Table of Contents

- 1. Introduction

- 2. Operations Overview

- 3. Set Up Your Printer

- 4. Printing

- 5. Operation

- 6. LCD Overview

- 7. Brother Printer Management Tool (BPM)

- 8. Setting up the RFID

- 9. Product Specifications

- 10. Troubleshooting

- 11. Maintenance

Brother TD-4650TNWBR User Manual

Displayed below is the user manual for TD-4650TNWBR by Brother which is a product in the Label Printers category. This manual has pages.

Related Manuals

User's Guide

TD-4650TNWB/4650TNWBR/TD-4750TNWB/4750TNWBR

TD-4650TNWB/4650TNWBR

TD-4750TNWB/4750TNWBR

User's Guide (English)

User's Guide TD-4650TNWB/4650TNWBR/TD-4750TNWB/4750TNWBR

© 2020 Brother Industries, Ltd. All rights reserved.

Version 04

ENG

i

Copyright Information

The copyright in this manual, the software, and firmware in the printer described

therein are owned by Brother. All rights reserved.

Information in this document is subject to change without notice and does not

represent a commitment on the part of the company. No part of this manual may

be reproduced or transmitted in any form or by any means, for any purpose

other than the purchaser’s personal use, without the expressed written

permission of the company.

Trademarks

The Bluetooth® word mark and logos are registered trademarks owned by the

Bluetooth SIG, Inc. and any use of such marks by Brother Industries, Ltd. is

under license.

Wi-Fi® is a registered trademark of Wi-Fi Alliance®.

CG Triumvirate is a trademark of Agfa Corporation. CG Triumvirate Bold

Condensed font is under license from the Monotype Corporation. All other

trademarks are the property of their respective owners.

Any trade names and product names of companies appearing on Brother

products, related documents and any other materials are all trademarks or

registered trademarks of those respective companies.

ii

Contents

1. Introduction ........................................................................................................ 1

1.1 Product Introduction .............................................................................................. 1

1.2 Additional Product Reference ............................................................................... 1

2. Operations Overview ......................................................................................... 2

2.1 Unpack the printer and check the components .................................................... 2

2.2 Printer Overview ................................................................................................... 3

2.2.1 Front View ................................................................................................ 3

2.2.2 Interior View .............................................................................................. 4

2.2.3 Rear View ................................................................................................. 5

2.3 Connect the Power Cord ...................................................................................... 6

2.4 Control Panel ........................................................................................................ 7

2.5 LED Indicator ........................................................................................................ 8

3. Set Up Your Printer ............................................................................................ 9

3.1 Load the Ribbon ................................................................................................... 9

3.2 Load the Media ................................................................................................... 11

3.2.1 Load Label Roll ....................................................................................... 11

3.2.2 Install the External Roll Holder (Optional) .............................................. 14

3.2.3 Install the Label Roll When Using the Cutter Module (Dealers only) ...... 16

3.2.4 Install the Label Roll When Using the Label Peeler (Dealers only) ........ 18

4. Printing ............................................................................................................. 21

4.1 Printer Driver Installation ..................................................................................... 21

4.1.1 USB Connection (Windows/Mac/Linux) .................................................. 21

4.1.2 Bluetooth Connection (Windows) ........................................................... 22

4.1.3 Wi-Fi Network Connection (Windows) .................................................... 22

4.1.4 Wired Network Connection (Windows) ................................................... 23

4.2 Creating and Printing Labels Using BarTender ................................................. 24

5. Operation ......................................................................................................... 26

5.1 Power-on Utilities ................................................................................................ 26

5.1.1 Ribbon and Gap/Black Mark Sensor Calibration .................................... 27

5.1.2 Gap/Black Mark Sensor Calibration, Self-Test, and Entering

Dump Mode ............................................................................................ 27

5.1.3 Printer Initialization ................................................................................. 31

5.1.4 Media Sensor Calibration (for the Black Mark Sensor) .......................... 32

5.1.5 Media Sensor Calibration (for the Gap Sensor) ..................................... 32

5.1.6 Skip the AUTO.BAS program ................................................................. 32

iii

6. LCD Overview .................................................................................................. 33

6.1 Access the Main Menu ....................................................................................... 33

6.2 Main Menu Overview .......................................................................................... 34

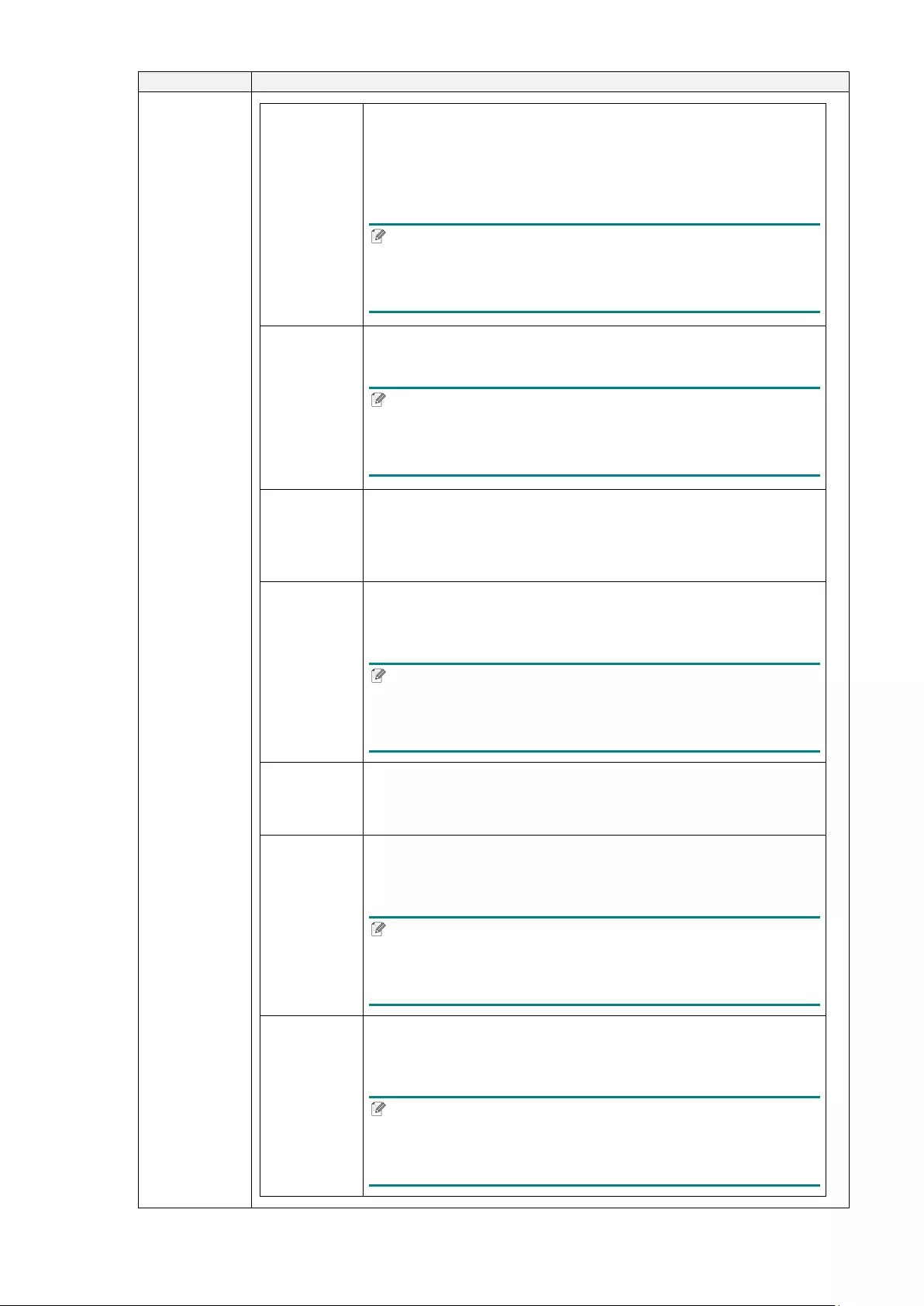

6.3 Setting Menu ....................................................................................................... 35

6.3.1 FBPL Settings ......................................................................................... 35

6.3.2 ZPL2 Settings ......................................................................................... 37

6.4 Sensor Settings ................................................................................................... 39

6.5 Interface Settings ................................................................................................ 40

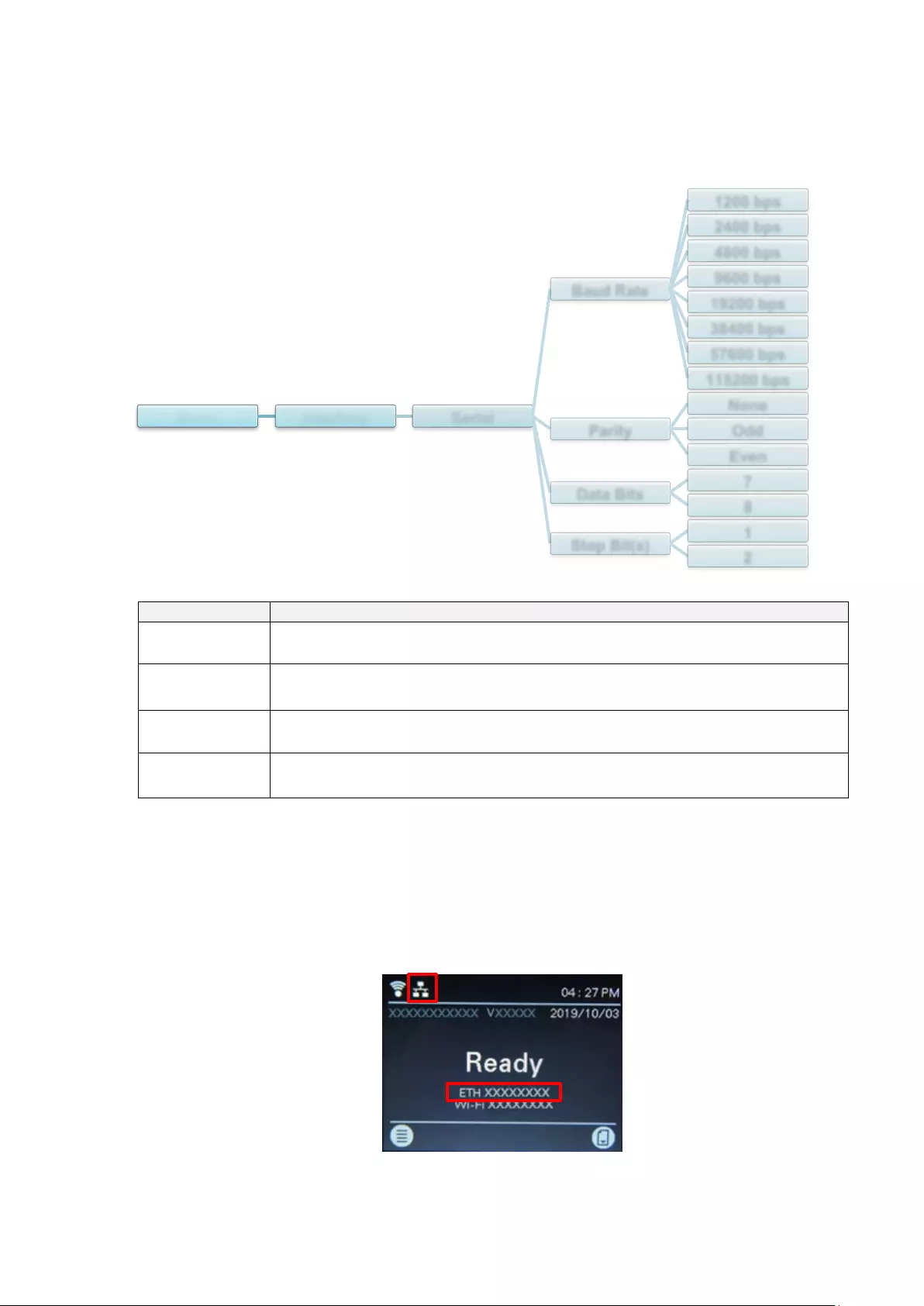

6.5.1 Serial Communication Settings .............................................................. 41

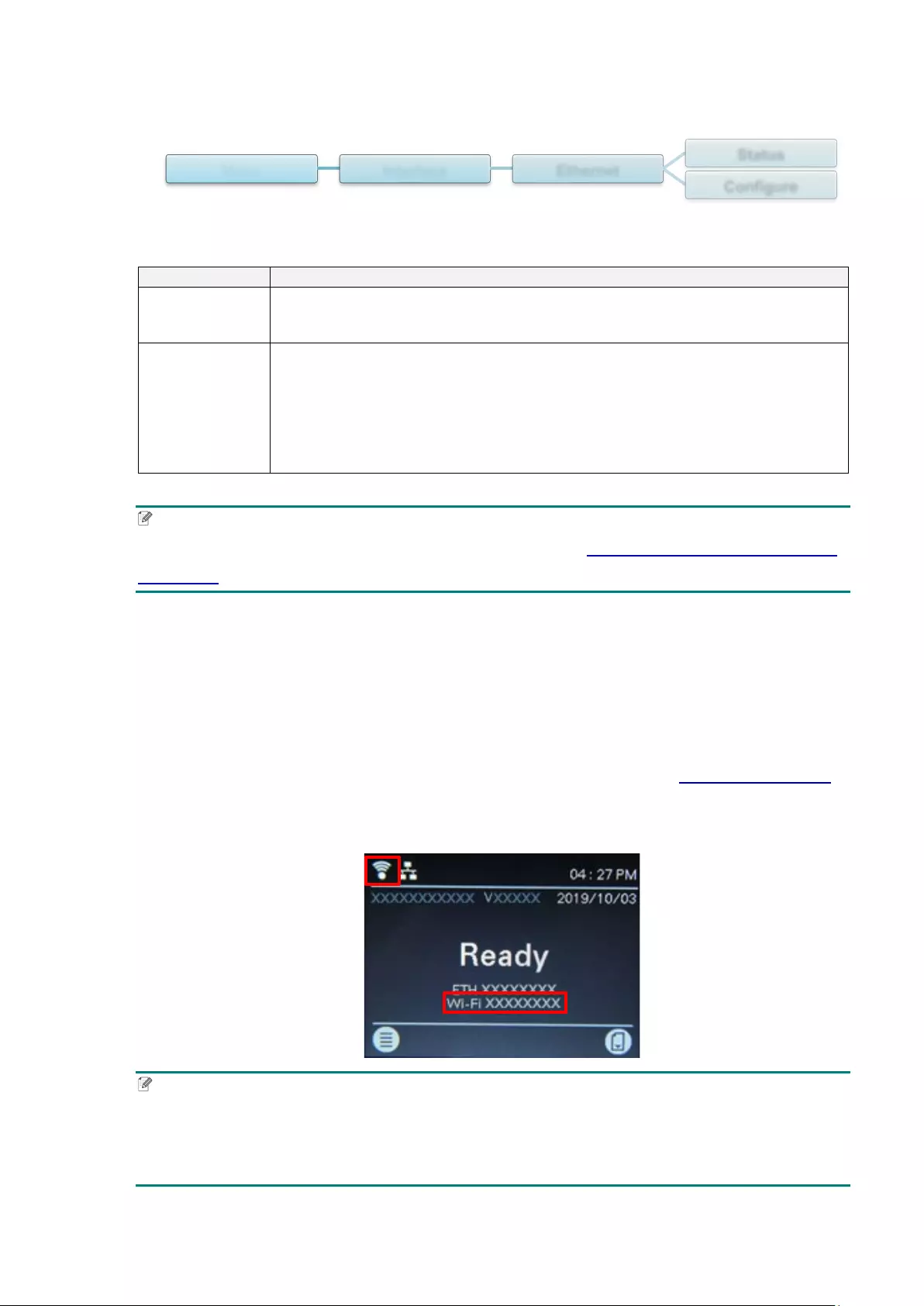

6.5.2 Ethernet Settings .................................................................................... 41

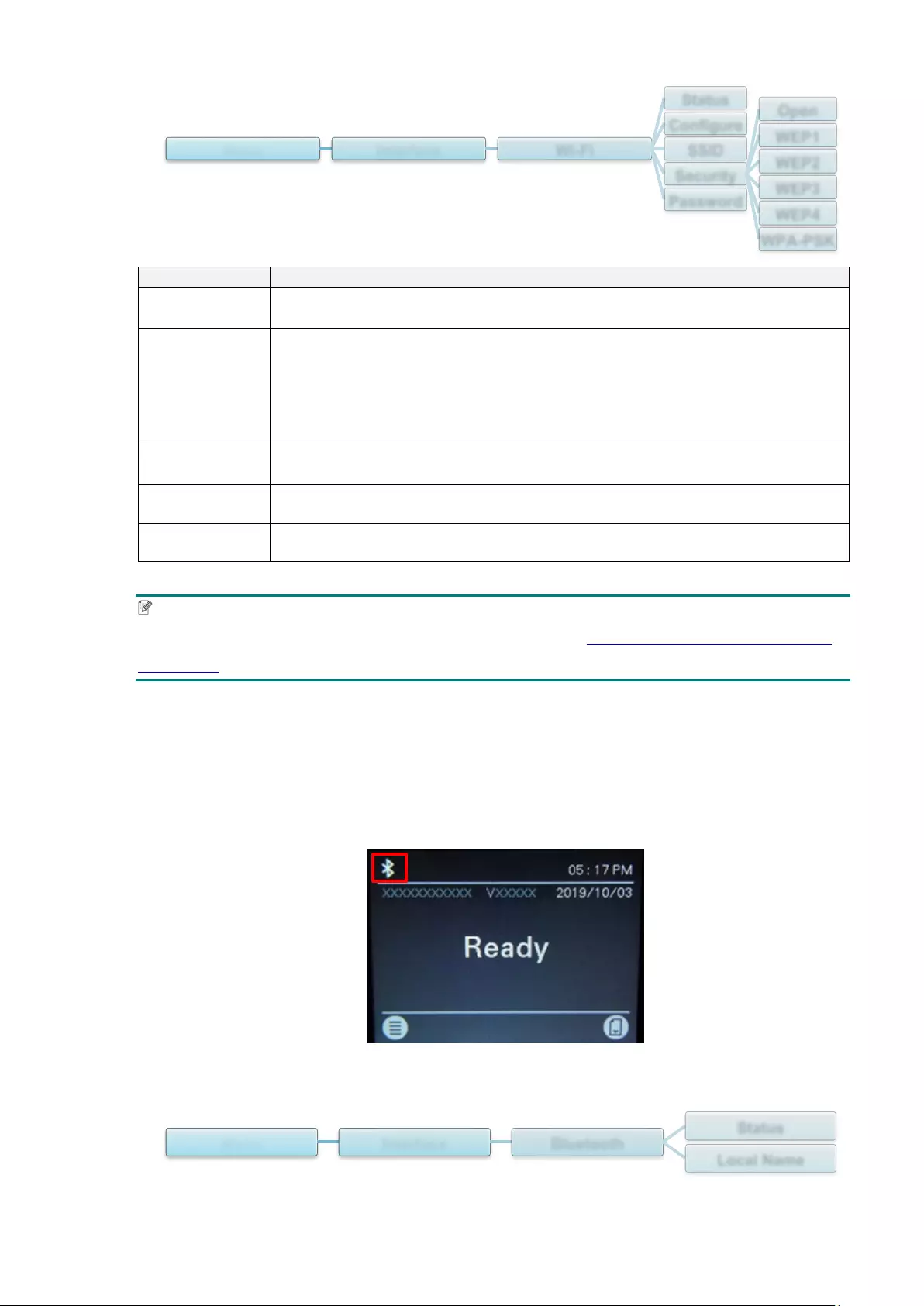

6.5.3 Wi-Fi Settings ......................................................................................... 42

6.5.4 Bluetooth Settings .................................................................................. 43

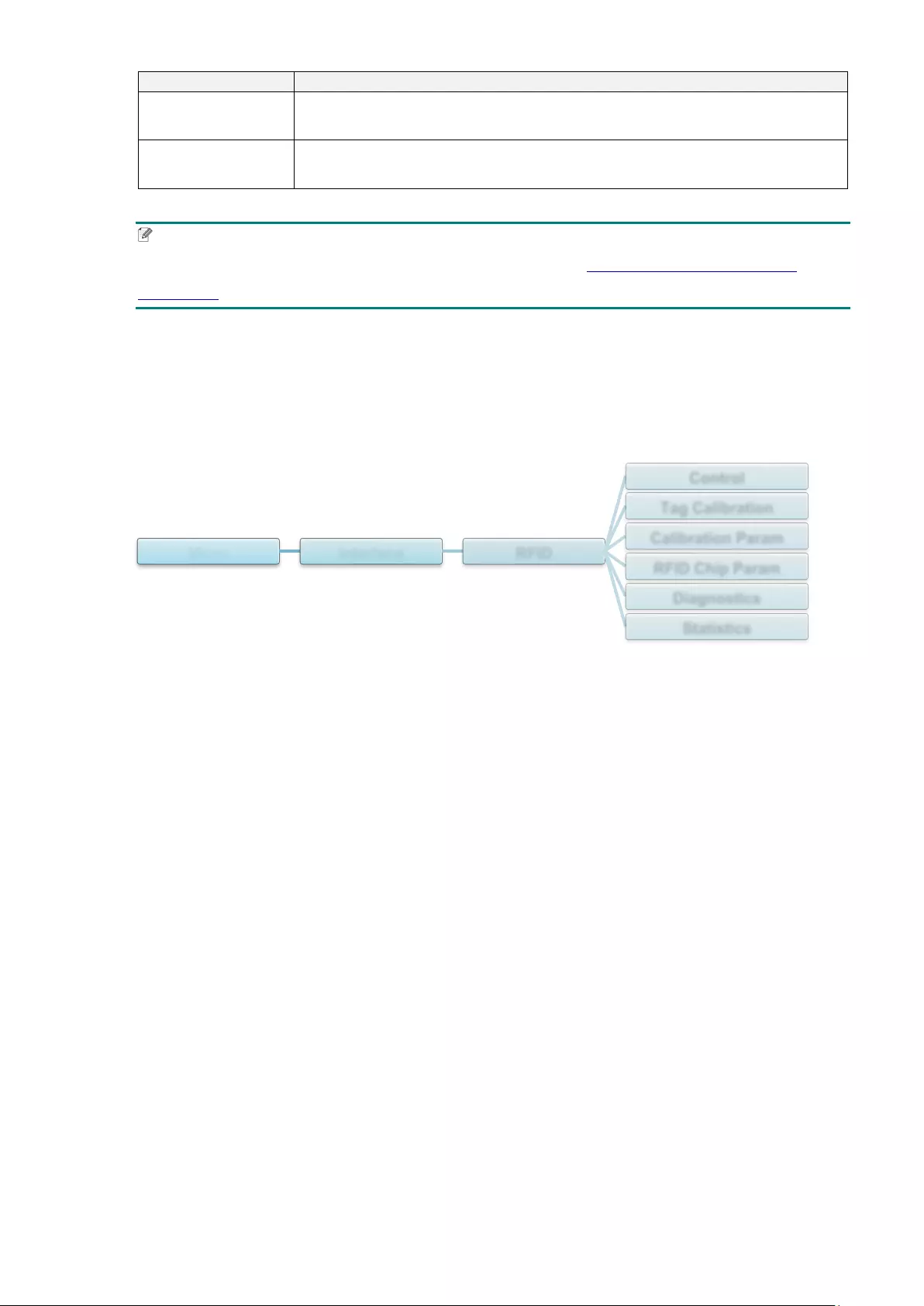

6.5.5 RFID (Radio Frequency Identification) Settings ..................................... 44

6.6 Advanced Settings .............................................................................................. 50

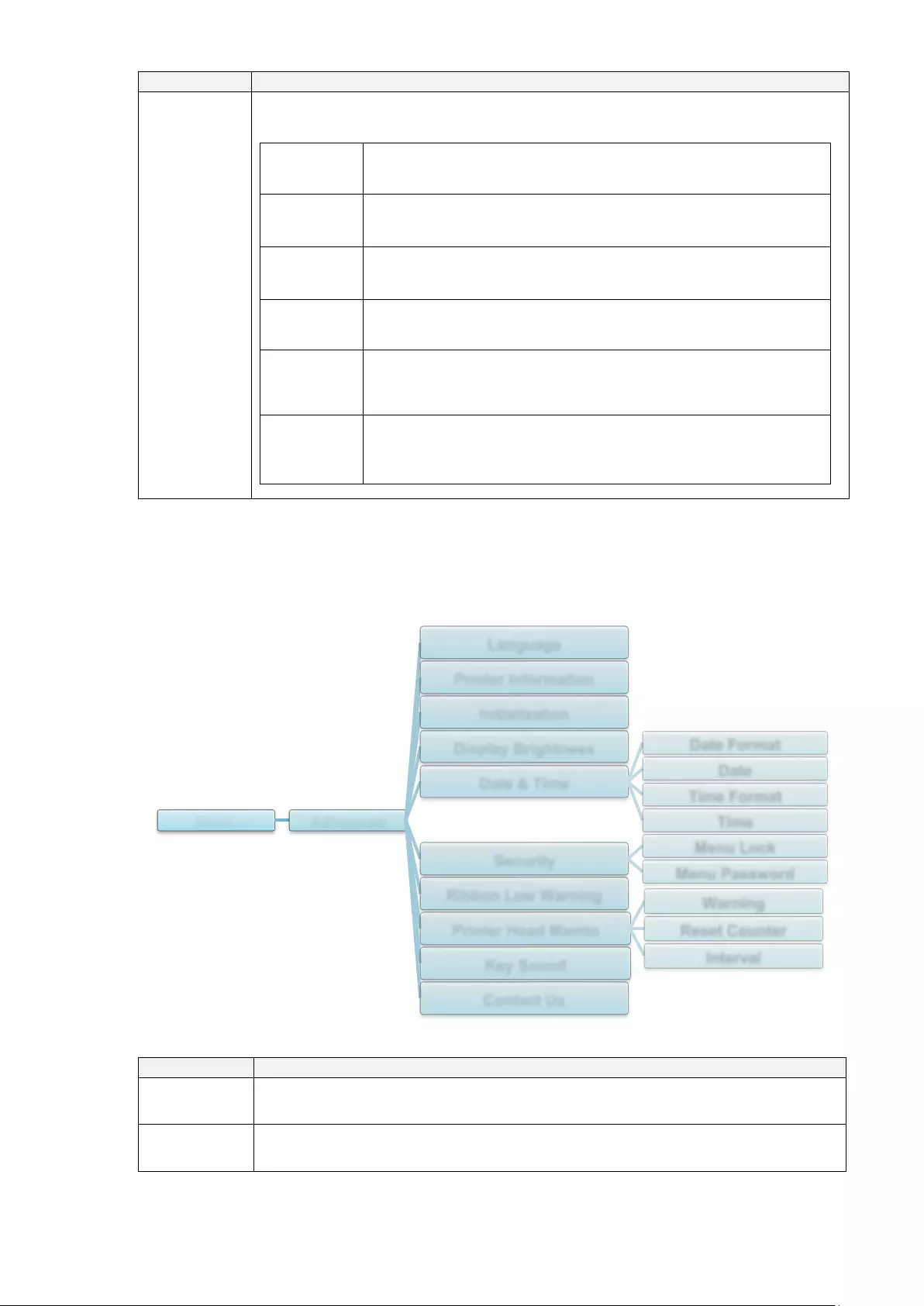

6.7 File Manager ....................................................................................................... 51

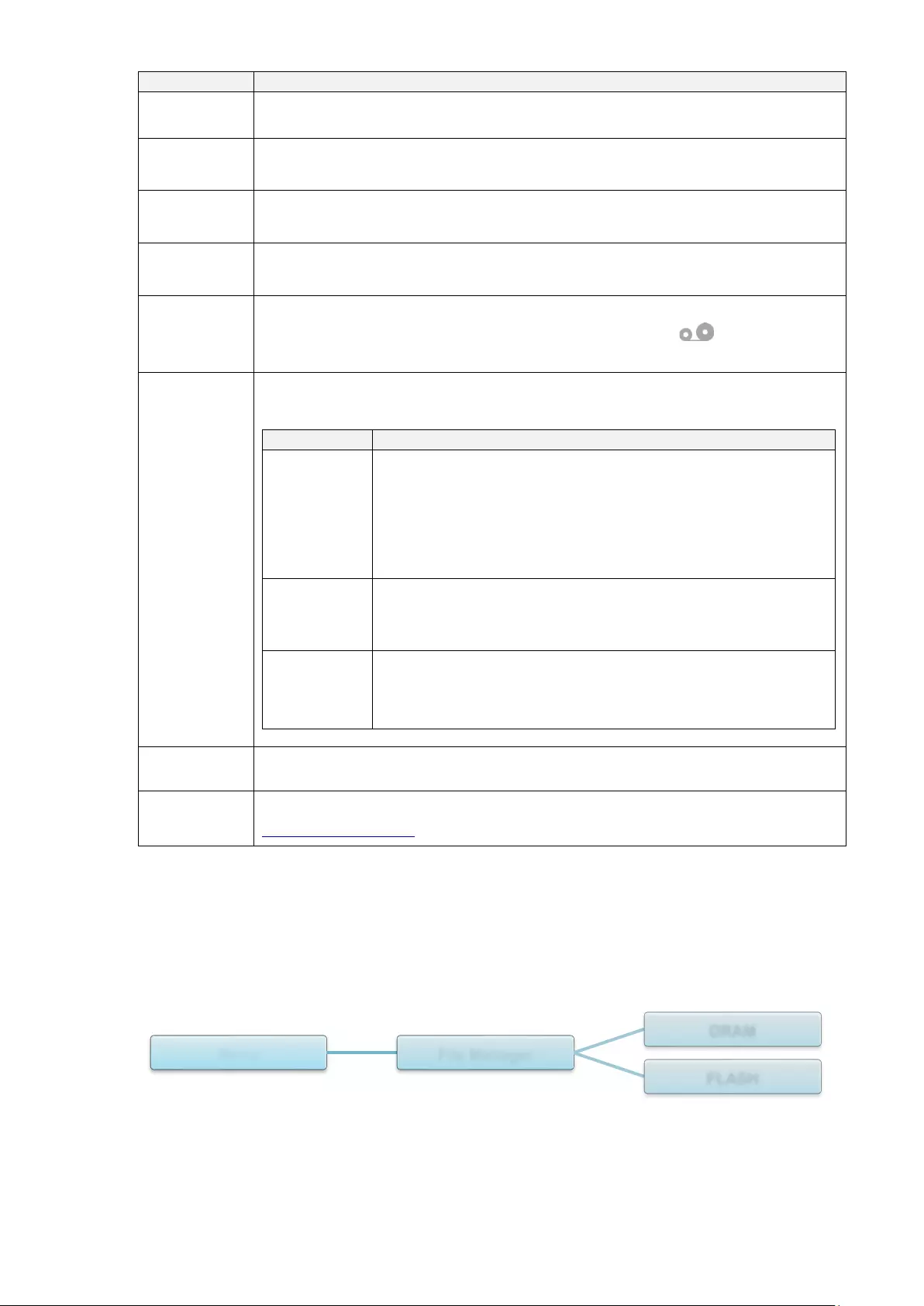

6.8 Diagnostic Functions .......................................................................................... 52

7. Brother Printer Management Tool (BPM) ........................................................ 53

7.1 Start the BPM ...................................................................................................... 53

7.2 Auto-Calibrating the Media Sensor using the BPM ........................................... 54

8. Setting up the RFID ......................................................................................... 55

8.1 Introduction ......................................................................................................... 55

8.2 RFID Calibration (available for TD-4650TNWBR and

TD-4750TNWBR only) ....................................................................................... 56

8.2.1 Select the Antenna Position ................................................................... 56

8.2.2 RFID Calibration Procedure ................................................................... 56

9. Product Specifications ..................................................................................... 59

10. Troubleshooting ............................................................................................... 62

10.1 Common Problems ............................................................................................. 62

10.2 RFID Error Messages ......................................................................................... 65

11. Maintenance .................................................................................................... 67

1

1. Introduction

1.1 Product Introduction

The sleek design of the TD-4650TNWB/4650TNWBR/4750TNWB/4750TNWBR label printer

can handle up to 984 ft (300 m) of ribbon and label rolls. Its internal 5" (127 mm) label capacity

can be further expanded with an External Roll Holder to handle 8" (203.2 mm) rolls, designed

for industrial label printers. The printer's movable Black Mark Sensor is compatible with a wide

range of label media.

The printer uses its high-performance, high-quality, built-in Monotype Imaging® TrueType font

engine with the CG Triumvirate Bold Condensed smooth scalable font. It also provides a

choice of eight different sizes of the alphanumeric bitmap font. The printer's flexible firmware

design allows users to download additional TrueType fonts from a computer to print custom

labels. It also supports most of the standard barcode formats and can print fonts and barcodes

in four directions.

1.2 Additional Product Reference

For information on how to write custom programs for your Label Printer, see the Command

Reference Manuals on your model's Manuals page at support.brother.com.

2

2. Operations Overview

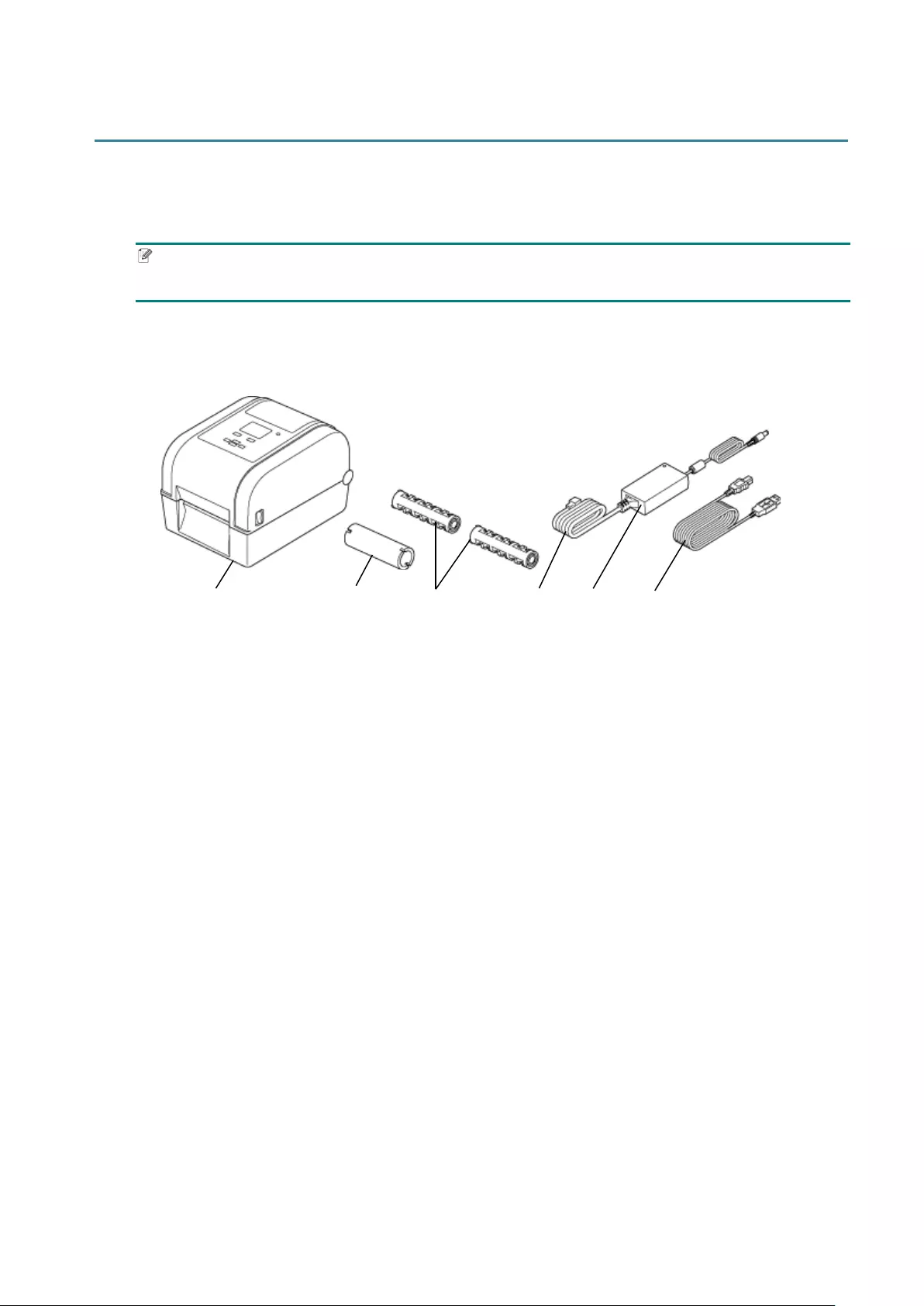

2.1 Unpack the printer and check the components

Note

Keep the packaging materials in case you must ship the printer.

The components included in the box:

1. Printer Unit

2. 1" (25.4 mm) Ribbon Paper Core

3. Two 1" (25.4 mm) Ribbon Spindles

4. Power Cord

5. External Universal Switching Power Supply

6. USB Cable

If any components are missing, contact the product manufacturer's customer service or your

local dealer.

1

2

3

4

5

6

3

2.2 Printer Overview

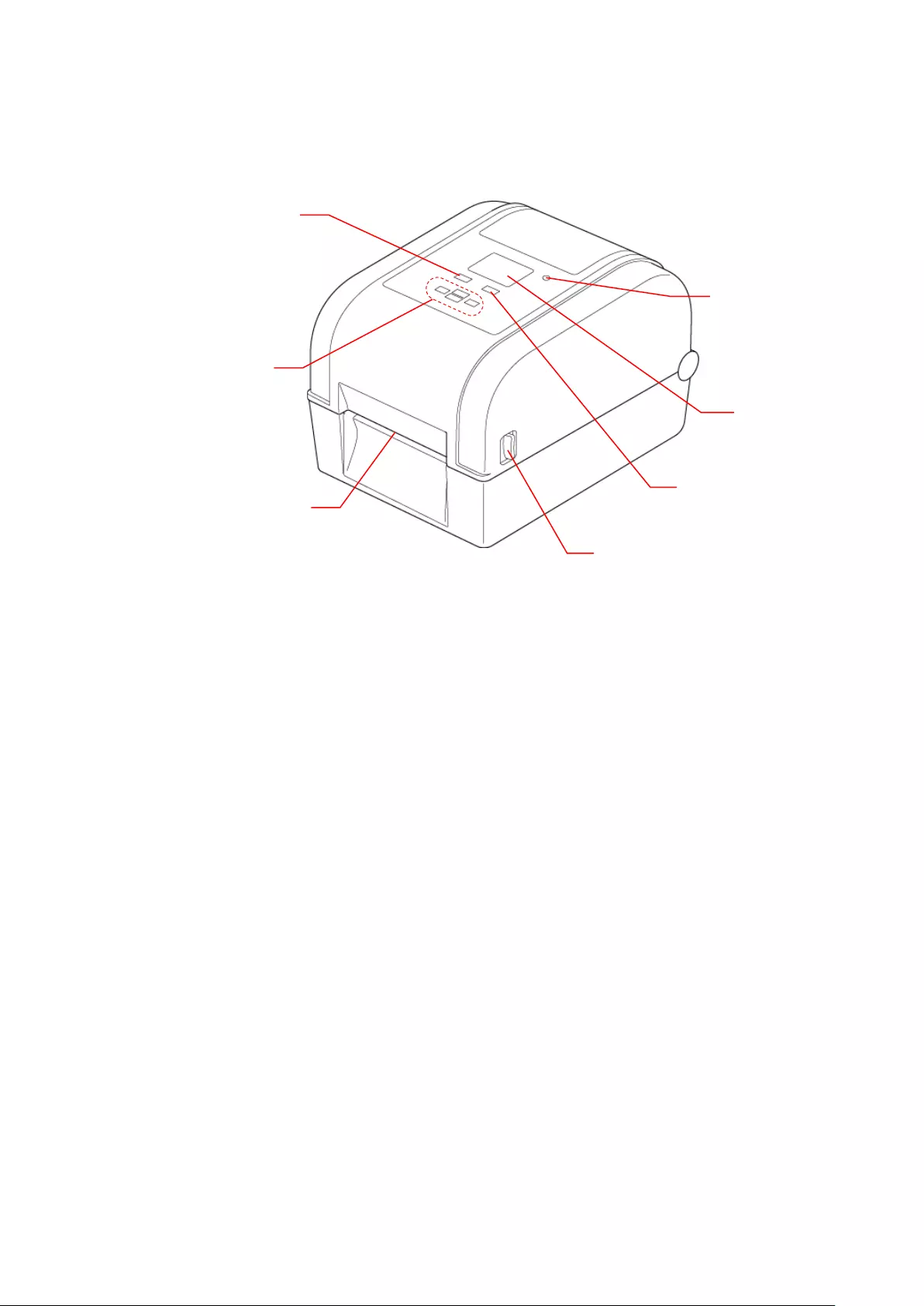

2.2.1 Front View

1. LED Indicator

2. LCD

3. Feed/Pause Button (controls the icon on the right side of the LCD)

4. Roll Compartment Cover Open Tab

5. Label Output Slot

6. Navigation Buttons

7. Menu Button (controls the icon on the left side of the LCD)

1

2

5

3

4

7

6

4

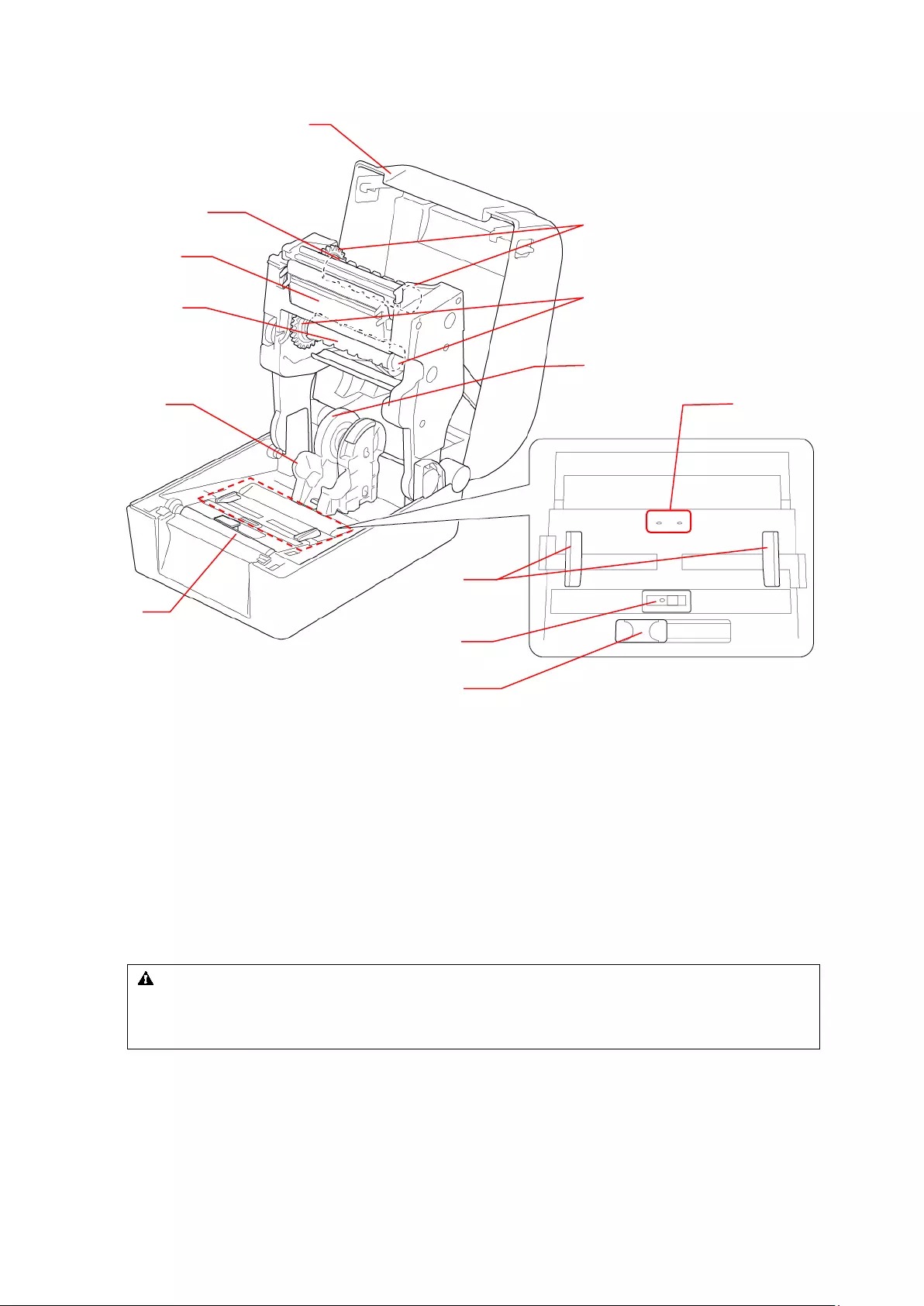

2.2.2 Interior View

1.

Roll Compartment Cover

8.

Ribbon Supply Hub

2.

Ribbon Rewind Spindle

9.

Media Adapter

3.

Print Head

10.

Gap Sensor

4.

Ribbon Supply Spindle

11.

Media Guide Tips

5.

Roll Guides

12.

Black Mark Sensor

6.

Platen Roller 13. RFID Antenna Slider (TD-4650TNWBR

and TD-4750TNWBR only)

7.

Ribbon Rewind Hub

WARNING

DO NOT touch rotating parts. There is a risk of injury if your finger is caught in the

rotating gear. Turn off the product before touching any metal parts.

1

4

5

2

3

6

10

12

13

7

8

11

9

6

2.3 Connect the Power Cord

Note

Before you plug the Power Cord into the Power Port, make sure the printer's Power Switch

is in the OFF position.

Place the printer on a flat, secure surface.

For more information, see 9. Product Specifications.

1. Plug the Power Cord into the Power Port at the rear of the printer, and then plug the other

end into the AC power outlet (electrical socket).

2. Connect the printer to the computer with the provided USB cable.

3. Push the “-” side of the Power Switch to turn on the printer.

7

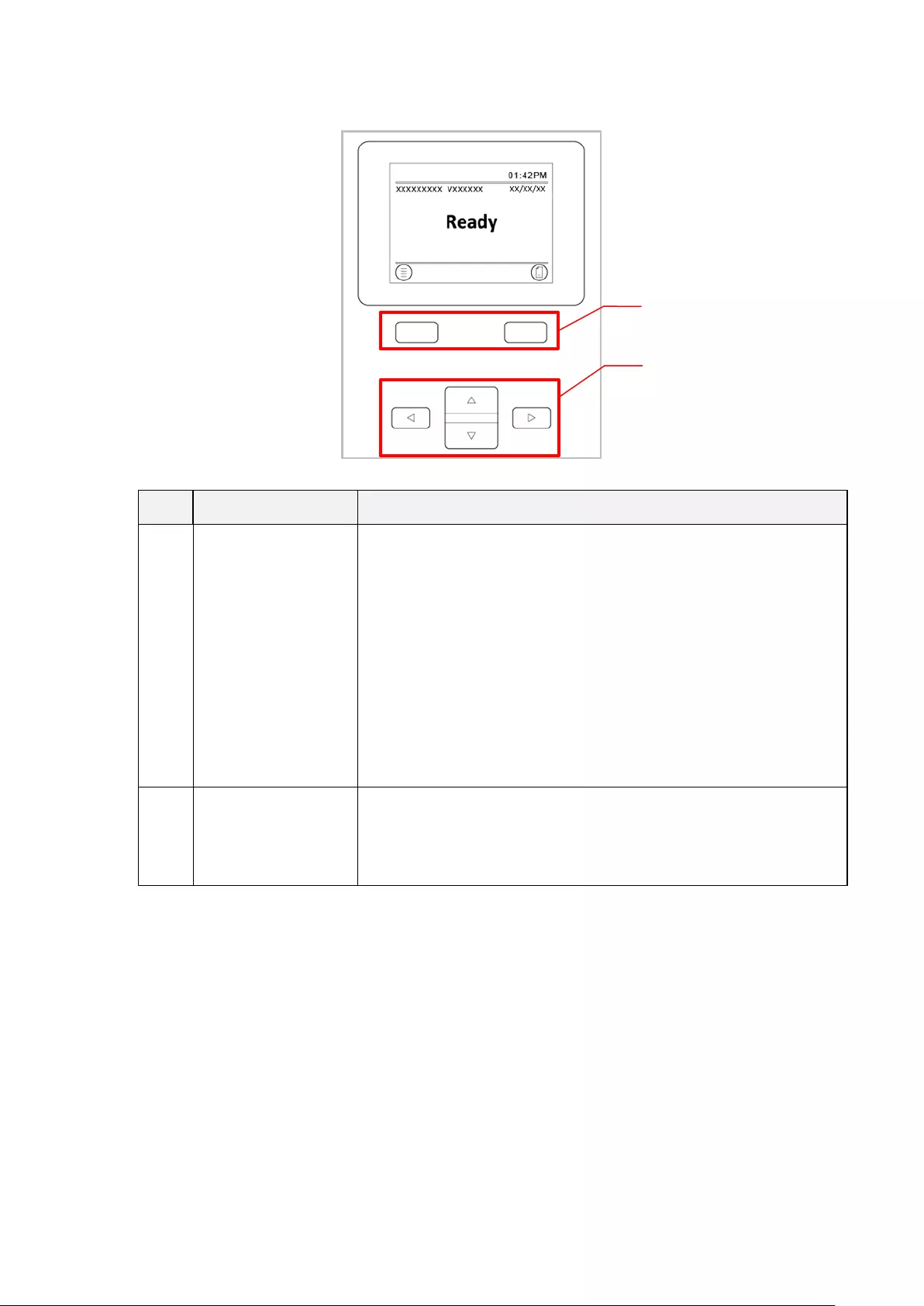

2.4 Control Panel

No. Description Functionality

1 Soft Buttons

Menu Button (Left):

- Opens the LCD menu in Ready Mode.

- Selects the left icon in the LCD footer.

Feed/Pause Button (Right):

- Ejects one label length of the media in Ready Mode.

- Selects the right icon in the LCD footer.

- Pauses a print job.

The LED flashes in green. To resume the print job, press

the button again.

2 Navigation

Buttons

Select menu items.

Pressing the Up and Down arrows together locks or unlocks

the control panel.

1

2

8

2.5 LED Indicator

LED Color Description

Green (Lit) The power is on and the printer is ready to use.

Green (Flashing) The printer is downloading data from a computer.

The printer is paused.

Amber The printer is removing data.

Red (Lit) The Print Head is open.

There is a problem with the Cutter Module.

Red (Flashing) There is a memory error or printing error (for example:

jammed paper,

no paper, no ribbon).

9

3. Set Up Your Printer

3.1 Load the Ribbon

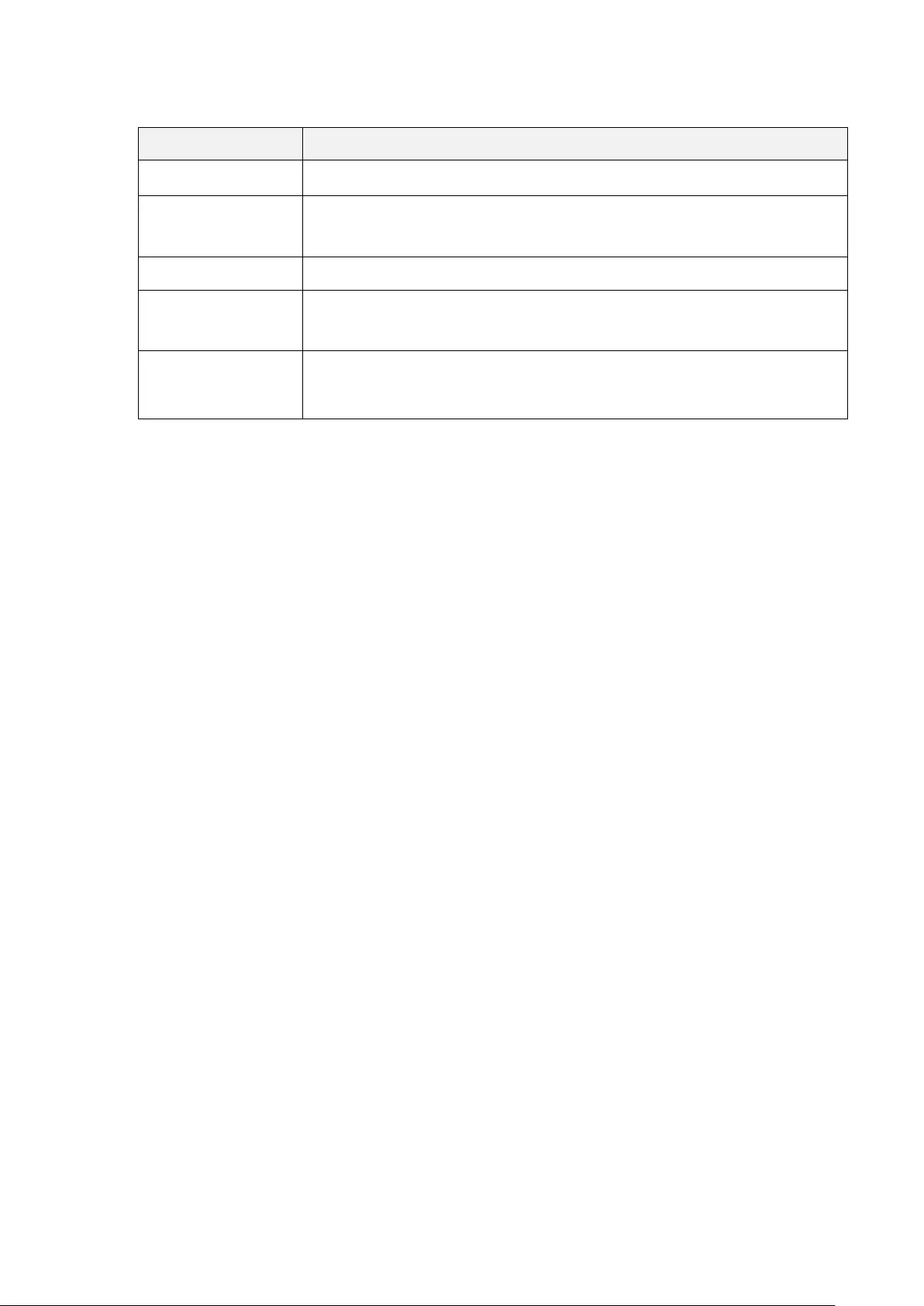

1. Press the tabs located on each side

of the printer, and then lift the Roll

Compartment Cover.

2. Use one of the following paper

cores:

For 1" (25.4 mm) and 0.5"

(12.7 mm) paper cores with

notches, you do not need to install

the ribbon spindles.

For 1" (25.4 mm) paper core

without notches, insert the ribbon

spindles into the paper core and

ribbon.

Note

Follow these directions when

installing the ribbon spindle.

10

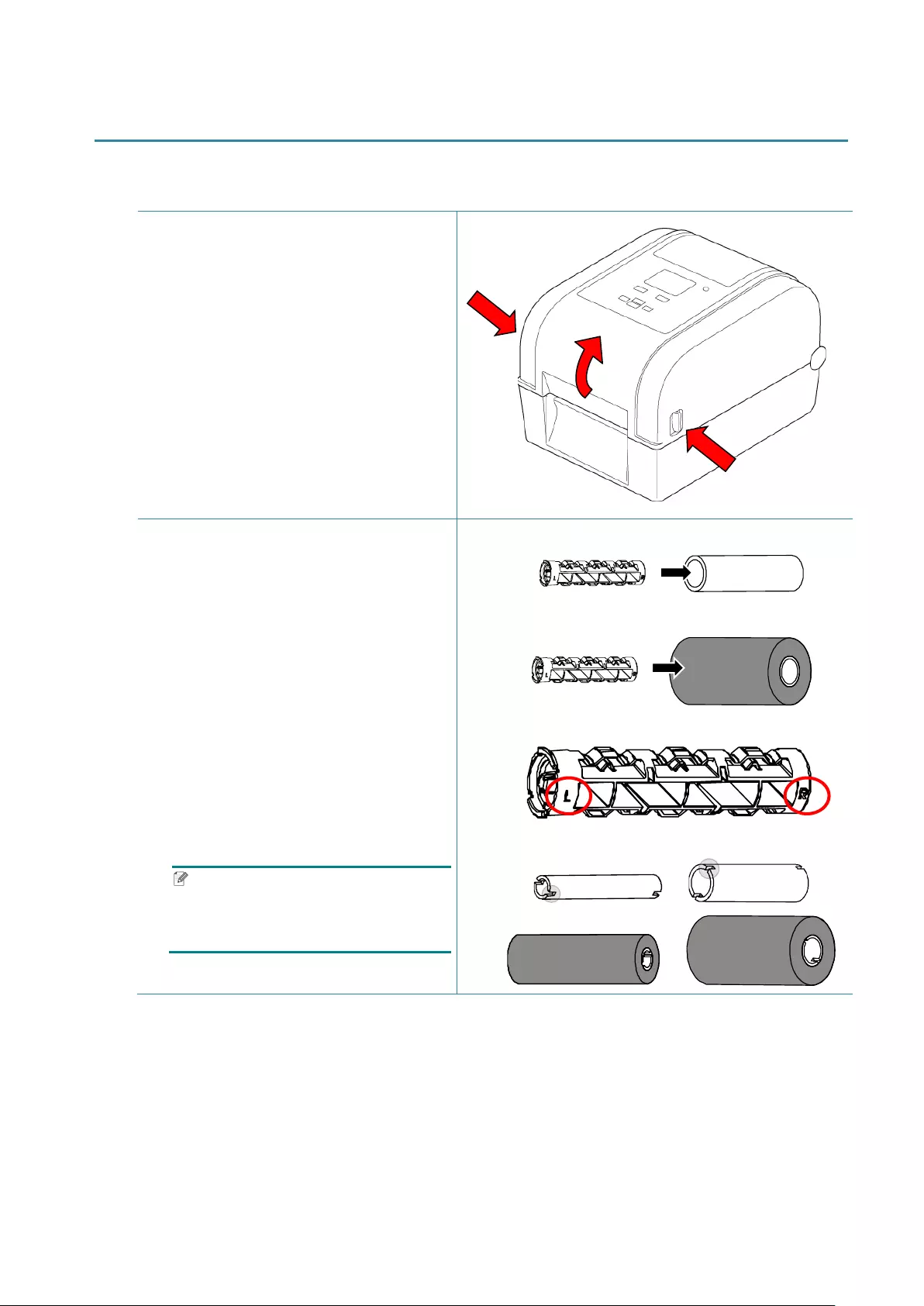

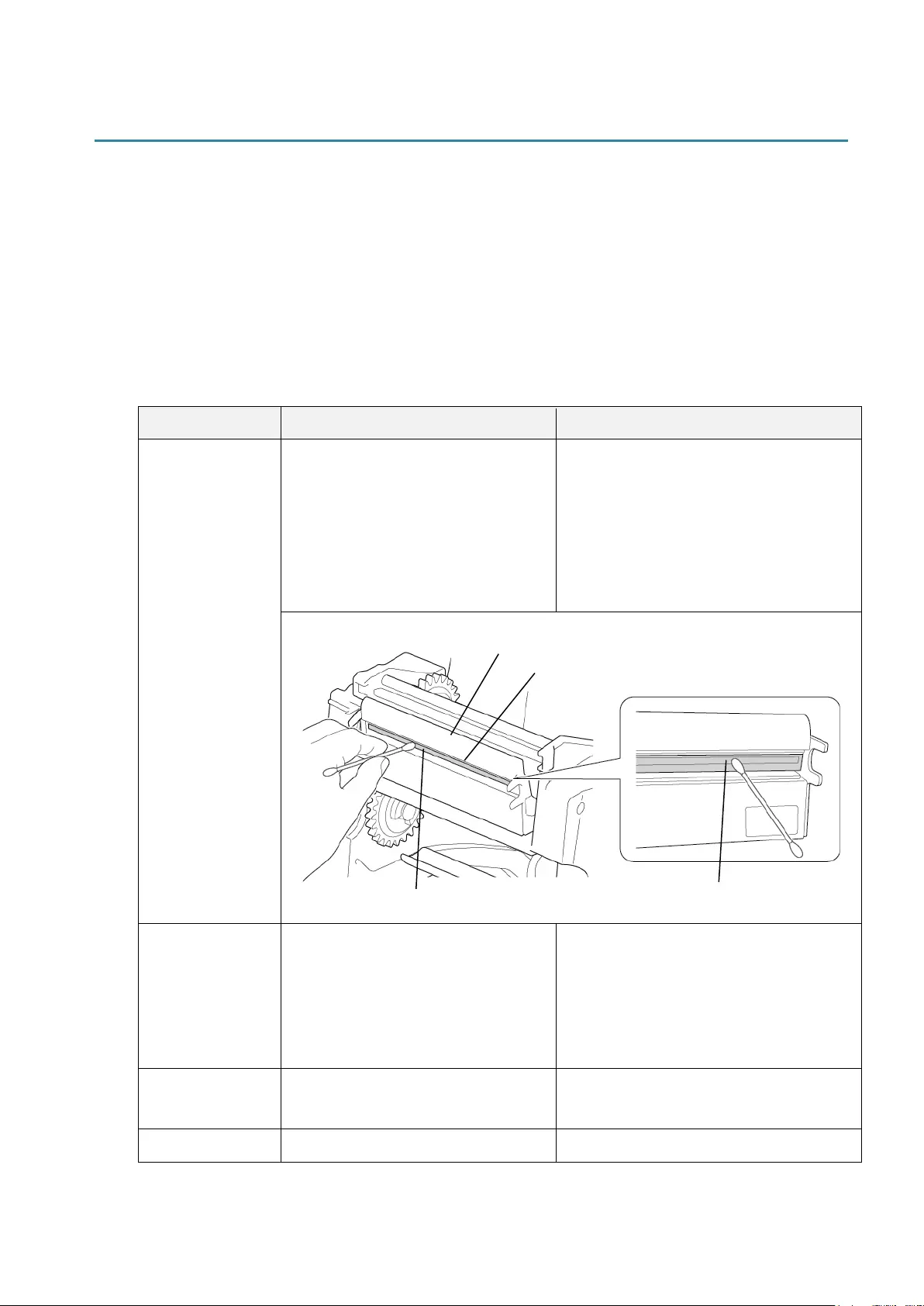

3.

a. First, insert the right side of the

Ribbon Rewind Spindle (marked “R”)

into the Ribbon Rewind Hub. Then,

insert the left side of the Ribbon

Rewind Spindle into the hole on the

left side of the Ribbon Rewind Hub.

b. Insert the right side of the Ribbon

Supply Spindle (marked “R”) into the

Ribbon Supply Hub. Then, insert the

left side of the Ribbon Supply

Spindle into the hole on the left side

of the Ribbon Supply Hub.

4. Thread the ribbon through the Print

Head and adhere the leader of the

ribbon onto the Ribbon Rewind

Paper Core.

IMPORTANT

Do not dispose of the Ribbon

Rewind Paper Core when replacing

the ribbon roll. This part is

necessary for the ribbon roll

replacement.

5. Using the Ribbon Rewind Gear,

rotate the Ribbon Rewind Hub until

the ribbon plastic leader is

thoroughly wound and the black

section of the ribbon covers the Print

Head.

a.

b.

11

3.2 Load the Media

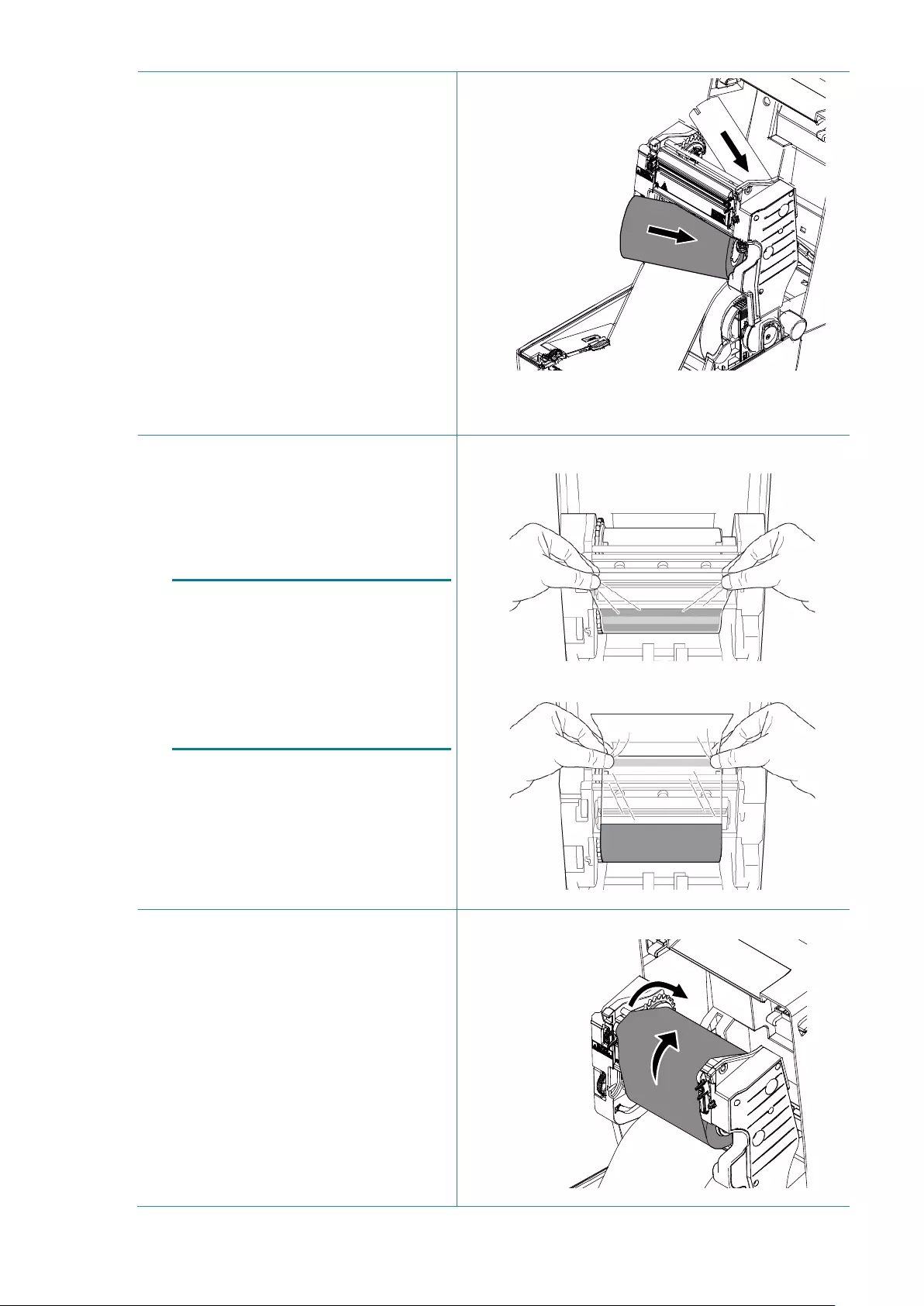

3.2.1 Load Label Roll

1. Press the tabs located on each

side of the printer, and then lift the

Roll Compartment Cover.

2. Slide both Roll Guides outwards.

3. Insert the paper roll with the labels

facing up, as shown in the

illustration.

Push down and slide the lock tab to

lock the Roll Guides into place.

Note

Make sure that the label print side

is facing up.

12

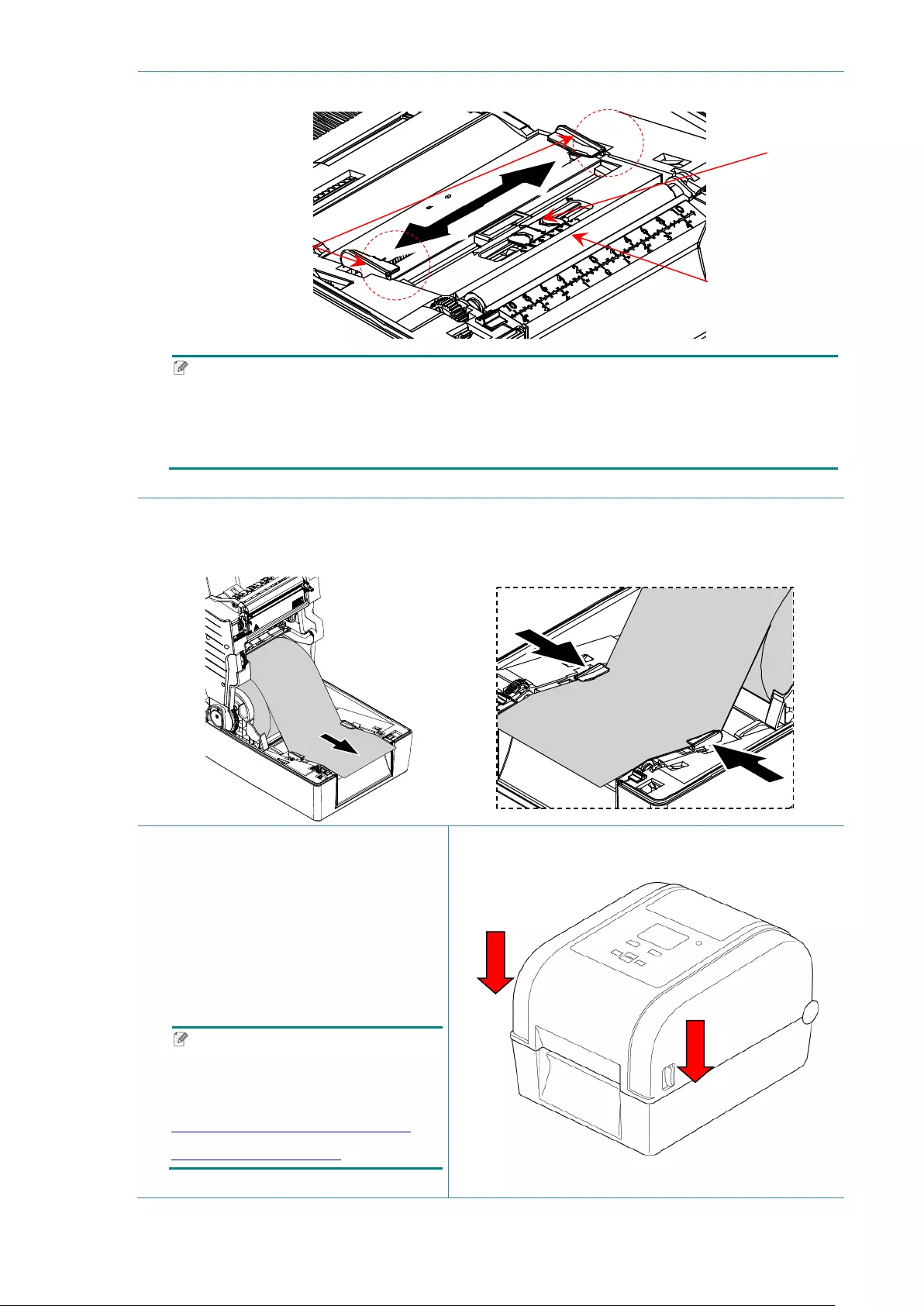

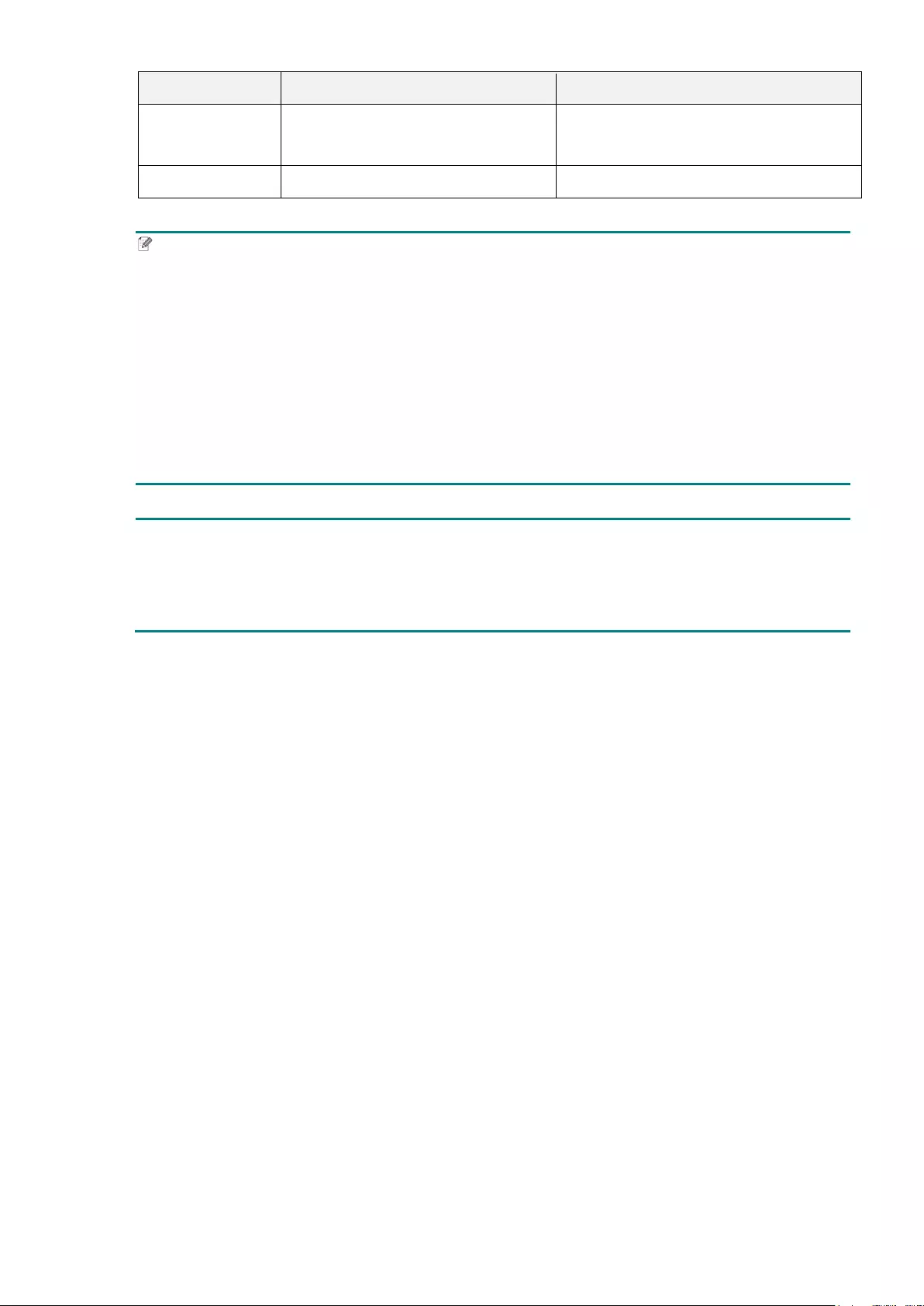

4. Slide the Media Guide Tips to the correct position.

Note

For black mark media or media with notches or holes used to indicate the label length,

the Black Mark sensor is moveable. Slide the Media Guide Tips to the correct position.

• For RFID models, slide the green RFID Antenna Slide to the correct position.

5. Place the paper, printing side face up, through the media sensor and place the first label’s

leading edge onto the Platen Roller. Adjust the green Media Guide Tips to fit the label width.

6. Press down on both sides of the Roll

Compartment Cover to close it gently.

7. Use the LCD menu or the Brother

Printer Management Tool (BPM) to

set the media sensor type and

calibrate the selected sensor.

Note

For more information about sensor

calibration, see section

7.2. Auto-Calibrating the Media

Sensor using the BPM.

M

edia Guide Tips

Black

Mark

S

ensor

RFID

Antenna Slide

(

TD-

4650TNWBR and

TD

-4750TNWBR)

13

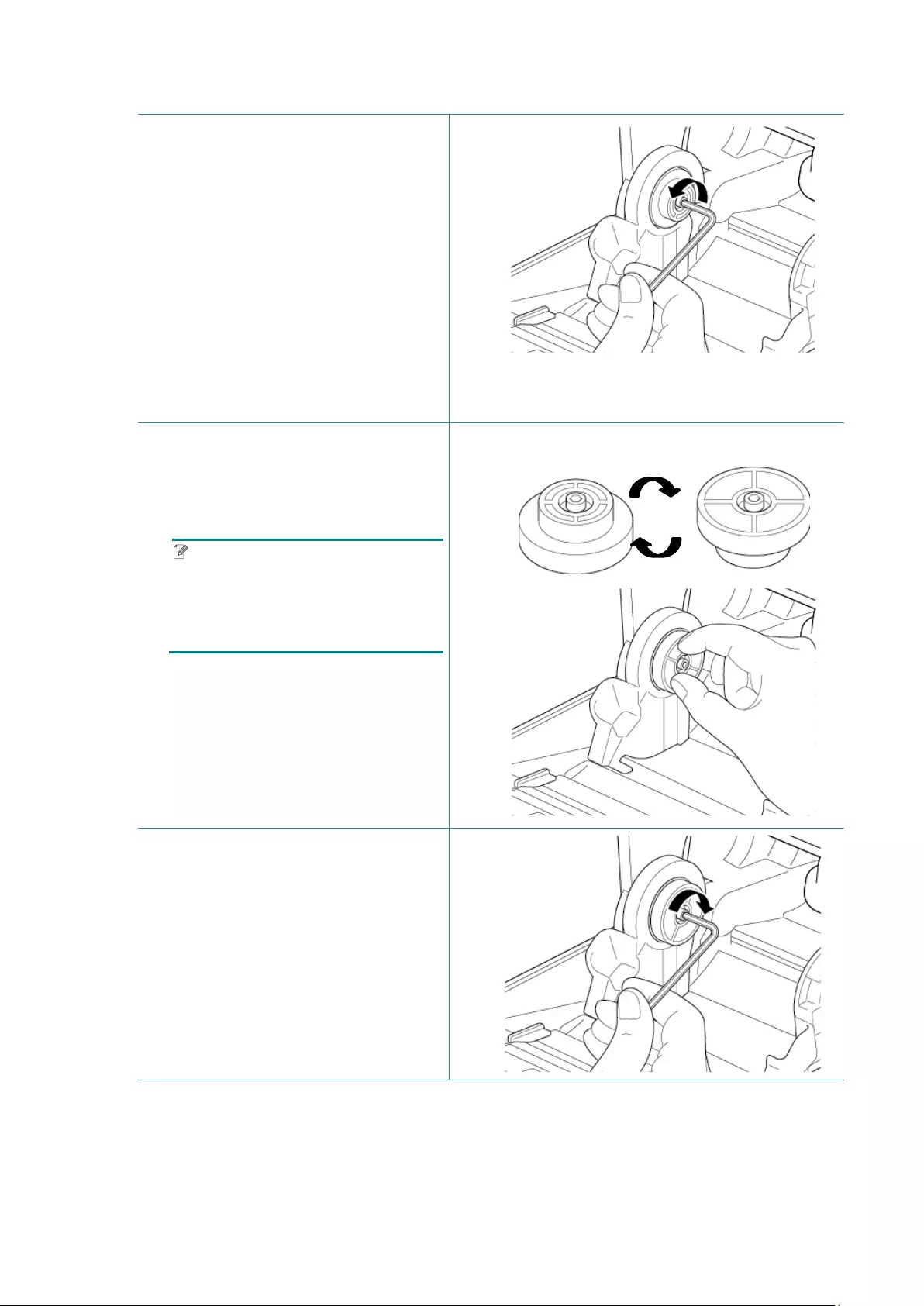

Convert 1" (25.4 mm) to 1.5" (38.1 mm) Core Roll Guides

1. Use a 3/32" (2.5 mm) hex key

(purchased separately) to remove

the Media Adapter located on both

sides of the Roll Guides.

2. Reverse the direction of the Media

Adapter and align it with the Roll

Guide.

Note

The Roll Guide can be converted

from a 1" core to 1.5" core by

reversing the Media Adapter.

For 1" core For 1.5" core

3. Reinstall the Media Adapter and

use the hex key to secure it onto

the Roll Guides.

14

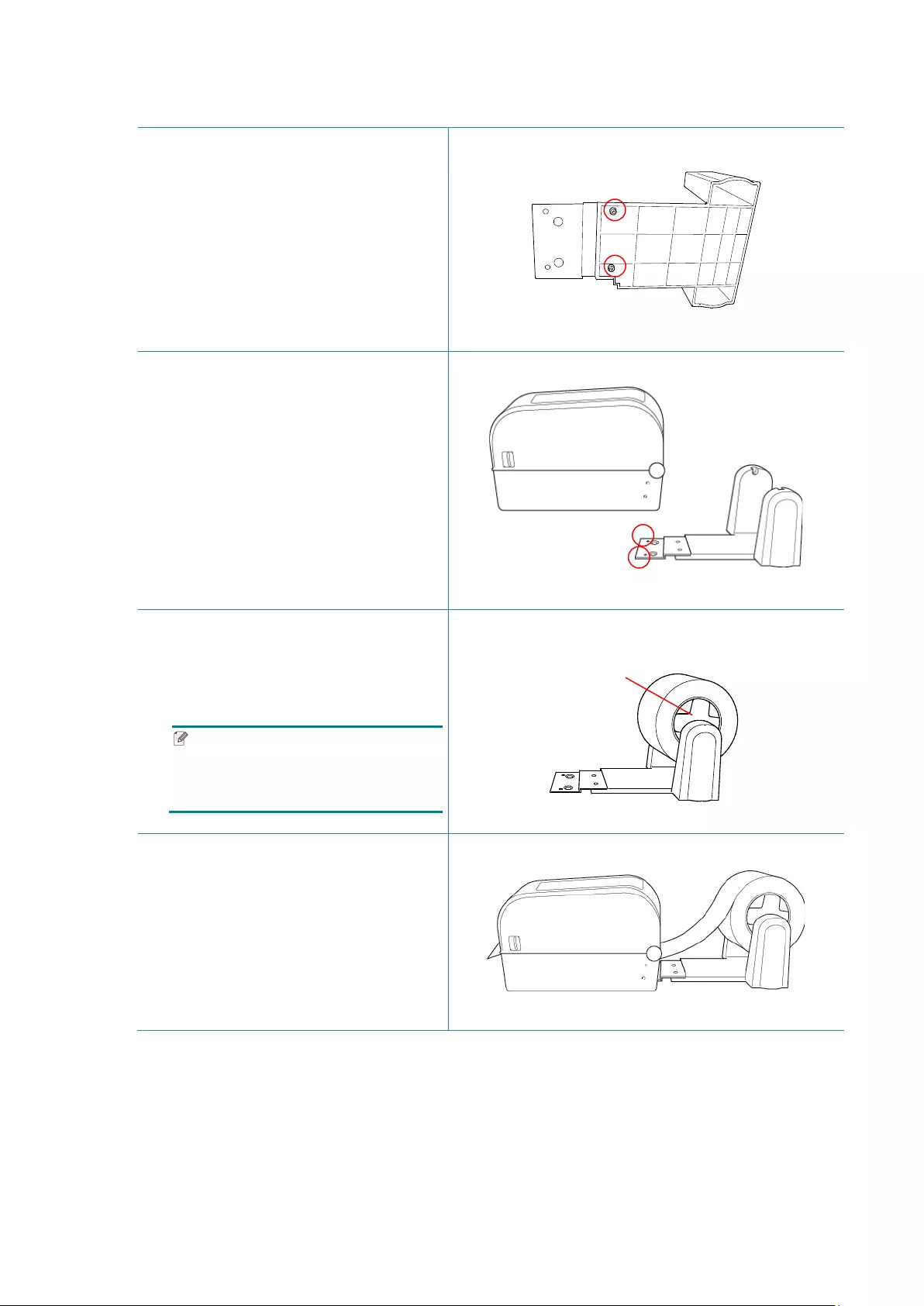

3.2.2 Install the External Roll Holder (Optional)

1. Tighten the screws on the metal

fittings of the extended plate.

2. Attach the extended plate to the

bottom of the printer.

3. Insert a 3" (76.2 mm) Label Spindle

into a paper roll. Then, install it on

the External Roll Holder.

Note

Make sure that the label print side

is facing up.

4. Feed the media through the feed

slot in the back of the printer.

3" (76.2 mm)

Label Spindle

15

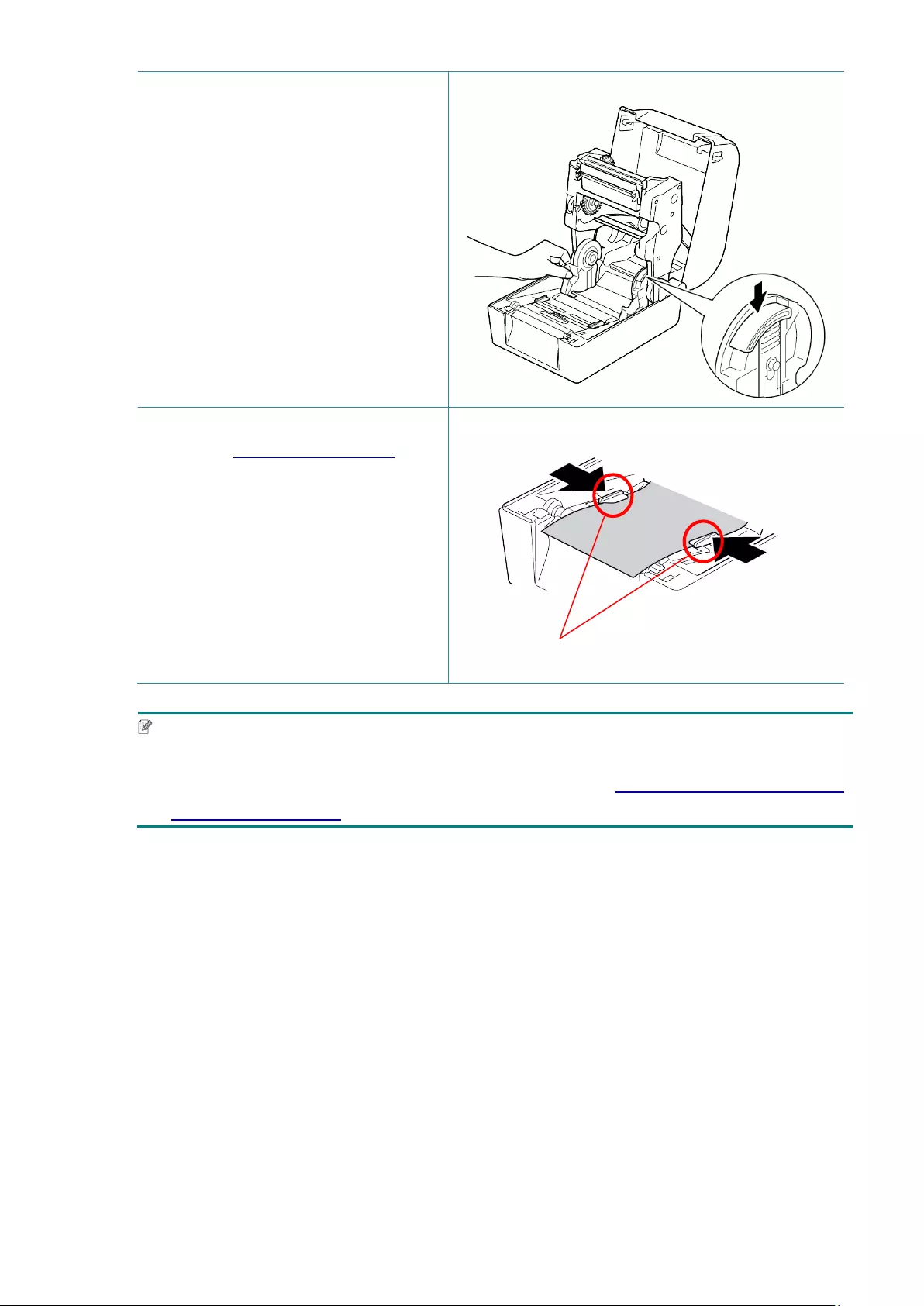

5. Open the Roll Compartment Cover.

Slide the Roll Guides outwards,

and then align the paper width with

the Roll Guides. Push down and

slide the lock tab to lock the Roll

Guides into place.

6. Install the label roll as described in

section 3.2.1 Load Label Roll.

7. Feed the media through the media

sensor. Adjust the Media Guide

Tips to fit the label width.

8. Use the Brother Printer

Management Tool (BPM) or LCD

menu to set the media sensor type

and calibrate the selected sensor.

Note

Calibrate the Gap/Black Mark Sensor every time you change the media.

For more information about sensor calibration, see section 7.2 Auto-Calibrating the Media

Sensor using the BPM.

Media Guide Tips

16

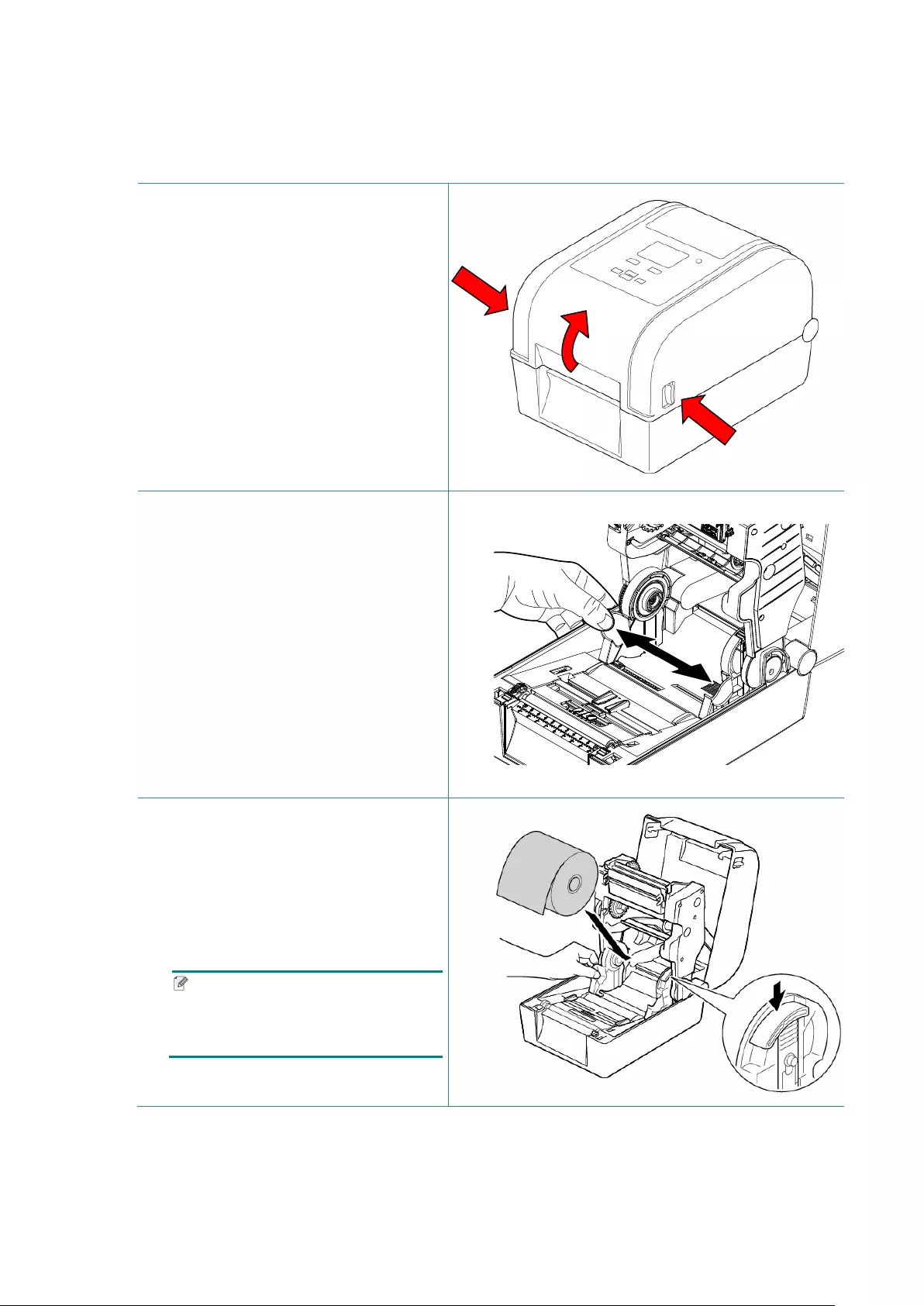

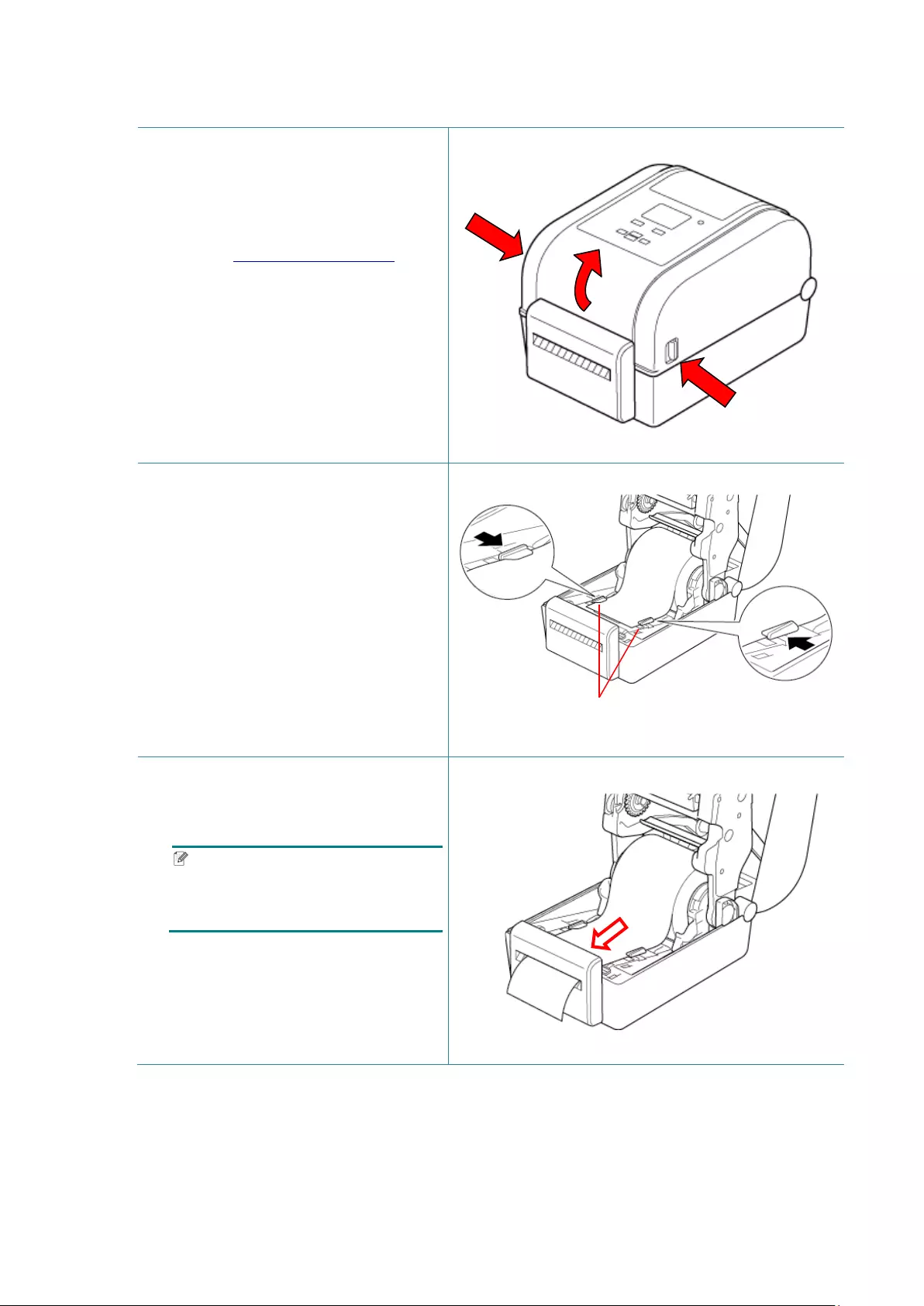

3.2.3 Install the Label Roll When Using the Cutter Module (Dealers only)

1. Press the tabs located on each

side of the printer, and then lift the

Roll Compartment Cover.

2. Install the label roll as described in

section 3.2.1 Load Label Roll.

3. Use the Brother Printer

Management Tool (BPM) to set the

media sensor type and calibrate

the selected sensor.

4. Feed the label roll through the

media sensor. Adjust the Media

Guide Tips to fit the label width.

5. Push the label roll through the

Cutter Output Slot.

Note

Make sure that the label print side

is facing up.

Media Guide Tips

17

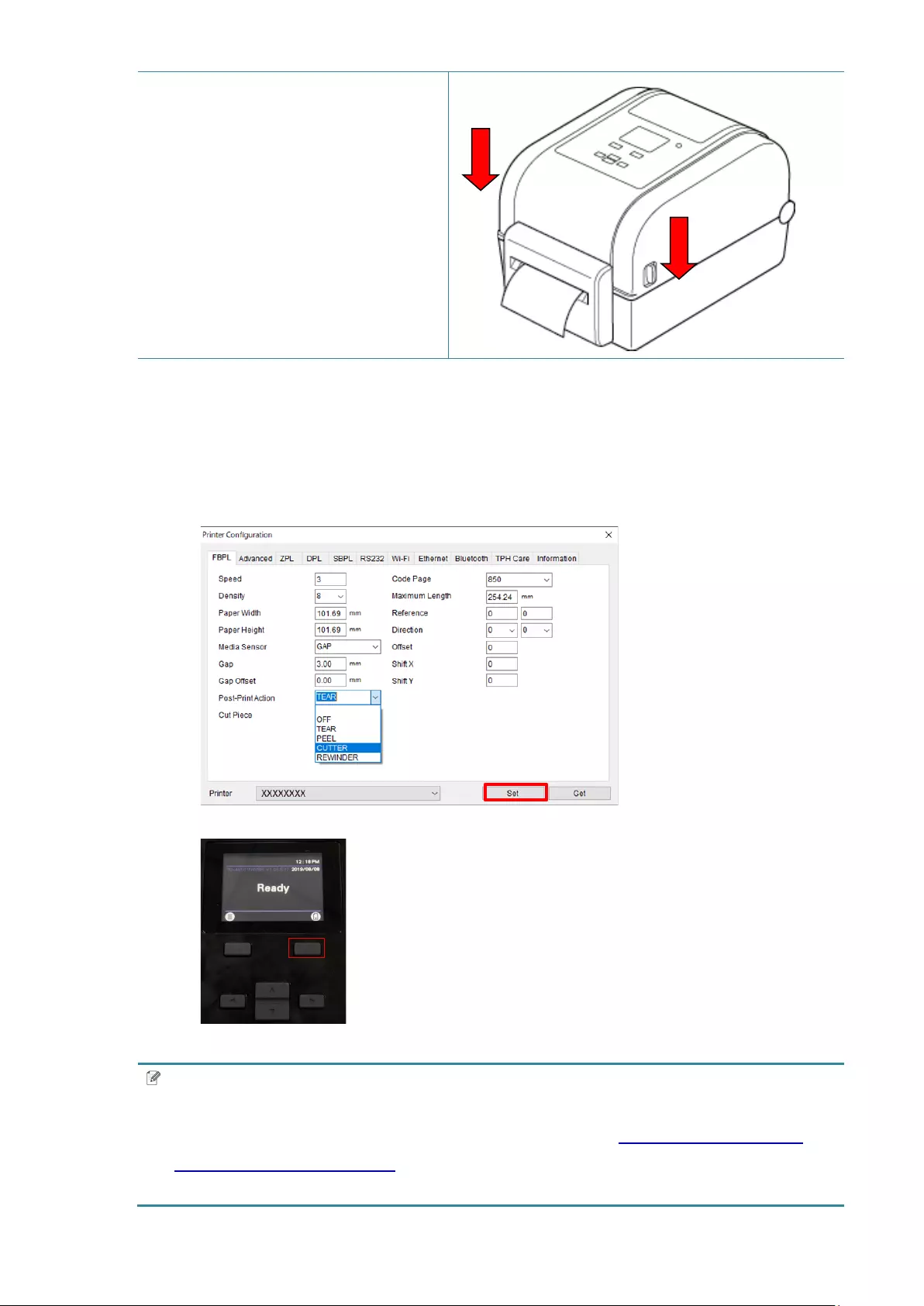

6. Close the Roll Compartment

Cover.

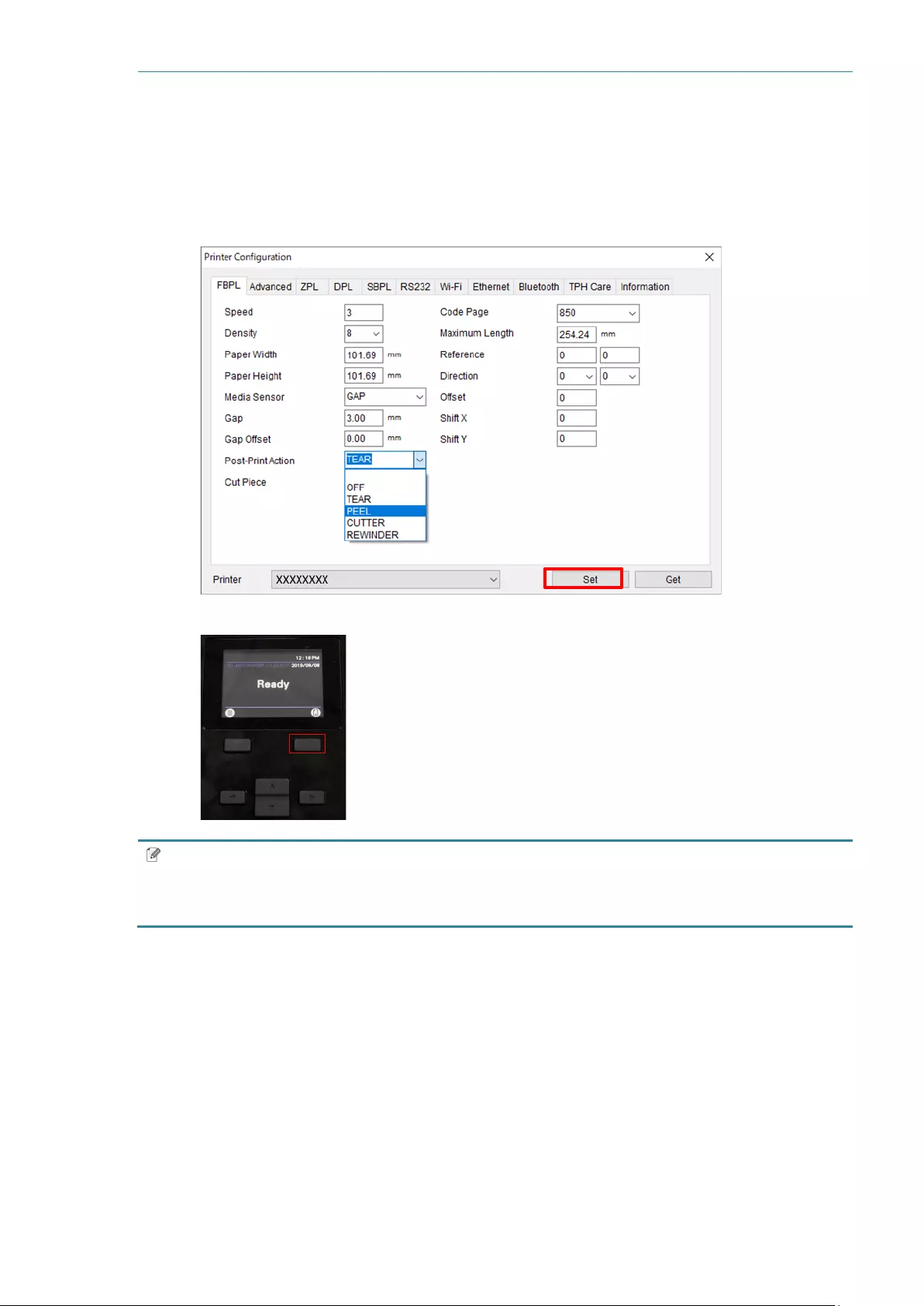

7. Use the Brother Printer Management Tool (BPM) to set the printer for Cutter Mode.

a. Start the BPM.

b. Click the Printer Configuration button.

c. Click the FBPL tab.

d. Click the CUTTER option from the Post-Print Action drop-down list.

e. Click Set.

f. Press the Feed/Pause button to test.

Note

Calibrate the Gap/Black Mark Sensor every time you change the installed media.

For more information about sensor calibration, see section 7.2 Auto-Calibrating the

Media Sensor using the BPM.

Printer settings can also be changed using the LCD.

18

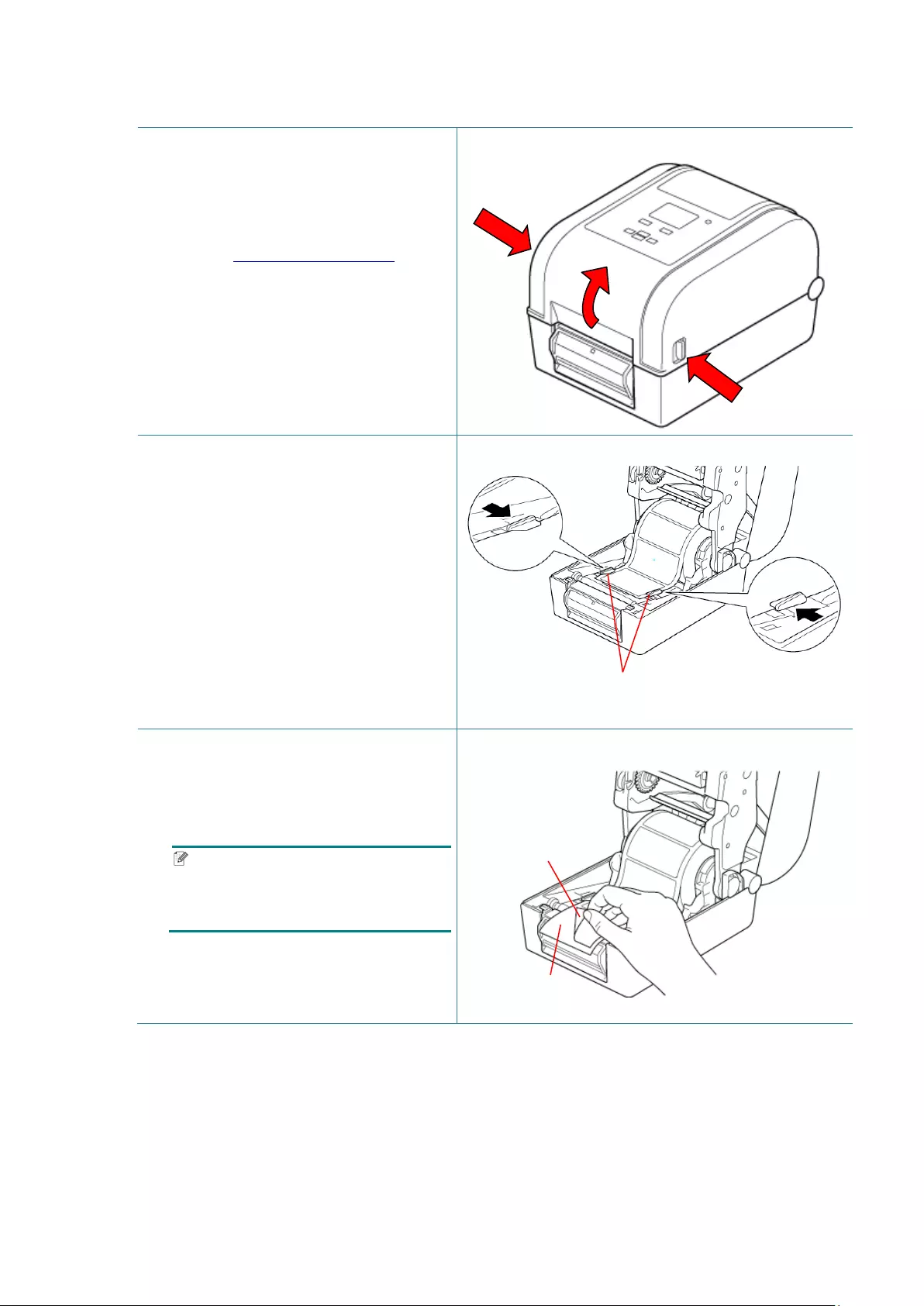

3.2.4 Install the Label Roll When Using the Label Peeler (Dealers only)

1. Press the tabs located on each side

of the printer, and then lift the Roll

Compartment Cover.

2. Install the label roll as described in

section 3.2.1 Load Label Roll.

3. Use the Brother Printer

Management Tool (BPM) to set the

media sensor type and calibrate the

selected sensor.

4. Feed the label roll through the

media sensor. Adjust the Media

Guide Tips to fit the label width.

5. Pull the media out of the printer and

remove some labels, leaving only

the liner.

Note

Make sure that the label print side is

facing up.

Media Guide Tips

Liner

Label

19

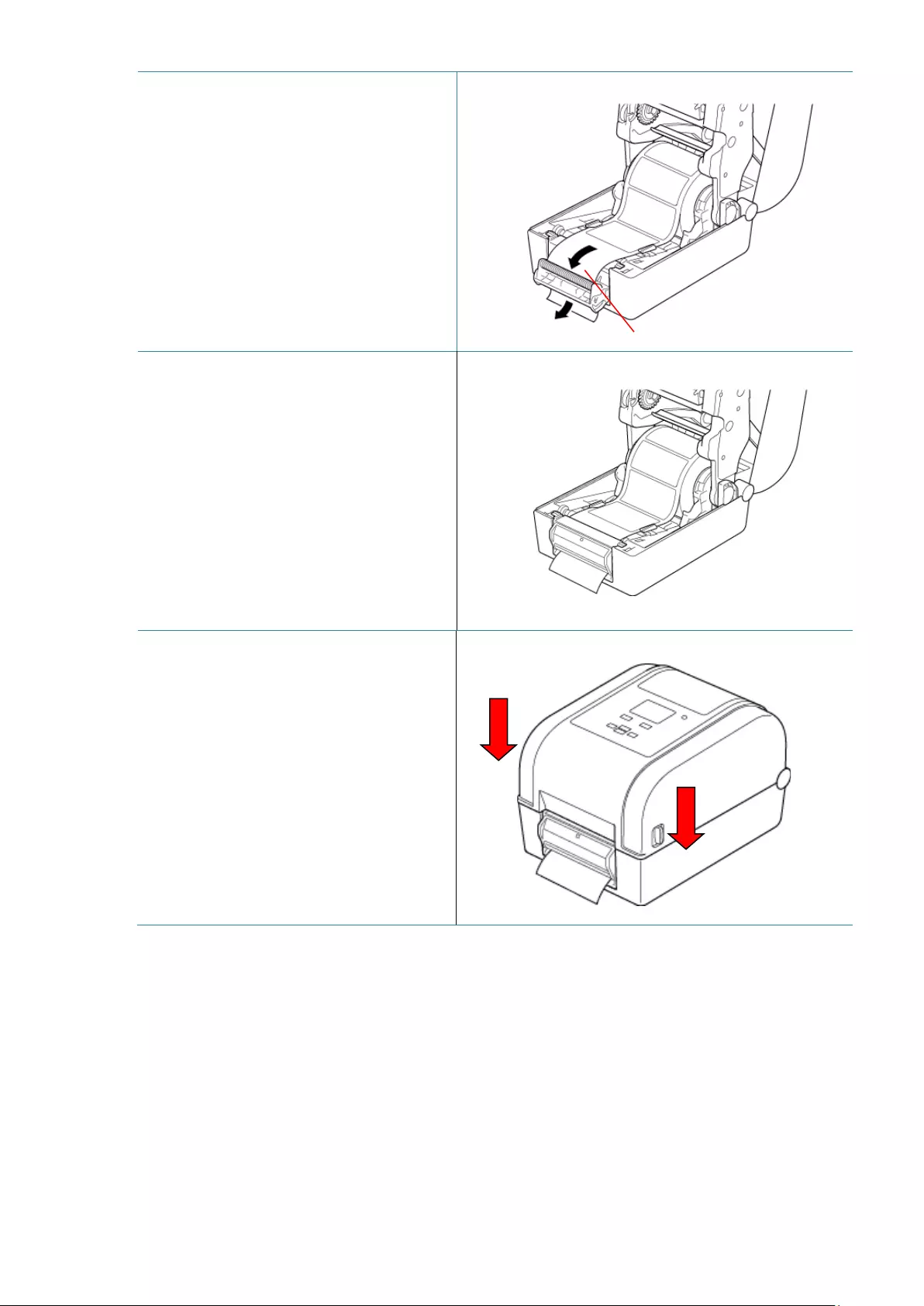

6. Open the Label Peeler Cover. Feed

the liner into the Label Peeler Cover

Slot.

7. Close the Label Peeler Module.

8. Close the Roll Compartment Cover.

Label Peeler Cover Slot

20

9. Use the Brother Printer Management Tool (BPM) to set Label Peeler Mode.

a. Start the BPM.

b. Click the Printer Configuration button.

c. Click the FBPL tab.

d. Click the PEEL option from the Post-Print Action drop-down list.

e. Click Set.

f. Press the Feed/Pause button to test.

Note

The Label Peeler Module supports only plain paper labels.

Printer settings can also be changed using the LCD.

21

4. Printing

4.1 Printer Driver Installation

Note

The model name and serial number are located on the back of the printer.

The driver installation method depends on the connection type:

USB Connection (Windows/Mac/Linux)

Bluetooth Connection (Windows)

Wi-Fi Network Connection (Windows)

Wired Network Connection (Windows)

4.1.1 USB Connection (Windows/Mac/Linux)

Note

Mac/Linux Users

For more information about driver installation, see the driver installation guide provided with

the driver.

1. Connect your printer to the computer using a USB cable.

2. Visit support.brother.com, go to your model's Downloads page, and download the latest

printer driver and software.

3. Run the Seagull Driver Wizard application and select Install printer drivers and USB.

4. Follow the on-screen instructions.

Note

If you cannot install a printer driver:

Install a printer driver manually:

In the Seagull Driver Wizard application, select Install printer drivers > Others.

Remove the printer drivers:

In the Seagull Driver Wizard application, select Remove printer drivers > Automatically

remove all Drivers by Seagull or Use advanced printer driver removal options.

Reset the printer settings:

Start the BPM, and then click Printer Function > Factory Default.

22

4.1.2 Bluetooth Connection (Windows)

1. Check the Bluetooth Local Name:

Using the BPM

a. Connect the printer to the computer using a USB cable.

b. Click Printer Configuration > Bluetooth.

Using the LCD

Select Interface > Bluetooth.

2. Turn on your computer’s Bluetooth feature.

3. Pair the computer with the printer by selecting Start > Settings > Devices > Bluetooth &

other devices and enabling Bluetooth.

4. Select Add Bluetooth or other device and select your printer.

5. Visit support.brother.com, go to your model's Downloads page, and download the latest

printer driver and software.

6. Run the Seagull Driver Wizard application and select Install printer drivers and Bluetooth.

7. Follow the on-screen instructions.

Note

If you cannot install a printer driver:

Remove the printer drivers:

In the Seagull Driver Wizard application, select Remove printer drivers > Automatically

remove all Drivers by Seagull or Use advanced printer driver removal options.

Reset the printer settings:

Start the BPM, and then click Printer Function > Factory Default.

4.1.3 Wi-Fi Network Connection (Windows)

Make sure both your wireless router/access point's and your printer's network settings are correctly

set up. For more information, see the documentation provided with your wireless router/access point,

or contact the router manufacturer, your system administrator, or Internet service provider.

1. Configure the network settings:

- Using the BPM

a. Connect your printer to the computer using a USB cable.

b. Click Printer Configuration > Wi-Fi.

c. Specify SSID, Encryption, and Key (Network Password), and then click Set.

d. Click Get and confirm that the printer's IP address is correct.

When finished, the Wi-Fi icon and printer's IP address appear on the LCD.

23

- Using the LCD

a. Select Interface > Wi-Fi.

b. Specify SSID, Encryption, and Password.

c. When finished, the Wi-Fi icon and printer's IP address appear on the LCD.

2. Visit support.brother.com, go to your model's Downloads page, and download the latest

printer driver and software.

3. Run the Seagull Driver Wizard application and select Install printer drivers and Network.

4. Select your printer, and then click Next.

5. If your TCP/IP port does not appear in the list, click Create port and select Standard

TCP/IP port > New Port.

6. Type your printer’s IP address and port name, and then click Next.

7. Click Finish.

8. Return to the Specify Port window and select the port you created.

9. Follow the on-screen instructions.

Note

If you cannot install a printer driver:

Remove the printer drivers:

In the Seagull Driver Wizard application, select Remove printer drivers > Automatically

remove all Drivers by Seagull or Use advanced printer driver removal options.

Reset the printer settings:

Start the BPM, and then click Printer Function > Factory Default.

4.1.4 Wired Network Connection (Windows)

1. Connect both the printer and the computer to your router/access point using LAN cables.

The printer automatically receives a default IP address and displays it on the LCD.

2. Visit support.brother.com, go to your model's Downloads page, and download the latest

printer driver and software.

3. Run the Seagull Driver Wizard application and select Install printer drivers and Network.

4. Select your printer, and then click Next.

5. If your TCP/IP port does not appear in the list, click Create port and select Standard

TCP/IP port > New Port.

6. Type your printer’s IP address and port name, and then click Next.

7. Click Finish.

8. Return to the Specify Port window and select the port you created.

9. Follow the on-screen instructions.

24

Note

If you cannot install a printer driver:

Remove the printer drivers:

In the Seagull Driver Wizard application, select Remove printer drivers > Automatically

remove all Drivers by Seagull or Use advanced printer driver removal options.

Reset the printer settings:

Start the BPM, and then click Printer Function > Factory Default.

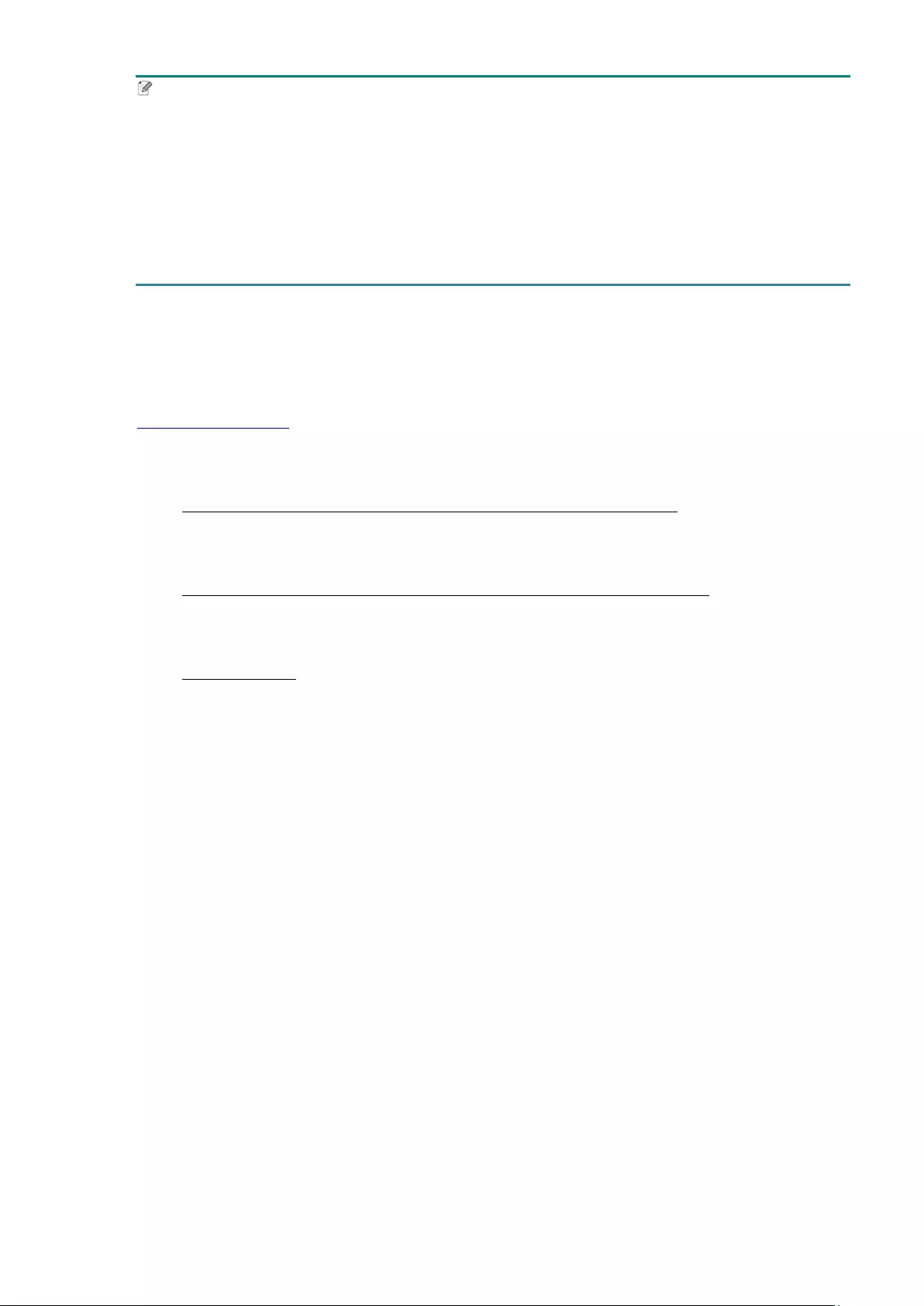

4.2 Creating and Printing Labels Using BarTender

BarTender is a label creation tool, which can be downloaded for free from the product's page at

support.brother.com.

1. Launch BarTender.

• For Windows 10, Windows Server 2016, or Windows Server 2019:

Start > BarTender 2016 R7 UltraLite > click BarTender UltraLite, or double-click the

BarTender UltraLite icon on the desktop.

• For Windows 8.1, Windows Server 2012, or Windows Server 2012 R2:

Click BarTender UltraLite on the application screen, or double-click the BarTender

UltraLite icon on the desktop.

• For Windows 7:

Start > All Programs > BarTender 2016 R7 UltraLite > click BarTender UltraLite, or

double-click the BarTender UltraLite icon on the desktop.

25

2. Follow the on-screen steps to create a label.

Note

For more information on using BarTender, click Help.

3. Click File > Print to print the label.

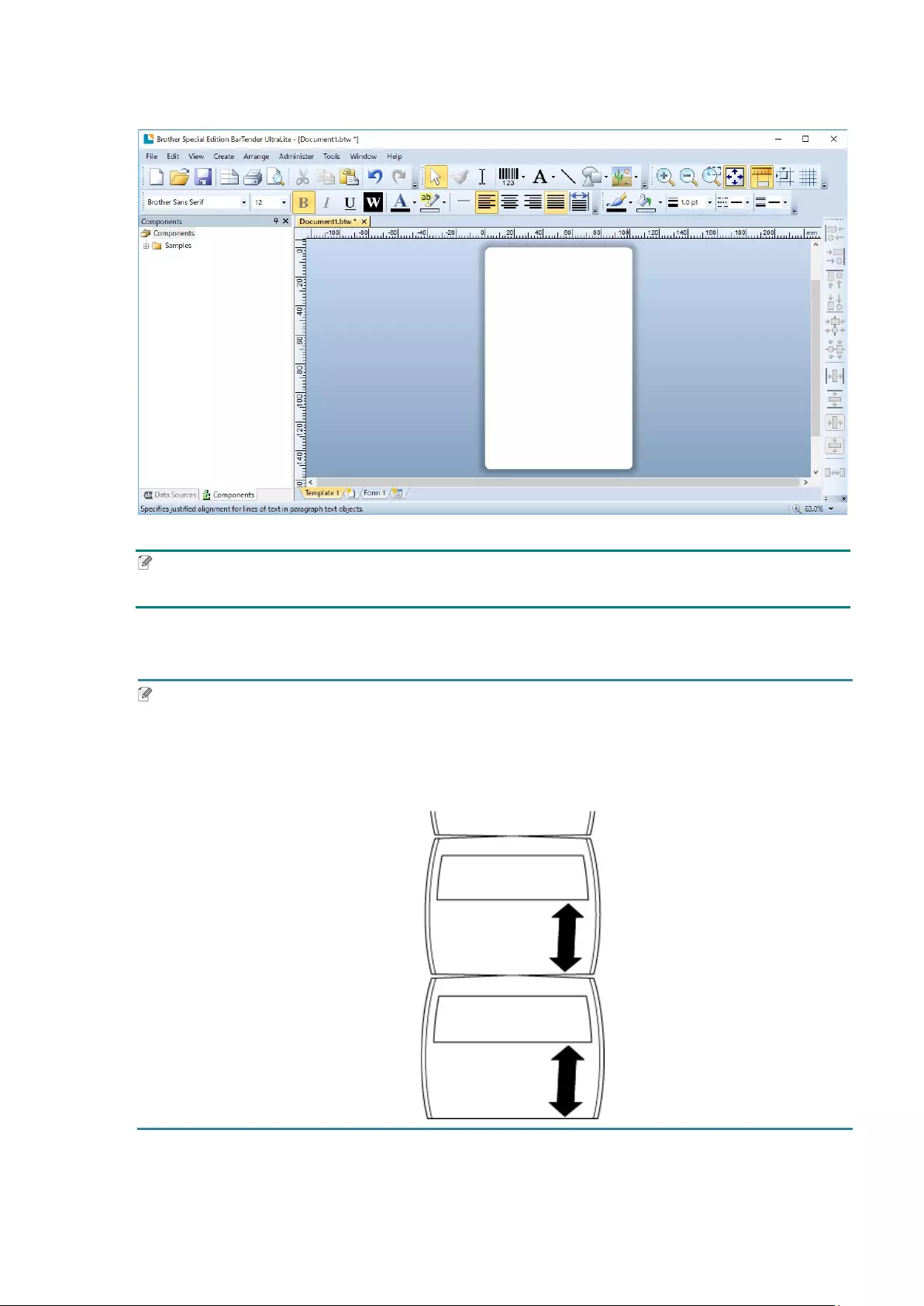

Note

When the Partial Cut setting is selected, a blank area of about

2.4" (60 mm) is added between

the cut line and the print area, as illustrated

.

Partial Cut

is only available when the Cutter Module is installed on your printer.

additional

length

additional

length

26

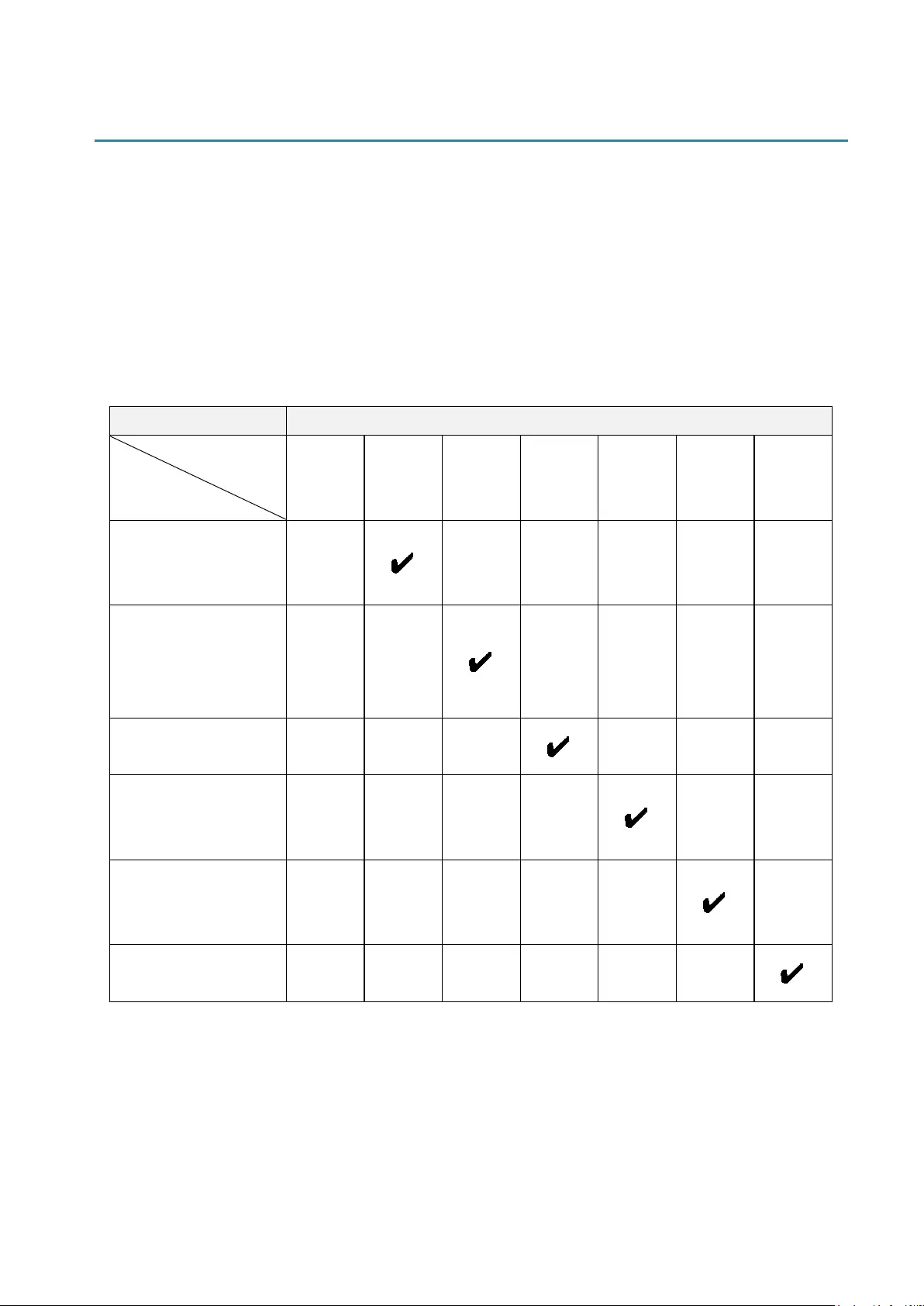

5. Operation

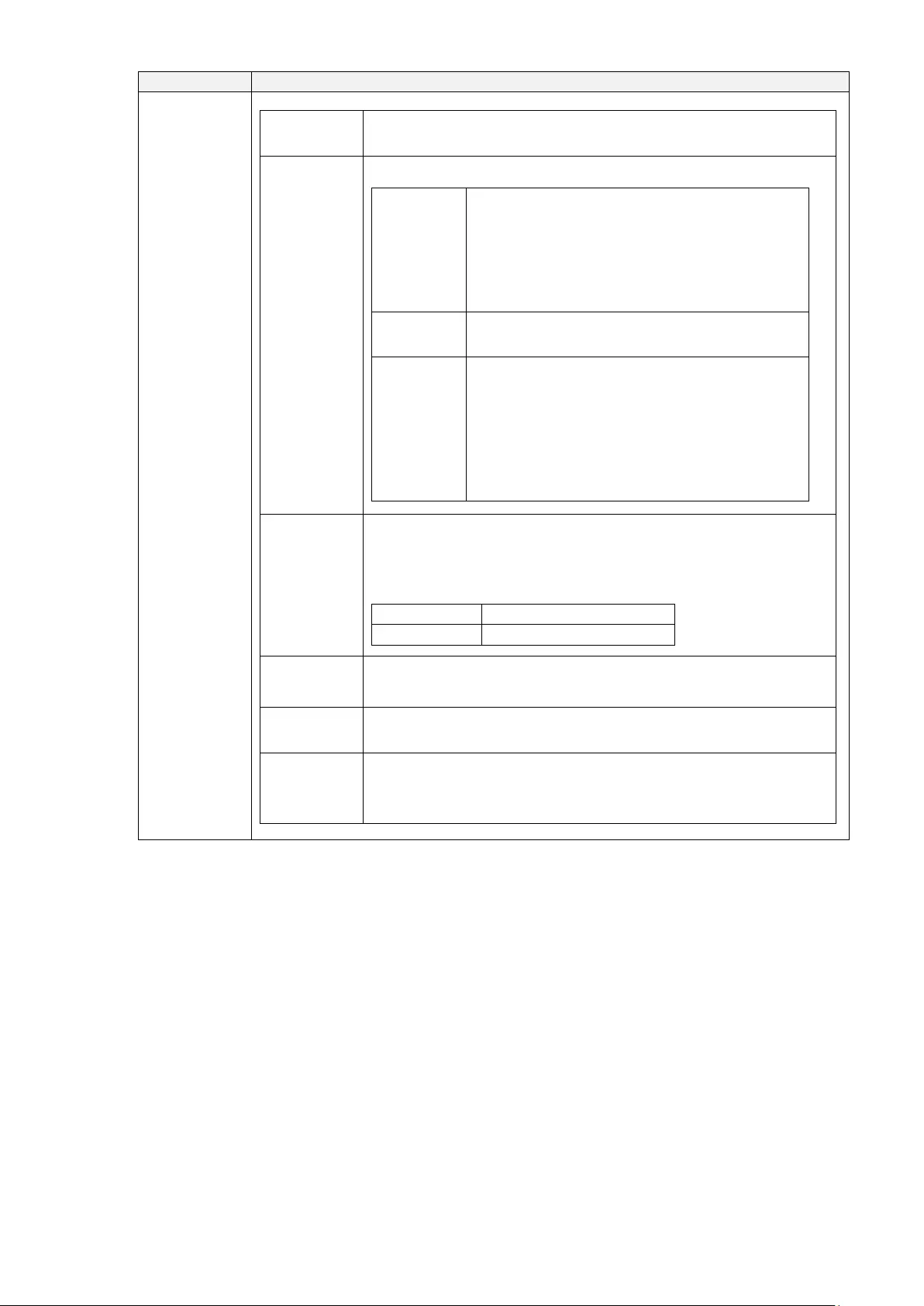

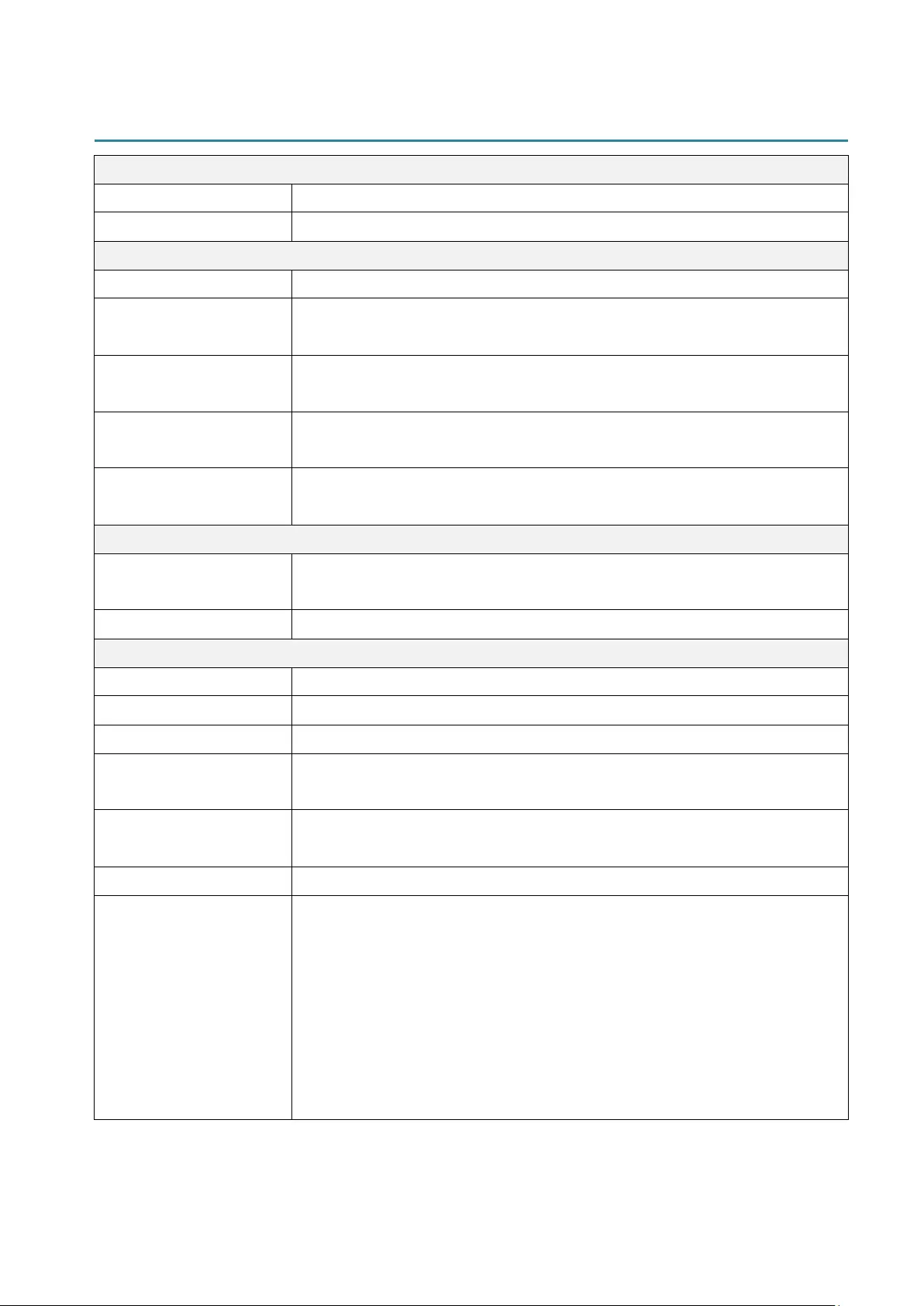

5.1 Power-on Utilities

There are six power-on utilities to set up and test the printer's functions.

To activate a power-on utility:

1. Turn off the printer.

2. Press and hold the Feed/Pause button, and then turn on the printer.

3. Release the button when the LED indicates the function you want:

Power-On Utility LED Patterns

LED color

Function

Amber

(Lit)

Red/

Amber

(5 times)

Amber

(5 times)

Green/

Red

(5 times)

Green

(5 times)

Red

(5 times)

Green

(Lit)

1. Ribbon and

Gap/Black Mark

Sensor calibration

2. Gap/Black Mark

Sensor calibration,

self-

test, and entering

dump mode

3. Printer initialization

4. Media sensor

calibration (for the

Black Mark Sensor)

5. Media sensor

calibration (for the

Gap Sensor)

6. Skip the AUTO.BAS

program

27

5.1.1 Ribbon and Gap/Black Mark Sensor Calibration

The Gap/Black Mark Sensors’ sensitivity should be calibrated when:

You purchase a new printer.

You change label stock.

The label printer initializes.

To calibrate the Ribbon and Gap/Black Mark Sensors:

1. Turn off the printer.

2. Press and hold the Feed/Pause button, and then turn on the printer.

3. Release the button when the LED is flashing in red/amber.

Note

The LED color will change as follows:

Amber (lit) red/amber (5 times) amber (5 times) green/red (5 times)

green (5 times) red (5 times) green (lit)

To select the sensor for calibration, send the correct command to the printer:

For the Gap Sensor: send the GAP command

For the Black Mark Sensor: send the BLINE command

For more information about the available commands, see the FBPL Command Reference

Manual on your model's Manuals page at support.brother.com.

5.1.2 Gap/Black Mark Sensor Calibration, Self-Test, and Entering Dump

Mode

Calibrate the Gap or Black Mark Sensor if the sensor's settings used in the last print job are not

suitable for the current print job. During the calibration of the Gap/Black Mark Sensor, the

printer detects the label length, prints the internal configuration (self-test), and then enters

Dump Mode.

To calibrate the Gap/Black Mark Sensor:

1. Turn off the printer.

2. Press and hold the Feed/Pause button, and then turn on the printer.

3. Release the button when the LED is flashing in amber.

Note

The LED color will change as follows:

Amber (lit) red/amber (5 times) amber (5 times) green/red (5 times) green (5 times)

red (5 times) green (lit)

28

4. The printer calibrates the sensor and detects the label length, prints the internal settings,

and then enters Dump Mode.

Note

To select the sensor for calibration, send the correct command to the printer:

For the Gap Sensor: send the GAP command

For the Black Mark Sensor: send the BLINE command

For more information about the available commands, see the FBPL Command Reference

Manual on your model's Manuals page at support.brother.com.

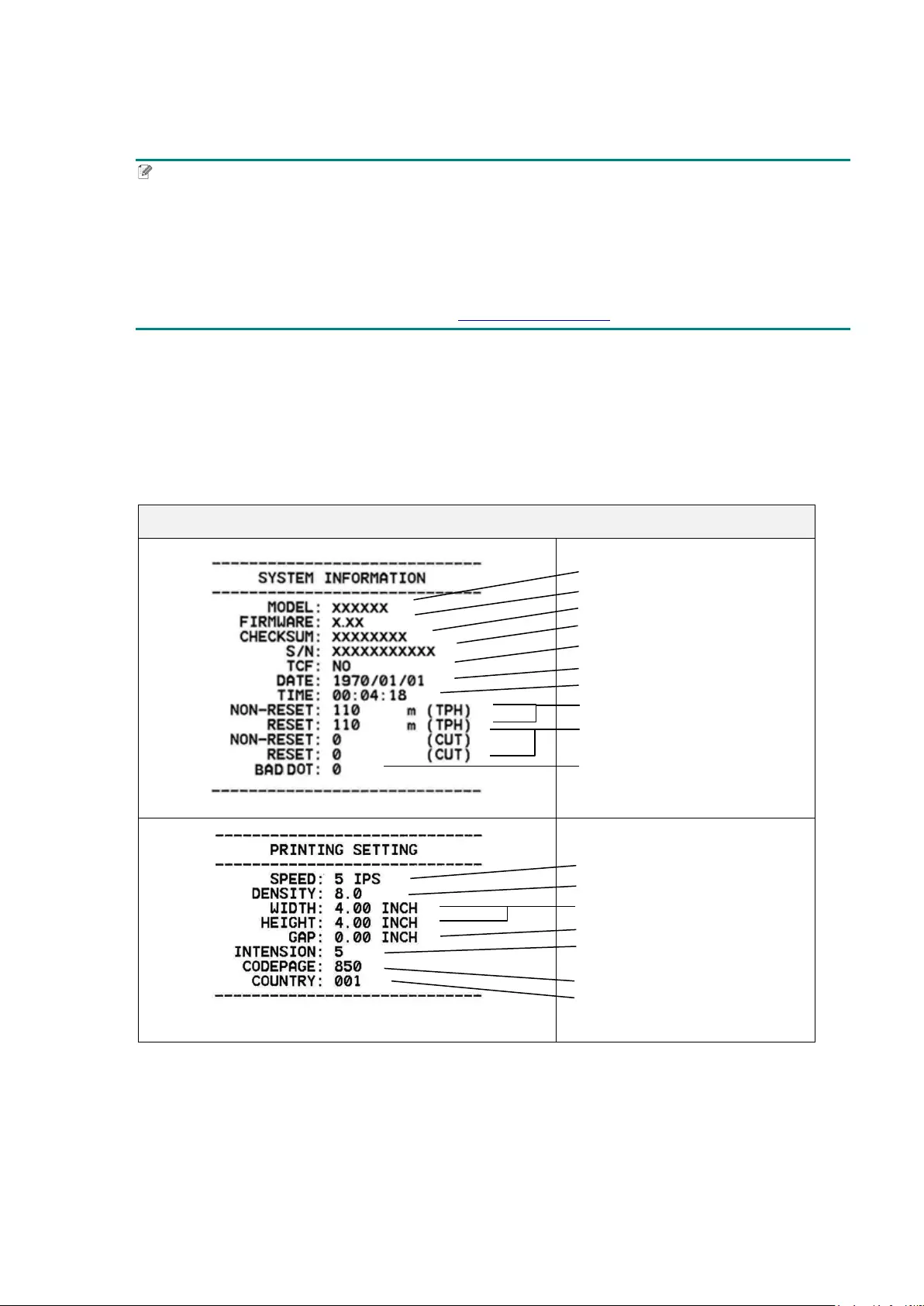

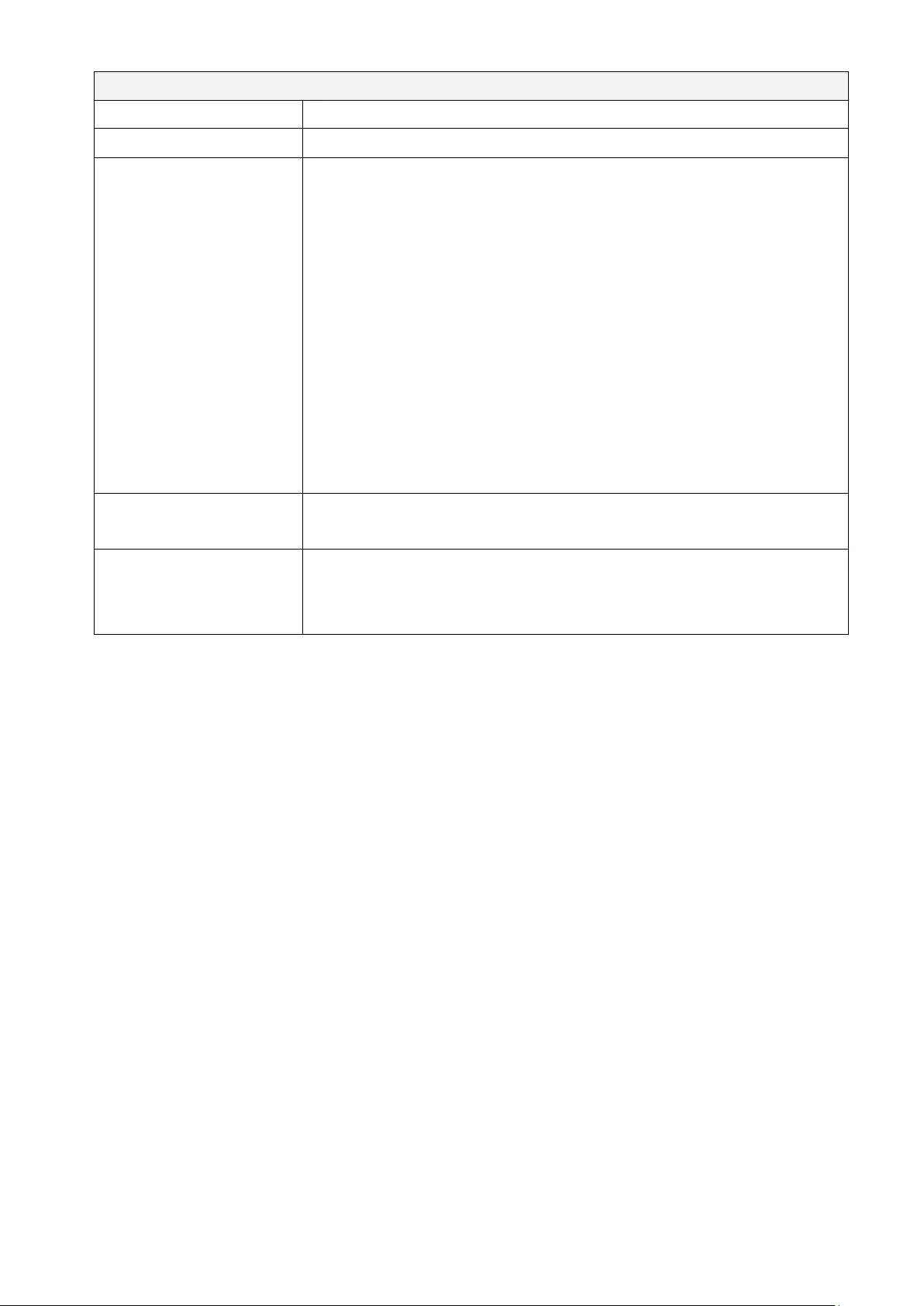

Self-test

Print the printer configuration after you run Gap/Black Mark Sensor calibration. The self-test

printout lists the printer's configuration and available memory, and can indicate if there is any

dot damage on the heater component.

Self-test printout

Model name

Firmware version

Firmware checksum

Printer serial number

Configuration file

System date

System time

Printed mileage (meter)

Cutting counter

Number of defective dots

Print speed (inch/sec)

Print density

Label size (inch)

Gap distance (inch)

Gap/Black Mark Sensor

sensitivity

Code page

Country code

29

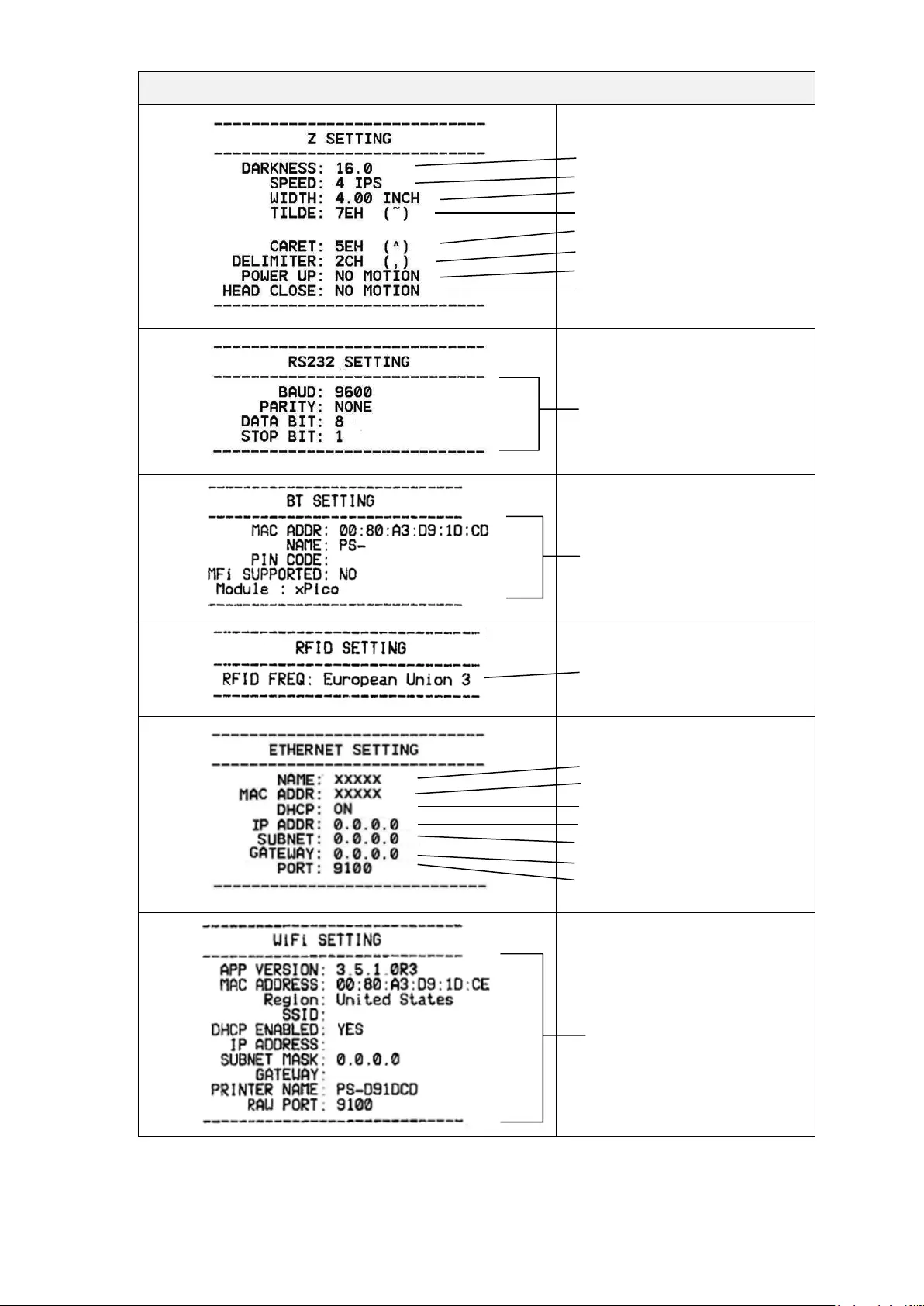

Self-test printout

Print darkness

Print speed (inch/sec)

Label size

Control prefix

Format prefix

Delimiter prefix

Printer power up motion

Print Head close motion

RS232 Serial Port

configuration

Bluetooth configuration

Country of RFID frequency

band

Printer name

Mac Address

DHCP

IP Address

Subnet Mask

Gateway

RAW Port

Wi-Fi configuration

30

Self-test printout

Number of downloaded files

Total and available memory

space

Print Head check pattern

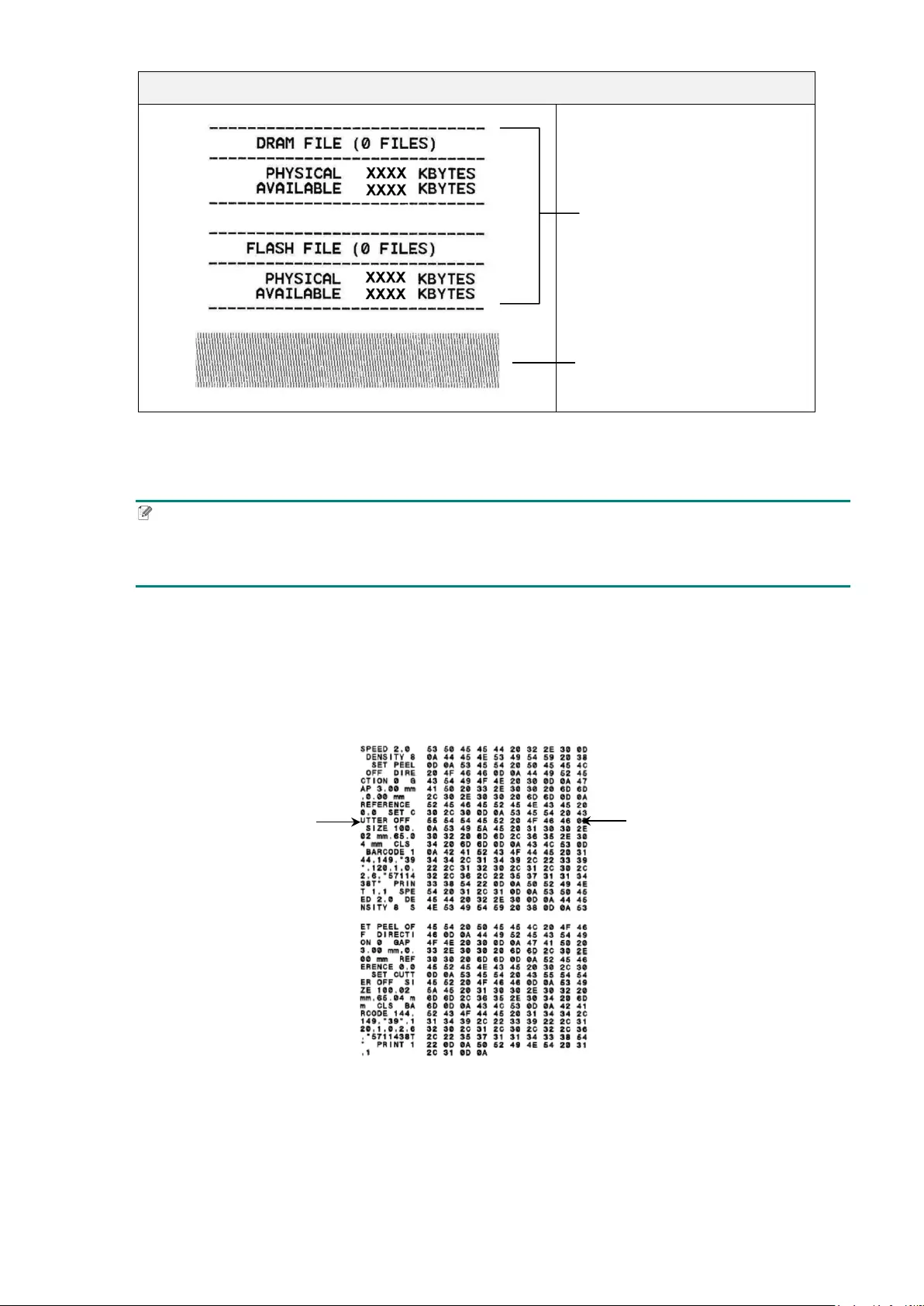

Dump Mode

Note

Dump Mode requires 4" (101.5 mm) wide paper.

To resume normal printing, turn the printer off and then on again.

The printer enters Dump Mode after printing the printer configuration. Dump Mode allows

users to verify and debug the printer's programs. The characters in the left column are

received from the printer's system and those in the right column are their hexadecimal

representation.

ASCII data Hexadecimal

representation of the

ASCII data

31

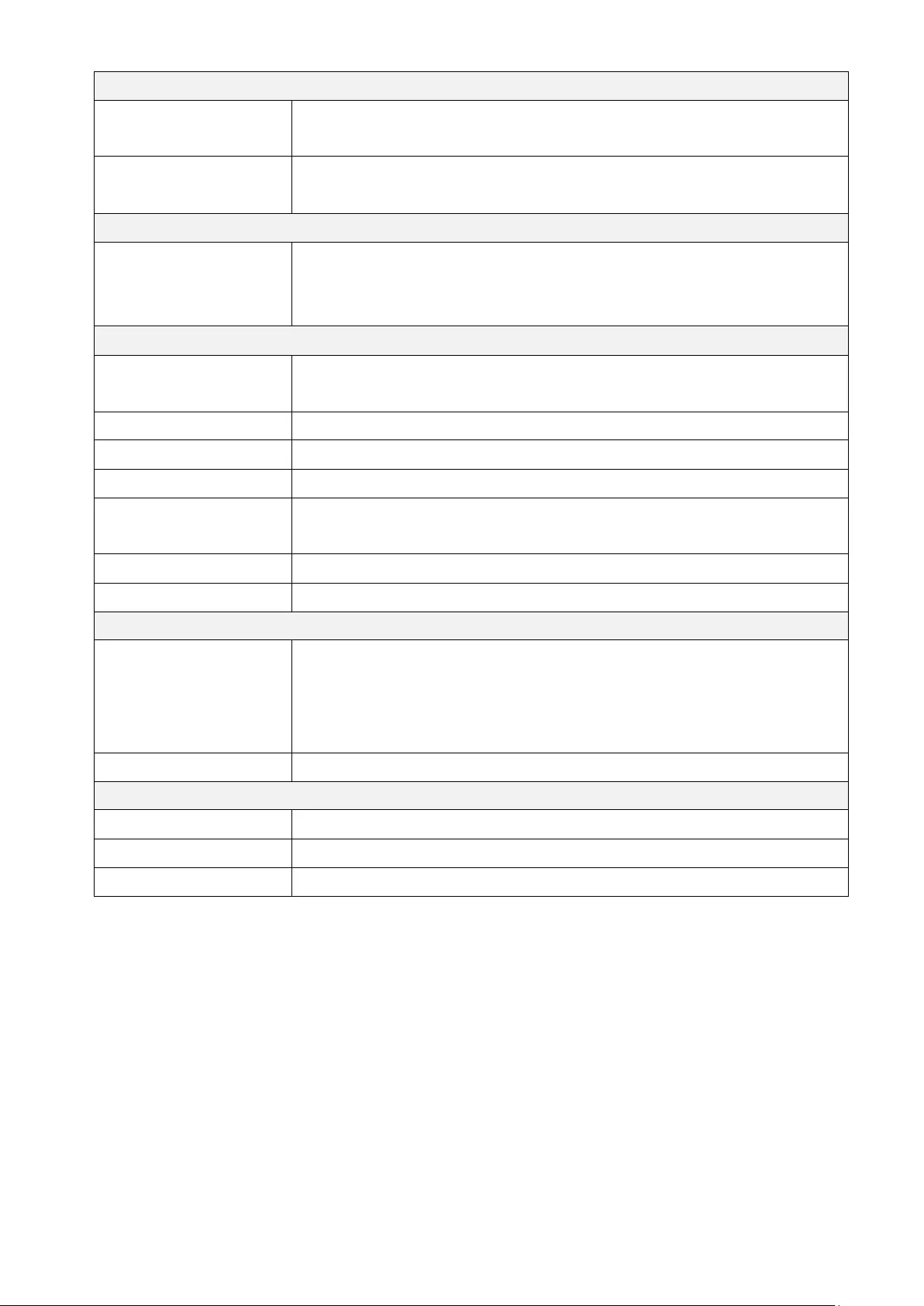

5.1.3 Printer Initialization

Printer initialization clears the printer's DRAM and restores its factory settings.

1. Turn off the printer.

2. Press and hold the Feed/Pause button, and then turn on the printer.

3. Release the button after the amber LED flashes five times and the LED is lit in green/red.

Note

The LED color will change as follows:

Amber (lit) red/amber (5 times) amber (5 times) green/red (5 times) green (5 times)

red (5 times) green (lit)

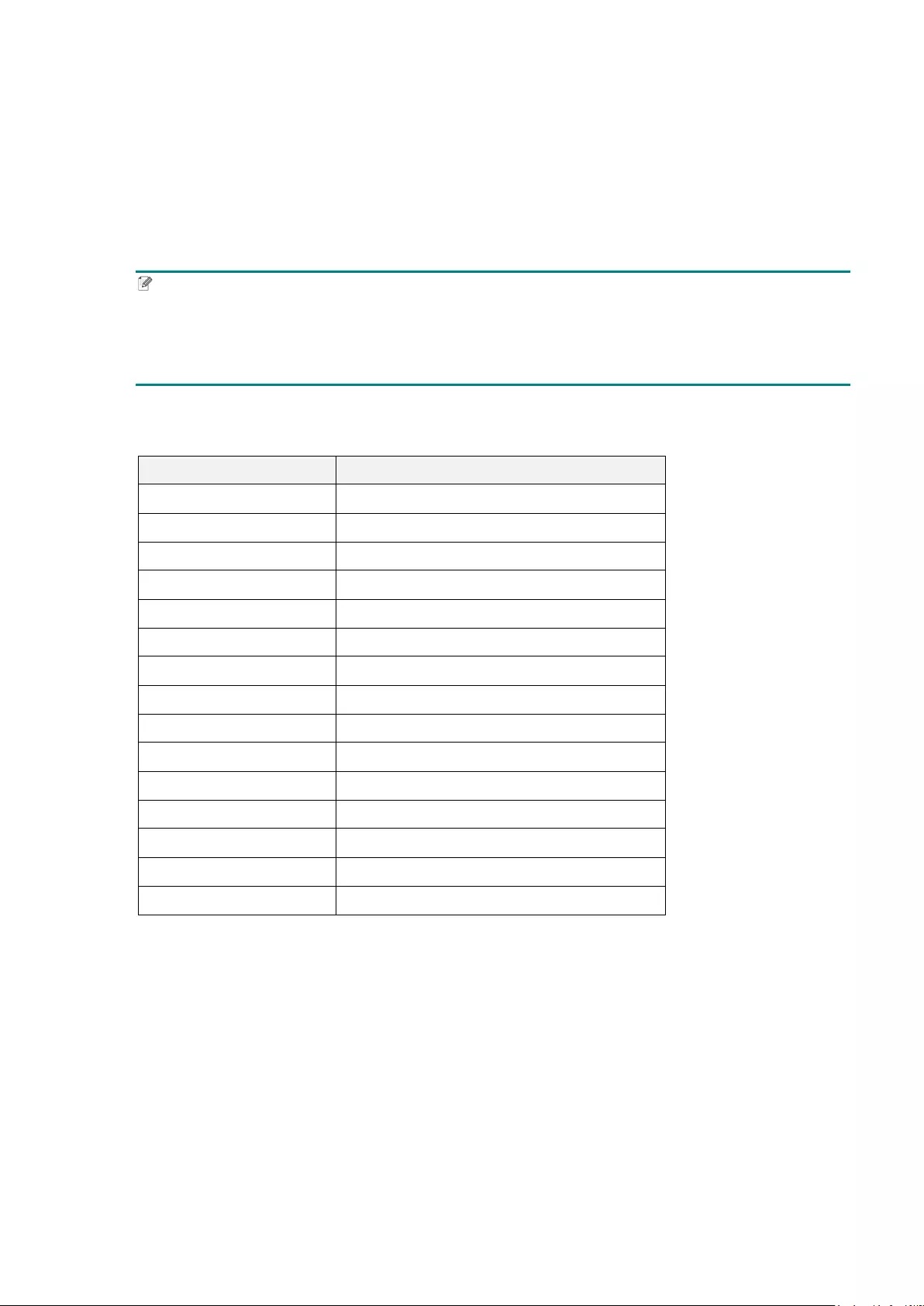

After the initialization, the following factory settings will be restored:

Parameter Default setting

Speed 76 mm/sec (3 ips)

Density 8

Label Width 4" (101.5 mm)

Label Height 4" (101.5 mm)

Sensor Type Gap sensor

Gap Setting 0.12" (3 mm)

Print Direction 0

Reference Point 0,0 (upper left corner)

Offset 0

Tear Mode On

Peeler Mode Off

Cutter Mode Off

Code Page 850

Country Code 001

Clear Flash Memory No

32

5.1.4 Media Sensor Calibration (for the Black Mark Sensor)

1. Turn off the printer.

2. Press and hold the Feed/Pause button, and then turn on the printer.

3. Release the button after the green/red LED flashes five times and the LED is lit in green.

Note

The LED color will change as follows:

Amber (lit) red/amber (5 times) amber (5 times) green/red (5 times) green (5 times)

red (5 times) green (lit)

5.1.5 Media Sensor Calibration (for the Gap Sensor)

1. Turn off the printer.

2. Press and hold the Feed/Pause button, and then turn on the printer.

3. Release the button after the green LED flashes five times and the LED is lit in red.

Note

The LED color will change as follows:

Amber (lit) red/amber (5 times) amber (5 times) green/red (5 times) green (5 times)

red (5 times) green (lit)

5.1.6 Skip the AUTO.BAS program

You can upload the AUTO.BAS program to the printer's flash memory so that it runs

automatically at startup, but if you do not want it to run automatically, follow these steps:

1. Turn off the printer.

2. Press the Feed/Pause button, and then turn on the printer.

3. Release the button when the LED is lit in green.

Note

The LED color will change in the following order:

Amber (lit) red/amber (5 times) amber (5 times) green/red (5 times) green (5 times)

red (5 times) green (lit)

4. The printer will start without running the AUTO.BAS program.

33

6. LCD Overview

6.1 Access the Main Menu

Make sure the printer's LCD displays "Ready". If not, select the Menu icon .

Use the Navigation buttons to browse the Main menu options.

- To select a highlighted icon, press the button under the icon.

- To return to the previous screen, press the button under the icon.

34

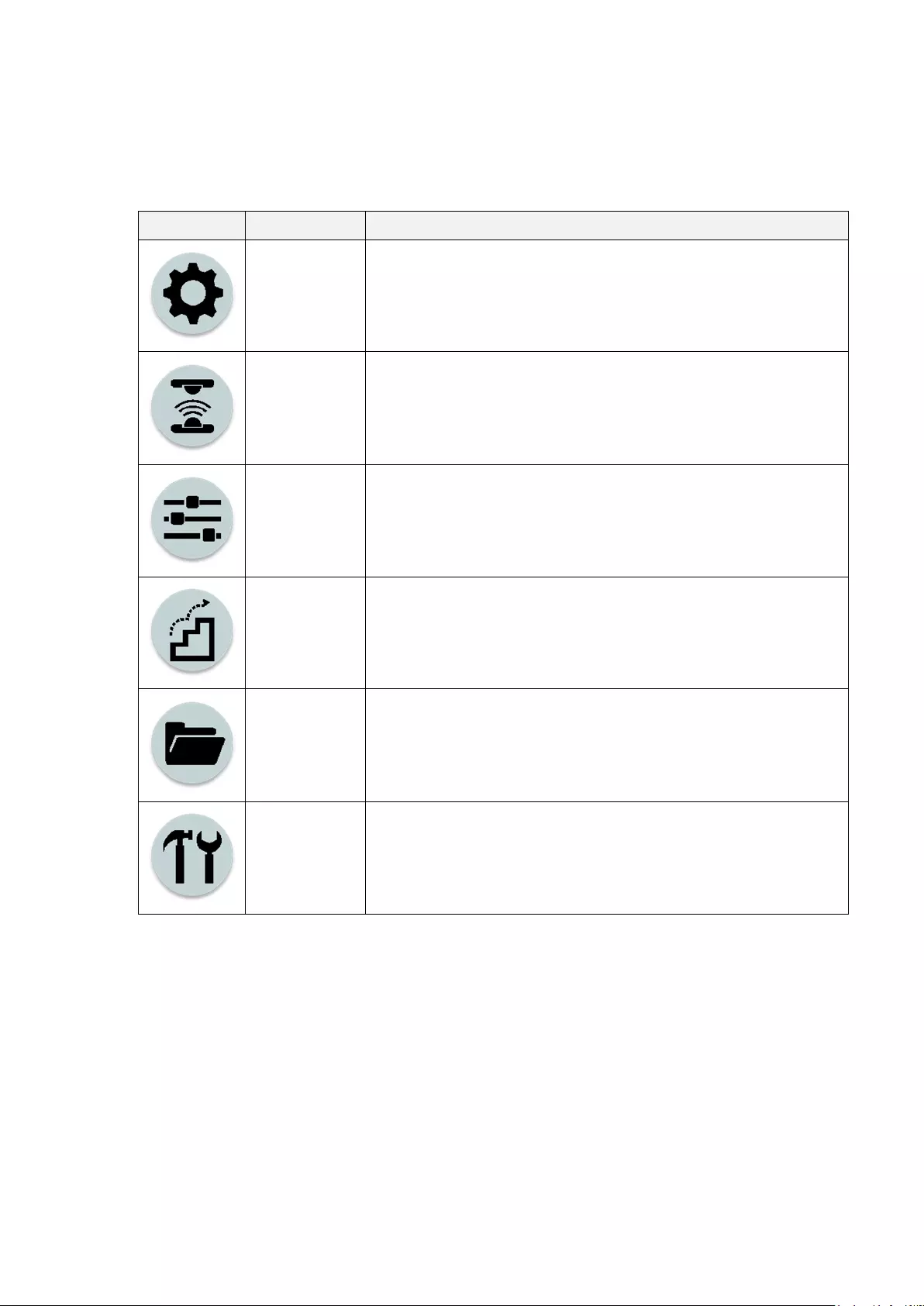

6.2 Main Menu Overview

Use the Main menu options to configure various printer settings without connecting the printer

to a computer.

Icon Option Description

Setting Configure the printer's FBPL and ZPL2 settings.

Sensor Calibrate the selected media sensor. We recommend

calibrating the sensor every time you change the media.

Interface Configure the printer interface settings.

Advanced Configure the printer's LCD, initialization, cutter type, or media

low warning settings.

File

Manager

Check or manage the available printer memory.

Diagnostic Check the printer status to help troubleshoot any issues.

35

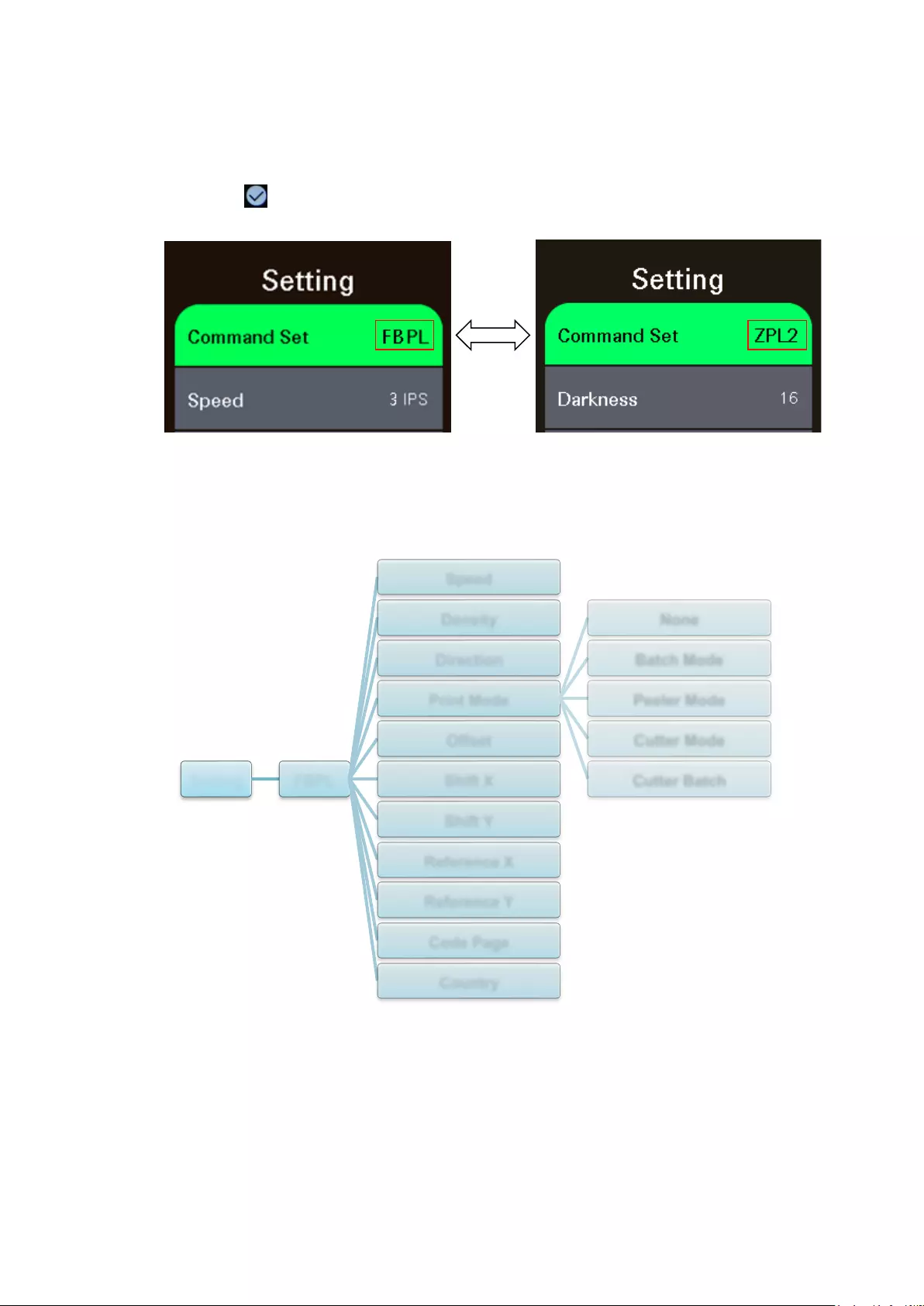

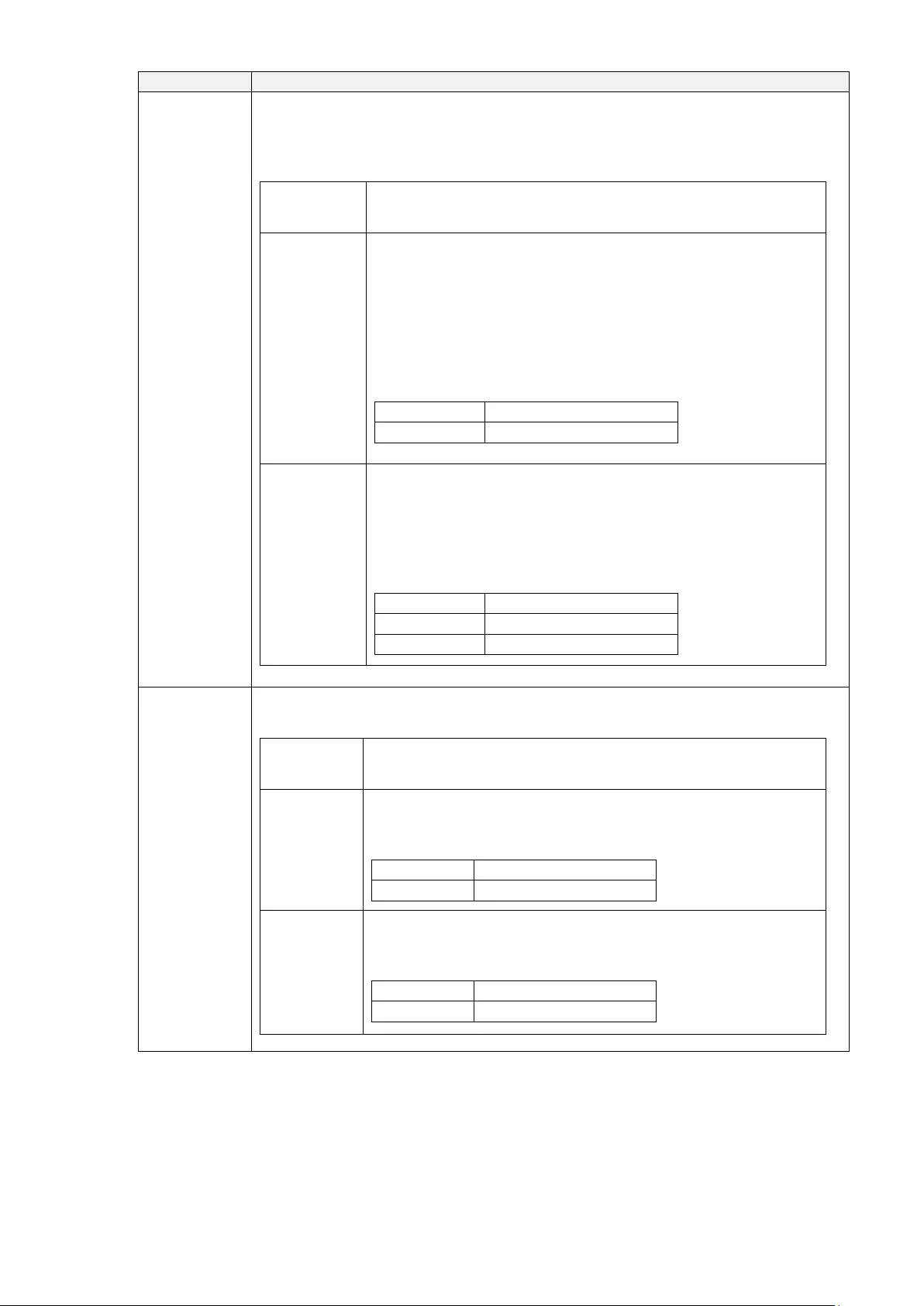

6.3 Setting Menu

1. In the Main menu, select Setting.

2. Press Command Set, and then select the programming language you want.

3. Select the icon.

6.3.1 FBPL Settings

Available FBPL settings:

Setting FBPL

Speed

Density

Direction

Print Mode

None

Batch Mode

Peeler Mode

Cutter Mode

Cutter Batch

Offset

Shift X

Shift Y

Reference X

Reference Y

Code Page

Country

36

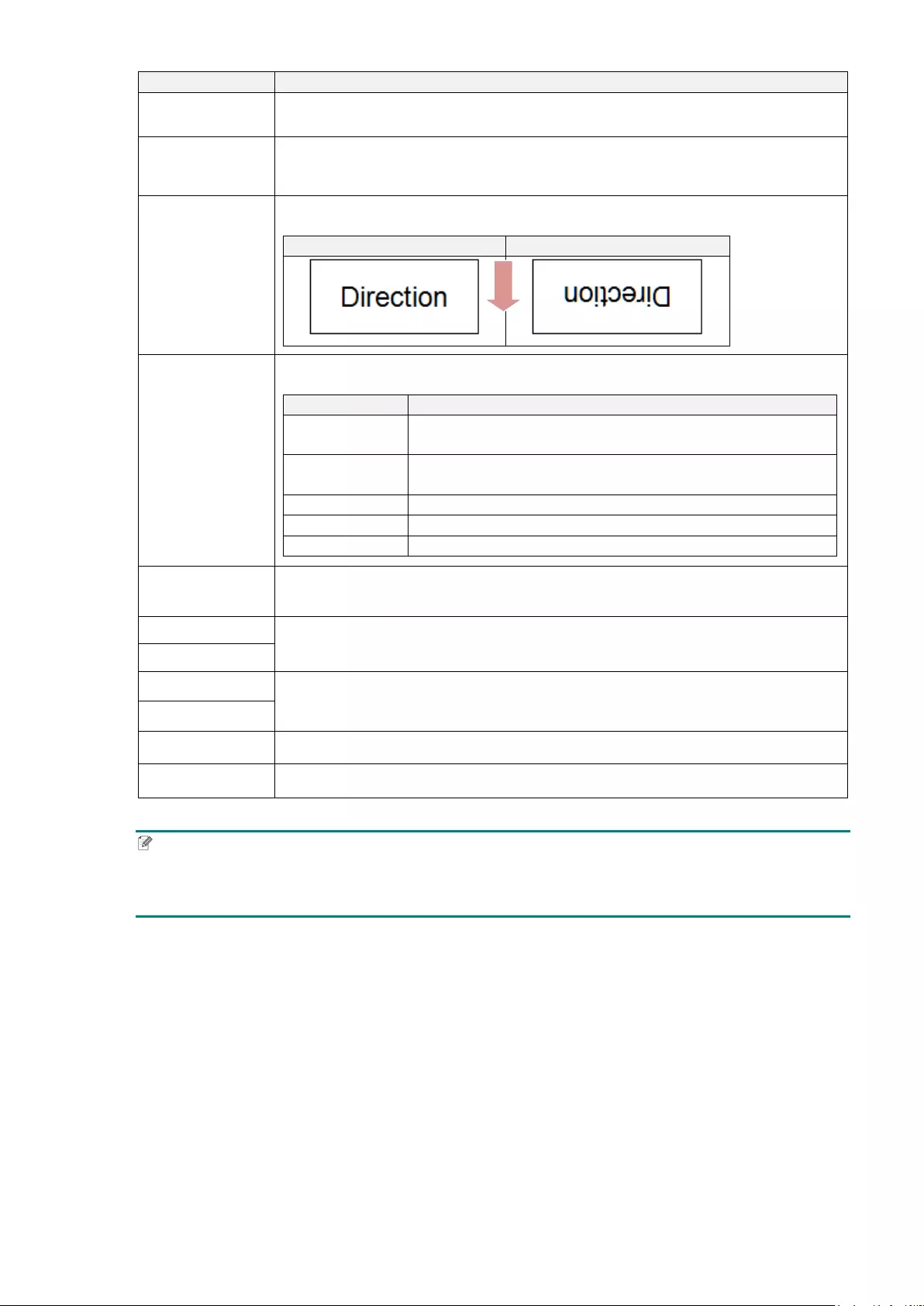

Setting

Description

Speed Set up the print speed.

Density Adjust the print darkness/lightness. Settings range from 0 to 15. You may

need to adjust the print density based on the media.

Direction

Specify print direction.

DIRECTION 0

DIRECTION 1

Print Mode

Set the print mode.

Print Mode

Description

None

The top of the next label is aligned with the Print Head

burn line (Tear Off Mode).

Batch Mode

When the image is printed, the Gap/Black Mark is fed

through the tear plate for tear away.

Peeler Mode

Enables label Peeler Mode.

Cutter Mode

Enables label Cutter Mode.

Cutter Batch

Cuts the label once at the end of the printing job.

Offset Fine-tune the media stop location. Settings range from -999 dots to

999 dots.

Shift X

Fine-tune the print position. Settings range from -999 dots to 999 dots.

Shift Y

Reference X Set the origin of the printer coordinate system horizontally and vertically.

Settings range from 0 dots to 999 dots.

Reference Y

Code Page Set the international character set code page.

Country Set the country code. Settings range from 1 to 358.

Note

If printing from the downloaded software/driver, the software/driver commands will overwrite

the settings set from the LCD.

FEED

37

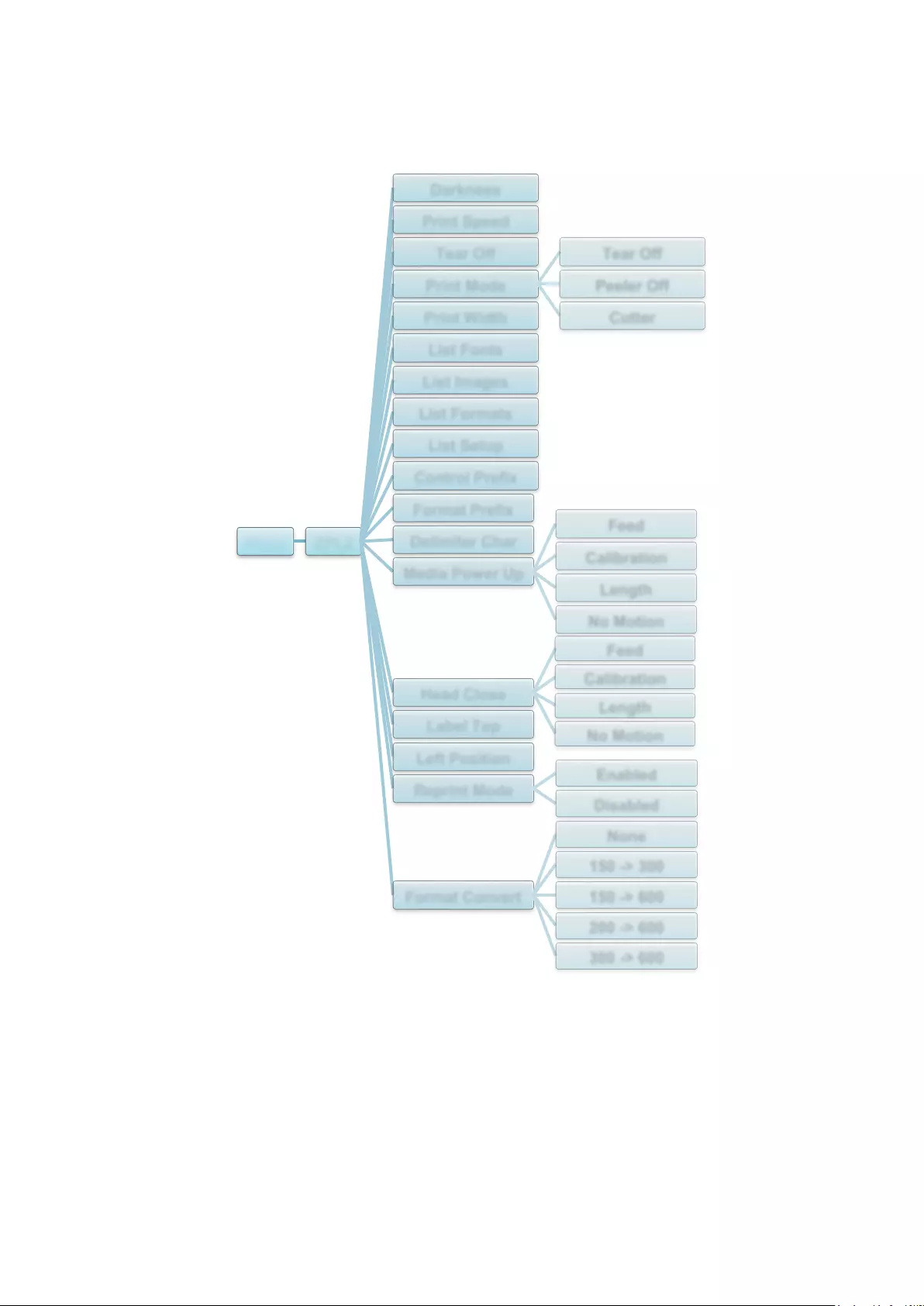

6.3.2 ZPL2 Settings

Available ZPL2 settings:

Menu ZPL2

Darkness

Print Speed

Tear Off

Print Mode

Tear Off

Peeler Off

CutterPrint Width

List Fonts

List Images

List Formats

List Setup

Control Prefix

Format Prefix

Delimiter Char

Media Power Up

Feed

Calibration

Length

No Motion

Head Close

Feed

Calibration

Length

No Motion

Label Top

Left Position

Reprint Mode

Enabled

Disabled

Format Convert

None

150 -> 300

150 -> 600

200 -> 600

300 -> 600

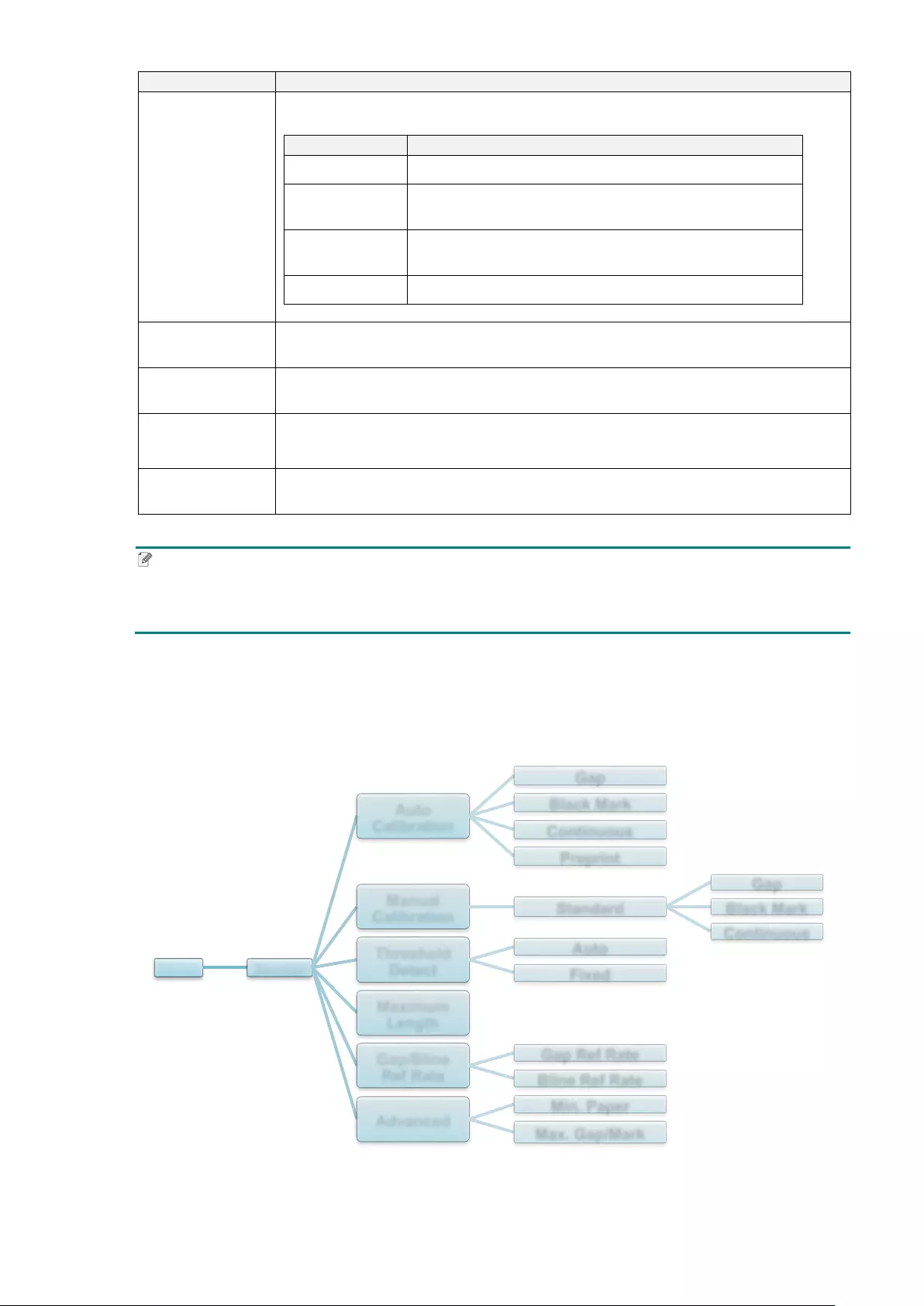

38

Setting

Description

Darkness Set up the print darkness. Settings range from 0 to 30. You may need to

adjust the print density based on the selected media.

Print Speed

Set up the print speed. Settings range from:

2 to 8 for 203 dpi

2 to 6 for 300 dpi

Tear Off Fine-tune the media stop location. Settings range from -120 dots to

120 dots.

Print Mode

Set the print mode.

Print Mode

Description

Tear Off

The top of the next label is aligned with the Print

Head burn line.

Peeler Off

Enable the label Peeler Off mode.

Cutter

Enable the label Cutter mode.

Print Width

Set the print width. Settings range from:

2 dots to 864 dots for 203 dpi

2 dots to 1248 dots for 300 dpi

List Fonts Print the current printer fonts list to the label. The fonts can be stored in the

printer’s DRAM, Flash, or optional memory card.

List Images Print the current printer images list to the label. The images can be stored

in the printer’s DRAM, Flash, or optional memory card.

List Formats Print the current printer formats list to the label. The formats can be stored

in the printer’s DRAM, Flash, or optional memory card.

List Setup Print the current printer configuration.

Control Prefix Set the control prefix character.

Format Prefix Set the format prefix character.

Delimiter Char Set the delimiter character.

Media Power

Up

Set the media action you want when you turn the printer on.

Action

Description

Feed The printer ejects one label.

Calibration The printer calibrates the sensor levels,

determines the label length, and feeds one label.

Length The printer determines the label length and feeds

the label.

No Motion

No action.

39

Setting

Description

Head Close

Set the media action when you close the Print Head.

Action

Description

Feed The printer ejects one label.

Calibration

The printer calibrates the sensor levels,

determines the label length, and feeds one label.

Length The printer determines the label length and feeds

the label.

No Motion No action.

Label Top

Adjust the print position vertically on the label. Settings range from

-120 dots to +120 dots.

Left Position Adjust the print position horizontally on the label. Settings range from

-9999 dots to +9999 dots.

Reprint Mode Reprint the last label by pressing the Up arrow (△) button on the control

panel.

Format

Convert

Selects the bitmap scaling factor. The first number is the original DPI

value; the second number is the DPI setting you want.

Note

If printing from the downloaded software/driver, the software/driver commands will overwrite

the settings set from the LCD.

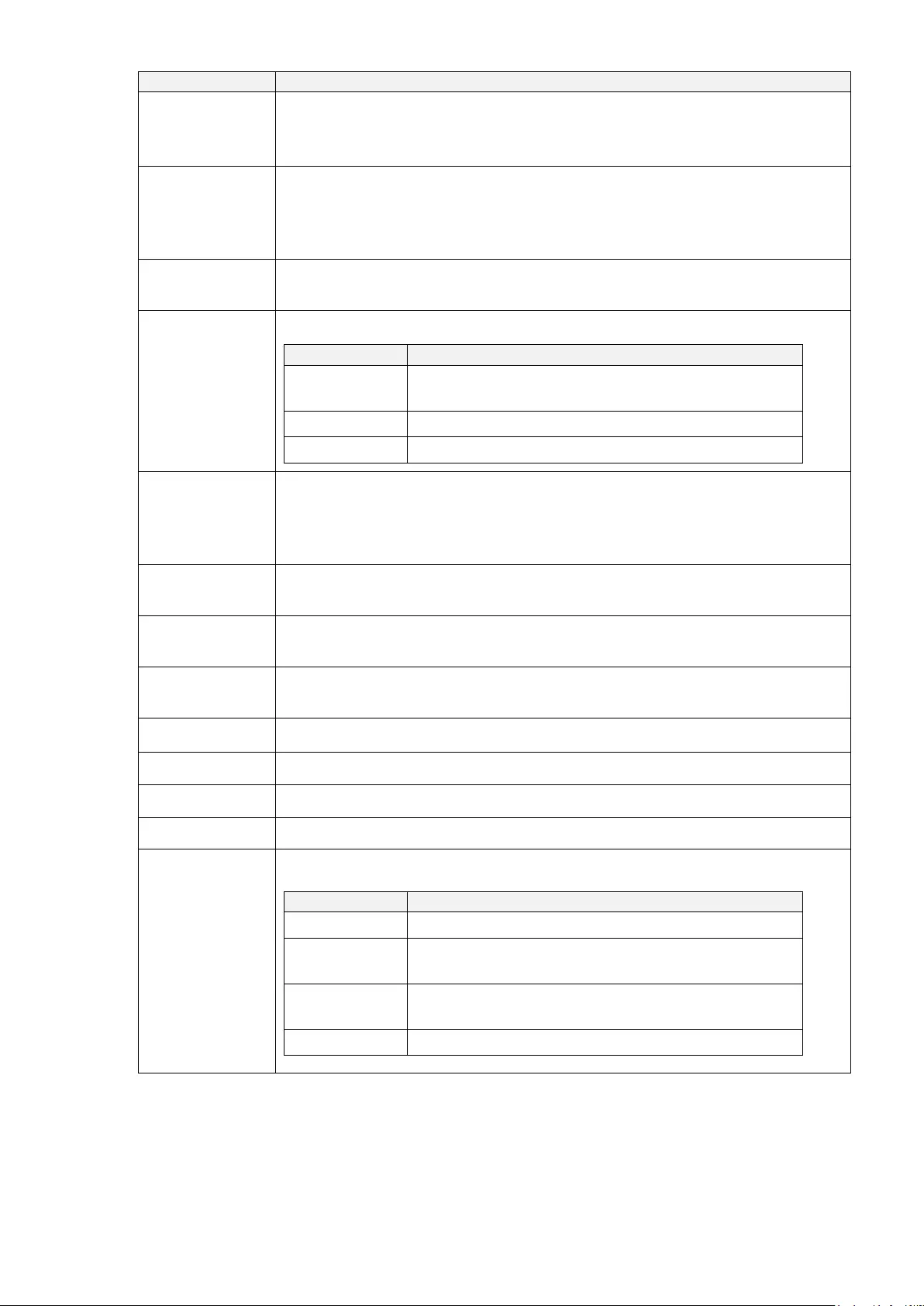

6.4 Sensor Settings

We recommend calibrating the sensors every time you change the media.

Menu Sensor

Auto

Calibration

Gap

Black Mark

Continuous

Preprint

Manual

Calibration Standard

Gap

Black Mark

Continuous

Threshold

Detect

Auto

Fixed

Maximum

Length

Gap/Bline

Ref Rate

Gap Ref Rate

Bline Ref Rate

Advanced

Min. Paper

Max. Gap/Mark

40

Setting

Description

Auto Calibration

Set the media sensor type and calibrate the selected sensor

automatically. The printer feeds up to three gap labels to calibrate

the sensor sensitivity automatically.

Manual Calibration

If “Automatic” cannot apply to the media, use the “Manual” function

to set the paper length and gap/BLINE size, and then scan the

backing/mark to calibrate the sensor sensitivity.

Threshold Detect Set the sensor sensitivity to Fixed or Auto.

Maximum Length Set the maximum length for label calibration.

Gap/Bline Ref Rate Adjusts sensitivity for gap (spacing) detection on die-cut labels or for

black mark detection.

Advanced Set the minimum paper length and maximum gap/BLINE length to

calibrate the sensor sensitivity automatically.

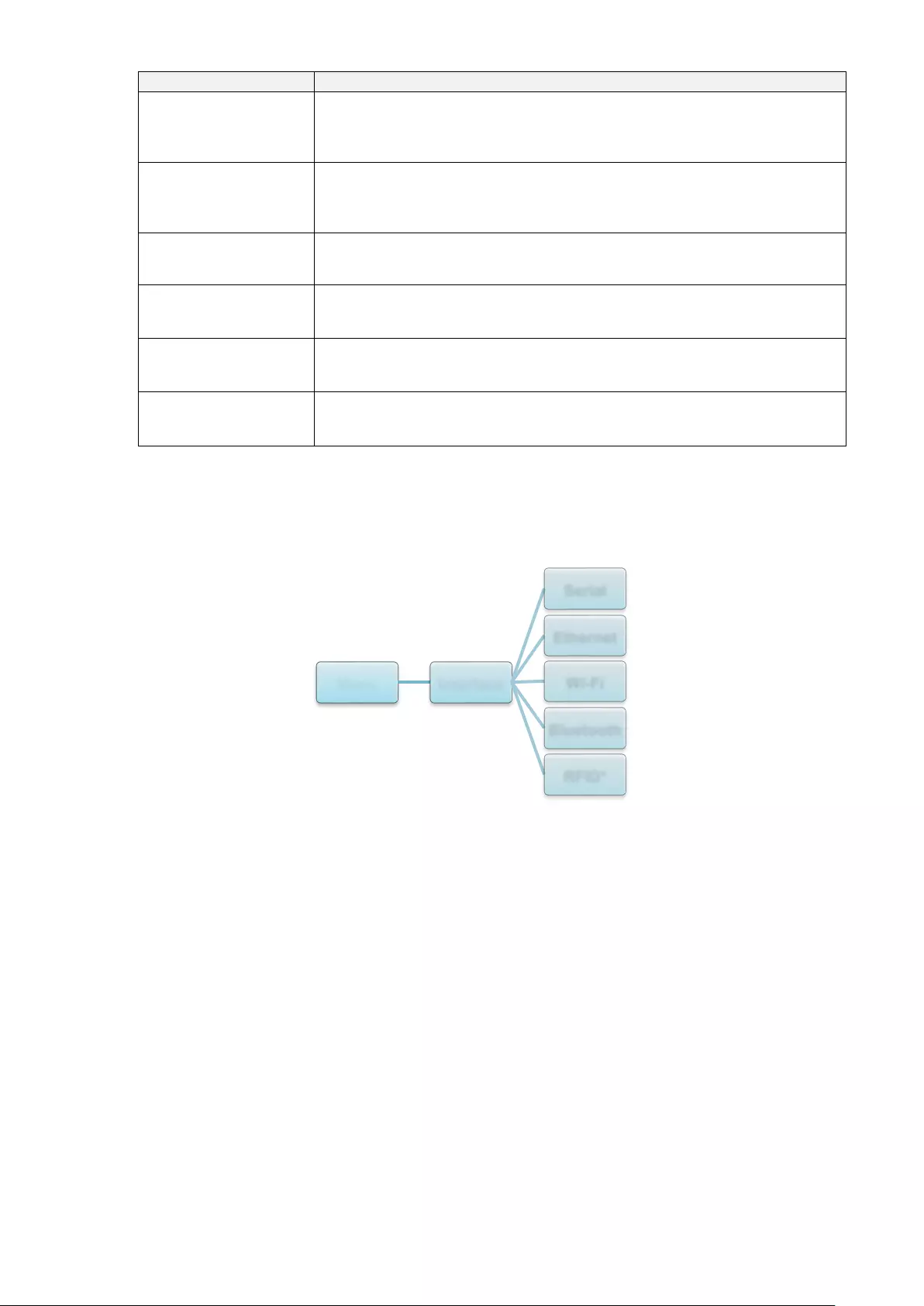

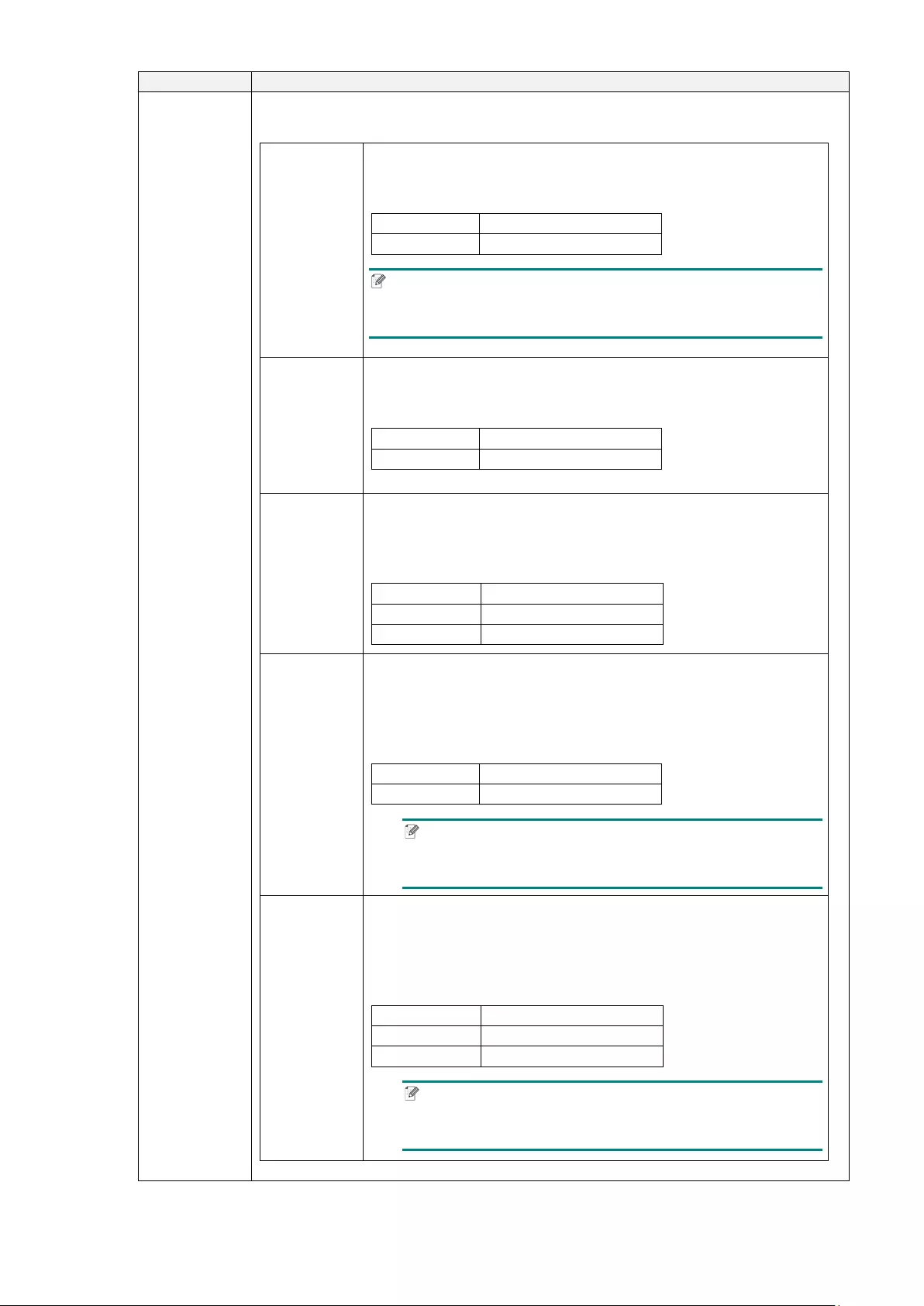

6.5 Interface Settings

Set the printer interface settings.

* Available for: TD-4650TNWBR and TD-4750TNWBR.

Menu Interface

Serial

Ethernet

RFID*

Wi-Fi

Bluetooth

41

6.5.1 Serial Communication Settings

Set the printer RS-232 settings.

Setting

Description

Baud Rate Set the RS-232 Baud rate.

Parity Set the RS-232 Parity.

Data Bits Set the RS-232 Data bits.

Stop Bit(s) Set the RS-232 Stop bits.

6.5.2 Ethernet Settings

Configure your printer's Ethernet (wired) connection and check its status.

When the Ethernet is connected, the Ethernet icon and IP address are displayed on the LCD

as shown below.

Menu Interface Serial

Baud Rate

1200 bps

2400 bps

4800 bps

9600 bps

19200 bps

38400 bps

57600 bps

115200 bps

Parity

None

Odd

Even

Data Bits 7

8

Stop Bit(s) 1

2

42

Item

Description

Status Check the Ethernet IP address and Mac address setting status.

Configure

DHCP:

Enable (On) or disable (Off) the Dynamic Host Configuration Protocol

(DHCP) network protocol.

Static IP:

Set the printer’s IP address, subnet mask, and gateway.

Note

For information about installing a printer driver, see section 4.1.4 Wired Network Connection

(Windows).

6.5.3 Wi-Fi Settings

Configure your printer's Wi-Fi connection and check its status.

To use this feature, set up the Enterprise configuration with the Brother Printer Management

Tool (BPM). For more information on setting Wi-Fi using BPM, see the Brother Printer

Management Tool Quick Start Guide on your model's Manuals page at support.brother.com.

When the Wi-Fi module is connected, the Wi-Fi icon and IP address are displayed on the LCD

as shown below.

Note

Make sure both your wireless router/access point's and your printer's network settings are correctly

set up. For more information, see the documentation provided with your wireless router/access point,

or contact the router manufacturer, your system administrator, or Internet service provider.

Menu Interface Ethernet

Status

Configure

43

Item

Description

Status Check the Wi-Fi IP address and Mac address setting status.

Configure

DHCP:

Enable (On) or disable (Off) the Dynamic Host Configuration Protocol

(DHCP) network protocol.

Static IP:

Set the printer’s IP address, subnet mask, and gateway.

SSID Set the SSID (Network Name).

Security Select the Wi-Fi encryption.

Password Set the password (Network Key).

Note

For information about installing a printer driver, see section 4.1.3 Wi-Fi Network Connection

(Windows).

6.5.4 Bluetooth Settings

Configure your printer's Bluetooth connection, check its status, and reset the local name.

Enable the Bluetooth feature to allow your mobile device to discover and connect your printer.

Menu Interface Wi-Fi

Status

Configure

SSID

Security

Open

WEP1

WEP2

WEP3

WEP4

WPA-PSK

Password

Menu Interface Bluetooth

Status

Local Name

44

Item

Description

Status Check the Bluetooth setting status.

Local Name Reset the Bluetooth local name.

Note

For information about installing a printer driver, see section 4.1.2 Bluetooth Connection

(Windows).

6.5.5 RFID (Radio Frequency Identification) Settings

Set the printer RFID settings.

(Available for TD-4650TNWBR and TD-4750TNWBR only)

Menu Interface RFID

Control

Tag Calibration

Calibration Param

RFID Chip Param

Diagnostics

Statistics

45

Item

Description

Control

RFID

Active

Select “Enable” to enable the RFID encoder module.

Error

Handling

Select the error handling mode for RFID errors.

Overstrike

(Default)

Each incorrectly processed label prints with

the Overstrike

pattern, and the form retries

on a new label until the Label Retry

count is

exhausted. Whether an error message

appears or the label gets reprinted

depends on the Max Retry Error

setting.

None No specific action is taken when a tag fails

to be

programmed.

Stop The printer will

halt and display the error

message “RFID Error: Check Media”. The

label is discarded and reprinting of the label

must be

initiated from the host. When the

error is cleared, the label with the

incorrect

tag moves forward until the next label is in

position to be

printed.

Label

Retry

Specifies the number of label retries that the RFID

encoder

will attempt before declaring a fault. This may indicate a

problem with the RFID encoder, the printer setup, or the

label stock.

Minimum

1

Maximum

10 (Default)

Max Retry

Error

Determines if errors occur when the Label Retry count is

exceeded.

EPC Write

Ctrl

Controls how the printer encodes the RFID tag EPC

field.

Non-RFID

Warning

Displays a warning if the printer receives a print job that does

not contain any RFID commands when RFID media is

installed in the printer.

46

Item

Description

Tag

Calibration

This submenu is used to perform an RFID calibration. The user must perform

a tag calibration when installing a new tag in the printer. RFID calibration

determines the RFID chip type, the write/read power, program position, and

the length of the EPC/User field.

RFID

Calibrate

Performs the RFID calibration.

Execute it every time you change the RFID tag type.

Num Label

for

Calibration

Determines the number of tags to use for calibration.

However, this value does not include tags moved when

seeking gaps during the calibration process. Depending on

the difficulty in calibrating the installed tags, the printer may

use more or fewer labels, but generally, the greater the

number selected in this menu, the more tags will be used

to determine the calibration result. The default value (3) is

most commonly used.

Minimum

3 (Default)

Maximum

7

Test EPC

Length

Determines the size of the EPC data that will be used to

perform the RFID calibration. This length can be increased

to improve the accuracy of the RFID calibration, but it

should not be increased to a value greater than the

maximum EPC length that the current Tag Type can

support.

Minimum

16

Maximum

256

Default

96

Calibration

Param

Contains the settings used for optimal tag encoding. These parameters can

be obtained automatically through RFID calibration.

Tag

Position

Determines how far the RFID tag encoding position of the

currently installed tag should be offset from Top of Form.

Write

Power

Specifies the write power level to be used in the RFID

encoder. Normally, this value is set automatically by the

RFID calibration process and should not be changed.

Minimum

1

Maximum

30

Read

Power

Specifies the read power level to be used in the RFID

encoder. Normally, this value is set automatically by the

RFID calibration process and should not be changed.

Minimum

1

Maximum

30

47

Item

Description

RFID Chip

Param

These settings are used to configure the system when custom RFID tags are

required.

USR Size Specifies the USR block bytes size within the RFID tag

memory. Normally, this value is set automatically by the

RFID calibration process and should not be changed.

Minimum

0 (Default)

Maximum

256

Note

This value is hidden if Higgs 3 tags are detected, and the

Higgs 3 USR Len menu is shown instead.

USR

Address

Specifies the starting location of the USR block within the

RFID tag memory. Normally, this value is set automatically

by the RFID calibration process and should not be changed.

Minimum

0 (Default)

Maximum

32

TID Size Indicates the size of the memory block within the RFID tag

memory that contains the Tag ID. Normally, this value is set

automatically by the RFID calibration process and should

not be changed.

Minimum

0

Maximum

12

Default

8

Higgs 3

USR Len

Higgs 3 tags differ from other RFID tags in that their memory

bank size is not fixed. To accommodate EPC lengths longer

than 96 bits, Higgs 3 borrows memory from the USR bank.

This read-only menu indicates the size in bits of the USR

block within the RFID tag memory.

Minimum

128

Maximum

512 (Default)

Note

This menu will only be shown if a Higgs 3 tag is

detected.

Higgs 3

EPC Len

Higgs 3 tags differ from other RFID tags in that their memory

bank size is not fixed. To accommodate EPC lengths longer

than 96 bits, Higgs 3 borrows memory from the USR bank.

This menu item allows you to select the number of bits

dedicated to the EPC block within the RFID tag memory.

Minimum

96

Maximum

480

Default

96

Note

This menu will only be shown if a Higgs 3 tag is

detected.

48

Item

Description

RFID Chip

Param

Tag

Length

Specifies the EPC block bytes size within the RFID tag

memory. This value is set automatically by the RFID

calibration process and should not be changed.

Minimum

8

Maximum

64

Default

12

Note

This value is hidden if Higgs 3 tags are detected, and the

Higgs 3 EPC Len menu is shown instead.

EPC

Address

Specifies the starting location of the EPC block within the

RFID tag memory. Normally, this value is set automatically

by the RFID calibration process and should not be changed.

Minimum

0 (Default)

Maximum

32

Block Size Specifies the maximum number of bytes written to the USR

block within the RFID tag memory at one time. Normally,

this value is set automatically by the RFID calibration

process and should not be changed.

Minimum

0

Maximum

32

Default

8

Diagnostics

These settings are used to run test procedures to help determine the

accuracy of the RFID system and troubleshoot it.

Read Tag Reads the tag in range of the internal RFID coupler and

reports the tag data to the debug port and displays it on the

LCD. It is primarily intended for development verification by

checking that the system is working.

Note

This menu item does not position the RFID tag over the

coupler. Make sure to position the tag over the coupler to

receive an accurate reading.

Read Tag

& Eject

This menu item works exactly the same as Read Tag,

except that after the printer reads the tag, it feeds the label

to the next top-of-form.

Note

This menu item does not position the RFID tag over the

coupler. Make sure to position the tag over the coupler to

receive an accurate reading.

49

Item

Description

Diagnostics

Read USR Reads the User Memory bank of the tag in range of the

internal RFID coupler and reports the data to the debug port

and displays it on the LCD. It is primarily intended for

development verification by checking that the system is

working.

Note

This menu item does not position the RFID tag over the

coupler. Make sure to position the tag over the coupler to

receive an accurate reading.

Read TID Reads the Tag ID (TID) from the tag in range of the

internal

RFID coupler and displays the value read in the Tag ID

menu.

Note

This menu item does not position the RFID tag over the

coupler. Make sure to position the tag over the coupler to

receive an accurate reading.

Tag ID Displays the first Tag ID (TID) read since power-up, or if

using the Read TID menu, the most recently read TID. If no

tag is in range of the internal RFID coupler, “Unknown”

appears on the LCD.

Read PC Reads the PC (Protocol Control) field from an RFID tag in

range of the internal RFID coupler and displays the value

read in the Tag PC menu.

Note

This menu item does not position the RFID tag over the

coupler. Make sure to position the tag over the coupler to

receive an accurate reading.

Tag PC Displays the last PC (Protocol Control) field read from an

RFID tag. If no tag is in range of the internal RFID coupler,

“Unknown” appears on the LCD.

Write EPC

with 1s

Writes all ones to the tag in range of the internal RFID

coupler. It is primarily intended for development verification

by checking that the system is working.

Note

This menu item does not position the RFID tag over the

coupler. Make sure to position the tag over the coupler to

receive an accurate writing.

Write EPC

with 2s

Writes all twos to the tag in range of the internal RFID

coupler. It is primarily intended for development verification

by checking that the system is working.

Note

This menu item does not position the RFID tag over the

coupler. Make sure to position the tag over the coupler to

receive an accurate writing.

50

Item

Description

Statistics

These settings are generally read-only and used to collect and report

statistics on how the RFID system is reporting on print jobs sent to the printer.

Tag Write

Count

Displays the number of tags attempted to be written since

the last Clear Tag Stat operation has been initiated.

Tag Failed

Count

Displays the number of failed RFID tags since the last Clear

Tag Stat operation has been initiated.

Tag Read

Count

Displays the number of tags read since the last

Clear Tag

Stat operation.

Clear Tag

Stat

Clears the Count menu items in this submenu.

RFID

Reader

F/W

Displays the RFID firmware version installed in the encoder.

(Available for TD-4650TNWBR and TD-4750TNWBR)

RFID

Reader

Hd/W

Displays the RFID hardware version installed in the encoder.

(Available for TD-4650TNWBR and TD-4750TNWBR)

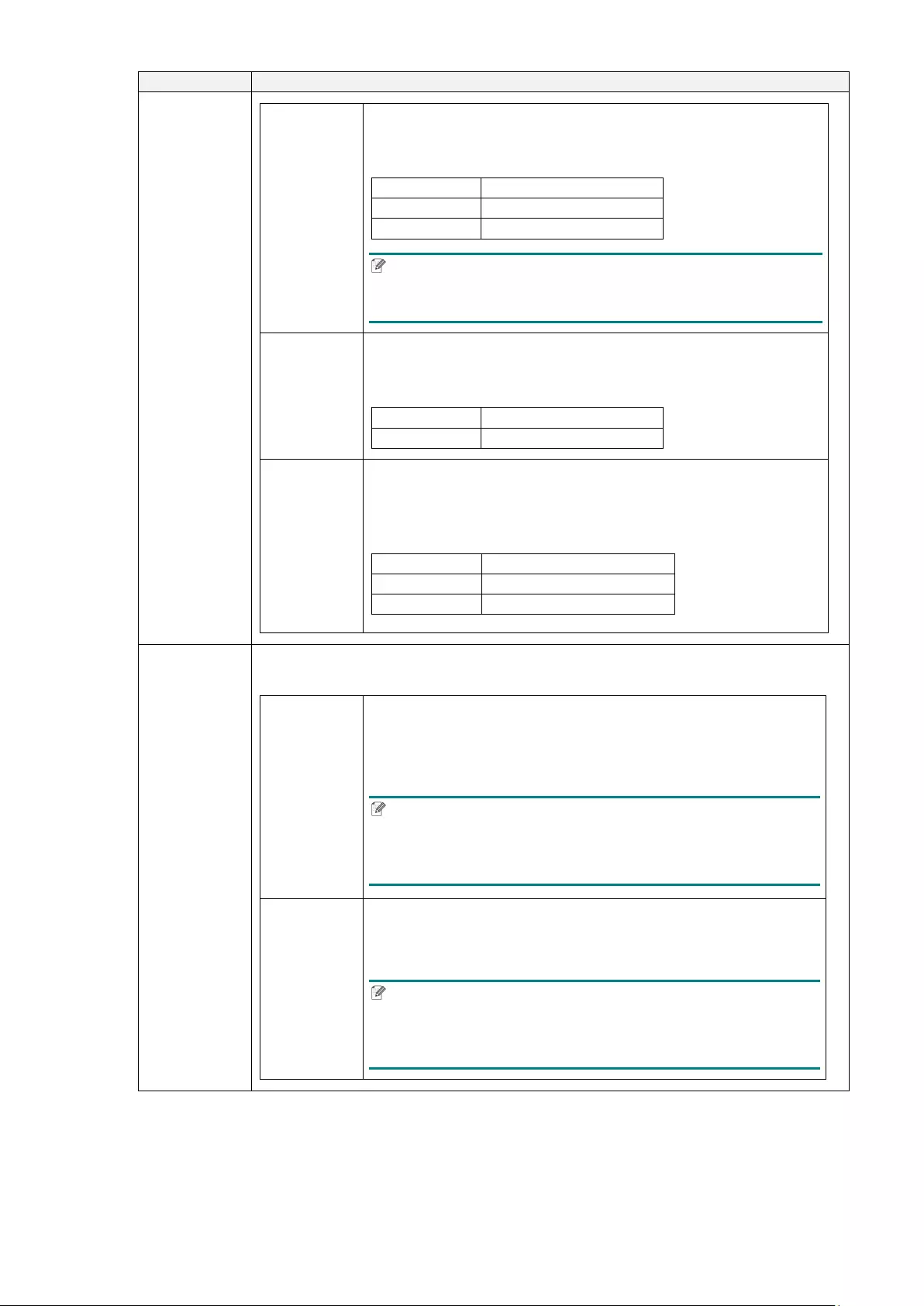

6.6 Advanced Settings

Item

Description

Language Specify the LCD language.

Printer

Information

Check the printer serial number, printed mileage (in./m), number of printed

labels (pcs), and cutting counter.

Menu Advanced

Language

Printer Information

Initialization

Display Brightness

Date & Time

Date Format

Date

Time Format

Time

Security Menu Lock

Menu Password

Ribbon Low Warning

Printer Head Maintn

Warning

Reset Counter

Interval

Key Sound

Contact Us

51

Item

Description

Initialization Restore the printer settings to the default settings.

Display

Brightness Adjust the LCD brightness (settings range from 0 to 100).

Date & Time Adjust the date and time displayed on the LCD.

Security Set the password for locking the menu or favorites. The default password is

8888.

Ribbon Low

Warning

Set the ribbon low warning message. For example, if you set the value at

30 m, when the ribbon capacity is lower than 30 m, the icon appears in

red.

Printer

Head

Maintn

Check the Print Head status and maintenance notifications.

Item

Description

Warning

Enable or disable the Print Head cleaning warning. If this

setting is enabled and the Print Head has reached the

setting mileage limit, a warning appears on the LCD to

remind you to clean the Print Head. The default setting is

"Disable".

Reset

Counter

Reset the Print Head mileage warning after the Print Head

has been cleaned.

Interval

Set the mileage for when to display the Print Head cleaning

warning. You must enable the “TPH warning lock” to use it.

The default setting is 1 km.

Key Sound Enable or disable the button press sound.

Contact us Display a QR code to access the Brother Support website at

support.brother.com using a mobile device.

6.7 File Manager

Check the printer's available memory, show the files list, delete the files, or run the files that

are saved in the printer's DRAM/Flash memory.

Menu File Manager

DRAM

FLASH

52

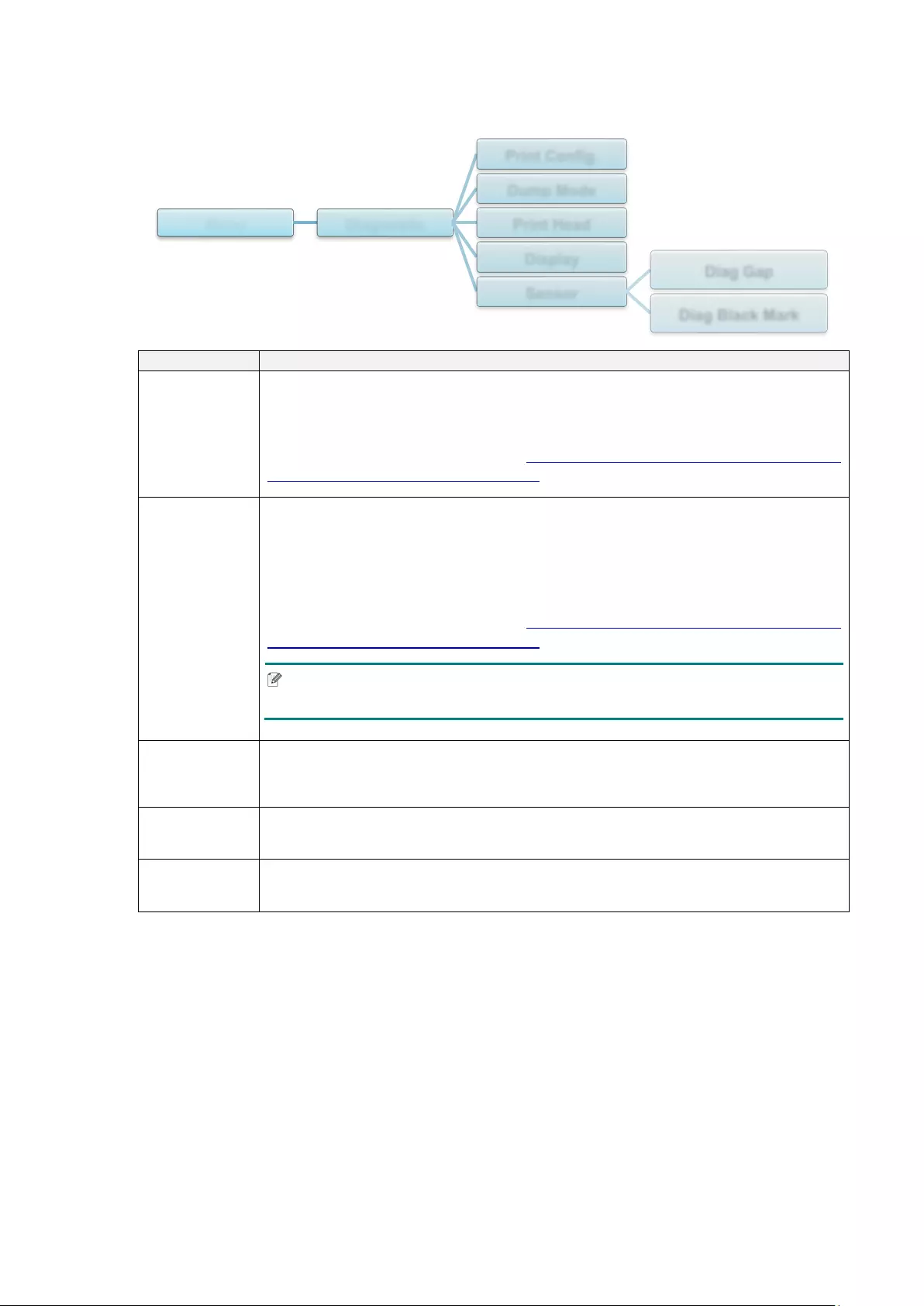

6.8 Diagnostic Functions

Item

Description

Print Config.

Print the current printer configuration. On the configuration printout, there is

a Print Head test pattern, which is useful for checking if there is dot damage

to the Print Head Heating Element.

For more information, see section 5.1.2 Gap/Black Mark Sensor Calibration,

Self-Test, and Entering Dump Mode.

Dump Mode

Captures the data from the communications port and prints out the data

received by the printer. In the dump mode, all characters will be printed in

two columns. The characters in the left column are received from the

printer's system and those in the right column are their hexadecimal

representation. It allows you to verify and debug the program.

For more information, see section 5.1.2 Gap/Black Mark Sensor Calibration,

Self-Test, and Entering Dump Mode.

Note

Dump mode requires 4" (101.6 mm) paper width.

Print Head Check for any visible dots and the Print Head's temperature.

Display Check the LCD’s color state.

Sensor Check the sensors’ intensity and reading state.

Menu Diagnostic

Print Config.

Dump Mode

Print Head

Display

Sensor

Diag Gap

Diag Black Mark

53

7. Brother Printer Management Tool (BPM)

The Brother Printer Management Tool (BPM) is an integrated tool that lets you:

Check a printer’s status and settings

Change printer settings

Send additional commands to a printer

Download graphics and fonts

Create a printer bitmap font

Download and update firmware

Configure Wireless LAN (Wi-Fi) and Bluetooth settings

Using this tool, you can also review your printer's status and settings to troubleshoot any

problems.

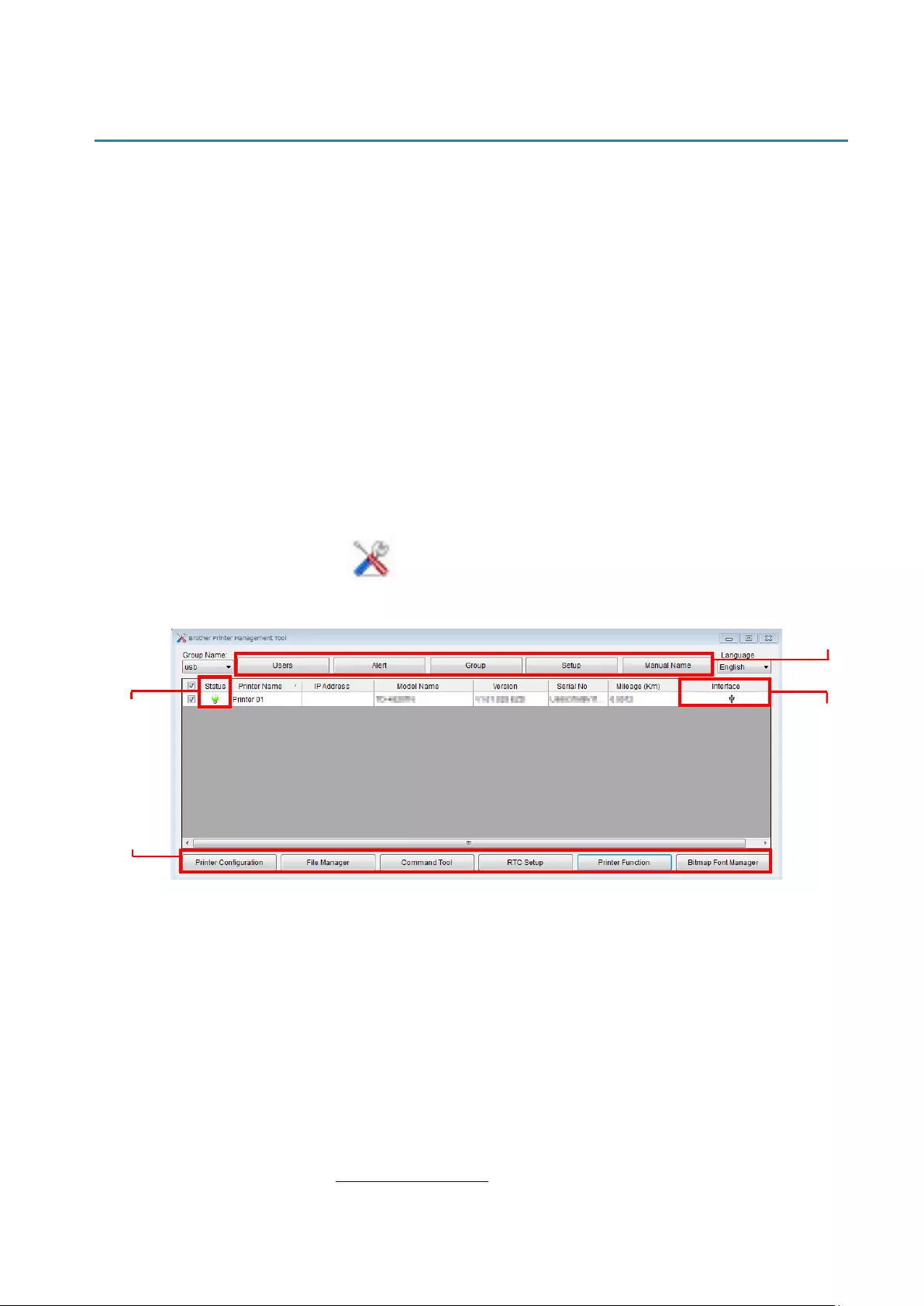

7.1 Start the BPM

Double-click the BPM icon to start the software.

BPM's main screen allows you to access the following options:

Printer Configuration

File Manager

Command Tool

RTC Setup

Printer Function

Bitmap Font Manager

For more information, see the Brother Printer Management Tool Quick Start Guide on your

model's Manuals page at support.brother.com.

Features

Buttons

Interface

Type

Printer

Status

Configuration

Buttons

54

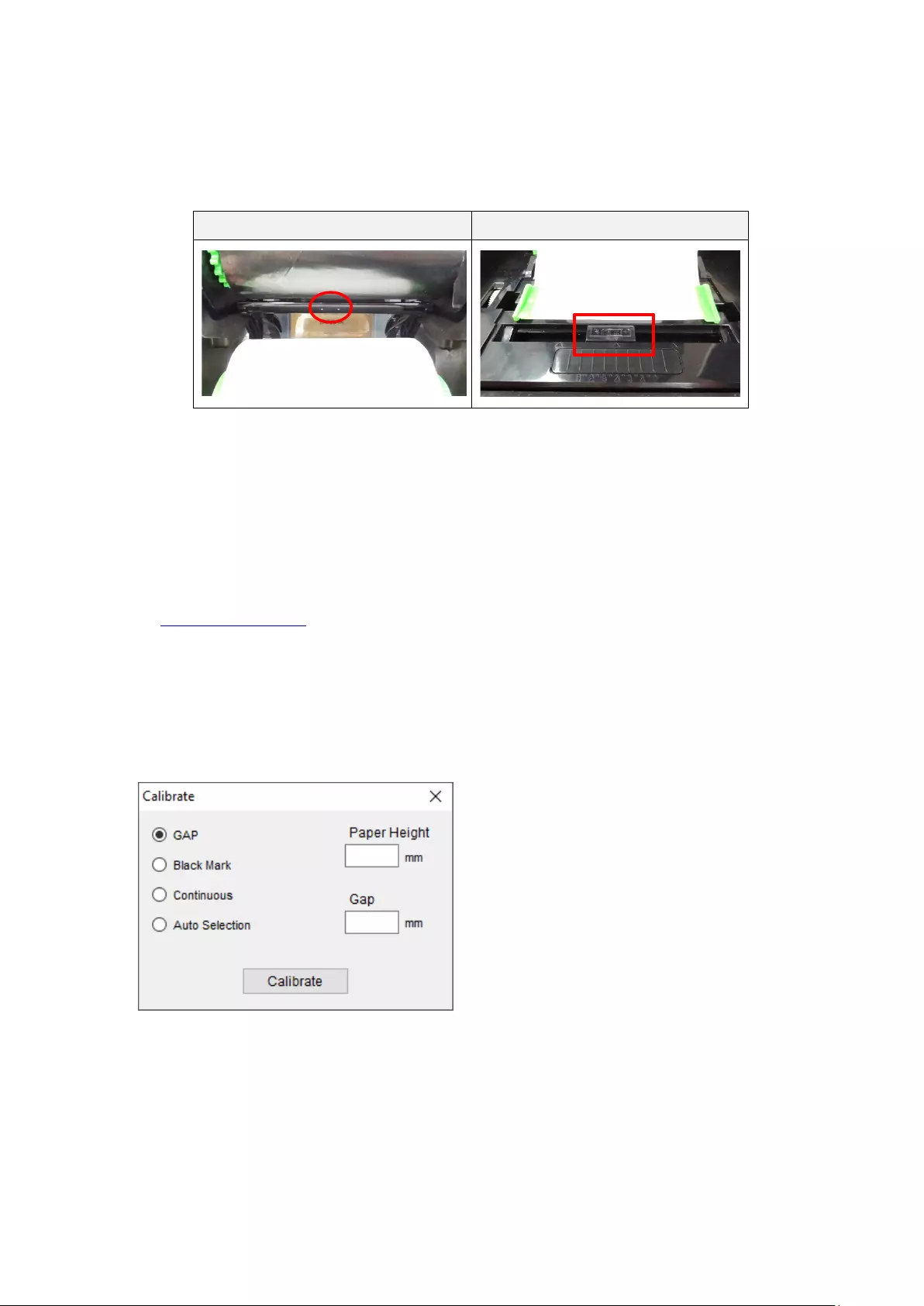

7.2 Auto-Calibrating the Media Sensor using the BPM

Use the BPM to set the media sensor type (Gap Sensor or Black Mark Sensor) and calibrate

the selected sensor.

Gap Sensor Black Mark Sensor

The Gap Sensor (transmissive sensor) detects the beginning of the label and feeds the label to

the correct position.

The Black Mark Sensor (reflective sensor) detects the mark and feeds the media to the correct

position.

1. Make sure the media is already installed and the Print Head is closed. (See section

3.2 Load the Media.)

2. Turn on the printer.

3. Start the BPM.

4. Click the Printer Function button.

5. Click the Calibrate button.

6. Select the sensor media type and click Calibrate.

55

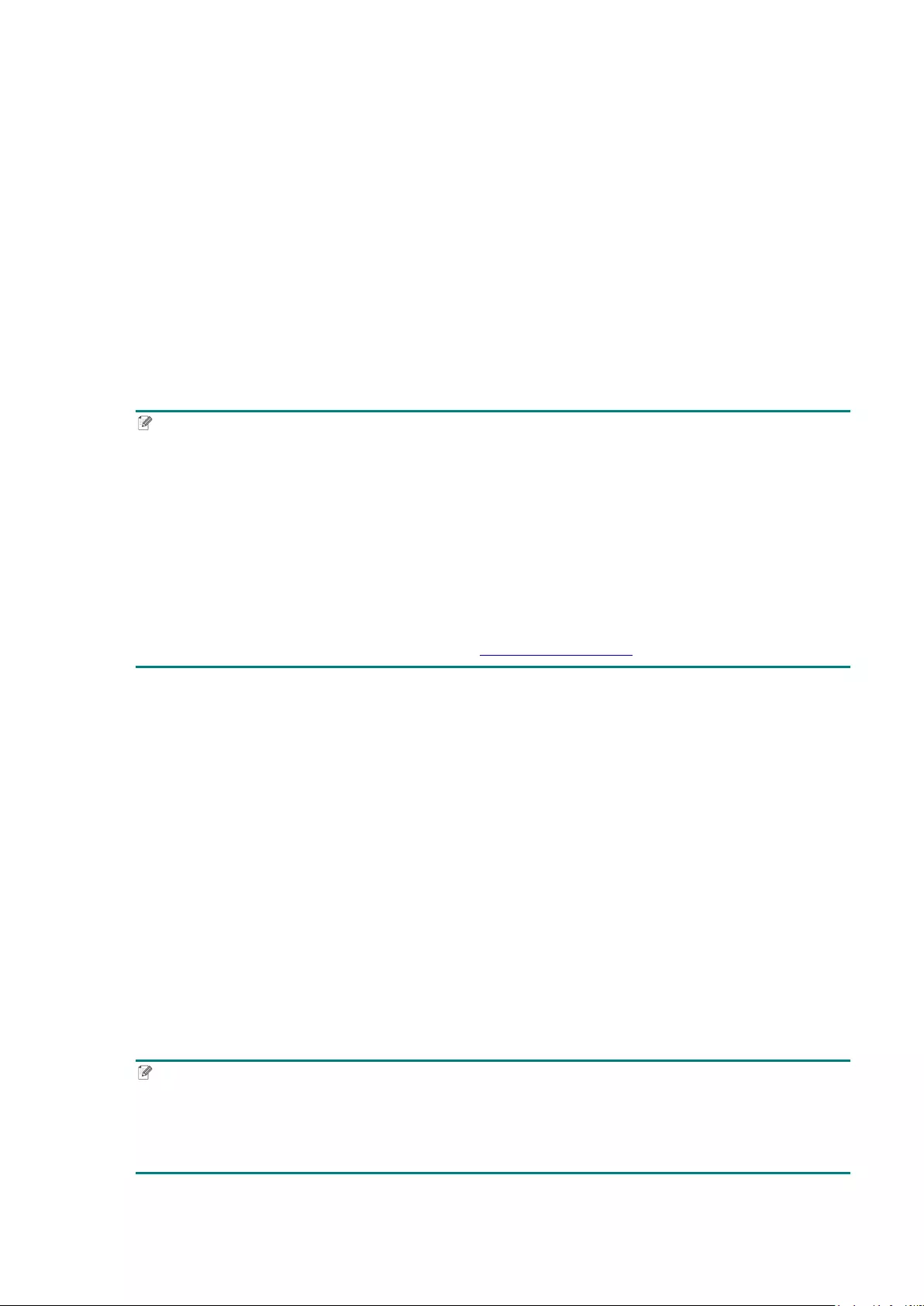

8. Setting up the RFID

8.1 Introduction

When printing smart labels that use an EEPROM technology, the printer may need to write and

verify some RFID tags more than once before accepting them. This additional processing may

result in a short pause between each printed label, but is necessary to ensure consistent

quality and reliability.

Note

Static electricity can damage smart labels. Before you handle smart labels, open the printer's

Media Cover and touch an unpainted metal part to discharge any static electricity that may have

built up on your hands.

This printer is equipped with an Auto-Calibration feature, which eliminates the need to specify

exact inlay placement or RFID power settings. The calibration routine is compatible with most

major inlays embedded in typical label sizes and will work with many other inlays as well.

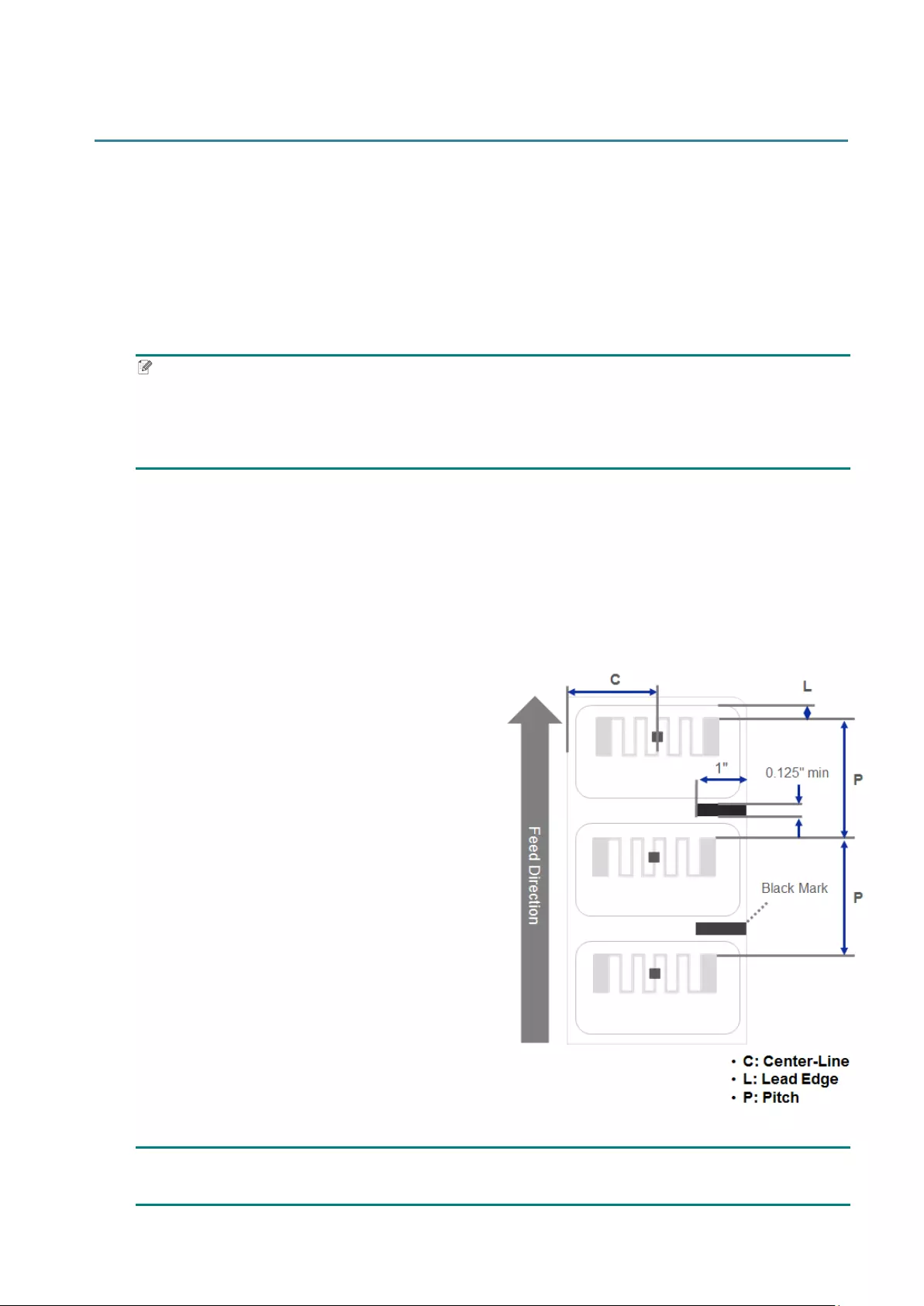

For optimum performance:

Center inlays horizontally across the media

(dimension "C"). Consistent, tag-to-tag

placement of the inlays is more important

than their proximity to the center.

The pitch is the overall distance from inlay to

inlay (dimension "P"). On-pitch tags and

tags with a pitch less than 1" may require the

printer to back-feed during the encoding and

printing process, thus slowing the

throughput of the printer. To avoid this, this

pitch should be greater than 1".

Set the inlay back from the lead edge of the

media (dimension "L") at the same

tag-to-tag distance. To avoid back-feeding,

for labels longer than 1", this distance should

be greater than 0.5".

IMPORTANT

Always test RFID media on your printer before purchasing large quantities of media.

56

8.2 RFID Calibration (available for TD-4650TNWBR and TD-4750TNWBR only)

8.2.1 Select the Antenna Position

Check the label to determine the best position for the antenna, locating the antenna loop within

the tag. In most cases, the antenna loop is directly above or below the chip. The loop may be

off to one side of the chip in some tags.

Open the Roll Compartment Cover. Move the Antenna Slide so that the Position Indicator

aligns with the loop in the tag.

8.2.2 RFID Calibration Procedure

Note

For optimal calibration results, perform Media Calibration before RFID Calibration. Make sure

you correctly install both the ribbon and the label roll.

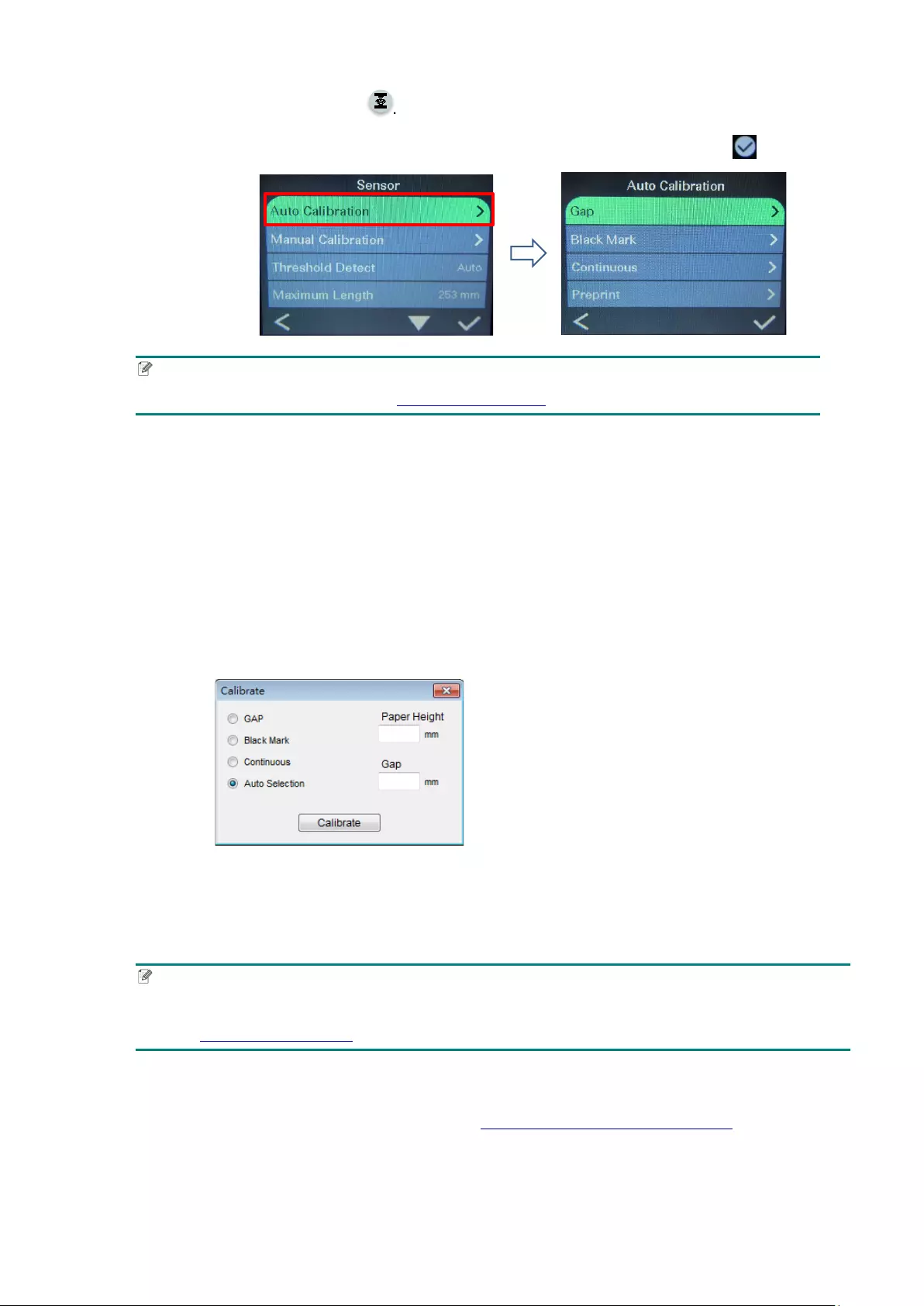

1. Perform Media Auto Calibration:

Using the LCD menu:

a. Load the RFID media into the printer.

b. (Thermal transfer only) Load the ribbon into the printer.

c. Select the Menu .

Position Indicator Numbered

Position Strip

Antenna Slide

57

d. Select the Sensor .

e. Select Auto Calibration, select the media type, and then select the icon.

Note

For more information, see section 6.4 Sensor Settings.

Using the BPM:

a. Load the RFID media into the printer.

b. (Thermal transfer only) Load the ribbon into the printer.

c. Connect the USB cable between the computer and the printer.

d. Start the BPM.

e. Select the printer in the list, and then click the Printer Function button.

f. Click Calibrate.

g. Click Printer Configuration and make sure the paper width and height in the FBPL

tab are set correctly.

Using the AUTODETECT command:

Note

For more information, see the FBPL Command Reference Manual on your model's Manuals

page at support.brother.com.

2. Check that the RFID antenna is set at the center of the RFID chip or the antenna loop on

the tag. For more information, see section 8.2.1 Select the Antenna Position.

58

3. Start RFID Calibration.

Using the LCD Menu:

Go to the RFID menu. Select Interface RFID Tag Calibration Do RFID

Calibrate, and select the icon.

Note

For more information, see section 6.5.5 RFID (Radio Frequency Identification) Settings.

Using the RFIDDETECT command:

Note

For more information, see the FBPL Command Reference Manual on your model's

Manuals page at support.brother.com.

4. Depending on the tag type and tag length, the calibration can take several minutes. At the

end of calibration either a green or red screen appears. The green screen appears when

the calibration is successful and the red one when it is not.

5. If calibration fails, select the or icon to clear the error. In most cases when this

error occurs, it is necessary to reposition the Antenna Slide. In some cases, it may be due

to an incompatibility between the tag and the reader. After the calibration is complete, select

the or icon to continue and save the RFID calibration values.

59

9. Product Specifications

Display

LCD 2.3" color LCD

LED 1 (3 colors - Green, Red, Amber)

Printing

Print Method Thermal Transfer & Direct Thermal

Maximum Print Width 4.25" (108 mm) max. (TD-4650TNWB, TD-4650TNWBR)

4.16" (105.7 mm) max. (TD-4750TNWB, TD-4750TNWBR)

Maximum Print Length 1000" (25,400 mm) (TD-4650TNWB, TD-4650TNWBR)

450" (11,430 mm) (TD-4750TNWB, TD-4750TNWBR)

Maximum Print Speed 8" (203.2 mm) / second (TD-4650TNWB, TD-4650TNWBR)

6" (152.4 mm) / second (TD-4750TNWB, TD-4750TNWBR)

Print Resolution 203 dpi (TD-4650TNWB, TD-4650TNWBR)

300 dpi (TD-4750TNWB, TD-4750TNWBR)

Size

Dimensions Approximately 8.62" (W) × 11.18" (D) × 7.52" (H) (219 mm (W) ×

284 mm (D) × 191 mm (H))

Weight Approximately 6.6 lbs (3 kg)

Interface

USB USB Ver.2.0 (High Speed) (Type B)

Serial RS-232

Wired LAN 10/100 Mbps

USB Host Port Stand alone: USB keyboard, USB scanner

Storage: USB flash drive

Bluetooth Bluetooth Ver.5.0

SPP (Bluetooth Classic), GATT (Bluetooth Low Energy)

Wi-Fi IEEE 802.11 a/b/g/n

Wi-Fi Security

Authentication method (encryption scheme)

* Infrastructure mode

- Open system (None/WEP64/WEP128)

- WPA/WPA2-PSK (TKIP+AES)

- EAP-FAST (TKIP/AES)

- PEAPv0 (TKIP/AES)

- EAP-TLS (TKIP/AES)

- EAP-TTLS (TKIP/AES)

60

Environment

Temperature Operation: 41°F - 104°F (5°C - 40°C)

Storage: -40°F - 140°F (-40°C - 60°C)

Humidity Operation: 25% - 85% (without condensation)

Storage: 10% - 90% (without condensation)

Power Supply

Power Supply

External Universal Switching Power Supply

Input: AC 100 V - 240 V, 2.0 A, 50 Hz - 60Hz

Output: DC 24 V, 3.75 A, 90 W

Paper Specification

Media Type Continuous, die-cut, black mark, fan-fold, notch, punched hole media,

Gen2 RFID tag (TD-4650TNWBR, TD-4750TNWBR)

Wound Type Outside wound

Media Width 0.8" - 4.4" (20 mm - 112 mm)

Media Thickness 2.36 mil - 7.48 mil (0.06 mm - 0.19 mm)

Roll Outside Diameter

(maximum) 5" (127 mm)

Core Size 1", 1.5" (25.4 mm, 38.1 mm)

Media Sensor Gap (Transmissive), Black mark (Reflective)

Ribbon Specification

Width

984.2" (300 m) long, max. Outer Diameter 2.64" (67 mm), 1" (25.4 mm)

core (ink coated outside)

360.1" (110 m) long, max. Outer Diameter 1.57" (40 mm), 0.5" (12.7 mm)

core (ink coated outside)

Ribbon Width 1.6" - 4.3" (40 mm - 110 mm)

RFID Specification (TD-4650TNWBR and TD-4750TNWBR only)

RF Protocol UHF EPC global Class 1 Gen2 / ISO 18000-63

Operating Frequency Global (902 MHz - 928 MHz) and EU (866 MHz - 868 MHz)

Minimum Pitch 0.625" (15.875 mm)

61

Other

Cutter Guillotine & Partial Auto cutter option (Not User Replaceable)*1,2

Label Peeler Label Peeler option (Not User Replaceable)*1,2

Bar Code

1D barcodes

Code128 subsets A, B, C, Code128UCC, EAN128, Interleaved 2

of 5, Interleaved 2 of 5 with check digit, Standard 2 of 5, Industrial 2

of 5, Code39, Code93, Code39 with check digit, EAN-13, EAN-8,

Codabar, Postnet, UPC-A, UPC-E, EAN and UPC 2 (5) digits

add-on, MSI, MSI with check digit, PLESSEY, China post, ITF14,

EAN14, Code11, TELEPEN, TELEPEN number, PLANET, Code49,

Deutsche Post Identcode, Deutsche Post Leitcode, LOGMARS

2D barcodes

CODABLOCK F mode, GS1 DataMatrix, Maxicode, PDF417,

AZTEC, Micro PDF417, QR Code, RSS Barcode (GS1 Databar),

TLC39

Printer Control Command FBPL-EZD (Compatible to EPL II, ZPL II, DPL)

FBPL-EZS (Compatible to EPL II, ZPL II, SBPL)

Built in Fonts

8 alphanumeric bitmap fonts

Monotype Imaging® TrueType font engine with one CG Triumvirate

Bold Condensed scalable font

*1 Not compatible with RFID tags.

*2 Only authorized Brother Dealers should perform accessory replacements.

62

10. Troubleshooting

10.1 Common Problems

This chapter explains how to resolve typical problems you may encounter when using the

printer. If you have any problems with the printer, first make sure you have performed the

following tasks correctly.

If you still have problems, contact the product manufacturer's customer service or your local

dealer.

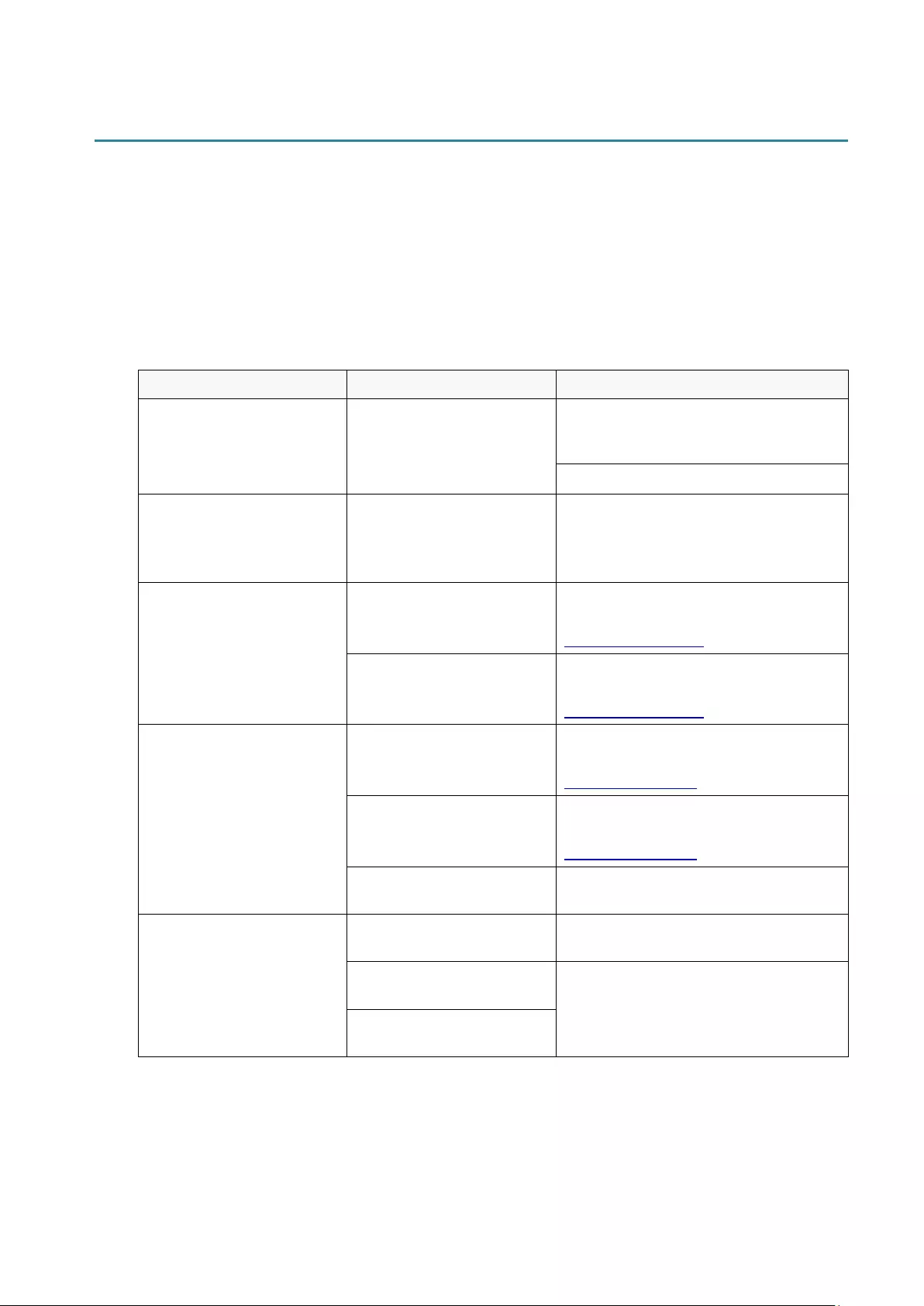

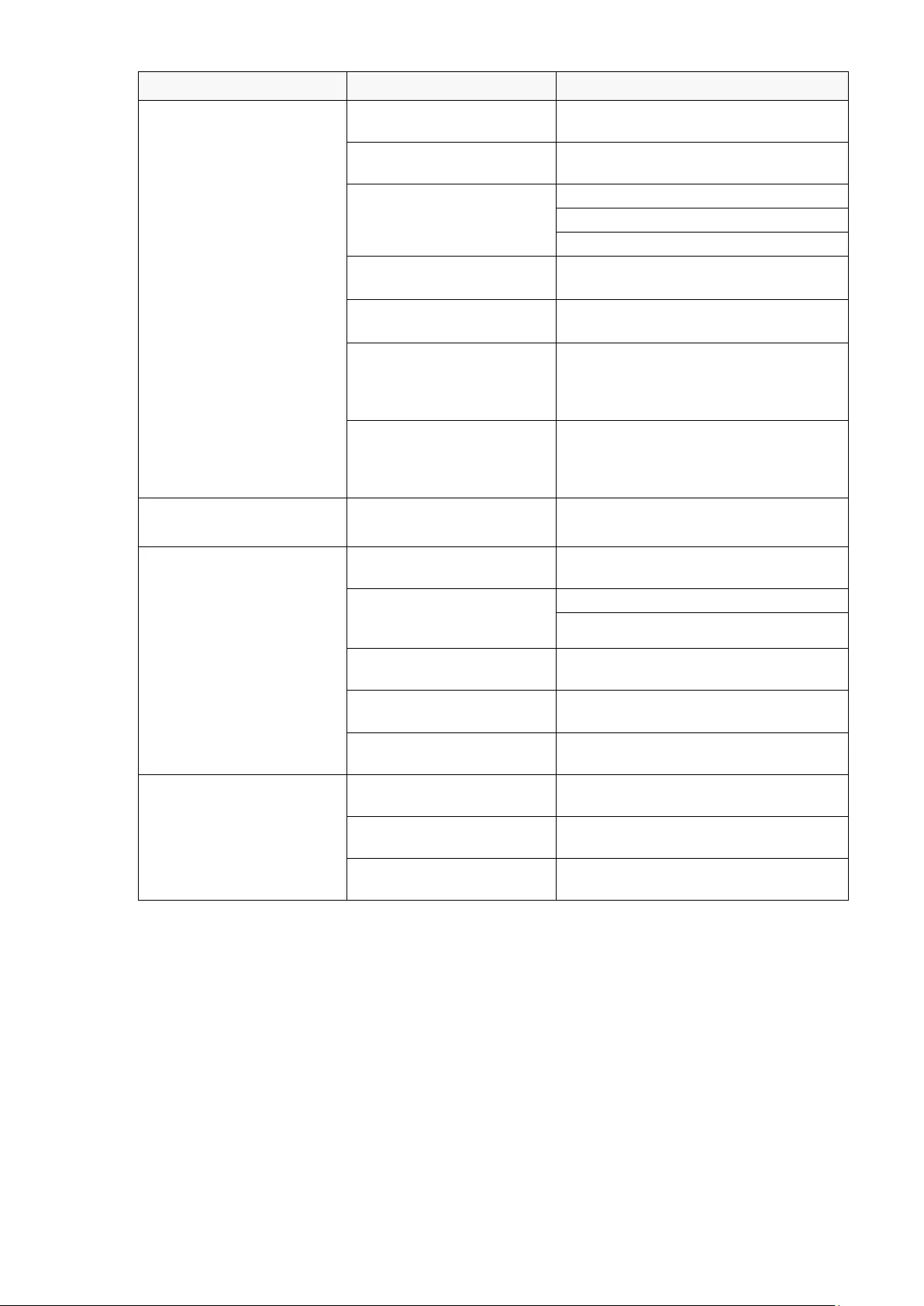

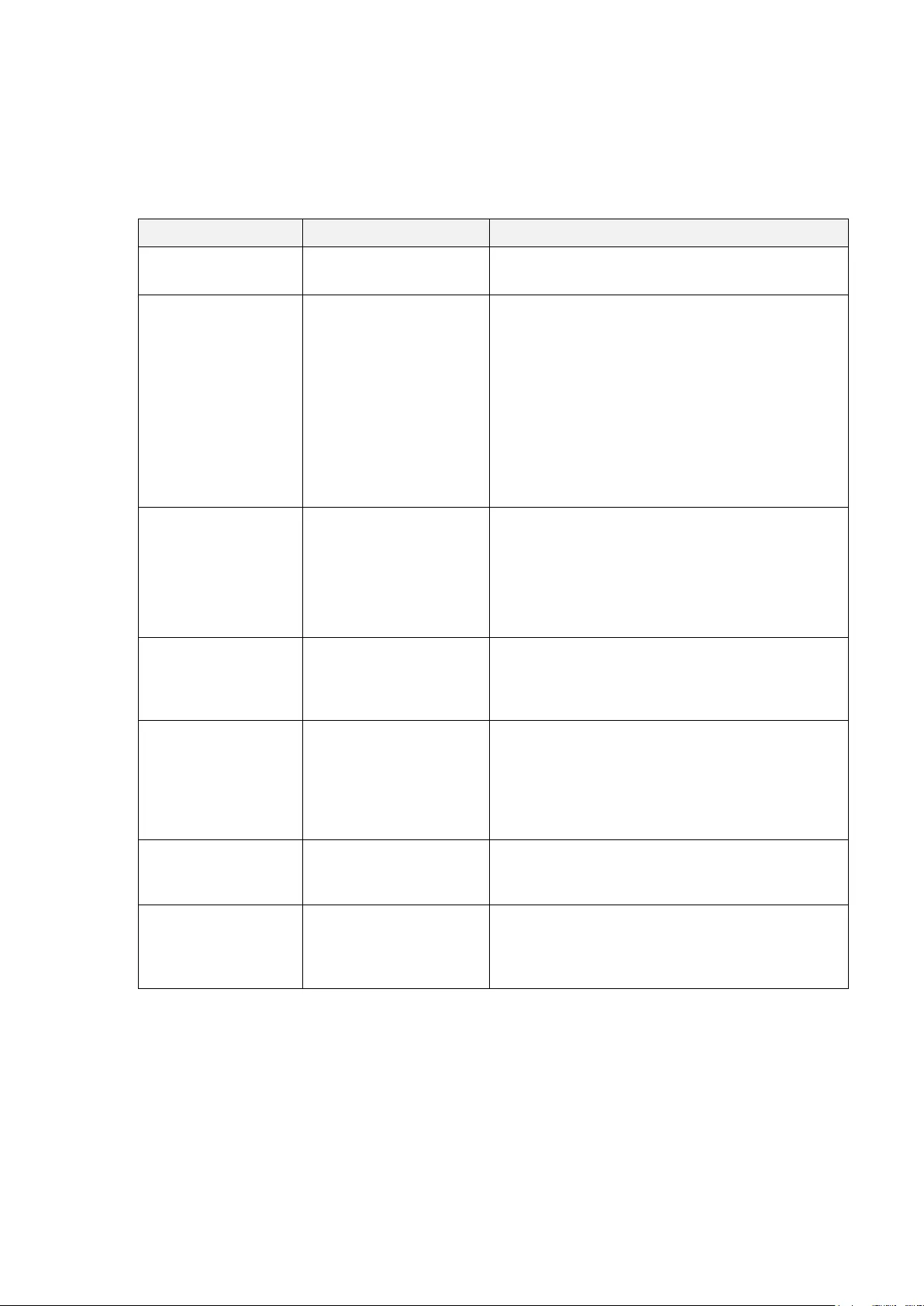

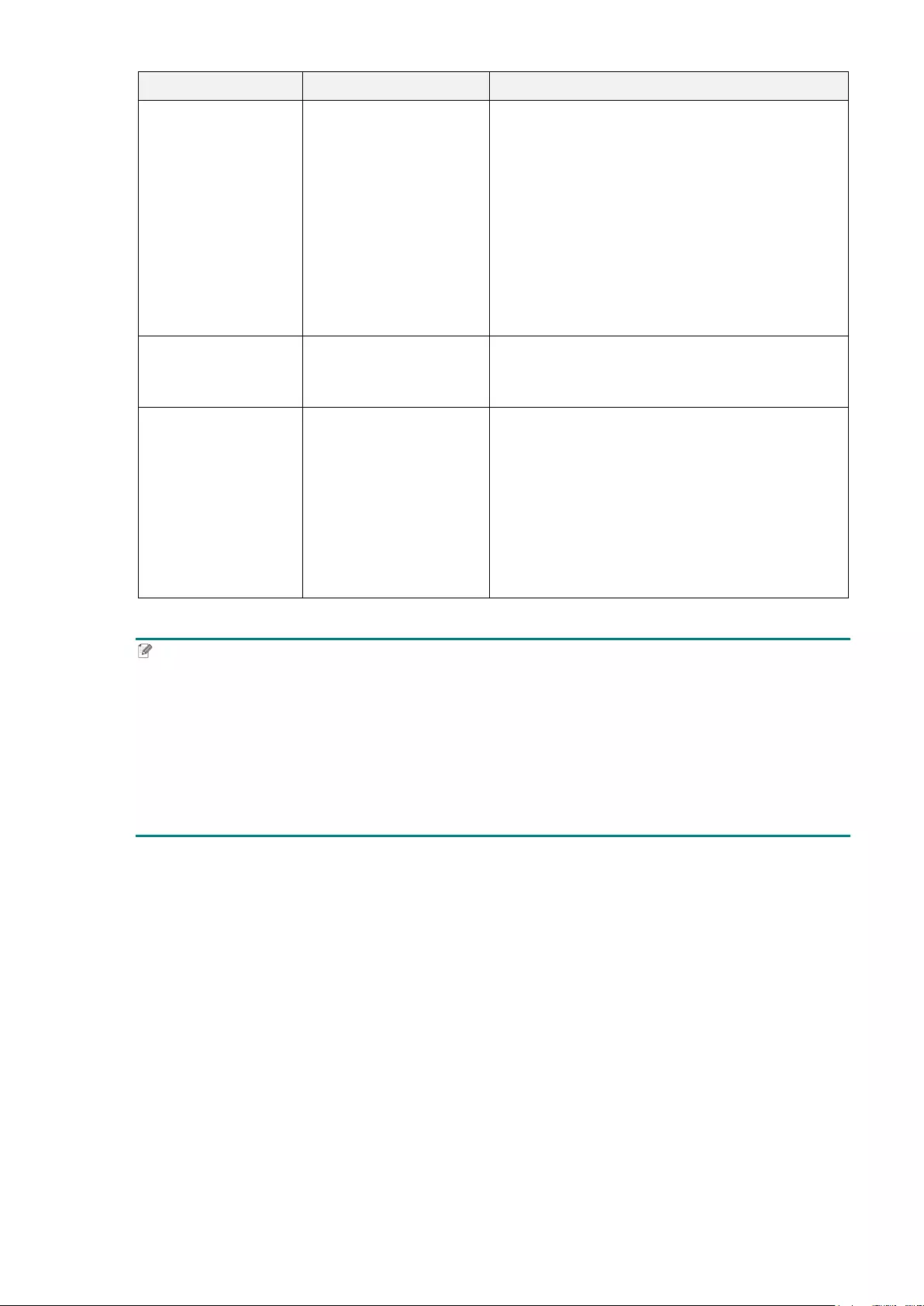

Problem Possible Cause Solution

The LED Indicator is not lit. The Power Cord is not

correctly connected.

Make sure the printer is correctly

connected to the power outlet (electrical

socket) using the Power Cord.

Turn the printer on.

- The Brother Printer

Management Tool shows

Head Open.

- The LED flashes in red.

The Print Head is open. Close the Print Head.

- The Brother Printer

Management Tool shows

Out of Ribbon or Ribbon

Encoder Err.

- The LED flashes in red.

The ribbon has finished. Install a new ribbon roll.

To install a new ribbon roll, see section

3.1 Load the Ribbon.

The ribbon is installed

incorrectly.

Reinstall the ribbon.

To install the ribbon roll, see section

3.1 Load the Ribbon.

- The Brother Printer

Management Tool shows

Out of Paper.

- The LED flashes in red.

The label roll has finished. Install a new label roll.

To install a new label roll, see section

3.2 Load the Media.

The label is installed

incorrectly.

Reinstall the label roll.

To install the label roll, see section

3.2 Load the Media.

The Gap/Black Mark

Sensor is not calibrated.

Calibrate the Gap/Black Mark Sensor.

- The Brother Printer

Management Tool shows

Paper Jam.

- The LED flashes in red.

The Gap/Black Mark

Sensor is not calibrated.

Calibrate the Gap/Black Mark Sensor.

Make sure the label size is

set correctly.

Set the label size correctly.

Labels may be jammed

inside the Printer Head.

63

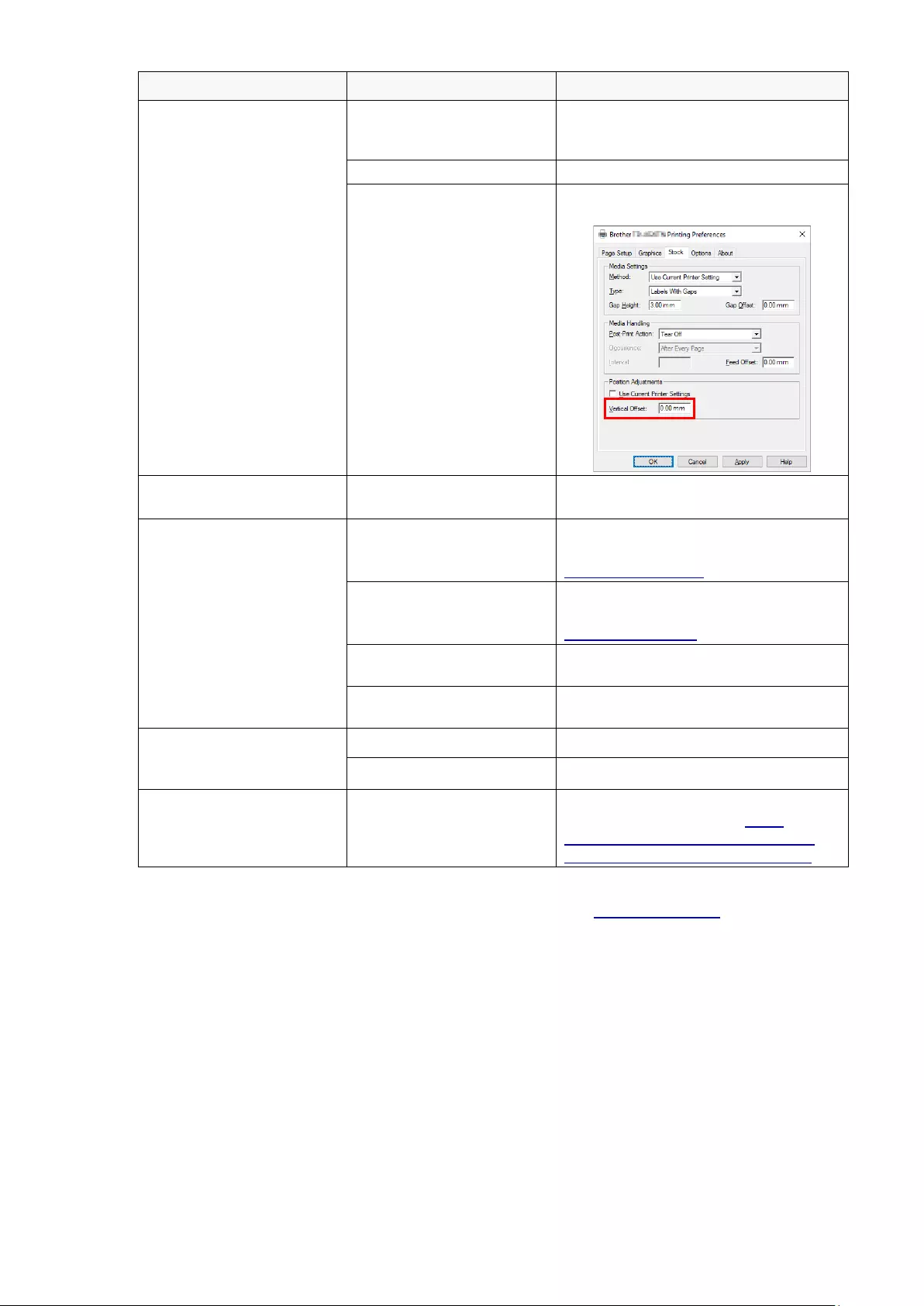

Problem Possible Cause Solution

I cannot print. The serial or USB cable is

not connected correctly.

Reconnect the serial or USB cable.

The serial or USB cable

may be damaged.

Try a new cable.

The ribbon or media may be

incorrect or damaged.

Use a correct ribbon or media.

Check the ribbon for damage.

Reinstall the ribbon.

The Print Head may need

cleaning.

Clean the Print Head.

The print density and speed

may be set incorrectly.

Adjust the print density and print speed.

The Print Head's harness

connector may not be

connected correctly with the

Print Head.

Turn off the printer and plug the Print

Head's harness connector to the Print

Head again.

Your custom program may

not contain the necessary

commands.

Make sure that your program contains

the PRINT command at the end of the

file and a CRLF at the end of each

command line.

Memory full

(FLASH/DRAM).

The printer's FLASH/DRAM

memory is full.

Delete unused files from the

FLASH/DRAM memory.

Poor Print Quality.

The ribbon/media is loaded

incorrectly.

Reload the media/ribbon.

Dust or adhesive has

accumulated on the Print

Head.

Clean the Print Head.

Clean the Platen Roller.

The print density is set

incorrectly.

Adjust the print density and print speed.

The Print Head is damaged. Run the printer self-test and check the

Print Head test pattern for missing dots.

The ribbon/media is

incompatible.

Install the correct ribbon/media.

Labels are skipped when

printing.

The label size is not

specified correctly.

Check if the label size is set up

correctly.

The sensor sensitivity is not

set correctly.

Calibrate the sensor using the Auto Gap

or Manual Gap options.

The media sensor is dirty.

Clean the Gap/Black Mark Sensor using

a blower brush.