Table of Contents

- Safety

- General Information

- Unit Overview

- Component Identification

- Dimensions and Weights

- Diagrams

- Installation

- Unit Connections

- Charging the Refrigeration System

- Worldwide Customer Support

APC MRA0221I User Manual

Displayed below is the user manual for MRA0221I by APC which is a product in the Split-System Air Conditioners category. This manual has pages.

Related Manuals

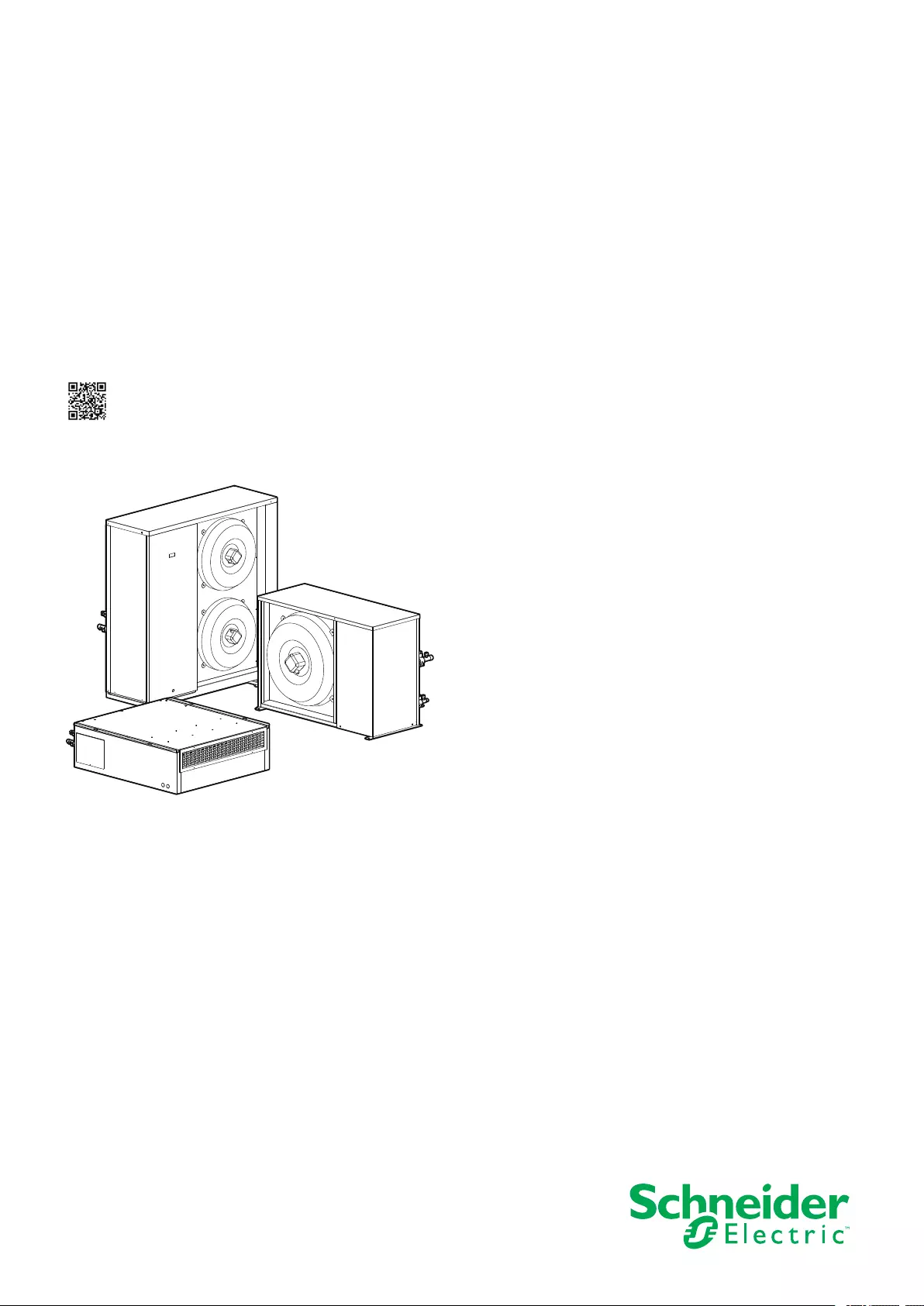

Uniflair™SP

Uniflair™UCF, MRA

Installation Manual

990-91229A-001

06MM0368@00B0110

Release Date: 05/2019

www.schneider-electric.com

Legal Information

The Schneider Electric brand and any trademarks of Schneider Electric SE and its

subsidiaries referred to in this guide are the property of Schneider Electric SE or its

subsidiaries. All other brands may be trademarks of their respective owners.

This guide and its content are protected under applicable copyright laws and

furnished for informational use only. No part of this guide may be reproduced or

transmitted in any form or by any means (electronic, mechanical, photocopying,

recording, or otherwise), for any purpose, without the prior written permission of

Schneider Electric.

Schneider Electric does not grant any right or license for commercial use of the guide

or its content, except for a non-exclusive and personal license to consult it on an "as

is" basis. Schneider Electric products and equipment should be installed, operated,

serviced, and maintained only by qualified personnel.

As standards, specifications, and designs change from time to time, information

contained in this guide may be subject to change without notice.

To the extent permitted by applicable law, no responsibility or liability is assumed by

Schneider Electric and its subsidiaries for any errors or omissions in the informational

content of this material or consequences arising out of or resulting from the use of the

information contained herein.

Uniflair™UCF, MRA

Table of Contents

Safety............................................................................................................5

Important Safety Instructions — SAVE THESE INSTRUCTIONS....................5

Safety During Installation ............................................................................6

Symbols on Unit or Packaging ...............................................................7

Intended Use........................................................................................7

General Information....................................................................................8

Document Overview ...................................................................................8

Save These Instructions ........................................................................8

Manual Updates ...................................................................................8

Cross-Reference Symbol Used in This Manual........................................8

Documentation Included with the Unit.....................................................9

Compliance................................................................................................9

Receiving and Inspecting the Cooling Unit..................................................10

Filing a Claim......................................................................................10

Storing the Cooling Unit Before Installation ................................................. 11

Moving the Unit ........................................................................................ 11

Equipment Disposal..................................................................................12

Waste Electrical and Electronic Equipment (WEEE) Disposal.................12

Radio Frequency Interference ...................................................................12

California Proposition 65—Warning Statement for California

Residents ................................................................................................12

Equipment Guidelines...............................................................................13

Working Conditions and Environmental Limits.......................................13

Unit Overview ............................................................................................14

Model Nomenclature.................................................................................14

Indoor Units........................................................................................14

Outdoor Units .....................................................................................14

Nameplate Example .................................................................................15

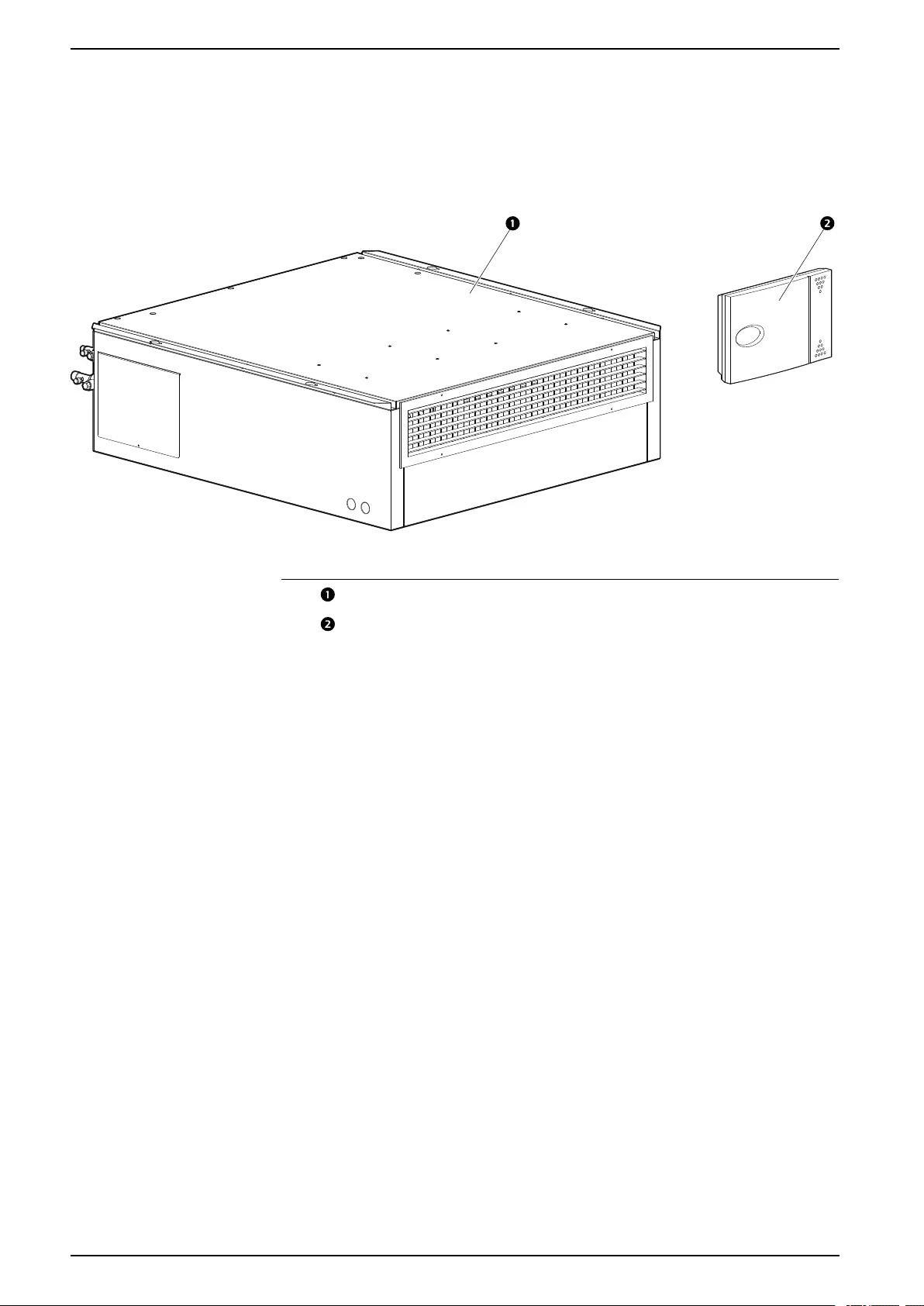

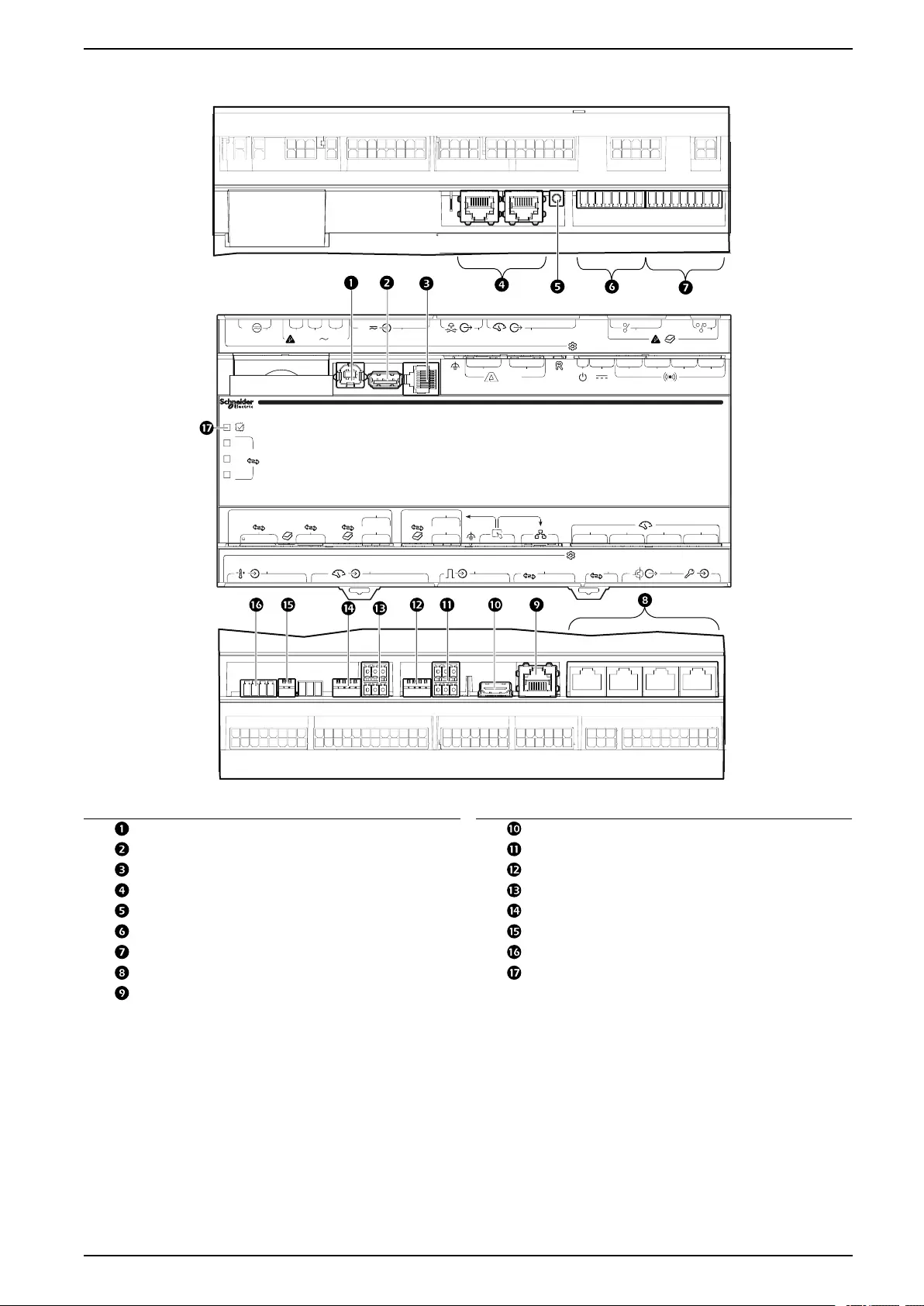

Component Identification.........................................................................16

Inventory..................................................................................................16

UCF0341I and UCF0481I ....................................................................16

MRA0221I..........................................................................................17

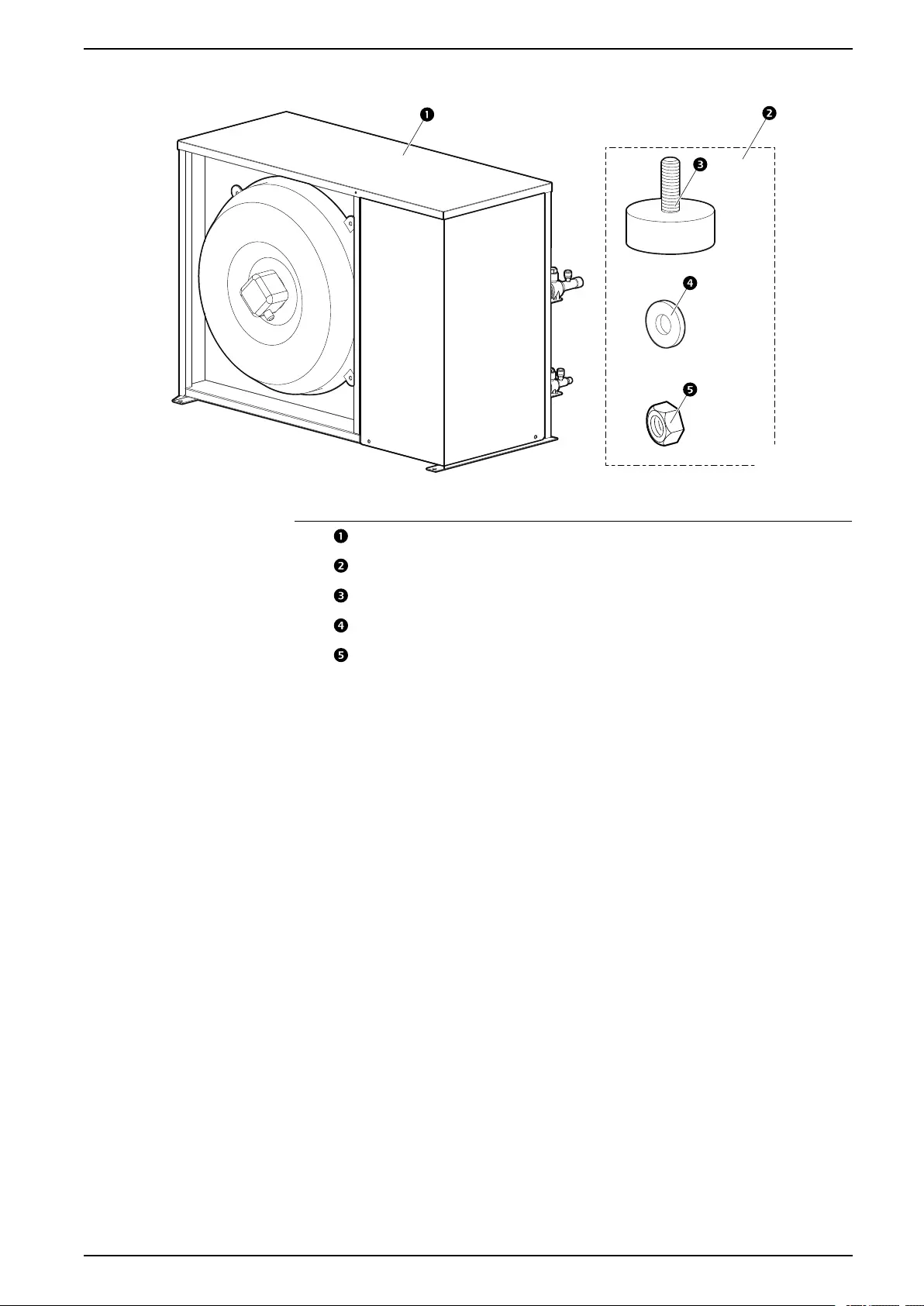

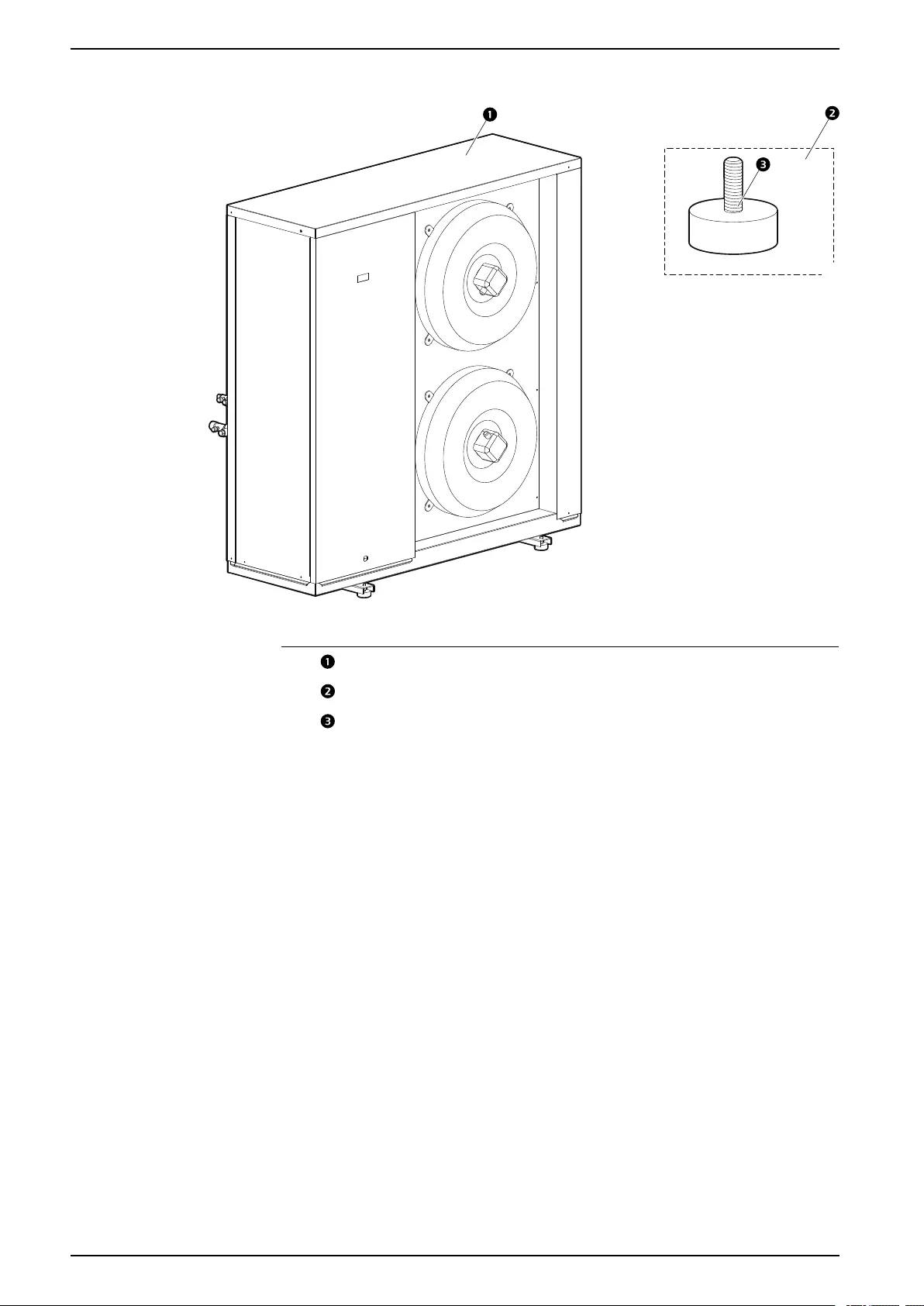

MRA0611D.........................................................................................18

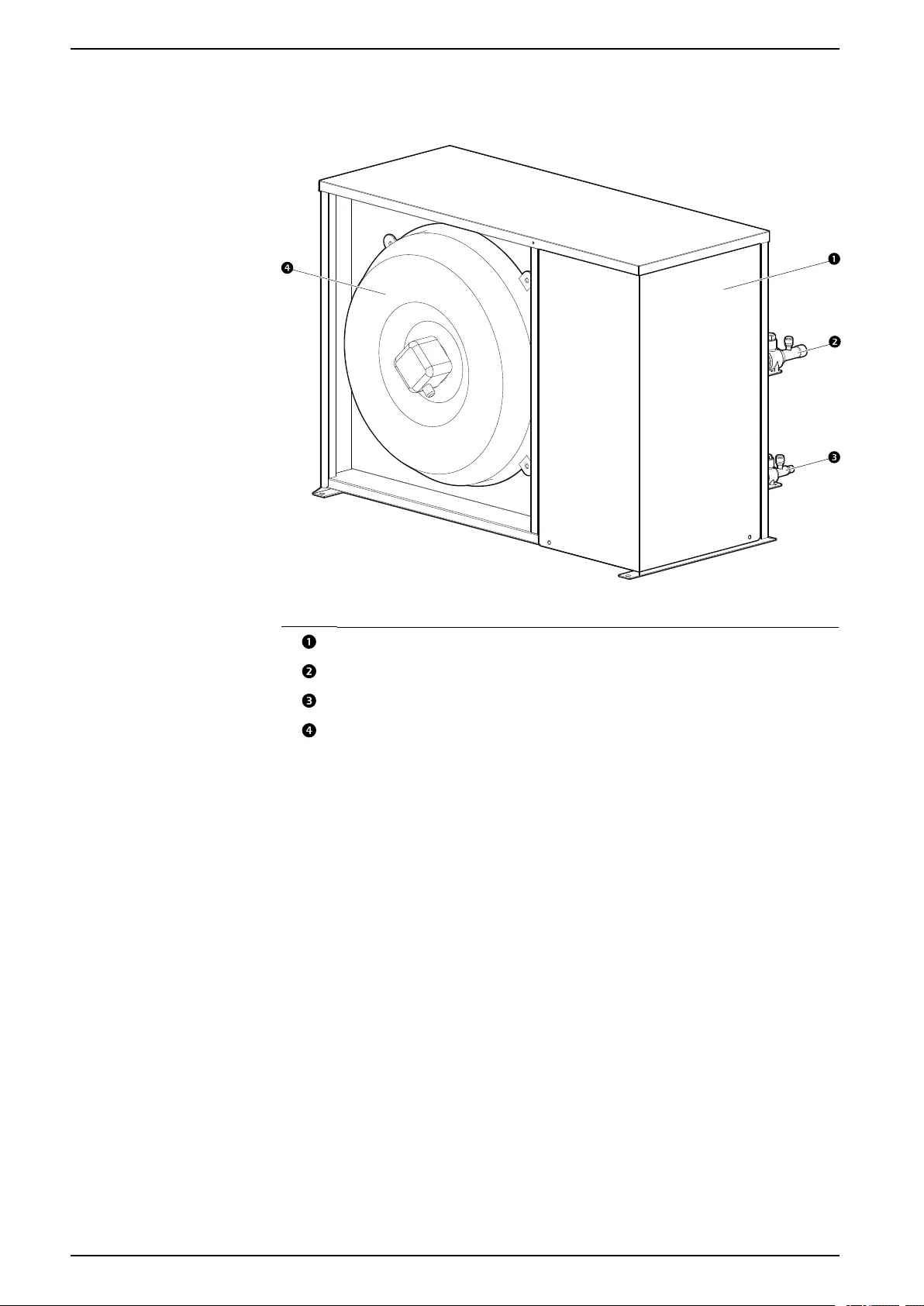

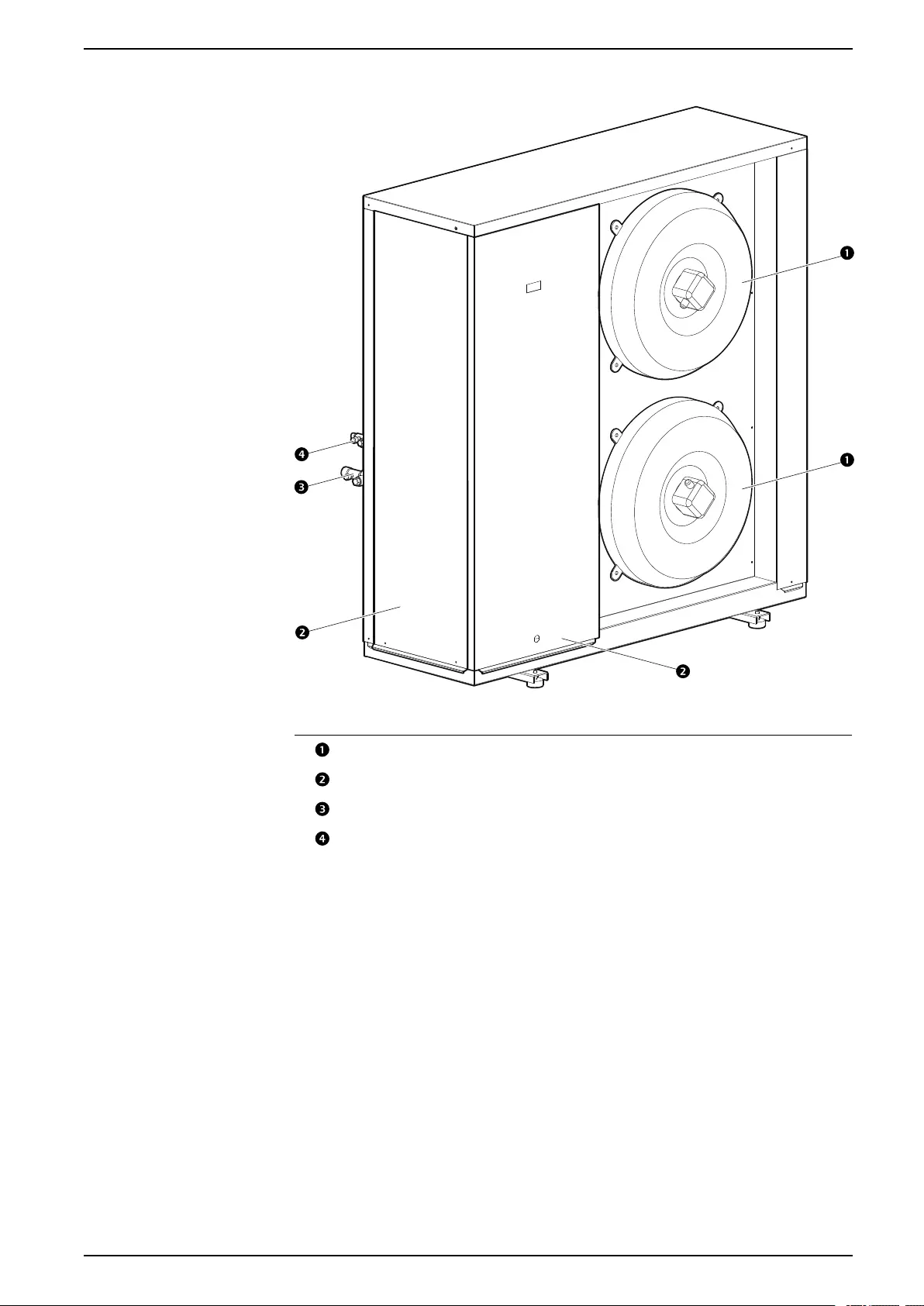

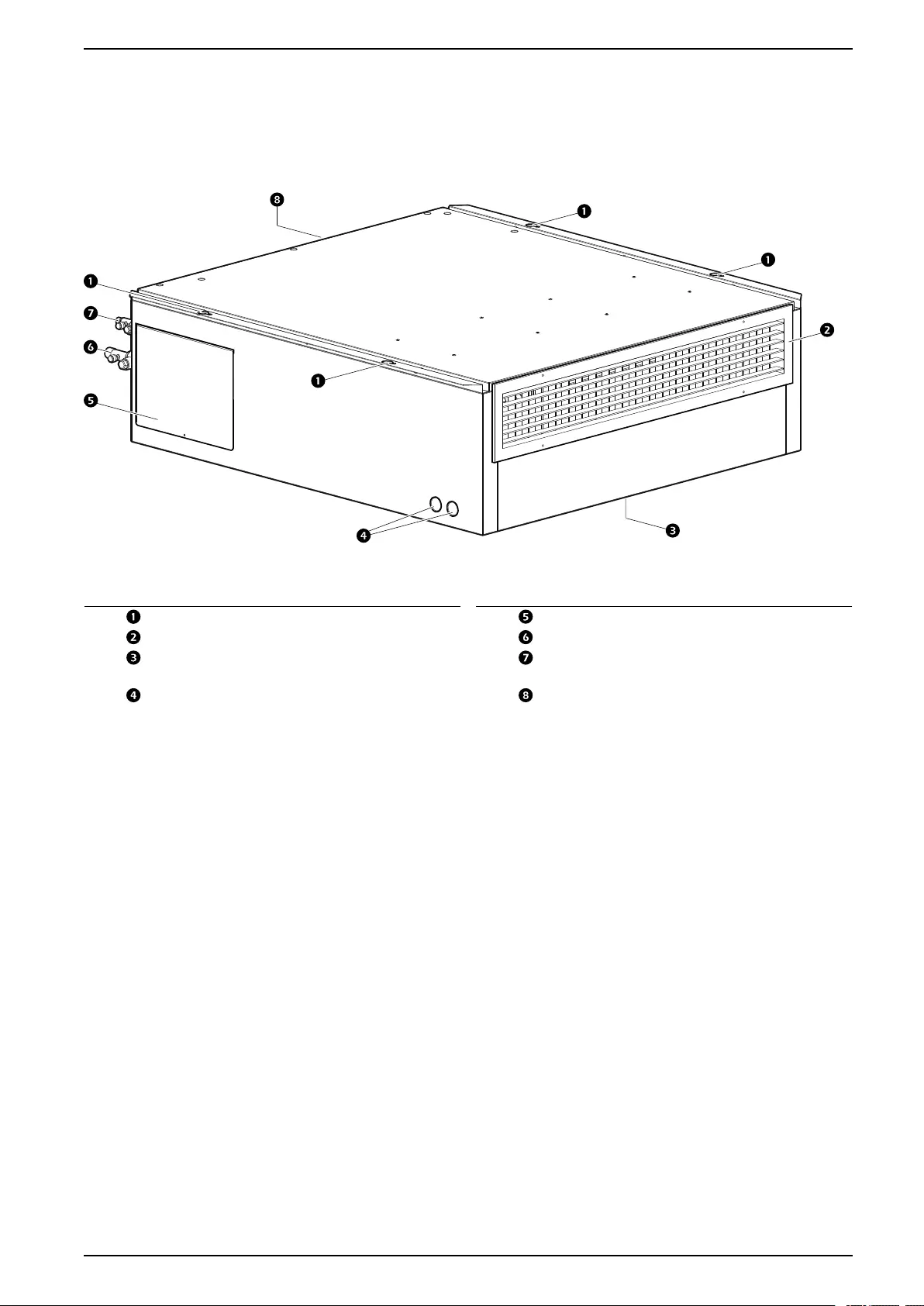

External Components ...............................................................................19

Indoor Units........................................................................................19

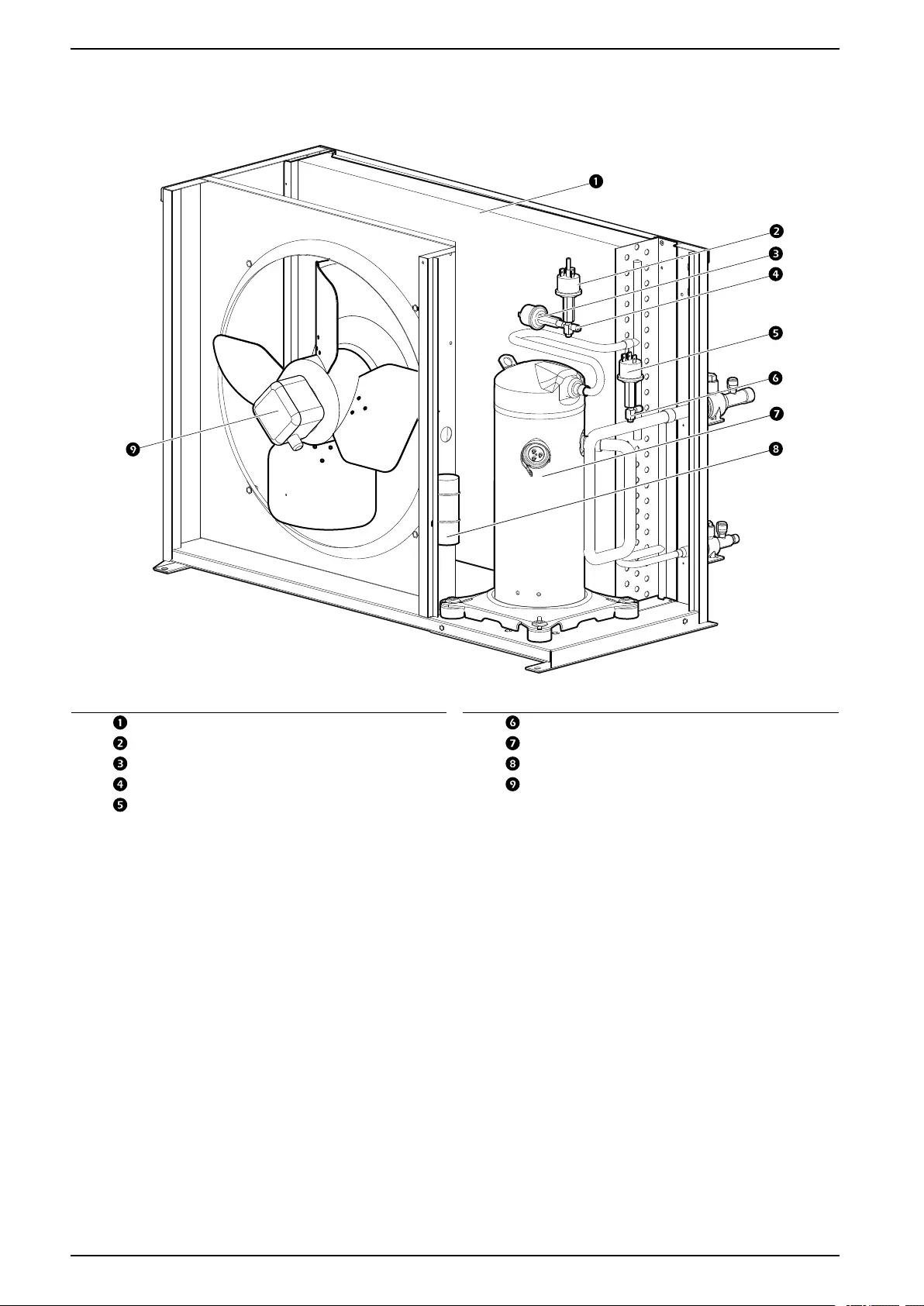

Outdoor Units .....................................................................................20

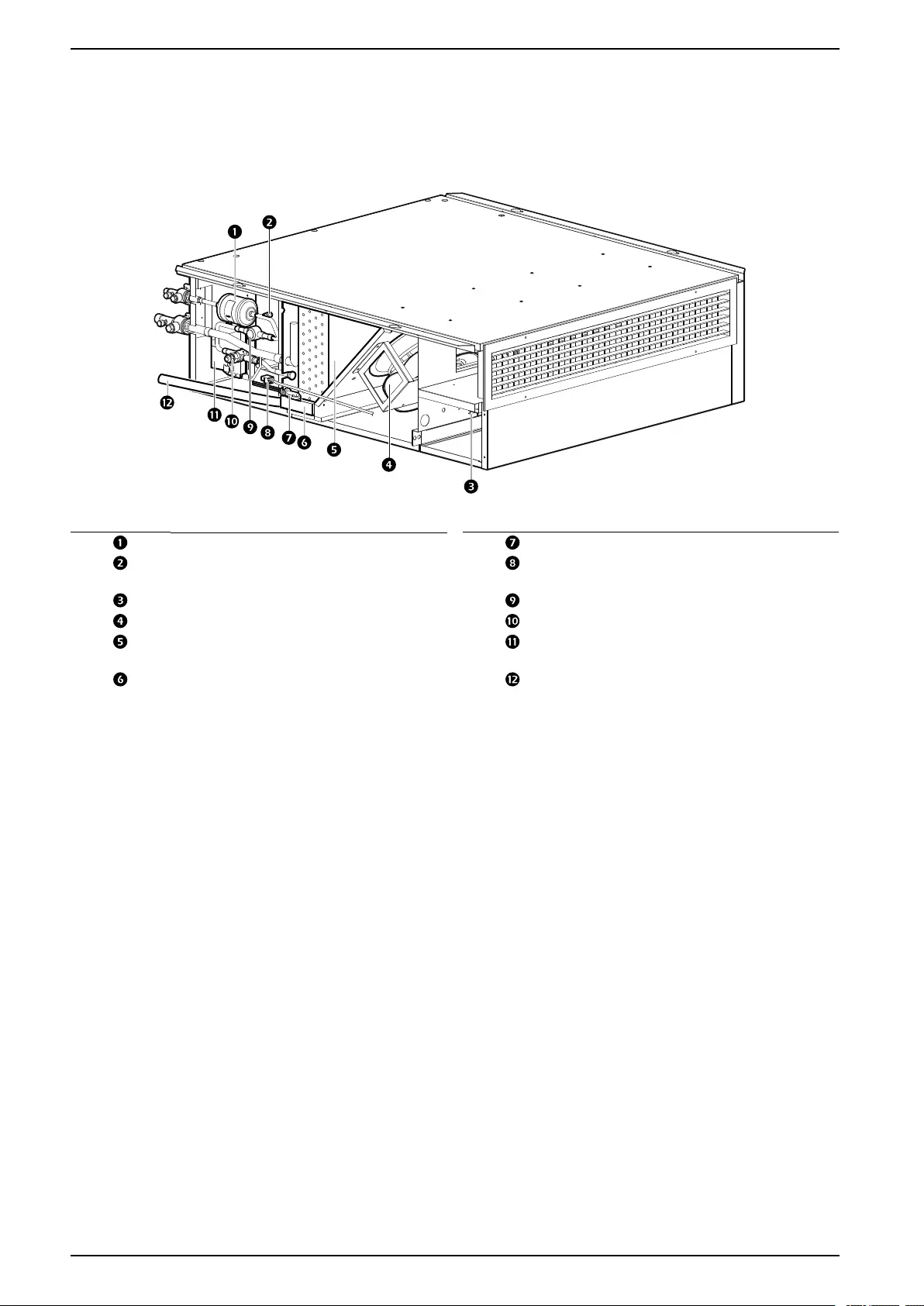

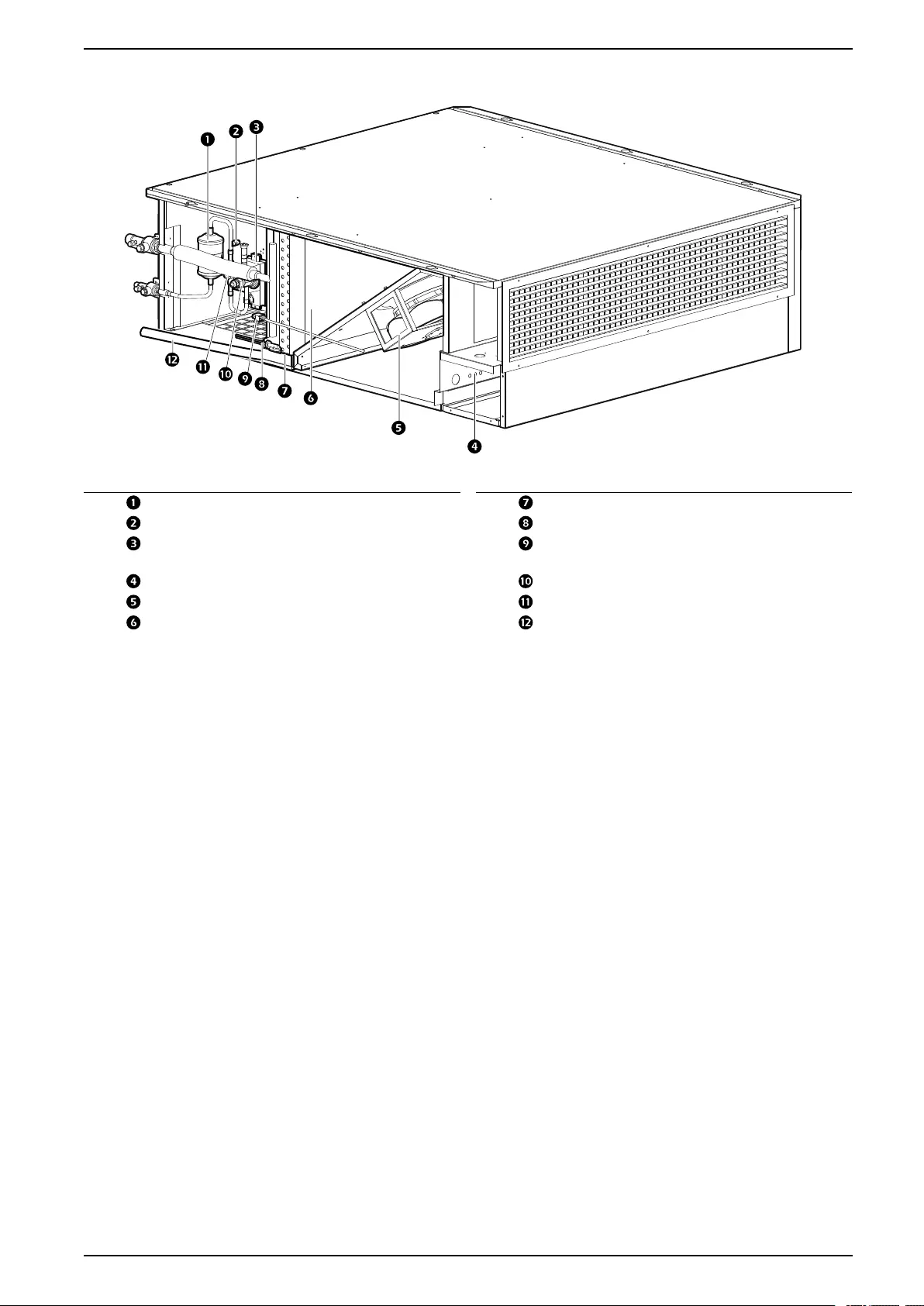

Internal Components ................................................................................22

Indoor Units........................................................................................22

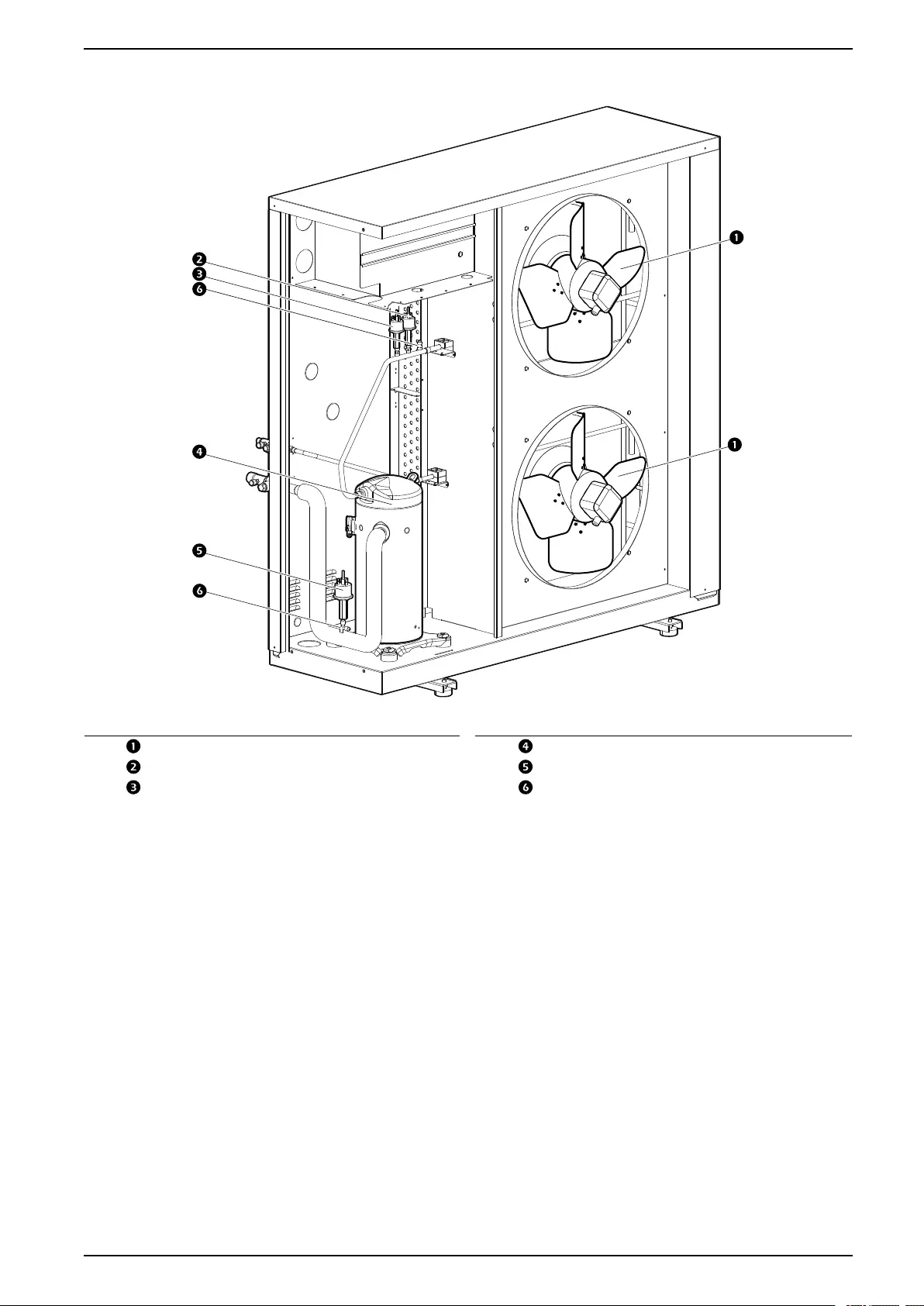

Outdoor Units .....................................................................................24

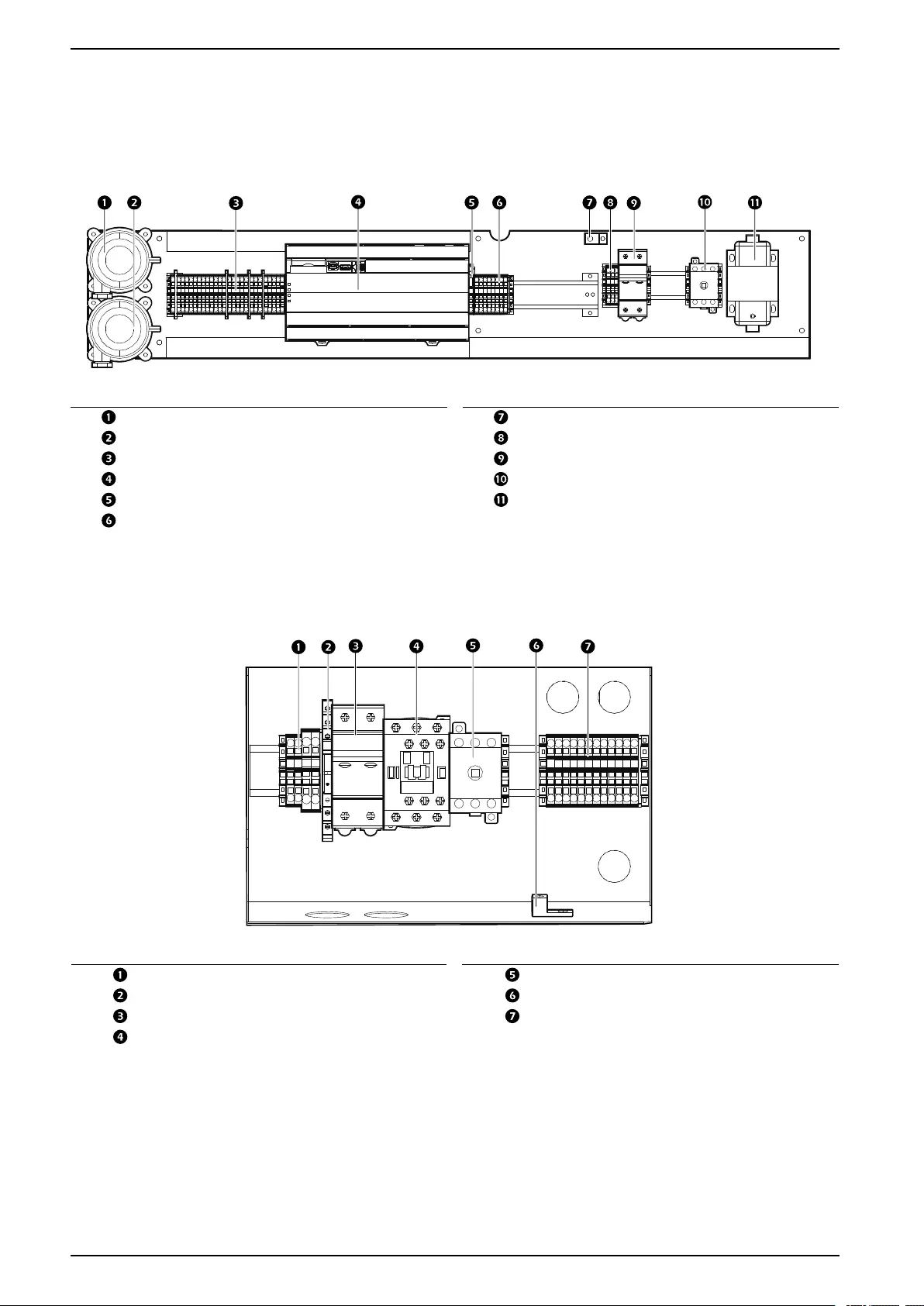

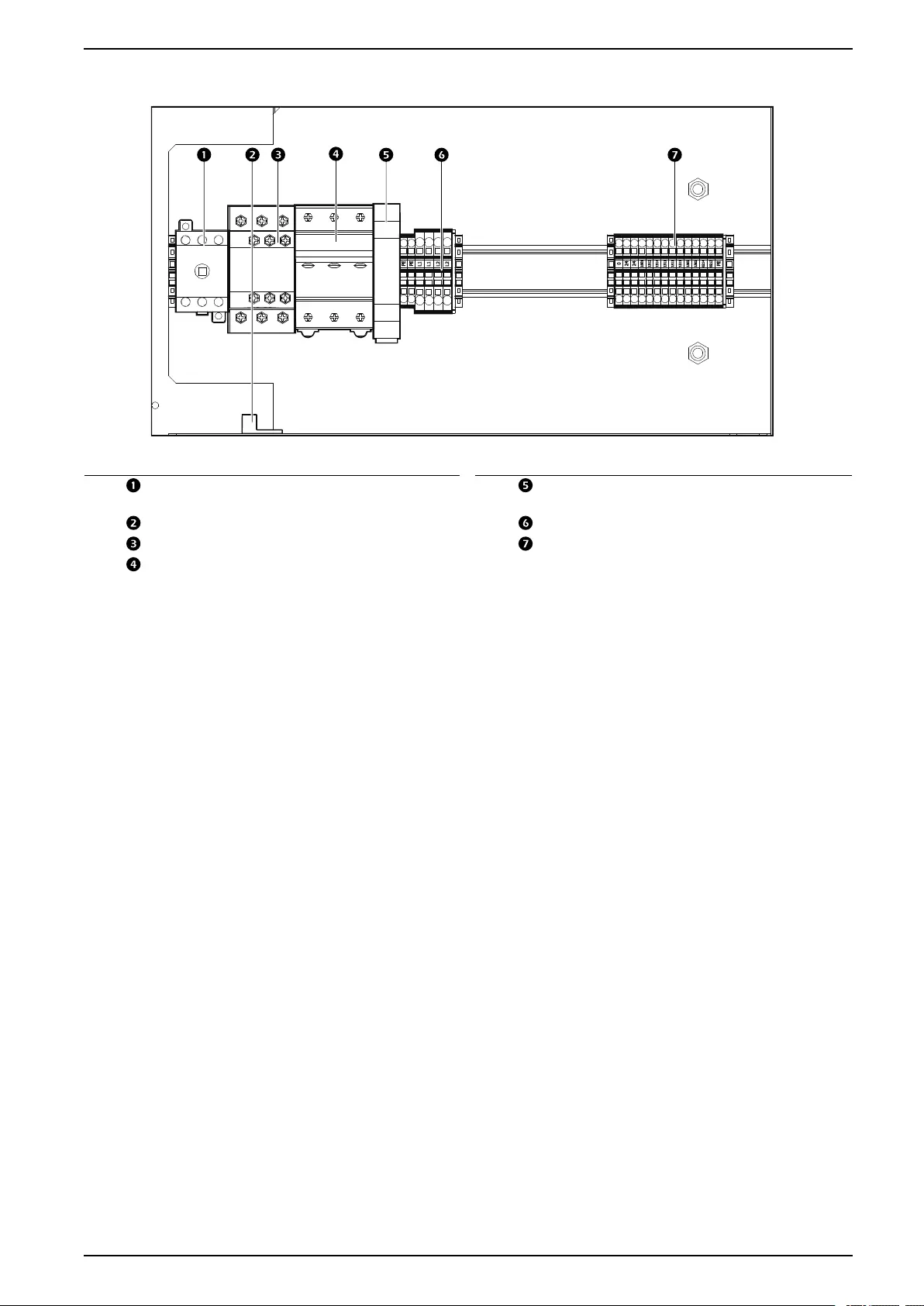

Electrical Panels.......................................................................................26

Indoor Units........................................................................................26

Outdoor Units .....................................................................................26

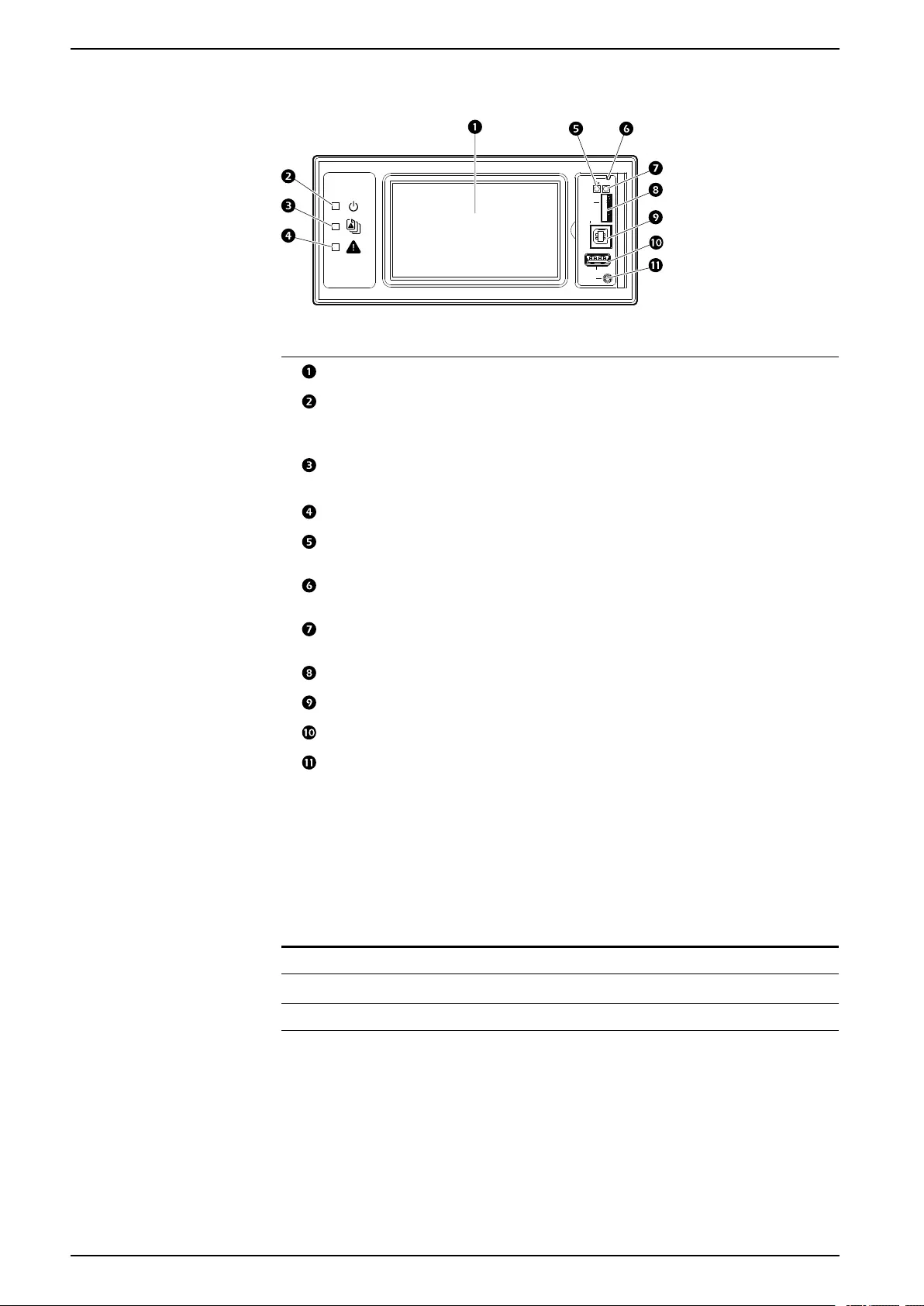

Display Interface.......................................................................................28

Alarm LED..........................................................................................28

Status LED.........................................................................................29

Link-RX/TX (10/100) LED ....................................................................29

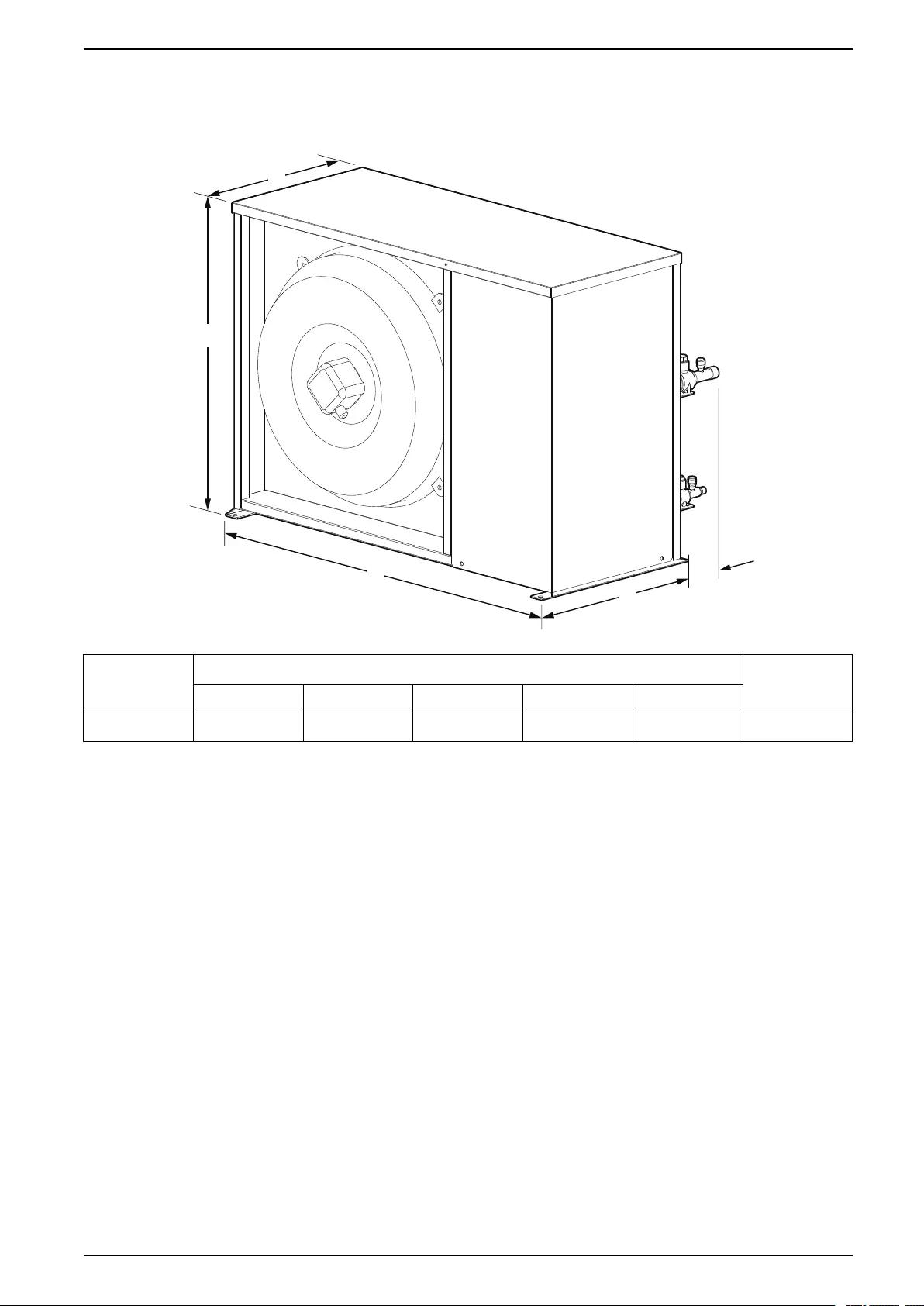

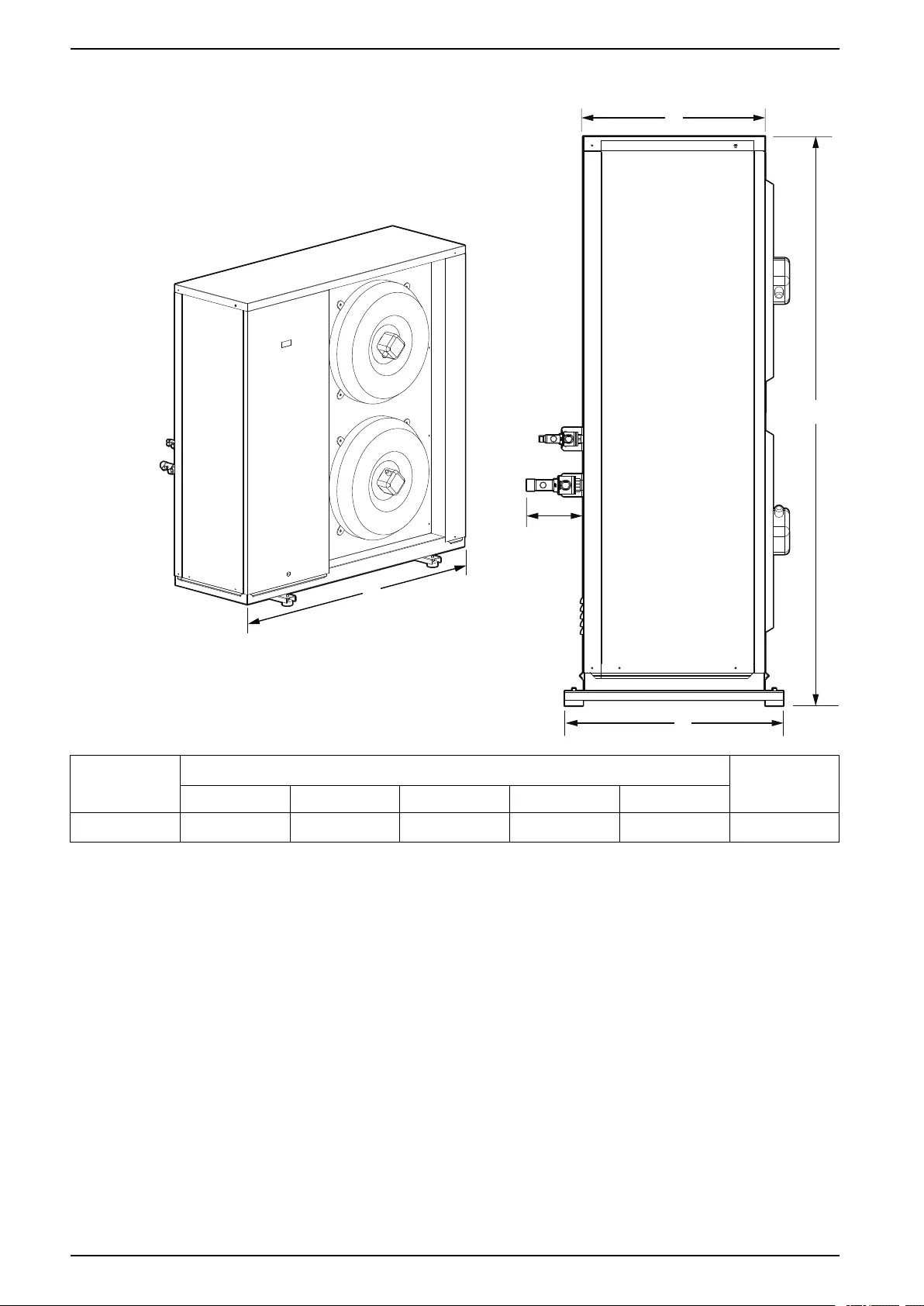

Dimensions and Weights .........................................................................30

990-91229A-001 / 06MM0368@00B0110 3

Uniflair™UCF, MRA

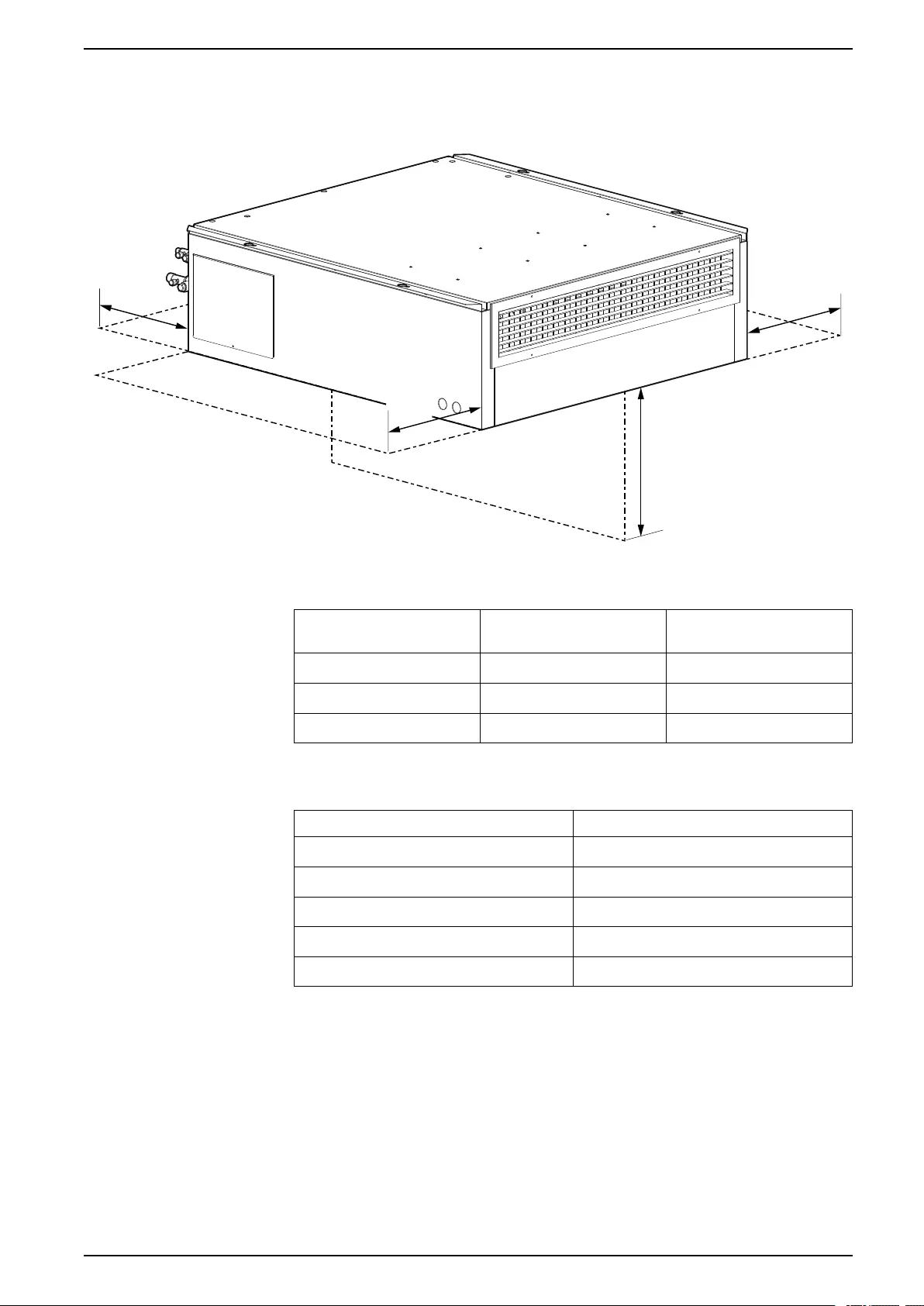

Indoor Units .............................................................................................30

Outdoor Units...........................................................................................31

Piping and Electrical Access Locations.......................................................33

Indoor Units........................................................................................33

Outdoor Units .....................................................................................35

Service Clearance ....................................................................................37

Diagrams....................................................................................................38

Refrigeration Piping Diagram.....................................................................38

Installation..................................................................................................39

Site Preparation .......................................................................................39

Positioning Units.................................................................................39

External Air Free-Cooling–UCF Units ...................................................40

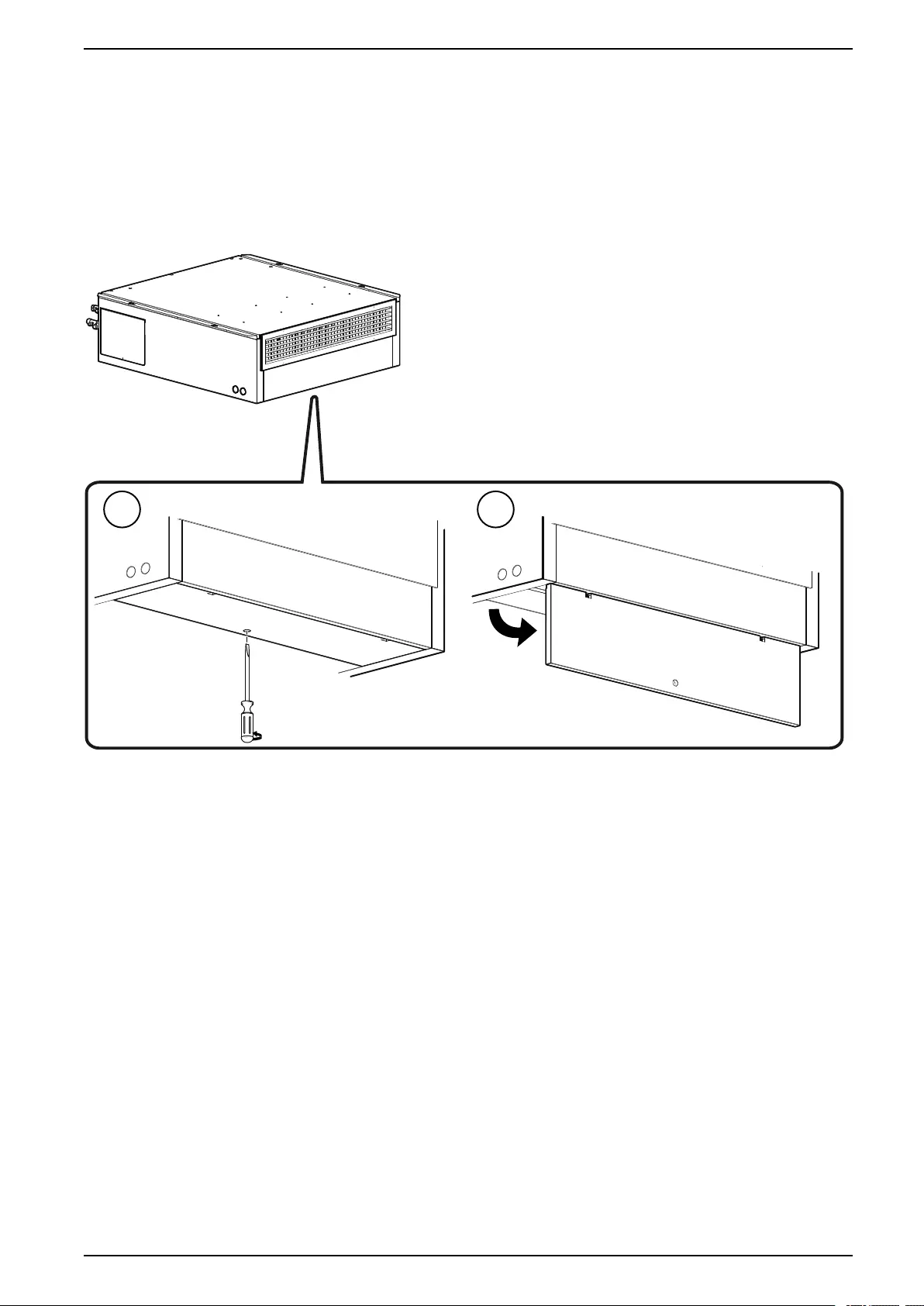

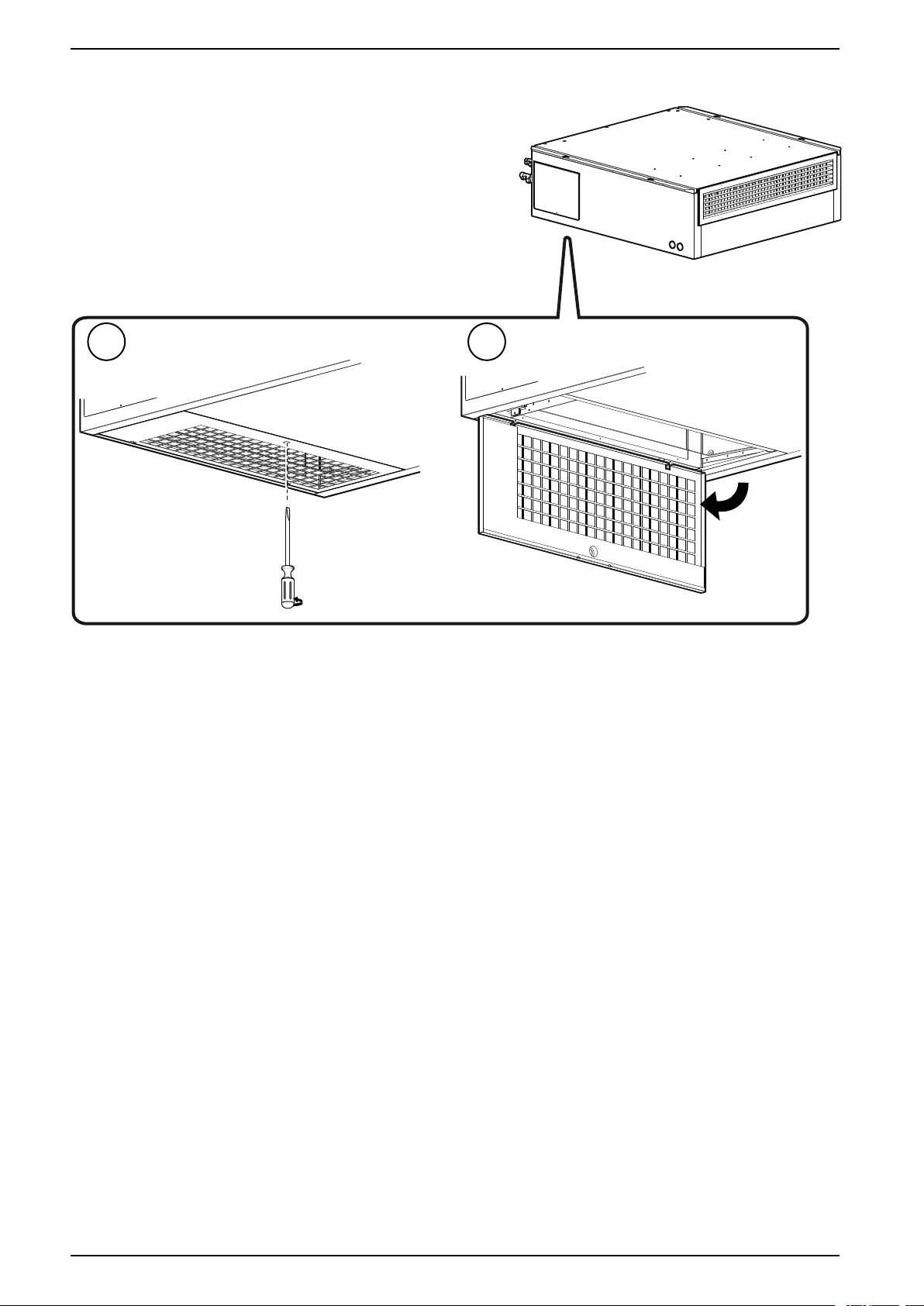

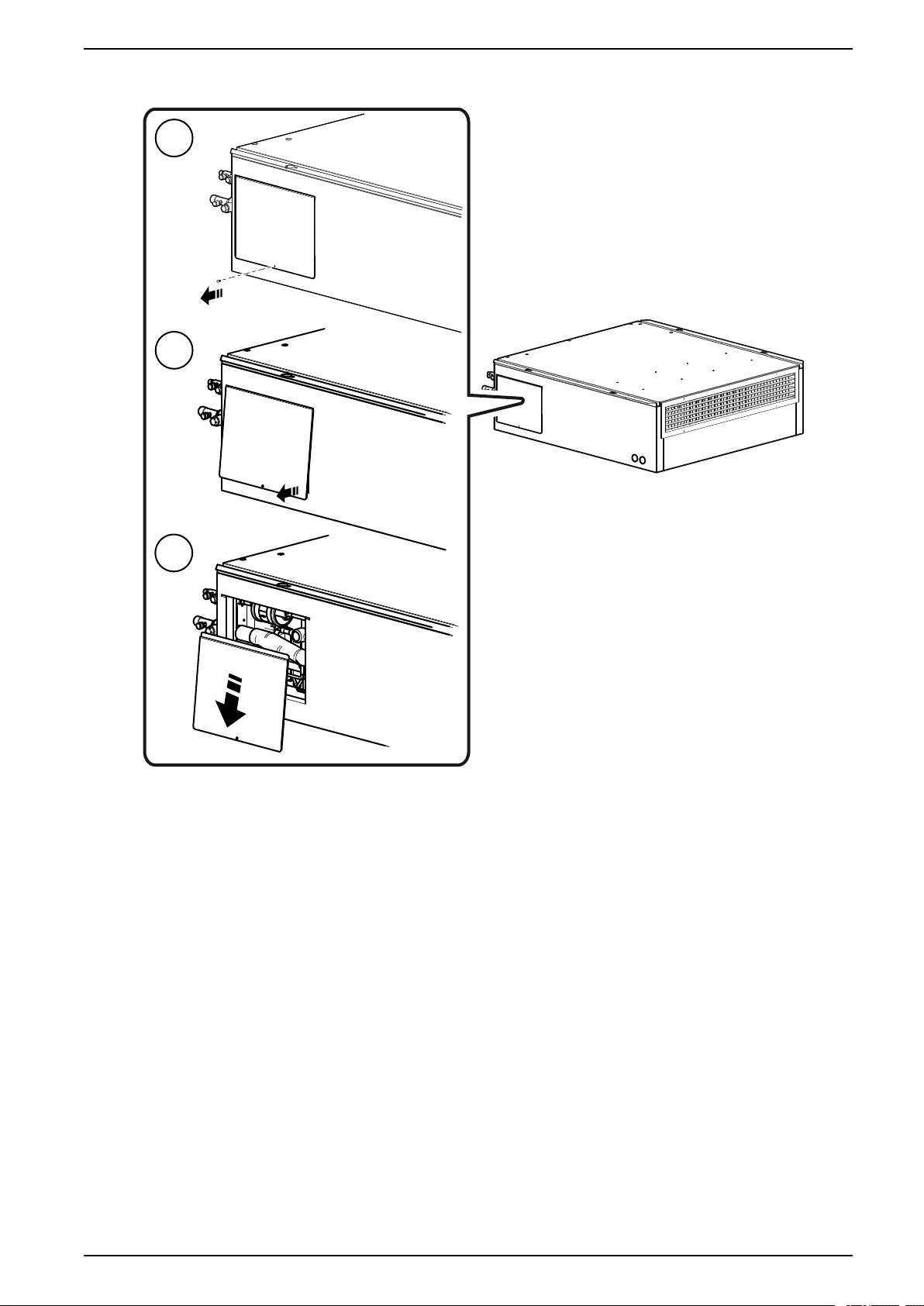

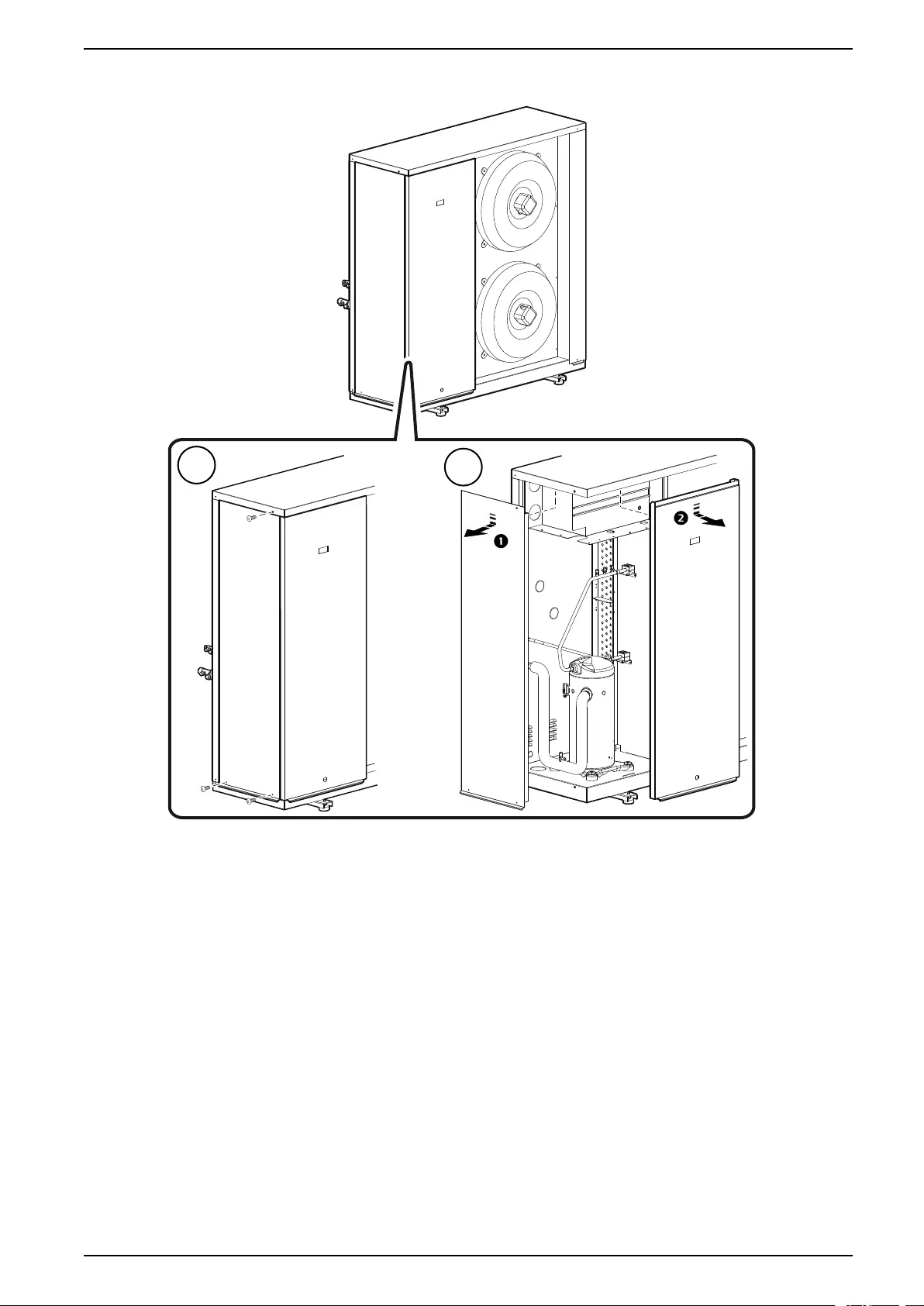

Panel Removal.........................................................................................41

Indoor Units........................................................................................41

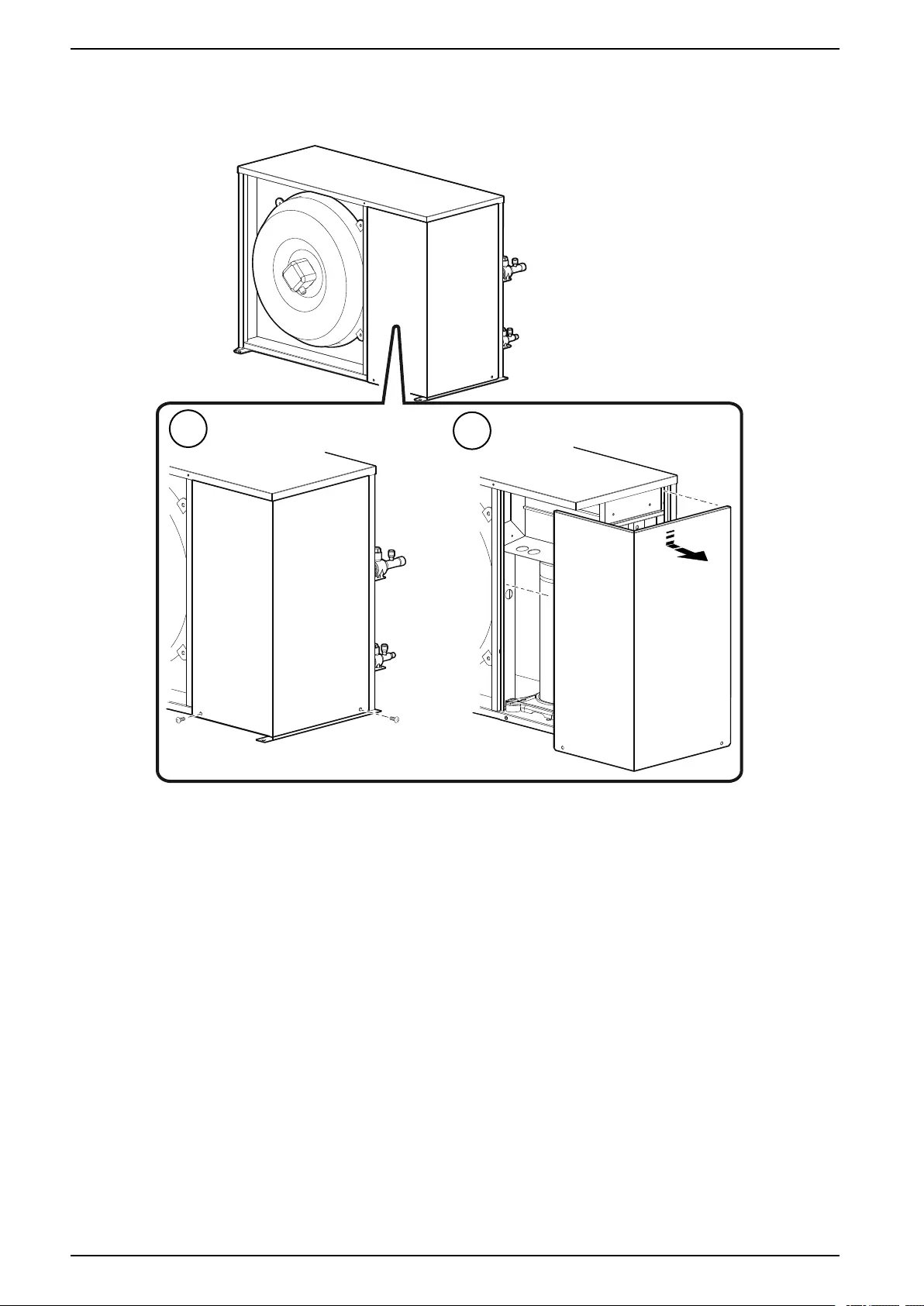

Outdoor Units .....................................................................................44

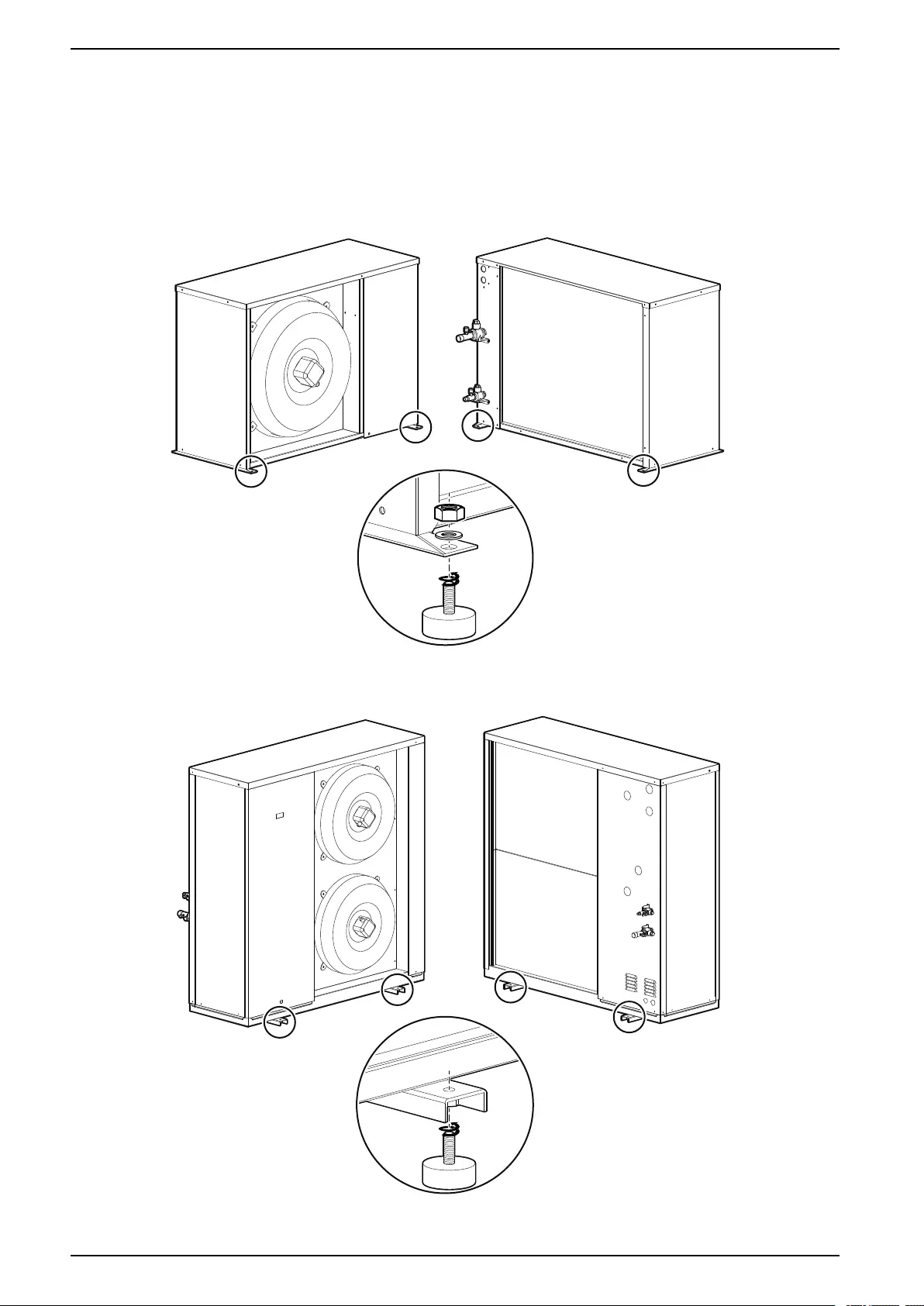

Placing the Outdoor Unit ...........................................................................46

Attaching the Mounting Feet ................................................................46

Unit Connections.......................................................................................47

Mechanical Connections ...........................................................................47

Mounting the Indoor Unit to the Ceiling .................................................47

Installing the Display Interface .............................................................48

Connecting the Condensate Drain........................................................49

Refrigerant Piping ...............................................................................50

Connect Refrigerant Lines ...................................................................52

Electrical Connections ..............................................................................55

Power Supply .....................................................................................55

Electrical Data..........................................................................................57

Indoor Units........................................................................................57

Outdoor Units .....................................................................................57

Communication Connections ...............................................................58

Temperature Sensor ...........................................................................63

Charging the Refrigeration System........................................................64

Calculating R410A Charge ........................................................................64

Charging the Equipment............................................................................65

Compressor Oil Charge ............................................................................66

Oil Charging Procedure.......................................................................66

R410A Refrigerant Charging Charts...........................................................66

Thermostatic Expansion Valve Adjustment .................................................69

Worldwide Customer Support .................................................................71

4 990-91229A-001 / 06MM0368@00B0110

Safety Uniflair™UCF, MRA

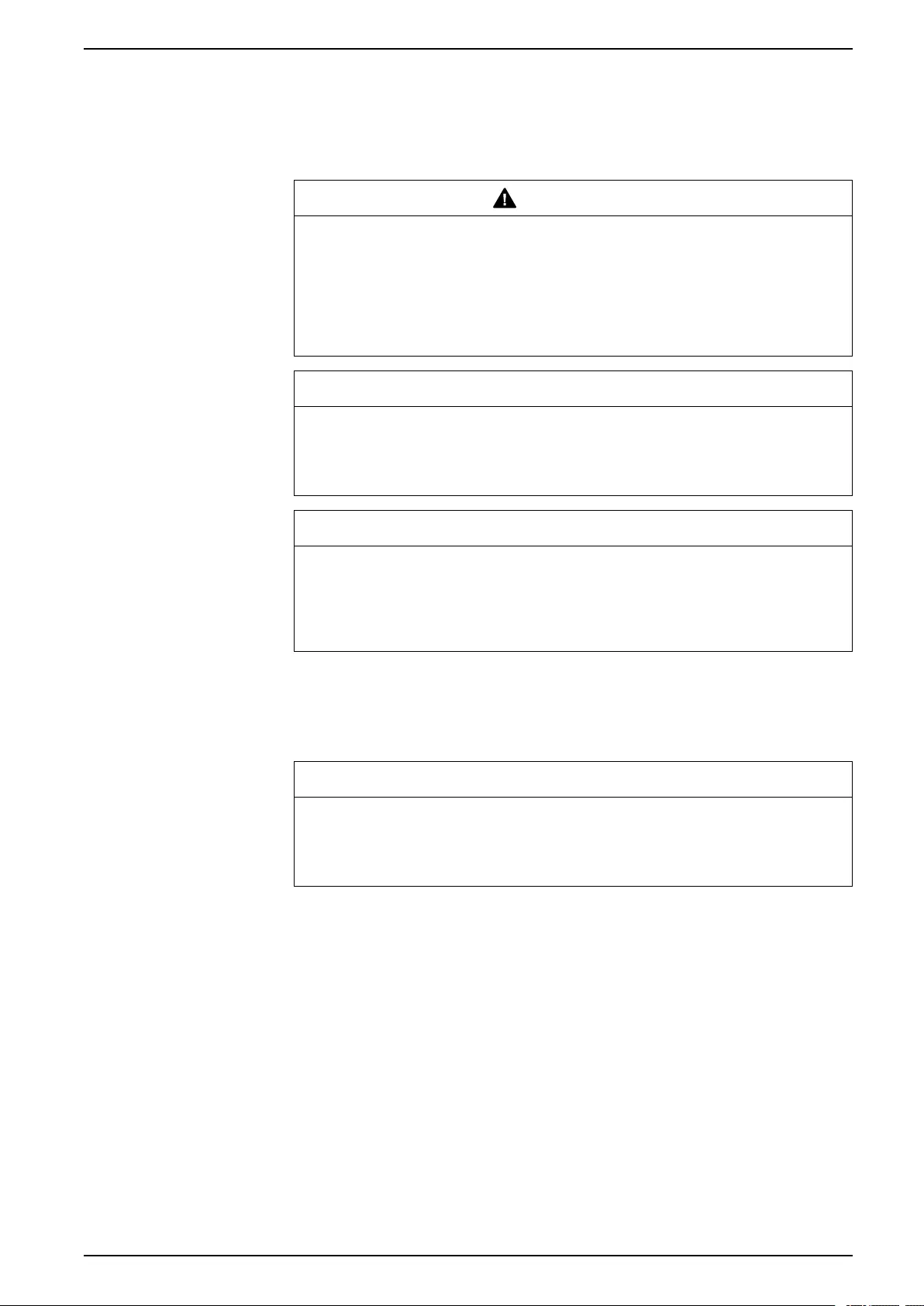

Safety

Important Safety Instructions — SAVE THESE INSTRUCTIONS

Read these instructions carefully and look at the equipment to become familiar

with it before trying to install, operate, service or maintain it. The following safety

messages may appear throughout this manual or on the equipment to warn of

potential hazards or to call attention to information that clarifies or simplifies a

procedure.

The addition of this symbol to a “Danger” or “Warning” safety

message indicates that an electrical hazard exists which will

result in personal injury if the instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages with this

symbol to avoid possible injury or death.

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

Failure to follow these instructions will result in death or serious injury.

WARNING

WARNING indicates a hazardous situation which, if not avoided, could result

in death or serious injury.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

Failure to follow these instructions can result in injury or equipment

damage.

NOTICE

NOTICE is used to address practices not related to physical injury. The safety

alert symbol shall not be used with this type of safety message.

Failure to follow these instructions can result in equipment damage.

Please Note

Electrical equipment should only be installed, operated, serviced, and maintained

by qualified personnel. No responsibility is assumed by Schneider Electric for any

consequences arising out of the use of this material.

A qualified person is one who has skills and knowledge related to the construction,

installation, and operation of electrical equipment and has received safety training

to recognize and avoid the hazards involved.

990-91229A-001 / 06MM0368@00B0110 5

Uniflair™UCF, MRA Safety

Safety During Installation

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Apply appropriate personal protective equipment (PPE) and follow safe

electrical work practices.

• This equipment must be installed and serviced by qualified personnel only.

• Turn off all power supplying this equipment before working on or inside the

equipment.

• Replace all devices, doors, and covers before turning on power to this

equipment.

Failure to follow these instructions will result in death or serious injury.

WARNING

HAZARD FROM MOVING PARTS

Keep hands, clothing, and jewelry away from moving parts. Check the

equipment for foreign objects before closing the doors and starting the

equipment.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

WARNING

DAMAGE TO EQUIPMENT OR PERSONNEL

• The equipment is heavy. For safety purposes, adequate personnel must be

present when moving this item.

• The load must always be solidly anchored to the bearing element of the

lifting equipment and means of transport.

• No one should be near the suspended load, nor in the working area of the

crane, forklift, truck, or any other lifting equipment or means of transport.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

CAUTION

HAZARD FROM UNPROTECTED OUTPUT

Apply circuit protection to all outputs.

Failure to follow these instructions can result in injury or equipment

damage.

NOTICE

STATIC ELECTRICITY HAZARD

Circuit boards contained within this unit are sensitive to static electricity. Use

one or more electrostatic-discharge devices while handling the board.

Failure to follow these instructions can result in equipment damage.

6 990-91229A-001 / 06MM0368@00B0110

Safety Uniflair™UCF, MRA

NOTICE

DAMAGE FROM EXPOSURE

Leaving the equipment uncovered and exposed to possible damage from the

environment will void the factory warranty.

Failure to follow these instructions can result in equipment damage.

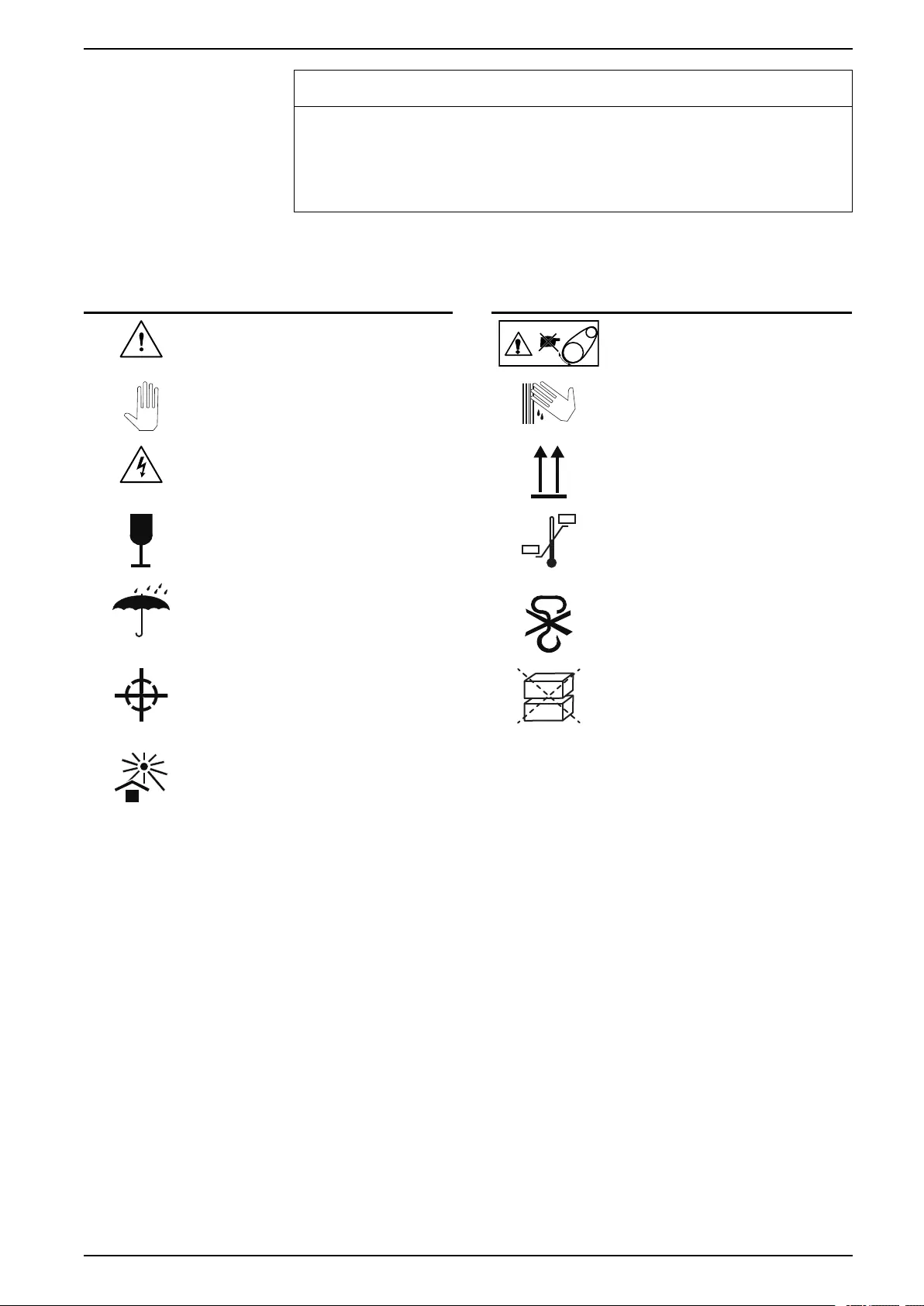

Symbols on Unit or Packaging

Symbol Meaning Symbol Meaning

Danger Moving parts

Important notice Sharp surface

High voltage: Risk of electric shock

This side up: Shows the correct

orientation of the packed unit

Fragile: Handle unit with care Temperature limits: The packed

unit must be stored in a place

within the indicated limits

Keep dry: The packed unit must be

stored in a dry place

Do not use hooks: Do not lift

packed unit with hooks

Center of gravity: Shows the

center of gravity of the packed unit

Do not stack: The packed units

must not be stacked

Keep away from the heat: The unit

must be stored away from heat

sources

Intended Use

The cooling units provide air conditioning within the limits and methods described

in this manual. This equipment must be installed and applied in accordance with

the instructions provided. No modifications may be made to the units or their parts

without explicit written consent from Schneider Electric. Any mechanical or

electrical modification voids factory warranty.

990-91229A-001 / 06MM0368@00B0110 7

Uniflair™UCF, MRA General Information

General Information

Document Overview

The Uniflair SP cooling unit is a precision unit used to control environments for

telecom rooms, internet hubs, and data processing centers.

This manual describes Unisplit air-cooled, direct expansion air conditioning units.

It supplies general information, safety instructions, unit transportation, and

necessary information on how to install the units.

Save These Instructions

This manual contains important instructions that must be followed during the

installation of this equipment.

Manual Updates

Schneider Electric™policy is one of continuous technological innovation and the

company reserves the right to amend any data herein without prior notice. The

images shown in this manual are for descriptive purposes only and they may differ

from specific models that are selected.

NOTE: Unit images and component identification information are examples

only. The final configuration of the unit may change according to the different

options.

Check for updates to this manual on the Schneider Electric Web site,

www.schneider-electric.com/support. Select the Download Documents and

Software link under the Support tab and enter the manual part number or SKU

for your equipment in the search field. See the back cover of this manual for the

part number.

Cross-Reference Symbol Used in This Manual

See another section of this document or another document for more

information on this subject.

8 990-91229A-001 / 06MM0368@00B0110

General Information Uniflair™UCF, MRA

Documentation Included with the Unit

Every Uniflair SP cooling unit is delivered with the following documentation

enclosed:

•Uniflair SP Operation and Maintenance Manual

•Uniflair SP Installation Manual

• Refrigeration circuit diagrams

• Electrical diagrams

• List of spare parts

• Conditions of Warranty

Compliance

These units are intended for installation in a non-public location with restricted

access, and with installation, use, and maintenance performed by professionally

trained personnel.

The manufacturer declares that this product is compliant with the following

standards:

• UL 1995

• CSA 22.2 No. 236-11

• FCC Part 15 Subpart B

• CSA ICES-003 Issue 5

The appliance operates safely in the areas of application for which it was

intended, provided its installation, commissioning, and maintenance are

performed in compliance with the documentation for the unit and with the labels

affixed to the unit.

It is necessary to install a supply disconnect on the fixed wiring located near the

unit to provide the safety shutdown and disconnection of the power supply. Follow

local and national codes and regulations.

The installed mains power disconnect must do the following:

• Isolate the electrical equipment from the supply and have one OFF and one

ON position.

• Be provided with a means for locking the device in the OFF (isolated) position

with Lockout Tagout

• Have a breaking capacity sufficient to interrupt the rated current (see rated

parameter on the unit nameplate or Technical Specifications)

• Be easily accessible and located between 0.6 m (2 ft) and 1.9 m (6 ft) above

where the service personnel stands to service the unit

After unit installation, it is necessary to evaluate the fault-loop impedance and

automatic protection coordination.

990-91229A-001 / 06MM0368@00B0110 9

Uniflair™UCF, MRA General Information

Receiving and Inspecting the Cooling Unit

NOTICE

DAMAGE TO EQUIPMENT

The indoor unit is shipped upside down. Use extreme caution when turning the

unit right side up taking care to not bend the flanges.

Failure to follow these instructions can result in equipment damage.

The cooling unit is packaged in a wooden crate or anchored to a pallet and

covered with transparent film.

Upon delivery, check to make sure the unit is intact and immediately notify the

carrier in writing of any damage that can be attributed to careless or improper

transportation. Check for any damage on the area upon which the display

interface is mounted.

In case of shipping damage, do not operate the cooling unit. Keep all packaging

for inspection by the shipping company and contact Schneider Electric

Corporation.

Filing a Claim

If damage is identified on receipt of the equipment, note the damage on the bill of

lading and file a damage claim with the shipping company. Contact Schneider

Electric Worldwide Customer Support at one of the numbers listed on the Web

page on the back page of this manual for information on how to file a claim with

the shipping company. The shipping claim must be filed at the receiving end of the

delivery.

NOTE: In case of shipping damage, do not operate the equipment. Keep all

packaging for inspection by the shipping company and contact Schneider

Electric.

10 990-91229A-001 / 06MM0368@00B0110

General Information Uniflair™UCF, MRA

Storing the Cooling Unit Before Installation

NOTICE

DAMAGE FROM EXPOSURE

Leaving the equipment uncovered and exposed to possible damage from the

environment will void the factory warranty.

Failure to follow these instructions can result in equipment damage.

If storing the unit for a period of time, the following procedures must be followed:

• The storage area must be dry (<85% R.H.) and protected against minimum

storage temperatures –23°C (–10°F) and extreme storage temperatures 50°C

(122°F).

• The unit should remain in its original packaging if stored for long periods of

time.

Moving the Unit

WARNING

DAMAGE TO EQUIPMENT OR PERSONNEL

• The equipment is heavy. For safety purposes, adequate personnel must be

present when moving this item.

• The load must always be solidly anchored to the bearing element of the

lifting equipment and means of transport.

• No one should be near the suspended load, nor in the working area of the

crane, forklift, truck, or any other lifting equipment or means of transport.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

Lifting and transporting the units must be carried out by qualified personnel as

described in this manual.

Use all relevant safety standards to prevent any possible damage to people or

objects.

Indoor Unit

The cooling unit is packaged in a wooden crate or anchored to a pallet and

covered with transparent film. The recommended tools for moving and installing

the equipment include the following:

Forklift Pallet Jack

Outdoor Unit

The condensing unit is packaged in a wooden crate. The recommended tools for

moving and installing the equipment include the following:

Pallet Jack Forklift Crane

990-91229A-001 / 06MM0368@00B0110 11

Uniflair™UCF, MRA General Information

Equipment Disposal

Waste Electrical and Electronic Equipment (WEEE) Disposal

Schneider Electric products comply with international directives on

the Restriction of Hazardous Substances (RoHS) in electronic and

electrical equipment and the disposal of Waste Electrical and

Electronic Equipment (WEEE). Dispose of any waste electronic or

electrical equipment with the appropriate recycling center. Contact

Schneider Electric for assistance.

Radio Frequency Interference

The SKUs UCF0341I, UCF0481I, MRA0221I, and MRA0611D comply with part 15

of the FCC Rules. Operation is subject to the following two conditions:

1. These devices may not cause harmful interference.

2. These devices must accept any interference received, including interference

that may cause undesired operation.

Any changes or modifications not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

California Proposition 65—Warning Statement for California

Residents

WARNING: This product can expose you to chemicals including lead and lead

compounds, that are known to the State of California to cause cancer and birth

defects or other reproductive harm. For more information go to

www.P65Warnings.ca.gov.

12 990-91229A-001 / 06MM0368@00B0110

General Information Uniflair™UCF, MRA

Equipment Guidelines

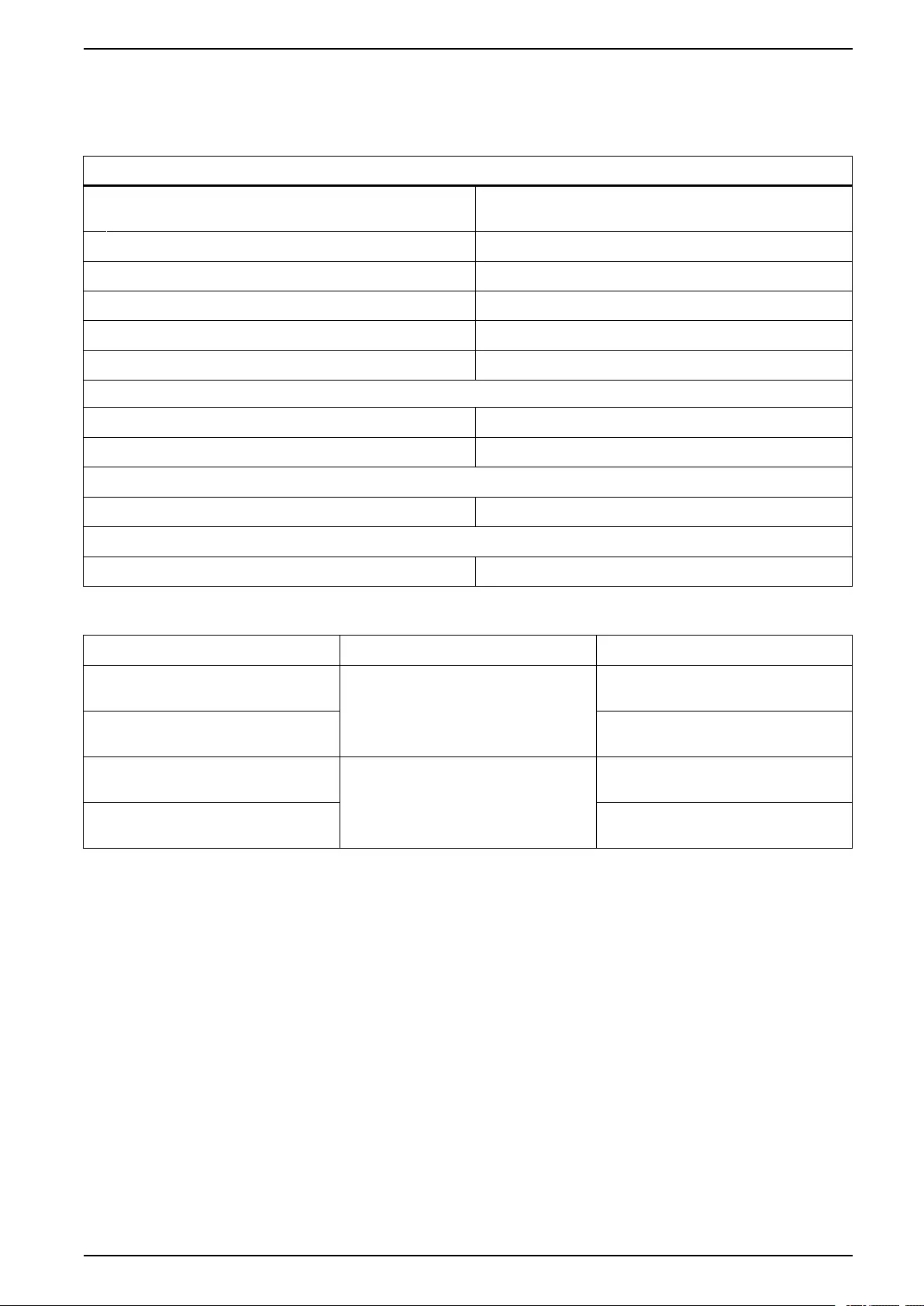

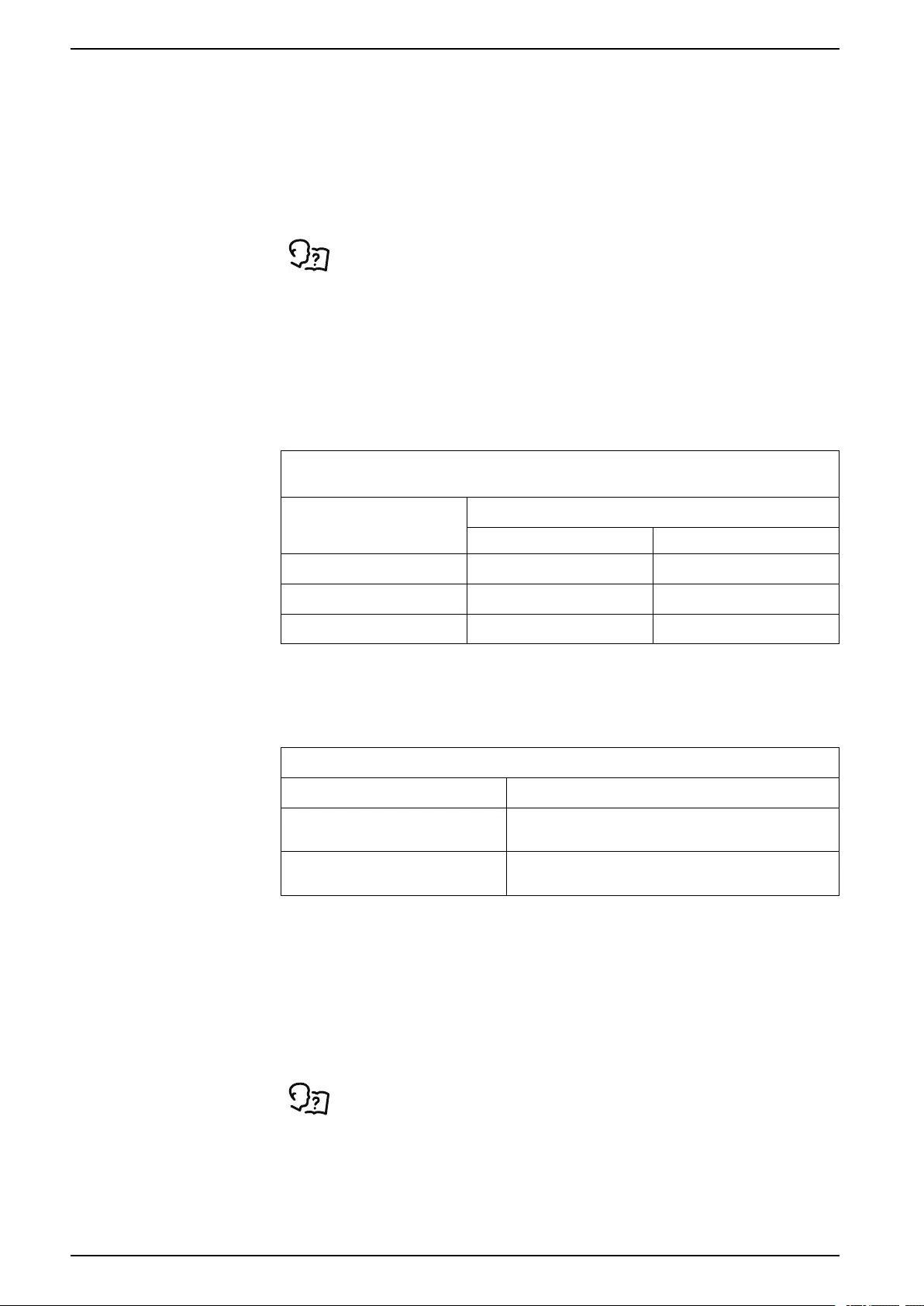

Working Conditions and Environmental Limits

Limit Working Conditions

Power supply 208 V, 1 Ph, 60 Hz

230 V, 1 Ph, 60 Hz

Voltage input tolerance ±10%*

Voltage imbalance Maximum 3% for 3-phase units

Frequency input tolerance—continuously ±0.5 Hz

Frequency input tolerance—short time ±1 Hz

Maximum altitude 2000 m (6562 ft)

Room Conditions

Temperature 18°C to 40°C (64.4°F to 104°F)

Humidity Relative humidity: 30 to 70%RH

DX Operational Conditions

Temperature –23°C to 46°C (–10°F to 115°F)

Storage Temperature

Temperature –23°C to 50°C (–10°F to 122°F)

*MRA0221I is only -5%/+10%

Unit Assembly Power Supply

UCF0341I Indoor 208 V, 1 Ph, 60Hz

230 V, 1 Ph, 60Hz

UCF0481I 208 V, 1 Ph, 60Hz

230 V, 1 Ph, 60Hz

MRA0221I Outdoor 208 V, 1 Ph, 60Hz

230 V, 1 Ph, 60Hz

MRA0611D 208 V, 3 Ph, 60Hz

230 V, 3 Ph, 60Hz

990-91229A-001 / 06MM0368@00B0110 13

Uniflair™UCF, MRA Unit Overview

Unit Overview

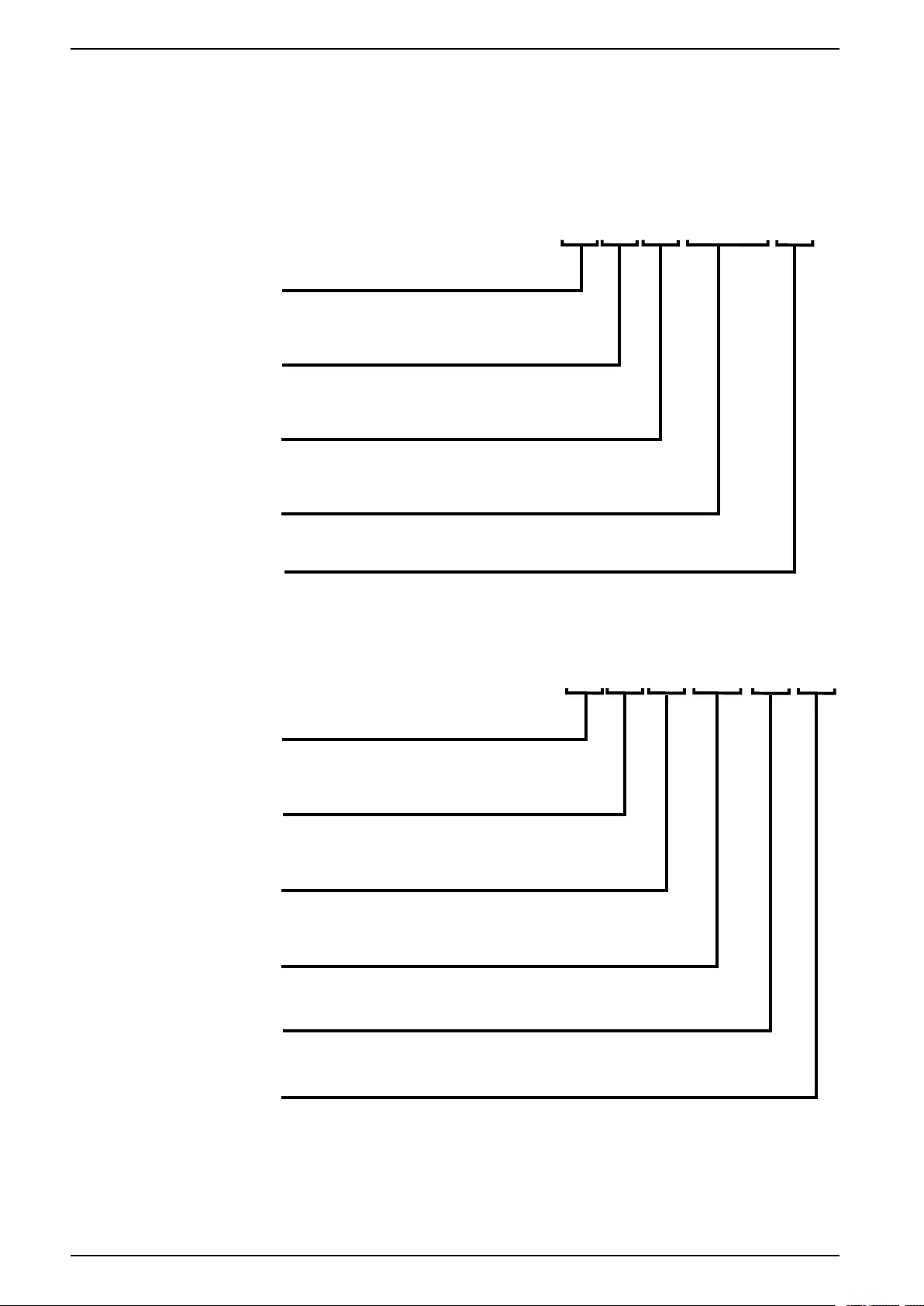

Model Nomenclature

Indoor Units

U C F

na4524c

I

XXXX

IDENTIFYING PREFIX

UNIT TYPE

C = CEILING-MOUNTED UNIT

FUNCTION MODE

F = FREE COOLING (OPTIONAL)

MODEL NUMBER

VOLTAGE

I = 208/230 V/1 Ph/60 Hz

0341, 0481

Outdoor Units

M R A

na4523b

022

1 I

IDENTIFYING PREFIX

COMPRESSOR TYPE

R = HERMETIC ROTARY SCROLL

FUNCTION MODE

A = MECHANICAL COOLING

MODEL NUMBER

NUMBER OF COMPRESSORS

VOLTAGE

I = 208/230 V/1 Ph/60 Hz

D = 208/230 V/3 Ph/60 Hz

M = MONOBLOCK

022, 061

14 990-91229A-001 / 06MM0368@00B0110

Unit Overview Uniflair™UCF, MRA

Nameplate Example

The units can be identified by the nameplate, which is located in the electrical

panel of the cooling unit. The model and any accessories that are installed are

indicated by an ‘X’ in the corresponding box. The nameplate contains the following

information:

• Model and series number of the unit

• Power supply type

• Power absorbed by the unit and individual components

• Current absorbed by the unit and individual components

• The setpoints of the air pressure switches

• Setpoints for the regulation and safety devices

Indoor Unit

UCF0341I

R410A

ELECTRICAL RATING:

MODEL/SKU:

208/230 VAC, 1~, 60 Hz

MCA: 15 AMPS

MOP: 15 AMPS

REFRIGERANT:

650 / 44.8

DESIGN PRESSURE:

Contains fluorinated greenhouse gases covered by the Kyoto protocol.

Foam blown with fluorinated greenhouse gases.

PSIG/Bar Low,High Side

TAAD056 3X3A

REMOTE AIR-COOLED CONDENSER

FAN: FLA 1.5 H.P. 0.23 QTY. 2

DESIGNED UNIT CHARGE: 10 / 0.28 oz/kg

SERIAL NO.

FACTORY CHARGE: Nitrogen

10 / 0.68 PSIG/Bar

FLA: 3.0 AMPS

4009332

Certification

ID

EXAMPLE

EXAMPLE

R410AR410A

AC, 1~, 60 Hz

AC, 1~, 60 Hz

AMPS

AMPS

REFRIGERANTREFRIGERANT

:

:

DESIGN PRESSURE

DESIGN PRESSURE

::

AN:

AN:

FLA

FLA

1.51.5

H.

H.

P

P

..

0.23

0.23

DESIGNED UNI

DESIGNED UNI

NO.

NO.

R

R

YY

RR

R

CHARGE

CHARGE

:

:

10 / 0.68

10 / 0.68

4009332

4009332

na7076a

Outdoor Unit

MRA0221I

R410A

ELECTRICAL RATING:

MODEL/SKU:

208-230 VAC, 1~, 60 Hz

MCA: 19.6 AMPS

MOP: 30.0 AMPS

REFRIGERANT

DESIGN PRESSURE

Contains fluorinated greenhouse gases covered by the Kyoto protocol.

Foam blown with fluorinated greenhouse gases.

TAAD056 4X3A

OUTDOOR USE (UTILISATION À L’EXTÉRIEUR)

COMPRESSOR: RLA 12.8 LRA 64

FAN: FLA 3.6 H.P. 0.46 QTY. 1

SYSTEM CHARGE: _________________________________ oz/kg

SERIAL NO.

FACTORY CHARGE:

FLA: 16.4 AMPS

Nitrogen

10 / 0.68 PSIG/Bar

650 / 44.8 PSIG/Bar Low,High Side

DESIGNED UNIT CHARGE: 81.0 / 2.29 oz/kg

4009332

Certification

ID

EXAMPLE

R410A

R410A

AMPS

AMPS

REFRIGERANT

REFRIGERANT

DESIGN PRESSURE

DESIGN PRESSURE

OUTDOOR USE (UTILIS

OUTDOOR USE (UTILIS

RLA

RLA

12.8

12.8

LRALRA

64

64

F

F

AN:

AN:

F

FF

FLA

FLA

3.6

3.6

H.

H.

P

P

NO.NO.

TT

OO

RR

Y

Y

R

R

R

CHARGE:

CHARGE:

10 / 0.68

10 / 0.68

na7077a

990-91229A-001 / 06MM0368@00B0110 15

Component Identification Uniflair™UCF, MRA

External Components

Indoor Units

UCF0341I and UCF0481I

na7062a

NOTE: Model shown is UCF0341I.

Item Description Item Description

Mounting holes Service panel

Fan protection grille Suction line service valve

Electrical panel cover (on bottom of

unit)

Liquid line service valve

Low-voltage conduit knock-out

panels*

Damper connection cover panel (on

rear of unit)

* High-voltage conduit knock-out panels are located on the opposite side.

990-91229A-001 / 06MM0368@00B0110 19

Uniflair™UCF, MRA Component Identification

Internal Components

Indoor Units

UCF0341I

na7066a

Item Description Item Description

Filter drier Float switch

Service port Direct Air Economizer damper

actuator connection (optional)

Electrical panel (facing bottom of unit) Sight glass

Evaporative fans Thermostatic expansion valve (TXV)

Evaporative coil Motorized free-cooling damper

actuator (optional with damper kit)

Condensate drain pan Condensate drain hose

22 990-91229A-001 / 06MM0368@00B0110

Component Identification Uniflair™UCF, MRA

UCF0481I

na7096a

Item Description Item Description

Filter drier Condensate drain pan

Service port Float switch

Motorized free-cooling damper

actuator (optional with damper kit)

Direct Air Economizer damper

actuator connection (optional)

Electrical panel (facing bottom of unit) Thermostatic expansion valve (TXV)

Evaporative fans Sight glass

Evaporative coil Condensate drain hose

990-91229A-001 / 06MM0368@00B0110 23

Uniflair™UCF, MRA Component Identification

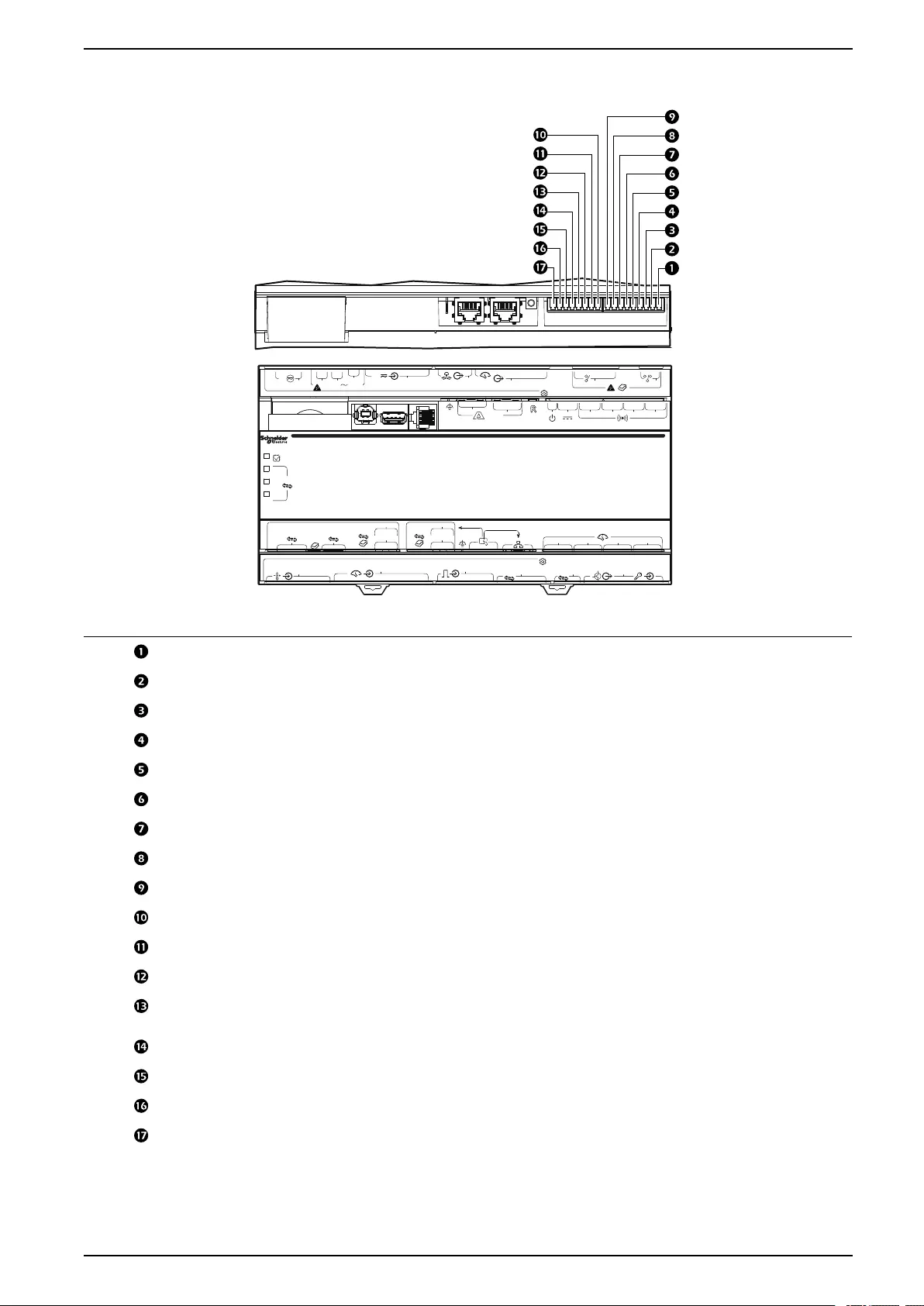

Outdoor Units

MRA0221I

na7067a

Item Description Item Description

Condensing coil Suction service port

High-pressure switch Scroll compressor

Pressure transducer Capacitor

Discharge service port Condensing fan

Low-pressure switch

NOTE: Crankcase heater and compressor blanket are not shown.

24 990-91229A-001 / 06MM0368@00B0110

Uniflair™UCF, MRA Component Identification

Electrical Panels

Indoor Units

UCF0341I, UCF0481I

na7052a

PE

L1

L2

1313

0

24

24

1601

1311

1312

1314

1502

1511

0213

0214

CHG

0210

0219

0220

0221

CHG

0204

0215

CHG

24VDC

5057

5059

24

24

0

0

CHG

CHG

CHG

24

CHG

DGND

F2

T1

Q1

F1

PE

TB2F2

PLC1

TB3

PFS

FS

TB1

Item Description Item Description

Clogged filter pressure switch (PFS) Ground (PE)

Air flow pressure switch (FS) Terminal block (TB1)

Terminal block (TB3) Fuse (F1)

J5 controller (PLC1) Internal power disconnect switch (Q1)

Fuse (F2) Transformer (T1)

Terminal block (TB2)

Outdoor Units

MRA0221I

na7053a

0

24

24

1601

1312

1314

1311

1511

1502

0214

0213

PE

PE

PE

L1

L2

Q1

F1

PE

TB02

K2

TB01

K1

Item Description Item Description

Terminal block (TB01) Internal power disconnect switch (Q1)

Voltage presence relay (K2) Ground (PE)

Fuse (F1) Terminal block (TB02)

Compressor contactor (K1)

26 990-91229A-001 / 06MM0368@00B0110

Component Identification Uniflair™UCF, MRA

MRA0611D

L1

L1

L2

L2

0

24

24

1601

1312

1314

1311

1511

1511

1502

1502

0214

0213

PE

PE

PE

Q1

F1

PE

TB02

TB01

K1

K2

na7054a

Item Description Item Description

Internal power disconnect switch (Q1) Voltage presence relay/3-phase

monitor (K2)

Ground (PE) Terminal block (TB01)

Compressor contactor (K1) Terminal block (TB02)

Fuse (F1)

990-91229A-001 / 06MM0368@00B0110 27

Uniflair™UCF, MRA Component Identification

Display Interface

Display

Reset

Micro

SD

Service

Port

USB

Console

10/100

na4820a

Item Description Function

LCD Display 4.3-inch touch-screen color display

Power LED The cooling unit is powered when the LED is

illuminated. Unit firmware is updating when

LED is blinking.

Check Log LED When this LED is illuminated, a new entry has

been made to the event log.

Alarm LED Displays current alarm condition of unit.

Status LED Displays current network management card

status.

Display Reset button Resets the display microprocessor. This has

no effect on the air conditioner controller.

Link-RX/TX (10/100)

LED

Displays current network link status.

Micro SD card slot Memory card expansion slot.

Service port USB-B port used only by service personnel.

USB-A port Supports firmware upgrades.

Serial Configuration

port

Connects the display to a local computer to

configure initial network settings or access the

command line interface (CLI).

Alarm LED

This LED indicates active alarms on the display.

Condition Description

Off No alarm

Solid yellow Warning alarm

Solid red Critical alarm

28 990-91229A-001 / 06MM0368@00B0110

Component Identification Uniflair™UCF, MRA

Status LED

This LED indicates the status of the display.

Condition Description

Off One of the following situations exist:

• The display is not receiving input

power.

• The display is not operating

properly. It may need to be

repaired or replaced. Contact

Schneider Electric Customer

Support.

Solid green The display has valid TCP/IP settings.

Solid orange A hardware malfunction has been

detected in the display. Contact

Schneider Electric Customer Support.

Flashing green The display does not have valid TCP/

IP settings.

Flashing orange The display is making BOOTP

requests.

Alternately flashing green and orange If the LED is flashing slowly, the

display is making DHCP requests. If

the LED is flashing rapidy, the display

is starting up.

Link-RX/TX (10/100) LED

This LED indicates the network status of the display.

Condition Description

Off One or more of the following situations exist:

• The display is not receiving input power.

• The cable or device that connects the cooling unit

to the network is disconnected or not functioning

properly.

• The display itself is not operating properly. It may

need to be repaired or replaced. Contact

Schneider Electric Customer Support.

Solid green The display is connected to a network operating at 10

megabits per second (Mbps).

Solid orange The display is connected to a network operating at 100

Mbps.

Flashing green The display is receiving or transmitting at 10 Mbps.

Flashing orange The display is receiving data packets at 100 Mbps.

990-91229A-001 / 06MM0368@00B0110 29

Uniflair™UCF, MRA Dimensions and Weights

Dimensions and Weights

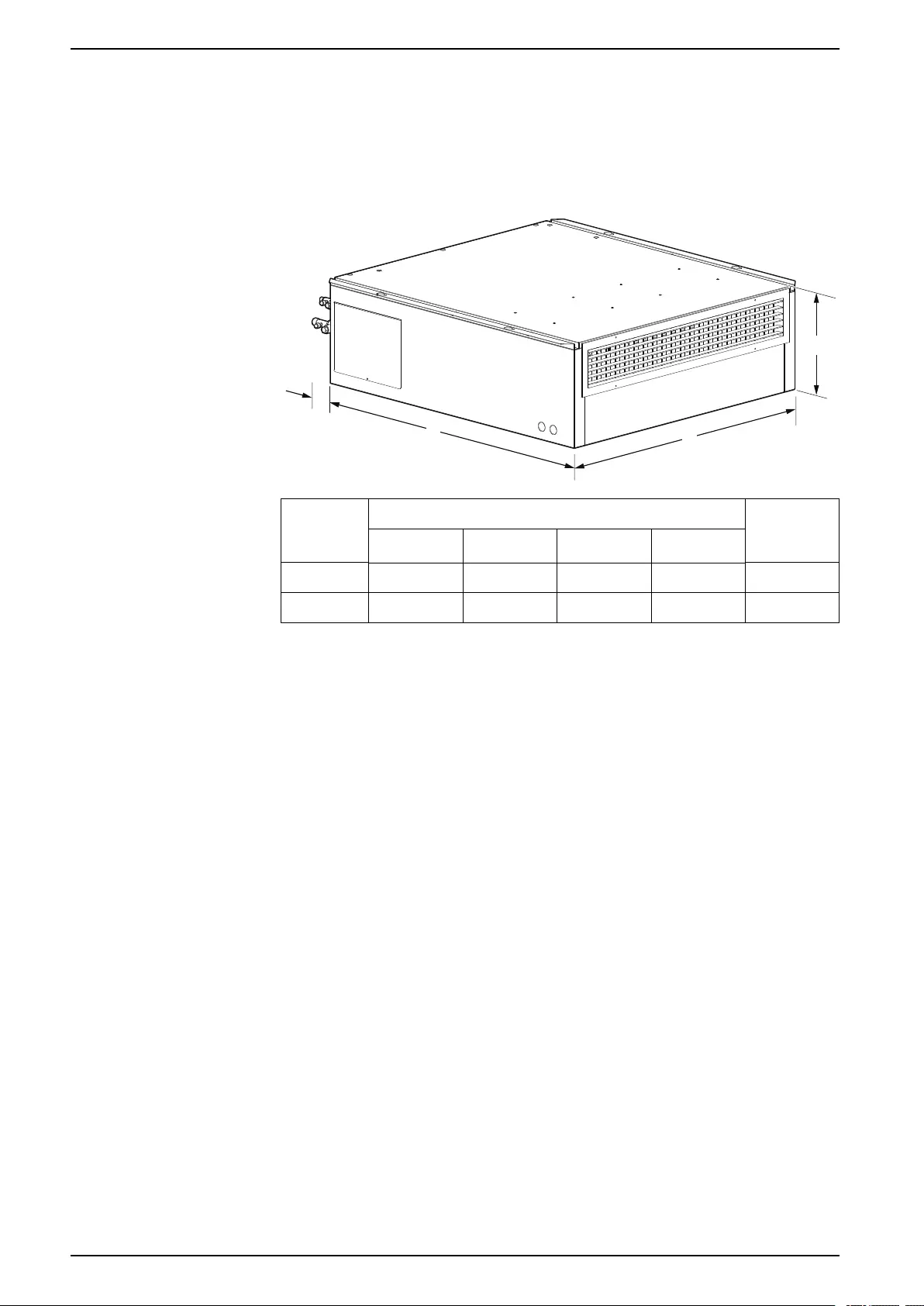

Indoor Units

UCF0341I, UCF0481I

A

B

C

D

na7055a

Model Dimensions – mm (in.) Net

Weight –

kg (lb)

A B CD

UCF0341I 950 (37.4) 1050 (41.3) 330 (13.0) 125 (4.9) 75 (165.4)

UCF0481I 1150 (45.3) 1300 (51.2) 411 (16.2) 124 (4.8) 146 (321.9)

30 990-91229A-001 / 06MM0368@00B0110

Dimensions and Weights Uniflair™UCF, MRA

Piping and Electrical Access Locations

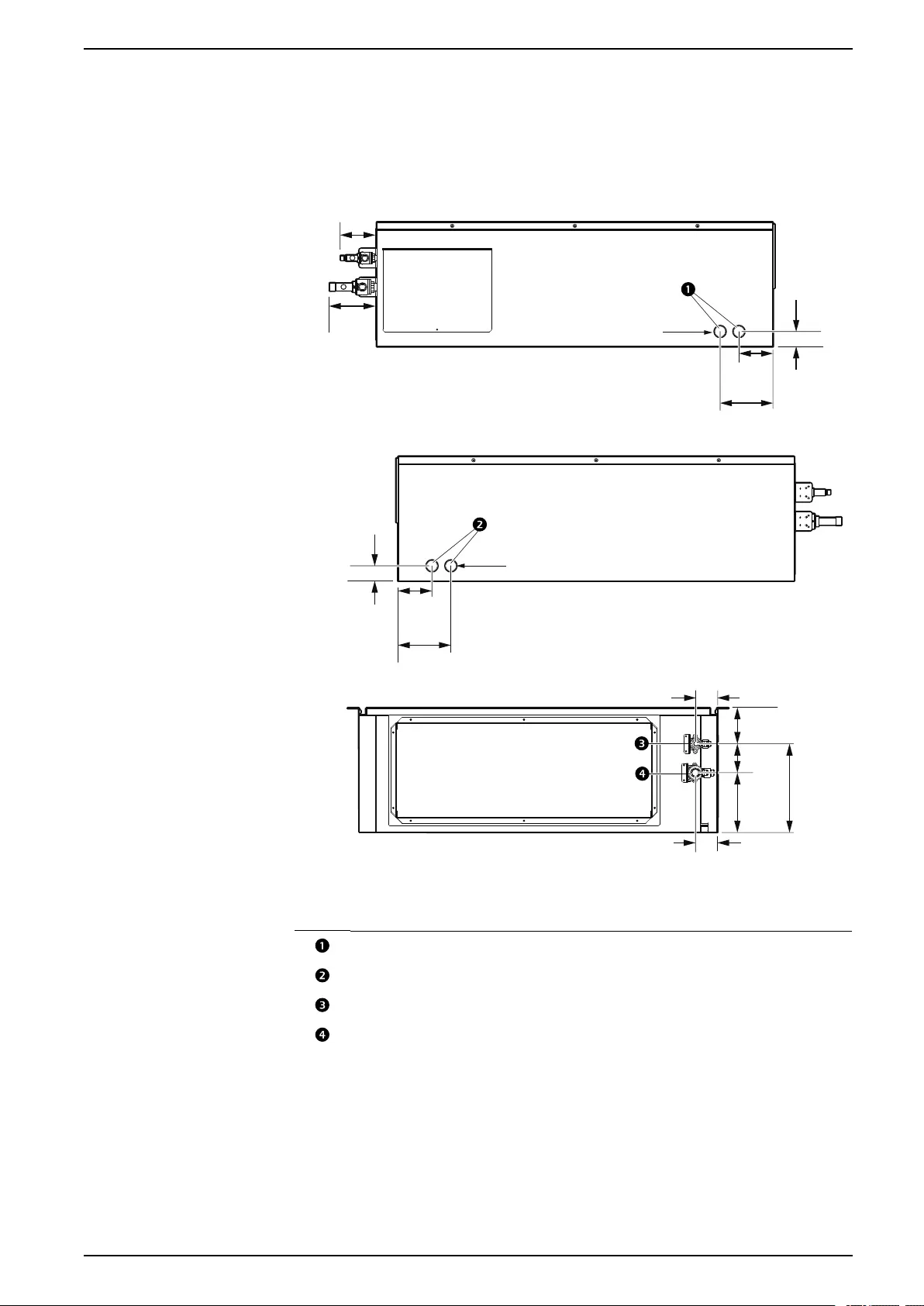

Indoor Units

UCF0341I

140.0

(5.5)

158.3

(6.2)

235.0

(9.3)

58.0 (2.3)

40.0 (1.6)

90.0

(3.5)

40.0 (1.6)

140.0

(5.5)

90.0

(3.5)

125.0

(4.9)

95.5

(3.8)

56.6 (2.2)

95.0 (3.7)

76.7

(3.0)

na7058a

Ø28 (Ø1.1)

Ø28 (Ø1.1)

LEFT SIDE

RIGHT SIDE

REAR VIEW

NOTE: Dimensions shown in mm (in.).

Item Description

Low-voltage conduit knock-out panel

High-voltage conduit knock-out panel

Liquid line

Gas line

990-91229A-001 / 06MM0368@00B0110 33

Uniflair™UCF, MRA Dimensions and Weights

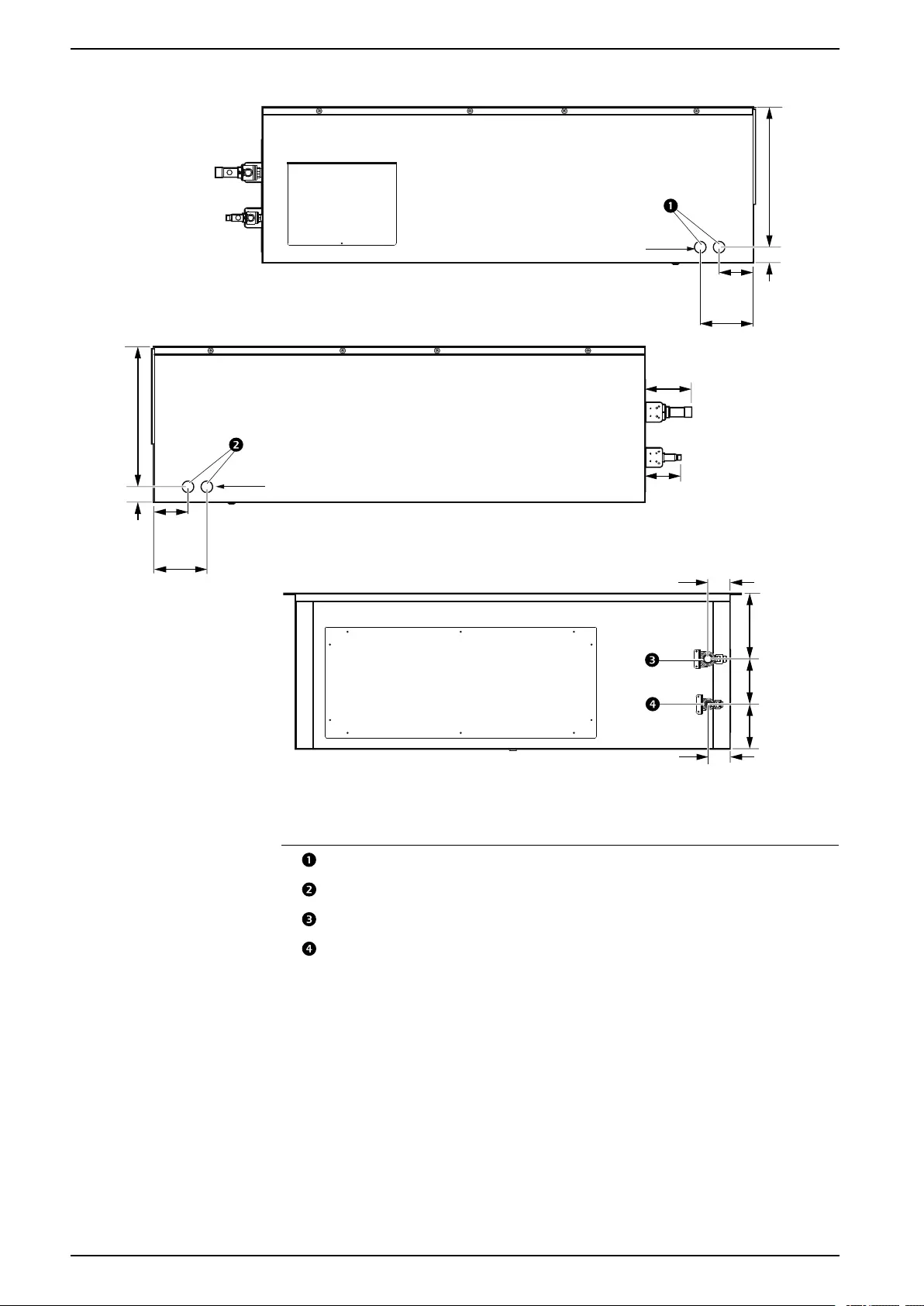

UCF0481I

140.0 (5.5)

95.5 (3.8)

124.0 (4.9)

118.0 (4.6)

120.0 (4.7)

173.0 (6.8)

58.0 (2.3)

56.6 (2.2)

371.0

(14.6)

40.0 (1.6)

90.0

(3.5)

371.0

(14.6)

40.0 (1.6) 90.0

(3.5)

140.0 (5.5)

LEFT SIDE

RIGHT SIDE

REAR VIEW

Ø28 (Ø1.1)

Ø28 (Ø1.1)

na7059a

NOTE: Dimensions shown in mm (in.).

Item Description

Low-voltage conduit knock-out panel

High-voltage conduit knock-out panel

Gas line

Liquid line

34 990-91229A-001 / 06MM0368@00B0110

Dimensions and Weights Uniflair™UCF, MRA

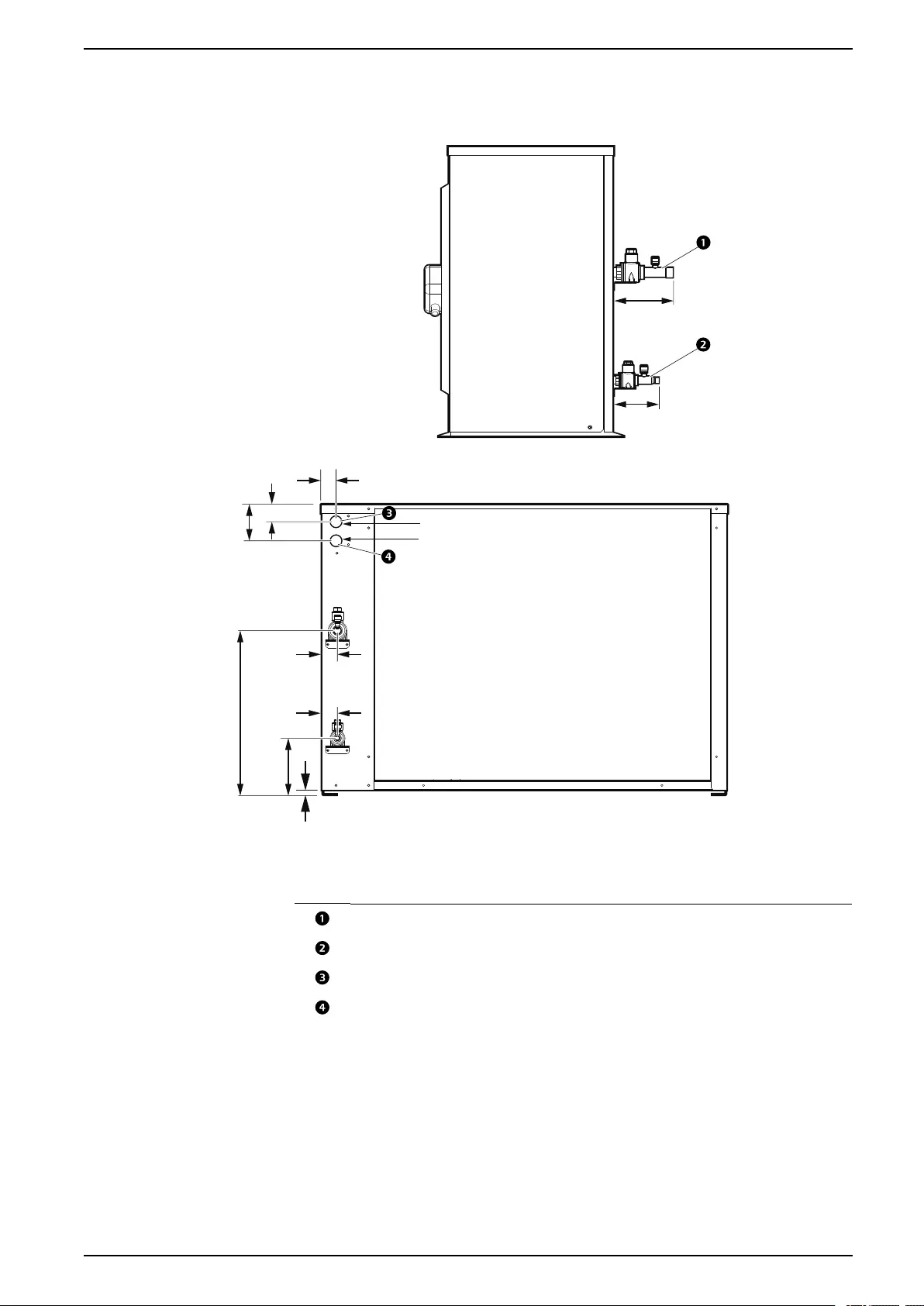

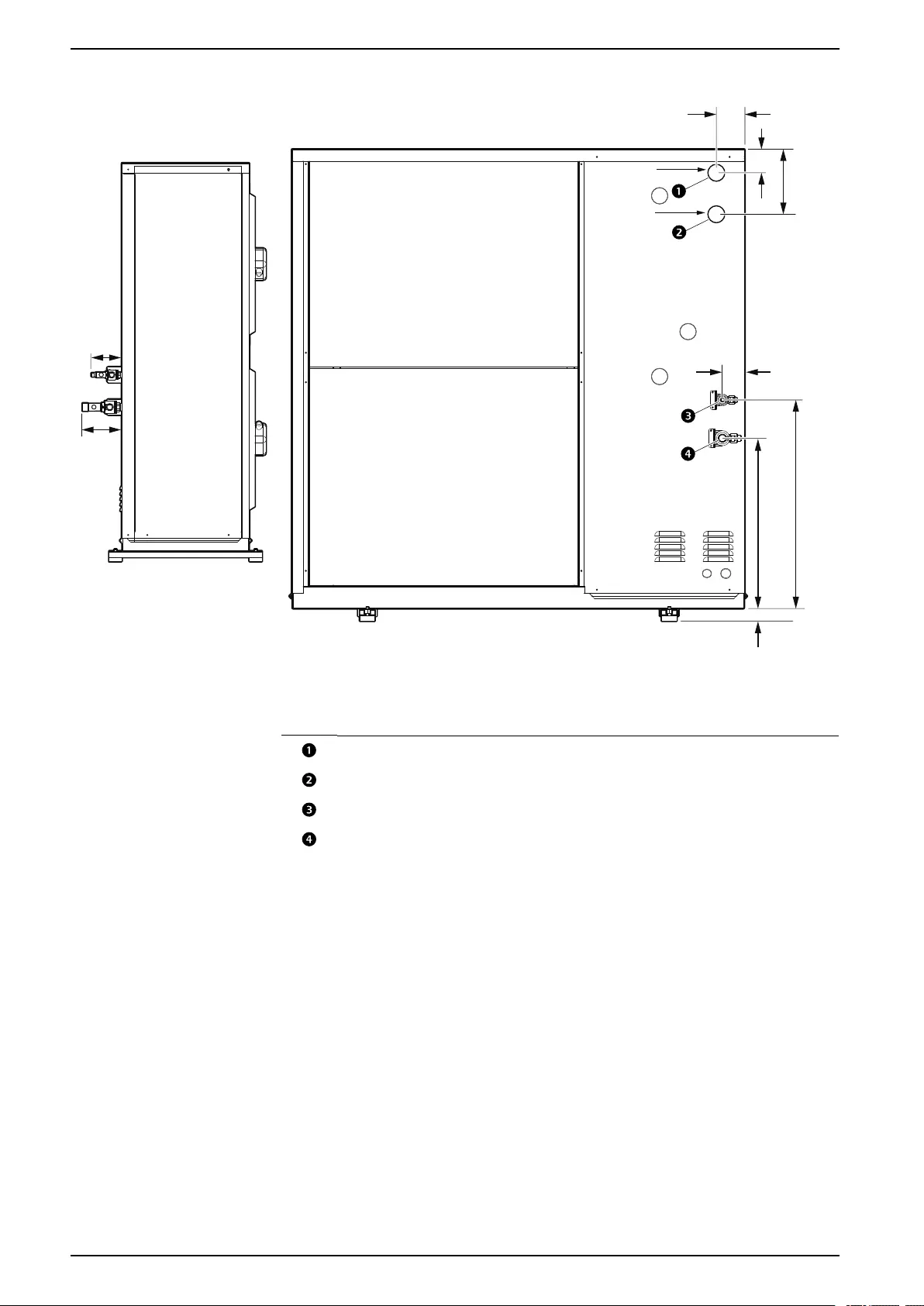

Outdoor Units

MRA0221I

REAR

95.5 (3.7)

30.0 (1.2)

37.0 (1.5)

77.0

(3.0)

10.1 (0.4)

119.1

(4.7)

345.1

(13.6)

125.0 (4.9)

33.0

(1.3)

33.0

(1.3)

Ø22.5 (Ø0.9)

Ø22.5 (Ø0.9)

na7060a

NOTE: Dimensions shown in mm (in.).

Item Description

Gas line

Liquid line

High–voltage conduit knock-out panel

Low–voltage conduit knock-out panel

990-91229A-001 / 06MM0368@00B0110 35

Uniflair™UCF, MRA Dimensions and Weights

MRA0611D

na7061a

59.0 (2.3)

451.5 (17.8)

553.0 (21.8)

33.0 (1.3)

75.0 (3.0)

62.5 (2.5)

172.5

(6.8)

95.5

(3.8)

124.0

(4.9)

Ø42.0 (Ø1.7)

Ø42.0 (Ø1.7)

NOTE: Dimensions shown in mm (in.).

Item Description

High–voltage conduit knock-out panel

Low–voltage conduit knock-out panel

Liquid line

Gas line

36 990-91229A-001 / 06MM0368@00B0110

Dimensions and Weights Uniflair™UCF, MRA

Service Clearance

Indoor Units

914 mm

(36 in.)

457 mm

(18 in.)

457 mm

(18 in.)

304 mm

(12 in.)

na7065a

Routine service and maintenance is performed from below the unit. Consider

service accessibility when planning equipment positioning in the data center.

Location Minimum Clearance Recommended

Clearance

Rear of unit 304 mm (12 in.) —

Sides of unit 457 mm (18 in.) 914 mm (36 in.)

Below unit 914 mm (36 in.) 1981.2 mm (78 in.)

Outdoor Units

Location Recommended Clearance

Rear of unit 152 mm (6 in.)

Top of unit 304 mm (12 in.)

Front of unit 914 mm (36 in.)

Service side of unit 508 mm (20 in.)

Non-service side of unit 152 mm (6 in.)

990-91229A-001 / 06MM0368@00B0110 37

Uniflair™UCF, MRA Diagrams

Diagrams

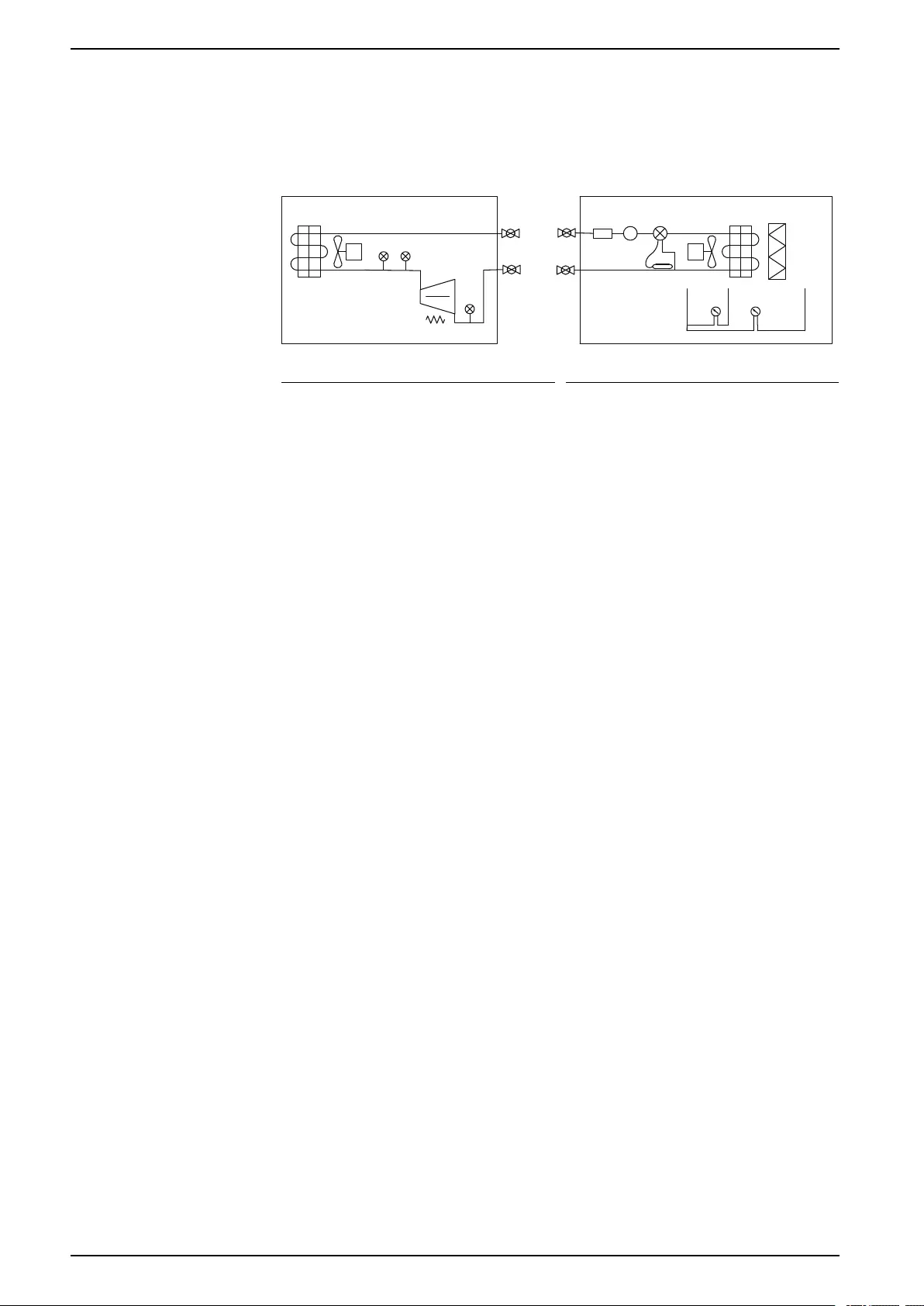

Refrigeration Piping Diagram

na7207a

OUTDOOR UNIT (MRA UNITS) INDOOR UNIT (UCF UNITS)

VS HPS PT

LPS

CCH

LIQUID

SV

SUCTION

SV

FD SG TXV

FS

AF

DP1 DP2

Item Description Item Description

FS Fixed speed fan AF Air filter

VS Variable speed fan FD Filter drier

PT Pressure transducer

(variable speed fan

control)

SG Sight glass

HPS High pressure switch,

manual reset

TXV Thermostatic expansion

valve

LPS Low pressure switch, auto

reset

DP1 Air pressure sensor, indoor

fan flow

CCH Crankcase heater DP2 Air pressure sensor, air

filter

SV Service valve, ball type

38 990-91229A-001 / 06MM0368@00B0110

Installation Uniflair™UCF, MRA

Installation

Site Preparation

WARNING

HAZARD FROM MOVING PARTS

Keep hands, clothing, and jewelry away from moving parts. Check the

equipment for foreign objects before closing the doors and starting the

equipment.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

NOTICE

EQUIPMENT DAMAGE RISK

Install the unit in an area that is protected from adverse conditions.

Failure to follow these instructions can result in equipment damage.

NOTICE

WATER DAMAGE

Installing the unit on an uneven surface may result in overflow spilling from the

condensate tray.

Failure to follow these instructions can result in equipment damage.

Positioning Units

Internal Units (UCF)

NOTICE

EQUIPMENT DAMAGE RISK

Install the unit in an area that is protected from adverse conditions.

Failure to follow these instructions can result in equipment damage.

UCF units must be attached to (or suspended from) the ceiling of the room by the

side flanges; check that the ceiling is strong enough to support the weight of the

unit.

When installing the unit, check that it is level.

The ceiling mount must be installed in accordance with local, regional, and

national codes, and this Installation Manual.

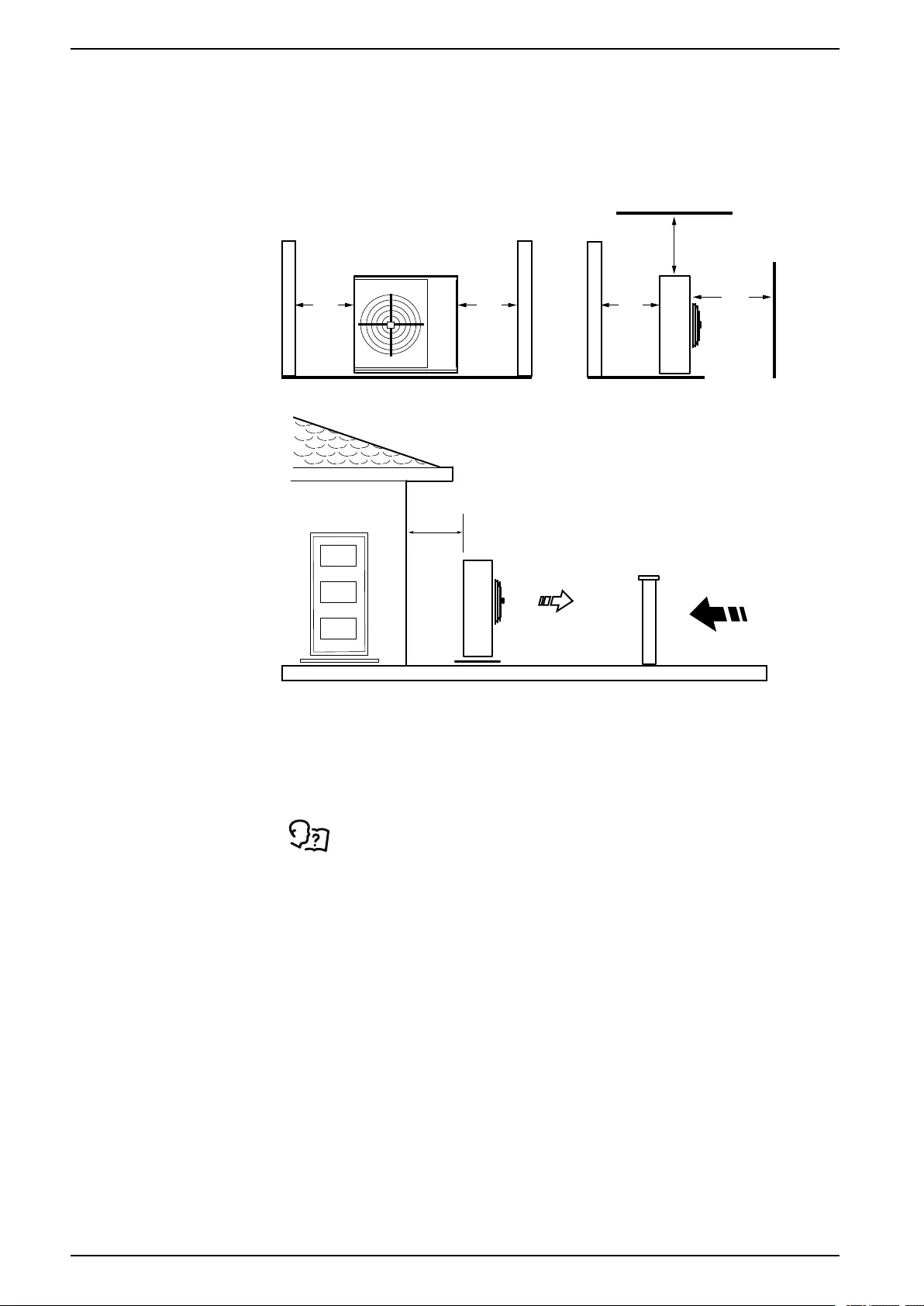

External Units (MRA)

This is an outdoor unit. Protect the unit from water flowing from drains or gutters.

Do not expose the unit to air containing flammable or greasy substances.

Do not obstruct intake airflow from the fans and through the condensing coil. Free

airflow ensures efficiency of the unit and prevents compressor safety devices from

ending unit operation.

990-91229A-001 / 06MM0368@00B0110 39

Uniflair™UCF, MRA Installation

Never direct the air-discharge side (the fan side) toward a wall. If the installation

location is windy, install the unit in a sheltered position; the wind could obstruct the

airflow through the cooling coil or make it excessive. If this is not possible, take

adequate wind-protection measures.

Check that the load capacity of the surface under the unit is sufficient to support its

weight.

na6340a

152

(6)

152

(6)

508

(20)

914

(36)

304 (12)

NOTE: Dimensions are in mm (in.)

na6341a

150

(6)

NOTE: Dimensions are in mm (in.)

External Air Free-Cooling–UCF Units

UCF units have the option to be converted for use with a free-cooling kit.

See the Damper Kit Installation Instructions for the requirements.

These free-cooling units have a butterfly damper that introduces external air when

the outside temperature is low enough to dissipate the thermal load in the air-

conditioned room.

40 990-91229A-001 / 06MM0368@00B0110

Unit Connections Uniflair™UCF, MRA

Unit Connections

Mechanical Connections

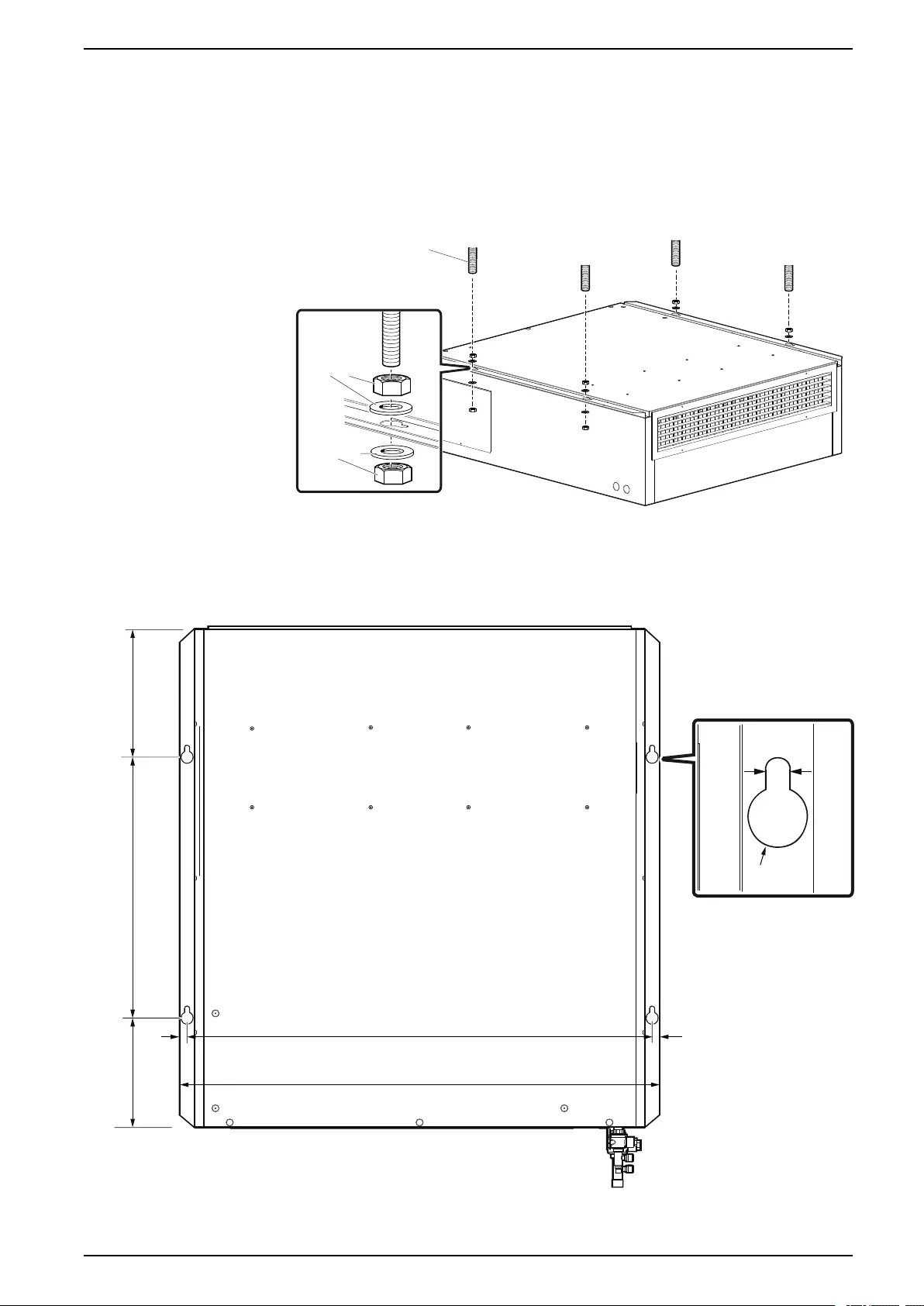

Mounting the Indoor Unit to the Ceiling

FIELD

SUPPLIED

FIELD

SUPPLIED

CUSTOMER SUPPLIED

MOUNTING SUPPORTS

na7094a

NOTE: Framing systems may also be used to suspend the unit.

Dimensions for Mounting Holes–UCF0341

na7074a

REAR

FRONT

230.0

(9.1)

550.0

(21.7)

270.0

(10.6)

980 (38.6)

1010 (39.8)

15.0

(0.6)

15.0

(0.6)

Ø25 (Ø1.0)

10.0

(0.4)

990-91229A-001 / 06MM0368@00B0110 47

Uniflair™UCF, MRA Unit Connections

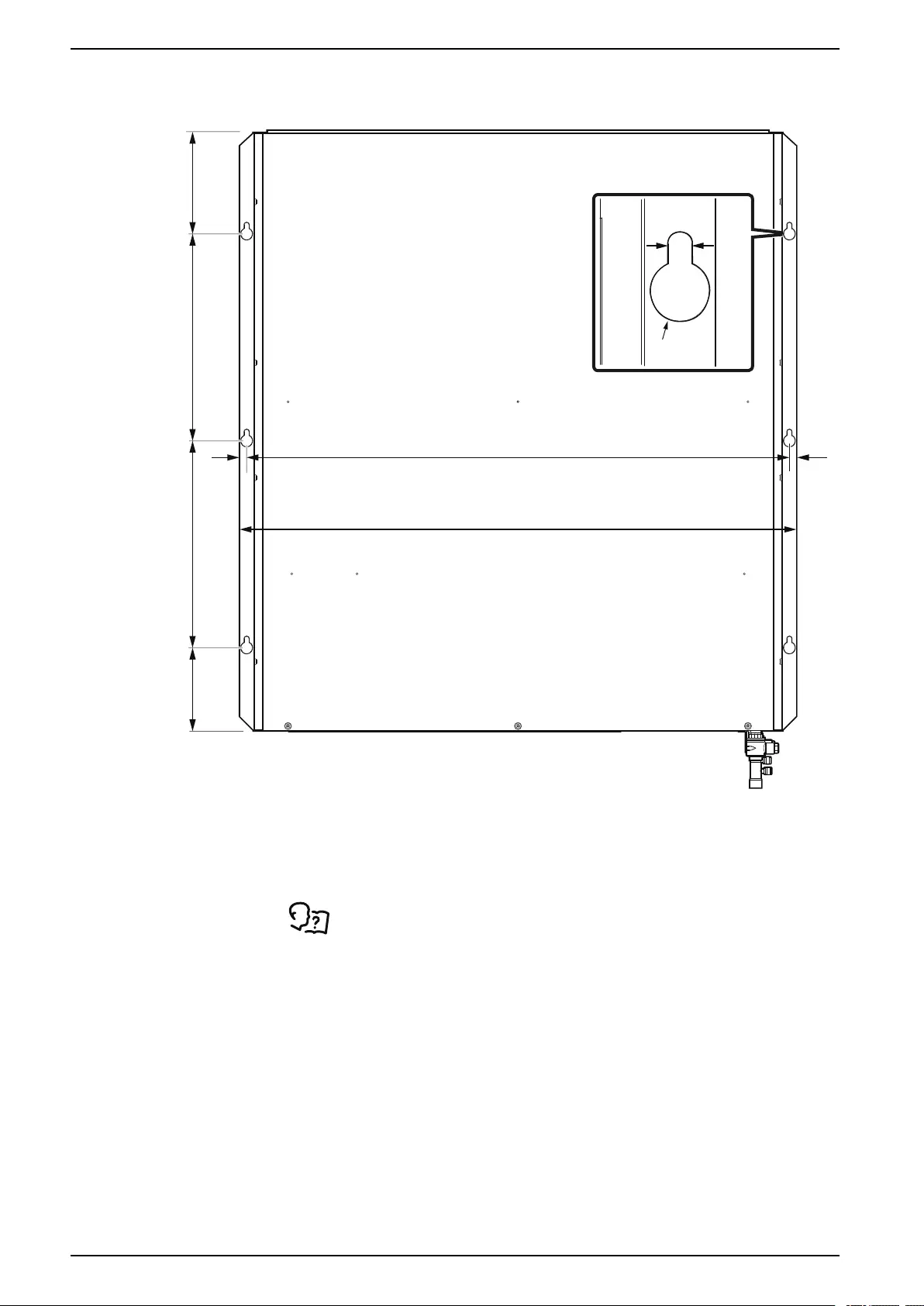

Dimensions for Mounting Holes–UCF0481

1180.0 (46.5)

1210.0 (47.6)

15.0

(0.6)

15.0

(0.6)

220.0

(8.7)

450.0

(17.7)

450.0

(17.7)

180.0

(7.1)

Ø25 (Ø1.0)

10.0

(0.4)

na7075a

REAR

FRONT

Installing the Display Interface

NOTE: The display interface is not for use with external power supply.

See the installation instructions packed with the display interface.

48 990-91229A-001 / 06MM0368@00B0110

Unit Connections Uniflair™UCF, MRA

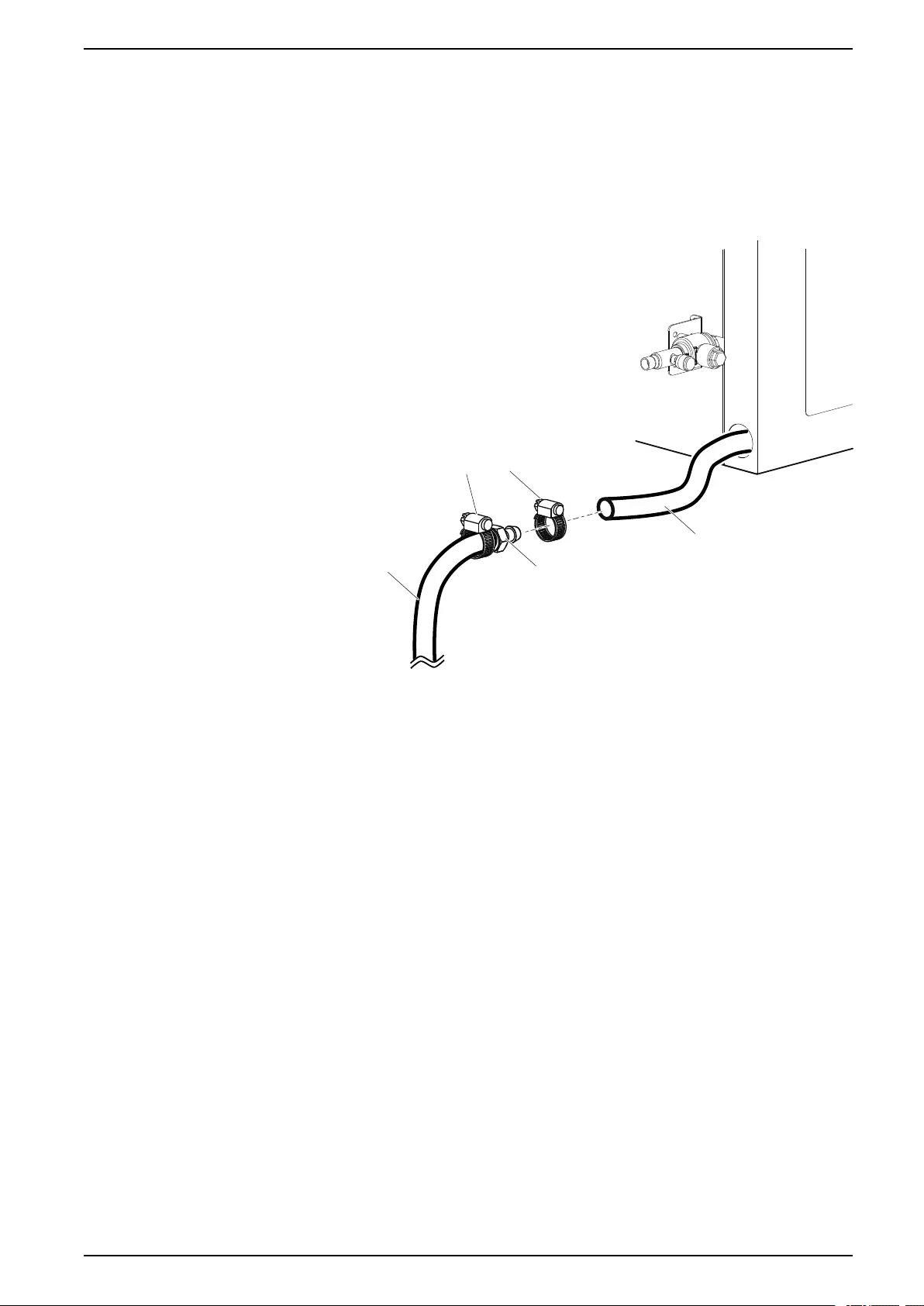

Connecting the Condensate Drain

Condensation drains from the drain pan under the coil through a Ø18 mm (ID)

flexible hose to the rear of the indoor unit. Use a 3/4 in. or 7/8 in. diameter hose

barb fitting and hose clamp (both field supplied) to connect the drain line under the

refrigerant service valves. Horizontal sections of the condensate drain lines should

have a slope of 6.4 mm (1/4 in.) to 12.7 mm (1/2 in.) per 0.3 m (1 ft). Vertical

sections of gravity drains should include an S- or P-trap at the top of the riser. Size

gravity drain piping for a maximum capacity of 100 lb/hr (12 gph).

na7090a

Ø18-MM (ID)

UNIT CONDENSATE

DRAIN HOSE

3/4-IN. OR 7/8-IN.

BARBED HOSE

CONNECTION

(FIELD SUPPLIED)

HOSE CLAMP

(FIELD SUPPLIED)

CUSTOMER

DRAIN HOSE

(FIELD SUPPLIED)

These units only support the use of an external condensate pump. If a condensate

pump is required for the application, a field-supplied unit may be installed in the

condensate drainage piping system. The pump should have its own water

reservoir located below the condensate drain pan of the unit and should be

independently mounted and supported. Do not attach the pump to the exterior

sheet metal of the indoor UCF units. The piping between the UCF unit and the

pump should maintain the gravity drain system requirements noted above.

990-91229A-001 / 06MM0368@00B0110 49

Uniflair™UCF, MRA Unit Connections

Refrigerant Piping

The indoor and outdoor units must only be connected and installed as a matched

set. Systems may not be mixed with equipment from other manufacturers or

aftermarket components except as detailed in these instructions. Install all

refrigerant lines in accordance with these instructions and applicable industry

guidelines. All refrigerant piping must comply with local, regional, and national

codes and regulations.

Before installation of the equipment piping, create a piping plan based on the

installation location, equipment elevations, and actual distances between the

equipment. Calculate an equivalent length based on the actual length of the run,

including valves and fittings. Construct all piping runs from hard-drawn, Type ACR

or Type L copper piping rated for HVAC/R service in accordance with ASTM B280.

Make all refrigerant lines as short and direct as possible. All pipe fittings should

have long-radius bends to minimize the line-set pressure drop. Piping should be

properly supported and isolated from structural surfaces using vibration clamps.

All horizontal lines must be sloped in the direction of flow. Suction lines must be

pitched downward at a minimum of 4 mm per m (1/2 in. per 10 ft) in the direction of

flow to aid in oil return. Suction lines must be insulated for their entire length.

Insulation should have a 13 mm (1/2 in.) wall thickness or at a minimum, have an

R-value of 3 (ft2*°F*hr/Btu). When possible, place piping supports on the exterior

of the piping insulation.

Piping Connection Sizes

Model Liquid Line Suction Line

UCF0341I

MRA0221I

3/8 in. ODF 3/4 in. ODF

UCF0481I

MRA0611D

3/8 in. ODF 7/8 in. ODF

For equipment installed with the evaporator above the condenser, if the

compressor is expected to operate at ambient conditions below freezing, the

system must include inverted piping loops to protect the compressor from liquid

flood-back during off cycles. The bottom of the inverted piping loops must be at

least 25 mm (1 in.) above the top of the evaporator coil. Other system setups may

also require inverted piping loops: the following sections provide more information

for these configurations.

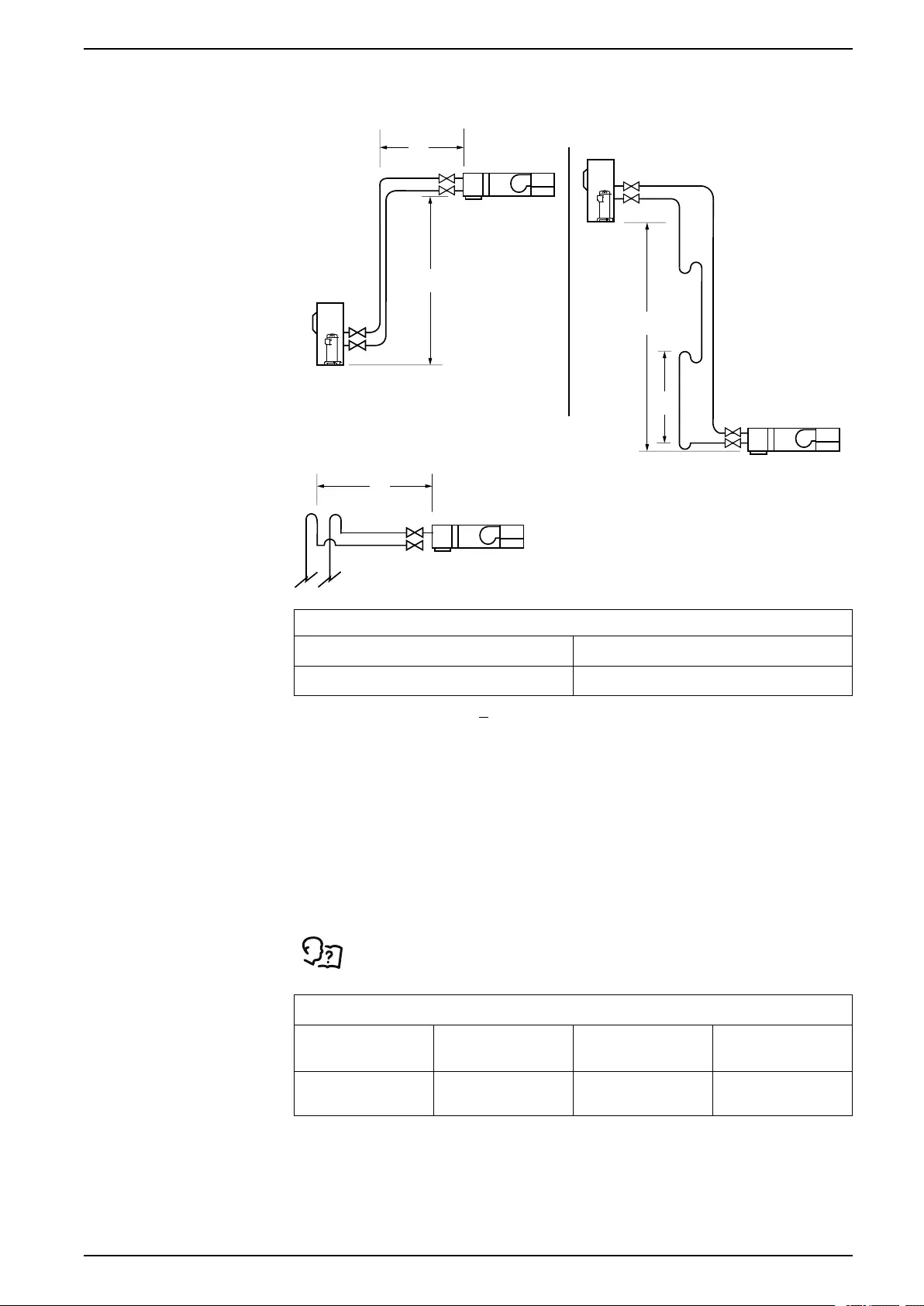

Piping between the indoor and outdoor units should minimize any elevation

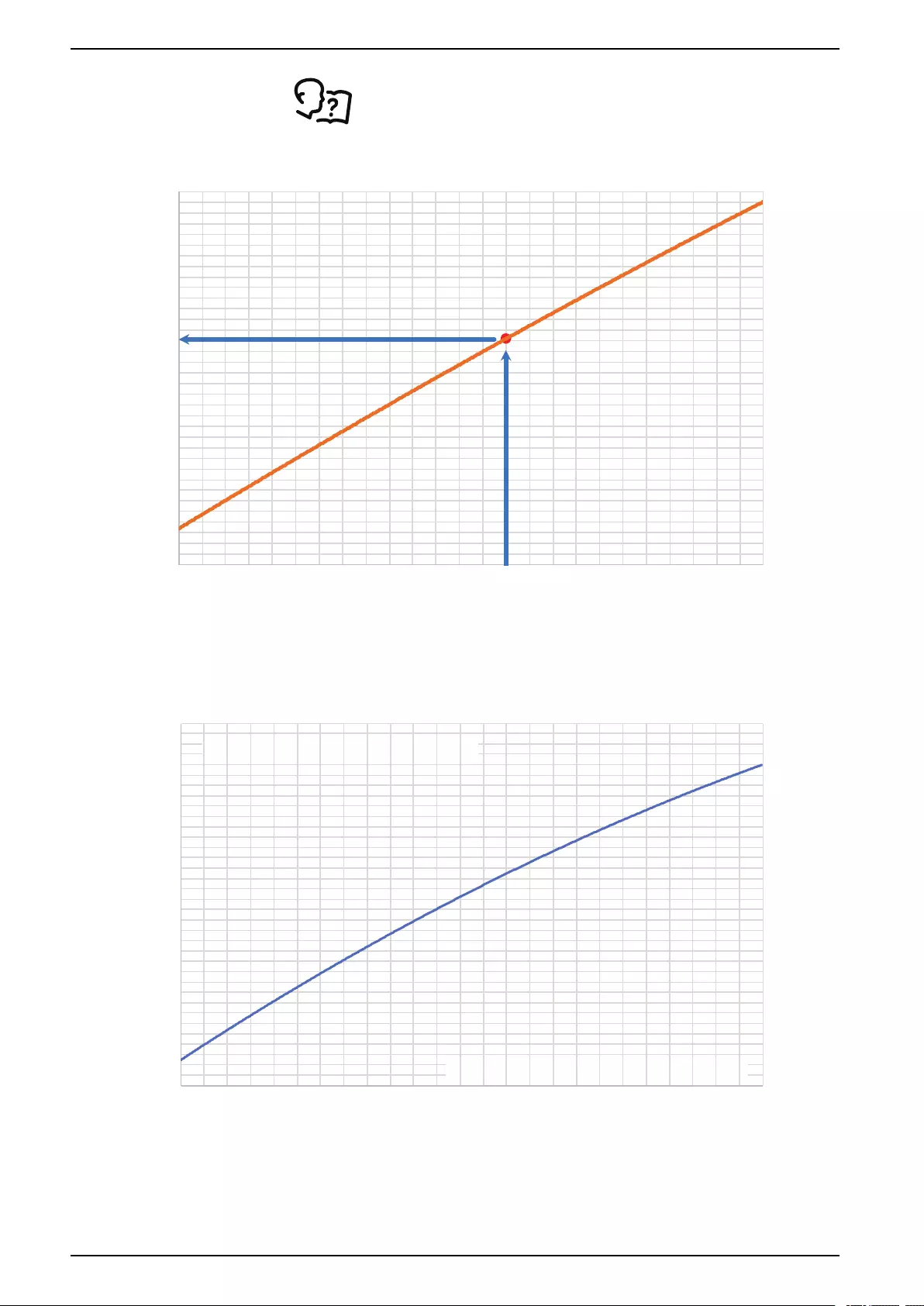

changes between the units. Depending upon installation type, the maximum

recommended elevation between units is shown in the image below with the

recommendations listed in the table.

50 990-91229A-001 / 06MM0368@00B0110

Unit Connections Uniflair™UCF, MRA

na7091a

L

L

H1

H2

h

WHEN L ≥ 14 m (45 ft)

MRA UNIT

MRA

UNIT

UCF UNIT

UCF UNIT

EVAPORATOR

ABOVE

CONDENSER

CONDENSER

ABOVE

EVAPORATOR

UCF UNIT

Maximum Recommended Unit Elevations

Evaporator above Condenser Condenser above Evaporator

4.7 m (15.5 ft)* 13.7 m (45 ft)**

*For applications where L > 13.7 m (45 ft) and the actual piping length is 19.8 m

(65 ft) or longer, the liquid and suction risers should include inverted piping

loops to protect the compressor from liquid flood-back during off cycles.

Additionally, the suction piping loop should contain a P-trap for oil control.

**For applications that exceed 4.8 m (16 ft) of elevation, one oil trap should be

included in the riser for every 4.5 m (15 ft) of elevation. All risers should include

a P-trap at the base of the riser.

See the tables below for the recommended piping sizes that can be used for most

applications assuming a maximum differences in elevation of up to 8.5 m (28 ft).

Suction risers should also conform to the unit connection size of the suction line.

See the Piping Connection Sizes table.

Minimum Interconnecting Suction Pipe Sizes

Equivalent

Length

0-12 m

(0-40 ft)

12.4-22.8 m

(41-75 ft)

23.2-30.4 m

(76-100 ft)

UCF0341I

MRA0221I

3/4 in. ACR 7/8 in. ACR 7/8 in. ACR*

* Applications with significant elevation between units may require horizontal

sections to be increased to 1 1/8 in. ACR

990-91229A-001 / 06MM0368@00B0110 51

Uniflair™UCF, MRA Unit Connections

Minimum Interconnecting Suction Pipe Sizes

Equivalent

Length

0-6.0 m

(0-20 ft)

6.4-22.8 m

(21-75 ft)

23.2-30.4 m

(76-100 ft)

UCF0481I

MRA0611D

3/4 in. ACR 7/8 in. ACR 1 1/8 in. ACR

Applications of 22.8 m (75 ft) or less use 3/8 in. ACR for liquid lines.

NOTE: Install all piping in accordance with applicable industry guidelines as

well as local and national codes and regulations.

Consult with your installation contractor for the following conditions:

• Elevations greater than 8.5 m (28 ft)

• Refrigerant piping noise is a concern

Connect Refrigerant Lines

NOTICE

COMPLIANCE REQUIREMENT

Install all refrigerant lines in accordance with these instructions and applicable

industry guidelines. All refrigerant piping must comply with local, regional, and

national codes and regulations.

Failure to follow these instructions can result in equipment damage.

See Refrigerant Piping, page 50 for more information.

Before making the piping connections, dry fit the piping section together and verify

that the actual piping constructed meets the piping plan layout and applicable

sections of this manual. Then prepare the units and piping for joining. Only use

joining techniques approved for HVAC/R service and that meet or exceed the

rated, high-side pressure of the equipment. For equipment using R-410A

refrigerant, the high–side pressure is typically rated for 4481.6 kPa (650 psig).

See the equipment nameplate for the pressure requirement.

Construct refrigerant piping systems to minimize the contamination of the

refrigeration system during the brazing process.

When brazing copper piping joints, always do the following:

• Use a dry nitrogen gas (or other inert gas) to purge the air from the piping

system.

• Use a high silver content BCuP brazing material (15% is recommended).

• Properly clean, prepare, and deburr each joint.

• If a flux is used, always ensure that it is matched for the brazing material,

application, and temperature of the joint. Do not over-apply flux to the joint.

Always clean excess flux from both the interior and exterior of the joint after

brazing.

NOTE: For field-installed copper refrigeration lines, failure to use a nitrogen

purge during brazing voids the compressor warranty. A properly applied

nitrogen purge at 1-2 cfm prevents the formation of copper oxides (black

scale) inside the piping during brazing operations. Always maintain the flow of

the nitrogen purging gas while the joint is cooling. Allow the purge gas to

continue until the joint has reached the ambient temperature.

52 990-91229A-001 / 06MM0368@00B0110

Unit Connections Uniflair™UCF, MRA

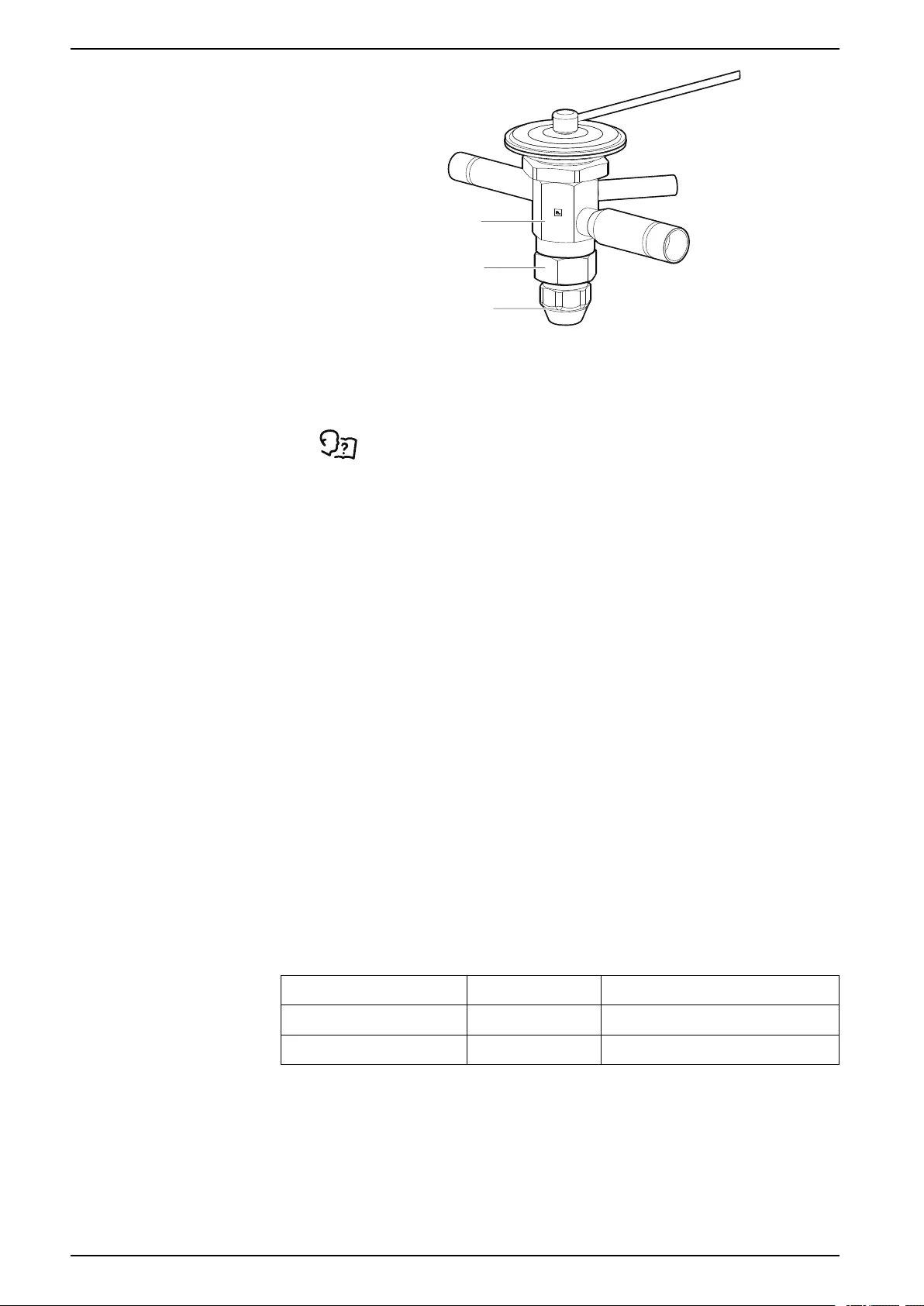

Before brazing any joints near the equipment or at the service valves, always

protect the equipment from the brazing operation. Remove the service valve caps

(1) and valve cores (2) to protect the seals that can be removed. Use a heat-sink

compound or wet rags to protect the internal seals of the ball valve that cannot be

removed. Additionally, place heat shields on the equipment to protect the exterior

panels and paint coating from flame damage.

Pressure Testing

1. After all piping joints have been made, and cooled if they were brazed,

pressure test the piping with nitrogen to ensure that all joints are secure.

2. Pressurize both lines to a minimum of 1723.7 kPa (250 psig) and isolate for at

least 15 minutes.

The line-set should not lose any pressure during this time.

3. If the system passes the initial pressure test, increase the pressure in each

pipe to its specific design pressure.

4. Allow the system to hold the nitrogen charge for at least another 30 minutes.

5. While this pressure testing is being conducted, inspect all joints and fittings in

the system for leaks with a soap and water solution.

The system pressure should not change.

6. If any leaks are present, isolate the line with the leak, and repair the leak.

7. Perform the pressure testing again after all repairs have been made.

8. If a leak is present and cannot be located with a soap and water solution,

remove the nitrogen charge and perform a helium leak test using a quality

instrument.

9. Once the leak has been located, repair it, and perform the nitrogen pressure

test again.

10. Once the line-set has passed the pressure test, install remaining piping

insulation and supports as necessary.

Initial Evacuation, Line-Set

1. When the piping system construction has been completed, evacuate the line-

set to less than 1000 microns.

Use a vacuum gauge to perform this measurement, a standard refrigeration

gauge set is not accurate enough for this operation.

2. Install the vacuum gauge on the opposite end of the equipment line-set from

the vacuum pump.

Only use high quality equipment and hoses that are rated for vacuum

operations.

NOTE: Test the equipment independently of the line-set for its ability to

hold a vacuum before installing it on the line-set.

3. Once the line-set has been evacuated to below 1000 microns, isolate the line-

set from the vacuum pump and allow the line-set to hold a vacuum for at least

10 minutes.

The vacuum micron level may increase slightly once it is isolated from the

pump. This is normal.

4. As long as the reading stabilizes at or below 2500 microns, proceed to the

next step.

If a leak is present, or if an excessive amount of condensibles are in the line-

set, the vacuum micron level may not stabilize on any micron reading within

20 minutes and may even quickly return to atmospheric pressure.

If this is the case, inspect the line-set with a helium leak tester.

5. If a leak is present, find and repair the leak.

6. Perform the pressure testing and evacuation of the line-set again.

990-91229A-001 / 06MM0368@00B0110 53

Uniflair™UCF, MRA Unit Connections

Final Evacuation, System

If the line-set stabilizes on a micron reading of less than 2500 and holds this

reading steady for more than 10 minutes, open the equipment service valves.

These split systems have been dehydrated at the factory and are shipped with a

68.9 kPa (10 psig) holding charge of nitrogen.

1. Open the valves in the following order:

• Open both valves on the indoor unit.

• Open the suction valve on the outdoor unit.

• Open the liquid service valve on the outdoor unit.

This opening procedure prevents oil that is trapped on the pressure side of

the compressor scroll plate from being blown into the system.

2. Bleed the system pressure down to 6.9 kPa (1 psig) with a gauge set, and

restart the vacuum pump.

3. Evacuate the system to 350 microns.

4. Once 350 microns has been attained, isolate the system from the vacuum

pump and allow it to hold a vacuum for at least 10 minutes.

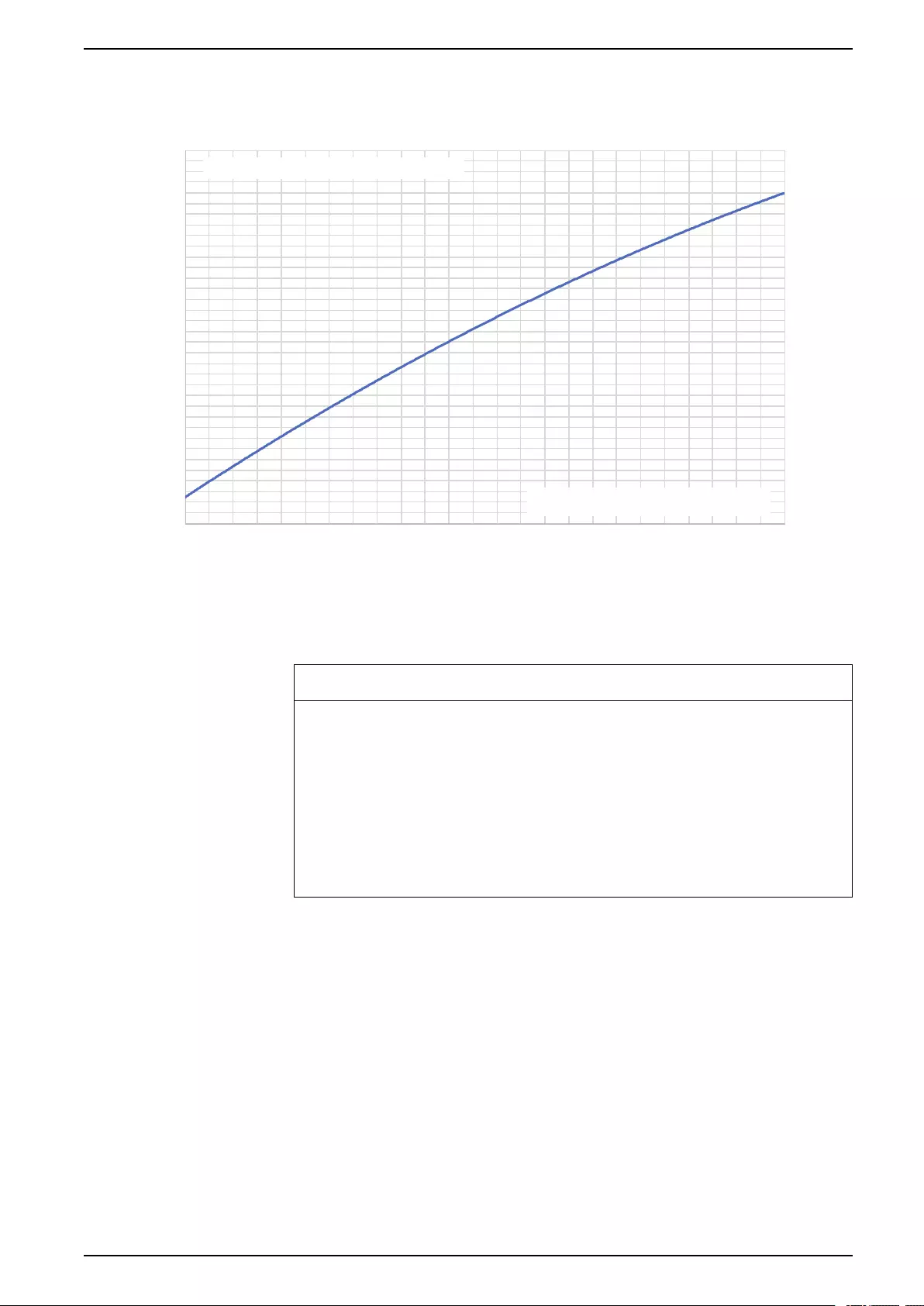

5. The system should stabilize on a value of 1000 microns or less before the

equipment can be charged with refrigerant.

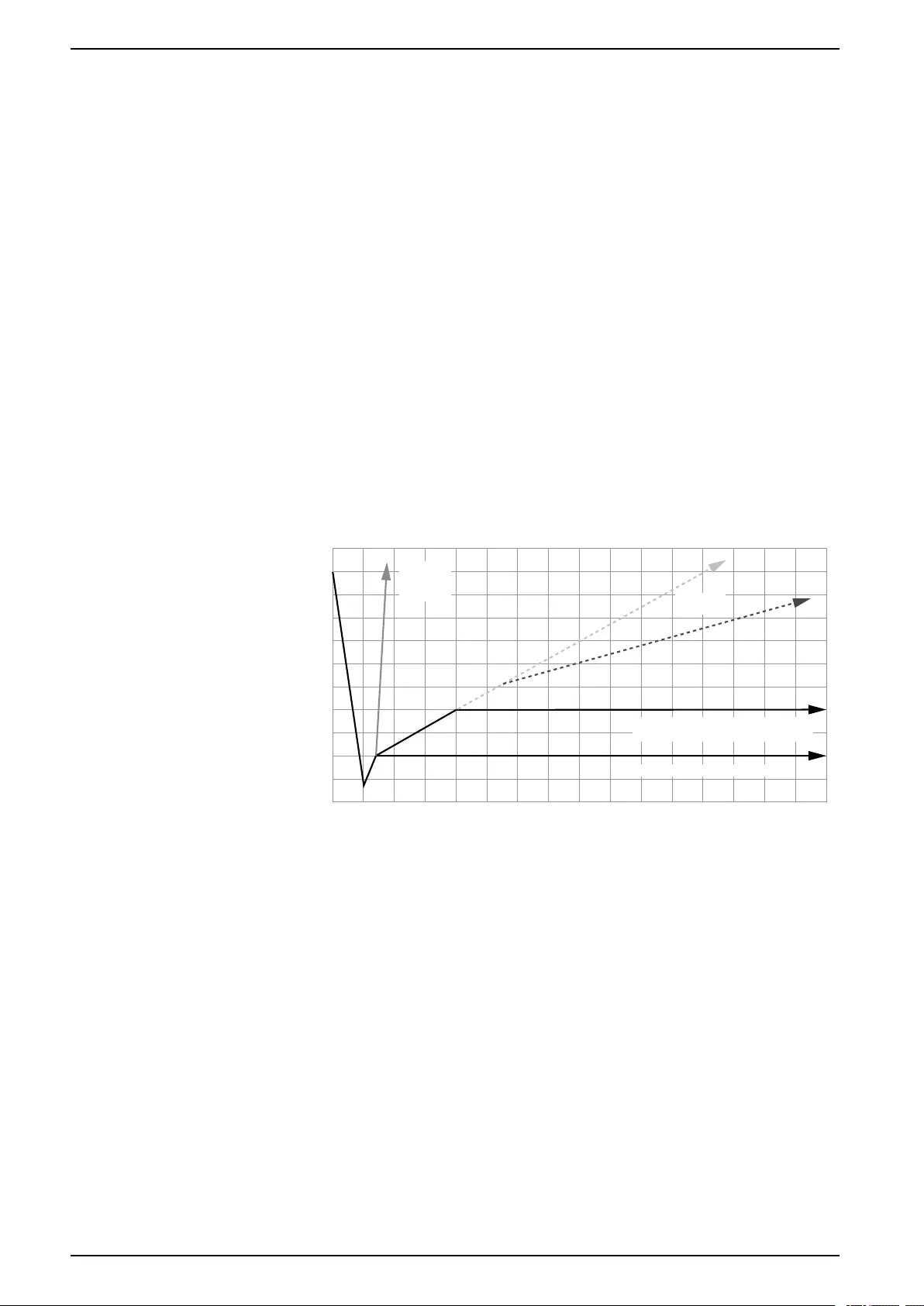

6. See the chart below for examples of different conditions that may be

encountered during the final evacuation.

-1 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

0

500

1000

1500

5500

5000

4500

4000

3500

3000

2500

2000

VACUUM (MICRONS)

TIME (MINUTES)

LARGE

LEAKS

PRESENT LEAKS

PRESENT

GOOD VACUUM, CONDENSIBLES

PRESENT—WET SYSTEM

TIGHT VACUUM—DRY SYSTEM

na7210a

54 990-91229A-001 / 06MM0368@00B0110

Unit Connections Uniflair™UCF, MRA

Electrical Connections

WARNING

ELECTRICAL HAZARD

• Electrical service must conform to local and national electrical codes and

regulations.

• The equipment must be grounded.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

WARNING

ELECTRICAL HAZARD

Ensure that all electrical connections are unplugged before you introduce water

into the unit.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

WARNING

SHARP EDGES

When using power tools be sure to read and follow the rules that come with that

tool.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

NOTICE

HAZARD FROM SHARP EDGES

• Edges of the knock-out panel may be sharp.

• Use a grommet, bushing, or other protective covering for the section of

power cable routed through the knock-out panel.

Failure to follow these instructions can result in equipment damage.

Power Supply

NOTICE

EQUIPMENT DAMAGE

Power supply cables must conform to local and national electrical codes and

regulations.

Failure to follow these instructions can result in equipment damage.

Power supply cables are field supplied and must be sized by the installer.

The power cable must be selected according to the following conditions:

• The length and type of laying

• The maximum current absorbed by the conditioning unit

Power Connections

1. Check that the mains voltage and frequency correspond to those of the unit.

Compare them with the nameplate inside the electric panel.

990-91229A-001 / 06MM0368@00B0110 55

Uniflair™UCF, MRA Unit Connections

The power cables (and the control circuit cables) can pass through the pre-

drilled holes on the unit.

2. Open the door of the electrical panel and perform connections as indicated in

the wiring diagram attached to the documentation of the unit.

3. Tighten the screws.

See the installation drawings included with the unit for more

information.

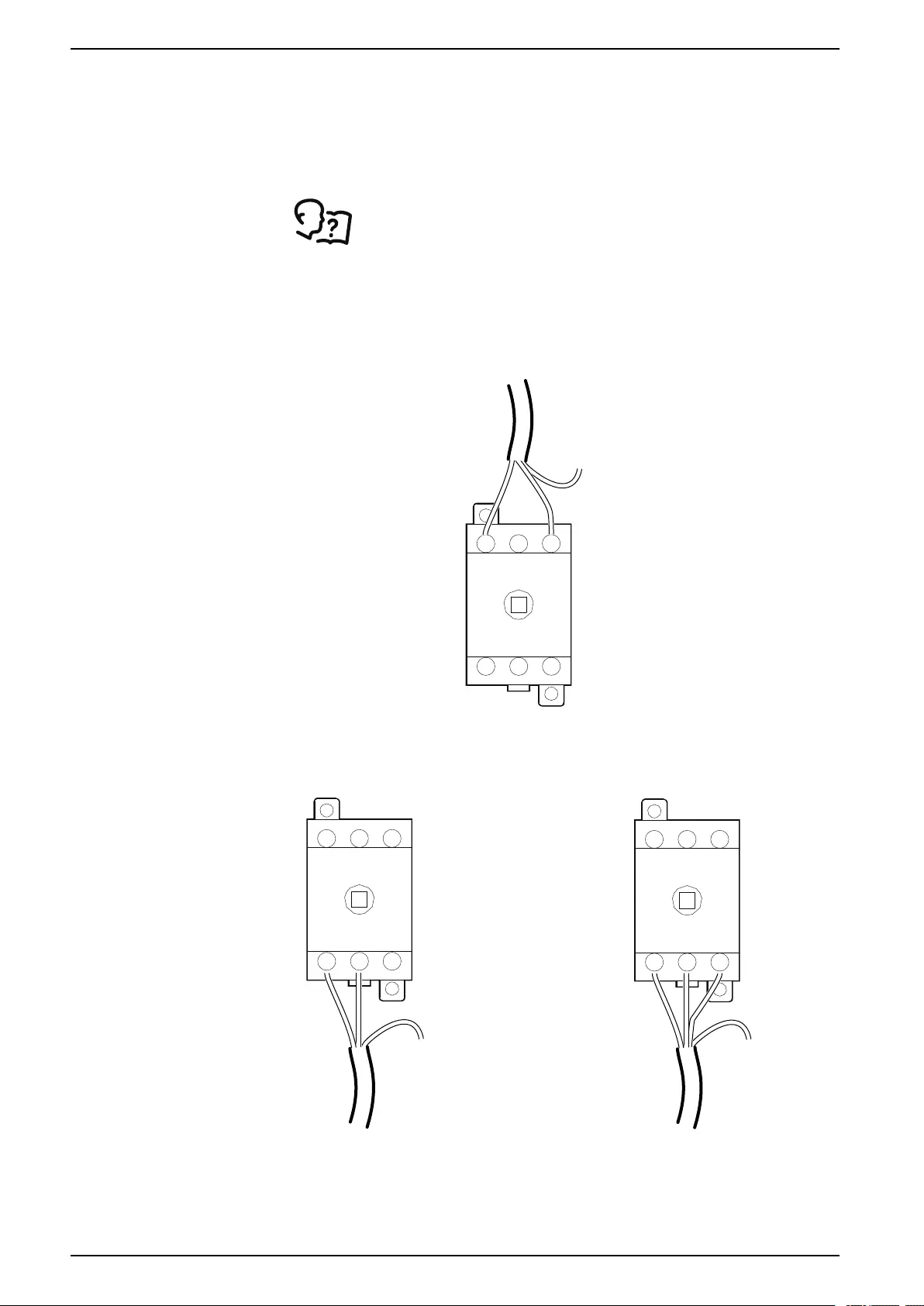

Indoor Units

Q1

L1

L2

TO GROUND

UCF0341I

UCF0481I

11 5

na7092a

Outdoor Units

Q1 Q1

L1 L2 L1 L2

L3

TO GROUND

TO GROUND

MRA0221I MRA0611D

2626

4

na7093a

56 990-91229A-001 / 06MM0368@00B0110

Unit Connections Uniflair™UCF, MRA

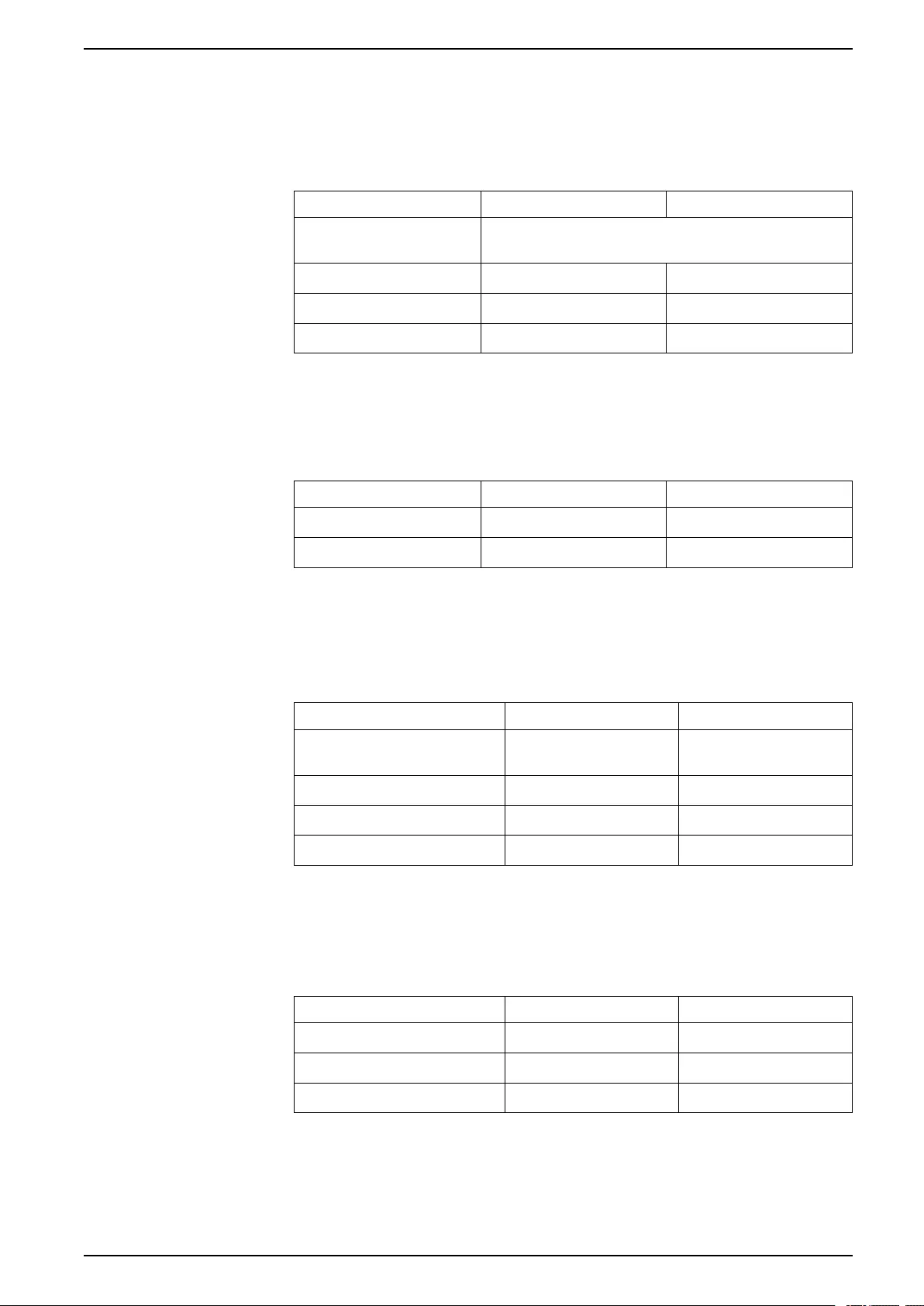

Electrical Data

Indoor Units

Overall Unit

Model UCF0341I UCF0481I

Voltage 208 V, 1 Ph, 60 Hz

230 V, 1 Ph, 60 Hz

FLA (A) 3.0 4.5

MCA (A) 4.5 6.4

MOP (A) 15 15

FLA: Full Load Amps

MCA: Minimum Circuit Amps

MOP: Maximum Overcurrent Protection

Fans

Model UCF0341I UCF0481I

Quantity 2 3

FLA (A) 1.5 1.5

FLA: Full Load Amps

Outdoor Units

Overall Unit

Model MRA0221I MRA0611D

Voltage 208 V, 1 Ph, 60 Hz

230 V, 1 Ph, 60 Hz

208 V, 3 Ph, 60 Hz

230 V, 3 Ph, 60 Hz

FLA (A) 16.4 23.1

MCA (A) 19.6 27.0

MOP (A) 30.0 40.0

FLA: Full Load Amps

MCA: Minimum Circuit Amps

MOP: Maximum Overcurrent Protection

Compressor

Model MRA0221I MRA0611D

Quantity 1 1

LRA (A) 64.0 110.0

RLA (A) 12.8 15.9

LRA: Locked Rotor Amps

RLA: Rated Load Amps

990-91229A-001 / 06MM0368@00B0110 57

Uniflair™UCF, MRA Unit Connections

Axial Fans

Model MRA0221I MRA0611D

Quantity 1 2

FLA (A) 3.6 3.6

FLA: Full Load Amps

Communication Connections

`

PE

L1

L2

1313

0

24

24

1601

1311

1312

1314

1502

1511

0213

0214

CHG

0210

0219

0220

0221

CHG

0204

0215

CHG

24VDC

5057

5059

24

24

0

0

CHG

CHG

CHG

24

CHG

DGND

F2

T1

Q1

F1

PE

TB2F2

PLC1

TB3

PFS

FS

TB1

na7089a

SMOKE/FIRE

SENSOR INPUT

CONDENSING UNIT

CONNECTIONS

(TO TB02 IN

OUTDOOR UNIT)

OUTDOOR

TEMPERATURE/HUMIDITY

SENSOR

REMOTE

TEMPERATURE

SENSOR

REMOTE DISPLAY

CONNECTIONS

6 CONDUCTOR,

18 AWG,

300 V MINIMUM

(CONTROL)

4 CONDUCTOR,

18 AWG,

300 V MINIMUM,

SHIELDED WITH DRAIN

(ANALOG)

2 CONDUCTOR,

18–22 AWG,

SHIELDED WITH DRAIN

(ANALOG)

4 CONDUCTOR,

18–22 AWG,

300 V MINIMUM,

SHIELDED WITH DRAIN

2 PAIR, 18–22 AWG,

SHIELDED WITH DRAIN,

120 OHM

CHARACTERISTIC

IMPEDANCE

CONNECTIONS ON

REMOTE DISPLAY

24VDC

CANL

CANH

D0-

D1+

COM

– +

J2

J4 MODBUS J5 CANBUS

J3

1313

0

24

24

1601

1311

1312

1314

1502

1511

0213

0214

CHG

0210

0219

0220

0221

CHG

0204

0215

CHG

24VDC

5057

5059

CHG

DGND

TB3

See the electrical schematics for more information.

58 990-91229A-001 / 06MM0368@00B0110

Unit Connections Uniflair™UCF, MRA

Interface Connections

J15

J9

24V

J10 J11 J12

100-240V

J13

24V

J14 J16 J17

123

NC COM NONC COM NONC COM NO

4

24V 12V 0V

– +

21 – Link

21

3 4

(1)

(2)

(3)

RS485

RS485 (1)

FIELDBUS

CAN

CANH CANL 0V D0- D1+ 0V

RS485 (2)

2W/4W D0- D1+ 0V

D0- D1+ 0V

TX

RX

RS485 (3)

2W/4W D0- D1+ 0V

D0- D1+ 0V

TX

RX

MODBUS NETWORK

12 3 4

J6

J5J4 CAN

RS485

J3J2J1

na6256b

Item Description Item Description

USB device port Touch screen display connection

USB host port Modbus connection

Serial port Modbus configuration switches

A-Link ports Fieldbus Modbus connection

Reset button Fieldbus Modbus configuration switches

Output relay 4/standby input Fieldbus CANbus configuration switches

Output relay 1–3 Fieldbus CANbus connection

Universal sensor ports Processor status LED

Network connection

990-91229A-001 / 06MM0368@00B0110 59

Uniflair™UCF, MRA Unit Connections

A-Link Ports

NOTICE

CAT 5 PINOUT

Devices connected on the A-Link ports should use a standard pin-out (1-1, 2-2,

3-3, 4-4, 5-5, 6-6, 7-7, 8-8) CAT5 cable only.

Failure to follow these instructions can result in equipment damage.

NOTE: All input and output connections should be wired as Class 2 circuits.

The A-Link bus connection allows a maximum group of twelve units to

communicate with one another.

To enable the units to function as a group, link them together using a standard pin-

out CAT-5 cable with RJ-45 connectors. The A-Link bus must be terminated at the

first and last unit installed in the group. See example below. An A-Link terminator

is supplied with the unit.

NOTE: The maximum wire length for the entire group must not exceed 305 m

(1,000 ft).

60 990-91229A-001 / 06MM0368@00B0110

Unit Connections Uniflair™UCF, MRA

Output Relays and Standby Input

na4400c

Item Name Description

Output relay 1 N.O. Normally Open contact

Output relay 1 COM Common contact

Output relay 1 N.C. Normally Closed contact

Output relay 2 N.O. Normally Open contact

Output relay 2 COM Common contact

Output relay 2 N.C. Normally Closed contact

Output relay 3 N.O. Normally Open contact

Output relay 3 COM Common contact

Output relay 3 N.C. Normally Closed contact

Output relay 4 N.O. Normally Open contact

Output relay 4 COM Common contact

Output relay 4 N.C. Normally Closed contact

Ground Ground reference, typically connected to the negative connection of

Standby Input, when using the 12 VDC or 24 VDC power supply.

12 VDC Standby input 12 VDC supply current limited to 20 mA

24 VDC Standby input 24 VDC supply current limited to 20 mA

Standby Input + Positive connection used for Standby Input

Standby Input – Negative connection used for Standby Input. Typically connected to

ground.

990-91229A-001 / 06MM0368@00B0110 61

Uniflair™UCF, MRA Unit Connections

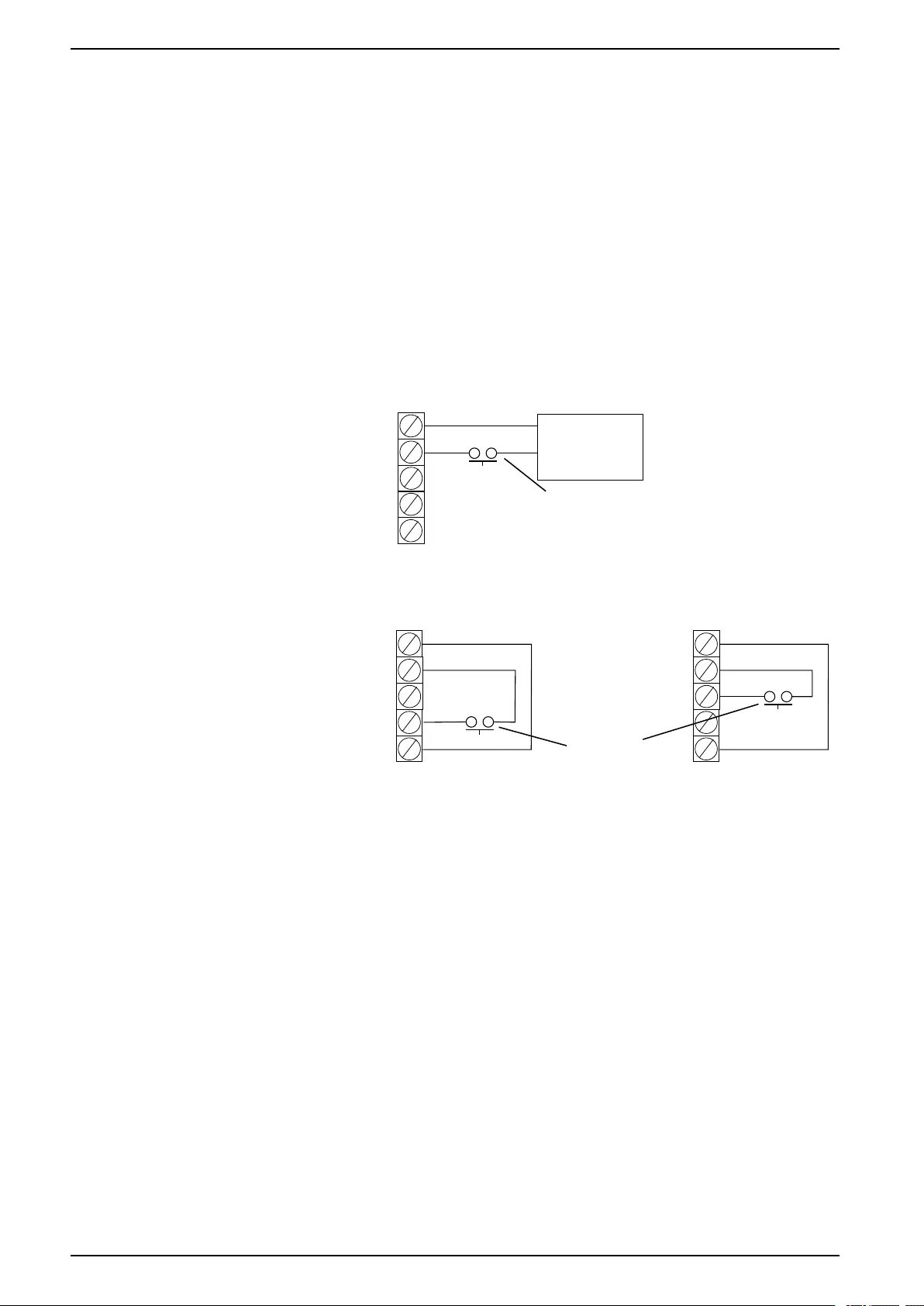

Output Relays

Four output relays connections are available. These relays can be configured,

through the user interface, to various alarms detecting normal or abnormal

conditions.

Output relays are Form C type, having a Normally Open (N.O.), Normally Closed

(N.C.), and Common (COM) contacts.

NOTE: Output Relays are rated at 24 VDC, 0.6 A maximum.

Standby Input

Standby input allows the cooling unit to be remotely placed in Standby mode.

Standby mode is configured through the user interface and can be set as a

normally “active” or “not active” input.

NOTE: Standby Input is rated at 12/24-V AC DC. If using field supplied

voltage, the Standby Input consumes 10 mA maximum at 24 VDC.

na4478a

EXTERNAL POWER SUPPLY

STANDBY

12-30 V AC/DC

SD–

SD+

24V_SD

12V_SD

GND

NOT USED

NOT USED

NOT USED

12–30V AC/DC

POWER SUPPLY

N.O. OR N.C.

CONTACTS

12V POWER SUPPLY 24V POWER SUPPLY

STANDBY

12-30 V AC/DC

STANDBY

12-30 V AC/DC

N.O. OR N.C.

CONTACTS

SD–

SD+

24V_SD

12V_SD

GND

SD–

SD+

24V_SD

12V_SD

GND

NOT USED

NOT USED

*Normally open contacts shown.

62 990-91229A-001 / 06MM0368@00B0110

Unit Connections Uniflair™UCF, MRA

Temperature Sensor

See unit wiring diagrams for more information.

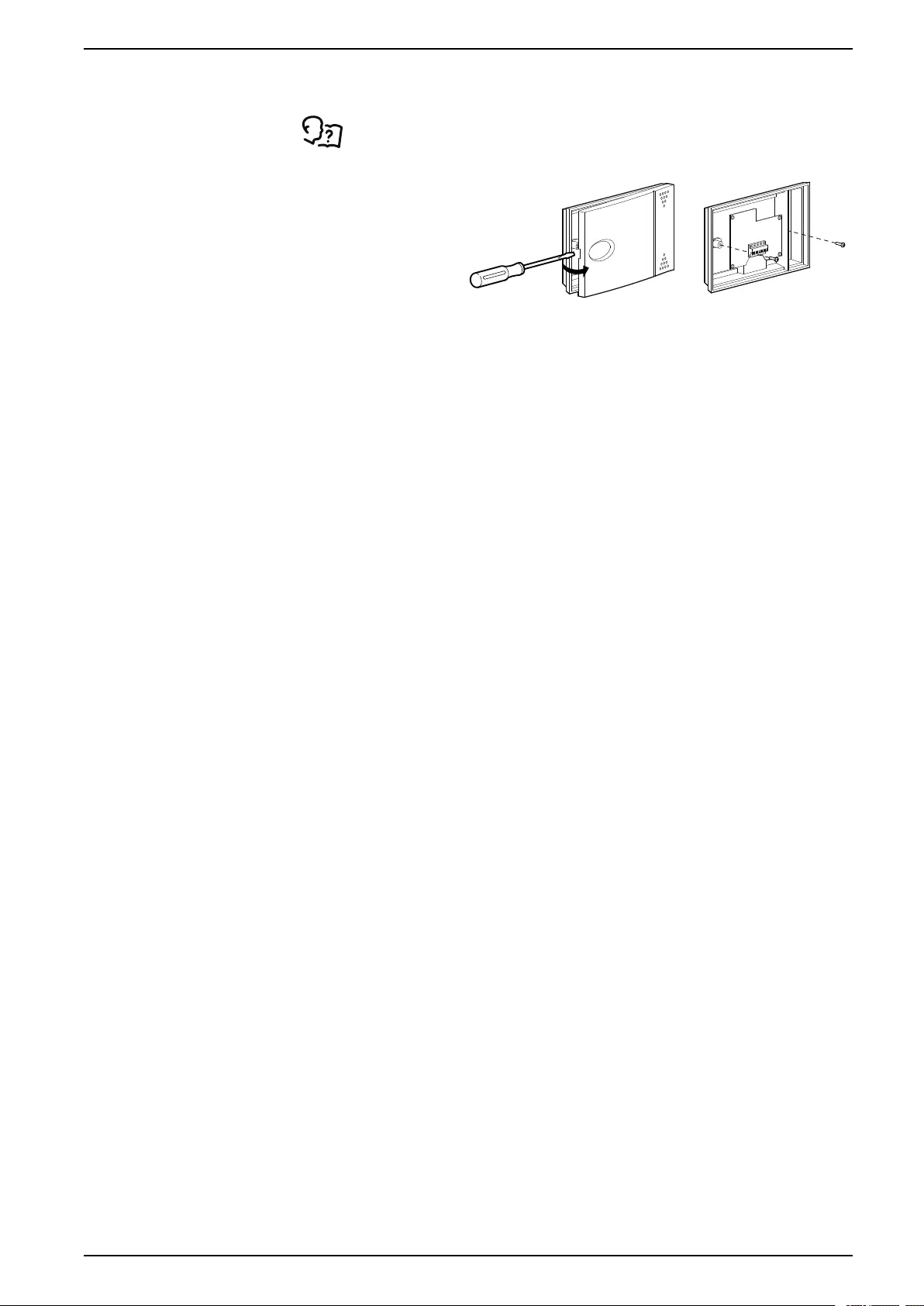

1. Insert a

screwdriver in the

slot and release

the front cover of

the sensor.

2. Remove the lid

and fasten the

screws inside the

sensor to the

mounting

location.

3. Connect the

shielded cable to

the two terminals

on the sensor,

using the

electrical diagram

in the unit as

reference.

na4730a

990-91229A-001 / 06MM0368@00B0110 63

Uniflair™UCF, MRA Charging the Refrigeration System

Charging the Refrigeration System

Calculating R410A Charge

To calculate the initial charge requirement of the equipment, see the piping plan

layout for the actual lengths of the equipment line-set.

See Refrigerant Piping, page 50 for more information.

Verify that the actual piping matches the planned layout. If necessary, measure

the actual lengths of piping used for traps and loops to get the total pipe length.

Using the table below, find the installed liquid and suction line sizes and look up

the R410A multiplier for your application. The table provides the amount of

R410A, in ounces per foot for different combinations of suction and liquid line

sizes (ACR tubing only). Multiply the value in the table by the length of the line-set

to provide the total ounces of R410A for the line-set.

Line-Set Charge Adjustment, Initial Charge,

Ounces of R410A/Foot (Grams of R410A/Centimeter)

Liquid Line Size

Suction Line Size 3/8 in. ACR 1/2 in. ACR

3/4 in. ACR 14.0 g (0.62 oz) N/A

7/8 in. ACR 18.7 g (0.66 oz) 32.3 g (1.14 oz)

1-1/8 in. ACR 20.9 g (0.74 oz) 34.5 g (1.22 oz)

Charge amount is based on the actual line-set length.

Look up the equipment charge in the table. A standard line-set is sized to the

service valve sizes of the equipment.

Initial R410A Charge Weight Calculation

Unit Indoor and Outdoor Units Only Charge

UCF0341I

MRA0221I

2.5 kg (5 lb 10 oz)

UCF0481I

MRA0611D

4.9 kg (10 lb 15 oz)

NOTE: Always verify the equipment charge amount listed on the nameplates.

If the nameplate charge differs from that listed in these instructions, use the

nameplate value.

Add the “Indoor and Outdoor Units Only” charge amount to the calculated line-set

charge. This is the initial charge for the equipment before start-up.

Total charge = Outdoor Equipment charge + Indoor Equipment charge + Line-set

charge

See R410A Refrigerant Charging Charts, page 66.

64 990-91229A-001 / 06MM0368@00B0110

Charging the Refrigeration System Uniflair™UCF, MRA

Charging the Equipment

WARNING

HAZARD TO EQUIPMENT OR PERSONNEL

All work must be performed by Schneider Electric qualified personnel.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

CAUTION

HAZARD OF HIGH PRESSURE REFRIGERANT OR EQUIPMENT DAMAGE

• Use R410A refrigerant only.

• The unit display should be used to obtain pressure readings.

Failure to follow these instructions can result in injury or equipment

damage.

NOTICE

DAMAGE TO EQUIPMENT OR PERSONNEL

POE oil is highly hygroscopic and can attract more moisture from surroundings

and the atmosphere. Do not use any POE oil that has been left in an unsealed

or improperly sealed container for any length of time. This could lead to

problems with the equipment or lead to acid formation in the equipment.

Failure to follow these instructions can result in equipment damage.

Before installing the initial refrigerant charge always complete a system

evacuation.

See Connect Refrigerant Lines, page 52 for more information.

When first commissioning a system, weight in the calculated, initial refrigerant

charge before equipment start-up. If a POE oil charge is also required, charge the

oil before equipment startup. Charge with oil through any of the service ports on

the discharge line located in the outdoor unit. Always use a high quality POE oil

approved for use by the compressor manufacturer. These units should use

Copeland Ultra 32-3MAF, Copeland Ultra22 CC, or an approved equivalent.

See Calculating R-410A Charge, page 64 for details on calculating the

initial charge amount.

After the initial refrigerant and oil charge (if necessary) has been weighted in, the

equipment may be started if all other install steps are completed. Always verify the

equipment charge upon startup with the charging chart provided in these

instructions. If the equipment does not meet the charging chart requirements,

adjust the equipment charge in accordance with the instructions on the charging

chart.

990-91229A-001 / 06MM0368@00B0110 65

Uniflair™UCF, MRA Charging the Refrigeration System

Compressor Oil Charge

Oil Charging Procedure

NOTICE

DAMAGE TO EQUIPMENT

Do not charge the compressor with too much oil: compressor damage could

result. The only way to drain oil from the compressor is to remove the

compressor from the equipment. The following system damage could also

occur:

• Failure of valves and pistons due to oil slugging.

• Excessive oil carryover.

• Loss of evaporator performance due to oil level build-up in the low-pressure

side of the system.

Failure to follow these instructions can result in equipment damage.

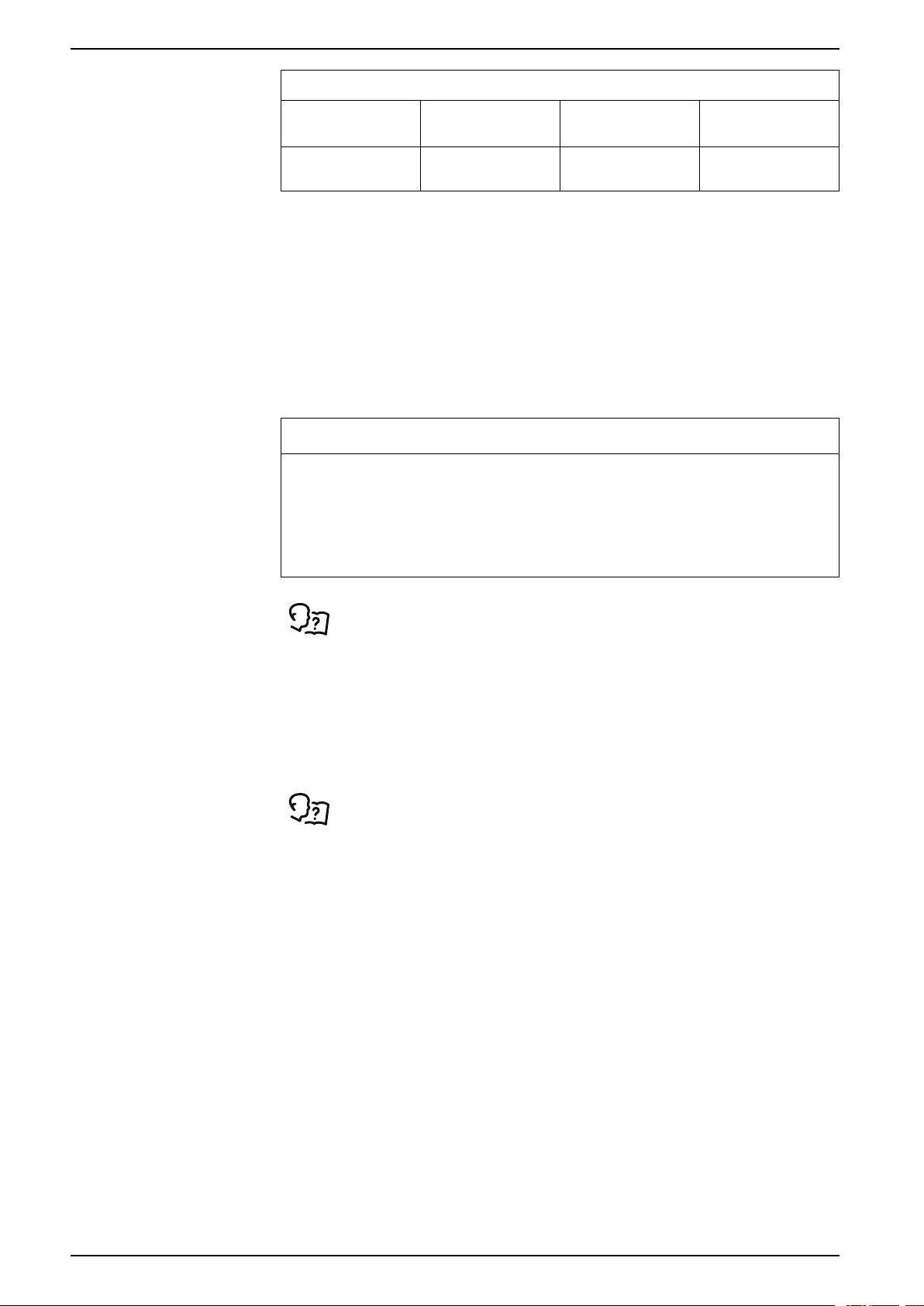

Calculating POE Oil Charge

If the total R410A refrigerant charge for the system exceeds 9 kg (20 lb), use the

chart to determine the appropriate POE oil charge required.

Final System

R410A Charge

9–11 kg

(20–25 lb)

11–13 kg

(25–30 lb)

13–16 kg

(30–35 lb)

POE Oil Addition

Requirements

0.02 kg (1 oz) 0.06 kg (2 oz) 0.08 kg (3 oz)

R410A Refrigerant Charging Charts

CAUTION

HAZARD OF HIGH PRESSURE REFRIGERANT OR EQUIPMENT DAMAGE

• Use R410A refrigerant only.

• Contents are under pressure: use caution when releasing pressure in the

system or refilling.

• Charging and maintaining the refrigeration circuit must only be performed by

qualified personnel.

Failure to follow these instructions can result in injury or equipment

damage.

The equipment comes factory supplied with a dry nitrogen holding charge.

The unit charging charts shown below are only intended to be used with the listed

indoor and outdoor equipment matches as shown in the titles of the charts

(MRA0611D and UCF0481I) and (MRA0221I and UCF0341I) and should not be

used for any other equipment.

The charging charts are only intended for final verification of the unit charge.

When first commissioning a unit during installation, always weigh in the proper

equipment charge to the listed nameplate value plus the proper line-set

adjustment.

See the previous sections of this Installation Manual for additional

details.