Whirlpool ADN 102 User Manual

Displayed below is the user manual for ADN 102 by Whirlpool which is a product in the Ice Cube Makers category. This manual has pages.

Related Manuals

ICE FLAKERS

Range

2

TABLE OF CONTENTS

Introduction

Warnings.......................................................................................................................................3

Description....................................................................................................................................3

Operating Principle........................................................................................................................4

Specifications

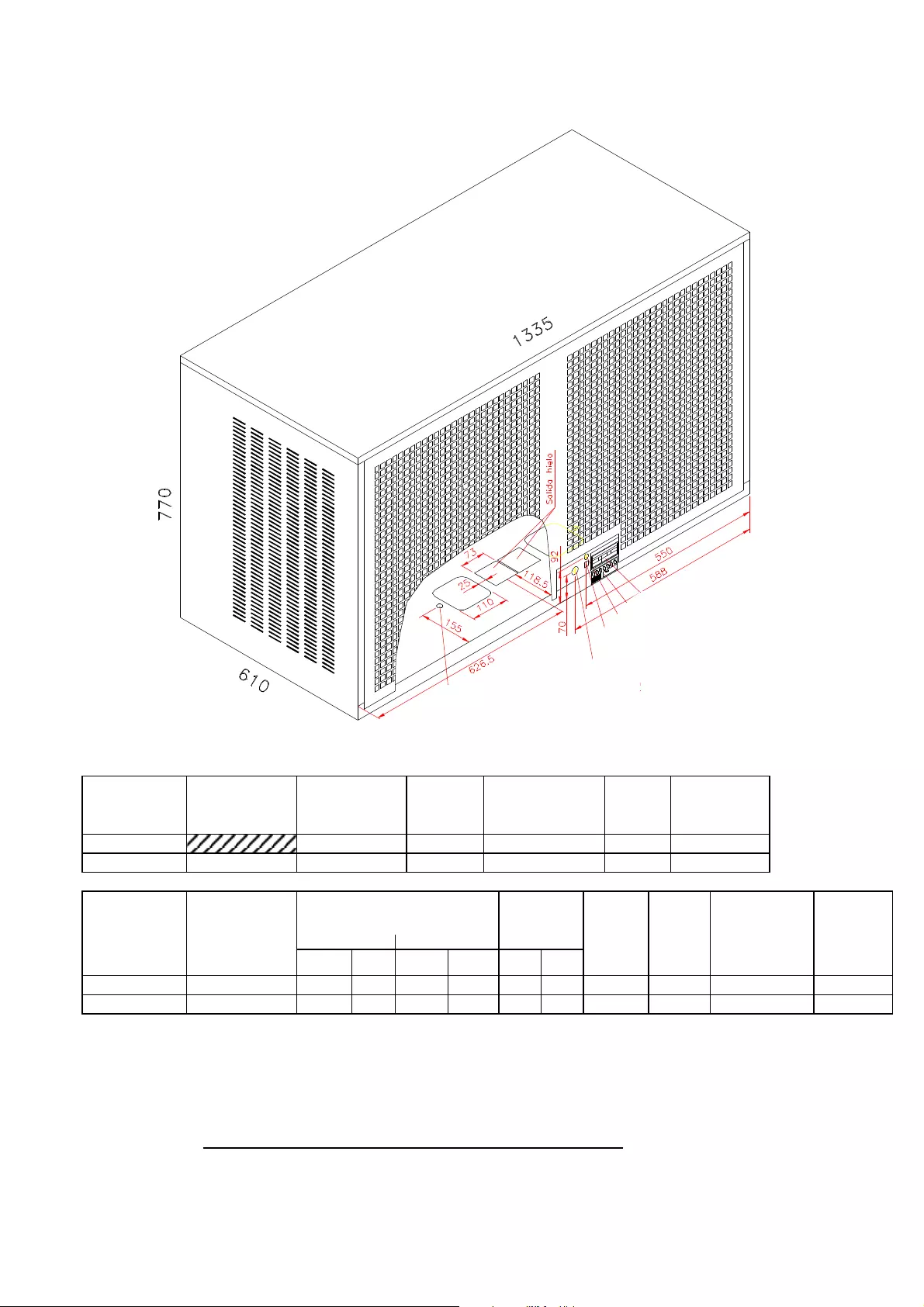

Installation diagrams for inlet/outlet tubes and dimensions.............................................................8

Consumption data, weights, crated dimensions and volumes.........................................................8

Technical data...............................................................................................................................8

Model IQ 135 + S60 “Compact”..........................................................................................8

Model IQ 150/200/400/550..................................................................................................9

Model IQ 1100...................................................................................................................10

Production Tables.......................................................................................................................11

About Ice Production...................................................................................................................12

Delivery & Unpacking

Packing.......................................................................................................................................13

Machine body..............................................................................................................................14

Rating plate and serial number....................................................................................................14

Installation

Recommended placement of unit................................................................................................15

Water and drainage.....................................................................................................................15

Connecting unit to water source (water-cooled units)...................................................................16

Connecting unit to drain...............................................................................................................16

Electrical connections..................................................................................................................16

Assembling the dispersion cone..................................................................................................16

Operation

Preliminary checks......................................................................................................................17

Starting up...................................................................................................................................17

Inspection and adjustment of water level in the trough.................................................................18

Cross check................................................................................................................................18

Adjustments

Expansion valve......................................................................................................................... 18

Water level..................................................................................................................................19

Pressure-controlled valve on cooling water circuit .......................................................................20

Fan pressostat (air-cooled models)..............................................................................................20

High pressure safety pressostat.................................................................................................. 21

Start-up timer..............................................................................................................................21

Safety elements

..................................................................................................................................................21

Inspection/replacement procedures

Lower bearing.............................................................................................................................22

Speed reducer (gearbox).............................................................................................................22

Upper flange...............................................................................................................................23

Upper bearing (depending on model)...........................................................................................24

Maintenance and cleaning instructions

Maintenance table.......................................................................................................................25

Water condenser.........................................................................................................................26

Air condenser..............................................................................................................................26

Evaporator/ water trough..................................................................................................................................

26

Cleaning the water inlet filters..........................................................................................................................

27

Checking for water leaks..................................................................................................................................

27

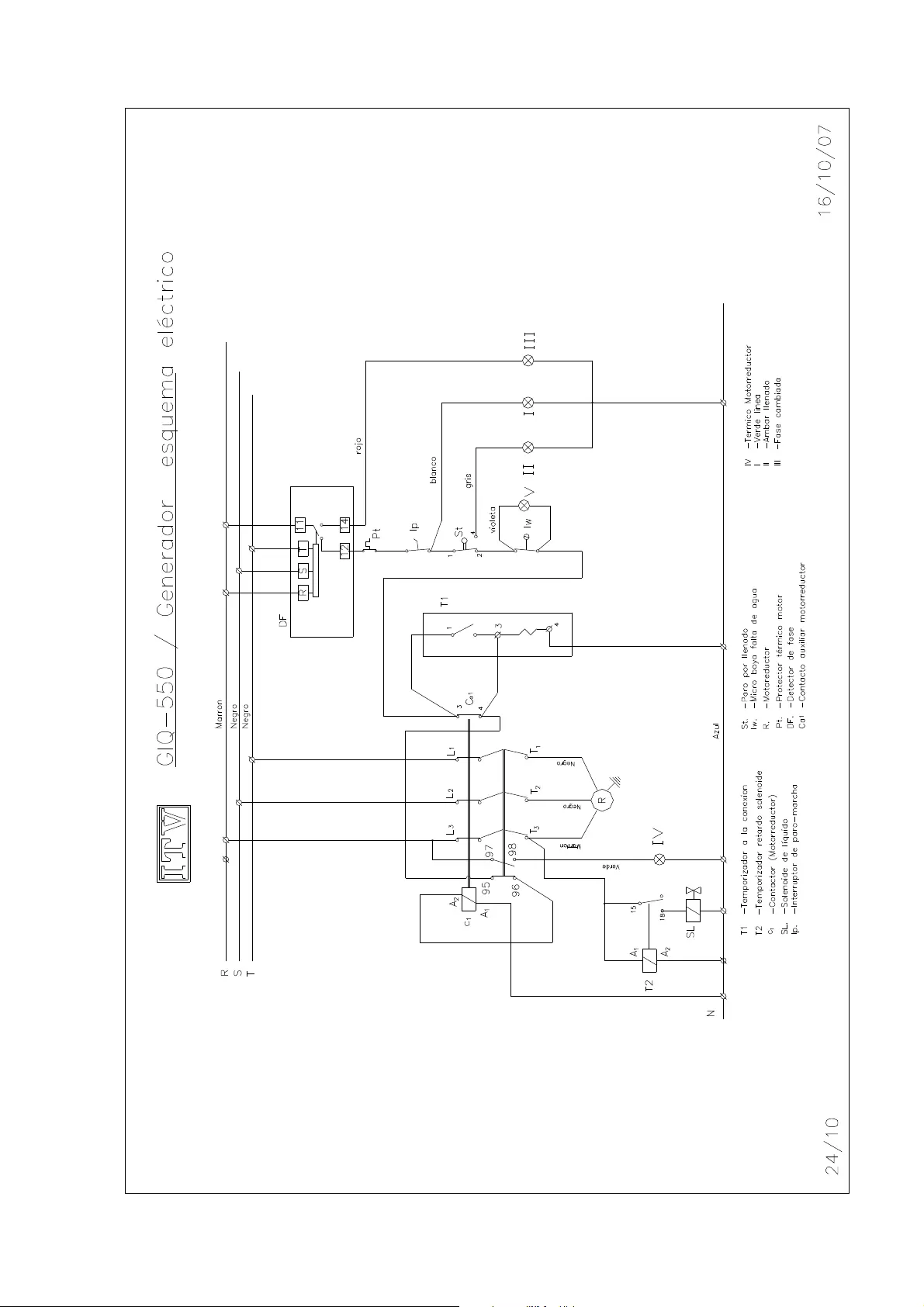

Ice Queen 550. Installation instructions28

3

Troubleshooting ................................................................................................................................32

INTRODUCTION

Thank you for choosing ITV's ICE QUEEN flaker.

You have purchased one of the most reliable ice-making products on the market today. Carefully

read the instructions contained in this manual since they provide important information relative to

safety during installation, use, and maintenance.

WARNINGS

This appliance should be installed by approved Technical Service Personnel.

This plug should be accessible at all times.

To reduce the risk of electrical shock, ALWAYS disconnect the machine BEFORE cleaning or

maintaining the equipment. Do not attempt to install, service, or modify this machine. Improper

use by other than specially trained technicians is extremely dangerous and may result in a fire or

electric shock.

This machine should not be placed outdoors or exposed to rain.

Connect to drinking water mains.

This appliance is not intended for use by young children or infirm persons without supervision.

Young children should be supervised to ensure that they do not play with the appliance.

IMPORTANT!

• DO NOT ATTEMPT TO SERVICE THIS MACHINE AS IT IS DANGEROUS AND COULD

CAUSE SEVERE DAMAGE TO THE UNIT.

•SERVICE SHOULD ONLY BE CARRIED OUT BY TRAINED, QUALIFIED PERSONNEL.

•WE STRONGLY RECOMMEND USING ONLY ORIGINAL REPLACEMENT PARTS

AVAILABLE FROM AN AUTHORIZED DISTRIBUTOR.

•WASTE AND OTHER MATERIAL SHOULD BE DISPOSED OF ACCORDING TO LOCAL

REGULATIONS AND PROCEDURES FOR WASTE DISPOSAL.

•CLEANING AND MAINTENANCE ARE NOT COVERED BY THE WARRANTY.

4

DESCRIPTION

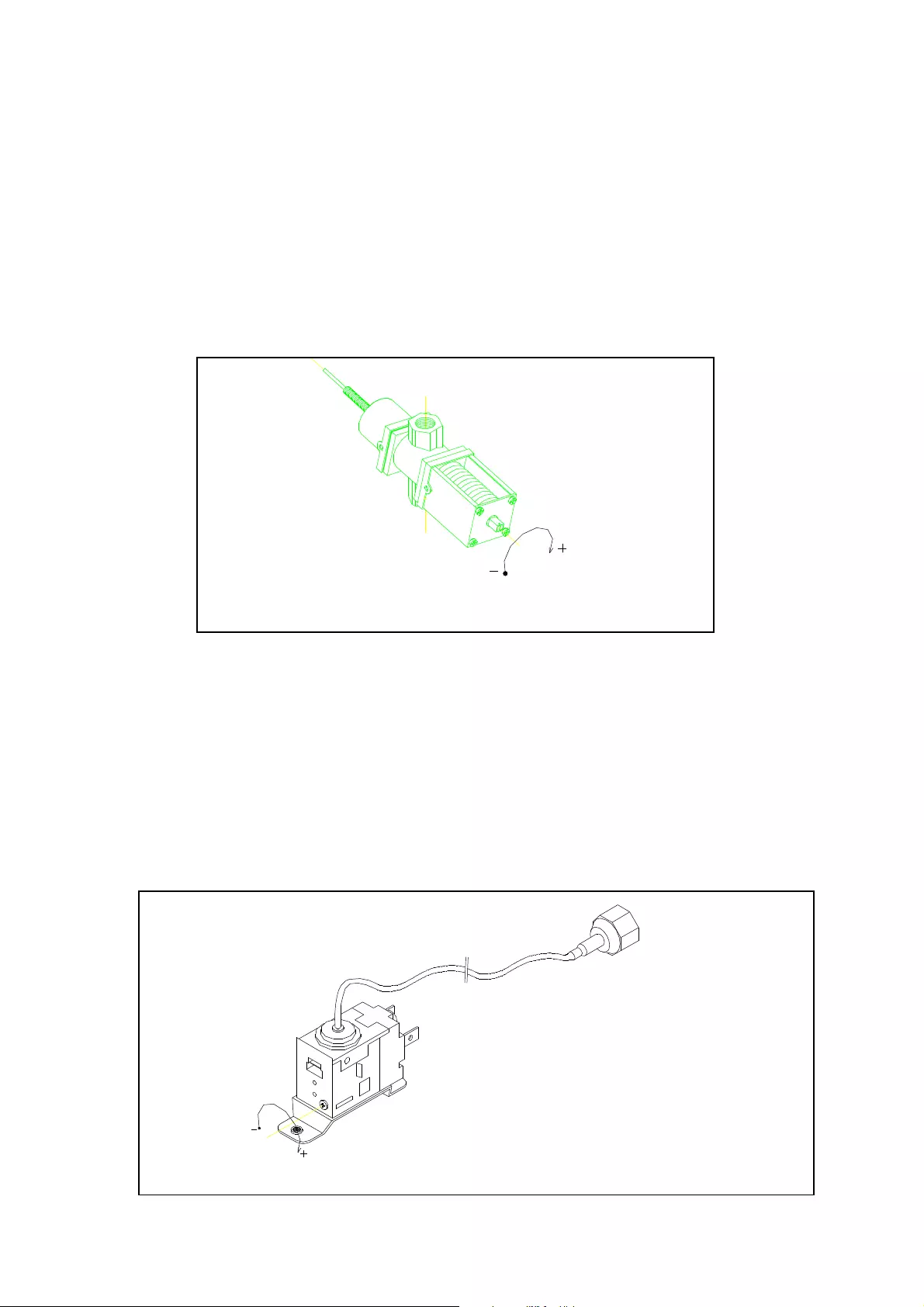

Main Features of the Machine

§ 18/8 stainless steel housing

§ Powerful speed reducer (24Kg./m. @ 7 rpm.)

§ Copper evaporator on precision bored tubing (HB 50)

§ Durable stainless steel auger with resilient coating

§ Ice drops out of the bottom of unit

§ Speed reducer in top part of the unit

§ Ecological refrigerant R404a

OPERATING PRINCIPLE

Water enters water trough via a float valve which provides a constant head of water. Through a

hole in the bottom of the trough, water flows into the bottom of the evaporator and floods it to the

same height as in the water trough. Water freezes upon contact with evaporator wall, and is

scraped off as ice by the vertical, rotating auger. Ice is carried upward until it passes through

discharge flap and falls into bin. When bin is full, automatic shut-off sensor (micro-switch on

discharge flap) switches off machine.

IMPORTANT!

If unit is placed on top of a cold room, and/or ice has to fall a long distance from unit, a

MECHANICAL ICE LEVEL SENSOR should be installed. To prevent ice from compressing in

cold storage, we recommend transferring ice through a plastic tube (80-

100 mm diameter)

attached to its lower end the DISPERSION CONE which is PROVIDED WITH THE MACHINE in

all models.

5

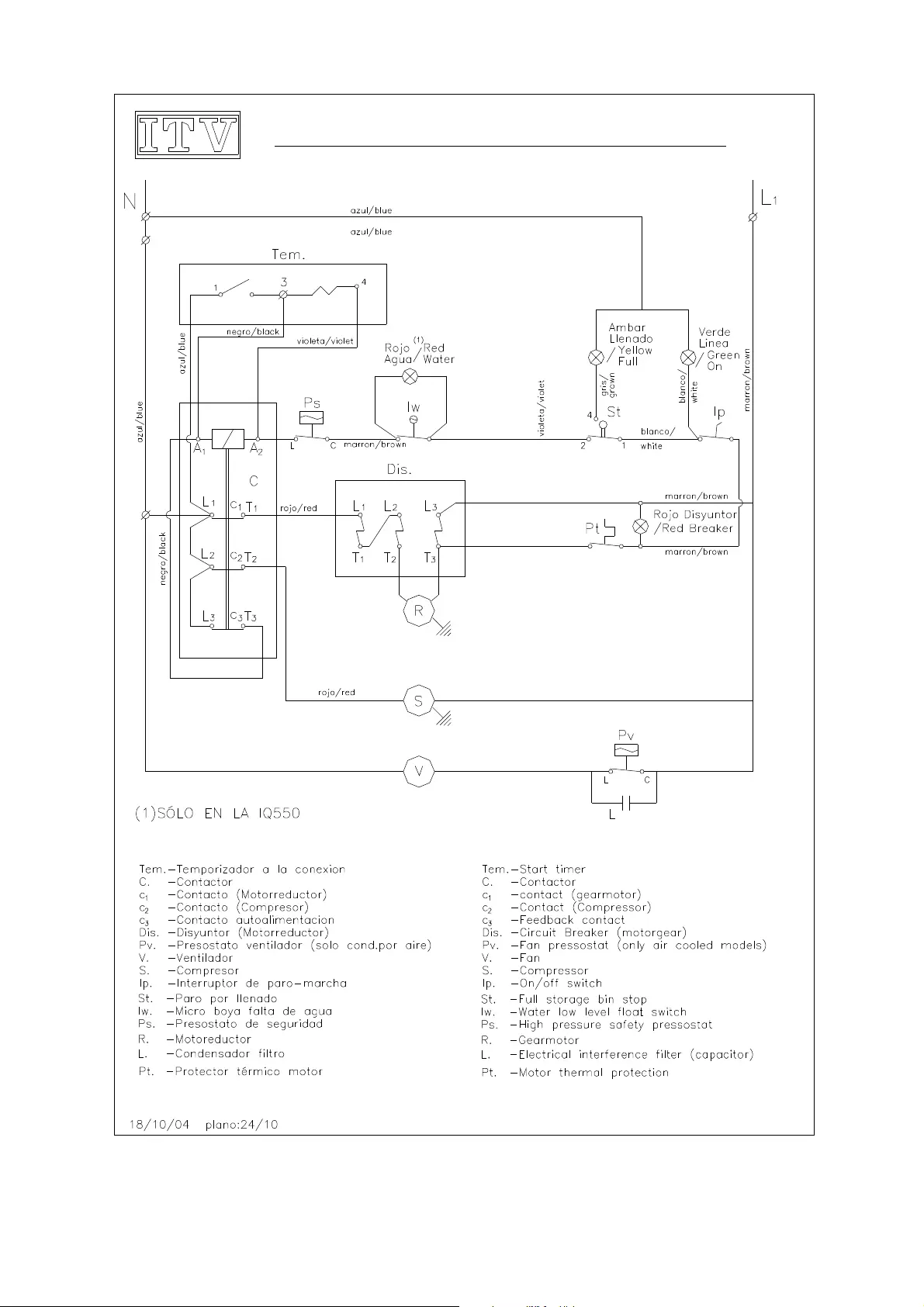

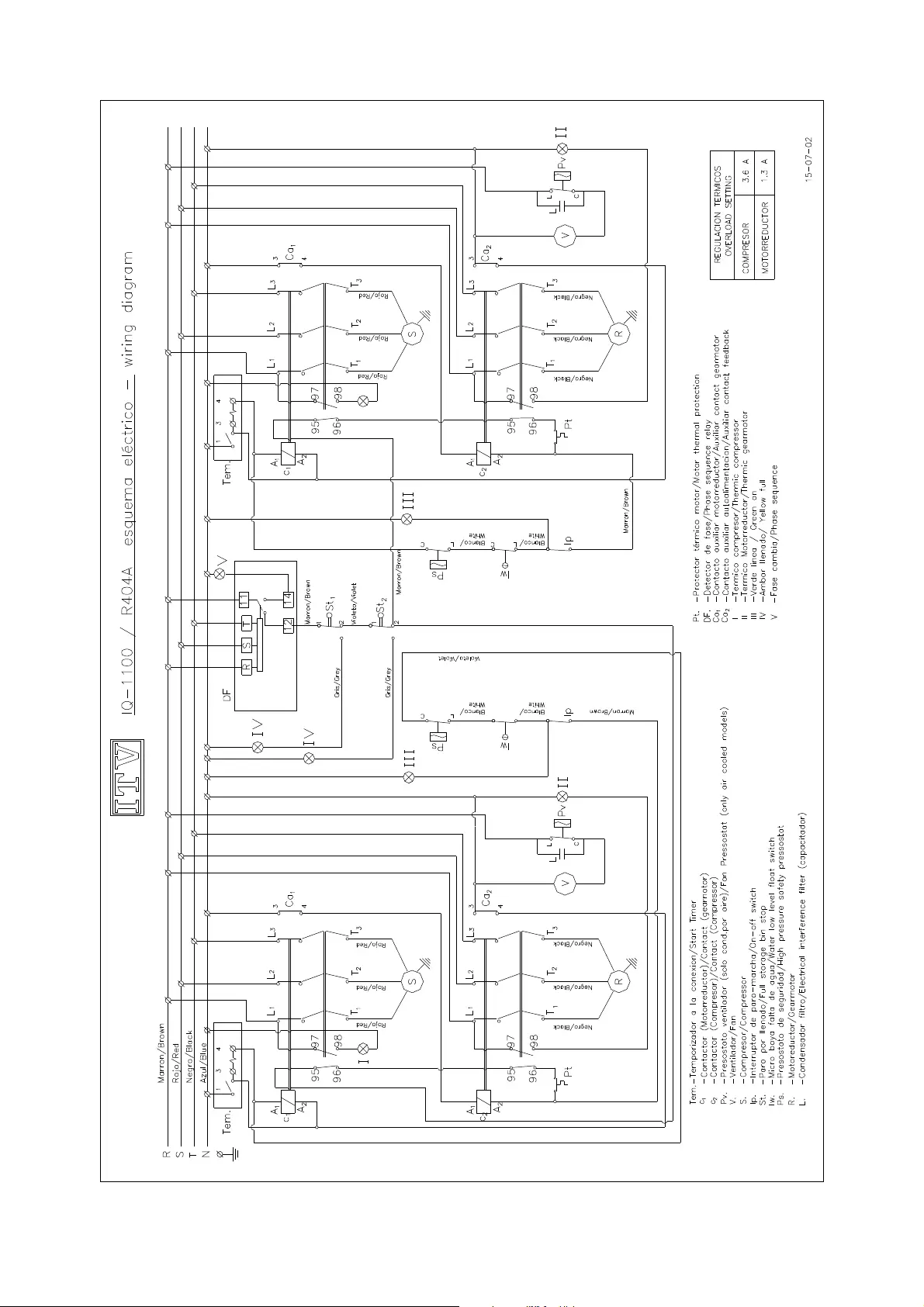

IQ monofásica esquema eléctrico - wiring diagram

6

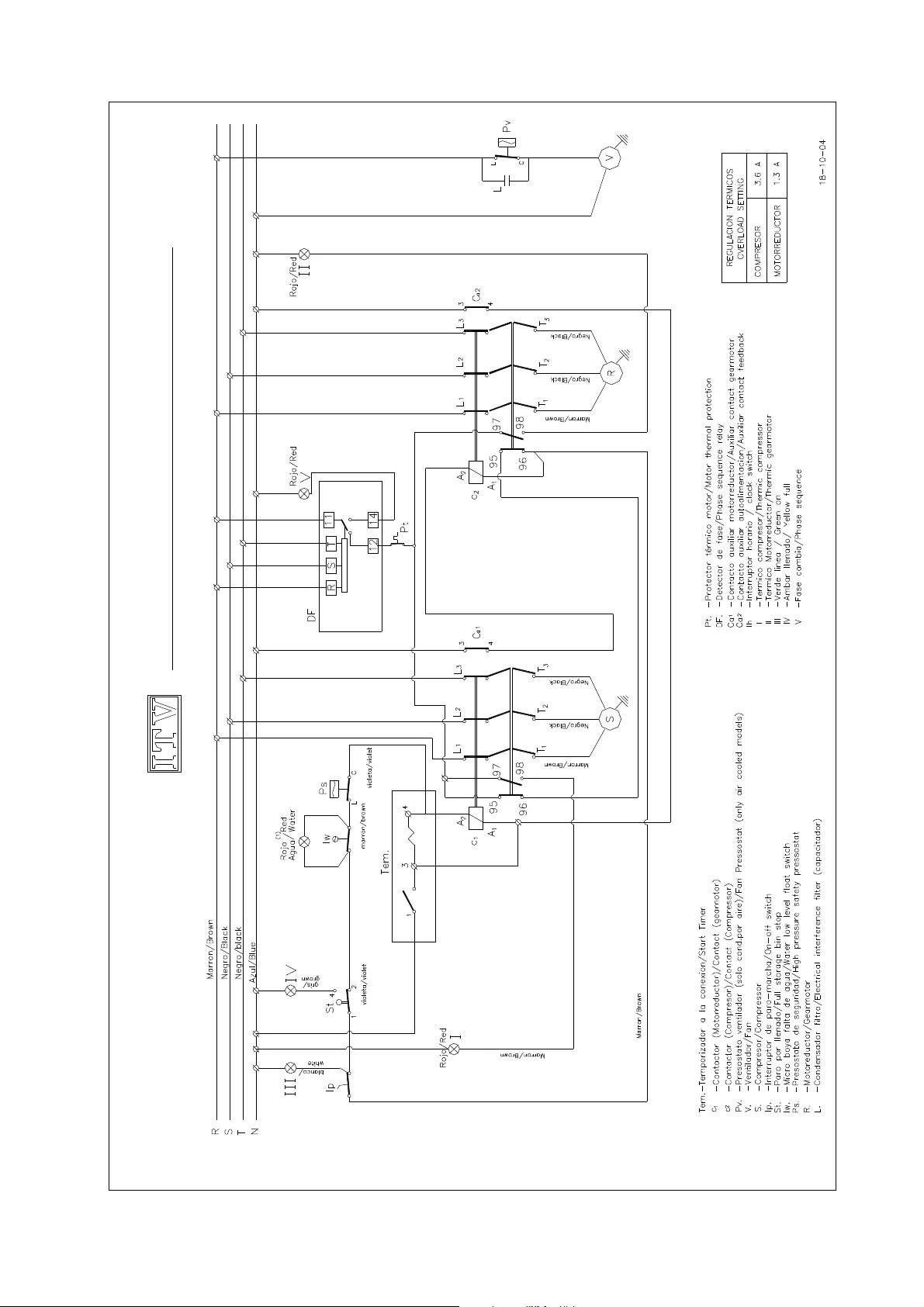

IQ-400-550 / R404A/ trifásica esquema eléctrico - wiring diagram

7

8

9

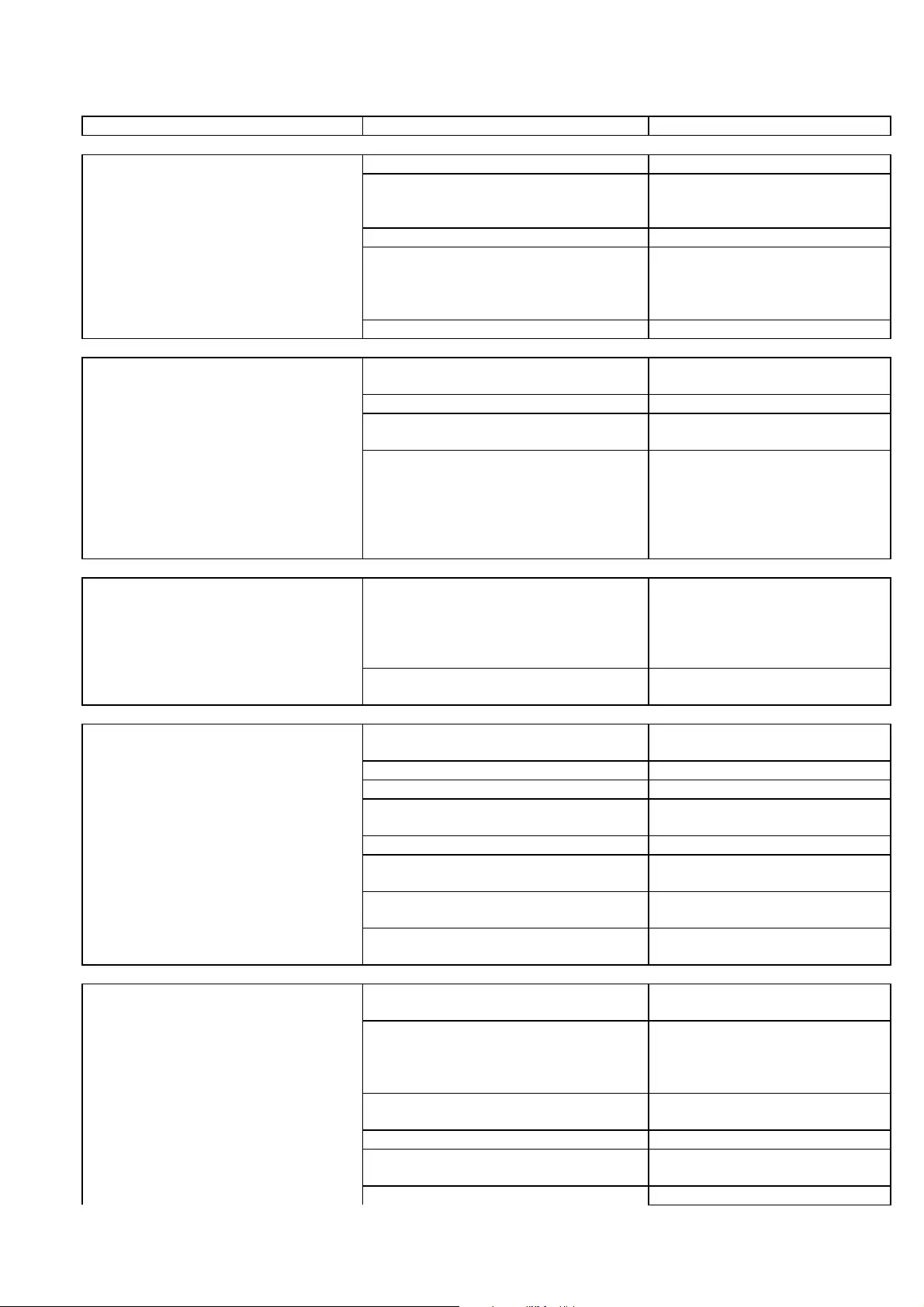

SPECIFICATIONS

Model: ICE QUEEN 135 S60

MODEL ICE BIN

STORAGE

CAPACITY

(KG)

COOLING

WATER

CONSUMPTION

(L/Hour)

WATER

CONSUMPTION

(L/Hour)

NET

WEIGHT

(KG)

DIMENSIONS

(CRATED)

X*Y*Z

GROSS

WEIGHT

(KG)

VOLUME

(M3)

IQ 135 A 60 5.5 70 615x650x146

5 85 0.58

IQ 135 W 60 40 5.5 68 615x650x146

5 83 0.58

MODEL REFRIGERANT

CHARGE

HIGH PRESURE LOW

PRESURE TOTAL

AMPS

FUSE

RATING

COMPRESSO

R POWER TOTAL

POWER

MINIMUM MAXIMUM AVERAGE (2) (1) (2)

(gr) Kg/cm

2 Psi Kg/cm

2 Psi Kg/cm

2 Psi (A) (A) (W) (W)

IQ 135 A 500 16 228 17 242 2.5 35 4.2 16 360 650

IQ 135 W 360 16 228 17 242 2.5 35 4.2 16 360 650

(1) Data obtained at room temperature 20°C, water introduced at 15°C; water quality = 500ppm

(2) Maximum consumption obtained at room temperature = 43°C, according to UNE climate classification, Class T

(TROPICALISED).

NOTE: Expansion controlled by capillary.

Ice discharge slot

Water trough

overflow

Rating Plate

Serial number

Cooling water drain

(water-cooled models)

Electrical connection

Water inlet

Height increases by 80 mm

when feet are fitted

Ice bin drain

1

3

6

9

5

0

0

10

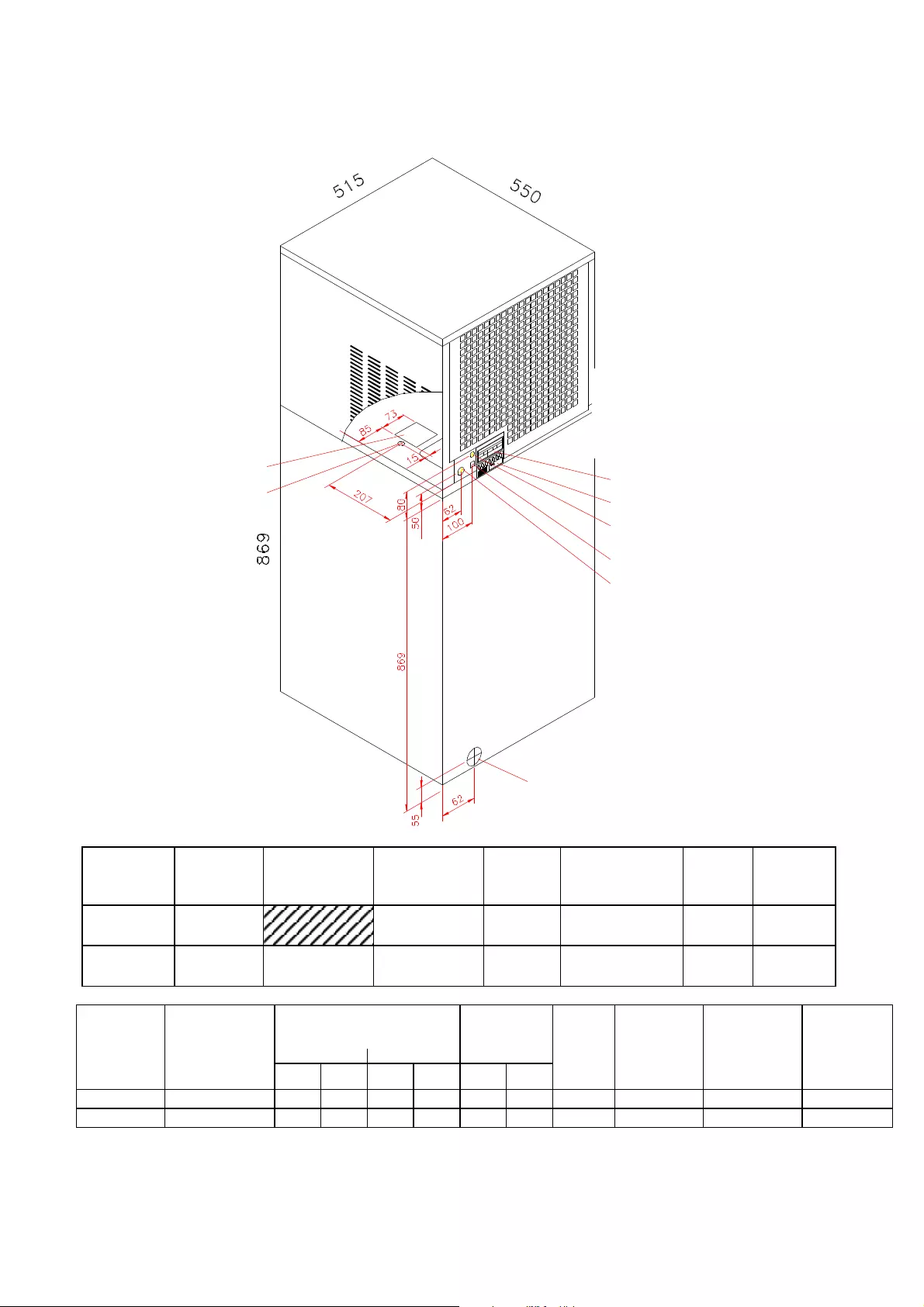

Model: ICE QUEEN 150 / 200 / 400 / 550

MODEL COOLING

WATER

CONSUMPTION

(L/Hour)

WATER

CONSUMPTION

(L/Hour)

NET WEIGHT

(KG) DIMENSIONS

(CRATED)

X*Y*Z

GROSS

WEIGHT

(KG)

VOLUME

(M3)

IQ 150 A 5.6 45 580x630x560

55 0.20

IQ 150 W 40 5.6 43 580x630x560

53 0.20

IQ 200 A 8.5 52 580x630x645

60 0.23

IQ 200 W 60 8.5 50 580x630x645

58 0.23

IQ 400 A 16 85 740x630x730

94 0.33

IQ 400 W 114 16 80 740x630x730

589 0.33

IQ 550 A 25 95 740x630x865

115 0.39

IQ 550 W 177 25 93 740x630x865

113 0.39

MODEL X Y Z A B C D

IQ 150 A/W 515 550 500 50 80 207 85

IQ 200 A/W 515 550 575 70 92 207 85

IQ 400 A/W 675 550 660 70 92 227 89

IQ 550 A/W 675 550 800 70 92 227 89

Ice discharge slot

Water trough overflow

Rating Plate

Serial number

Cooling water drain

(water-cooled models)

Electrical connection

Water inlet

11

MODEL REFRIGERANT

CHARGE HIGH PRESURE LOW

PRESURE TOTAL

AMPS

FUSE

RATING

COMPRESSOR

POWER TOTAL

POWER

MINIMUM MAXIMUM AVERAGE (2) (1) (2)

(gr) Kg/cm

2 Psi Kg/cm

2 Psi Kg/cm

2 Psi (A) (A) (W) (W)

IQ 150 A 500 16 228 17 242 2.5 35 4.2 16 365 660

IQ 150 W 360 16 228 17 242 2.5 35 4.2 16 365 660

IQ 200 A 430 16 228 17 242 2.5 35 4.6 16 440 800

IQ 200 W 400 16 228 17 242 2.5 35 4.6 16 440 800

IQ 400 A 630 16 228 17 421 2.5 35 5.8 16 690 1100

IQ 400 W 440 16 228 17 242 2.5 35 5.8 16 690 1100

IQ 550 A 1050 16 228 17 242 2.5 35 9.2 20 1000 1700

IQ 550 W 1050 16 228 17 242 2.5 35 9.2 20 1000 1700

(1) Data obtained at room temperature (20°C), water introduced at 15°C; water quality = 500ppm

(2) Maximum consumption obtained at room temperature = 43°, according to UNE climate classification

Class T (TROPICALISED).

NOTE: Expansion controlled by capillary, except for model IQ400 and 550 which is controlled by a

thermostatic valve.

Models: ICE QUEEN 400 & 550 380V+III+N

MODEL REFRIGERAN

T

CHARGE

HIGH PRESURE LOW

PRESURE TOTAL

AMPS

FUSE

RATING

COMPRESSO

R POWER TOTAL

POWER

404ª MÍNIMA MÁXIMA MEDIA (2) (1) (2)

(GR) Kg/cm

2 Psi Kg/cm

2 Psi Kg/cm

2 Psi (A) (A) (W) (W)

IQ 400 A 635 16 228 17 242 2.3

33.4

3.5 10 750 1350

IQ 400 W 635 16 228 17 242 2.3

33.

4 3.5 10 750 1350

IQ 550 A 1500 16 228 17 242 2.3

33.4

5 16 2200 2x2700

IQ 550 W 1500 16 228 17 242 2.3

33.

4 5 16 2200 2x2700

NOTE: Expansion controlled by a thermostatic valve.

12

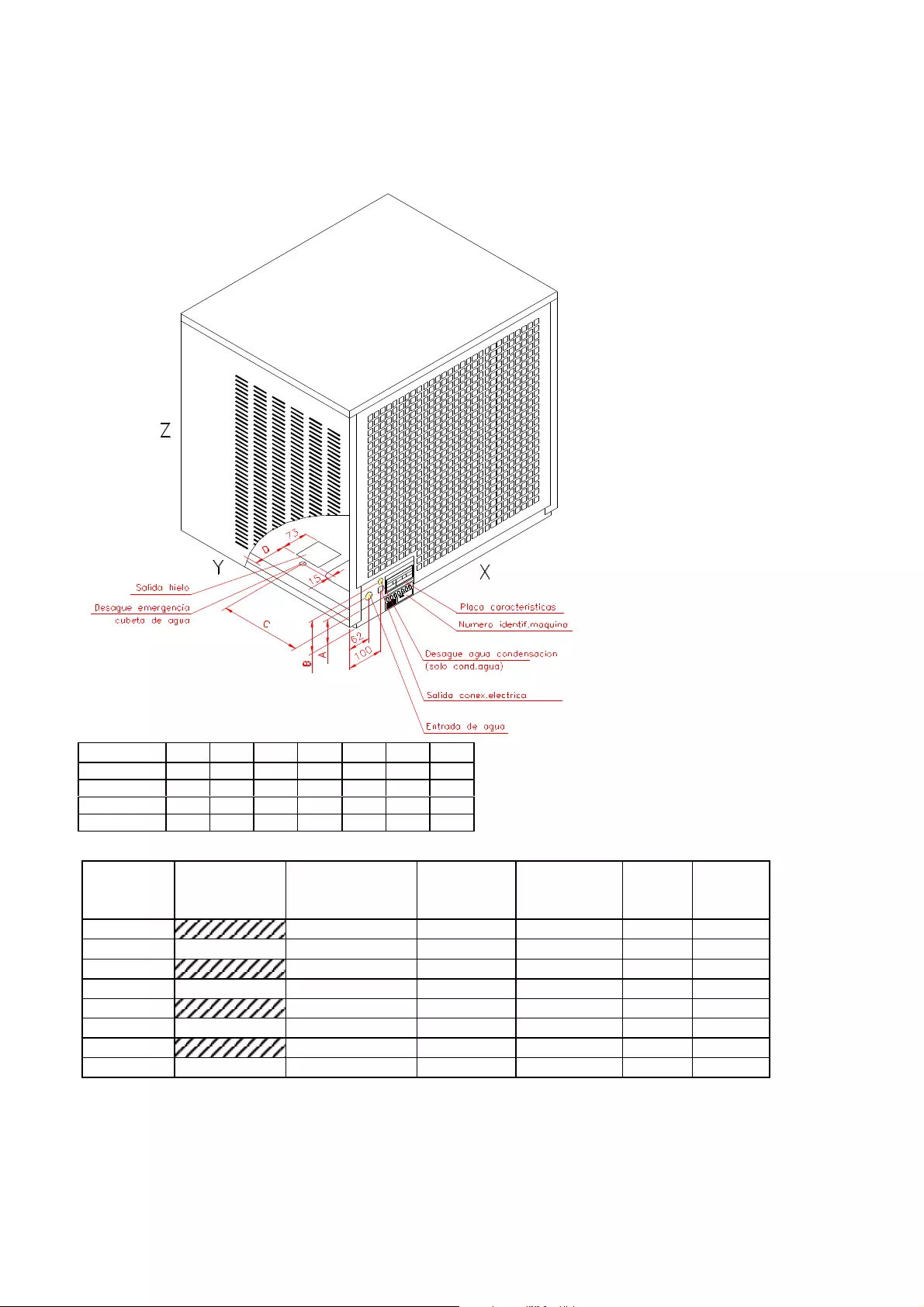

Model: ICE QUEEN 1100

MODEL COOLING

WATER

CONSUMPTION

(L/Hour)

WATER

CONSUMPTION

(L/Hour)

NET

WEIGHT

(KG)

DIMENSIONS

(CRATED)

X*Y*Z

GROSS

WEIGHT

(KG)

VOLUME

(M3)

IQ 1100 A 50 192 1400x685x835 225 0.80

IQ 1100W 354 50 185 1400x685x835 218 0.80

MODEL REFRIGERANT

CHARGE HIGH PRESURE LOW

PRESURE TOTAL

AMPS

FUSE

RATING

COMPRESSOR

POWER TOTAL

POWER

MINIMUM MAXIMUM AVERAGE (2) (1) (2)

(gr) Kg/cm2 Psi Kg/cm2 Psi Kg/c

m2 psig (A) (A) (W) (W)

IQ 1100 A 2x1500 16 228 17 242 2.5 35 9 2x16 2x2200 2x2700

IQ 1100 W 2x1500 16 228 17 242 2.5 35 9 2x16 2x2200 2x2700

(1) Data obtained at room temperature 20°C, water introduced at 15°C; water quality = 500ppm

(2) Maximum consumption obtained at room temperature = 43°, according to UNE climate classification

Class T

(TROPICALISED).

NOTE: Expansion controlled by a thermostatic valve.

-Power inlet should be 3-phase III+N+T (380 V/50 HZ)

Water trough

overflow

Rating Plate

Serial number

Cooling water drain

(water-cooled models

Electrical connection

Water inlet

13

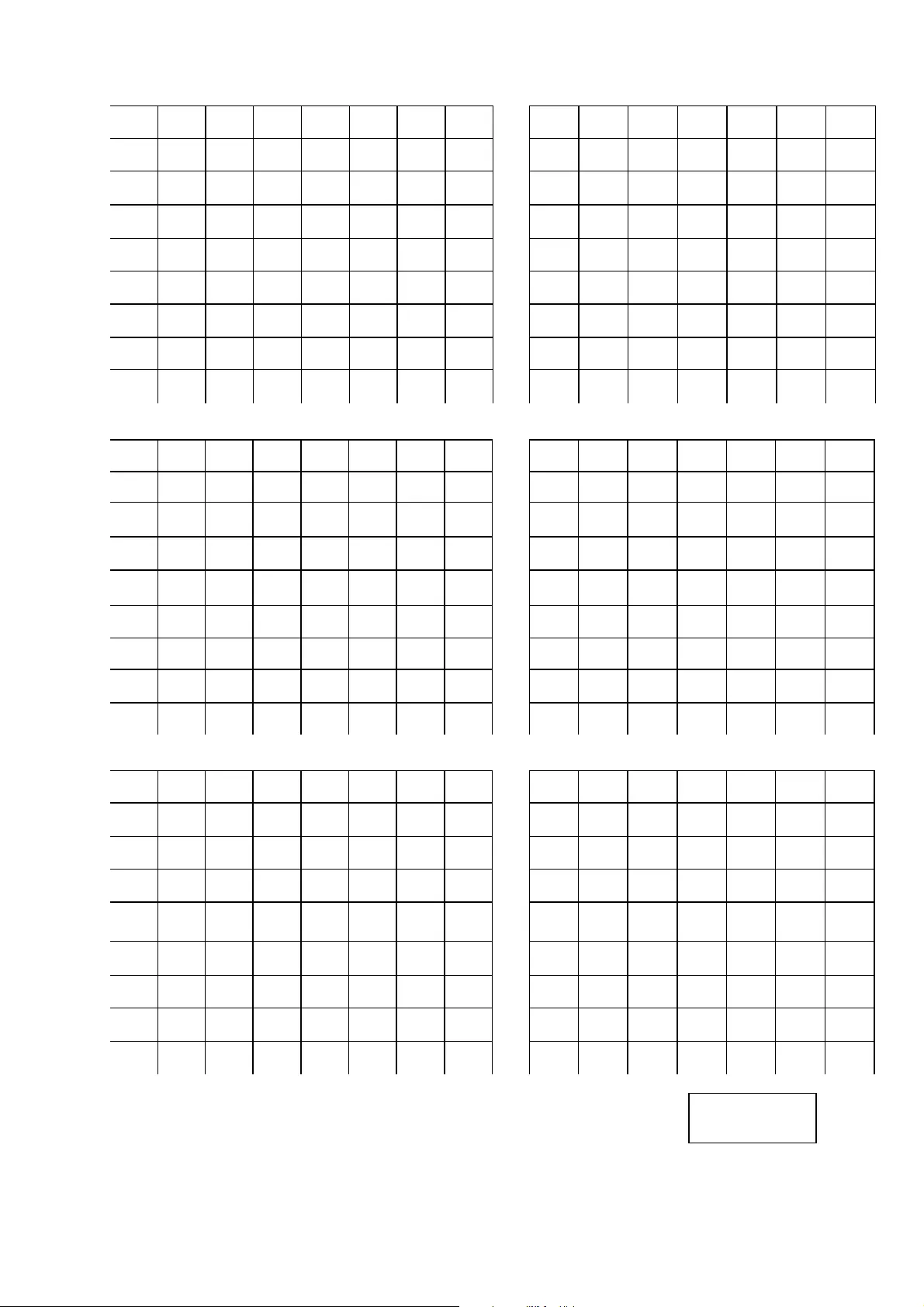

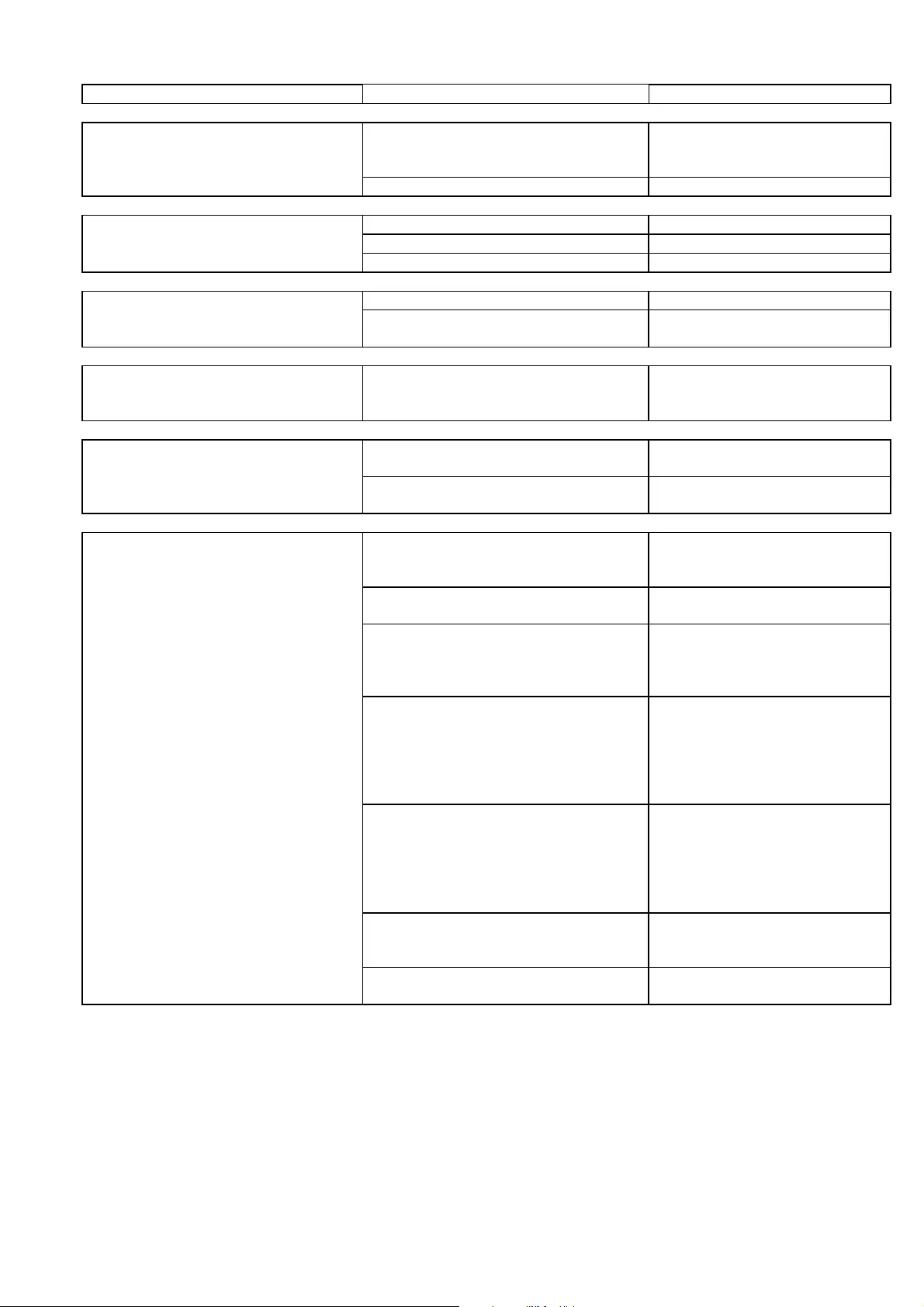

PRODUCTION TABLES FOR ICE FLAKERS

IQ135A IQ150A

45 104 102 96 92 86 82 78 106 104 99 94 88 84 80

40 119 114 111 102 98 95 94 120 118 109 107 104 101 97

35 134 124 118 115 110 106 102 129 122 119 117 115 113 104

30 136 134 123 120 111 109 106 137 128 123 120 118 115 112

25 139 135 126 121 119 115 110 139 137 129 122 120 117 114

20 141 138 131 123 121 119 114 141 139 136 124 122 119 116

15 142 141 132 126 124 122 118 145 144 138 134 124 121 120

10 144 142 134 128 126 124 120 150 145 141 137 134 124 122

5 10 15 20 25 30 35 5 10 15 20 25 30 35

IQ200 A IQ 400 A

45 192 184 168 156 144 138 118 330 325 310 300 280 251 232

40 198 192 184 169 155 143 136 352 342 334 324 306 275 255

35 204 196 190 176 168 154 142 370 360 354 338 313 287 275

30 207 204 194 188 174 168 154 385 378 372 360 332 310 300

25 210 206 202 191 187 174 167 400 395 378 360 343 325 308

20 213 209 205 201 190 186 173 410 405 387 365 354 335 315

15 221 211 208 205 200 190 185 418 409 400 375 365 346 326

10 224 220 211 208 204 198 188 430 420 412 395 380 360 340

5 10 15 20 25 30 35 5 10 15 20 25 30 35

IQ550A IQ1100A

45 470 450 420 400 370 360 345 1960 1940

1912 1816 1760

1656 1600

40 500 480 454 430 405 390 375 2064 2048

1976 1904 1800

1760 1656

35 520 540 490 455 435 425 405 2296 2232

2040 1976 1904

1800 1752

30 600 566 538 510 480 465 455 2360 2320

2248 2136 1960

1880 1792

25 611 568 549 522 500 486 471 2400 2376

2320 2232 2136

1960 1872

20 622 570 560 535 515 498 482 2436 2424

2400 2320 2224

2120 1960

15 626 589 567 540 520 502 488 2448 2432

2420 2384 2312

2224 2112

10 630 608 575 545 525 506 495 2480 2444

2432 2416 2384

2296 2200

5 10 15 20 25 30 35 5 10 15 20 25 30 35

WATER TEMPERATURE (°C)

Water quality = 500 ppm (240 Microhms/cm)

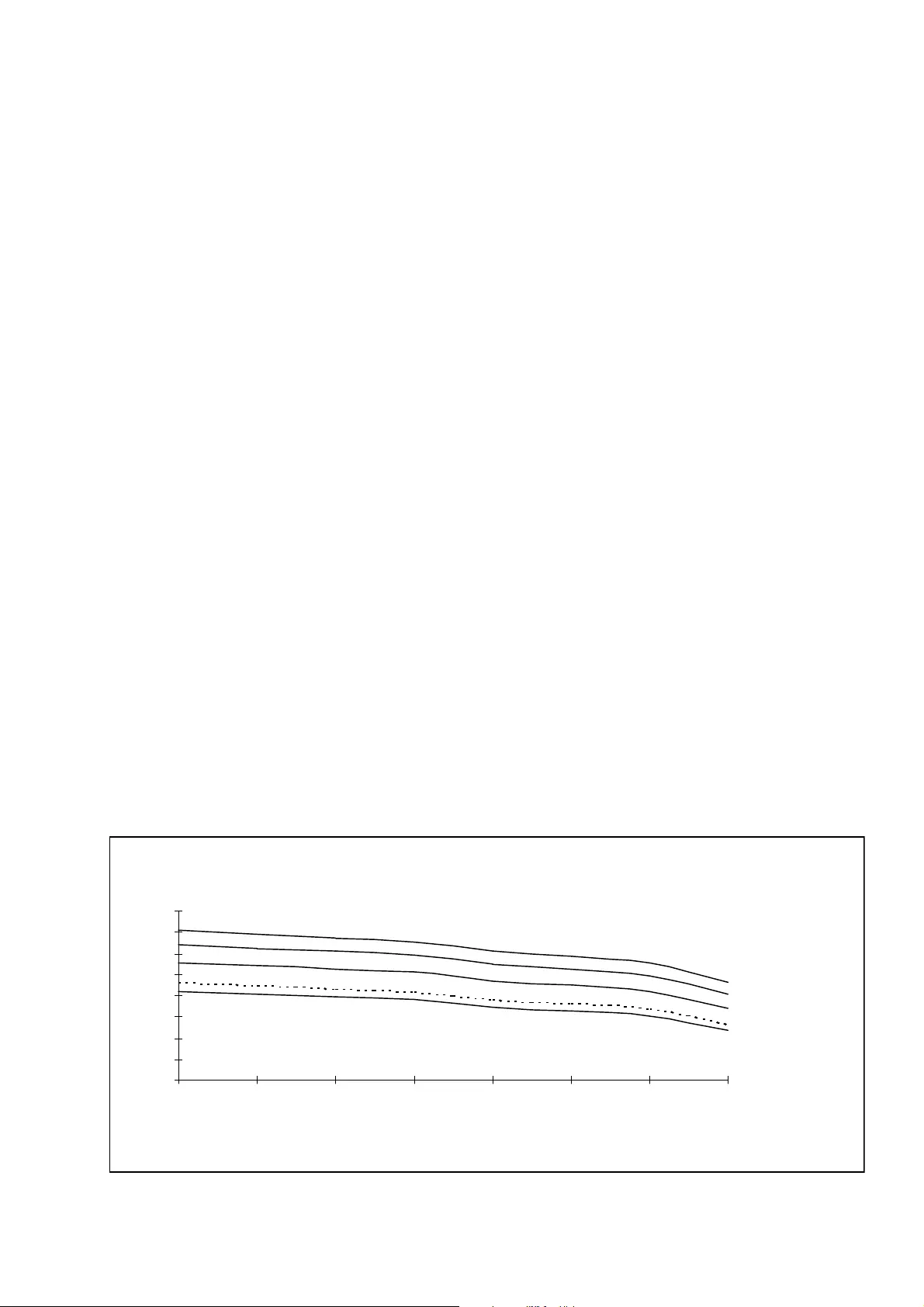

About ice production

IMPORTANT: Production figures have been obtained under the following conditions:

A

M

B

I

E

N

T

T

E

M

P

E

R

A

T

U

R

E

ºC

Kg/Day

14

Water Quality: 550 ppm. total solids

Water Temperature: 15°C

Ambient Temperature: 20°C

Ice production and quality is heavily dependent on the following:

a) Ambient temperature

b) Water temperature

c) Water quality

d) Level of water in evaporator

The following graph illustrates variations in production according to these fact

ors. As shown,

production decreases as water temperature increases.

IT IS IMPORTANT THAT WATER INTAKE TUBE IS NOT CLOSE TO ANY HEAT SOURCE.

THIS WILL AFFECT ICE PRODUCTION AND QUALITY.

• Ambient temperature should be taken 4cm away from the centre of the front grille

• Water temperature should be taken inside the water trough. Check that water line and filter do

not receive hot air from condenser + fan. If so, then re-direct water inlet line + filter to avoid hot

air current.

• Ice quality can be improved by lowering the position of the water trough. The trough is attached

to a panel with two screws. This panel has several slots, so that the trough can be moved up or

down as required.

• The trough may be lowered up to 80mm (IQ 550/1100). This will result in decrease of

production (see dotted line in graph below), but harder, drier ice.

• Water content in ice (obtained by straining ice) may be as much as 10%

• Ice production also decreases with improved water quality. (See graph for approximate

production variations).

10

15

20

25

30

35

40

45

Production Variations According to Water Quality

When Water Temperature is Maintained at 15°C.

Room temperature

* 1500 ppm

* 1000 ppm

* 500 ppm

* Level -60 mm

(500 ppm)

* 30 ppm

DELIVERY & UNPACKING

15

Upon receipt, thoroughly inspect the packing container. If there appears to be damage to the

container contact the shipper immediately. Unpack unit in the presence of delivery personnel

noting any damage on the waybill.

ITV packing bears the “Green Point” on all models according to the European Directives on

management of Packaging and Waste Disposal.

Be sure to include model name and serial number on all claims. Serial number is located in the

following three places:

(1) Packing

There is a label stuck onto the cardboard packing bearing this serial number (1).

(2) Machine body

On the back of the machine (1).

(3) Rating plate and serial number

WARNING: DO NOT LEAVE PACKING

MATERIALS (PLASTIC BAGS, CARDBOARD BOXES, ETC.) WITHIN REACH OF CHILDREN.

Located at the back of the machine.

Water cooled machines: check that the draina

ge hose

at the back of the machine is in good condition.

Verify that the installation kit is inside the bin, and

has the following pieces: scoop, 3/4’ water hose, two

small filters and user manual.

In all models there is a large particle filter (5 micres

)

with accessories, and an ice dispersion cone.

16

INSTALLATION

Recommended Placement of Unit

IMPORTANT!

ICE QUEEN machines are intended to operate at room temperature between 5°C and 43°C and

with water temperature rangin

g between 5°C and 35°C. You may encounter evaporator/gearbox

malfunctions should the machine run at temperatures below the recommended minimum. When

running above maximum recommended temperatures you can expect shorter compressor life

and decreased production.

Air-cooled units receive air input via front of machine and expel air through rear grille.

IMPORTANT!

If front and/or rear ventilation is inadequate, obstructed, or in close proximity to other heat

producing machinery, use of a water-cooled unit is strongly recommended.

The above mentioned also applies should unit be installed in an area where dust, smoke, or other

airborne pollutants may be present. Units—especially air-cooled ones—should not be installed in

kitchens. To facilitate access to condense

r and/or water pressure valve, allow sufficient space at

front of the machine. Ensure that flooring is firm and even.

Water and Drainage

Water quality influences ice hardness, flavour, and quality as well as condenser life.

Keep in mind the following points:

a) WATER IMPURITIES: Major impurities are eliminated by the two small wire mesh filters

provided and installed on either end of the water inlet hose. Filters should be cleaned/replaced

regularly depending on purity of water. For minor impurities we recommend installing a 5-

micron

filter such as the one provided with the unit: Part # ITV 207499. This filter will need to be replaced

only when machine stops due to insufficient water flow (filter is obstructed with impurities).

b) WATER WITH MORE THAN 500 PPM: Ice will be less hard and tend to adhere. Lime deposits

may impede proper function. In water-cooled models, condenser obstruction is likely. Installation

of a high quality water softener is recommended.

c) CHLORINATED WATER: In most cases the filter which is included in the machine should be

sufficient. However, if mains water smells or tastes of bleach, this indicates an excess of chlorine,

which may eventually corrode the stainless steel auger. A carbon filter will remove chlorine in

water (average filter life: 6 months), not included with machine. (Part # ITV 207509).

(NOTE: You may encounter water with ALL aforementioned properties.)

17

d) PURIFIED WATER: A 10% reduction in overall production may occur.

Connecting Unit To Water Source

• Use 1.3 m. flexible tube (with the two filters attached) provided. NOTE: We advise using a

single faucet fixture.

• Water pressure should be between 0.7 and 6 Kgs/cm2. (10/85 Psi.)

• If water pressure exceeds these values, installation of appropriate corrective units will be

necessary.

• It is important that water tubing does not come close to or in contact with any heat sources or

heat generated by unit as this could decrease production.

Connecting Unit To Drain (Water -cooled Models)

• Drain must be located at least 150mm below machine level. Drain tube must have an inner

diameter of 30mm and a minimum gradient of 3 cm per metre.(3%)

Electrical connection

• Unit is provided with a 1.5 m cord and Schucko socket (except for models IQ550 and IQ1100).

• A switch and adequate fuses should be installed. Nominal voltage and intensity are indicated on

rating plate as well as on this manual's technical pages. Voltage fluctuations greater than 10%

can cause problems or prevent machine from starting.

• Line to base of plug must have a minimum section=2.5 mm2 for models up to IQ 200 and 4

mm2 for other models.

• Be sure voltage indicated on rating plate corresponds to that of mains supply.

IMPORTANT!

Supply socket must be properly earthed. Be sure to check standard for country where appliance

is going to be installed.

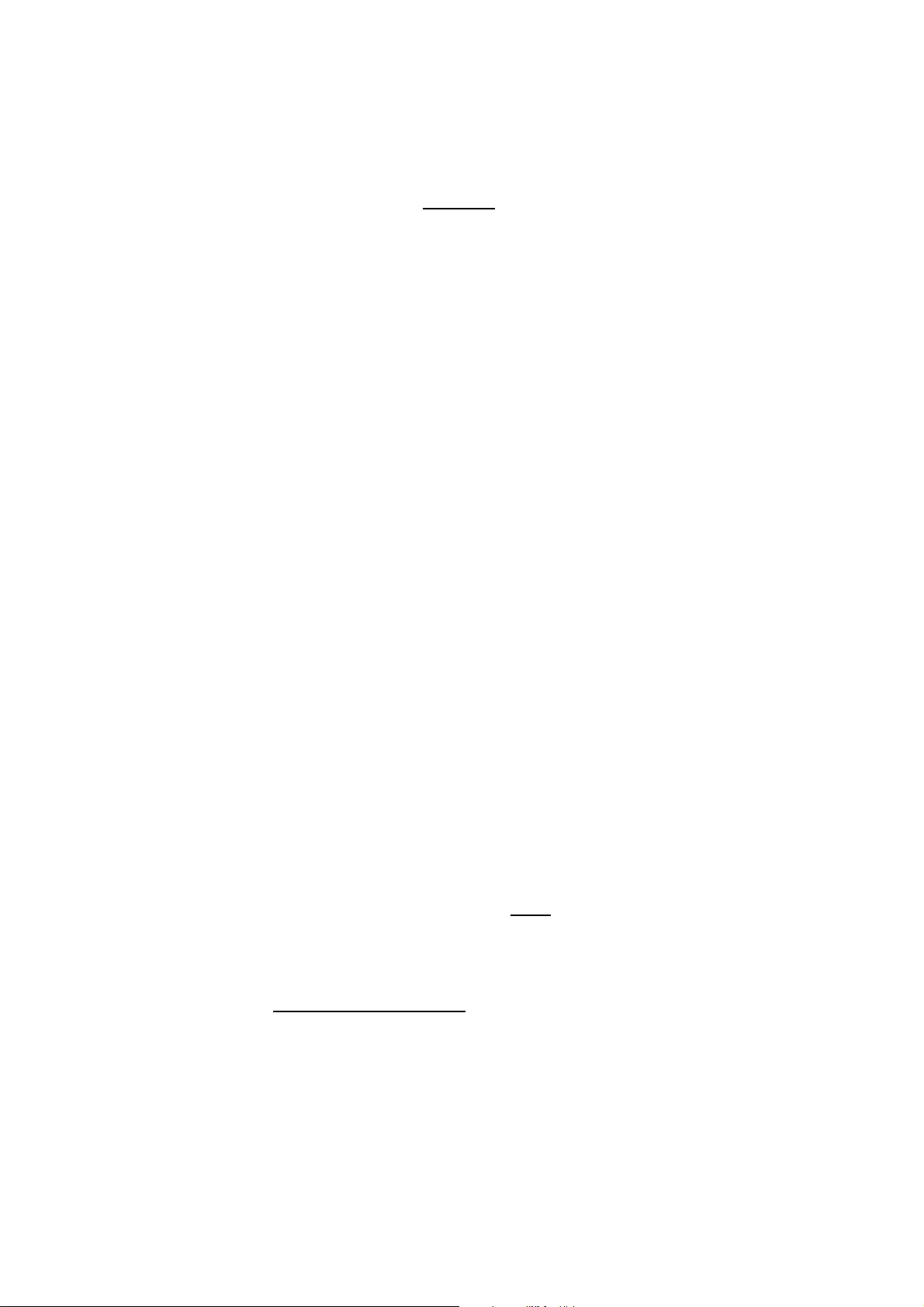

Assembling the dispersion cone

This device spreads ice evenly so it does not pile up

beneath exit tube. Its position can be altered to

redirect ice, and hence prevent the “pyramid effect”.

18

OPERATION

Preliminary Checks

a) Is machine levelled?

b) Are voltage and frequency of mains supply the same as indicated on rating plate?

c) Is drainage system working properly?

d) Is air circulation and room temperature adequate? (Air-cooled models)

AMBIENT TEMPERATURE WATER TEMPERATURE

MAXIMUM 43° C 35° C

MINIMUM 5° C 5° C

e) Is water pressure adequate?

MAXIMUM 0.7 Kg/cm2

MINIMUM 6 Kg/cm2

ATENTION: Check that voltage and mains frequency is the same as in the rating plate.

Starting up

Once preliminary check has been completed (ventilation, connections, temperature, etc.),

proceed as follows:

1. Remove top cover of unit

2. Open faucet, make sure there are no leaks and check that water level is adequate.

4. Set switch to OFF position.

5. Connect unit.

6. Check for air bubbles in water supply tubing (water trough to evaporator)

IMPORTANT!

Be sure voltage and frequency of mains supply is as indicated on rating plate.

1. Set appliance switch to ON position. All elements should be working except for fan (air-cooled

machines) which will commence operation only when high pressure activates it. All pilot lights

should be switched off except for power display (green), indicating that power is on. Otherwise

check the troubleshooting section of this manual.

19

2. Make sure fan blades don't come into contact with anything and that none of the tubes vibrate.

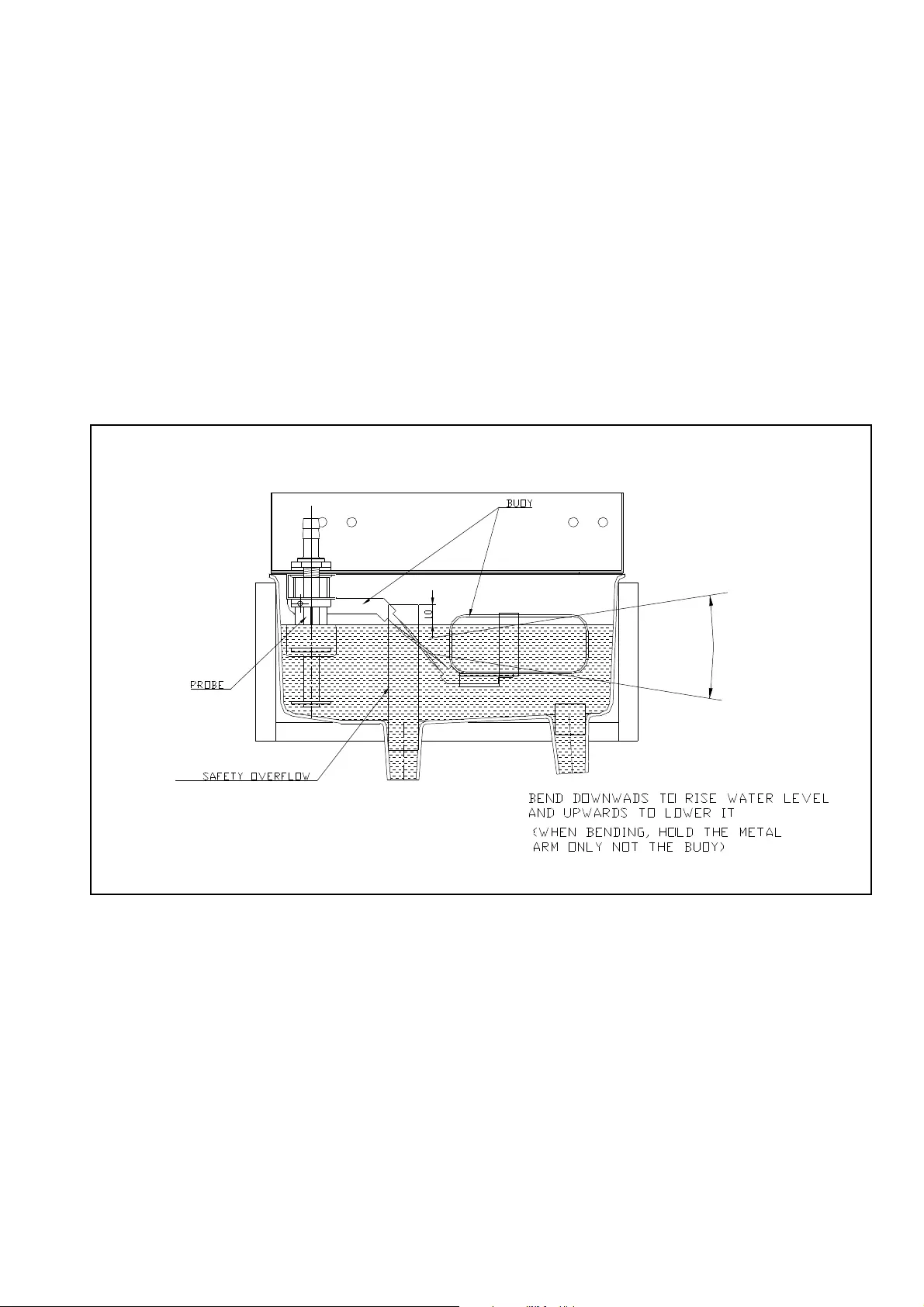

Inspection and Adjustment of Water Level in the Trough

1. Make sure water level in trough does not go down completely as this will set off "WATER

LOW" sensor while machine is operating. Should this happen with a pressure higher than

1Kg/cm2 and filters in good condition, INCREASE LEVEL by bending the float arm upwards.

2. Turn machine off and wait for flotation valve to close before water escapes through maximum

level drain. If that happens and pressure is lower than 6kg./cm2, slowly bend and lower the

float’s arm until you have achieved an adequate flow.

IMPORTANT!

If water pressure exceeds 6 kg./cm2., a pressure reduction unit should be installed to maintain

pressure at 4kg./cm2.

Cross Check

a) Shut off water faucet. Water level will recede until automatic shut-off occurs.

b) Open water faucet. Water level will rise and machine operations will commence in 3 minutes’

time.

IMPORTANT!

Please instruct end user as to the correct maintenance procedures as described above.

The manufacturer declines all responsibili

ty for damage caused by failure to properly

maintain the equipment.

20

ADJUSTMENTS

Expansion valve.

DO NOT TOUCH THE EXPANSION VALVE.

Water Level

The purpose of maintaining proper water levels is to allow adequate water flow to the evaporator.

A water level sensor has been incorporated to shut off unit until required minimum water level is

achieved.

The optimal water level is indicated in diagram below.

21

Pressure-controlled Valve on cooling water circuit

• The purpose of this valve is to control cooling water flow to the condenser, so as to maintain the

high pressure at 16.5 bar (232-

240 Psi), which corresponds to water temperature of 40°C (exit

temperature).

• If mains water temperature exceeds 32

°C, the above values of high pressure and water

temperature at exit will be higher.

ADJUSTMENT: High pressure (and water temperature) can be decreased by opening valve (turn

screw clockwise).

Fan pressostat (air–cooled models)

High pressure is controlled by starting and stopping fan, which provides airflow through

condenser. Differential is fixed. (1Kg/cm2 or 14 Psi.) Cut-off pressure should be 16 Kg/cm2 (228

Psi.) Low pressure values in circuit may cause gearbox malfunction due to excessive ice

production. Pressure values higher than 14 Kg/cm2 will diminish ice production and may shorten

compressor life. Pressure can be regulated by rotating screw on Pressure Control Valve

(clockwise to increase pressure). One full turn is equivalent to about 1.5 Kg/cm2.

22

Safety pressostat

Start up timer

This timer delays start up for 2-

3 minutes after machine is switched on. This delay allows ice

formed on evaporator to partially melt. When the machine restarts ice will be wet and loose in

evaporator, and hence gearbox/auger breakage risk is reduced.

THIS TIMER ONLY WORKS WHEN MACHINE IS WARM.

Safety devices.

•

Overload protection device: will trip if maximum current intensity (A) is exceeded, hence

preventing the motor from overheating due to current peaks. When overload trip

s, a red light

will switch on in the front panel. The overload must be reset manually, to do so the front grille

and overload cover must be removed.

• Thermal protection device: will trip if temperature in motor exceeds set point. When this

device trips, the same red light will switch on in the front panel. In this case, however, reset is

automatic.

• Low water level sensor: a magnetically activated sensor (buoy) located inside the water

trough will switch off the machine should the level of water fall below the set minimum. A red

light will switch on in the front panel labelled “low water level”. Reset is automatic.

• Bin full of ice: a micro-switch located at the top of the evaporator will stop the machine when

the bin (and the ice discharge tube leading to th

e bin) is full of ice. An orange light will switch

on in the front panel labelled “bin full”. Reset is automatic.

This safety device trips when pressure is too

high. Pressure might reach

the set limit of 27 Kg/cm2 when:

a)

Air circulation is not sufficient, room temperature is too high, condenser

is dirty or fan motor is broken. (air-cooled models)

b

) Insufficient water in the cooling circuit, inlet water temperature is too high

or fan motor is broken (water -cooled models).

The safety pressostat will switch off the machine completely until pressure

drops again to its lower set point value (21 Kg/cm2)

HIGH PRESSURE SET POINTS (non-adjustable):

27-21 Kg/cm2 (380-296 Psi.)

23

INSPECTION AND REPLACEMENT PROCEDURES

Lower bearing

Materials needed:

- PHILLIPS N°2 Screwdriver

- M8 Screws (*)

- 5 mm Allen key

- Nylon head hammer

- No. 12-13 wrench

Procedure:

1) Disconnect unit.

2) Close faucet.

3) Remove square black plastic lower lid on machine base.

4) Remove drain plug on lower bearing.

5) Remove side screw that holds bearing with a 5 mm Allen key.

6) Introduce M8 50 mm screw in drain plug hole. Bearing will come out as you

tighten screw.

7) Check for wear inside bearing and replace if more than 0.25 mm.

8) Replace o-rings, add silicone and grease, clean evaporator and reassemble.

IMPORTANT!

Side hole must be aligned with the one in evaporator, otherwise you will not be able to

insert Allen screw in place.

1) Open water faucet and check for leaks.

2) Assemble unit and connect to power source.

3) IMPORTANT: DISCARD ICE PRODUCED DURING FIRST 15 MINUTES.

Speed Reducer (Gearbox)

Materials needed:

§ Extractor

§ M8 Screws

§ No.12-13 monkey wrench (2)

§ No.8-9 monkey wrench

§ 6 mm Allen key

§ M8 nuts (2)

24

Procedure:

1) Remove top screw on gearbox.

2) Remove the four screws that hold flange.

3) Remover gearbox using extractor

Assembly:

1) Lubricate motor axle with grease.

2) Place gearbox face up.

3) Screw in (*) screw, place washer and lower gearbox by tightening nut.

WARNING: Do not hammer.

1) Face up clamps socket.

2) Remove (*) screw.

Place washer and tighten until spindle is flush with gearbox axle.

Upper flange

Materials needed:

§ Extractor

§ PHILLIPS N°2 Screwdriver

§ M8 Screws (110 mm)

§ No.12-13 monkey wrench (2)

§ No.8-9 monkey wrench

§ 4, 5 and 6 mm Allen key

§ M8 nuts (2)

Procedure:

1) Disassemble gearbox (see previous section)

2) Remove all four screws holding brackets.

3) Remove all three screws that keep plate and evaporator together.

4) Remove gearbox by hand or using extractor.

Assembly:

1) Clean lodging and neck plate.

2) Mount plate.

IMPORTANT: End of ice discharge flap must be to the right of evaporator's window.

IMPORTANT: Carefully lubricate seal lips (depending on model), avoid damaging them.

1) Replace the three evaporator/plate screws.

2) Replace brackets.

3) Reassemble gearbox. (see previous section)

25

Upper bearing (depending on the model)

Materials needed:

§ Extractor

§ PHILLIPS N°2 Screwdriver

§ M8 Screws (110 mm)

§ No.12-13 monkey wrench (2)

§ No.8-9 monkey wrench

§ 4, 5 and 6 mm Allen key

§ M8 nuts (2)

1) Disassemble gearbox (see previous sections)

2) Disassemble plate/flange (see previous section)

3) Remove top seals.

4) Place and fix extracting ring.

5) Strike chisel placed over extracting ring using nylon head hammer.

Assembly:

1) Install new seals and lubricate (SHELL MULTIFAK EP2 TE code ITV420).

2) Secure bearing.

3) Mount plate.

IMPORTANT: Be careful not to damage seals. Lubricate seal lips with grease.

26

MAINTENANCE AND CLEANING INSTRUCTIONS

IMPORTANT!

**Maintenance and cleaning procedures as well as problems derived from f

ailing to carry them

out are not covered by the warranty.

Proper maintenance is essential to obtain favourable ice quality and optimum functioning of unit.

Frequency depends on water quality and characteristics of room where unit is installed.

** Maintenance/cleaning procedures should take place at least once every six months. If

concentration of air pollutants is high, complete procedures on a monthly basis.

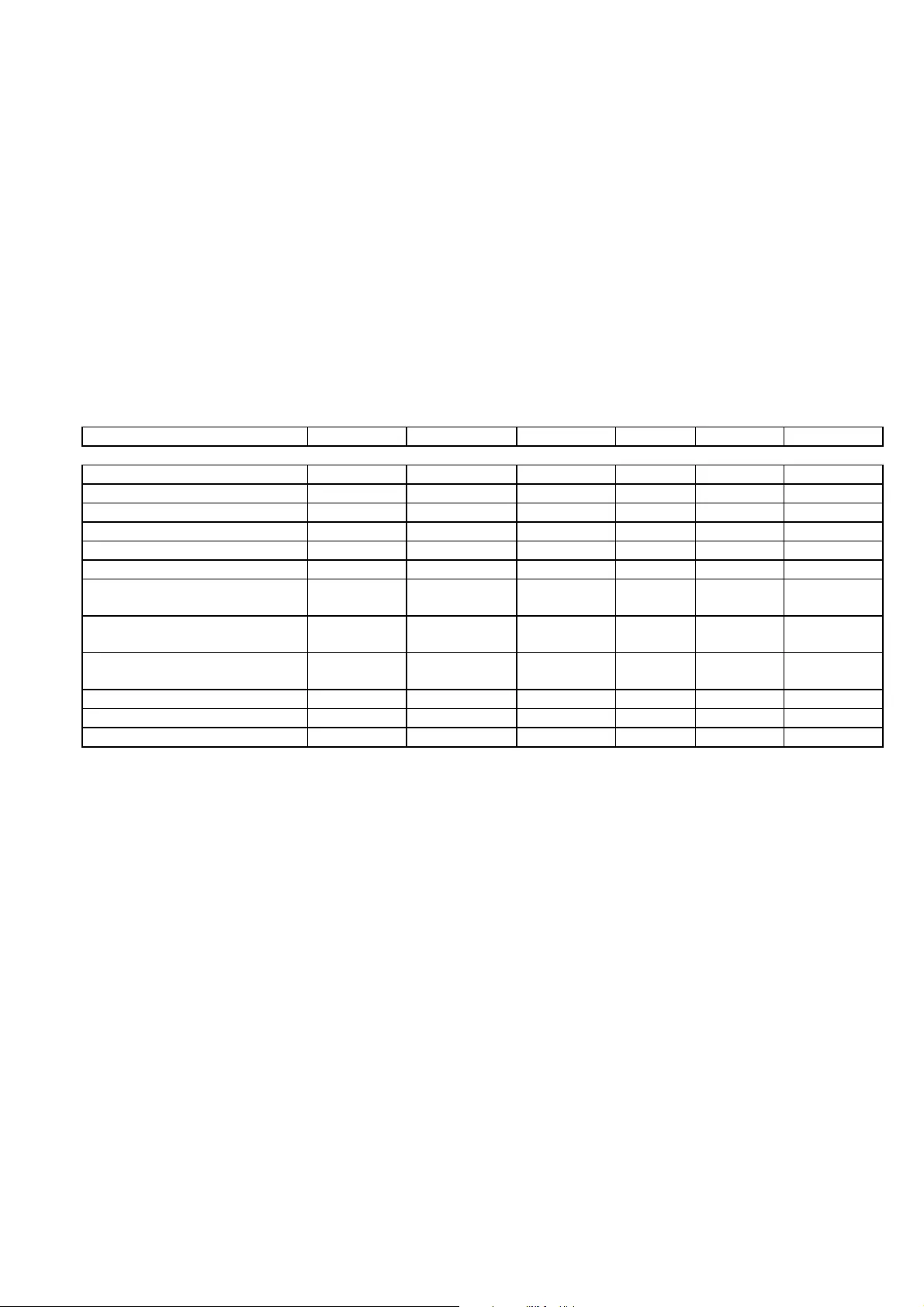

MAINTENANCE TABLE:

PROCEDURE MONTHLY QUARTERLY

BIANNUAL YEARLY BIENNIAL DURATION

Air condenser cleaning 0000 0000 **** **** **** 30 minutes

Water condenser cleaning #### **** 90 minutes

Lower bearing check #### **** 60 minutes

Upper bearing check 90 minutes

Water circuit cleaning #### #### 45 minutes

Sanitary cleaning #### #### 30 minutes

Motor reducer (gearbox)

cleaning 0000 0000 30 minutes

Motor reducer (gearbox) oil

level 60 minutes

Water filter

cleaning/replacement 0000 0000 30 minutes

Upper bearing lubrication 30 minutes

Gearbox oil change 60 minutes

General unit cleaning &&& &&& &&& &&& &&& --

0000 Depending on room characteristics

#### Depending on water quality

&&& Carried out by owner

**** Essential

Maintenance and cleaning procedures as well as problems derived from failing to car

ry them out

ARE NOT COVERED BY THE WARRANTY. Service personnel will invoice you for travel

expenses, time invested and materials required for maintenance and cleaning of unit.

27

MAINTENANCE AND CLEANING PROCEDURES

WARNING: Unit should always be disconnected during maintenance/cleaning procedures.

Water Condenser

1) Disconnect machine.

2) Close water faucet.

3) Disconnect water entry/exit from condenser.

4) Prepare a solution of 50% phosphoric acid in distilled water.

5) Distribute solution through condenser. (Solution is more effective at 35°-40°C).

WARNING!

DO NOT USE HYDROCHLORIC ACID

Air Condenser

1) Disconnect machine.

2) Close water faucet.

3) Clean condenser using a vacuum cleaner, soft brush and/or low-pressure air.

Evaporator/Water Trough

1) Disconnect machine.

2) Remove drain plug situated in lower bearing of evaporator. Use a container to collect water.

3) Allow water to flow for 2 to 3 minutes.

4) Close water faucet and replace plug in evaporator.

5) Prepare a solution of 50% phosphoric acid in distilled water. Do not use hydrochloric acid.

Slowly pour solution into water trough. (Solution is more effective at 35°-40°C).

6) Allow solution to stand for 20 minutes.

7) Remove lower plug and empty trough. Replace plug.

8) Fill trough with solution to maximum capacity. Connect machine and wait for unit to

automatically shut off when remaining liquid drains.

WARNING:** Discard ice produced during cleaning procedure.

9) Disconnect machine, remove plug, open faucet and let water run for 2 to 3 minutes.

10) Close faucet, place plug, open faucet and connect the machine.

**At this point sanitary cleaning starts

28

11) Slowly add bleach to water trough for at least 5 minutes. Allow machine to make ice for at

least 15 minutes.

WARNING:** Discard ice produced during cleaning procedure.

12) Disconnect unit, place cover and check for water leaks. Change seal in water plug if

necessary.

13) Replace filters if necessary. (Machines provided with 5mm wire gauze filters).

14) Reconnect machine.

Cleaning the water inlet filters

These round wire gauze filters placed on either end of the water hose to mains, often become

blocked in the first few days of use, especially when the plumbing installation is new. Clean them

under a jet of water.

Checking for water leaks

This must be done whenever maintenance is carried out on the machine: check all water

connections, braces, tubes and hoses in order to eliminate leaks and prevent breakages and

flooding. Check that the valve closes tightly on models with an automatic cleaning system.

NOTE: You will observe that after a certain period of functioning (the running-in period), low-

pressure pressostats may need to be adjusted. This second adjustment will be final.

RUNNING-IN CHECK

It is essential to service the machine after about 10 working days, or earlier if any incident has

occurred.

CHECK:

• Water level

• Minimum high pressure (fan should stop at 35-37ºC, equivalent to 5.25 bar, 67.5 psi)

• By-pass opening at -21ºC ± 0,5ºC during the first few minutes after start-up

• Ice dispersion cone is spreading ice uniformly inside the bin.

• Refrigerant charge (when fan switches off, bubbles should appear at the sight glass, and

return line to the compressor should be covered in frost right up to the weld). If high-pressure

manometer is connected do not disconnect until you stop the machine and pressures have

stabilised. Check that a large amount of gas has not been lost in connecting/disconnecting

manometers, and use the shortest hoses you can find in H.P.

• Any gearbox oil leaks?

29

NOTE:

Newly installed electromechanical control devices will suffer variations in their adjustment caused

by the machine’s own functioning. Once a second adjustment of these devices is carried out, this

should be good for several years. It is recommended, however, to check these devices yearly,

this is best done between October to April.

SAFETY TRIP (CIRCUIT-

BREAKER) IN NEW MACHINES WILL SWITCH OFF THE MACHINE

DUE TO ONE OF THE FOLLOWING:

• Ambient temperature is below 5ºC

• Water temperature is below 5ºC

• Evaporation temperature is below -20ºC

• Cooling temperature below +30ºC

• Refrigerant charge slightly low

In the first three cases, so long as temperatures do not drop below 3ºC (machine limit), re-

adjust

fan pressostat to 42ºC and check that by-pass opens at -21ºC. In the last two cases bypass will

open and close very often. Adjust bypass, fan pressostat and add refrigerant if necessary.

Gearbox current consumption should be between 1.9A (min) and 2.6A (peaks) with an average

2.2A. Safety trip will work at 2.4-2.6A and switch off the machine immediately.

If the machine is over 2 years old, also inspect the auger, bearings, and grease on bearings.

In case of excess current consumption, you can verify that the problem is in the gear-

box by

either physically detaching gearbox and motor from auger and checking current consumption, or

by removing only the brown wire which provides current to the compressor.

In order to avoid damage to the gear-box, the safety trip is very sensitively adjusted and may trip

easily. You may teach the end user to re-connect the machine (by inserting a pen/screwdriver

through the front grille blades). This is best done after a one hour pause.

Should the machine trip on a regular basis (more than once a week), the end user must get in

touch with the service department.

30

SPECIAL ADVICE CONCERNING R-404 REFRIGERANT

• R-404 is a mixture of 3 liquid-phase gases. On evaporating, the 3 component gases separate

• Always use the liquid phase valve (at the end of condenser or accumulator) for refills and

purges.

•

When replacing a compressor, wash inside of circuit with a suitable solvent + pump, dry with

nitrogen gas, REPLACE THE DRIER WITH ONE SUITABLE FOR R-404, which must also

have ANTI-ACID properties.

• If you need to add oil, use one which is specific for R-4

04 (POE). If you are in doubt, contact

the machine manufacturer.

• If there is a leak anywhere in the circuit where R-404 in the GAS phase, and a refill of over

10% is required, then ALL THE GAS IN THE CIRCUIT MUST BE PURGED AND THEN

REFILL AS DESCRIBED PREVIOUSLY (LIQUID PHASE VALVE)

• When charging via low-pressure valve, do not start compressor immediately, allow about one

hour for liquid to gasify.

31

TROUBLESHOOTING

PROBLEM PROBABLE CAUSE SOLUTION

1) Machine not running. A) There is no power. A) Check power source.

B) Water trough is empty. B) Check the water supply.

Check filters.

Open faucet

C) “Full bin” sensor malfunction. C) Fix/replace sensor.

D) No apparent cause. D) Check: contactor, circuit,

breaker, pressostat, timer,

electric installation and magnetic

micro

E) Timer is faulty. E) Replace.

2) Machine works, but doesn’t make

ice. A) Refrigerant leak. A) Repair leak and recharge

refrigerant .

B) Faulty compressor. B) Replace compressor.

C) valvula de expansion cerrada o

estropeada or capillary obstructed C) Open or Replace valve (or

capillary) and dehydrating filter.

D) Water/humidity in refrigerating

system. D) Charge compressor oil,

replace capillary and dehydrator

(use an anti-acid one), create a

vacuum in the installation, slightly

warm up all components and

charge refrigerant.

3) Machine works inconsistently

A) Water pressure lower than 0’7 BAR

(pressure may sometimes drop greatly

when several taps are opened

elsewhere in premises)

A) For smaller units try regulating

the water trough float. Larger

machines might require

installation of a mains pressure

raising unit.

B) Water pressure is appropriate (0’7 a

6’5 BAR) B) Regulate water level in trough.

4) Compressor works in intermittent

manner. A) Condenser is dirty A) Clean condenser.

B) Air circulation obstructed. B) Re-establish air circulation.

C) Defective condenser fan. C) Check and replace fan.

D) Fan pressostat is defective or needs

adjustment. D) Check and replace/adjust

E) Safety pressostat is defective. E) Check and replace.

F) Compressor start system is

defective. F) Check and replace.

G) Pressostat valve is defective or

needs adjustment. G) Adjust, repair or replace

valve.

H) Voltage too low/insufficient line

section H) Inspect and replace if

necessary.

5) Ice is too wet. A) Room temperature too high (over

35ºC) A) Relocate unit to a cooler

place.

B) Water temperature too high (over

30ºC). B) Ensure that filter and inlet tube

are away from heat sources,

such as hot air blown by

machine’s own fan.

C) Poor water quality (over 1500 ppm) C) Lower the water trough. Install

water purifier.

D) Condenser is dirty. D) Clean condenser.

E) Pressure-controlled valve on cooling

water needs adjustment or is defective. E) Adjust or replace valve.

F) Low compressor output F) Replace compressor.

32

G) Refrigerant leak G) Repair leak and recharge

refrigerant.

H) Water level in trough is low. Water

consumption is greater than buoy valve

pass.

H) Check water pressure. Look

for obstruction in filters or valve.

Adjust water level in trough

33

PROBLEM PROBABLE CAUSE SOLUTION

6) Water leaks A) Water from trough overflows and

falls into ice bin. Buoy valve does not

close.

A) Adjust water level. Reduce

water pressure. Clean or replace

valve.

B) Defective o-rings in lower bearing. B) Seal with silicone or replace.

7) Machine is unusually noisy A) Defective fan or loose blades A) Tighten blades or replace fan.

B) Vibrating components B) Tighten loose parts

C) Compressor makes noise. C) Replace compressor

8) Motor is unusually noisy A) Back fan within motor is loose A) Open motor and tighten fan.

B) Worn ball bearings. B) Replace ball bearings or

motor.

9) Gearbox is unusually noisy A) Defective/worn parts within gearbox A) Open gearbox and replace

defective parts, or replace entire

gearbox.

10) Evaporator is unusually noisy A) Upper or lower bearings are

defective or dirty. A) Replace, clean and/or

lubricate bearings.

B) Auger and/or evaporator are

scratched. B) Check and replace if

necessary.

11) Machine not working. Red pilot

light is switched on in front panel. A) Input voltage subject to oscillation

which trips the machine. A) Check voltage and rearm

circuit breaker. Need a voltage

stabiliser?

B) Electrical condenser on motor is

faulty B) Replace electrical condenser

C) Condensation pressure in

refrigeration circuit is too low C) Adjust fan pressostat (air-

cooled models) or cooling-water

control valve (water-cooled

models)

D) Evaporation pressure (and

temperature) too low D) Adjust fan pressostat (air-

cooled models) or cooling-water

control valve (water-cooled

models), check refrigerant

charge and expansion valve

setting if applicable.

E) Lower or upper bearing is damaged

and auger may be scratching

evaporator.

E) Replace damaged bearing(s).

Look for scratches on the

bearings and on the vertical

grooves inside evaporator.

Check auger blade for sharpness

and scratches

F) Defective/worn parts within gearbox F) Open gearbox and replace

faulty parts, or replace entire

gearbox.

G) Bearing on motor reducer is

blocked. G) Repair or replace motor.