Table of Contents

- Galaxy Lithium-ion Battery Cabinet

- Important Safety Instructions — SAVE THESE INSTRUCTIONS

- Specifications

- Overview of Accessory Kits

- Installation Procedure

- Prepare for Installation

- Install the Rear Seismic Anchoring

- Position and Interconnect the Battery Cabinets

- Install the Front Seismic Anchoring

- Install the Battery Modules in the Battery Cabinet

- Connect the Power Cables

- Overview of Communication Interface

- Route the Signal Cables to the Switchgear, Rack BMS, and System BMS Ports

- Operation Procedures

- Troubleshooting

- Blank Page

- Blank Page

APC LIBSESMG16UL User Manual

Displayed below is the user manual for LIBSESMG16UL by APC which is a product in the UPS Battery Cabinets category. This manual has pages.

Related Manuals

Galaxy Lithium-ion Battery Cabinet

With 13, 16, or 17 Battery Modules

Installation and Operation

LIBSESMG13IEC, LIBSESMG16IEC, LIBSESMG17IEC

LIBSESMG13UL, LIBSESMG16UL, LIBSESMG17UL

Latest updates are available on the Schneider Electric website

5/2021

www.se.com

Legal Information

The Schneider Electric brand and any trademarks of Schneider Electric SE and its

subsidiaries referred to in this guide are the property of Schneider Electric SE or its

subsidiaries. All other brands may be trademarks of their respective owners.

This guide and its content are protected under applicable copyright laws and

furnished for informational use only. No part of this guide may be reproduced or

transmitted in any form or by any means (electronic, mechanical, photocopying,

recording, or otherwise), for any purpose, without the prior written permission of

Schneider Electric.

Schneider Electric does not grant any right or license for commercial use of the guide

or its content, except for a non-exclusive and personal license to consult it on an "as

is" basis. Schneider Electric products and equipment should be installed, operated,

serviced, and maintained only by qualified personnel.

As standards, specifications, and designs change from time to time, information

contained in this guide may be subject to change without notice.

To the extent permitted by applicable law, no responsibility or liability is assumed by

Schneider Electric and its subsidiaries for any errors or omissions in the informational

content of this material or consequences arising out of or resulting from the use of the

information contained herein.

Go to https://www.productinfo.schneider-electric.com/galaxyliion/

or scan the QR code above for digital experience and translated manuals.

With 13, 16, or 17 Battery Modules

Table of Contents

Important Safety Instructions — SAVE THESE

INSTRUCTIONS.........................................................................................5

FCC Statement ..........................................................................................6

Electromagnetic Compatibility .....................................................................6

Safety Precautions .....................................................................................6

Electrical Safety .........................................................................................8

Battery Safety ............................................................................................9

Specifications ............................................................................................10

Recommended Cable Sizes ......................................................................10

Recommended Cable Lugs.......................................................................11

Torque Specifications................................................................................11

Weights and Dimensions........................................................................... 11

Clearance ................................................................................................12

Environment.............................................................................................12

Overview of Accessory Kits.....................................................................13

Installation Procedure ..............................................................................14

Prepare for Installation..............................................................................15

Install the Rear Seismic Anchoring.............................................................17

Position and Interconnect the Battery Cabinets ...........................................19

Install the Front Seismic Anchoring ............................................................21

Install the Battery Modules in the Battery Cabinet........................................22

Connect the Power Cables........................................................................25

Overview of Communication Interface........................................................28

Route the Signal Cables to the Switchgear, Rack BMS, and System BMS

Ports .......................................................................................................29

Overview of Signal Cables between the Battery Cabinets and the

Auxiliary Contacts in the UPS ..............................................................32

Overview of Signal Cables for Alarms and Battery Breaker Trip ..............33

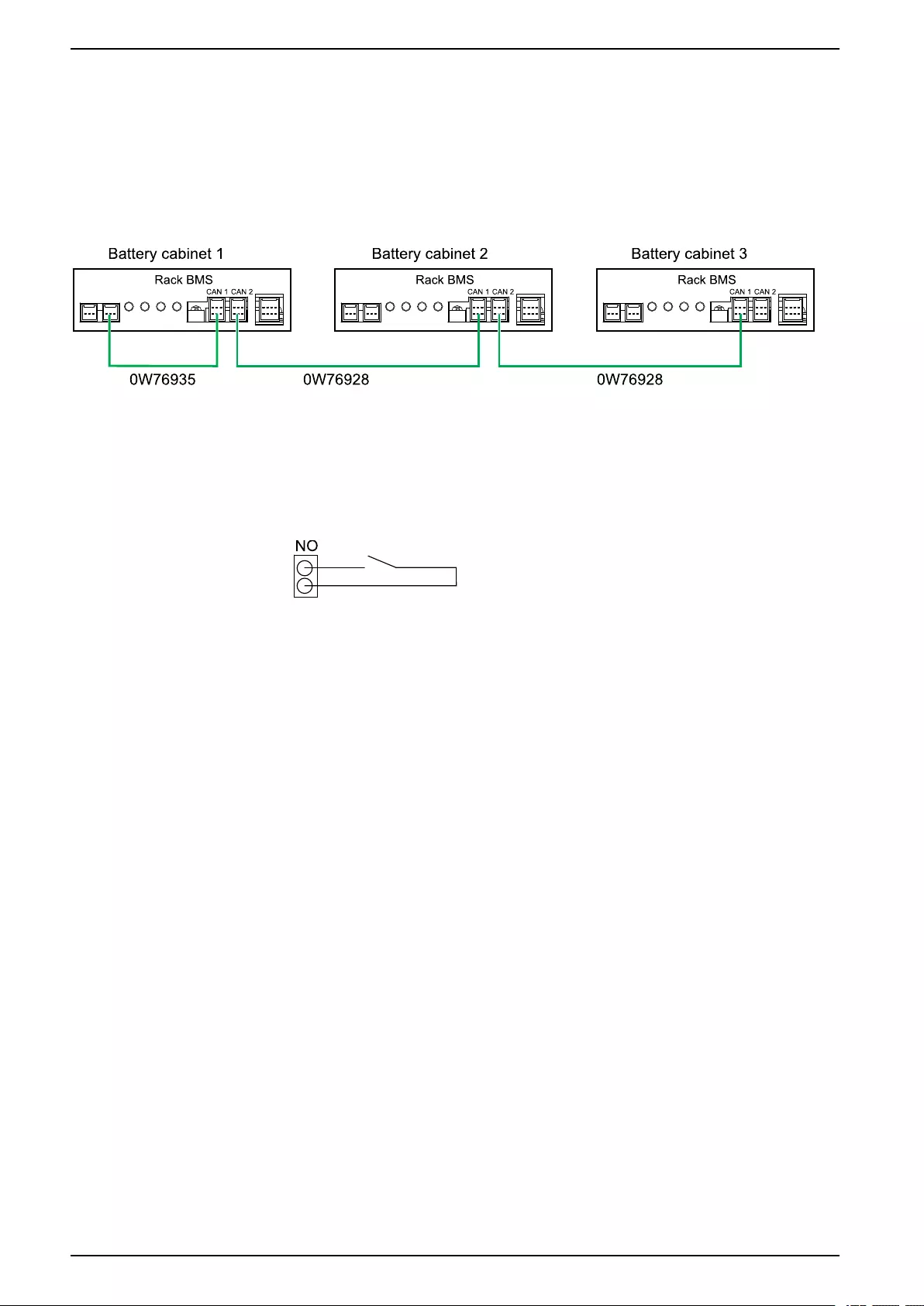

Overview of CAN Bus Cables between the Battery Cabinets ..................34

Overview of EPO Signal Cables...........................................................34

Operation Procedures..............................................................................35

Shut Down the Battery Solution .................................................................35

Restart the Battery Solution.......................................................................35

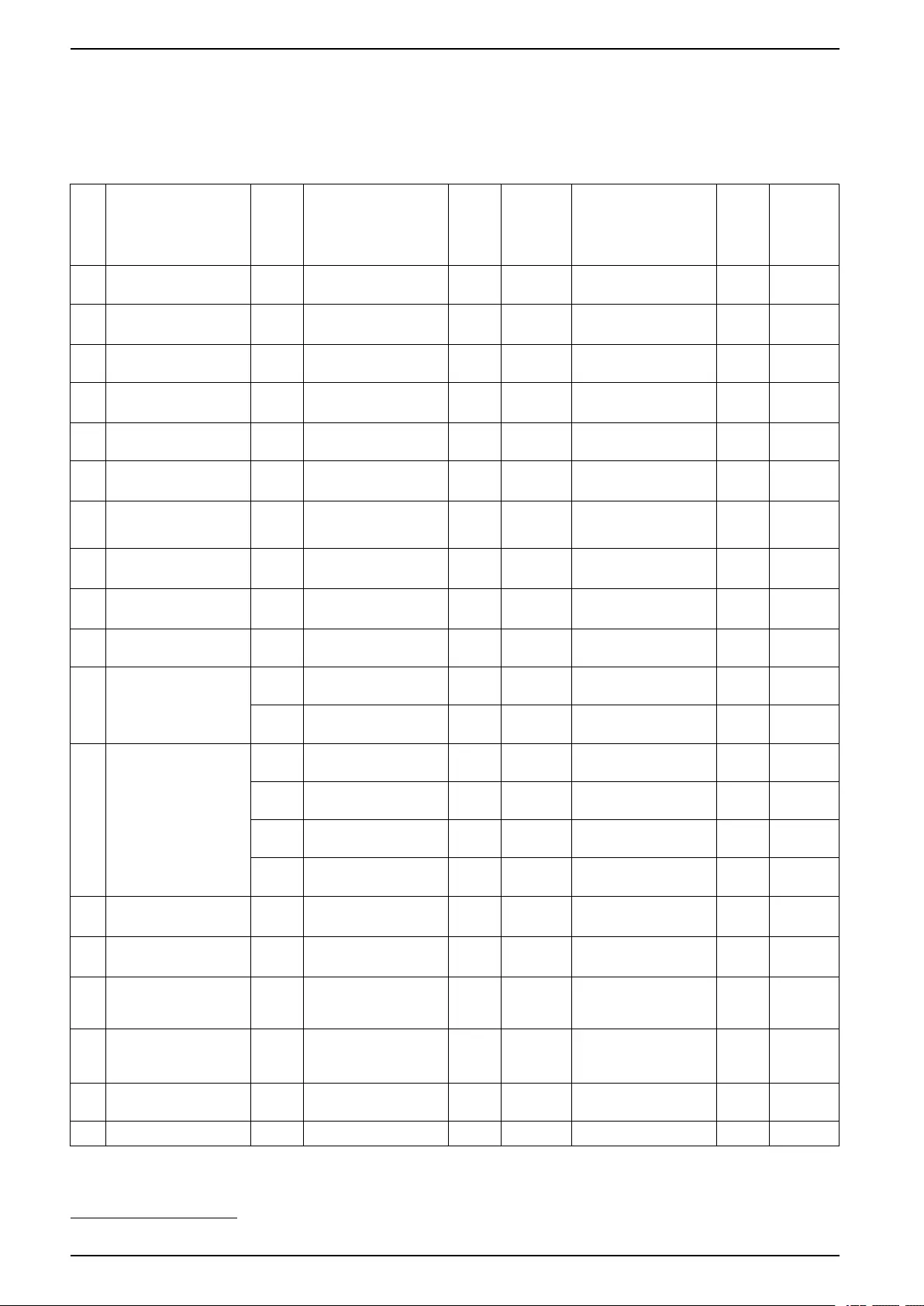

Troubleshooting ........................................................................................36

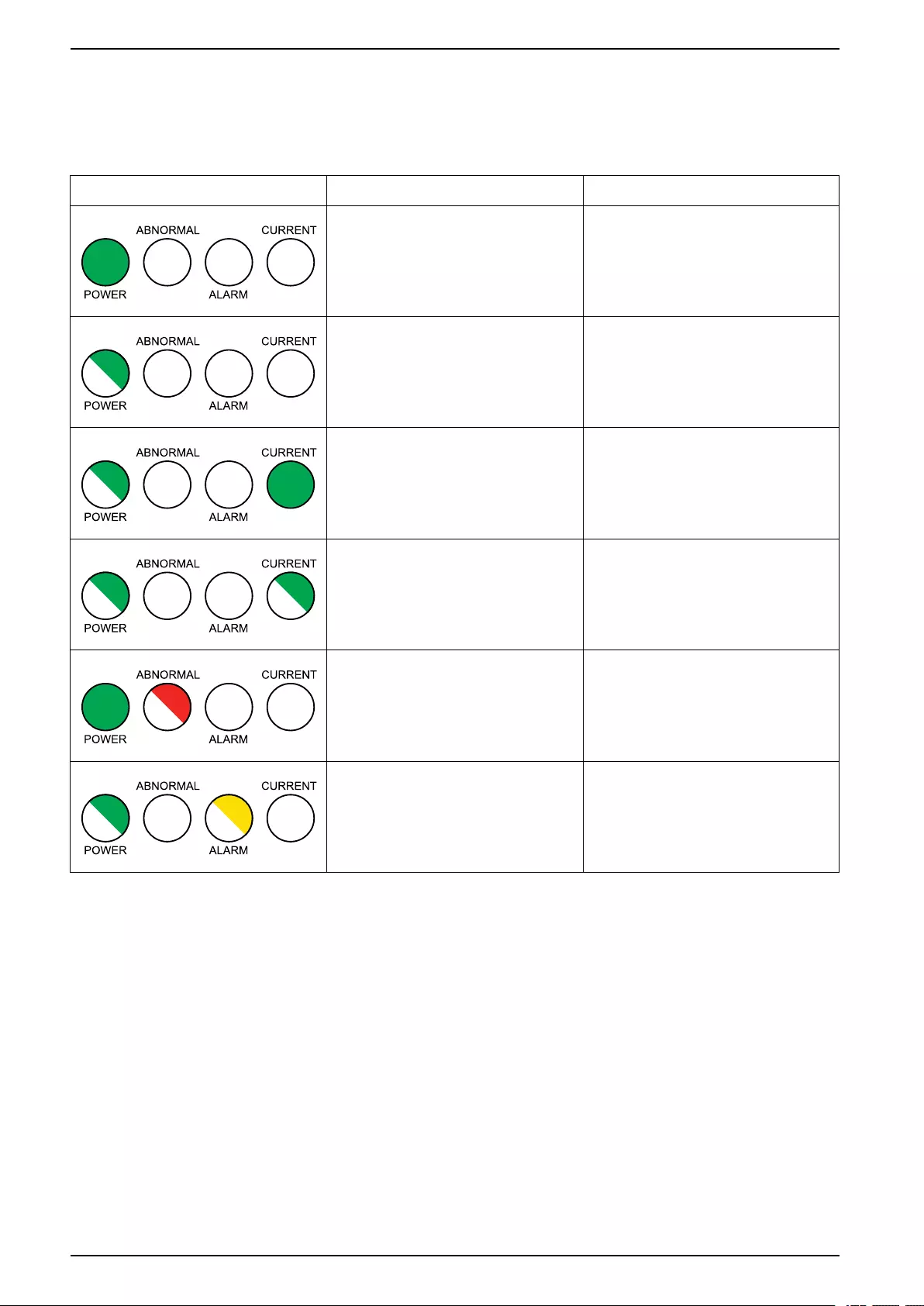

Status LEDs.............................................................................................36

PSU LEDs ...............................................................................................37

Alarm List.................................................................................................38

Protection Protocols............................................................................38

990-91430A-001 3

Important Safety Instructions — SAVE THESE

INSTRUCTIONS With 13, 16, or 17 Battery Modules

Important Safety Instructions — SAVE THESE

INSTRUCTIONS

Read these instructions carefully and look at the equipment to become familiar

with it before trying to install, operate, service or maintain it. The following safety

messages may appear throughout this manual or on the equipment to warn of

potential hazards or to call attention to information that clarifies or simplifies a

procedure.

The addition of this symbol to a “Danger” or “Warning” safety

message indicates that an electrical hazard exists which will result in

personal injury if the instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages with this symbol

to avoid possible injury or death.

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

Failure to follow these instructions will result in death or serious injury.

WARNING

WARNING indicates a hazardous situation which, if not avoided, could result

in death or serious injury.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

Failure to follow these instructions can result in injury or equipment

damage.

NOTICE

NOTICE is used to address practices not related to physical injury. The safety

alert symbol shall not be used with this type of safety message.

Failure to follow these instructions can result in equipment damage.

Please Note

Electrical equipment should only be installed, operated, serviced, and maintained

by qualified personnel. No responsibility is assumed by Schneider Electric for any

consequences arising out of the use of this material.

A qualified person is one who has skills and knowledge related to the construction,

installation, and operation of electrical equipment and has received safety training

to recognize and avoid the hazards involved.

990-91430A-001 5

With 13, 16, or 17 Battery Modules Important Safety Instructions — SAVE THESE

INSTRUCTIONS

FCC Statement

NOTE: This equipment has been tested and found to comply with the limits for

a Class A digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user

will be required to correct the interference at his own expense.

Any changes or modifications not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

Electromagnetic Compatibility

NOTICE

RISK OF ELECTROMAGNETIC DISTURBANCE

This is a product category C2 UPS product. In a residential environment, this

product may cause radio inference, in which case the user may be required to

take additional measures.

Failure to follow these instructions can result in equipment damage.

Safety Precautions

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Read all instructions in the installation manual before installing or working on

this product.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Do not install the product until all construction work has been completed and

the installation room has been cleaned.

• Build a clear, permanent, restricted access area around the system.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

The product must be installed according to the specifications and requirements

as defined by Schneider Electric. It concerns in particular the external and

internal protections (upstream breakers, battery breakers, cabling, etc.) and

environmental requirements. No responsibility is assumed by Schneider Electric

if these requirements are not respected.

Failure to follow these instructions will result in death or serious injury.

6 990-91430A-001

Important Safety Instructions — SAVE THESE

INSTRUCTIONS With 13, 16, or 17 Battery Modules

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

The UPS system must be installed according to local and national regulations.

Install the UPS according to:

• IEC 60364 (including 60364–4–41- protection against electric shock, 60364–

4–42 - protection against thermal effect, and 60364–4–43 - protection

against overcurrent), or

• NEC NFPA 70, or

• Canadian Electrical Code (C22.1, Part 1)

depending on which one of the standards apply in your local area.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Install the product in a temperature controlled indoor environment free of

conductive contaminants and humidity.

• Install the product on a non-flammable, level and solid surface (e.g.

concrete) that can support the weight of the system.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

The product is not designed for and must therefore not be installed in the

following unusual operating environments:

• Damaging fumes

• Explosive mixtures of dust or gases, corrosive gases, or conductive or

radiant heat from other sources

• Moisture, abrasive dust, steam or in an excessively damp environment

• Fungus, insects, vermin

• Salt-laden air or contaminated cooling refrigerant

• Pollution degree higher than 2 according to IEC 60664-1

• Exposure to abnormal vibrations, shocks, and tilting

• Exposure to direct sunlight, heat sources, or strong electromagnetic fields

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Do not drill or cut holes for cables or conduits with the gland plates installed and

do not drill or cut holes in close proximity to the product.

Failure to follow these instructions will result in death or serious injury.

WARNING

HAZARD OF ARC FLASH

Do not make mechanical changes to the product (including removal of cabinet

parts or drilling/cutting of holes) that are not described in the installation manual.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

990-91430A-001 7

With 13, 16, or 17 Battery Modules Important Safety Instructions — SAVE THESE

INSTRUCTIONS

WARNING

CHEMICAL HAZARD

This product can expose you to chemicals including Tetrabromobisphenol A,

which is known to the State of California to cause cancer. For more information,

go to www.P65Warnings.ca.gov

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

NOTICE

RISK OF OVERHEATING

Respect the space requirements around the product and do not cover the

ventilation openings when the product is in operation.

Failure to follow these instructions can result in equipment damage.

Electrical Safety

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

• Electrical equipment must be installed, operated, serviced, and maintained

only by qualified personnel.

• Apply appropriate personal protective equipment (PPE) and follow safe

electrical work practices.

• Turn off all power supplying the UPS system before working on or inside the

equipment.

• Before working on the UPS system, check for hazardous voltage between all

terminals including the protective earth.

• The battery cabinet contains an internal energy source. Hazardous voltage

can be present even when the UPS system is disconnected from the utility/

mains supply. Before installing or servicing the UPS system, ensure that the

units are OFF and that utility/mains and batteries are disconnected.

• A disconnection device (e.g. disconnection circuit breaker or switch) must be

installed to enable isolation of the system from upstream power sources in

accordance with local regulations. This disconnection device must be easily

accessible and visible.

• The battery cabinet must be properly earthed/grounded and due to a high

leakage current, the earthing/grounding conductor must be connected first.

Failure to follow these instructions will result in death or serious injury.

8 990-91430A-001

Important Safety Instructions — SAVE THESE

INSTRUCTIONS With 13, 16, or 17 Battery Modules

Battery Safety

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Battery circuit breakers must be installed according to the specifications and

requirements as defined by Schneider Electric.

• Servicing of batteries must only be performed or supervised by qualified

personnel knowledgeable of batteries and the required precautions. Keep

unqualified personnel away from batteries.

• Disconnect charging source prior to connecting or disconnecting battery

terminals.

• Do not dispose of batteries in a fire as they can explode.

• Do not open, alter, or mutilate batteries.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Batteries can present a risk of electric shock and high short-circuit current. The

following precautions must be observed when working on batteries

• Remove watches, rings, or other metal objects.

• Use tools with insulated handles.

• Wear protective glasses, gloves and boots.

• Do not lay tools or metal parts on top of batteries.

• Disconnect the charging source prior to connecting or disconnecting battery

terminals.

• Determine if the battery is inadvertently grounded. If inadvertently grounded,

remove source from ground. Contact with any part of a grounded battery can

result in electric shock. The likelihood of such shock can be reduced if such

grounds are removed during installation and maintenance (applicable to

equipment and remote battery supplies not having a grounded supply

circuit).

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

When replacing batteries, always replace with the same battery module type.

Failure to follow these instructions will result in death or serious injury.

NOTICE

RISK OF EQUIPMENT DAMAGE

• Batteries should not be stored beyond 12 months from the date of

production. If they are stored for longer the calendar degradation will cause

the batteries to be irreversible degraded beyond what is expected – a

reduced runtime will be the consequence. Performance guarantee will be

measured from the time of deployment or from production date +12 months,

whichever comes first. For storage beyond 12 months, contact Schneider

Electric.

• If the UPS system remains de-energized for a long period, Schneider

Electric recommends to shut down the battery cabinet completely.

Failure to follow these instructions can result in equipment damage.

990-91430A-001 9

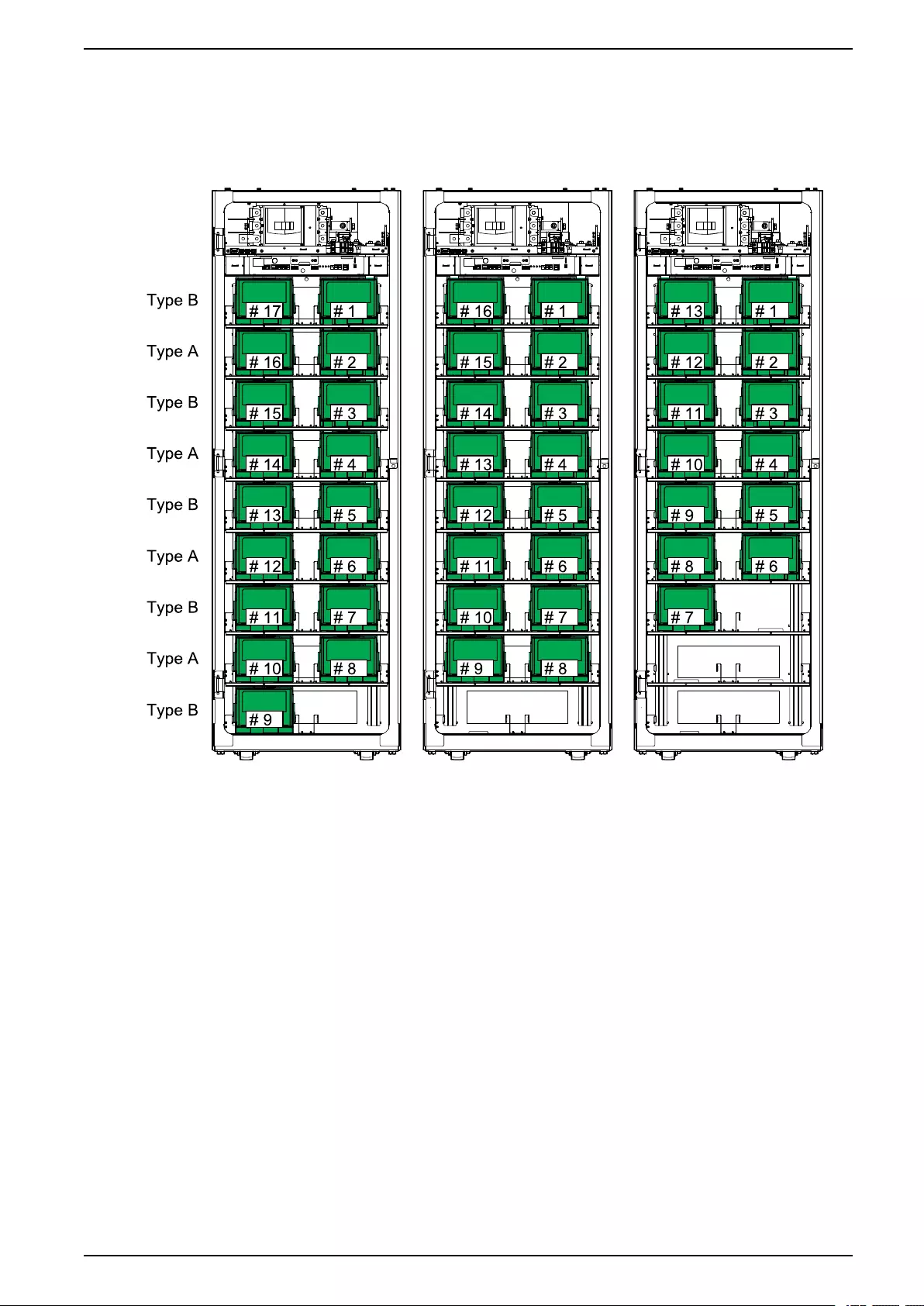

With 13, 16, or 17 Battery Modules Specifications

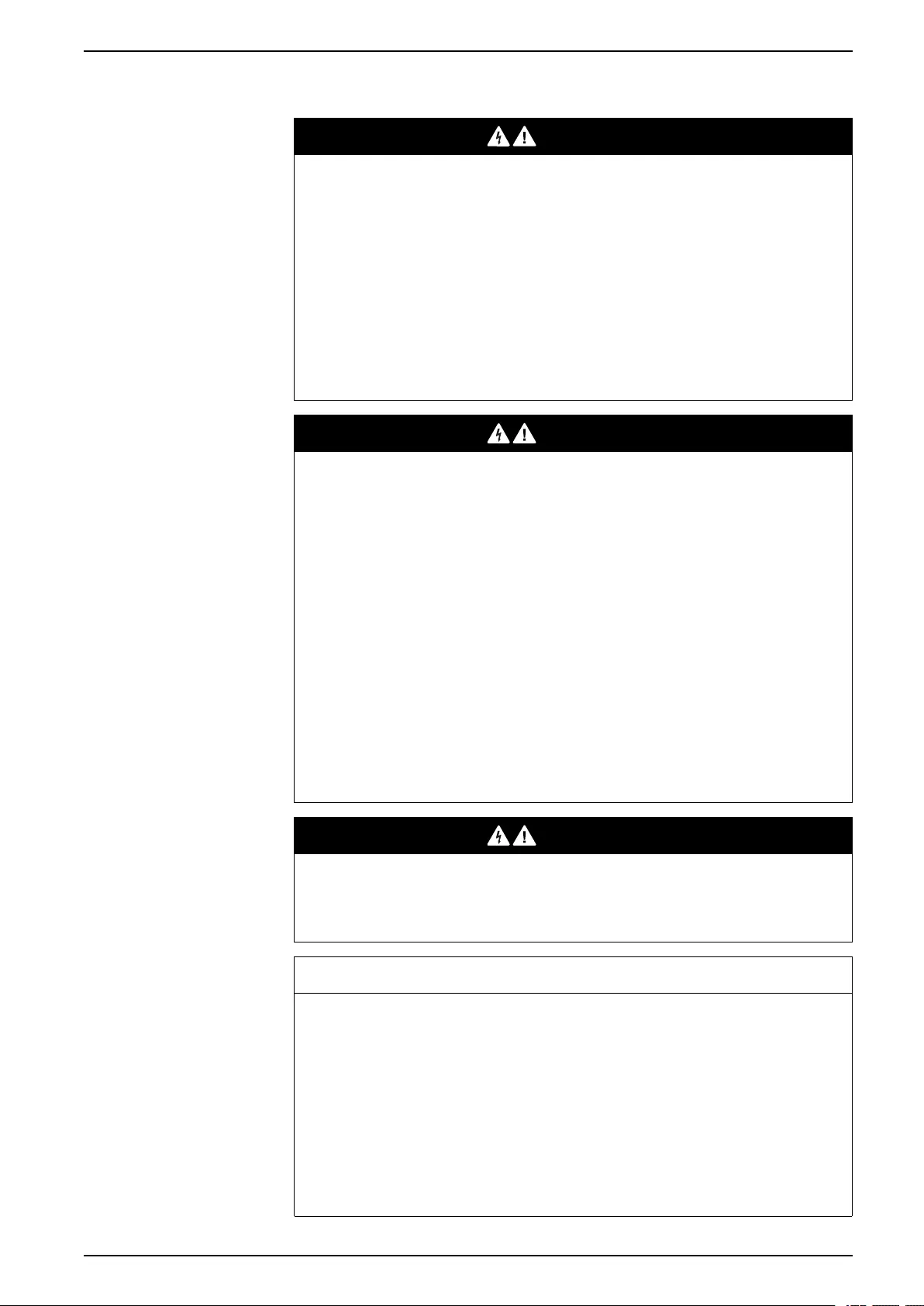

Specifications

Commercial reference LIBSESMG13IEC/

LIBSESMG13UL

LIBSESMG16IEC/

LIBSESMG16UL

LIBSESMG17IEC/

LIBSESMG17UL

Battery designation IMP46/175/127/[(8S)13S]M/-20

+60/90 IMP46/175/127/[(8S)16S]M/-20

+60/90 IMP46/175/127/[(8S)17S]M/-20

+60/90

Number of battery modules 13 16 17

Number of type A battery

modules (LIBSMG95MODA) 6 8 8

Number of type B battery

modules (LIBSMG95MODB) 7 8 9

Number of battery cells in a

string 104 128 136

Nominal energy (kWh) 26.5 32.6 34.6

Nominal battery voltage (VDC) 395 486 517

Nominal capacity (Ah) 67 67 67

Charge current rate (CA rate) 0.7 0.7 0.7

Float charge voltage (VDC) 436 537 571

End of discharge voltage (VDC) 312 384 408

Maximum continuous discharge

power (kW) 140 173 184

Peak current at end of

discharge (A) 450 450 450

Maximum short circuit current

(kA) 9.0 9.0 9.0

NOTE: If the battery temperature is higher than the threshold after a full

discharge at maximum continuous discharge power, the UPS may have to

reduce the charge current to zero to protect the battery.

NOTE: The battery temperature must return to ±3 °C / ±37.4 °F of the room

temperature before a new discharge at maximum continuous discharge

power. If not, the battery breaker may be tripped due to overtemperature

protection.

Recommended Cable Sizes

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

All wiring must comply with all applicable national and/or electrical codes. The

maximum allowable cable size is 185 mm² (IEC) / 350 kcmil (UL).

Failure to follow these instructions will result in death or serious injury.

NOTE: Refer to the UPS installation manual for recommended cable sizes.

10 990-91430A-001

Specifications With 13, 16, or 17 Battery Modules

Recommended Cable Lugs

Copper – One Hole Cable Lug

Cable size Bolt size Cable lug type Crimp tool Die

3/0 AWG M10x30 LCA3/0-12-X CT-720 CD-720-2 Orange P50

4/0 AWG M10x30 LCA4/0-12-X CT-720 CD-720-3 Purple P54

300 kcmil M10x30 LCA300-12-X CT-720 CD-720-4 White P66

350 kcmil M10x30 LCA350-12-X CT-720 CD-720-5 Red P71

Copper – Two Hole Cable Lug

Cable size Bolt size Cable lug type Crimp tool Die

3/0 AWG M10x30 LCC3/0-12D-X CT-930 CD-920-3/0 Orange P50

4/0 AWG M10x30 LCC4/0-12D-X CT-930 CD-920-4/0 Purple P54

300 kcmil M10x30 LCC300-12-X CT-930 CD-920-300 White P66

350 kcmil M10x30 LCC350-12-X CT-930 CD-920-350 Red P71

Torque Specifications

Bolt size Torque

M4 1.7 Nm (1.25 lb-ft)

M6 5 Nm (3.69 lb-ft)

M8 14 Nm (10.33 lb-ft)

M10 30 Nm (22.13 lb-ft)

M12 46 Nm (33.93 lb-ft)

Weights and Dimensions

Commercial reference Weight kg (lbs) Height mm (in) Width mm (in) Depth mm (in)

LIBSESMG13IEC/

LIBSESMG13UL 415 (915) 1970 (77.56) 650 (25.59) 587 (23.11)

LIBSESMG16IEC/

LIBSESMG16UL 470 (1036) 1970 (77.56) 650 (25.59) 587 (23.11)

LIBSESMG17IEC/

LIBSESMG17UL 490 (1080) 1970 (77.56) 650 (25.59) 587 (23.11)

990-91430A-001 11

With 13, 16, or 17 Battery Modules Specifications

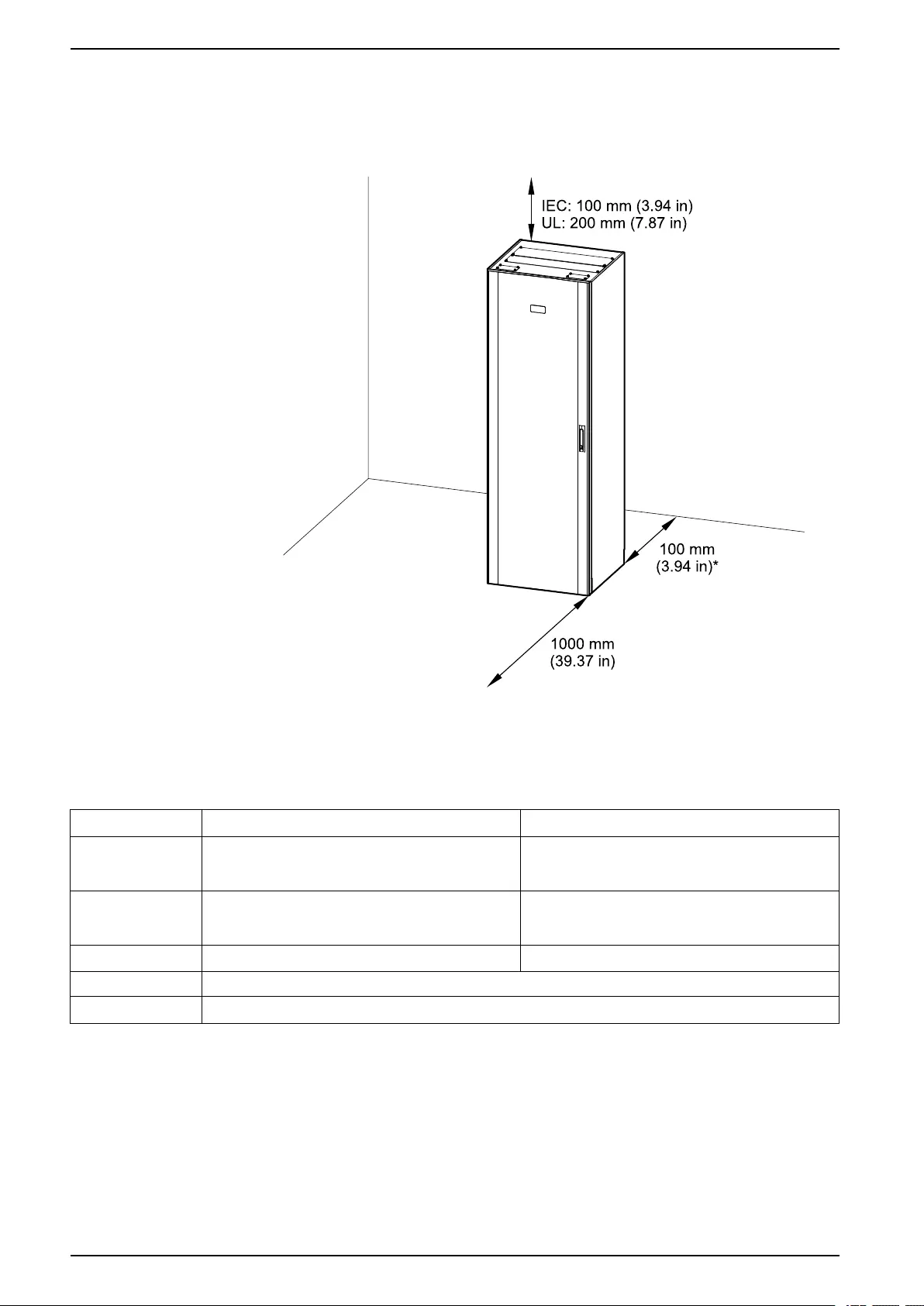

Clearance

NOTE: Clearance dimensions are published for airflow and service access

only. Consult with the local safety codes and standards for additional

requirements in your local area.

* For system with seismic anchoring.

Environment

Operating Storage

Temperature Recommended operating temperature: 18 to 28 °C (64

to 82 °F) Battery cabinet: 0 °C to 40 °C (32 °F to 104 °F)

Battery modules: Recommended storage for battery

modules is 20 °C (68 °F) or cooler (non-freezing)

Relative humidity 0-95% non-condensing Battery cabinet: 0-90% non-condensing

Battery modules: Recommended storage for battery

modules is 40-80% non-condensing

Elevation 0-3000 m (0-10000 feet)

Protection class IP20

Color RAL 9003, gloss level 85%

12 990-91430A-001

Overview of Accessory Kits With 13, 16, or 17 Battery Modules

Overview of Accessory Kits

Accessory Kit 0M-95318: Busbar Kit

NOTE: Save this accessory kit for the field service representative. The

busbars will be installed by Schneider Electric during the start-up service.

Accessory Kit 0M-95319: Cover Kit

NOTE: Save this accessory kit for the field service representative. The covers

will be installed by Schneider Electric during the start-up service.

Accessory Kit 0M-95320: Cable Kit

Part Number Description Quantity Used in

0W76926 Signal cable from battery module to

battery module – standard 15 Note: Save these signal cables for the

field service representative. These

signal cables will be installed by

Schneider Electric during the start-up

service.

0W76936 Signal cable from battery module to

battery module – long 1

0W76933 Signal cable from battery module to

RBMS 1

0W76928 Signal cable from RBMS CAN 2 to

RBMS CAN 1 in next battery cabinet 1Route the Signal Cables to the

Switchgear, Rack BMS, and System

BMS Ports, page 29

0W76929 Signal cable from MCCB AUX 1 to

UPS 1

0W76934 Signal cable from MCCB AUX 2 to

MCCB AUX 1 in next battery cabinet 1

0W13444 Signal cable from SGB I/O 1 to the

UPS 1

0W13442 Signal cable from SGB I/O 2 to the

UPS 1

0W76972 Signal cable from SGB I/O 1 to SGB I/

O 1 between the battery cabinets 1

Accessory Kit 0M-95331: Seismic Anchoring and Fuse Kit

Part Number Description Quantity Used in

870-50102 Anchor parts 4 Install the Rear Seismic Anchoring,

page 17

870-51172 Interconnection plate between seismic

brackets 1

803-0684 M6 x 12 torx screw with washer 4

803-0686 M6 x 16 torx with washer 18 Install the Rear Seismic Anchoring,

page 17 and Position and Interconnect

the Battery Cabinets, page 19

TME00409 500 A fast acting fuse 3 Note: Save for the field service

representative. The fuses will be

installed by Schneider Electric during

the start-up service.

HUA29593 Washer 6

HUA13751 M12 x 16 hexagonal screw 6

HUA41574 3 A rated fuse 2

990-91430A-001 13

With 13, 16, or 17 Battery Modules Installation Procedure

Installation Procedure

1. Prepare for Installation, page 15.

2. Install the Rear Seismic Anchoring, page 17.

3. Position and Interconnect the Battery Cabinets, page 19.

4. Install the Front Seismic Anchoring, page 21.

5. Install the Battery Modules in the Battery Cabinet, page 22.

6. Connect the Power Cables, page 25.

7. Route the Signal Cables to the Switchgear, Rack BMS, and System BMS

Ports, page 29.

14 990-91430A-001

Installation Procedure With 13, 16, or 17 Battery Modules

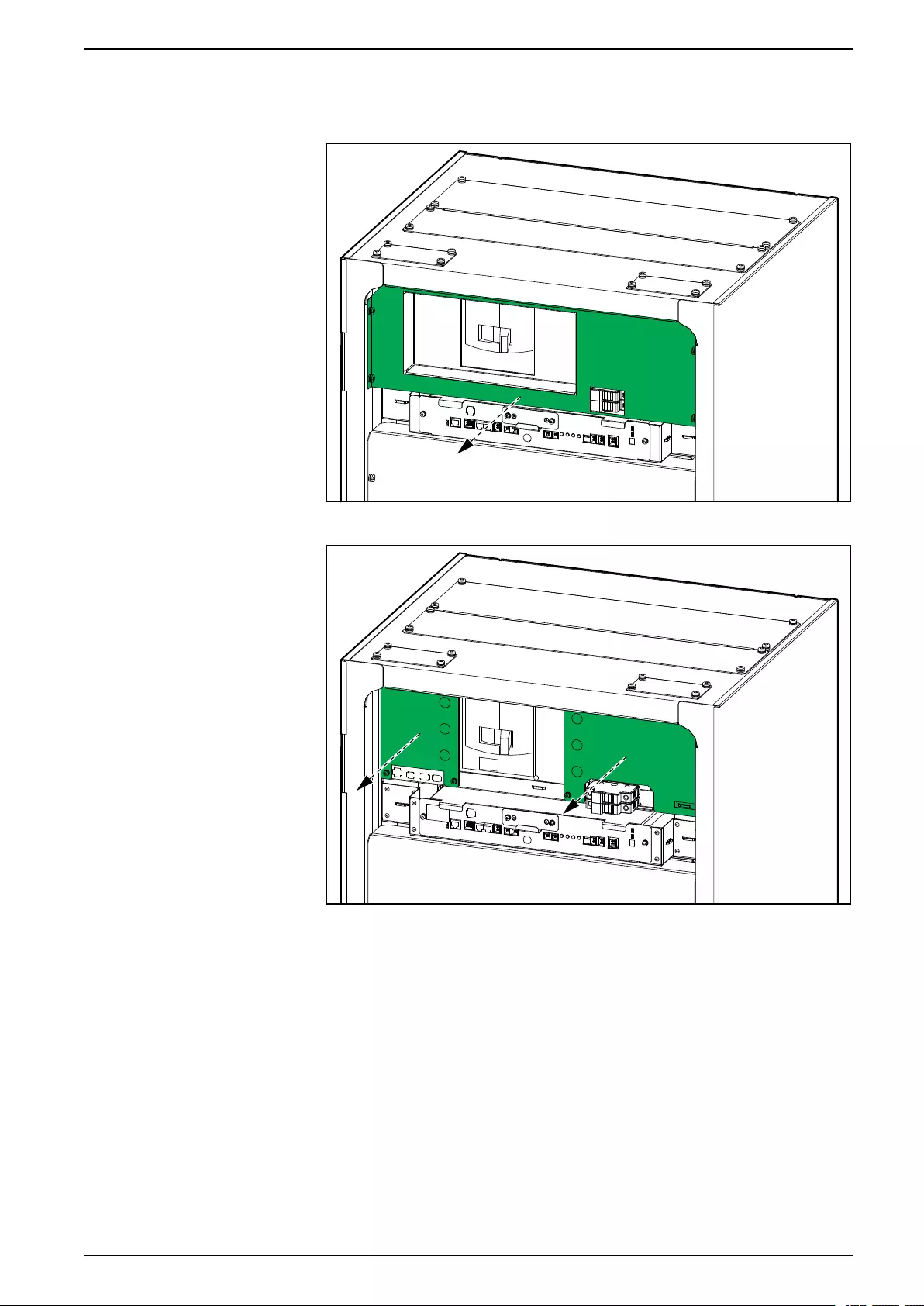

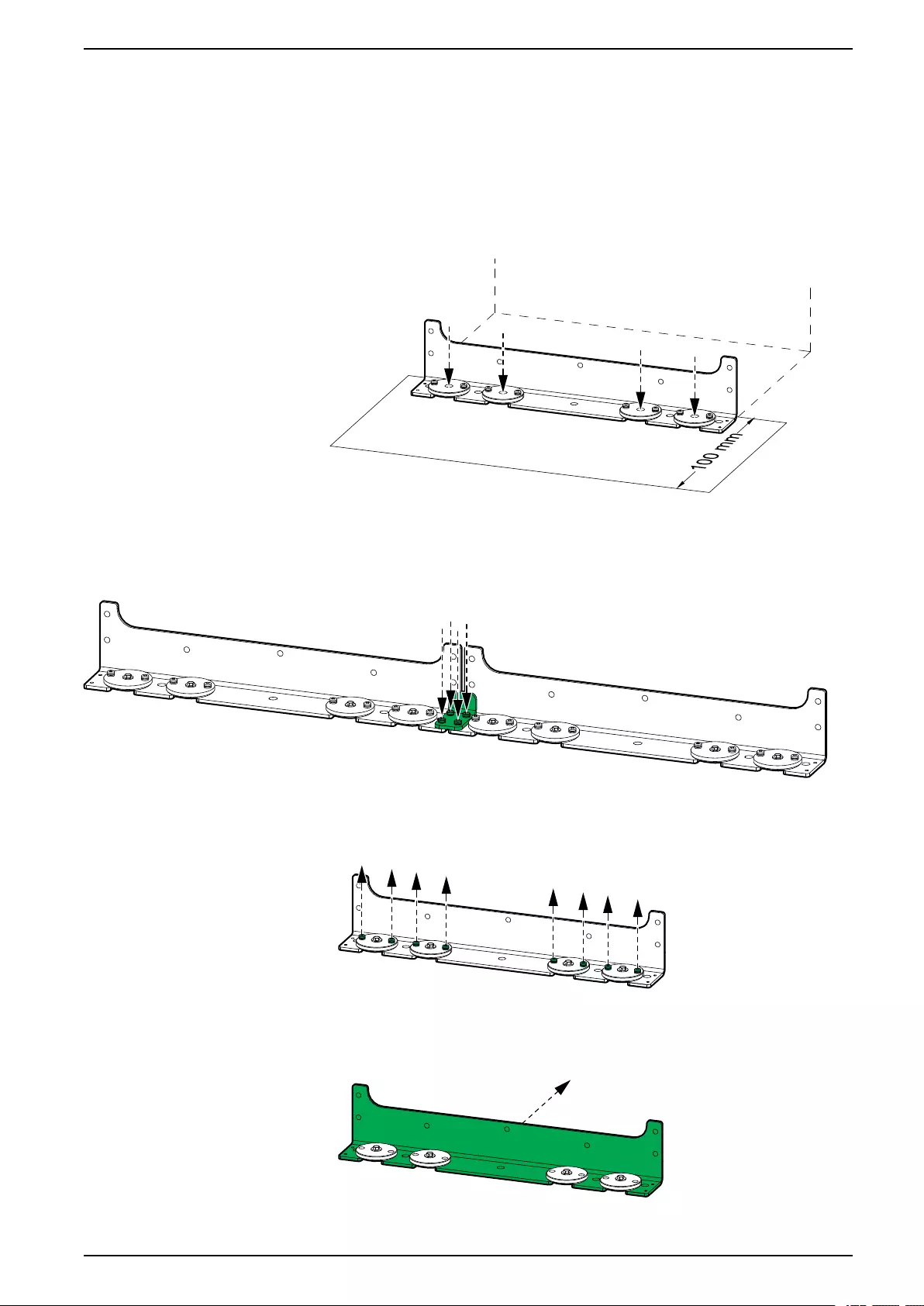

Install the Rear Seismic Anchoring

1. Mount the rear seismic assembly (4 x 870-50102 and M6 x 16 torx screws

from accessory kit 0M-95331 and the rear shipping bracket) to the floor. Use

appropriate hardware for the floor type – the hole diameter in the rear seismic

bracket is ø14 mm. The minimum requirement is M12 strength grade 8.8

hardware.

Rear View

2. In systems with more battery cabinets, interconnect the seismic assemblies

with the interconnection plate 870-51172 from the accessory kit 0M-95331.

Rear View

3. Remove the indicated screws.

Rear View

4. Remove the rear seismic bracket.

Rear View

990-91430A-001 17

Installation Procedure With 13, 16, or 17 Battery Modules

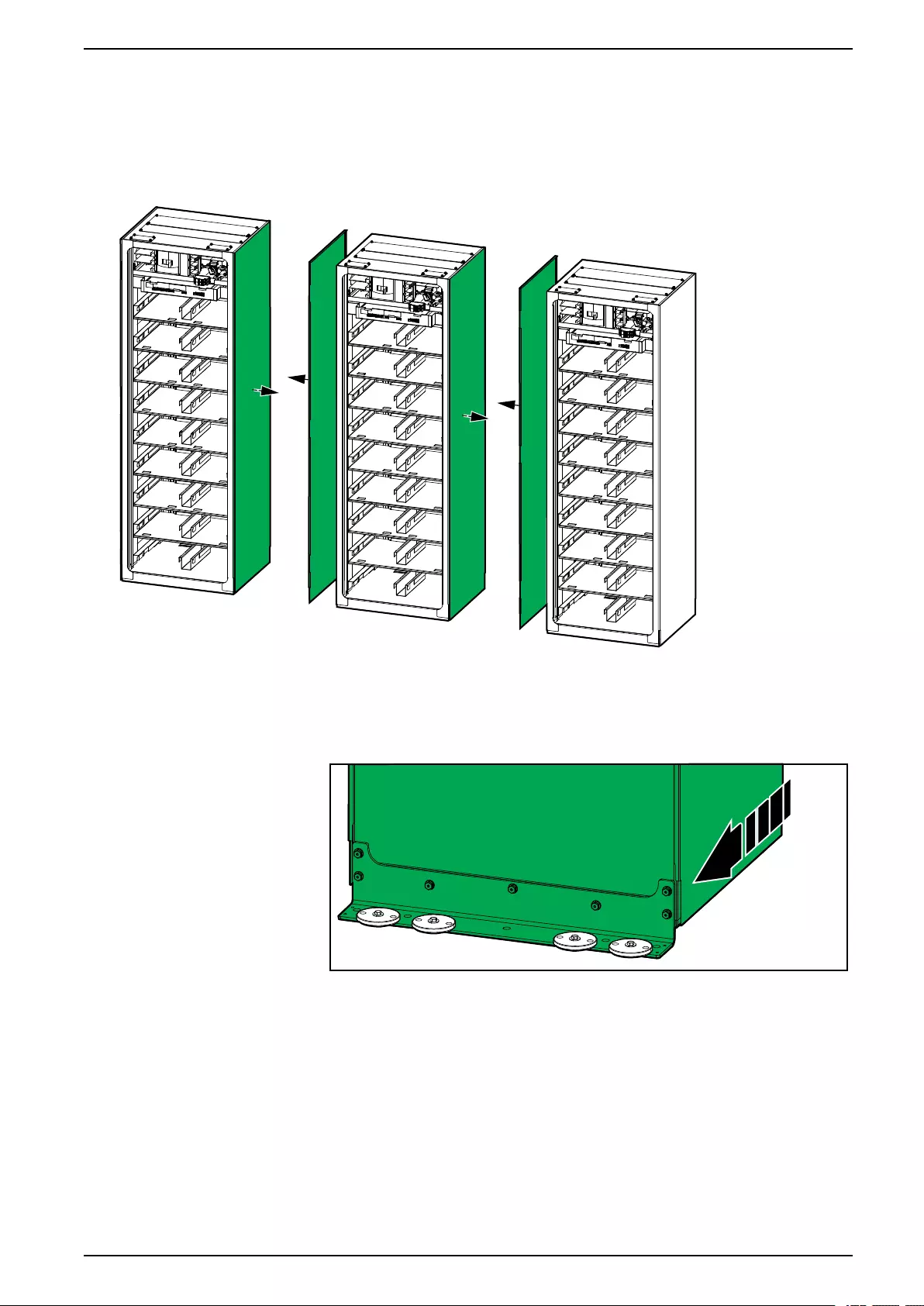

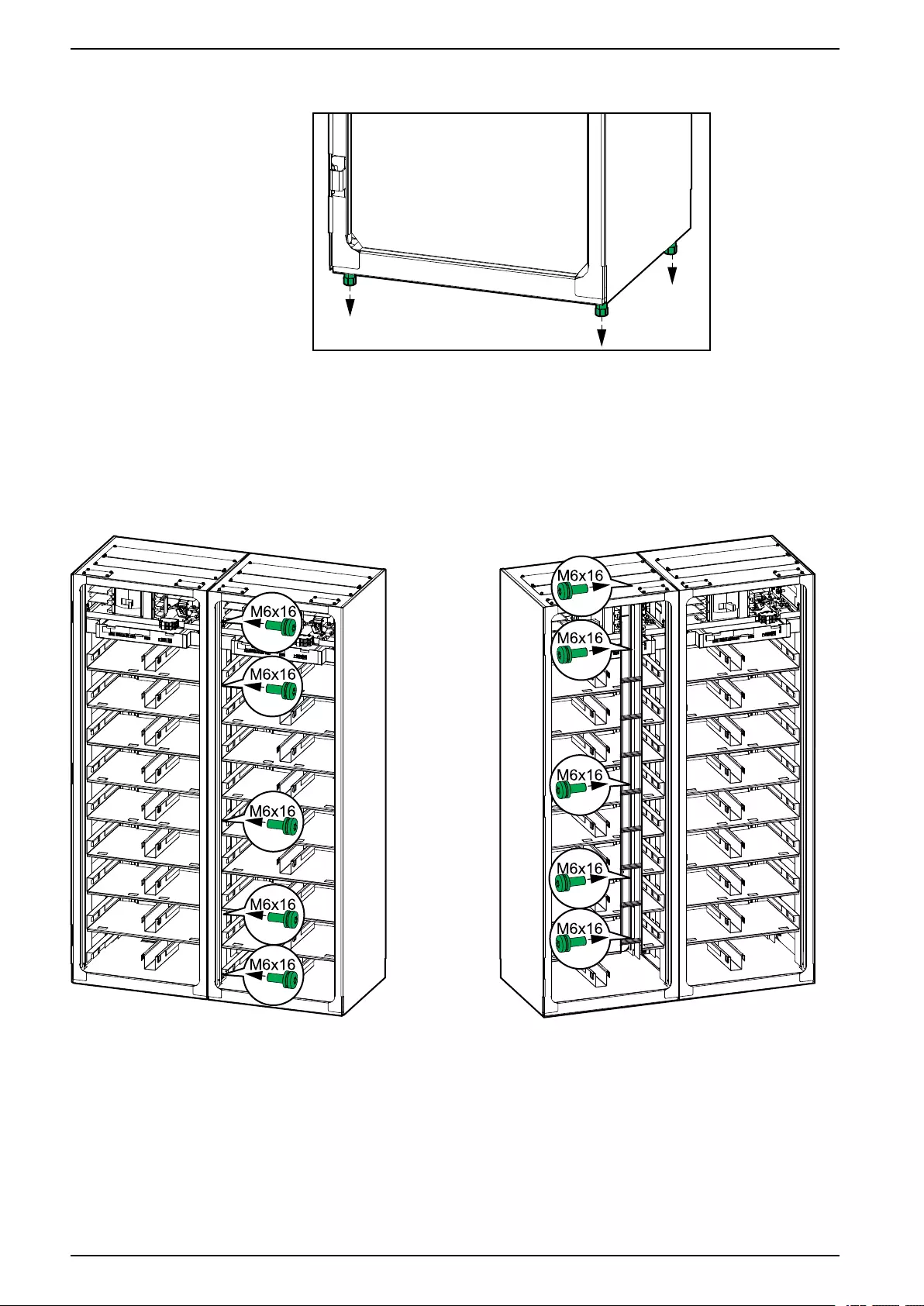

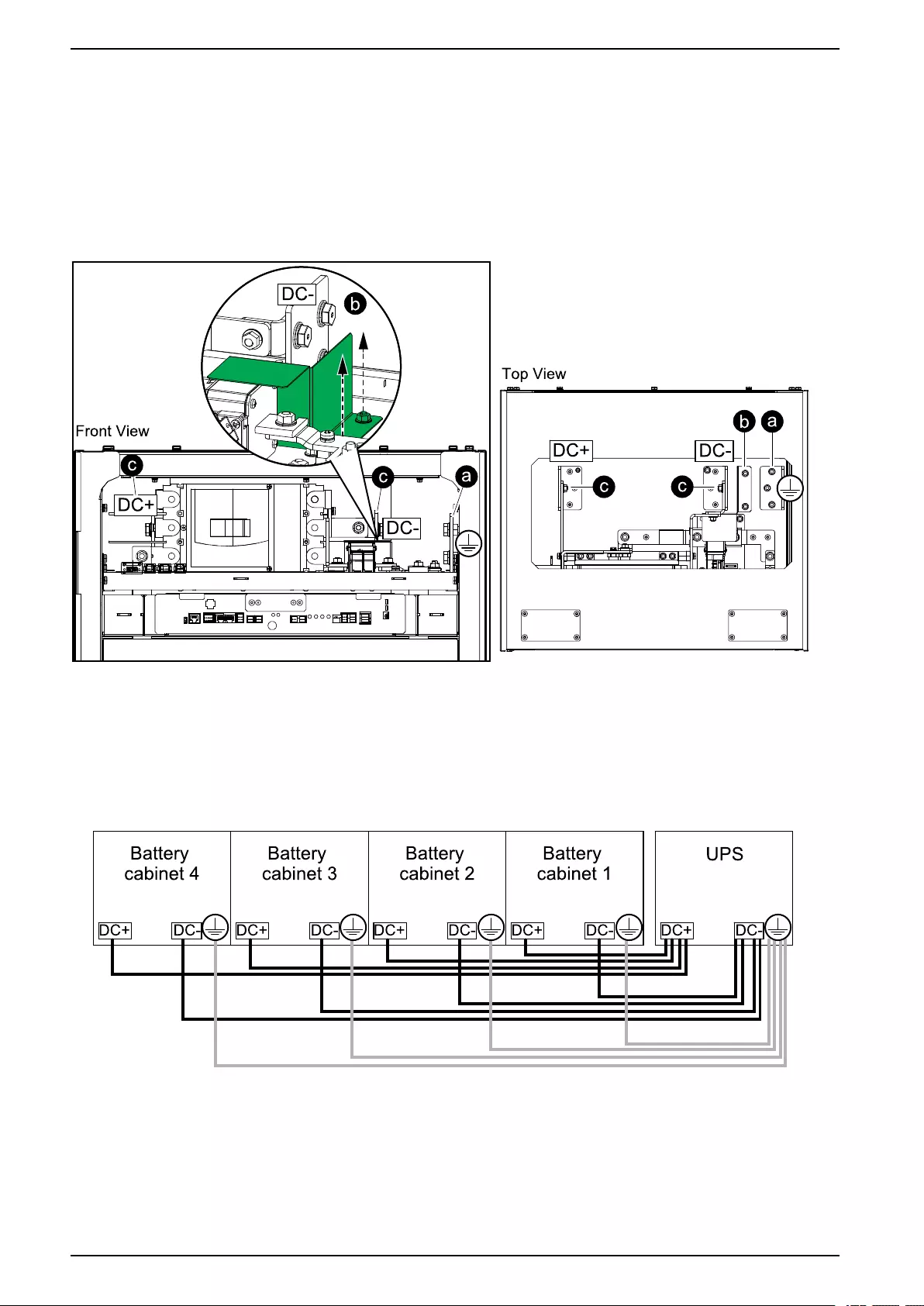

Position and Interconnect the Battery Cabinets

NOTE: This procedure describes how to position and interconnect several

battery cabinets. If your system only has one battery cabinet, you only need to

follow step 2 and step 3.

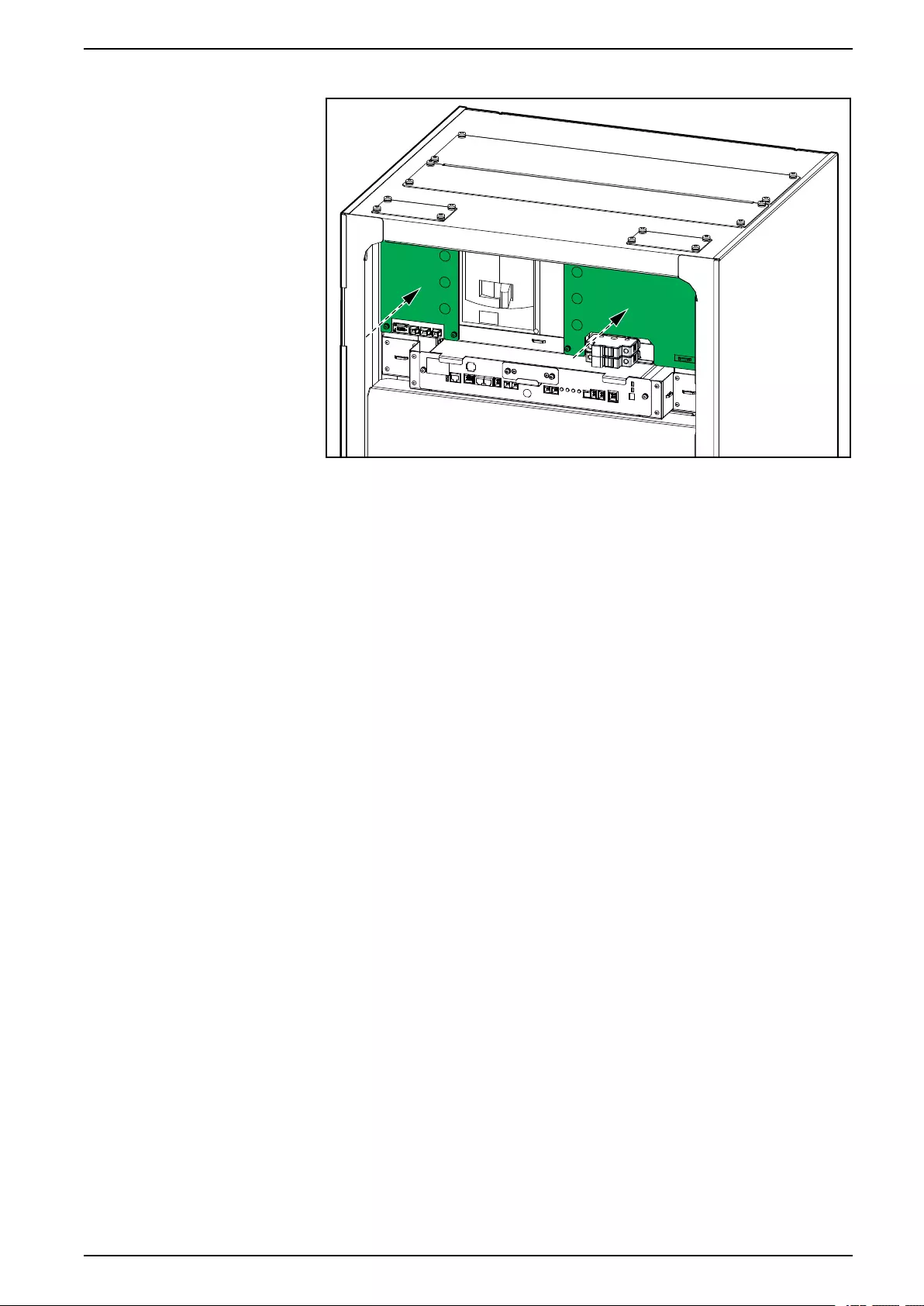

1. Remove the side panels that are adjacent to the other battery cabinets.

2. Push the right-most battery cabinet into position. For seismic anchoring,

ensure that the rear seismic bracket connects to the rear anchors.

Rear View

990-91430A-001 19

With 13, 16, or 17 Battery Modules Installation Procedure

3. Lower the levelling feet until they connect with the floor - use a bubble-leveler

to ensure that the cabinet is level.

4. Push the second right-most battery cabinet into position, align with the

seismic anchoring (if any), and level the battery cabinet as described in step 2

and step 3.

5. Install the ten interconnection screws (five in the front and five in the rear)

between the two battery cabinets.

NOTE: To reach the five interconnection screws in the rear of the left-

most battery cabinet, the left side panel can be removed. Reinstall the left

side panel on the left-most battery cabinet after interconnection.

6. Push the third battery cabinet into position, align with the seismic anchoring (if

any), level the battery cabinet, and interconnect with the other battery

cabinets as described in step 2, step 3, and step 5. Continue until all the

battery cabinets are in place, levelled, and interconnected.

20 990-91430A-001

Installation Procedure With 13, 16, or 17 Battery Modules

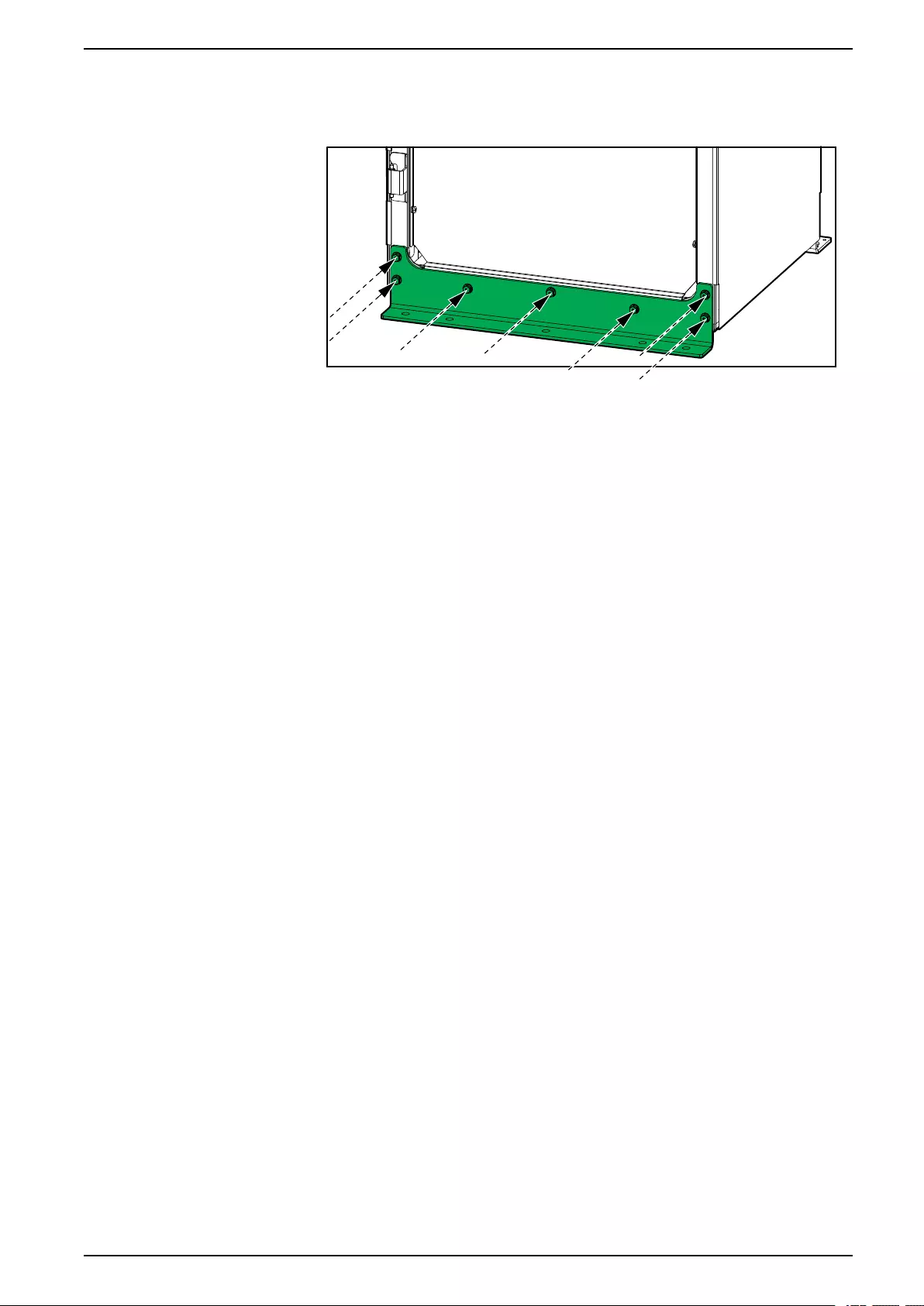

Install the Front Seismic Anchoring

1. Install the front seismic bracket (front shipping bracket) on the battery cabinet.

2. Anchor the front seismic bracket to the floor using appropriate hardware for

the floor type – the hole diameter in the front seismic bracket is ø14 mm. The

minimum requirement is M12 strength grade 8.8 hardware.

NOTE: Floor anchoring bolts are not supplied.

990-91430A-001 21

With 13, 16, or 17 Battery Modules Installation Procedure

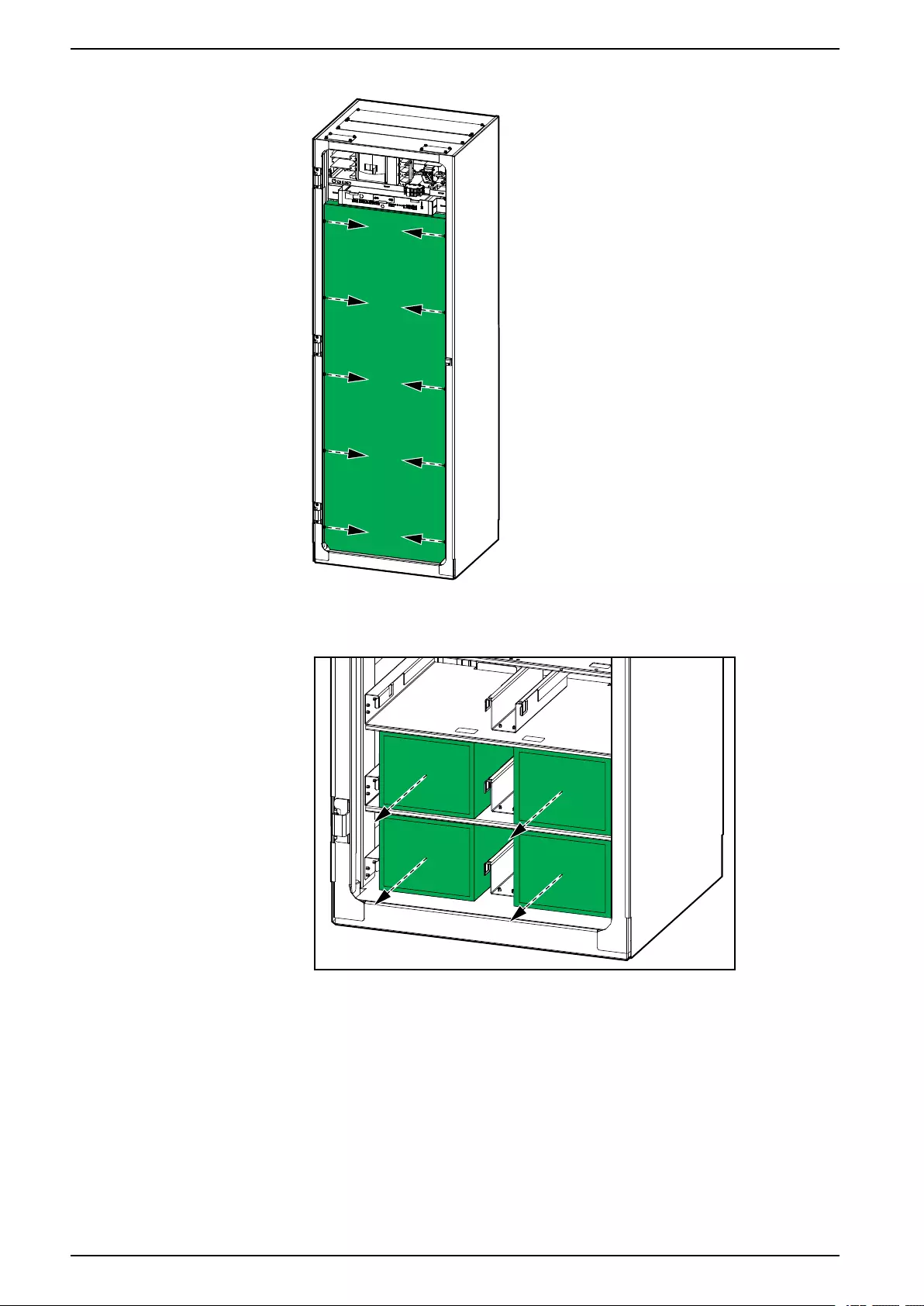

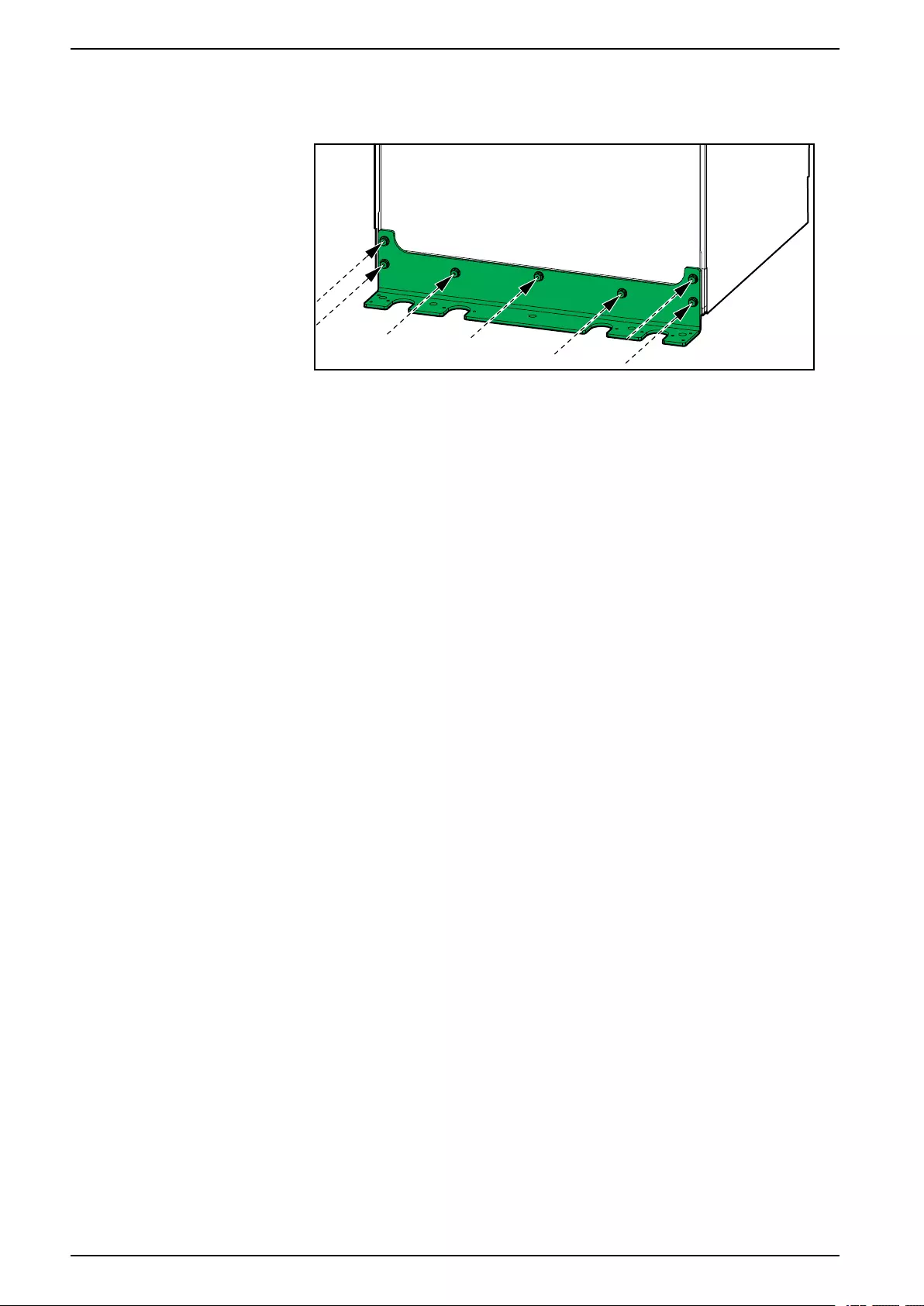

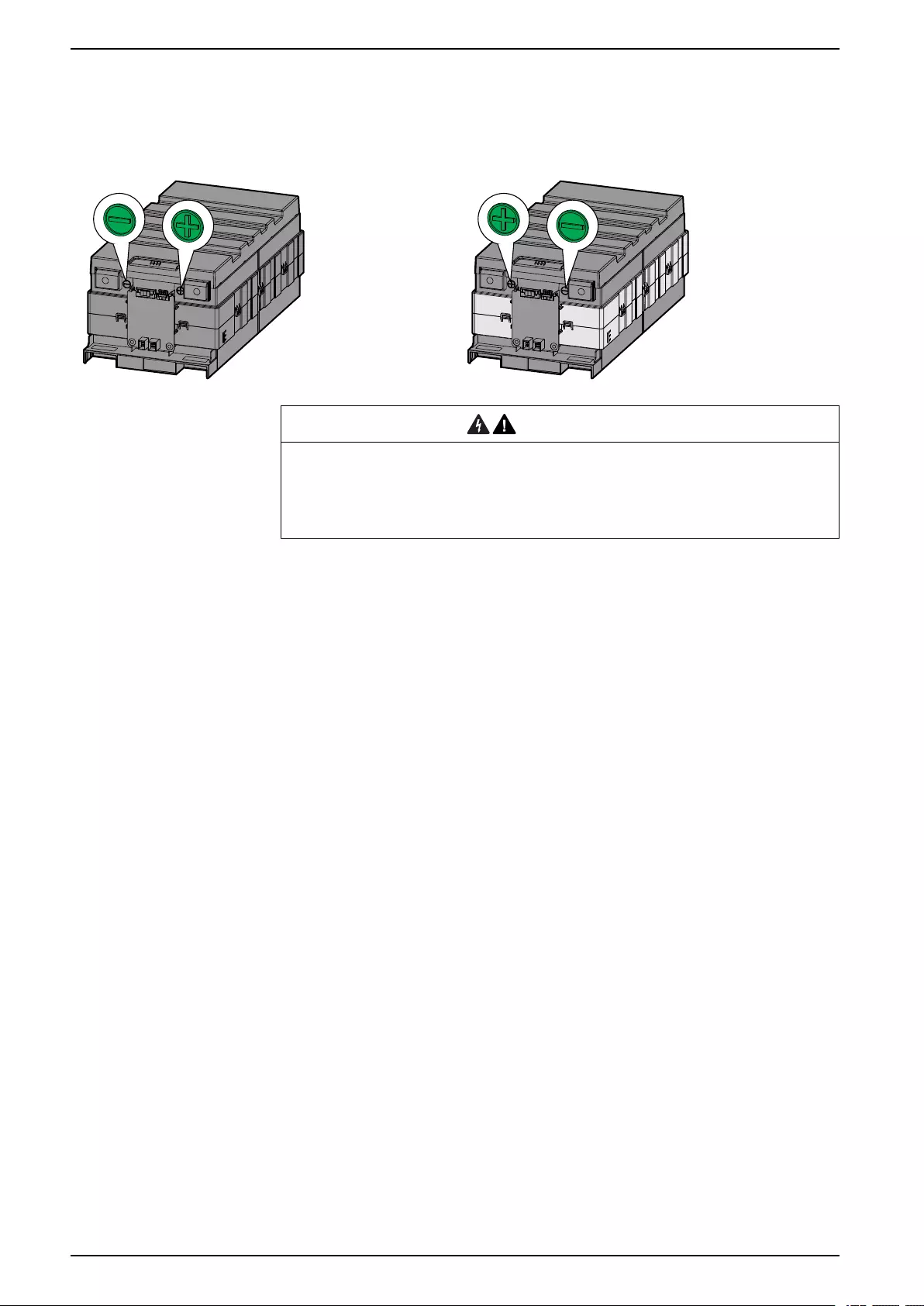

Install the Battery Modules in the Battery Cabinet

Type A Battery Module Type B Battery Module

WARNING

HAZARD OF INJURY AND ELECTRIC SHOCK

• Be careful when installing and removing the battery modules (>17 kg).

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

22 990-91430A-001

Installation Procedure With 13, 16, or 17 Battery Modules

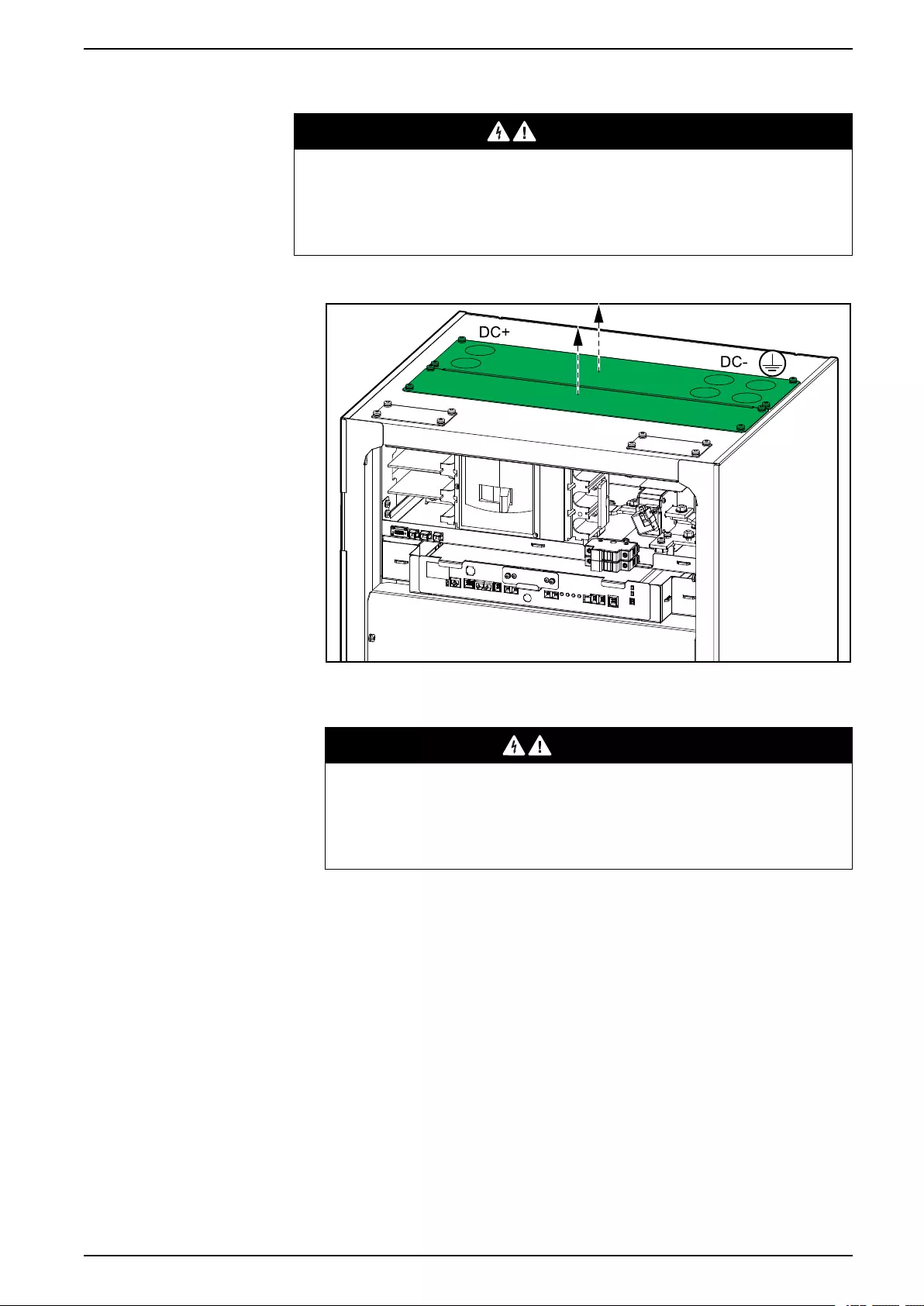

Connect the Power Cables

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Do not drill or punch holes with the gland plates installed and do not drill or

punch holes in close proximity to the battery cabinet.

Failure to follow these instructions will result in death or serious injury.

1. Remove the gland plates.

2. Drill or punch holes for cables/conduits in the rear gland plate according to

the label on the gland plate.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Ensure that there are no sharp edges that can damage the cables.

Failure to follow these instructions will result in death or serious

injury.

3. Install conduits (if applicable) and reinstall the gland plates.

990-91430A-001 25

With 13, 16, or 17 Battery Modules Installation Procedure

4. Route the power cables through the gland plate and connect to the terminals:

a. Connect the PE cable to the PE terminal/Connect the EGC cable to the

grounding terminal.

b. For installations with two hole cable lugs only, temporarily remove the

protection cover.

NOTE: The protection cover must be reinstalled when the DC- cable

has been connected.

c. Connect the DC+ and DC- cables to the DC+ and DC- terminals.

5. Connect the power cables in the UPS. If more battery cabinets are part of the

solution, connect all battery cabinets to the UPS according to the diagram

below.

NOTE: If the combined short circuit current of the battery cabinets

exceeds the short circuit rating of the UPS, a pull box with fuses or an

external box with a battery breaker must be installed. Please contact

Schneider Electric for more information and refer to the submittal

drawings for your specific UPS.

26 990-91430A-001

With 13, 16, or 17 Battery Modules Installation Procedure

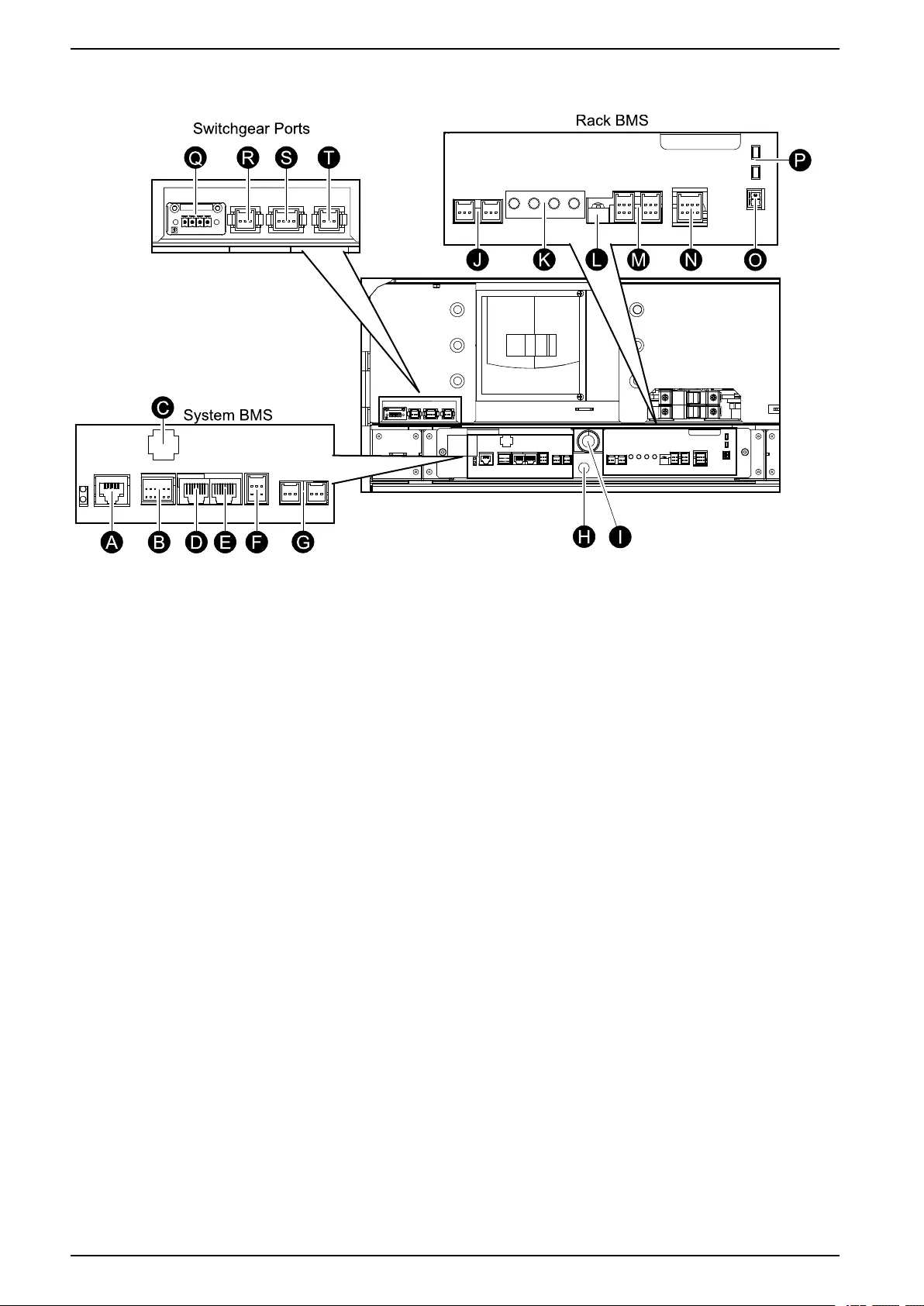

Overview of Communication Interface

A. TCP/IP

B. Dry contact

C. SMPS I/O

D. CAN I/O

E. RS485

F. System BMS CAN I/O

G. DC OUT 1 and DC OUT 2

H. Reset switch

I. Start-up button

J. DC IN 1 and DC IN 2

K. Status LEDs

L. CAN bus loop termination resistor switch

M. CAN 1 port, CAN 2 port

N. Module

O. EPO

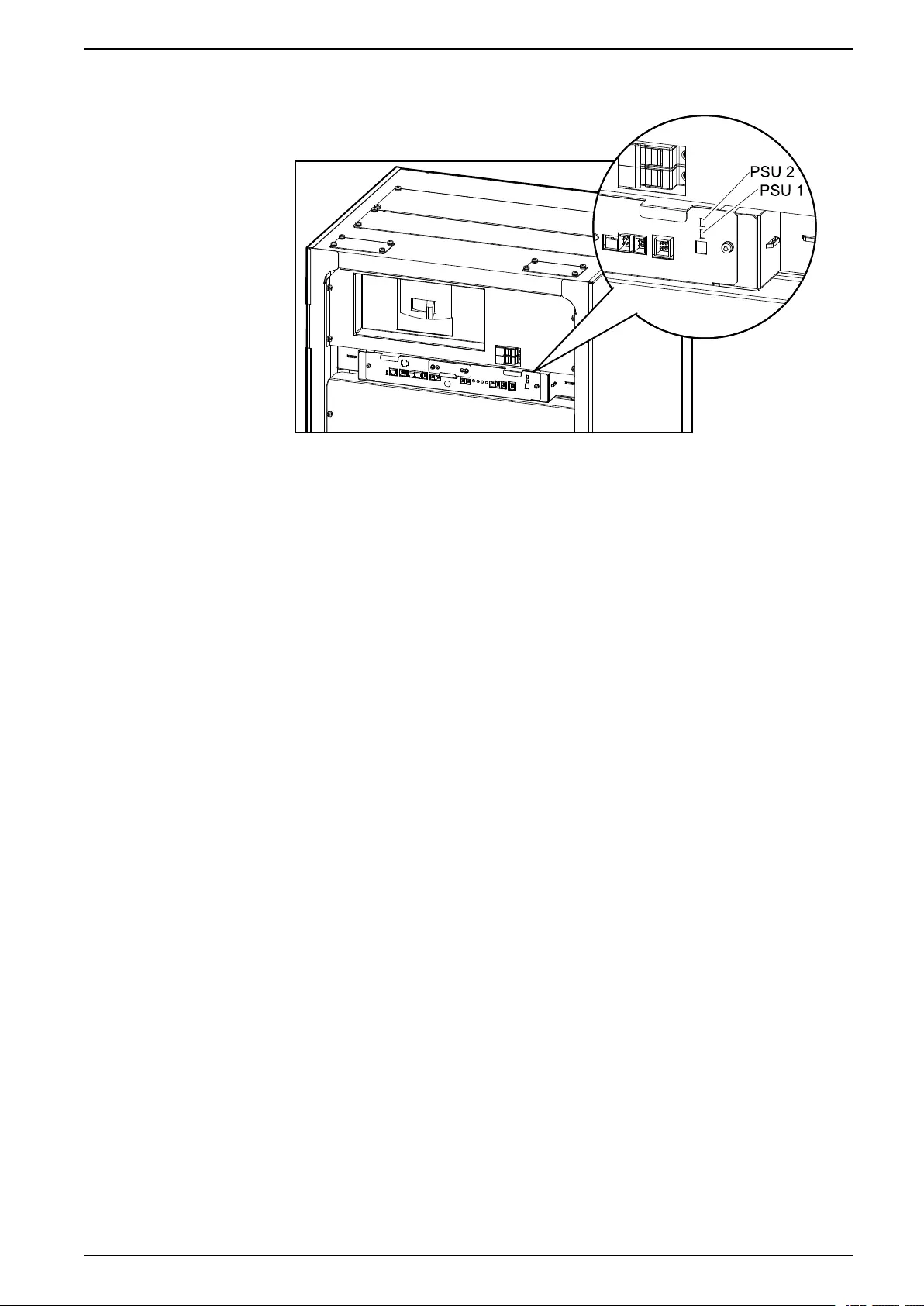

P. PSU 1 and PSU2 LEDs

Q. SG IO 1

R. SG IO 2

S. MCCB AUX 1

T. MCCB AUX 2

28 990-91430A-001

Installation Procedure With 13, 16, or 17 Battery Modules

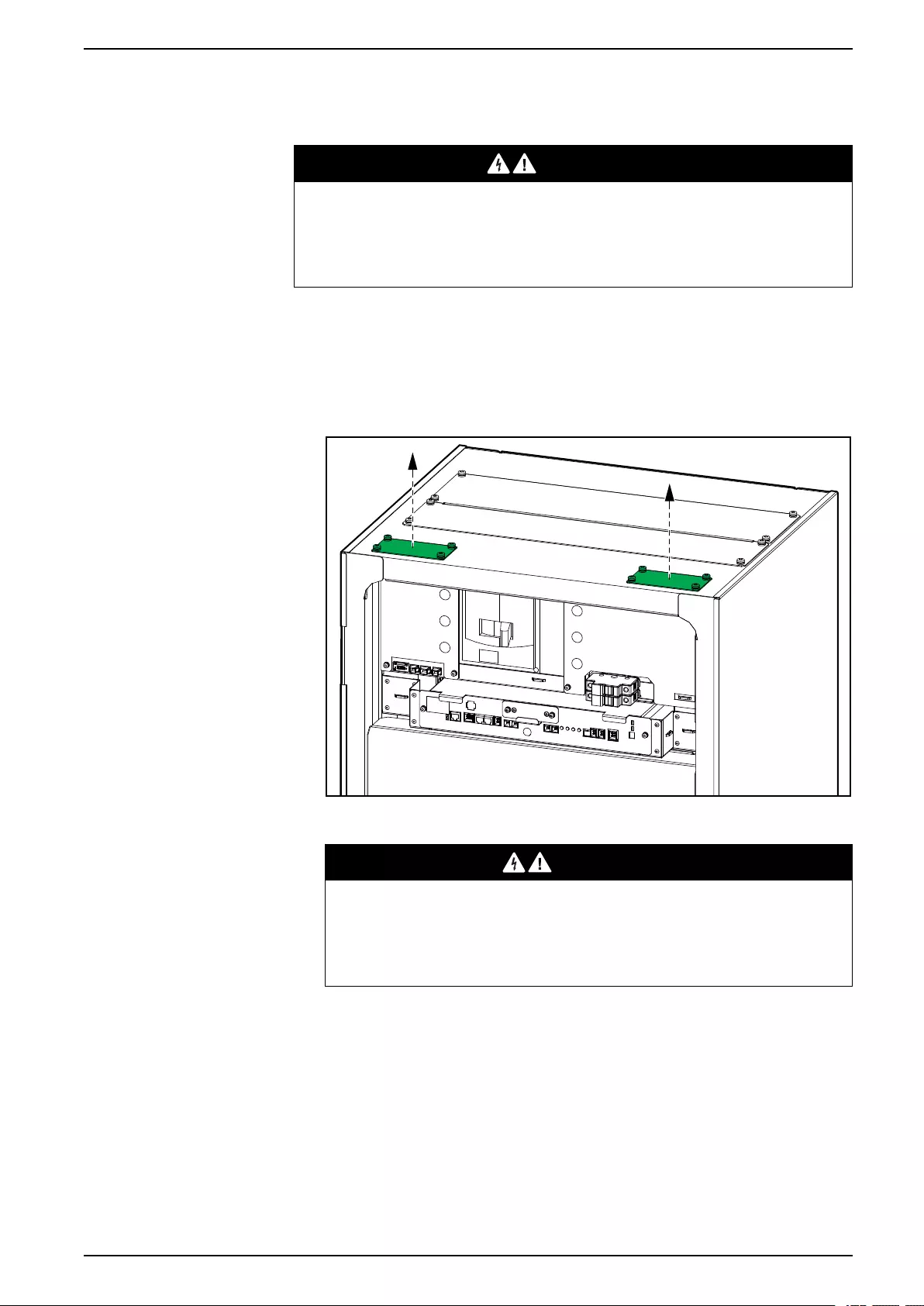

Route the Signal Cables to the Switchgear, Rack BMS, and

System BMS Ports

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Do not drill or punch holes with the gland plates installed and do not drill or

punch holes in close proximity to the battery cabinet.

Failure to follow these instructions will result in death or serious injury.

NOTE: Please refer to the UPS submittal drawings to get a complete overview

of the connections before preparing for and routing the signal cables.

NOTE: The signal cables provided with the battery cabinet are 5 m (16.4 ft)

long. A 25 m (82 ft) signal cable kit LIBSEOPT001 can be ordered from

Schneider Electric.

1. Remove the gland plates for signal cables.

2. Drill or punch holes for cables/conduits and install conduits (if applicable).

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Ensure that there are no sharp edges that can damage the cables.

Failure to follow these instructions will result in death or serious

injury.

990-91430A-001 29

With 13, 16, or 17 Battery Modules Installation Procedure

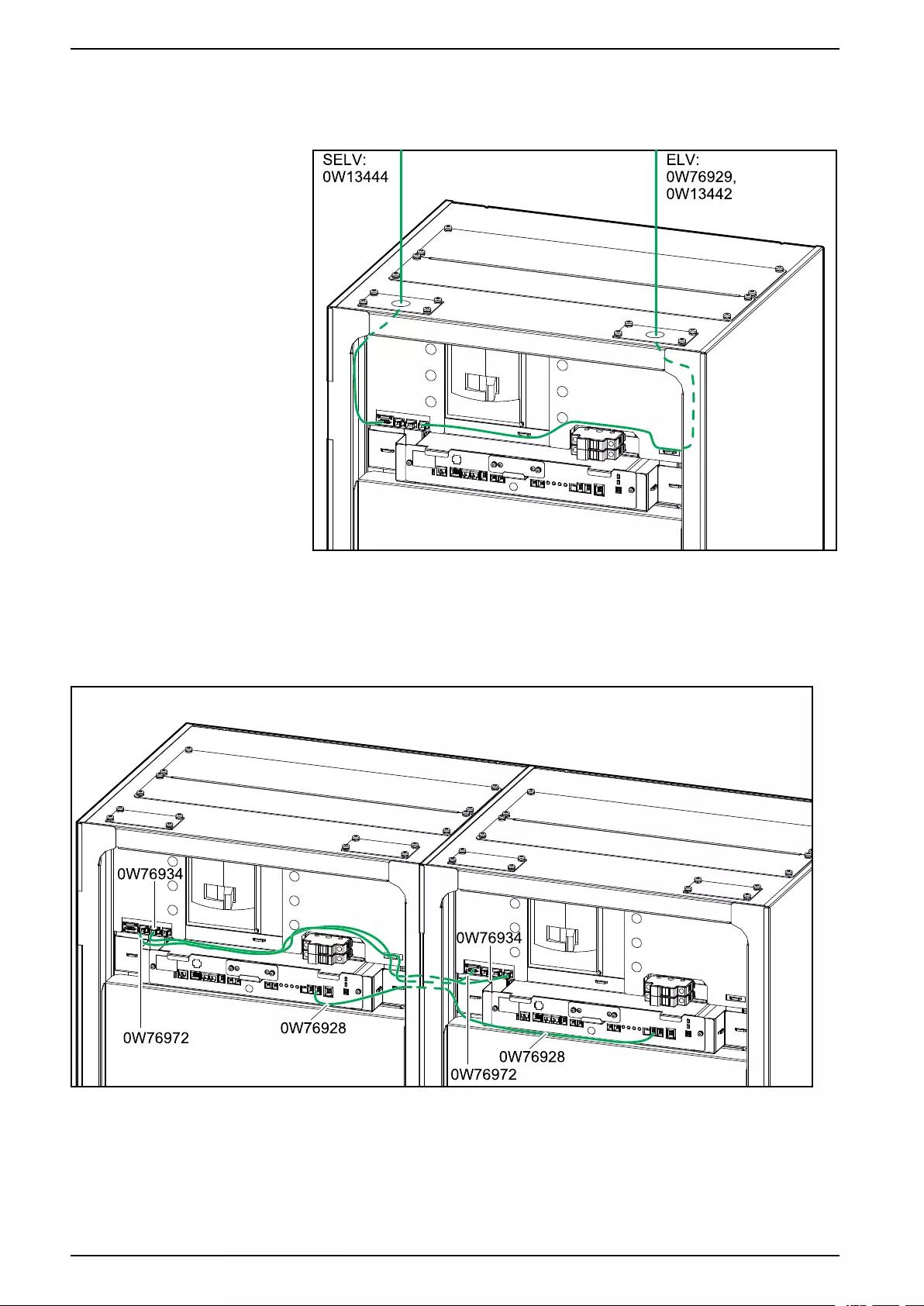

3. Route the SELV signal cable 0W13444 and the ELV signal cables 0W76929

and 0W13442 into the battery cabinet and to the switchgear ports. Do not

connect the signal cables, Schneider Electric service will complete the

connections during start-up.

4. Route the signal cable 0W76928, 0W76934, and 0W76972 through the

openings in the sides of the battery cabinets and to the ports in the rack BMS

and the switchgear ports. Do not connect the signal cables, Schneider

Electric service will complete the connections during start-up.

NOTE: All cables between rack BMS and rack BMS as well as between

system BMS and rack BMS are considered Class 2/SELV.

30 990-91430A-001

Installation Procedure With 13, 16, or 17 Battery Modules

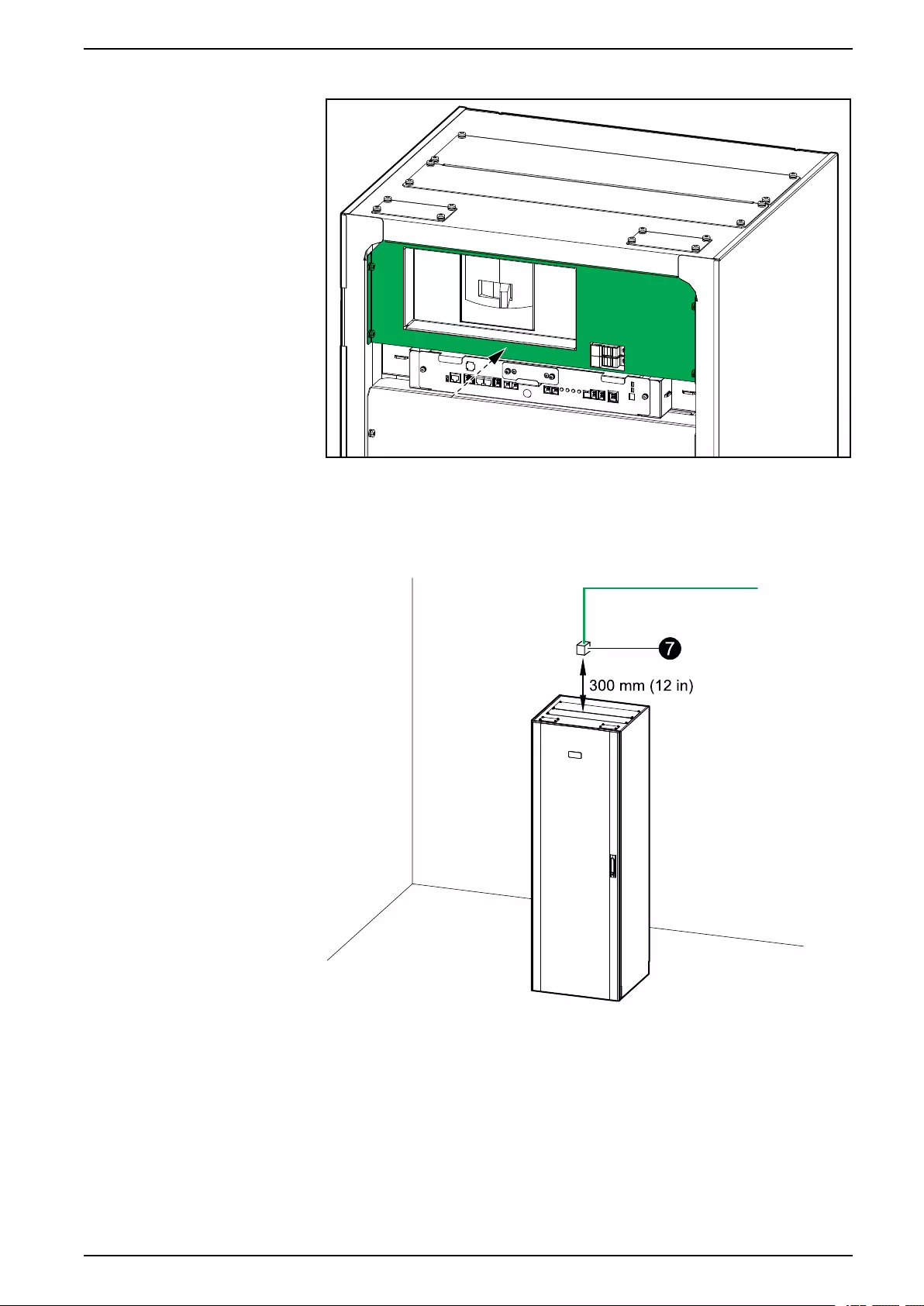

5. Reinstall the plate in front of the battery breaker.

6. Reinstall the front door of the battery cabinet.

7. Install the temperature sensor provided with the UPS above the battery

cabinet, approximately 300 mm (12 in) from the top. Route the signal cable to

the UPS and connect according to the instructions in the UPS installation

manual.

NOTE: The temperature sensor measures the ambient temperature. Do

not place the temperature sensor close to external heating or cooling

equipment which may give an incorrect measurement of the ambient

temperature.

990-91430A-001 31

With 13, 16, or 17 Battery Modules Installation Procedure

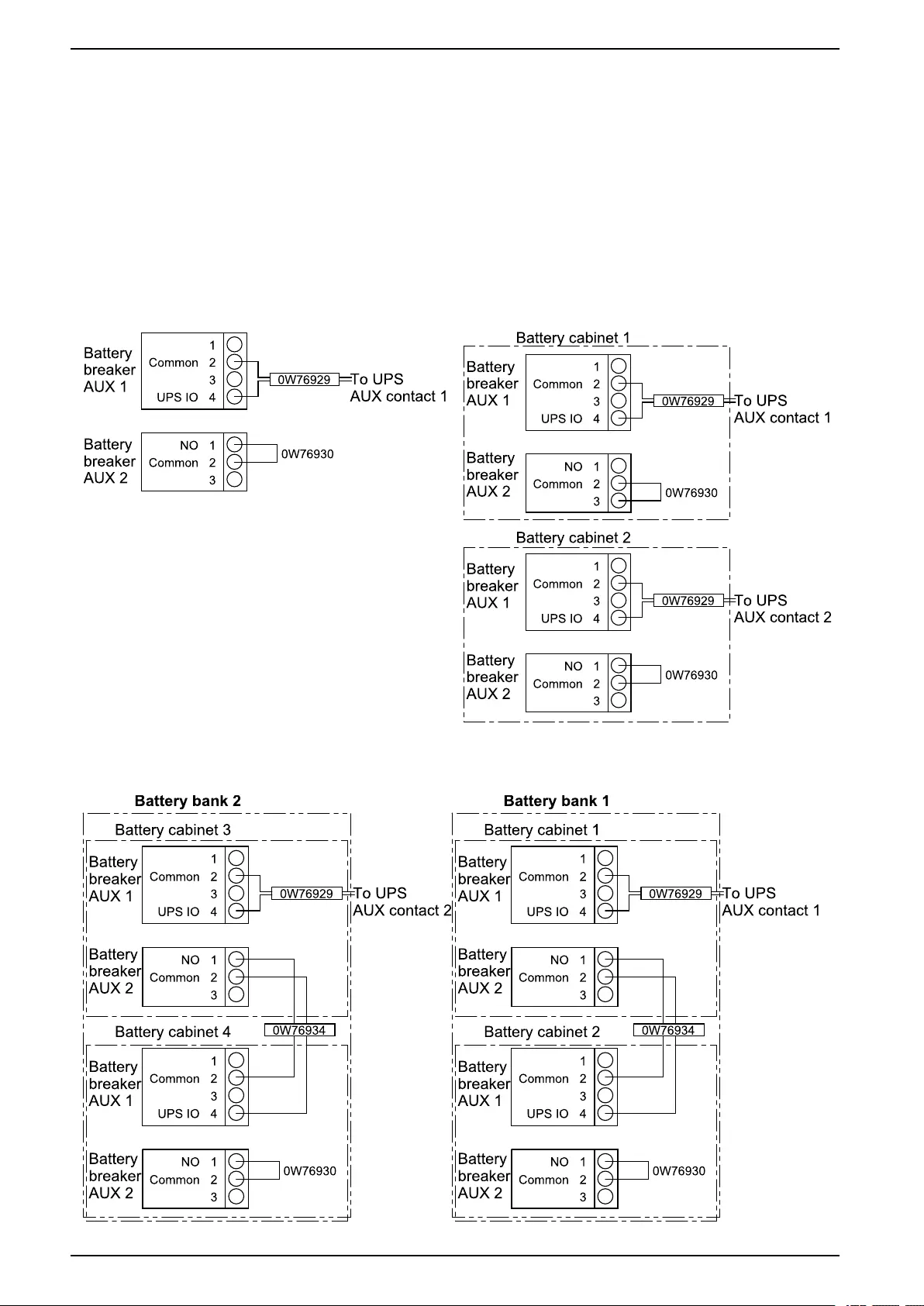

Overview of Signal Cables between the Battery Cabinets and the Auxiliary Contacts in

the UPS

The connection of auxiliary contacts is dependent on the number of battery

breakers supported by the UPS. In the examples below two banks of battery

breakers are supported.

NOTE: If the combined short circuit current of the battery cabinets exceeds

the short circuit rating of the UPS, a pull box with fuses or an external box with

a battery breaker must be installed. Please contact Schneider Electric for

more information.

System with One Battery Cabinet System with Two Battery Cabinets

System with Four Battery Cabinets in Two Battery Banks

32 990-91430A-001

Installation Procedure With 13, 16, or 17 Battery Modules

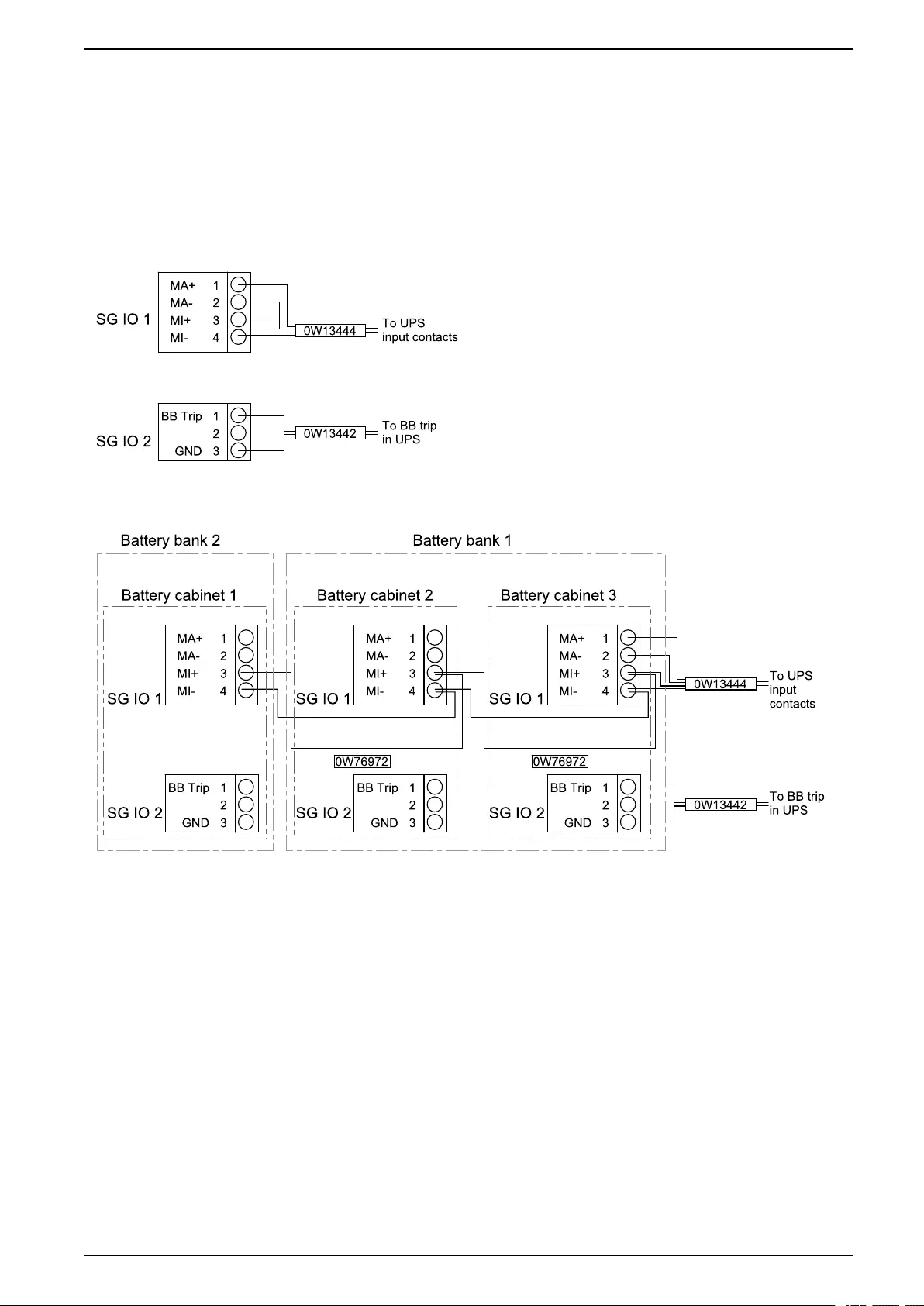

Overview of Signal Cables for Alarms and Battery Breaker Trip

Only the system BMS of battery cabinet 1 (cabinet closest to the UPS) is

connected to the UPS.

• SG IO 1: Used for sending signals for minor and major alarms to the UPS.

• SG IO 2: Used for receiving trip signal from the UPS.

System with One Battery Cabinet

System with Three Battery Cabinets in Two Battery Banks

990-91430A-001 33

With 13, 16, or 17 Battery Modules Installation Procedure

Overview of CAN Bus Cables between the Battery Cabinets

NOTE: In systems with more battery cabinets, remove the cables 0W76935

from CAN 1 in the rack BMS to the System BMS CAN I/O except in battery

cabinet 1.

1. Route signal cable 0W76928 from CAN 2 port of battery cabinet 1 to the CAN 1

port of battery cabinet 2. Repeat for the remaining battery cabinets. Do not

connect the CAN cables, Schneider Electric service will complete the connections

during start-up.

Overview of EPO Signal Cables

Connect the Class 2/SELV signal cables from the building EPO to the rack BMS.

Class 2/SELV circuits must be isolated from the primary circuitry. Do not connect

any circuit to the EPO terminal block unless it can be confirmed that the circuit is

Class 2/SELV.

34 990-91430A-001

Operation Procedures With 13, 16, or 17 Battery Modules

Operation Procedures

Shut Down the Battery Solution

NOTE: This procedure is only for a short temporary shutdown of the battery

solution. If the battery solution should remain shut down for a longer period,

please contact Schneider Electric.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

The battery cabinet contains an internal energy source. Hazardous voltage is

still present after the battery breaker has been opened.

Failure to follow these instructions will result in death or serious injury.

1. Manually set the battery breaker of each individual battery cabinet to the OFF

(open) position to disconnect the battery power from the UPS.

NOTE: The system BMS and rack BMS will still be operating.

Restart the Battery Solution

1. Perform the following steps on all battery cabinets in the battery solution.

a. Remove the cover in front of the start-up button and push the start-up

button.

• The PSU2 LED and the POWER LED will turn on.

• The ABNORMAL and ALARM LEDs should remain off.

b. Reinstall the cover in front of the start-up button.

c. Set the battery breaker to the ON (closed) position.

990-91430A-001 35

With 13, 16, or 17 Battery Modules Troubleshooting

Troubleshooting

Status LEDs

LED Battery Status Description

Normal The battery breaker is in the OFF

(open) position.

Normal The battery breaker is in the ON

(closed) position.

Normal The batteries are being

discharged.

Normal The batteries are being recharged.

Major alarm The battery breaker has tripped

and is in the OFF (open) position.

Minor alarm The battery breaker is in the ON

(closed) position.

36 990-91430A-001

With 13, 16, or 17 Battery Modules Troubleshooting

Alarm List

Protection Protocols

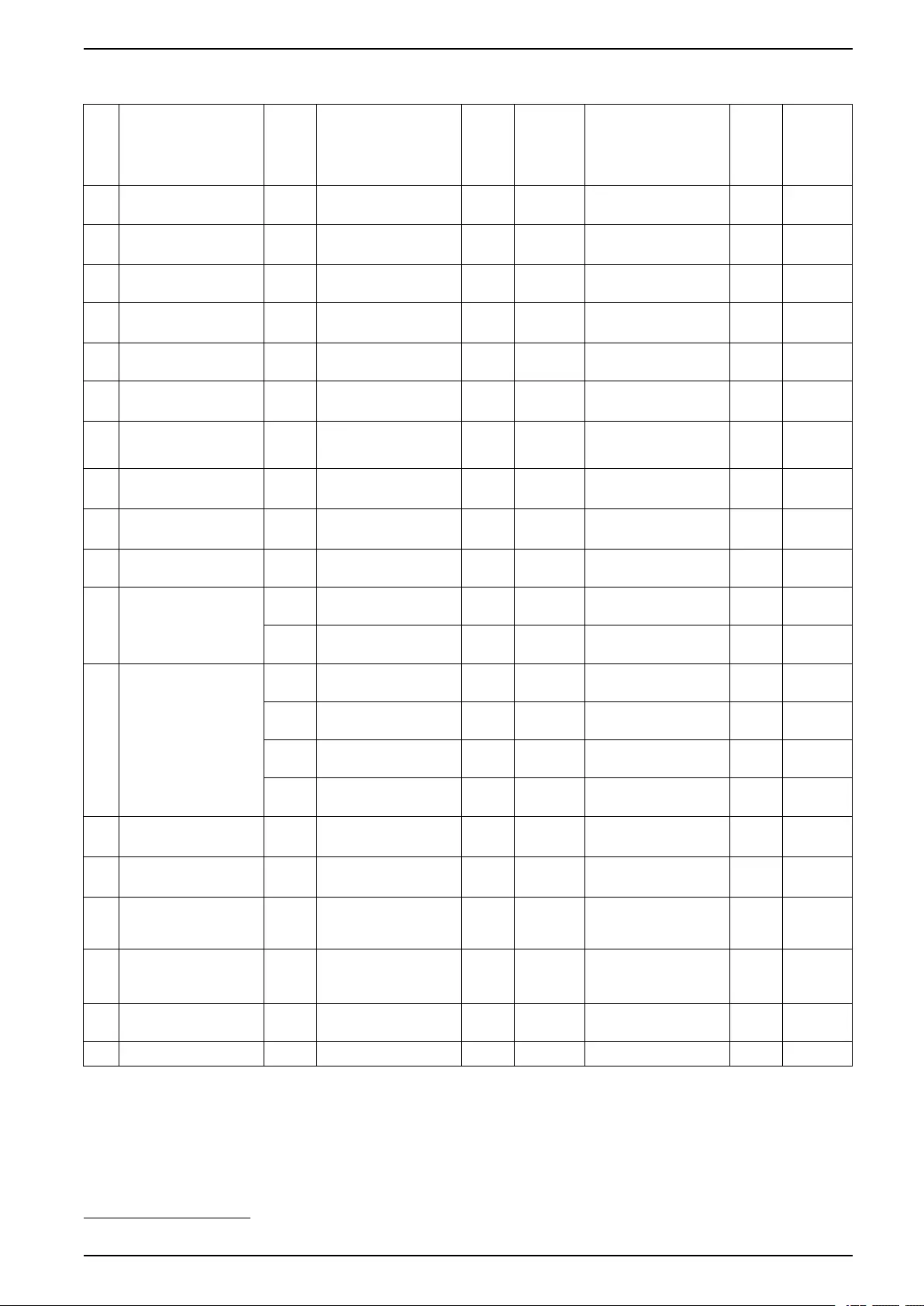

Protection Protocol for Battery Cabinet with 17 Battery Modules

No Item Level Set condition Soft-

ware

set

time

(sec)

Battery

breaker

status1

Release condition Time

(sec)

Battery

breaker

status

1 Over voltage protection

- cell Major Max cell ≥ 4.28 V 5 OFF Max cell <4.25 V and

reset 5ON

2 Under voltage

protection - cell Major Min cell ≤ 2.5 V 3 OFF Min cell > 2.70 V and

reset 3 ON

3 Over voltage protection

- cabinet Major Cabinet voltage ≥

582.08 V 5OFF Cabinet voltage < 578

V and reset 5ON

4 Under voltage

protection - cabinet Major Cabinet voltage ≤ 340

V3 OFF Cabinet voltage >

367.2 V and reset 3 ON

5 Voltage imbalance Major Max cell ≥ 3.80 V and

△Vcell ≥ 100 mV 5OFF △Vcell 30 mV and reset 5 ON

6 Voltage sensing error

(cabinet) Minor Cabinet V - cell sum V│

≥40.8 V

10 ON │Rack V - cell sum V│

< 20.4 V and reset

3 ON

7 Voltage sensing error

(module) Minor │Module V - cell sum

V│ ≥190 mV

5ON │Module V - cell sum

V│ < 190 mV and reset

3 ON

8 Over temperature

protection Major Max temp ≥ 75 ℃3 OFF Max temp < 65 ℃and

reset 3 ON

9 Under temperature

protection Minor Min temp ≤ 0 ℃3 ON Min temp > 5℃& reset 3 ON

10 Temperature imbalance Major Max cell T - min cell T ≥

40 ℃

30 OFF Max cell T - min cell T <

20 ℃and reset 3 ON

11 Over current protection

(charge) Major Level2 current ≥ 250 A 2 OFF |Current| < 10 A and

reset 3 ON

Major Level1 current ≥ 200 A 60 OFF |Current| < 10 A and

reset 3 ON

12 Over current protection

(discharge) Major Level4 |current| ≥ 600 A 1 OFF |Current| < 10 A and

reset 3 ON

Major Level3 |current| ≥ 540 A 10 OFF |Current| < 10 A and

reset 3 ON

Major Level2 |current| ≥ 495 A 30 OFF |Current| < 10 A and

reset 3 ON

Major Level1 |current| ≥ 470 A 60 OFF |Current| < 10 A and

reset 3 ON

13 Communication lost

(module ↔ cabinet) Major No communication 30 OFF Communication

reestablished + reset -ON

14 Communication lost

(cabinet ↔ system ) Minor No communication 30 ON Communication

reestablished + reset -ON

15 SW failure - battery

breaker Minor Battery breaker OFF

and |current| ≥ 2.4 A 3 ON (Battery breaker OFF

and (|current| < 2.4 A)

and reset

-ON

16 SW sensor failure -

battery breaker Minor Battery breaker contact

ON = battery breaker

trip ON

3 ON (Battery breaker

contact ≠ battery

breaker trip) and reset

-ON

17 Current sensing error Minor No communication with

Current IC 3 ON Communication with

current IC OK -ON

18 Fuse failure Minor Fuse blown 10 ON Fuse ON and reset -ON

38 990-91430A-001

1. The battery breaker status will switch from ON to OFF within three seconds after the software set time.

Troubleshooting With 13, 16, or 17 Battery Modules

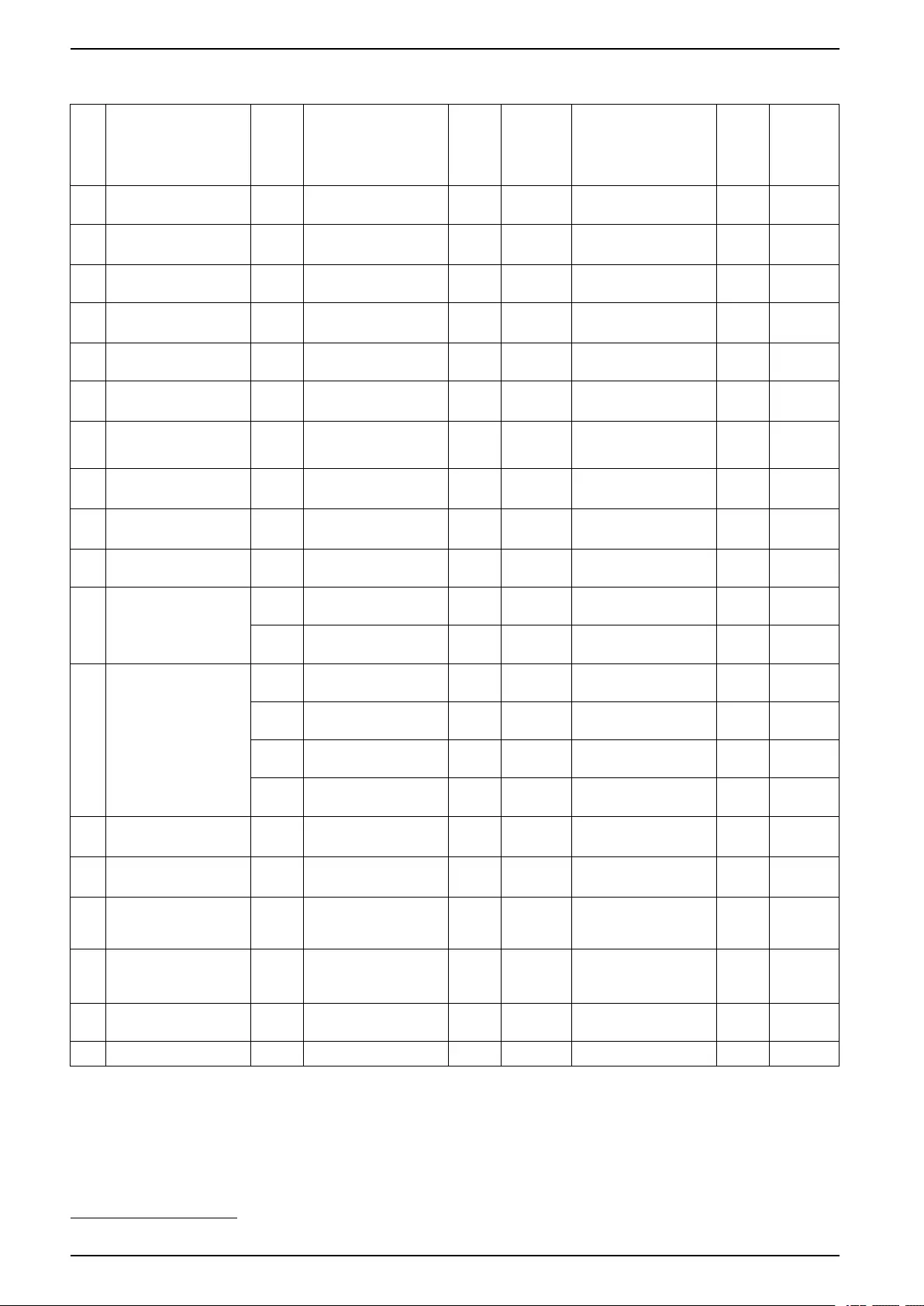

Protection Protocol for Battery Cabinet with 16 Battery Modules

No Item Level Set condition Soft-

ware

set

time

(sec)

Battery

breaker

status2

Release condition Time

(sec)

Battery

breaker

status

1 Over voltage protection

- cell Major Max cell ≥ 4.28 V 5 OFF Max cell < 4.25 V and

reset 5ON

2 Under voltage

protection - cell Major Min cell ≤ 2.5 V 3 OFF Min cell > 2.70 V and

reset 3 ON

3 Over voltage protection

- cabinet Major Cabinet voltage ≥

547.84 V 5OFF Cabinet voltage < 544

V and reset 5ON

4 Under voltage

protection - cabinet Major Cabinet voltage ≤ 320

V3 OFF Cabinet voltage >

345.6 V and reset 3 ON

5 Voltage imbalance Major Max cell ≥ 3.80 V and

△Vcell ≥ 100 mV 5OFF △Vcell < 30 mV and

reset 5ON

6 Voltage sensing error

(cabinet) Minor Cabinet V - cell sum V│

≥38.4 V

10 ON │Rack V - cell sum V│

< 19.2 V and reset

3 ON

7 Voltage sensing error

(module) Minor │Module V - cell sum

V│ ≥190 mV

5ON │Module V - cell sum

V│ < 190 mV and reset

3 ON

8 Over temperature

protection Major Max temp ≥ 75 ℃3 OFF Max temp < 65 ℃and

reset 3 ON

9 Under temperature

protection Minor Min temp ≤ 0 ℃3 ON Min temp > 5℃& reset 3 ON

10 Temperature imbalance Major Max cell T - min cell T ≥

40 ℃

30 OFF Max cell T - min cell T <

20 ℃and reset 3 ON

11 Over current protection

(charge) Major Level2 current ≥ 250 A 2 OFF |Current| < 10 A and

reset 3 ON

Major Level1 current ≥ 200 A 60 OFF |Current| < 10 A and

reset 3 ON

12 Over current protection

(discharge) Major Level4 |current| ≥ 600 A 1 OFF |Current| < 10 A and

reset 3 ON

Major Level3 |current| ≥ 540 A 10 OFF |Current| < 10 A and

reset 3 ON

Major Level2 |current| ≥ 495 A 30 OFF |Current| < 10 A and

reset 3 ON

Major Level1 |current| ≥ 470 A 60 OFF |Current| < 10 A and

reset 3 ON

13 Communication lost

(module ↔ cabinet) Major No communication 30 OFF Communication

reestablished + reset -ON

14 Communication lost

(cabinet ↔ system ) Minor No communication 30 ON Communication

reestablished + reset -ON

15 SW failure - battery

breaker Minor Battery breaker OFF

and |current| ≥ 2.4 A 3 ON (Battery breaker OFF

and (|current| < 2.4 A)

and reset

-ON

16 SW sensor failure -

battery breaker Minor Battery breaker contact

ON = battery breaker

trip ON

3 ON (Battery breaker

contact ≠ battery

breaker trip) and reset

-ON

17 Current sensing error Minor No communication with

Current IC 3 ON Communication with

current IC OK -ON

18 Fuse failure Minor Fuse blown 10 ON Fuse ON and reset -ON

990-91430A-001 39

2. The battery breaker status will switch from ON to OFF within three seconds after the software set time.

With 13, 16, or 17 Battery Modules Troubleshooting

Protection Protocol for Battery Cabinet with 13 Battery Modules

No Item Level Set condition Soft-

ware

set

time

(sec)

Battery

breaker

status3

Release condition Time

(sec)

Battery

breaker

status

1 Over voltage protection

- cell Major Max cell ≥ 4.28 V 5 OFF Max cell <4.25 V and

reset 5ON

2 Under voltage

protection - cell Major Min cell ≤ 2.5 V 3 OFF Min cell > 2.70 V and

reset 3 ON

3 Over voltage protection

- cabinet Major Cabinet voltage ≥

445.12 V 5OFF Cabinet voltage < 442

V and reset 5ON

4 Under voltage

protection - cabinet Major Cabinet voltage ≤ 260

V3 OFF Cabinet voltage >

280.8 V and reset 3 ON

5 Voltage imbalance Major Max cell ≥ 3.80 V and

△Vcell ≥ 100 mV 5OFF △Vcell < 30 mV and

reset 5ON

6 Voltage sensing error

(cabinet) Minor Cabinet V - cell sum V│

≥31.2 V

10 ON │Rack V - cell sum V│

< 15.6 V and reset

3 ON

7 Voltage sensing error

(module) Minor │Module V - cell sum

V│ ≥190 mV

5ON │Module V - cell sum

V│ < 190 mV and reset

3 ON

8 Over temperature

protection Major Max temp ≥ 75 ℃3 OFF Max temp < 65 ℃and

reset 3 ON

9 Under temperature

protection Minor Min temp ≤ 0 ℃3 ON Min temp > 5℃& reset 3 ON

10 Temperature imbalance Major Max cell T - min cell T ≥

40 ℃

30 OFF Max cell T - min cell T <

20 ℃and reset 3 ON

11 Over current protection

(charge) Major Level2 current ≥ 250 A 2 OFF |Current| < 10 A and

reset 3 ON

Major Level1 current ≥ 200 A 60 OFF |Current| < 10 A and

reset 3 ON

12 Over current protection

(discharge) Major Level4 |current| ≥ 600 A 1 OFF |Current| < 10 A and

reset 3 ON

Major Level3 |current| ≥ 540 A 10 OFF |Current| < 10 A and

reset 3 ON

Major Level2 |current| ≥ 495 A 30 OFF |Current| < 10 A and

reset 3 ON

Major Level1 |current| ≥ 470 A 60 OFF |Current| < 10 A and

reset 3 ON

13 Communication lost

(module ↔ cabinet) Major No communication 30 OFF Communication

reestablished + reset -ON

14 Communication lost

(cabinet ↔ system ) Minor No communication 30 ON Communication

reestablished + reset -ON

15 SW failure - battery

breaker Minor Battery breaker OFF

and |current| ≥ 2.4 A 3 ON (Battery breaker OFF

and (|current| < 2.4 A)

and reset

-ON

16 SW sensor failure -

battery breaker Minor Battery breaker contact

ON = battery breaker

trip ON

3 ON (Battery breaker

contact ≠ battery

breaker trip) and reset

-ON

17 Current sensing error Minor No communication with

Current IC 3 ON Communication with

current IC OK -ON

18 Fuse failure Minor Fuse blown 10 ON Fuse ON and reset -ON

40 990-91430A-001

3. The battery breaker status will switch from ON to OFF within three seconds after the software set time.

Schneider Electric

35 rue Joseph Monier

92500 Rueil Malmaison

France

+ 33 (0) 1 41 29 70 00

*990-91430A-001*

As standards, specifications, and design change from time to time,

please ask for confirmation of the information given in this publication.

© 2021 – 2021 Schneider Electric. All rights reserved.

990-91430A-001