Table of Contents

Brother TD-4420TN User Manual

Displayed below is the user manual for TD-4420TN by Brother which is a product in the Label Printers category. This manual has pages.

Related Manuals

User's Guide TD-4420TN/4520TN

TD-4420TN/4520TN User's Guide (English)

© 2019 Brother Industries, Ltd. All rights reserved.

Version 01

ENG

i

Copyright Information

The copyright in this manual, the software, and firmware in the printer described

therein are owned by Brother. All rights reserved.

CG Triumvirate is a trademark of Agfa Corporation. CG Triumvirate Bold

Condensed font is under license from the Monotype Corporation.

All other trademarks are the property of their respective owners.

Any trade names and product names of companies appearing on Brother

products, related documents and any other materials are all trademarks or

registered trademarks of those respective companies.

Information in this document is subject to change without notice and does not

represent a commitment on the part of the company. No part of this manual may

be reproduced or transmitted in any form or by any means, for any purpose other

than the purchaser’s personal use, without the expressed written permission of

the company.

ii

Contents

1. Introduction ............................................................................................................ 1

1.1 Product Introduction ......................................................................................... 1

1.2 Product Features .............................................................................................. 2

1.2.1 Standard Features ............................................................................... 2

1.2.2 Optional Features ................................................................................ 3

1.3 General Specifications ..................................................................................... 3

1.4 Print Specifications ........................................................................................... 3

1.5 Ribbon Specifications ....................................................................................... 4

1.6 Media Specifications ........................................................................................ 4

2. Operations Overview .............................................................................................. 5

2.1 Unpack the printer and check the components ................................................ 5

2.2 Printer Overview ............................................................................................... 6

2.2.1 Front View ............................................................................................ 6

2.2.2 Interior View ......................................................................................... 7

2.2.3 Rear View ............................................................................................ 8

3. Setup ...................................................................................................................... 9

3.1 Setting up the Printer ........................................................................................ 9

3.2 Loading the Ribbon ........................................................................................ 10

3.3 Loading the Media .......................................................................................... 14

3.3.1 Loading the Label Rolls ..................................................................... 14

3.3.2 External Label Roll Mount Installation (Optional) ............................... 18

3.3.3 Loading the Media in Cutter mode (Dealers only) ............................. 20

3.3.4 Loading the Media in Peel-off Mode (Dealers only) ........................... 22

4. The LED Indicator and Feed/Pause Button Functions ......................................... 25

4.1 The LED Indicator .......................................................................................... 25

4.2 The Feed/Pause Button Functions ................................................................. 25

4.3 Power-on Utilities ........................................................................................... 25

4.3.1 Ribbon and Gap/Black Mark Sensors Calibration .............................. 26

4.3.2 Gap/Black Mark Sensor Calibration, Self-Test, and Entering Dump

Mode .................................................................................................. 27

4.3.3 Printer Initialization ............................................................................. 30

4.3.4 Media Sensor Calibration (For the Black Mark Sensor) ..................... 31

4.3.5 Media Sensor Calibration (For the Gap Sensor) ................................ 32

4.3.6 Skip the AUTO.BAS program ............................................................ 32

iii

5. BPM (Brother Printer Management Tool) ............................................................. 33

5.1 Start the BPM ................................................................................................. 33

5.2 Printer Function .............................................................................................. 34

5.3 Calibrating the Media Sensor using the BPM ................................................. 35

5.3.1 Auto Calibration ................................................................................. 35

6. Troubleshooting ................................................................................................... 36

7. Maintenance ......................................................................................................... 38

1

1. Introduction

1.1 Product Introduction

The sleek design of the TD-4420TN/4520TN label printer can handle up to 984 ft. (300 m) of

ribbon and label rolls. Its internal 5” (127 mm) label capacity can be further expanded with an

external label roll mount to handle 8” (203.2 mm) rolls, designed for industrial label printers.

The printer's movable Black Mark Sensor is compatible with a wide range of label media.

The printer uses its high-performance, high-quality, built-in Monotype Imaging® TrueType font

engine with the CG Triumvirate Bold Condensed smooth scalable font. It also provides a choice

of eight different sizes of the alphanumeric bitmap font. The printer's flexible firmware design

allows the user to download additional TrueType fonts from a computer to print custom labels.

It also supports most of the standard barcode formats and can print fonts and barcodes in four

directions.

• For more information about printing labels, see your labelling software's documentation.

• For more information about writing custom programs, see the FBPL Command Reference

Manual.

2

1.2 Product Features

1.2.1 Standard Features

Thermal transfer printing

Direct thermal printing

Gap Sensor

Fully movable reflective Black Mark Sensor

Ribbon Sensor

Head Open Sensor

USB 2.0 (Hi-Speed)

64 MB DRAM memory

128 MB Flash memory

RTC

BUZZER

Feed/Pause Button

Three-color LED Indicator

Standard industry emulation (including the Eltron® and Zebra® languages)

8 built-in alphanumeric bitmap fonts

Fonts and barcodes can be printed in four directions (0°, 90°, 180°, 270°)

Internal Monotype Imaging® TrueType font engine with CG Triumvirate Bold Condensed

scalable font

Downloadable fonts (from a computer)

Downloadable firmware upgrades

Text, barcode, graphics/image printing (See the FBPL Command Reference Manual for

the supported codes.)

Supported barcodes

1D barcodes

Code128UCC, Code128 subsets A/B/C, EAN128, Interleaved 2 of 5, Interleaved 2 of

5 with check digit, Code39, Code39 with check digit, Code93, EAN13, EAN8, UPCA,

UPCE, EAN and UPC 2 (5) digits add-on, Codabar, Postnet, MSI, MSI with check digit,

PLESSEY, China Post, ITF14, Code11, TELEPEN, TELEPENN, PLANET, Code49,

Deutsche Post Identcode, Deutsche Post Leitcode, LOGMARS

2D barcodes

GS1 DataBar, GS1 DataMatrix, Maxicode, AZTEC, PDF417, QR Code, Micro PDF 417

Supported image formats

BITMAP, BMP, PCX (Max. 256 colors graphics)

Supported Protocols

Ethernet

ARP, MAC, BOOTP, DHCP, DNS, WINS, FTP SERVER, HTTP server, SNTP client,

SMTP client, SNMP V1, Telnet, LPR/LPD, RAW 9100, IPV4, ICMP, IGMP, TCP, UDP

3

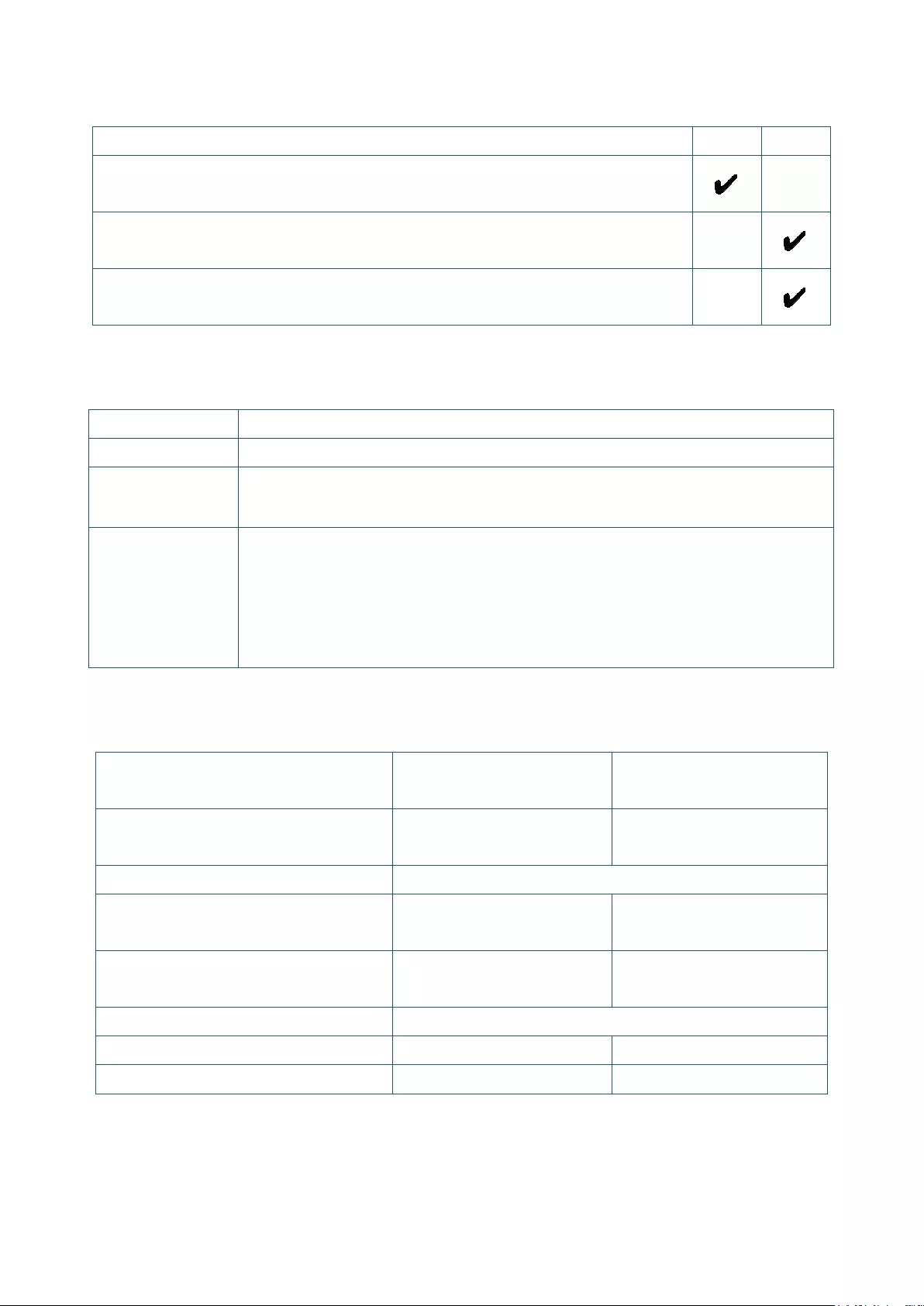

1.2.2 Optional Features

Feature User Dealer

External Media Roll Mount with 3” (76.2 mm) Core Label Spindle (8.4” (213.4 mm)

outer diameter)

Label Peeler

Regular Full/Partial Cutter (Guillotine cutter)

Paper thickness: From 2.36 mil to 7.48 mil (from 0.06 mm to 0.19 mm)

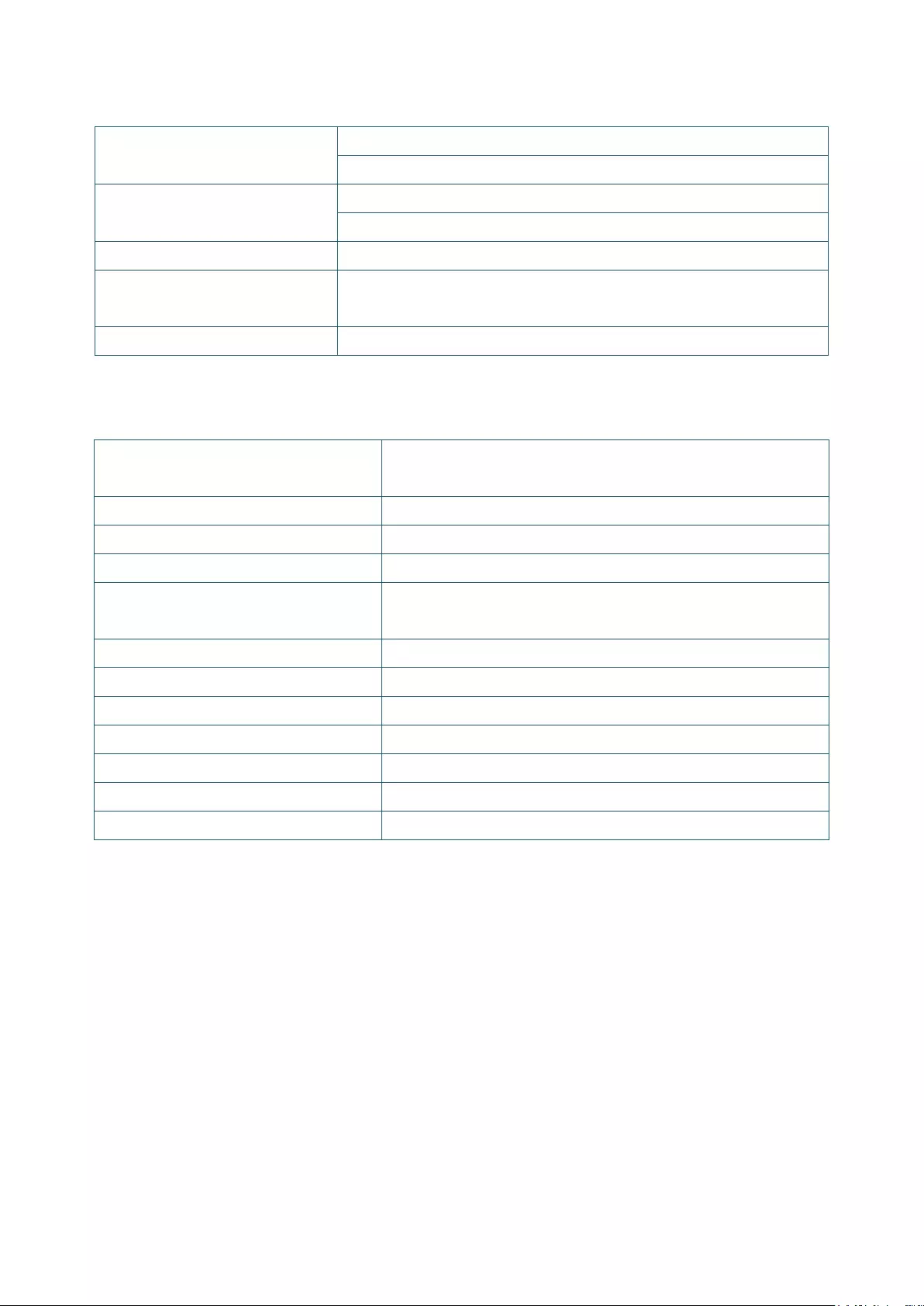

1.3 General Specifications

Dimensions 8.03” (W) × 6.99” (H) × 11.02” (L) (204 mm (W) × 177.5 mm (H) × 280 mm (L))

Weight 2.5 kg

Power Supply Input: AC 100 V - 240 V, 1.5 A, 50 Hz - 60 Hz

Output: DC 24 V, 2.5 A, 60 W, LPS

Environment Operating temperature: Between 41˚F and 104˚F (between 5˚C and 40˚C)

Operating humidity: Between 25% and 85% (without condensation)

Storage temperature: Between -40˚F and 140˚F (between -40˚C and 60˚C)

Storage humidity: Between 10% and 90% (without condensation)

1.4 Print Specifications

Print Specifications TD-4420TN

(203 dpi model)

TD-4520TN

(300 dpi model)

Print Resolution 203 dots/inch

(8 dots/mm)

300 dots/inch

(12 dots/mm)

Printing Technology Thermal transfer and direct thermal

Print Size

(width × length)

0.125 mm × 0.125 mm

(1 mm = 8 dots)

0.084 mm × 0.084 mm

(1 mm = 11.8 dots)

Print Speed

(inches per second) Up to 6 ips Up to 5 ips

Print Speed for Label Peeler Mode Up to 3 ips

Maximum Print Width 4.25” (108 mm) 4.16” (105.7 mm)

Maximum Print Length 1000” (25,400 mm) 450” (11,430 mm)

4

1.5 Ribbon Specifications

Ribbon Diameter 1” (25.4 mm) core: Max. 2.63” (67 mm)

0.5” (12.7 mm) core: Max. 1.57” (40 mm)

Ribbon Length 1” (25.4 mm) inner core: 984 ft (300 m)

0.5” (12.7 mm) inner core: 360 ft (110 m)

Ribbon Core Diameter 0.5” (12.7 mm) and 1” (25.4 mm)

Ribbon Width Between 1.57” and 4.33” (between 40 mm and 110 mm) (with

the 4.33” (110 mm) paper core and notches on both sides)

Ribbon Wound Type Outside wound

1.6 Media Specifications

Label Roll Capacity (Outer

Diameter) Max. 5” (127 mm)

Media Type Continuous, die-cut, black mark, fan-fold, notch

Media Wound Type Outside wound

Media Width Between 0.79” and 4.40” (between 20 mm and 112 mm)

Media Thickness Between 2.36 mil and 7.48 mil (between 0.06 mm and

0.19 mm)

Media Core Diameter 1” (25.4 mm) and 1.5” (38 mm)

Label Length From 0.2” (5 mm) to the max. print length

Label Length (Label Peeler mode) Between 1” and 6” (between 25.4 mm and 152.4 mm)

Label Length (Cutter mode) From 1” (25.4 mm) to the max. print length

Gap Height Min. 0.09” (2 mm)

Black Mark Height Min. 0.09” (2 mm)

Black Mark Width Min. 0.31” (8 mm)

5

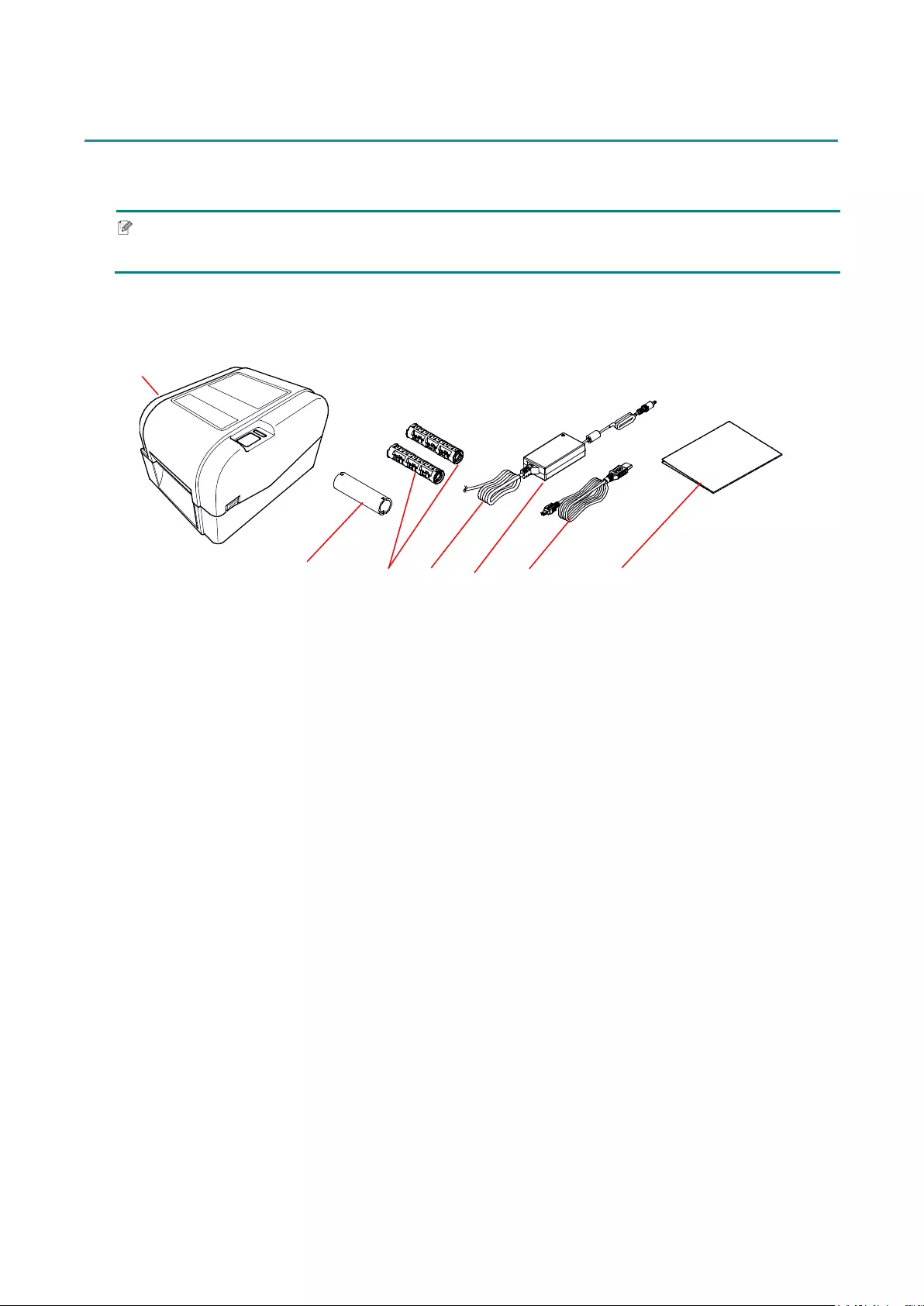

2. Operations Overview

2.1 Unpack the printer and check the components

Note

Keep the packaging materials in case you need to ship the printer.

The components included in the box:

1. Printer Unit

2. 1” (25.4 mm) Ribbon Paper Core

3. Two 1” (25.4 mm) Ribbon Spindles for the 984 ft (300 m) ribbon

4. Power Cord

5. External Universal Switching Power Supply

6. USB Interface Cable

7. Quick Setup Guide

If any components are missing, contact the product manufacturer's customer service or your

local dealer.

1

2

3

4

5

6

7

6

2.2 Printer Overview

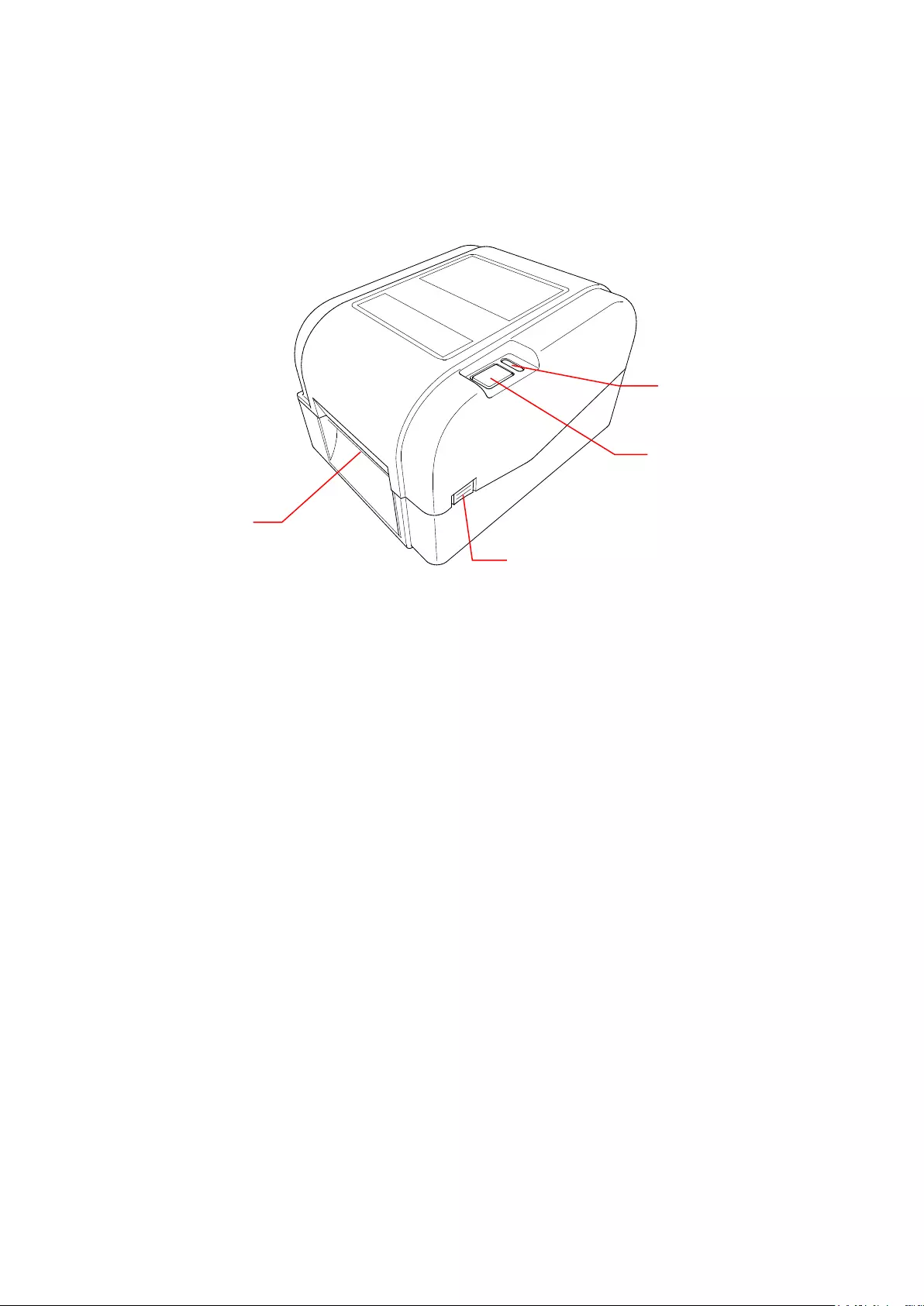

2.2.1 Front View

1. LED Indicator

2. Feed/Pause Button

3. Roll Compartment Cover Open Tab

4. Label Output Slot

1

2

4

3

7

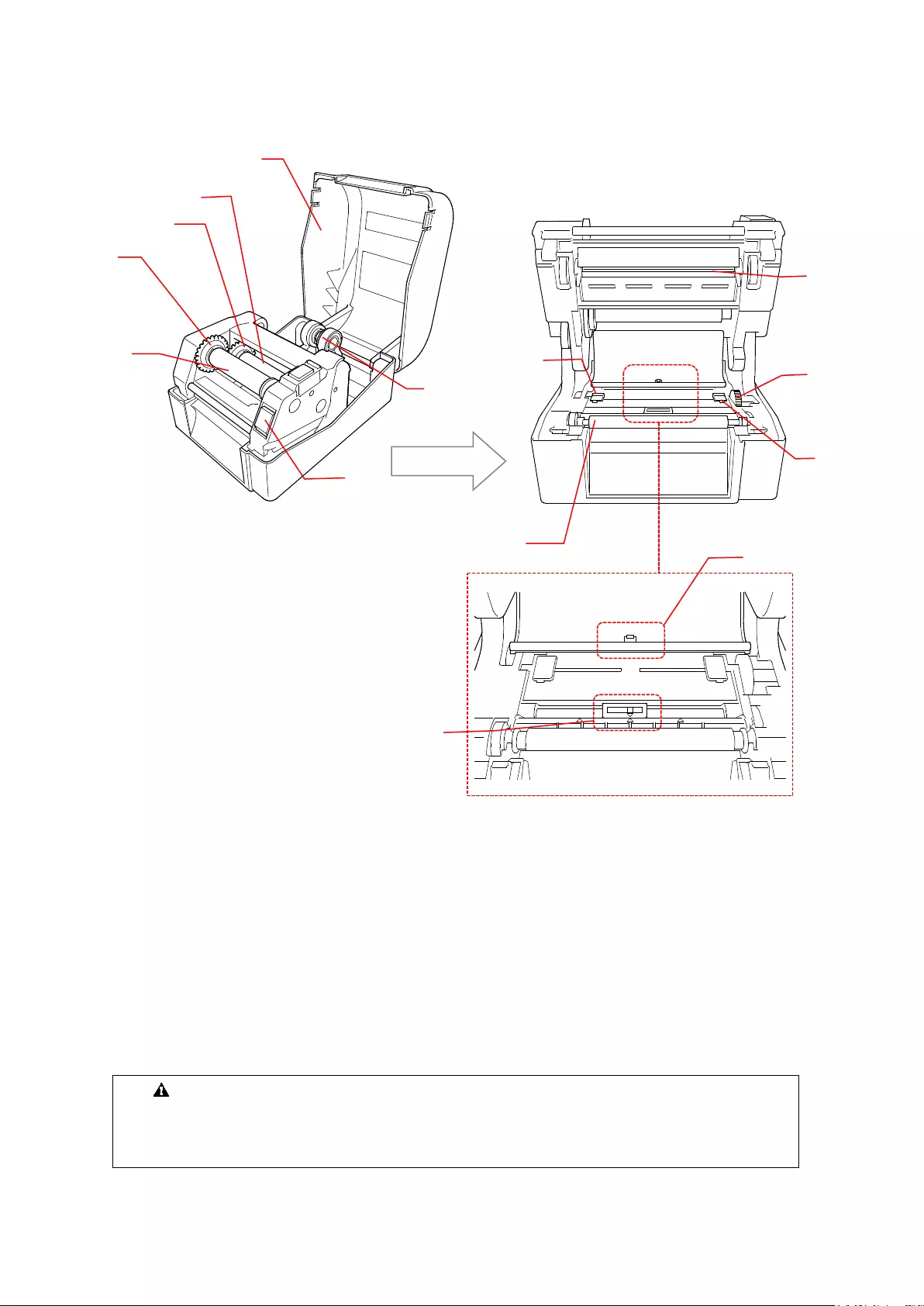

2.2.2 Interior View

1. Roll Compartment Cover 8. Platen Roller

2. Ribbon Supply Spindle 9. Black Mark Sensor

3. Ribbon Supply Hub 10. Gap Sensor

4. Ribbon Rewind Hub 11. Media Guide Tips

5. Ribbon Rewind Spindle 12. Media Guide Hub

6. Print Head Release Button 13. Print Head

7. Roll Guides

WARNING

DO NOT touch rotating parts. There is a risk of injury if your finger is caught in the

rotating gear. Turn off the product before touching the mechanism.

7

4

5

12

11

2

3

OPEN

1

6

8

13

10

9

11

8

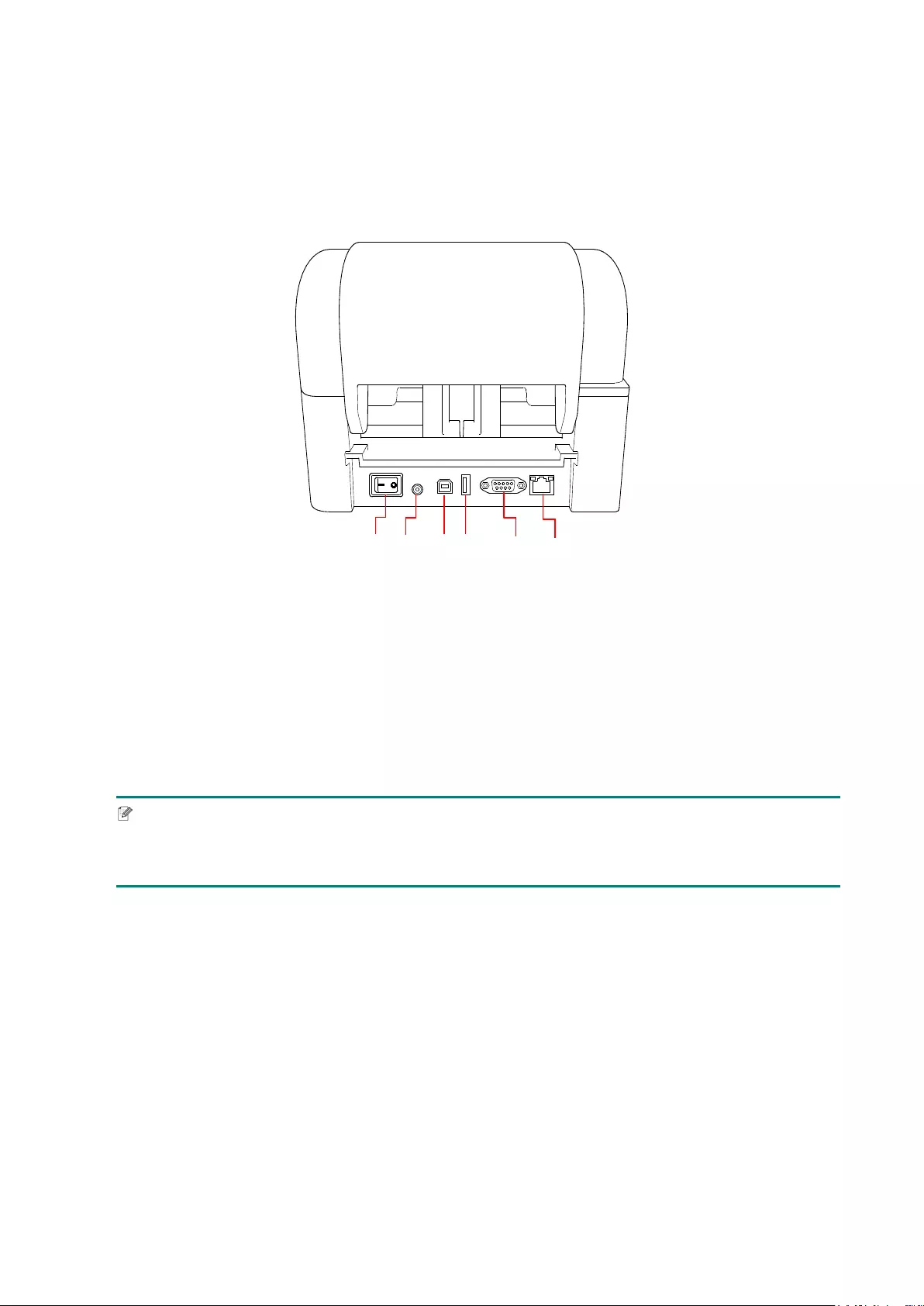

2.2.3 Rear View

1. Power Switch

2. Power Port

3. USB Port (USB 2.0/Hi-Speed mode)

4. USB Host Port

5. RS-232 Serial Port

6. Ethernet Port

Note

Some features are not available depending on the model. For more information, see the product

specification.

1

2

3

6

5

4

9

3. Setup

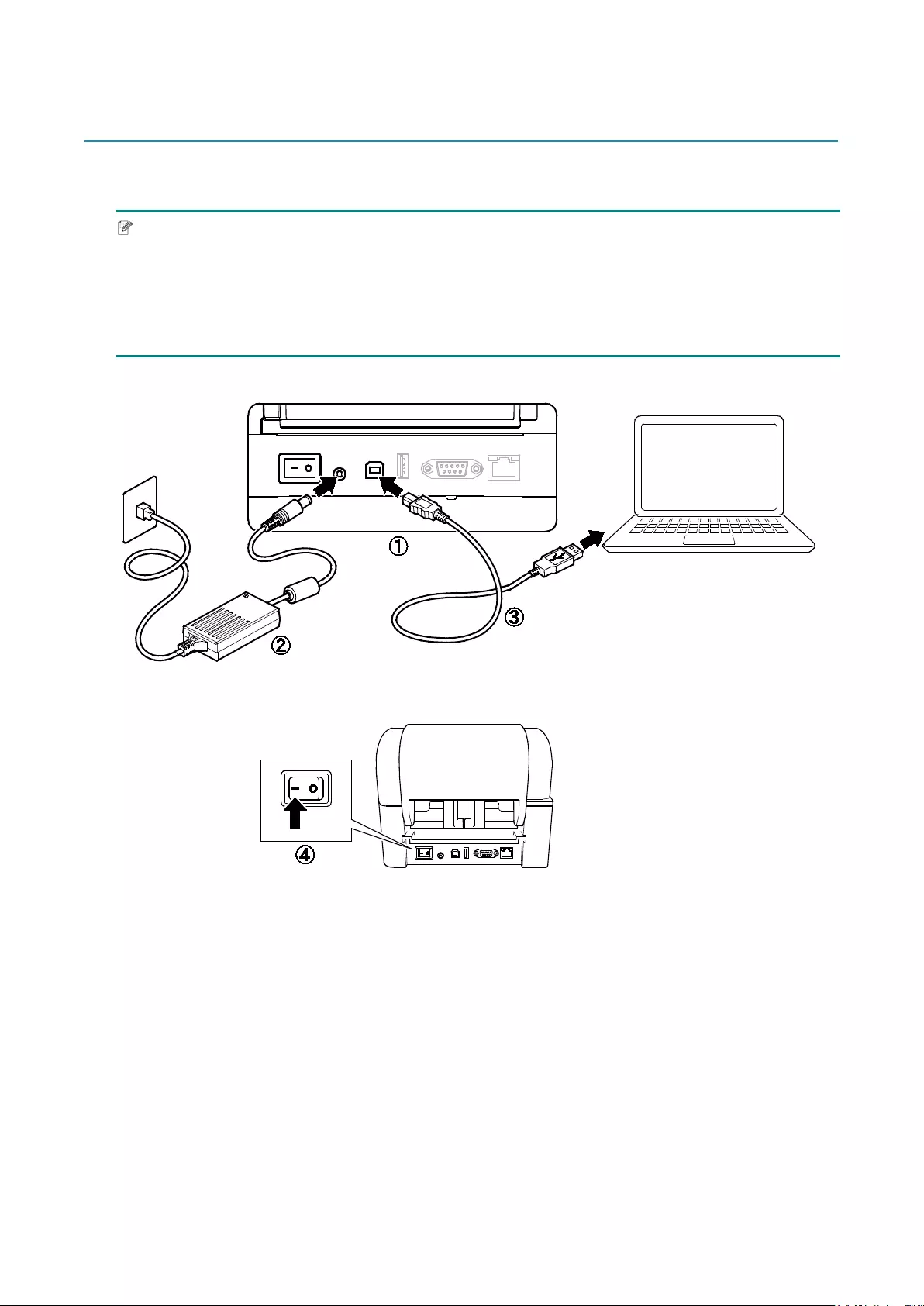

3.1 Setting up the Printer

Note

Before you plug the Power Cord into the Power Port, make sure the printer's Power Switch

is in the OFF position.

Some features are not available depending on the model. For more information, see the

product specification.

1. Place the printer on a flat, secure surface.

2. Plug the Power Cord into the Power Port at the rear of the printer. Then, plug the other end

into the AC power outlet (electrical socket).

3. Connect the printer to the computer with the provided USB cable.

4. Push the “-” side of the Power Switch to turn on the printer.

10

3.2 Loading the Ribbon

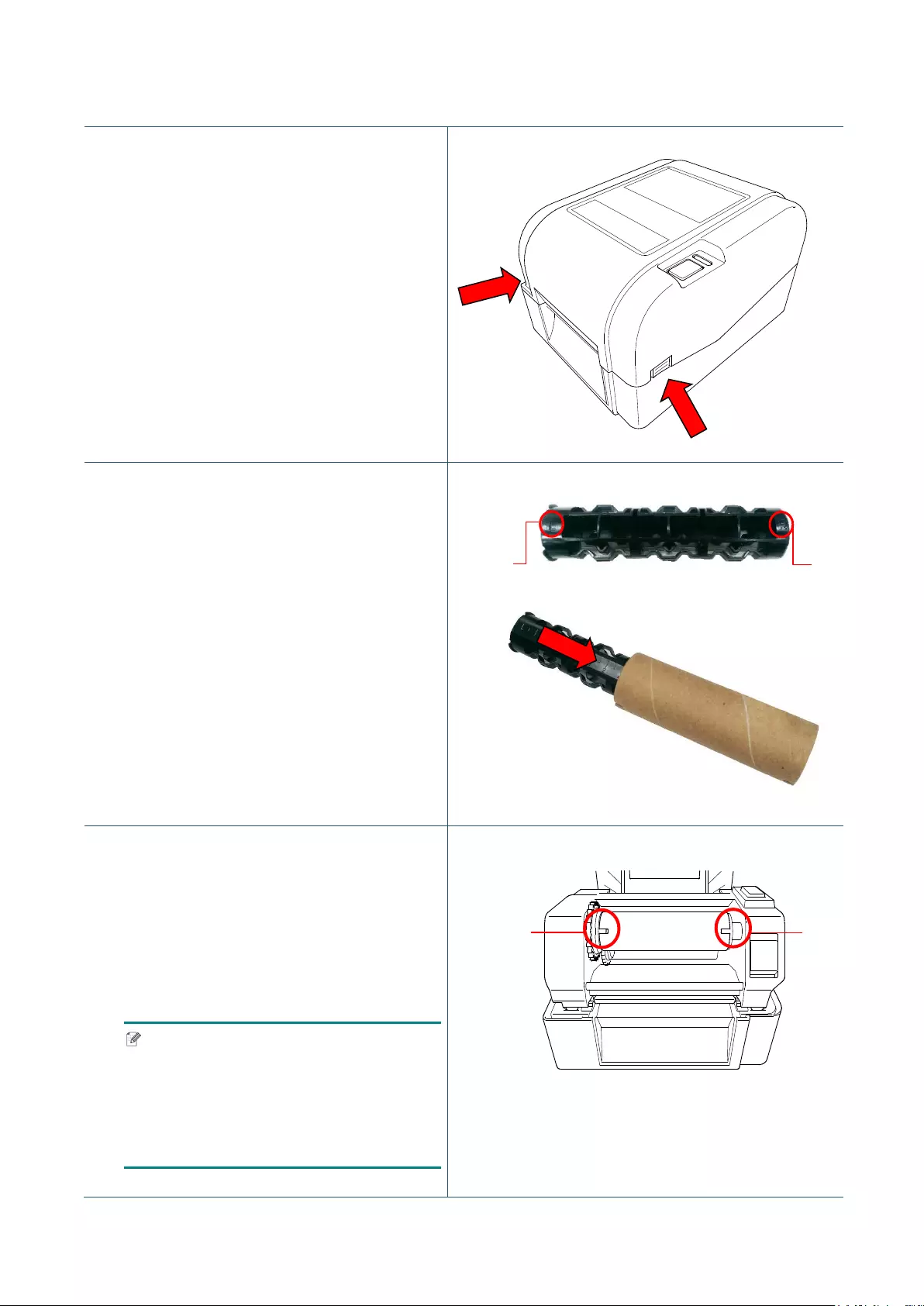

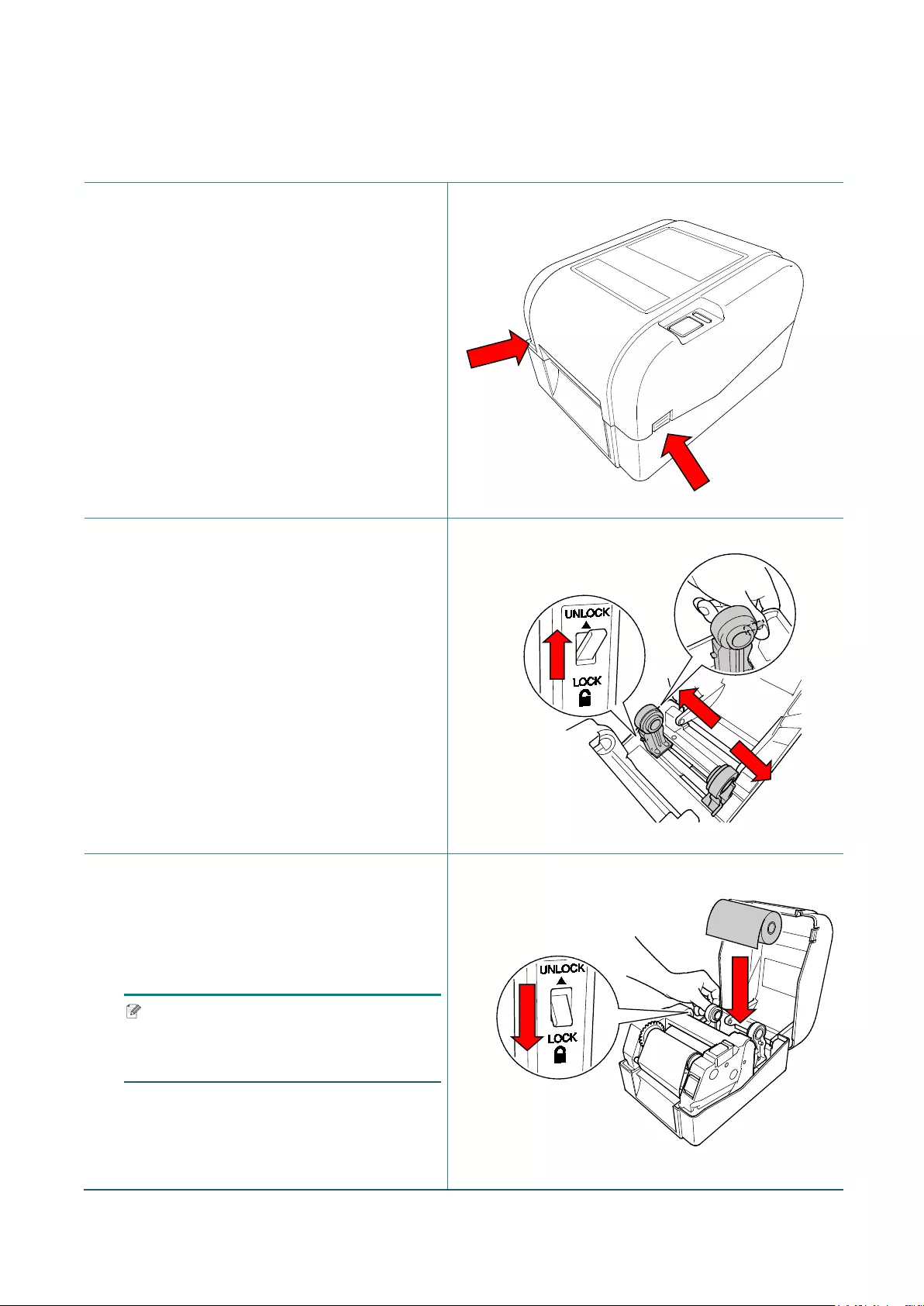

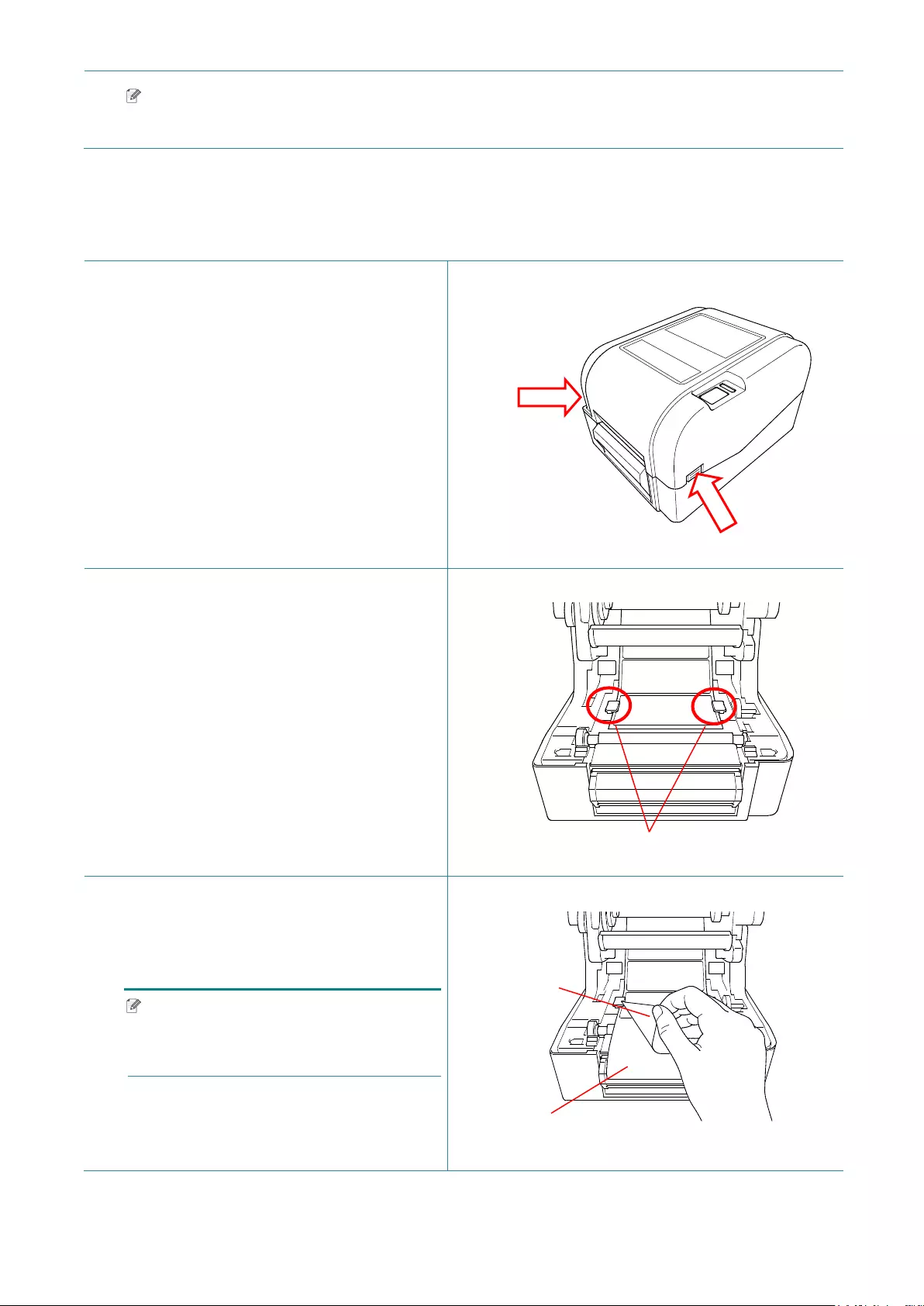

1. Open the Roll Compartment Cover by

pressing the tabs located on each side of

the printer.

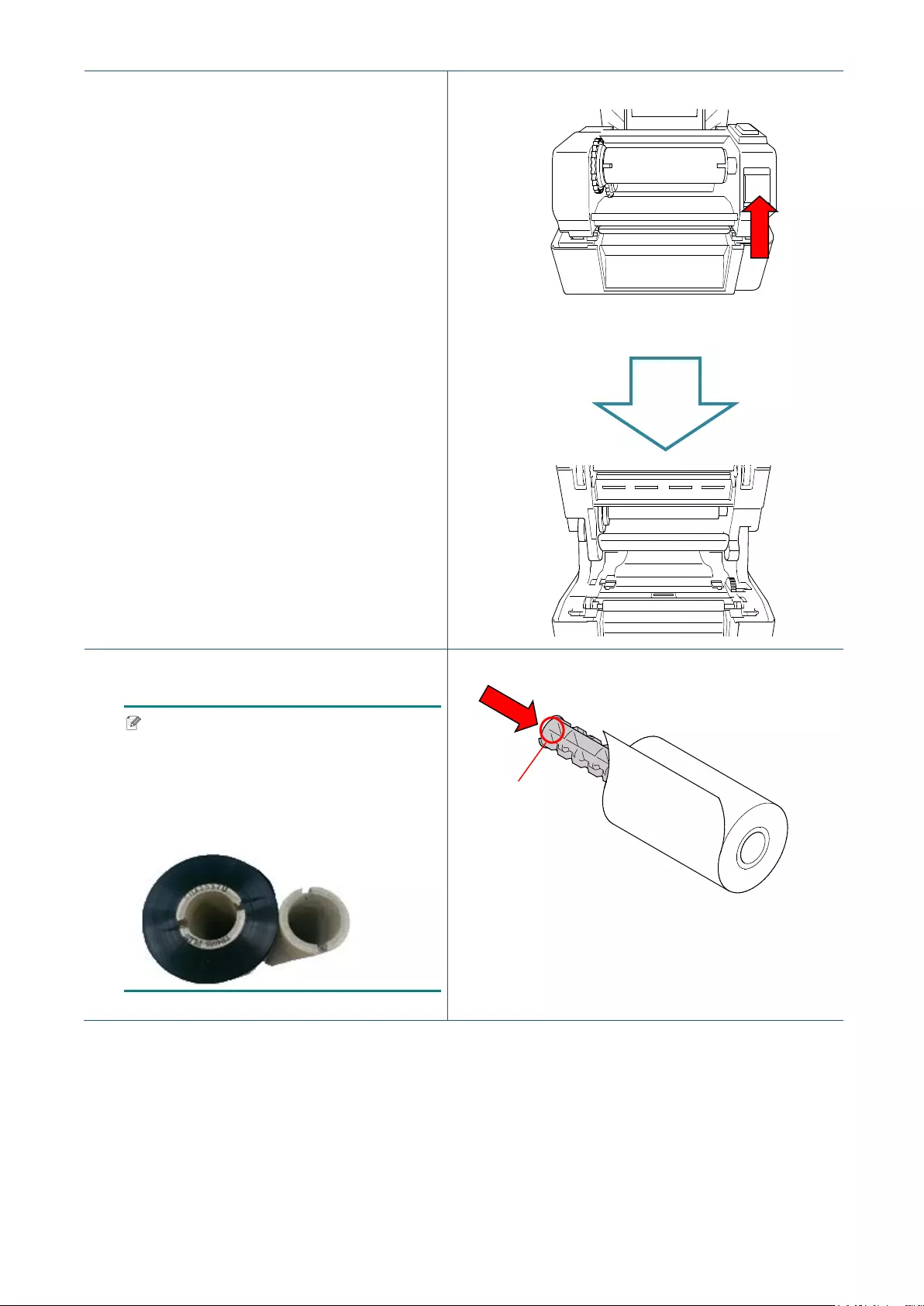

2. Insert the Ribbon Rewind Spindle into

the Paper Core in the direction shown in

the illustrations.

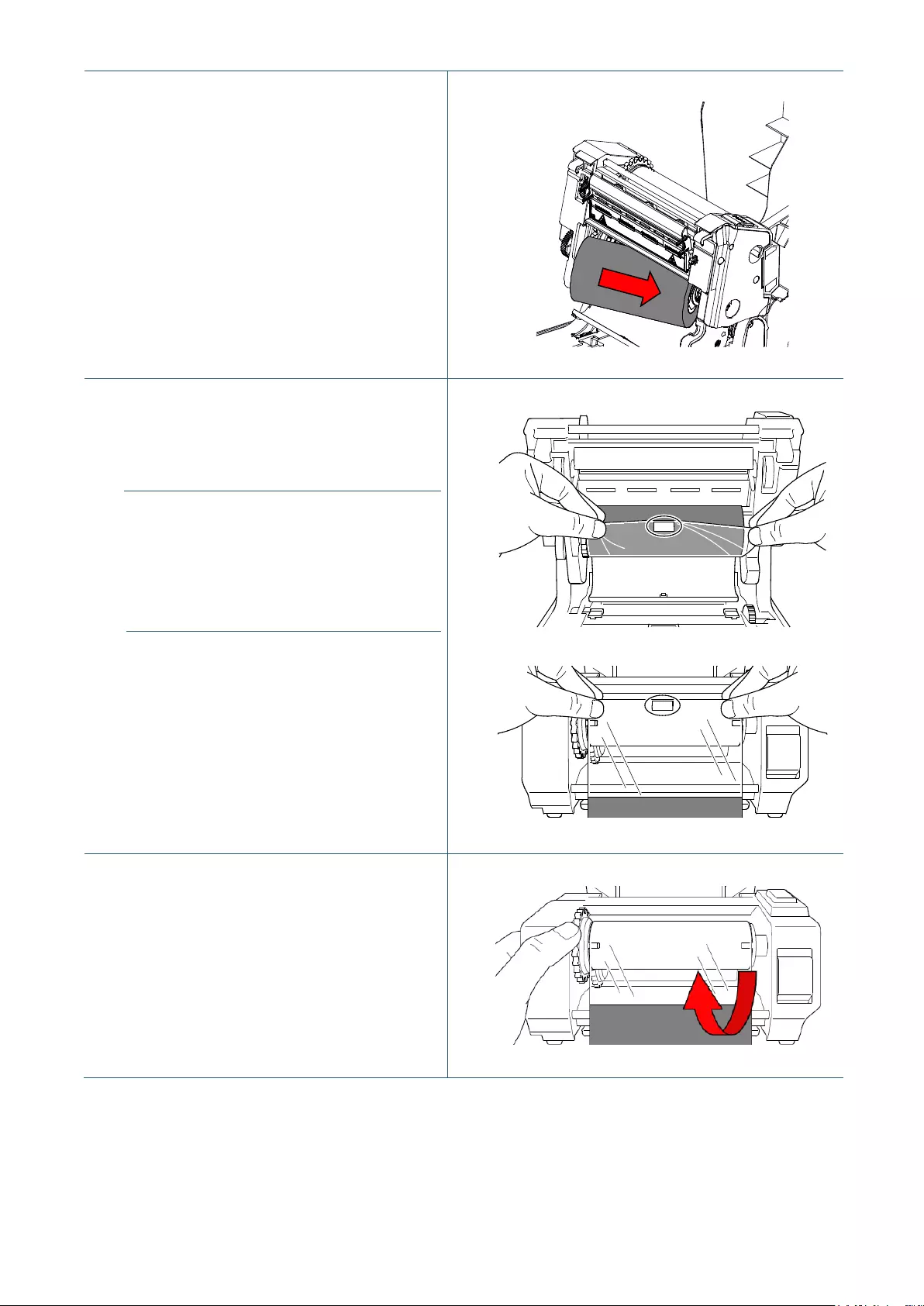

3. First, insert the right side of the Ribbon

Rewind Spindle (marked “R”) into the

Ribbon Supply Hub. Then, insert the left

side of the Ribbon Rewind Spindle into

the hole on the left side of the Ribbon

Rewind Hub.

Note

Alternatively, you can use a 0.5” (12.7 mm)

or 1” (25.4 mm) ribbon roll with notches on

both sides. Insert it into the Ribbon Rewind

Hub directly.

R

L

L

R

11

4. Push the Print Head Release Button to

open the Print Head mechanism.

5. Lift the Print Head until it locks into place.

6. Insert the Ribbon Spindle into the ribbon.

Note

The Ribbon Spindle can be substituted

with the ribbon with notches on both

sides, which can be inserted into the

ribbon mechanism directly.

L

Interior

View

12

7. First, insert the right side of the Ribbon

Supply Spindle (marked “R”) into the

Ribbon Supply Hub. Then, insert the left

side of the Ribbon Supply Spindle into

the hole on the left side of the Ribbon

Supply Hub.

8. Thread the ribbon through the Print Head

and adhere the leader of the ribbon onto

the Ribbon Rewind Paper Core.

IMPORTANT

Do not dispose of the Ribbon Rewind

Paper Core when replacing the ribbon

roll. This part is necessary for the ribbon

roll replacement.

9. Using the Ribbon Rewind Gear, rotate

the Ribbon Rewind Hub until the ribbon

plastic leader is thoroughly wound and

the black section of the ribbon covers the

Print Head.

13

10. Close the Print Head mechanism with

both hands until it locks into place.

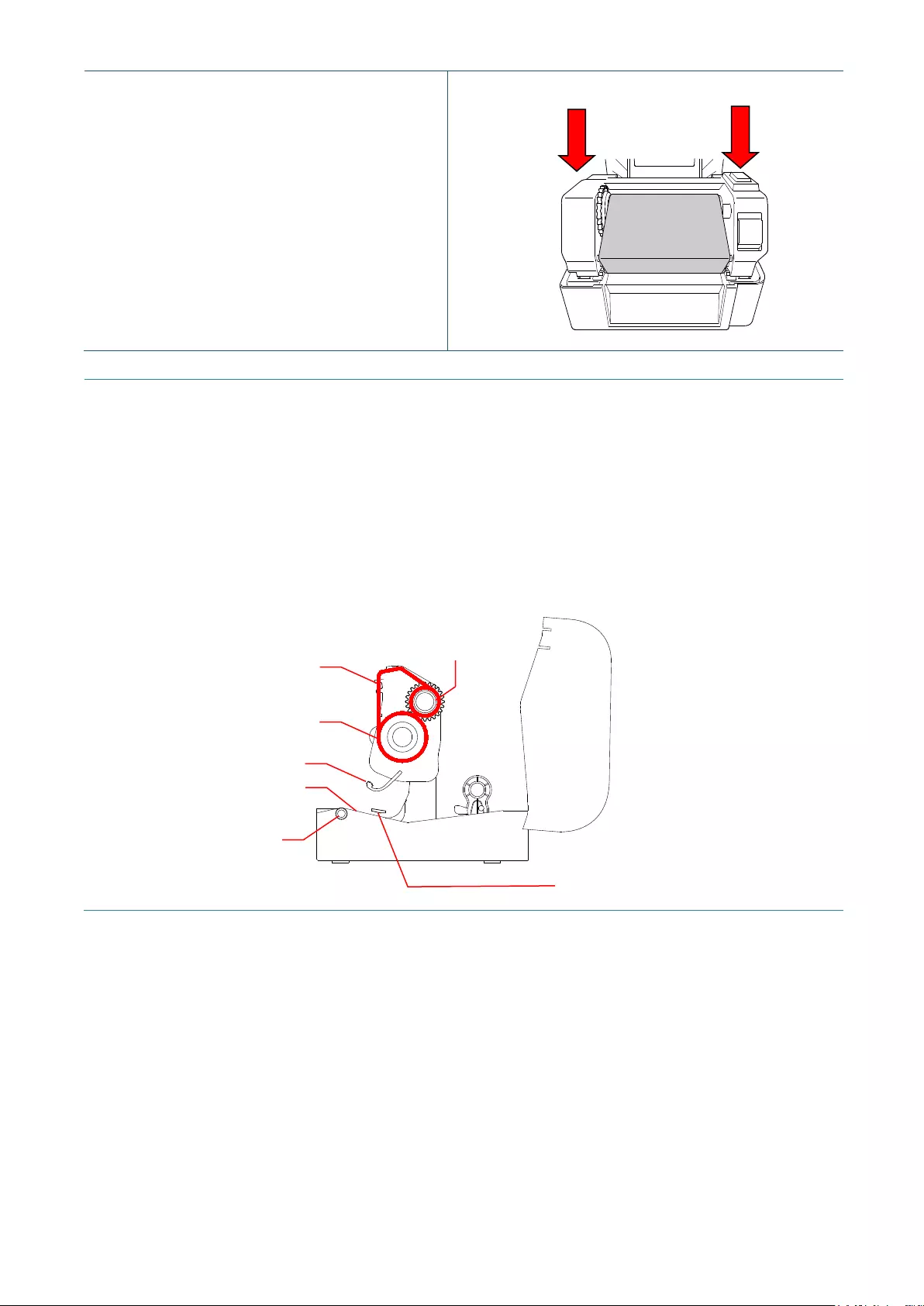

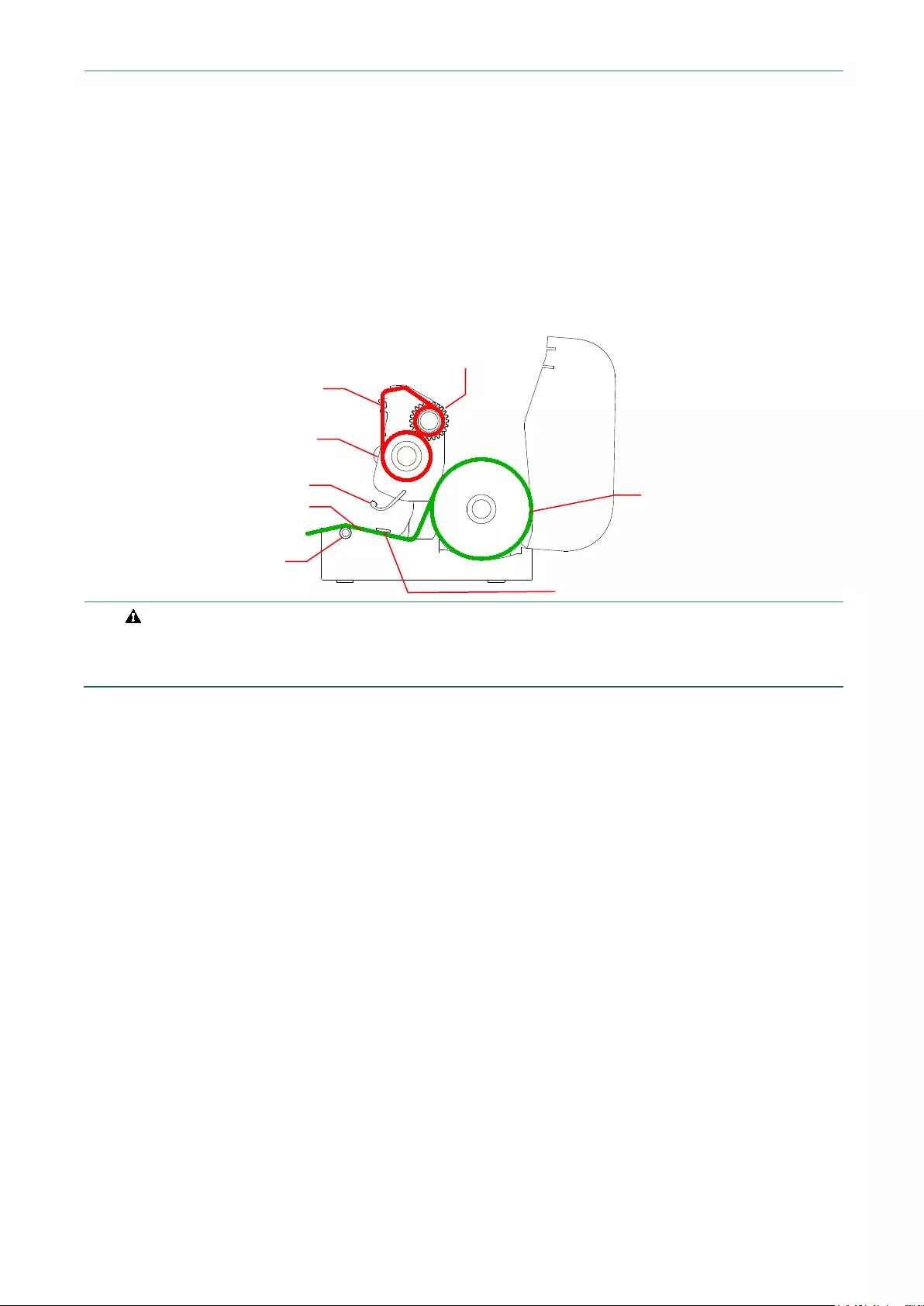

Ribbon Loading Path

1. Print Head

2. Ribbon Rewind Gear

3. Media Guide Tips

4. Platen Roller

5. Black Mark Sensor

6. Gap Sensor

7. Ribbon

1

7

6

3

4

2

5

14

3.3 Loading the Media

3.3.1 Loading the Label Rolls

1. Open the Roll Compartment Cover by

pressing the tabs located on each side of

the printer.

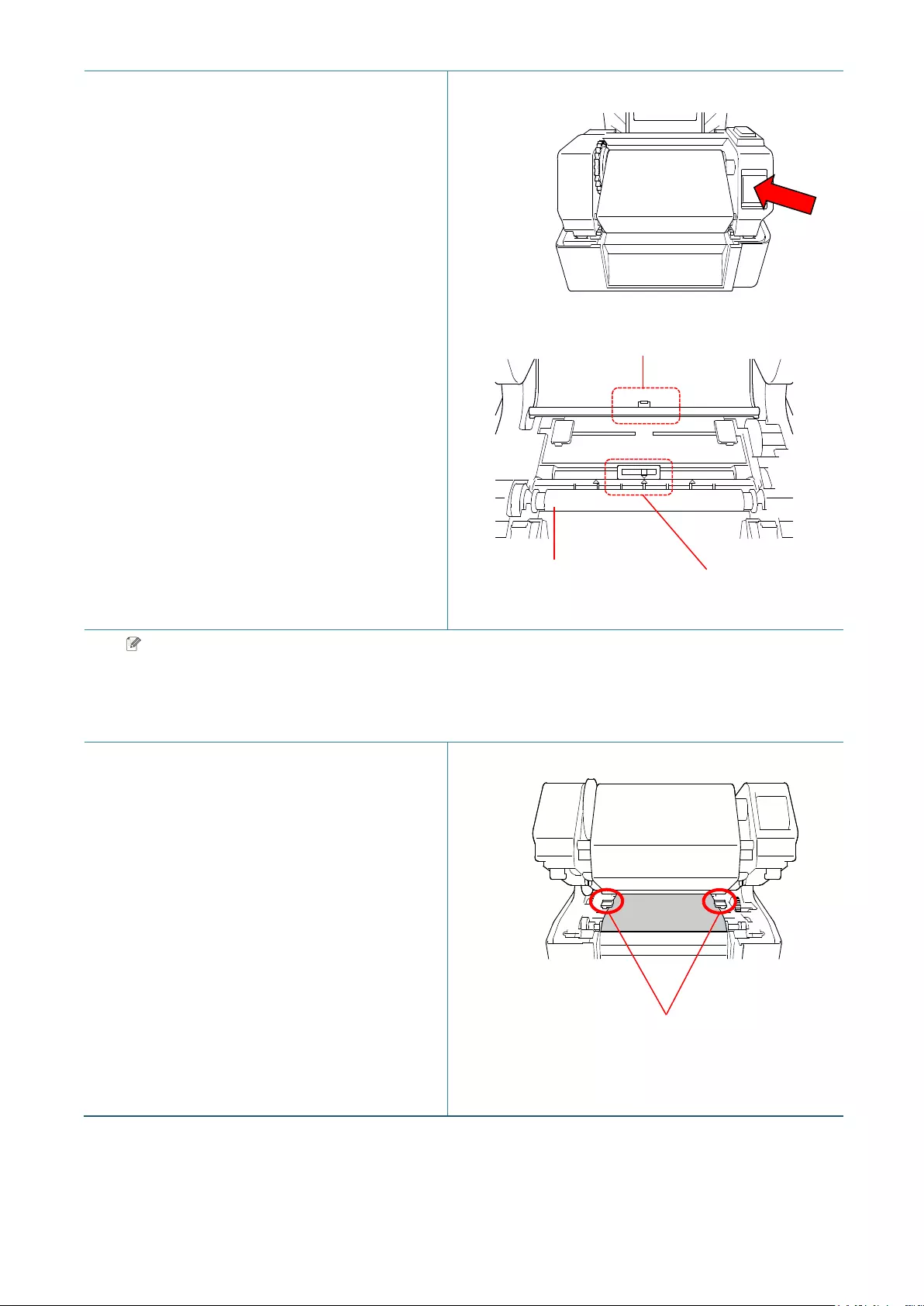

2. Push up the lock switch to unlock the Roll

Guides.

Slide both Roll Guides outwards.

3. Insert the paper roll with the labels facing

up, as shown in the illustration.

Push down the lock switch to lock the

Roll Guides into place.

Note

Make sure that the label print side is

facing up.

15

4. Push the Print Head Release Button to

open the Print Head mechanism.

5. Thread the labels under the Print Head

mechanism and feed the paper through

the Label Output Slot. Position the end of

the paper slightly out of the Label Output

Slot.

Note

The Black Mark Sensor is moveable and the Gap Sensor is fixed. Make sure you align the

Black Mark Sensor Slider with the installed media and that the position of the media's

gap/black mark is aligned with the Gap Sensor.

6. Adjust the Media Guide Tips to fit the

label width.

Media Guide Tips

Platen Roller

Gap Sensor

Black Mark Sensor

16

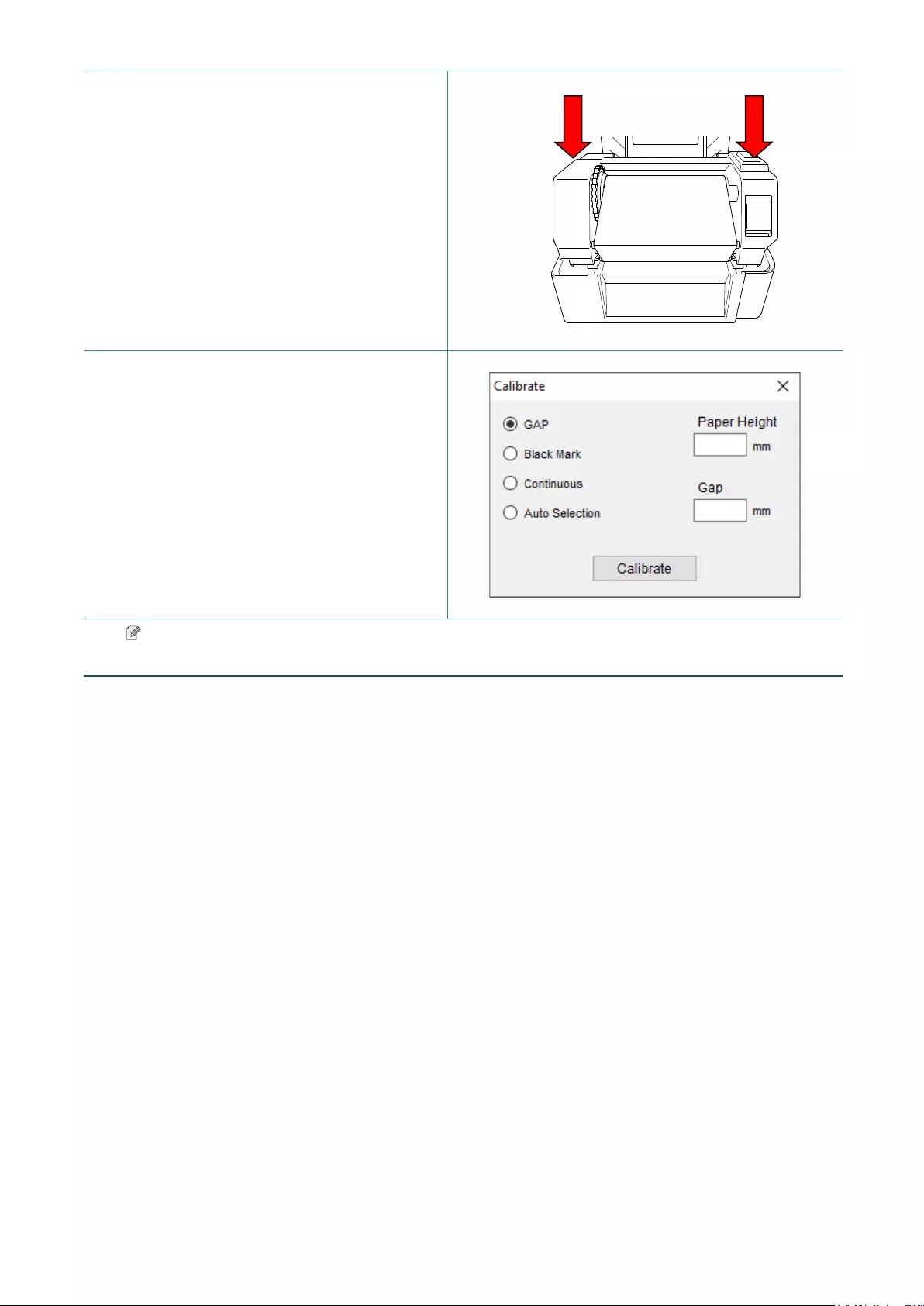

7. Close the Print Head mechanism with

both hands until it locks into place.

8. Use the Brother Printer Management

Tool to set the media sensor type and

calibrate the selected sensor.

a. Start the BPM.

b. Click the Printer Function button.

c. Click the Calibrate button.

For more information about sensor

calibration, see section 5.3.

Note

Calibrate the Gap/Black Mark Sensor every time you change the media.

17

Media Loading Path

1. Print Head

2. Ribbon Rewind Gear

3. Media

4. Media Guide Tips

5. Platen Roller

6. Black Mark Sensor

7. Gap Sensor

8. Ribbon

WARNING

DO NOT touch rotating parts. There is a risk of injury if your finger is caught in the rotating

gear. Turn off the product before touching the mechanism.

2

1

3

4

5

6

7

8

18

3.3.2 External Label Roll Mount Installation (Optional)

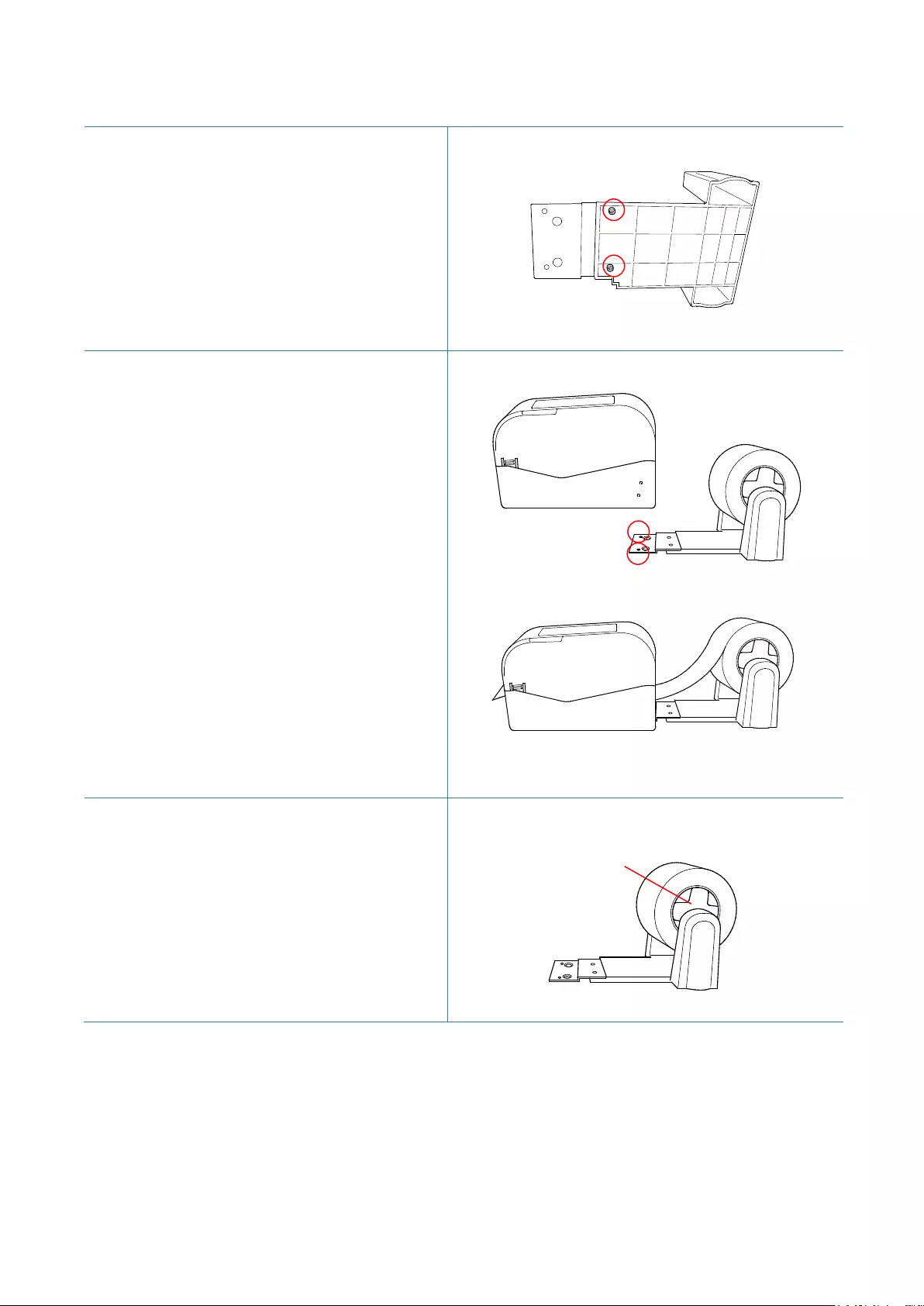

1. Tighten the screws on the metal fittings

of the extended plate.

2. Attach the extended plate to the bottom

of the printer.

3. Insert a 3” (76.2 mm) Label Spindle into a

paper roll. Then, install it on the External

Paper Roll Mount.

3” (76.2 mm)

Label Spindle

19

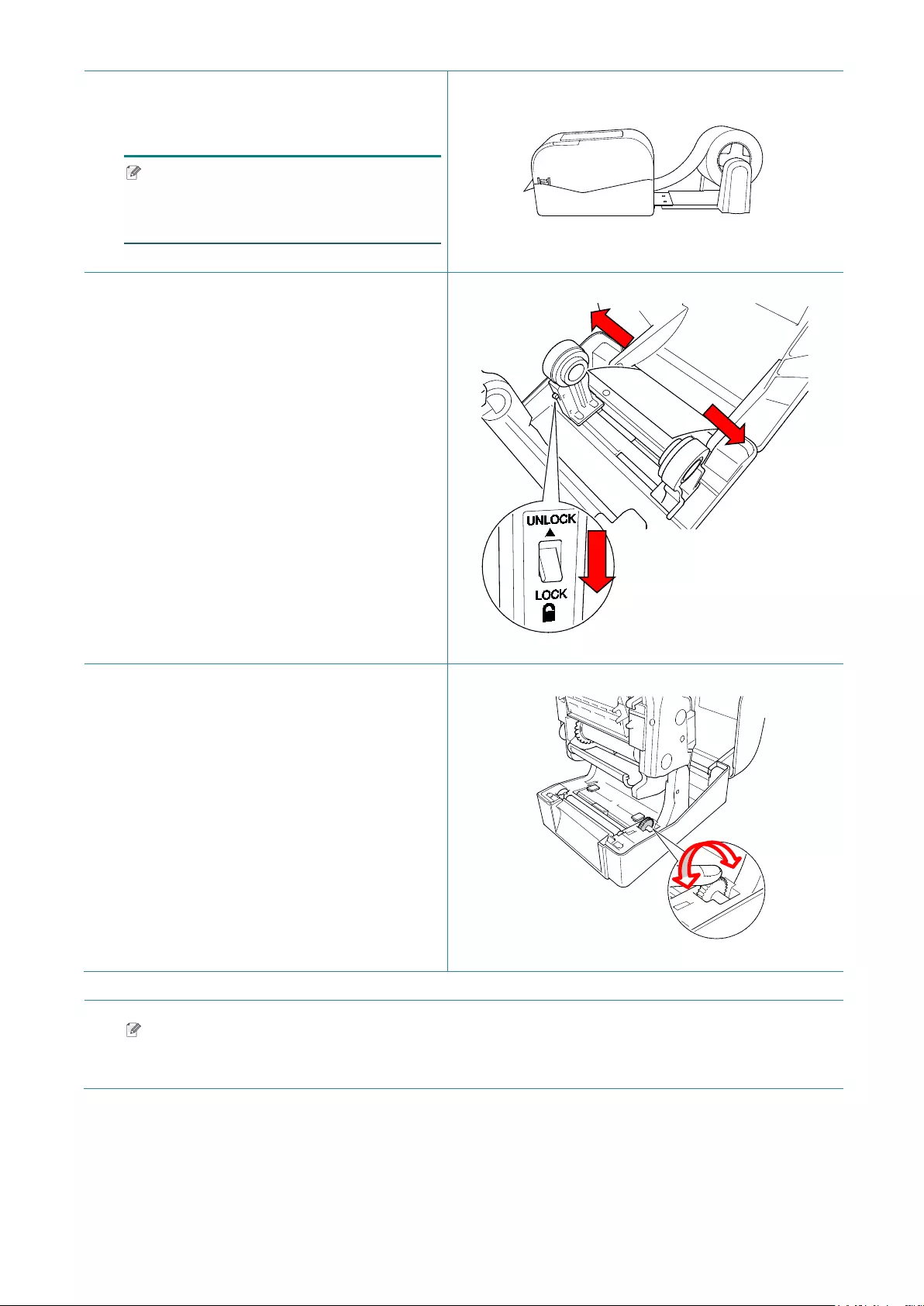

4. Feed the media through the rear label

feed slot.

Note

Make sure that the label print side is

facing up.

5. Open the Roll Compartment Cover. Slide

the Roll Guides outwards, and then align

the paper width with the Roll Guides.

Push down the lock switch to lock the

Roll Guide.

6. Install the label roll as described in

section 3.3.1.

7. Turn the Media Guide Hub, and match

the Media Guide width to the paper

width.

8. Use the Brother Printer Management

Tool to set the media sensor type and

calibrate the selected sensor.

Note

Calibrate the Gap/Black Mark Sensor every time you change the media.

20

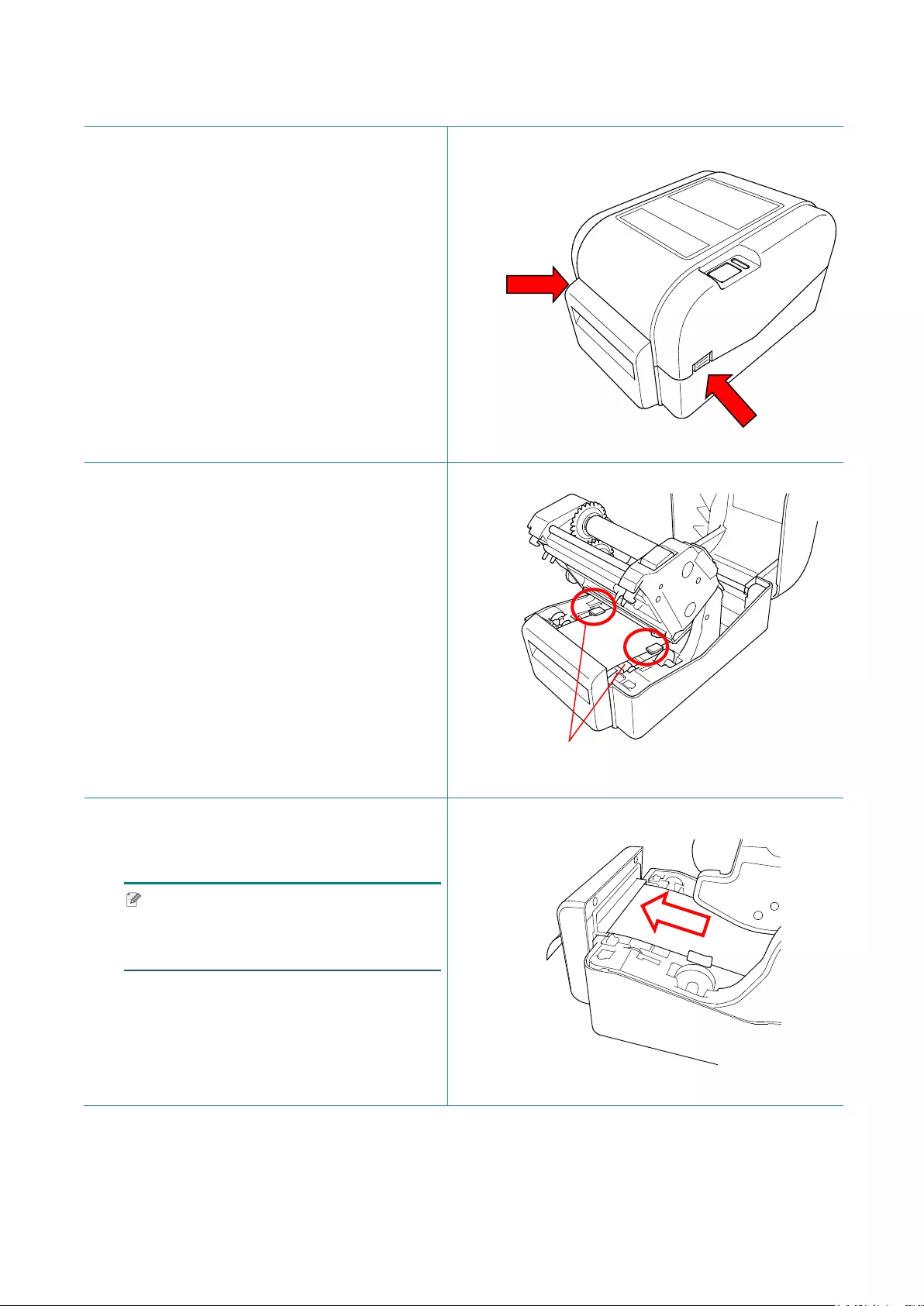

3.3.3 Loading the Media in Cutter mode (Dealers only)

1. Install the label roll as described in

section 3.3.1.

2. Use the Brother Printer Management

Tool to set the media sensor type and

calibrate the selected sensor.

3. Open the Roll Compartment Cover by

pressing the tabs located on each side of

the printer.

4. Push the Print Head Release Button to

open the Print Head mechanism and

feed the media through the media

sensor. Adjust the Media Guide Tips to fit

the label width.

5. Push the media through the Cutter

Output Slot.

Note

Make sure that the label print side is

facing up.

Media Guide Tips

21

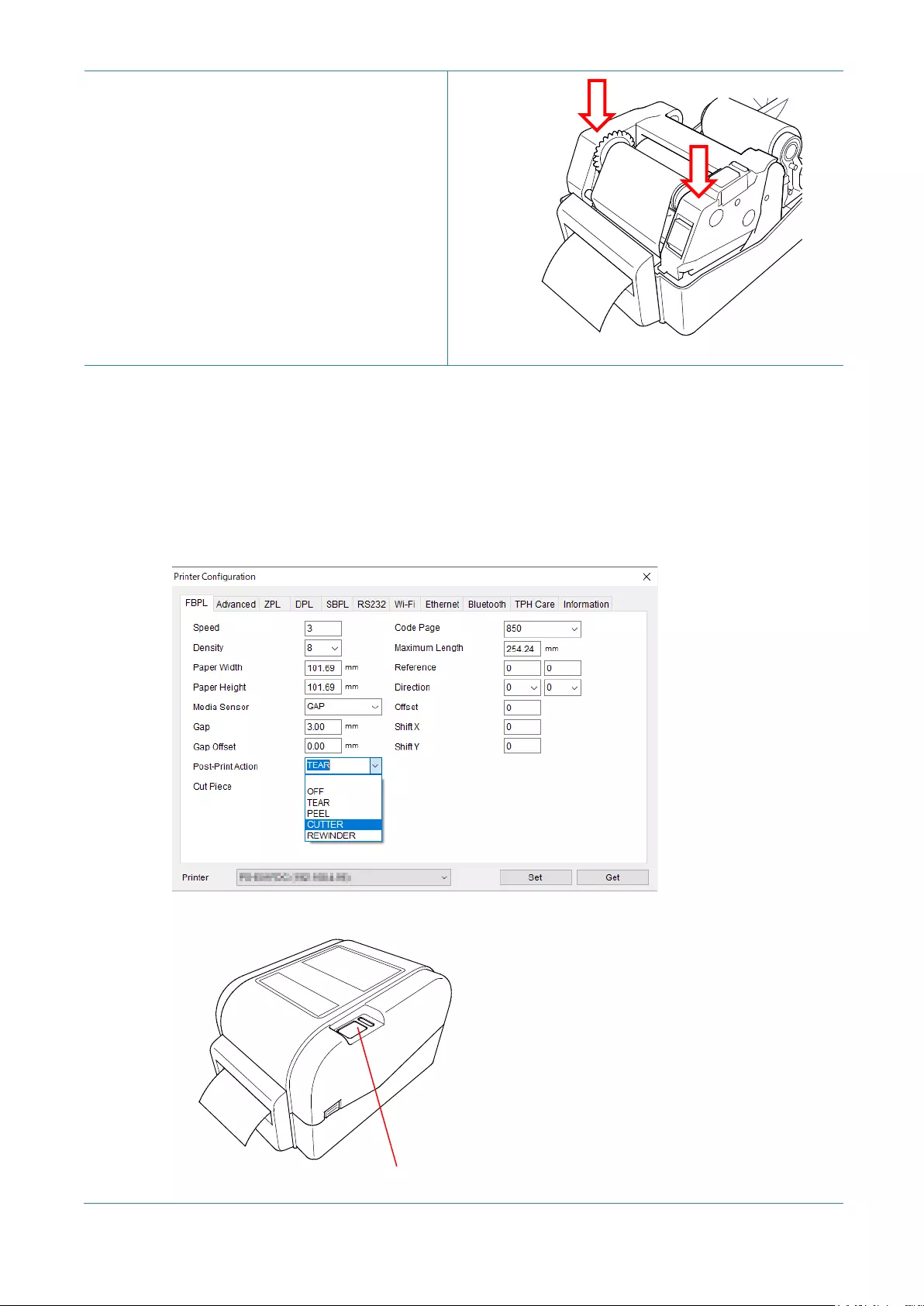

6. Close the Print Head mechanism with

both hands until it locks into place.

7. Close the Roll Compartment Cover.

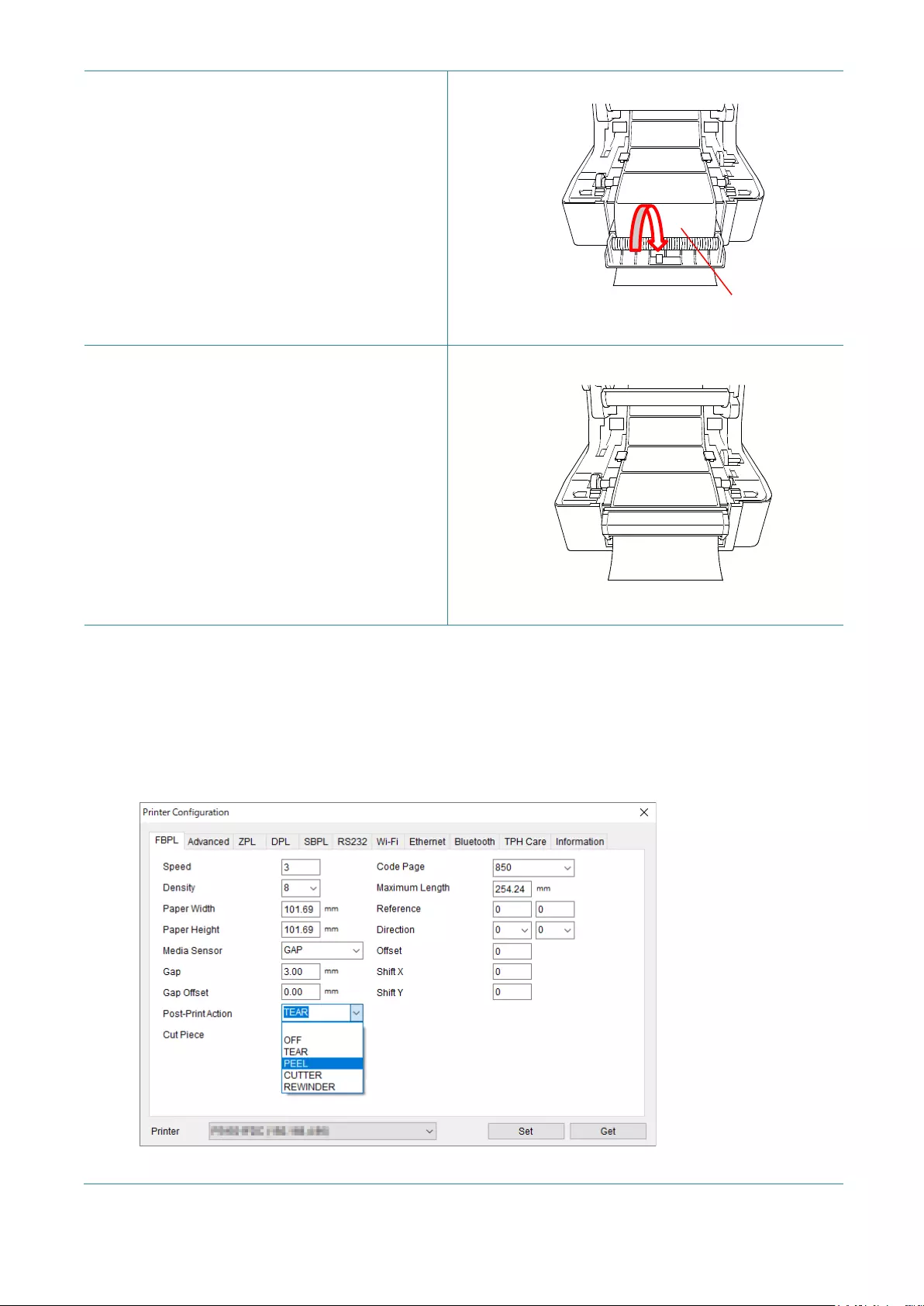

8. Use the Brother Printer Management Tool to set the printer for cutter mode.

a. Start the BPM.

b. Click the Printer Configuration button.

c. Select the FBPL tab.

d. Select the CUTTER option from the Post-Print Action drop-down list.

e. Click Set.

f. Press the Feed/Pause Button to test.

Feed/Pause Button

22

Note

Calibrate the Gap/Black Mark Sensor every time you change the installed media.

3.3.4 Loading the Media in Peel-off Mode (Dealers only)

1. Install the label roll as described in

section 3.3.1.

2. Use the Brother Printer Management

Tool to set the media sensor type and

calibrate the selected sensor.

3. Open the Roll Compartment Cover by

pressing the tabs located on each side of

the printer.

4. Push the Print Head Release Button to

open the Print Head mechanism and

feed the media through the media

sensor. Adjust the Media Guide Tips to fit

the label width.

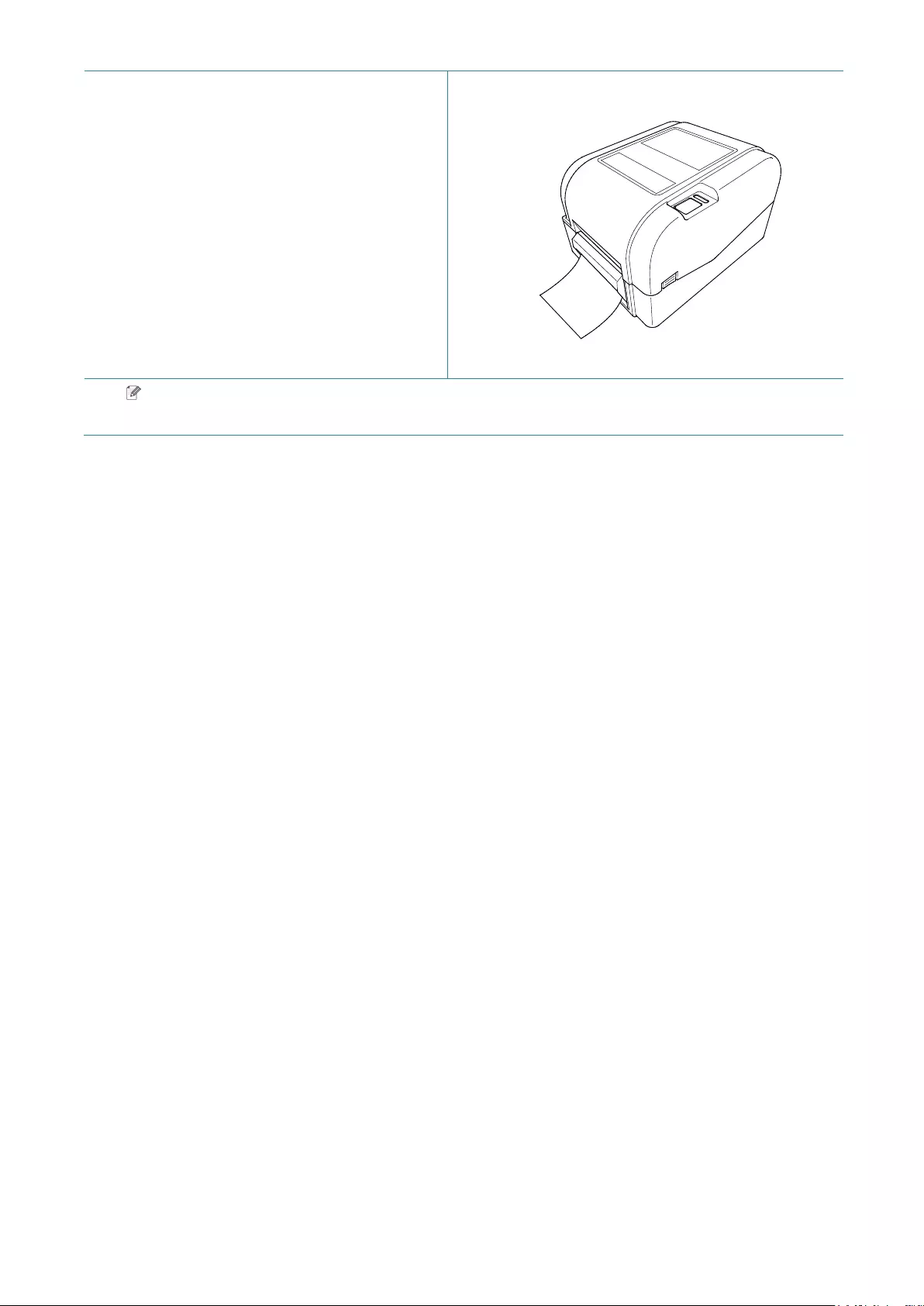

5. Pull the media out of the printer and

remove some labels, leaving the liner

only.

Note

Make sure that the label print side is

facing up.

Media Guide Tips

Liner

Label

23

6. Open the Label Peeler Cover. Feed the

liner into Label Peeler Cover Slot.

7. Close the Label Peeler Module.

8. Use the Brother Printer Management Tool to set the Label Peeler mode.

a. Start the BPM.

b. Click the Printer Configuration button.

c. Select the FBPL tab.

d. Select the PEEL option from the Post-Print Action drop-down list.

e. Click Set.

Label Peeler Cover Slot

24

9. Close the Roll Compartment Cover.

Note

The Label Peeler Module supports only plain paper.

25

4. The LED Indicator and Feed/Pause Button

Functions

By using the printer's Feed/Pause Button and the three-color LED Indicator, you can feed labels,

pause print jobs, select and calibrate sensors, print the printer self-test report, and restore the

printer's factory settings.

4.1 The LED Indicator

LED Color Description

Green (Lit) The power is on and the printer is ready to use.

Green (Flashing) The printer is downloading data from a computer.

The printer is paused.

Amber The printer removes data.

Red (Lit) The Print Head is open.

There is a problem with the Cutter.

Red (Flashing) There is a memory error or printing error (for example: paper

jam, Print Head is open, paper is empty, or the ribbon is

empty).

4.2 The Feed/Pause Button Functions

1. Feed Labels

To feed a label, press the Feed/Pause Button when the printer's LED is lit in green.

2. Pause Print Jobs

To pause a print job, press the Feed/Pause Button.

The LED flashes in green. To resume the print job, press the button again.

4.3 Power-on Utilities

There are six power-on utilities to set up and test the printer's functions.

To activate a power-on utility:

1. Turn off the printer.

2. Press and hold the Feed/Pause Button, and then turn on the printer.

3. Release the button when the LED indicates the function you want:

26

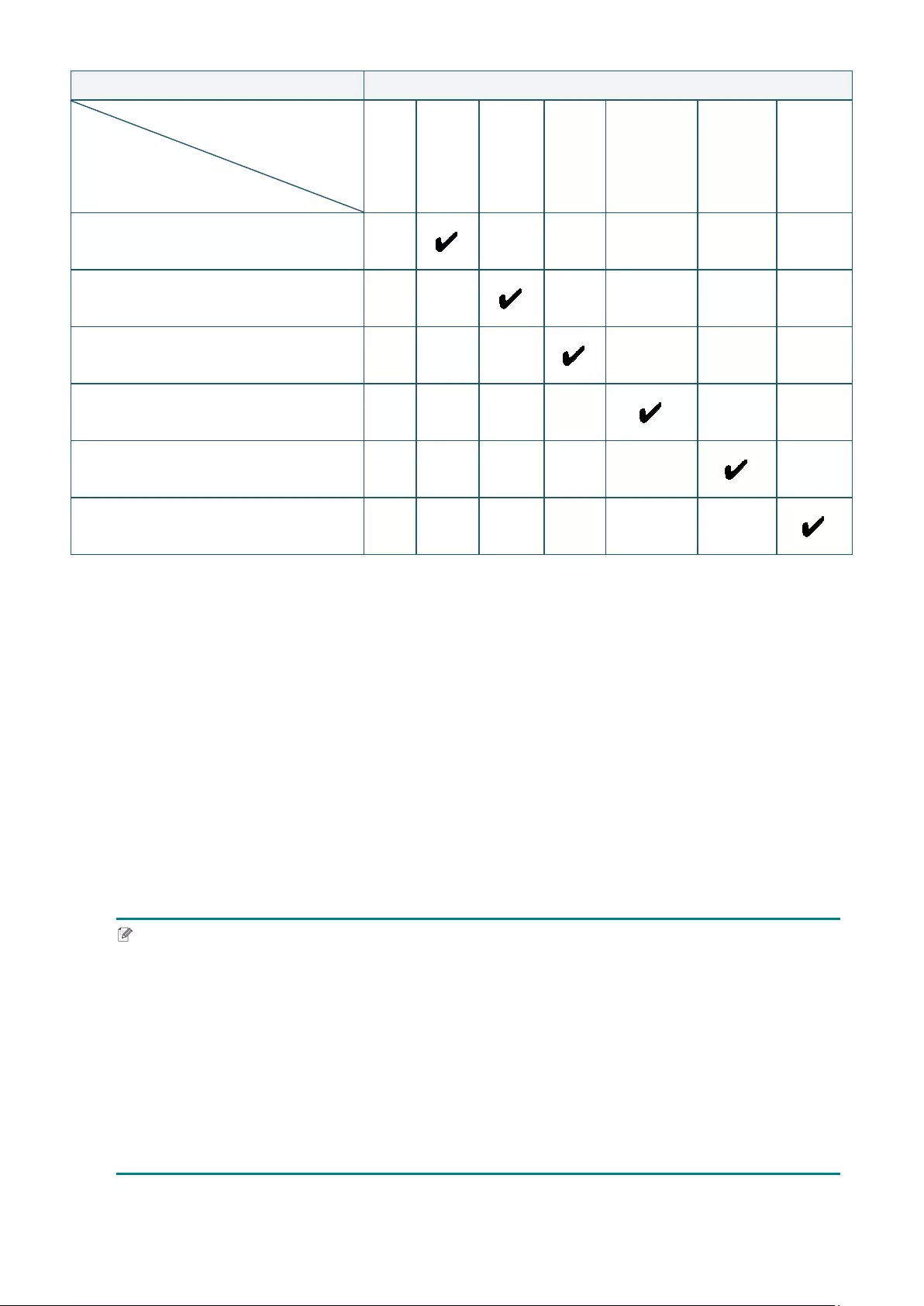

Power-On Utility LED Patterns

LED color

Function

Amber Red

(5 times)

Amber

(5 times)

Green

(5 times)

Green/Amber

(5 times)

Red/Amber

(5 times)

Green (Lit)

1. Ribbon and Gap/Black Mark Sensors

calibration

2. Gap/Black Mark Sensor calibration,

self-test, and entering dump mode

3. Printer initialization

4.

Media sensor calibration (For the Black

Mark Sensor)

5. Media sensor calibration (For the Gap

Sensor)

6. Skip the AUTO.BAS program

4.3.1 Ribbon and Gap/Black Mark Sensors Calibration

The Gap/Black Mark Sensor sensitivity should be calibrated when:

A new printer is purchased

Label stock is changed

Printer initialization takes place

To calibrate the ribbon and Gap/Black Mark Sensors:

1. Turn off the printer.

2. Press and hold the Feed/Pause Button, and then turn on the printer.

3. Release the button when the LED is flashing in red.

Note

The LED color will change as follows:

Amber red (5 times) amber (5 times) green (5 times) green/amber (5 times)

red/amber (5 times) green (lit)

To select the sensor for calibration, send the correct command to the printer:

For the Gap Sensor: send the GAP command

For the Black Mark Sensor: send the BLINE command

For more information about the available commands, see the FBPL Command Reference

Manual.

27

4.3.2 Gap/Black Mark Sensor Calibration, Self-Test, and Entering Dump Mode

During the calibration of the Gap/Black Mark Sensor, the printer will detect the label length, print

the internal configuration (self-test), and then enter the dump mode. Calibrate the Gap or Black

Mark Sensor if the sensor's settings used in the last print job are not suitable for the current print

job.

To calibrate the Gap/Black Mark Sensor:

1. Turn off the printer.

2. Press and hold the Feed/Pause Button, and then turn on the printer.

3. Release the button when the LED is flashing in amber.

Note

The LED color will change as follows:

Amber red (5 times) amber (5 times) green (5 times) green/amber (5 times)

red/amber (5 times) green (lit)

4. The printer calibrates the sensor and detects the label length, prints the internal settings, and

then enters the dump mode.

Note

To select the sensor for calibration, send the correct command to the printer:

For the Gap Sensor: send the GAP command

For the Black Mark Sensor: send the BLINE command

For more information about the available commands, see the FBPL Command Reference

Manual.

28

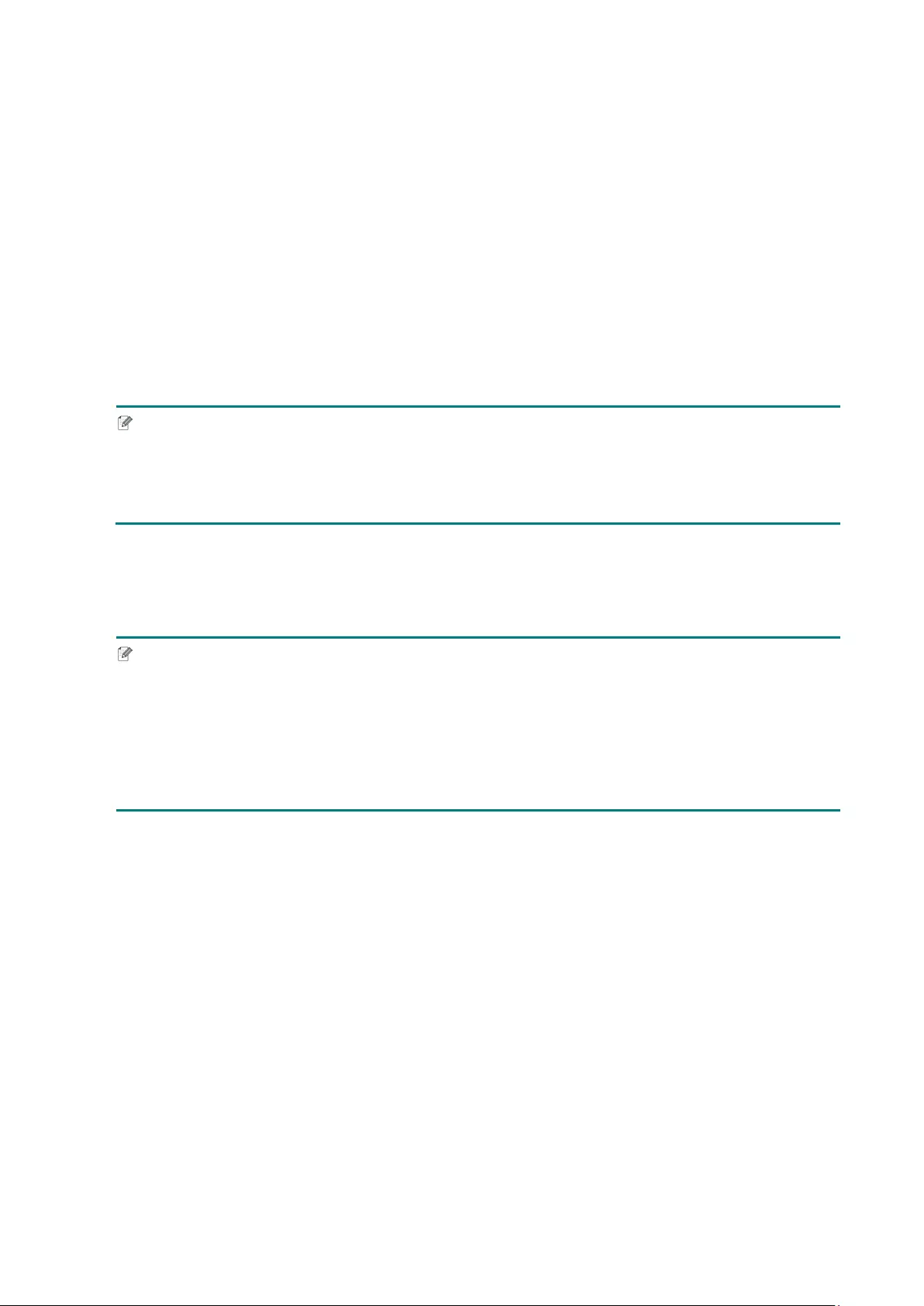

Self-test

You can print the printer configuration after the Gap/Black Mark Sensor calibration. Self-test

printouts list the printer's configuration and available memory space, and can indicate whether

there is any dot damage on the heater component.

Self-test printout

Model name

Firmware version

Firmware checksum

Printer serial number

Configuration file

System date

System time

Printed mileage (meter)

Cutting counter

Number of defective dots

Print speed (inch/sec)

Print density

Label size (inch)

Gap distance (inch)

Gap/Black Mark Sensor

sensitivity

Code page

Country code

Print darkness

Print speed (inch/sec)

Label size

Control prefix

Format prefix

Delimiter prefix

Printer power up motion

Print Head close motion

RS232 Serial Port

configuration

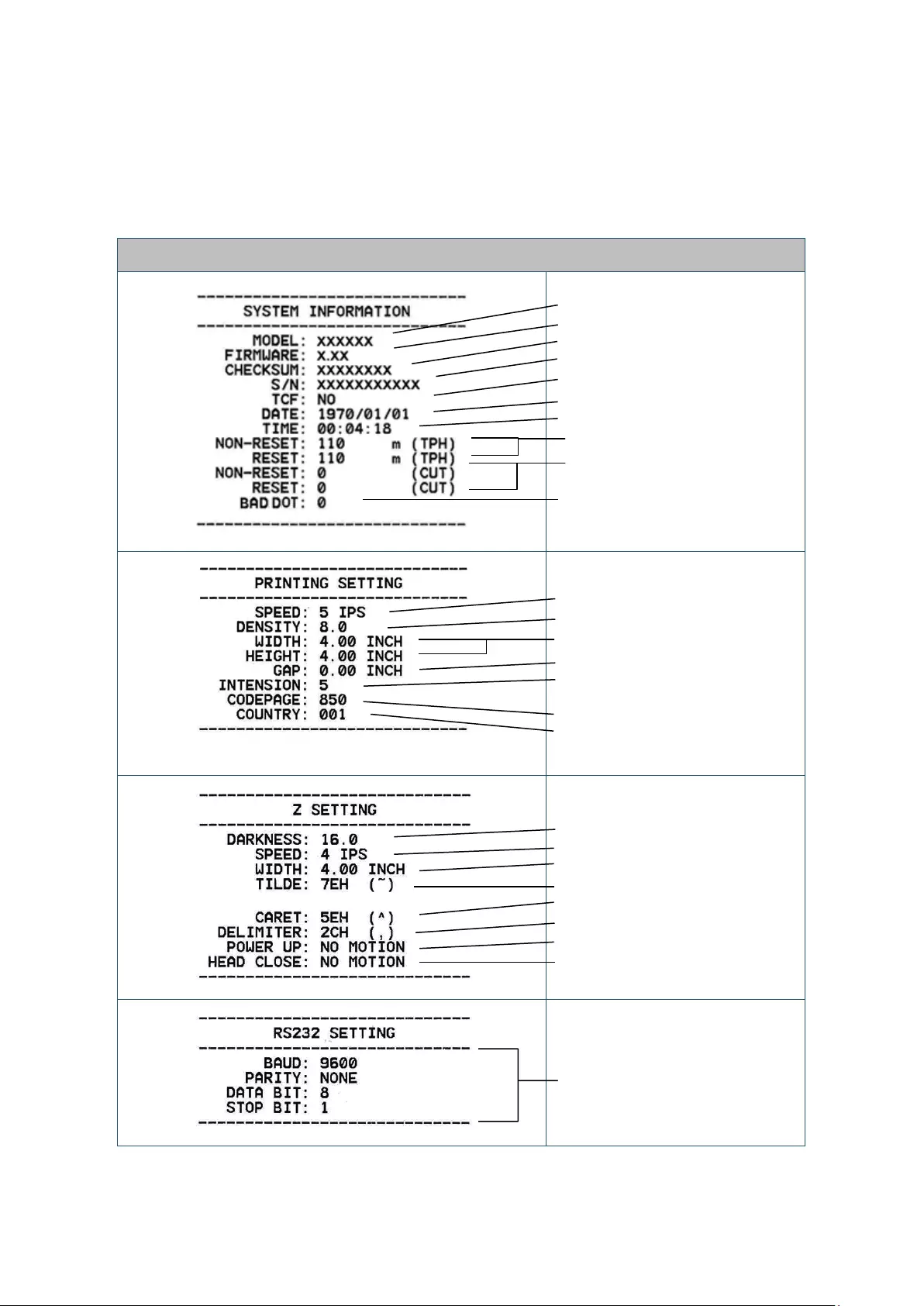

29

Printer name

Mac Address

DHCP

IP Address

Subnet Mask

Gateway

RAW Port

Number of downloaded files

Total and available memory

space

Print Head check pattern

30

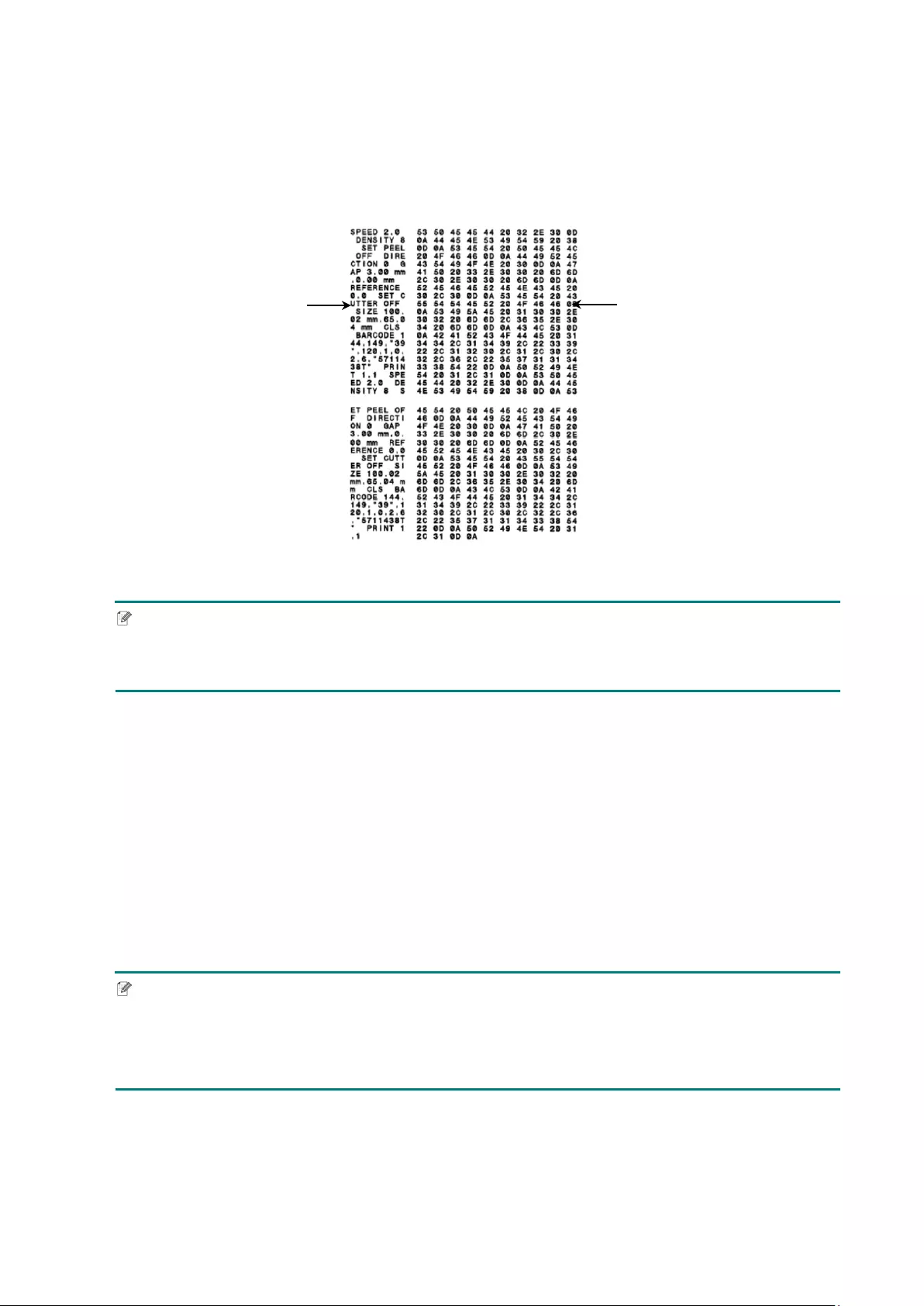

Dump mode

The printer will enter dump mode after printing the printer configuration. This mode allows users

to verify and debug the printer's programs. The characters in the left column are received from

the printer's system and those in the right column are their hexadecimal representation.

Note

Dump mode requires 4” (101.5 mm) wide paper.

To resume normal printing, turn the printer off and then on again.

4.3.3 Printer Initialization

Printer initialization clears the printer's DRAM and restores its factory settings.

To activate printer initialization:

1. Turn off the printer.

2. Press and hold the Feed/Pause Button, and then turn on the printer.

3. Release the button after the amber LED flashes five times and the LED is lit in green.

Note

The LED color will change as follows:

Amber red (5 times) amber (5 times) green (5 times) green/amber (5 times)

red/amber (5 times) green (lit)

ASCII data Hexadecimal representation of

the ASCII data

31

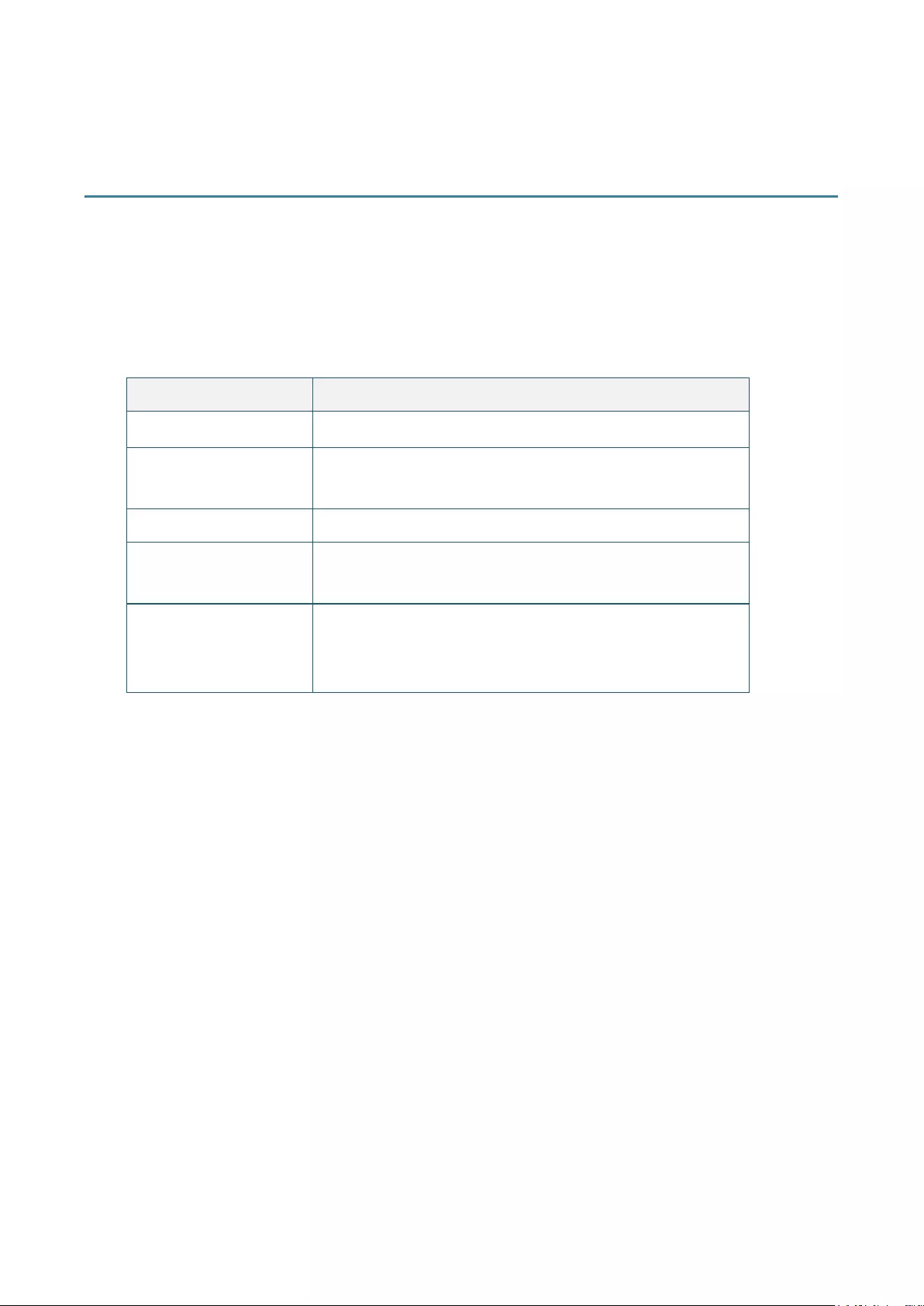

After the initialization, the following factory settings will be restored:

Parameter Default Values

Speed 127 mm/sec (5 ips) (203DPI)

76 mm/sec (3 ips) (300DPI)

Density 8

Label Width 4” (101.5 mm)

Label Height 4” (101.5 mm)

Sensor Type Gap Sensor

Gap Setting 0.12” (3 mm)

Print Direction 0

Reference Point 0,0 (upper left corner)

Offset 0

Tear Mode On

Label Peeler Off Mode Off

Cutter Mode Off

Code Page 850

Country Code 001

Clear Flash Memory No

4.3.4 Media Sensor Calibration (For the Black Mark Sensor)

1. Turn off the printer.

2. Press and hold the Feed/Pause Button, and then turn on the printer.

3. Release the button after the green LED flashes five times and when the LED is lit in

green/amber.

Note

The LED color will change as follows:

Amber red (5 times) amber (5 times) green (5 times) green/amber (5 times)

red/amber (5 times) green (lit)

32

4.3.5 Media Sensor Calibration (For the Gap Sensor)

1. Turn off the printer.

2. Press and hold the Feed/Pause Button, and then turn on the printer.

3. Release the button after the green/amber LED flashes five times and the LED is lit in

red/amber.

Note

The LED color will change as follows:

Amber red (5 times) amber (5 times) green (5 times) green/amber (5 times)

red/amber (5 times) green (lit)

4.3.6 Skip the AUTO.BAS program

The user can upload the AUTO.BAS program to the printer's flash memory so that it can be run

automatically at startup.

To prevent the AUTO.BAS program from running at startup:

1. Turn off the printer.

2. Press the Feed/Pause Button, and then turn on the printer.

3. Release the button when the LED is lit in green.

Note

The LED color will change in the following order:

Amber red (5 times) amber (5 times) green (5 times) green/amber (5 times)

red/amber (5 times) green (lit)

4. The printer will start without running the AUTO.BAS program.

33

5. BPM (Brother Printer Management Tool)

The Brother Printer Management Tool is an integrated tool allowing you to:

Check a printer’s status and settings.

Change printer settings.

Send additional commands to a printer.

Download graphics and fonts.

Create a printer bitmap font.

Download and update firmware.

Using this tool, you can also review your printer's status and settings to troubleshoot any

problems.

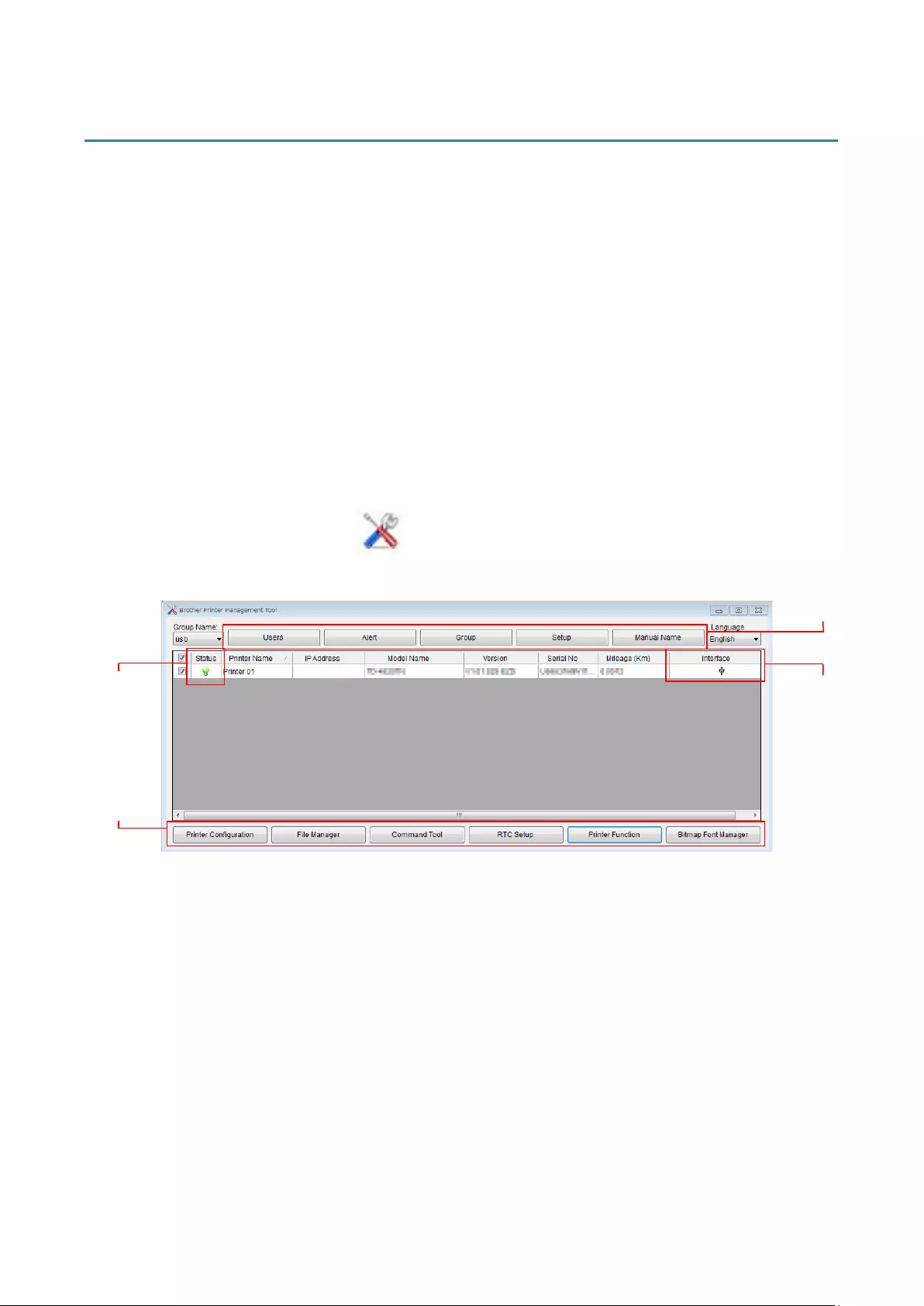

5.1 Start the BPM

1. Double-click the BPM icon to start the software.

BPM's main screen allows you to access the following options:

Printer Configuration

File Manager

Command Tool

RTC Setup

Printer Function

Bitmap Font Manager

For more information, see the Brother Printer Management Tool Quick Start Guide.

Features

buttons

Interface

type

Printer

status

Configuration

buttons

34

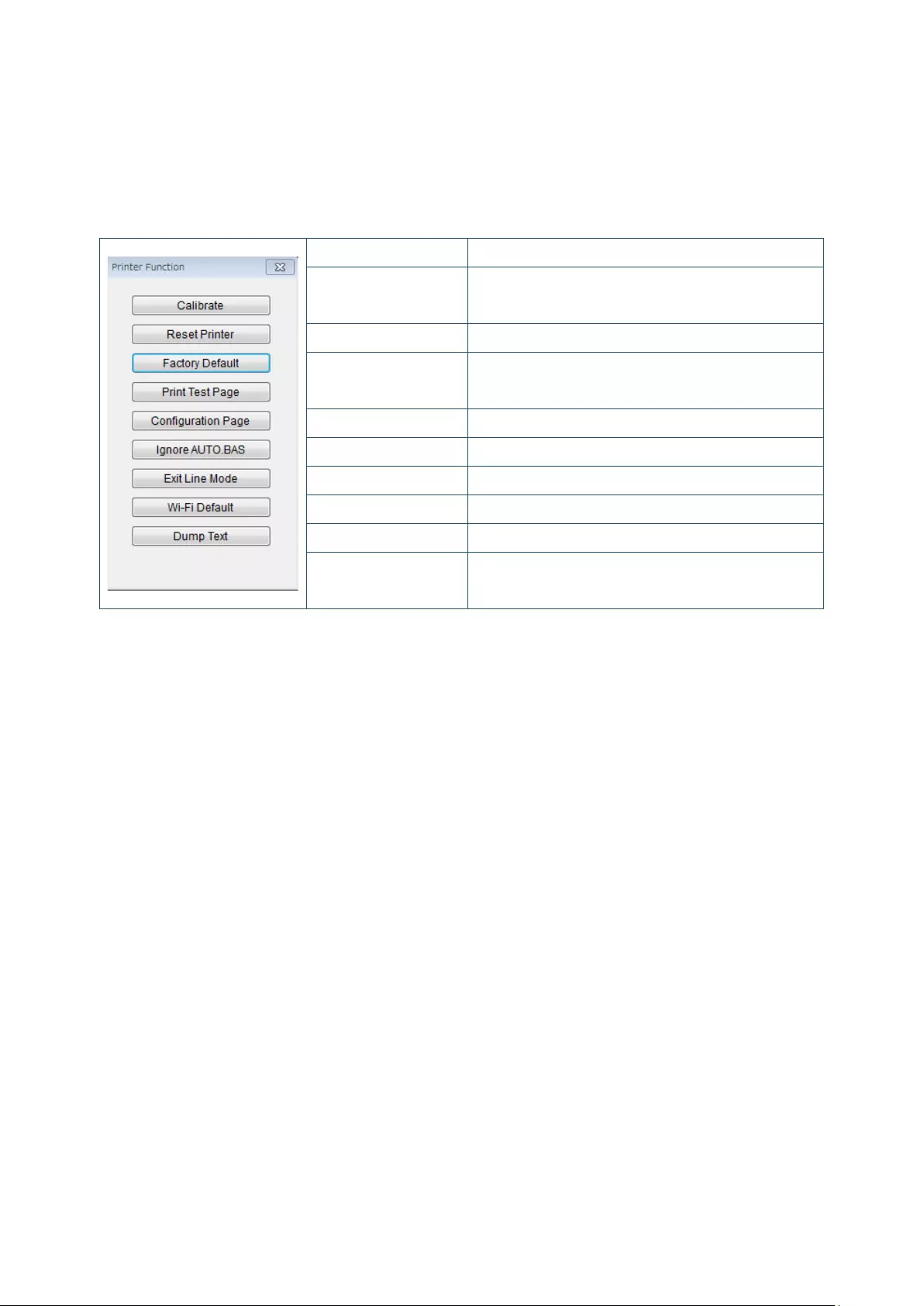

5.2 Printer Function

1. Click the Printer Function button.

2. The following functions are available:

Function Description

Calibrate Calibrate the sensor selected in the Media

Sensor in the Printer Configuration feature.

Reset Printer Reboot the printer.

Factory Default Initialize the printer and restore the settings to

their default values. (See section 4.3.3)

Print Test Page Print a test page.

Configuration Page Print the printer configuration. (See section 4.3.2)

Ignore AUTO.BAS Ignore the downloaded AUTO.BAS program.

Exit Line Mode Exit the line mode.

Wi-Fi Default Reset the Wi-Fi settings to their default values.

Dump Text Activate the printer's dump mode. (See

section 4.3.2)

For more information, see the Brother Printer Management Tool Quick Start Guide.

35

5.3 Calibrating the Media Sensor using the BPM

5.3.1 Auto Calibration

Use the BPM to set the media sensor type (Gap Sensor or Black Mark Sensor) and calibrate the

selected sensor.

Gap Sensor Black Mark Sensor

The transmissive/gap sensor detects the beginning of the label and feeds the label to the correct

position.

The reflective/black mark sensor detects the mark and feeds the media to the correct position.

1. Make sure the media is already installed and the Print Head mechanism is closed.

(See section 3.3)

2. Turn on the printer.

3. Start the BPM.

4. Click the Printer Function button.

5. Click the Calibrate button.

6. Select the sensor media type and click Calibrate.

36

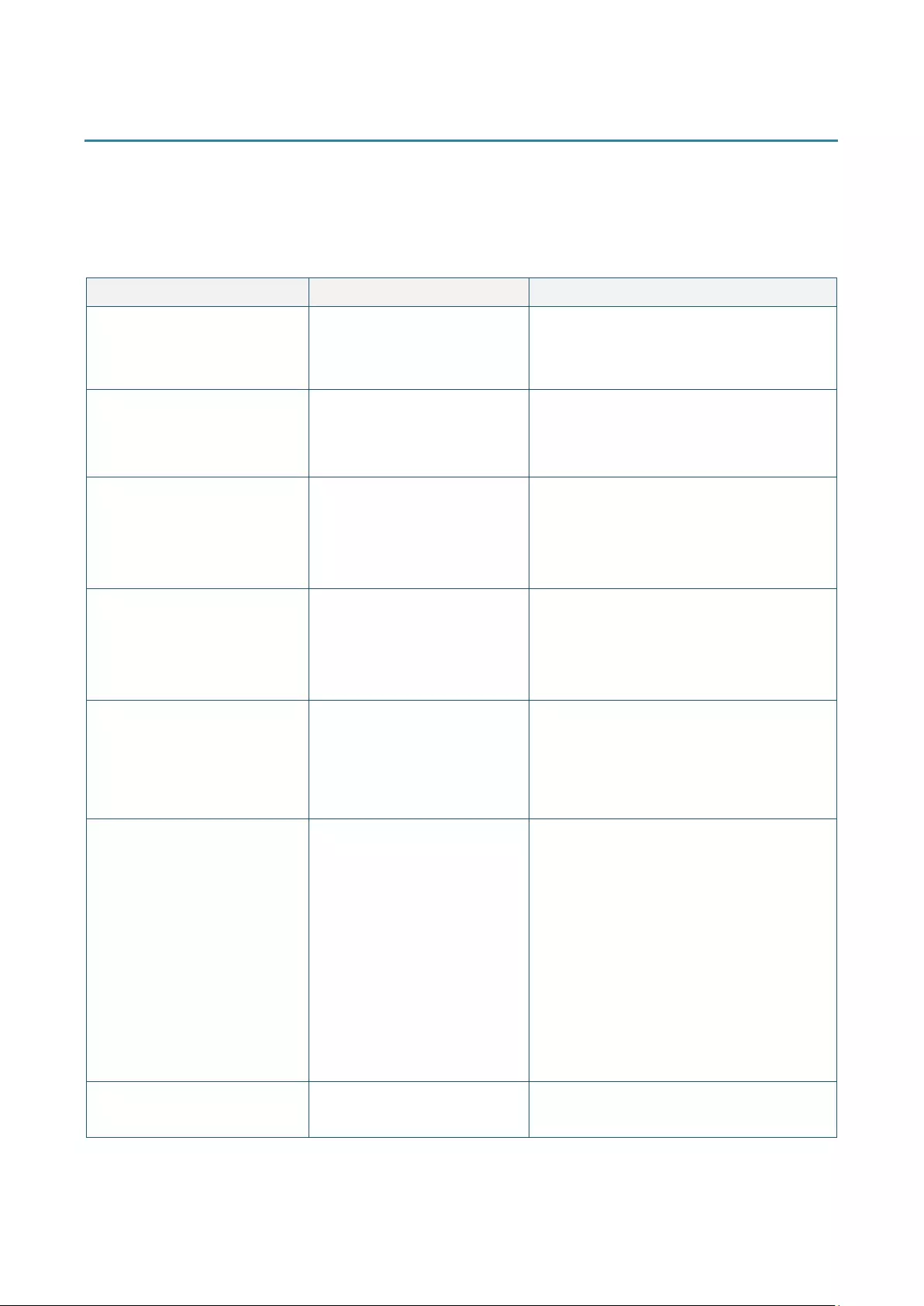

6. Troubleshooting

This chapter explains how to resolve typical problems you may encounter when using the printer. If

you have any problems with the printer, first make sure you have performed the following tasks

correctly.

If you still have problems, contact the product manufacturer's customer service or your local dealer.

Problem Possible Cause Solution

The LED Indicator is not lit. The Power Cord is not

correctly

connected.

Make sure the printer is correctly

connected to the power outlet (electrical

socket) using the Power Cord.

Turn the printer on.

- The Brother Printer

Management Tool shows

Head Open.

- The LED flashes in red.

The Print Head mechanism is

open. Close the Print Head mechanism.

- The Brother Printer

Management Tool shows

Out of Ribbon or Ribbon

Encoder Err.

- The LED flashes in red.

The ribbon has run out.

The ribbon is installed

incorrectly.

Install a new ribbon roll.

To install a new ribbon roll, see

section 3.2.

- The Brother Printer

Management Tool shows

Out of Paper.

- The LED flashes in red.

The label has run out.

The label is installed

incorrectly.

The Gap/Black Mark Sensor

is not calibrated.

Install a new label roll.

To install a new label roll, see section 3.3.

Calibrate the Gap/Black Mark Sensor.

- The Brother Printer

Management Tool shows

Paper Jam.

- The LED flashes in red.

The Gap/Black Mark Sensor

is not calibrated.

Make sure label size is set

correctly.

Labels may be stuck inside

the Printer Head mechanism.

Calibrate the Gap/Black Mark Sensor.

Set the label size correctly.

I cannot print.

The cable is not connected

to the serial or USB

interface.

The serial port cable is not

correctly connected.

Re-connect the serial or USB cable.

Try a new cable.

Use a correct ribbon or media.

Check the ribbon for damage.

Reinstall the ribbon.

Clean the Print Head.

Adjust the print density and print speed.

The Print Head's harness connector is not

connected correctly with the Print Head.

Turn off the printer and plug the connector

again.

Make sure that your program contains the

PRINT command at the end of the file a

nd

a CRLF at the end of each command line.

Memory full

(FLASH/DRAM).

The FLASH/DRAM storage is

full. Delete unused files from the FLASH/DRAM.

37

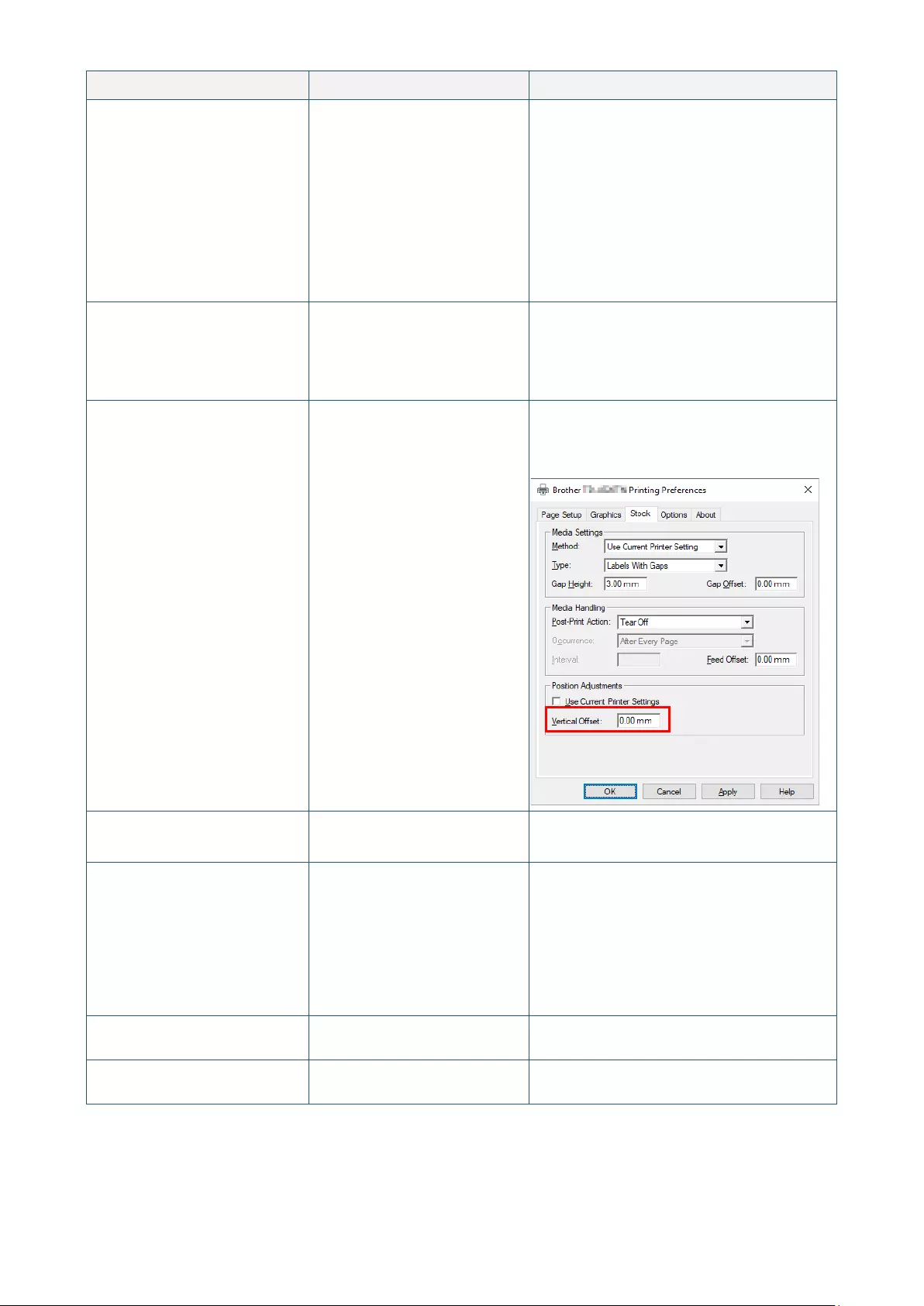

Problem Possible Cause Solution

Poor Print Quality.

The ribbon/media is loaded

incorrectly.

Dust or adhesive has

accumulated on the Print

Head.

The print density is set

incorrectly.

The Print Head mechanism

is damaged.

The ribbon/media are

incompatible.

Reload the media/ribbon.

Clean the Print Head.

Clean the Platen Roller.

Adjust the print density and print speed.

Run the printer self-test and check the

Print Head test pattern for missing dots.

Install the correct ribbon/media.

Labels are skipped when

printing.

The label size is not

specified correctly.

The sensor sensitivity is not

set correctly.

The media sensor is dirty.

Check if the label size is set up correctly.

Calibrate the sensor using the Auto Gap

or Manual Gap options.

Clean the Gap/Black Mark Sensor using

a blower brush.

The printing position of small

labels is incorrect.

The media sensor sensitivity

is not set correctly.

The label size is incorrect.

The vertical offset setting in

the driver is incorrect.

Calibrate the sensor sensitivity again.

Set the correct label size and gap size.

If using the BarTender software, set the

Vertical Offset in the driver.

Incomplete printing on the left

or right side of label.

The label size is set up

incorrectly. Set the correct label size.

Warped labels.

The ribbon is installed

incorrectly.

The media is installed

incorrectly.

The print density setting is

incorrect.

The media is not fed

correctly.

Adjust the print density to improve the

print quality.

Make sure the label guide touches the

edge of the Media Guide Tips.

Blank labels with gray lines. The Print Head is dirty.

The Platen Roller is dirty.

Clean the Print Head.

Clean the Platen Roller.

Irregular printing. The printer is in Hex Dump

mode.

Turn the printer on and off to skip the dump

mode. (See section 4.3.2)

For more information about cleaning the printer, see section 7.

38

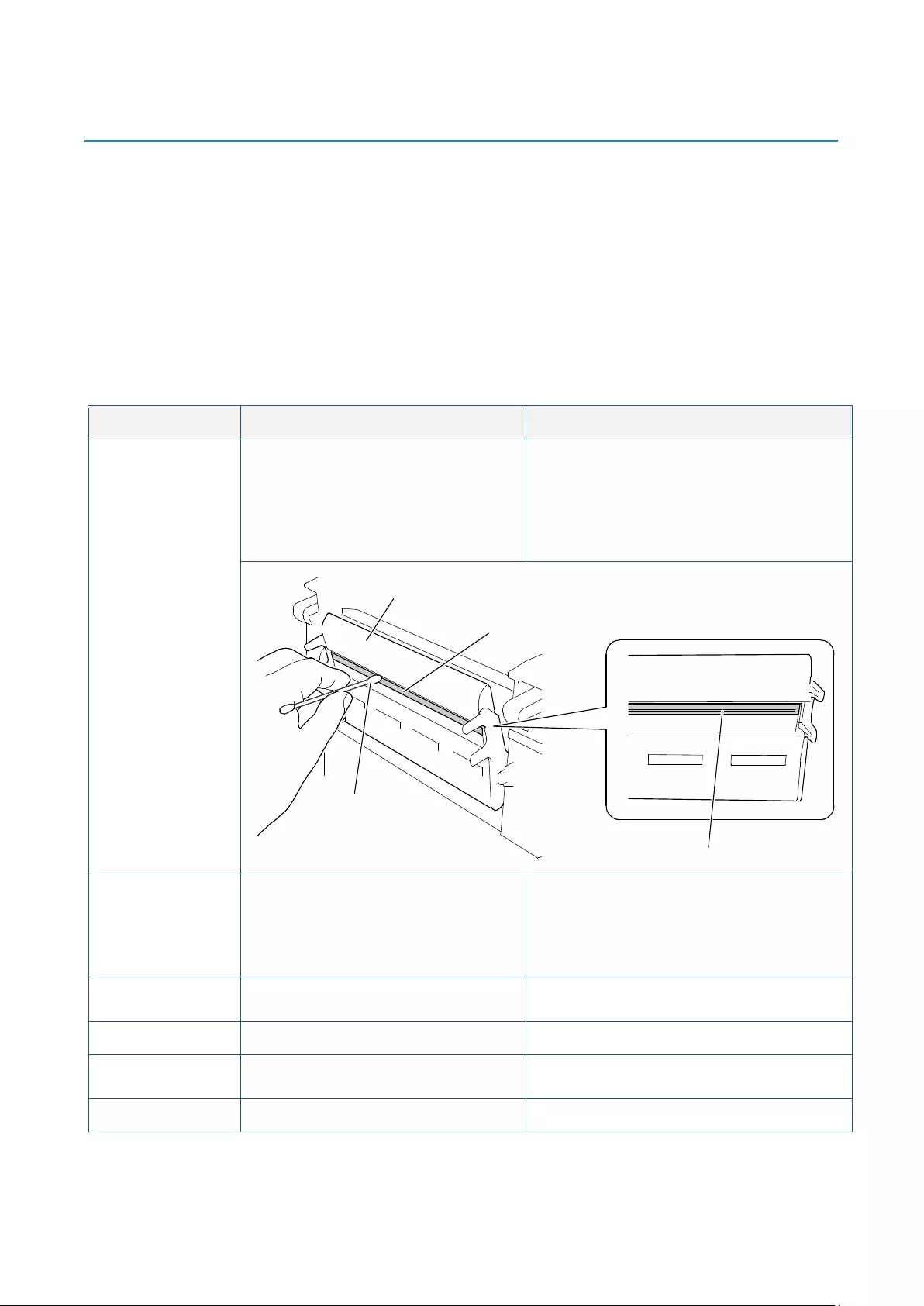

7. Maintenance

We recommend cleaning your printer on a regular basis to maintain its correct performance.

Recommended cleaning materials:

Cotton swab

Lint-free cloth

Vacuum / Blower brush

Compressed air

Isopropyl alcohol or ethanol

Printer Part Cleaning Method Interval

Print Head

1. Turn the printer off.

2. Allow the Print Head to cool down

for at least one minute.

3. Wipe the Print Head with a cotton

swab dipped in isopropyl alcohol or

ethanol.

Clean the Print Head when changing a

label roll.

Platen Roller

1. Turn the printer off.

2. Rotate the Platen Roller and wipe

it thoroughly with a lint-

free cloth or

cotton swab dipped in isopropyl

alcohol or ethanol.

Clean the Platen Roller when changing a

new label roll.

Tear Bar/Peel Bar

Wipe it with a lint-free cloth dipped in

isopropyl alcohol or ethanol.

As needed.

Sensor Use compressed air or vacuum. Monthly.

Exterior

Wipe the printer exterior with a

lint-free cloth dipped in water.

As needed.

Interior Use a brush or vacuum. As needed.

Print Head

Print Head

Element

Element

Cotton Swab

39

Note

Do not touch the Print Head. If you have touched it, clean it as described above.

Do not use medical alcohol as it may damage the Print Head. Use isopropyl alcohol or

ethanol according to the manufacturer's safety guidelines, as applicable.

To maintain the printer's correct performance, we recommend cleaning its Print Head and

sensors every time you install a new ribbon.

IMPORTANT

Securely dispose of any printers, components, and supplies if they are no longer going to be used.

Ensure there is no jammed paper in the printer and destroy the thermal transfer ribbon if it has

retained any visible prints.