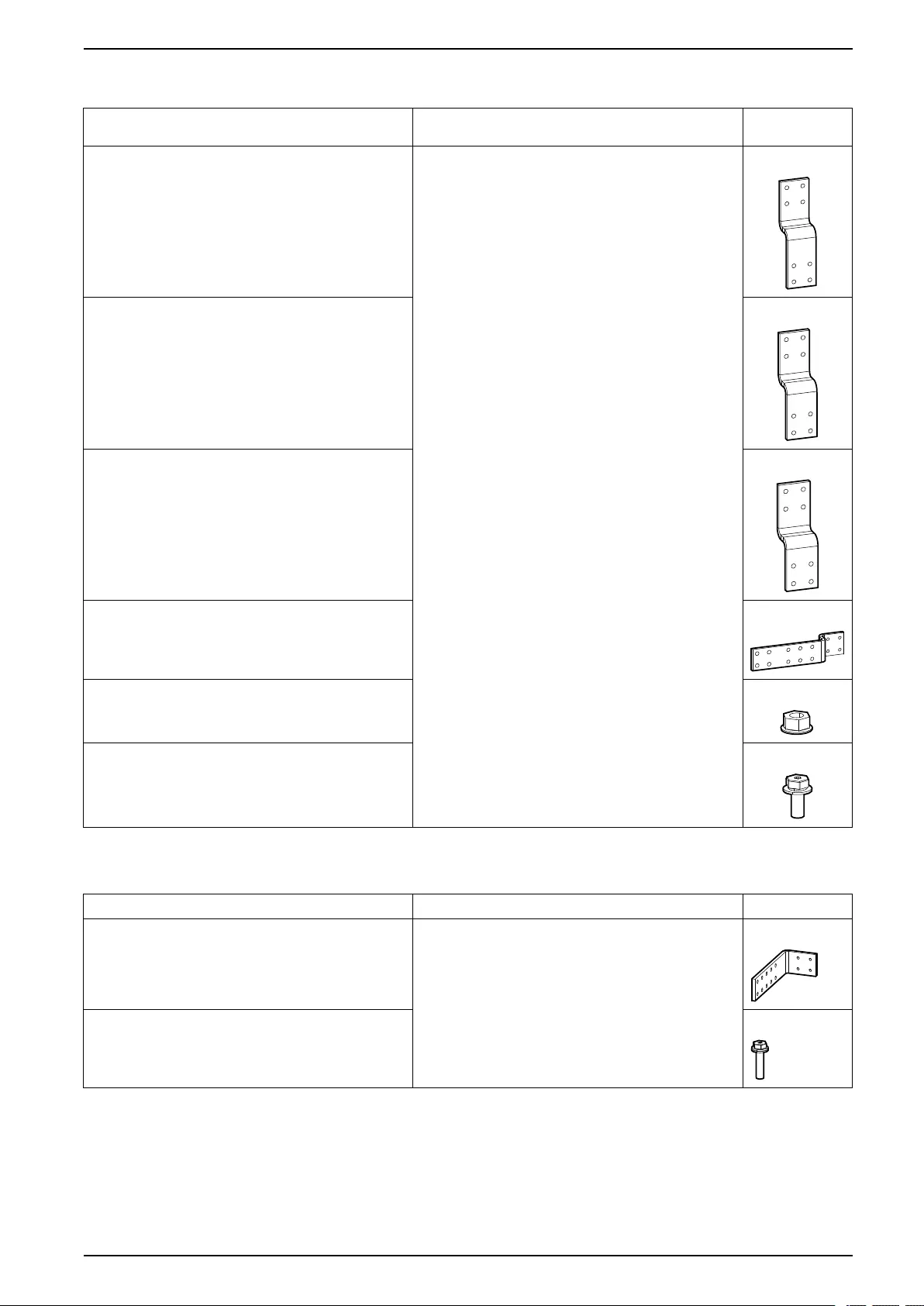

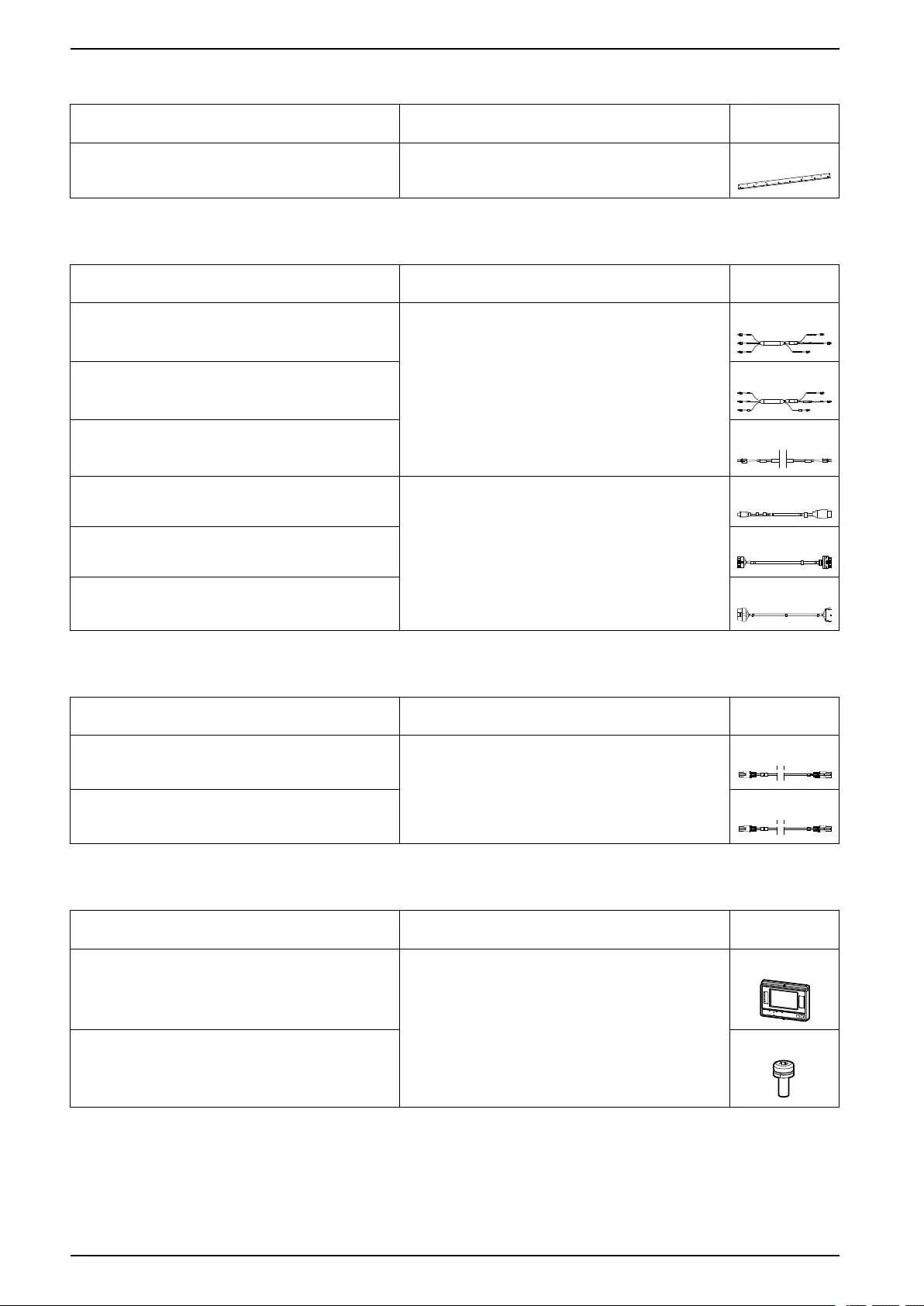

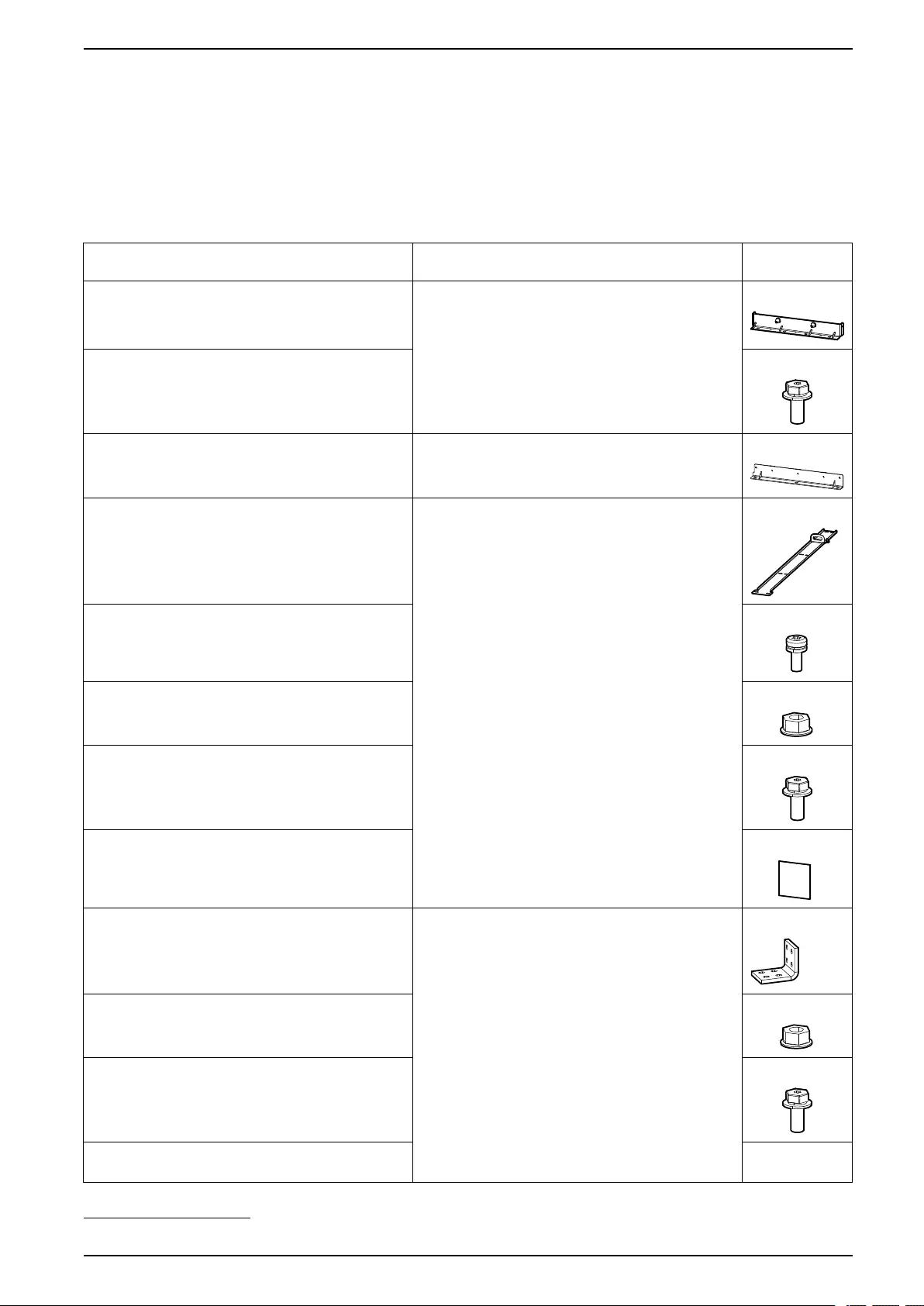

Overview of Supplied Installation Kits....................................................35

Installation Kits Shipped with the I/O Cabinet ..............................................35

Installation Kits Shipped with the Power Cabinet .........................................41

Installation Procedure ..............................................................................43

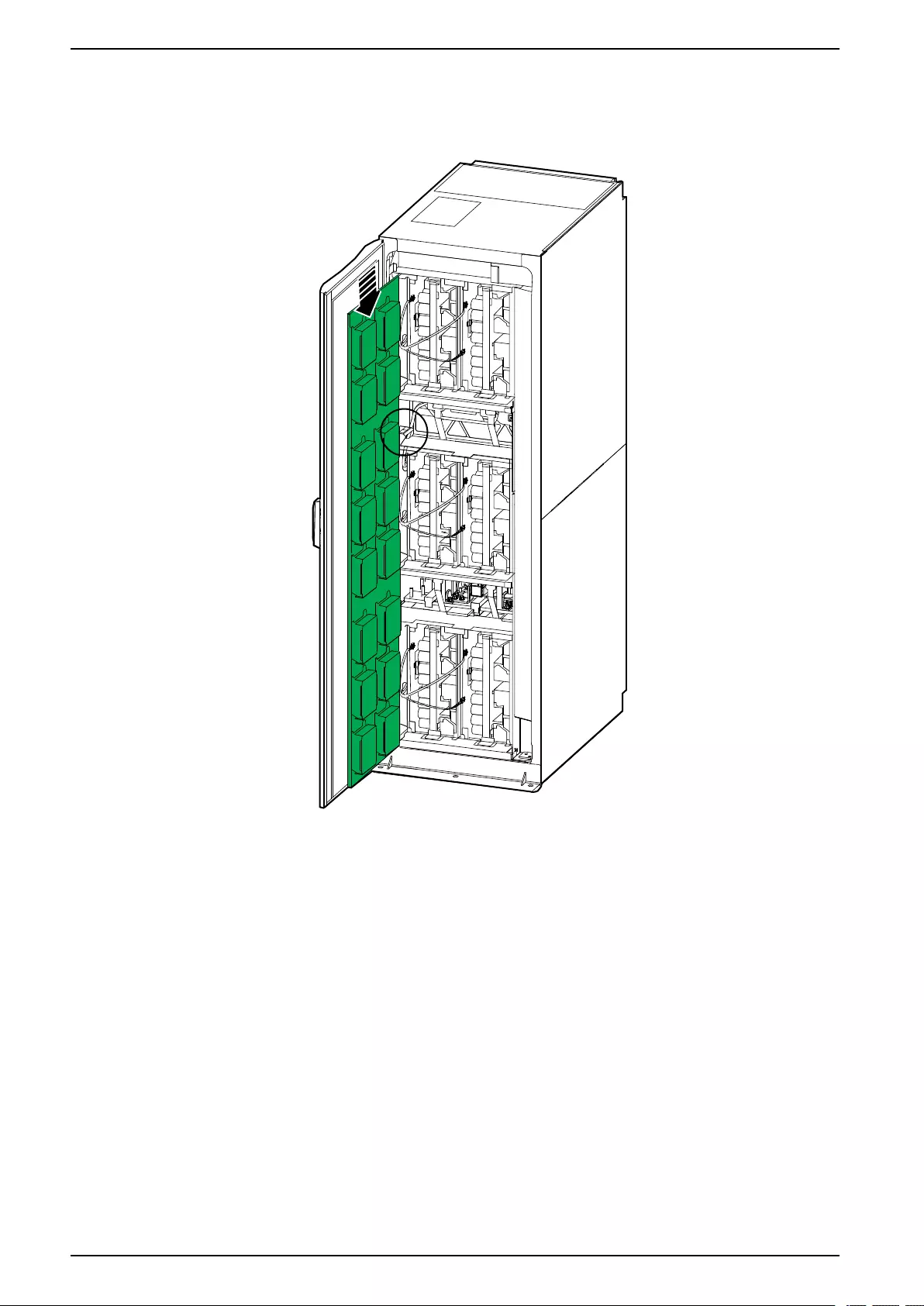

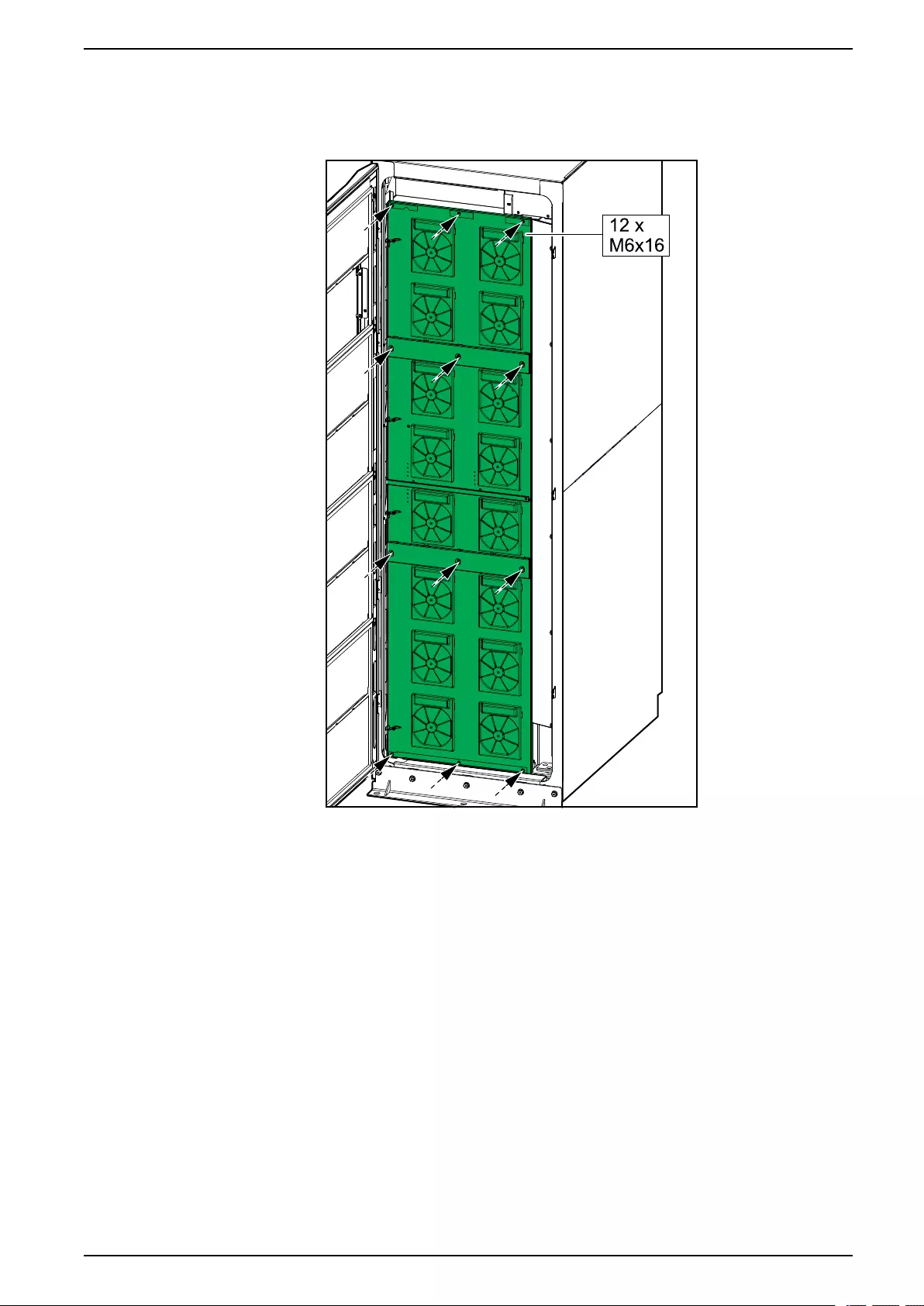

Mechanical Installation.............................................................................44

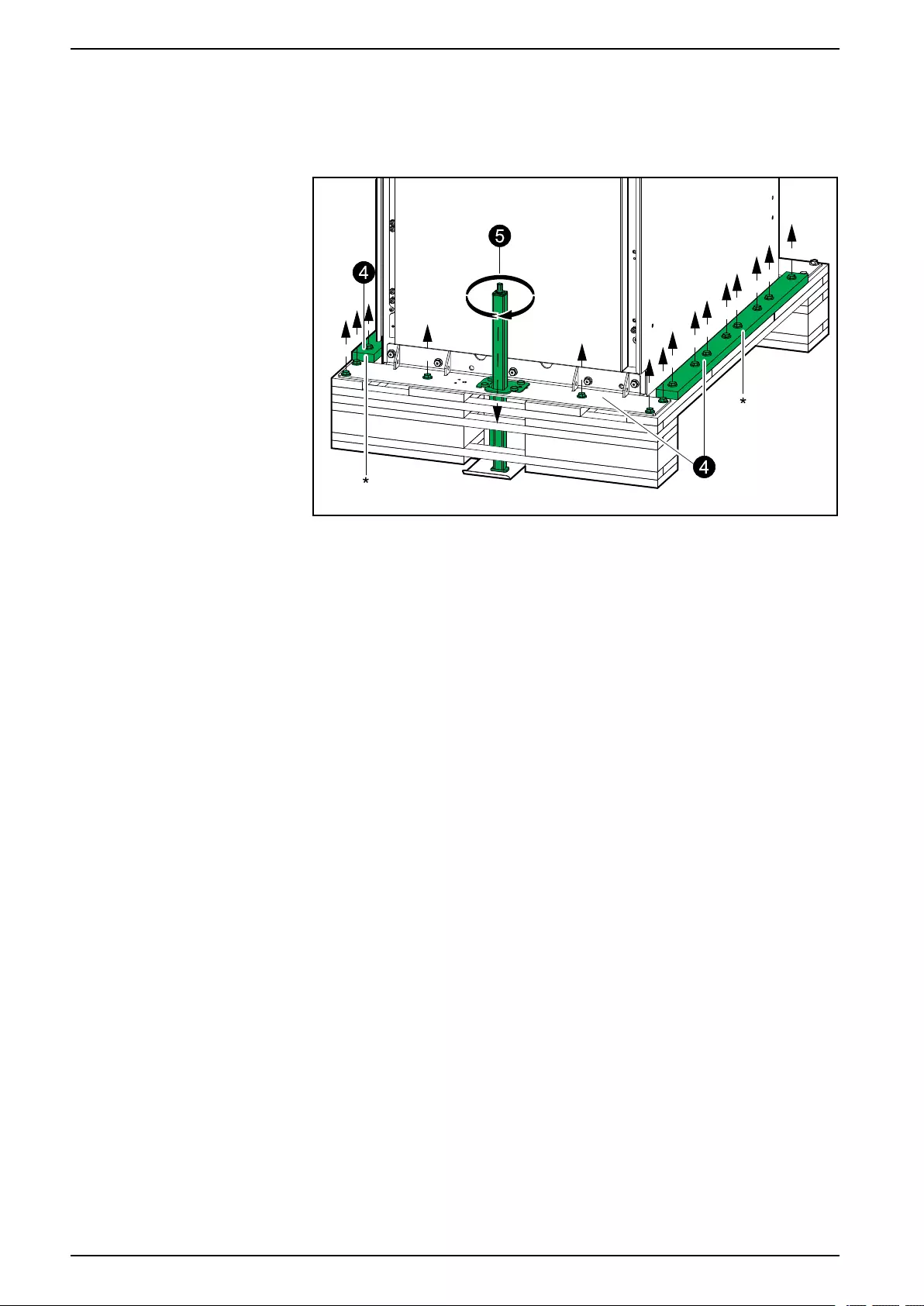

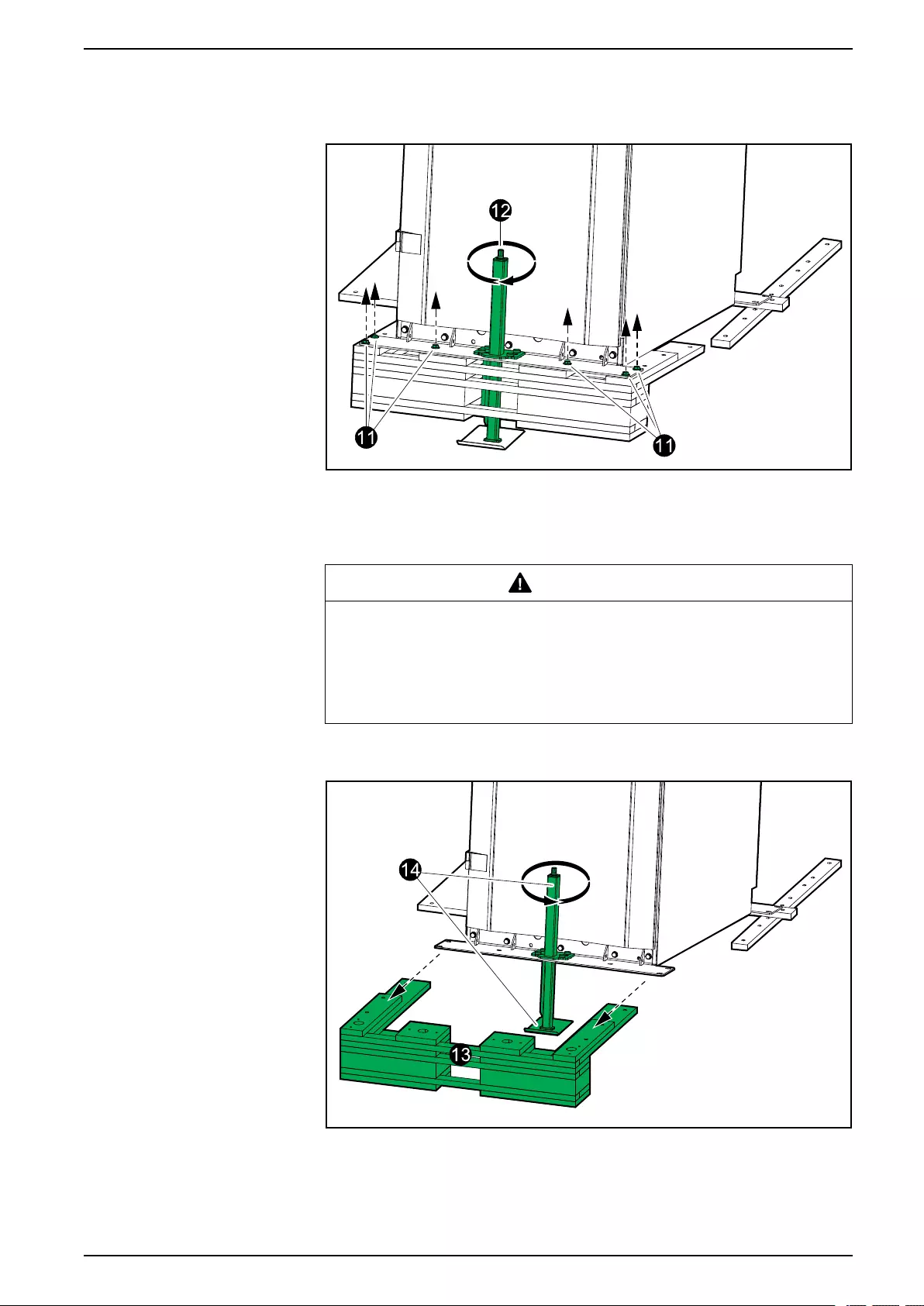

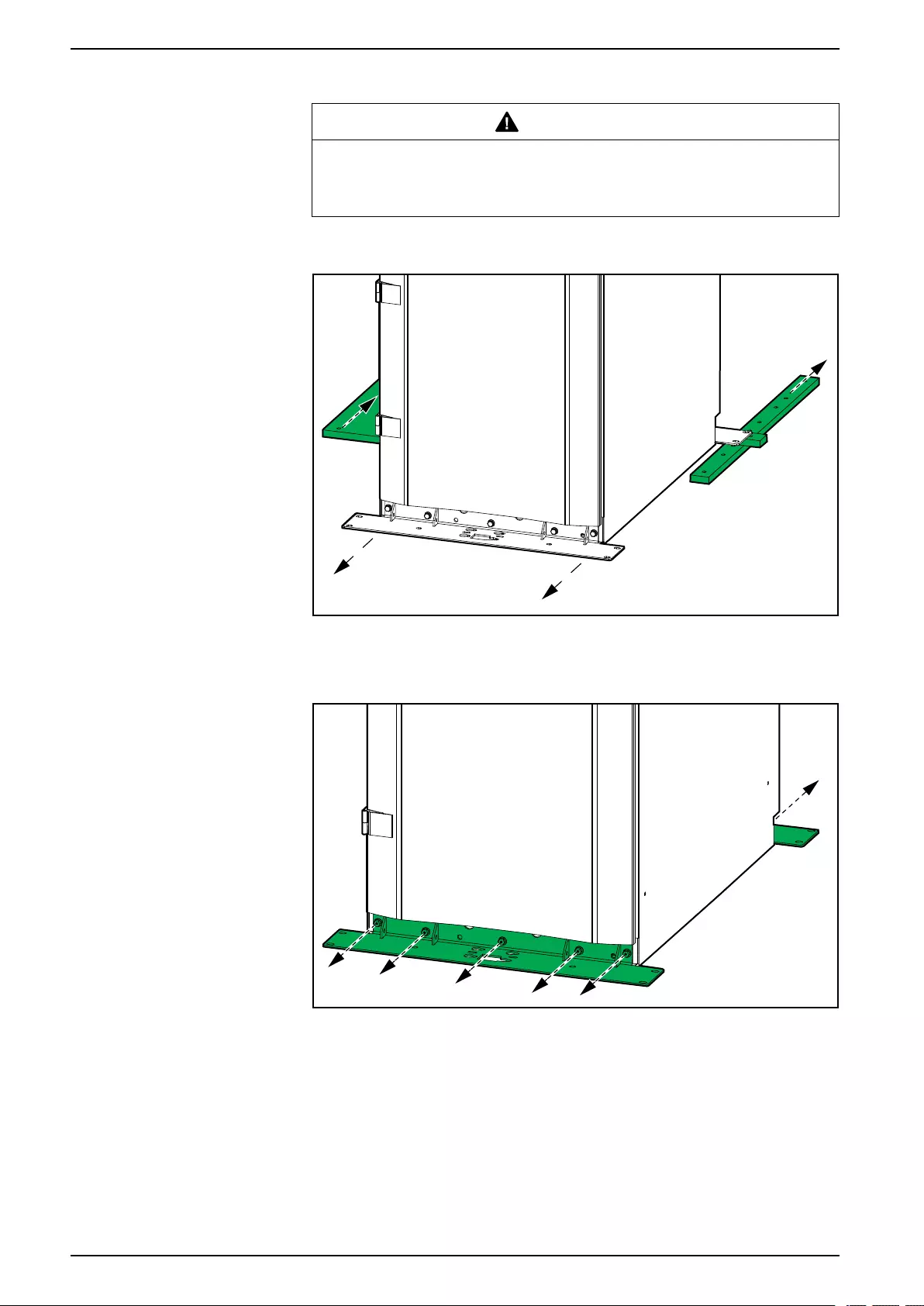

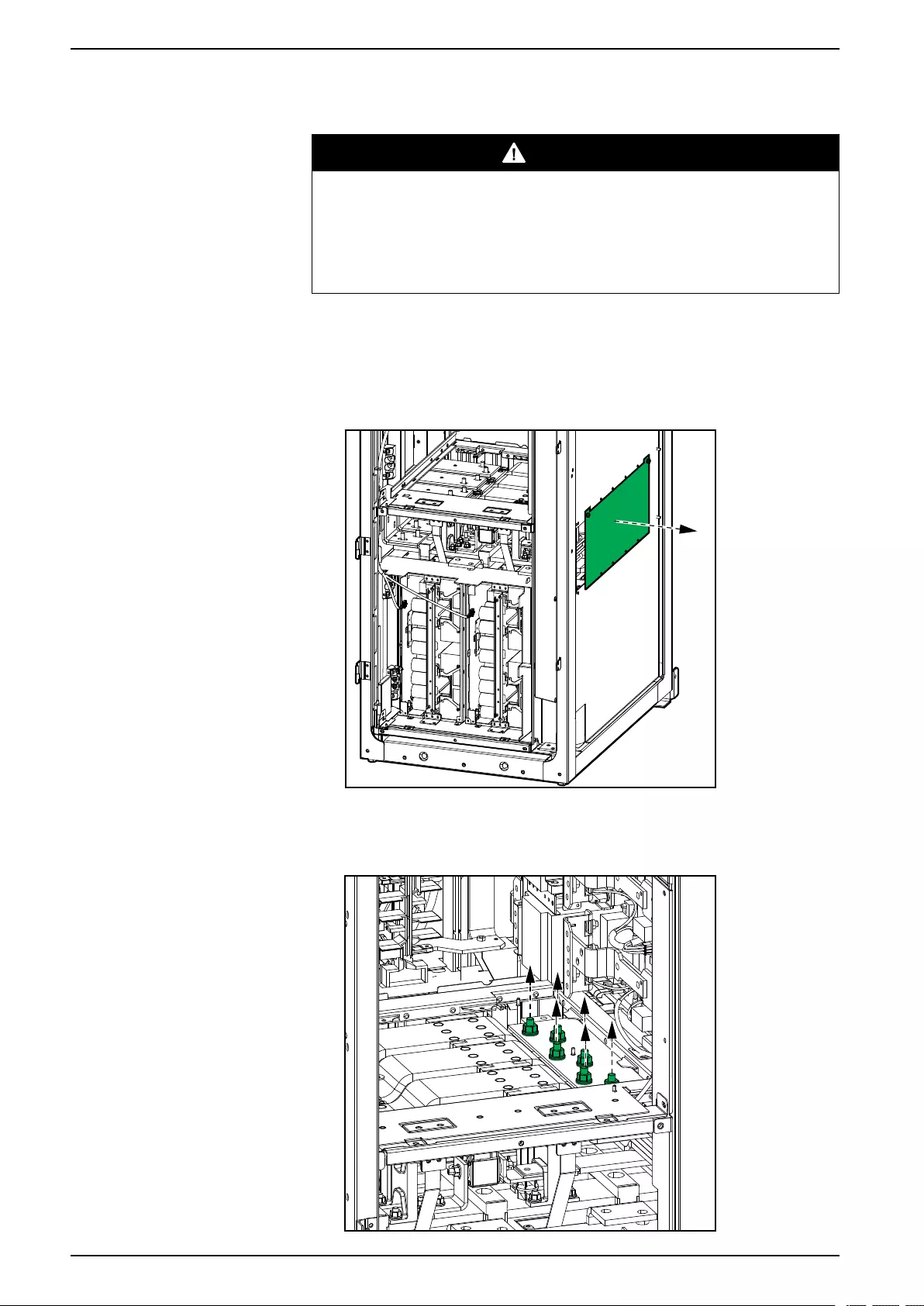

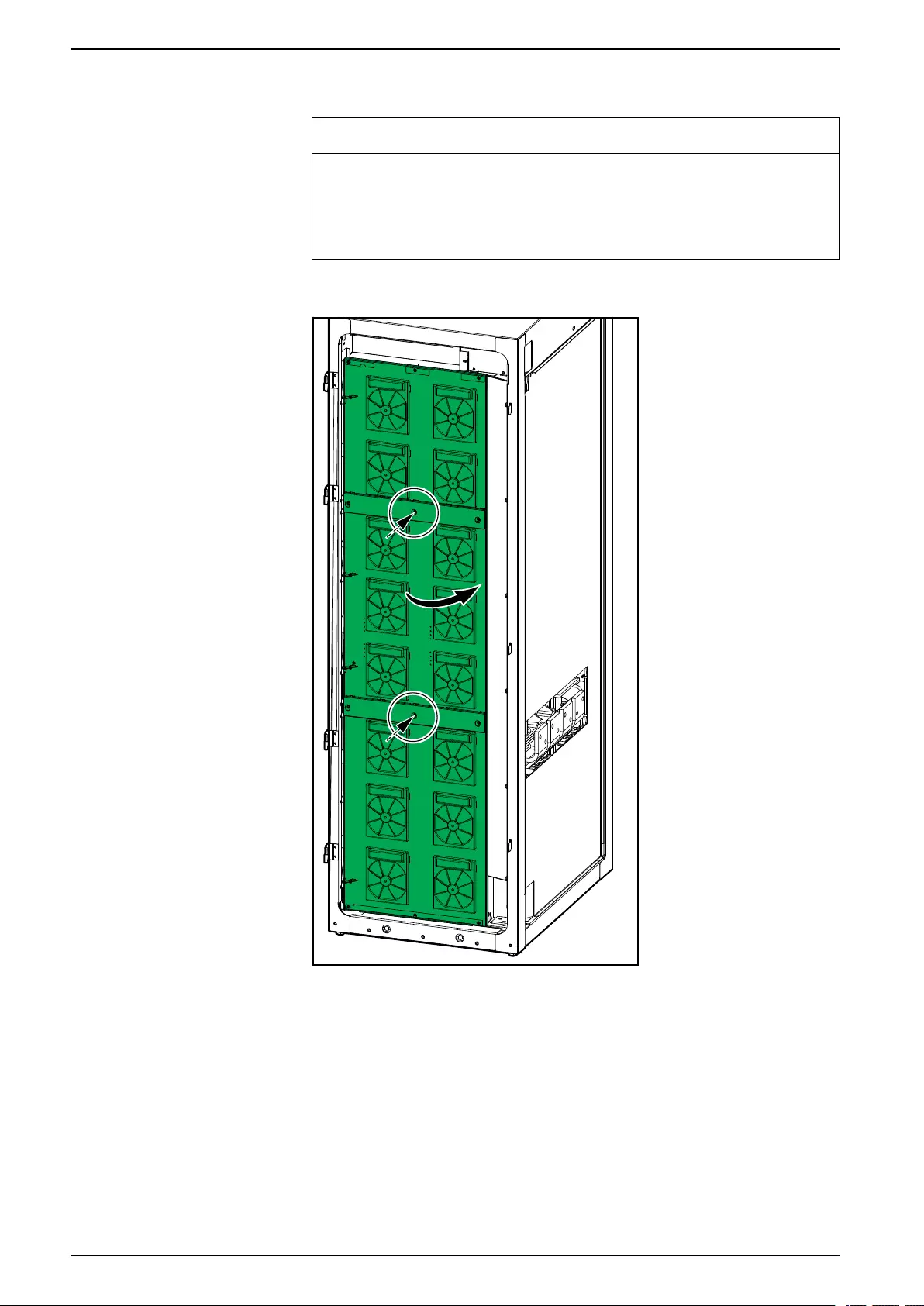

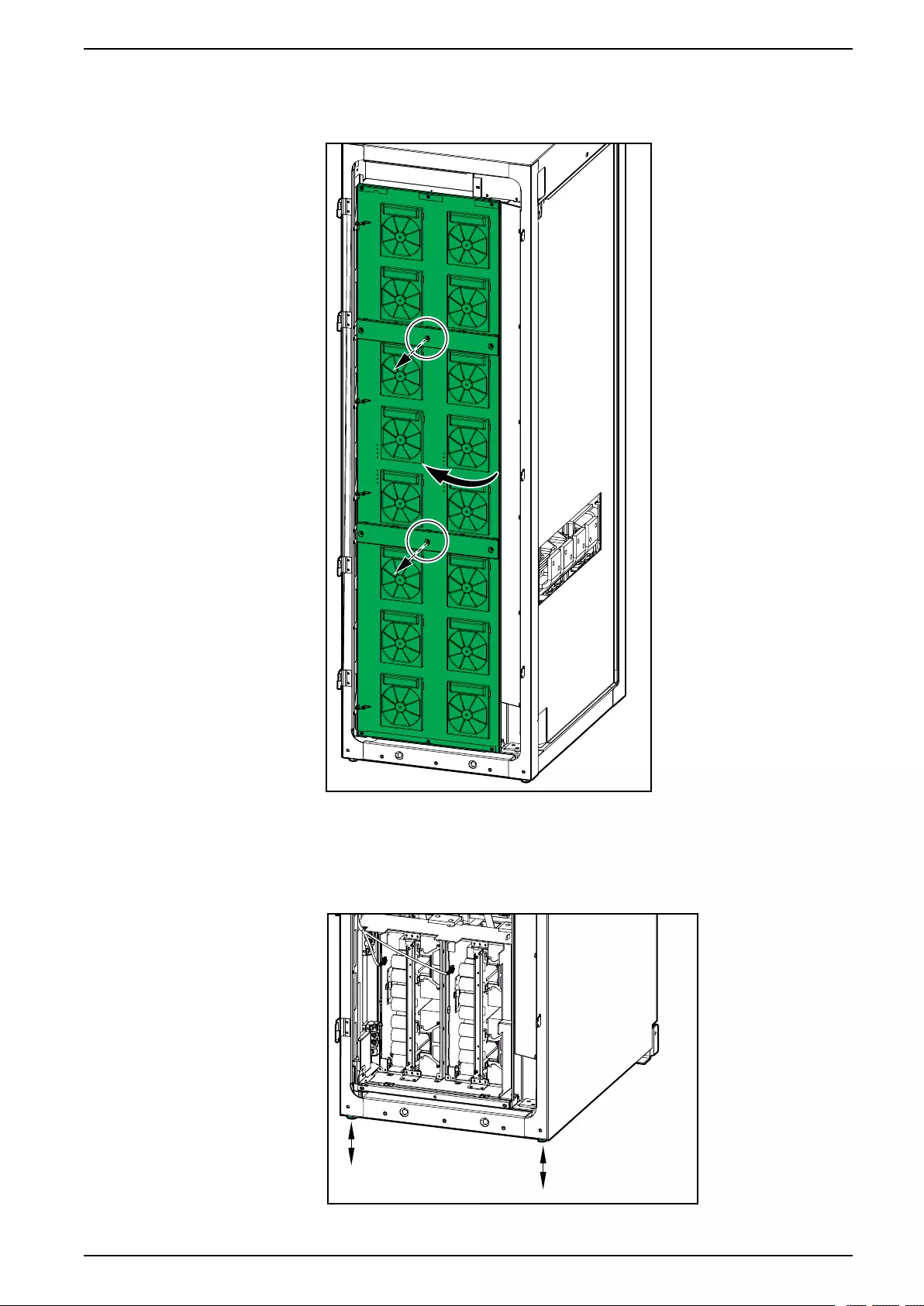

Remove the Cabinets from the Pallet .........................................................44

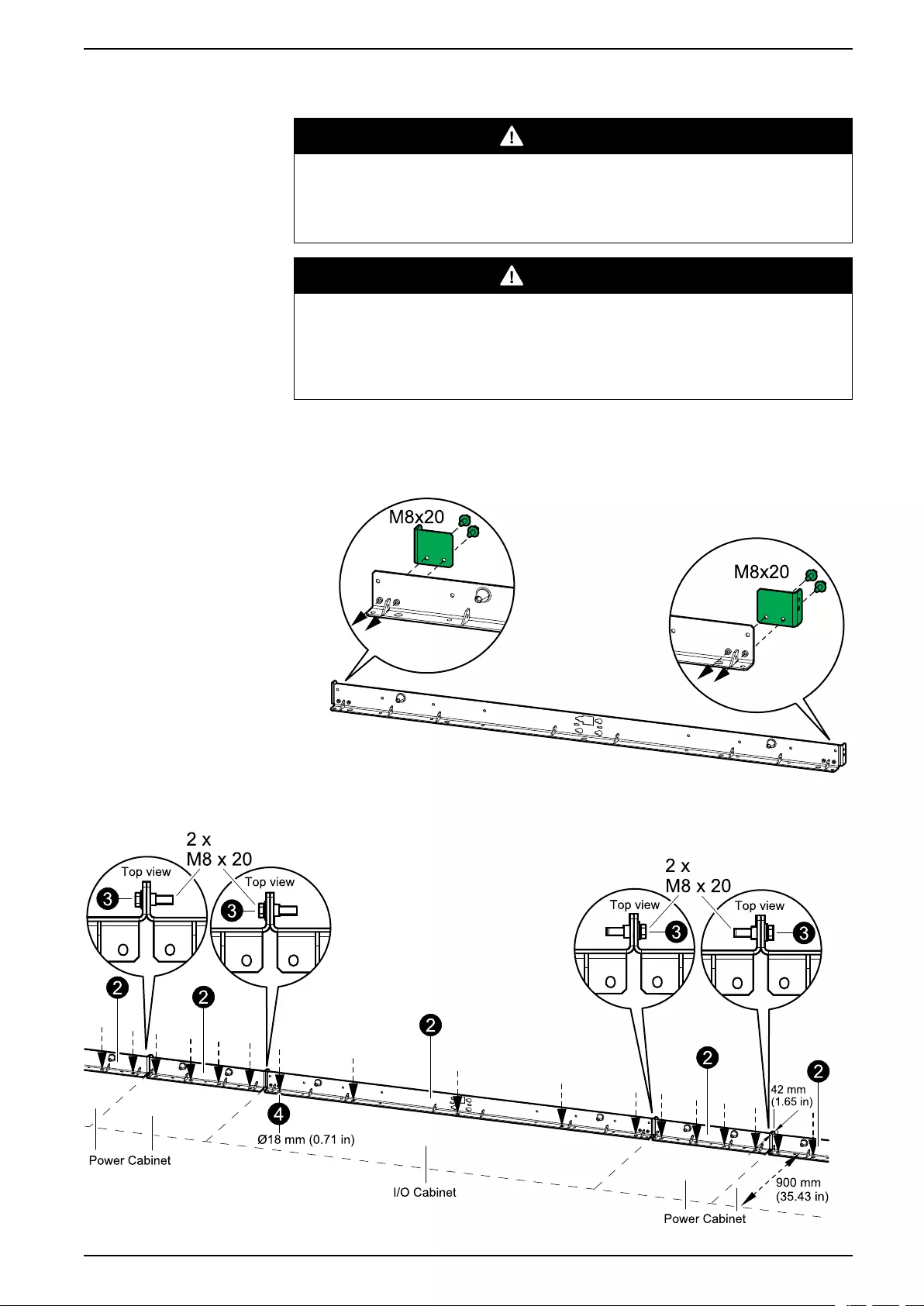

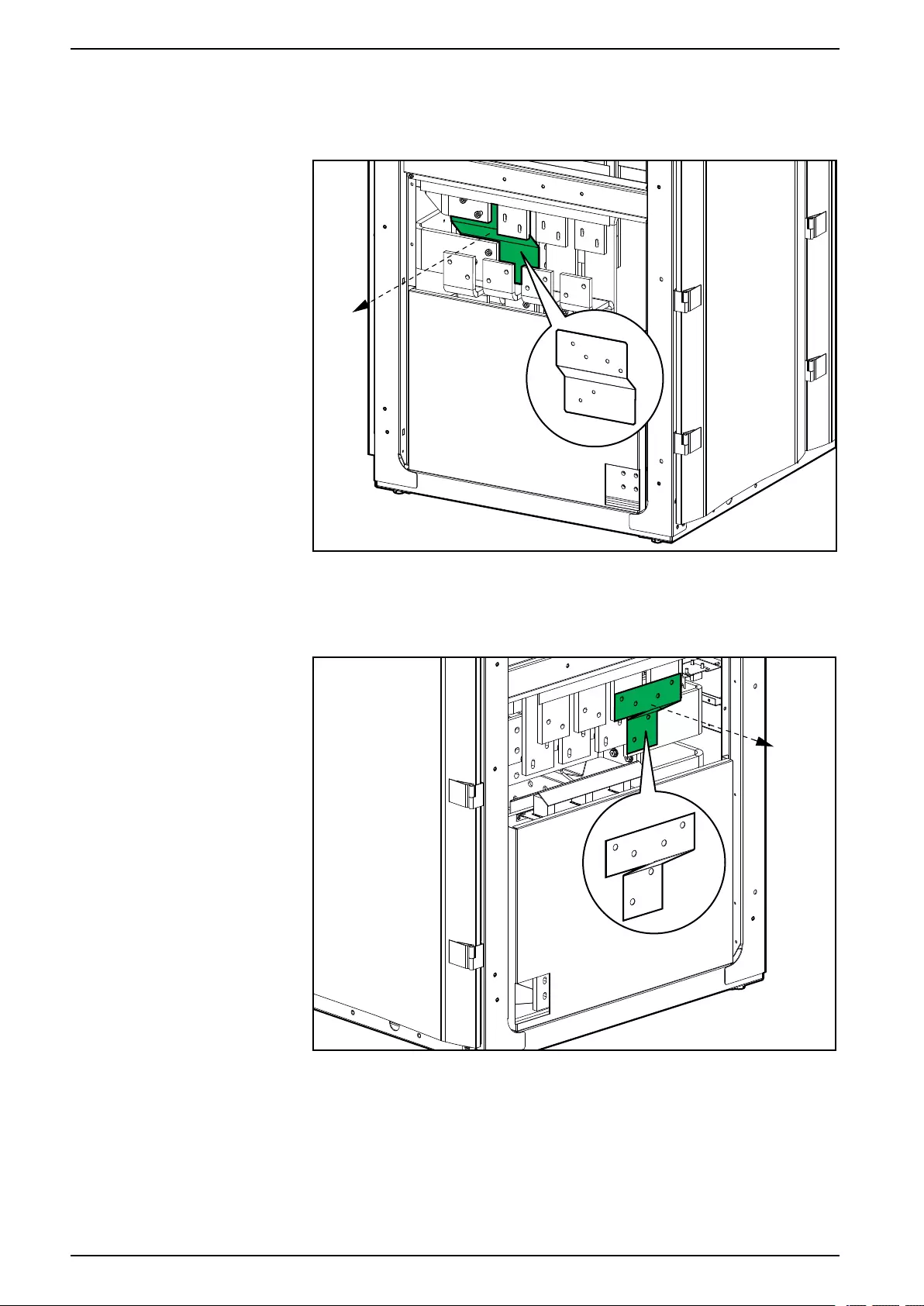

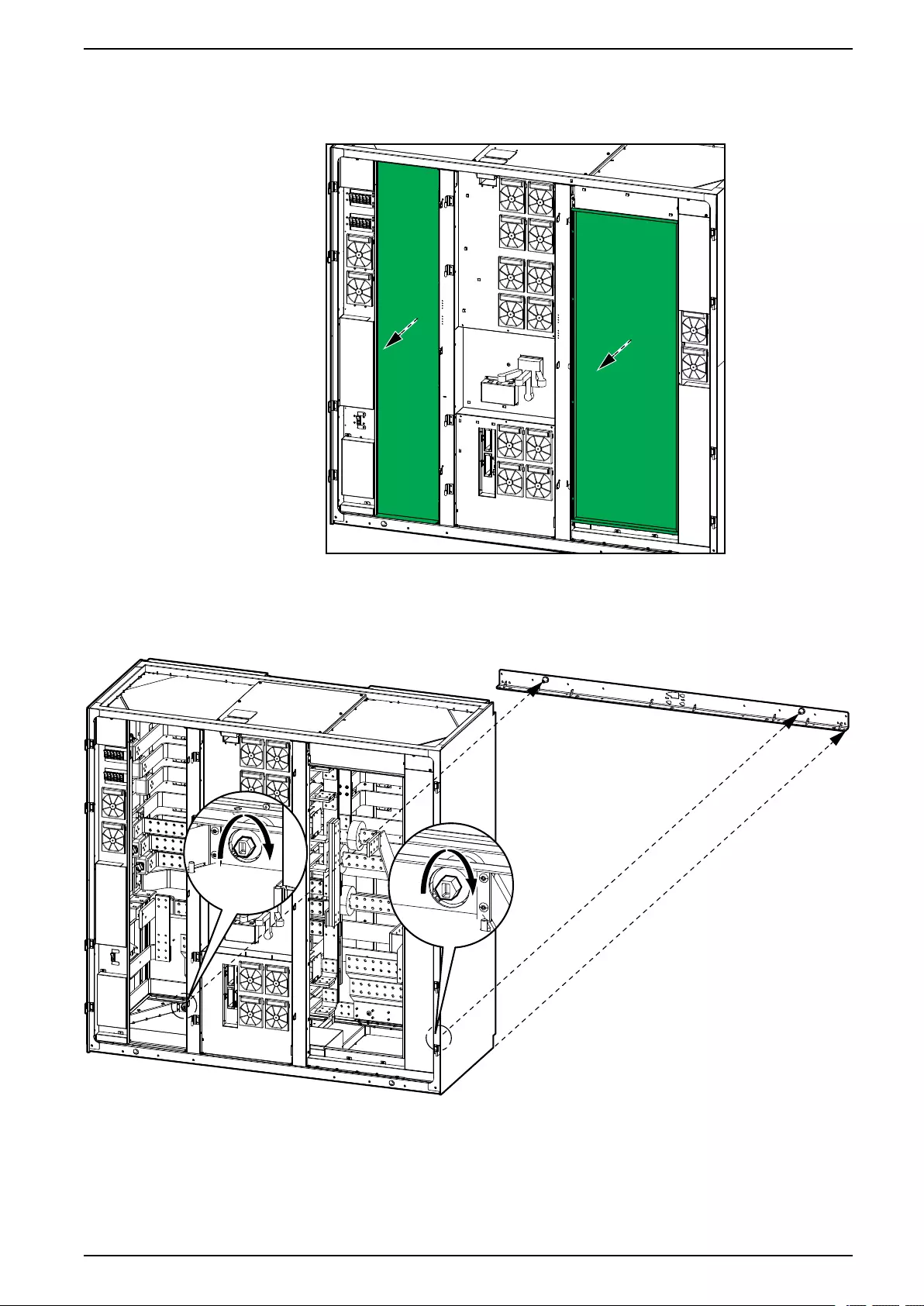

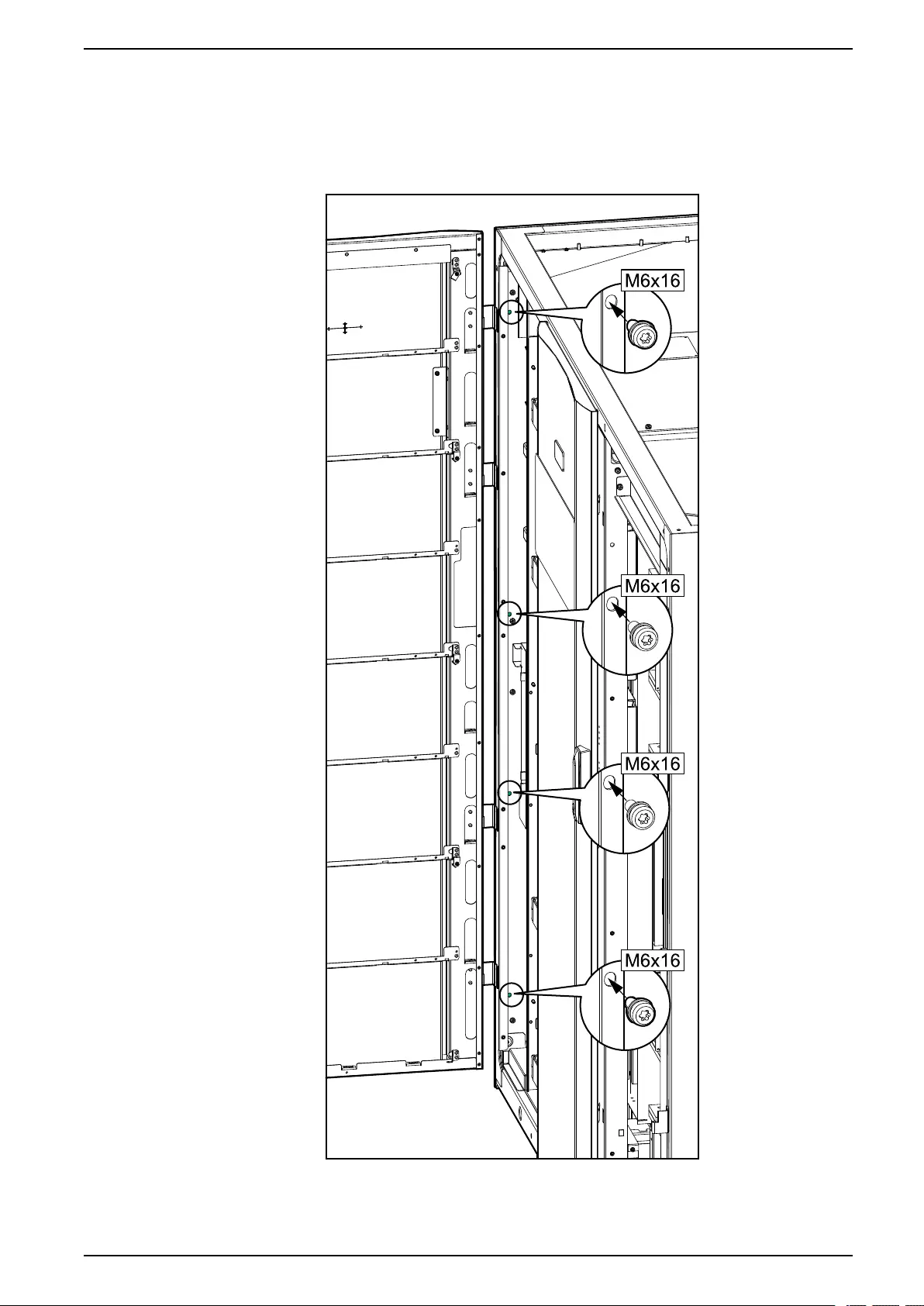

Mount the Rear Anchoring Brackets ...........................................................51

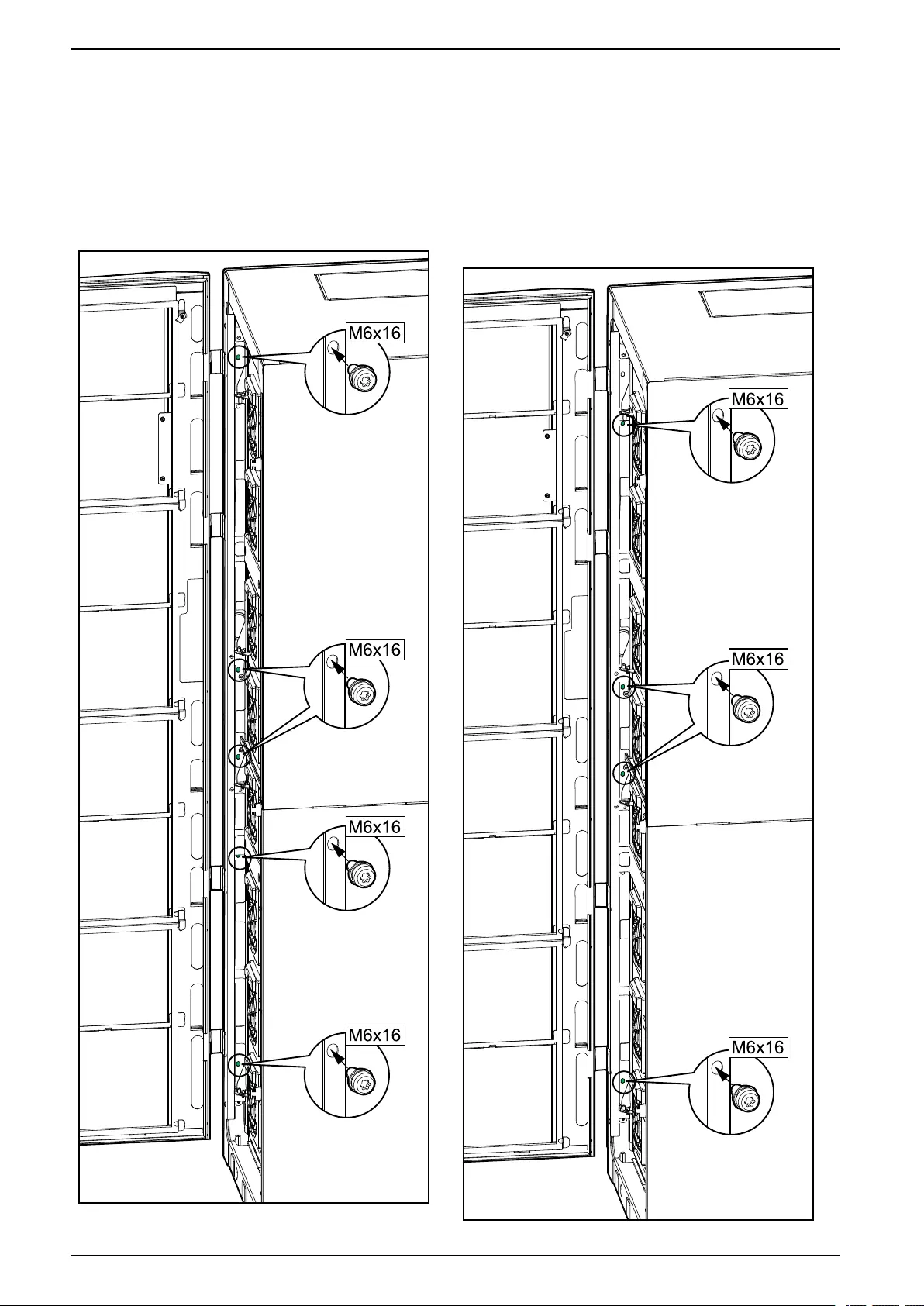

Position the Cabinets................................................................................52

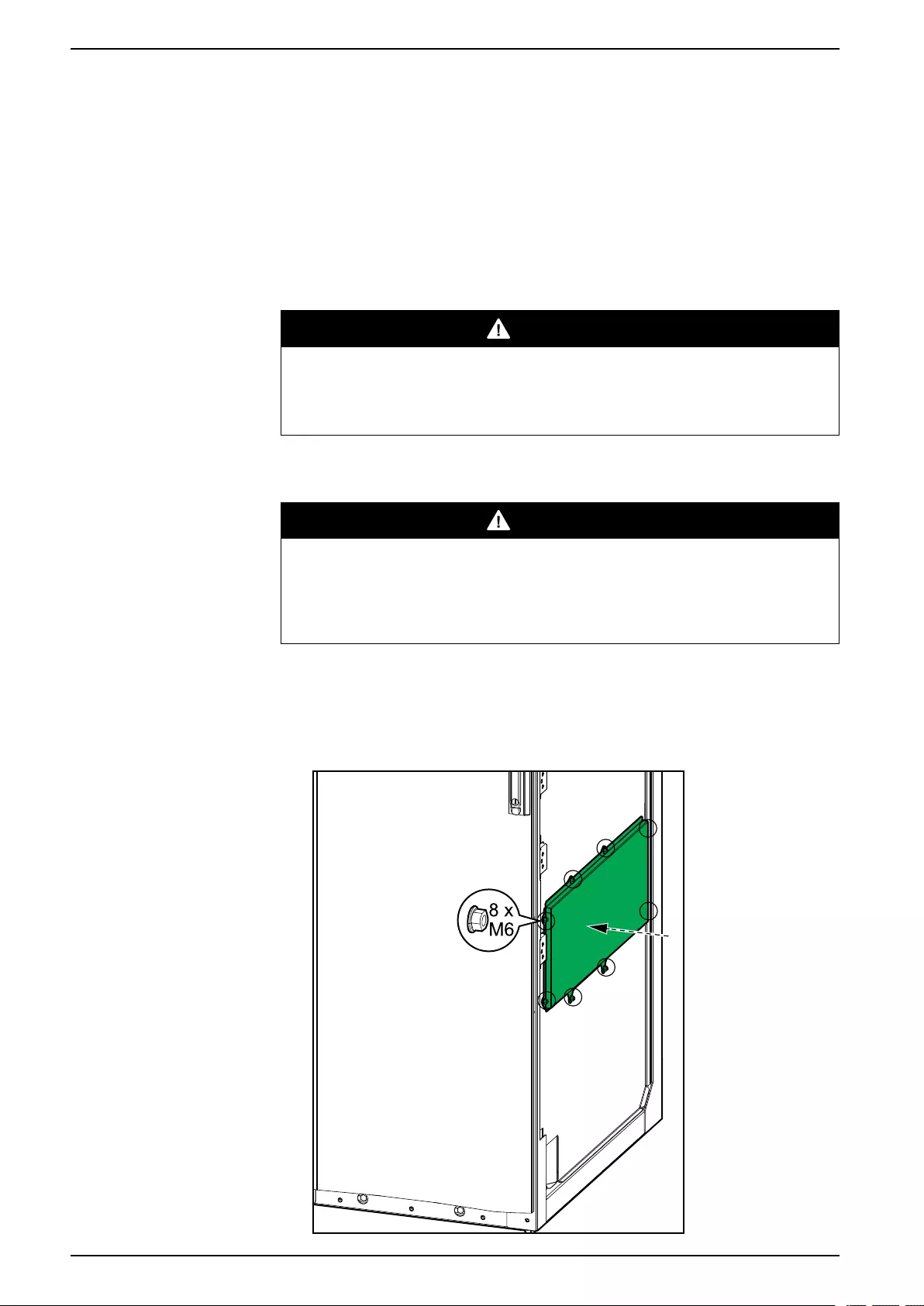

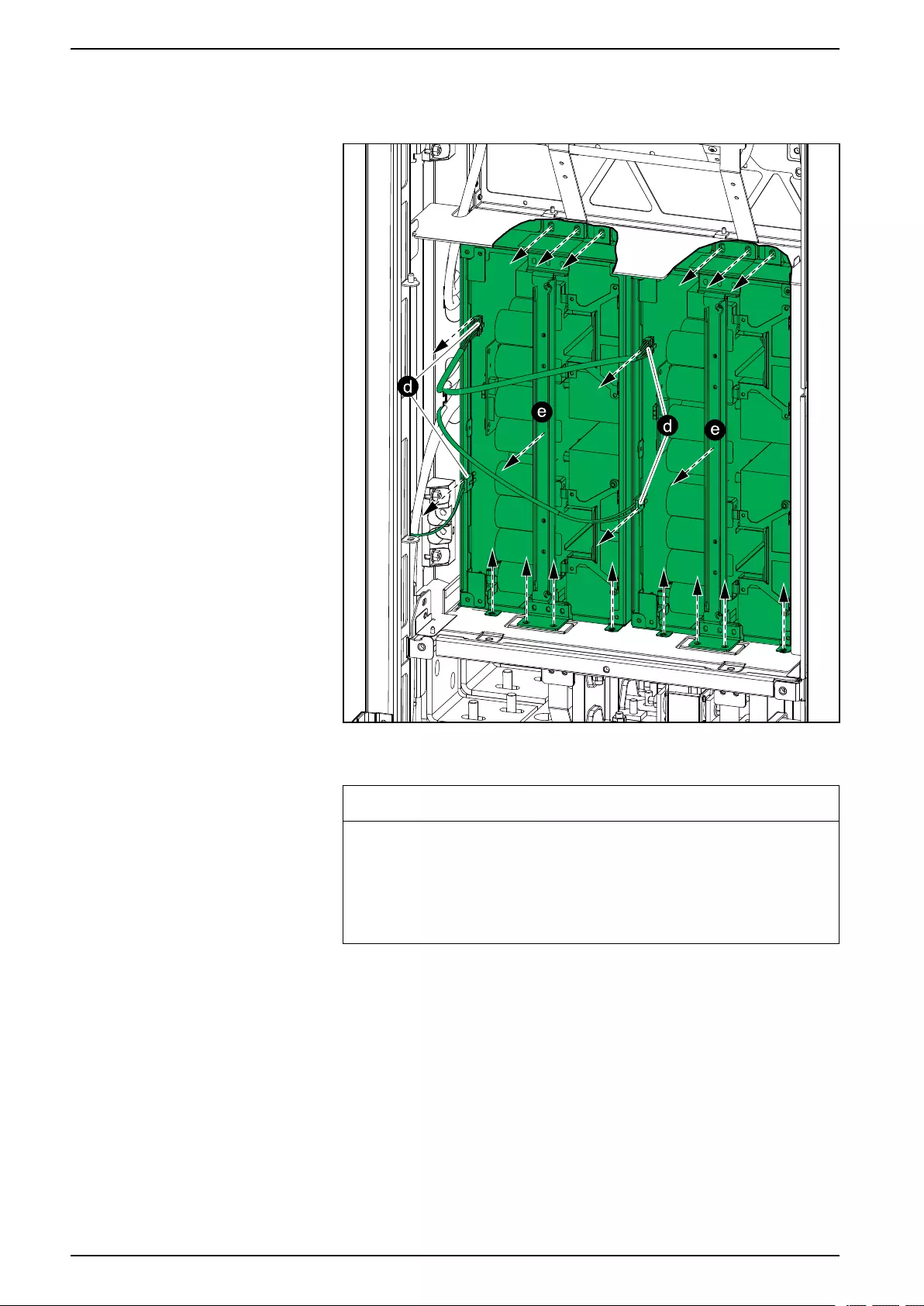

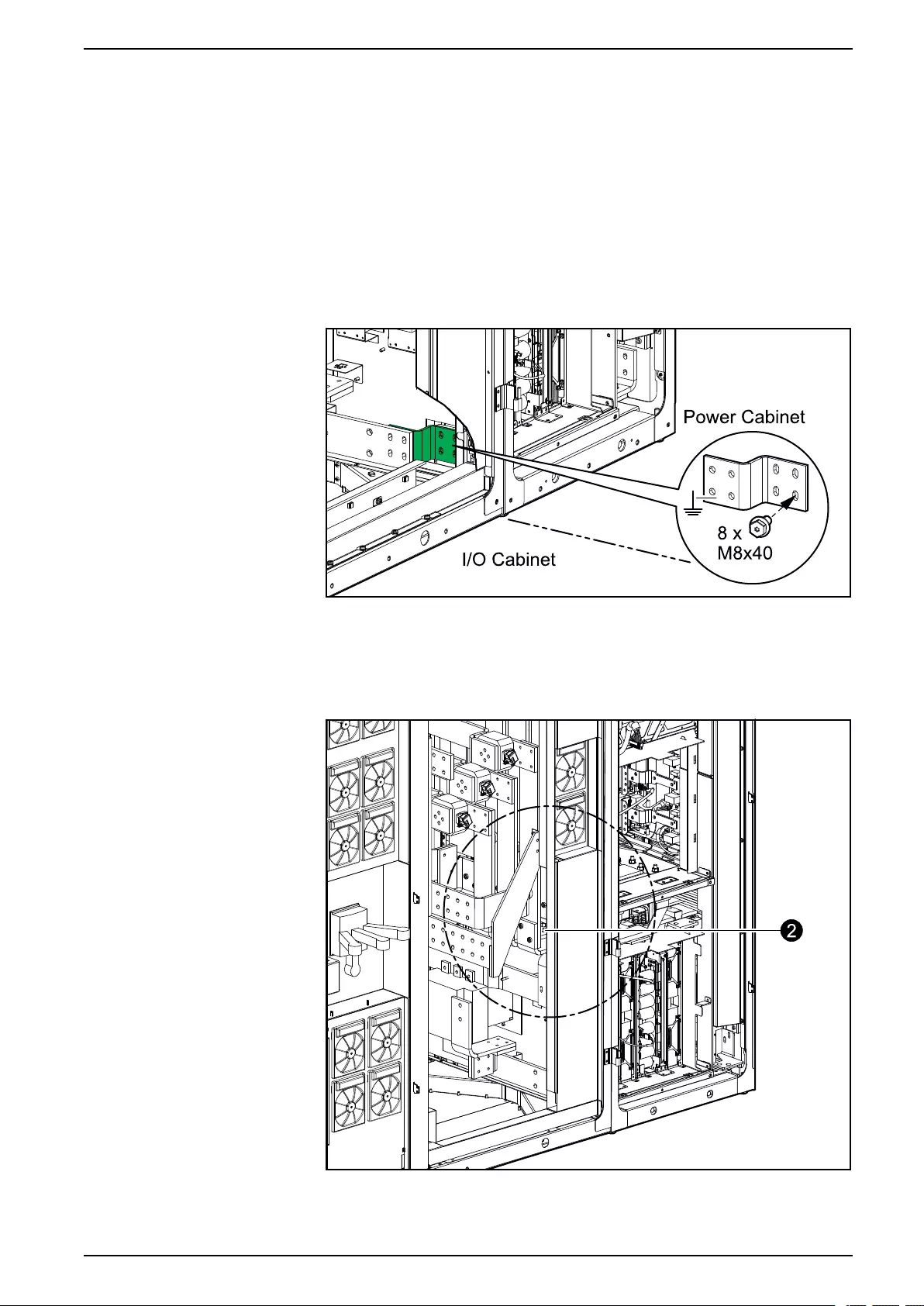

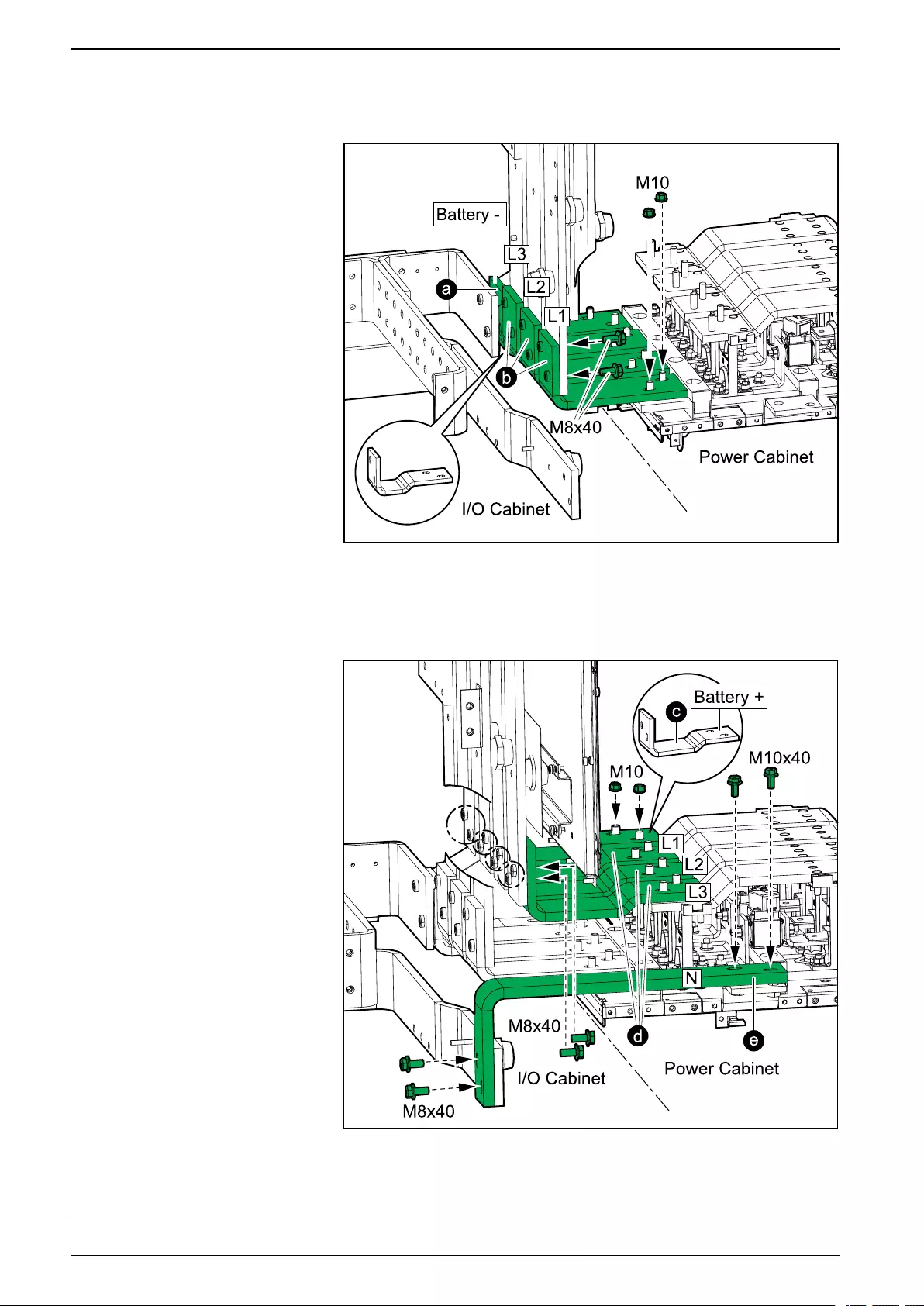

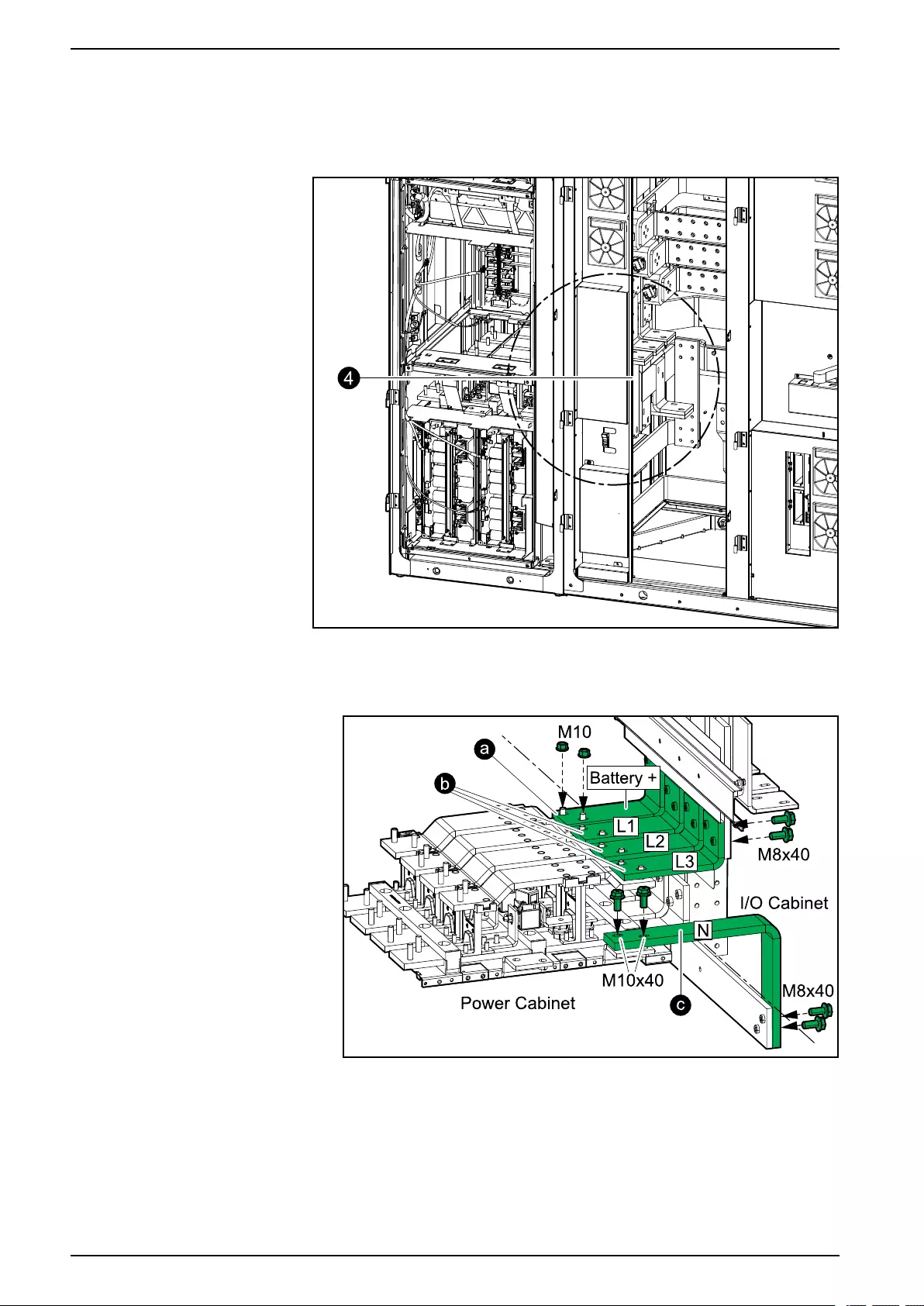

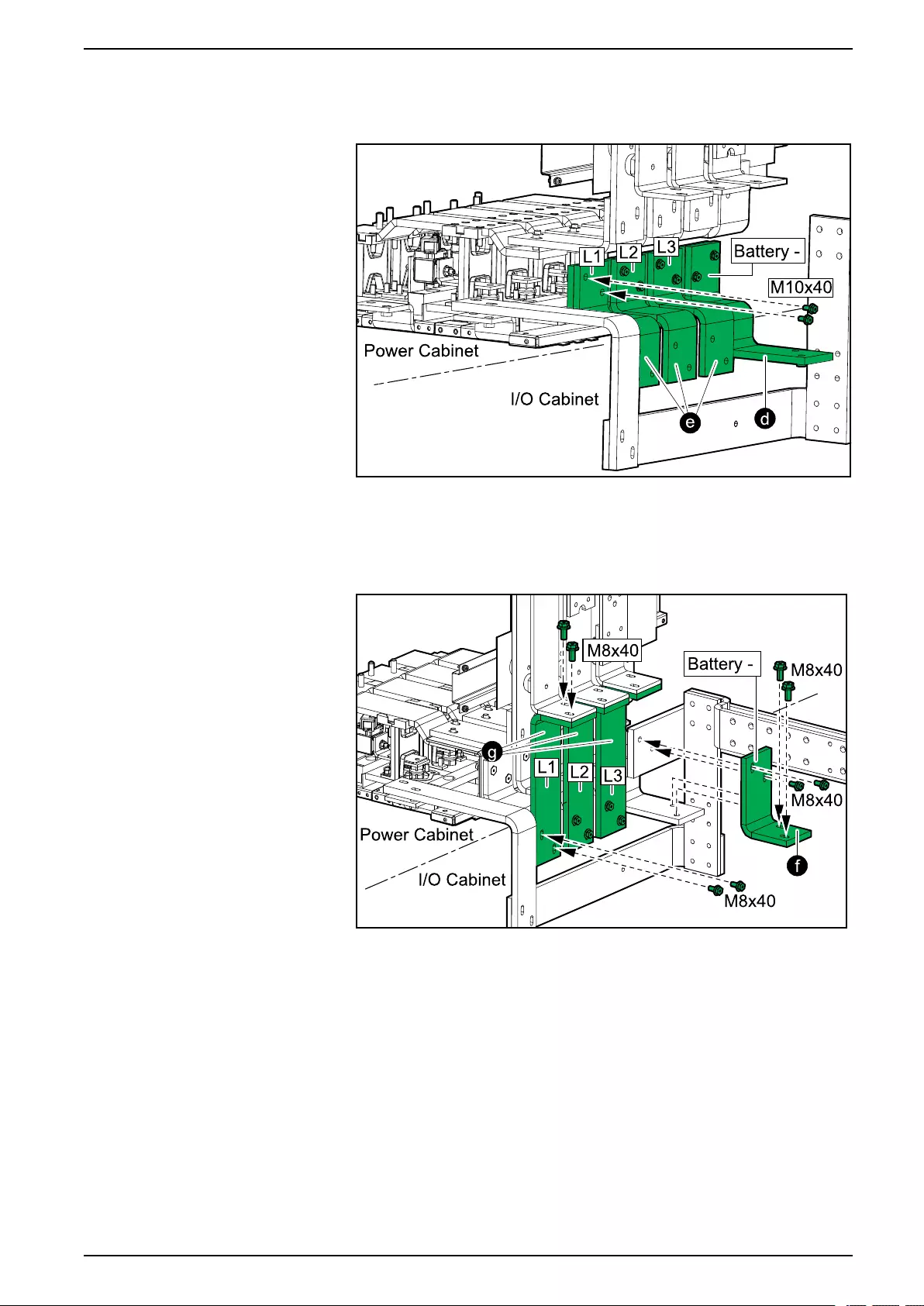

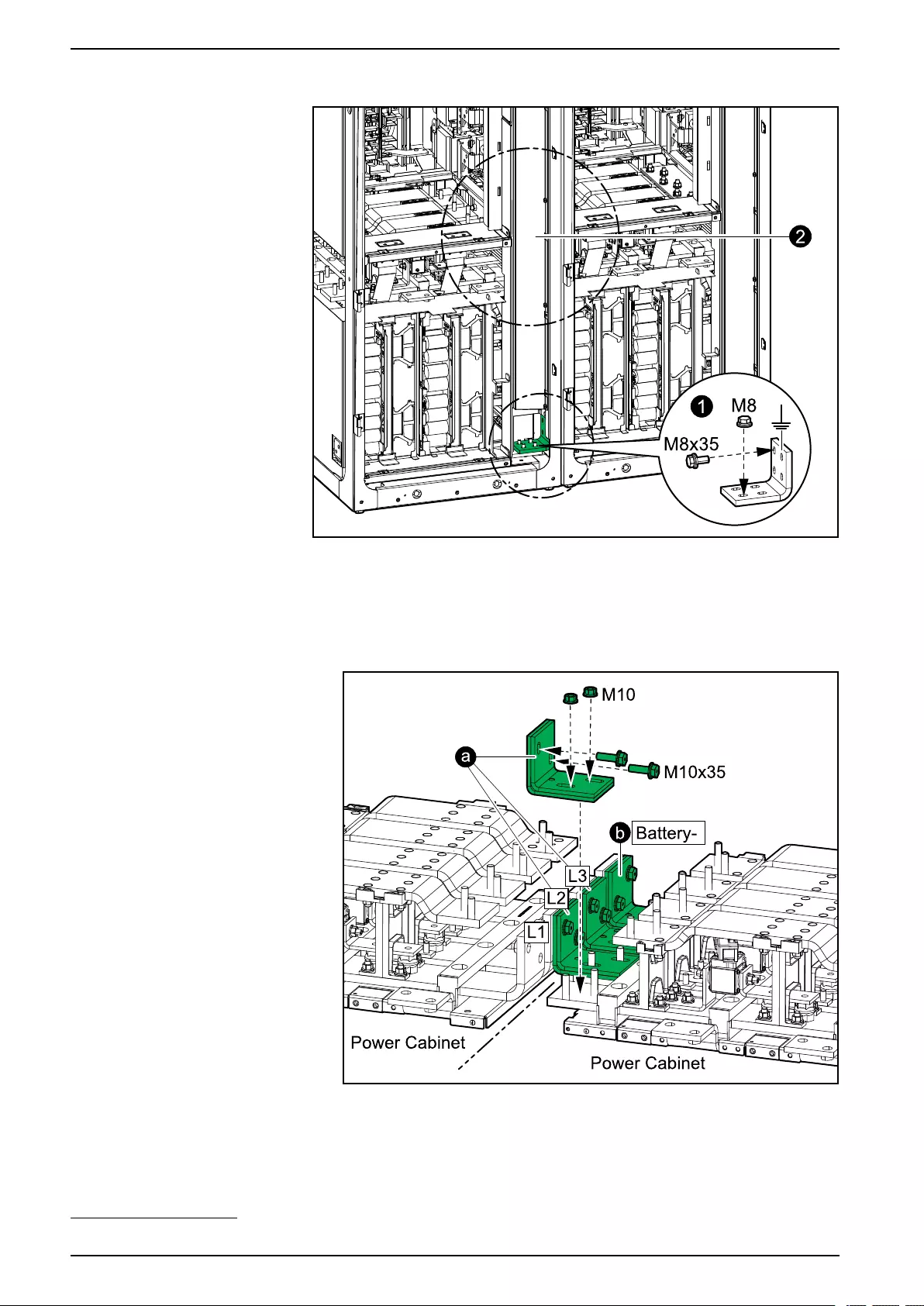

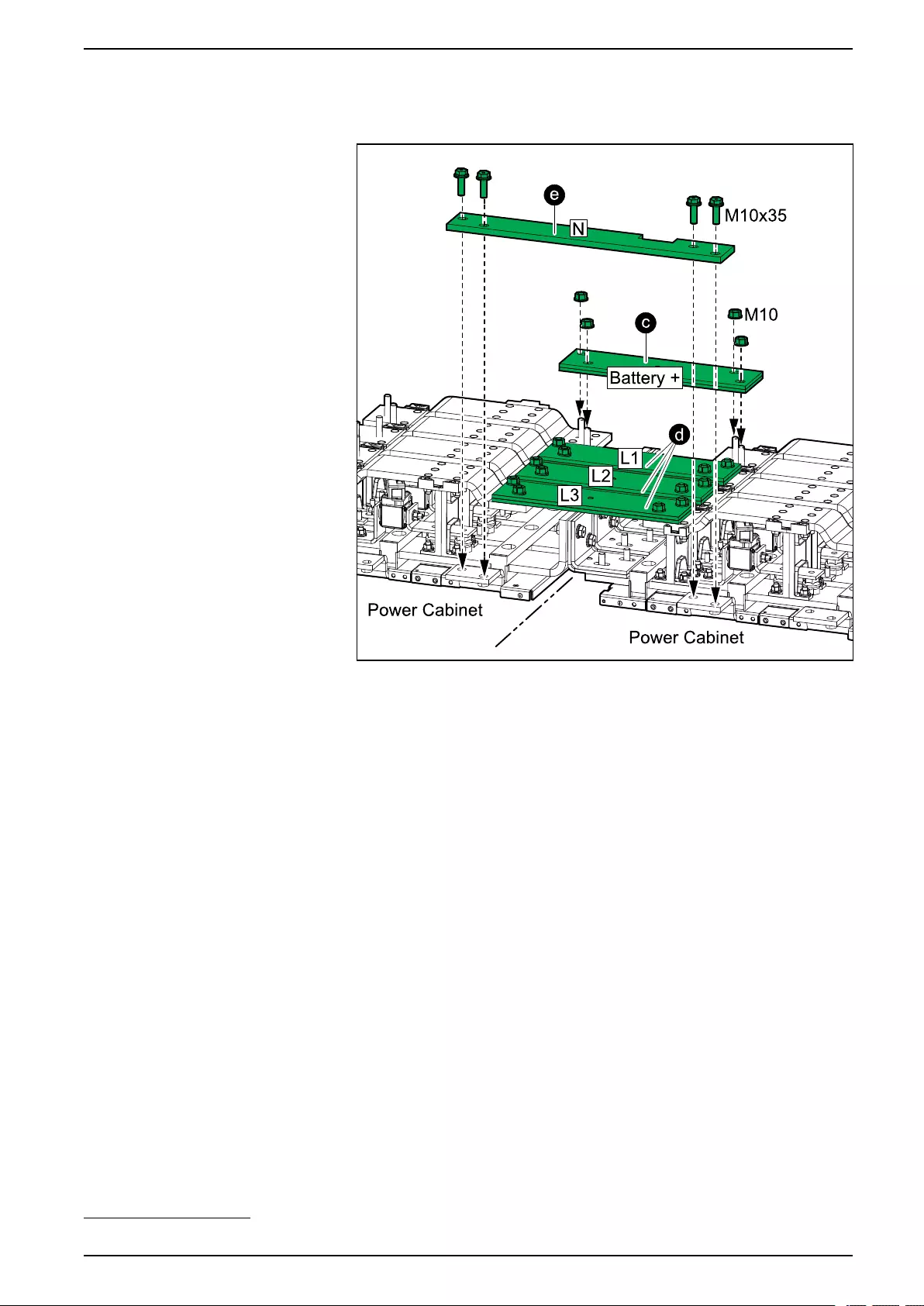

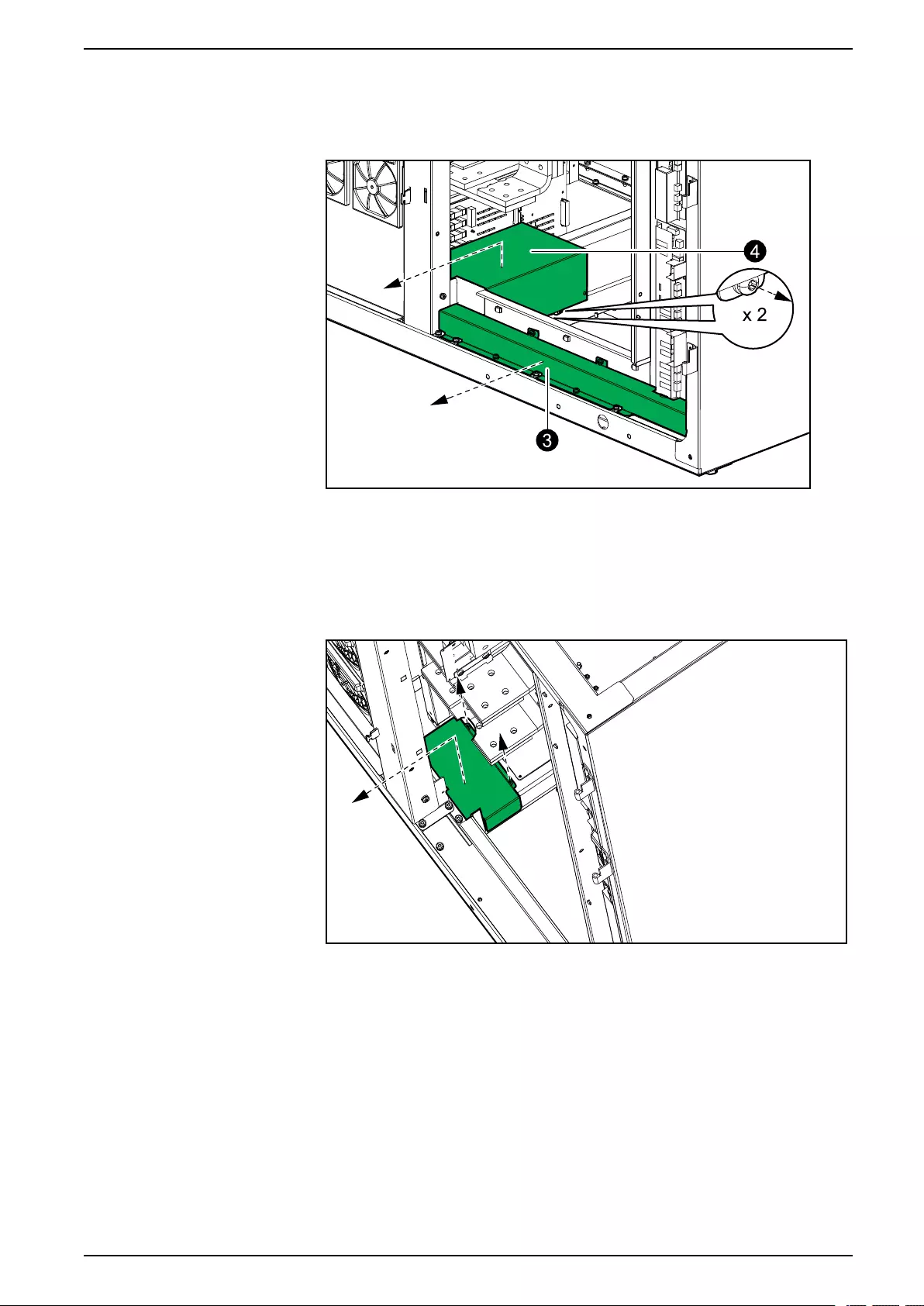

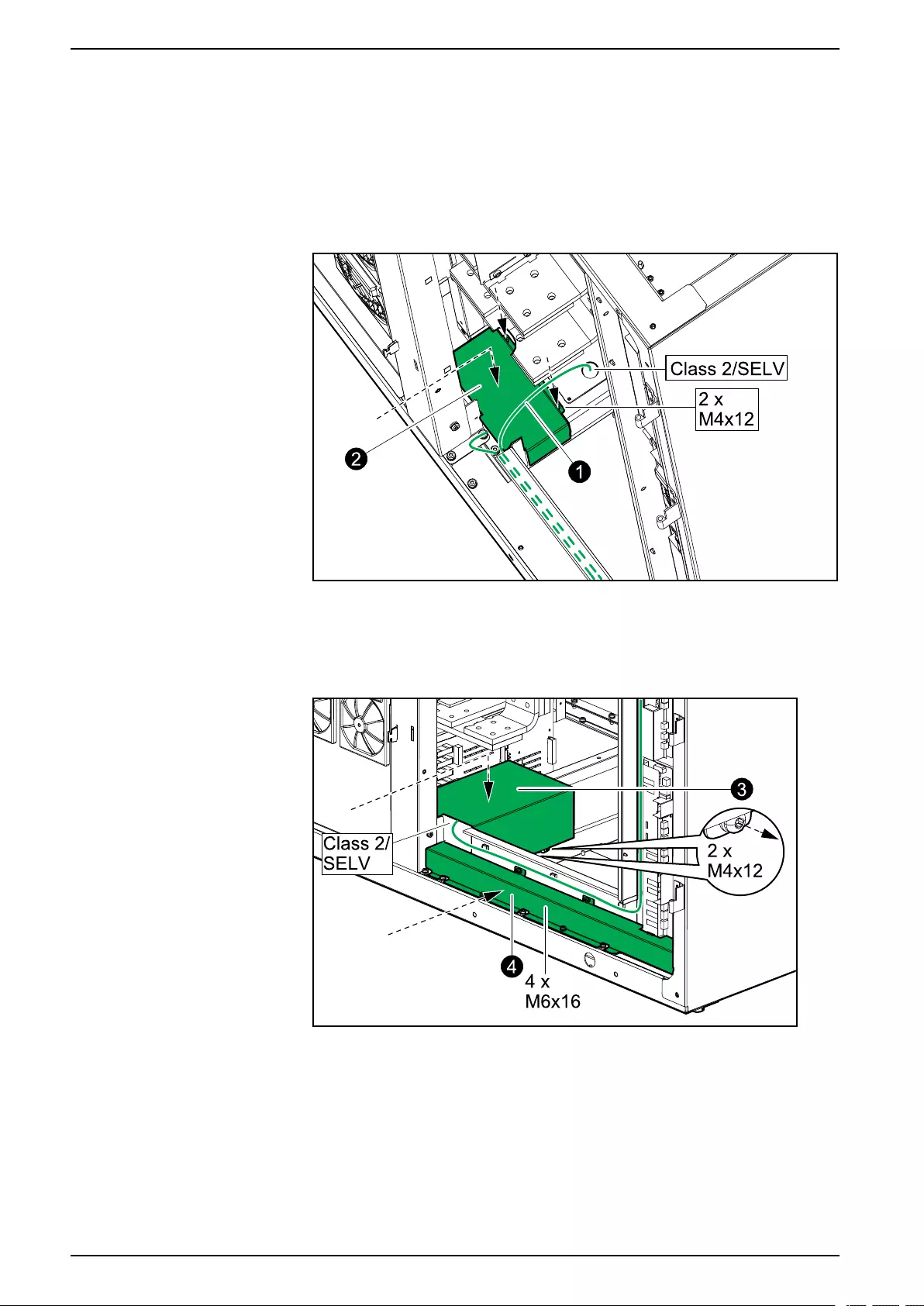

Install the Busbars between the I/O Cabinet and the Power Cabinets ...........71

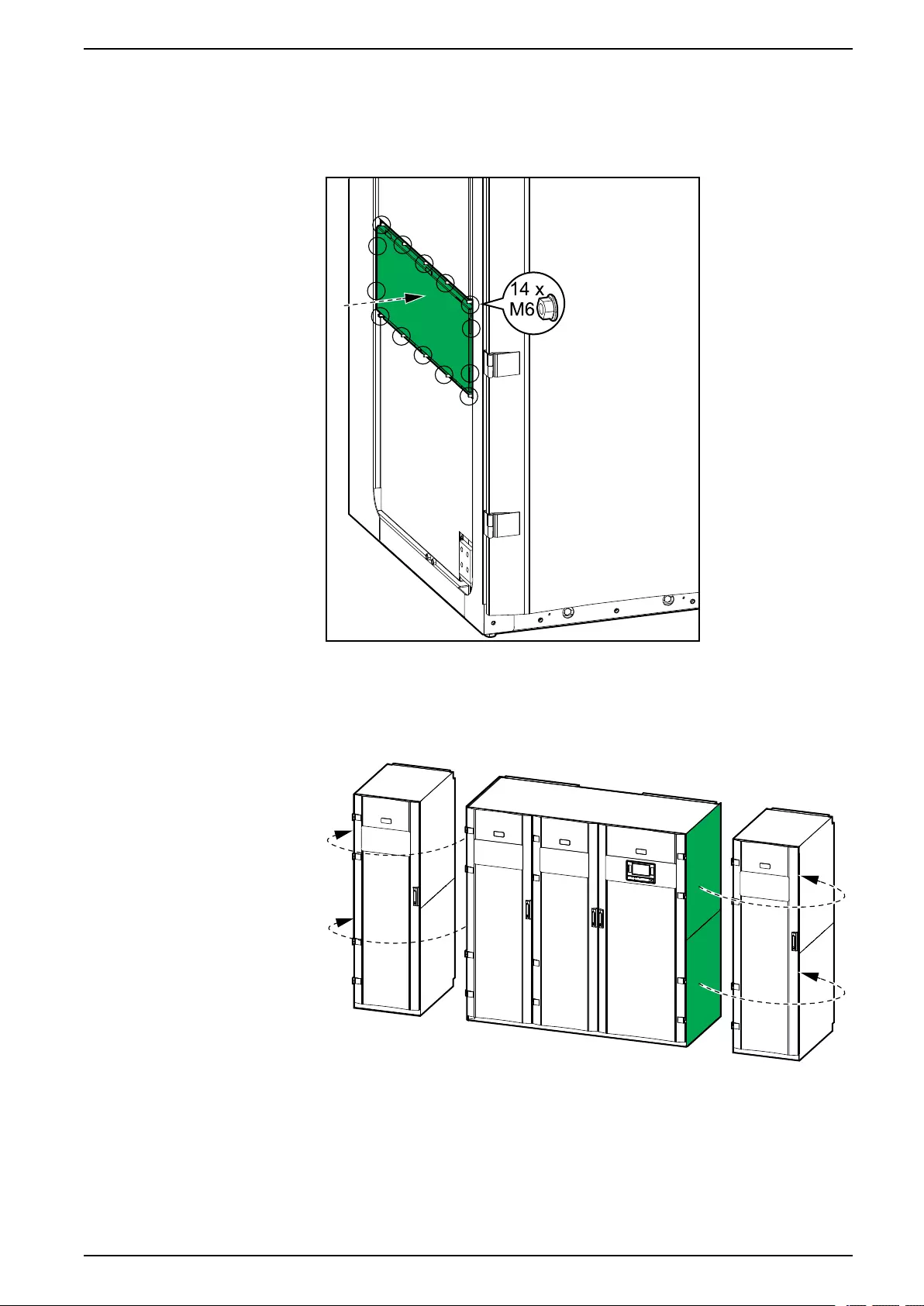

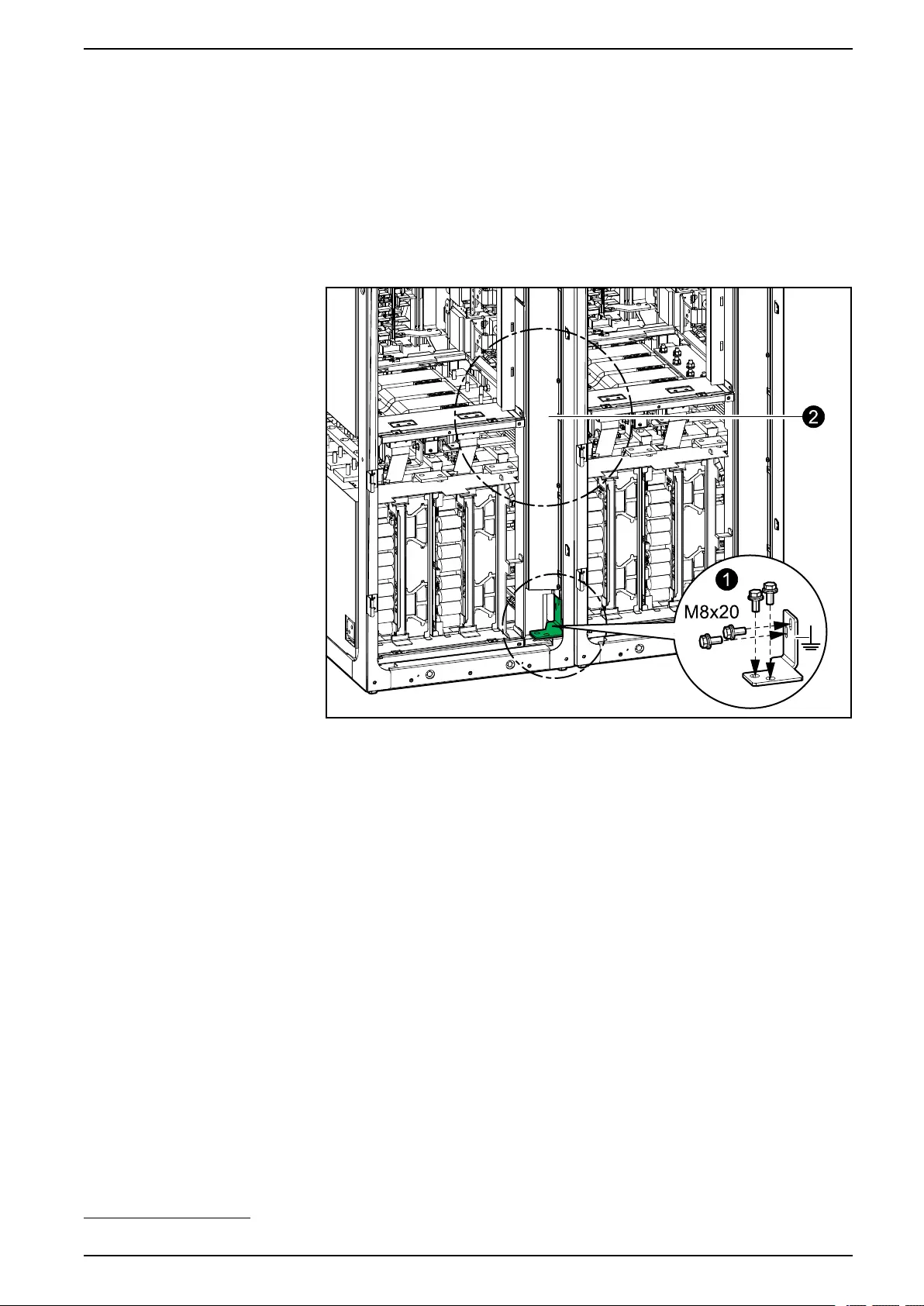

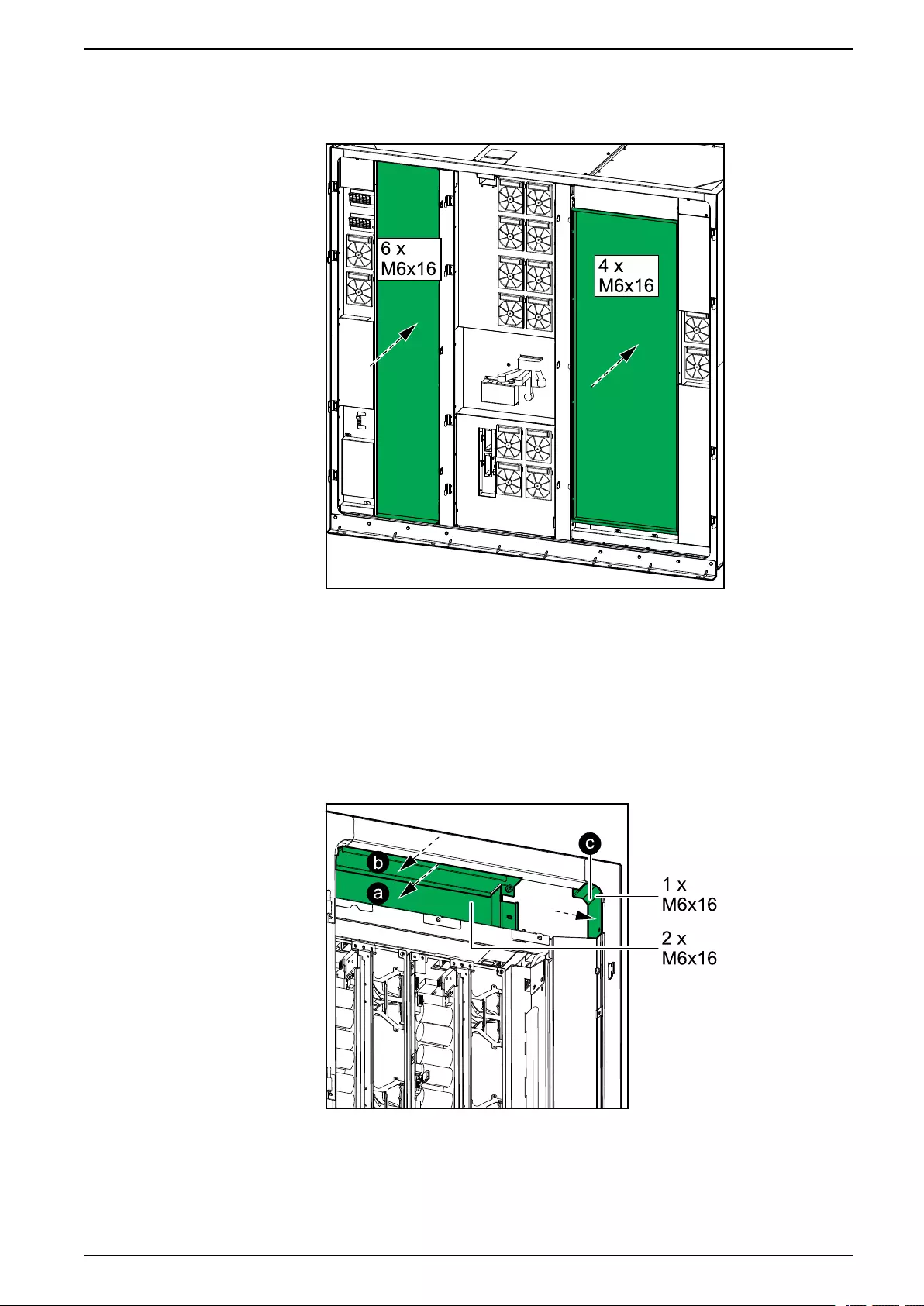

Install the Busbars between the Power Cabinets .........................................77

Connect the Power Cables......................................................................80

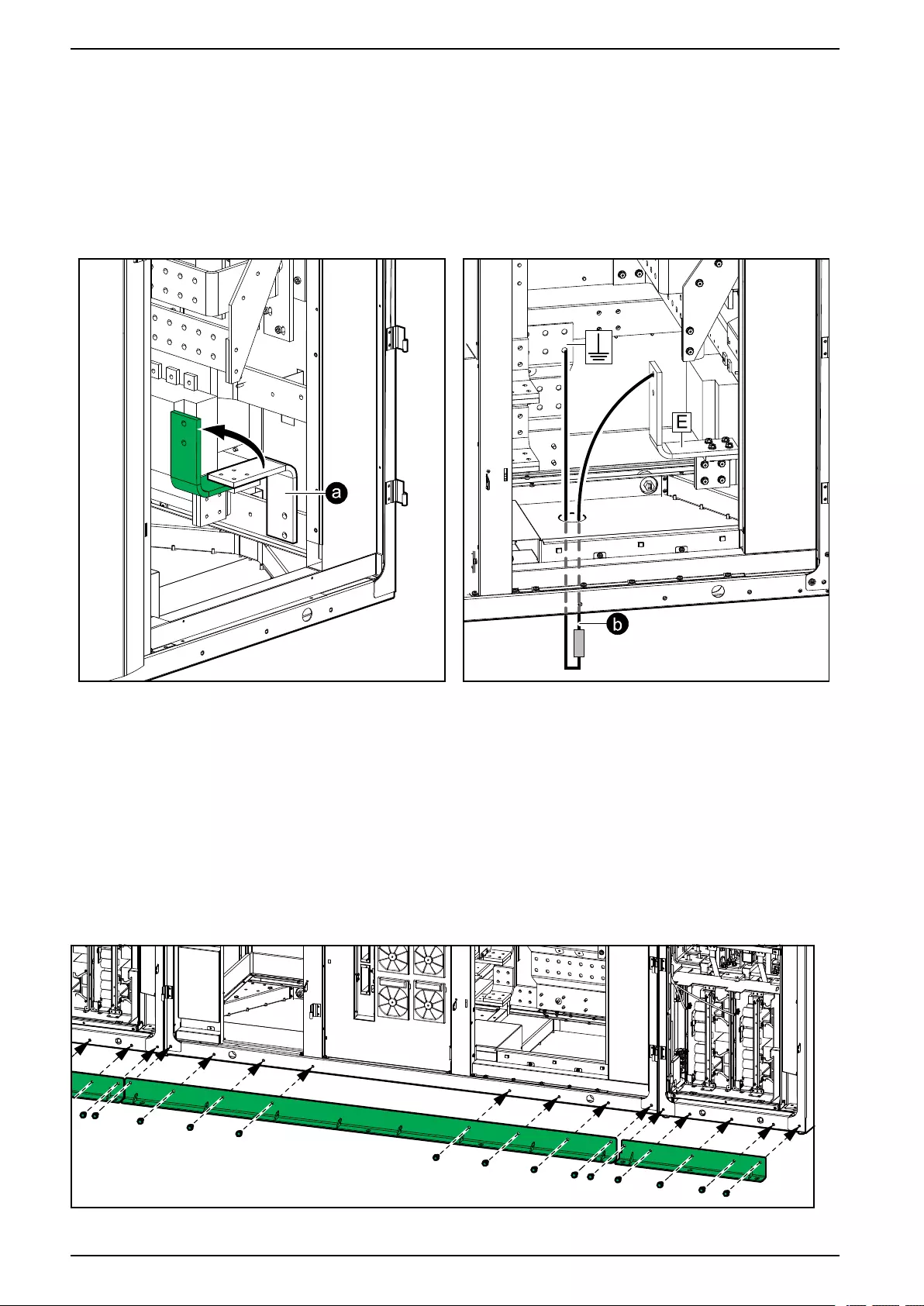

Prepare the I/O Cabinet for Power Cables in Top Cable Entry

Systems ..................................................................................................80

990-5783E-001 3

UPS with 1500 kW I/O Cabinet

Prepare the I/O Cabinet for Power Cables in Bottom Cable Entry

Systems ..................................................................................................81

Install the Single Utility/Mains Installation Kit 0H-9161 .................................82

Connect the Power Cables in a 380 V, 400 V, 415, and 440 V

System ....................................................................................................83

Connect the Power Cables in a 480 V System ............................................85

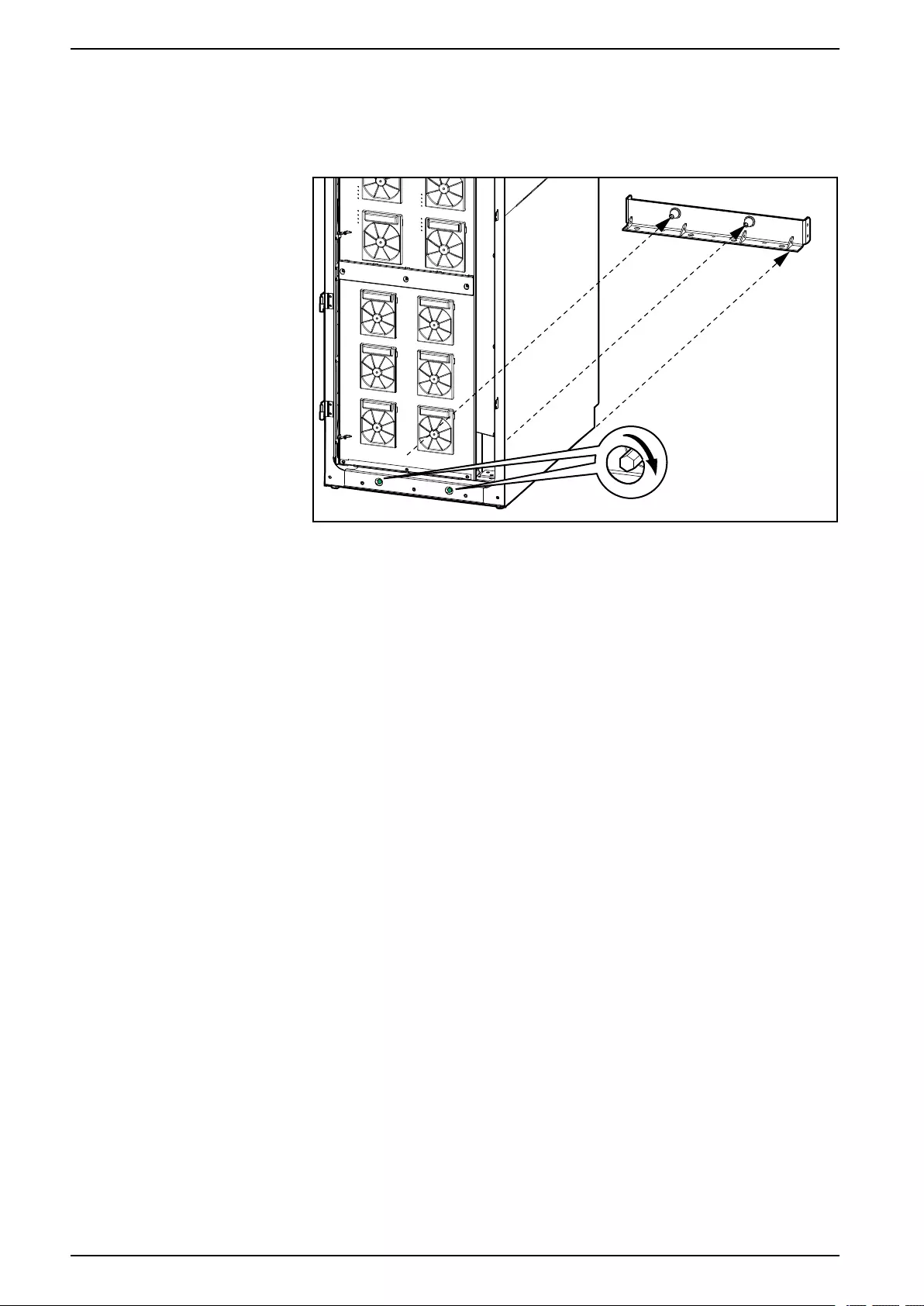

Mount the Front Anchoring Brackets ..........................................................86

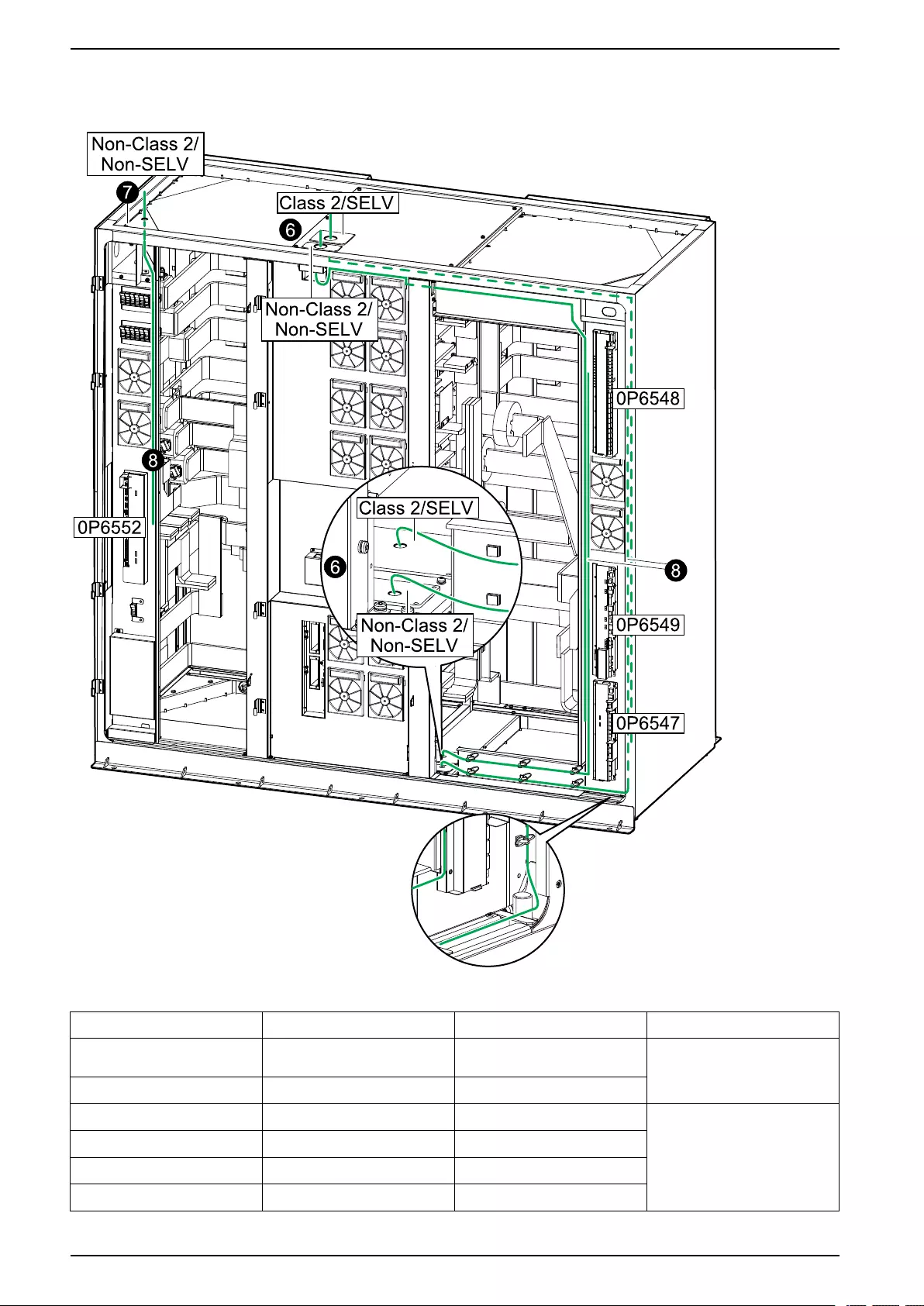

Connect the Signal Cables......................................................................88

Prepare for Signal Cables .........................................................................88

Connect the Signal Cables between the I/O Cabinet and the Power

Cabinets ..................................................................................................92

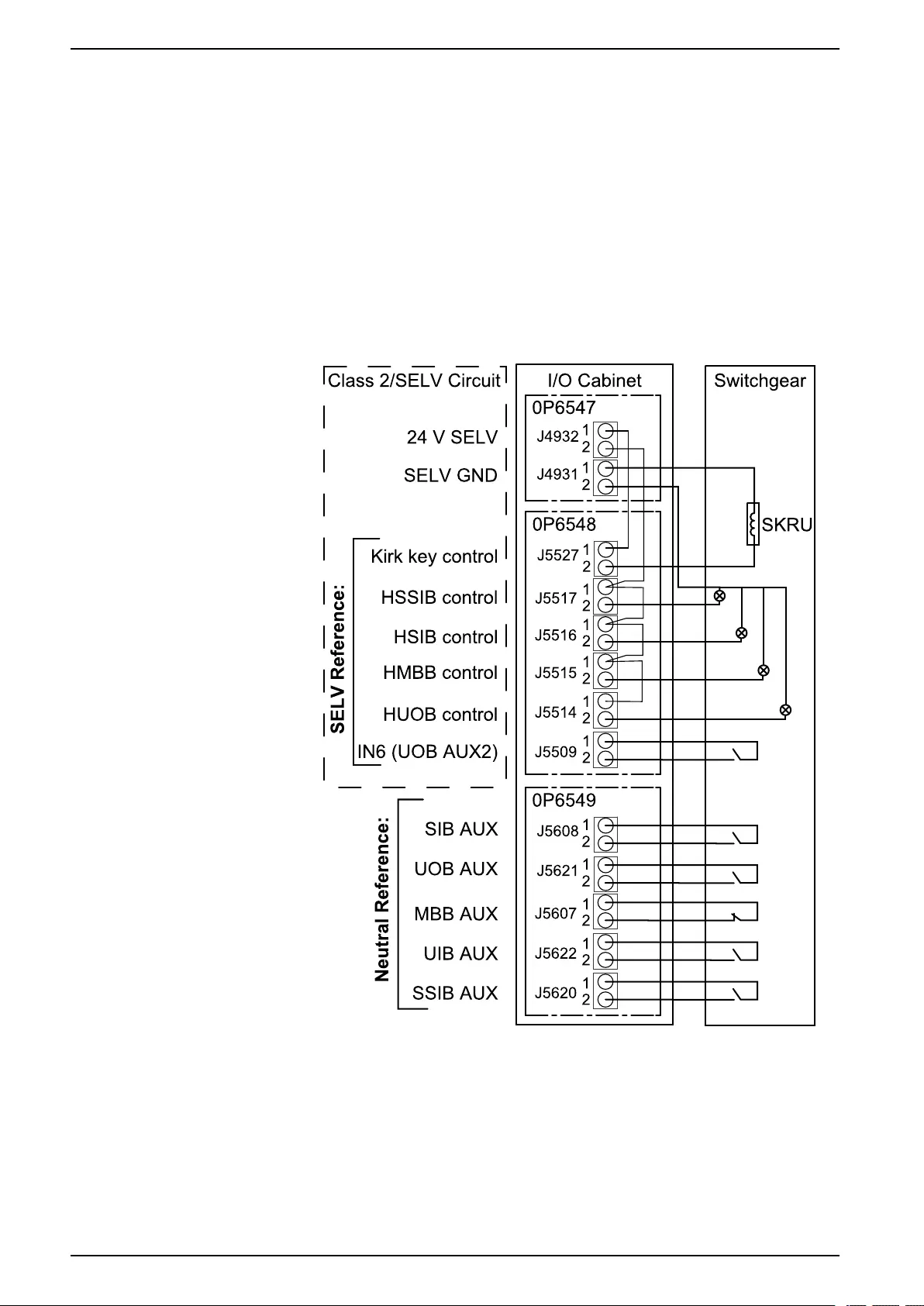

Connect the Signal Cables between the I/O Cabinet and the

Switchgear...............................................................................................98

Connect the Signal Cables for Battery Solutions .........................................98

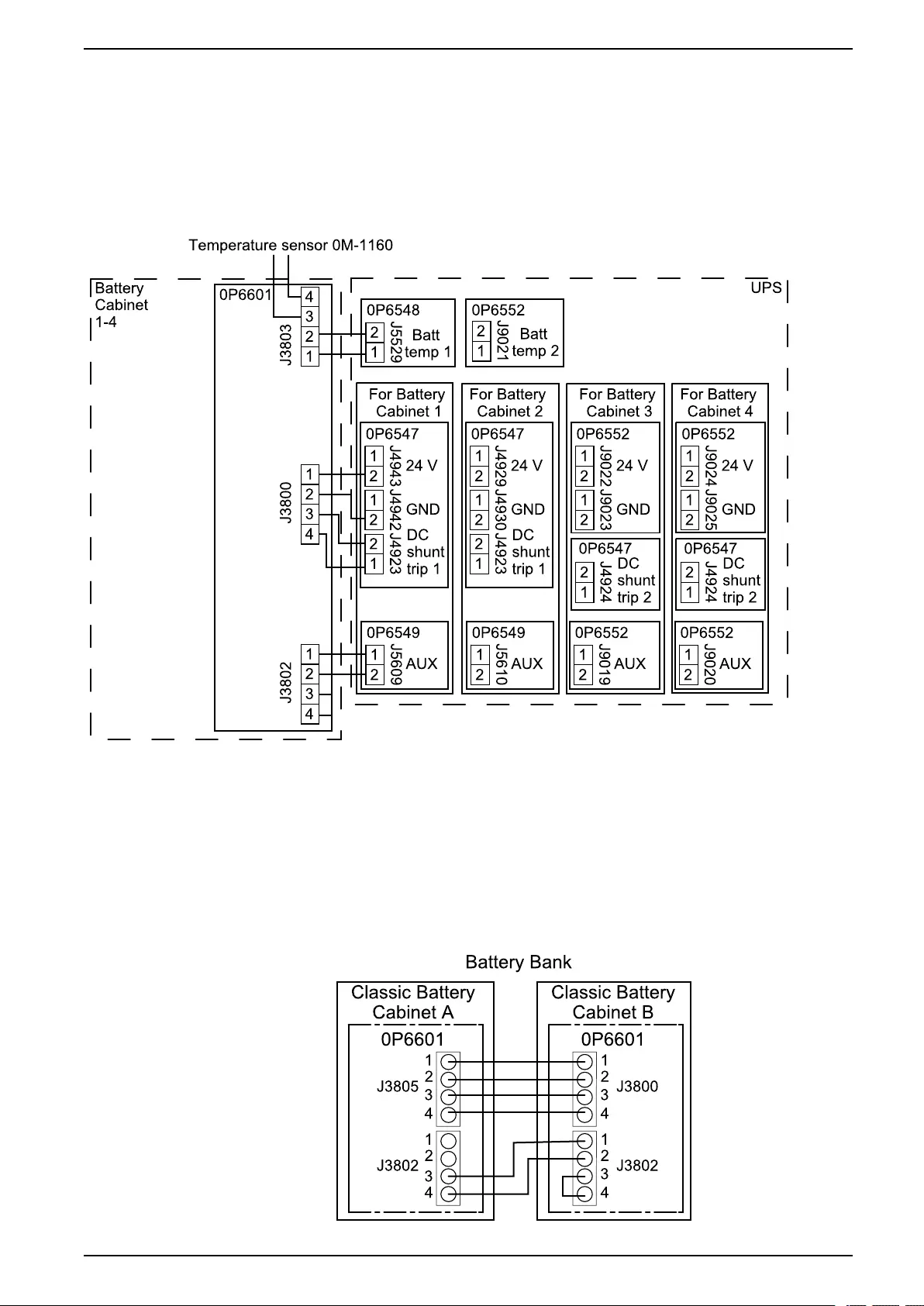

Connect the Signal Cables between the I/O Cabinet and the Classic

Battery Cabinets .................................................................................98

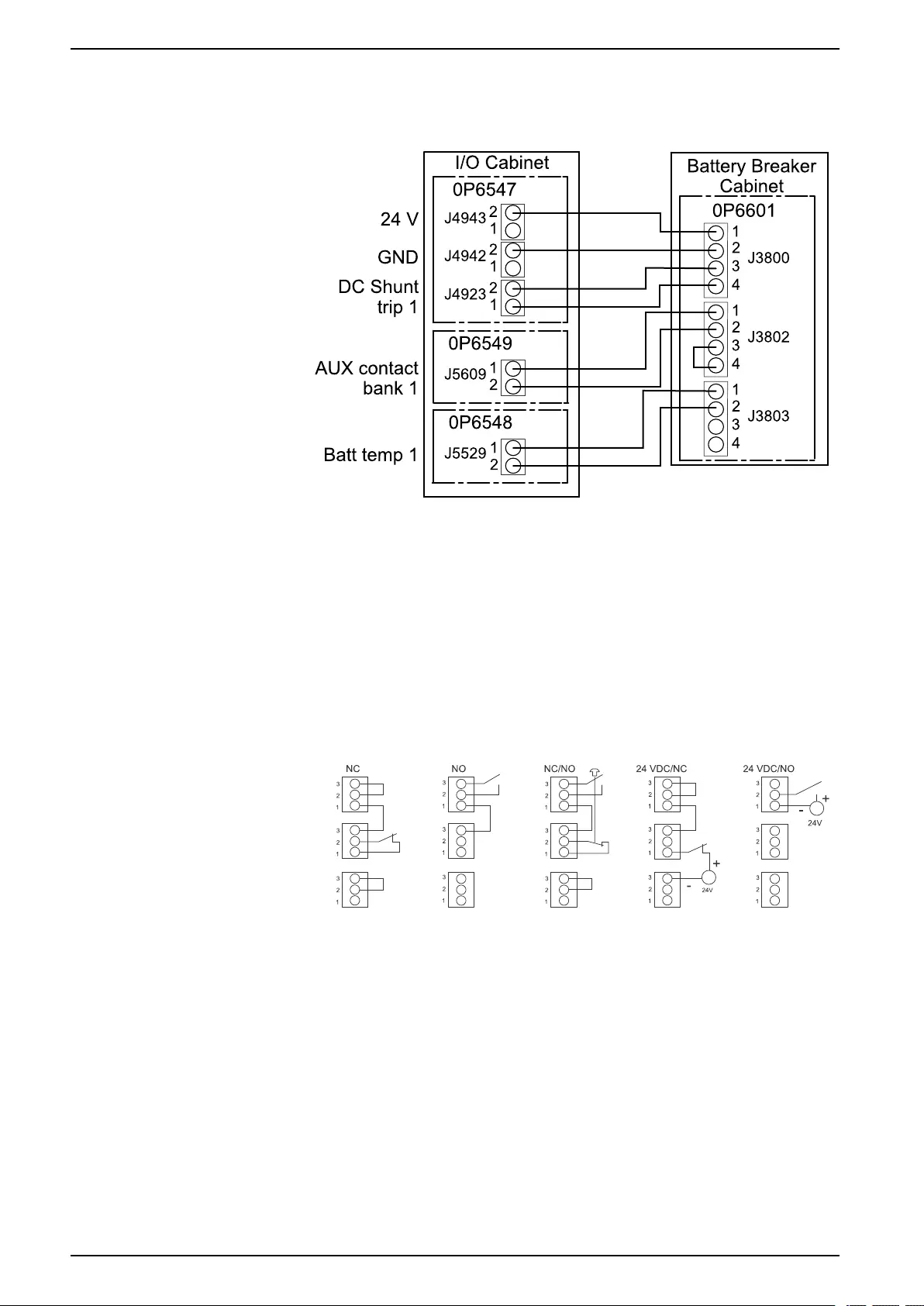

Connect Signal Cables between the I/O Cabinet and the Battery

Breaker Cabinet................................................................................100

Connect the Emergency Power Off (EPO) ................................................ 100

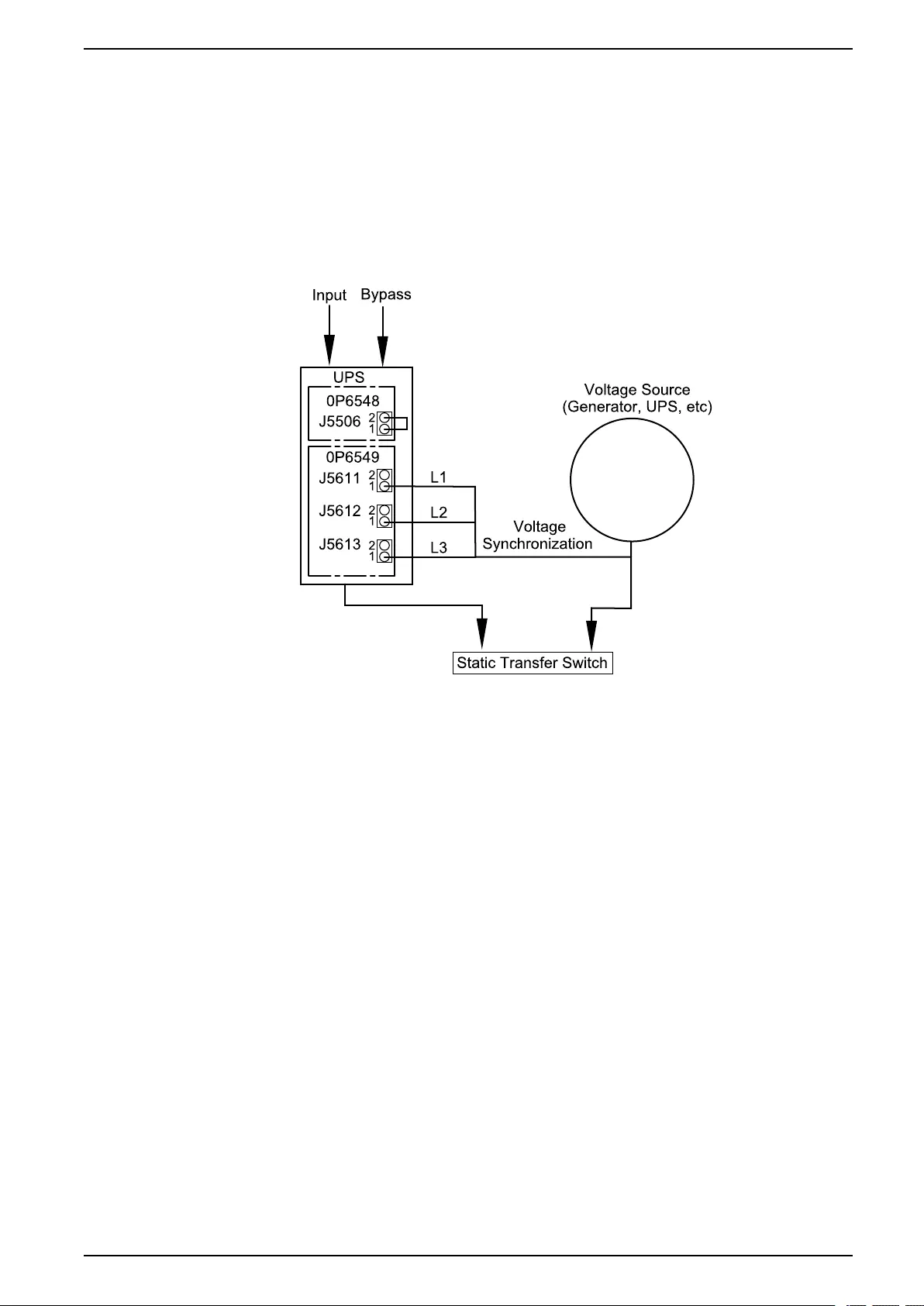

Connect External Synchronization ........................................................... 100

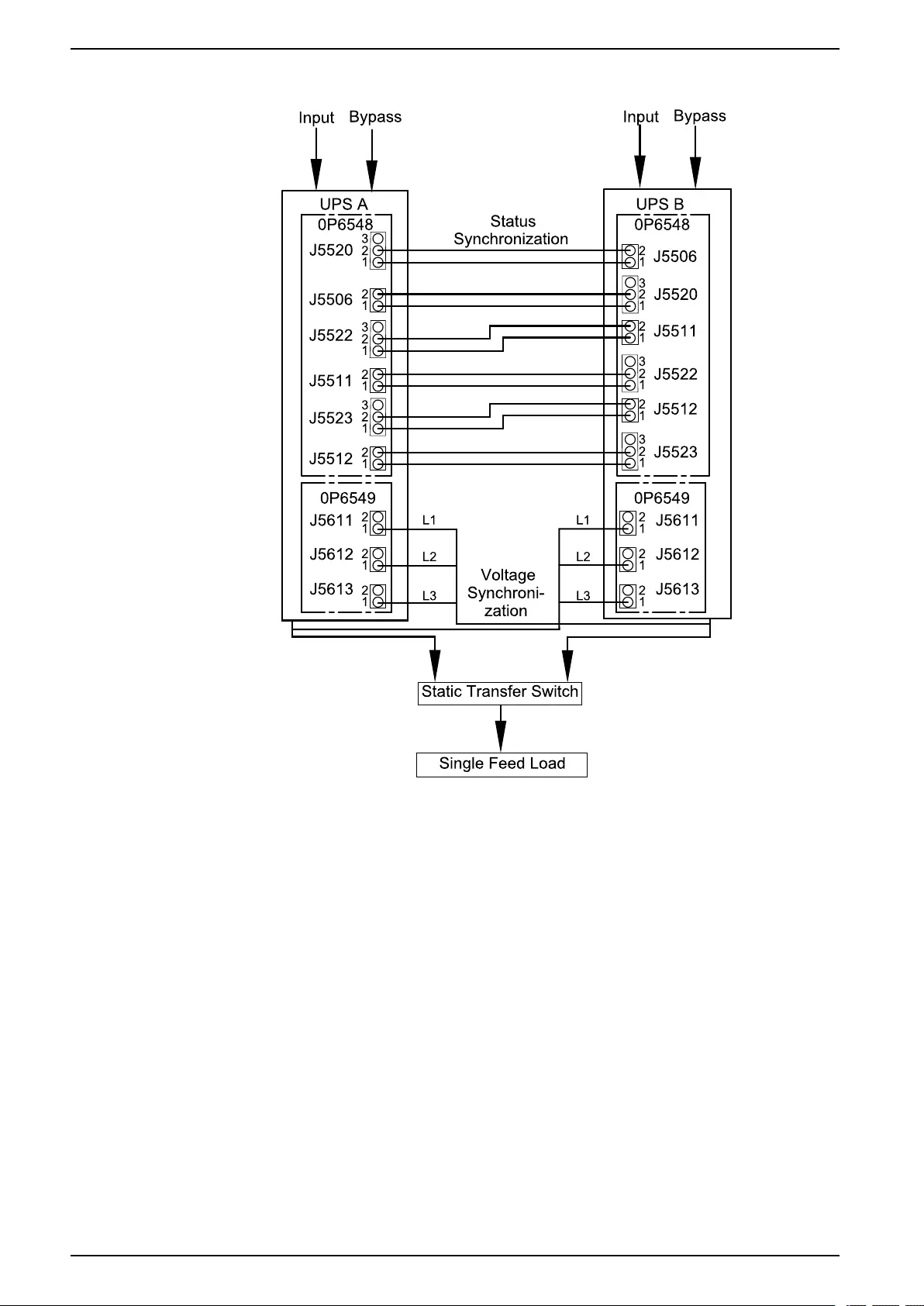

Basic UPS Synchronization to a Fixed Voltage Source......................... 101

Dual UPS Synchronization with a Floating Synchronization

Master .............................................................................................102

Fixed Parallel Synchronization Master ................................................ 103

Connect Equipment to Input Contacts and Output Relays .......................... 103

Overview of Input Contacts and Output Relays.................................... 103

Connect the PBUS Cables between Parallel UPS Units............................. 105

External Communication .........................................................................106

Connect the Modbus Cables..............................................................107

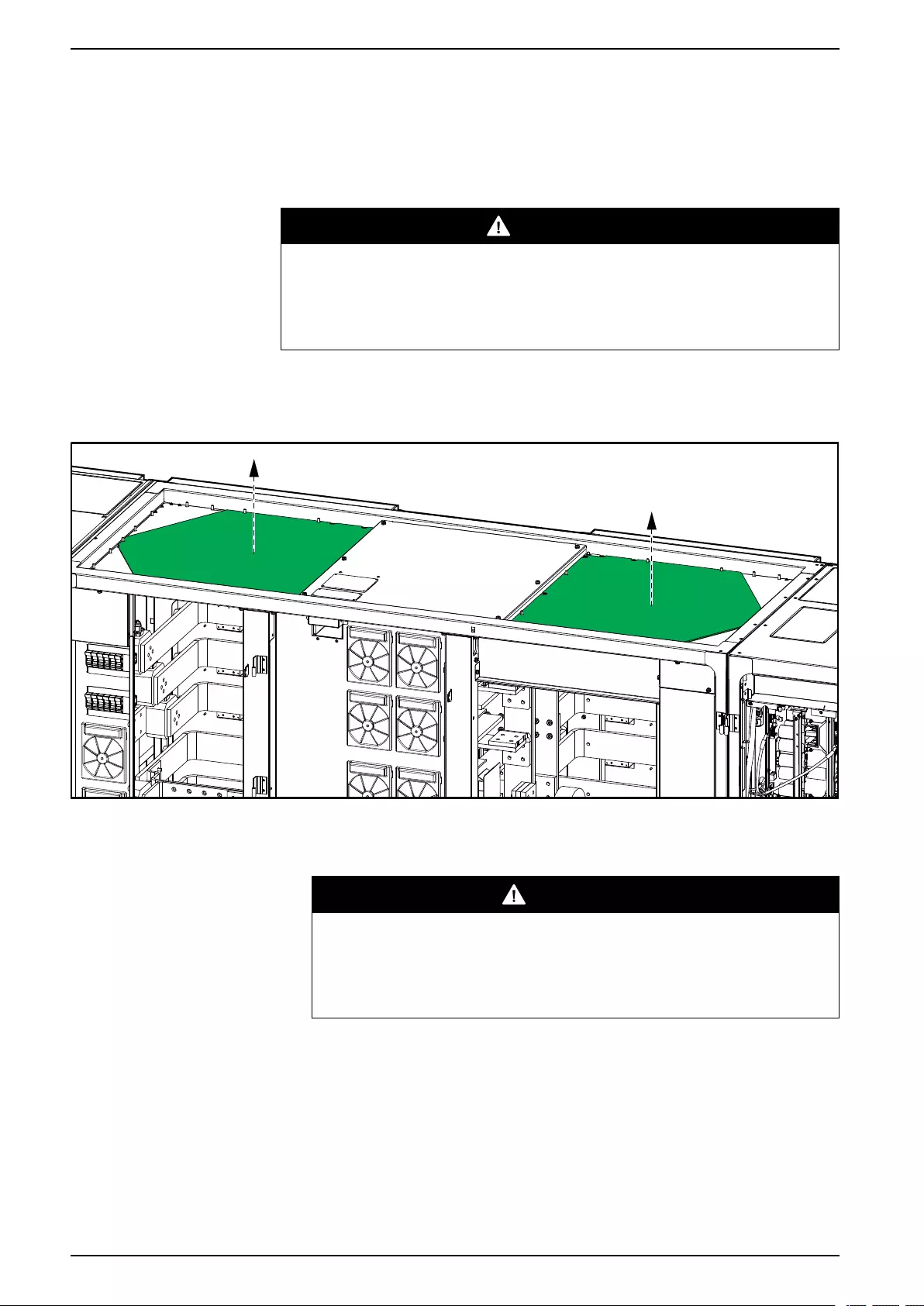

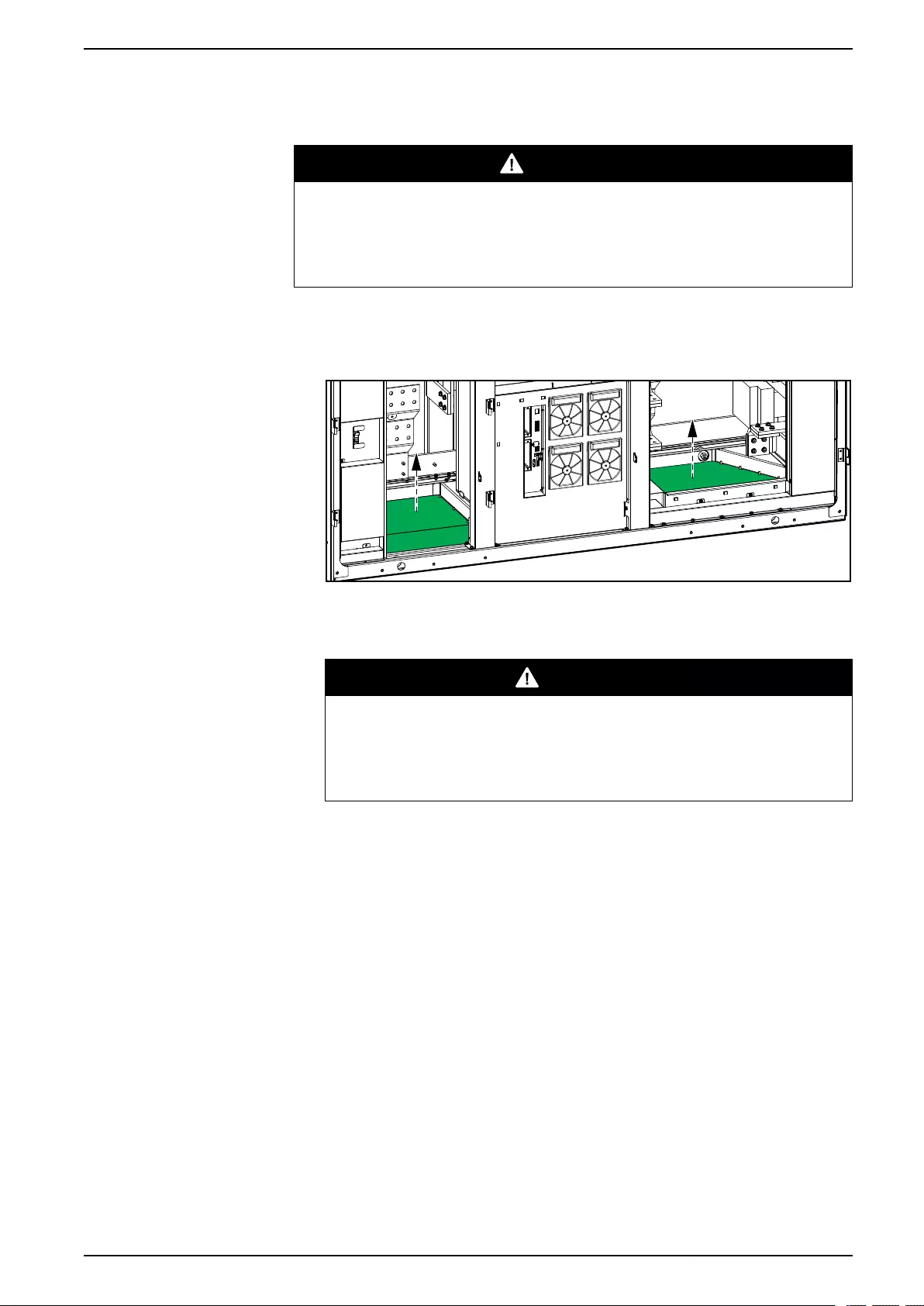

Final Mechanical Assembly................................................................... 110

Final Mechanical Assembly of the I/O Cabinet .......................................... 110

Final Mechanical Assembly of the Power Cabinets.................................... 113

4 990-5783E-001

Important Safety Instructions — SAVE THESE

INSTRUCTIONS UPS with 1500 kW I/O Cabinet

Important Safety Instructions — SAVE THESE

INSTRUCTIONS

Read these instructions carefully and look at the equipment to become familiar

with it before trying to install, operate, service or maintain it. The following safety

messages may appear throughout this manual or on the equipment to warn of

potential hazards or to call attention to information that clarifies or simplifies a

procedure.

The addition of this symbol to a “Danger” or “Warning” safety

message indicates that an electrical hazard exists which will result in

personal injury if the instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages with this symbol

to avoid possible injury or death.

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

Failure to follow these instructions will result in death or serious injury.

WARNING

WARNING indicates a hazardous situation which, if not avoided, could result

in death or serious injury.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

Failure to follow these instructions can result in injury or equipment

damage.

NOTICE

NOTICE is used to address practices not related to physical injury. The safety

alert symbol shall not be used with this type of safety message.

Failure to follow these instructions can result in equipment damage.

Please Note

Electrical equipment should only be installed, operated, serviced, and maintained

by qualified personnel. No responsibility is assumed by Schneider Electric for any

consequences arising out of the use of this material.

A qualified person is one who has skills and knowledge related to the construction,

installation, and operation of electrical equipment and has received safety training

to recognize and avoid the hazards involved.

990-5783E-001 5

UPS with 1500 kW I/O Cabinet

Important Safety Instructions — SAVE THESE

INSTRUCTIONS

FCC Statement

NOTE: This equipment has been tested and found to comply with the limits for

a Class A digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user

will be required to correct the interference at his own expense.

Any changes or modifications not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

Electromagnetic Compatibility

NOTICE

RISK OF ELECTROMAGNETIC DISTURBANCE

This is a product Category C3 according to IEC 62040-2. This is a product for

commercial and industrial applications in the second environment - installation

restrictions or additional measures may be needed to prevent disturbances. The

second environment includes all commercial, light industry, and industrial

locations other than residential, commercial, and light industrial premises

directly connected without intermediate transformer to a public low-voltage

mains supply. The installation and cabling must follow the electromagnetic

compatibility rules, e.g.:

• the segregation of cables,

• the use of shielded or special cables when relevant,

• the use of grounded metallic cable tray and supports.

Failure to follow these instructions can result in equipment damage.

Safety Precautions

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

All safety instructions in this document must be read, understood and followed.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Read all instructions in the Installation Manual before installing or working on

this UPS system.

Failure to follow these instructions will result in death or serious injury.

6 990-5783E-001

Important Safety Instructions — SAVE THESE

INSTRUCTIONS UPS with 1500 kW I/O Cabinet

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Do not install the UPS system until all construction work has been completed

and the installation room has been cleaned.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• The product must be installed according to the specifications and

requirements as defined by Schneider Electric. It concerns in particular the

external and internal protections (upstream breakers, battery breakers,

cabling, etc.) and environmental requirements. No responsibility is assumed

by Schneider Electric if these requirements are not respected.

• After the UPS system has been electrically wired, do not start up the system.

Start-up must only be performed by Schneider Electric.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

The UPS system must be installed according to local and national regulations.

Install the UPS according to:

• IEC 60364 (including 60364–4–41- protection against electric shock, 60364–

4–42 - protection against thermal effect, and 60364–4–43 - protection

against overcurrent), or

• NEC NFPA 70, or

• Canadian Electrical Code (C22.1, Part 1)

depending on which one of the standards apply in your local area.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Install the UPS system in a temperature controlled indoor environment free

of conductive contaminants and humidity.

• Install the UPS system on a non-flammable, level and solid surface (e.g.

concrete) that can support the weight of the system.

Failure to follow these instructions will result in death or serious injury.

990-5783E-001 7

UPS with 1500 kW I/O Cabinet

Important Safety Instructions — SAVE THESE

INSTRUCTIONS

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

The UPS is not designed for and must therefore not be installed in the following

unusual operating environments:

• Damaging fumes

• Explosive mixtures of dust or gases, corrosive gases, or conductive or

radiant heat from other sources

• Moisture, abrasive dust, steam or in an excessively damp environment

• Fungus, insects, vermin

• Salt-laden air or contaminated cooling refrigerant

• Pollution degree higher than 2 according to IEC 60664-1

• Exposure to abnormal vibrations, shocks, and tilting

• Exposure to direct sunlight, heat sources, or strong electromagnetic fields

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Do not drill or cut holes for cables or conduits with the gland plates installed and

do not drill or cut holes in close proximity to the UPS.

Failure to follow these instructions will result in death or serious injury.

WARNING

HAZARD OF ARC FLASH

Do not make mechanical changes to the product (including removal of cabinet

parts or drilling/cutting of holes) that are not described in the Installation Manual.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

NOTICE

RISK OF OVERHEATING

Respect the space requirements around the UPS system and do not cover the

product’s ventilation openings when the UPS system is in operation.

Failure to follow these instructions can result in equipment damage.

NOTICE

RISK OF EQUIPMENT DAMAGE

Do not connect the UPS output to regenerative load systems including

photovoltaic systems and speed drives.

Failure to follow these instructions can result in equipment damage.

Electrical Safety

This manual contains important safety instructions that should be followed during

the installation and maintenance of the UPS system.

8 990-5783E-001

Important Safety Instructions — SAVE THESE

INSTRUCTIONS UPS with 1500 kW I/O Cabinet

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Electrical equipment must be installed, operated, serviced, and maintained

only by qualified personnel.

• Apply appropriate personal protective equipment (PPE) and follow safe

electrical work practices.

• Disconnection devices for AC and DC must be provided by others, be readily

accessible, and the function of the disconnect device marked for its function.

• Turn off all power supplying the UPS system before working on or inside the

equipment.

• Before working on the UPS system, check for hazardous voltage between all

terminals including the protective earth.

• The UPS contains an internal energy source. Hazardous voltage can be

present even when disconnected from the mains supply. Before installing or

servicing the UPS system, ensure that the units are OFF and that mains and

batteries are disconnected. Wait five minutes before opening the UPS to

allow the capacitors to discharge.

• The UPS must be properly earthed/grounded and due to a high leakage

current, the earthing/grounding conductor must be connected first.

Failure to follow these instructions will result in death or serious injury.

When the UPS input is connected through external isolators that, when opened,

isolate the neutral or when the automatic backfeed isolation is provided external to

the equipment or is connected to an IT power distribution system, a label must be

fitted at the UPS input terminals, and on all primary power isolators installed

remotely from the UPS area and on external access points between such isolators

and the UPS, by the user, displaying the following text (or equivalent in a language

which is acceptable in the country in which the UPS system is installed):

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Risk of voltage backfeed. Before working on this circuit: Isolate the UPS and

check for hazardous voltage between all terminals including the protective

earth.

Failure to follow these instructions will result in death or serious injury.

Battery Safety

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Battery circuit breakers must be installed according to the specifications and

requirements as defined by Schneider Electric.

• Servicing of batteries must only be performed or supervised by qualified

personnel knowledgeable of batteries and the required precautions. Keep

unqualified personnel away from batteries.

• Disconnect charging source prior to connecting or disconnecting battery

terminals.

• Do not dispose of batteries in a fire as they can explode.

• Do not open, alter, or mutilate batteries. Released electrolyte is harmful to

the skin and eyes. It may be toxic.

Failure to follow these instructions will result in death or serious injury.

990-5783E-001 9

UPS with 1500 kW I/O Cabinet

Important Safety Instructions — SAVE THESE

INSTRUCTIONS

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Batteries can present a risk of electric shock and high short-circuit current. The

following precautions must be observed when working on batteries

• Remove watches, rings, or other metal objects.

• Use tools with insulated handles.

• Wear protective glasses, gloves and boots.

• Do not lay tools or metal parts on top of batteries.

• Disconnect the charging source prior to connecting or disconnecting battery

terminals.

• Determine if the battery is inadvertently grounded. If inadvertently grounded,

remove source from ground. Contact with any part of a grounded battery can

result in electric shock. The likelihood of such shock can be reduced if such

grounds are removed during installation and maintenance (applicable to

equipment and remote battery supplies not having a grounded supply

circuit).

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

When replacing batteries, always replace with the same type and number of

batteries or battery packs.

Failure to follow these instructions will result in death or serious injury.

NOTICE

RISK OF EQUIPMENT DAMAGE

• Wait until the system is ready to be powered up before installing batteries in

the system. The time duration from battery installation until the UPS system

is powered up must not exceed 72 hours or 3 days.

• Batteries must not be stored more than six months due to the requirement of

recharging. If the UPS system remains de-energized for a long period,

Schneider Electric recommends that you energize the UPS system for a

period of 24 hours at least once every month. This charges the batteries,

thus avoiding irreversible damage.

Failure to follow these instructions can result in equipment damage.

10 990-5783E-001

Specifications for 380, 400, 415, and 440 V Systems UPS with 1500 kW I/O Cabinet

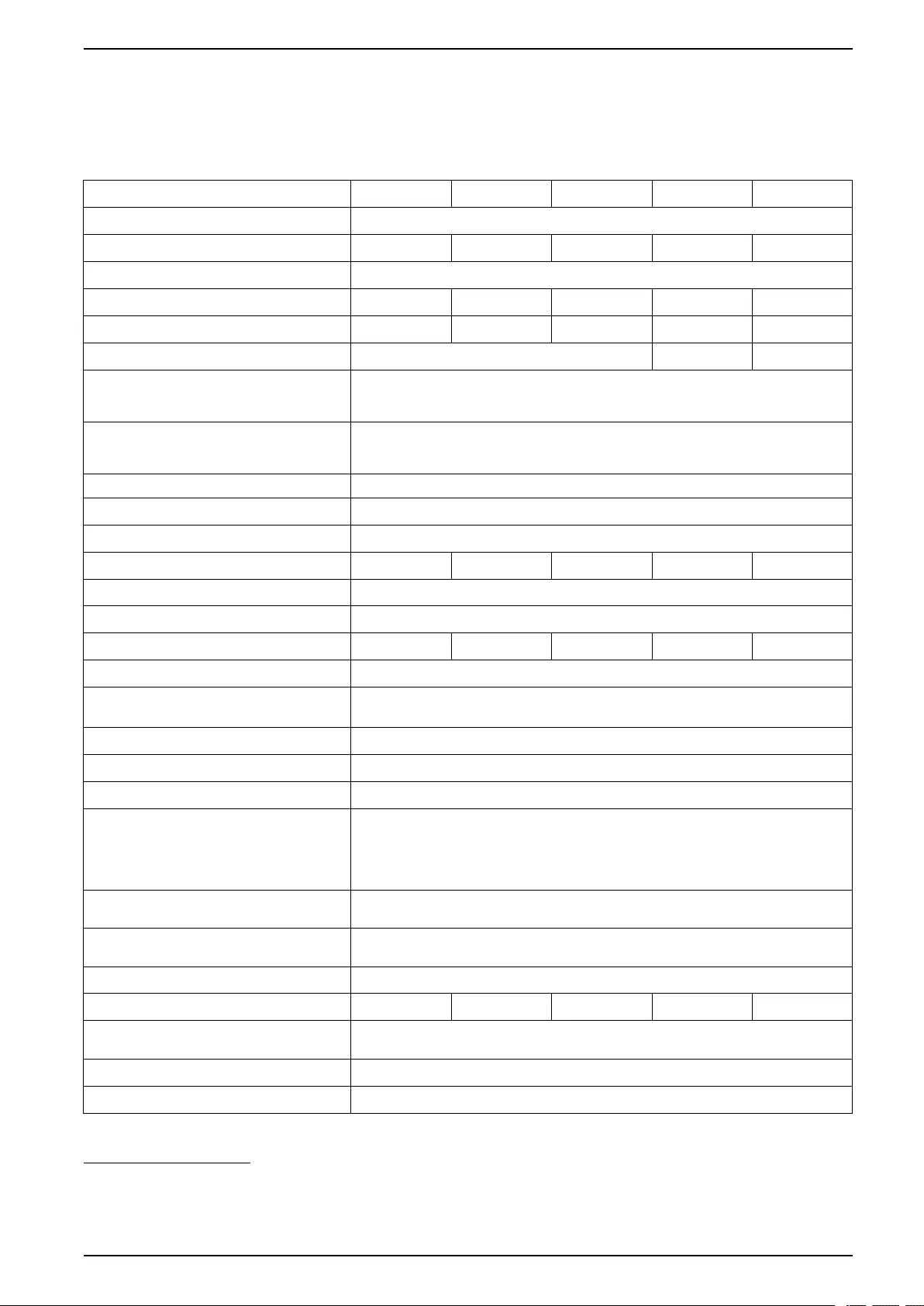

Specifications for 380, 400, 415, and 440 V Systems

Specifications for 500 kW UPS

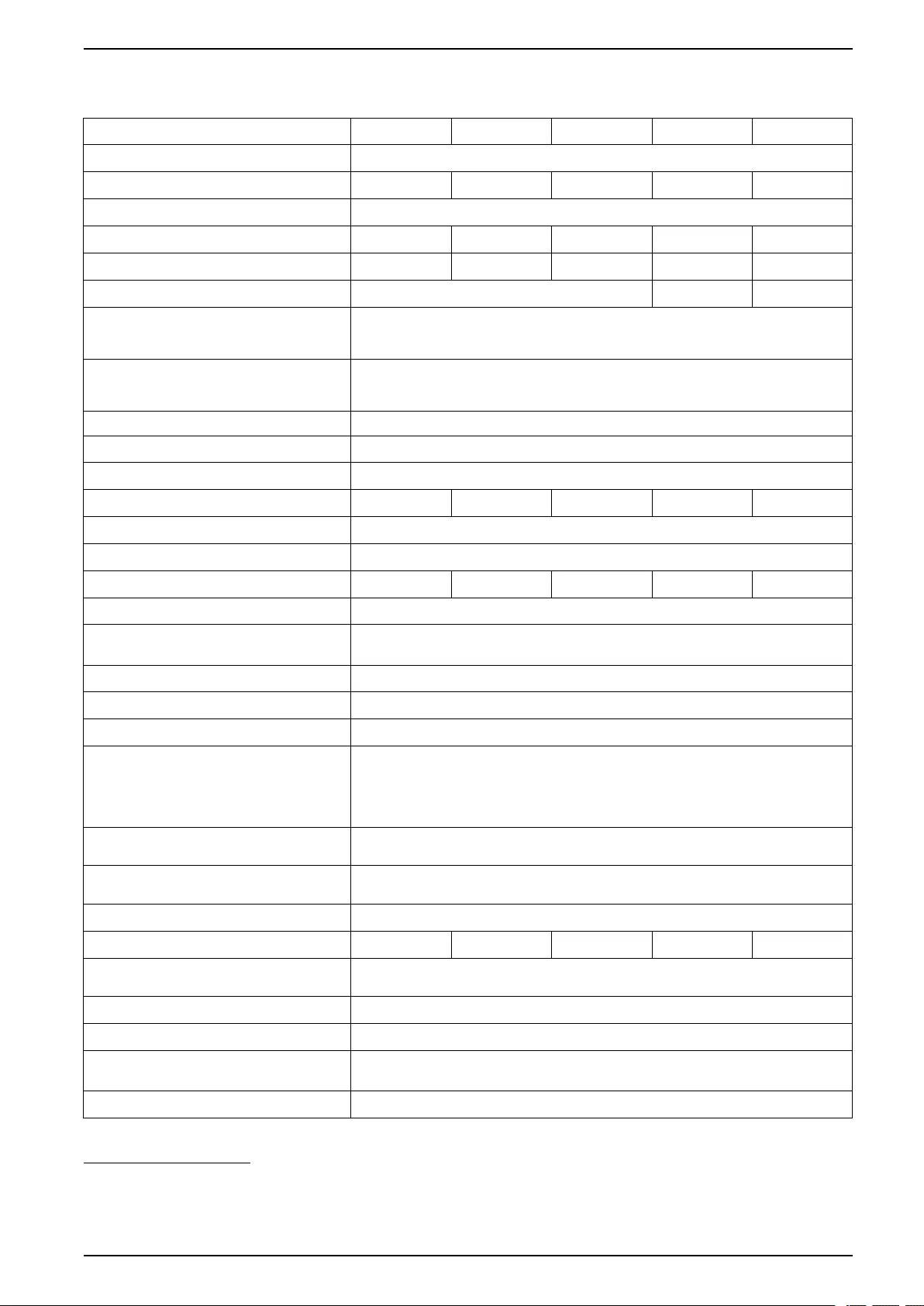

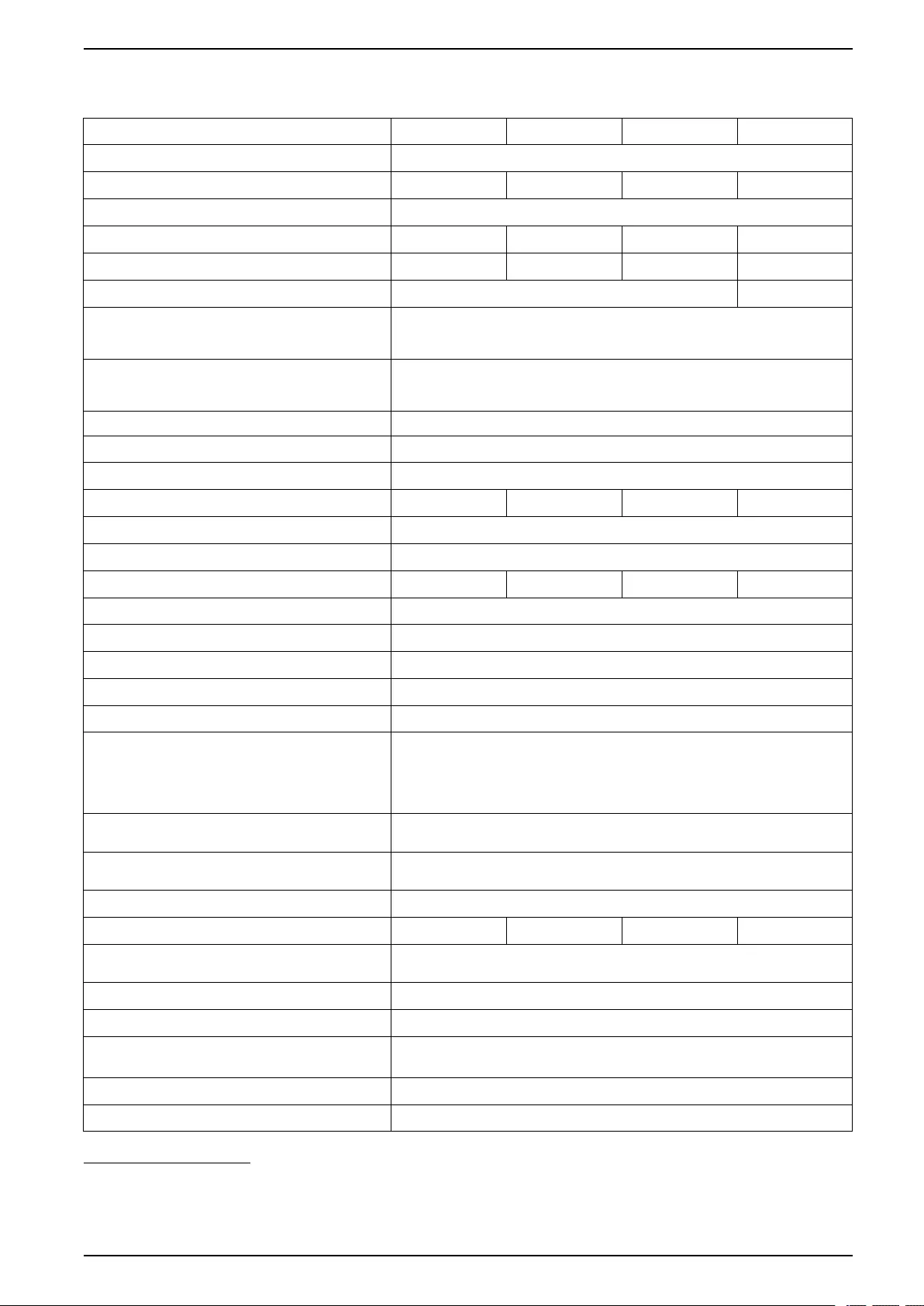

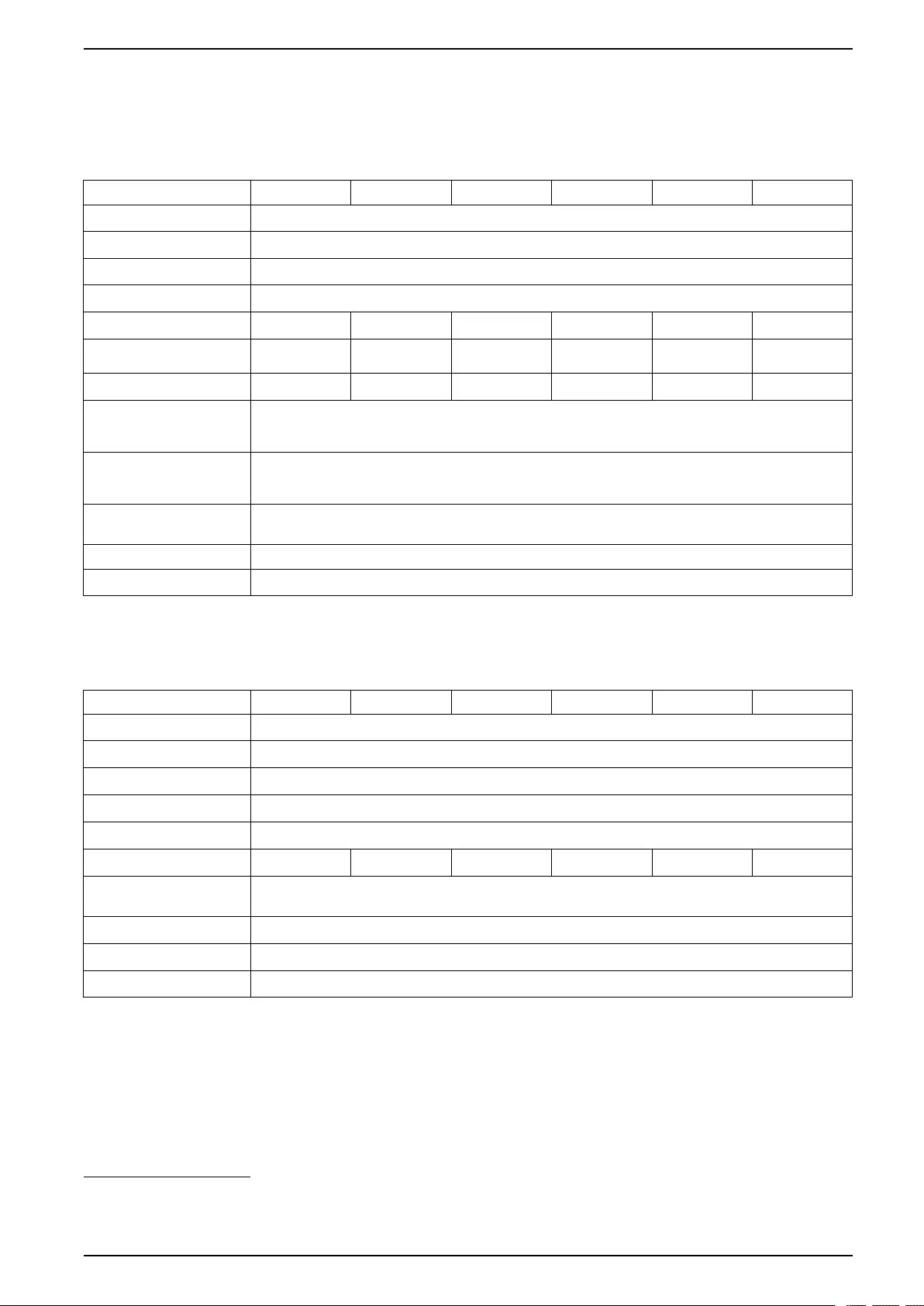

Voltage (V) 380 400 415 440 480

Connections 3–wire (L1, L2, L3, PE)1

Input voltage range (V)2340-456 340-480 353-498 374-528 408-576

Frequency (Hz) 40 – 70

Nominal input current (A) 800 760 731 685 633

Maximum input current (A)3886 851 819 767 725

Input current limitation (A) 890 832 760

Total harmonic distortion (THDI) <3% at 100% load

<4% at 50% load

<9% at 25% load

Input power factor 0.99 at >40% load

0.98 at >20% load

0.97 at >10% load

Protection Contactors

Ramp-in Adaptive 1 – 40 secs

Connections 4–wire (L1, L2, L3, N, PE) or 3–wire (L1, L2, L3, PE)1

Bypass voltage range (V) 342-418 360-440 374-457 396-484 432-528

Frequency (Hz) 50 or 60

Frequency range (Hz) Programmable: +/-0.1, +/-3, +/-10. Default is +/-3.

Nominal bypass current (A) 767 729 703 663 606

Maximum short circuit rating 100 kA RMS4

Thyristor I²t (kA*s²) 72205for systems with 1000 kW I/O cabinet

162455for systems with 1500 kW I/O cabinet

BF2 magnetic trip 39 kA

Protection Molded switch with trip for backfeed protection

Connections 4–wire (L1, L2, L3, N, PE) or 3–wire (L1, L2, L3, PE)

Overload capacity 150% for 1 minute (normal operation)

125% for 10 minutes (normal operation)

115% for 1 minute (battery operation)

110% continuous (bypass operation)

1000% for 100 milliseconds (bypass operation)

Output voltage tolerance Balanced load: +/- 1%

Unbalanced load: +/- 3%

Dynamic load response +/- 5% after 2 ms

+/- 1% after 50 ms

Output power factor 1

Nominal output current (A) 760 722 696 656 601

Total harmonic distortion (THDU) <2% at 100% linear load

<3% at 100% non–linear load

Output frequency (Hz) 50/60 (synchronized to bypass), 50/60 Hz +/-0.1% (free-running)

Slew rate (Hz/sec) Programmable: 0.25, 0.5, 1, 2, 4, 6

990-5783E-001 11

1. TN, TT, and IT power distribution systems are supported. Corner (line) grounding is not supported.

2. The system can operate at 600 V for 1 minute.

3. At nominal input voltage and full charge.

4. Conditioned by the internal molded switch with a 90 kA peak magnetic trip

5. If this value is exceeded, the thyristors can short.

UPS with 1500 kW I/O Cabinet Specifications for 380, 400, 415, and 440 V Systems

Voltage (V) 380 400 415 440 480

Output performance classification (according

to IEC/ EN62040-3)

Double-conversion: VFI-SS-111

Load crest factor Up to 3 (THDU < 5%)

Load power factor 0.7 leading to 0.5 lagging without derating

Charging power in % of output power 35% at ≤ 80% load

12% at 100% load

Maximum charging power (kW) 60 at 100% load

175 at <80% load

Nominal battery voltage (VDC) 480

Nominal float voltage (VDC) 546

End of discharge voltage (full load) (VDC) 384

End of discharge voltage (no load) (VDC) 420

Battery current at full load and nominal battery

voltage (A)

1090 1090 1090 1090 1090

Battery current at full load and minimum

battery voltage (A)

1362 1362 1362 1362 1362

Maximum battery backup time Unlimited

Temperature compensation (per cell) -3.3 mV per °C for T ≥ 25 °C

0 mV per °C for T < 25 °C

Ripple current < 5% C20 (5 minutes backup time)

Battery test Manual/automatic (selectable)

Deep discharge protection Yes

Recharge according to battery temperature Yes

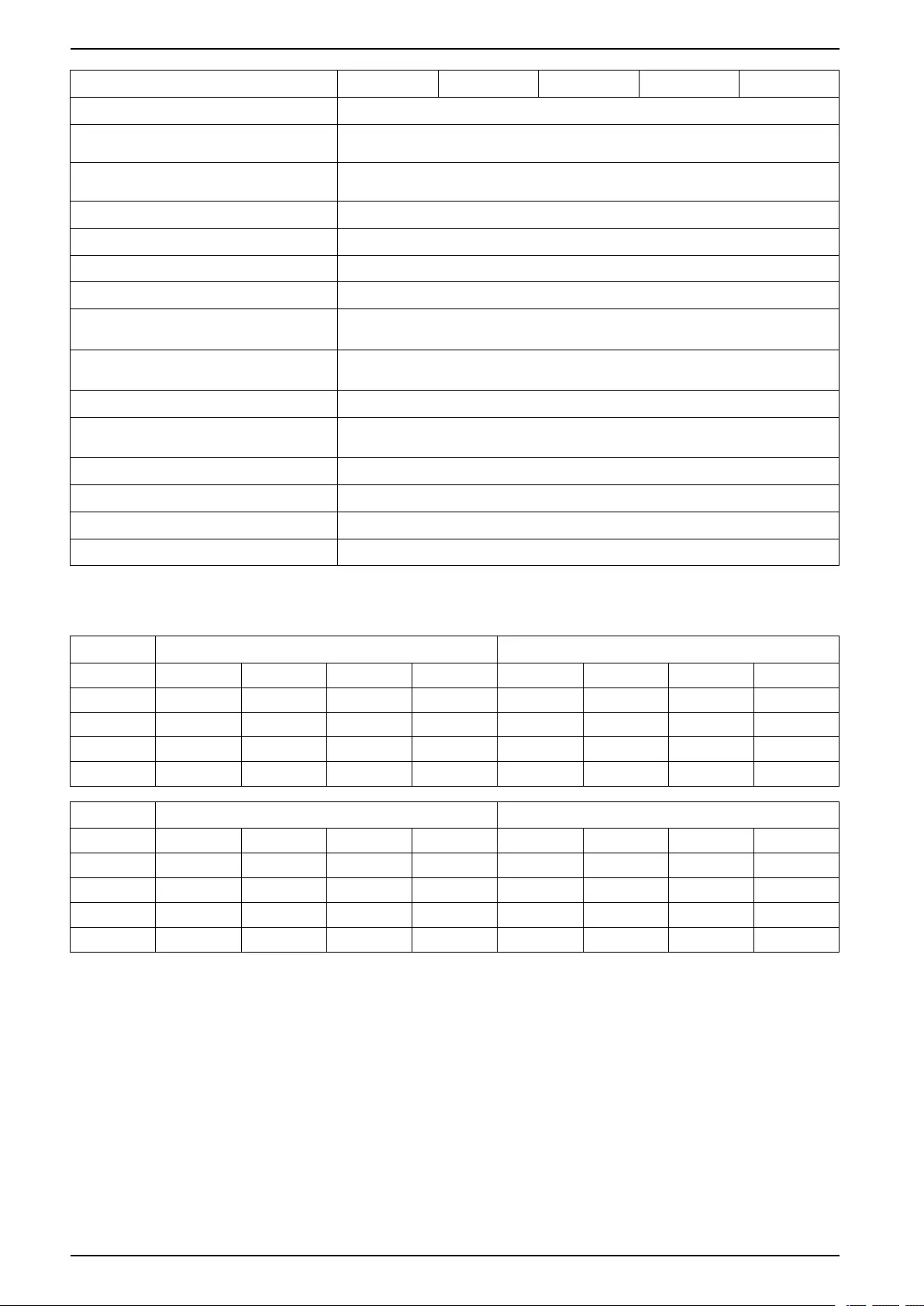

Heat Dissipation (BTU/hr) for 500 kW UPS

Normal Operation ECO Mode

Load 380 V 400 V 415 V 440 V 380 V 400 V 415 V 440 V

25% 17309 16387 16387 16387 5618 5618 5618 6056

50% 32774 30938 30938 31396 7747 7747 7747 7747

75% 53313 50542 50542 50542 11620 11620 11620 10969

100% 86017 82260 82260 75723 13758 13758 13758 13758

ECOnversion Battery Operation

Load 380 V 400 V 415 V 440 V 380 V 400 V 415 V 440 V

25% 6495 6495 6495 7155 18234 18234 18234 18234

50% 7747 7747 7747 7747 31855 31855 31855 31855

75% 11620 11620 11620 10969 53313 53313 53313 53313

100% 15493 13758 13758 13758 78519 78519 78519 78519

12 990-5783E-001

Specifications for 380, 400, 415, and 440 V Systems UPS with 1500 kW I/O Cabinet

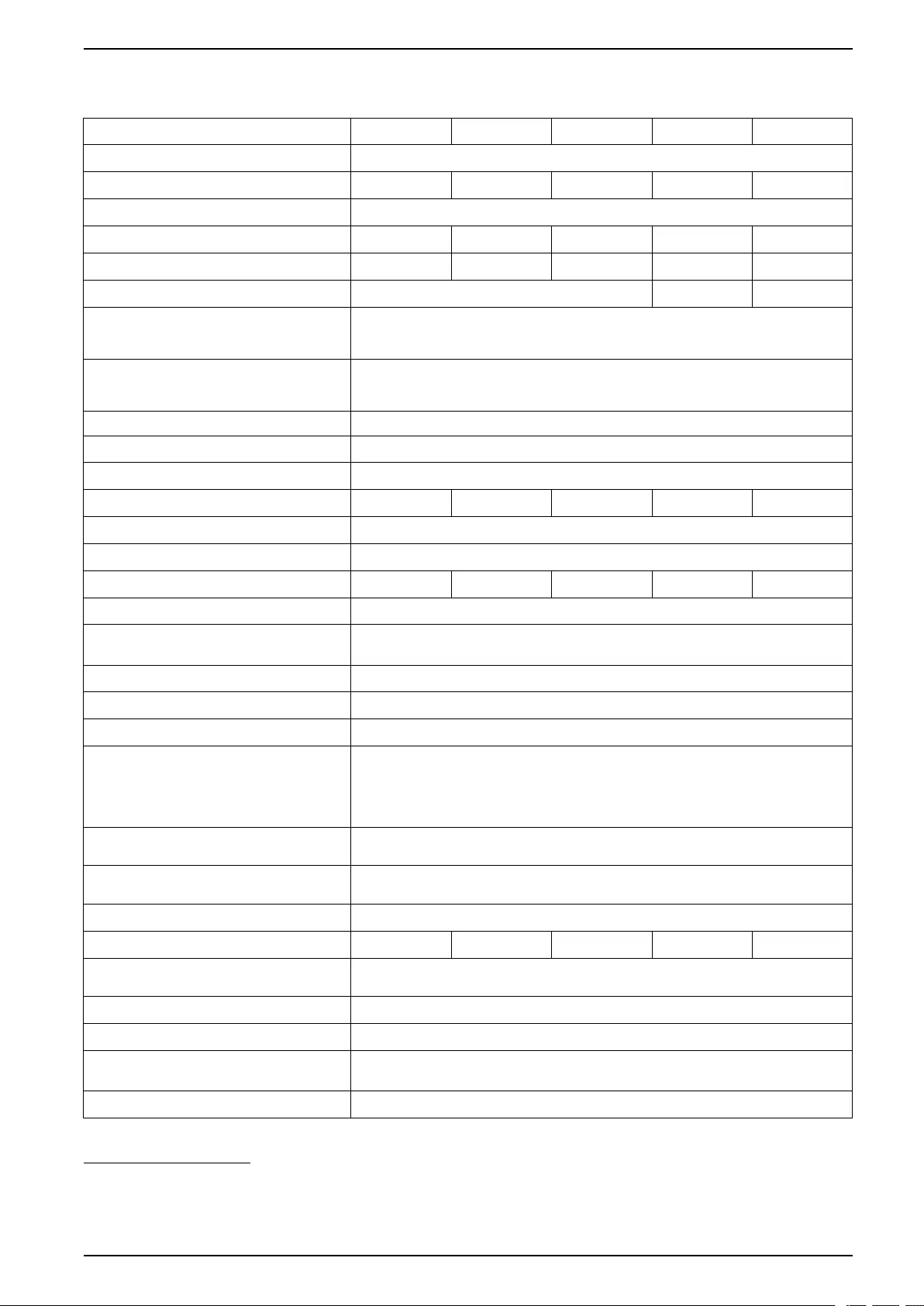

Specifications for 750 kW UPS

Voltage (V) 380 400 415 440 480

Connections 3–wire (L1, L2, L3, PE)6

Input voltage range (V)7340-456 340-480 353-498 374-528 408-576

Frequency (Hz) 40 – 70

Nominal input current (A) 1201 1139 1097 1029 950

Maximum input current (A)81328 1276 1229 1153 1092

Input current limitation (A) 1335 1248 1140

Total harmonic distortion (THDI) <3% at 100% load

<4% at 50% load

<9% at 25% load

Input power factor 0.99 at >40% load

0.98 at >20% load

0.97 at >10% load

Protection Contactors

Ramp-in Adaptive 1 – 40 secs

Connections 4–wire (L1, L2, L3, N, PE) or 3–wire (L1, L2, L3, PE)6

Bypass voltage range (V) 342-418 360-440 374-457 396-484 432-528

Frequency (Hz) 50 or 60

Frequency range (Hz) Programmable: +/-0.1, +/-3, +/-10. Default is +/-3.

Nominal bypass current (A) 1151 1093 1054 994 909

Maximum short circuit rating 100 kA RMS9

Thyristor I²t (kA*s²) 722010 for systems with 1000 kW I/O cabinet

1624510 for systems with 1500 kW I/O cabinet

BF2 magnetic trip 39 kA

Protection Molded switch with trip for backfeed protection

Connections 4–wire (L1, L2, L3, N, PE) or 3–wire (L1, L2, L3, PE)

Overload capacity 150% for 1 minute (normal operation)

125% for 10 minutes (normal operation)

115% for 1 minute (battery operation)

110% continuous (bypass operation)

1000% for 100 milliseconds (bypass operation)

Output voltage tolerance Balanced load: +/- 1%

Unbalanced load: +/- 3%

Dynamic load response +/- 5% after 2 ms

+/- 1% after 50 ms

Output power factor 1

Nominal output current (A) 1140 1083 1043 984 902

Total harmonic distortion (THDU) <2% at 100% linear load

<3% at 100% non–linear load

Output frequency (Hz) 50/60 (synchronized to bypass), 50/60 Hz +/-0.1% (free-running)

Slew rate (Hz/sec) Programmable: 0.25, 0.5, 1, 2, 4, 6

Output performance classification (according

to IEC/ EN62040-3)

Double-conversion: VFI-SS-111

Load crest factor Up to 3 (THDU < 5%)

990-5783E-001 13

6. TN, TT, and IT power distribution systems are supported. Corner (line) grounding is not supported.

7. The system can operate at 600 V for 1 minute.

8. At nominal input voltage and full charge.

9. Conditioned by the internal molded switch with a 90 kA peak magnetic trip

10. If this value is exceeded, the thyristors can short.

UPS with 1500 kW I/O Cabinet Specifications for 380, 400, 415, and 440 V Systems

Voltage (V) 380 400 415 440 480

Load power factor 0.7 leading to 0.5 lagging without derating

Charging power in % of output power 35% at ≤ 80% load

12% at 100% load

Maximum charging power (kW) 90 at 100% load

262 at <80% load

Nominal battery voltage (VDC) 480

Nominal float voltage (VDC) 546

End of discharge voltage (full load) (VDC) 384

End of discharge voltage (no load) (VDC) 420

Battery current at full load and nominal battery

voltage (A)

1634 1634 1634 1634 1634

Battery current at full load and minimum

battery voltage (A)

2043 2043 2043 2043 2043

Maximum battery backup time Unlimited

Temperature compensation (per cell) -3.3 mV per °C for T ≥ 25 °C

0 mV per °C for T < 25 °C

Ripple current < 5% C20 (5 minutes backup time)

Battery test Manual/automatic (selectable)

Deep discharge protection Yes

Recharge according to battery temperature Yes

Heat Dissipation (BTU/hr) for 750 kW UPS

Normal Operation ECO Mode

Load 380 V 400 V 415 V 440 V 380 V 400 V 415 V 440 V

25% 26656 25271 25271 25271 9084 9084 9084 9413

50% 51926 49160 49160 47782 12924 12924 12924 12272

75% 86236 82053 82053 77888 17430 17430 17430 16453

100% 134684 129025 129025 117778 23240 23240 23240 21938

ECOnversion Battery Operation

Load 380 V 400 V 415 V 440 V 380 V 400 V 415 V 440 V

25% 9742 9742 9742 10733 27351 27351 27351 27351

50% 12924 12924 12924 12924 47782 47782 47782 47782

75% 17430 17430 17430 16453 79969 79969 79969 79969

100% 23240 23240 23240 21938 117778 117778 117778 117778

14 990-5783E-001

Specifications for 380, 400, 415, and 440 V Systems UPS with 1500 kW I/O Cabinet

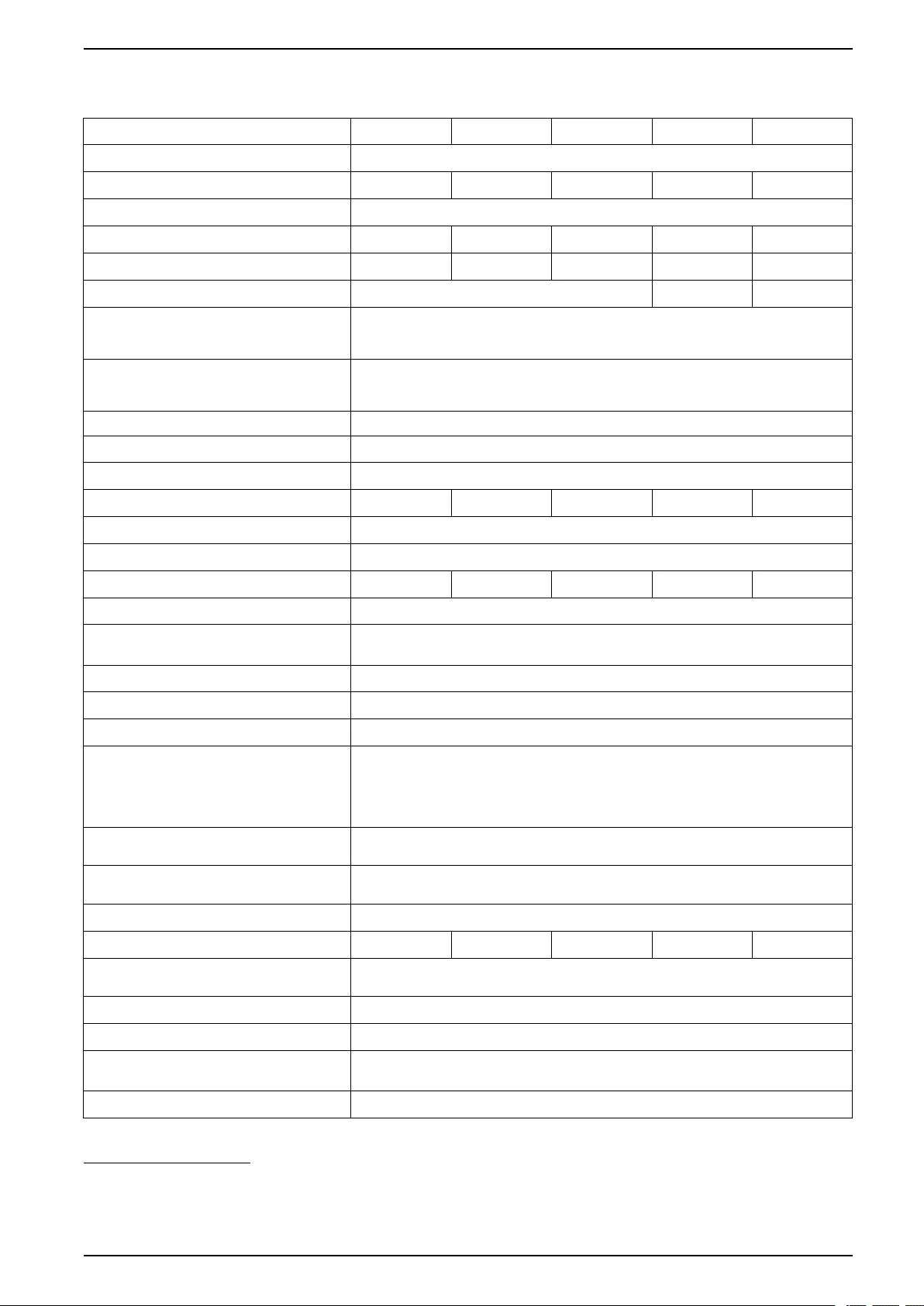

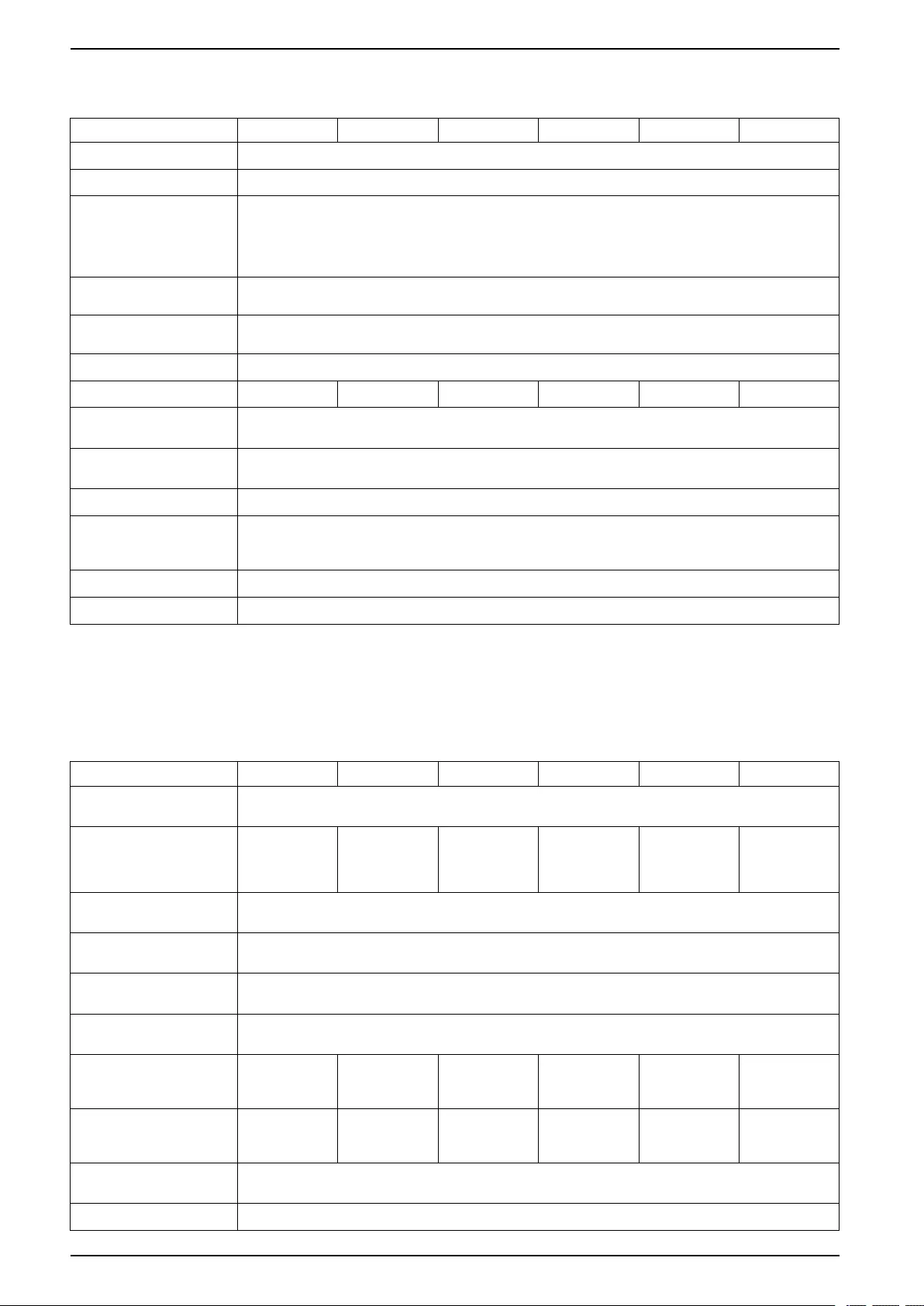

Specifications for 1000 kW UPS

Voltage (V) 380 400 415 440 480

Connections 3–wire (L1, L2, L3, PE)11

Input voltage range (V)12 340-456 340-480 353-498 374-528 408-576

Frequency (Hz) 40 – 70

Nominal input current (A) 1601 1519 1463 1370 1266

Maximum input current (A)13 1771 1702 1638 1534 1456

Input current limitation (A) 1780 1664 1520

Total harmonic distortion (THDI) <3% at 100% load

<4% at 50% load

<9% at 25% load

Input power factor 0.99 at >40% load

0.98 at >20% load

0.97 at >10% load

Protection Contactors

Ramp-in Adaptive 1 – 40 secs

Connections 4–wire (L1, L2, L3, N, PE) or 3–wire (L1, L2, L3, PE)11

Bypass voltage range (V) 342-418 360-440 374-457 396-484 432-528

Frequency (Hz) 50 or 60

Frequency range (Hz) Programmable: +/-0.1, +/-3, +/-10. Default is +/-3.

Nominal bypass current (A) 1535 1458 1405 1325 1211

Maximum short circuit rating 100 kA RMS14

Thyristor I²t (kA*s²) 722015 for systems with 1000 kW I/O cabinet

1624515 for systems with 1500 kW I/O cabinet

BF2 magnetic trip 39 kA

Protection Molded switch with trip for backfeed protection

Connections 4–wire (L1, L2, L3, N, PE) or 3–wire (L1, L2, L3, PE)

Overload capacity 150% for 1 minute (normal operation)

125% for 10 minutes (normal operation)

115% for 1 minute (battery operation)

110% continuous (bypass operation)

1000% for 100 milliseconds (bypass operation)

Output voltage tolerance Balanced load: +/- 1%

Unbalanced load: +/- 3%

Dynamic load response +/- 5% after 2 ms

+/- 1% after 50 ms

Output power factor 1

Nominal output current (A) 1519 1443 1391 1312 1203

Total harmonic distortion (THDU) <2% at 100% linear load

<3% at 100% non–linear load

Output frequency (Hz) 50/60 (synchronized to bypass), 50/60 Hz +/-0.1% (free-running)

Slew rate (Hz/sec) Programmable: 0.25, 0.5, 1, 2, 4, 6

Output performance classification (according

to IEC/ EN62040-3)

Double-conversion: VFI-SS-111

Load crest factor Up to 3 (THDU < 5%)

990-5783E-001 15

11. TN, TT, and IT power distribution systems are supported. Corner (line) grounding is not supported.

12. The system can operate at 600 V for 1 minute.

13. At nominal input voltage and full charge.

14. Conditioned by the internal molded switch with a 90 kA peak magnetic trip

15. If this value is exceeded, the thyristors can short.

UPS with 1500 kW I/O Cabinet Specifications for 380, 400, 415, and 440 V Systems

Voltage (V) 380 400 415 440 480

Load power factor 0.7 leading to 0.5 lagging without derating

Charging power in % of output power 35% at ≤ 80% load

12% at 100% load

Maximum charging power (kW) 120 at 100% load

350 at <80% load

Nominal battery voltage (VDC) 480

Nominal float voltage (VDC) 546

End of discharge voltage (full load) (VDC) 384

End of discharge voltage (no load) (VDC) 420

Battery current at full load and nominal battery

voltage (A)

2179 2179 2179 2179 2179

Battery current at full load and minimum

battery voltage (A)

2724 2724 2724 2724 2724

Maximum battery backup time Unlimited

Temperature compensation (per cell) -3.3 mV per °C for T ≥ 25 °C

0 mV per °C for T < 25 °C

Ripple current < 5% C20 (5 minutes backup time)

Battery test Manual/automatic (selectable)

Deep discharge protection Yes

Recharge according to battery temperature Yes

Heat Dissipation (BTU/hr) for 1000 kW UPS

Normal Operation ECO Mode

Load 380 V 400 V 415 V 440 V 380 V 400 V 415 V 440 V

25% 36468 34617 34617 33888 12112 12112 12112 12112

50% 71083 67389 67389 60137 17232 17232 17232 16362

75% 123390 117778 117778 98514 23240 23240 23240 21938

100% 187156 179579 179579 149141 30987 30987 30987 29251

ECOnversion Battery Operation

Load 380 V 400 V 415 V 440 V 380 V 400 V 415 V 440 V

25% 13334 13334 13334 14313 36468 35819 36468 36468

50% 17254 17254 17254 16956 63710 62976 63710 63710

75% 24358 24358 24358 22496 106625 104128 106625 106625

100% 31342 31342 31342 29428 157038 156664 157038 157038

16 990-5783E-001

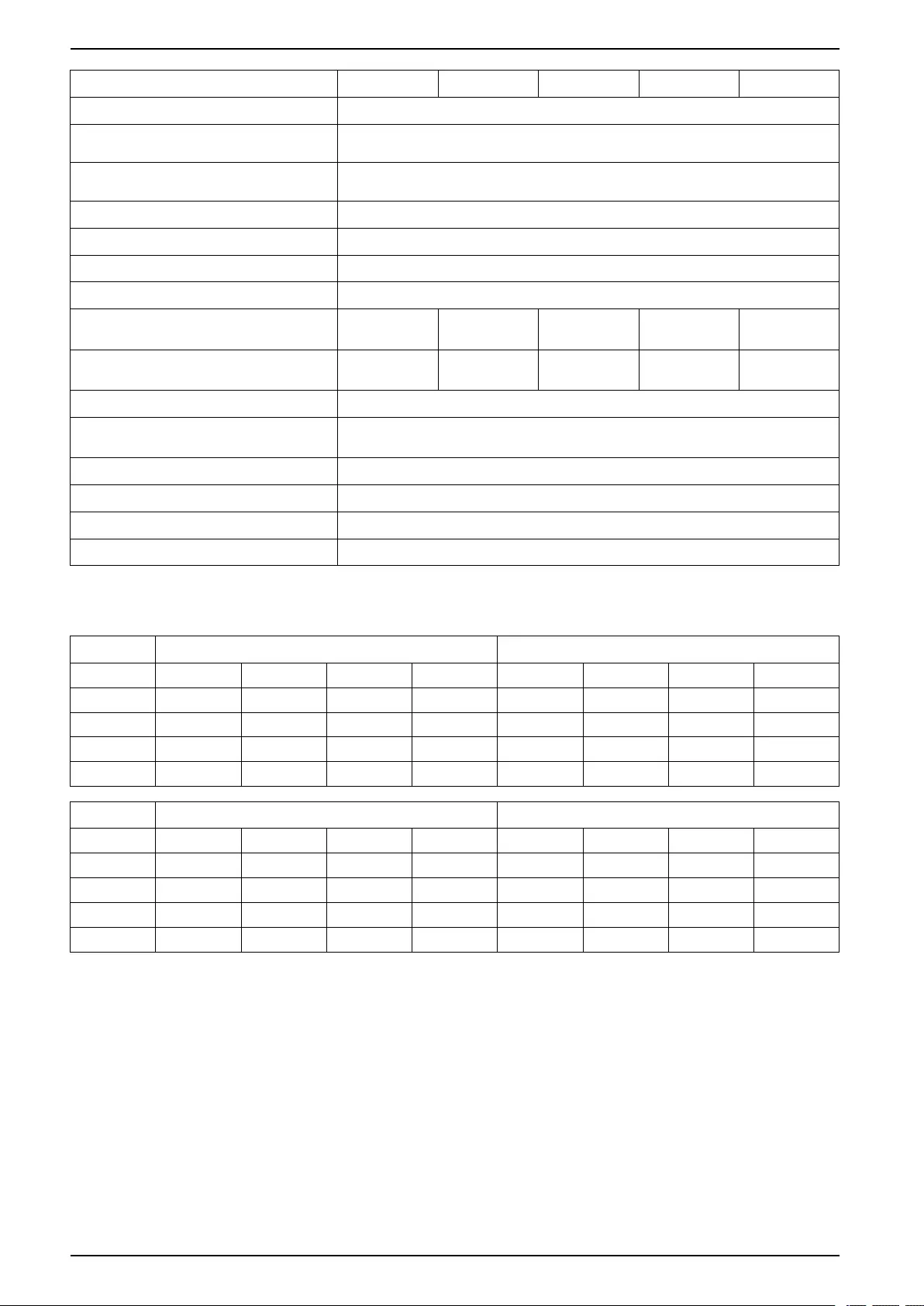

Specifications for 380, 400, 415, and 440 V Systems UPS with 1500 kW I/O Cabinet

Specifications for 1100 kW UPS

Voltage (V) 380 400 415 440 480

Connections 3–wire (L1, L2, L3, PE)16

Input voltage range (V)17 340-456 340-480 353-498 374-528 408-576

Frequency (Hz) 40 – 70

Nominal input current (A) 1761 1671 1609 1510 1393

Maximum input current (A)18 1948 1872 1802 1691 1602

Input current limitation (A) 1958 1830 1672

Total harmonic distortion (THDI) <3% at 100% load

<4% at 50% load

<9% at 25% load

Input power factor 0.99 at >40% load

0.98 at >20% load

0.97 at >10% load

Protection Contactors

Ramp-in Adaptive 1 – 40 secs

Connections 4–wire (L1, L2, L3, N, PE) or 3–wire (L1, L2, L3, PE)16

Bypass voltage range (V) 342-418 360-440 374-457 396-484 432-528

Frequency (Hz) 50 or 60

Frequency range (Hz) Programmable: +/-0.1, +/-3, +/-10. Default is +/-3.

Nominal bypass current (A) 1688 1604 1546 1458 1332

Maximum short circuit rating 100 kA RMS19

Thyristor I²t (kA*s²) 722020 for systems with 1000 kW I/O cabinet

1624520 for systems with 1500 kW I/O cabinet

BF2 magnetic trip 39 kA

Protection Molded switch with trip for backfeed protection

Connections 4–wire (L1, L2, L3, N, PE) or 3–wire (L1, L2, L3, PE)

Overload capacity 150% for 1 minute (normal operation)

125% for 10 minutes (normal operation)

115% for 1 minute (battery operation)

110% continuous (bypass operation)

1000% for 100 milliseconds (bypass operation)

Output voltage tolerance Balanced load: +/- 1%

Unbalanced load: +/- 3%

Dynamic load response +/- 5% after 2 ms

+/- 1% after 50 ms

Output power factor 1

Nominal output current (A) 1671 1588 1530 1443 1323

Total harmonic distortion (THDU) <2% at 100% linear load

<3% at 100% non–linear load

Output frequency (Hz) 50/60 (synchronized to bypass), 50/60 Hz +/-0.1% (free-running)

Slew rate (Hz/sec) Programmable: 0.25, 0.5, 1, 2, 4, 6

Output performance classification (according

to IEC/ EN62040-3)

Double-conversion: VFI-SS-111

Load crest factor Up to 3 (THDU < 5%)

990-5783E-001 17

16. TN, TT, and IT power distribution systems are supported. Corner (line) grounding is not supported.

17. The system can operate at 600 V for 1 minute.

18. At nominal input voltage and full charge.

19. Conditioned by the internal molded switch with a 90 kA peak magnetic trip

20. If this value is exceeded, the thyristors can short.

UPS with 1500 kW I/O Cabinet Specifications for 380, 400, 415, and 440 V Systems

Voltage (V) 380 400 415 440 480

Load power factor 0.7 leading to 0.5 lagging without derating

Charging power in % of output power 35% at ≤ 80% load

12% at 100% load

Maximum charging power (kW) 132 at 100% load

385 at <80% load

Nominal battery voltage (VDC) 480

Nominal float voltage (VDC) 546

End of discharge voltage (full load) (VDC) 384

End of discharge voltage (no load) (VDC) 420

Battery current at full load and nominal battery

voltage (A)

2397

Battery current at full load and minimum

battery voltage (A)

2996

Maximum battery backup time Unlimited

Temperature compensation (per cell) -3.3 mV per °C for T ≥ 25 °C

0 mV per °C for T < 25 °C

Ripple current < 5% C20 (5 minutes backup time)

Battery test Manual/automatic (selectable)

Deep discharge protection Yes

Recharge according to battery temperature Yes

Heat Dissipation (BTU/hr) for 1100 kW UPS

Normal Operation ECO Mode

Load 380 V 400 V 415 V 440 V 380 V 400 V 415 V 440 V

25% 44213 42160 42160 42160 11396 11396 11396 11877

50% 78192 74128 74128 70080 17043 17043 17043 16088

75% 108153 102095 102095 100584 22701 22701 22701 21271

100% 152315 144204 144204 150284 26458 26458 26458 26458

ECOnversion Battery Operation

Load 380 V 400 V 415 V 440 V 380 V 400 V 415 V 440 V

25% 13701 13701 13701 15272 40115 40115 40115 40115

50% 17067 17067 17067 17683 70080 70080 70080 70080

75% 23928 23928 23928 22957 117288 117288 117288 117288

100% 30658 30658 30658 28556 172741 172741 172741 172741

18 990-5783E-001

Specifications for 380, 400, 415, and 440 V Systems UPS with 1500 kW I/O Cabinet

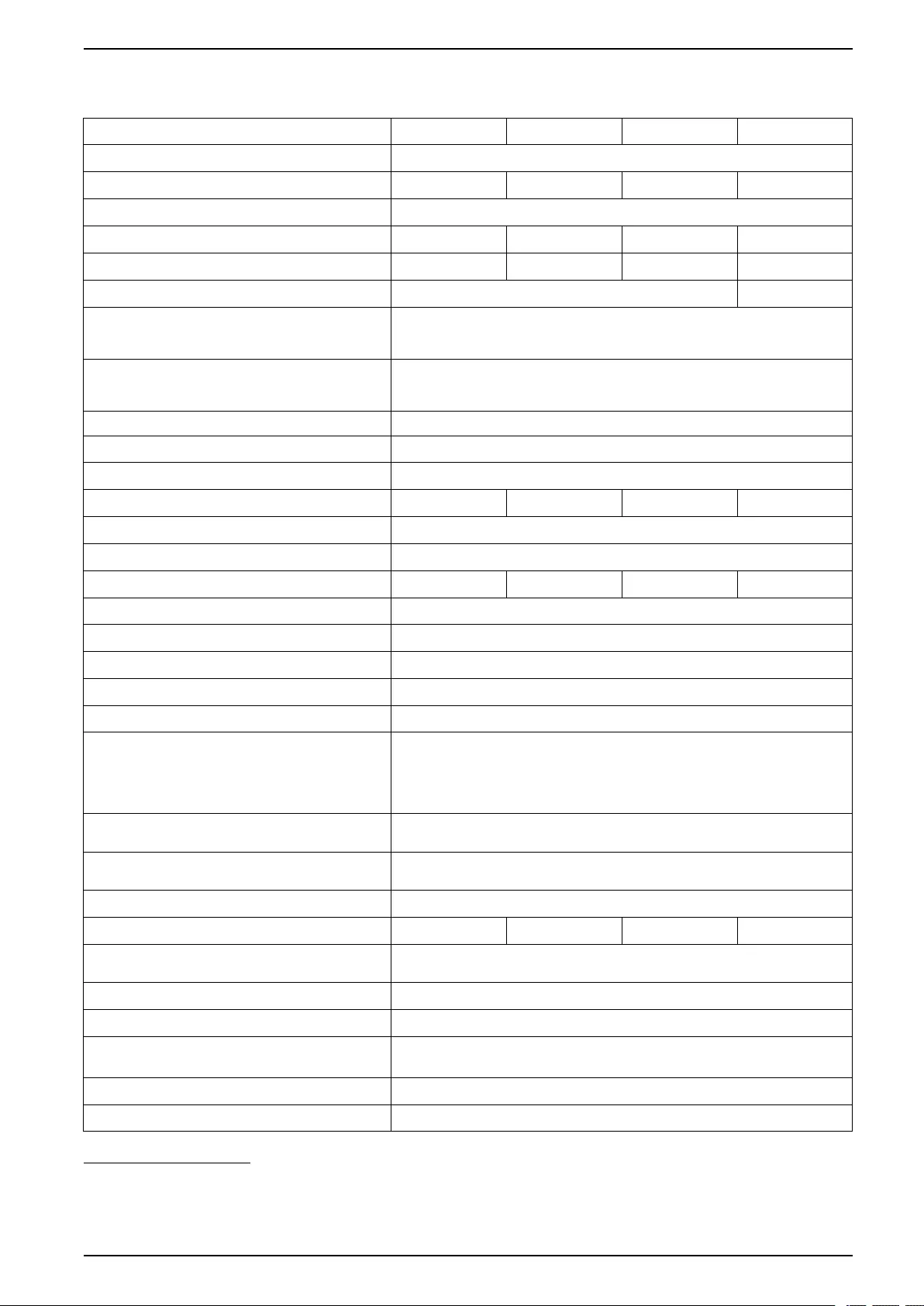

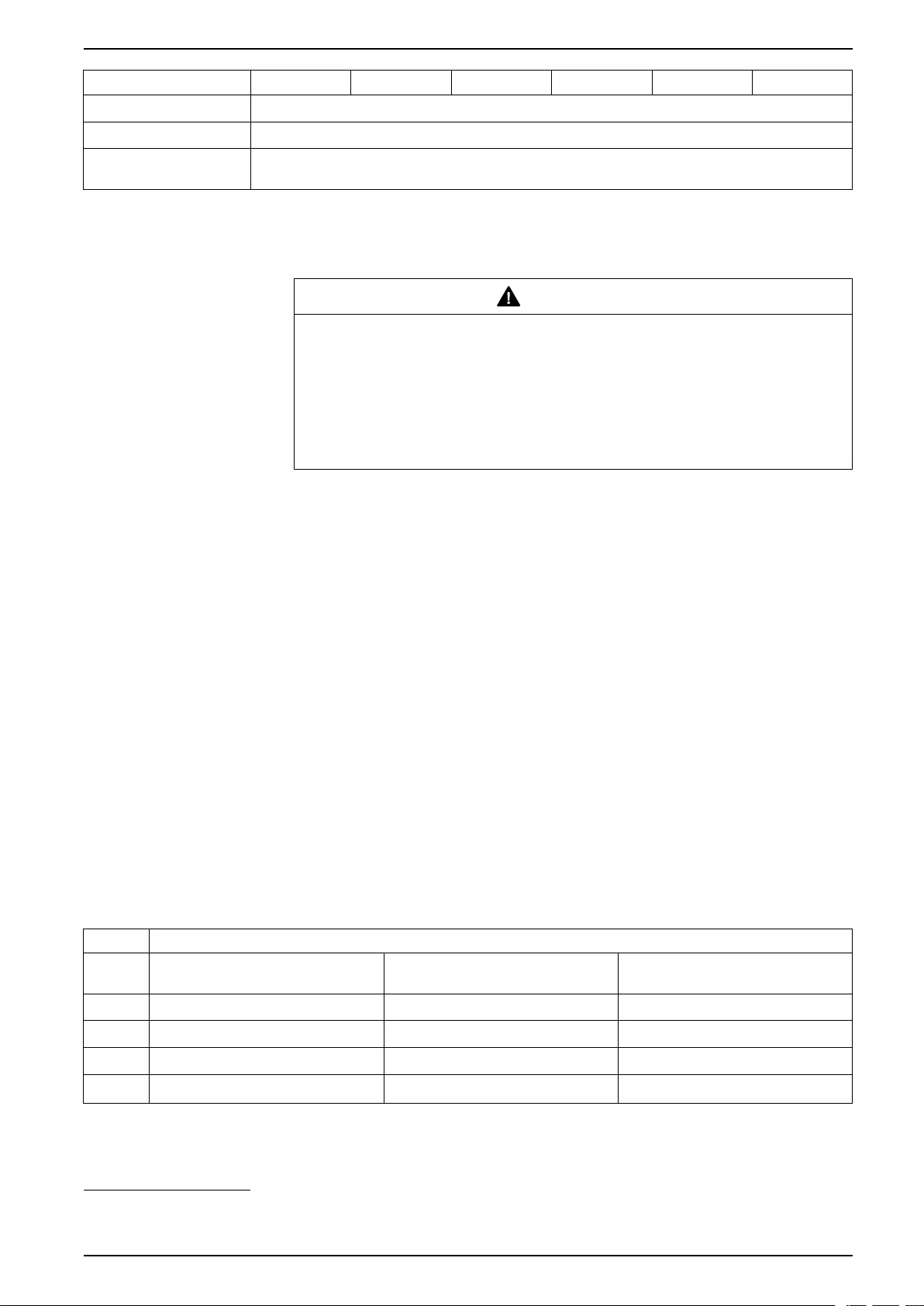

Specifications for 1250 kW UPS

Voltage (V) 380 400 415 440

Connections 3–wire (L1, L2, L3, PE)21

Input voltage range (V)22 340-456 340-480 353-498 374-528

Frequency (Hz) 40 – 70

Nominal input current (A) 2001 1899 1828 1716

Maximum input current (A)23 2214 2127 2048 1922

Input current limitation (A) 2225 2080

Total harmonic distortion (THDI) <3% at 100% load

<4% at 50% load

<9% at 25% load

Input power factor 0.99 at >40% load

0.98 at >20% load

0.97 at >10% load

Protection Contactors

Ramp-in Adaptive 1 – 40 secs

Connections 4–wire (L1, L2, L3, N, PE) or 3–wire (L1, L2, L3, PE)21

Bypass voltage range (V) 342-418 360-440 374-457 396-484

Frequency (Hz) 50 or 60

Frequency range (Hz) Programmable: +/-0.1, +/-3, +/-10. Default is +/-3.

Nominal bypass current (A) 1918 1822 1757 1657

Maximum short circuit rating 100 kA RMS24

Thyristor I²t (kA*s²) 1624525

BF2 magnetic trip 39 kA

Protection Molded switch with trip for backfeed protection

Connections 4–wire (L1, L2, L3, N, PE) or 3–wire (L1, L2, L3, PE)

Overload capacity 150% for 1 minute (normal operation)

125% for 10 minutes (normal operation)

115% for 1 minute (battery operation)

110% continuous (bypass operation)

1000% for 100 milliseconds (bypass operation)

Output voltage tolerance Balanced load: +/- 1%

Unbalanced load: +/- 3%

Dynamic load response +/- 5% after 2 ms

+/- 1% after 50 ms

Output power factor 1

Nominal output current (A) 1899 1804 1739 1640

Total harmonic distortion (THDU) <2% at 100% linear load

<3% at 100% non–linear load

Output frequency (Hz) 50/60 (synchronized to bypass), 50/60 Hz +/-0.1% (free-running)

Slew rate (Hz/sec) Programmable: 0.25, 0.5, 1, 2, 4, 6

Output performance classification (according to IEC/

EN62040-3)

Double-conversion: VFI-SS-111

Load crest factor Up to 3 (THDU < 5%)

Load power factor 0.7 leading to 0.5 lagging without derating

990-5783E-001 19

21. TN, TT, and IT power distribution systems with no earthed line conductors are supported.

22. The system can operate at 600 V for 1 minute.

23. At nominal input voltage and full charge.

24. Conditioned by the internal molded switch with a 90 kA peak magnetic trip

25. If this value is exceeded, the thyristors can short.

UPS with 1500 kW I/O Cabinet Specifications for 380, 400, 415, and 440 V Systems

Voltage (V) 380 400 415 440

Charging power in % of output power 35% at ≤ 80% load

12% at 100% load

Maximum charging power (kW) 150 at 100% load

437 at <80% load

Nominal battery voltage (VDC) 480

Nominal float voltage (VDC) 546

End of discharge voltage (full load) (VDC) 384

End of discharge voltage (no load) (VDC) 420

Battery current at full load and nominal battery

voltage (A)

2724 2724 2724 2724

Battery current at full load and minimum battery

voltage (A)

3405 3405 3405 3405

Maximum battery backup time 1 hour

Temperature compensation (per cell) -3.3 mV per °C for T ≥ 25 °C

0 mV per °C for T < 25 °C

Ripple current < 5% C20 (5 minutes backup time)

Battery test Manual/automatic (selectable)

Deep discharge protection Yes

Recharge according to battery temperature Yes

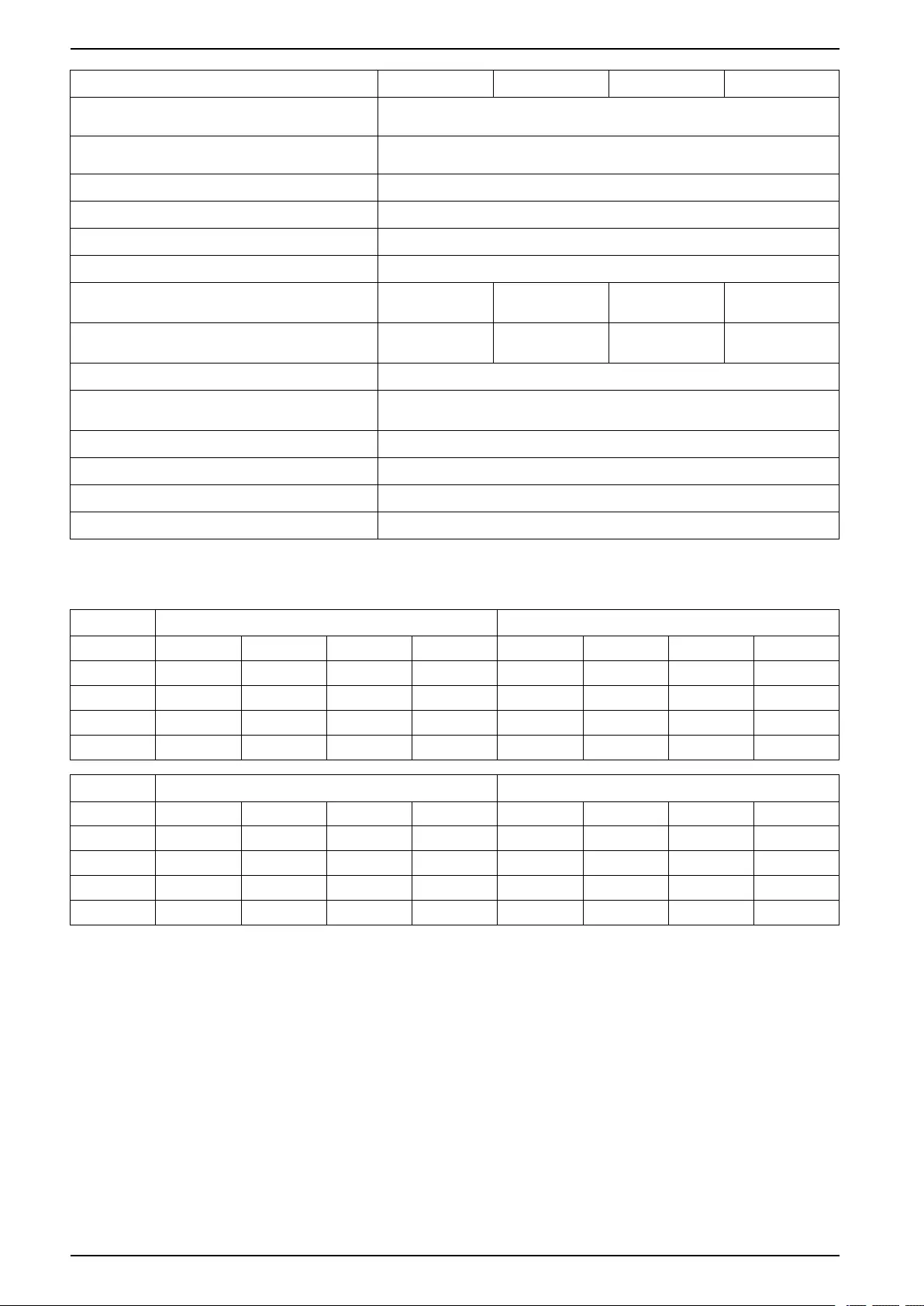

Heat Dissipation (BTU/hr) for 1250 kW UPS

Normal Operation ECO Mode

Load 380 V 400 V 415 V 440 V 380 V 400 V 415 V 440 V

25% 44427 42118 42118 42118 12950 12950 12950 13497

50% 86543 81934 81934 78490 19367 19367 19367 18282

75% 147223 140237 140237 129814 25796 25796 25796 24172

100% 224474 215042 215042 196297 30065 30065 30065 30065

ECOnversion Battery Operation

Load 380 V 400 V 415 V 440 V 380 V 400 V 415 V 440 V

25% 15569 15569 15569 17156 45585 45585 45585 45585

50% 19394 19394 19394 19721 79637 79637 79637 79637

75% 27191 27191 27191 25681 133281 133281 133281 133281

100% 34838 34838 34838 32451 196297 196297 196297 196297

20 990-5783E-001

Specifications for 380, 400, 415, and 440 V Systems UPS with 1500 kW I/O Cabinet

Specifications for 1500 kW UPS

Voltage (V) 380 400 415 440

Connections 3–wire (L1, L2, L3, PE)26

Input voltage range (V)27 340-456 340-480 353-498 374-528

Frequency (Hz) 40 – 70

Nominal input current (A) 2401 2279 2194 2059

Maximum input current (A)28 2657 2552 2457 2306

Input current limitation (A) 2670 2496

Total harmonic distortion (THDI) <3% at 100% load

<4% at 50% load

<9% at 25% load

Input power factor 0.99 at >40% load

0.98 at >20% load

0.97 at >10% load

Protection Contactors

Ramp-in Adaptive 1 – 40 secs

Connections 4–wire (L1, L2, L3, N, PE) or 3–wire (L1, L2, L3, PE)26

Bypass voltage range (V) 342-418 360-440 374-457 396-484

Frequency (Hz) 50 or 60

Frequency range (Hz) Programmable: +/-0.1, +/-3, +/-10. Default is +/-3.

Nominal bypass current (A) 2302 2187 2108 1988

Maximum short circuit rating 100 kA RMS29

Thyristor I²t (kA*s²) 1624530

BF2 magnetic trip 39 kA

Protection Molded switch with trip for backfeed protection

Connections 4–wire (L1, L2, L3, N, PE) or 3–wire (L1, L2, L3, PE)

Overload capacity 150% for 1 minute (normal operation)

125% for 10 minutes (normal operation)

115% for 1 minute (battery operation)

110% continuous (bypass operation)

1000% for 100 milliseconds (bypass operation)

Output voltage tolerance Balanced load: +/- 1%

Unbalanced load: +/- 3%

Dynamic load response +/- 5% after 2 ms

+/- 1% after 50 ms

Output power factor 1

Nominal output current (A) 2279 2165 2087 1968

Total harmonic distortion (THDU) <2% at 100% linear load

<3% at 100% non–linear load

Output frequency (Hz) 50/60 (synchronized to bypass), 50/60 Hz +/-0.1% (free-running)

Slew rate (Hz/sec) Programmable: 0.25, 0.5, 1, 2, 4, 6

Output performance classification (according to IEC/

EN62040-3)

Double-conversion: VFI-SS-111

Load crest factor Up to 3 (THDU < 5%)

Load power factor 0.7 leading to 0.5 lagging without derating

990-5783E-001 21

26. TN, TT, and IT power distribution systems with no earthed line conductors are supported.

27. The system can operate at 600 V for 1 minute.

28. At nominal input voltage and full charge.

29. Conditioned by the internal molded switch with a 90 kA peak magnetic trip

30. If this value is exceeded, the thyristors can short.

UPS with 1500 kW I/O Cabinet Specifications for 380, 400, 415, and 440 V Systems

Voltage (V) 380 400 415 440

Charging power in % of output power 35% at ≤ 80% load

12% at 100% load

Maximum charging power (kW) 180 at 100% load

525 at < 80% load

Nominal battery voltage (VDC) 480

Nominal float voltage (VDC) 546

End of discharge voltage (full load) (VDC) 384

End of discharge voltage (no load) (VDC) 420

Battery current at full load and nominal battery

voltage (A)

3269 3269 3269 3269

Battery current at full load and minimum battery

voltage (A)

4086 4086 4086 4086

Maximum battery backup time 1 hour

Temperature compensation (per cell) -3.3 mV per °C for T ≥ 25 °C

0 mV per °C for T < 25 °C

Ripple current < 5% C20 (5 minutes backup time)

Battery test Manual/automatic (selectable)

Deep discharge protection Yes

Recharge according to battery temperature Yes

Heat Dissipation (BTU/hr) for 1500 kW UPS

Normal Operation ECO Mode

Load 380 V 400 V 415 V 440 V 380 V 400 V 415 V 440 V

25% 53313 50542 50542 50680 15540 15540 15540 16131

50% 103851 98321 98321 91275 23240 23240 23240 21626

75% 176667 168285 168285 151832 30956 30956 30956 28889

100% 269368 258050 258050 234549 36079 36079 36079 37428

ECOnversion Battery Operation

Load 380 V 400 V 415 V 440 V 380 V 400 V 415 V 440 V

25% 18683 18683 18683 17234 54702 51372 54702 54702

50% 23273 23273 23273 20325 95564 95014 95564 95564

75% 32629 32629 32629 26436 159938 159521 159938 159938

100% 41806 41806 41806 35819 235556 236677 235556 235556

22 990-5783E-001

Specifications for 380, 400, 415, and 440 V Systems UPS with 1500 kW I/O Cabinet

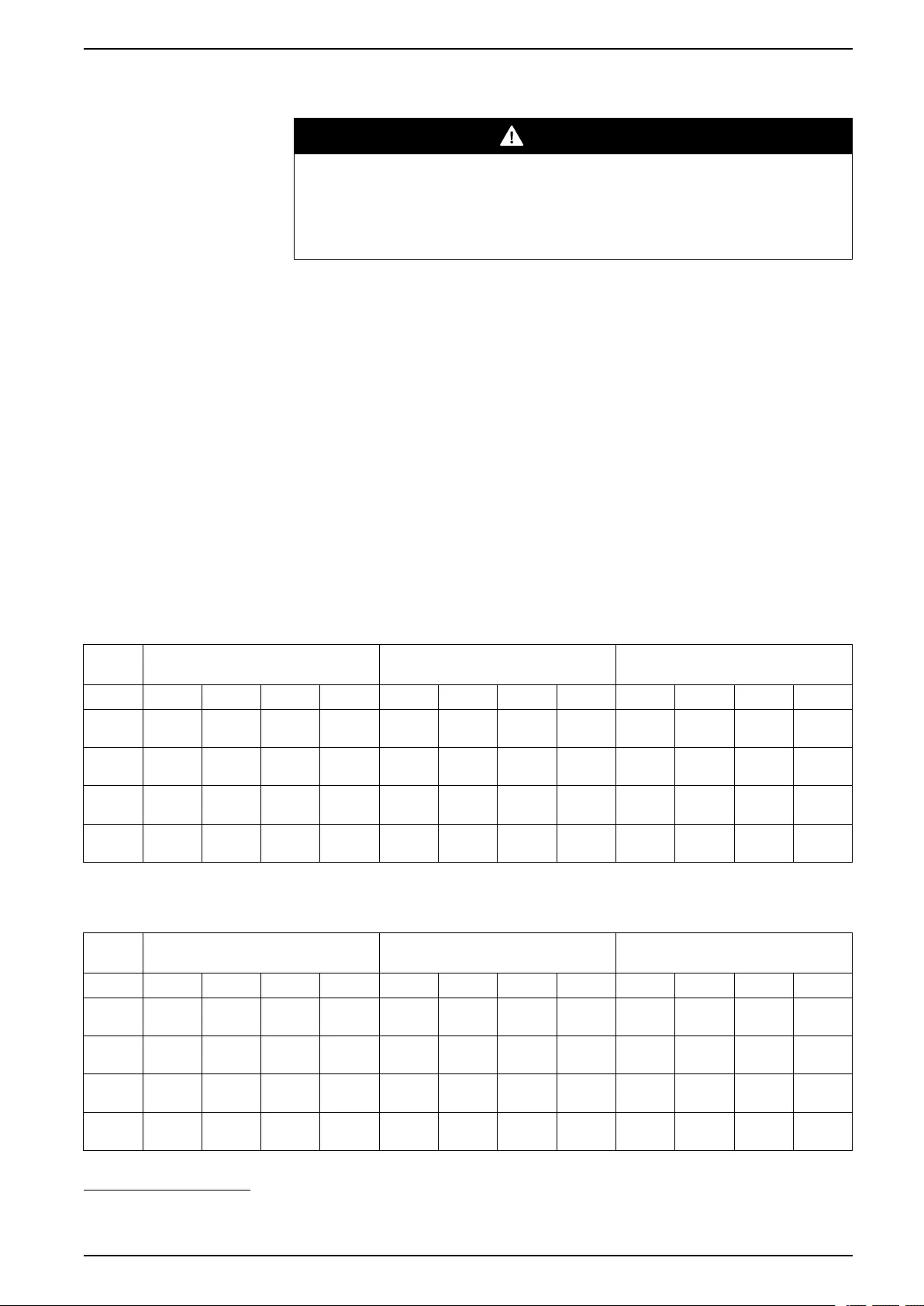

Recommended Upstream Protection and Cable Sizes

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

A readily accessible breaker is required for upstream protection. Maximum fault

current disconnection time: 46 seconds at 200% input.

Failure to follow these instructions will result in death or serious injury.

NOTE: Overcurrent protection is to be provided by others.

Cable sizes in this manual are based on table B.52.12 and B.52.13 of IEC 60364–

5–52 with the following assertions:

• 90 °C conductors

• An ambient temperature of 30 °C

• Use of copper or aluminium conductors

• Installation method F4 for DC cables and installation method F5 for AC

cables, corrected for single layer in perforated cable tray.

PE cables are sized in accordance with IEC 60364-5-54 table 54.2 Minimum

cross-sectional area of protective conductors.

NOTE: Alwasy consider the PE size according to the complete electrical

installation.

If the ambient temperature is greater than 30 °C, larger conductors are to be

selected in accordance with the correction factors of the IEC.

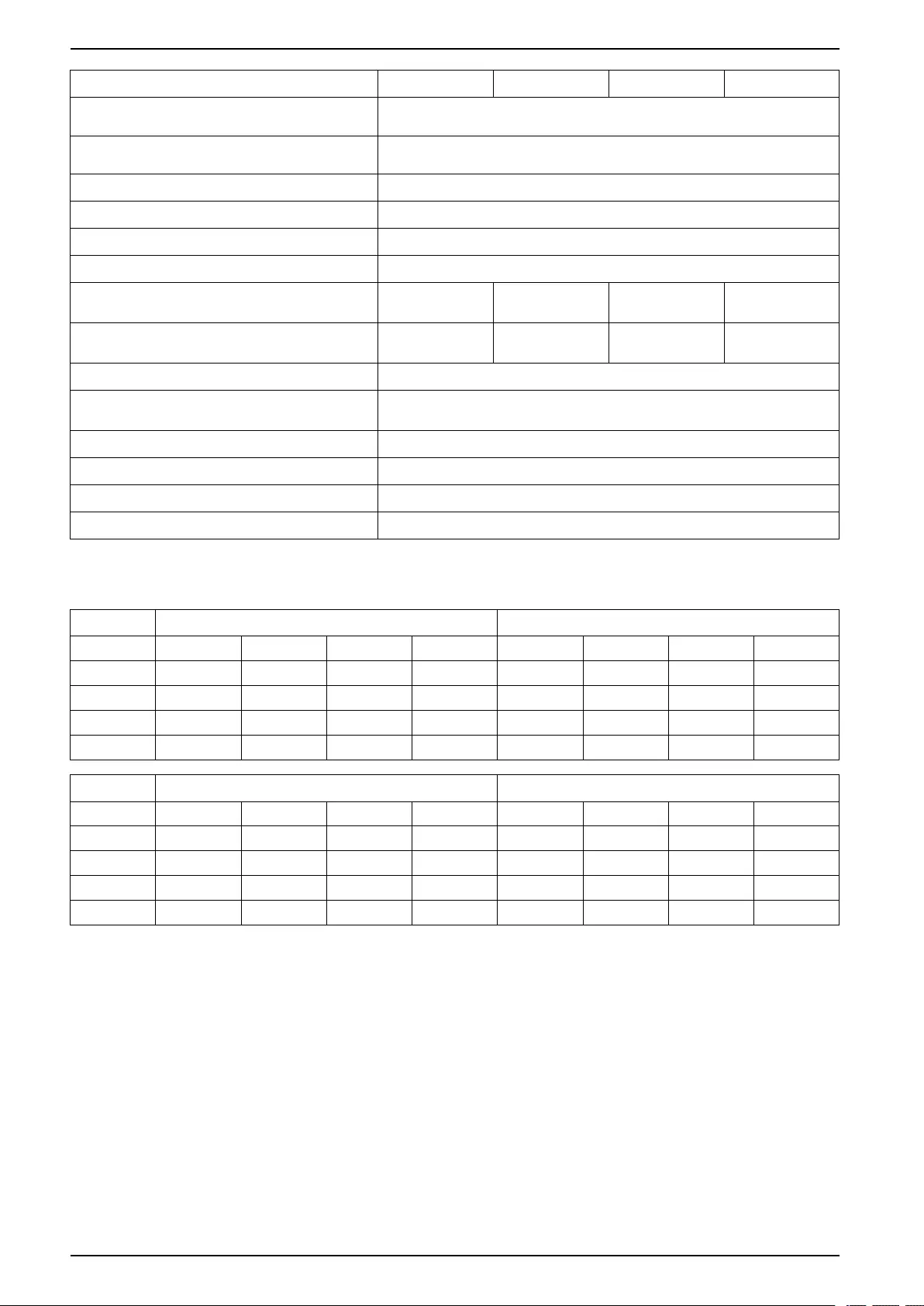

Recommended Upstream Protection and Cable Sizes for 1100 kW UPS

Maximum OCPD (A) Conductors per Phase Copper/

Aluminium (mm²)

PE Conductor (mm²)

380 V 400 V 415 V 440 V 380 V 400 V 415 V 440 V 380 V 400 V 415 V 440 V

Input 200031 200031 200031 200032 5x240/

6x240

5x240/

6x240

5x240/

6x240

5x185/

6x240

3x240/

3x240

3x240/

3x240

3x240/

3x240

3x185/

3x240

Bypass 200033 200033 160031 160032 4x240/

6x240

4x240/

6x240

4x185/

5x240

4x185/

5x240

2x240/

3x240

2x240/

3x240

2x185

3x240

2x185/

3x240

Output 200033 200033 160031 160032 4x240/

6x240

4x240/

6x240

4x185/

5x240

4x185/

5x240

2x240/

3x240

2x240/

3x240

2x185

3x240

2x185/

3x240

Battery 4000 4000 4000 4000 6x240/

8x240

6x240/

8x240

6x240/

8x240

6x240/

8x240

3x240/

4x240

3x240/

4x240

3x240/

4x240

3x240/

4x240

Recommended Upstream Protection and Cable Sizes for 1250 kW UPS

Maximum OCPD (A) Conductors per Phase Copper/

Aluminium (mm²)

PE Conductor (mm²)

380 V 400 V 415 V 440 V 380 V 400 V 415 V 440 V 380 V 400 V 415 V 440 V

Input 250033 250033 250033 250033 5x240/

7x240

5x240/

7x240

5x240/

7x240

5x240/

7x240

3x240/

4x240

3x240/

4x240

3x240/

4x240

3x240/

4x240

Bypass 200031 200032 200033 200033 5x240/

6x240

5x185/

6x240

4x240/

6x240

4x240/

6x240

3x240/

3x240

3x185/

3x240

2x240/

3x240

2x240/

3x240

Output 200031 200032 200033 200033 5x240/

6x240

5x185/

6x240

4x240/

6x240

4x240/

6x240

3x240/

3x240

3x185/

3x240

2x240/

3x240

2x240/

3x240

Battery 4000 4000 4000 4000 7x240/

9x240

7x240/

9x240

7x240/

9x240

7x240/

9x240

4x240/

5x240

4x240/

5x240

4x240/

5x240

4x240/

5x240

990-5783E-001 23

31. Long-time setting (Ir) = 0.98.

32. Long-time setting (Ir) = 0.95.

33. Long-time setting (Ir) = 0.9.

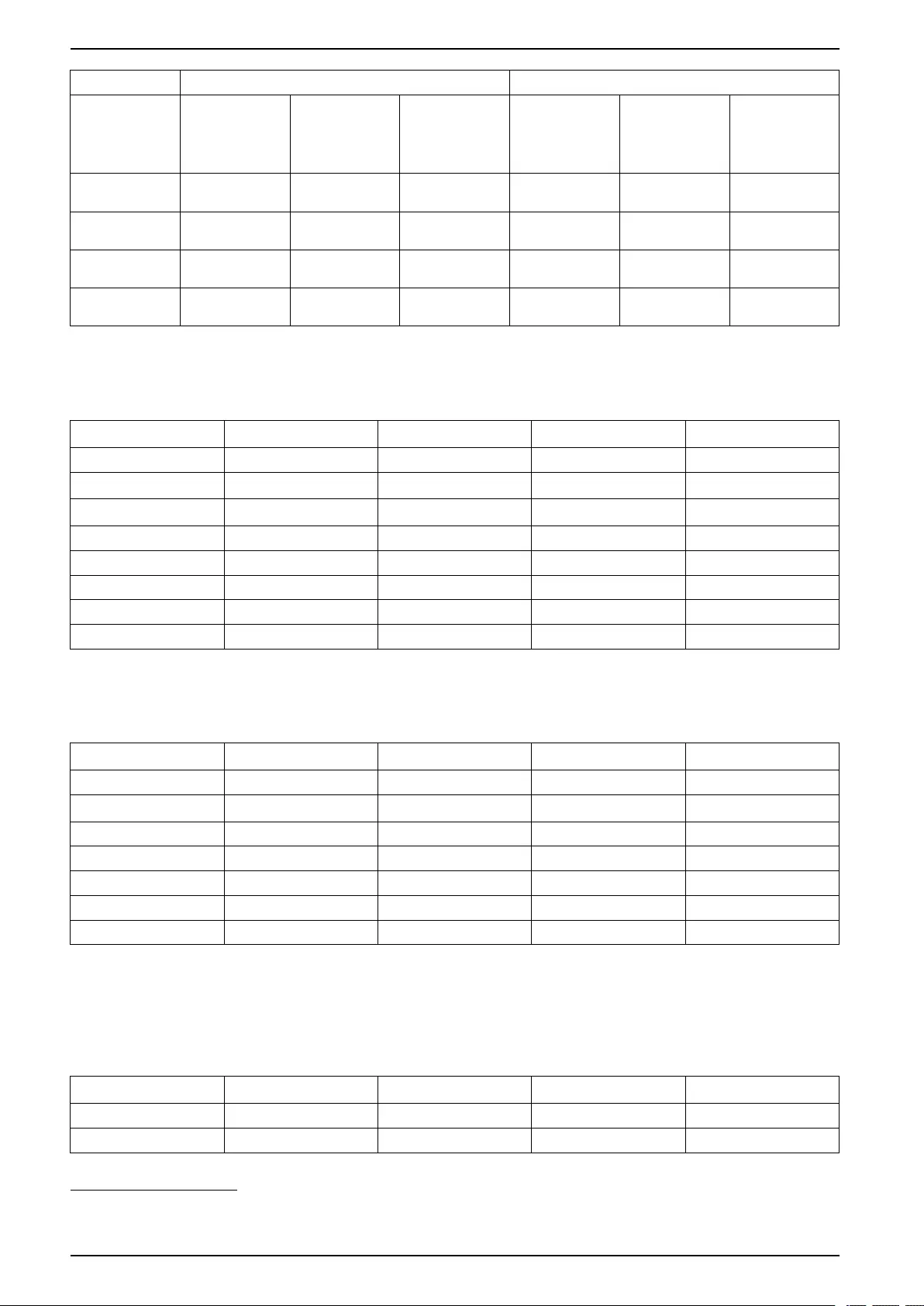

UPS with 1500 kW I/O Cabinet Specifications for 380, 400, 415, and 440 V Systems

Recommended Upstream Protection and Cable Sizes for 1500 kW UPS

Maximum OCPD (A) Conductors per Phase Copper/

Aluminium (mm²)

PE Conductor (mm²)

380 V 400 V 415 V 440 V 380 V 400 V 415 V 440 V 380 V 400 V 415 V 440 V

Input 320034 320034 320034 250035 7x240/

9x240

7x240/

9x240

7x240/

9x240

6x240/

8x240

4x240/

5x240

4x240/

5x240

4x240/

5x240

3x240/

4x240

Bypass 250036 250034 250034 200035 6x240/

7x240

5x240/

7x240

5x240/

7x240

5x240/

6x240

3x240/

4x240

3x240/

4x240

3x240/

4x240

3x240/

3x240

Output 250036 250034 250034 200035 6x240/

7x240

5x240/

7x240

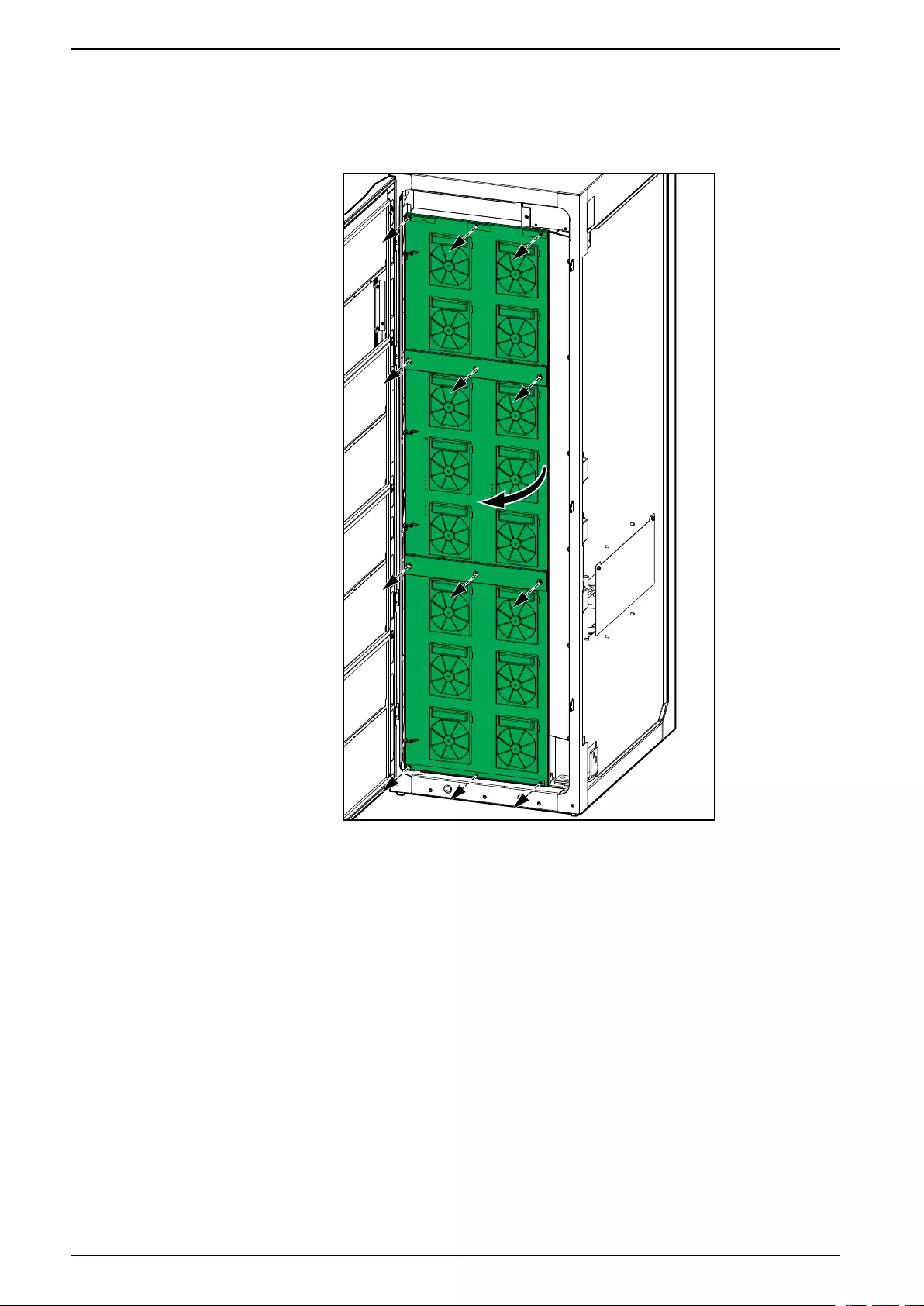

5x240/

7x240

5x240/

6x240

3x240/

4x240

3x240/

4x240

3x240/

4x240

3x240/

3x240

Battery 4000 4000 4000 4000 8x240/

10x240

8x240/

10x240

8x240/

10x240

8x240/

10x240

4x240/

5x240

4x240/

5x240

4x240/

5x240

4x240/

5x240

24 990-5783E-001

34. Long-time setting (Ir) = 0.9.

35. Long-time setting (Ir) = 1.0.

36. Long-time setting (Ir) = 0.95.

Specifications for 480 V Systems UPS with 1500 kW I/O Cabinet

Specifications for 480 V Systems

Input Specifications

500 kW 750 kW 1000 kW 1100 kW 1250 kW 1500 kW

Connections L1, L2, L3 + G37

Nominal input voltage (V) 480

Input voltage range (V)38 408-576

Frequency range (Hz) 40 – 70

Nominal input current (A) 633 950 1266 1393 1583 1899

Maximum input current (A)

39 728 1092 1456 1602 1820 2184

Input current limitation (A) 760 1140 1520 1672 1900 2280

Total harmonic distortion

(THDI)

<3% at 100% load

<4% at 50% load

<9% at 25% load

Input power factor 0.99 at >40% load

0.98 at >20% load

0.97 at >10% load

Maximum short circuit

rating

100 kA RMS

Protection Contactors

Ramp-in Adaptive 1 – 40 secs

Bypass Specifications

500 kW 750 kW 1000 kW 1100 kW 1250 kW 1500 kW

Connections L1, L2, L3 + G

Nominal bypass voltage (V) 480

Bypass voltage range (V) 432-528

Frequency (Hz) 50 or 60

Frequency range (Hz) Programmable: +/-0.1, +/-3, +/-10. Default is +/-3.

Nominal bypass current (A) 606 909 1211 1332 1514 1817

Maximum short circuit

rating

100 kA RMS40

Thyristor I^2t 16245

BF2 magnetic trip 39 kA

Protection Molded switch for backfeed protection

990-5783E-001 25

37. TN, TT, and IT power distribution systems are supported. Corner (line) grounding is not supported.

38. The system can operate at 600 V for 1 minute.

39. At nominal input voltage and full charge.

40. Conditioned by the internal molded switch with a 90 kA peak magnetic trip

UPS with 1500 kW I/O Cabinet Specifications for 480 V Systems

Output Specifications

500 kW 750 kW 1000 kW 1100 kW 1250 kW 1500 kW

Nominal output voltage (V) 480

Connections L1, L2, L3 + G

Overload capacity 150% for 1 minute (normal operation)

125% for 10 minutes (normal operation)

115% for 1 minute (battery operation)

125% continuous (bypass operation)

1000% for 100 milliseconds (bypass operation)

Output voltage regulation Balanced load: +/- 1%

Unbalanced load: +/- 3%

Dynamic load response +/- 5% after 2 ms

+/- 1% after 50 ms

Output power factor 1

Nominal output current (A) 601 902 1203 1323 1504 1804

Total harmonic distortion

(THDU)

<2% at 100% linear load

<3% at 100% non–linear load

Output frequency (Hz) 50/60 (synchronized to bypass)

50/60 Hz +/-0.1% (free-running)

Slew rate (Hz/sec) Programmable: 0.25, 0.5, 1, 2, 4, 6

Output performance

classification (according to

IEC/ EN62040-3)

Double-conversion: VFI-SS-111

Load crest factor Up to 3 (THDU < 5%)

Load power factor 0.7 leading to 0.5 lagging without derating

Battery Specifications

NOTE: Refer to the battery manufacturer’s manual for information on

installation and maintenance.

500 kW 750 kW 1000 kW 1100 kW 1250 kW 1500 kW

Charging power in % of

output power

40% at ≤ 80% load

15% at 100% load

Maximum charging power

(kW)

75 at 100%

load

200 at 80%

load

112.5 at 100%

load

300 at 80%

load

150 at 100%

load

400 at <80%

load

165 at 100%

load

440 at <80%

load

187.5 at 100%

load

500 at <80%

load

225 at 100%

load

600 at <80%

load

Nominal battery voltage

(VDC)

480

Nominal float voltage

(VDC)

546

End of discharge voltage

(full load) (VDC)

384

End of discharge voltage

(full load) (VDC)

420

Battery current at full load

and nominal battery voltage

(A)

1090 1634 2179 2397 2724 3269

Battery current at full load

and minimum battery

voltage (A)

1362 2043 2724 2996 3405 4086

Temperature compensation

(per cell)

-3.3 mV per °C for T ≥ 25 °C

0 mV per °C for T < 25 °C

Ripple current < 5% C20 (5 minutes backup time)

26 990-5783E-001

Specifications for 480 V Systems UPS with 1500 kW I/O Cabinet

500 kW 750 kW 1000 kW 1100 kW 1250 kW 1500 kW

Battery test Manual/automatic (selectable)

Deep discharge protection Yes

Recharge according to

battery temperature

Yes

Recommended Breaker and Cable Sizes

CAUTION

HAZARD OF FIRE

• Connect only to a circuit with the below specifications.

• Connect only to a circuit provided with a 2500 A branch circuit overcurrent

protection maximum in accordance with the National Electrical Code, ANSI/

NFPA70, and the Canadian Electrical Code, Part I, C22.1.

Failure to follow these instructions can result in injury or equipment

damage.

NOTE: Overcurrent protection is to be provided by others and marked with its

function.

NOTE: All wiring must comply with all applicable national and/or electrical

codes (National Electrical Code, ANSI/NFPA 70).

Cable sizes in this manual are based on Table 310.15 of the National Electrical

Code 2014 (NEC) with the following assertions:

• 90 °C conductors (THHN) for 75 °C termination

• Not more than three current carrying conductors in each conduit

• An ambient temperature of 30 °C

• Use of copper or aluminium conductors

• 100% rated breakers

• Nominal operating conditions

If the ambient room temperature is greater than 30 °C, use larger or additional

parallel conductors in accordance with the correction factors of the NEC. The

maximum allowable conductor size is 600 kcmil.

Equipment Grounding Conductors (EGC) are sized in accordance with NEC

Article 250.122 and Table 250.122 “Minimum size equipment conductor for

grounding equipment.

NOTE: Always consider the EGC size according to the complete electrical

installation.

1100 kW

Maximum OCPD (A) Conductors per Phase Copper/

Aluminium (kcmil)

Equipment Grounding Conductor

Copper/Aluminium41

Input 200042 5x500 / 6x500 250 kcmil/ 400 kcmil

Bypass 160042 4x500 / 5x500 4/0 AWG / 350 kcmil

Output 160042 4x500 / 5x500 4/0 AWG / 350 kcmil

Battery 300043 8x500 / 9x600 400 kcmil / 600 kcmil

990-5783E-001 27

41. If the conductors are run in conduits, there must be one conductor in each conduit.

42. Long-time setting (Ir) = 0.9

43. Long-time setting (Ir) = 1.0

UPS with 1500 kW I/O Cabinet Specifications for 480 V Systems

1250 kW 1500 kW

Maximum

OCPD (A)

Conductors per

Phase Copper/

Aluminium

(kcmil)

Equipment

Grounding

Conductor

Copper/

Aluminium44

Maximum

OCPD (A)

Conductors per

Phase Copper/

Aluminium

(kcmil)

Equipment

Grounding

Conductor

Copper/

Aluminium44

Input 200045 5x600/

6x600

250 kcmil/

400 kcmil

250045 6x600/

8x600

350 kcmil/

400 kcmil

Bypass 160045 4x600/

5x600

4/0 AWG/

350 kcmil

200045 5x600/

6x600

250 kcmil/

350 kcmil

Output 160045 4x600/

5x600

4/0 AWG/

350 kcmil

200045 5x600/

6x600

250 kcmil/

350

Battery 400046 9x600/

11x600

500 kcmil/

750 kcmil

500046 11x600/

14x600

700 kcmil/

–

Recommended Bolt and Lug Sizes for Copper Cables

Cable Size Terminal Bolt Diameter Cable Lug Type Crimping Tool Die

1/0 AWG M12 x 35 mm LCCF1/0–12–X CT930 CD-920–2/0 Black P45

2/0 AWG M12 x 35 mm LCCF2/0–12–X CT930 CD-920–3/0 Orange P50

3/0 AWG M12 x 35 mm LCCF3/0–12–X CT930 CD-920–4/0 Purple P54

250 kcmil M12 x 35 mm LCCF250–12–X CT-940CH/CT-2940 CD-920–300 White P66

300 kcmil M12 x 35 mm LCCF300–12–6 CT-940CH/CT-2940 CD-920–350 Red P71

400 kcmil M12 x 35 mm LCCF400–12–6 CT-940CH/CT-2940 CD-920–500 Brown P87

500 kcmil M12 x 35 mm LCCF500–12–6 CT-940CH/CT-2940 CD-920–500A Pink P99

600 kcmil M12 x 40 mm LCCF600–12–6 CT-940CH/CT-2940 CD-920–750 Black P106

Recommended Bolt and Lug Sizes for Aluminium Cables

Cable Size Terminal Bolt Diameter Cable Lug Type Crimping Tool Die

2/0 AWG M12 x 40 mm LAB2/0-12-5 CT930 Olive P54

3/0 AWG M12 x 40 mm LAB3/0-12-5 CT930 Ruby P60

250 kcmil M12 x 40 mm LAB250-12-5 CT930 Red P71

300 kcmil M12 x 40 mm LAB300-12-2 CT930 Blue P76

400 kcmil M12 x 40 mm LAB400-12-2 CT930 Green P94

500 kcmil M12 x 40 mm LAB500-12-2 CT930 Pink P99

600 kcmil M12 x 40 mm LAB600-12-2 CT930 Black P106

Heat Dissipation

Heat Dissipation (BTU/hr) for a 500 kW UPS

Load Normal Operation ECO Mode ECOnversion Battery Operation

25% 18698 6495 7818 18234

50% 31855 7747 7747 31855

28 990-5783E-001

44. If the conductors are run in conduits, there must be one conductor in each conduit

45. Long-time setting (Ir) = 1.0

46. Long-time setting (Ir) = 0.9

Specifications for 480 V Systems UPS with 1500 kW I/O Cabinet

Load Normal Operation ECO Mode ECOnversion Battery Operation

75% 50542 10319 10319 53313

100% 69234 13758 13758 78519

Heat Dissipation (BTU/hr) for a 750 kW UPS

Load Normal Operation ECO Mode ECOnversion Battery Operation

25% load 27351 9742 11727 27351

50% load 46407 11620 12924 47782

75% load 73741 15478 15478 79969

100% load 106625 20637 20637 117778

Heat Dissipation (BTU/hr) for a 1000 kW UPS

Load Normal Operation ECO Mode ECOnversion Battery Operation

25% 36468 12112 15294 36468

50% 61876 15493 16657 63710

75% 95564 20637 20637 106625

100% 145873 27516 27516 157038

Heat Dissipation (BTU/hr) for a 1100 kW UPS

Load Normal Operation ECO Mode ECOnversion Battery Operation

25% 35040 12359 16849 40115

50% 66050 15134 18298 70080

75% 99075 19843 21986 117288

100% 156383 26458 26458 172741

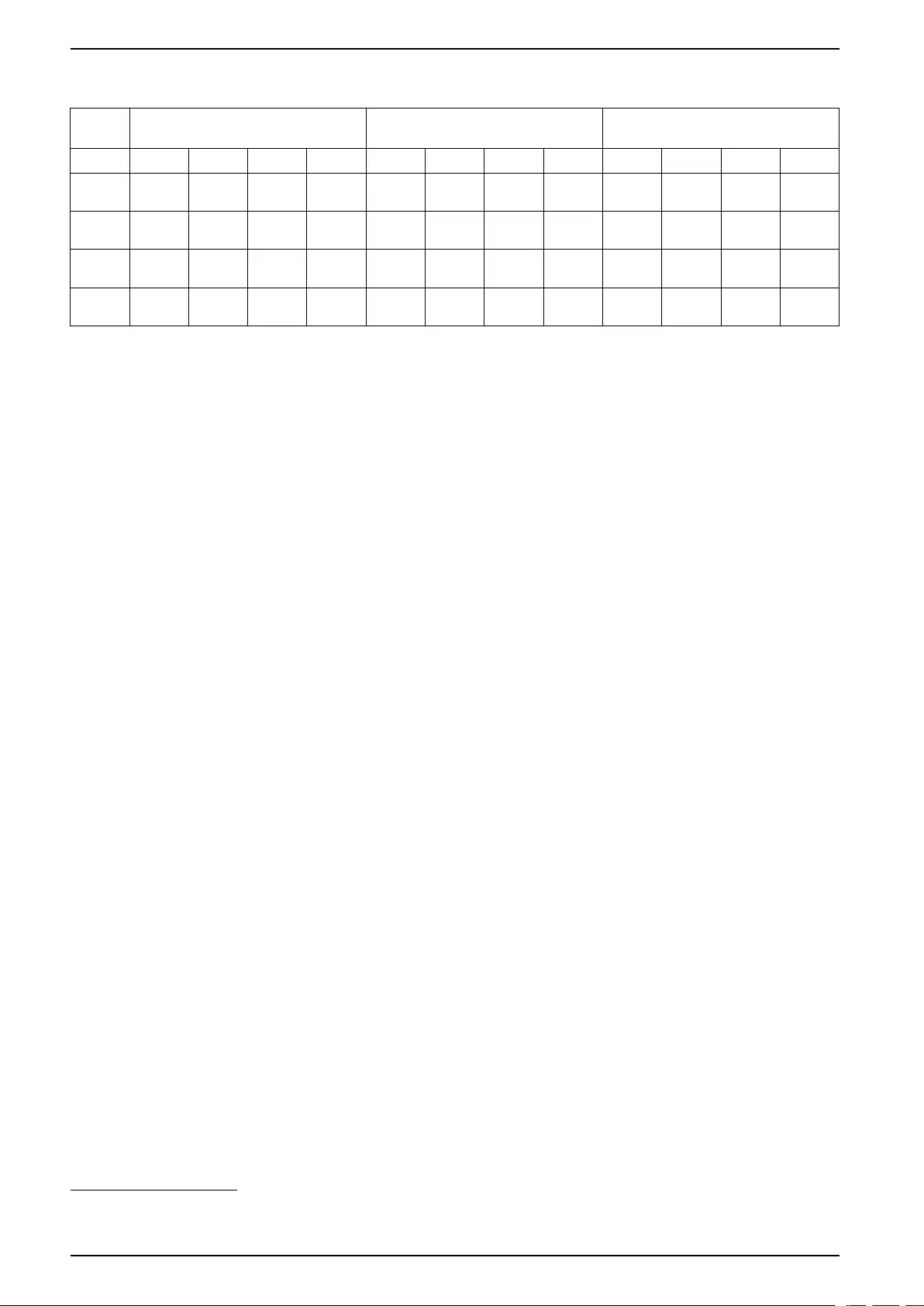

Heat Dissipation (BTU/hr) for a 1250 kW UPS

Load Normal Operation ECO Mode ECOnversion Battery Operation

25% 44427 14044 18748 45585

50% 75057 17198 20047 79637

75% 119455 22549 24172 133281

100% 177708 30065 30065 196297

Heat Dissipation (BTU/hr) for a 1500 kW UPS

Load Normal Operation ECO Mode ECOnversion Battery Operation

25% 53313 16853 22054 54285

50% 92813 23240 23129 96666

75% 147481 27059 27059 154530

100% 213250 36079 36079 229962

990-5783E-001 29

UPS with 1500 kW I/O Cabinet Specifications

Specifications

Torque Specifications

Bolt size Torque

M6 5 Nm (3.69 lb-ft)

M8 17.5 Nm (12.91 lb-ft)

M10 30 Nm (22 lb-ft)

M12 50 Nm (36.87 lb-ft)

Environment

Operating Storage

Temperature 0 °C to 40 °C ( 32 °F to 104 °F )

0 °C to 50 °C ( 32 °F to 122 °F ) when

derated to 75% power47

-15 °C to 40 °C (5 °F to 104 °F) for systems

with batteries

-25 °C to 55 °C (-13 °F to 131 °F) for

systems without batteries

Relative humidity 0 – 95% non-condensing 0 – 95% non-condensing

Altitude derating according to ANSI C57.96–

199948

1000 m (3300 ft): 1.000

1500 m (5000 ft): 0.975

2000 m (6600 ft): 0.950

2500 m (8300 ft): 0.925

3000 m (10000 ft): 0.900

0 – 15000 m (0 – 50000 ft)

Audible noise one meter (three feet) from

surface

62 dB at 70% load

69.5 dB at 100% load for 400 V systems

68 dB at 100% load for 480 V systems

Protection class IP20

Color RAL 9003 white

30 990-5783E-001

47. For temperatures between 40 °C and 50 °C, the load power rating must be derated with 2.5% per °C of rated output power. Above 40 °C

the minimum input voltage is 340 V, and from 380 V to 340 V, the charge power must be linearly derated from 12% to 1%.

48. Maximum operation altitude is 3000 m (10000 ft).

Specifications UPS with 1500 kW I/O Cabinet

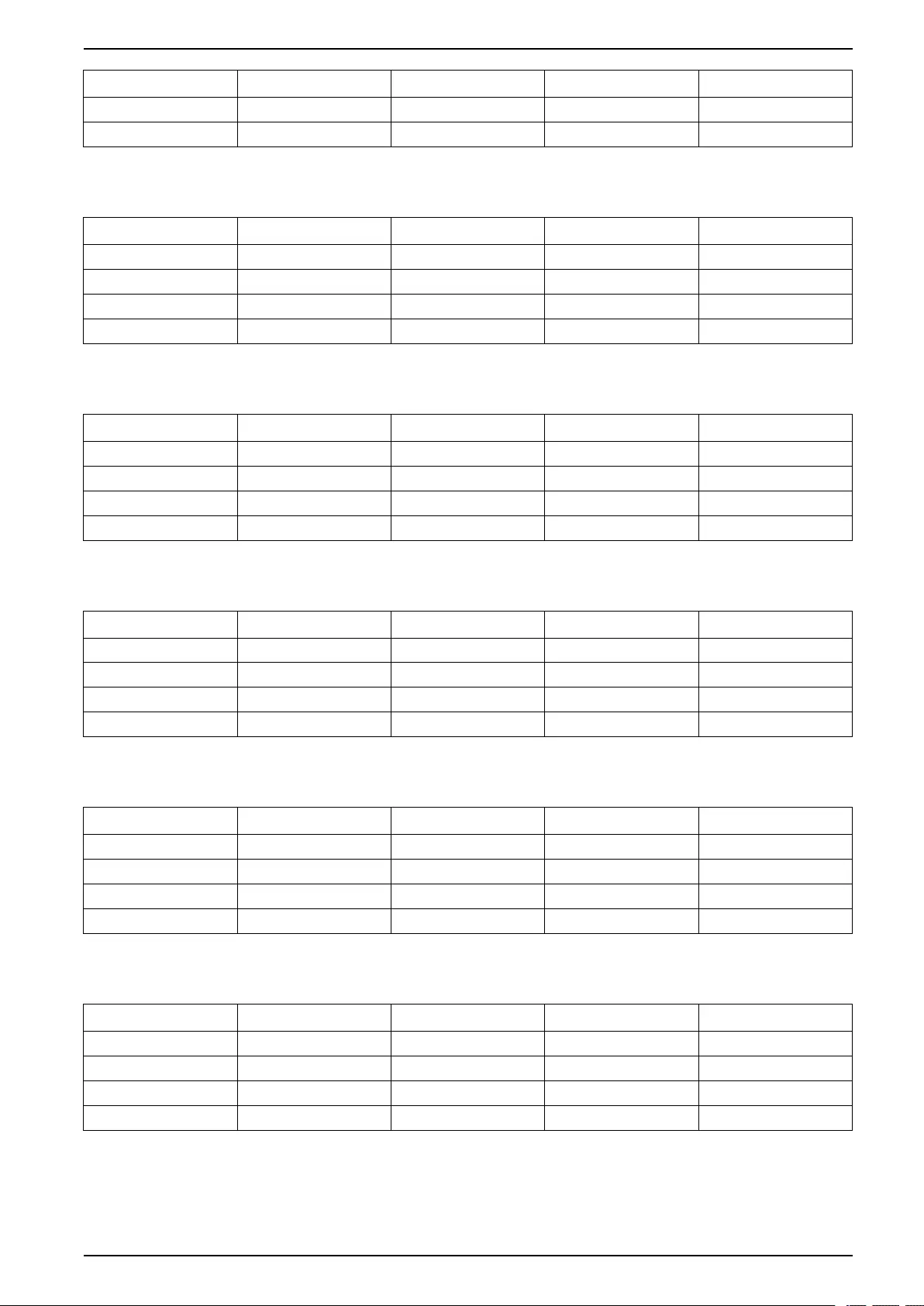

Weights and Dimensions for UPSs with 1500 kW I/O Cabinet

Part Number Parts Weight kg (lbs) Height mm (in) Width mm (in) Depth mm (in)

GVX500K1250HS

GVX500K1500HS

In total

– Power cabinets

– I/O cabinet

1956 (4312)

2x540 (2x1190)

876 (1931)

1970 (77.6) 3200 (126.0)

2x600 (2x23.6)

2000 (78.7)

900 (35.4)

GVX750K1250HS

GVX750K1500HS

In total

– Power cabinets

– I/O cabinet

2496 (5503)

3x540 (3x1190)

876 (1931)

1970 (77.6) 3800 (149.6)

3x600 (3x23.6)

2000 (78.7)

900 (35.4)

GVX1000K1250HS

GVX1000K1500HS

In total

– Power cabinets

– I/O cabinet

3036 (6693)

4x540 (4x1190)

876 (1931)

1970 (77.6) 4400 (173.2)

4x600 (4x23.6)

2000 (78.7)

900 (35.4)

GVX1250K1250HS

GVX1250K1500HS

In total

– Power cabinets

– I/O cabinet

3576 (7884)

5x540 (5x1190)

876 (1931)

1970 (77.6) 5000 (196.9)

5x600 (5x23.6)

2000 (78.7)

900 (35.4)

GVX1500K1250HS

GVX1500K1500HS

In total

– Power cabinets

– I/O cabinet

4116 (9074)

6x540 (6x1190)

876 (1931)

1970 (77.6) 5600 (220.5)

6x600 (6x23.6)

2000 (78.7)

900 (35.4)

GVX1750K1500HS In total

– Power cabinets

– I/O cabinet

4656 (10265)

7x540 (7x1190)

876 (1931)

1970 (77.6) 6200 (244.1)

7x600 (7x23.6)

2000 (78.7)

900 (35.4)

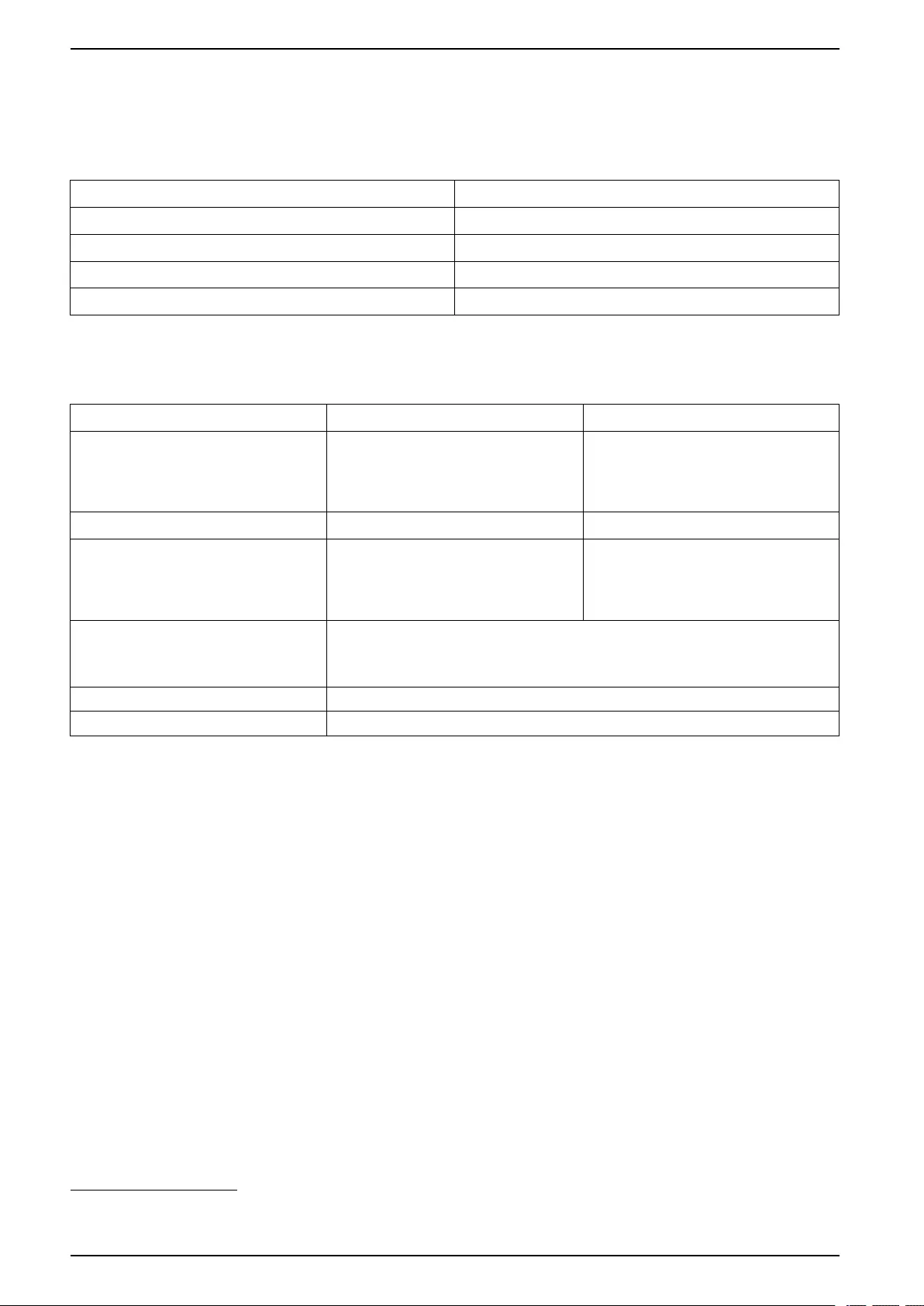

Clearance for UPSs with 1500 kW I/O Cabinet

NOTE: Clearance dimensions are published for airflow and service access

only. Consult with the local safety codes and standards for additional

requirements in your local area.

NOTE: The UPS system can be placed up against a wall with no requirement

for rear or side access.

Front View

Guidance for Organizing Battery Cables

NOTE: For 3rd party batteries, use only high rate batteries for UPS

applications.

990-5783E-001 31

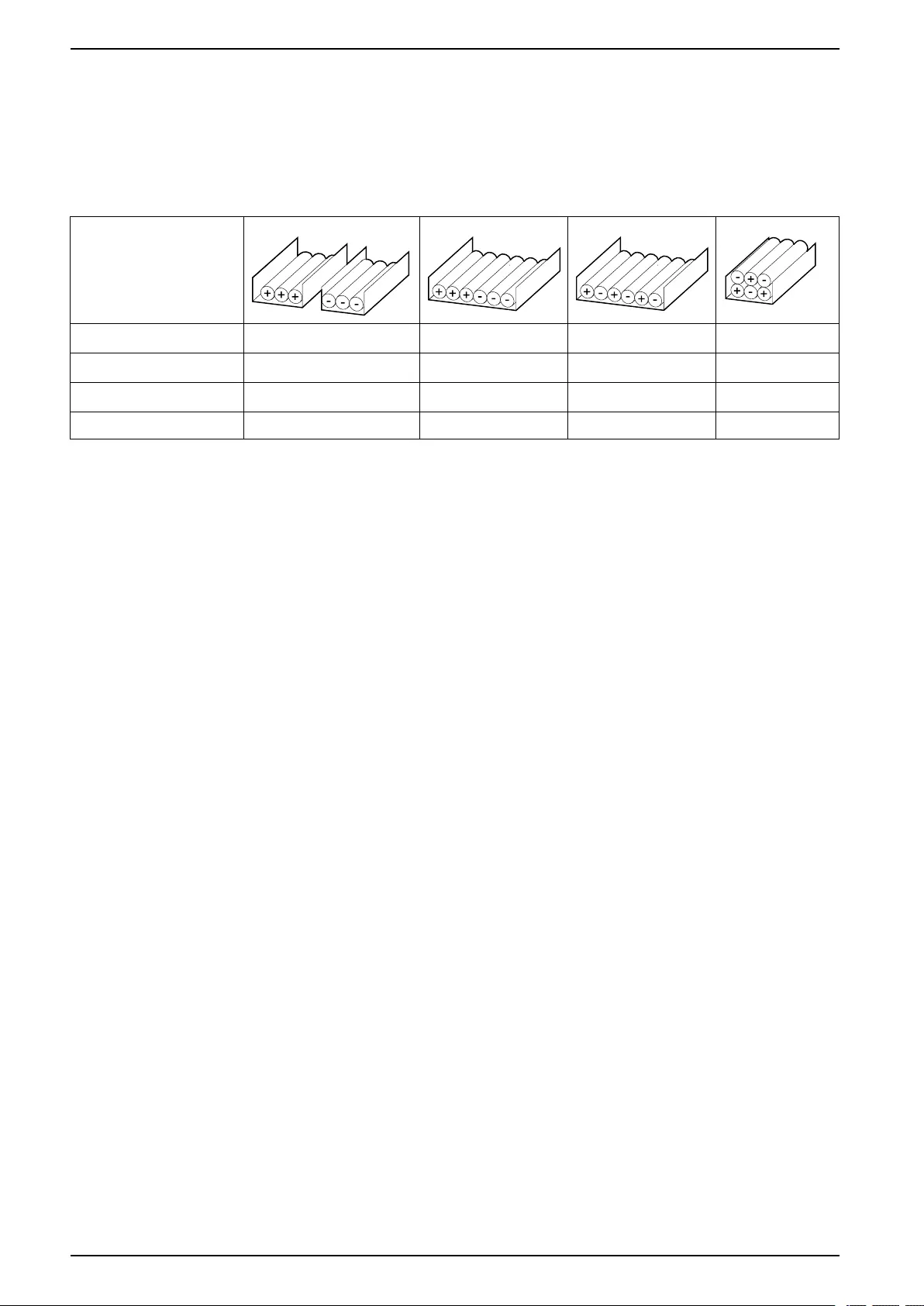

UPS with 1500 kW I/O Cabinet Specifications

NOTE: When the battery bank is placed remotely, the organizing of the cables

is important to reduce voltage drop and inductance. The distance between the

battery bank and the UPS must not exceed 200 m (656 ft). Contact Schneider

Electric for installations with a longer distance.

NOTE: To minimize the risk of electromagnetic radiation, it is highly

recommended to follow the below guidance and to use grounded metallic tray

supports.

Cable Length

<30 m Not recommended Acceptable Recommended Recommended

31–75 m Not recommended Not recommended Acceptable Recommended

76–150 m Not recommended Not recommended Acceptable Recommended

151–200 m Not recommended Not recommended Not recommended Recommended

32 990-5783E-001

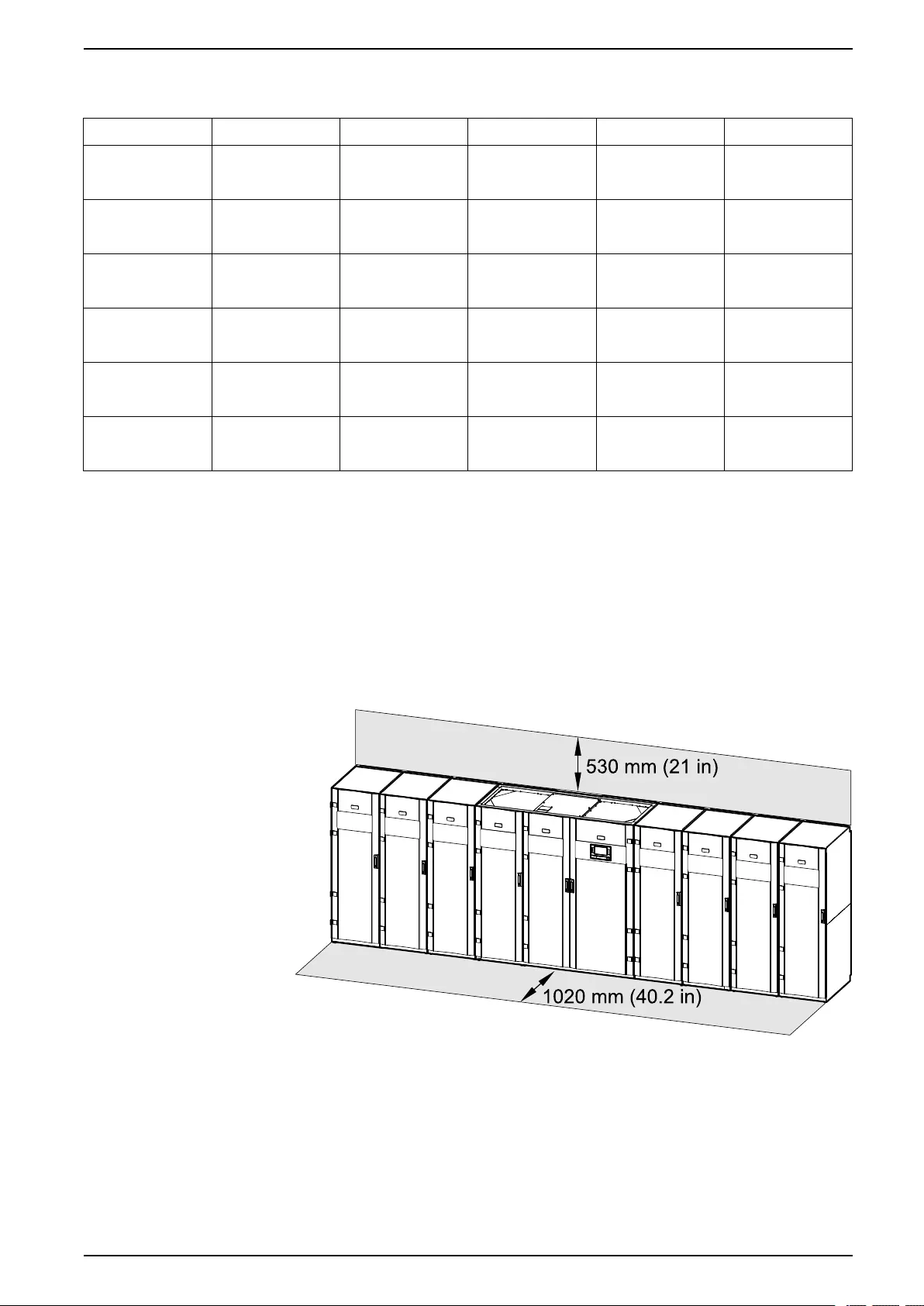

Overview of Configurations UPS with 1500 kW I/O Cabinet

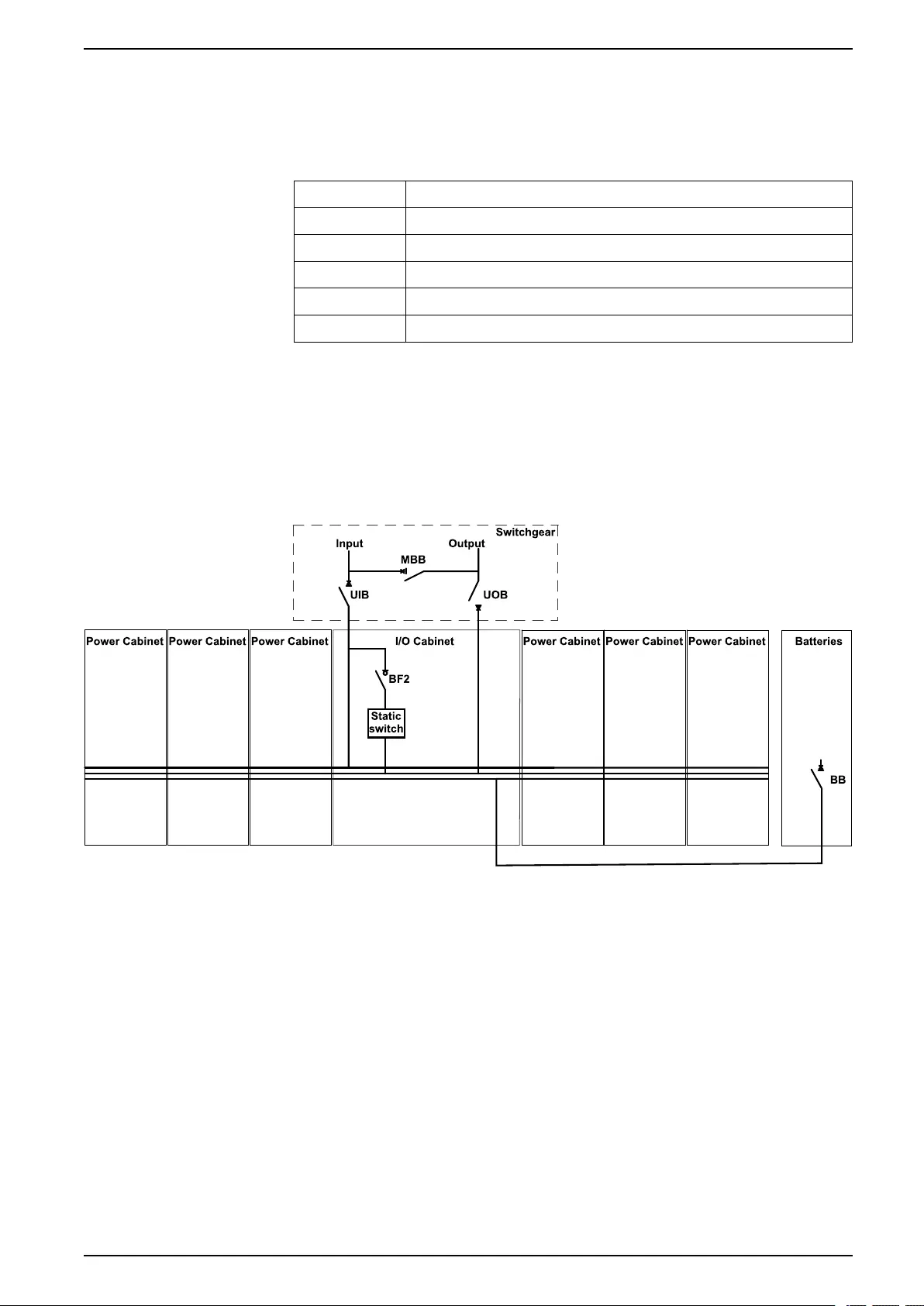

Overview of Configurations

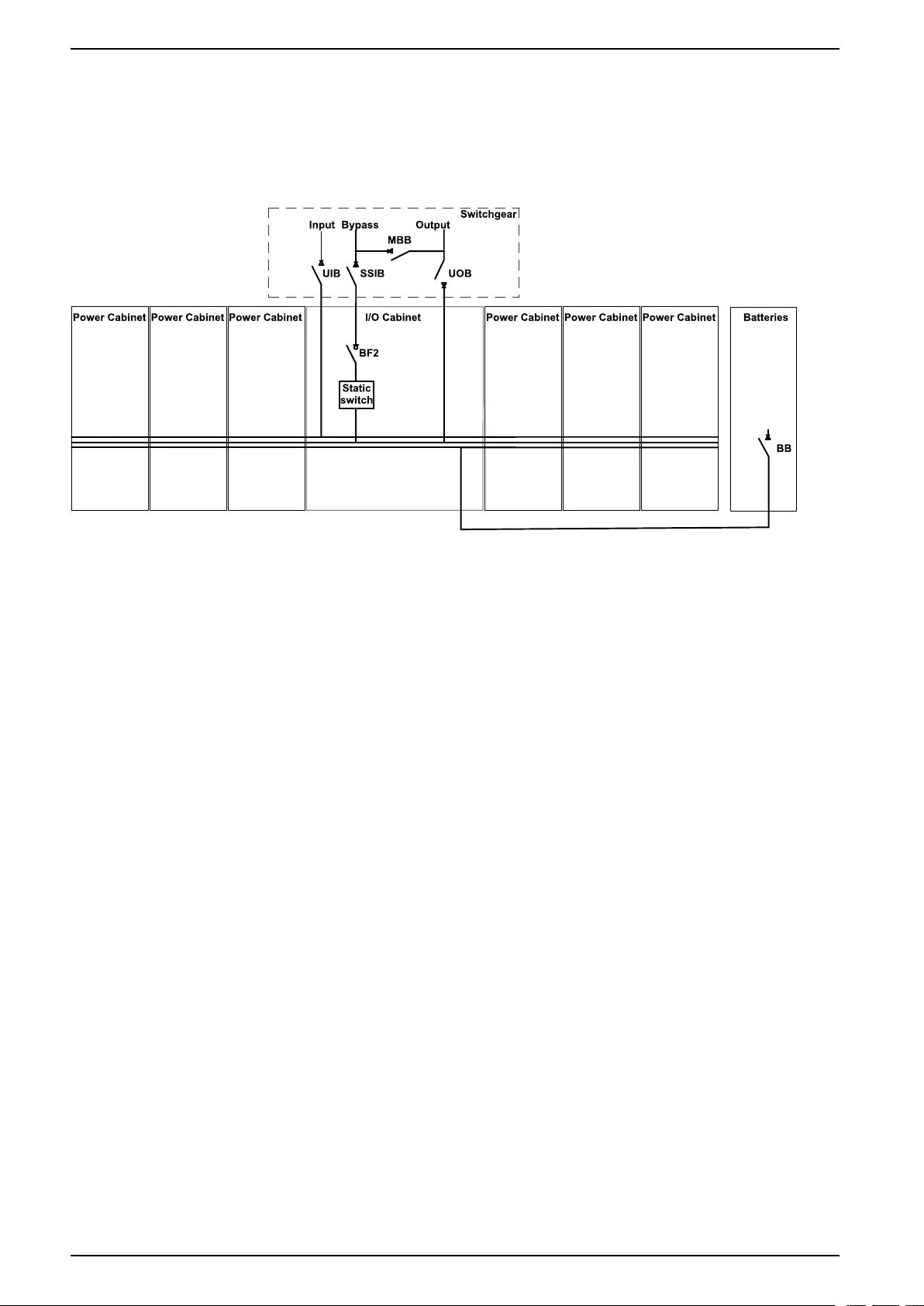

Breakers in the System

UIB Unit input breaker

SSIB Static switch input breaker

BB Battery breaker

MBB Maintenance bypass breaker

UOB Unit output breaker

BF2 Backfeed protection switch

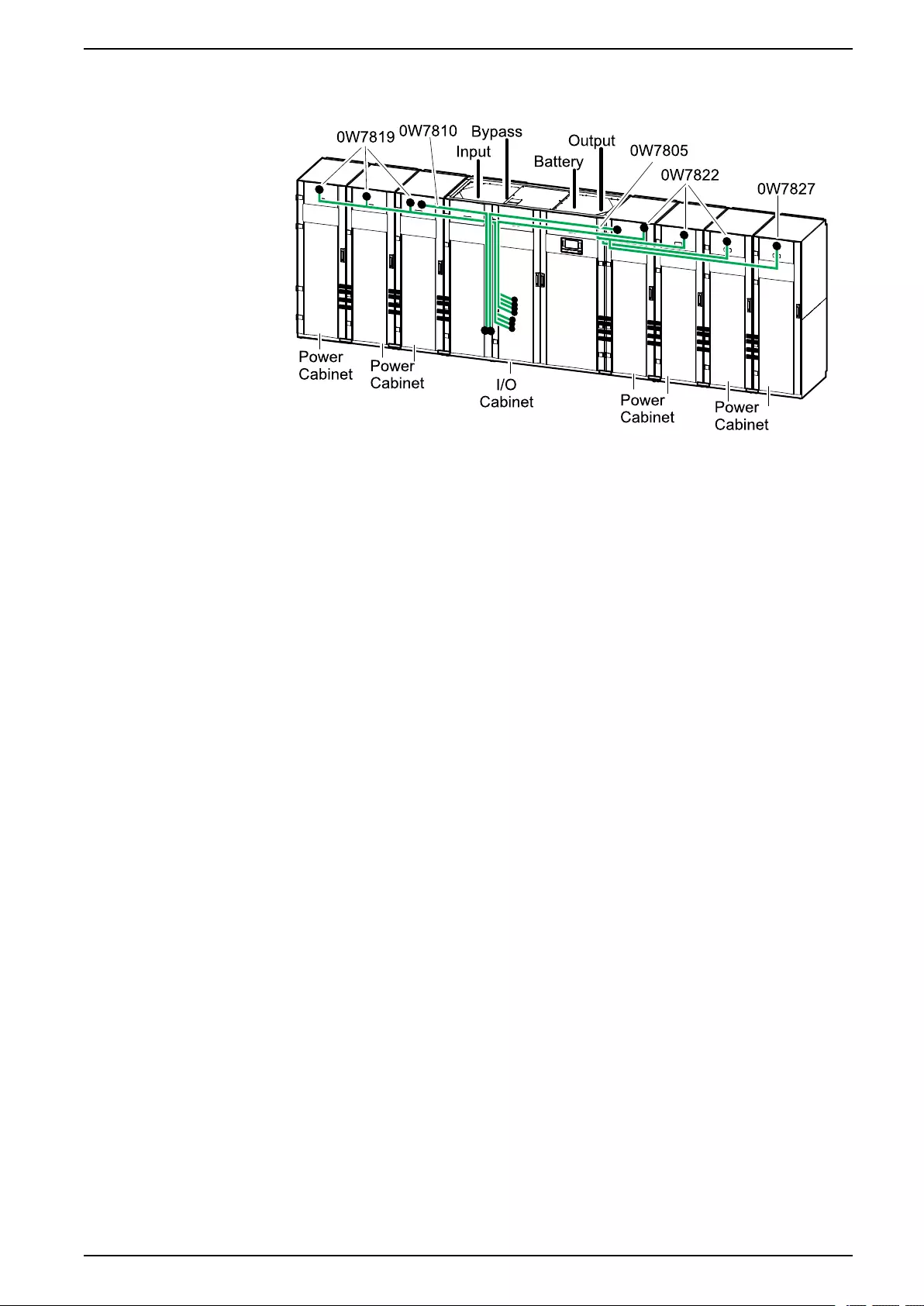

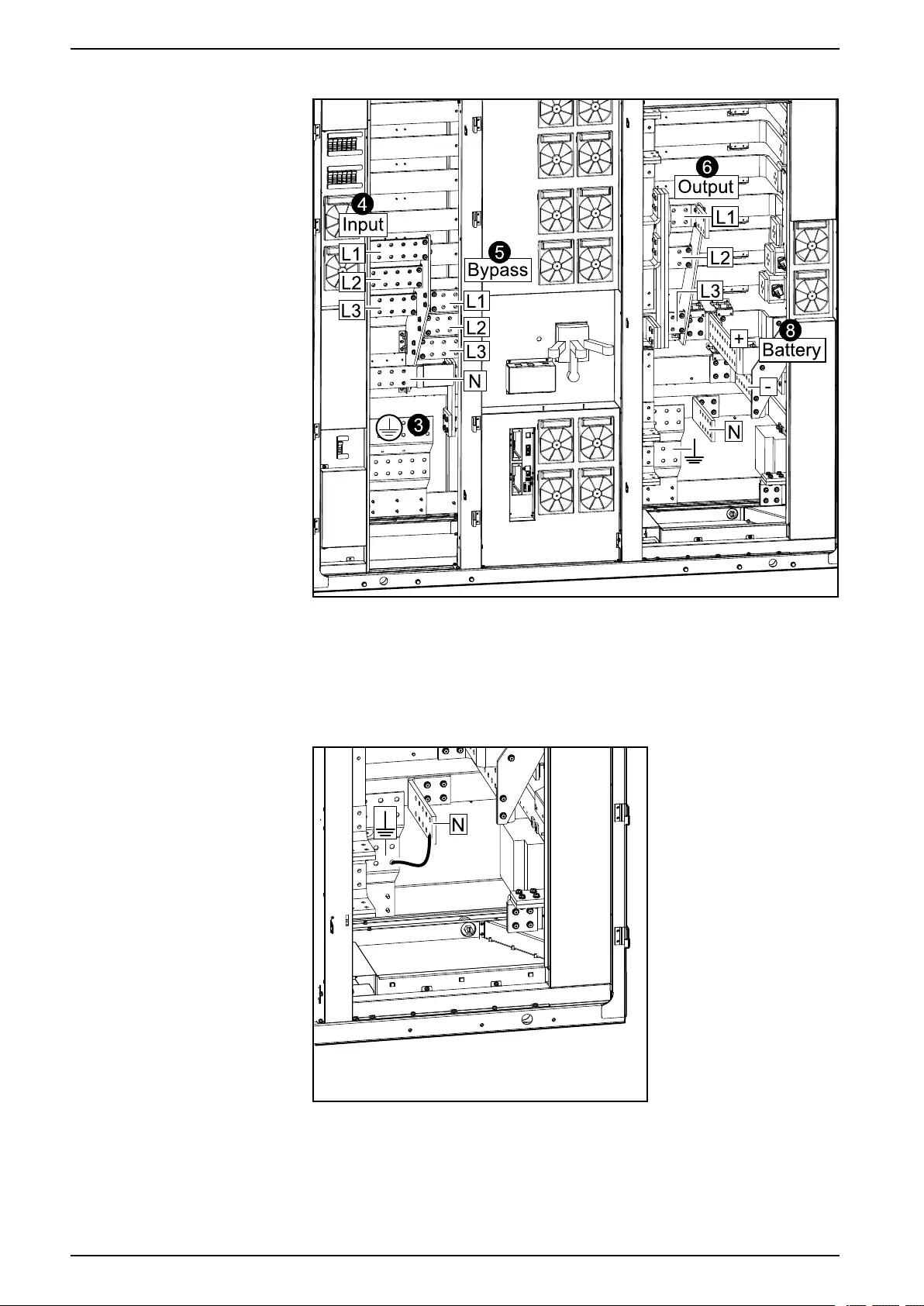

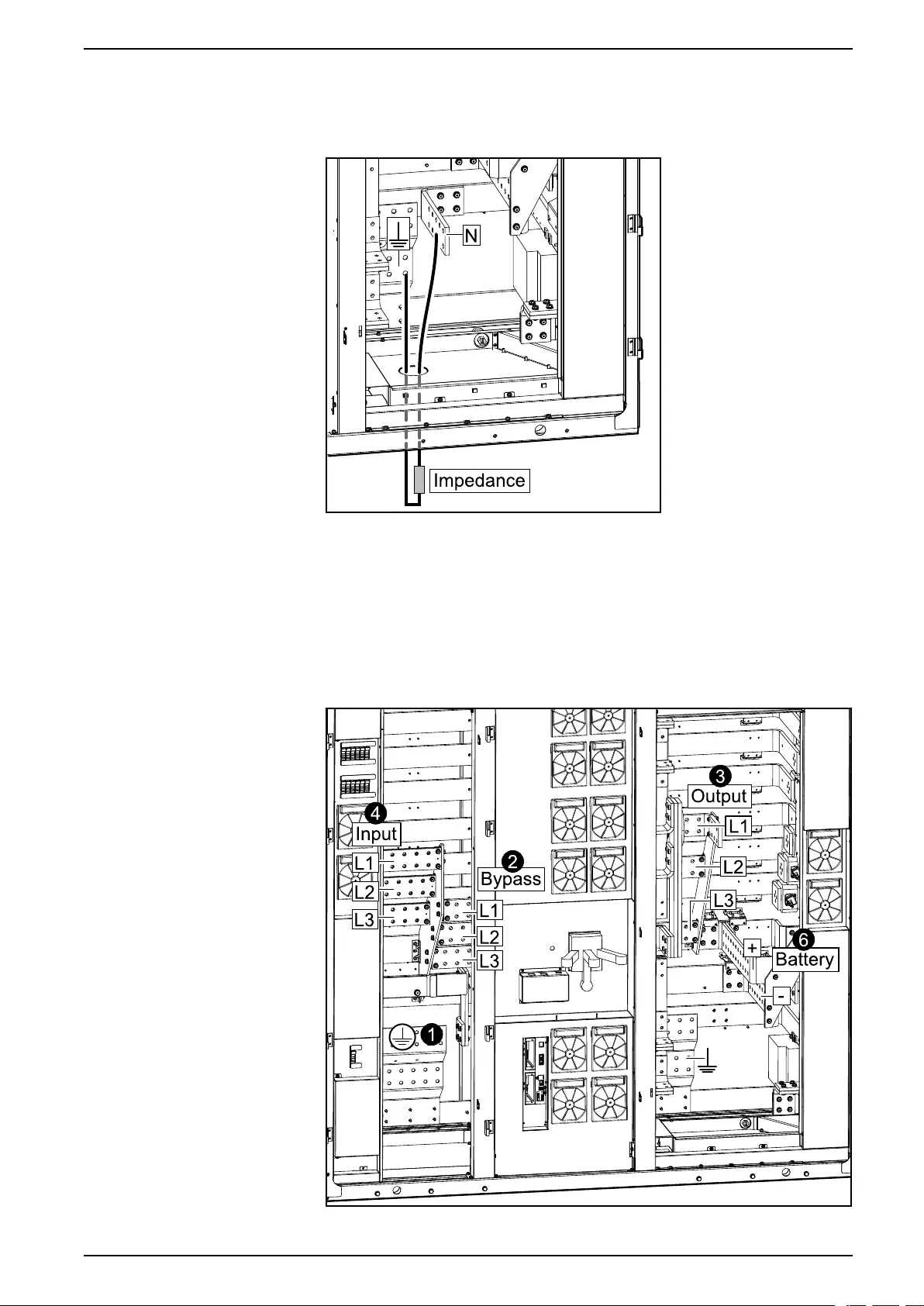

Overview of UPSs with 1500 kW I/O Cabinet – Single Utility/Mains

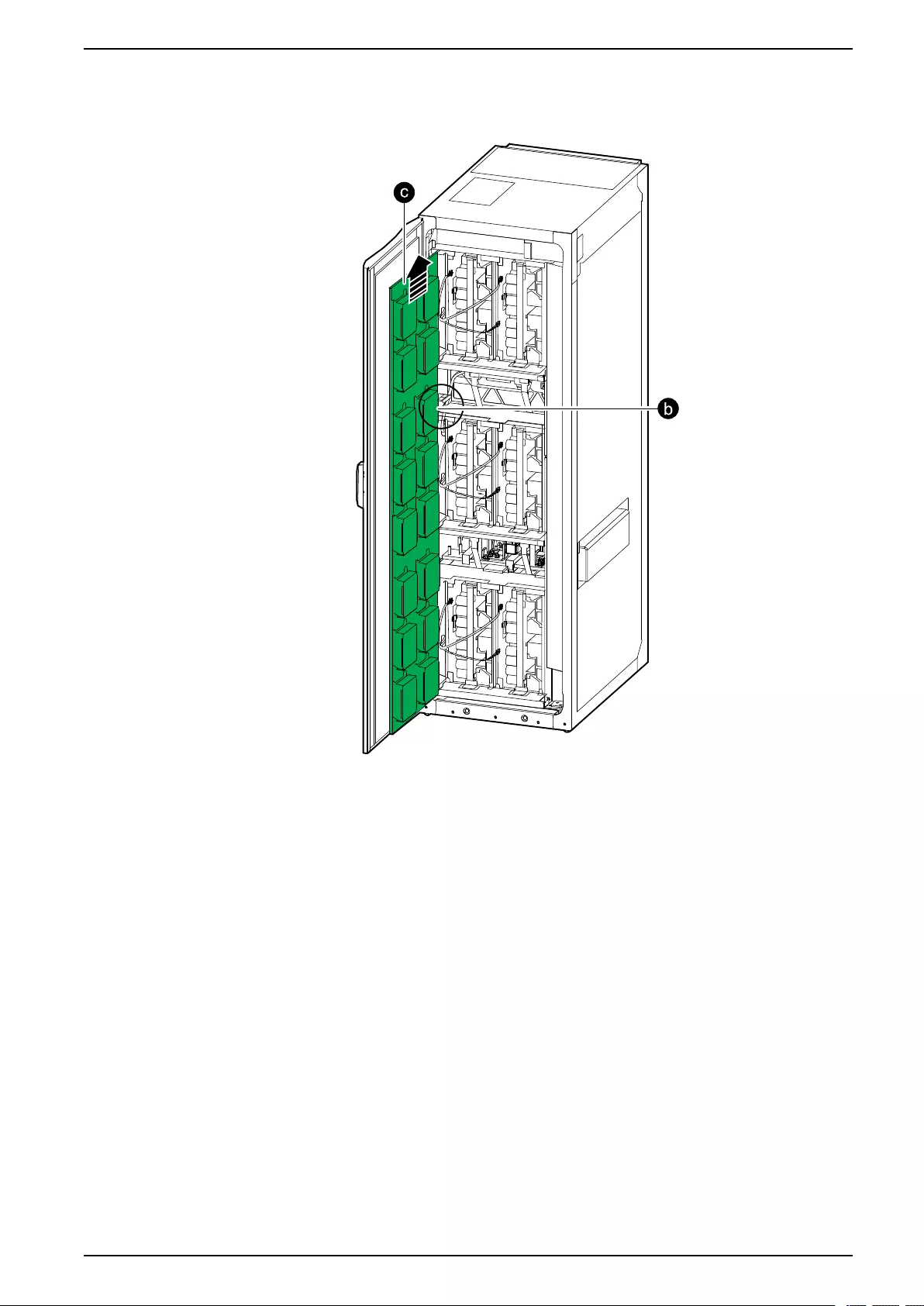

The illustration shows a 1500 kW UPS. The principle is the same for the other

UPSs with the 1500 kW I/O cabinet.

Galaxy VX 1500 kW UPS

990-5783E-001 33

Overview of Supplied Installation Kits UPS with 1500 kW I/O Cabinet

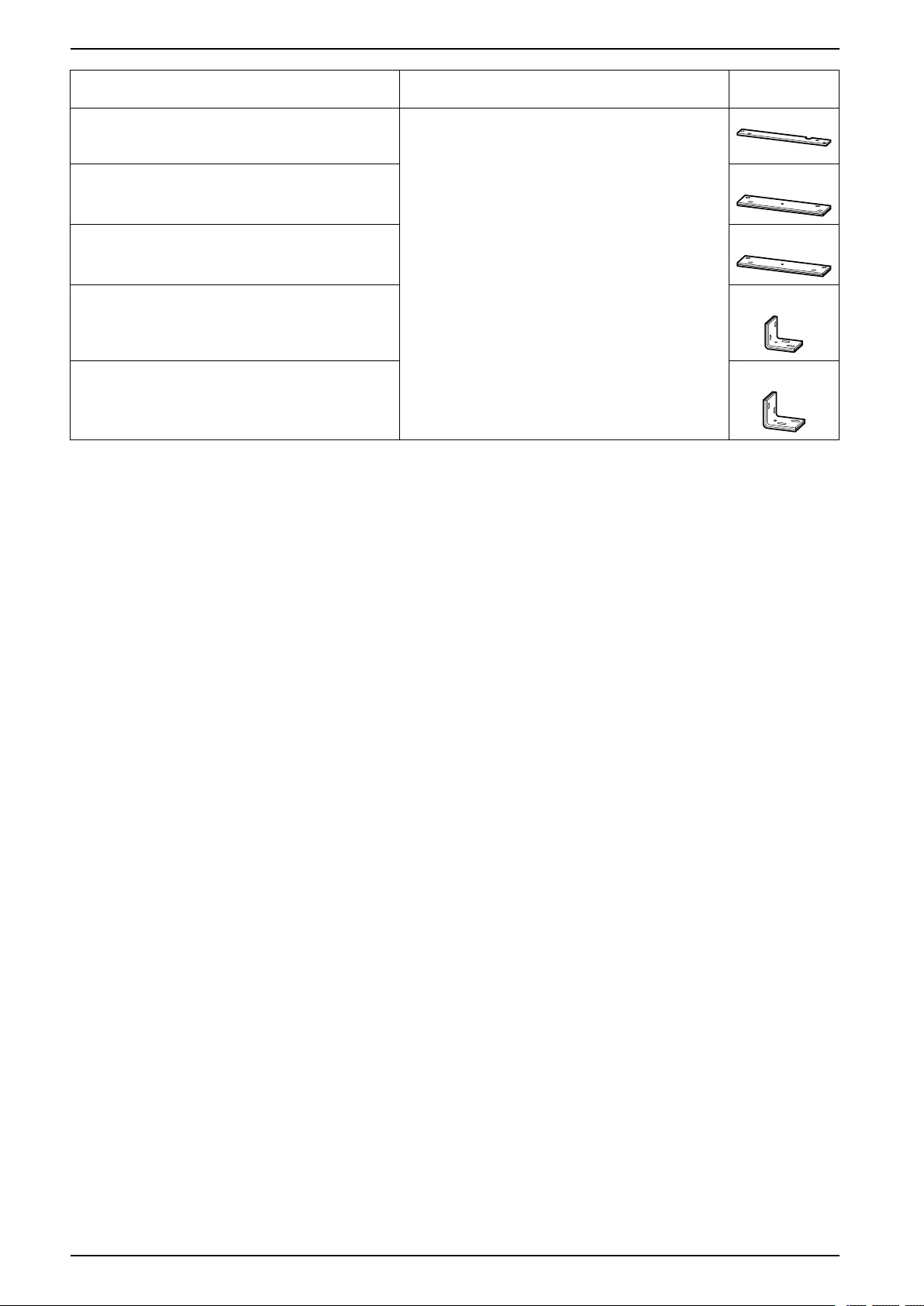

Overview of Supplied Installation Kits

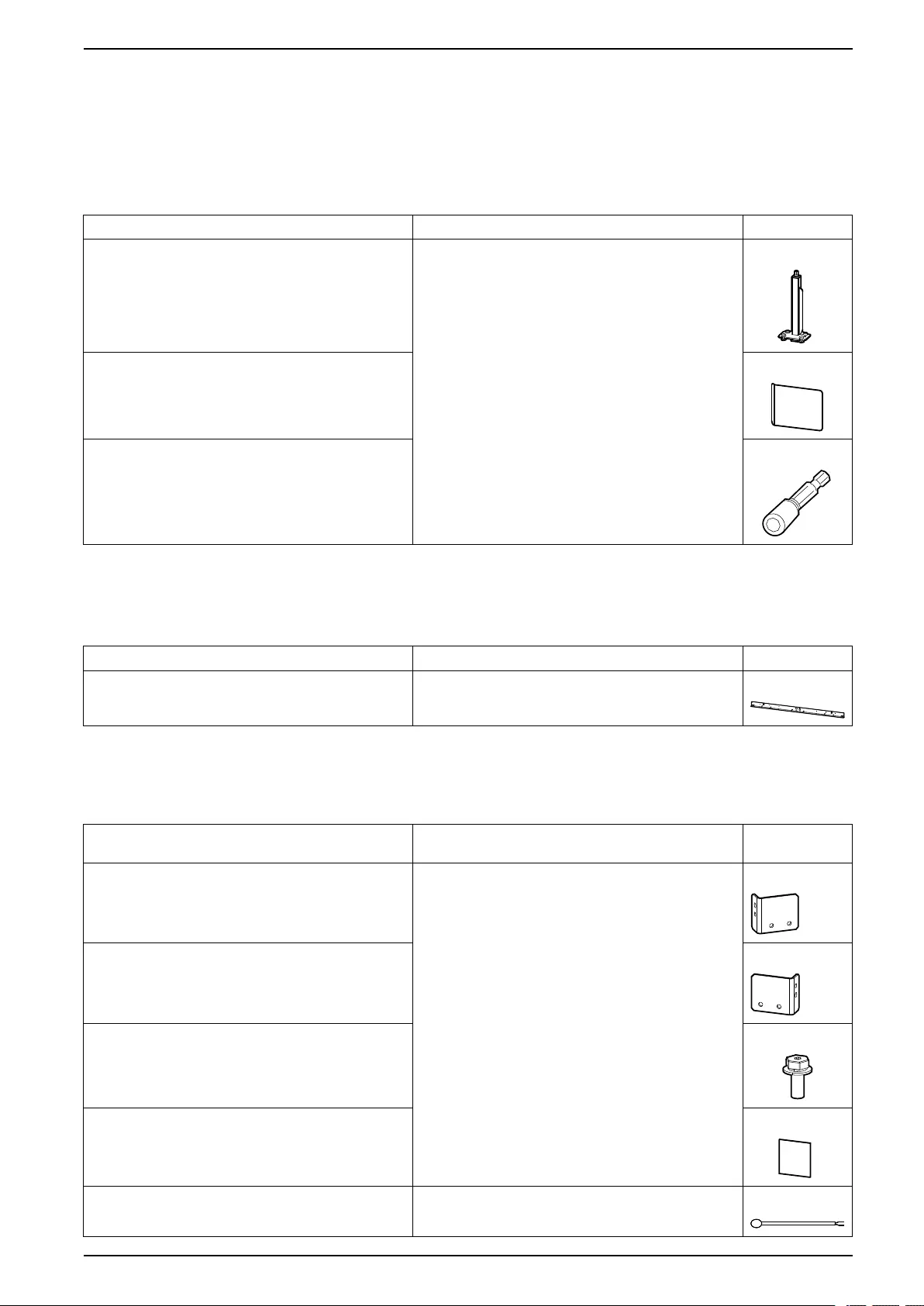

Installation Kits Shipped with the I/O Cabinet

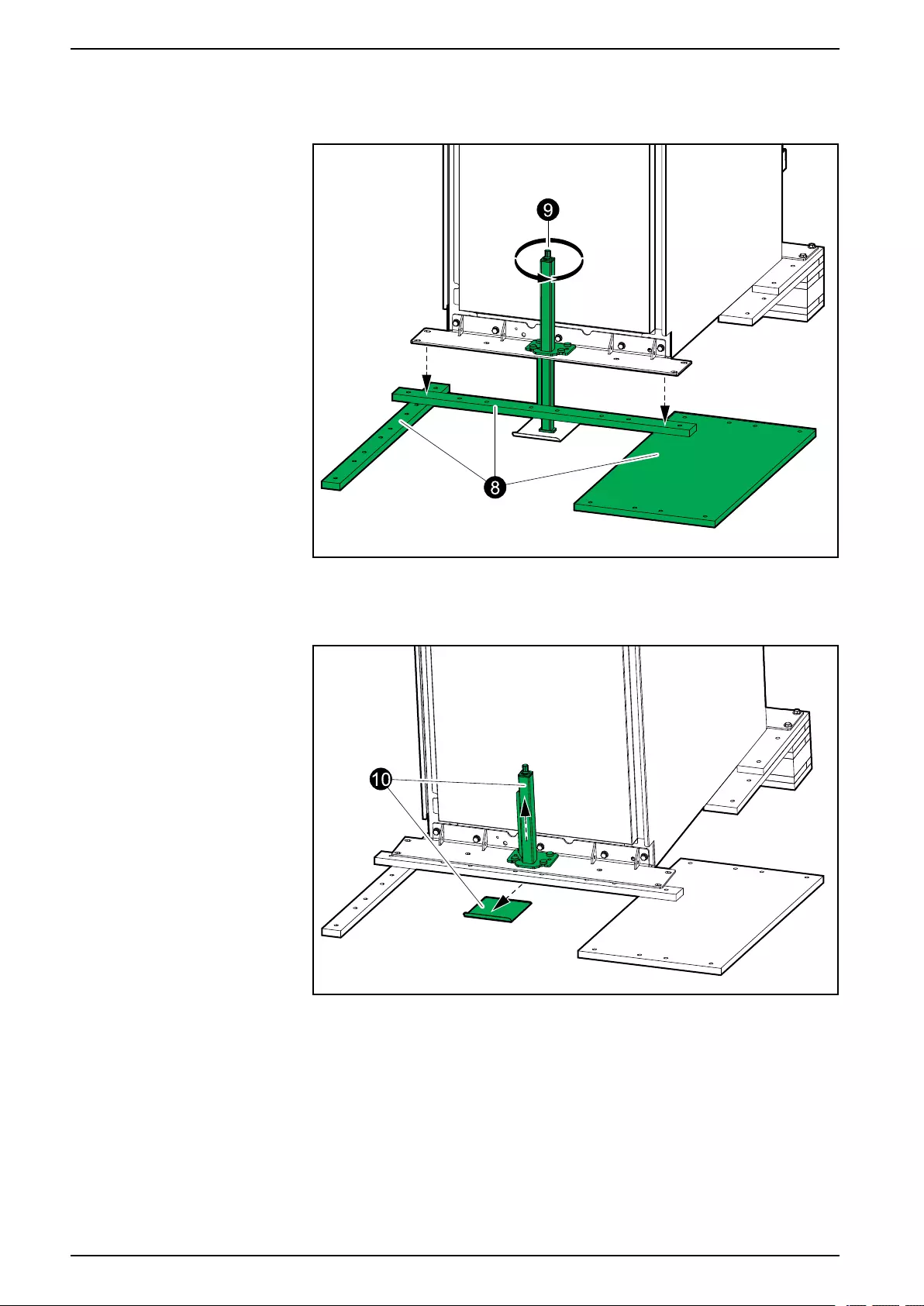

Installation Kit 0M-816661

Part Used in Number of units

Jack Remove the Cabinets from the Pallet, page 44 1

Floor protection plate 1

Hexagonal socket for drilling machine 1

Installation Kit 0M-821667

NOTE: The rear anchoring bracket is shipped on the pallet.

Part Used in Number of units

Rear anchoring bracket Mount the Rear Anchoring Brackets, page 51 1

Installation Kit 0H-9101

Part Used in Number of

Units

Angle for left side of the rear anchoring bracket 870–

30411

Mount the Rear Anchoring Brackets, page 51 1

Angle for right side of the rear anchoring bracket 870–

30412

1

M8 x 20 hexagonal torx with washer 8

1 mm leveling shims 30

Temperature sensor 0M-1160 Connect the Signal Cables between the I/O Cabinet and

the Classic Battery Cabinets, page 98

2

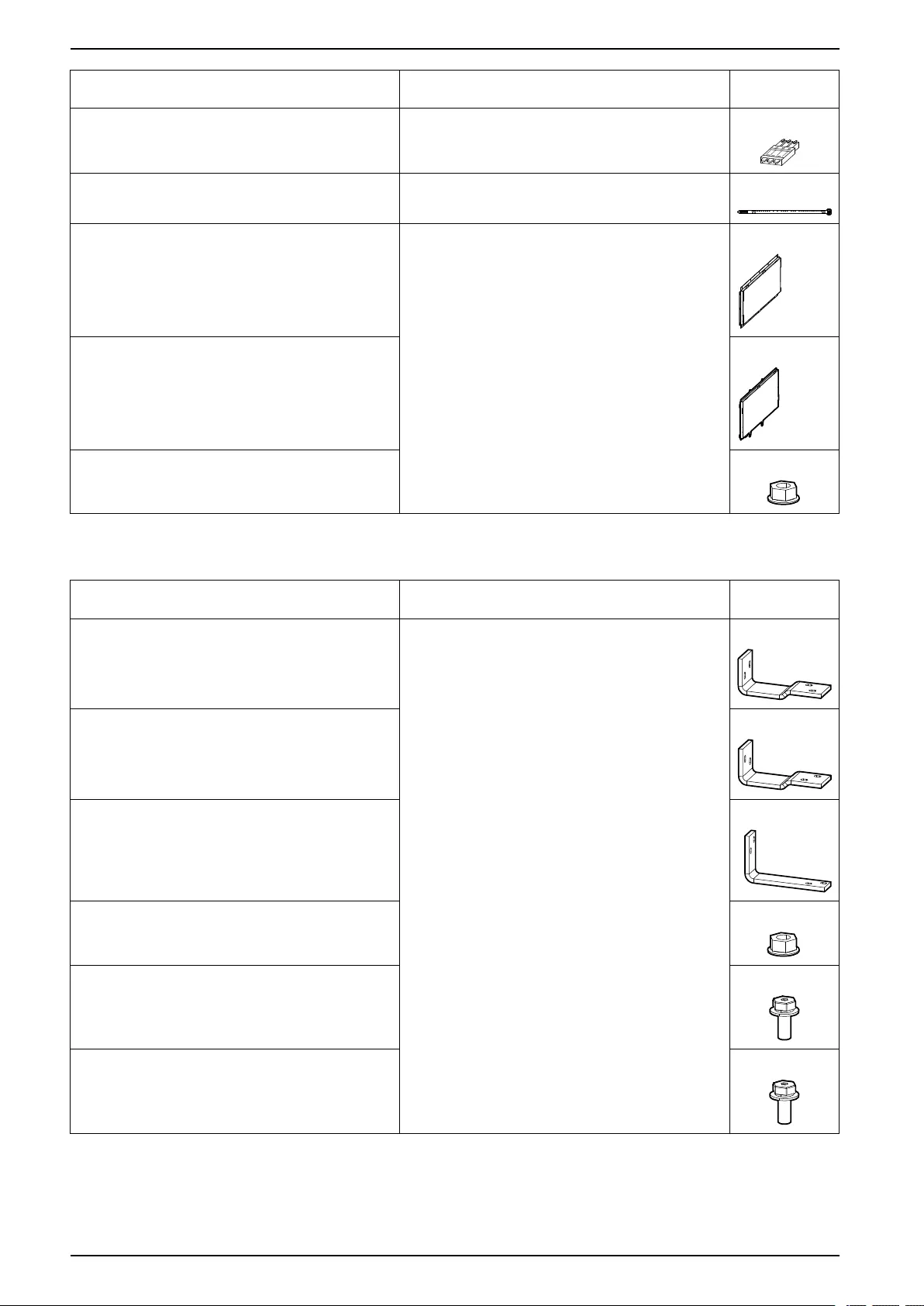

990-5783E-001 35

UPS with 1500 kW I/O Cabinet Overview of Supplied Installation Kits

Part Used in Number of

Units

Terminator for modbus Connect the Modbus Cables, page 107 2

Cable ties for signal cables Connect the Signal Cables, page 88 50

EMC cover left 0M-82316 Position the Cabinets, page 52 1

EMC cover right 0M-98993 1

M6 nut with washer 22

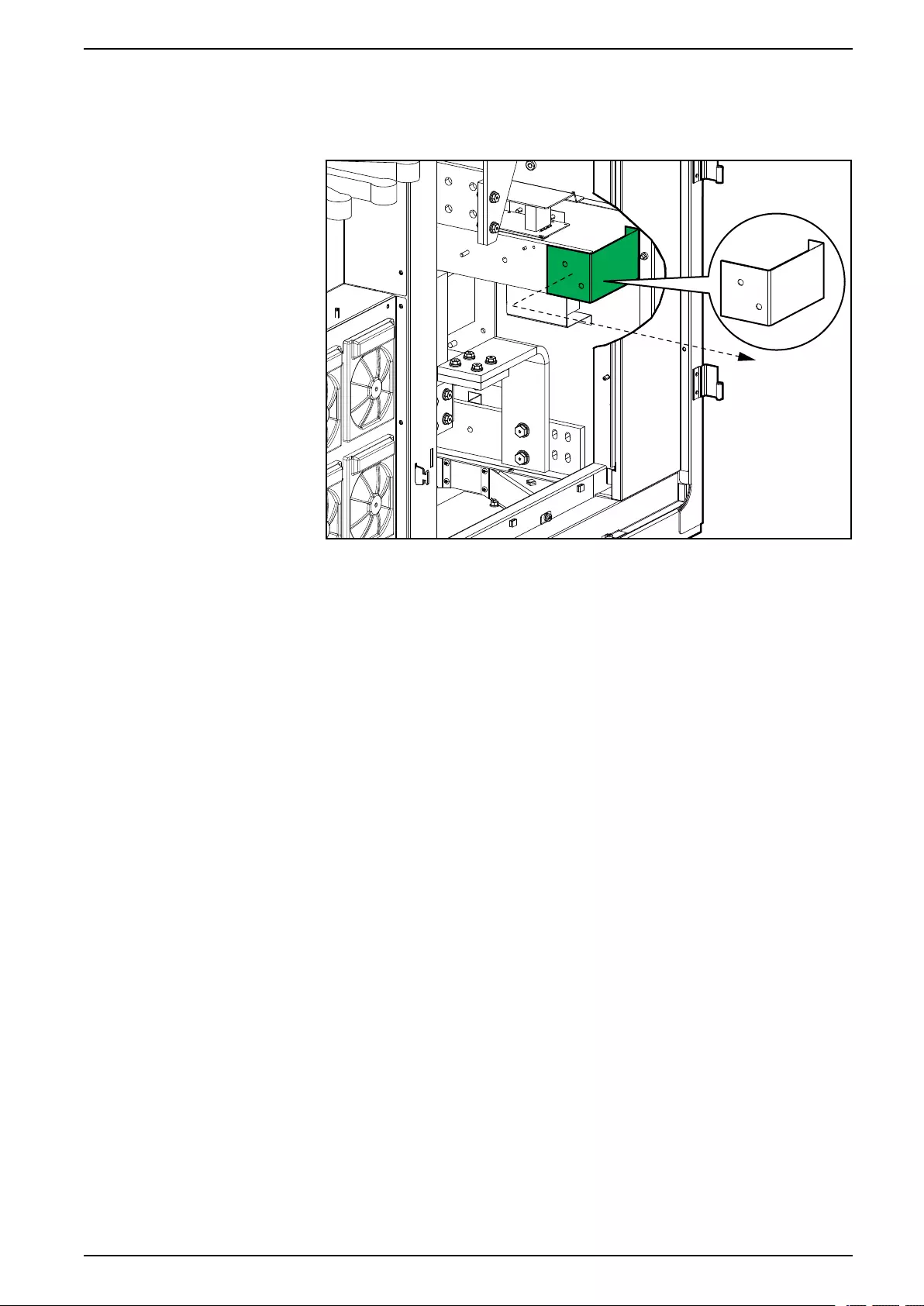

Installation Kit 0H-9097

Part Used in Number of

Units

Battery + interconnection busbar 880–90655 between I/O

cabinet and power cabinet to the right

Install the Busbars between the I/O Cabinet and the

Power Cabinets, page 71

1

Output interconnection busbars 880–90654 between I/O

cabinet and power cabinet to the right

3

Neutral interconnection busbar 880–5538 between I/O

cabinet and power cabinet to the right

1

M10 nut with washer 8

M10 x 40 hexagonal torx with washer 2

M8 x 40 hexagonal torx with washer 10

36 990-5783E-001

Overview of Supplied Installation Kits UPS with 1500 kW I/O Cabinet

Installation Kit 0H-9128

Part Used in Number of

Units

Grounding interconnection busbar 880–99029 between I/

O cabinet and power cabinet to the right

Install the Busbars between the I/O Cabinet and the

Power Cabinets, page 71

1

Battery - interconnection busbar 880–90658 between I/O

cabinet and power cabinet to the right

1

Input interconnection busbars 880–90657 between I/O

cabinet and power cabinet to the right

3

Neutral interconnection busbar 880–9614 between I/O

cabinet and power cabinet to the right

1

M10 nut with washer 8

M10 x 40 hexagonal torx with washer 2

M8 x 40 hexagonal torx with washer 18

M6 nuts with washer 3

Installation Kit 0H-9096

Part Used in Number of

Units

Grounding interconnection busbar 880–5662 between I/O

cabinet and power cabinet to the left

Install the Busbars between the I/O Cabinet and the

Power Cabinets, page 71

1

Battery + interconnection busbar 880–5503 between I/O

cabinet and power cabinet to the left

1

Neutral interconnection busbar 880–5507 between I/O

cabinet and power cabinet to the left

1

990-5783E-001 37

UPS with 1500 kW I/O Cabinet Overview of Supplied Installation Kits

Part Used in Number of

Units

First battery - interconnection busbar 880–5496 between

I/O cabinet and power cabinet to the left

1

First layer input interconnection busbars 880–5502

between I/O cabinet and power cabinet to the left

3

Second battery - interconnection busbar 880–5495

between I/O cabinet and power cabinet to the left

1

M10 nut with washer 2

M10 x 40 hexagonal torx with washer 10

M8 nut with washer 4

M8 x 40 hexagonal torx with washer 18

Installation Kit 0H-9129

Part Used in Number of

Units

Output interconnection busbars 880–9569 between I/O

cabinet and power cabinet to the left

Install the Busbars between the I/O Cabinet and the

Power Cabinets, page 71

3

Second layer input interconnection busbars 880–90650

between I/O cabinet and power cabinet to the left

3

M10 nut with washer 6

M8 x 40 hexagonal torx with washer 12

M6 nuts with washer 3

38 990-5783E-001

Overview of Supplied Installation Kits UPS with 1500 kW I/O Cabinet

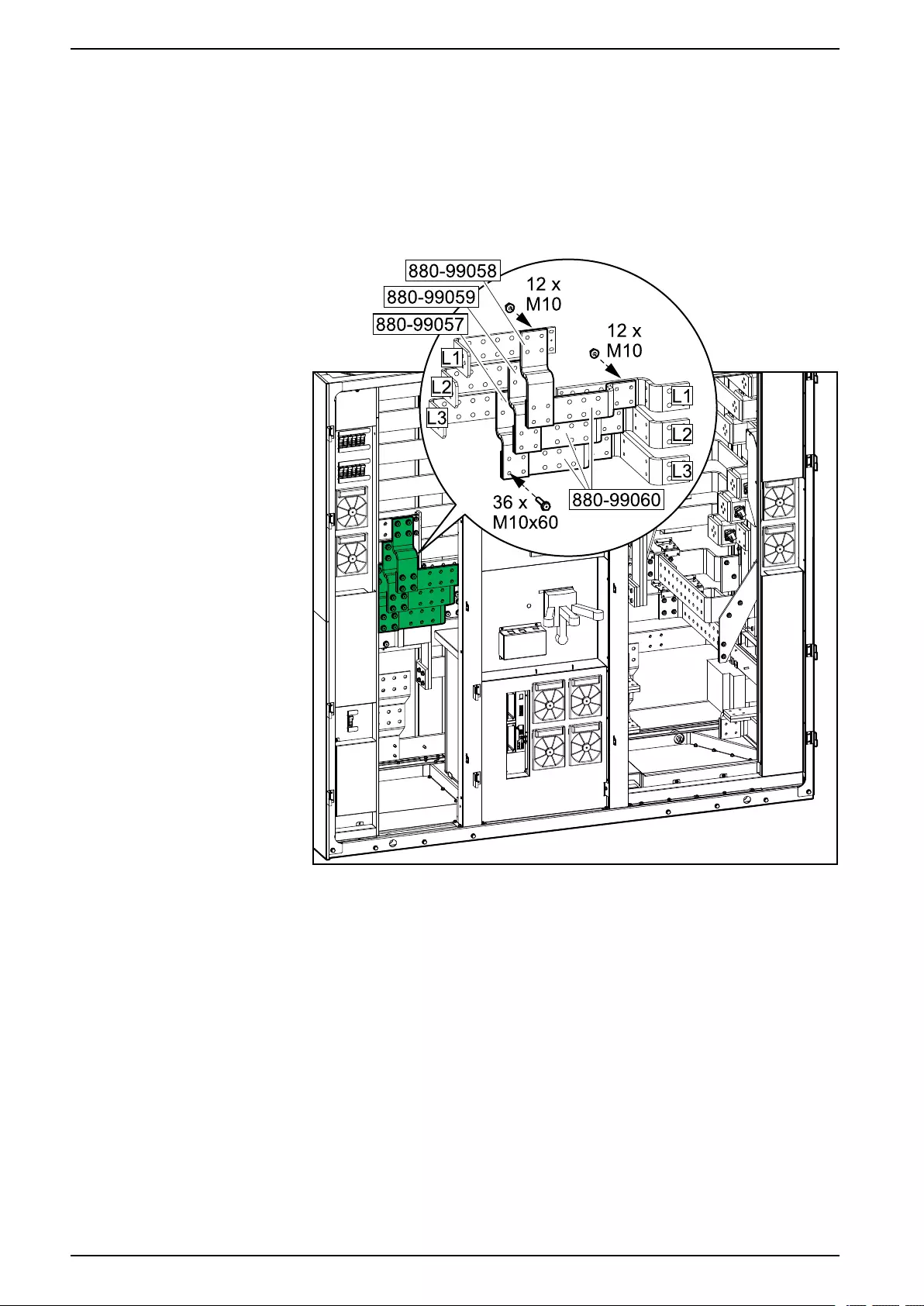

Installation Kit 0H-9161 for Single Mains

Part Used in Number of

Units

Vertical single mains busbar 880–99058 for L1 Install the Single Utility/Mains Installation Kit 0H-9161,

page 82

1

Vertical single mains busbar 880–99059 for L2 1

Vertical single mains busbar 880–99057 for L3 1

Horizontal single mains busbars 880–99060 3

M10 nut with washer 24

M10 x 60 hexagonal torx with washer 36

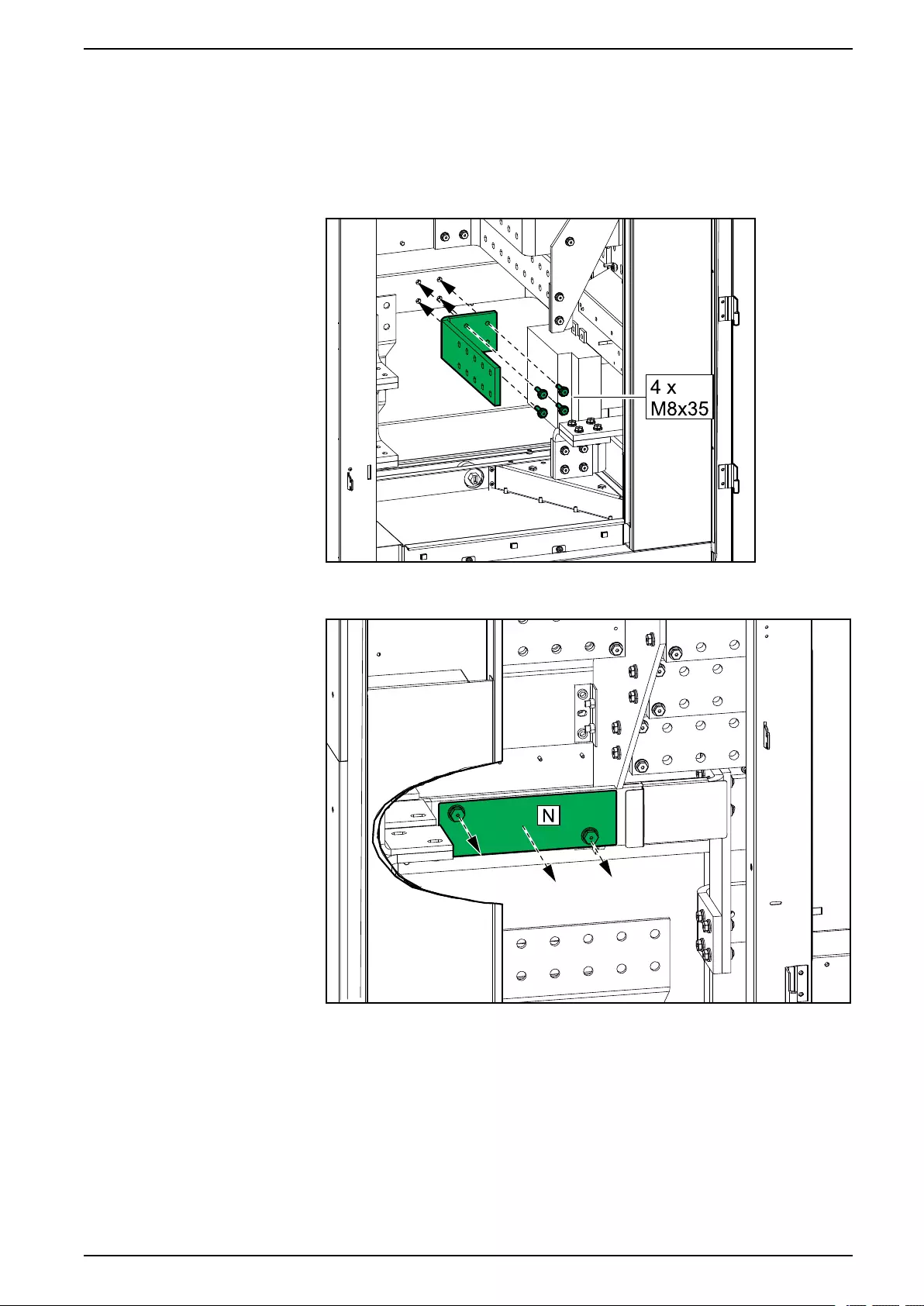

Installation Kit 0H-1102

Part Used in Number of units

Neutral busbar 880–5501 Connect the Power Cables in a 380 V, 400 V, 415, and

440 V System, page 83

1

M8 x 35 hexagonal torx with washer 4

990-5783E-001 39

UPS with 1500 kW I/O Cabinet Overview of Supplied Installation Kits

Installation Kit 0M-99259

Part Used in Number of

Units

Front anchoring bracket for I/O cabinet Mount the Front Anchoring Brackets, page 86 1

Installation Kit 0H-1074

Part Used in Number of

Units

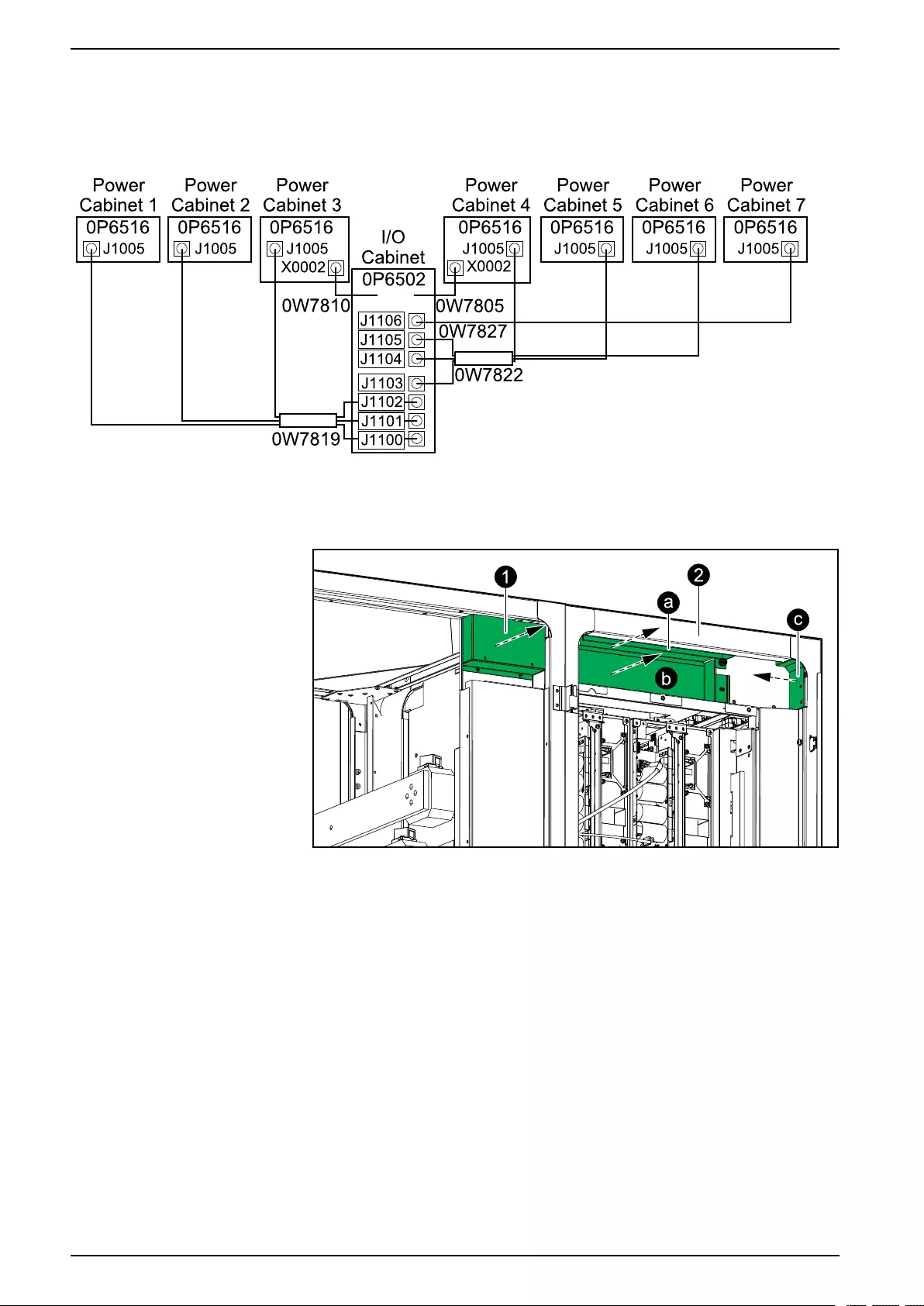

Optical fiber cable 0W7819 Connect the Signal Cables between the I/O Cabinet and

the Power Cabinets, page 92

1

Optical fiber cable 0W7822 1

Optical fiber cable 0W7827 1

Display cable 0W7853 Do not install. Installation must be performed by

Schneider Electric.

1

Display cable 0W7858 1

Display cable 0W7859 1

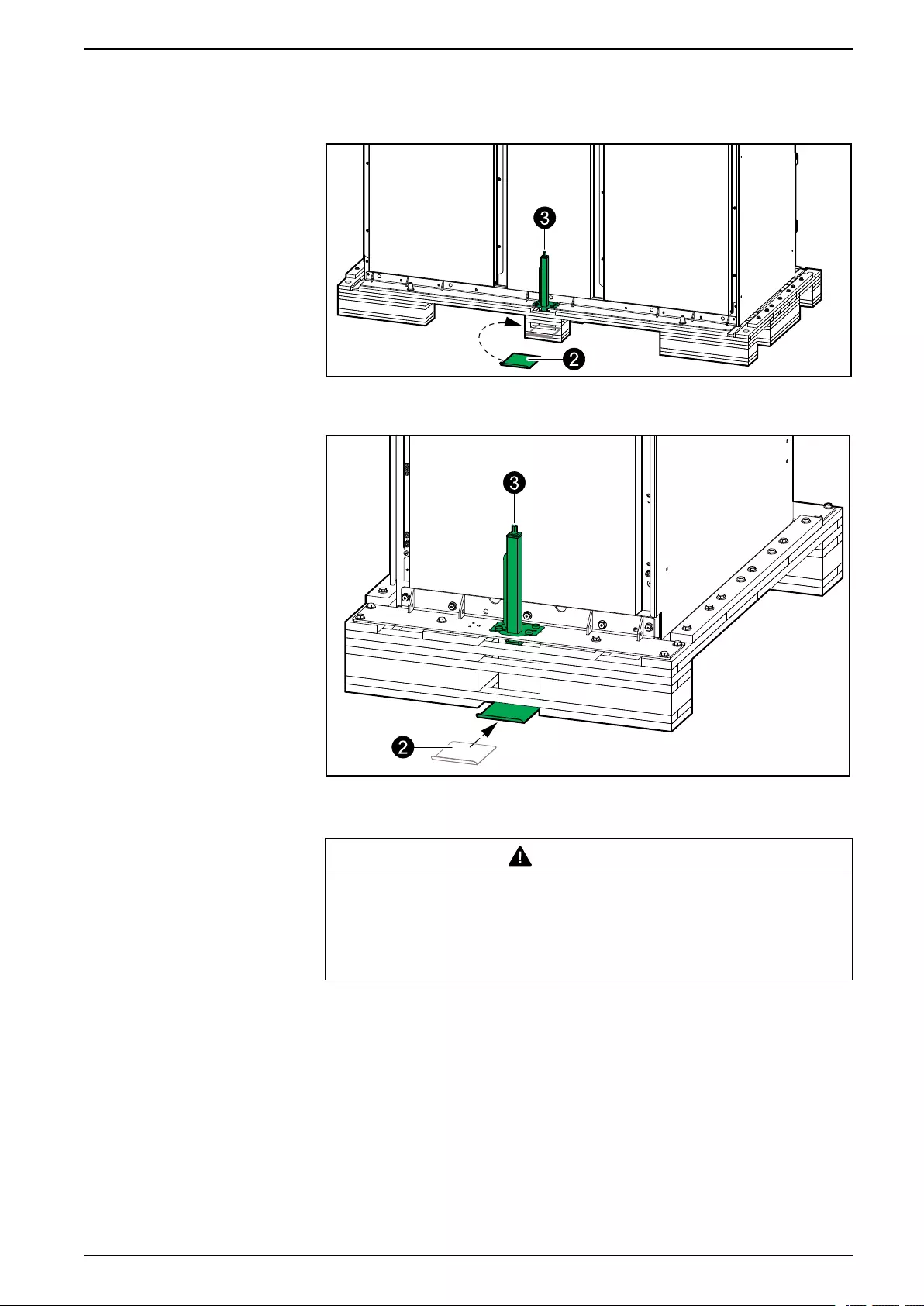

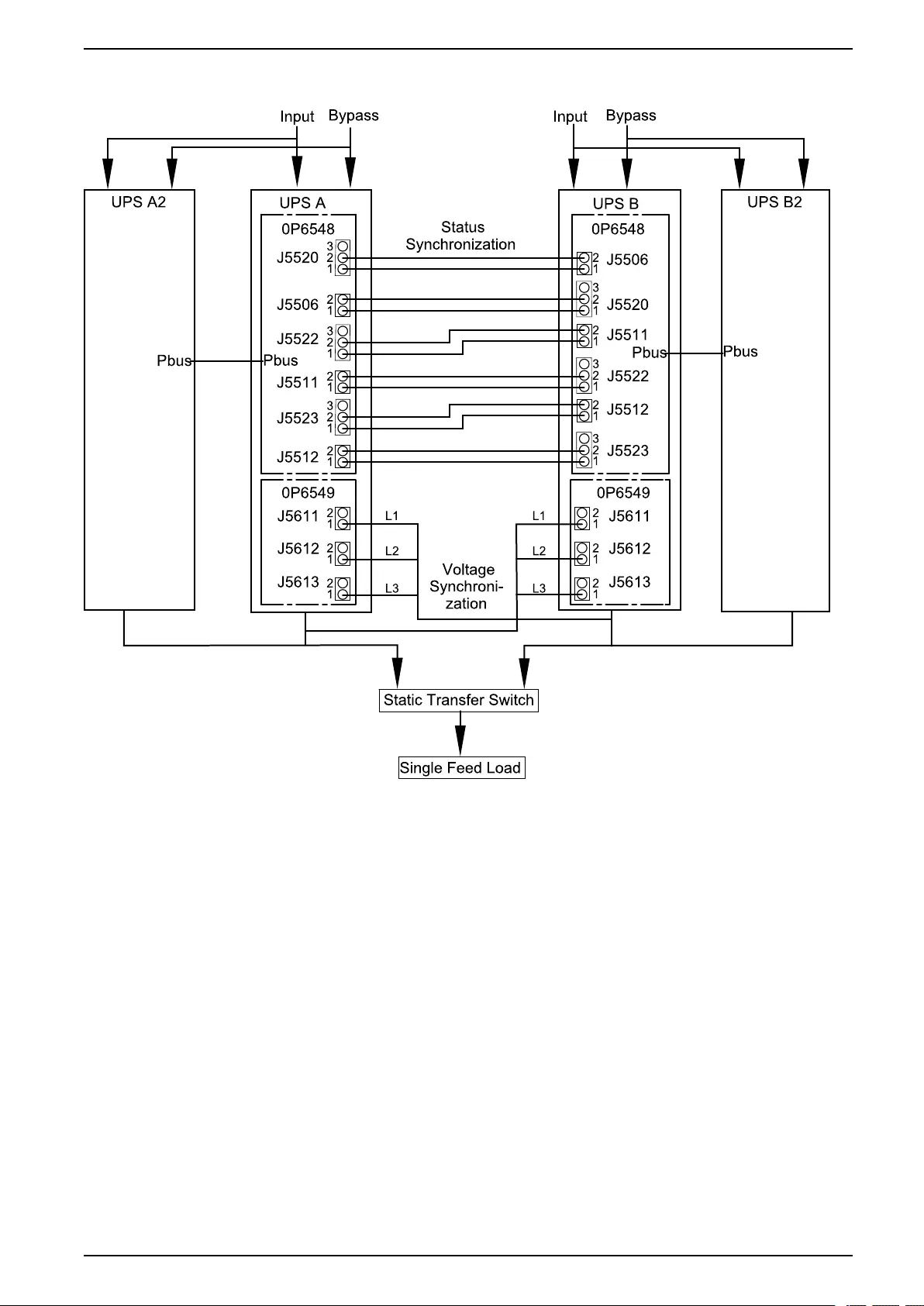

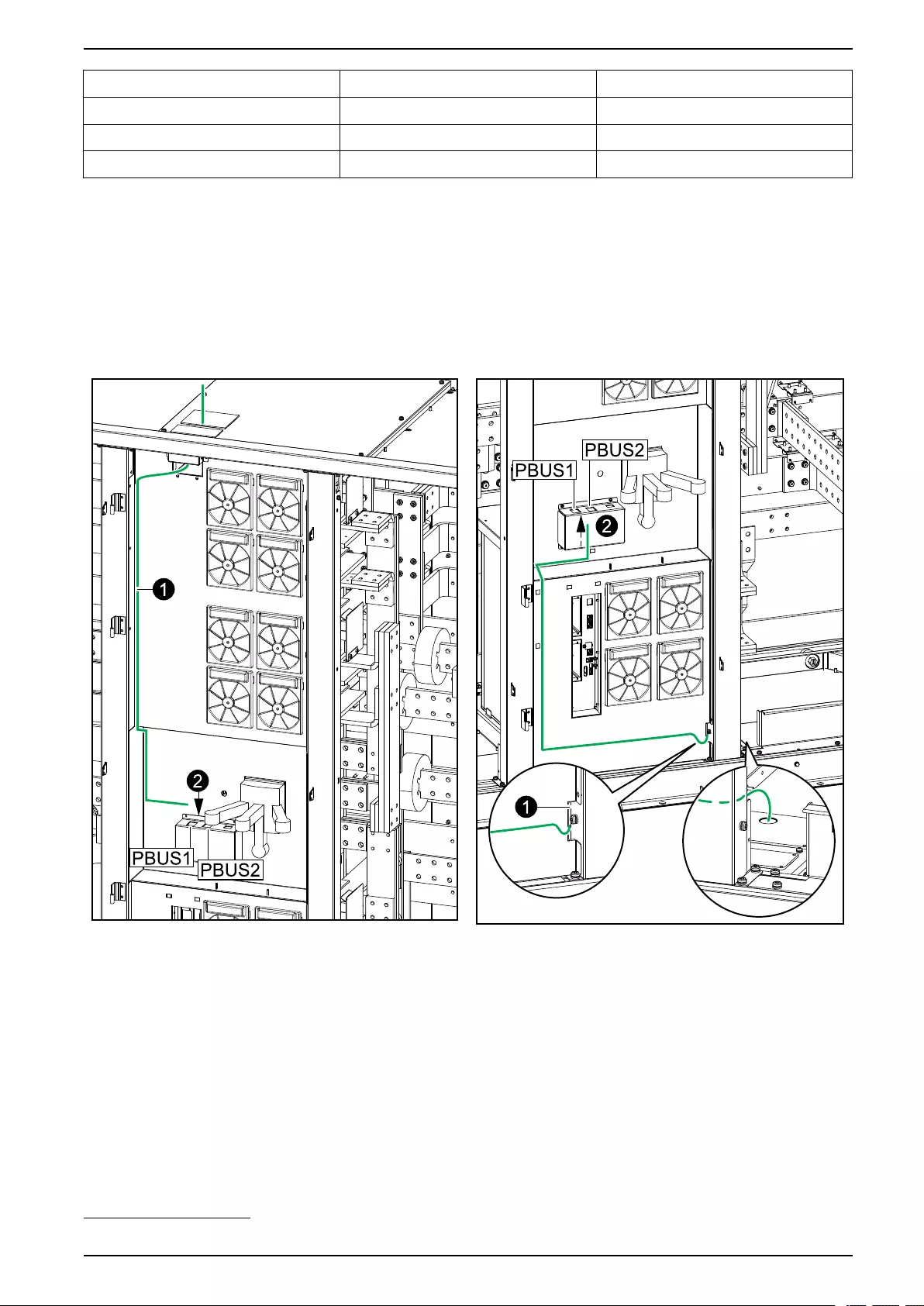

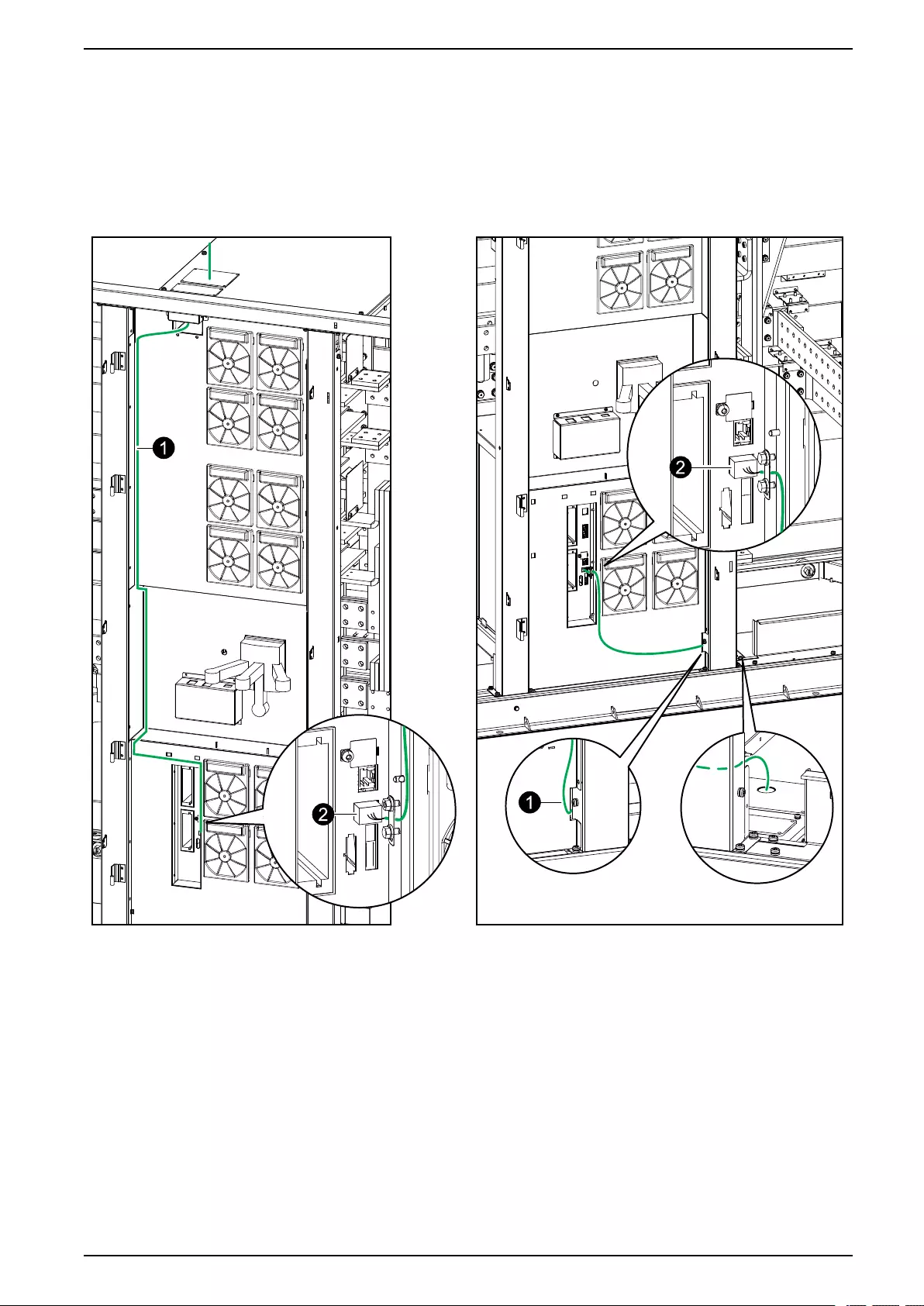

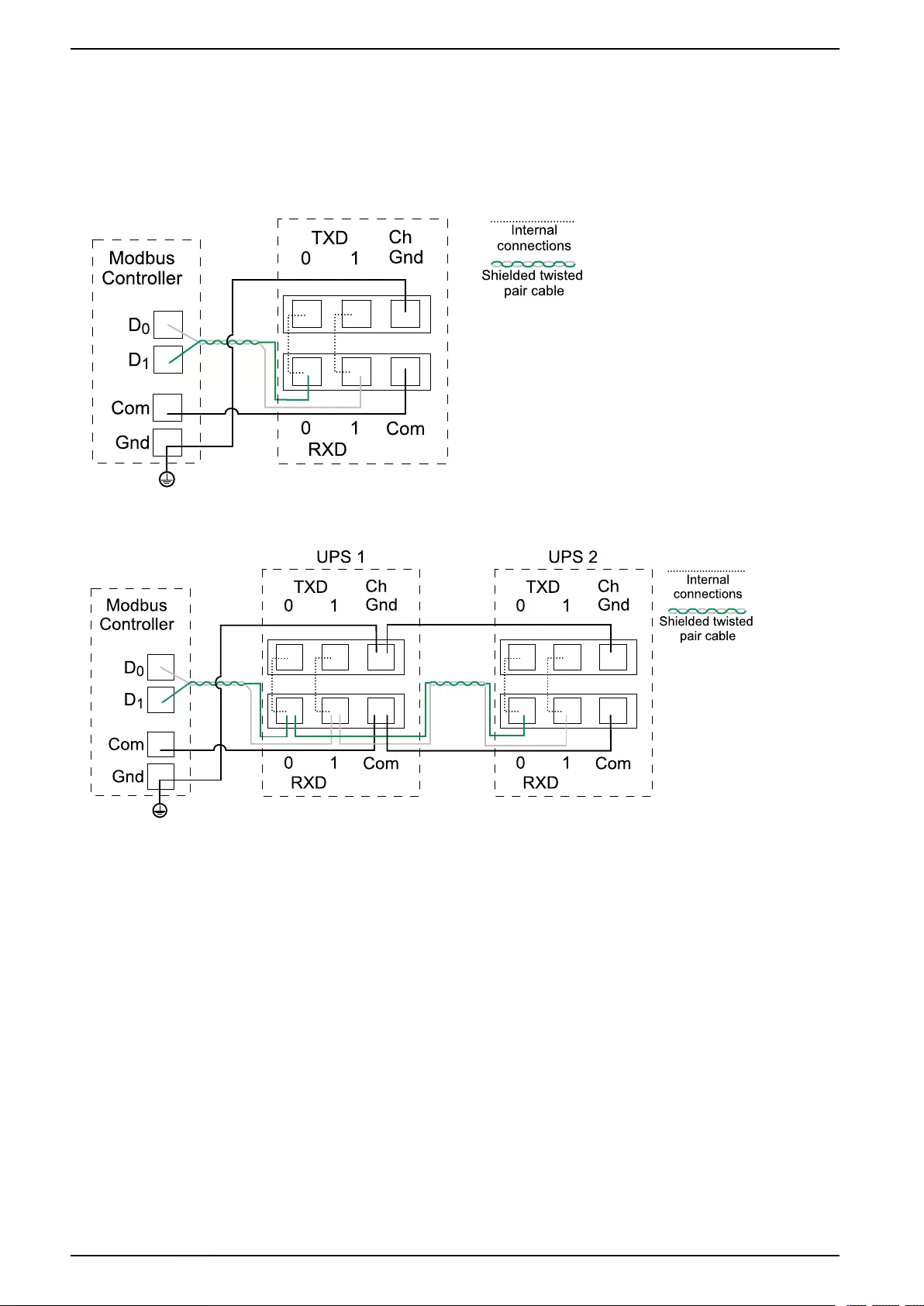

Installation Kit 0H-0889