Table of Contents

- Important Safety Instructions

- Table of Contents

- Tables

- Figures

- 1. About this Manual

- 2. Product Description

- 3. Battery System Operation

- 4. Maintenance Checks

- 5. Troubleshooting, Repair and Replacement

- 5.1 Troubleshooting

- 5.1.1 Overvoltage Protection – Cell (Major Protection)

- 5.1.2 Undervoltage Protection – Cell (Major Protection)

- 5.1.3 Overvoltage Protection – Rack (Major Protection)

- 5.1.4 Undervoltage Protection – Rack (Major Protection)

- 5.1.5 Voltage Imbalance (Major Protection)

- 5.1.6 Voltage Sensing Error (Minor Protection)

- 5.1.7 Overtemperature Protection (Major Protection)

- 5.1.8 Undertemperature Protection (Minor Protection)

- 5.1.9 Temperature Imbalance (Major Protection)

- 5.1.10 Overcurrent Protection (Charge) (Major Protection)

- 5.1.11 Overcurrent Protection (Discharge) (Major Protection)

- 5.1.12 Communication Failure (Module ↔ Rack) (Major Protection)

- 5.1.13 Communication Failure (Rack ↔ System) (Major Protection)

- 5.1.14 Communication Failure (System BMS ↔ Monitoring Software)

- 5.1.15 MCCB Failure (Minor Protection)

- 5.1.16 MCCB Sensor Failure (Minor Protection)

- 5.1.17 Current Sensing Error (Minor Protection)

- 5.1.18 Fuse Failure (Minor Protection)

- 5.1.19 BMS Power is Off

- 5.1.20 MCCB Handle Cannot be Set to “On”

- 5.2 Repair Procedures

- 5.3 Replacement Procedures

- 5.1 Troubleshooting

- 6. Appendix

APC LIBSMG95SUL1PH User Manual

Displayed below is the user manual for LIBSMG95SUL1PH by APC which is a product in the UPS Battery Cabinets category. This manual has pages.

Related Manuals

CONFIDENTIAL

English 8/2019. Rev 0.0

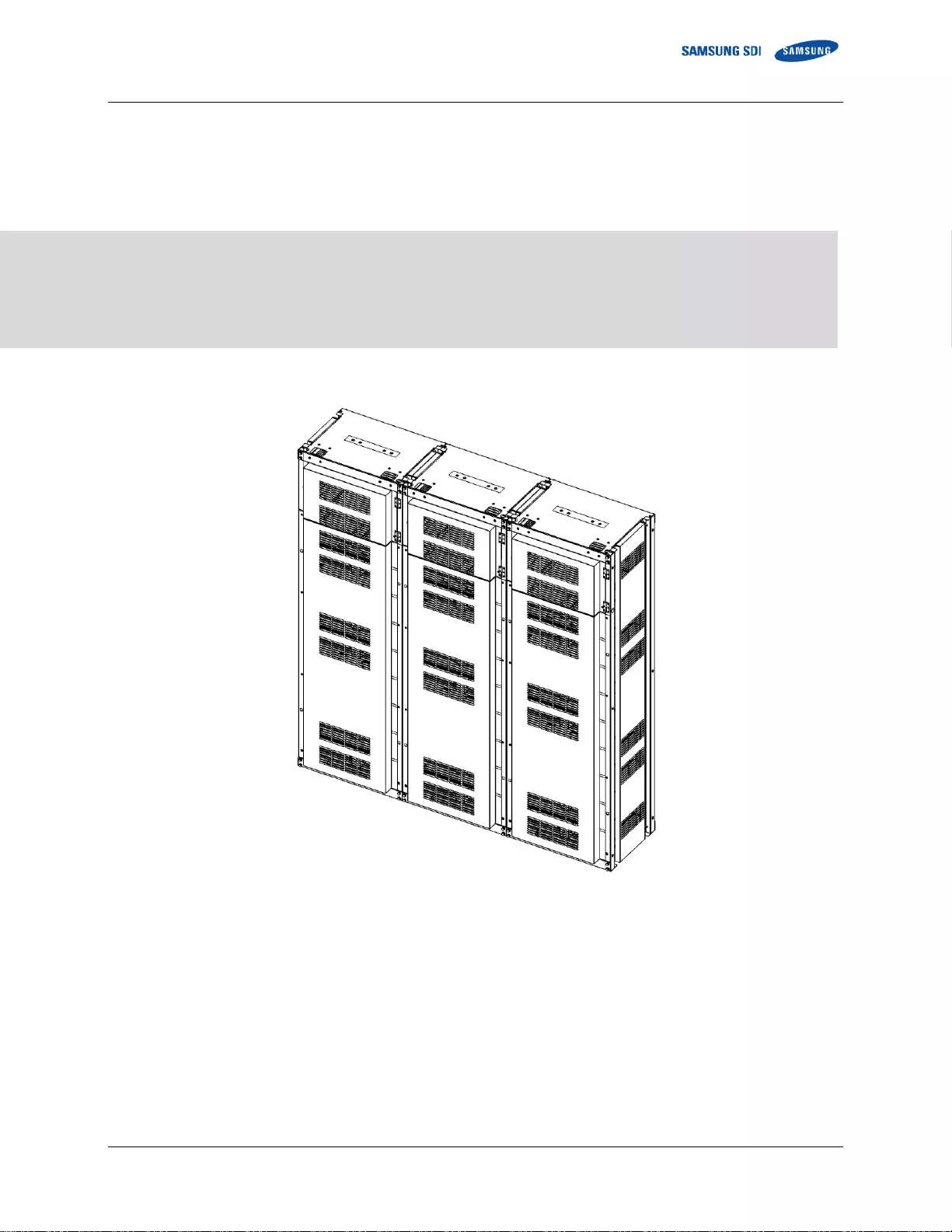

Lithium-ion Battery System for UPS

Operation and Maintenance Manual

CONFIDENTIAL

English 8/2019. Rev 0.0

Read this manual carefully before starting to install the battery system. Keep

these instructions for future reference.

CONFIDENTIAL

English 8/2019. Rev 0.0

Copyright © 2019 SAMSUNG SDI Co., Ltd. All rights reserved.

This document contains information that is the property of SAMSUNG SDI Co., Ltd., and provides for the sole

purpose of the installation, operation, and maintenance of products of SAMSUNG SDI Co., Ltd. No part of

this publication is to be used for any other purpose. It is not to be reproduced, copied, disclosed, transmitted,

stored in a retrieval system, or translated into any human or computer language in any form, by any means,

in whole or in part, without the prior written consent of SAMSUNG SDI Co., Ltd.

Although every possible effort has been made to ensure the accuracy of this document, SAMSUNG SDI Co.,

Ltd. assumes no responsibility for errors that may appear herein. The information is subject to change

without notice.

CONFIDENTIAL

English 8/2019. Rev 0.0

CONFIDENTIAL Important Safety Instructions

English 8/2019. Rev 0.0 i

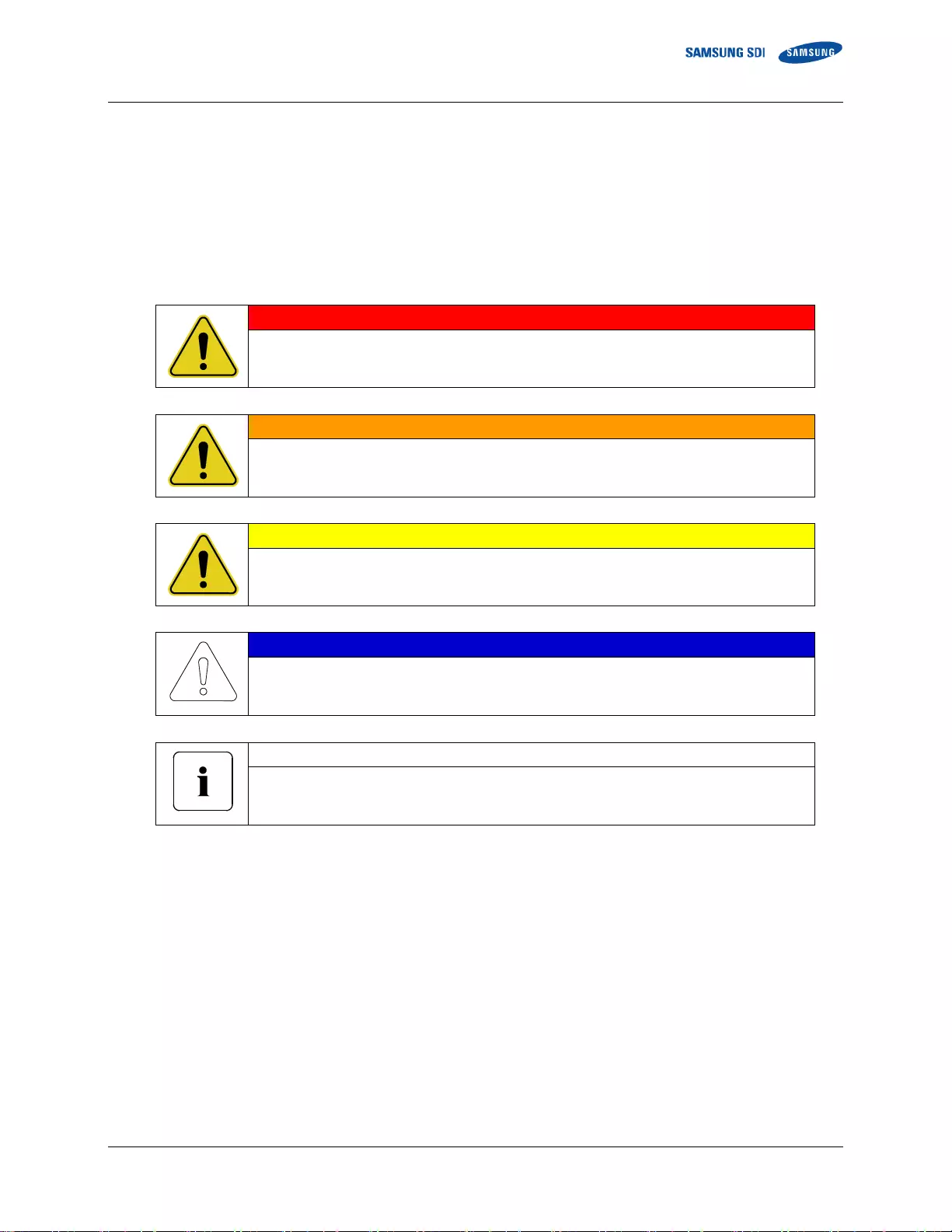

Important Safety Instructions

Read and follow these instructions!

The following precautions are intended to ensure your safety and prevent property damage. Before installing

this product, be sure to read all safety instructions in this document.

DANGER

Failure to comply with the instructions with this symbol may result in a serious accident, causing

death or severe injury.

WARNING

Failure to comply with the instructions with this symbol may result in a serious accident, causing

severe injury.

CAUTION

Failure to comply with the instructions with this symbol may result in minor or moderate injury.

NOTICE

Provides information considered important but not hazard-related. The information relates to

property damage.

Important

Indicates valuable tips for optimal installation and operation of the product.

Important Safety Instructions CONFIDENTIAL

ii English 8/2019. Rev 0.0

General Instructions

Be aware that a battery presents a risk of electric shock including high short-circuit current. Follow all safety

precautions while operating the batteries.

Remove watches, rings, and other metallic items.

Use tools with insulated handles to avoid inadvertent short circuits.

Wear rubber gloves and safety boots.

Do not put tools or any metal parts on the top of the batteries.

Disconnect the charging source and load before connecting or disconnecting terminals.

Use proper lifting means when moving batteries and wear all appropriate safety clothing and equipment.

Batteries must be handled, transported and recycled or discarded in accordance with federal, state and local

regulations. Do not dispose of the batteries in a fire because they can explode.

Do not open or mutilate the batteries.

Only authorized, properly trained and qualified technicians should perform maintenance.

Only qualified personnel who are familiar with the batteries and safety precautions should installor maintain

the battery system.

Do not allow unauthorized personnel to contact the batteries.

Safety Precautions

The following precautions are general safety guidelines that should be followed when working with or near

the Energy Storage System (ESS). The user should develop complete, site-specific safety parameters and

procedures.

Review and refer to all safety warnings and cautions in this manual before installation.

Build a clear, permanent, restricted access area around the system.

Only authorized, properly trained electrical operators should be able to access the system.

The interior of this equipment must be considered a “no-go area except for qualified personnel who are

familiar with the batteries and safety precautions.” Consult local codes and applicable rules and regulations

to determine permit requirements. If required, mark enclosures appropriately before beginning work.

CONFIDENTIAL Important Safety Instructions

English 8/2019. Rev 0.0 iii

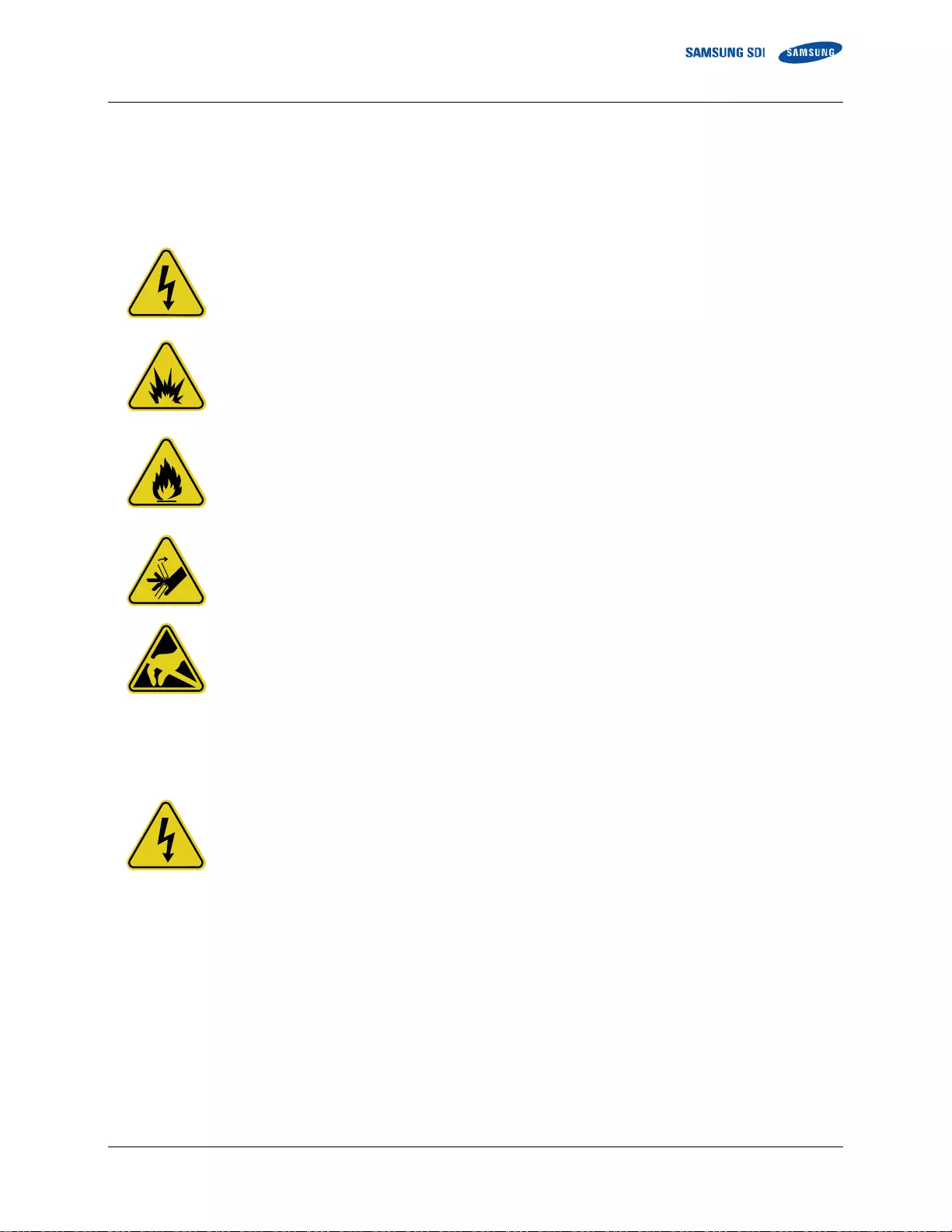

Personnel and Equipment Warnings

Personnel in contact with the battery system should be aware of the following hazards:

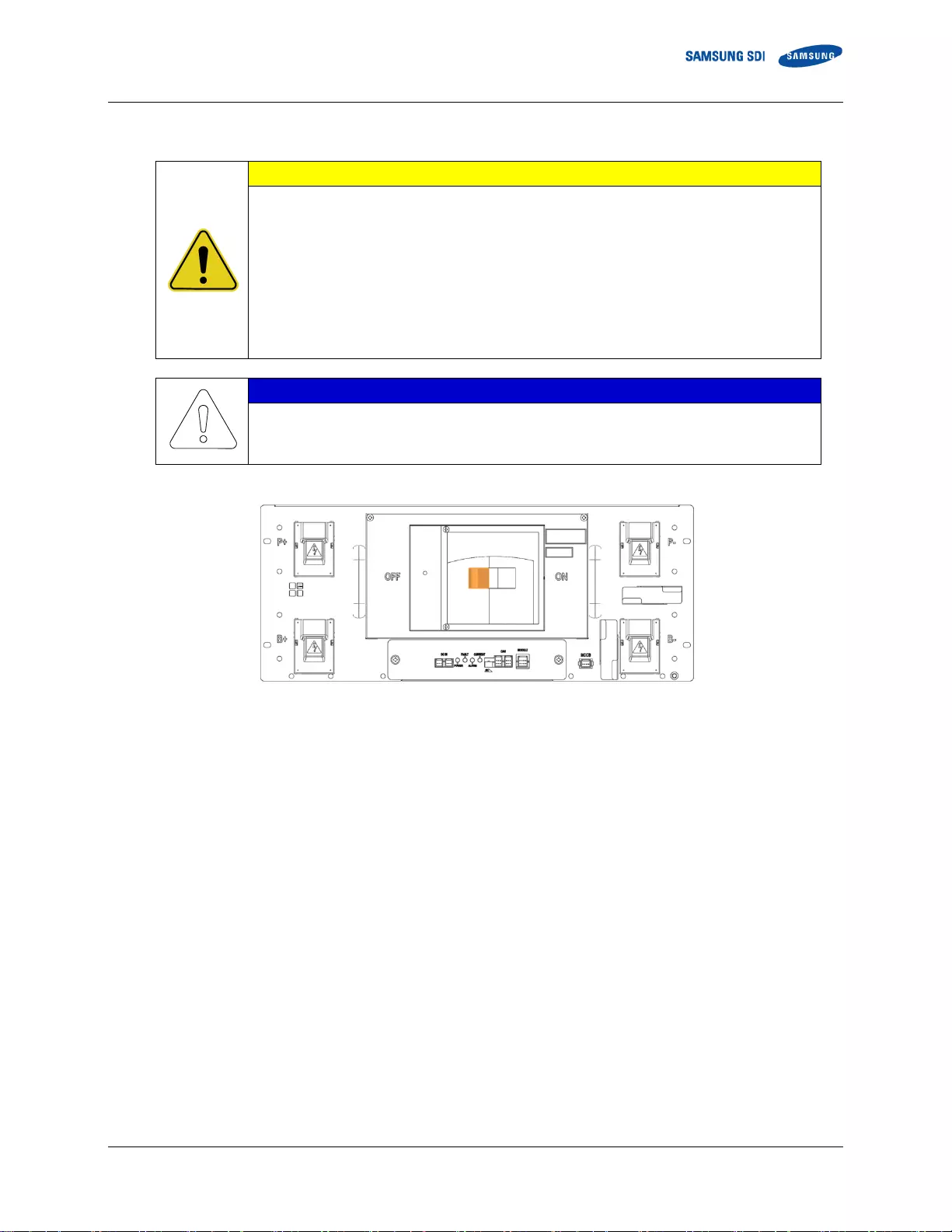

WARNING—SHOCK HAZARD

Do not contact system connectors or terminals. Do not open the enclosure doors unless proper lock out

and tag out procedures and related trainings are followed in accordance with local codes and regulations.

WARNING—ARC FLASH HAZARD

All electrical equipment presents an arc flash hazard. There is a serious risk of arc flash relating to any

equipment modification, such as opening doors. Serious injuries can occur in arc flash incidents.

Appropriate training is required in accordance with local codes and regulations.

WARNING—FIRE HAZARD

Certain faults may cause a fire.

In case of fire involving electrical equipment, use only carbon dioxide fire extinguishers or those approved

for use in fighting electrical fires

CAUTION—PINCH POINTS

Multiple pinch-points are present in most system components. Be aware that there is a serious risk of

injury while working around and in equipment enclosures.

CAUTION—STATIC SENSITIVE

Electronic devices can be damaged by electrostatic discharge. Proper handling procedures are required.

Be sure to wear a grounded anti-static wrist strap and to discharge static electricity by touching a

grounded surface near the equipment before touching any system components.

Dangerous Voltages

DANGER

The Energy Storage System (ESS) is powered by multiple power sources. Hazardous voltages may be

present in the equipment even when it does not appear operational. Make sure that you completely

understand the cautions and warnings in this manual. Failure to do so may result in serious injury or

death. Follow all manufacturer-published safety procedures.

Electrical equipment can present a risk of electrical shock and can cause arc flash. The following

precautions must be observed when working on or around electrical equipment:

Remove watches, jewelry, rings, and other metallic objects.

Use tools with insulated handles.

Safety clothing and shoes must comply with local codes and regulations.

Important Safety Instructions CONFIDENTIAL

iv English 8/2019. Rev 0.0

Lock Out/Tag Out Guidelines

DANGER

Failure to follow all the applicable lock out/tag out (LOTO) procedures at all times may result in serious

injury or death.

With power applied to the ESS, hazardous voltages are present on some components. To prevent death or

injury, do not touch any components within the enclosure unless specifically directed to do so. To reduce

the risk of electrical shock, make sure that all equipment is properly grounded. For more information,

refer to the installation manual.

WARNING

Enclosure doors must remain closed except when access to the enclosure interior is required. Personnel

should keep a safe distance from enclosures whenever the equipment is energized. Always comply with

local, state, and national lock out/tag out guidelines when working with or near the ESS. The LOTO

procedures must meet or exceed the requirements of all guidelines presented in SAMSUNG SDI safety

documentation. Follow these steps before entering potentially hazardous areas or beginning work on the

ESS:

Wear protective clothing and shoes.

Identify and isolate all power and stored energy sources.

Apply appropriate LOTO devices. When applying LOTO to the ESS, do not touch anything within the enclosure except as

specifically directed in the work procedures.

Complete the site-specific LOTO procedure and safety checklist before beginning work.

General Warnings

DANGER

When energized, this equipment presents a hazard of electric shock, death, and injury. Only

authorized, properly trained personnel who are thoroughly familiar with the equipment and

should install, operate, or maintain this equipment.

DANGER

To avoid death, injury, and property damage, follow all safety procedures promulgated by

Environmental Health and Safety (EHS) guidelines.

DANGER

To minimize the hazards of electrical shock, death, and injury, approved grounding practices and

procedures must be strictly followed.

WARNING

To avoid injury and equipment damage, personnel must adhere to the site protocol concerning

working at heights.

WARNING

To avoid personal injury or equipment damage caused by equipment malfunction, only properly

and qualified trained personnel should modify any programmable machine.

WARNING

Always ensure that applicable standards and regulations are followed and only properly

certified equipment is used as a critical component of a safety system. Never assume

that a safety-critical control loop is functioning correctly.

CONFIDENTIAL Important Safety Instructions

English 8/2019. Rev 0.0 v

Table of Contents CONFIDENTIAL

English 8/2019. Rev 0.0 i

Table of Contents

Important Safety Instructions ....................................................................................................... i

General Instructions ......................................................................................................................................................ii

Safety Precautions .........................................................................................................................................................ii

Personnel and Equipment Warnings .......................................................................................................................... iii

Dangerous Voltages ..................................................................................................................................................... iii

Lock Out/Tag Out Guidelines ...................................................................................................................................... iv

General Warnings ........................................................................................................................................................ iv

Table of Contents ........................................................................................................................ i

Tables....................................................................................................................................... iii

Figures ..................................................................................................................................... iv

1. About this Manual ..................................................................................................................1

1.1 Purpose ............................................................................................................................................................... 1

1.2 Target Audience .................................................................................................................................................. 1

1.3 Organization ........................................................................................................................................................ 1

1.4 Revision History .................................................................................................................................................. 2

1.5 Acronyms and Abbreviations ............................................................................................................................. 3

2. Product Description ................................................................................................................4

2.1 Major Components ............................................................................................................................................ 4

2.1.1 Battery Module (Type A / Type B) ...................................................................................................... 5

2.1.2 SMU (String Management Unit) ........................................................................................................ 7

2.1.3 SMPS Assembly (Type A / Type B).................................................................................................... 10

2.1.4 Rack Frame ........................................................................................................................................ 15

3. Battery System Operation .................................................................................................... 16

3.1 Indicator LED ..................................................................................................................................................... 16

3.2 Dry Contact Signals ........................................................................................................................................... 18

3.3 Operation Status ............................................................................................................................................... 22

3.3.1 Normal Status .................................................................................................................................... 32

3.3.2 Minor Protection Status (Alarm) ...................................................................................................... 32

3.3.3 Major Protection Status (Fault) ........................................................................................................ 32

4. Maintenance Checks ............................................................................................................ 33

4.1 Daily Checks ...................................................................................................................................................... 33

4.2 Monthly Checks ................................................................................................................................................ 33

4.3 Annual Check .................................................................................................................................................... 33

4.4 Maintenance Checklist ..................................................................................................................................... 34

5. Troubleshooting, Repair and Replacement ............................................................................. 35

5.1 Troubleshooting ................................................................................................................................................ 38

5.1.1 Overvoltage Protection – Cell (Major Protection) .......................................................................... 38

5.1.2 Undervoltage Protection – Cell (Major Protection) ........................................................................ 38

5.1.3 Overvoltage Protection – Rack (Major Protection) ........................................................................ 39

5.1.4 Undervoltage Protection – Rack (Major Protection) ...................................................................... 39

5.1.5 Voltage Imbalance (Major Protection) ............................................................................................ 39

5.1.6 Voltage Sensing Error (Minor Protection) ....................................................................................... 40

5.1.7 Overtemperature Protection (Major Protection) ........................................................................... 40

5.1.8 Undertemperature Protection (Minor Protection) ......................................................................... 40

5.1.9 Temperature Imbalance (Major Protection) ................................................................................... 40

5.1.10 Overcurrent Protection (Charge) (Major Protection) ..................................................................... 41

5.1.11 Overcurrent Protection (Discharge) (Major Protection) ................................................................ 41

5.1.12 Communication Failure (Module ↔ Rack) (Major Protection) .................................................... 41

5.1.13 Communication Failure (Rack ↔ System) (Major Protection)...................................................... 41

5.1.14 Communication Failure (System BMS ↔ Monitoring Software) .................................................. 43

5.1.15 MCCB Failure (Minor Protection) ..................................................................................................... 43

5.1.16 MCCB Sensor Failure (Minor Protection) ........................................................................................ 43

5.1.17 Current Sensing Error (Minor Protection) ....................................................................................... 43

5.1.18 Fuse Failure (Minor Protection) ....................................................................................................... 44

5.1.19 BMS Power is Off............................................................................................................................... 44

5.1.20 MCCB Handle Cannot be Set to “On” .............................................................................................. 44

5.2 Repair Procedures ............................................................................................................................................ 45

5.2.1 Module BMS Connection Check ...................................................................................................... 45

5.2.2 SMU Connection Check .................................................................................................................... 47

5.2.3 SMPS Assembly Connection Check .................................................................................................. 49

CONFIDENTIAL Table of Contents

ii English 8/2019. Rev 0.0

5.2.4 Busbar Connection Check................................................................................................................. 53

5.2.5 Cell Voltage Balancing ....................................................................................................................... 54

5.2.6 System Reset ..................................................................................................................................... 55

5.2.7 MCCB Handle Control ....................................................................................................................... 55

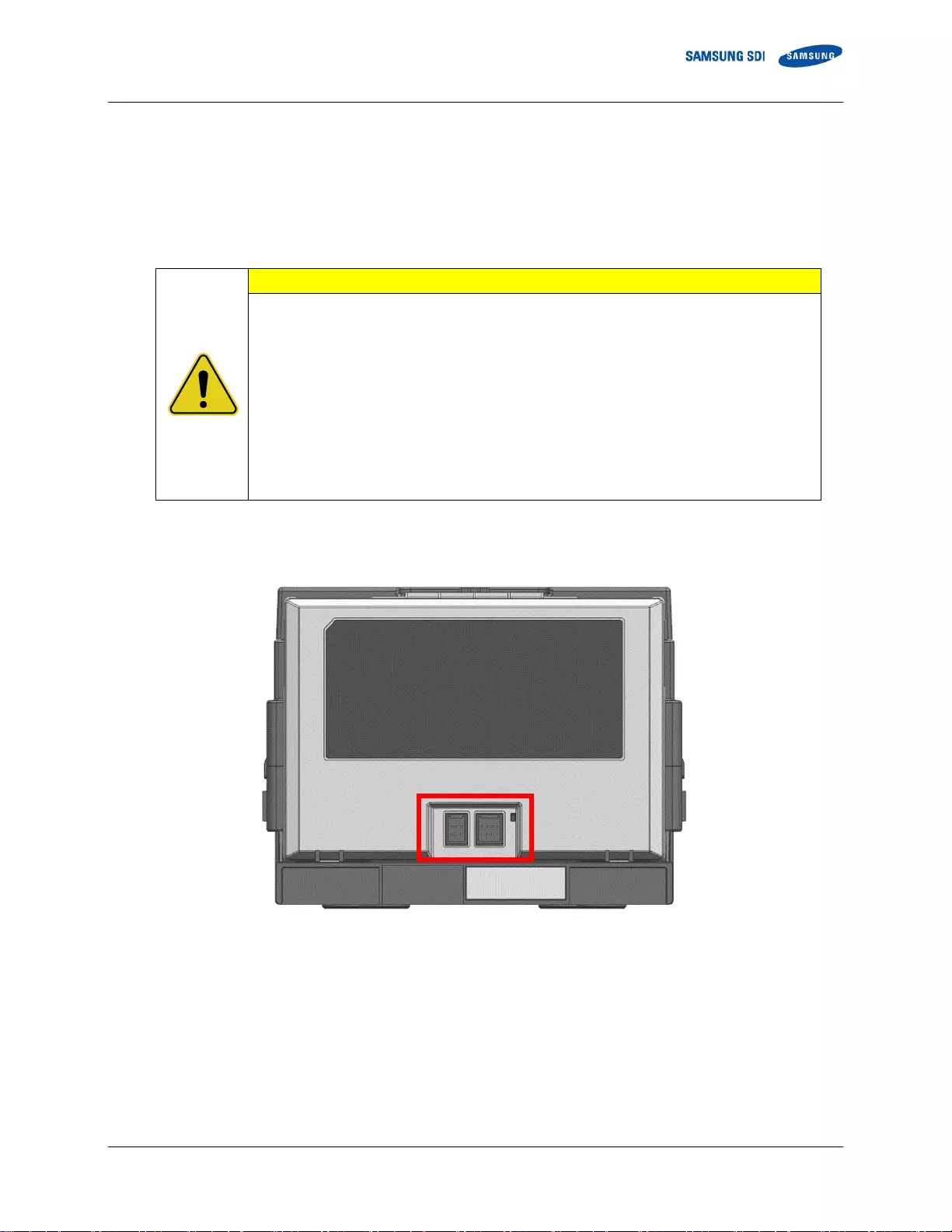

5.3 Replacement Procedures ................................................................................................................................. 57

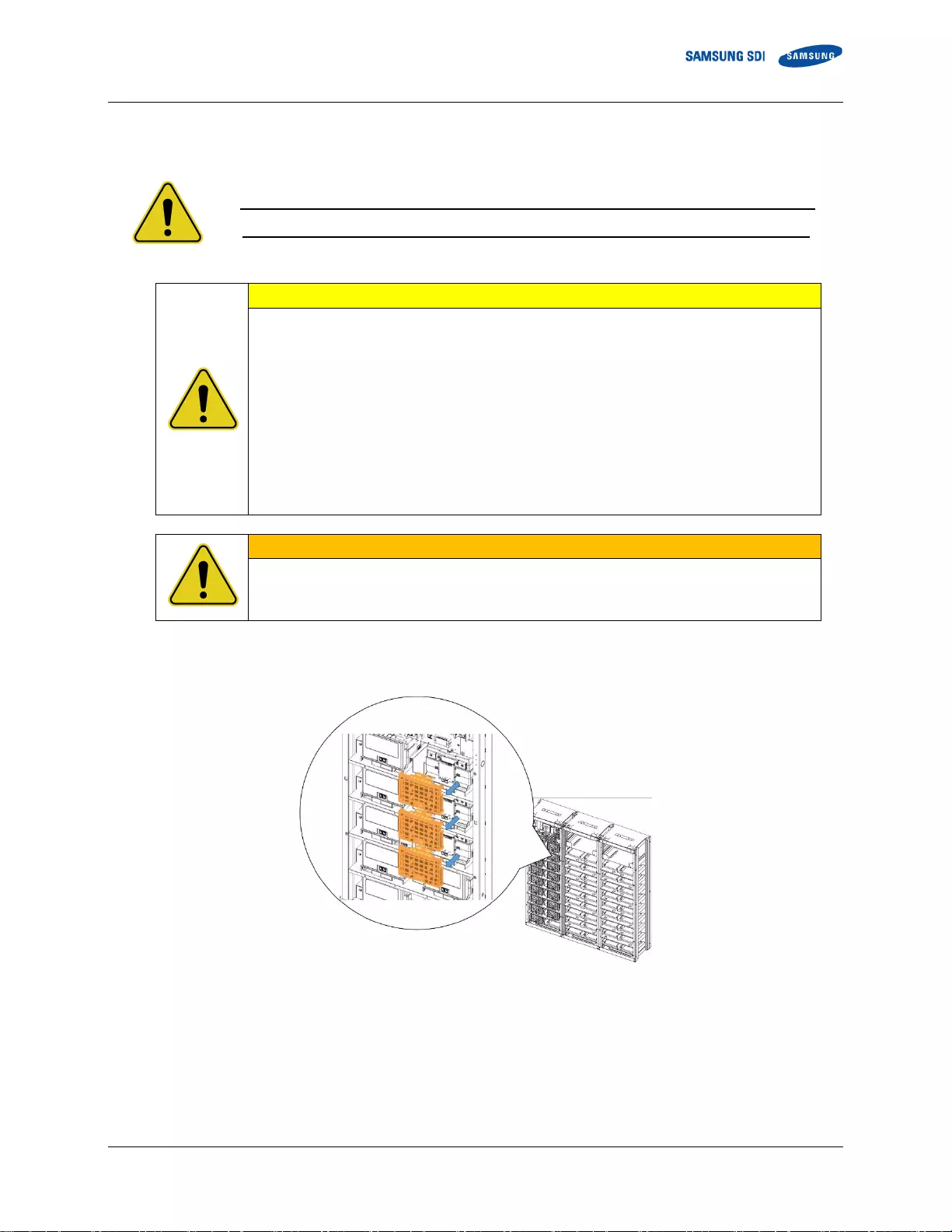

5.3.1 Wire Harness Replacement .............................................................................................................. 58

5.3.2 Battery Module Replacement .......................................................................................................... 64

5.3.3 Rack Fuse / Module Fuse Replacement .......................................................................................... 73

5.3.4 SMU Replacement ............................................................................................................................ 76

5.3.5 SMPS Assembly Replacement .......................................................................................................... 82

5.3.6 Module BMS Replacement ............................................................................................................... 92

6. Appendix ............................................................................................................................ 94

6.1 Disposal and Recycling ..................................................................................................................................... 94

Tables CONFIDENTIAL

English 8/2019. Rev 0.0 iii

Tables

Table 2-1: Extra Auxiliary Breaker Switch Connector Description ................................................................................ 8

Table 2-2: Terminal Block Description ........................................................................................................................ 9

Table 2-3: RS485 Connector Description .................................................................................................................. 12

Table 2-4: TCP/IP Connector Description ................................................................................................................. 12

Table 2-5: Dry Contact Connector Description ......................................................................................................... 13

Table 2-6: AC Terminal Description (3 phase) ........................................................................................................... 13

Table 2-7: AC Terminal Description (1 phase) ........................................................................................................... 13

Table 3-1: Indicator LED Status ................................................................................................................................ 16

Table 3-2: Indicated Codes ...................................................................................................................................... 17

Table 3-3: Dry Contact Connector Information......................................................................................................... 18

Table 3-4: Dry Contact Connector Description (Option 1. Customer ID = 0) ............................................................... 19

Table 3-5: Dry Contact Operation (Option 1. Customer ID = 0) ................................................................................. 19

Table 3-6: Dry Contact Connector Description (Option 2. Customer ID = 1) ............................................................... 20

Table 3-7: Dry Contact Operation (Option 2. Customer ID = 1) ................................................................................. 20

Table 8: Dry Contact Connector Description (Option 3. Customer ID = 2) .................................................................. 21

Table 9: Dry Contact Operation (Option 3. Customer ID = 2)..................................................................................... 21

Table 3-10: Range of Operation (136S Configuration)............................................................................................... 22

Table 3-11: Range of Operation (128S Configuration)............................................................................................... 23

Table 3-12: Range of Operation (112S Configuration)............................................................................................... 24

Table 3-13: Range of Operation (104S Configuration)............................................................................................... 25

Table 3-14: Range of Operation (80S Configuration) ................................................................................................ 26

Table 3-15. Protective Functions (136S Configuration) ............................................................................................. 27

Table 3-16. Protective Functions (128S Configuration) ............................................................................................. 28

Table 3-17. Protective Functions (112S Configuration) ............................................................................................. 29

Table 3-18. Protective Functions (104S Configuration) ............................................................................................. 30

Table 3-19. Protective Functions (80S Configuration) ............................................................................................... 31

Table 4-1: Maintenance Checklist Template............................................................................................................. 34

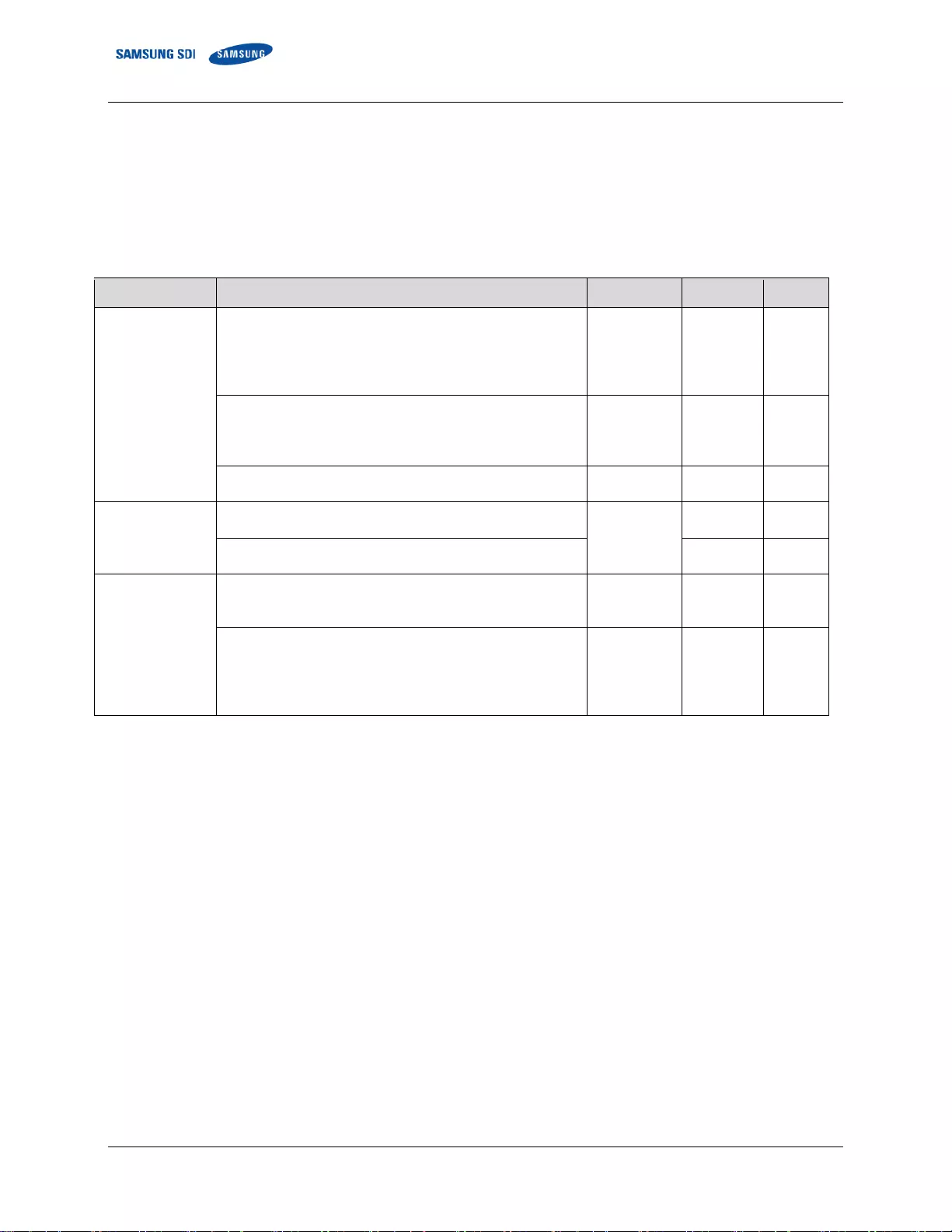

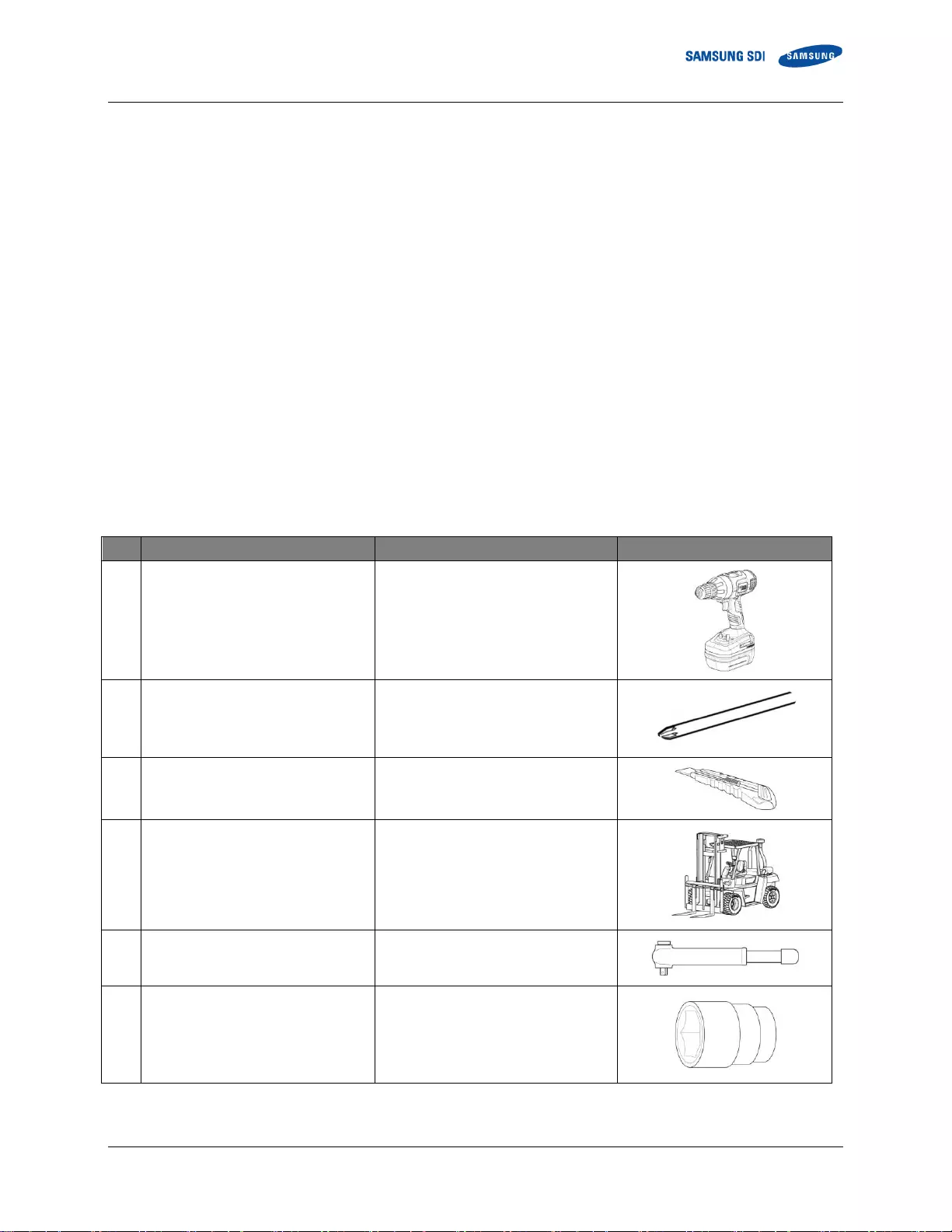

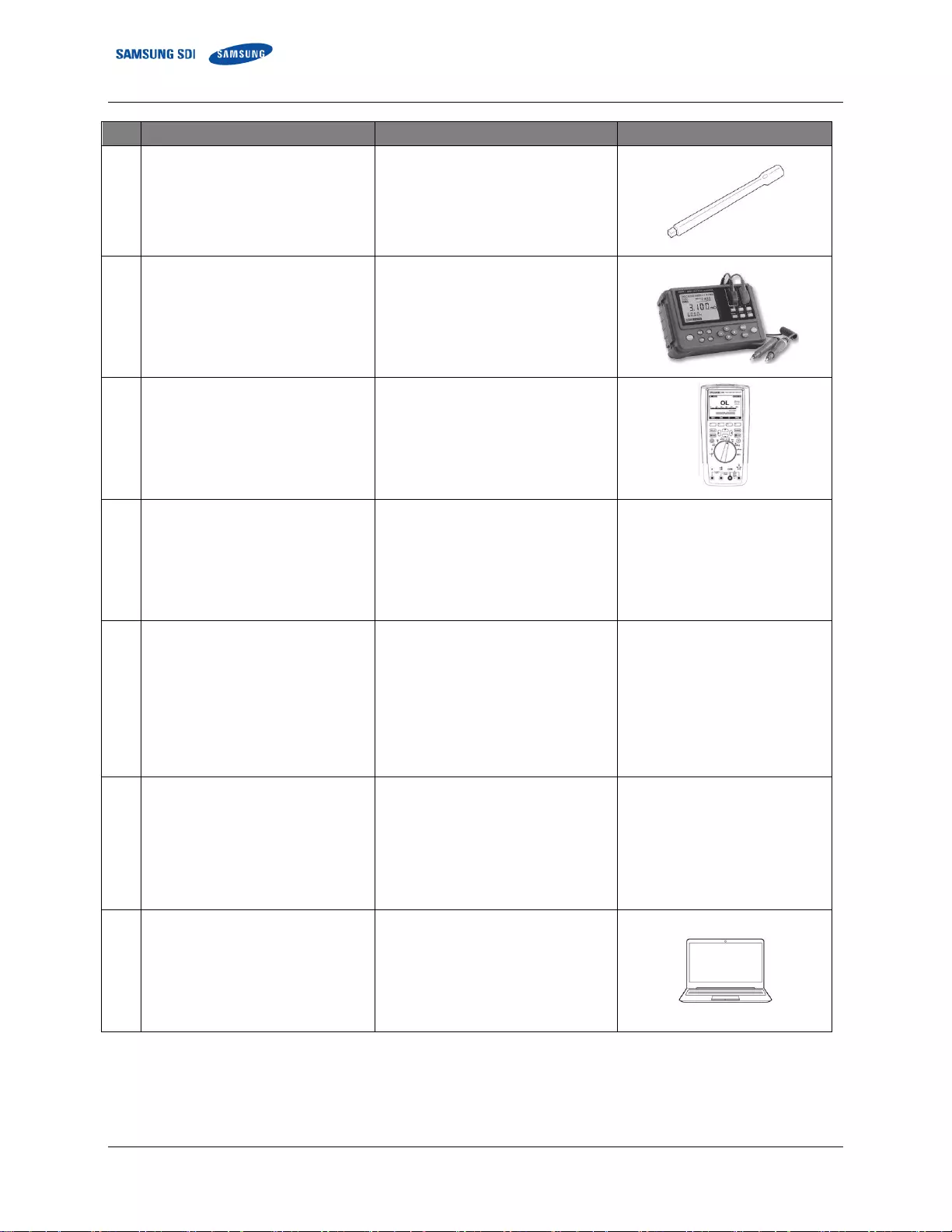

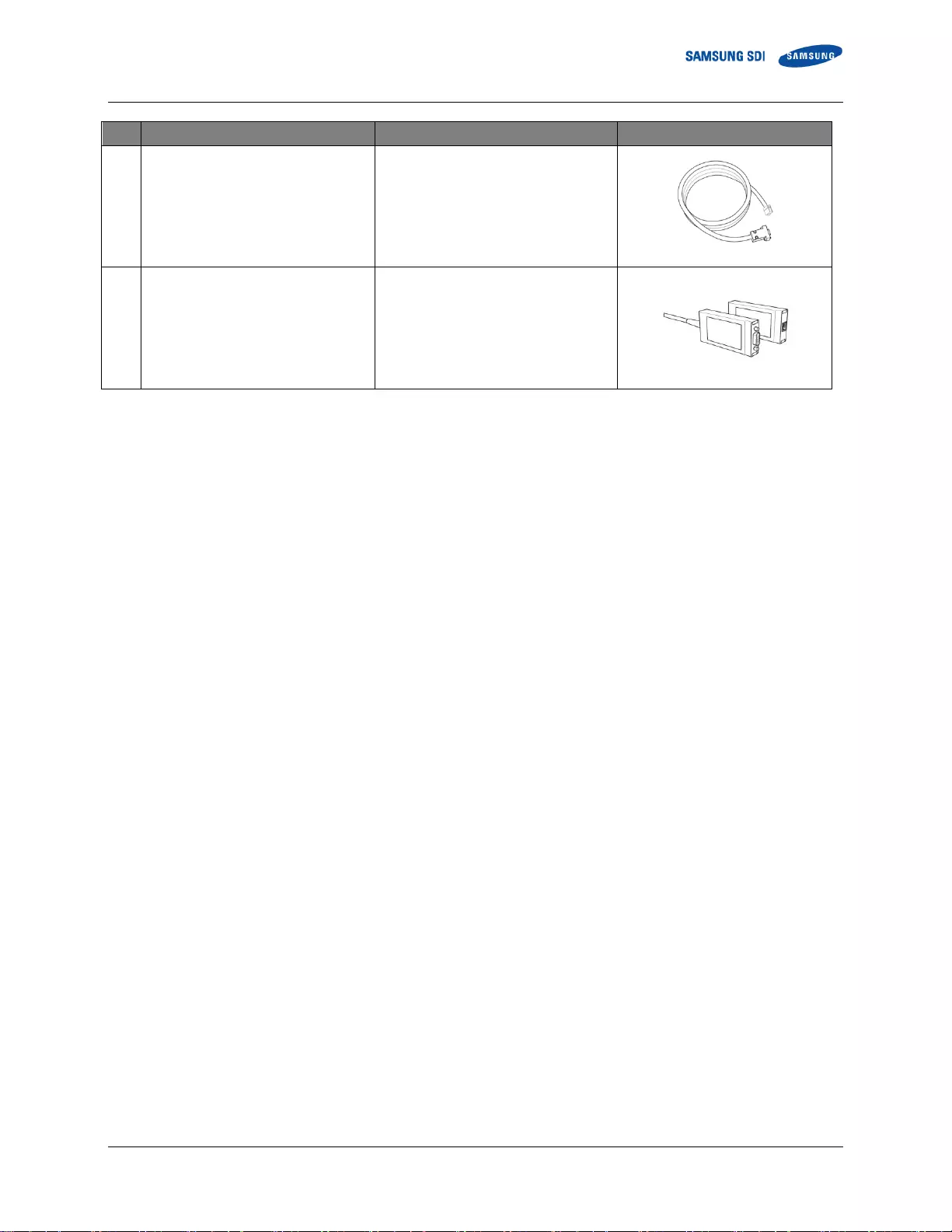

Table 5-1: Recommended Tools and Instruments for Repair and Replacement ......................................................... 35

CONFIDENTIAL Figures

iv English 8/2019. Rev 0.0

Figures

Figure 2-1: Battery Module Type A ............................................................................................................................ 5

Figure 2-2: Battery Module Type B ............................................................................................................................ 6

Figure 2-3: SMU ........................................................................................................................................................ 7

Figure 2-4: Auxiliary Breaker Switch .......................................................................................................................... 8

Figure 2-5: Terminal Block Isometric View ................................................................................................................. 8

Figure 2-6: Terminal Block Front / Top View (Cover Opened/Closed) .......................................................................... 9

Figure 2-7: SMPS Assembly ..................................................................................................................................... 10

Figure 2-8: Front View of SMPS Assembly Type A, 3-Phase Input .............................................................................. 11

Figure 2-9: Front View of SMPS Assembly Type A, 1-Phase Input .............................................................................. 11

Figure 2-10: SMPS Assembly Type A – System BMS Connections .............................................................................. 11

Figure 2-11: Front View of SMPS Assembly Type B, 1-Phase Input ............................................................................ 11

Figure 2-12: Rack Frame .......................................................................................................................................... 15

Figure 3-1: Dry Contact Connector Pinout ................................................................................................................ 18

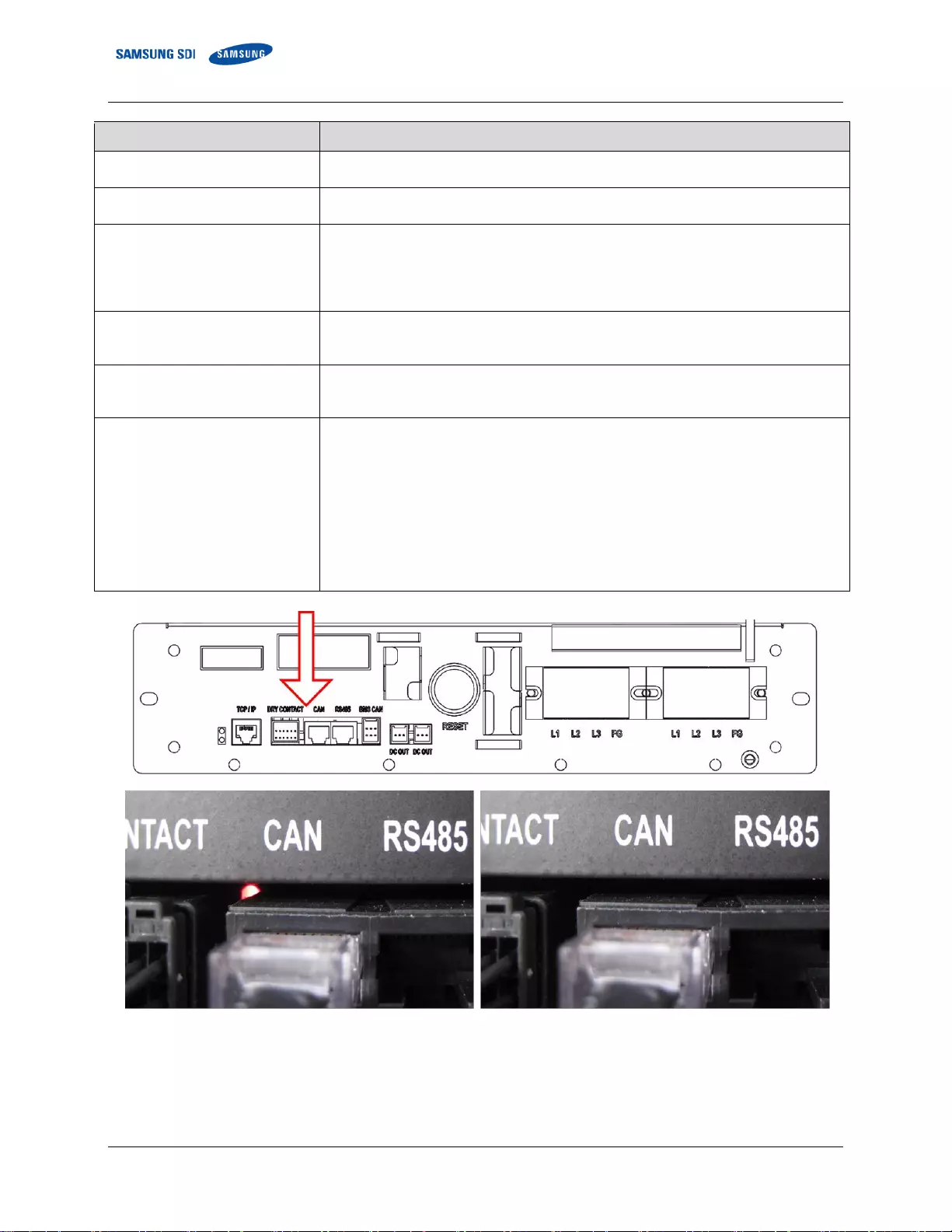

Figure 5-1. System BMS LED .................................................................................................................................... 42

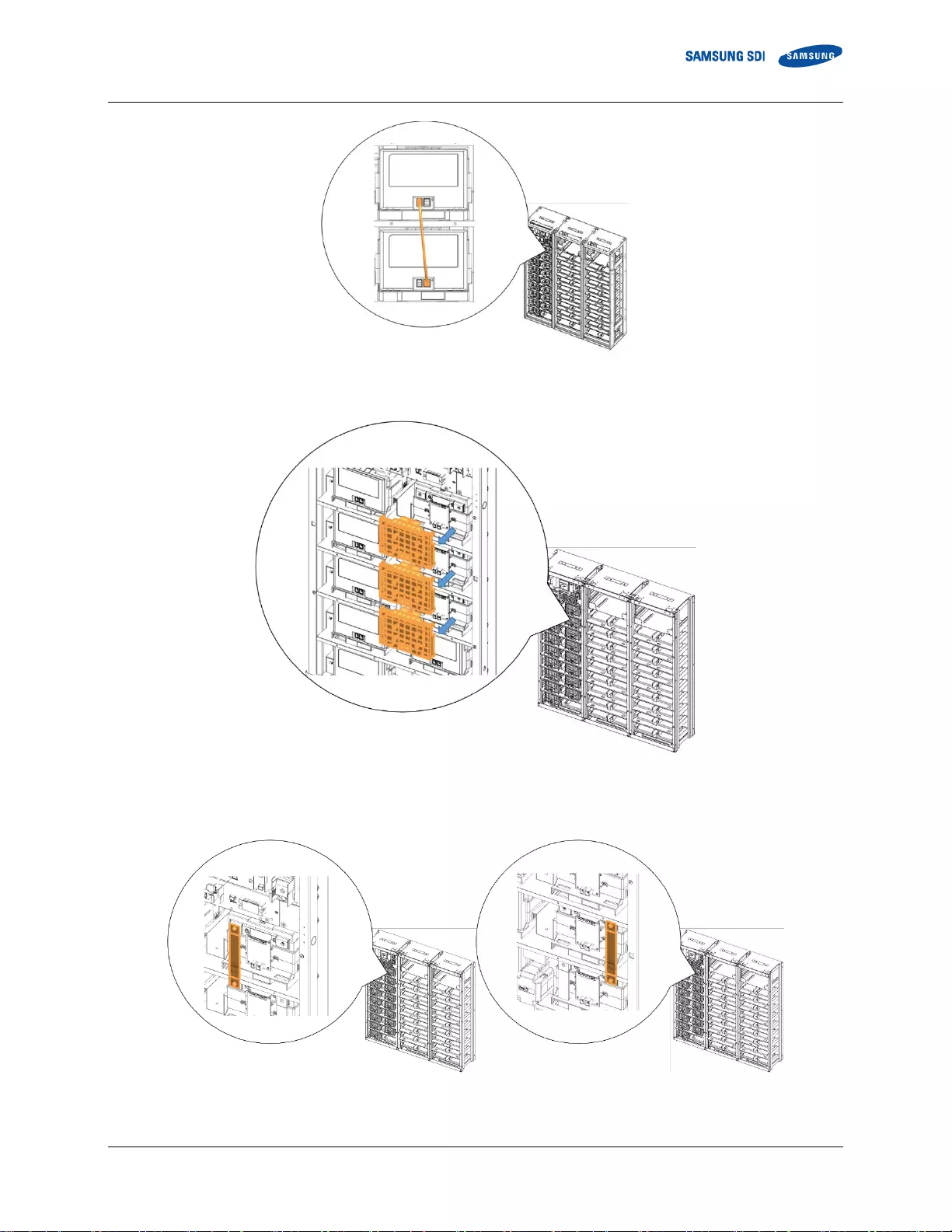

Figure 5-2: Signal Connectors .................................................................................................................................. 45

Figure 5-3: Removing the Battery Module Front Cover............................................................................................. 46

Figure 5-4: Voltage and Temperature Sensing Connectors ....................................................................................... 46

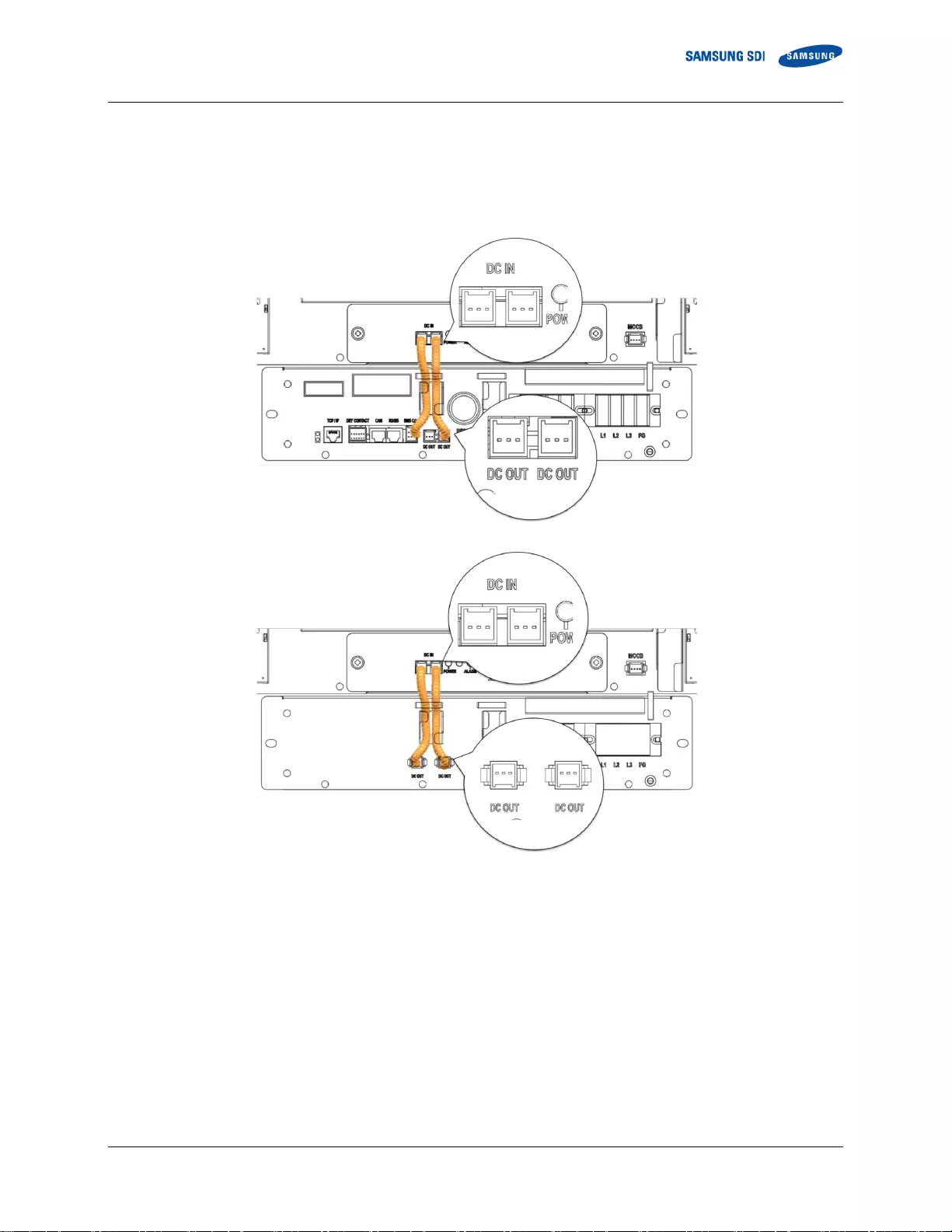

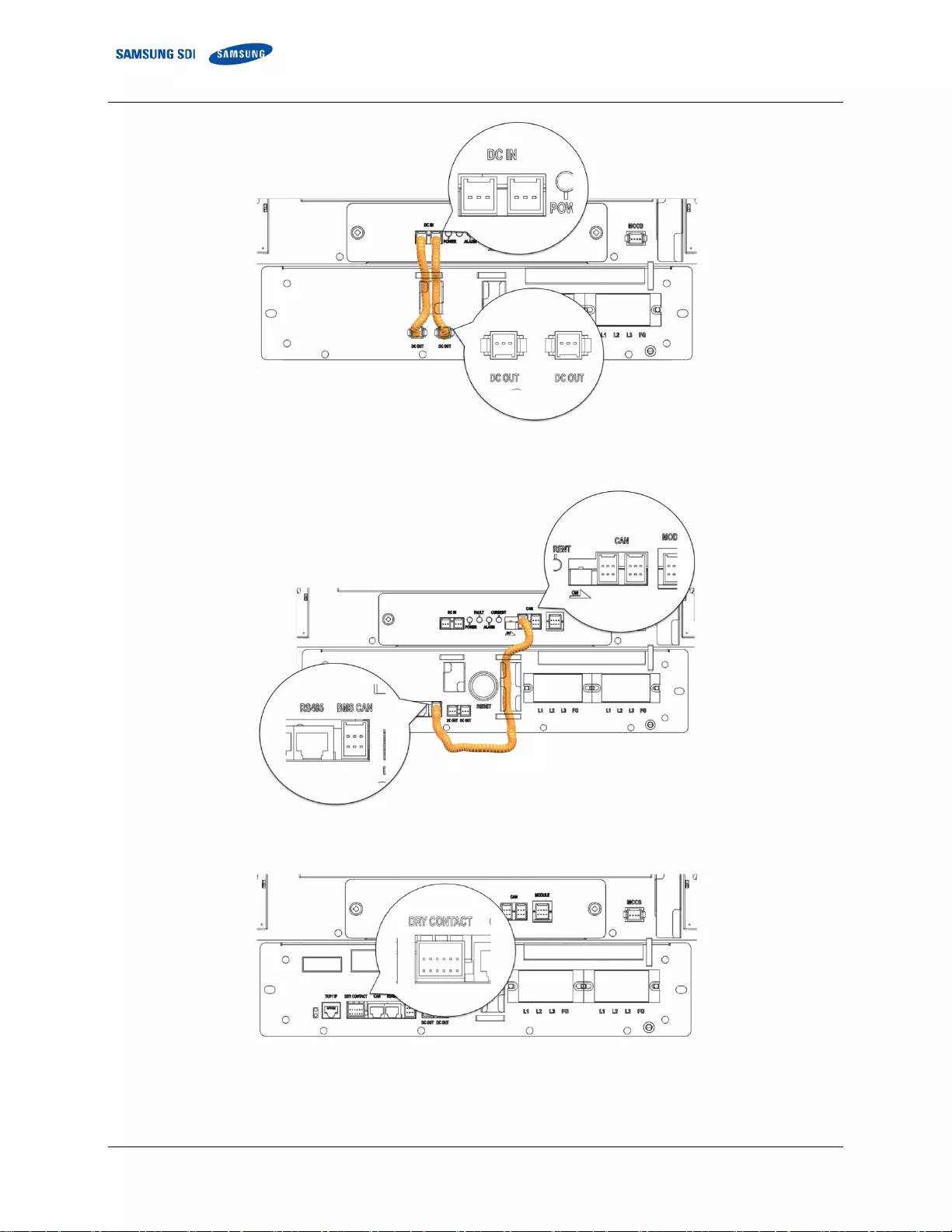

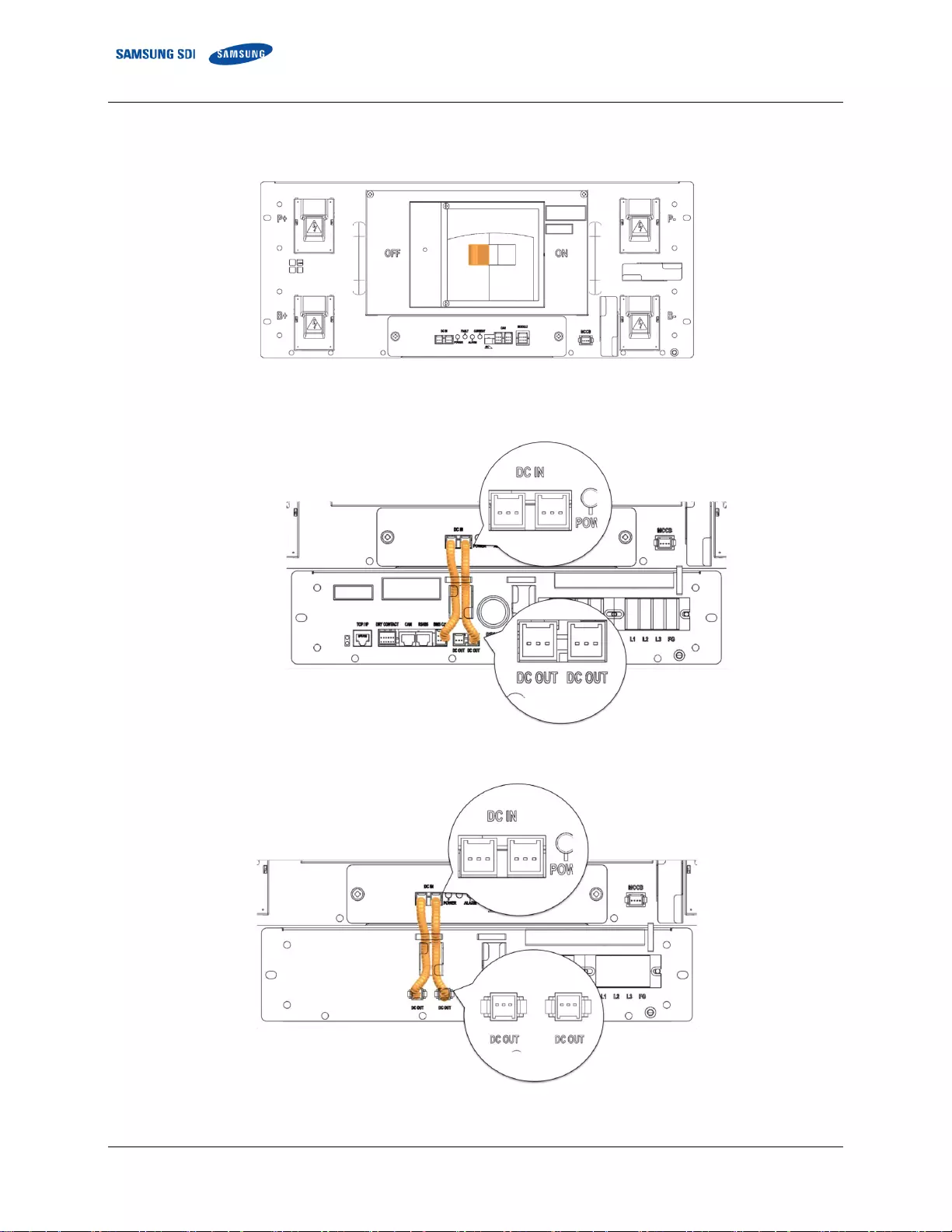

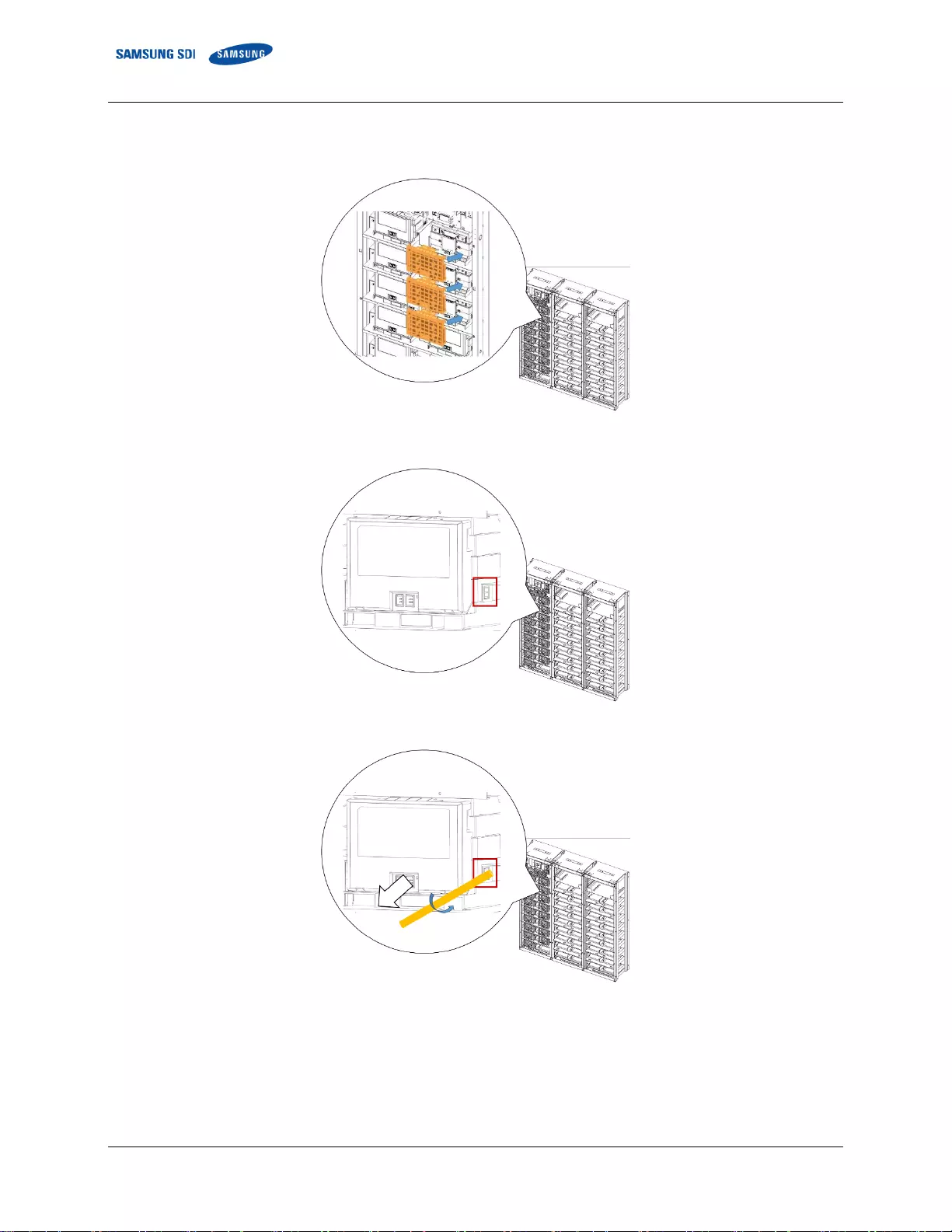

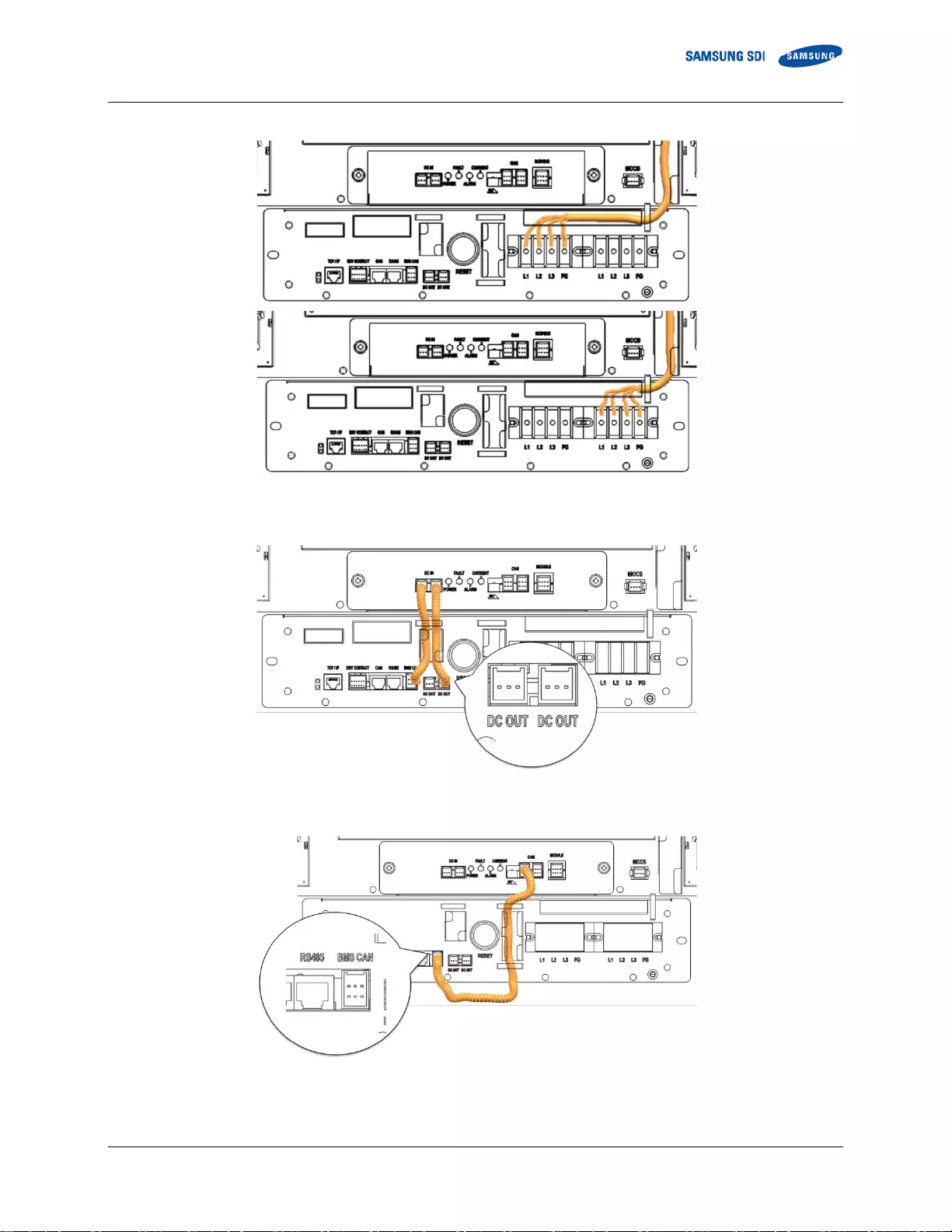

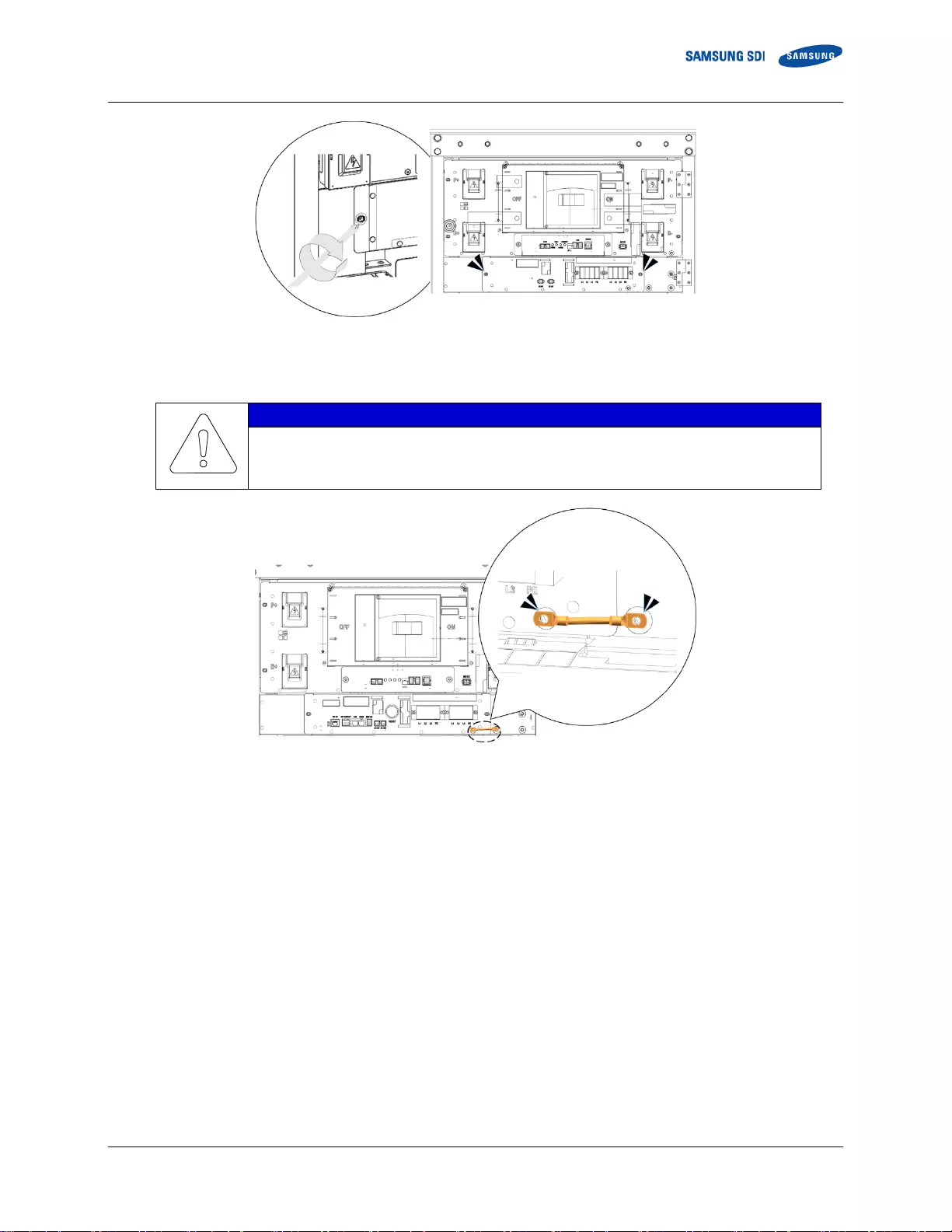

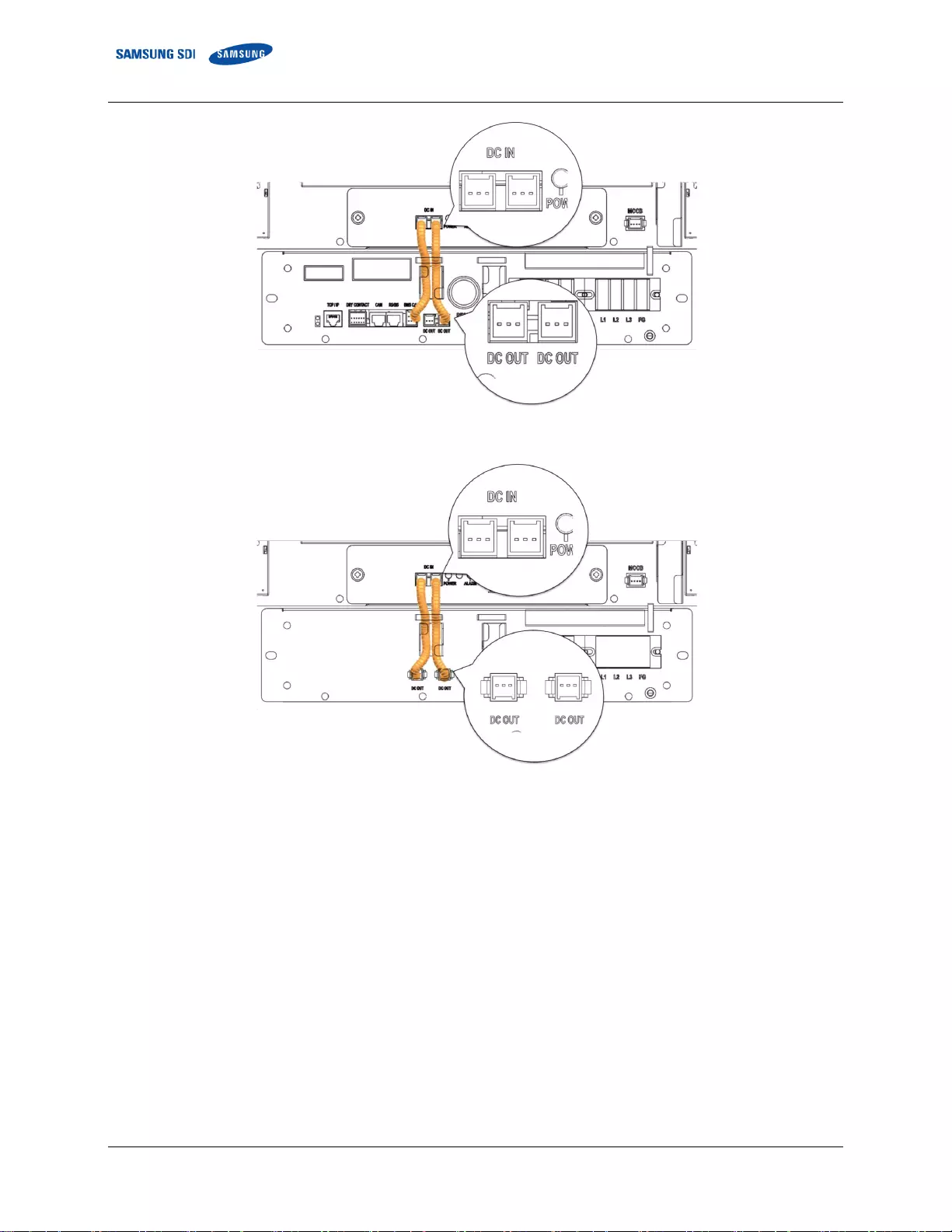

Figure 5-5: DC Power Cables from SMPS Assembly Type A to SMU ........................................................................... 47

Figure 5-6: DC Power Cables from SMPS Assembly Type B to SMU ........................................................................... 47

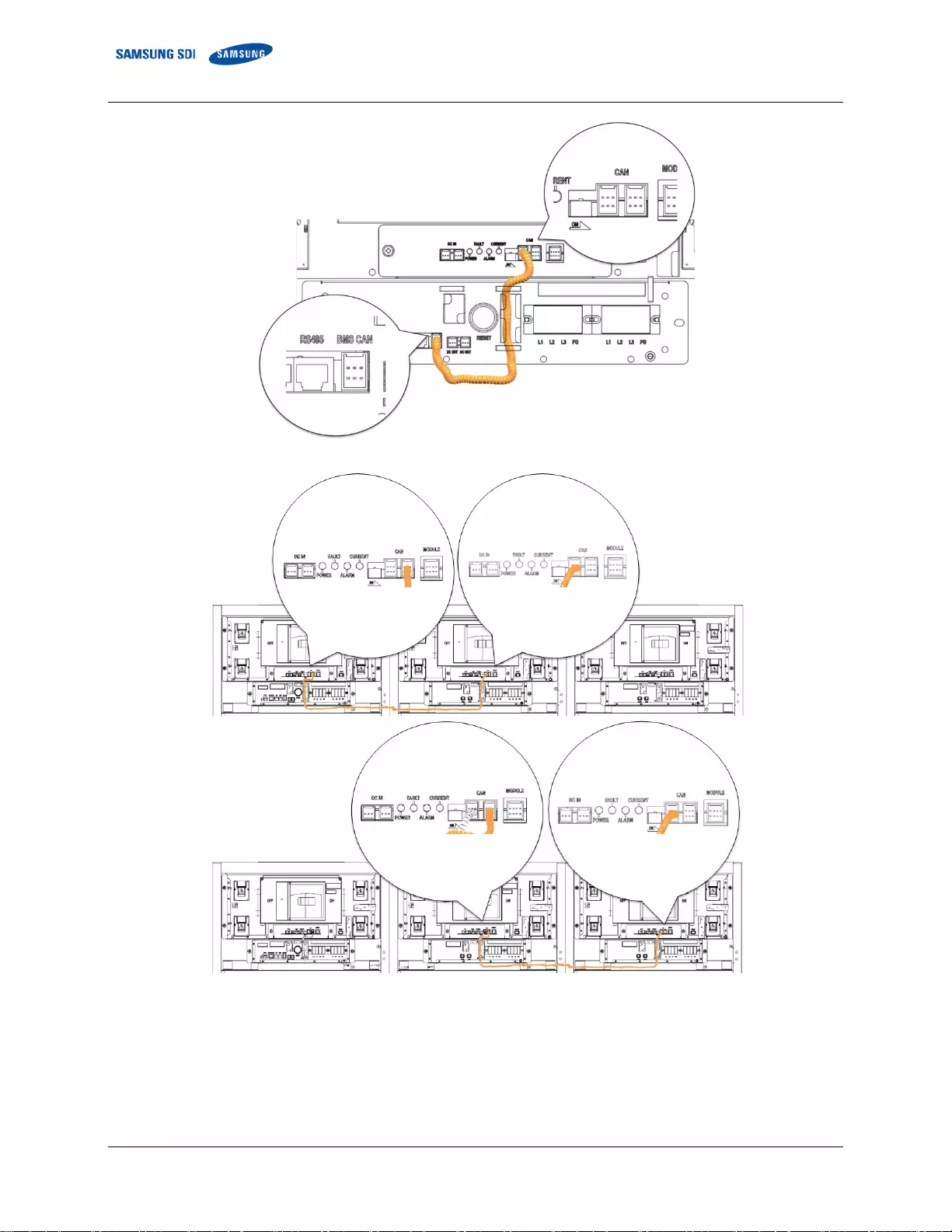

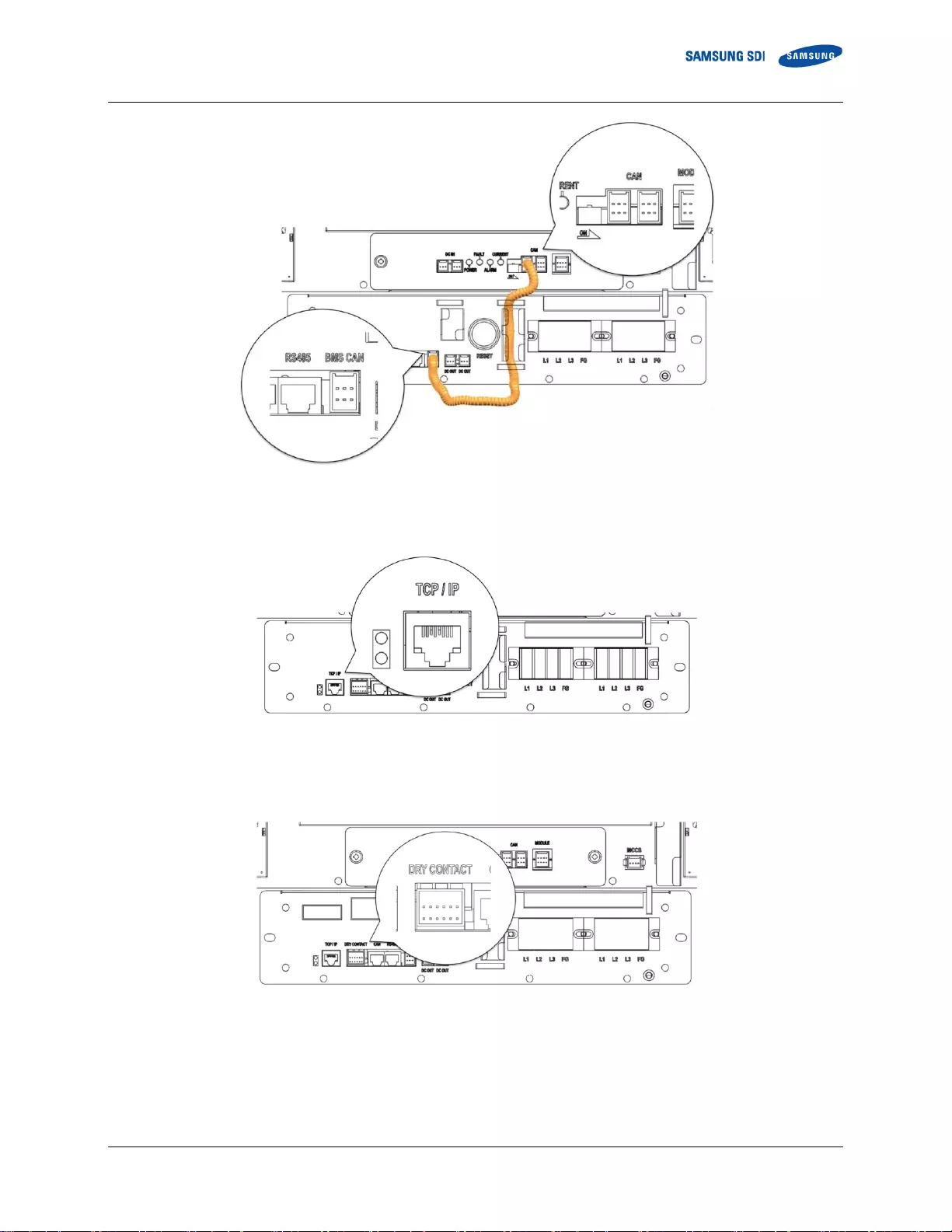

Figure 5-7: CAN Signal Cable Connection from SMPS Assembly to SMU .................................................................... 48

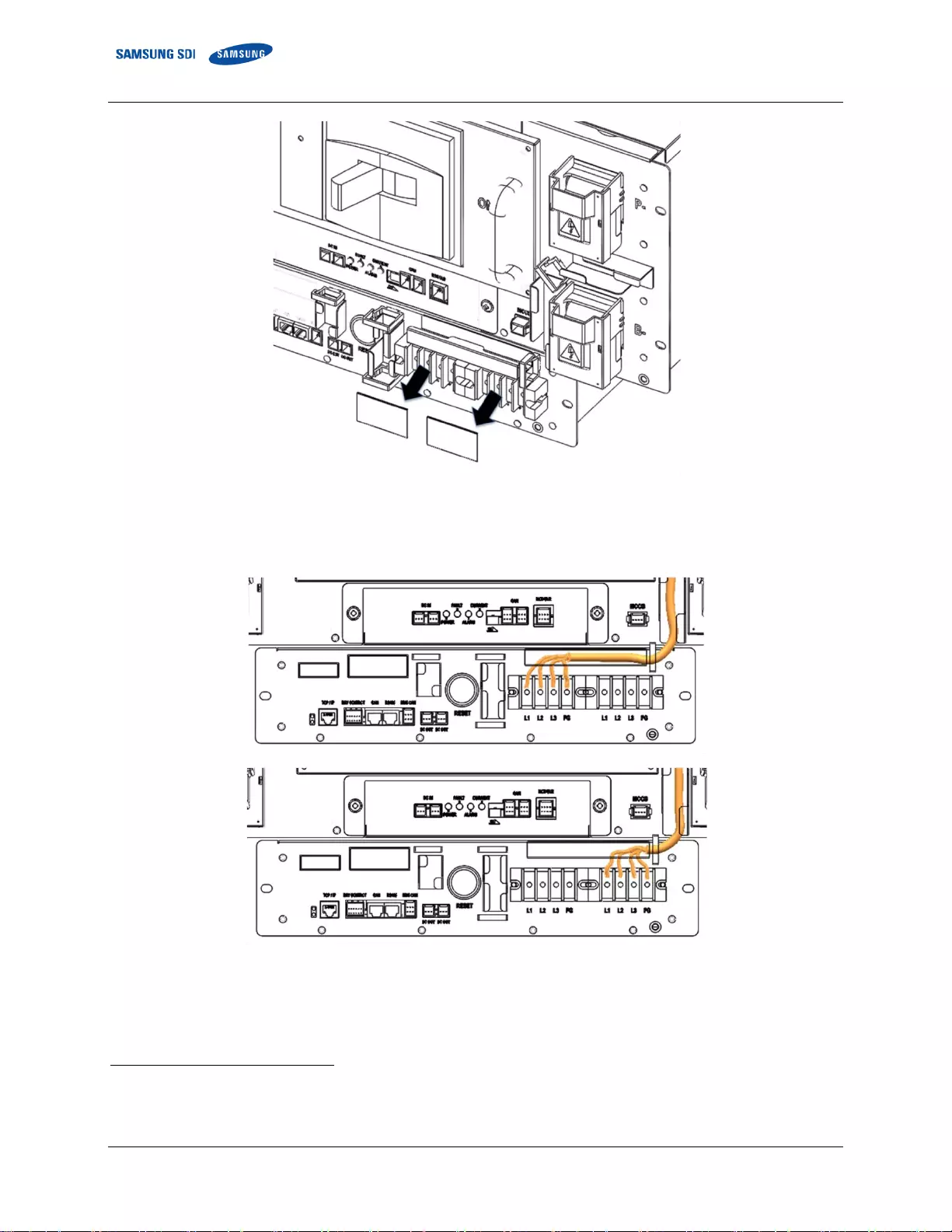

Figure 5-8: Signal Cabling Examples of Left Alignment of SMUs ................................................................................ 48

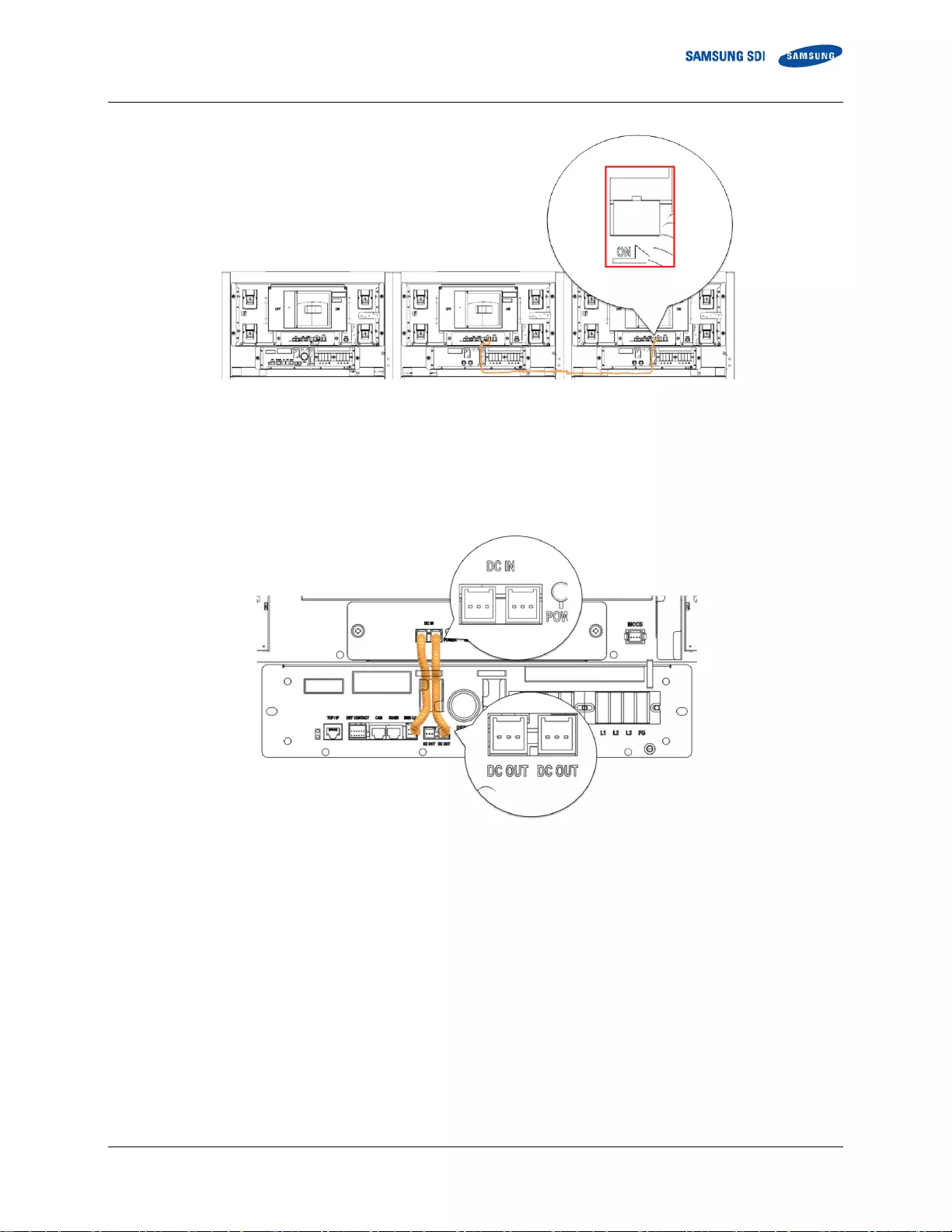

Figure 5-9: Termination resistor setting ................................................................................................................... 49

Figure 5-10: DC Power Cables from SMPS Assembly Type A to SMU ......................................................................... 49

Figure 5-11: DC Power Cables from SMPS Assembly Type B to SMU ......................................................................... 50

Figure 5-12: CAN Signal Cable Connection from SMPS Assembly to SMU .................................................................. 50

Figure 5-13: Dry Contact Cable Connection to SMPS Assembly ................................................................................. 50

Figure 5-14: AC Input Terminals .............................................................................................................................. 51

Figure 5-15: AC Input Terminals with Cables Attached ............................................................................................. 51

Figure 5-16: AC Input Terminals Protective Covers ................................................................................................... 52

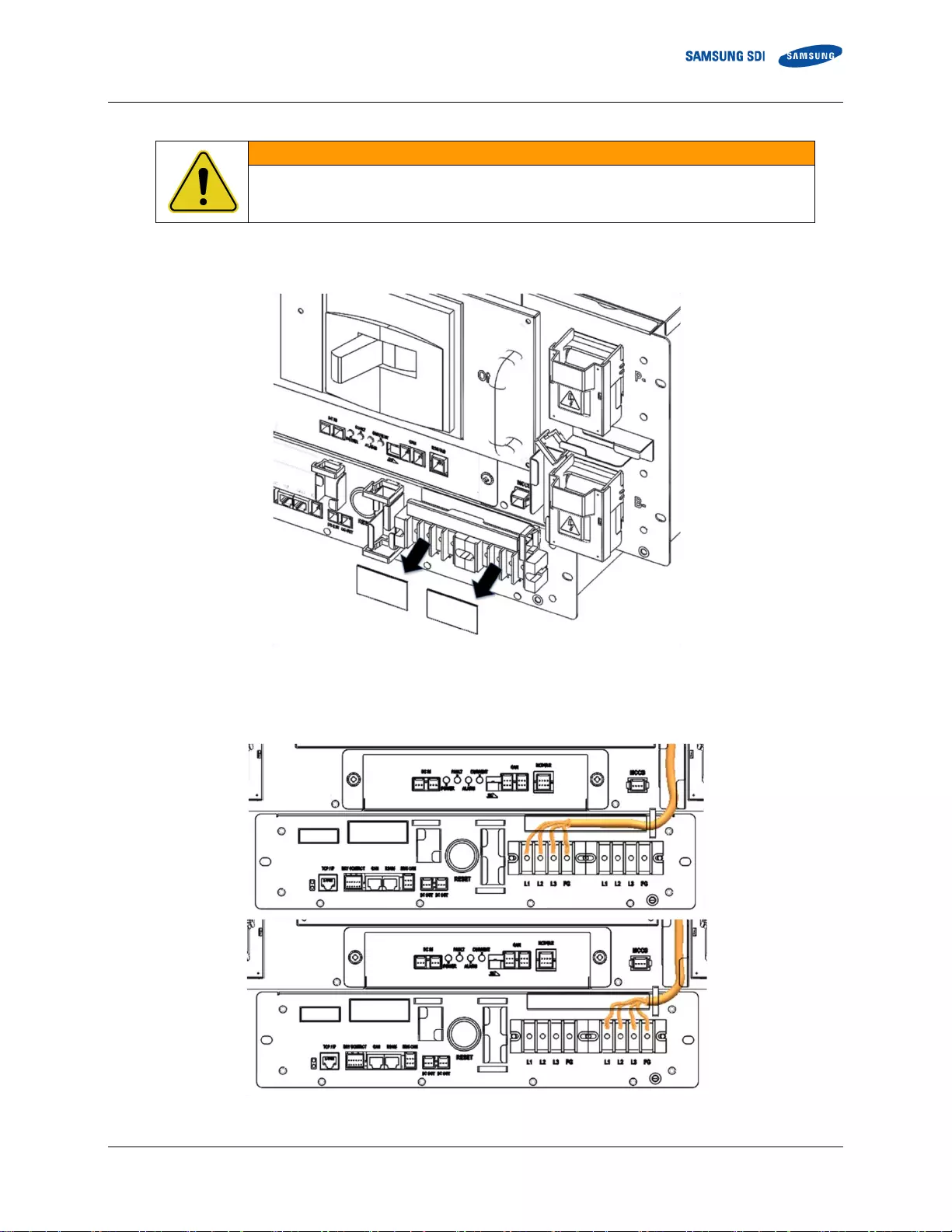

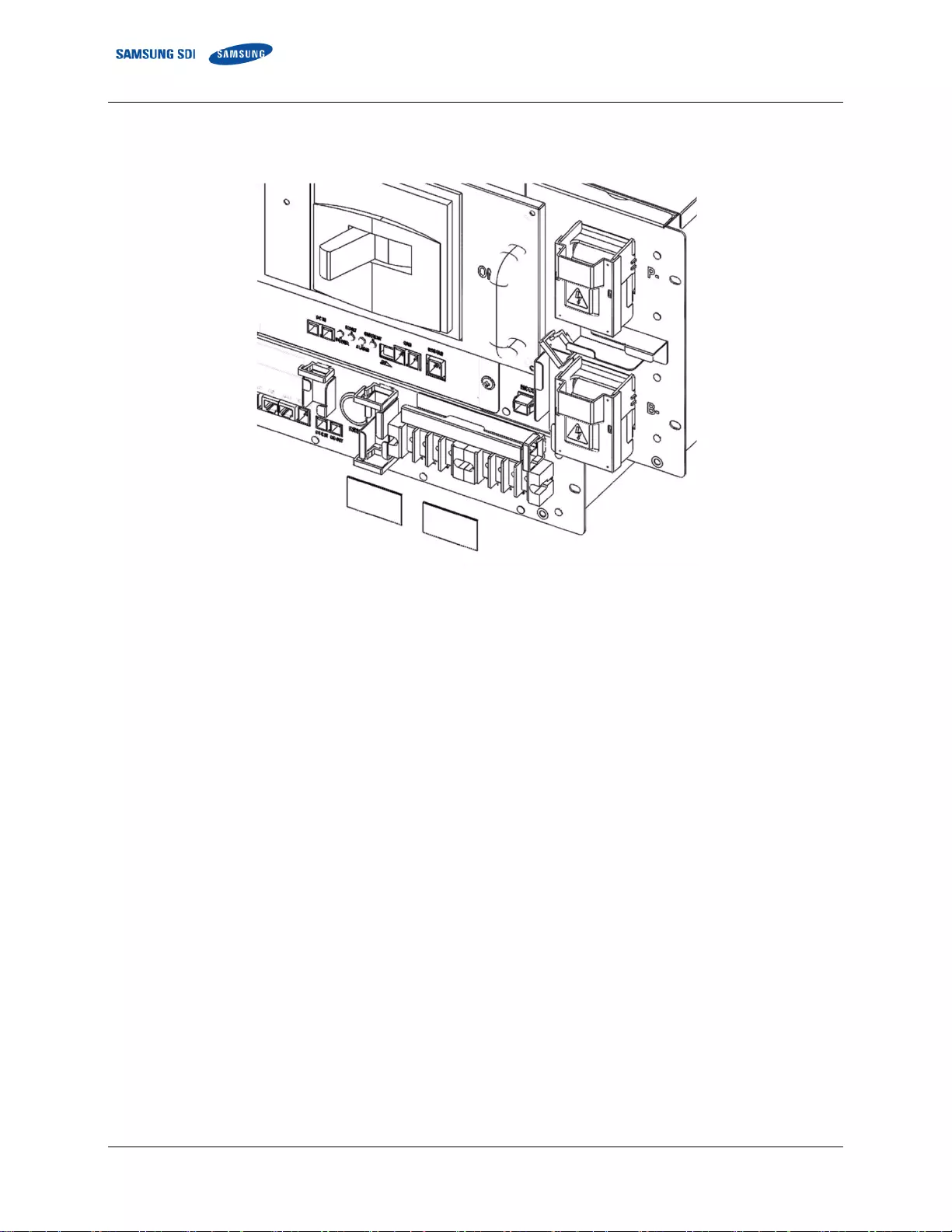

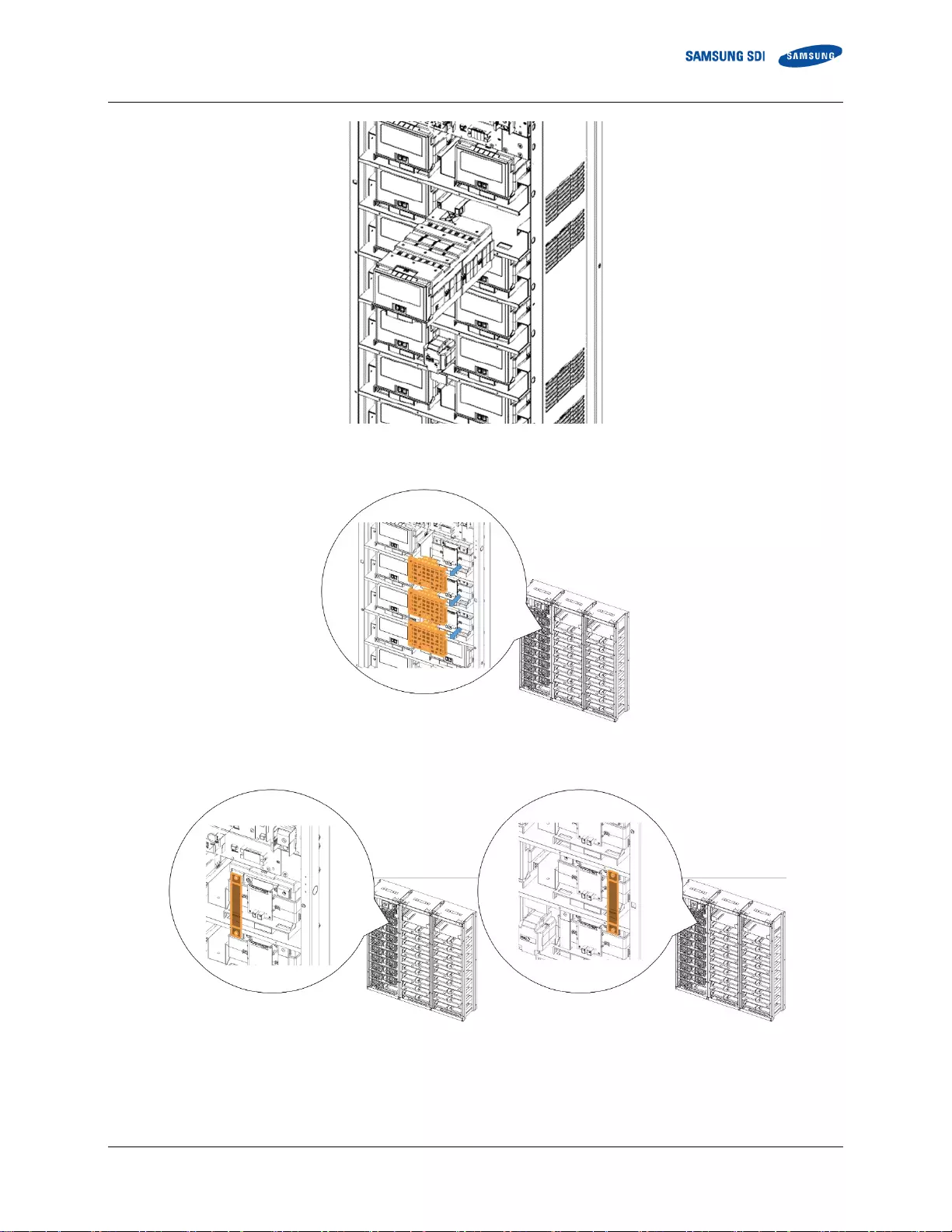

Figure 5-17: Remove the front covers ...................................................................................................................... 53

Figure 5-18: Reattach the Front Covers.................................................................................................................... 54

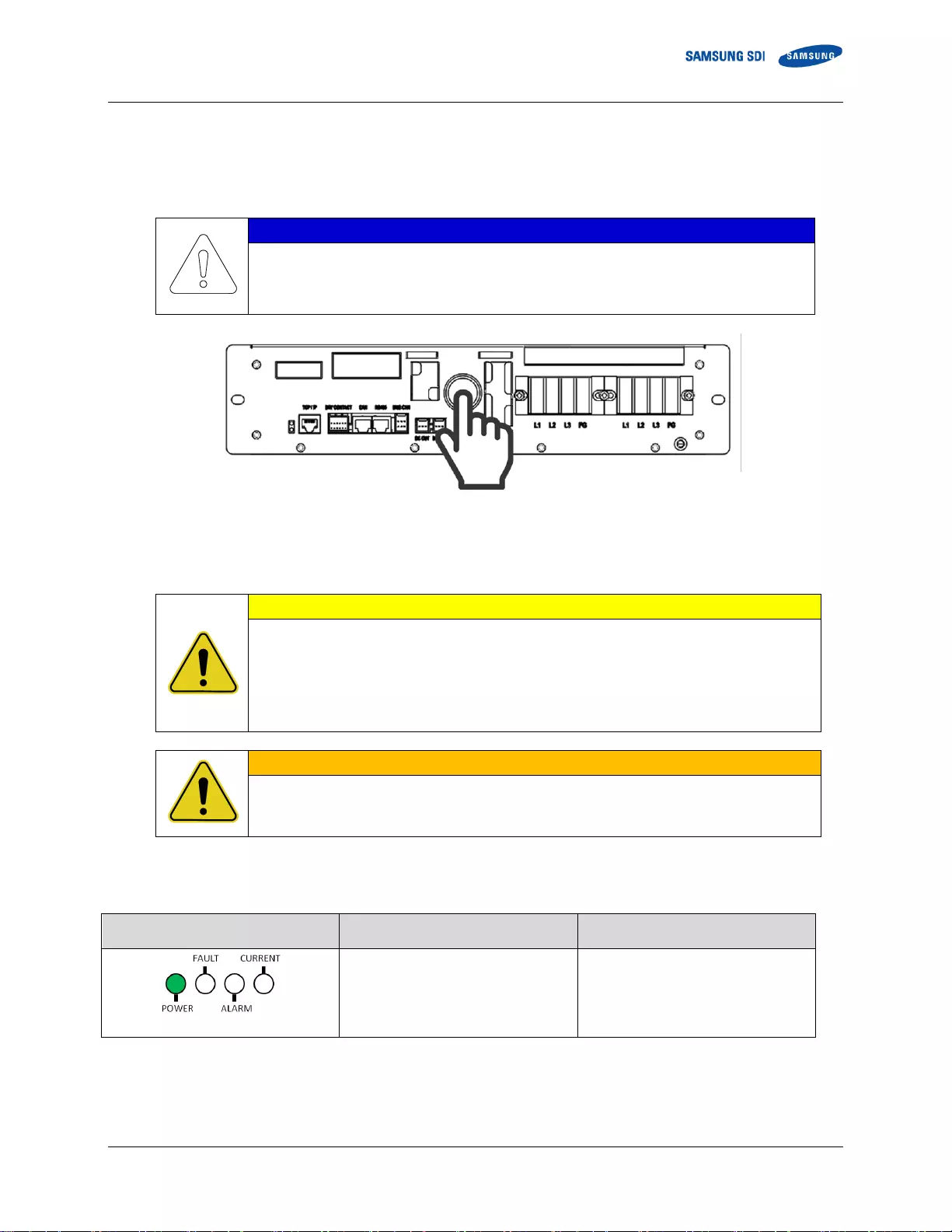

Figure 5-19: Pressing the Reset Button .................................................................................................................... 55

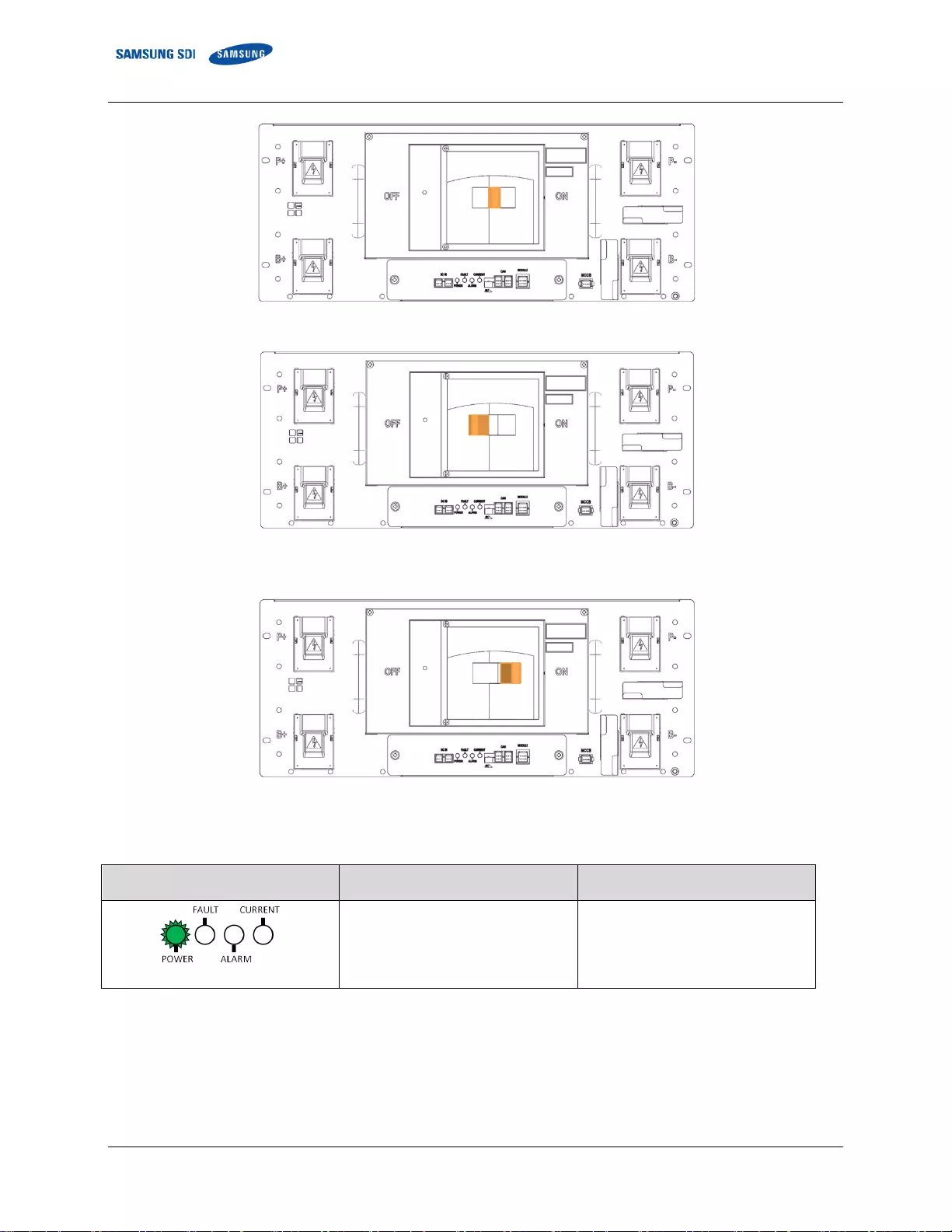

Figure 5-20: MCCB Handle in Trip Position ............................................................................................................... 56

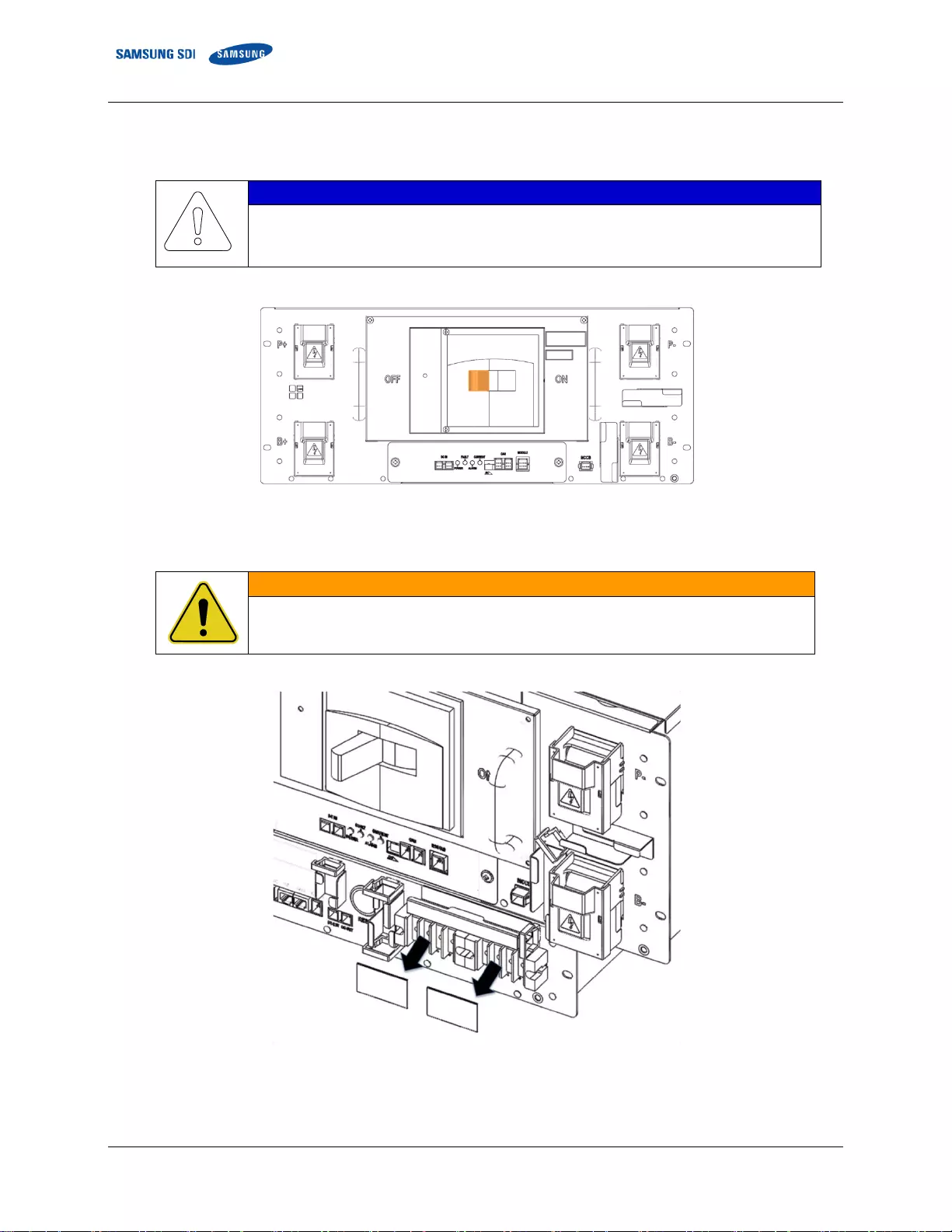

Figure 5-21: MCCB Handle in Off Position ................................................................................................................ 56

Figure 5-22: MCCB Handle in On Position ................................................................................................................ 56

Figure 5-23: Remove SMU to Module #1 Right Connector ........................................................................................ 58

Figure 5-24: Install Signal Cable Between the SMU and Battery Module #1 Right Connector ..................................... 59

Figure 5-25: Remove Module to Module Signal Cable .............................................................................................. 59

Figure 5-26: Install Module to Module Signal Cable.................................................................................................. 60

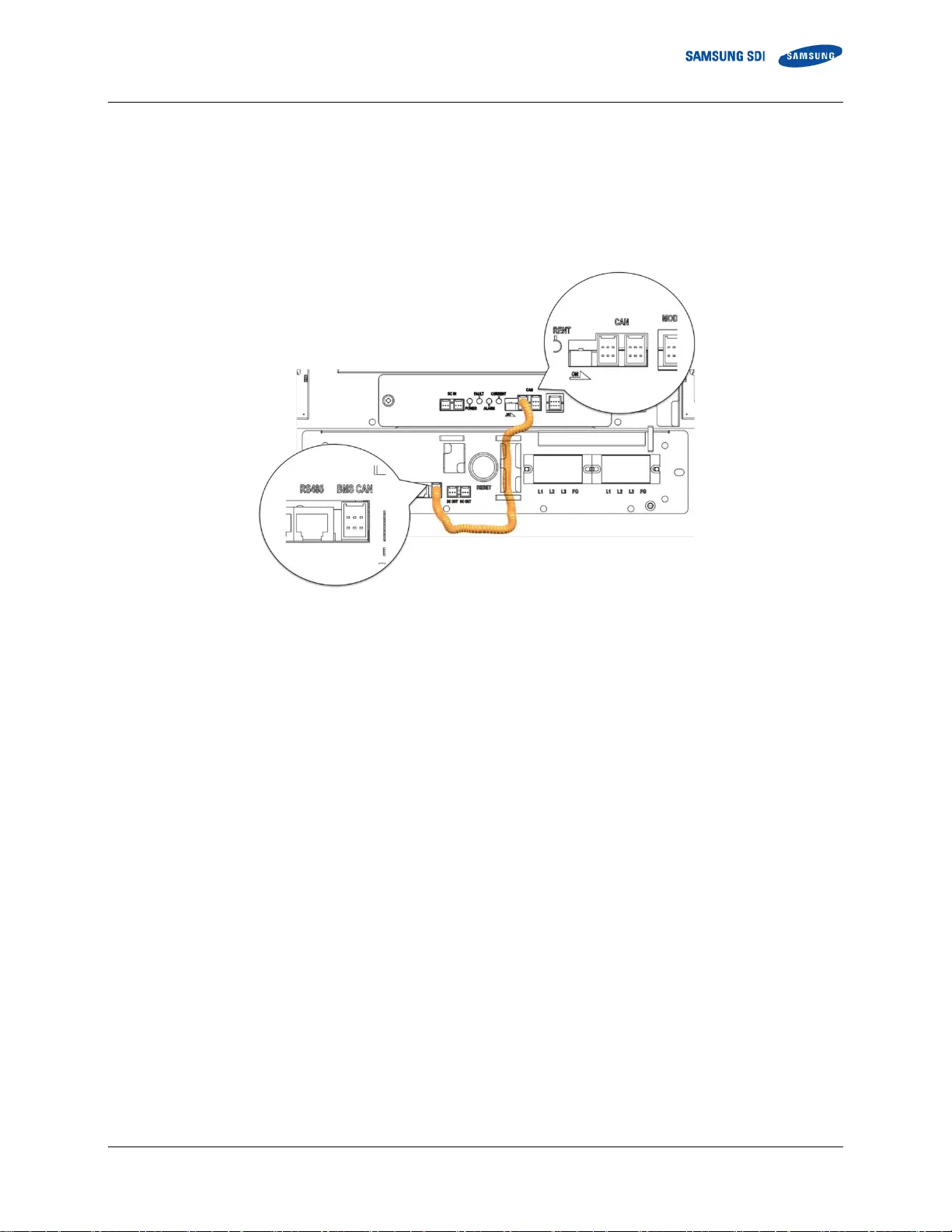

Figure 5-27: CAN Wire Harness Between SMU Assemblies ....................................................................................... 60

Figure 5-28: CAN Cable Connection from SMPS Assembly to SMU ............................................................................ 61

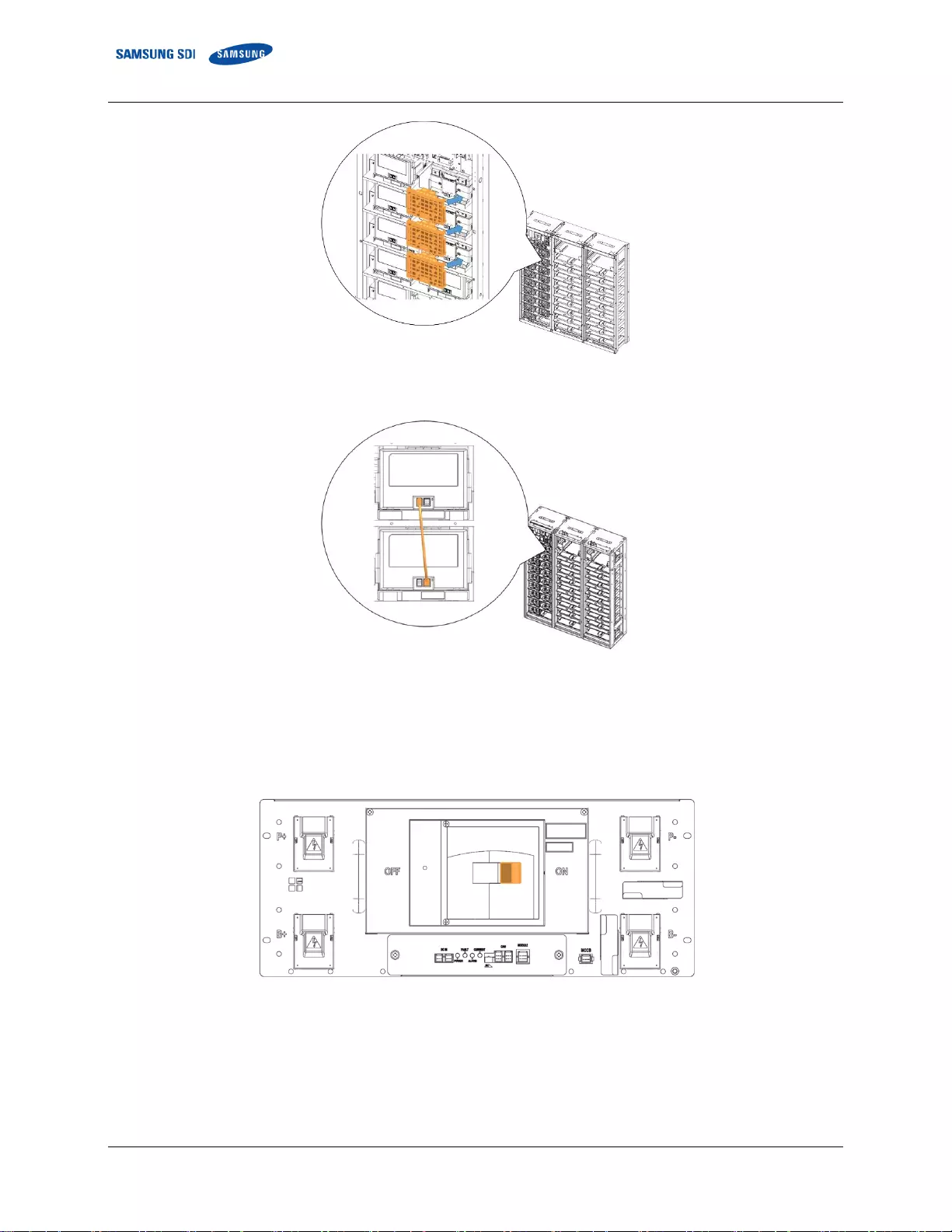

Figure 5-29: MCCB Handle in “OFF” position ............................................................................................................ 62

Figure 5-30: DC Power Cables from SMPS Assembly Type A to SMU ......................................................................... 62

Figure 5-31: DC Power Cables from SMPS Assembly Type B to SMU ......................................................................... 62

Figure 5-32: MCCB Handle in “ON” Position ............................................................................................................. 63

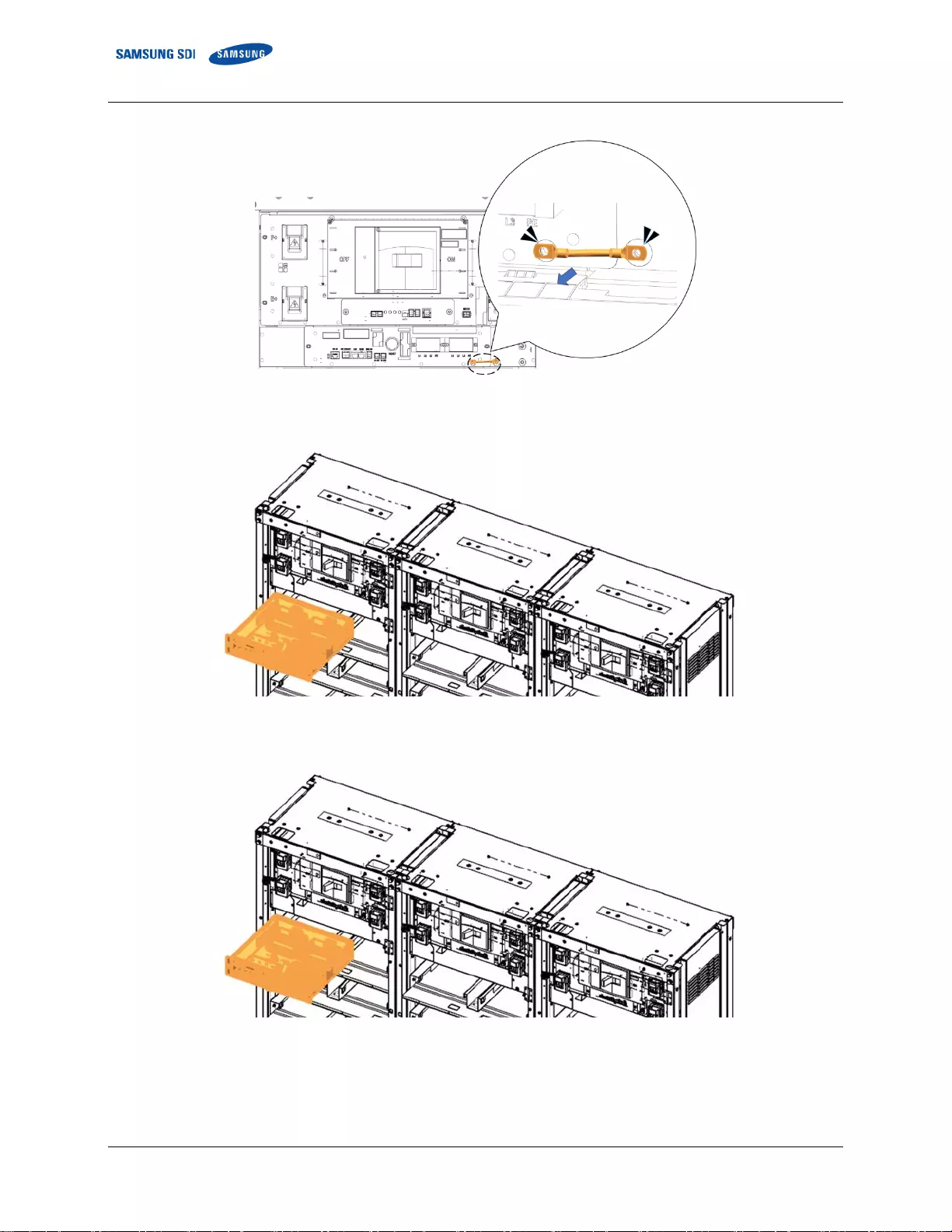

Figure 5-33: Removing the Battery Module Front Cover ........................................................................................... 65

Figure 5-34: Battery Module Type A ........................................................................................................................ 65

Figure 5-35: Battery Module Type B ........................................................................................................................ 66

Figure 5-36: MCCB Handle in “OFF” Position ............................................................................................................ 66

Figure 5-37: Remove Battery Module Front Covers .................................................................................................. 66

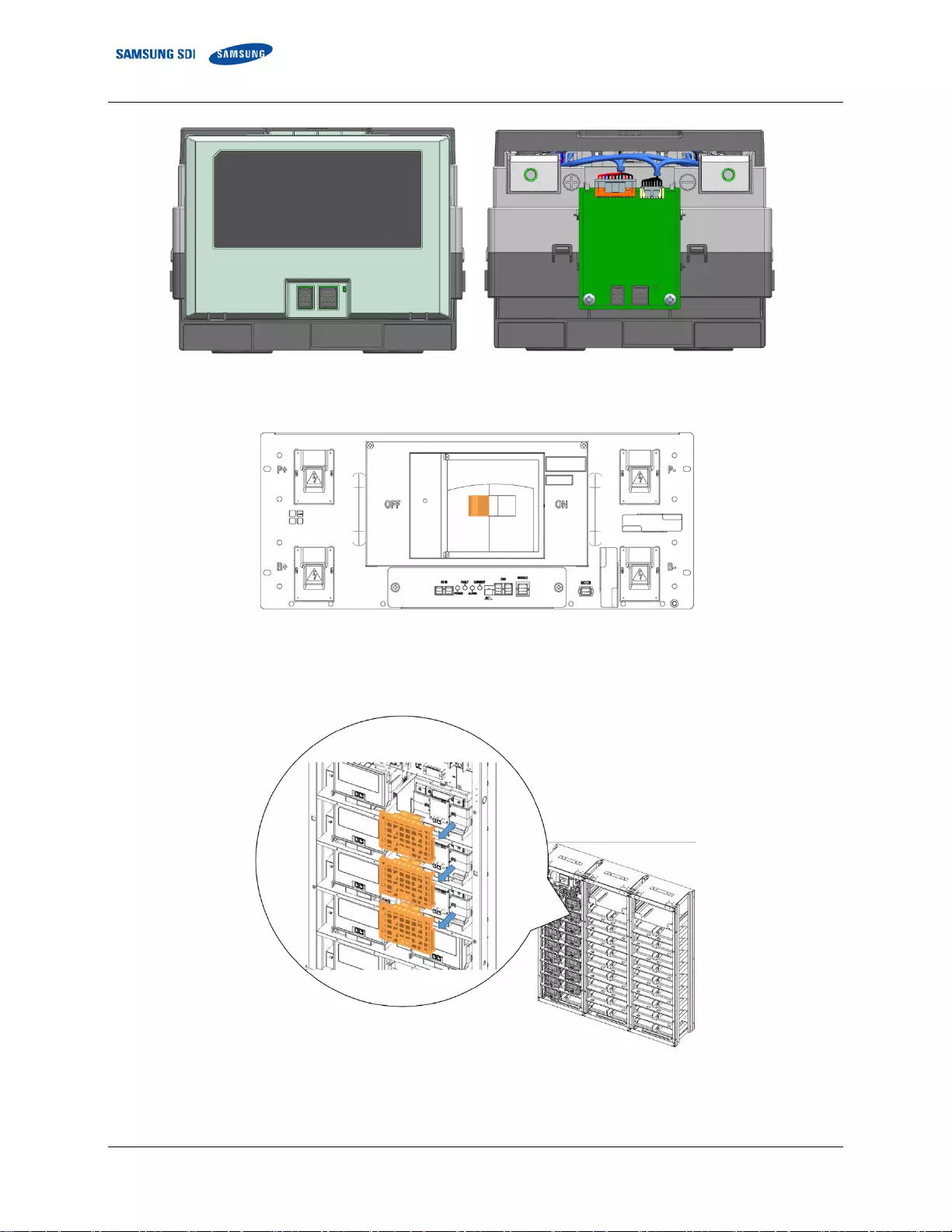

Figure 5-38: Measuring Each Battery Module’s Voltage ........................................................................................... 67

Figure 5-39: Assemble Battery Module Front Covers ................................................................................................ 67

Figure 5-40: DC Power Supply and Battery Module Connection ................................................................................ 68

Figure 5-41: Battery Module Signal Cables ............................................................................................................... 69

Figures CONFIDENTIAL

English 8/2019. Rev 0.0 v

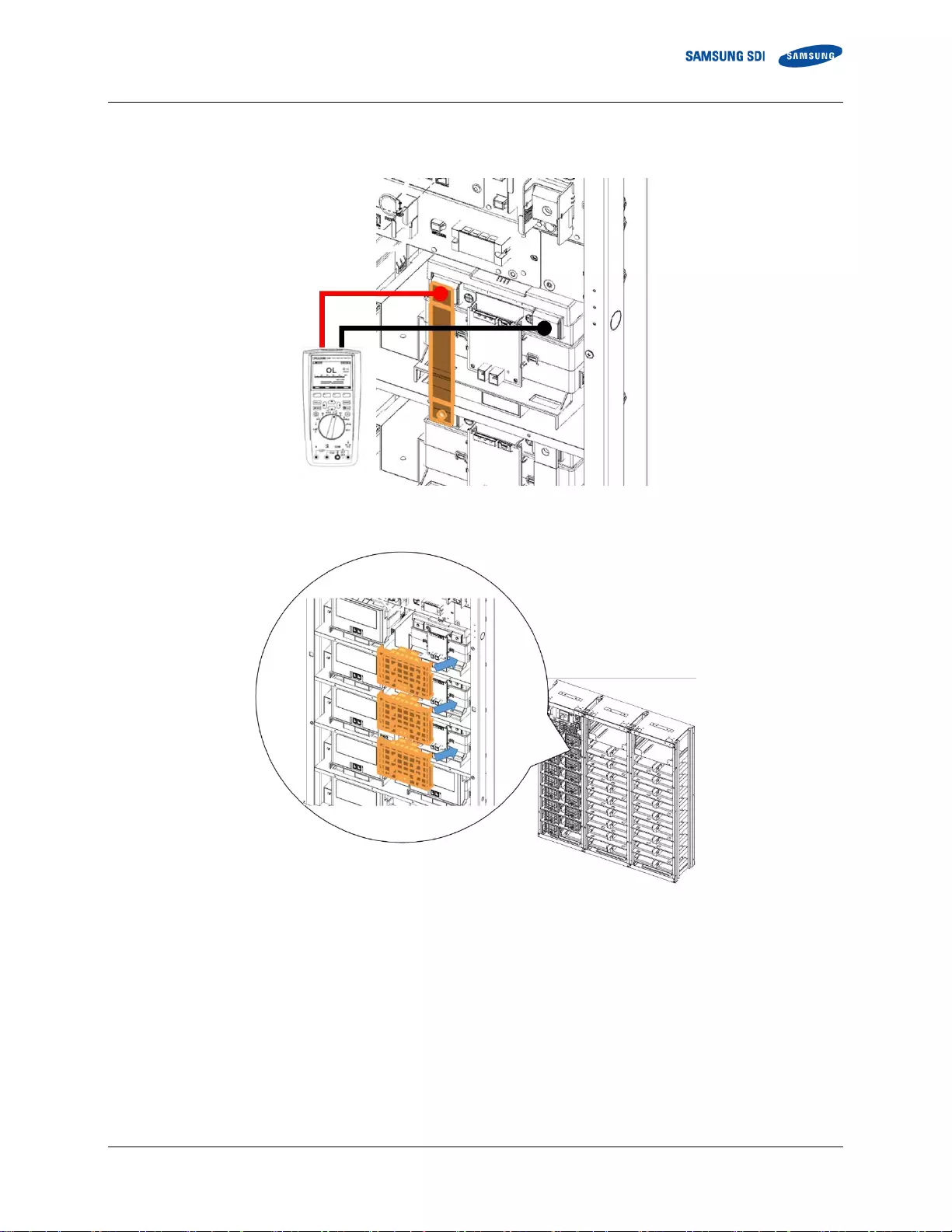

Figure 5-42: Remove Battery Module Front Covers .................................................................................................. 69

Figure 5-43: Busbars on Positive and Negative Terminals ......................................................................................... 69

Figure 5-44: Hook and slots on the rack frame ......................................................................................................... 70

Figure 5-45: Inserting the Replacement Battery Module .......................................................................................... 71

Figure 5-46: Removing the Front Covers .................................................................................................................. 71

Figure 5-47: Busbars ............................................................................................................................................... 71

Figure 5-48: Reattaching the Front Cover to the Battery Module .............................................................................. 72

Figure 5-49: Connecting the Signal Cables................................................................................................................ 72

Figure 5-50: MCCB Handle in “ON” Position ............................................................................................................. 72

Figure 5-51: MCCB Handle in “OFF” Position ............................................................................................................ 73

Figure 5-52: Remove the Battery Module Front Covers ............................................................................................ 74

Figure 5-53: MCCB Handle in “ON” Position ............................................................................................................. 74

Figure 5-54: MCCB Handle in “OFF” Position ............................................................................................................ 76

Figure 5-55: DC IN Cable ......................................................................................................................................... 76

Figure 5-56: CAN Cable to SMPS Assembly............................................................................................................... 76

Figure 5-57: CAN Cable to Adjacent Rack ................................................................................................................. 77

Figure 5-58: Module Signal Cable ............................................................................................................................ 77

Figure 5-59: SMU Terminal Covers .......................................................................................................................... 77

Figure 5-60: P+, P- Terminals ................................................................................................................................... 78

Figure 5-61: B+, B-, P+, P- Terminal Connections and Terminal Covers ...................................................................... 79

Figure 5-62: SMU to Module Signal Cable ................................................................................................................ 79

Figure 5-63: SMU to SMPS Assembly CAN Signal Cable............................................................................................. 80

Figure 5-64: DC Power Cables from SMPS Assembly Type A to SMU ......................................................................... 80

Figure 5-65: DC Power Cables from SMPS Assembly Type B to SMU ......................................................................... 80

Figure 5-66: MCCB Handle in “ON” Position ............................................................................................................. 81

Figure 5-67: MCCB Handle in “OFF” Position ............................................................................................................ 82

Figure 5-68: AC Input Terminals .............................................................................................................................. 82

Figure 5-69: Cables to the AC Input Terminals.......................................................................................................... 83

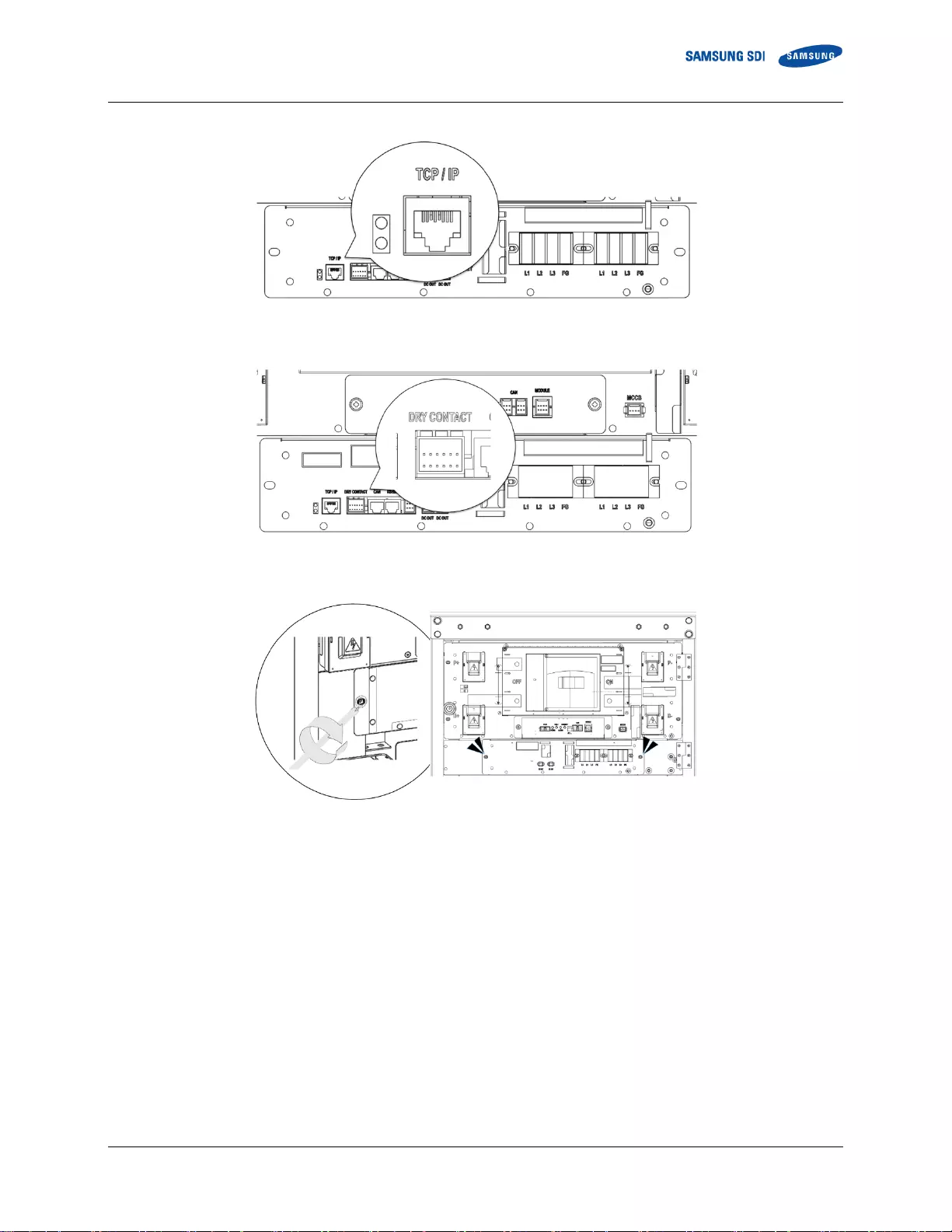

Figure 5-70: DC OUT Connection ............................................................................................................................. 83

Figure 5-71: BMS CAN Connection ........................................................................................................................... 83

Figure 5-72: TCP/IP Connection ............................................................................................................................... 85

Figure 5-73: Dry Contact Connection ....................................................................................................................... 85

Figure 5-74: Unscrew SMPS Assembly ..................................................................................................................... 85

Figure 5-75: Unscrew SMPS Assembly Grounding Cable ........................................................................................... 86

Figure 5-76: Remove the SMPS Assembly ................................................................................................................ 86

Figure 5-77: Insert the SMPS Assembly .................................................................................................................... 86

Figure 5-78: Screw on the SMPS Assembly ............................................................................................................... 87

Figure 5-79: Screw on the SMPS Assembly Grounding Cable .................................................................................... 87

Figure 5-80: DC Power Cables from SMPS Assembly Type A to SMU ......................................................................... 88

Figure 5-81: DC Power Cables from SMPS Assembly Type B to SMU ......................................................................... 88

Figure 5-82: BMS CAN Cable from SMPS Assembly to SMU ...................................................................................... 89

Figure 5-83: TCP/IP Cable ........................................................................................................................................ 89

Figure 5-84: Dry Contact Cable ................................................................................................................................ 89

Figure 5-85: AC Input Terminals .............................................................................................................................. 90

Figure 5-86: AC Input Terminals with Cables Attached ............................................................................................. 90

Figure 5-87: AC Input Terminals Protective Cover .................................................................................................... 91

Figure 5-88: MCCB Handle in “ON” Position ............................................................................................................. 91

CONFIDENTIAL 1. About this Manual

English 8/2019. Rev 0.0 1

1. About this Manual

This section briefly describes the purpose, audience, organization, revision history, and acronyms and

abbreviations used in this document.

1.1 Purpose

The purpose of this manual is to provide information for the safe and successful operation and maintenance

of the product.

1.2 Target Audience

This manual is intended for system administrators and operators who install, operate, maintenance and

configure the product.

1.3 Organization

This manual is composed of the following chapters:

Chapter 1, “About this Manual” introduces preliminary description about this document.

Chapter 2, “Product Description” describes the major components of the product.

Chapter 3, “Battery System Operation” explains the operation modes of the battery system.

Chapter 4, “Maintenance Check” lists items to inspect daily, monthly, and annually.

Chapter 5, “Troubleshooting” guides the reader through clearing protection modes and replacing

components.

1. About this Manual CONFIDENTIAL

2 English 8/2019. Rev 0.0

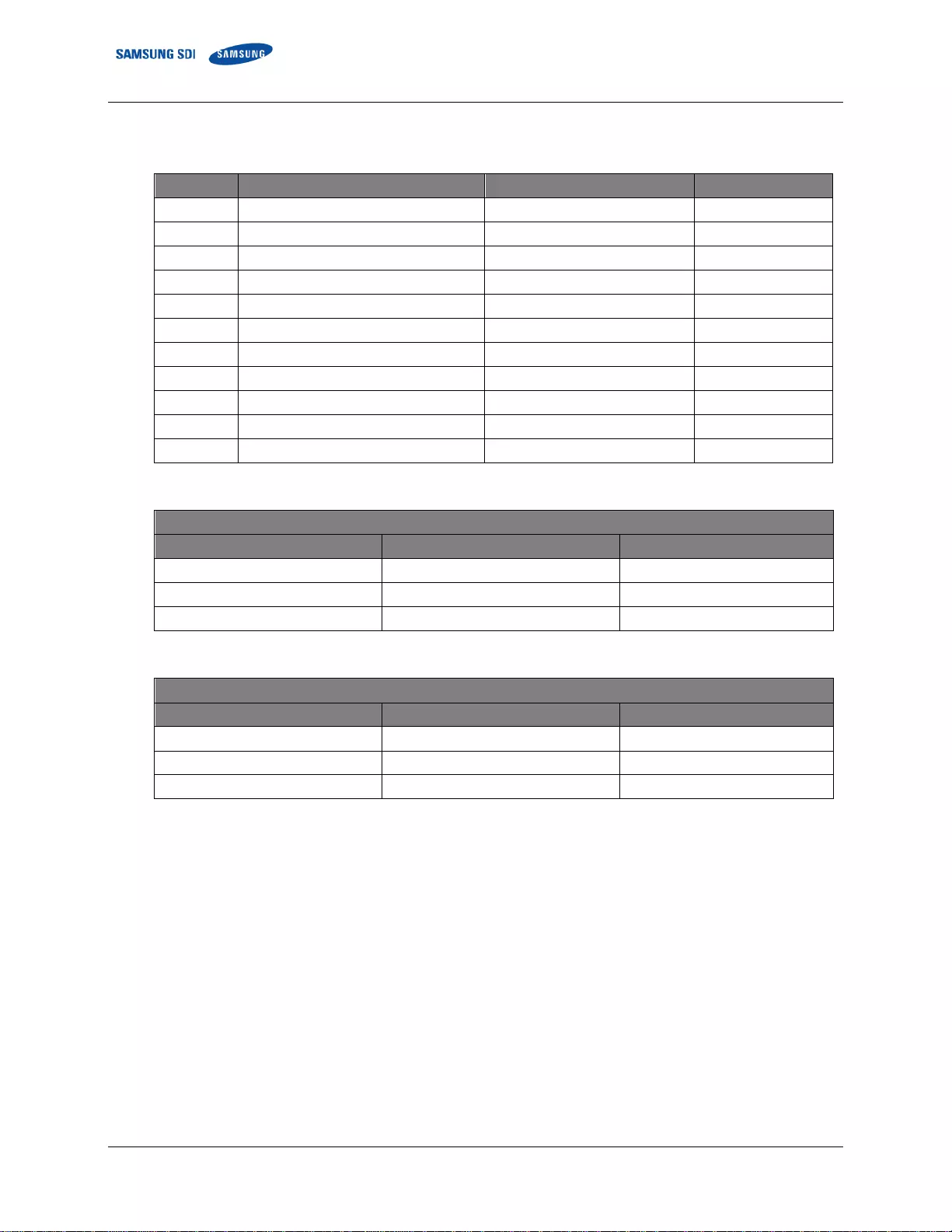

1.4 Revision History

Rev.

Description

Author

Date

0.0

First Draft (tentative release)

2019.08.20

Approved By:

Name

Signature

Date

Trusted Reviewers

Name

Signature

Date

CONFIDENTIAL 1. About this Manual

English 8/2019. Rev 0.0 3

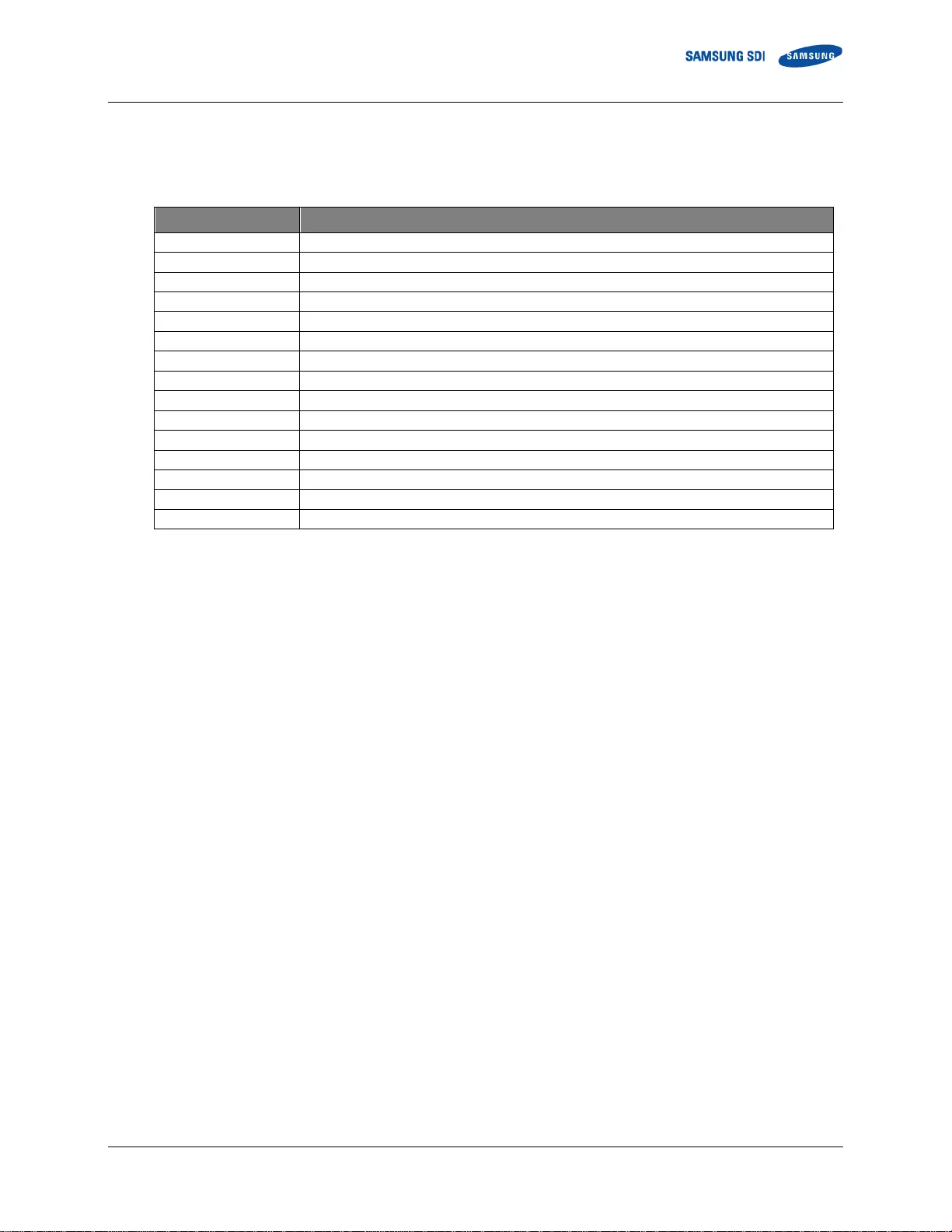

1.5 Acronyms and Abbreviations

The following acronyms and abbreviations are used in this manual.

Abbreviations

Full Name

AED

Automated External Defibrillator

BMS

Battery Management System

Comm.

Communication

EHS

Environmental Health and Safety

ESS

Energy Storage System

LOTO

LOCK OUT/TAG OUT

OT

Overtemperature

OVP

Overvoltage Protection

SMPS

Switched Mode Power Supply

SMU

String Management Unit

SOC

State Of Charge

SOH

State Of Health

UT

Undertemperature

UVP

Undervoltage Protection

UPS

Uninterruptible Power Supply

2. Product Description CONFIDENTIAL

4 English 8/2019. Rev 0.0

2. Product Description

Before operating the battery system, users must be familiar with its components.

2.1 Major Components

Samsung SDI’s Lithium Ion Battery System has the following components:

Battery Module (Type A / Type B)

SMU

Rack BMS (Embedded in SMU)

Rack Frame

SMPS Assembly (Type A / Type B)

System BMS (Embedded in SMPS Assembly Type A)

Refer to the “Product Specification” document for detailed specifications of the components.

CONFIDENTIAL 2. Product Description

English 8/2019. Rev 0.0 5

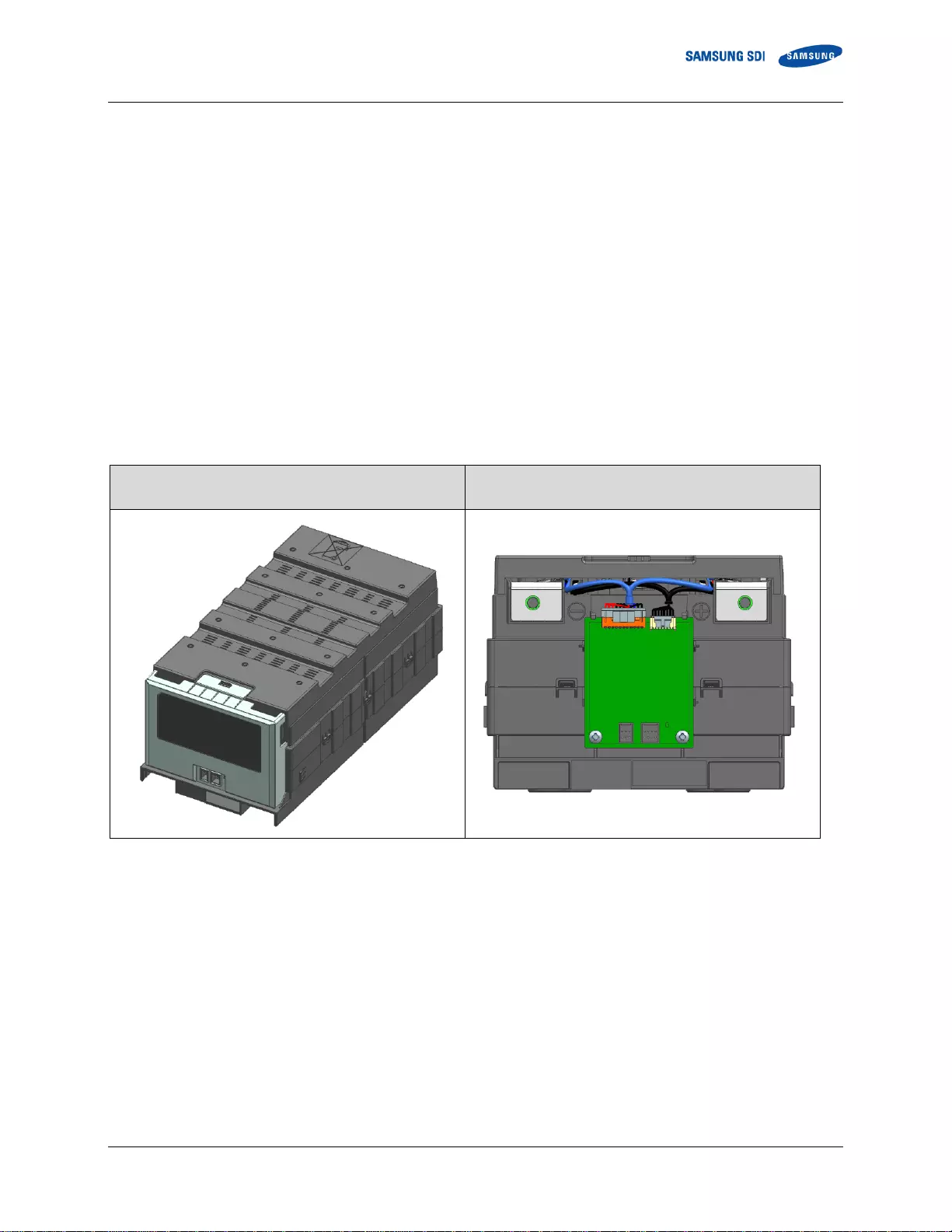

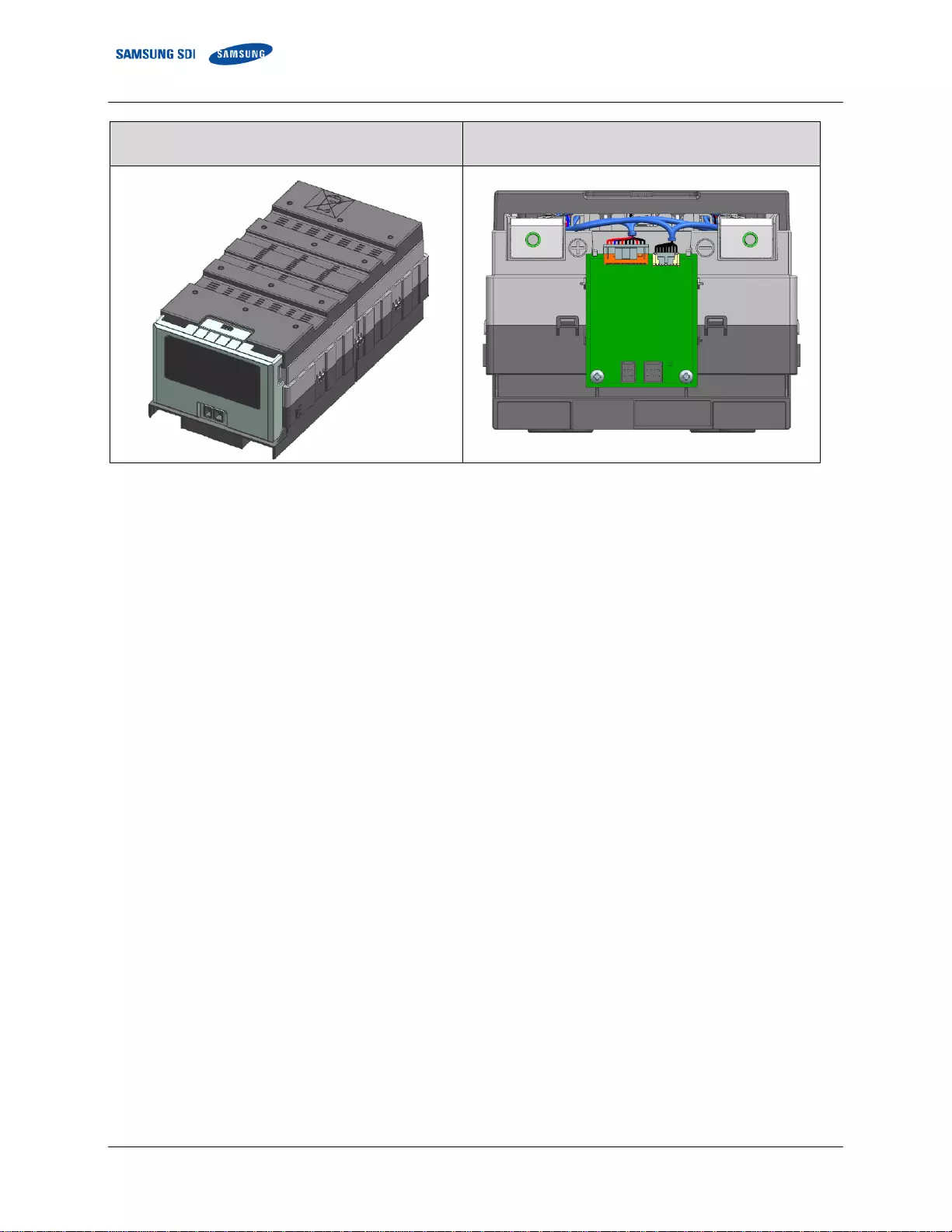

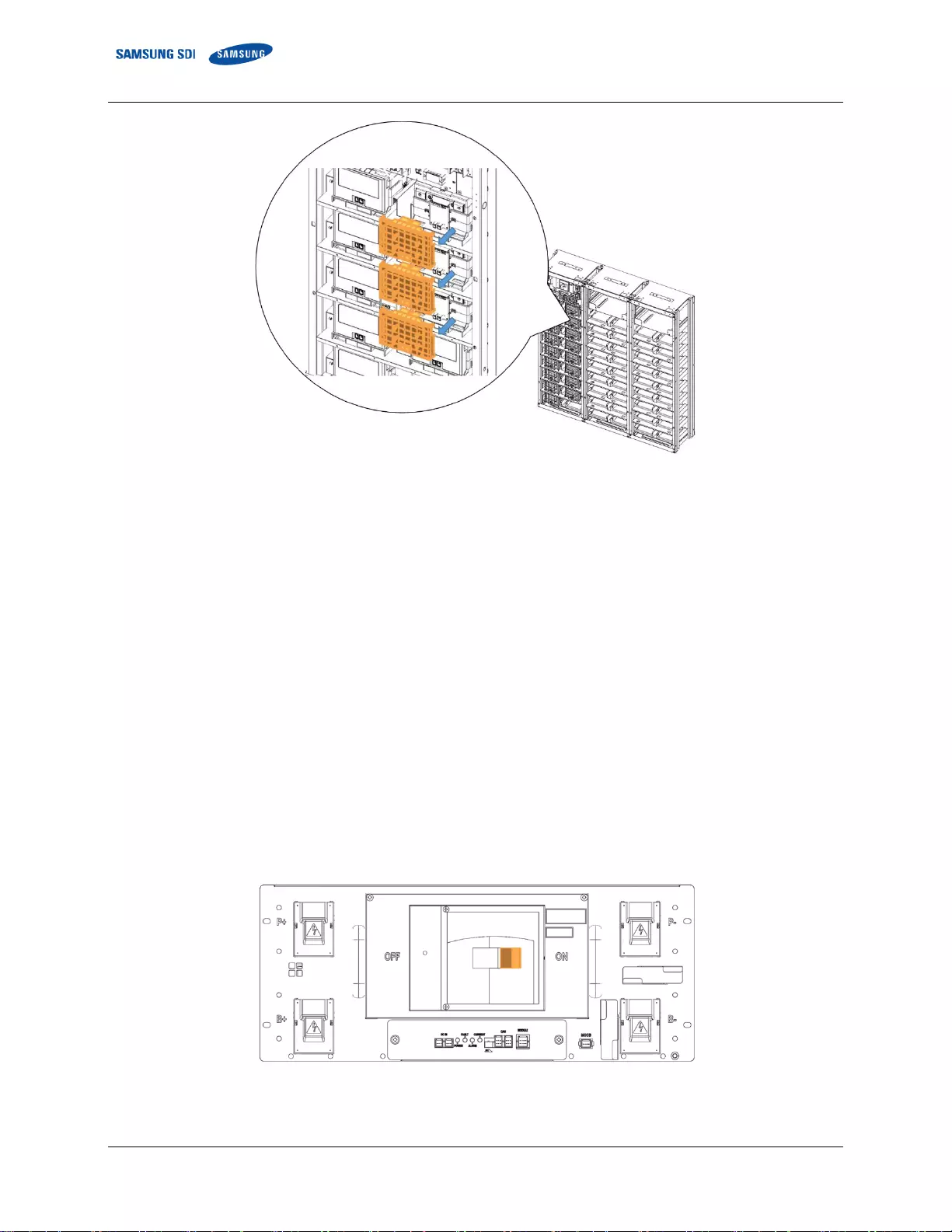

2.1.1 Battery Module (Type A / Type B)

Battery Module is the most basic component of the Battery System and it contains the energy storing battery cells.

There is a Module BMS inside each Battery Module. Module BMS checks the status of a Battery Module by

measuring its voltage and temperature. It also communicates with the SMU to send all measured voltage and

temperature data, and to receive commands to control cell balancing.

There are two types of 8S1P Battery Module depending on the position of terminal’s polarity.

Type A’s plus(+) terminal is on the right side. Type B is on the left.

Type A: EM2031AE00XA (X = 1, 3)

X = 1 for specific customer (customer SKU serial number barcode + SDI serial number barcode)

X = 3 for general customer (SDI serial number barcode only)

Type B: EM2031AE00YA (Y = 2, 4)

Y = 2 for specific customer (customer SKU serial number barcode + SDI serial number barcode)

Y = 4 for general customer (SDI serial number barcode only)

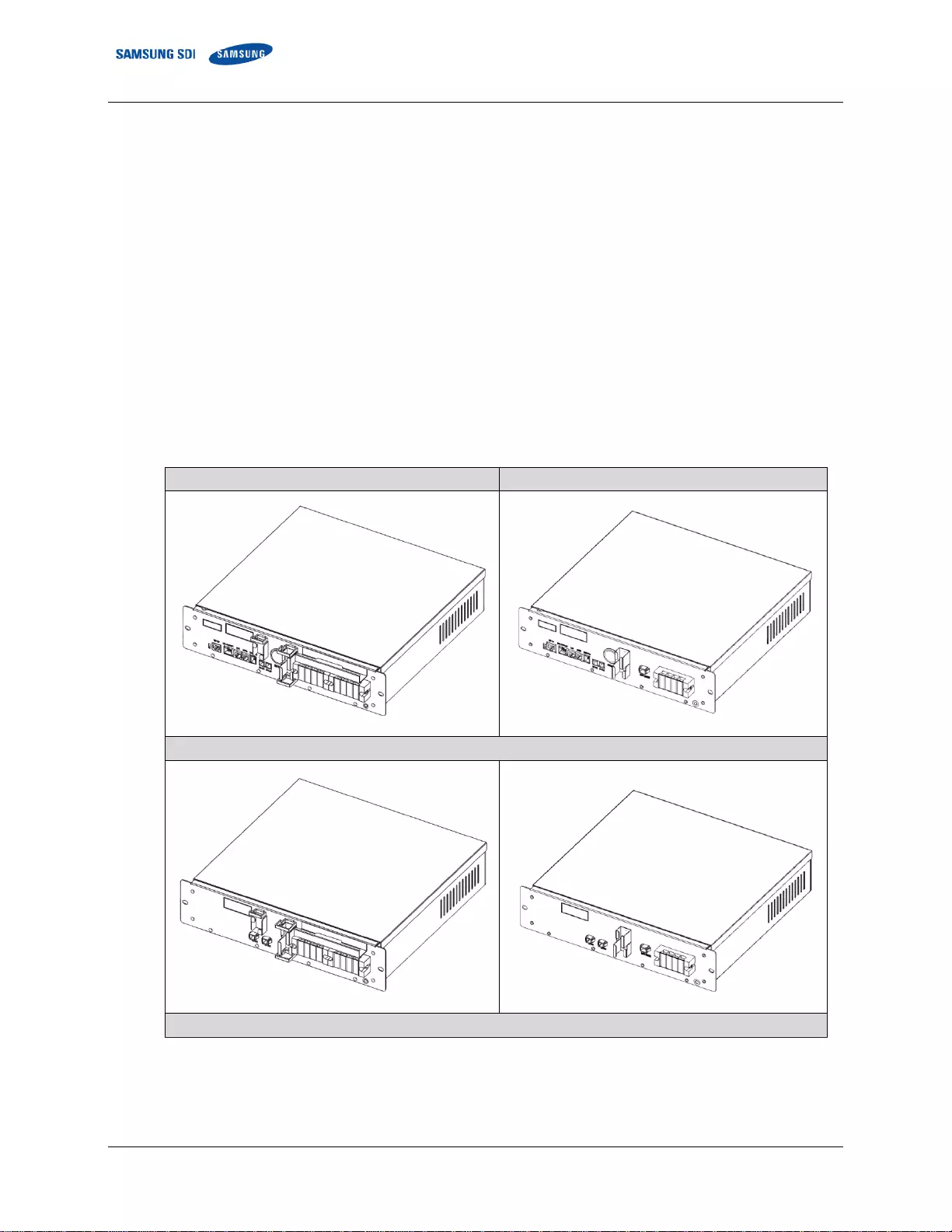

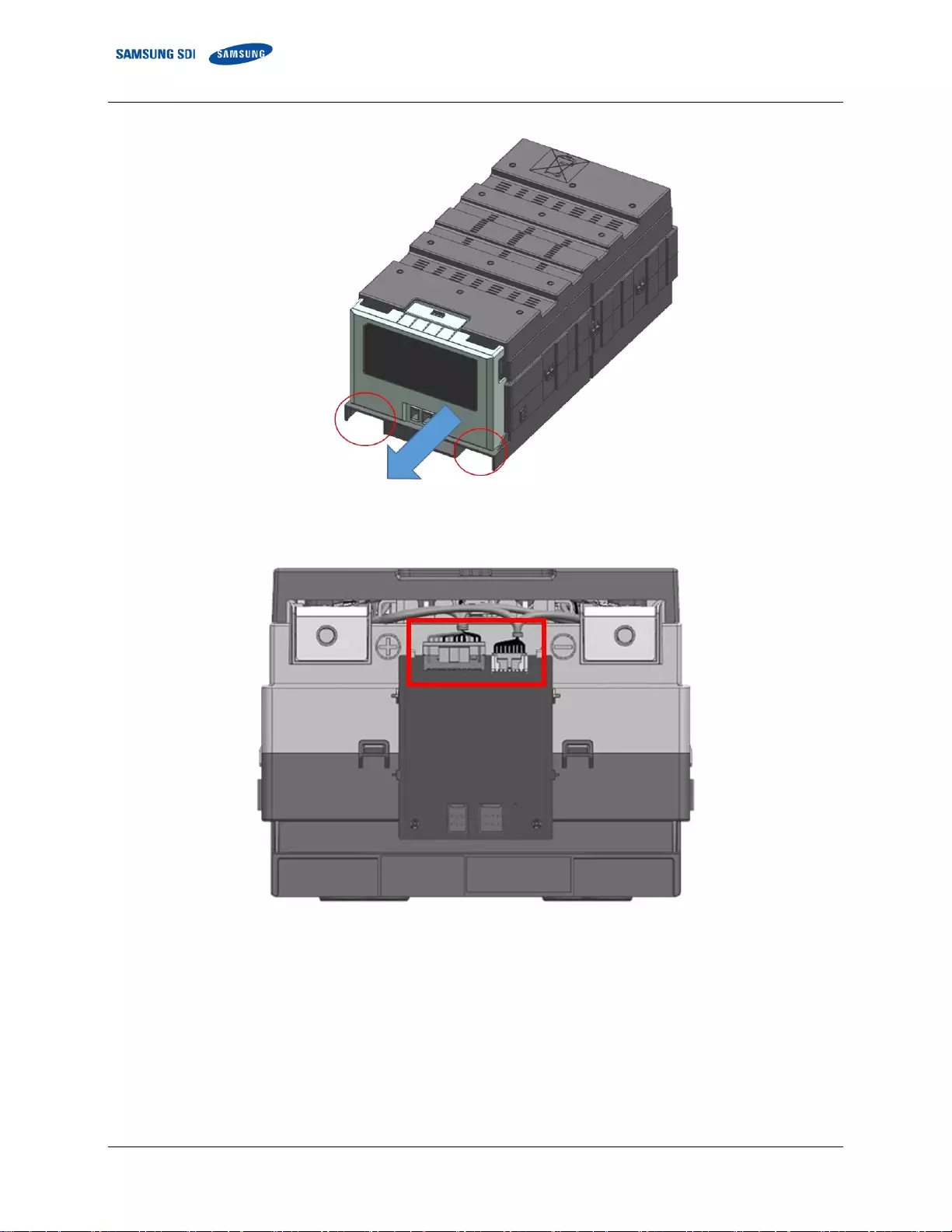

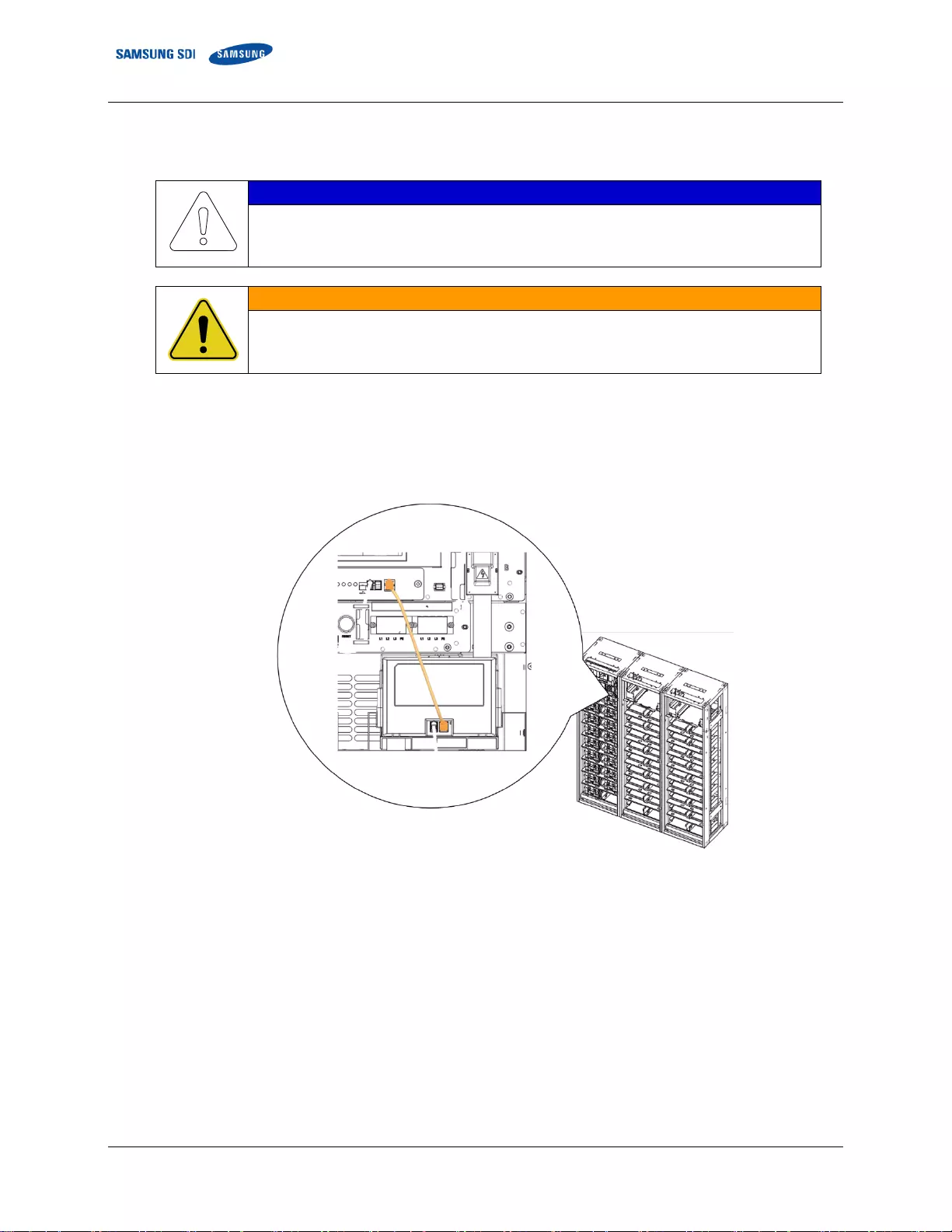

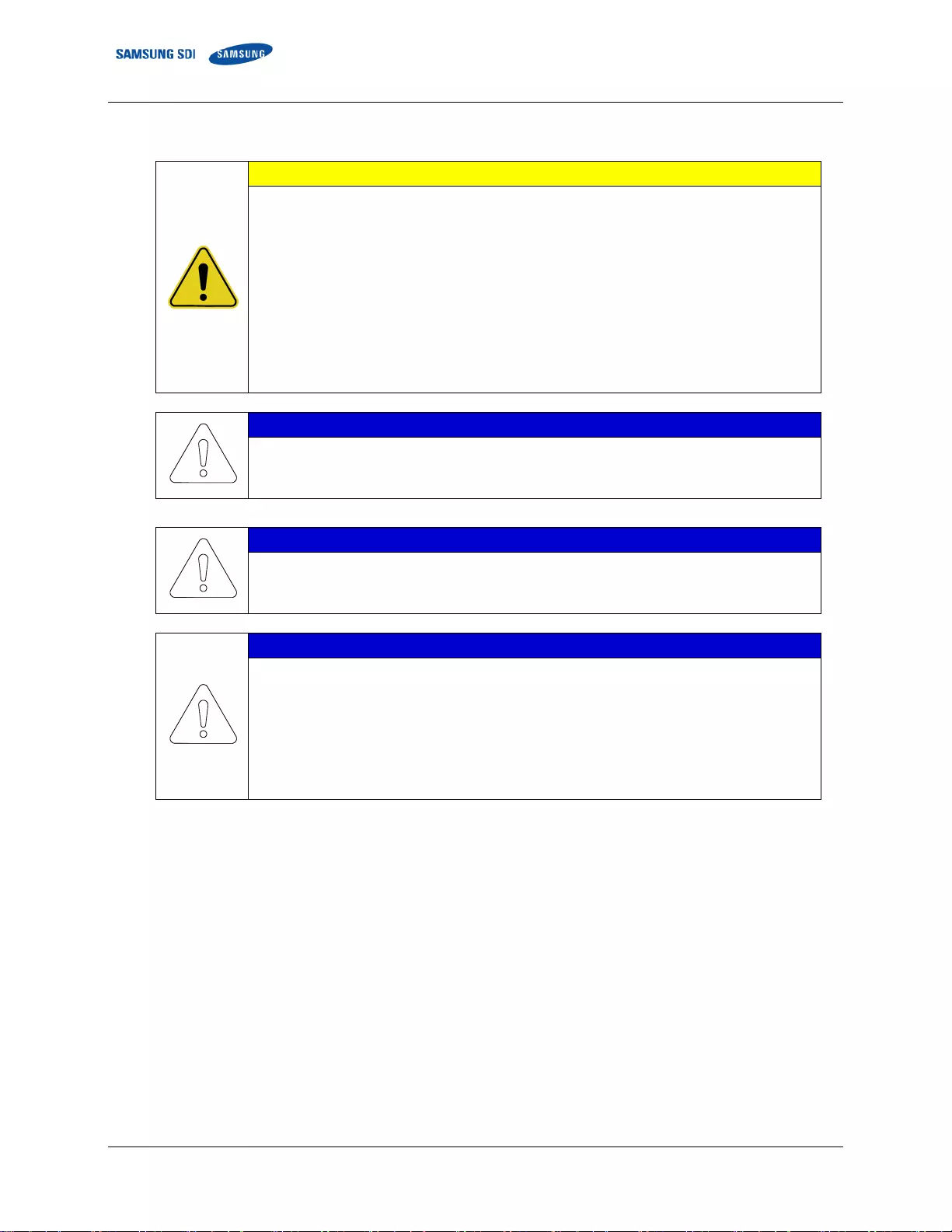

Battery Module Type A (Isometric)

Battery Module Type A

(Front. Front cover removed)

Figure 2-1: Battery Module Type A

2. Product Description CONFIDENTIAL

6 English 8/2019. Rev 0.0

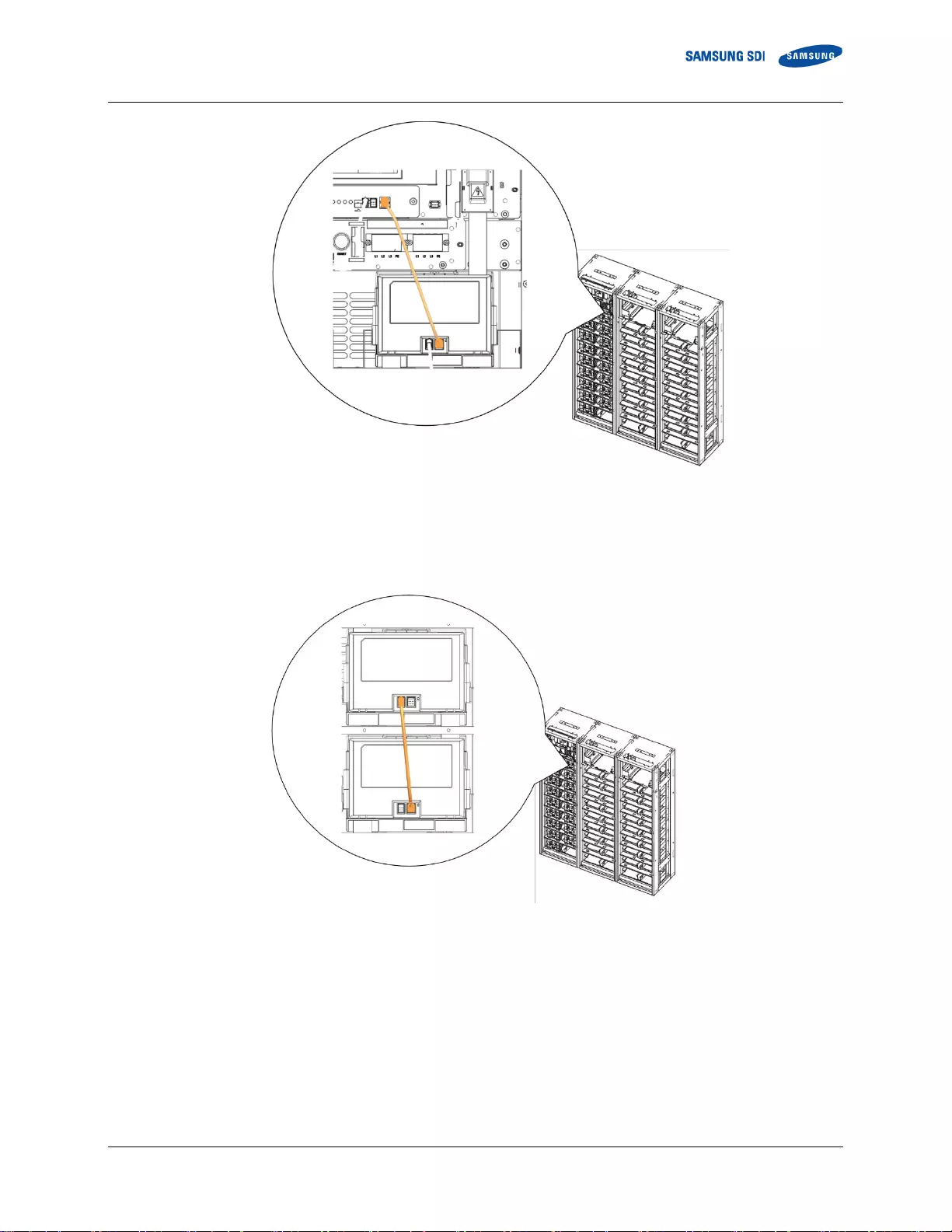

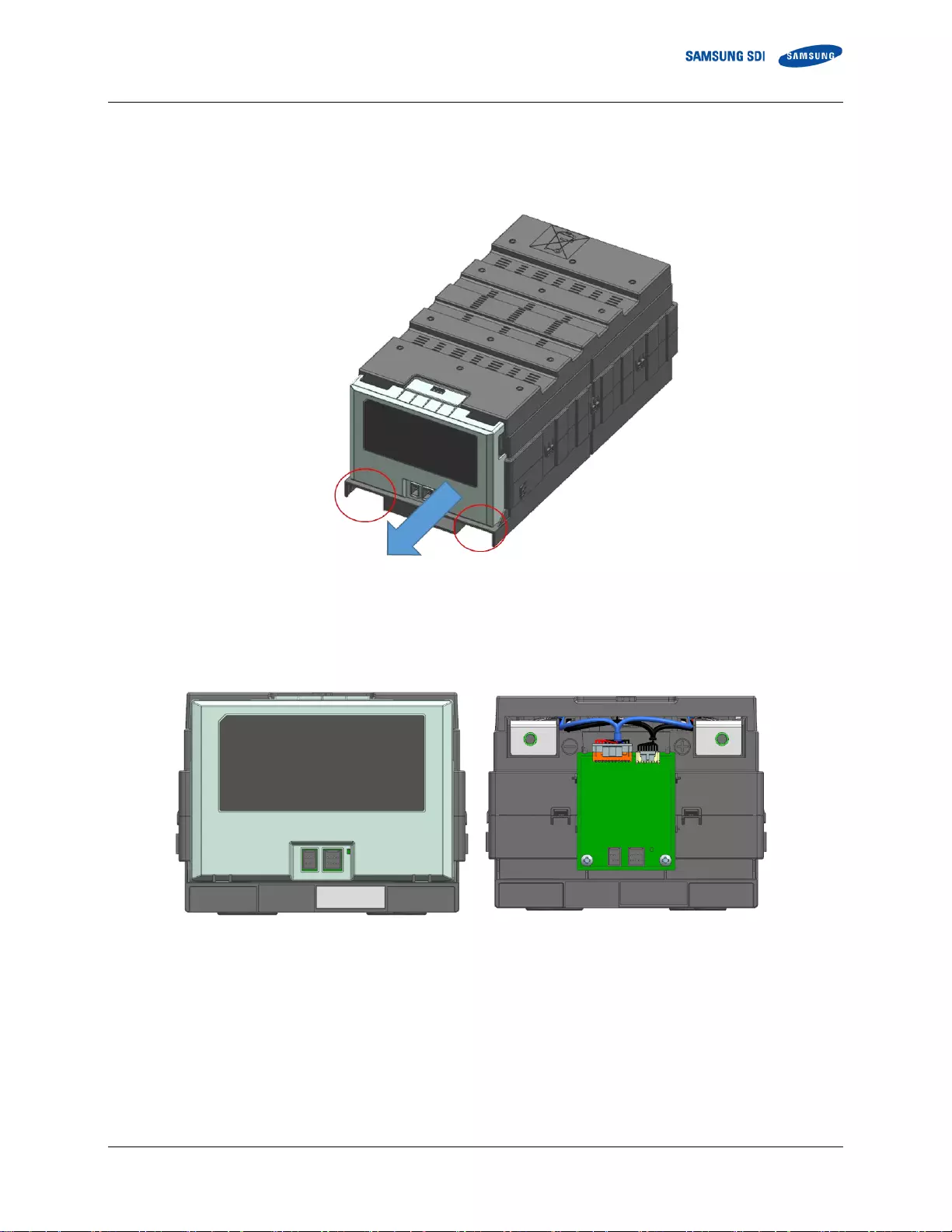

Battery Module Type B (Isometric)

Battery Module Type B

(Front. Front cover removed)

Figure 2-2: Battery Module Type B

CONFIDENTIAL 2. Product Description

English 8/2019. Rev 0.0 7

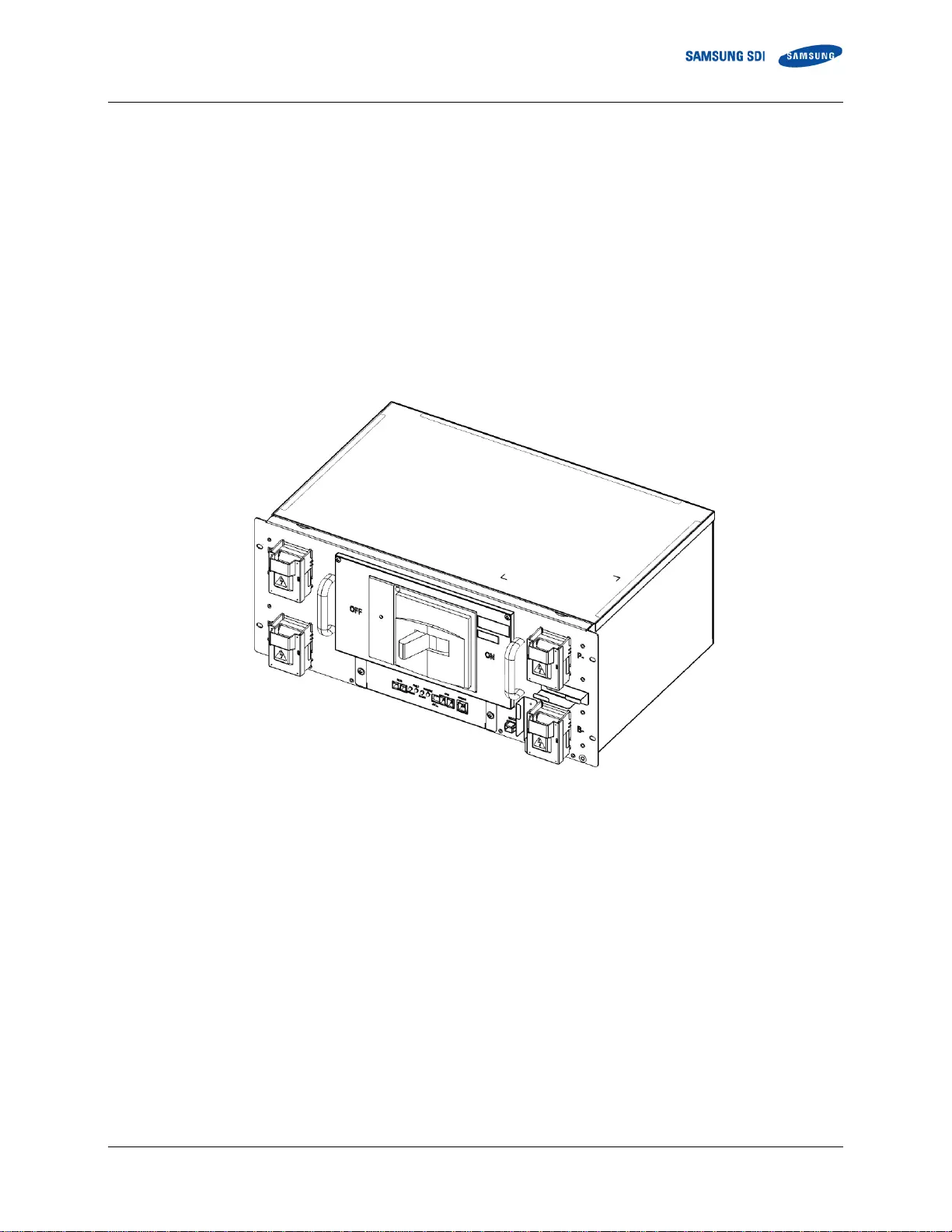

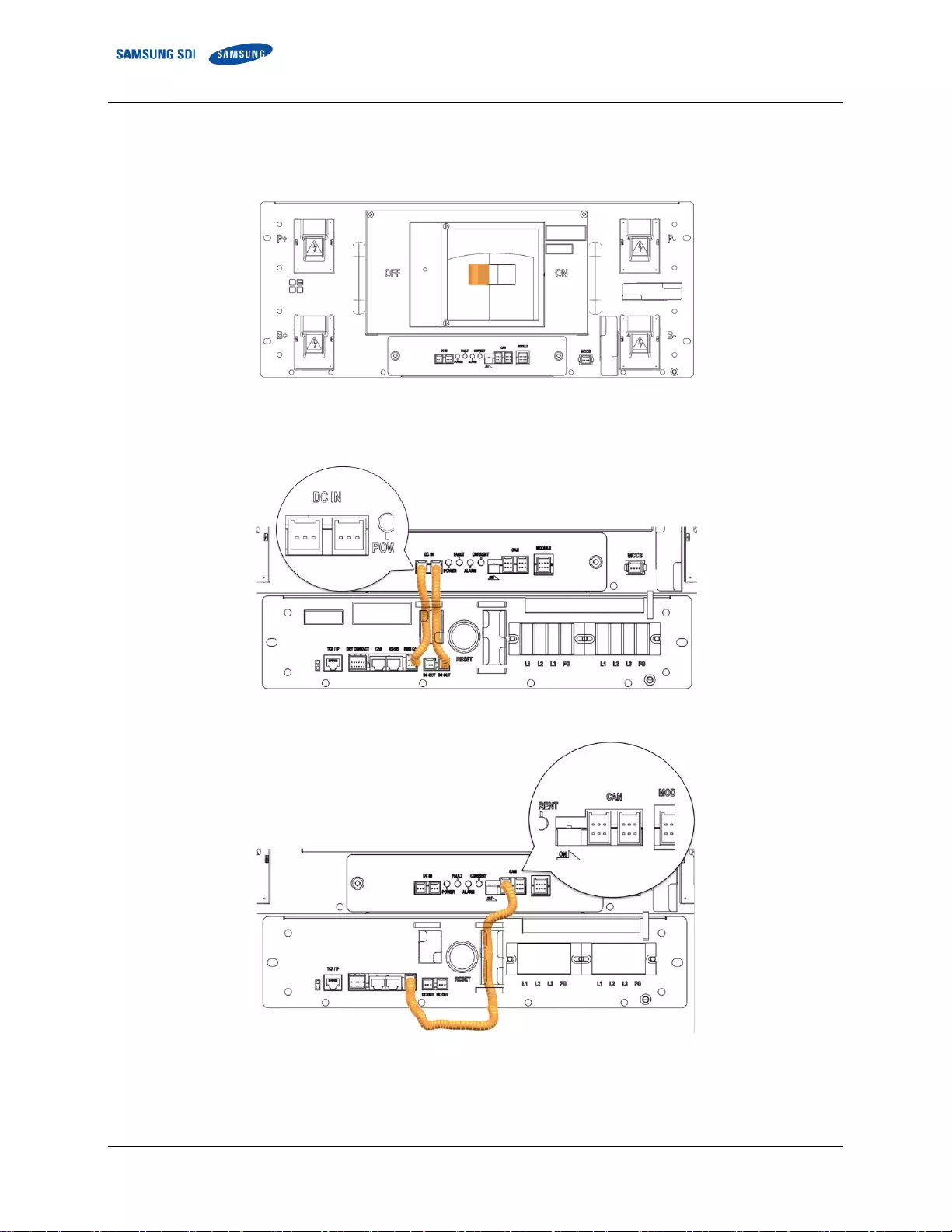

2.1.2 SMU (String Management Unit)

SMU collects all information about the battery system and controls the battery system by switching the main

power line and controls each Battery Module by cell balancing. SMU calculates the state-of-charge (SOC) and state-

of-health (SOH) of the battery system. Key components in the SMU are Rack BMS, MCCB, and shunt resistor. Rack

BMS is the main controller that takes all data from the Module BMS, measures the string voltage and current,

determines the state of the battery and controls the MCCB accordingly.

UL: V049-0011XA (X = A, B)

CE: V049-0012XA (X = A, B)

X = A for general customer (SDI serial number barcode only)

X = B for specific customer (customer SKU serial number barcode + SDI serial number barcode)

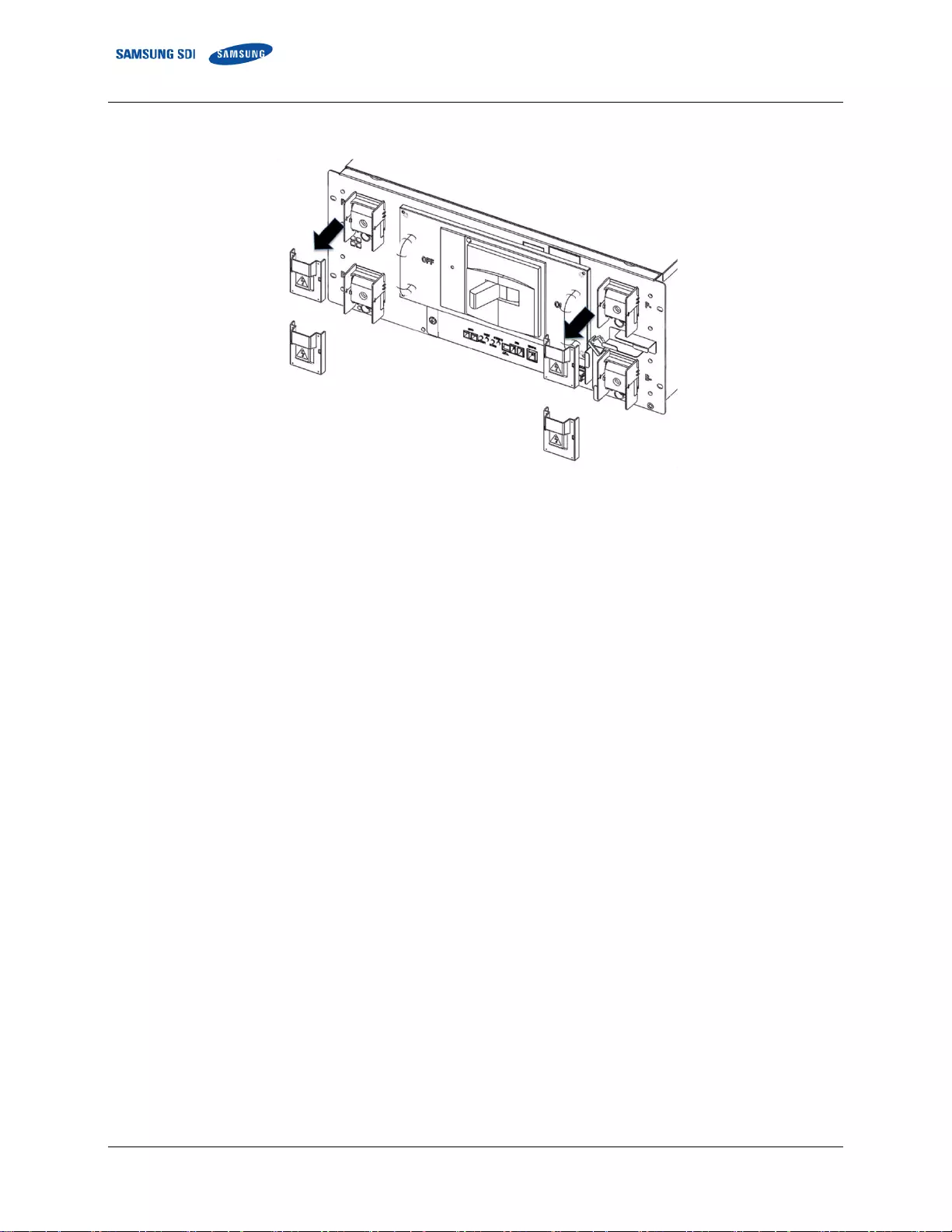

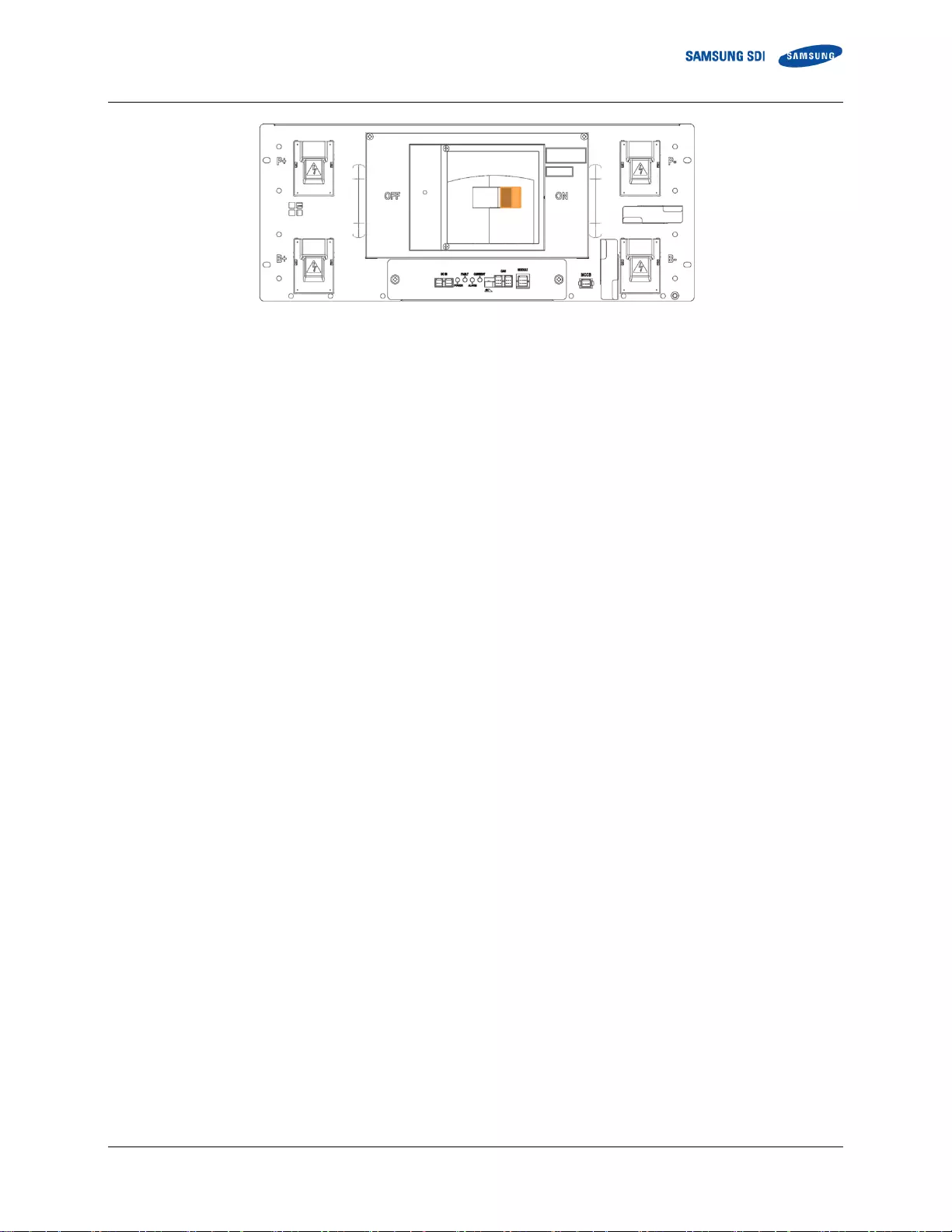

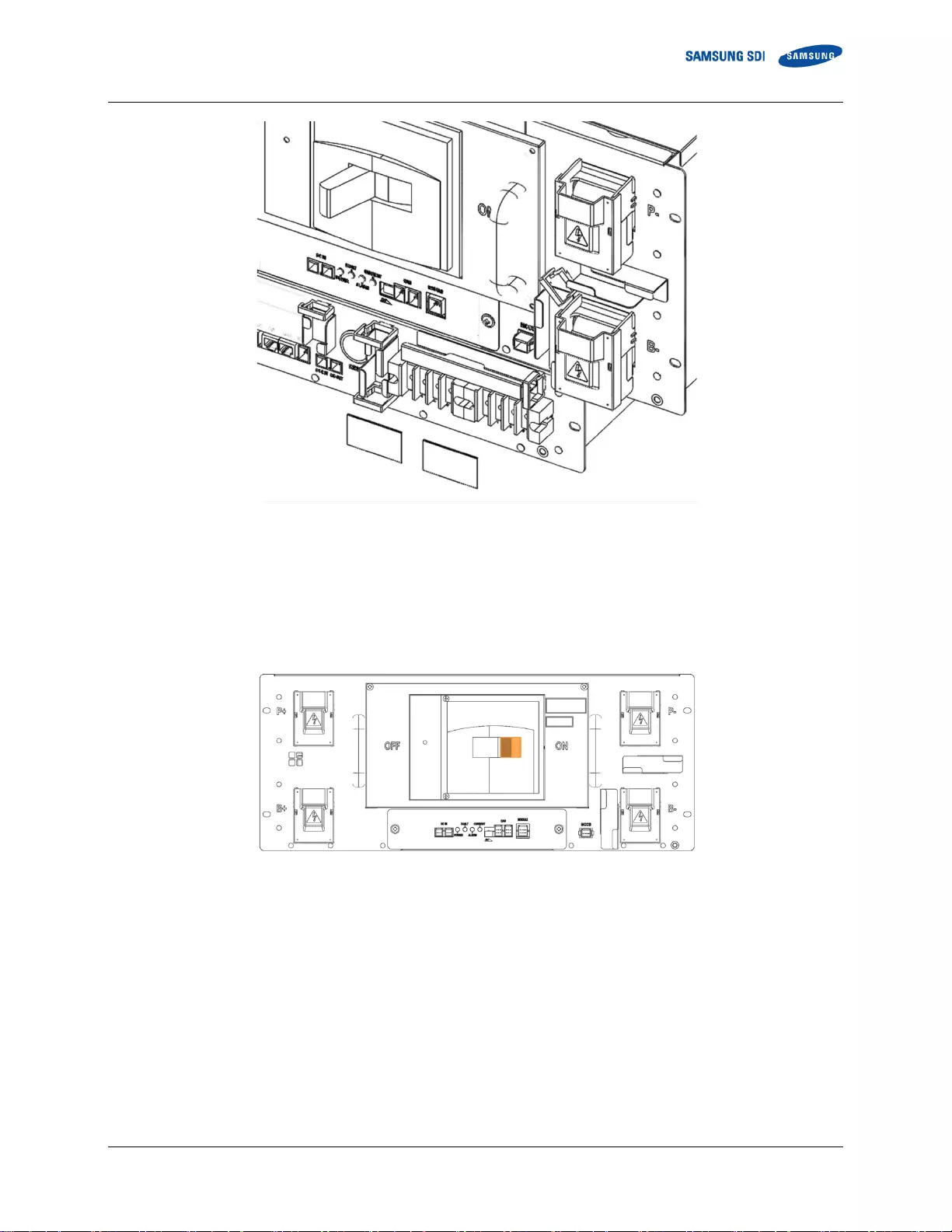

Figure 2-3: SMU

2. Product Description CONFIDENTIAL

8 English 8/2019. Rev 0.0

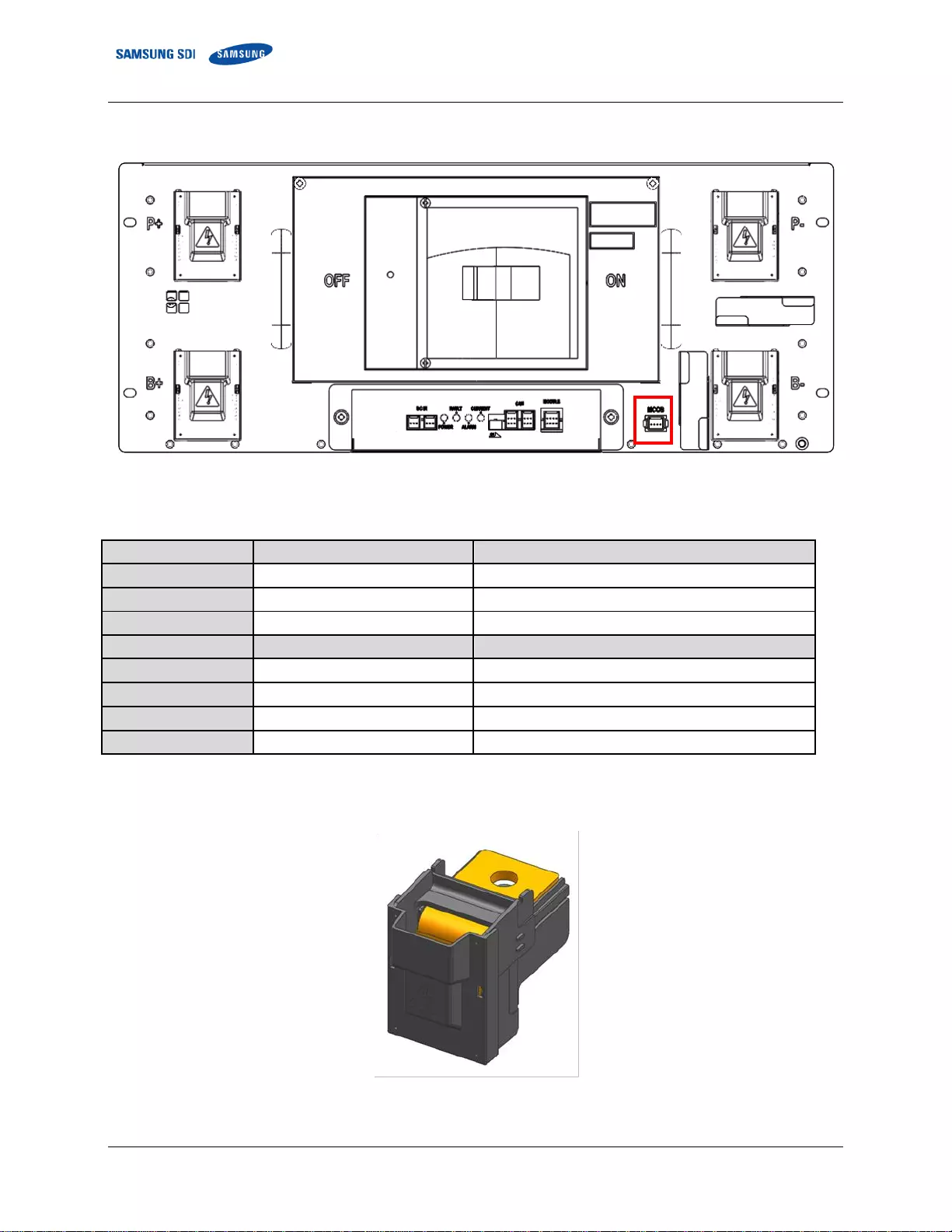

SMU provides an auxiliary breaker switch that can be connected to the building monitoring system.

Figure 2-4: Auxiliary Breaker Switch

Table 2-1: Extra Auxiliary Breaker Switch Connector Description

Item

Part Name

Description

Connector

J21SPM-04V-KX

-

Harness Housing

J21SF-04V-KX-L

-

Harness Terminal

SJ2F-01GF-P1.0

AWG 20~24

Pin No.

Pin Name

Function

1

Normal Open

2

Common

3

Normal Close

4

-

P+ and P- terminal blocks connect to the DC link from the UPS. Cable and lug terminals should be selected

according to the terminal block’s size and material.

Figure 2-5: Terminal Block Isometric View

CONFIDENTIAL 2. Product Description

English 8/2019. Rev 0.0 9

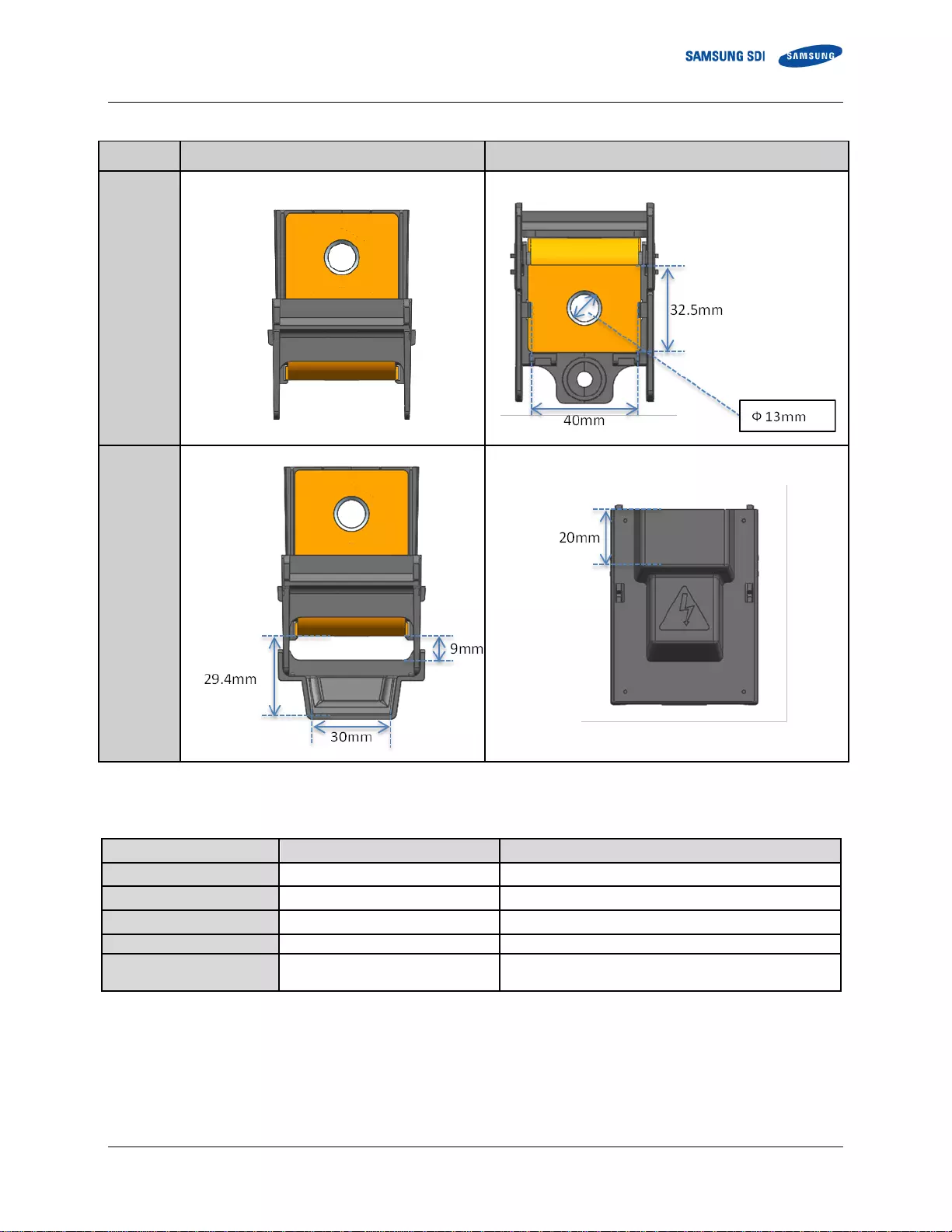

Top View

Front View

COVER

OPEN

COVER

CLOSED

Figure 2-6: Terminal Block Front / Top View (Cover Opened/Closed)

Table 2-2: Terminal Block Description

Item

Detail

Description

Conducting Material

Cu

C1100

Insulating Material (Guide)

PA66

GF25%

Insulating Material (Cover)

PC

Conductive Area

32.5mm x 40.0mm

Rated Current

473A

Calculated in accordance with

DIN 43670 MELSON & BOTH equation

2. Product Description CONFIDENTIAL

10 English 8/2019. Rev 0.0

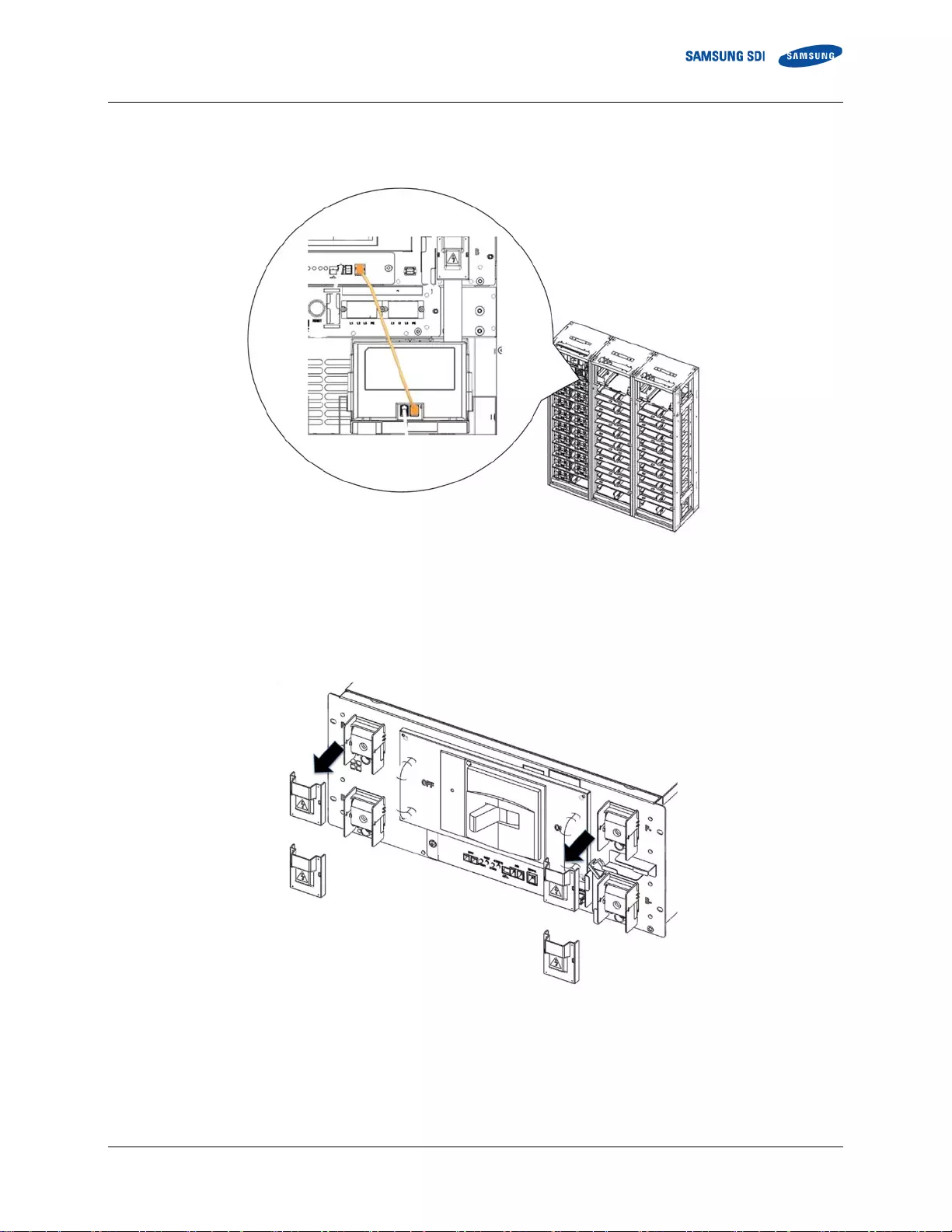

2.1.3 SMPS Assembly (Type A / Type B)

3-Phase Type A (with System BMS): V044-0006XA

X = A (for general customer)

X = B (for specific customer)

3-Phase Type B (without System BMS): SJ94-00238B (for general customer)

1-Phase Type A (with System BMS): V044-0004XA

X = A (for general customer)

X = B (for specific customer)

1-Phase Type B (without System BMS): V044-0005AA (for general customer)

SMPS Assembly houses the System BMS and SMPS, which provides power to the System BMS and SMU. Two

options are available for the SMPS depending on the AC input range and cabling: 3 phase and 1 phase. The System

BMS assembly provides data to the external systems (i.e. building management system, UPS, etc.) while controlling

and monitoring all connected Rack BMS.

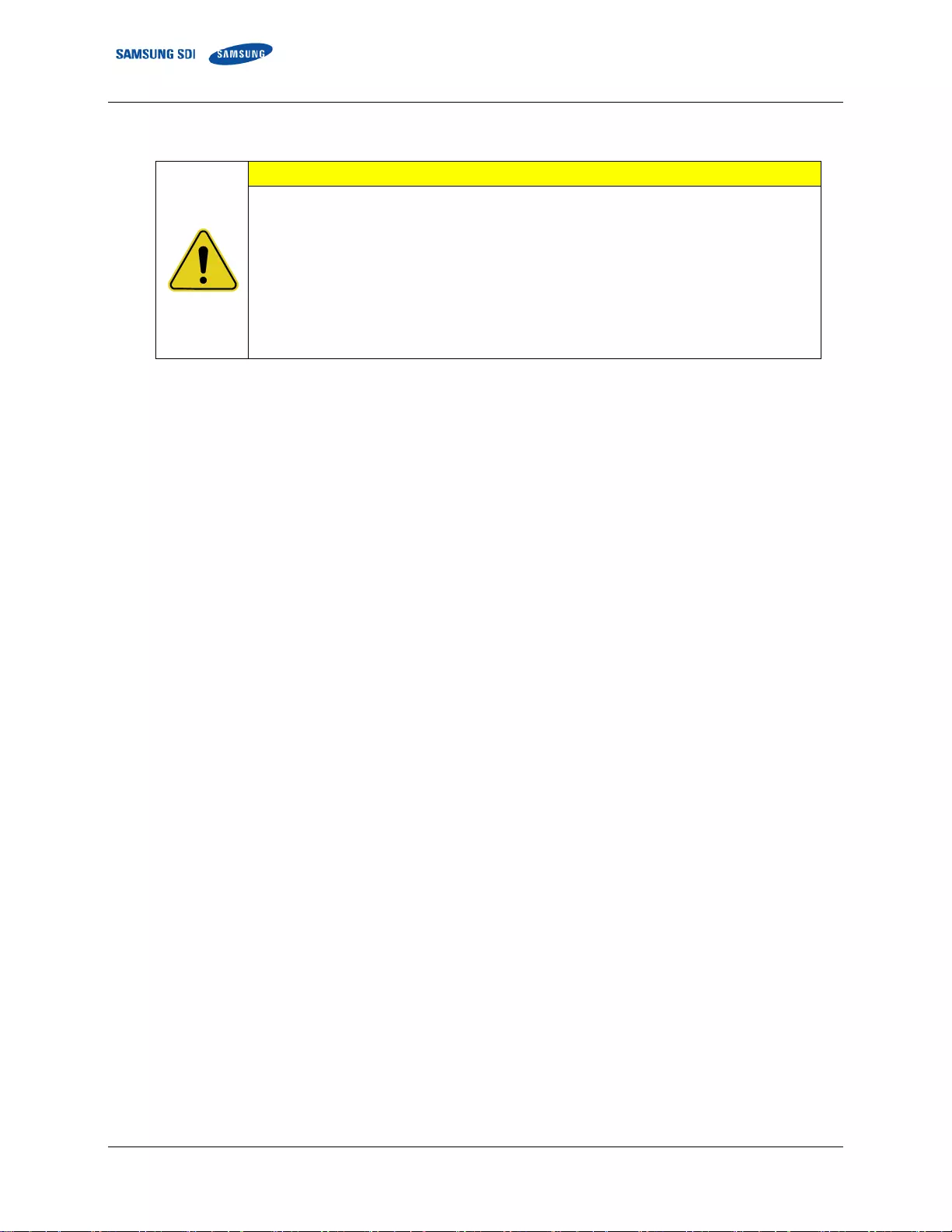

There are two types of SMPS Assembly: Type A is with System BMS and Type B is without System BMS.

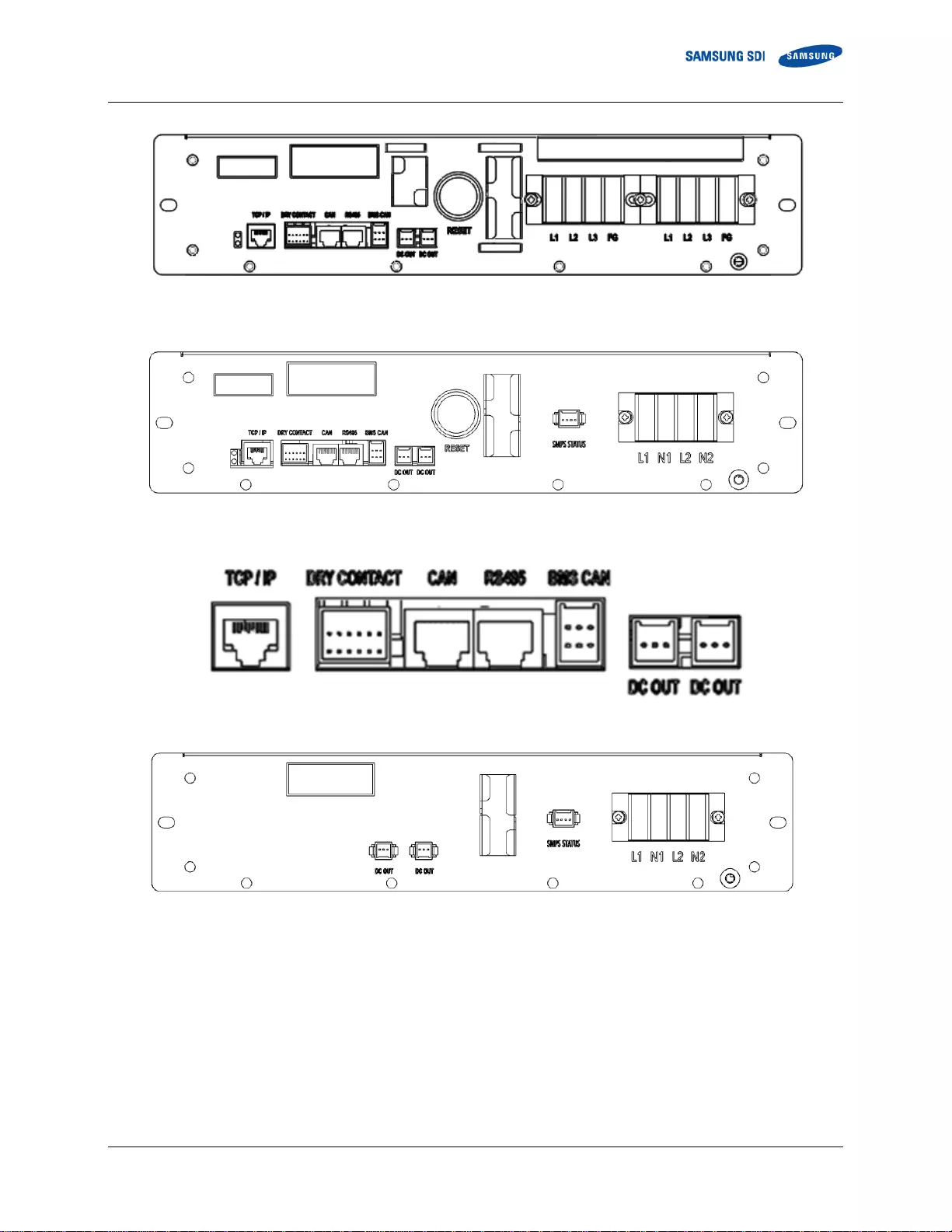

SMPS Assembly with 3 Phase AC Input

SMPS Assembly with 1 Phase AC Input

Type A (with System BMS)

Type B (without System BMS)

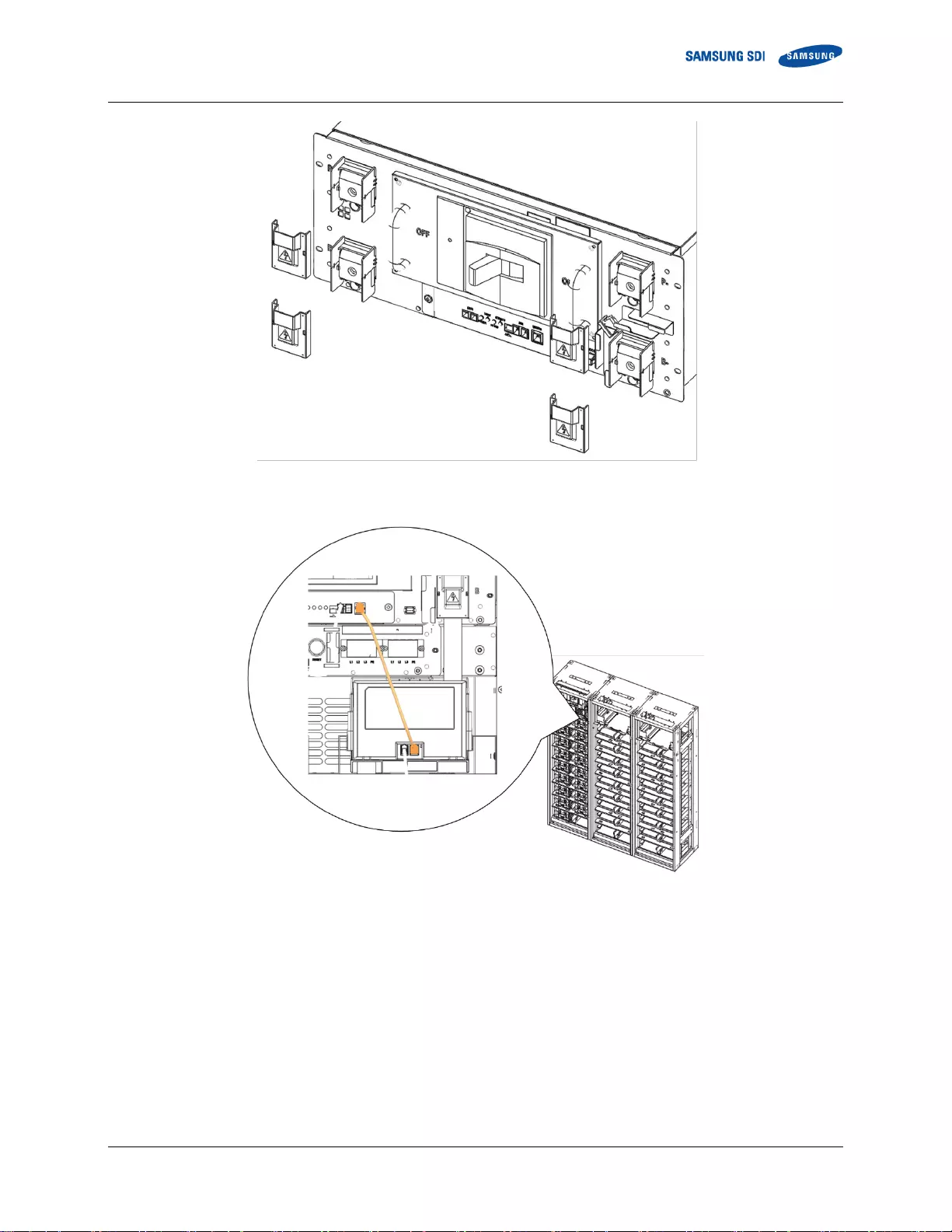

Figure 2-7: SMPS Assembly

CONFIDENTIAL 2. Product Description

English 8/2019. Rev 0.0 11

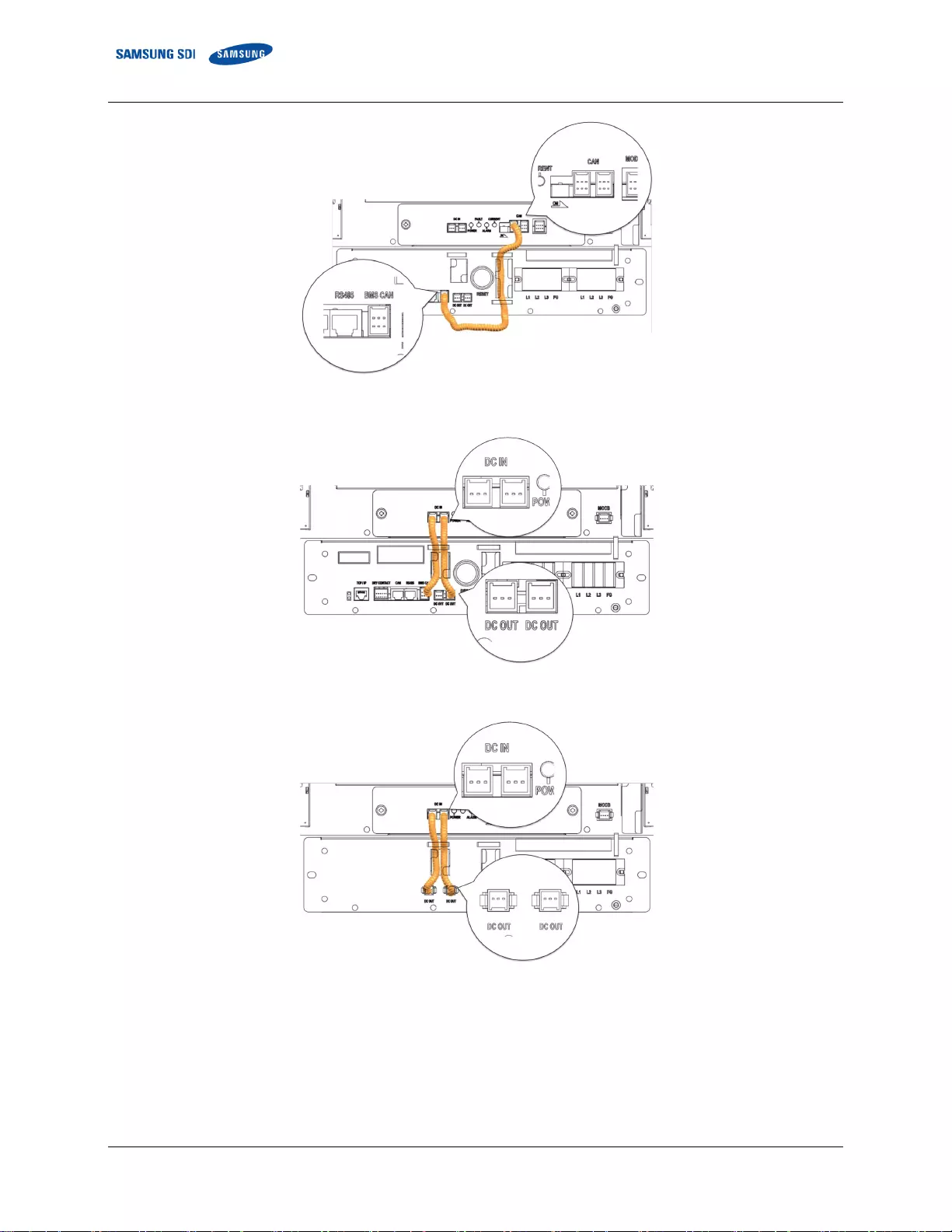

Figure 2-8: Front View of SMPS Assembly Type A, 3-Phase Input

Figure 2-9: Front View of SMPS Assembly Type A, 1-Phase Input

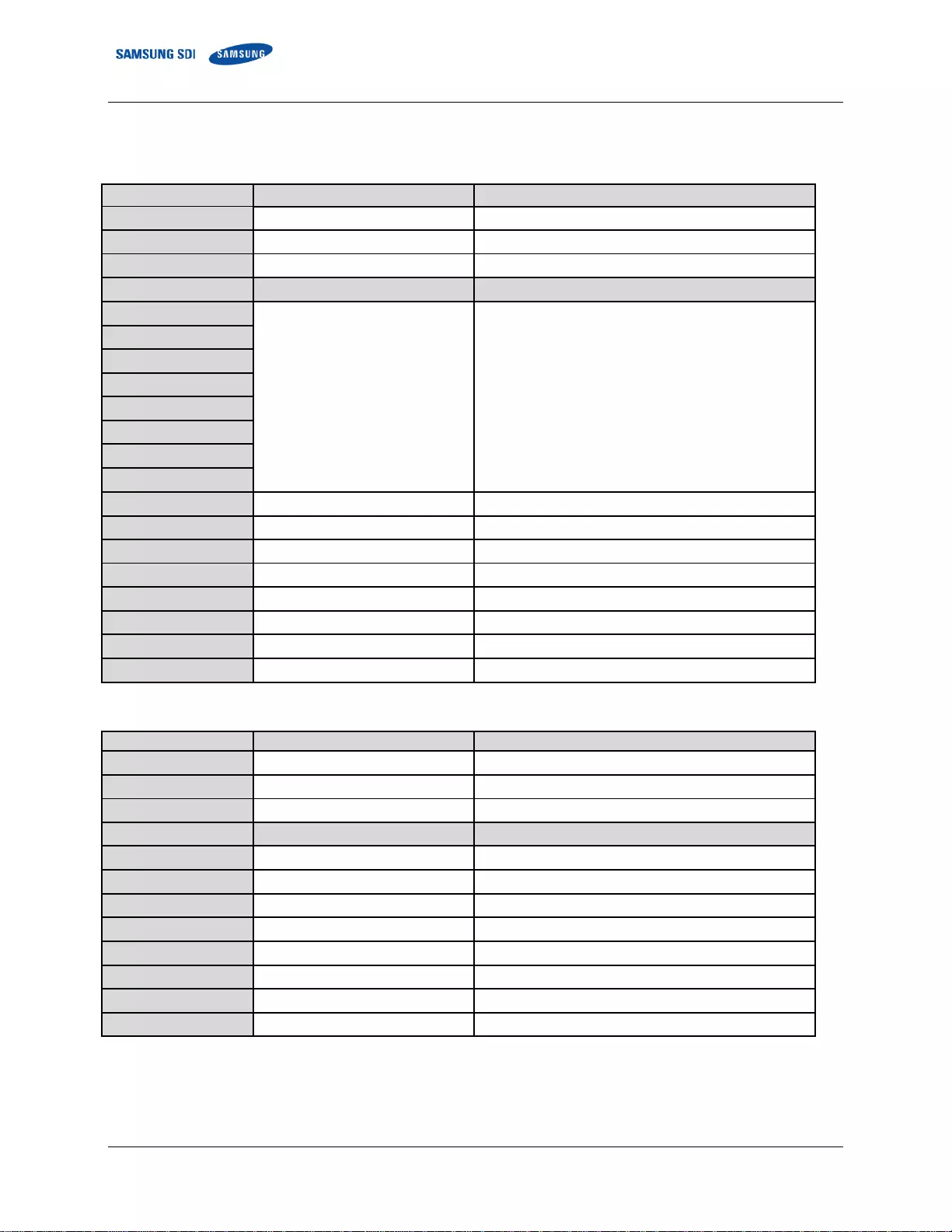

Figure 2-10: SMPS Assembly Type A – System BMS Connections

Figure 2-11: Front View of SMPS Assembly Type B, 1-Phase Input

2. Product Description CONFIDENTIAL

12 English 8/2019. Rev 0.0

SMPS Assembly Type A provides RS485, TCP/IP and Dry contact.

Table 2-3: RS485 Connector Description

Item

Part Name

Description

Connector

IM25G-008-256

2 Port, RJ45

Harness Housing

RJ45

-

Harness Terminal

RJ45

-

Pin No.

Pin Name

Function

Left. 1

CAN port

For debugging purpose only

Left. 2

Left. 3

Left. 4

Left. 5

Left. 6

Left. 7

Left. 8

Right. 1

RS485 A

Rx+ (Short to Tx+ externally)

Right. 2

RS485 B

Rx- (Short to Rx- externally)

Right. 3

RS485 Z

Tx- (Short to Rx- externally)

Right. 4

-

Right. 5

-

Right. 6

RS485 Y

Tx+

Right. 7

-

Right. 8

GND

Table 2-4: TCP/IP Connector Description

Item

Part Name

Description

Connector

VS-08-BU-RJ45/LP-1

PHOENIX CONTACT

Harness Housing

RJ45

-

Harness Terminal

RJ45

-

Pin No.

Pin Name

Function

1

TX+

TCP/IP TX+

2

TX-

TCP/IP TX-

3

RX+

TCP/IP RX+

4

GND

GND

5

GND

GND

6

RX-

TCP/IP RX-

7

GND

GND

8

GND

GND

CONFIDENTIAL 2. Product Description

English 8/2019. Rev 0.0 13

Table 2-5: Dry Contact Connector Description

Item

Part Name

Description

Connector

S12B-J11DK-TXR

JST

Harness Housing

J11DF-12V-KX

-

Harness Terminal

SF1F-21T-P0.6

AWG 18~22

Pin No.

Pin Name

Function

1A

DRY CONTACT 0 NC

Refer to the product specification.

2A

DRY CONTACT 1 COM

3A

DRY CONTACT 1 NO

4A

DRY CONTACT 2 NC

5A

-

6A

DRY CONTACT IN- (GND)

1B

DRY CONTACT 0 COM

2B

DRY CONTACT 0 NO

3B

DRY CONTACT 1 NC

4B

DRY CONTACT 2 COM

5B

DRY CONTACT 2 NO

6B

DRY CONTACT IN+

Table 2-6: AC Terminal Description (3 phase)

Item

Part Name

Description

Terminal Block

SL3T-4P

Seoil Electronics

Terminals

Ring terminal

320 ~ 575VAC, 6A

Pin No.

Pin Name

Function

1

L1

3 phase AC, L1

2

L2

3 phase AC, L2

3

L3

3 phase AC, L3

4

PE

-

Table 2-7: AC Terminal Description (1 phase)

Item

Part Name

Description

Terminal Block

SL3T-4P

Seoil Electronics

Terminals

Ring terminal

100 ~ 240VAC, 6A

Pin No.

Pin Name

Function

1

L1

SMPS #1 1 phase AC, L

2

N1

SMPS #1 1 phase AC, N

3

L2

SMPS #2 1 phase AC, L

4

N2

SMPS #2 1 phase AC, N

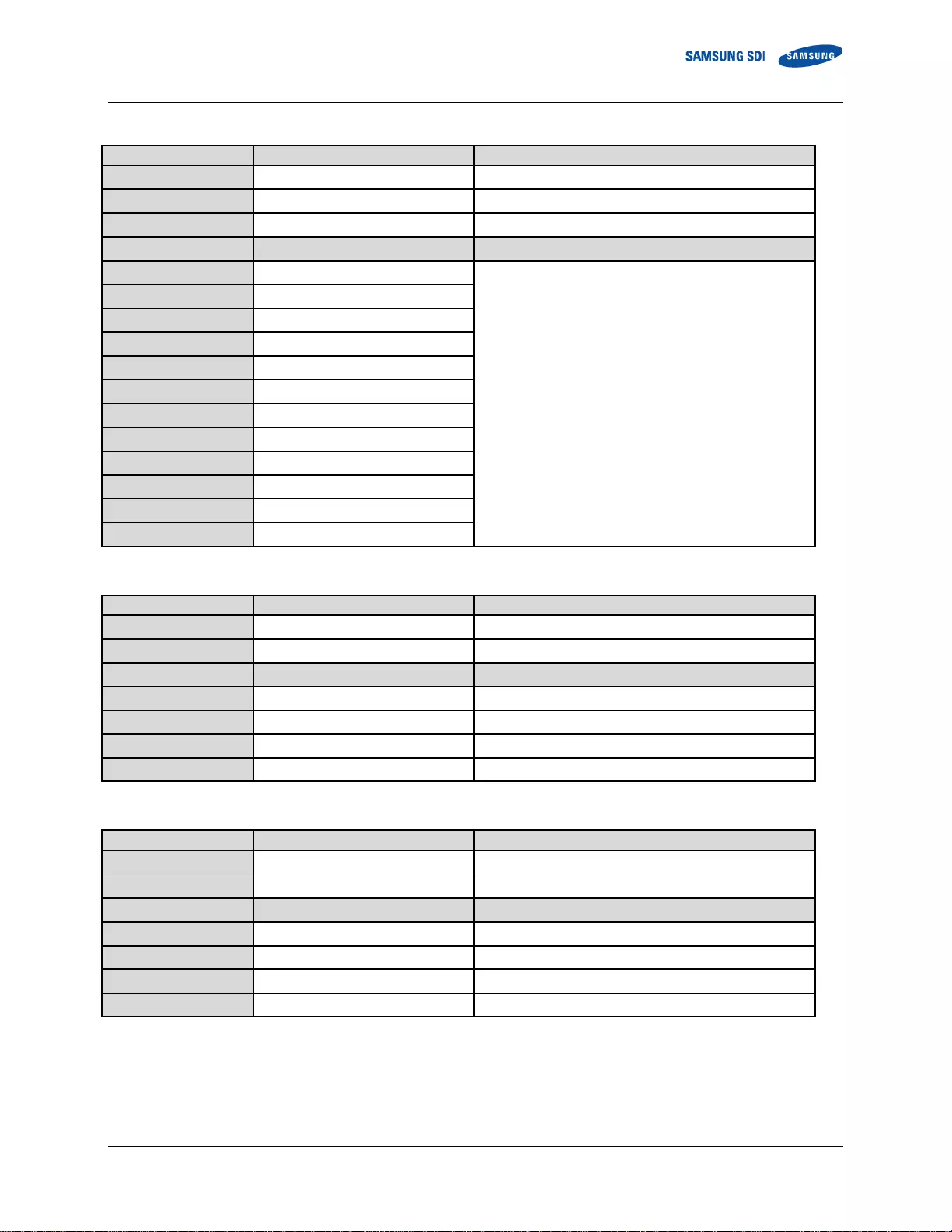

SMPS Assembly with 1 phase AC input has auxiliary connectors for the status of the SMPS.

2. Product Description CONFIDENTIAL

14 English 8/2019. Rev 0.0

Table 8: SMPS Status (SMPS Assembly 1 Phase Only)

Item

Part Name

Description

Connector

J21SPM-04V-KX

-

Harness Housing

J21SF-04V-KX-L

-

Harness Terminal

SJ2F-01GF-P1.0

AWG 20~24

Pin No.

Pin Name

Function

1

SMPS #1 STATUS (+)

SMPS #1 status

2

SMPS #1 STATUS (-)

SMPS #1 status

3

SMPS #2 STATUS (+)

SMPS #2 status

4

SMPS #2 STATUS (-)

SMPS #2 status

CONFIDENTIAL 2. Product Description

English 8/2019. Rev 0.0 15

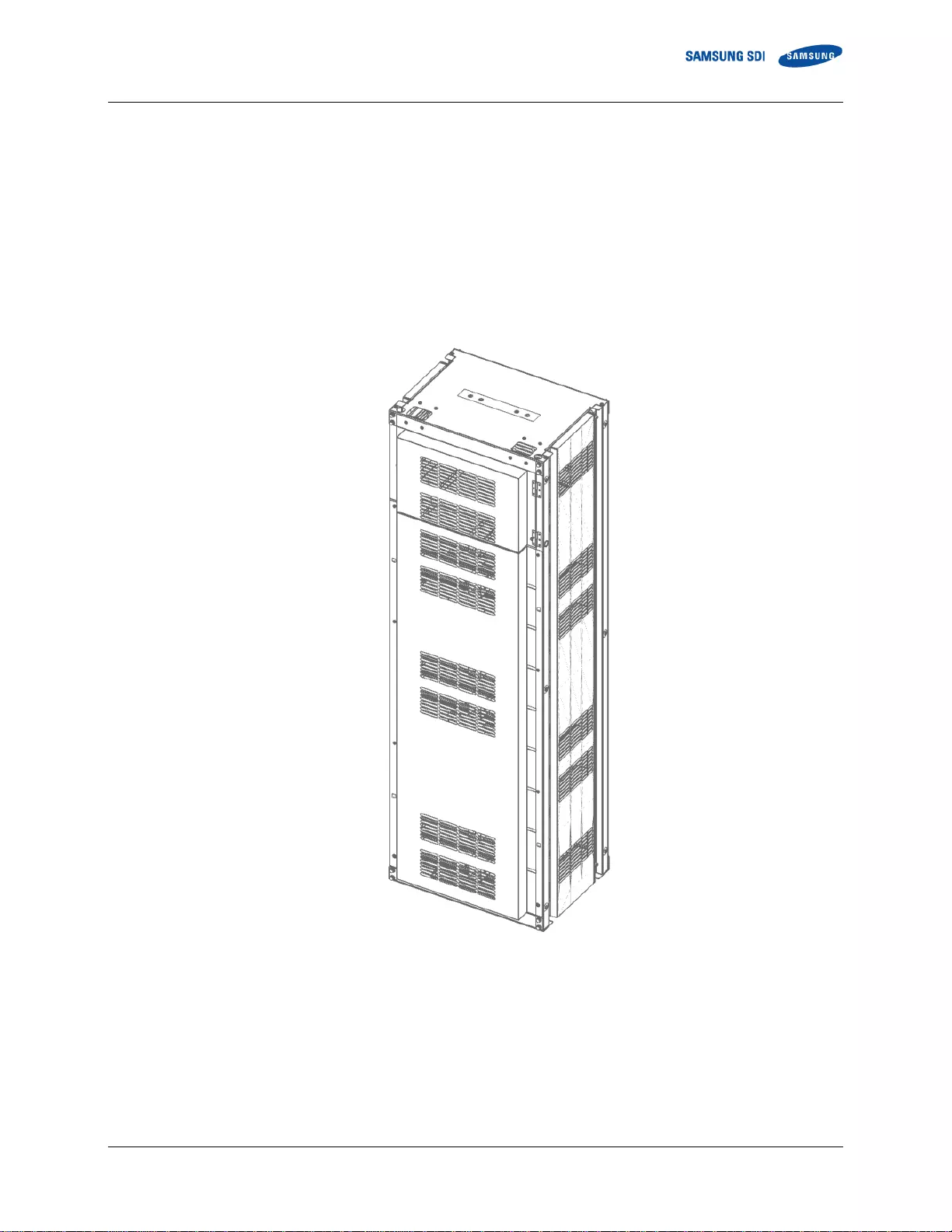

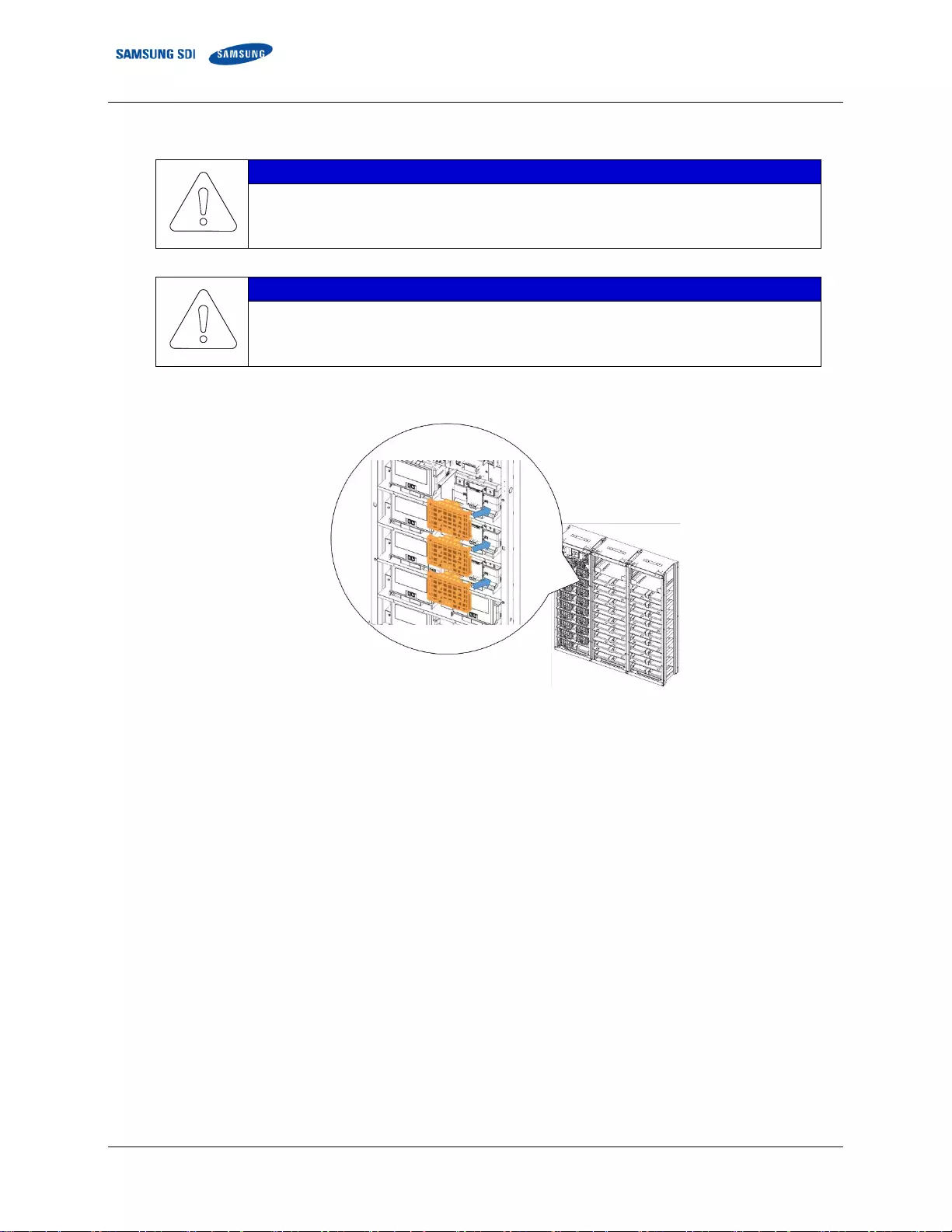

2.1.4 Rack Frame

White: V808-00066A

Black: V808-00068A

The Rack Frame is used to mount the modules, SMU and SMPS assembly and provides ground connections for SMU

and SMPS Assembly.

(Grounding cable/busbar for the rack frame is necessary for the SMU and SMPS Assembly as they are grounded to

the rack frame when installed. An equipment grounding conductor is required to ground the rack frames together

and to the UPS module).

Figure 2-12: Rack Frame

3. Battery System Operation CONFIDENTIAL

16 English 8/2019. Rev 0.0

3. Battery System Operation

The battery system for a UPS is designed to be always on. The UPS and the critical load must be set up so that the

battery system’s maximum allowable voltage and current are not exceeded.

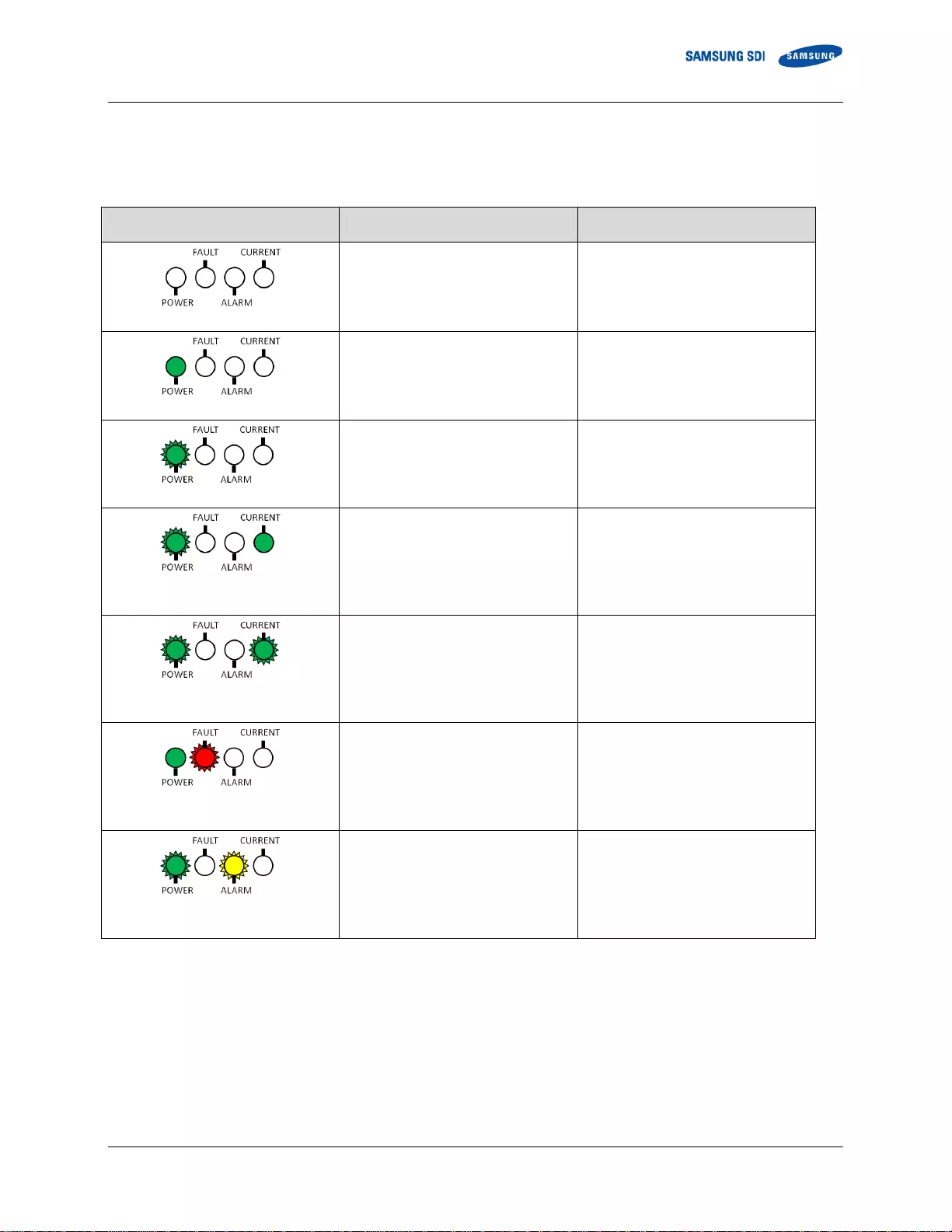

3.1 Indicator LED

Four indicator LED’s on the front of the SMU in each rack displays the status of the battery system per string. Table

3-1 shows each LED’s color and the battery status indicated.

Table 3-1: Indicator LED Status

Items

POWER(Green)

FAULT(Red)

ALARM(Yellow)

CURRENT(Green)

Location

Status

On : MCCB Off

Off : Power Off

Blink : MCCB On

On : N/A

Off : No Major

Protection

Blink : Major

Protection

On : N/A

Off : No Minor

Protection

Blink : Minor

Protection

On : Discharge

Off : Idle

Blink : Charge

CONFIDENTIAL 3. Battery System Operation

English 8/2019. Rev 0.0 17

Depending on the battery system’s operating conditions, each indicator LED may be on, blinking or off. Table 3-2

shows the LED indication for the battery status.

Table 3-2: Indicated Codes

LED Status

Battery Status

Remarks

All LED’s Off

BMS Power Off

MCCB Off

POWER LED Steady

Normal

MCCB Off

POWER LED Flashing

Normal

MCCB On

POWER LED Flashing

CURRENT LED Steady

Normal

Discharge

POWER LED Flashing

CURRENT LED Flashing

Normal

Charge

POWER LED Steady

FAULT LED Flashing

Major Protection

MCCB Tripped

Overvoltage Protection

Undervoltage Protection

Overtemperature Protection

Overcurrent Protection

POWER LED Flashing

ALARM LED Flashing

Minor Protection

MCCB On

Voltage Imbalance Error

Voltage Sensing Error

Undertemperature Protection

Temperature Imbalance Error

3. Battery System Operation CONFIDENTIAL

18 English 8/2019. Rev 0.0

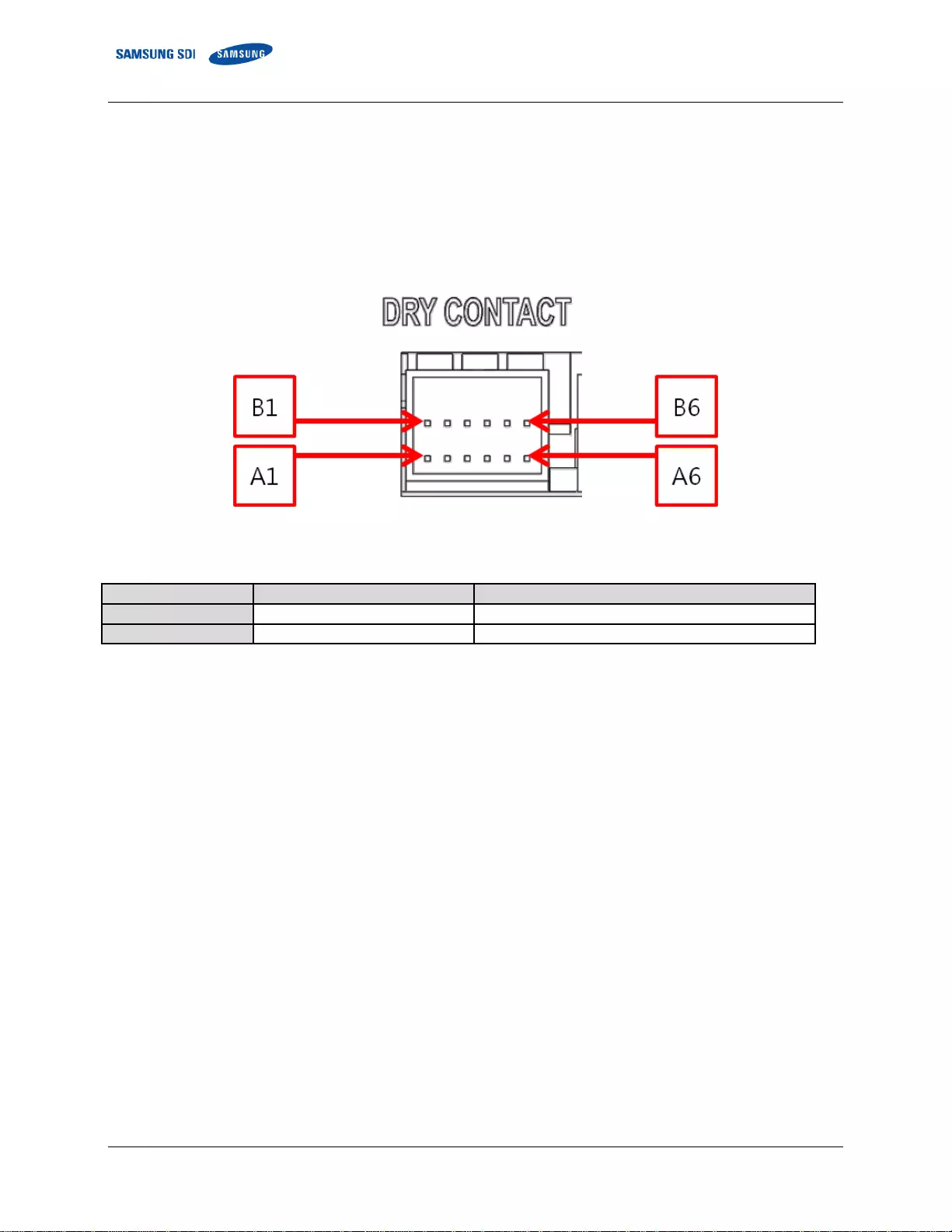

3.2 Dry Contact Signals

Dry contact signals are sent from the System BMS in the SMPS Assembly to let the UPS know the status of the

battery system. Three Form-C output channels send signals for major protection, minor protection, and charge stop

request. One input channel receives a signal to trip the MCCB when requested from the UPS.

Three options of dry contact operation can be selected during installation.

Figure 3-1: Dry Contact Connector Pinout

Table 3-3: Dry Contact Connector Information

Item

Part Name

Description

Connector

S12B-J11DK-GWXR

JST

Harness Housing

J11DF-12V-KX

JST

CONFIDENTIAL 3. Battery System Operation

English 8/2019. Rev 0.0 19

Table 3-4: Dry Contact Connector Description (Option 1. Customer ID = 0)

Pin No.

Pin Name

Function

B1

Major Common

Over-Voltage Protection

Under-Voltage Protection

Over-Temperature Protection

Over-Current Protection

A1

Major Normal Close

B2

Major Normal Open

A2

Minor Common

Voltage Imbalance Error

Voltage Sensing Error

Under Temperature protection

Temperature Imbalance Error

B3

Minor Normal Close

A3

Minor Normal Open

B4

Charge Common

Charge Stop Set Condition

1. Overvoltage alarm(4.25V/Cell)

2. SOC 100%

Charge Stop Release Condition

1. SOC < 97% or Discharge Current >│3A│

A4

Charge Normal Close

B5

Charge Normal Open

A5

Reserved

B6

Input

Set Condition: UPS closes B6, A6 contacts for more than

3 second.

Action : Battery MCCB Trip

A6

GND

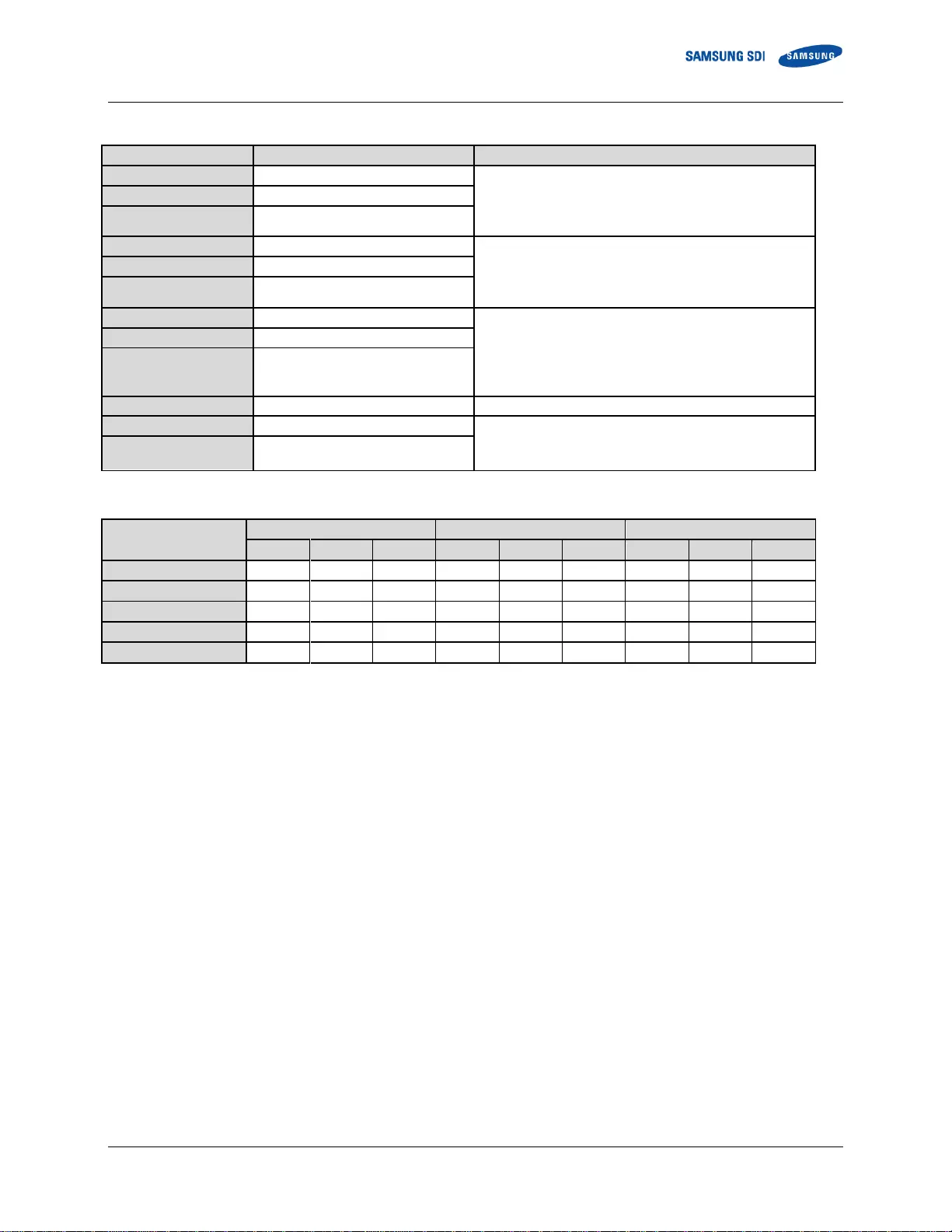

Table 3-5: Dry Contact Operation (Option 1. Customer ID = 0)

Battery Status

MAJOR

MINOR

CHARGE STOP

B1

A1

B2

A2

B3

A3

B4

A4

B5

Normal Status

COM

Open

Close

COM

Open

Close

COM

Open

Close

Major Protection

COM

Close

Open

COM

Open

Close

COM

Open

Close

Minor Protection

COM

Open

Close

COM

Close

Open

COM

Open

Close

Charge Stop

COM

Open

Close

COM

Open

Close

COM

Close

Open

BMS Power Off

COM

Close

Open

COM

Close

Open

COM

Close

Open

3. Battery System Operation CONFIDENTIAL

20 English 8/2019. Rev 0.0

Table 3-6: Dry Contact Connector Description (Option 2. Customer ID = 1)

Pin No.

Pin Name

Function

B1

Major Common

Overvoltage Protection

Undervoltage Protection

Overtemperature Protection

Overcurrent Protection

A1

Major Normally Closed

B2

Major Normally Open

A2

Minor Common

Voltage Imbalance Error

Voltage Sensing Error

Undertemperature Protection

Temperature Imbalance Error

B3

Minor Normally Closed

A3

Minor Normally Open

B4

MCCB Status Common

All MCCB’s are Off : A4, B4 are closed.

One of the MCCB’s is on : B5, B4 are closed.

A4

MCCB Status Normally Closed

B5

MCCB Status Normally Open

A5

Reserved

—

B6

Input

Set Condition: UPS opens B6, A6 contacts for more than

3 seconds.

Action : Battery MCCB Trip

A6

GND

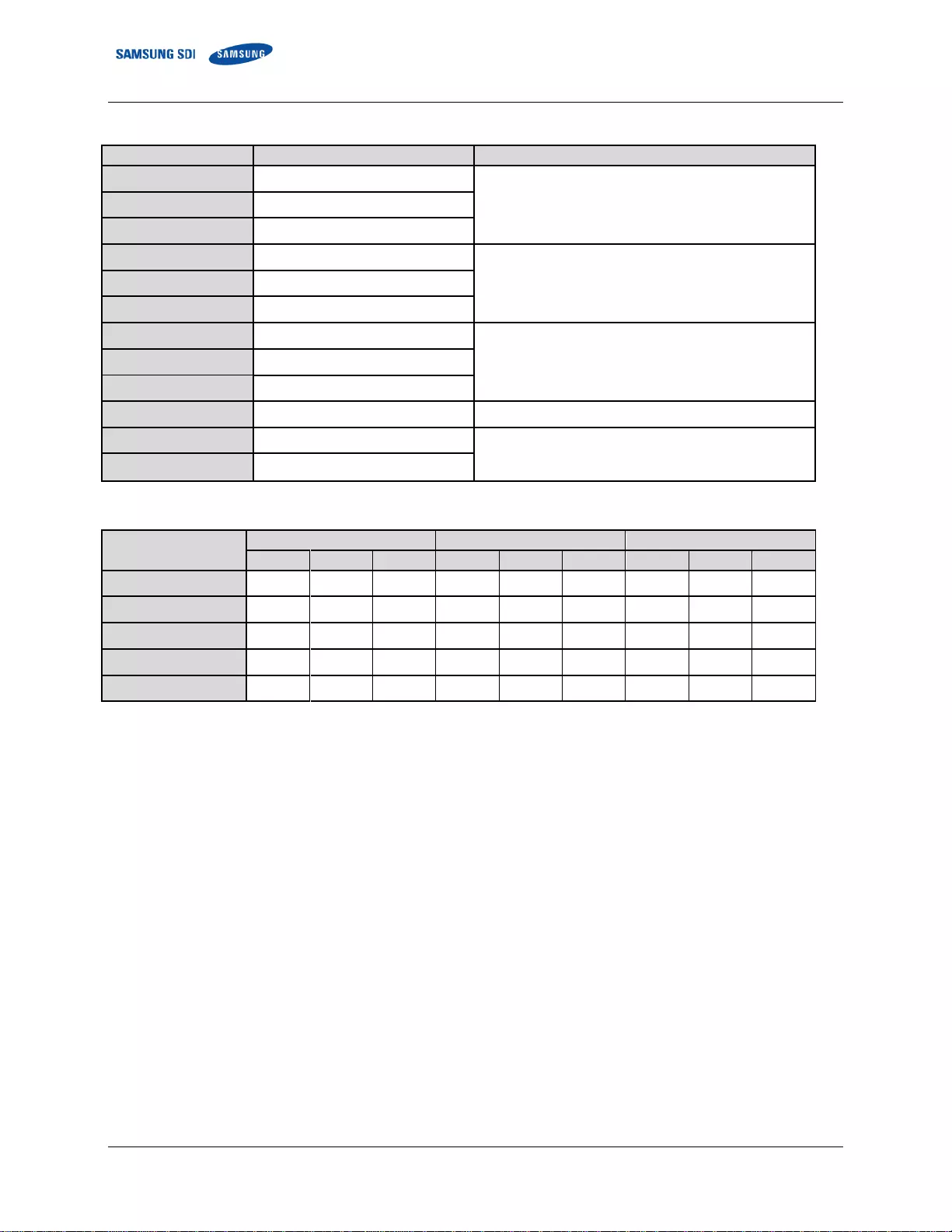

Table 3-7: Dry Contact Operation (Option 2. Customer ID = 1)

Battery Status

MAJOR

MINOR

MCCB Status

B1

A1

B2

A2

B3

A3

B4

A4

B5

Normal Status

COM

Open

Close

COM

Open

Close

COM

Open

Close

Major Protection

COM

Close

Open

COM

Open

Close

COM

Close

Open

Minor Protection

COM

Open

Close

COM

Close

Open

COM

Open

Close

MCCB Off

COM

Close

Open

COM

Open

Close

COM

Close

Open

BMS Power Off

COM

Close

Open

COM

Close

Open

COM

Close

Open

CONFIDENTIAL 3. Battery System Operation

English 8/2019. Rev 0.0 21

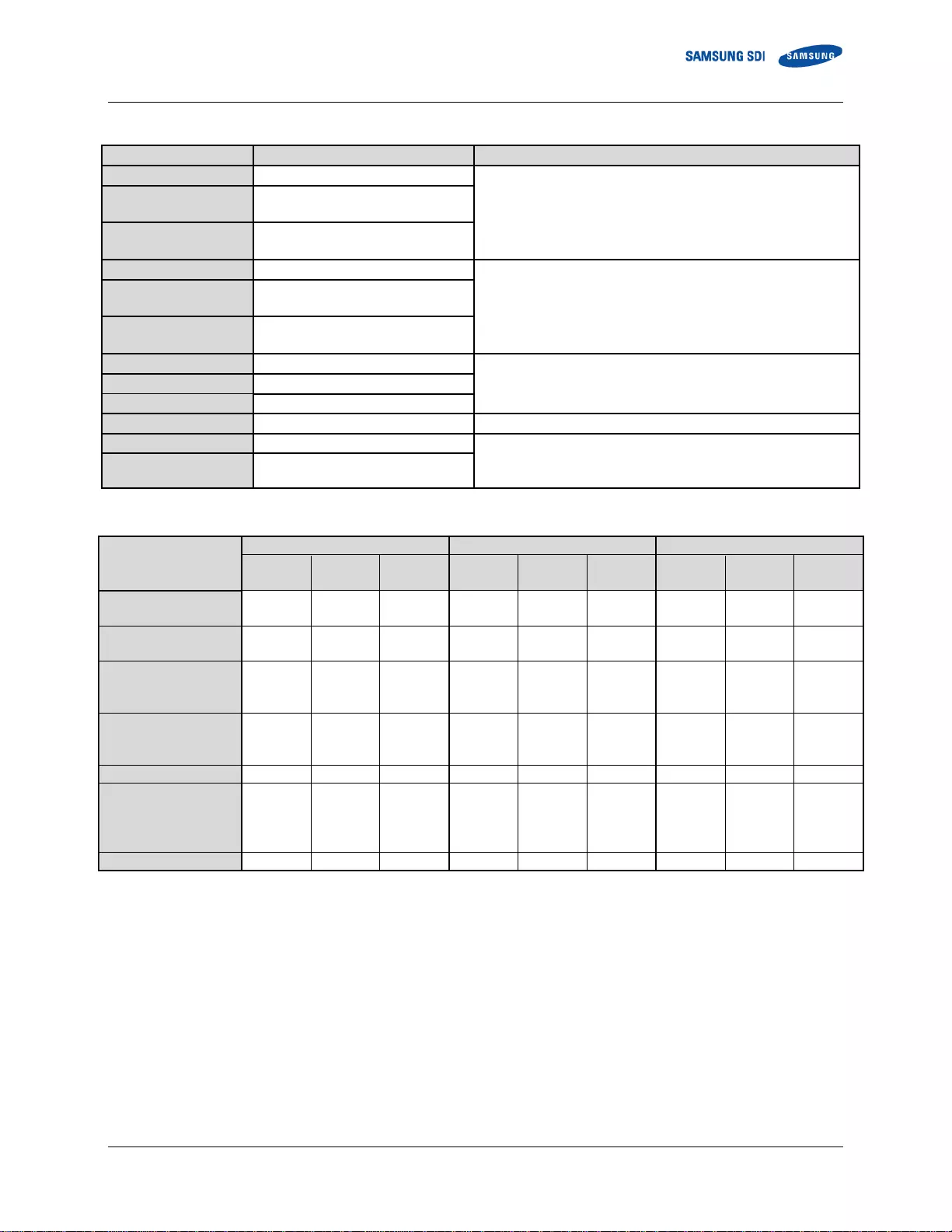

Table 8: Dry Contact Connector Description (Option 3. Customer ID = 2)

Pin No.

Pin Name

Function

B1

Discharge Prohibit Common

Undervoltage Protection

Overtemperature Protection

Discharge Overcurrent Protection

A1

Discharge Prohibit

Normal Close

B2

Discharge Prohibit

Normal Open

A2

Charge Prohibit Common

Overvoltage Alarm,

Overvoltage Protection

Overtemperature Protection

Charge Overcurrent Protection

B3

Charge Prohibit

Normal Close

A3

Charge Prohibit

Normal Open

B4

MCCB Status Common

All MCCBs are off : 4A, 4B is closed

One of MCCB is on : 5B, 4B is closed

A4

MCCB Status Normal Close

B5

MCCB Status Normal Open

A5

Reserved

B6

Input

Set Condition: UPS opens B6, A6 contacts for more than 1

second.

Action : Battery MCCB Trip

A6

GND

Table 9: Dry Contact Operation (Option 3. Customer ID = 2)

Battery Status

Discharge Prohibited

Charge Prohibited

MCCB Status

B1

(COM)

A1

(NC)

B2

(NO)

A2

(COM)

B3

(NC)

A3

(NO)

B4

(COM)

A4

(NC)

B5

(NO)

Normal Status

(All MCCB on)

COM

Close

Open

COM

Close

Open

COM

Open

Close

At least one MCCB is

on

COM

-

-

COM

-

-

COM

Open

Close

Discharge Prohibited

(UVP, OTP, Discharge

OCP)

COM

Open

Close

COM

-

-

COM

-

-

Charge Prohibited

(OV alarm, OVP, OTP,

Charge OCP)

COM

-

-

COM

Open

Close

COM

-

-

All MCCBs Off

COM

-

-

COM

-

-

COM

Close

Open

EPO Received

(B6, A6 contacts are

OPEN for more than 1

second)

COM

-

-

COM

-

-

COM

Close

Open

BMS Power Off

COM

Close

Open

COM

Close

Open

COM

Close

Open

3. Battery System Operation CONFIDENTIAL

22 English 8/2019. Rev 0.0

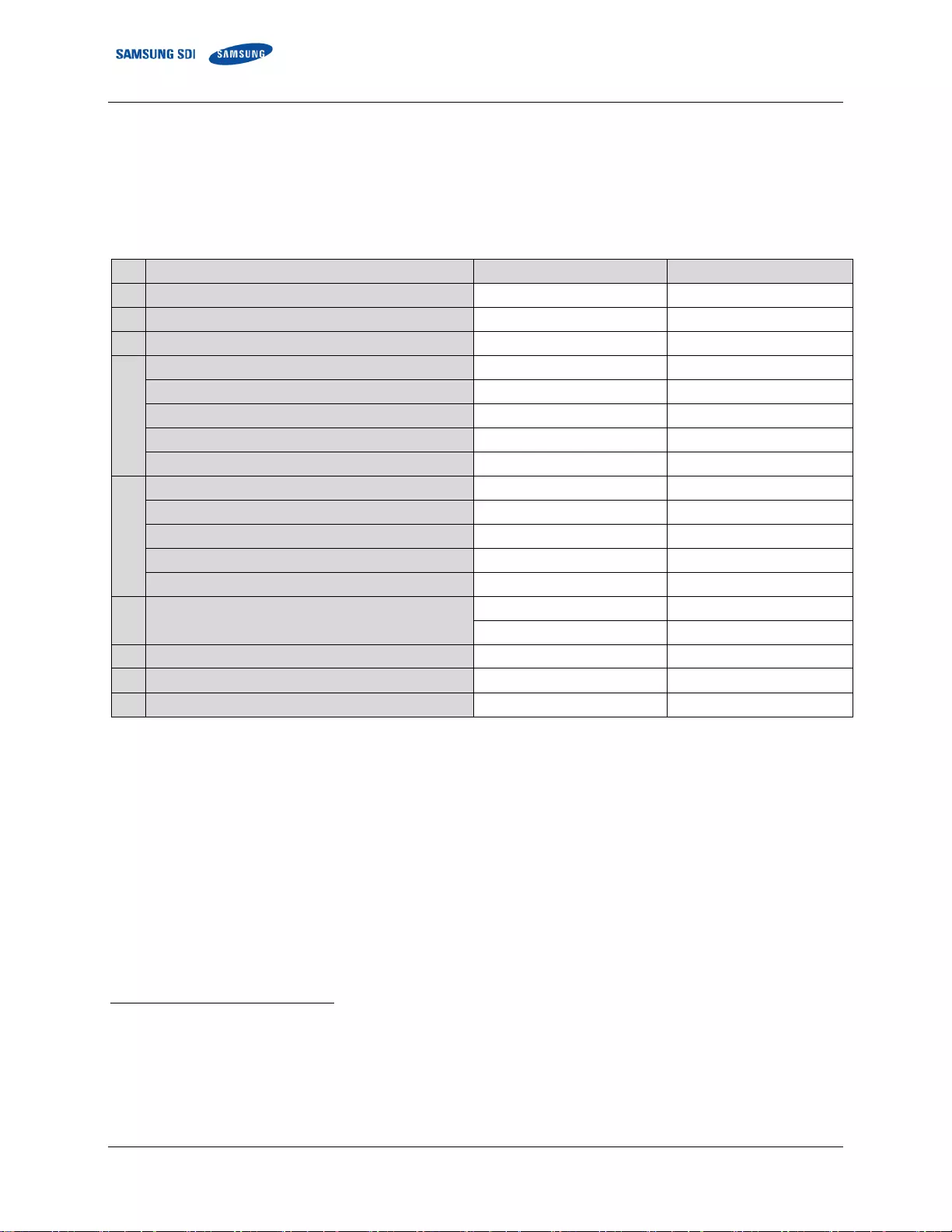

3.3 Operation Status

Refer to the table below for typical and maximum state of charge and discharge conditions to keep the battery

system in normal operation.

Table 3-10: Range of Operation (136S Configuration)

No.

Item

Specification

Remarks

1

Nominal Capacity

34.6kWh

1/3C@R.T

2

Nominal Voltage1

516.8V DC

3.8V/cell

3

Maximum Voltage1

571.2V DC

4.2V/cell

4

Discharging Method

Constant Power

End of Discharge Voltage1

408V DC

3.0V/cell

Recommended End of Discharge Voltage

435.2V DC

3.2V/cell

Standard Discharging Current

22.3A

1/3C@R.T

Maximum Continuous Discharge Power

183.6kW

Peak 450A @ EODV

5

Charging Method

CC-CV, Floating

Floating Charge Voltage

571.2V DC

4.2V/cell

Standard Charge Current

22.3A

1/3C

Maximum Peak Charge Current

250A

2 second pulse

Maximum Continuous Charging Current

67A

1C

6

Recommended Operation Temperature

23±5°C

7

Storage Temperature

0 ~ 40°C

8

Storage Humidity

Less than 90 % RH

Noncondensing

9

Recommended Storage Humidity

Less than 60 % RH

Noncondensing

10

Storage Period2

Less than 6 months

1

Specified voltage must be satisfied in all load and charging conditions.

2

Capacity degradation will occur depending on storage time. To minimize capacity degradation,

storage temperature of less than 10°C and 3.630V per cell is recommended.

CONFIDENTIAL 3. Battery System Operation

English 8/2019. Rev 0.0 23

Table 3-11: Range of Operation (128S Configuration)

No.

Item

Specification

Remarks

1

Nominal Capacity

32.6kWh

1/3C@R.T

2

Nominal Voltage1

486.4V DC

3.8V/cell

3

Maximum Voltage1

537.6V DC

4.2V/cell

4

Discharging Method

Constant Power

End of Discharge Voltage1

384V DC

3.0V/cell

Recommended End of Discharge Voltage

409.6V DC

3.2V/cell

Standard Discharging Current

22.3A

1/3C@R.T

Maximum Continuous Discharge Power

173kW

Peak 450A @ EODV

5

Charging Method

CC-CV, Floating

Floating Charge Voltage

537.6V DC

4.2V/cell

Standard Charge Current

22.3A

1/3C

Maximum Peak Charge Current

250A

2 second pulse

Maximum Continuous Charging Current

67A

1C

6

Recommended Operation Temperature

23±5°C

7

Storage Temperature

0 ~ 40°C

8

Storage Humidity

Less than 90 % RH

Noncondensing

9

Recommended Storage Humidity

Less than 60 % RH

Noncondensing

10

Storage Period2

Less than 6 months

1

Specified voltage must be satisfied in all load and charging conditions.

2

Capacity degradation will occur depending on storage time. To minimize capacity degradation, storage

temperature of less than 10°C and 3.630V per cell is recommended.

3. Battery System Operation CONFIDENTIAL

24 English 8/2019. Rev 0.0

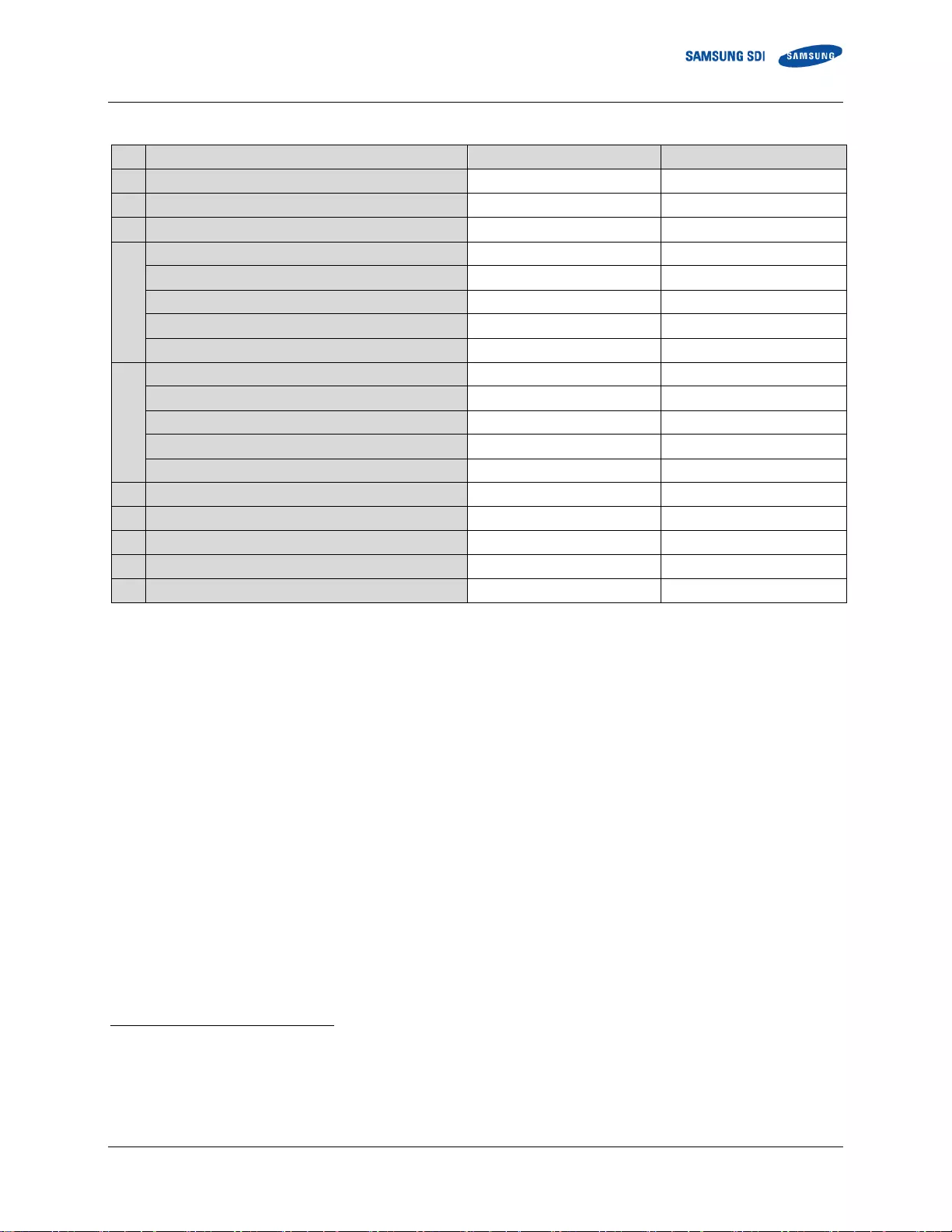

Table 3-12: Range of Operation (112S Configuration)

No.

Item

Specification

Remarks

1

Nominal Capacity

28.5kWh

1/3C@R.T

2

Nominal Voltage1

425.6V DC

3.8V/cell

3

Maximum Voltage1

470.4V DC

4.2V/cell

4

Discharging Method

Constant Power

End of Discharge Voltage1

336V DC

3.0V/cell

Recommended End of Discharge Voltage

358.4V DC

3.2V/cell

Standard Discharging Current

22.3A

1/3C@R.T

Maximum Continuous Discharge Power

151kW

Peak 450A @ EODV

5

Charging Method

CC-CV, Floating

Floating Charge Voltage

470.4V DC

4.2V/cell

Standard Charge Current

22.3A

1/3C

Maximum Peak Charge Current

250A

2 second pulse

Maximum Continuous Charging Current

67A

1C

6

Recommended Operation Temperature

23±5°C

7

Storage Temperature

0 ~ 40°C

8

Storage Humidity

Less than 90 % RH

Noncondensing

9

Recommended Storage Humidity

Less than 60 % RH

Noncondensing

10

Storage Period2

Less than 6 months

1

Specified voltage must be satisfied in all load and charging conditions.

2

Capacity degradation will occur depending on storage time. To minimize capacity degradation, storage

temperature of less than 10°C and 3.630V per cell is recommended.

CONFIDENTIAL 3. Battery System Operation

English 8/2019. Rev 0.0 25

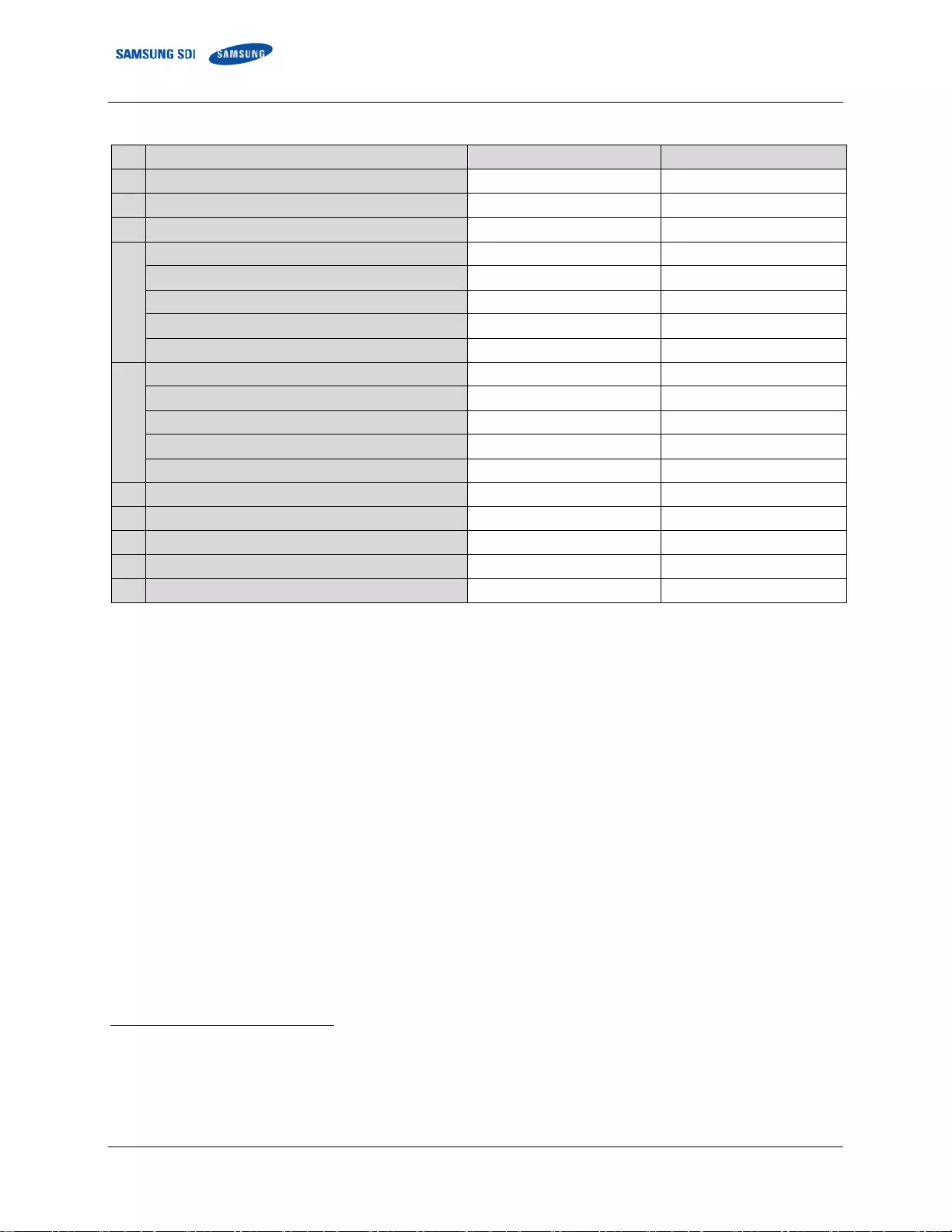

Table 3-13: Range of Operation (104S Configuration)

No.

Item

Specification

Remarks

1

Nominal Capacity

26.5kWh

1/3C@R.T

2

Nominal Voltage1

395.2V DC

3.8V/cell

3

Maximum Voltage1

436.8V DC

4.2V/cell

4

Discharging Method

Constant Power

End of Discharge Voltage1

312V DC

3.0V/cell

Recommended End of Discharge Voltage

332.8V DC

3.2V/cell

Standard Discharging Current

22.3A

1/3C@R.T

Maximum Continuous Discharge Power

140kW

Peak 450A @ EODV

5

Charging Method

CC-CV, Floating

Floating Charge Voltage

436.8V DC

4.2V/cell

Standard Charge Current

22.3A

1/3C

Maximum Peak Charge Current

250A

2 second pulse

Maximum Continuous Charging Current

67A

1C

6

Recommended Operation Temperature

23±5°C

7

Storage Temperature

0 ~ 40°C

8

Storage Humidity

Less than 90 % RH

Noncondensing

9

Recommended Storage Humidity

Less than 60 % RH

Noncondensing

10

Storage Period2

Less than 6 months

1

Specified voltage must be satisfied in all load and charging conditions.

2

Capacity degradation will occur depending on storage time. To minimize capacity degradation, storage

temperature of less than 10°C and 3.630V per cell is recommended.

3. Battery System Operation CONFIDENTIAL

26 English 8/2019. Rev 0.0

Table 3-14: Range of Operation (80S Configuration)

No.

Item

Specification

Remarks

1

Nominal Capacity

20.4kWh

1/3C@R.T

2

Nominal Voltage1

304V DC

3.8V/cell

3

Maximum Voltage1

336V DC

4.2V/cell

4

Discharging Method

Constant Power

End of Discharge Voltage1

240V DC

3.0V/cell

Recommended End of Discharge Voltage

256V DC

3.2V/cell

Standard Discharging Current

22.3A

1/3C@R.T

Maximum Continuous Discharge Power

108kW

Peak 450A @ EODV

5

Charging Method

CC-CV, Floating

Floating Charge Voltage

336V DC

4.2V/cell

Standard Charge Current

22.3A

1/3C

Maximum Peak Charge Current

250A

2 second pulse

Maximum Continuous Charging Current

67A

1C

6

Recommended Operation Temperature

23±5°C

7

Storage Temperature

0 ~ 40°C

8

Storage Humidity

Less than 90 % RH

Noncondensing

9

Recommended Storage Humidity

Less than 60 % RH

Noncondensing

10

Storage Period2

Less than 6 months

1

Specified voltage must be satisfied in all load and charging conditions.

2

Capacity degradation will occur depending on storage time. To minimize capacity degradation, storage

temperature of less than 10°C and 3.630V per cell is recommended.

CONFIDENTIAL 3. Battery System Operation

English 8/2019. Rev 0.0 27

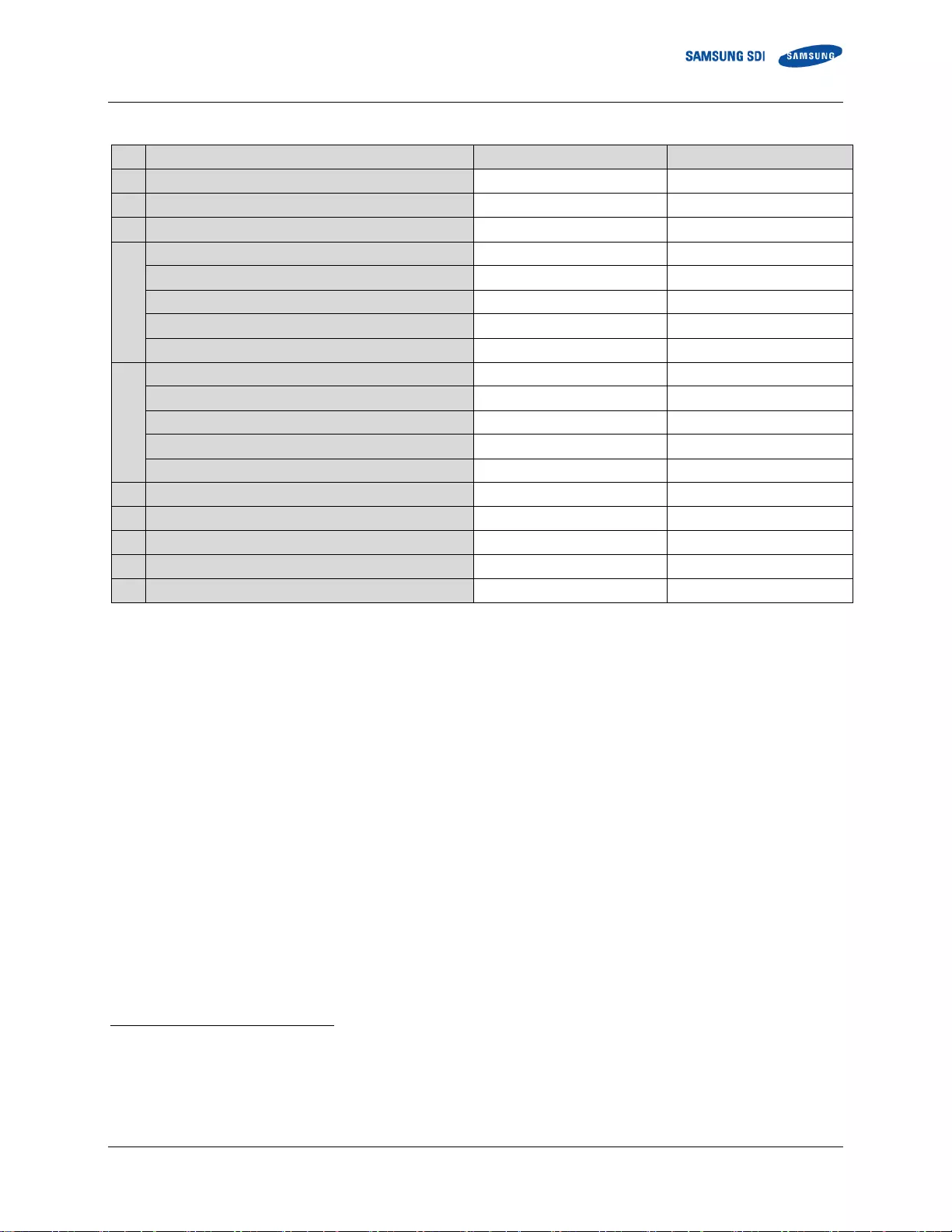

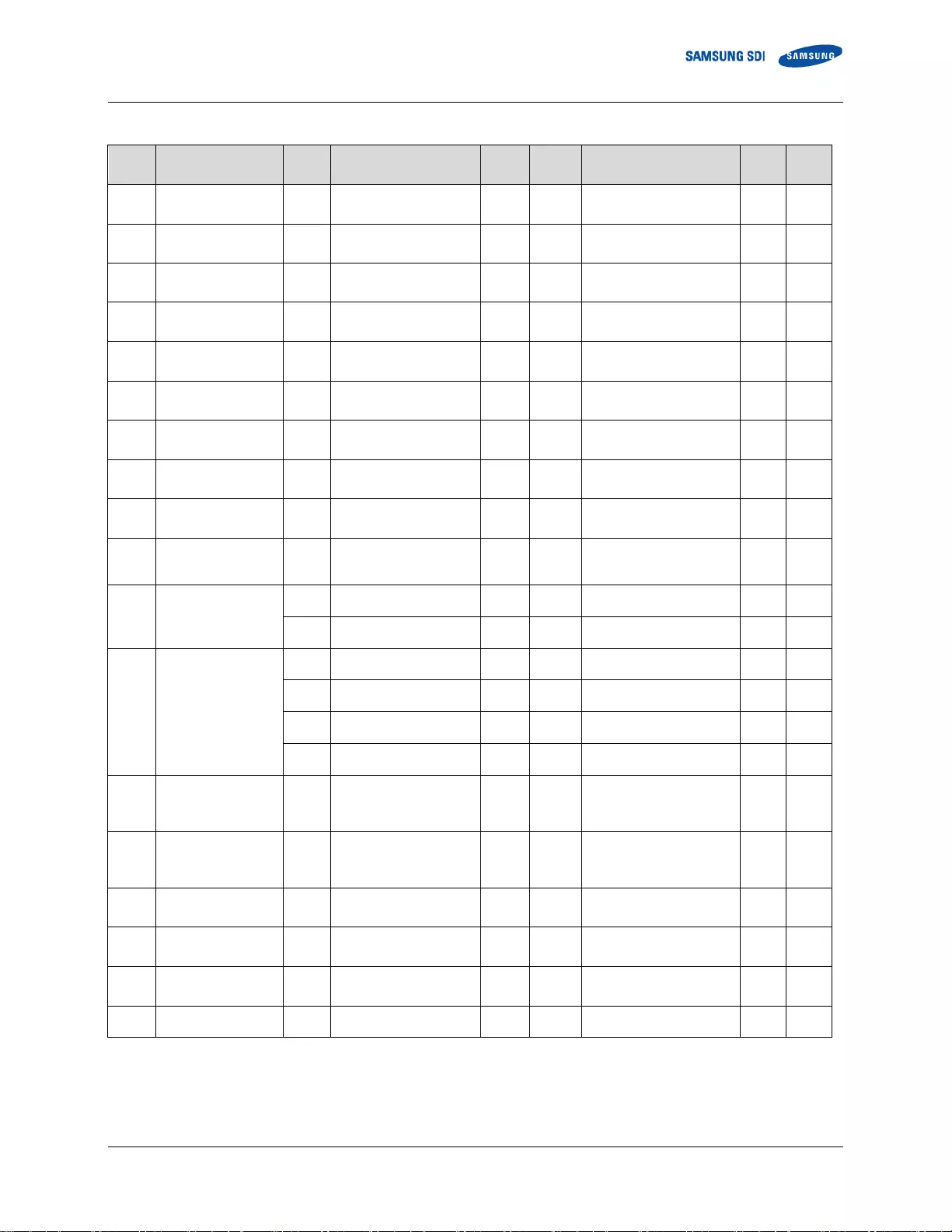

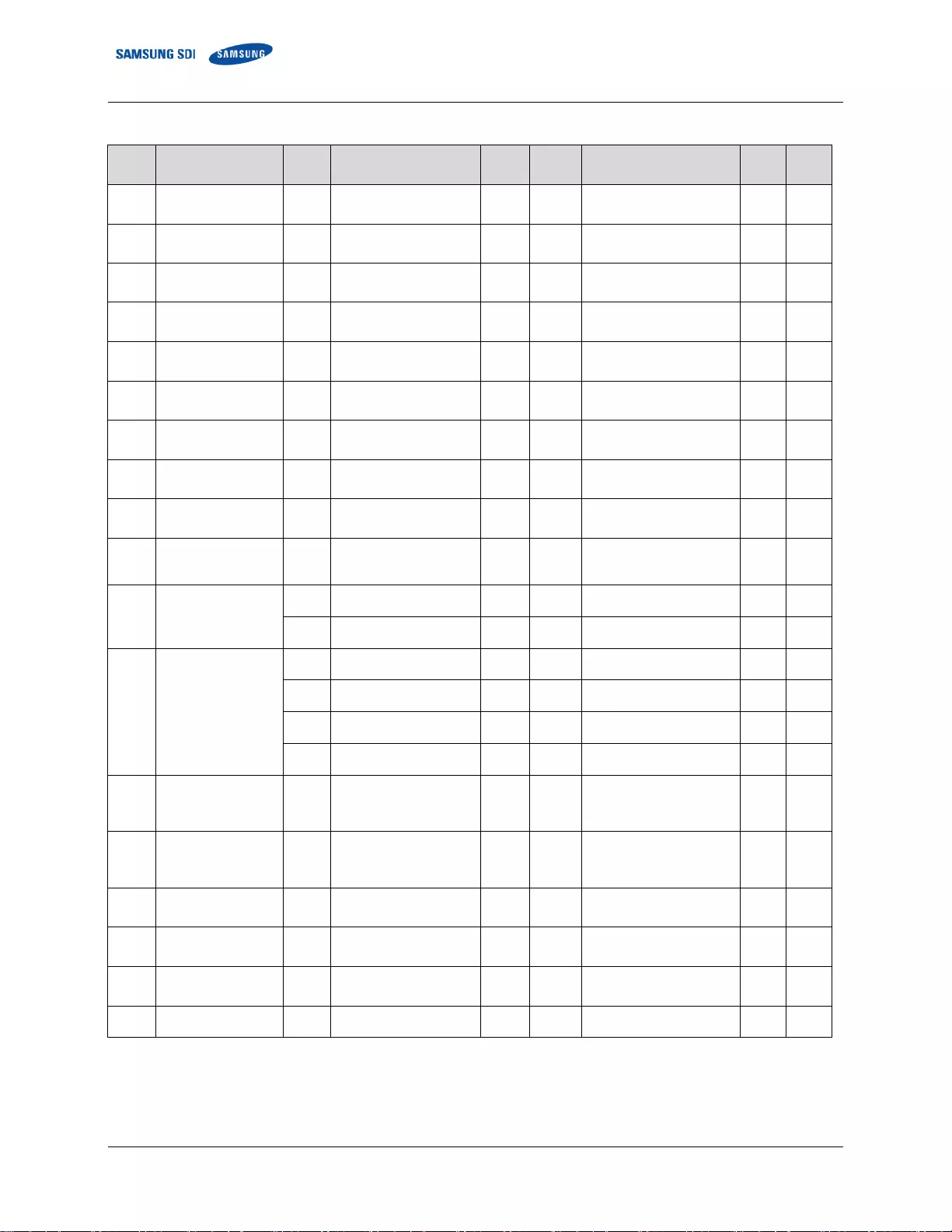

When the operating limits of the battery system are exceeded, protective measures are taken autonomously to

protect the system from failure. The following table lists the protective functions and their actions.

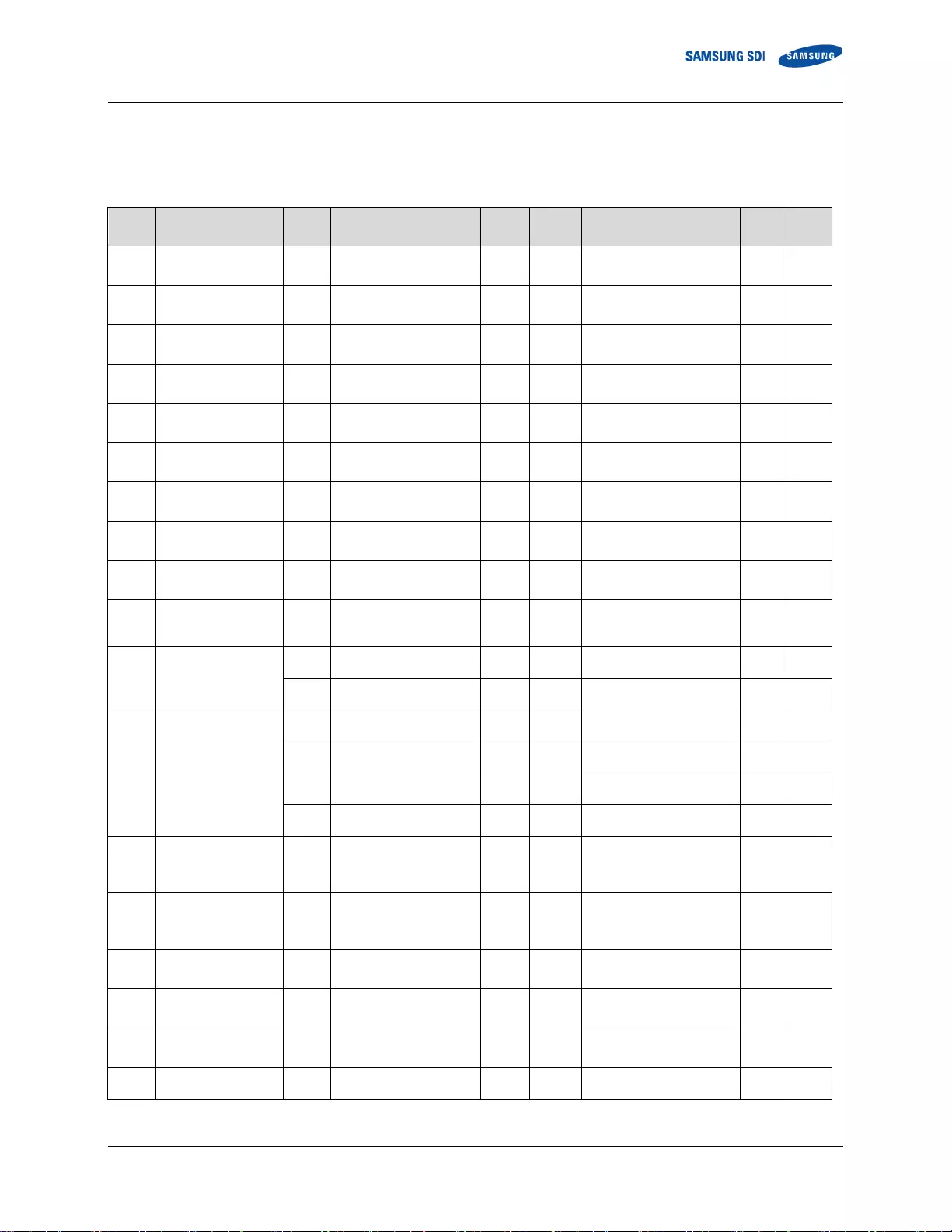

Table 3-15. Protective Functions (136S Configuration)

No

Items

Level

SET Condition

Time

(Sec)

MCCB

Release Condition

Time

(Sec)

MCCB

1

Over Voltage

Protection - Cell

Major

Max Cell ≥ 4.28V

5

OFF

Max Cell < 4.25V & Reset

5

ON

2

Under Voltage

Protection - Cell

Major

Min Cell ≤ 2.5V

3

OFF

Min Cell > 2.70V& Reset

3

ON

3

Over Voltage

Protection - Rack

Major

Rack Voltage ≥ 582.08V

5

OFF

Rack Voltage < 578V &

Reset

5

ON

4

Under Voltage

Protection - Rack

Major

Rack Voltage ≤ 340

3

OFF

Rack Voltage > 367.2V

& Reset

3

ON

5

Voltage Imbalance

Major

Max Cell ≥ 3.80V &

△Vcell ≥ 100mV

5

OFF

△Vcell < 30mV & Reset

5

ON

6

Voltage Sensing Error

(Rack)

Minor

│Rack V - Cell Sum V│

≥40.8V

10

ON

│Rack V - Cell Sum V│

< 20.4V & Reset

3

ON

7

Voltage Sensing Error

(Module)

Minor

│Module V - Cell Sum V│

≥190mV

5

ON

│Module V - Cell Sum V│

< 190mV & Reset

3

ON

8

Over Temperature

Protection

Major

Max Temp ≥ 75℃

3

OFF

Max Temp < 65℃ & Reset

3

ON

9

Under Temperature

Protection

Minor

Min Temp ≤ 0℃

3

ON

Min Temp > 5℃ & Reset

3

ON

10

Temperature

imbalance

Major

Max Cell T - Min Cell T

≥ 40℃

30

OFF

Max Cell T - Min Cell T

< 20℃ & Reset

3

ON

11

Over Current

Protection

(Charge)

Major

Level2 Current ≥ 250A

2

OFF

|Current| < 10A & Reset

3

ON

Major

Level1 Current ≥ 200A

60

OFF

|Current| < 10A & Reset

3

ON

12

Over Current

Protection

(Discharge)

Major

Lvel4 |Current| ≥ 600A

1

OFF

|Current| < 10A & Reset

3

ON

Major

Level3 |Current| ≥ 540A

10

OFF

|Current| < 10A & Reset

3

ON

Major

Level2 |Current| ≥ 495A

30

OFF

|Current| < 10A & Reset

3

ON

Major

Level1 |Current| ≥ 470A

60

OFF

|Current| < 10A & Reset

3

ON

13

Communication

Failure

(Module ↔ Rack)

Major

No Communication

30

OFF

Re Communication &

Reset

-

ON

14

Communication

Failure

(Rack ↔ System )

Major

No Communication

30

OFF

Re Communication &

Reset

-

ON

15

SW Failure - MCCB

Minor

MCCB OFF & |Current|

≥ 2.4A

3

ON

(MCCB OFF & (|Current| <

2.4A) & Reset

-

ON

16

SW Sensor Failure -

MCCB

Minor

MCCB contact ON

= MCCB Trip ON

3

ON

(MCCB contact ≠ MCCB

Trip) & Reset

-

ON

17

Current Sensing Error

Minor

No communication

with Current IC

3

ON

Re communication

with Current IC

-

ON

18

Fuse Failure

Minor

Fuse Blown

10

ON

Fuse ON & Reset

-

ON

3. Battery System Operation CONFIDENTIAL

28 English 8/2019. Rev 0.0

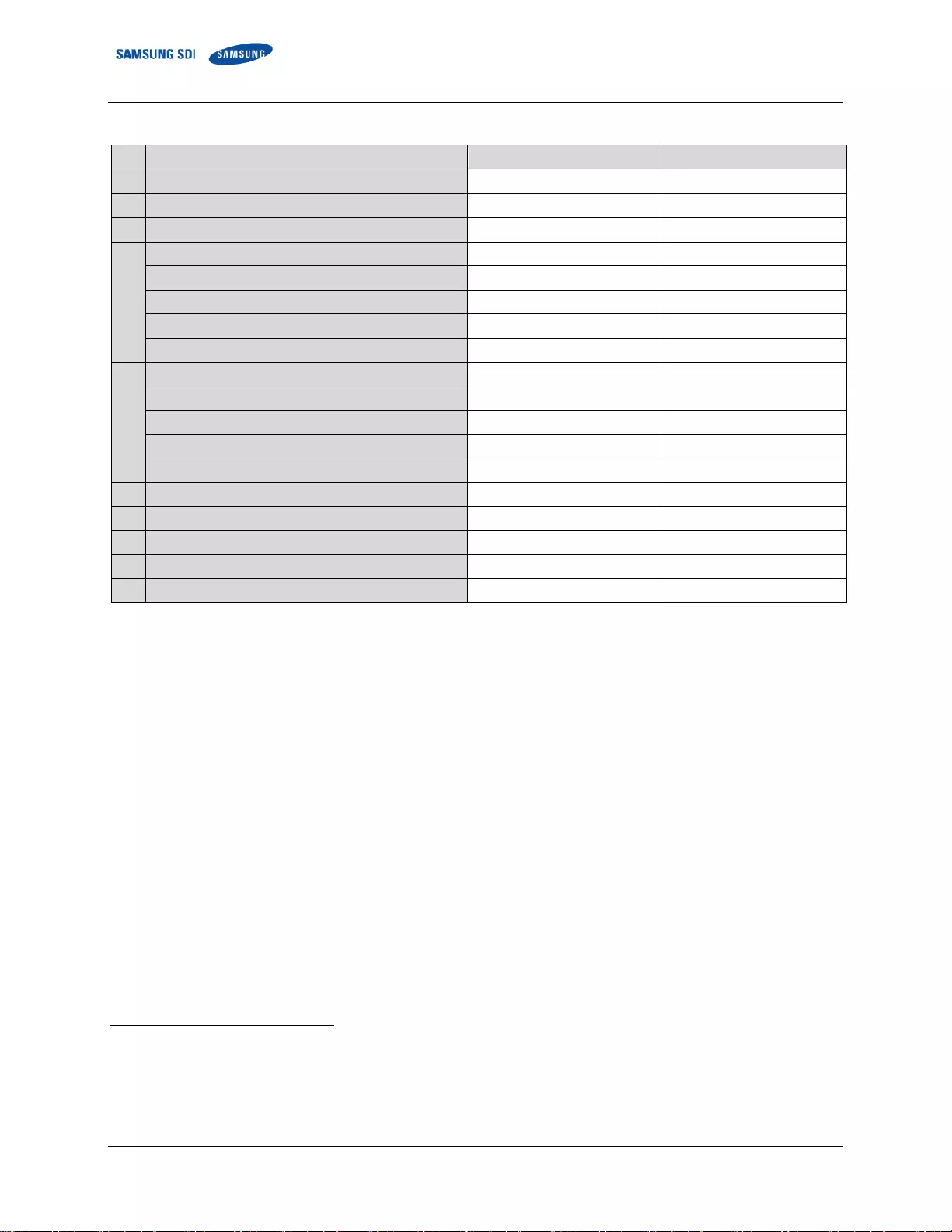

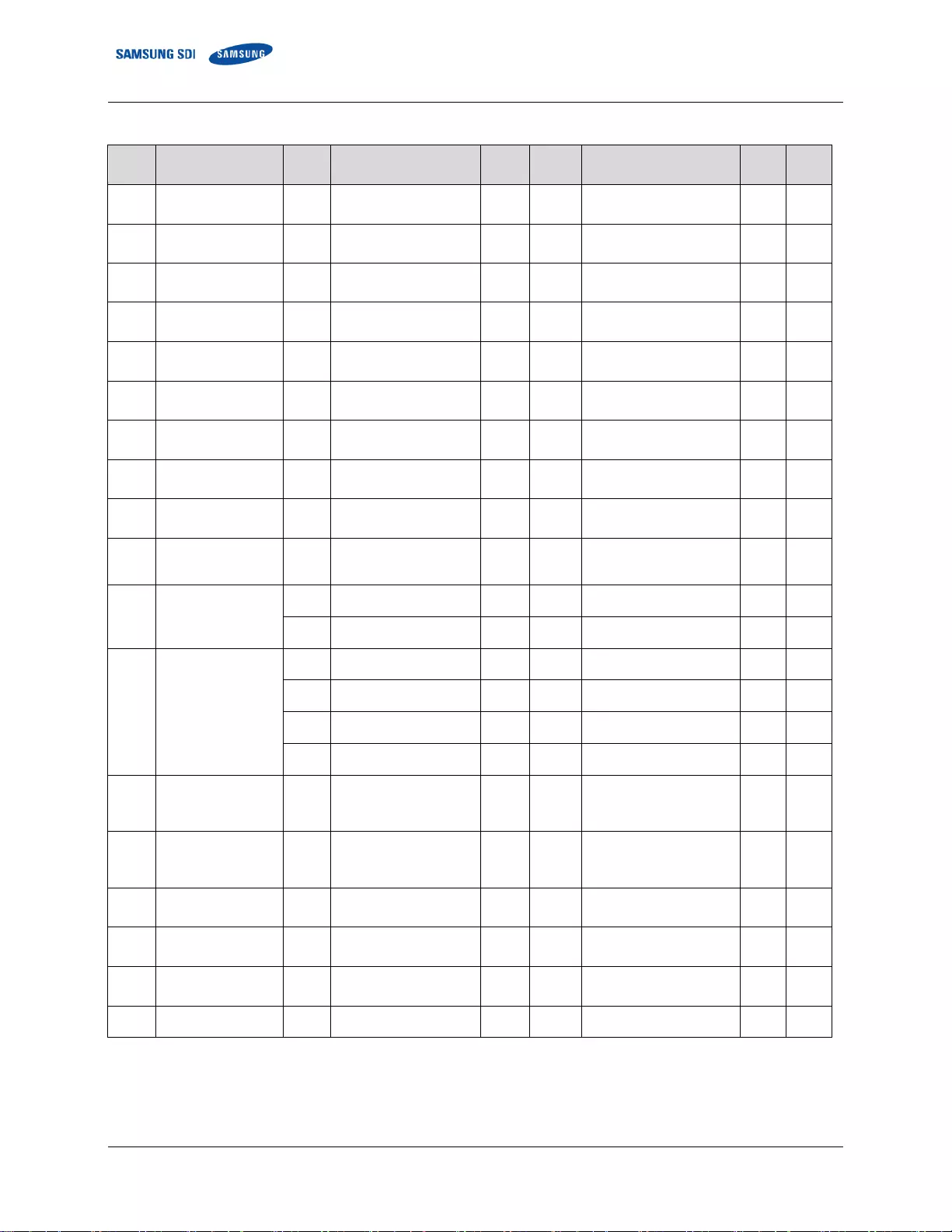

Table 3-16. Protective Functions (128S Configuration)

No

Items

Level

SET Condition

Time

(Sec)

MCCB

Release Condition

Time

(Sec)

MCCB

1

Over Voltage

Protection - Cell

Major

Max Cell ≥ 4.28V

5

OFF

Max Cell < 4.25V & Reset

5

ON

2

Under Voltage

Protection - Cell

Major

Min Cell ≤ 2.5V

3

OFF

Min Cell > 2.70V& Reset

3

ON

3

Over Voltage

Protection - Rack

Major

Rack Voltage ≥ 547.84V

5

OFF

Rack Voltage < 544V &

Reset

5

ON

4

Under Voltage

Protection - Rack

Major

Rack Voltage ≤ 320

3

OFF

Rack Voltage > 345.6V

& Reset

3

ON

5

Voltage Imbalance

Major

Max Cell ≥ 3.80V &

△Vcell ≥ 100mV

5

OFF

△Vcell < 30mV & Reset

5

ON

6

Voltage Sensing Error

(Rack)

Minor

│Rack V - Cell Sum V│

≥38.4V

10

ON

│Rack V - Cell Sum V│

< 19.2V & Reset

3

ON

7

Voltage Sensing Error

(Module)

Minor

│Module V - Cell Sum V│

≥190mV

5

ON

│Module V - Cell Sum V│

< 190mV & Reset

3

ON

8

Over Temperature

Protection

Major

Max Temp ≥ 75℃

3

OFF

Max Temp < 65℃ & Reset

3

ON

9

Under Temperature

Protection

Minor

Min Temp ≤ 0℃

3

ON

Min Temp > 5℃ & Reset

3

ON

10

Temperature

imbalance

Major

Max Cell T - Min Cell T

≥ 40℃

30

OFF

Max Cell T - Min Cell T

< 20℃ & Reset

3

ON

11

Over Current

Protection

(Charge)

Major

Level2 Current ≥ 250A

2

OFF

|Current| < 10A & Reset

3

ON