Table of Contents

APC SYWMBP96K160H2 User Manual

Displayed below is the user manual for SYWMBP96K160H2 by APC which is a product in the Uninterruptible Power Supplies (UPSs) category. This manual has pages.

Related Manuals

Symmetra™ PX 160

Maintenance Bypass Enclosure

Installation

05/2014

www.schneider-electric.com

Legal Information

The Schneider Electric brand and any registered trademarks of Schneider Electric

Industries SAS referred to in this guide are the sole property of Schneider Electric

SA and its subsidiaries. They may not be used for any purpose without the owner's

permission, given in writing. This guide and its content are protected, within the

meaning of the French intellectual property code (Code de la propriété

intellectuelle français, referred to hereafter as "the Code"), under the laws of

copyright covering texts, drawings and models, as well as by trademark law. You

agree not to reproduce, other than for your own personal, noncommercial use as

defined in the Code, all or part of this guide on any medium whatsoever without

Schneider Electric's permission, given in writing. You also agree not to establish

any hypertext links to this guide or its content. Schneider Electric does not grant

any right or license for the personal and noncommercial use of the guide or its

content, except for a non-exclusive license to consult it on an "as is" basis, at your

own risk. All other rights are reserved.

Electrical equipment should be installed, operated, serviced, and maintained only

by qualified personnel. No responsibility is assumed by Schneider Electric for any

consequences arising out of the use of this material.

As standards, specifications, and designs change from time to time, please ask for

confirmation of the information given in this publication.

Maintenance Bypass Enclosure

Table of Contents

Important Safety Information.....................................................................1

Safety Precautions .....................................................................................2

Electrical Safety....................................................................................4

Specifications ..............................................................................................6

Product Overview........................................................................................8

Installation..................................................................................................10

Prepare for Cables ...................................................................................10

Mount the Maintenance Bypass Enclosure to the Wall ................................. 11

Connect the Power Cables........................................................................ 11

Connect the Communication Cables ..........................................................13

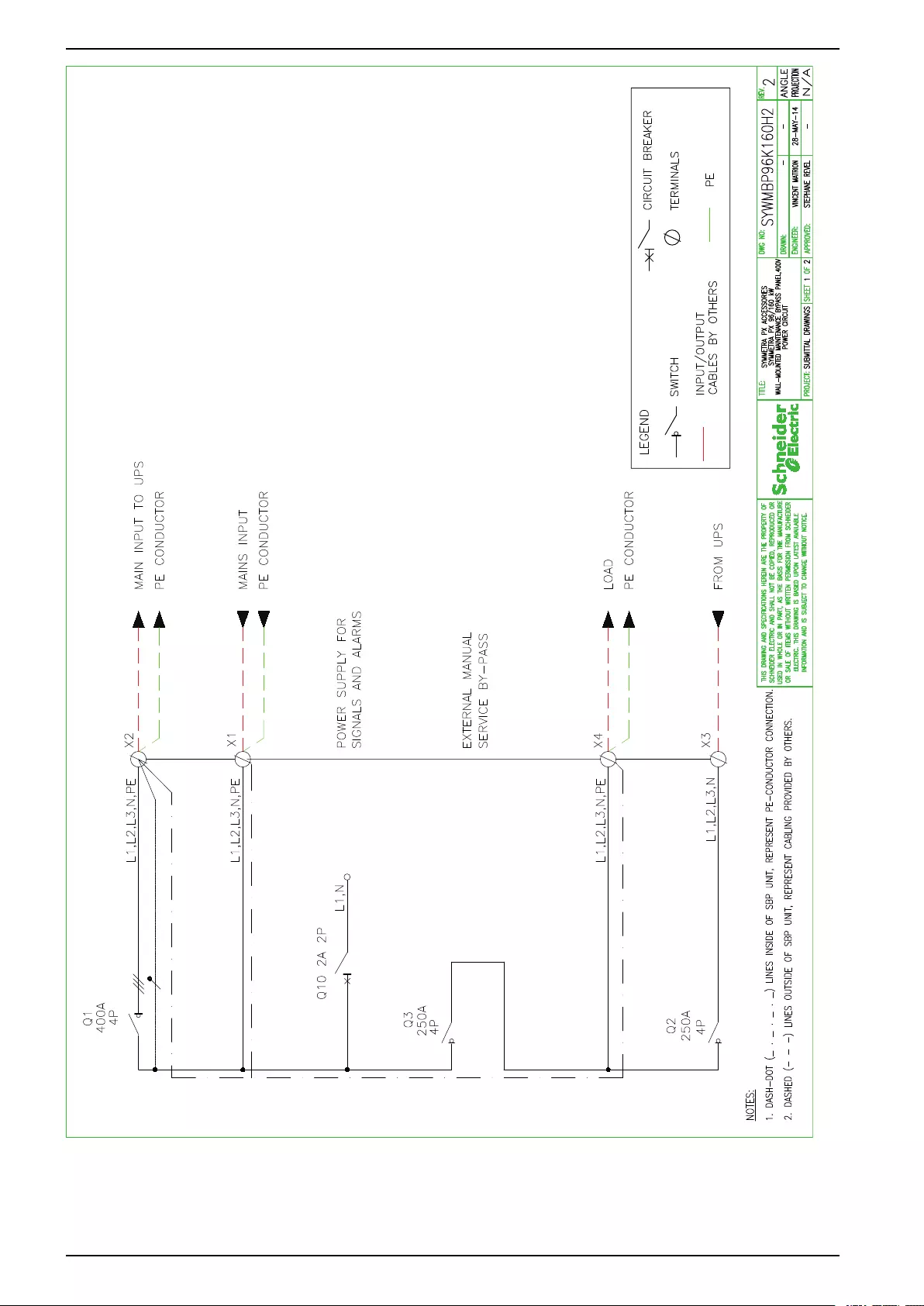

Diagram...................................................................................................13

990–4907A-001 i

Maintenance Bypass Enclosure

ii 990–4907A-001

Important Safety Information Maintenance Bypass Enclosure

Important Safety Information

Read these instructions carefully and look at the equipment to become familiar with

it before trying to install, operate, service or maintain it. The following safety

messages may appear throughout this manual or on the equipment to warn of

potential hazards or to call attention to information that clarifies or simplifies a

procedure.

The addition of this symbol to a “Danger” or “Warning” safety

message indicates that an electrical hazard exists which will result in

personal injury if the instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages with this symbol

to avoid possible injury or death.

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

Failure to follow these instructions will result in death or serious injury.

WARNING

WARNING indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

Failure to follow these instructions can result in injury or equipment

damage.

NOTICE

NOTICE is used to address practices not related to physical injury. The safety

alert symbol shall not be used with this type of safety message.

Failure to follow these instructions can result in equipment damage.

Please Note

Electrical equipment should only be installed, operated, serviced, and maintained

by qualified personnel. No responsibility is assumed by Schneider Electric for any

consequences arising out of the use of this material.

990–4907A-001 1

Maintenance Bypass Enclosure Important Safety Information

A qualified person is one who has skills and knowledge related to the construction,

installation, and operation of electrical equipment and has received safety training

to recognize and avoid the hazards involved.

Safety Precautions

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

All safety instructions in this document must be read, understood and followed.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

Read all instructions in the Installation Manual before installing or working on this

UPS system.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

Do not install the UPS system until all construction work has been completed

and the installation room has been cleaned.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

• The product must be installed according to the specifications and

requirements as defined by Schneider Electric. It concerns in particular the

external and internal protections (upstream circuit breakers, battery circuit

breakers, cabling, etc.) and environmental requirements. No responsibility is

assumed by Schneider Electric if these requirements are not respected.

• After the UPS system has been electrically wired, do not start up the system.

Startup must only be performed by Schneider Electric.

Failure to follow these instructions will result in death or serious injury.

2 990–4907A-001

Important Safety Information Maintenance Bypass Enclosure

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

The UPS System must be installed according to local and national regulations.

Install the UPS according to:

• IEC 60364 (including 60364–4–41- protection against electric shock, 60364–

4–42 - protection against thermal effect, and 60364–4–43 - protection against

overcurrent), or

• NEC NFPA 70

depending on which one of the standards apply in your local area.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

• Install the UPS system in a temperature controlled environment free of

conductive contaminants and humidity.

• Install the UPS system on a non-inflammable, level and solid surface (e.g.

concrete) that can support the weight of the system.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

The UPS is not designed for and must therefore not be installed in the following

unusual operating environments:

• Damaging fumes

• Explosive mixtures of dust or gases, corrosive gases, or conductive or radiant

heat from other sources

• Moisture, abrasive dust, steam or in an excessively damp environment

• Fungus, insects, vermin

• Salt-laden air or contaminated cooling refrigerant

• Pollution degree higher than 2 according to IEC 60664-1

• Exposure to abnormal vibrations, shocks, and tilting

• Exposure to direct sunlight, heat sources, or strong electromagnetic fields

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Do not drill/punch holes for cables or conduits with the gland plates installed and

do not drill/punch in close proximity to the UPS.

Failure to follow these instructions will result in death or serious injury.

990–4907A-001 3

Maintenance Bypass Enclosure Important Safety Information

WARNING

HAZARD OF ARC FLASH

Do not make mechanical changes to the product (including removal of cabinet

parts or drilling/cutting of holes) that are not described in the Installation Manual.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

WARNING

HAZARD OF OVERHEATING

Respect the space requirements around the UPS system and do not cover the

product’s ventilation openings when the UPS system is in operation.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

WARNING

HAZARD OF EQUIPMENT DAMAGE

Do not connect the UPS output to regenerative load systems including

photovoltaic systems and speed drives.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

Electrical Safety

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

• Electrical equipment must be installed, operated, serviced, and maintained

only by qualified personnel.

• The UPS system must be installed in a room with restricted access (qualified

personnel only).

• Apply appropriate personal protective equipment (PPE) and follow safe

electrical work practices.

• Turn off all power supplying the UPS system before working on or inside the

equipment.

• Before working on the UPS system, check for hazardous voltage between all

terminals including the protective earth.

• The UPS contains an internal energy source. Hazardous voltage can be

present even when disconnected from the mains supply. Before installing or

servicing the UPS system, ensure that the units are OFF and that mains and

batteries are disconnected. Wait five minutes before opening the UPS to

allow the capacitors to discharge.

• A disconnection device (e.g. disconnection circuit breaker or switch) must be

installed to enable isolation of the system from upstream power sources in

accordance with local regulations. This disconnection device must be easily

accessible and visible.

• The UPS must be properly earthed/grounded and due to a high leakage

current, the earthing/grounding conductor must be connected first.

Failure to follow these instructions will result in death or serious injury.

4 990–4907A-001

Important Safety Information Maintenance Bypass Enclosure

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

In systems where backfeed protection is not part of the standard design, an

automatic isolation device (backfeed protection option or other device meeting

the requirements of IEC/EN 62040–1 or UL1778 4th Edition – depending on

which of the two standards apply to your local area) must be installed to prevent

hazardous voltage or energy at the input terminals of the isolation device. The

device must open within 15 seconds after the upstream power supply fails and

must be rated according to the specifications.

Failure to follow these instructions will result in death or serious injury.

When the UPS input is connected through external isolators that, when opened,

isolate the neutral or when the automatic backfeed isolation is provided external to

the equipment or is connected to an IT power distribution system, a label must be

fitted at the UPS input terminals, and on all primary power isolators installed

remote from the UPS area and on external access points between such isolators

and the UPS, by the user, displaying the following text (or equivalent in a language

which is acceptable in the country in which the UPS system is installed):

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Risk of Voltage Backfeed. Before working on this circuit: Isolate the UPS and

check for hazardous voltage between all terminals including the protective earth.

Failure to follow these instructions will result in death or serious injury.

990–4907A-001 5

Maintenance Bypass Enclosure Specifications

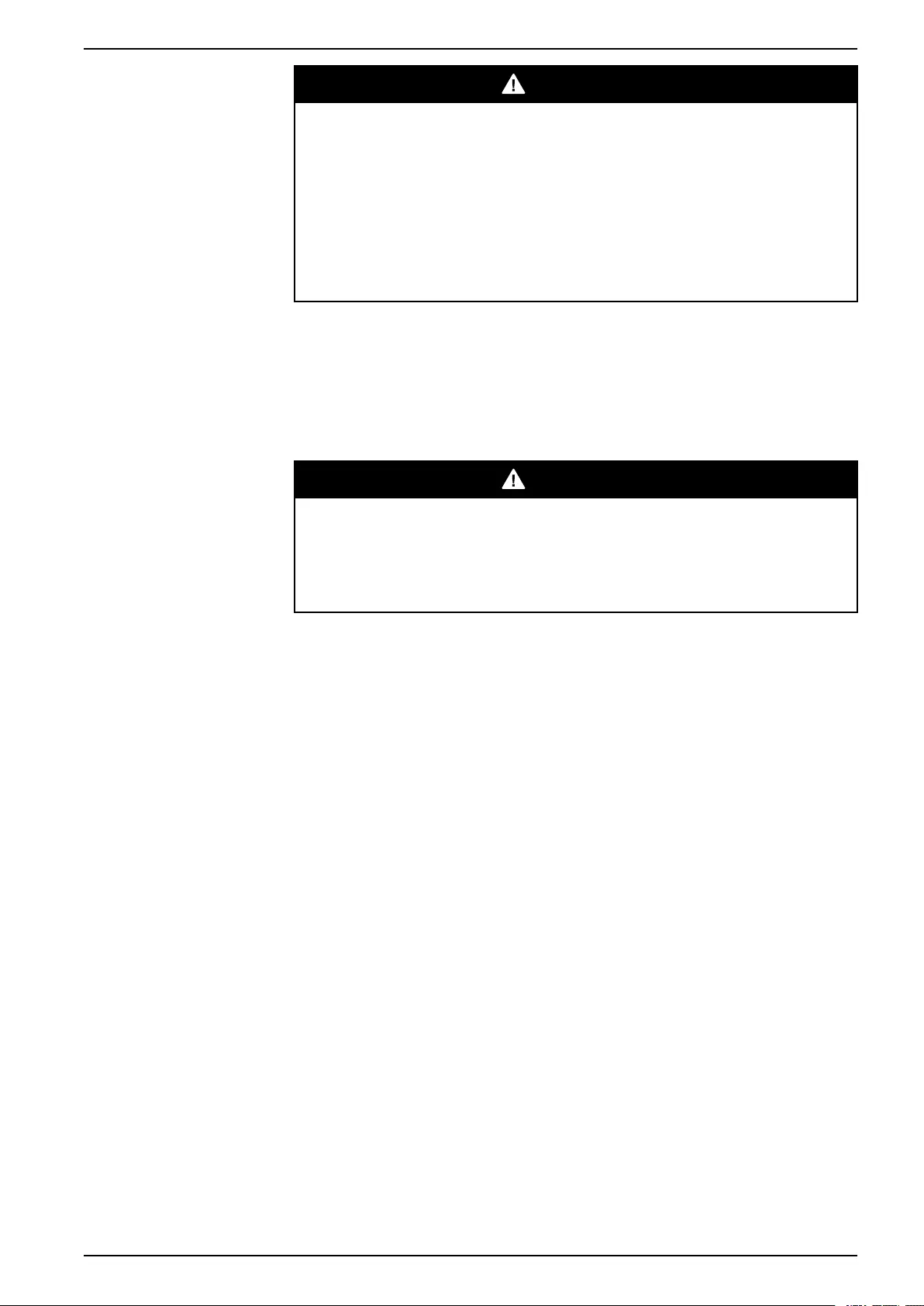

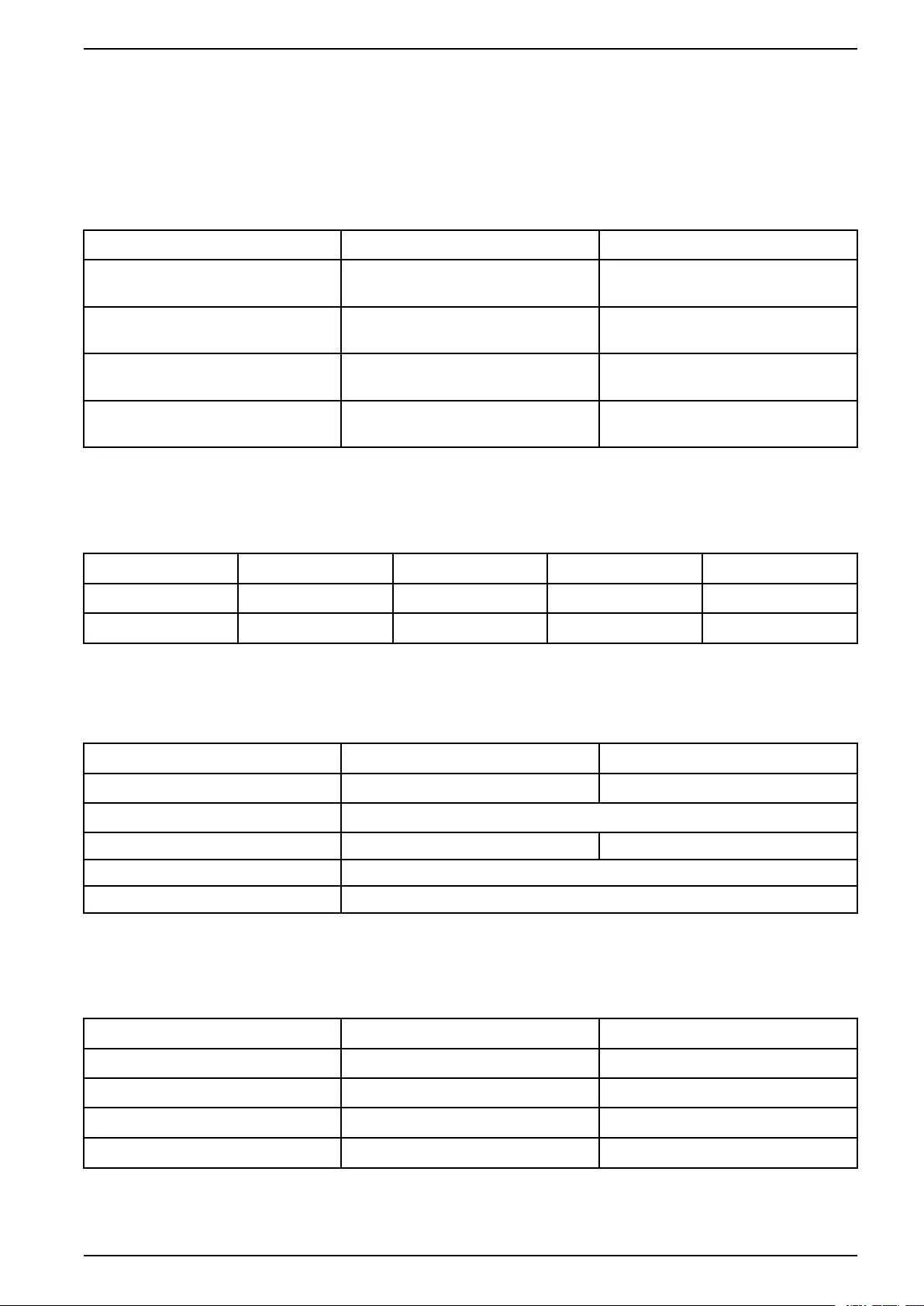

Specifications

Electrical

UPS rating 96 kVA 160 kVA

Input voltage

(V)

380 400 415 380 400 415

Nominal input

current (A)

154 146 141 256 243 234

Maximum

rated input

current (340

V input )(A)

169 160 155 281 267 258

Input

frequency

(Hz)

50/60

Maximum

short-circuit

withstand

(kA) Icc

Rated conditional short-circuit current Icc: 30 kA symmetrical rms

Rated peak withstand current Ipk: 63 kA

Device: NSX400F Mic2.3 3P 320 A setting (manufacturer: Schneider Electric) for 160 kVA, or

NSX250F TMD200 3P (manufacturer: Schneider Electric) for 96 kVA

Maximum

short-circuit

withstand

(kA) Icw

Rated short-time withstand current Icw: 13 kA symmetrical rms

Rated peak withstand current Ipk: 26 kA

Short-circuit withstand time: 3 cycles

Switch Sizes

Mains input switch Q1 (A) 400

UPS output switch Q2 (A) 250

Maintenance bypass switch Q3 (A) 250

Upstream Protection

NOTICE

For a maximum short-circuit withstand higher than 13 kA, it is mandatory to

install a circuit breaker (NSX250F TMD200 3P or NSX400F Mic2.3 3P 320 A

setting) upstream of the maintenance bypass enclosure.

Failure to follow these instructions can result in equipment damage.

UPS rating Required protection Max input current

96 kVA NSX250F TMD200 3P 169 A

160 kVA NSX400F Mic2.3 3P 320 A setting 281 A

6 990–4907A-001

Specifications Maintenance Bypass Enclosure

Recommended Cable Sizes

NOTE: Use only copper conductors with a minimum rating for 90 °C.

NOTE: 30 ℃ambient temperature, IEC standard 60364-5-52, Table A.52-4 (52-

C3), "C" method of installation. If the ambient room temperature is higher than 30

℃, larger conductors are to be selected in accordance with the correction factors

of the IEC.

UPS rating 96 kVA UPS 160 kVA UPS

Input cable (L1, L2, L3, N, PE)

(mm2)

70 120

Output cable (L1, L2, L3, N, PE)

(mm2)

50 95

Maintenance bypass to UPS input

cable (mm2)

70 120

UPS output to maintenance bypass

cable (mm2)

50 95

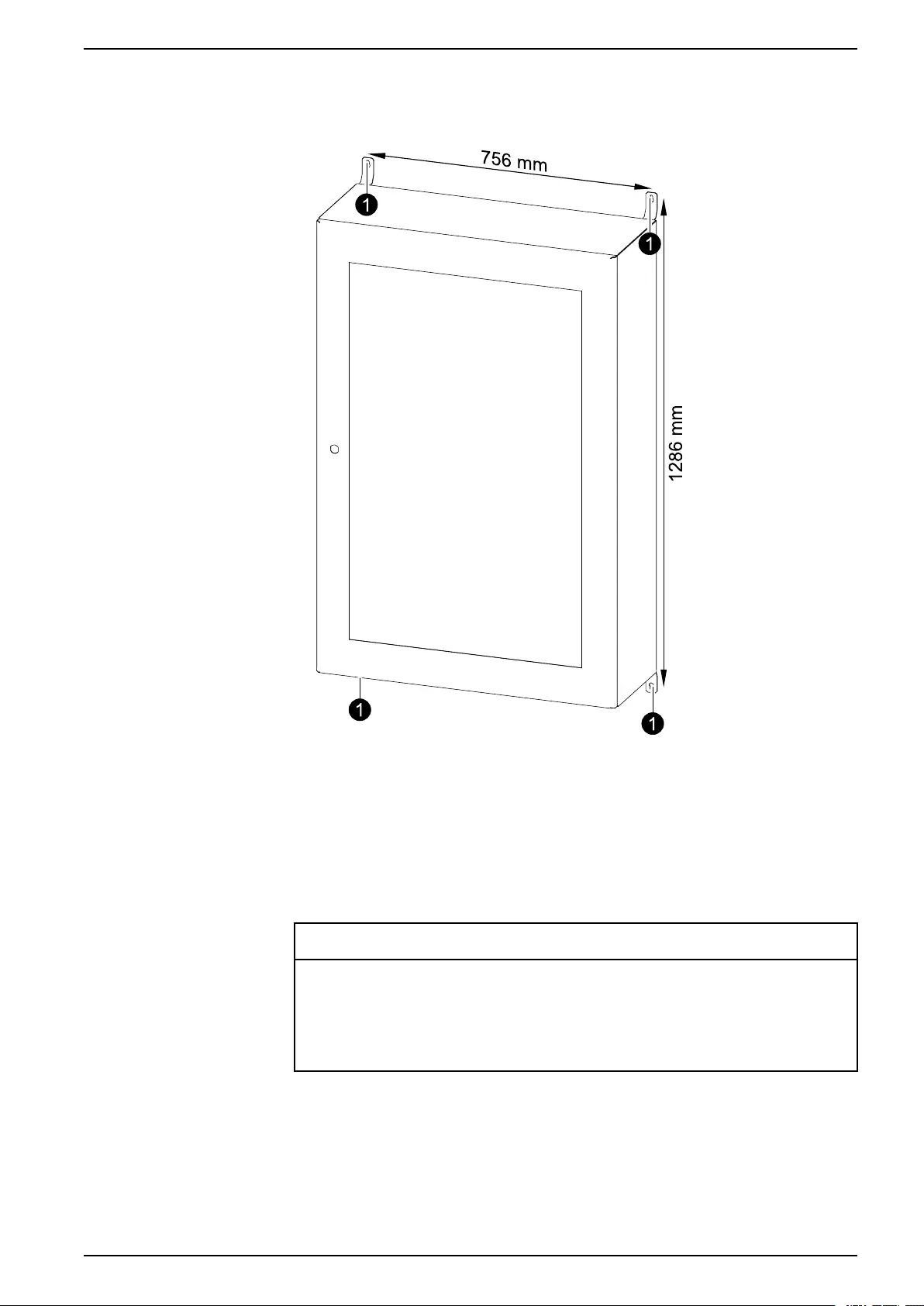

Weights and Dimensions

Weight (kg) Height (mm) Width (mm) Depth (mm)

Without packaging 90 1200 800 300

With packaging 105 1230 830 350

Environmental

Storage Operation

Temperature -25 °C to 55 °C 0 °C to 40 °C

Relative humidity 0 to 95% non-condensing

Elevation 0 to 15000 m 0 to 3000 m

Protection class IP20

Color Black

Torque

Torque (Nm) Screws

Mains input terminal block 23 M8 X 25 MSC HXG STL

Mains input to UPS terminal block 23 M8 X 25 MSC HXG STL

UPS output terminal block 23 M8 X 25 MSC HXG STL

System output terminal block 23 M8 X 25 MSC HXG STL

990–4907A-001 7

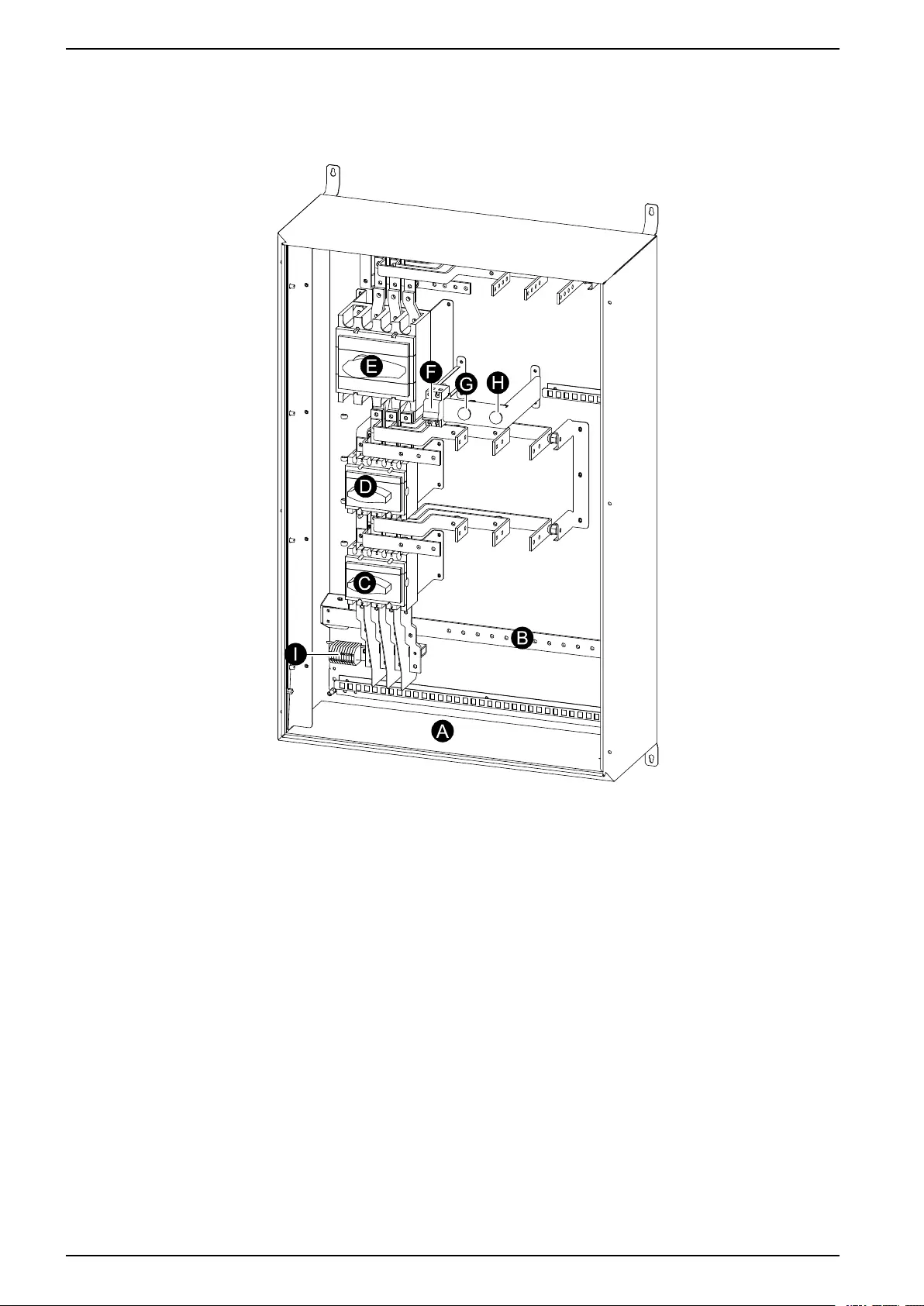

Maintenance Bypass Enclosure Product Overview

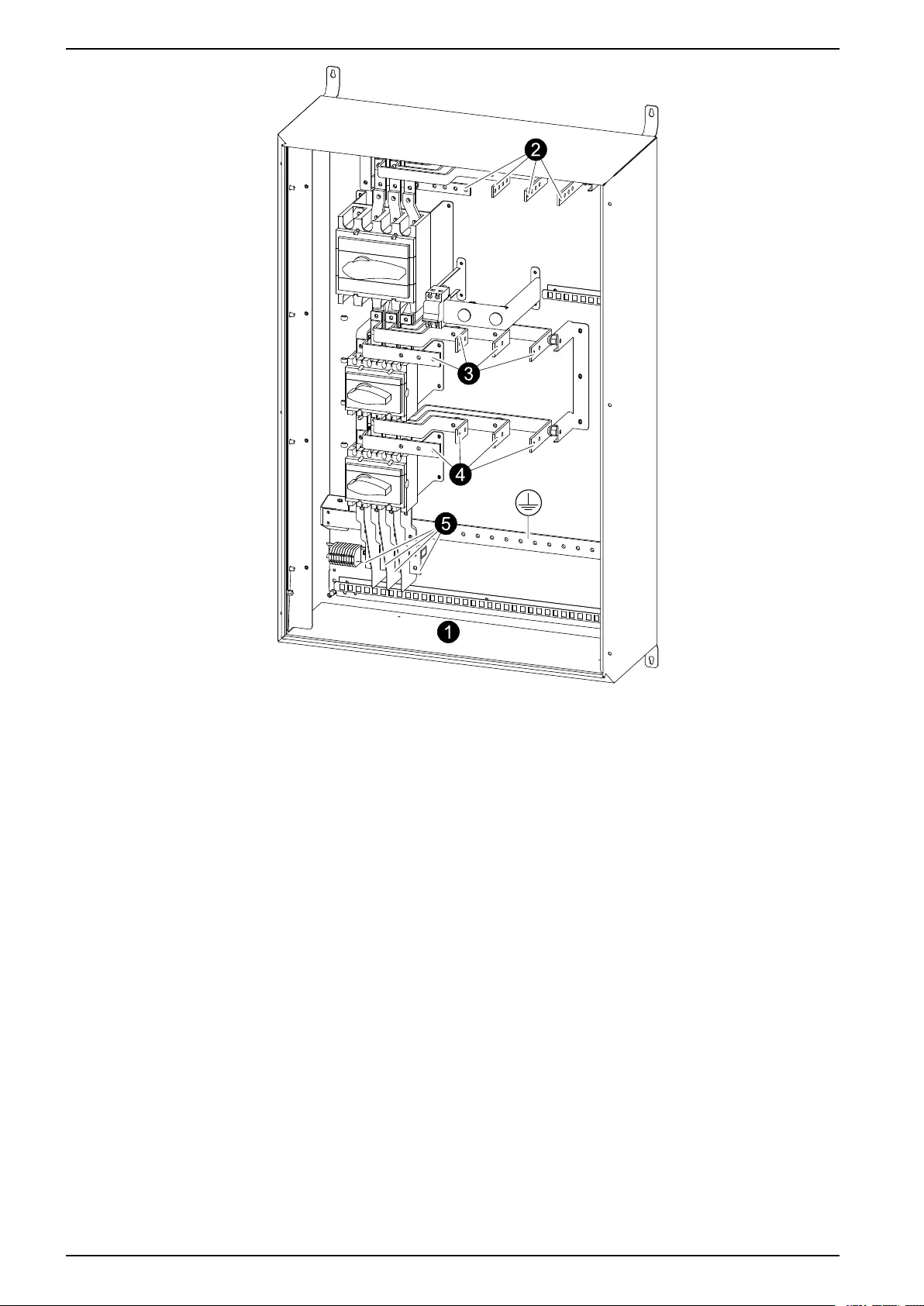

Product Overview

Front view (interior)

A. Cable entry

B. PE busbar

C. Q2 – UPS output switch

D. Q3 – Maintenance bypass switch

E. Q1 – Mains input switch

F. Q10 – LED protection breaker

G. LED H3 – OK to operate Q3 when light is ON

H. LED H2 – OK to operate Q2 when light is ON

I. Terminal block – signal connection to UPS

Site Planning

NOTE: Select a location for the maintenance bypass enclosure which provides

easy access to all breakers and internal components.

NOTE: Select a wall that is structurally sound and able to support the size and

weight of the maintenance bypass enclosure.

8 990–4907A-001

Product Overview Maintenance Bypass Enclosure

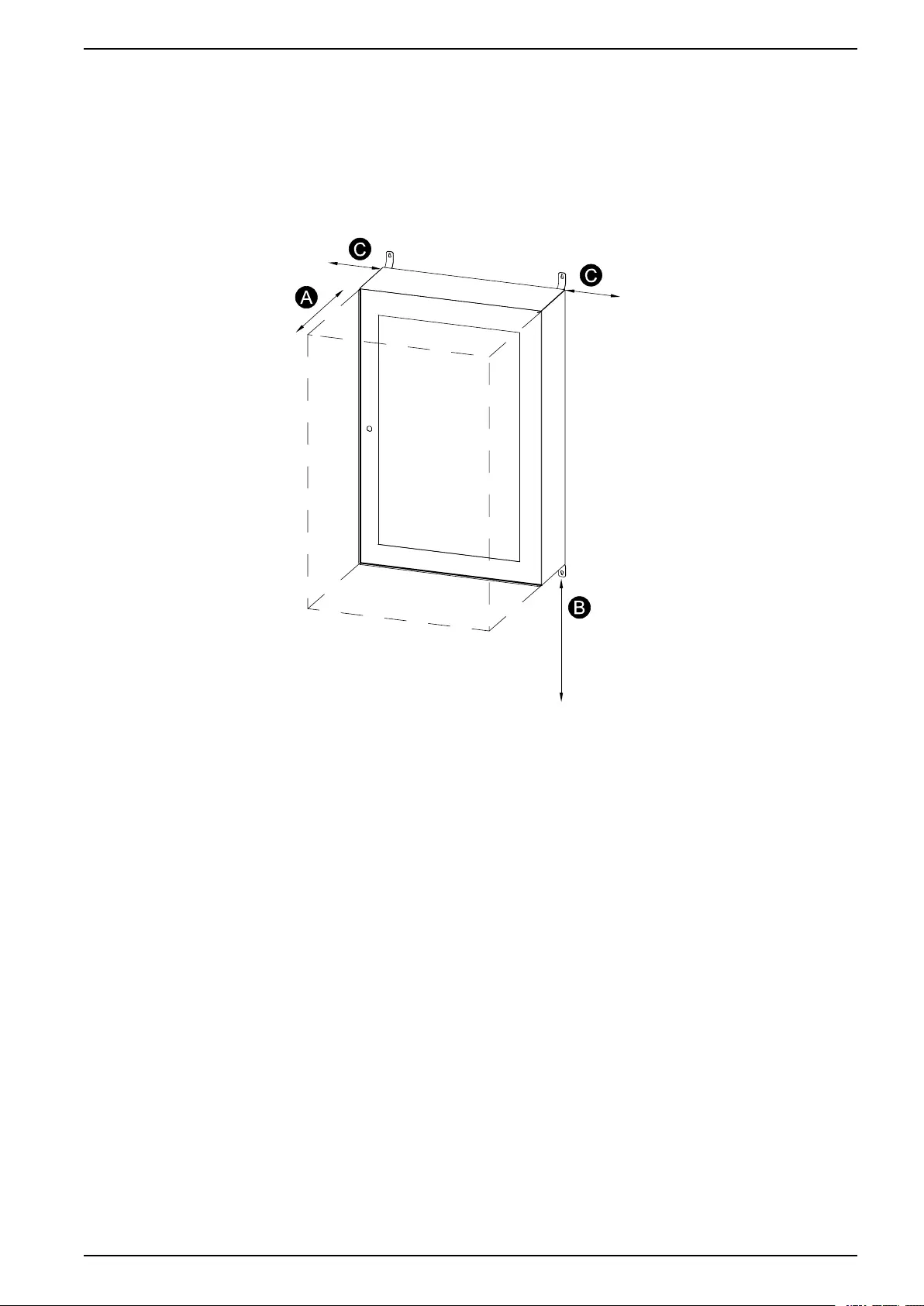

Clearance

Follow the listed clearance requirements and consult local codes for any additional

requirements.

The best location for the maintenance bypass enclosure is close to the UPS.

Front view

A. Minimum front clearance: 650 mm

B. Minimum enclosure–to–floor clearance: 600 mm

C. Minimum side clearance: 100 mm

990–4907A-001 9

Maintenance Bypass Enclosure Installation

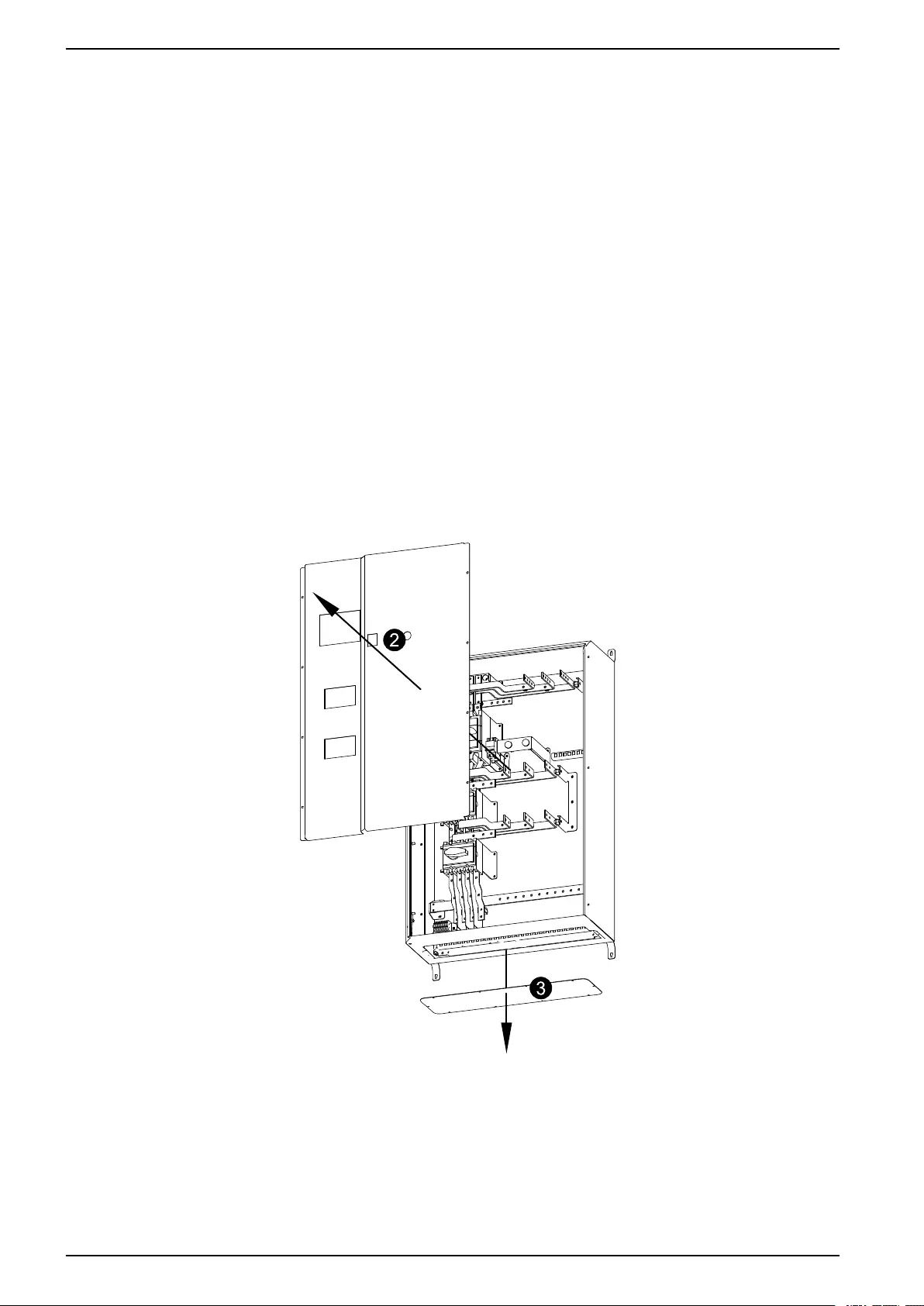

Installation

Prepare for Cables

NOTE: All power cables must be connected on site. External power cables are not

supplied with the maintenance bypass enclosure.

NOTE: Schneider Electric recommends to create the necessary holes for cable

access before mounting the maintenance bypass enclosure to the wall.

NOTE: The size of the holes and glands must be adapted to fit the size of the

cables.

1. Open the front door of the enclosure.

2. Remove the front panel.

3. Remove the bottom plate.

4. Drill holes for cables in the bottom plate. Make sure that the hole locations

correspond to the connector locations in the enclosure.

5. Reinstall the bottom plate.

Front view

10 990–4907A-001

Installation Maintenance Bypass Enclosure

Mount the Maintenance Bypass Enclosure to the Wall

1. Measure and mark the four mounting hole locations on the wall.

2. Drill holes in each of the four marked locations and mount the anchor bolts.

3. Lift the maintenance bypass enclosure, position it against the backing and line it

up with the four holes/anchor bolts. Secure the enclosure with the four bolts and

flat washers.

Connect the Power Cables

NOTICE

For a maximum short-circuit withstand higher than 13 kA, it is mandatory to

install a circuit breaker (NSX250F TMD200 3P or NSX400F Mic2.3 3P 320 A

setting) upstream of the maintenance bypass enclosure.

Failure to follow these instructions can result in equipment damage.

990–4907A-001 11

Maintenance Bypass Enclosure Installation

1. Route the cables through the holes in the bottom plate of the maintenance

bypass enclosure.

2. Connect the UPS input cables (L1, L2, L3, N) to the UPS input terminals and

the PE cable to the PE bar.

3. Connect the AC input cables (L1, L2, L3, N) to the AC input terminal block and

the PE cable to the PE bar.

4. Connect the system output cables from the UPS (L1, L2, L3, N) to the system

output terminals and the PE cable to the PE bar.

5. Connect the UPS output cables (L1, L2, L3, N) to the UPS output terminals and

the PE cable to the PE bar.

12 990–4907A-001

Installation Maintenance Bypass Enclosure

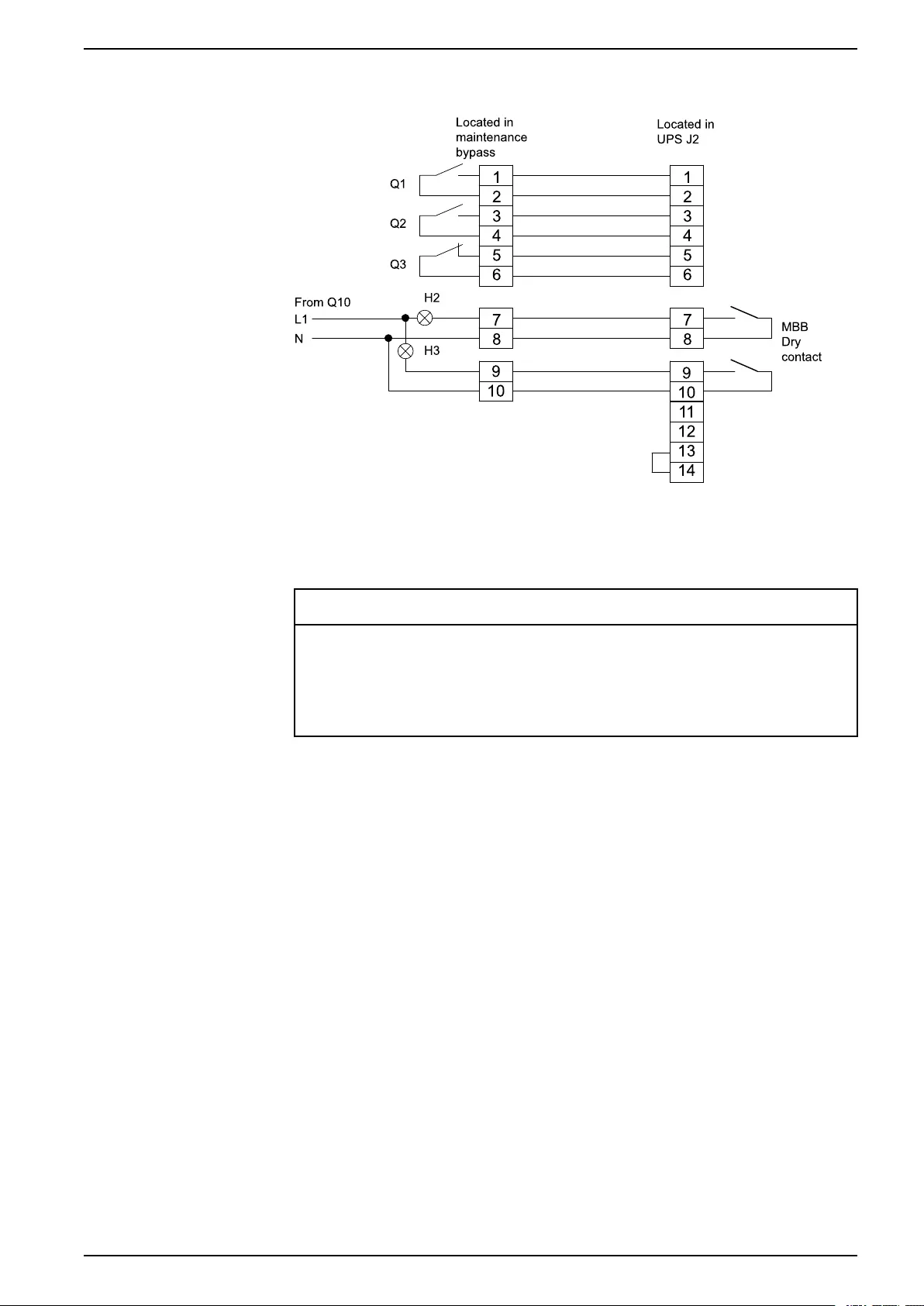

Connect the Communication Cables

Located in

maintenanc e

bypass

Located in

UPS J2

Q1

Q2

Q3

From Q10

L1

H2

H3

NMBB

Dry

contact

1

2

3

4

5

6

1

2

3

4

5

6

7

87

8

9

10

11

12

13

14

9

10

Diagram

NOTICE

For a maximum short-circuit withstand higher than 13 kA, it is mandatory to

install a circuit breaker (NSX250F TMD200 3P or NSX400F Mic2.3 3P 320 A

setting) upstream of the maintenance bypass enclosure.

Failure to follow these instructions can result in equipment damage.

990–4907A-001 13

Schneider Electric

35 rue Joseph Monier

92500 Rueil Malmason

France

+ 33 (0) 1 41 29 70 00

www.schneider-electric.com

As standards, specifications, and design change from

time to time, please ask for confirmation of the

information given in this publication.

© 2013 – 2014 Schneider Electric. All rights reserved.

990–4907A-001