Table of Contents

Brother TJ-4021TN User Manual

Displayed below is the user manual for TJ-4021TN by Brother which is a product in the Label Printers category. This manual has pages.

Related Manuals

User's Gui de TJ-4020TN/4021TN/4021TNR/TJ-4120TN/4121TN/4121TNR

TJ-4020TN/4021TN/4021TNR

TJ-4120TN/4121TN/4121TNR User's Guide (English)

© 2020 Brother Industries, Ltd. All rights reserved.

Version 02

ENG

i

Copyright Infor mation

The copyright in this manual, the software, and firmware in the printer described

therein are owned by Brother. All rights reserved.

Information in this document is subject to change without notice and does not

represent a commitment on the part of the company. No part of this manual may

be reproduced or transmitted in any form or by any means, for any purpose other

than the purchaser’s personal use, without the expressed written permission of

the company.

Trademarks

Wi-Fi® i s a re gi st ered trad em ar k o f Wi-Fi Alliance ®.

CG Triumvirate is a trademark of Agfa Corporation. CG Triumvirate Bold

Condensed font is under license from the Monotype Corporation.

All other trademarks are the property of their respective owners.

Any trade names and product names of companies appearing on Brother

products, related documents and any other materials are all trademarks or

registered trademarks of those respective companies.

Not all models are available in all countries or regions.

ii

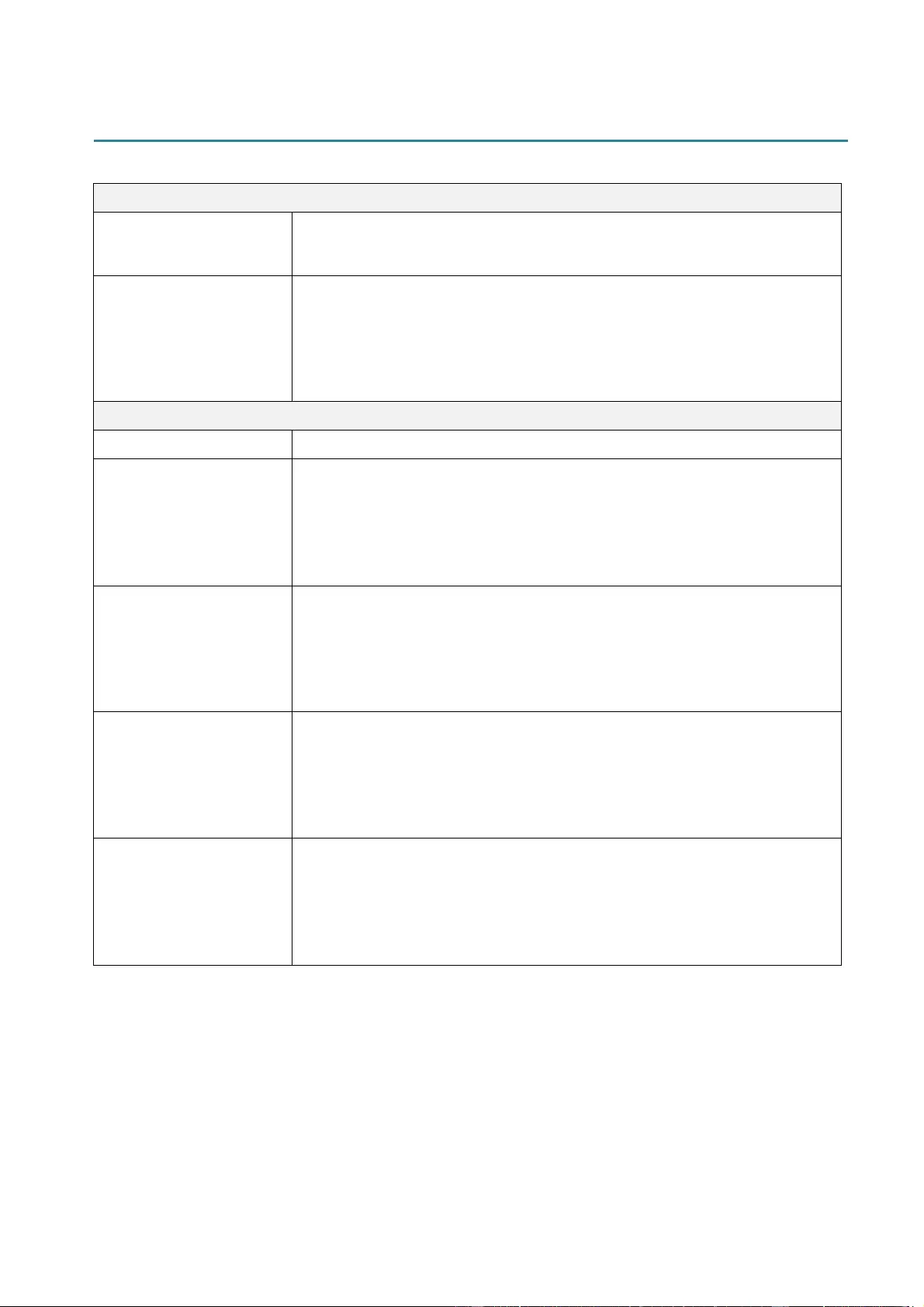

Contents

1. Introduction ........................................................................................................ 1

1.1 Product Introduction ...................................................................................... 1

1.2 Additional Product Reference ........................................................................ 1

2. Operations Overview .......................................................................................... 2

2.1 Unpack the Label Printer and Check the Components .................................. 2

2.2 Pr i nter Ov er vi ew ........................................................................................... 3

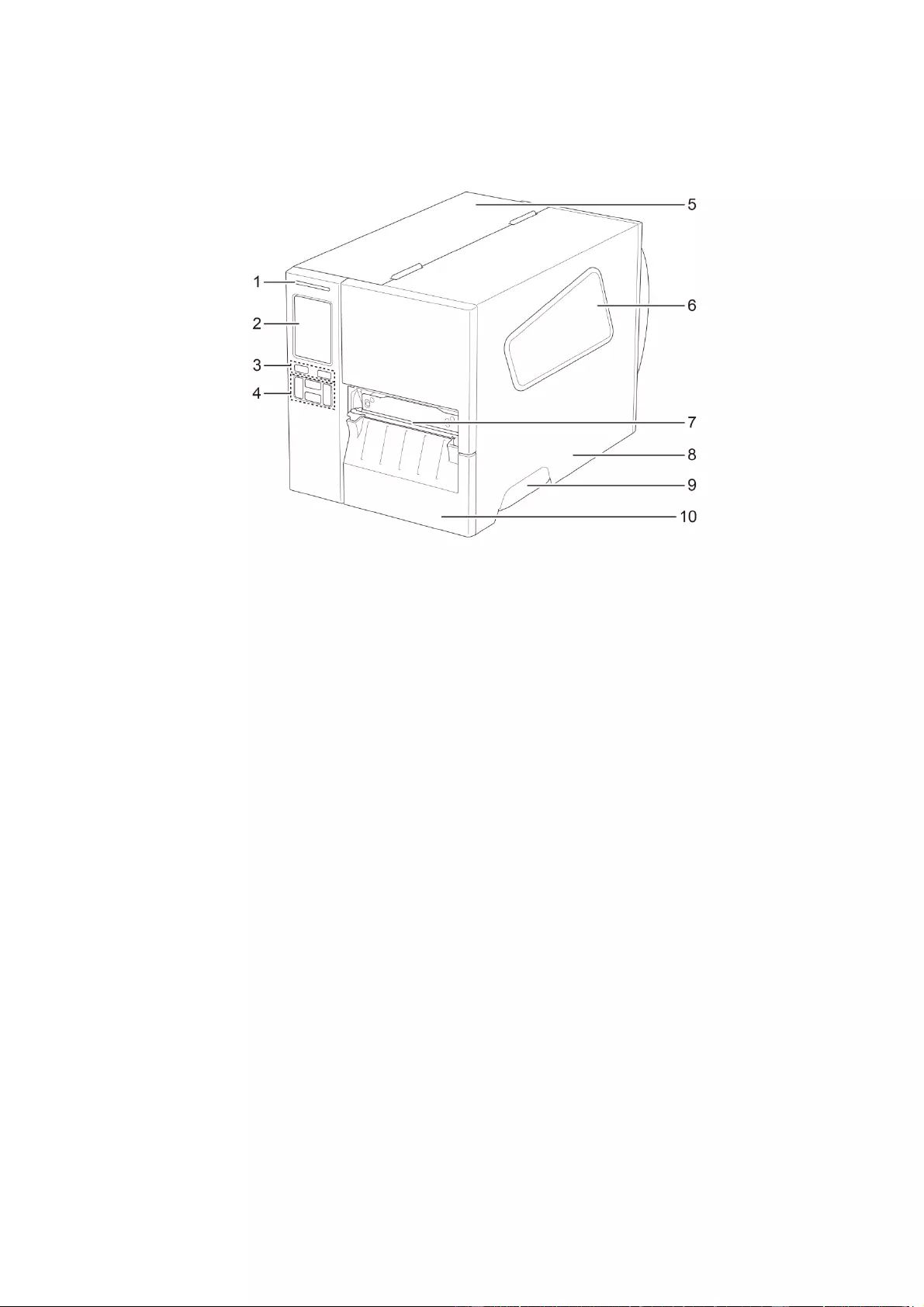

2.2.1 Front Vi ew .............................................................................................. 3

2.2.2 Interior View ........................................................................................... 6

2.2.3 Rear View............................................................................................... 7

2.3 Control Panels .............................................................................................. 8

2.3.1 LED Indicators and Buttons .................................................................... 9

2.3.2 Home Screen Icons (Touchscreen Models Only).................................. 10

2.3.3 Touchscre en Ov erv i ew ......................................................................... 11

3. Set Up Your Printer .......................................................................................... 16

3.1 Connect the Power Cord ............................................................................. 16

3.2 Lo ad t h e Rib bon .......................................................................................... 17

3.3 Rem ove Used R i bbon ................................................................................. 20

3.4 Lo ad the Media ........................................................................................... 21

3.4.1 Load Label Roll .................................................................................... 21

3.4.2 Load External M edia ............................................................................ 24

3.4.3 Load the Media in Peeler Mode (Optional) ........................................... 27

3.4.4 Load Media in Cutter Mode (Optional) .................................................. 31

4. Improve Print Quality ........................................................................................ 34

4.1 Adjust Print Head Tension to Improve Print Quality ..................................... 34

4.2 Avoid Wrinkled Labels ................................................................................. 34

4.2.1 Adjust Ribbon Tension ......................................................................... 34

4.2.2 Change the Print Density/Darkness Settings ........................................ 36

4.2.3 Try Different Media ............................................................................... 36

5. Printing ............................................................................................................. 37

5.1 Printer Driver Installation ............................................................................. 37

5.1.1 USB Connection (Windows/Mac/Linux) ................................................ 37

5.1.2 Wi-Fi Network Connection (Windows) .................................................. 38

5.1.3 Wired Network Connection (Windows) ................................................. 39

5.2 Create and Print Labels Using BarTender ................................................... 40

iii

6. Operation ......................................................................................................... 41

6.1 Power-on Utilities ........................................................................................ 41

6.1.1 Ribbon and Gap/Black Mark Sensor Calibration ................................... 42

6.1.2 Gap/Black Mark Sensor Calibration, Self-T est, an d Ent er i ng

Dump Mode.......................................................................................... 43

6.1.3 P rinter Init ialization ............................................................................... 47

6.1.4 Media Sensor Calibration (for the Black Mark Sensor) ......................... 48

6.1.5 Media Sensor Calibration (for the Gap Sensor) .................................... 48

6.1.6 Skip th e AUTO.BAS Program ............................................................... 49

7. Change Printer Settings using the Touchscreen............................................... 50

7.1 Setting Menu ............................................................................................... 50

7.1.1 FBPL Settings ...................................................................................... 50

7.1.2 ZPL2 Settings ....................................................................................... 52

7.2 Sensor Settings ........................................................................................... 55

7.3 Interface Settings ........................................................................................ 56

7.3.1 Serial Communication Settings............................................................. 56

7.3.2 Ethernet Settings .................................................................................. 57

7.3.3 Wi-Fi Settings ....................................................................................... 58

7.3.4 RFID (Radio Frequency Identification) Settings .................................... 60

7.4 Advanced Settings ...................................................................................... 66

7.5 File Manager ............................................................................................... 67

7.6 Diagnostic Functions ................................................................................... 68

8. Brother Printer Management Tool (BPM) ......................................................... 69

8.1 Start th e BPM .............................................................................................. 69

8.2 Auto-Calibrating the Media Sensor using the BPM ...................................... 70

9. Setting Up th e RF I D ......................................................................................... 71

9.1 Introduction ................................................................................................. 71

9.2 RFID Calibration ......................................................................................... 72

9.2.1 Load the RFID Media ........................................................................... 72

9.2.2 RFID Calibration Procedure ................................................................. 73

10. Product Specifications ...................................................................................... 76

11. Troubleshooting ............................................................................................... 79

11.1 Com m on Pr o bl em s ..................................................................................... 79

11.2 Touchscr e en Er r or M ess ag es ..................................................................... 81

11.3 RFID Error Messages ................................................................................. 82

12. Maintenance .................................................................................................... 84

1

1. Introduction

1.1 Product Introduction

The robust design of th e la bel pr i nter can handle up to 450 m of ribbon and has the capacity to

handle 8" label rolls.

The label printer comes equipped with a number of f unctions, including:

- Built-i n Eth er net

- RS-232C interface

- USB ports (for connecting a keyboard or barcode scanner)

- Wi-Fi Int erfa ce Ex p an s i on Slo t ( for th e opt ional Wi-Fi Interface (PA-WI-002))

- 3.5" color Touchscreen (TJ-4021TN/TJ-4021TNR/TJ-4121TN/TJ-412 1T N R onl y )

The label pr i n ter us es i ts hi gh-performance and high-quality built-in Monotype Imaging®

TrueType font engine with the CG Triumvirate Bold Condensed smooth scalable font. It also

provides a choice of eight differ e nt siz es o f the al p ha num er i c bi tm ap font and suppor ts most of

the standard b ar c od e for m ats.

1.2 Ad di tional Product Reference

For information on how to write custom programs for your lab el pri nt er, see the Command

Reference on your model's Manuals page at support.brother.com.

2

2. Operations Overview

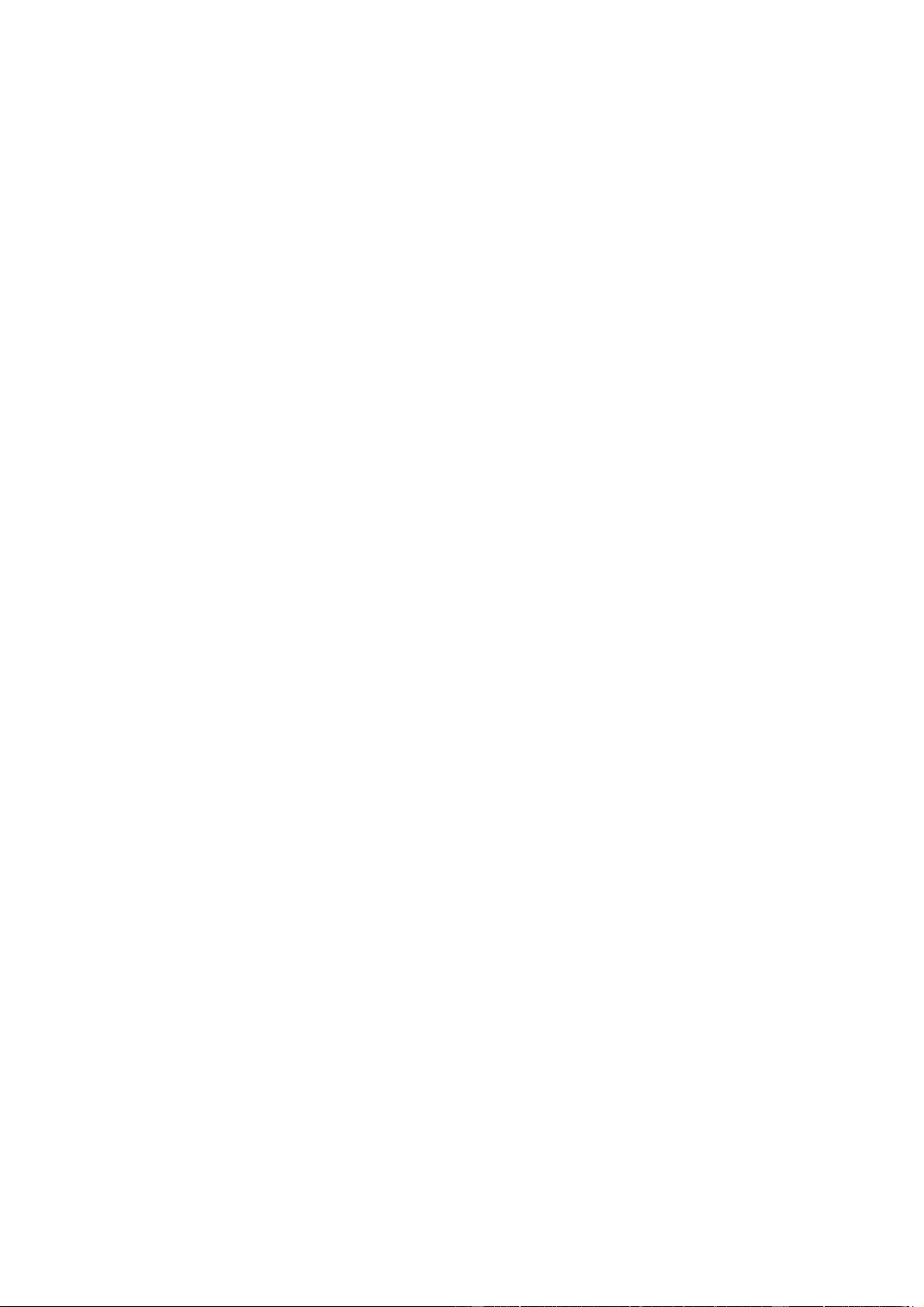

2.1 Unpack the Label Pri n ter and Check the Components

Note

Keep the packaging materials in case you must s h i p the pr i nt er .

The components included in the box:

1. Label Pr i nter

a. TJ-4020TN/TJ-4120TN

b. TJ-4021TN/TJ-4121TN

c. TJ-4021TNR/TJ-4121TNR

2. Power Cord

3. USB Cable

4. Paper Core

If any components are missing, contact the product manufacturer's customer service or your

local dealer .

3

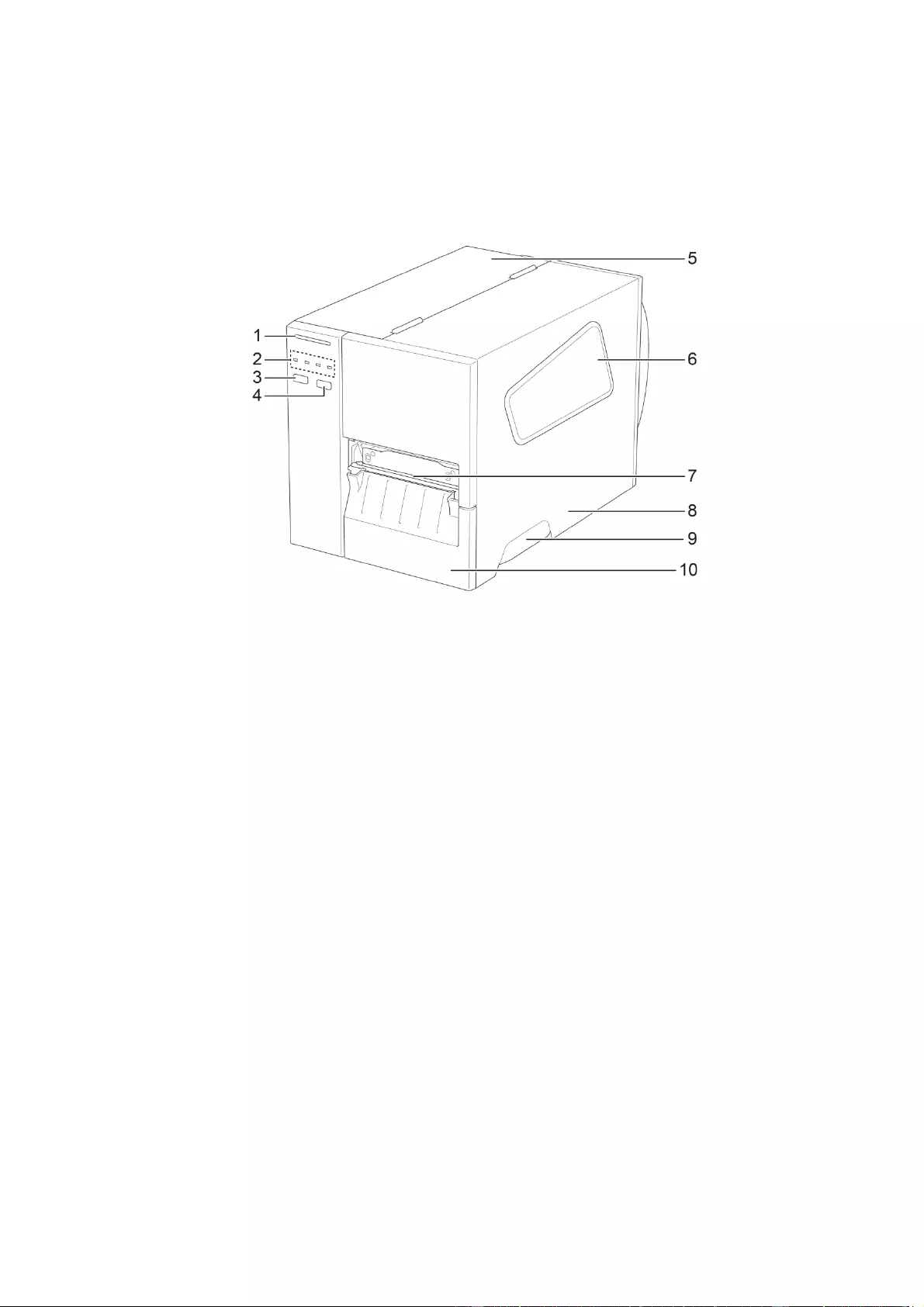

2.2 Printer Overview

2.2.1 Front View

TJ-4020TN/TJ-4120TN

1. Power LED

2. LED Indicators

3. Pause Button

4. Feed Button

5. PCB Cover

6. Media View Window

7. Medi a Output Slot

8. Media Cover

9. Media Cover Handle

10. Lower Front Panel

4

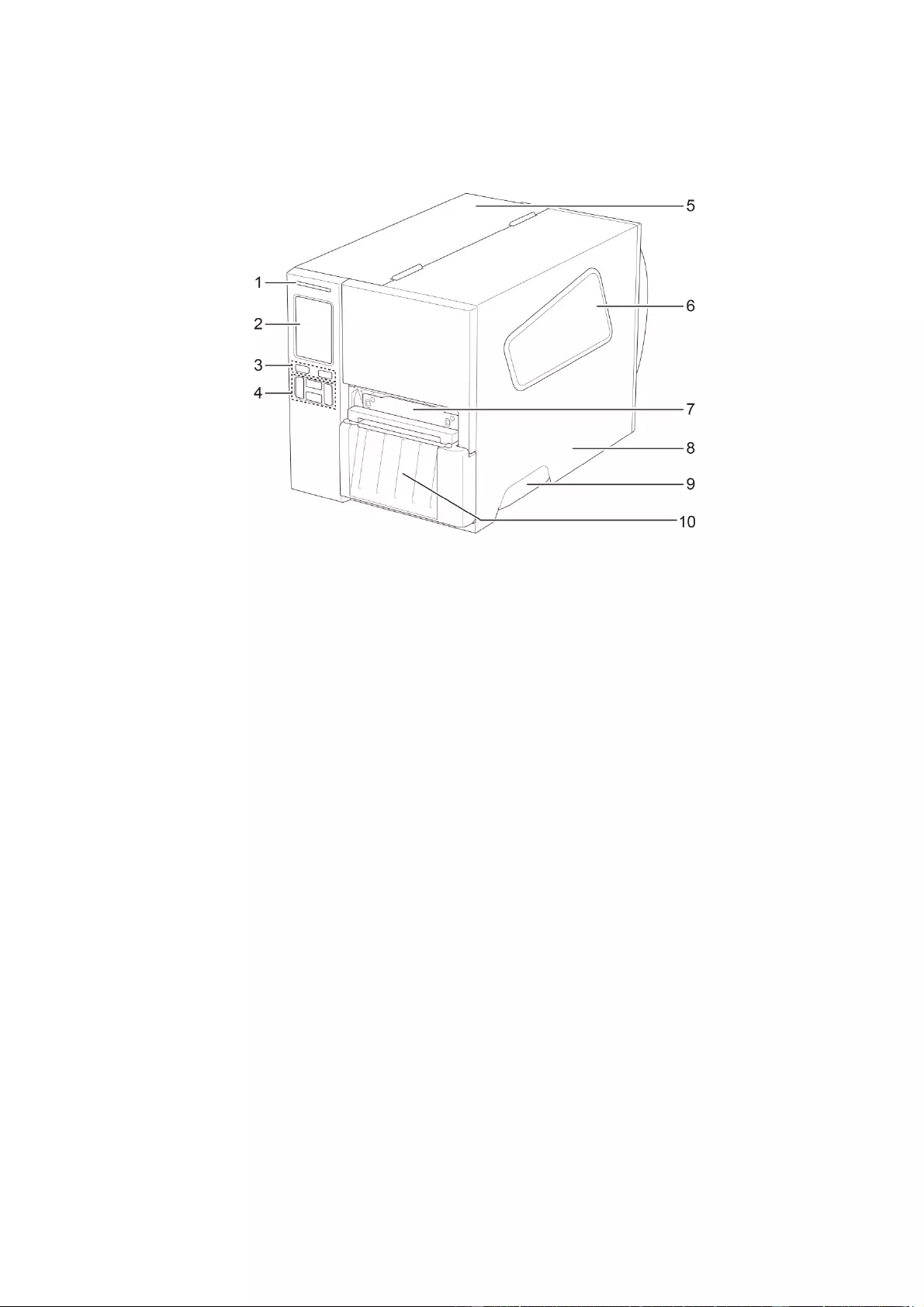

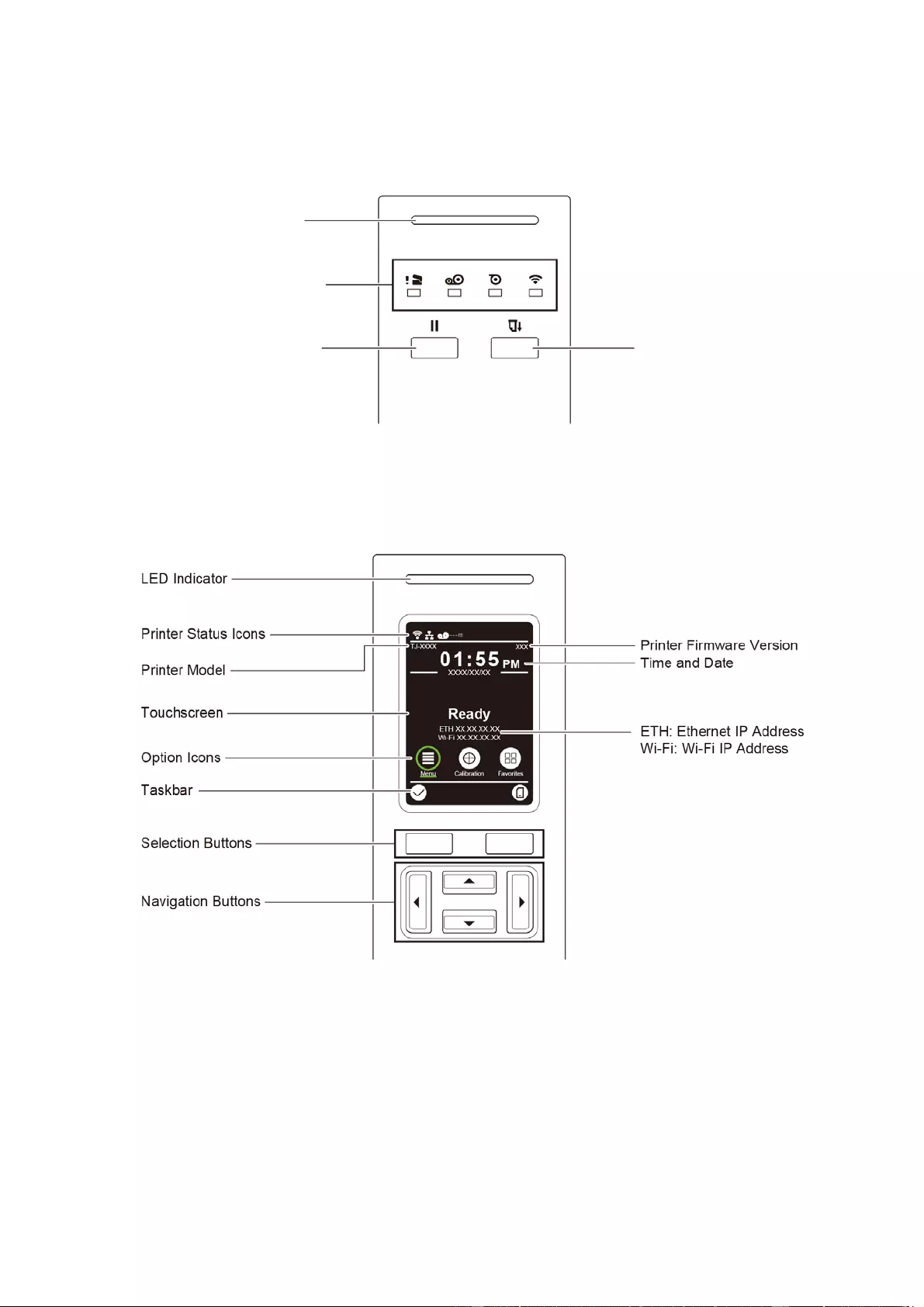

TJ-4021TN//TJ-4121TN

1. Power LED

2. Touchscreen

3. Selection Buttons

4. Navigation Buttons

5. PCB Cover

6. Media View Window

7. Medi a Output Slot

8. Media Cover

9. Media Cover Handle

10. Lower Front Panel

5

TJ-4021TNR/TJ-4121TNR

1. Power LED

2. Touchscreen

3. Selection Buttons

4. Navigation Buttons

5. PCB Cover

6. Media View Window

7. Media Output Slot

8. Media Cover

9. Media Cover Handle

10. RFID Tear Cover

6

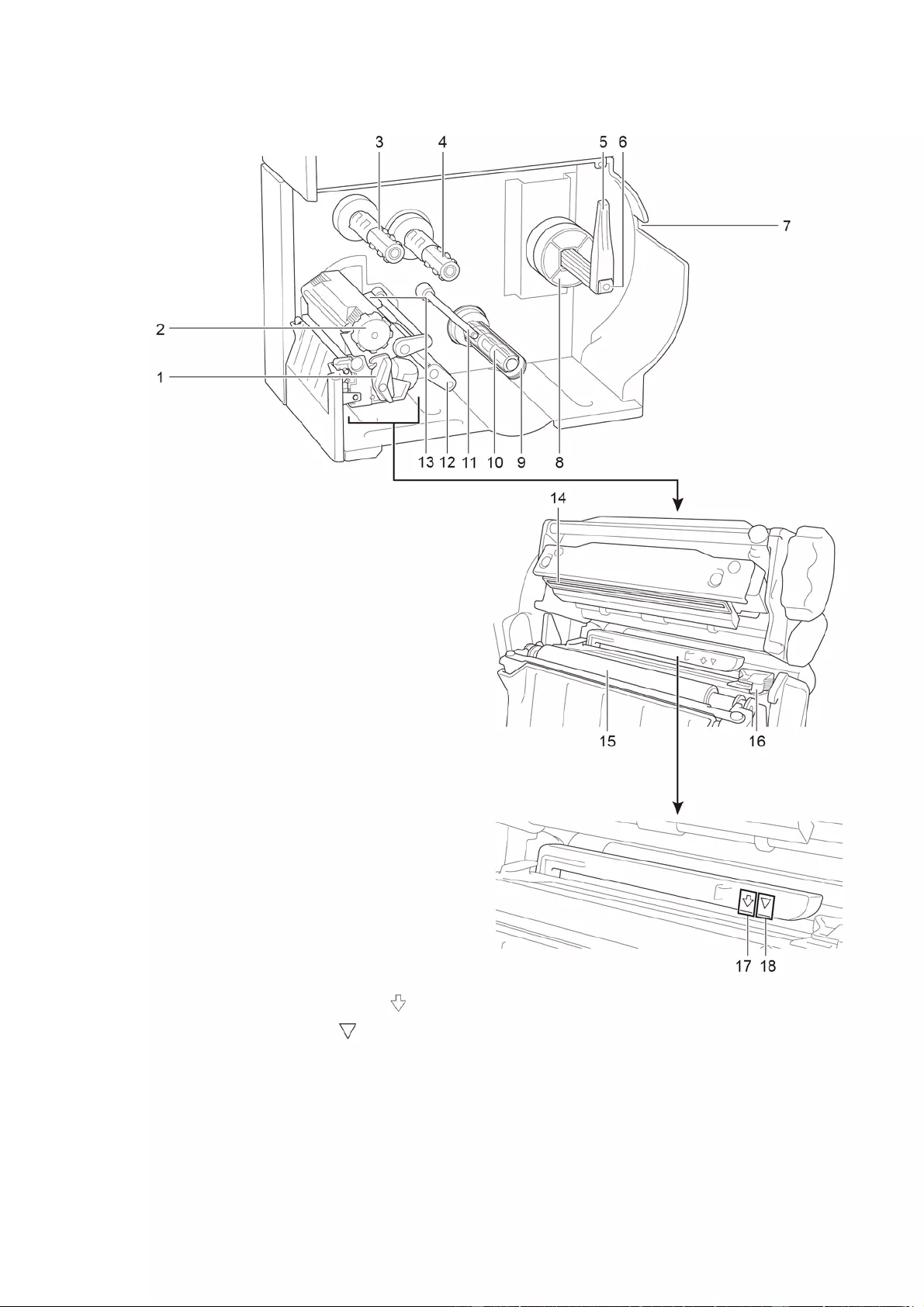

2.2.2 Interior View

1. Print Head Release Lever

2. Print Head Ten sion Adjustment Knob

3. Ribbon Rewind Spindle

4. Ribbon Supply Spindle

5. Label Roll Guard

6. Label Supply Spindle

7. External Label Entry Slot

8. 3" Core Adapter

9. Liner Securing Clip *

10. Liner Rewind Spindle *

11. Media Guide Bar *

12. Damper

13. Ribbon End Sensor

14. Print Head

15. Platen Roller

16. Front Label Guide

17. Black Mark Sensor (sh ow n as )

18. Gap Sensor (sh own as )

* Optional accessories for the Label Peeler Assembly.

7

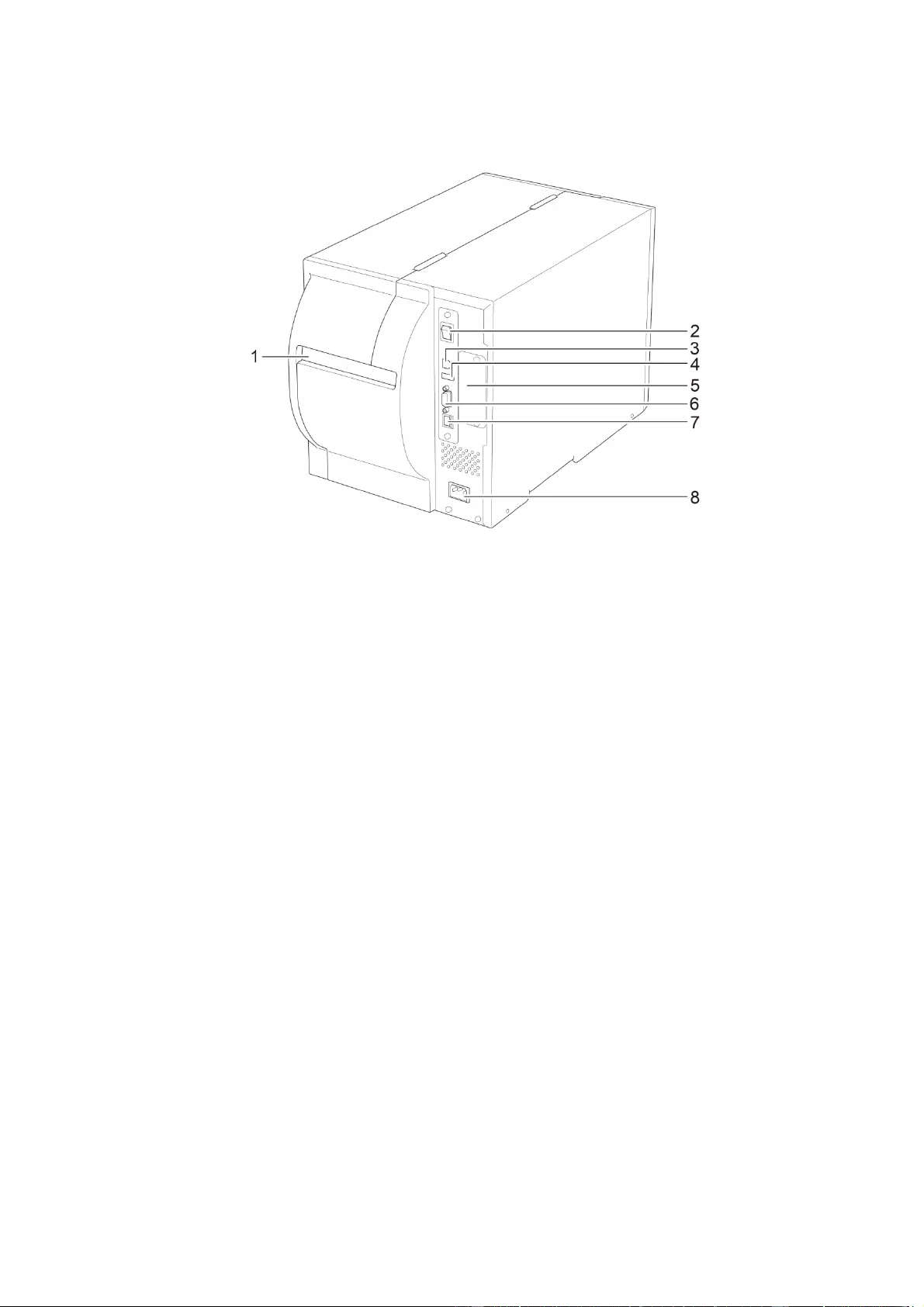

2.2.3 Rear View

1. Exter nal La bel Ent r y Slot

2. Power Switch

3. USB Port (USB 2.0/Hi-Speed Mode)

4. USB Host Port

5. Wi-Fi Interface Expansion Slot *

6. RS-232C Serial Port

7. Ethernet Port

8. Pow er C or d Soc ket

* For the optional Wi-Fi Interface (PA-WI-002).

8

2.3 Control Panels

TJ-4020TN/TJ-4120TN

TJ-4021TN/TJ-4021TNR/TJ-4121TN/TJ-4121TNR

Power LED

LED Indicat ors

Pause Button Feed Button

9

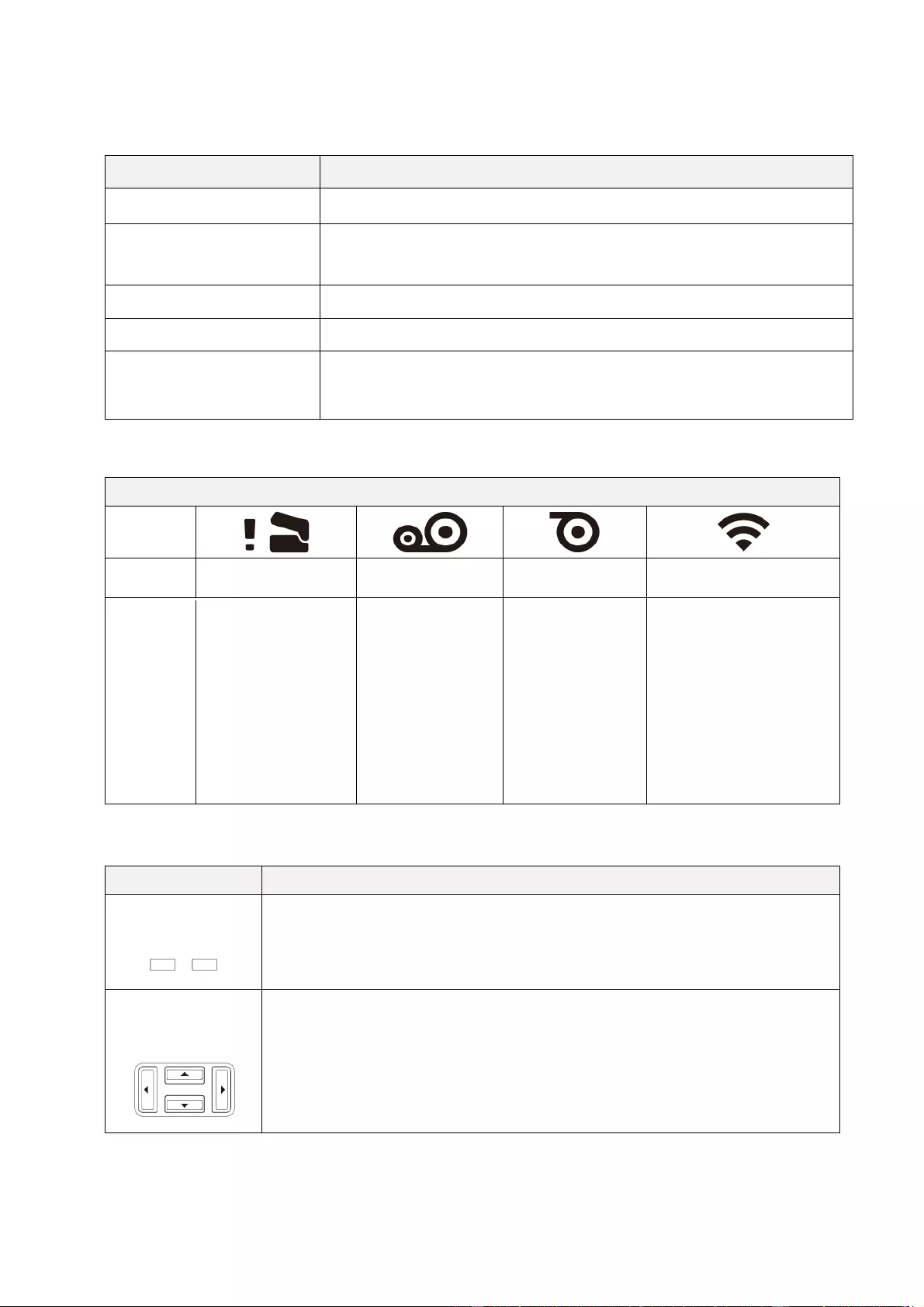

2.3.1 LED Indicators and Buttons

Power LED Indications (All Models)

LED Color Description

Green (Lit) The power is on and the printer is ready to use.

Green (Flashing) - The printer is downloading data from a computer.

- The printer is paused.

Amber The printer is removing data from memory.

Red (Lit) The Print Head is open or there is a Cutter error.

Red (Flashing) There is a printing error, such as "Pape r Emp ty", "Paper Jam",

"Ribbon Empt y", or "Memory Error".

TJ-4020TN/TJ-4120TN

TJ-4021TN/TJ-4021TNR/TJ-4121TN/TJ-4121TNR

LED Indicators

Icons

Name Print Head Ribbon Paper Communication

Status Lit: Print Head open

Lit: Out of ribbon

• Blin k ing (after

power ing th e

pri nter on) :

Awa iting the

first print job

• Blinking

(between print

jobs): Ribbon

near end

Lit: Out of paper

Blinking: Paper

jam

Lit: Radio-Frequency

connected

Blinking: Radio-

Frequency

communication

Buttons Function

Selection Buttons

Use to select highlighted icons and m enus.

Navigation Buttons

Use to navigate the Touchscreen and highlight icons and menus.

10

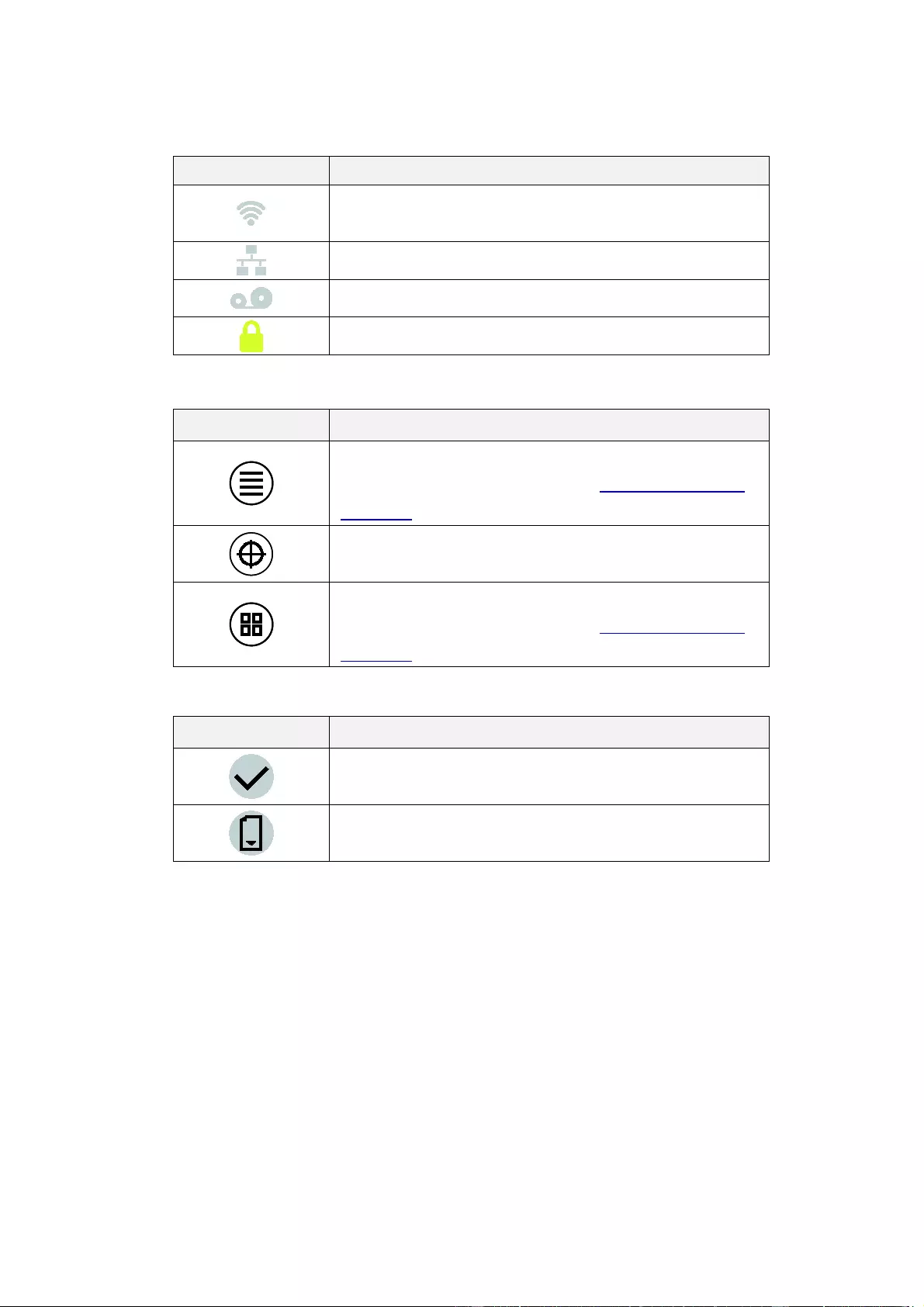

2.3.2 Home Screen Icons (Touchscreen Models Only)

Printer Sta tus Icons

Option Icons

Taskba r Icons

Icon Indication

Wi-Fi device is ready (Available when the Wi-Fi Interface

is installed)

Ethernet is connected

Ribbon capacity (%)

Security lock

Icon Function

Access the Main Menu

For more information, see section 2.3.3 Touchscreen

Overview.

Calibrate the media sensor

Enter the “Favorites” screen

For more information, see section 2.3.3 Touchscreen

Overview.

Icon Function

Accept your selection

Feed one label

11

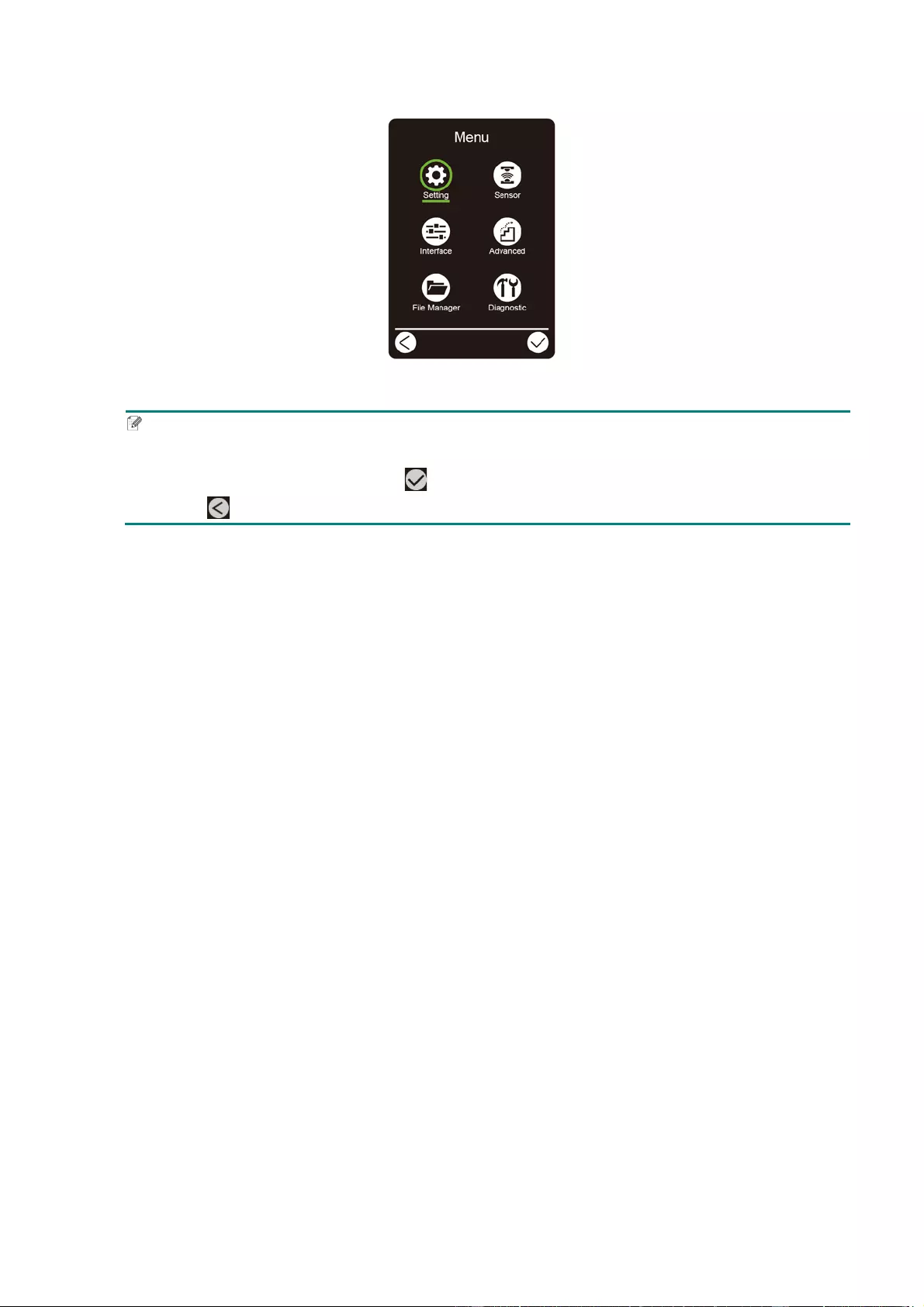

2.3.3 Touchscreen Overview

(Available for TJ-4021TN, TJ-4021TNR, TJ-4121TN and TJ-4121TNR only)

Tap the i cons to access printer features and change settings.

Access the Main Menu

Make sure the printer’s Touchscreen displays “Ready”. If not, tap the Menu icon .

Note

Y ou can al so use the Control Panel b uttons . U se the Nav igati on butto ns to select th e Menu icon,

and then press the Selection butto n un der icon.

12

To sel ec t an option on th e Main Menu, tap the option’s icon.

Note

Y ou can al so us e the Control Panel buttons. Use the Navigation butto ns t o brow s e the opt ions ,

and then press the button under the icon. To return to the previous screen, press the button

under the icon.

13

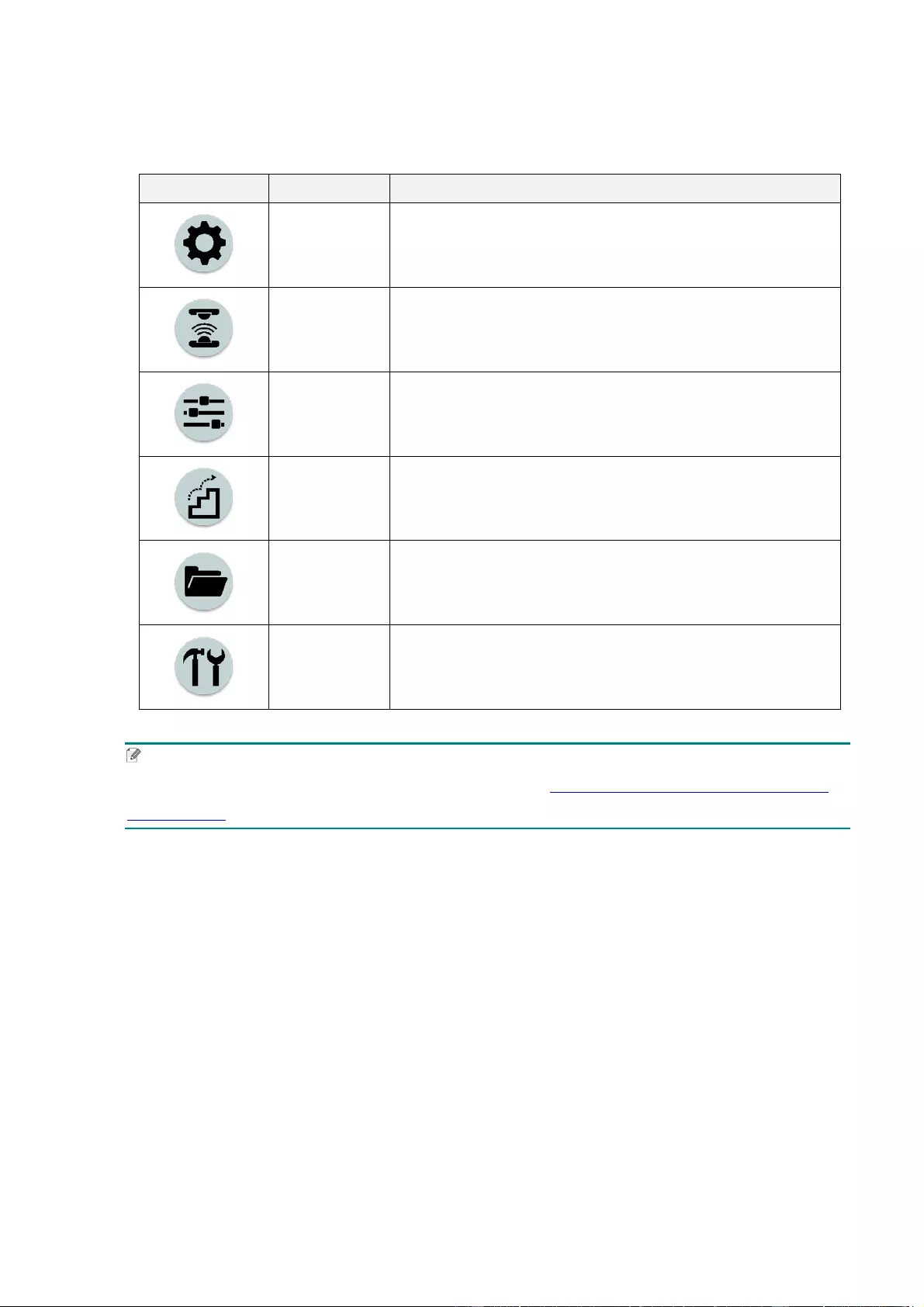

Main Menu Overview

Use the Main Menu options to configure various printer settings without connecting the

printer to a com p ut er.

Icon Option Description

Setting Configure the printer's FBPL and ZPL2 settings.

Sensor Calibrate the selected media sensor. We recommend

calibrating the sensor every time you change the media.

Interface Conf igure the printer interface settings.

Advanced Con fi gur e th e pri nt er's Touchscreen, i nitialization, cutter

type, or media low warning settings.

File Manager Check or manage the available printer memory.

Diagnostic Chec k t h e printer s tat us to help tr ou bl esh oot any is s ues .

Note

For more information about printer settings, see section 7. Ch an g e Pri n ter Settings usi ng th e

Touchscreen.

14

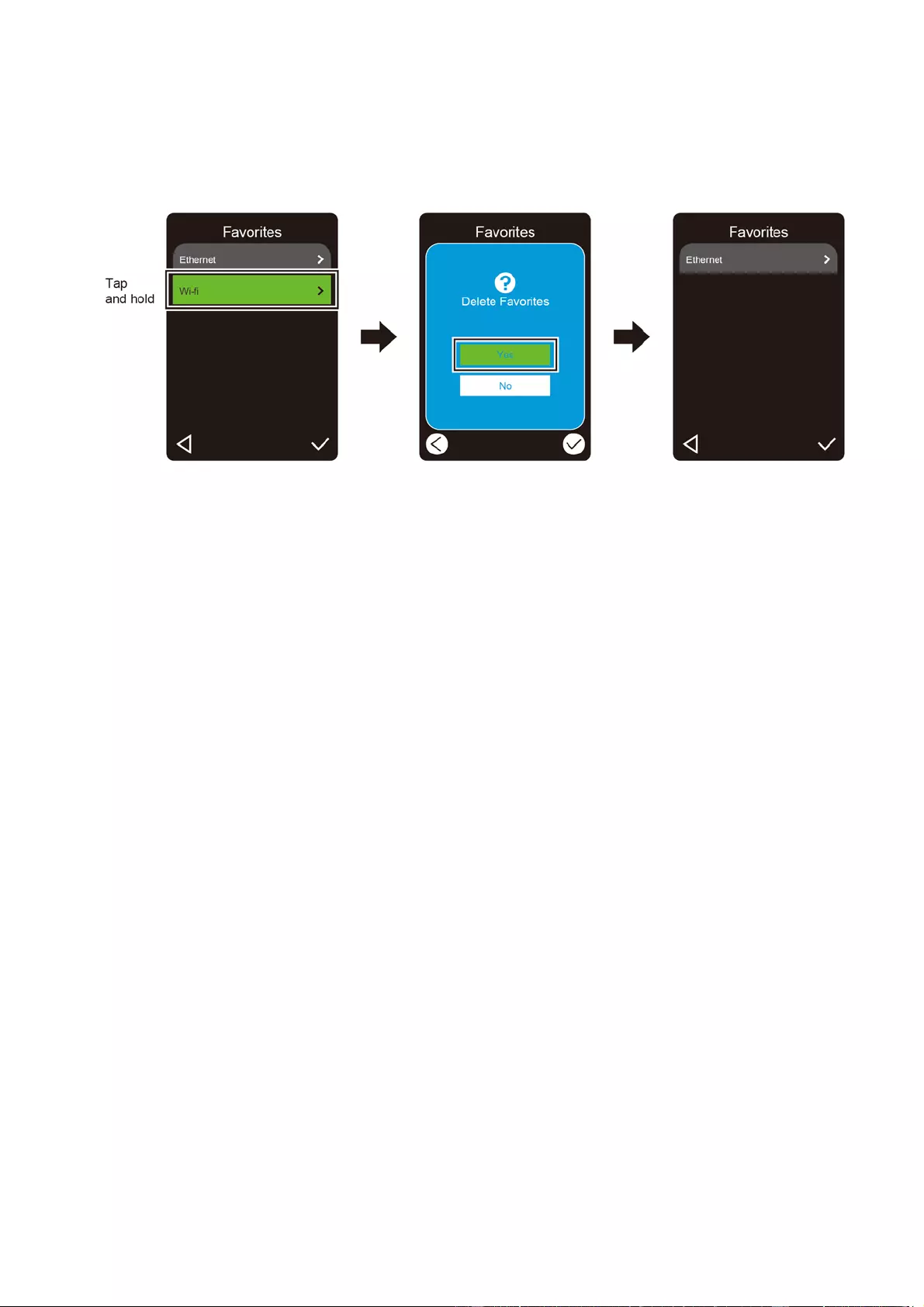

Favorites

Add frequently used Main Menu opti ons to “Favorites” for quick access. To display the

“Favorites” list, tap the Favorites icon .

To add an option to the "Favorites" list:

1. Tap and hold the option you want to add to favorites until “Join Favorites” appears.

2. Tap “Yes”.

15

To remove an option from the "Favorites" list:

1. Tap and hold the option you want to r em ove from favori t es unti l “Delete Favorites”

appears.

2. Tap “Yes”.

16

3. Set Up Your Printer

3.1 Connect the Power C ord

1. Place the printer on a flat, secure surface.

2. Mak e sure th e Power Switch is in the OFF pos ition.

3. Connect the printer to the computer us i n g a USB cable.

4. Plug the Power Cord into the Power Cord Socket at the rear of the printer, and then plug

the Power Cor d int o a correctly grounde d pow er o ut let (ear thed el ect r ical socket).

Note

Before plugging the Power Cord into the printer's Power Cord Socket, make sure the

printer's Power Switch is in the OFF position.

A fter p ow er i n g the pr i nt er on, th e LED blinks unti l t he pr i nter rec ei v es the fi r st pr int j ob .

17

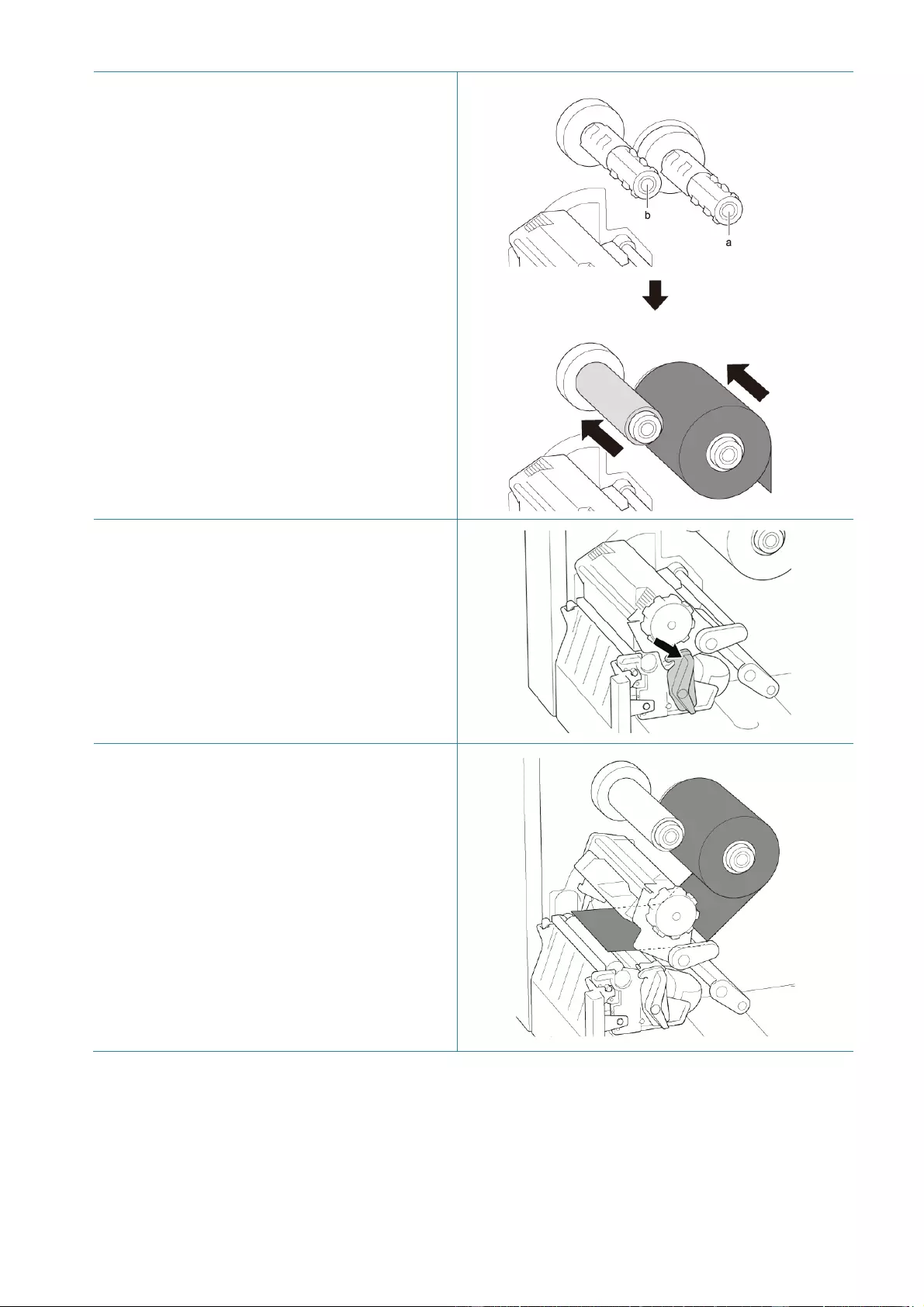

3.2 Load the Ribbon

Ribbon loading path

1. Open the Media Cover.

Ink coated outside

Ink coated inside

18

2.

a. Install the ribbon onto the Ribbon

Sup ply Spi n dl e .

b. Install the Paper Core onto the Ribbon

Rew i nd Spindl e.

3. Push the Print Head Release Lever to

open the Print H ead.

4. Thread the ribbon under the ri b bo n gui d e

bar and through the ribbon sensor slot

following the loading path printed on the

Label Pr i nter C ov er.

19

5. Adhere the ribbon leader onto the Ribbon

Rew i nd Pa per C or e. Keep the ribbon flat

and without wrinkles.

6. Wind the Ribbon Rewind Spindle

counterclockwise about t hr ee to five turns

until the ribbon is smooth, flat and w i t hout

wrinkles.

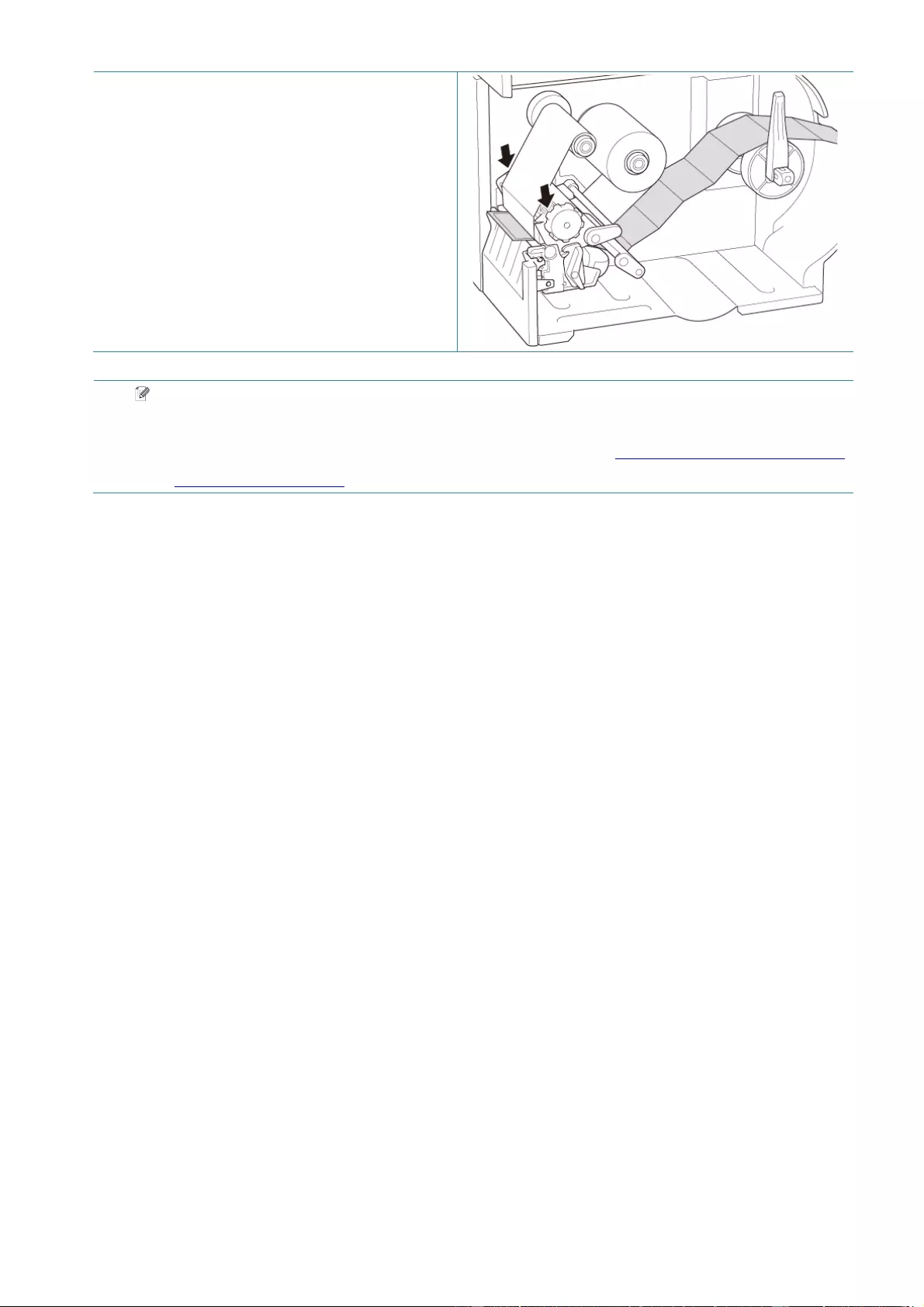

7. Close the Print Head by pus hi n g dow n on

bot h sid es o f the P r i nt Head Release

Lever.

20

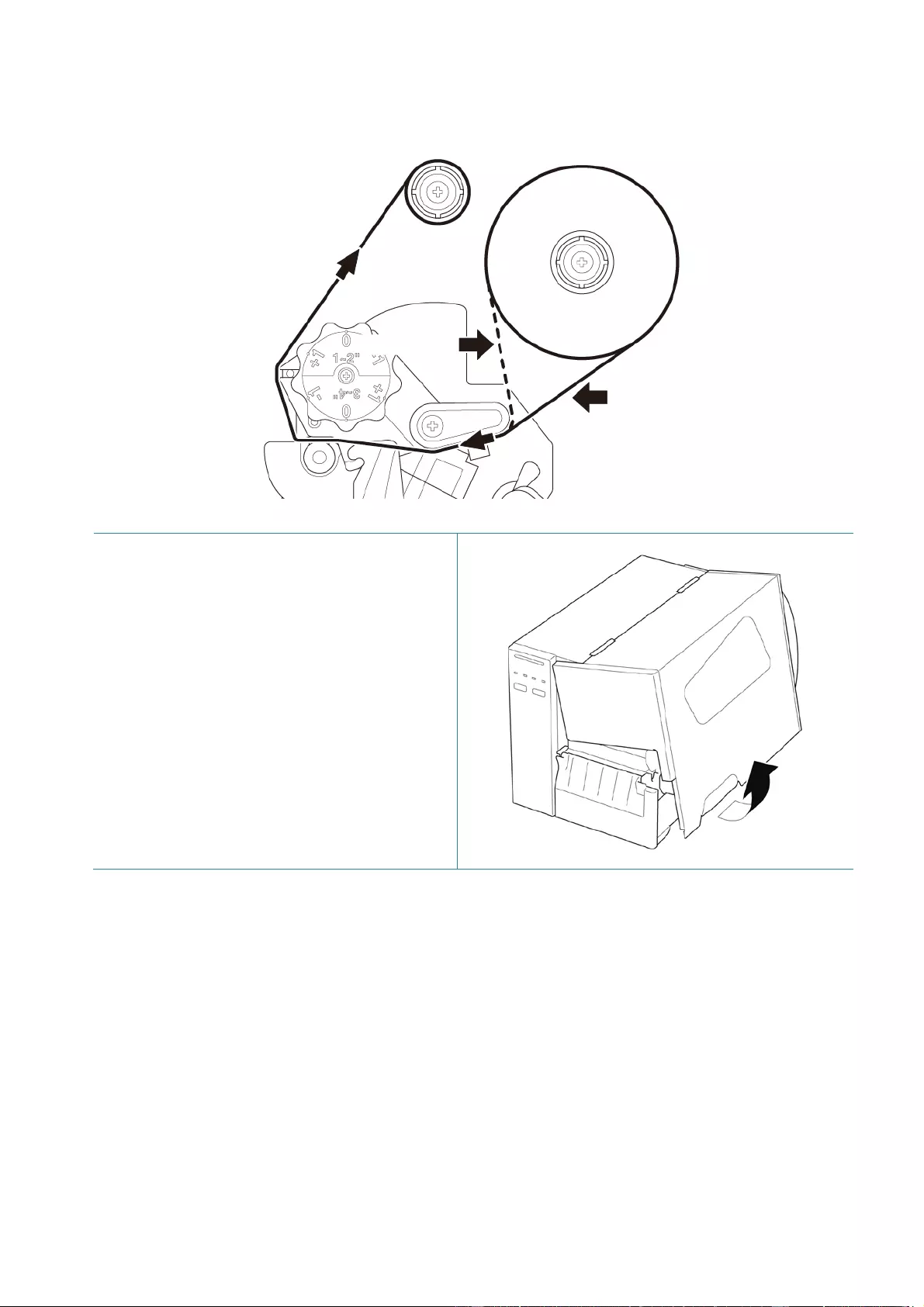

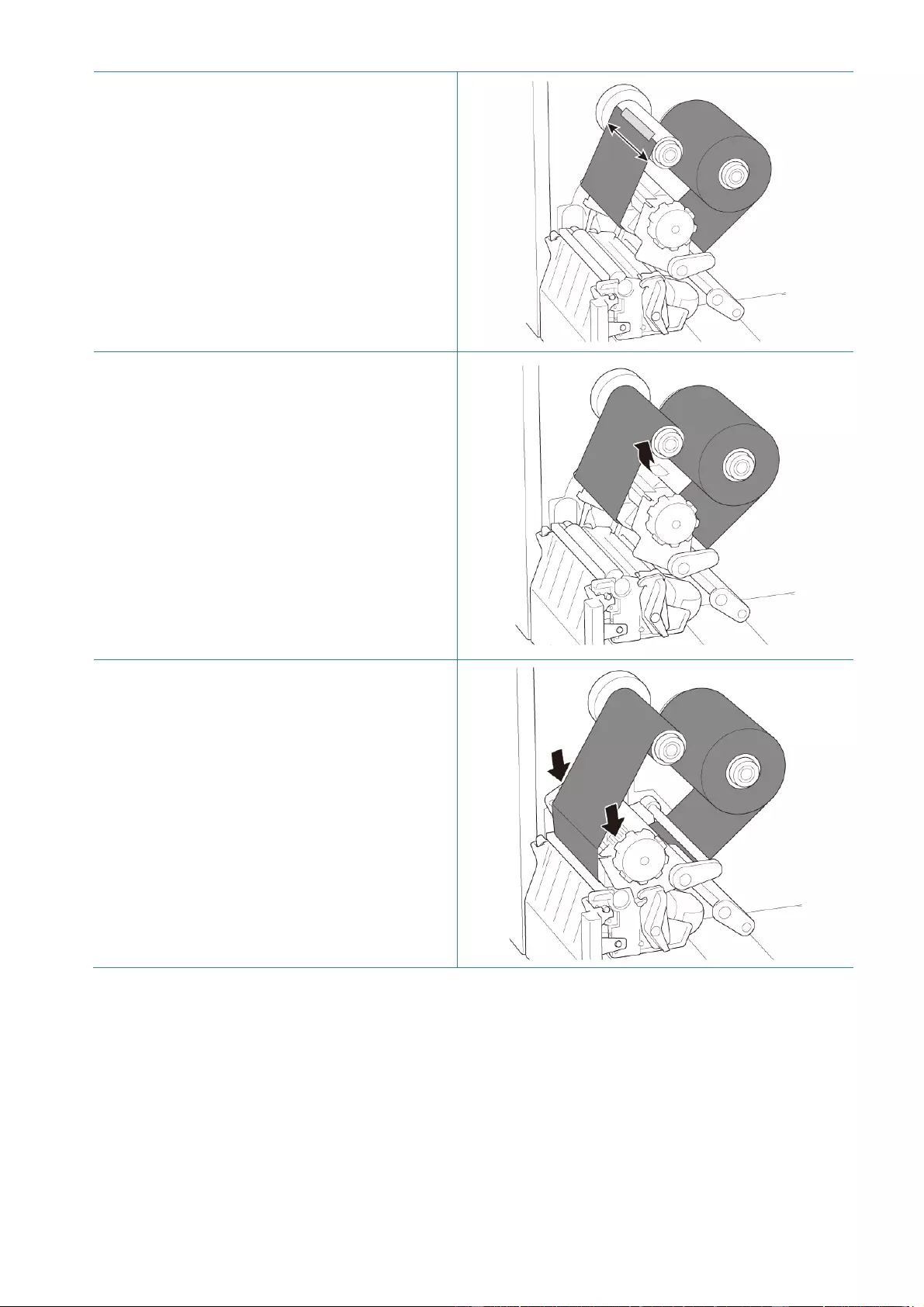

3.3 Remo ve Used Ribbon

1. Cut the used ribbon with scissors along

the dotted line.

2. Remove the ribbon from the Ribbon

Rew i nd Spindl e.

Note

W e recommend destroying the used

ribbon if it has retained any visible prints.

21

3.4 Loa d the Media

3.4.1 Load Label Roll

Label Roll loading path

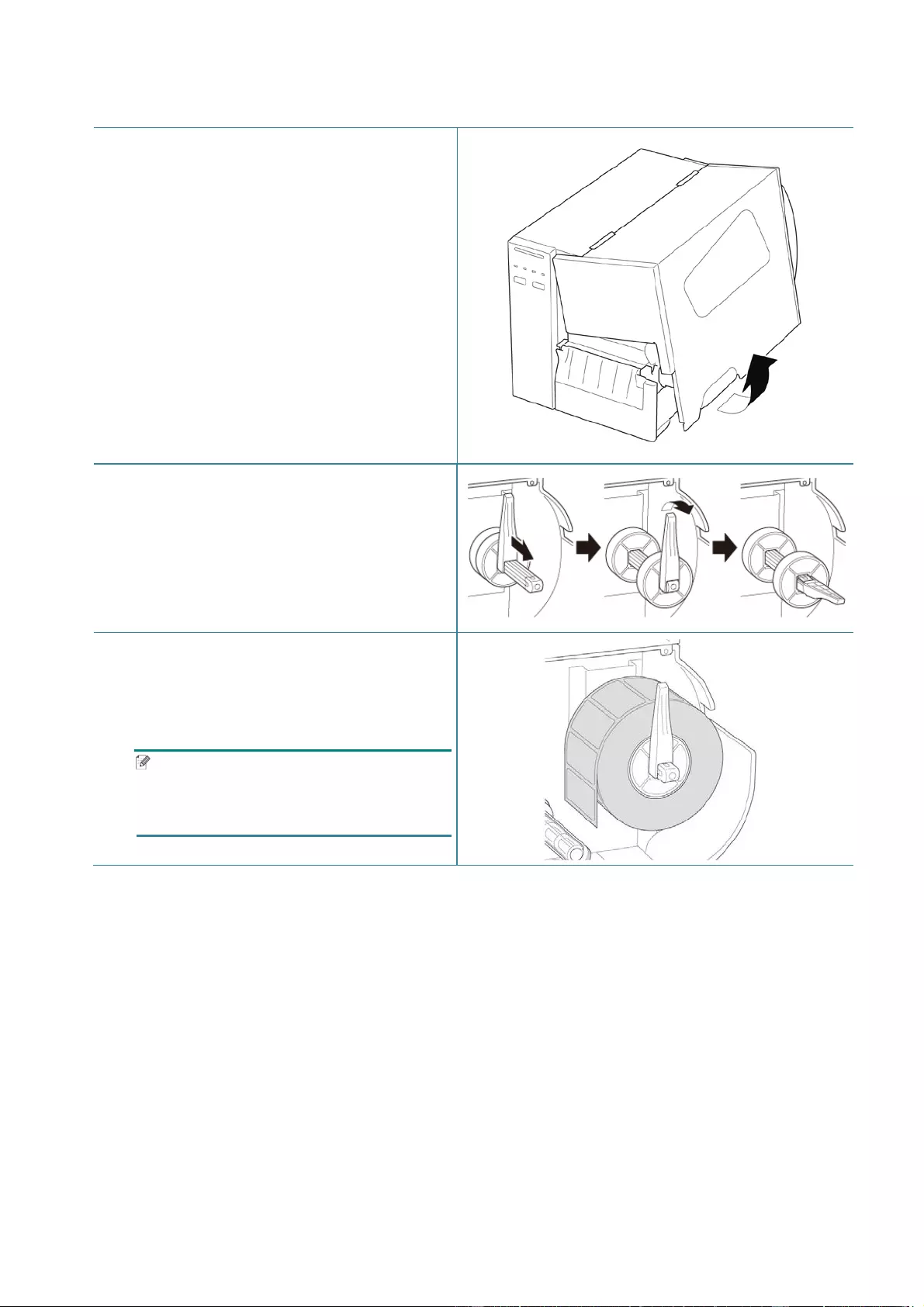

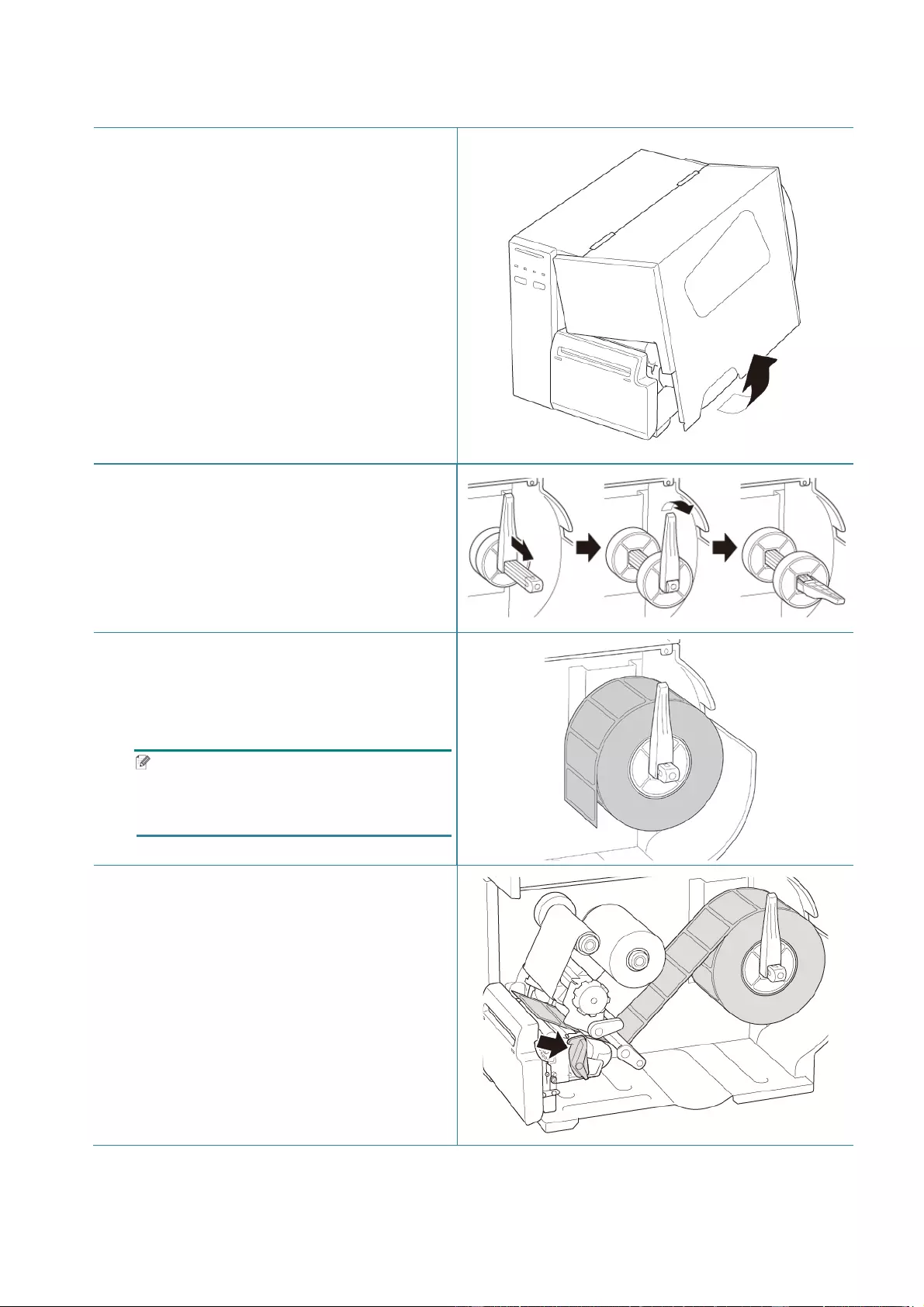

1. Open the Media Cover.

2. Slide the Label Roll Guard horizontally to

the end of the L abel Su ppl y Spindle, and

the n flip d ow n the Label Roll Guard.

22

3. Place the label roll on the Label Supply

Spindle and then flip the Label Roll Guard

upwards to hold it in place.

Note

M ak e sure the l a bel pr i nt si de is facing

up.

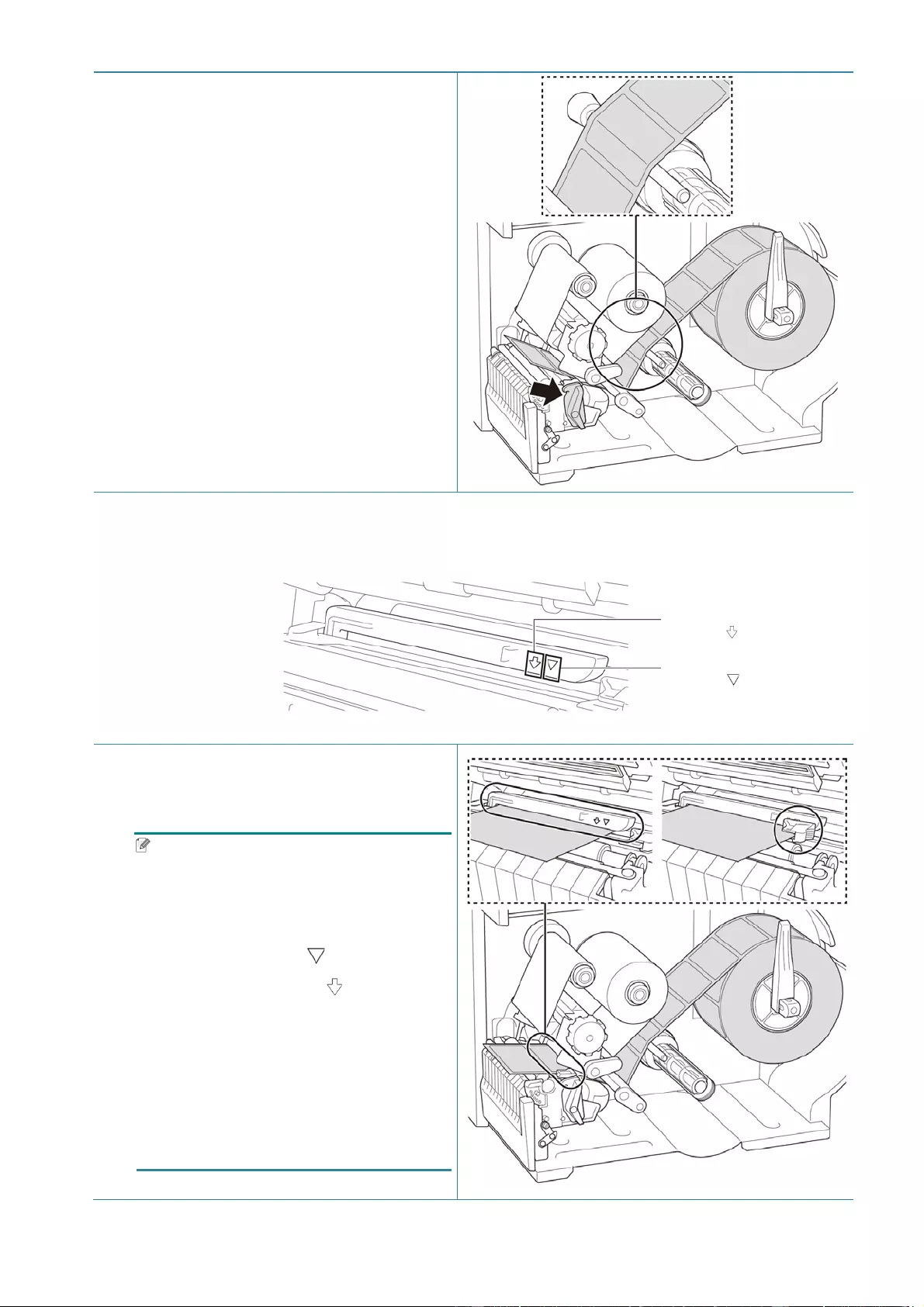

4. Push the Print Head Release Lever and

thread the label through the Damper,

Media Sensor, and Fr ont Labe l Guide to

install the media.

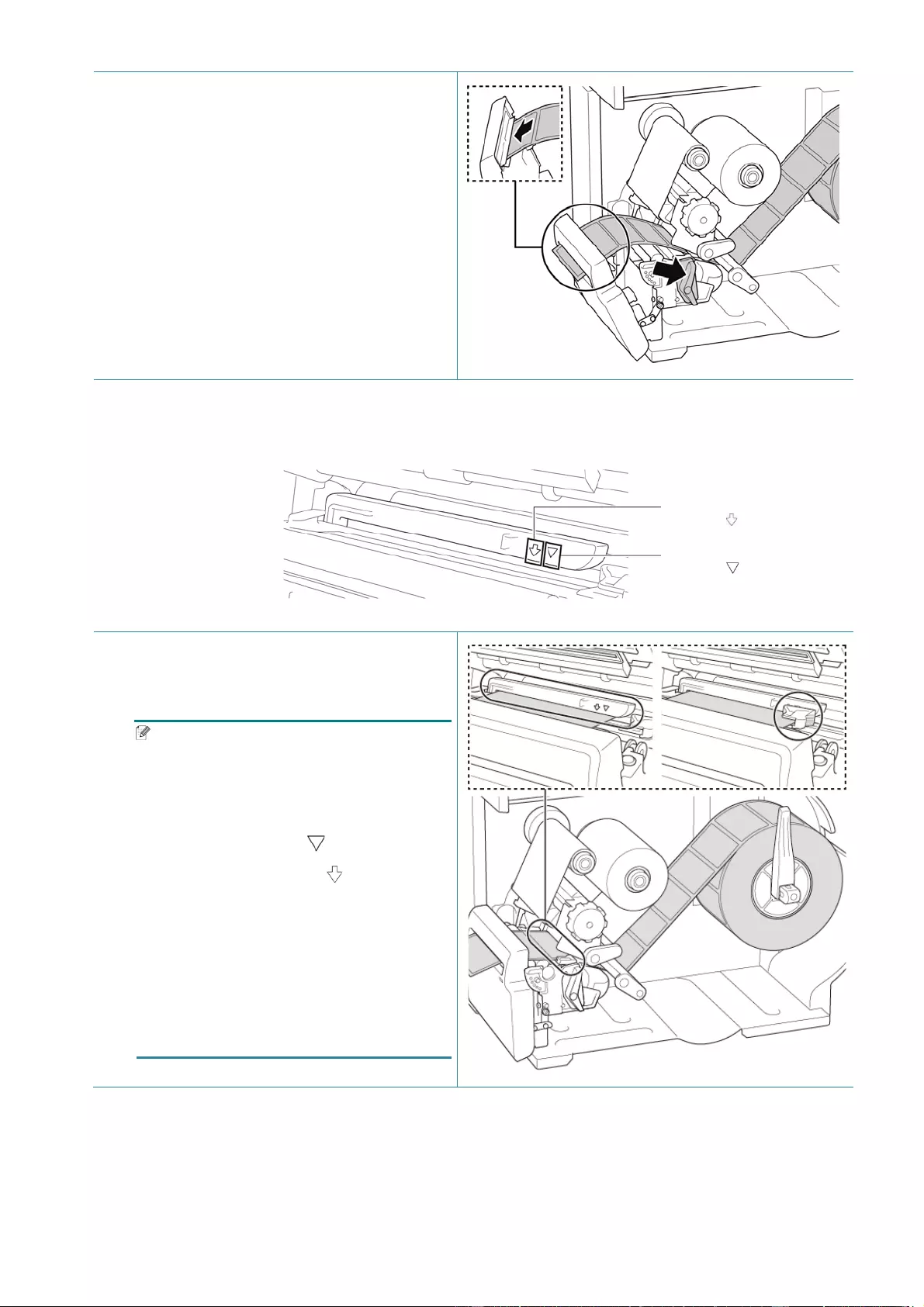

5. Move the Media Se ns or by adjusti ng t he Media Sensor Position Adjustment Knob. Make sure

the position of the Gap or Black Mark Sensor matches the position of the Gap/Black Mark on

th e la be l roll.

Black Mark Sensor

(shown as )

Gap Sensor

(shown as )

23

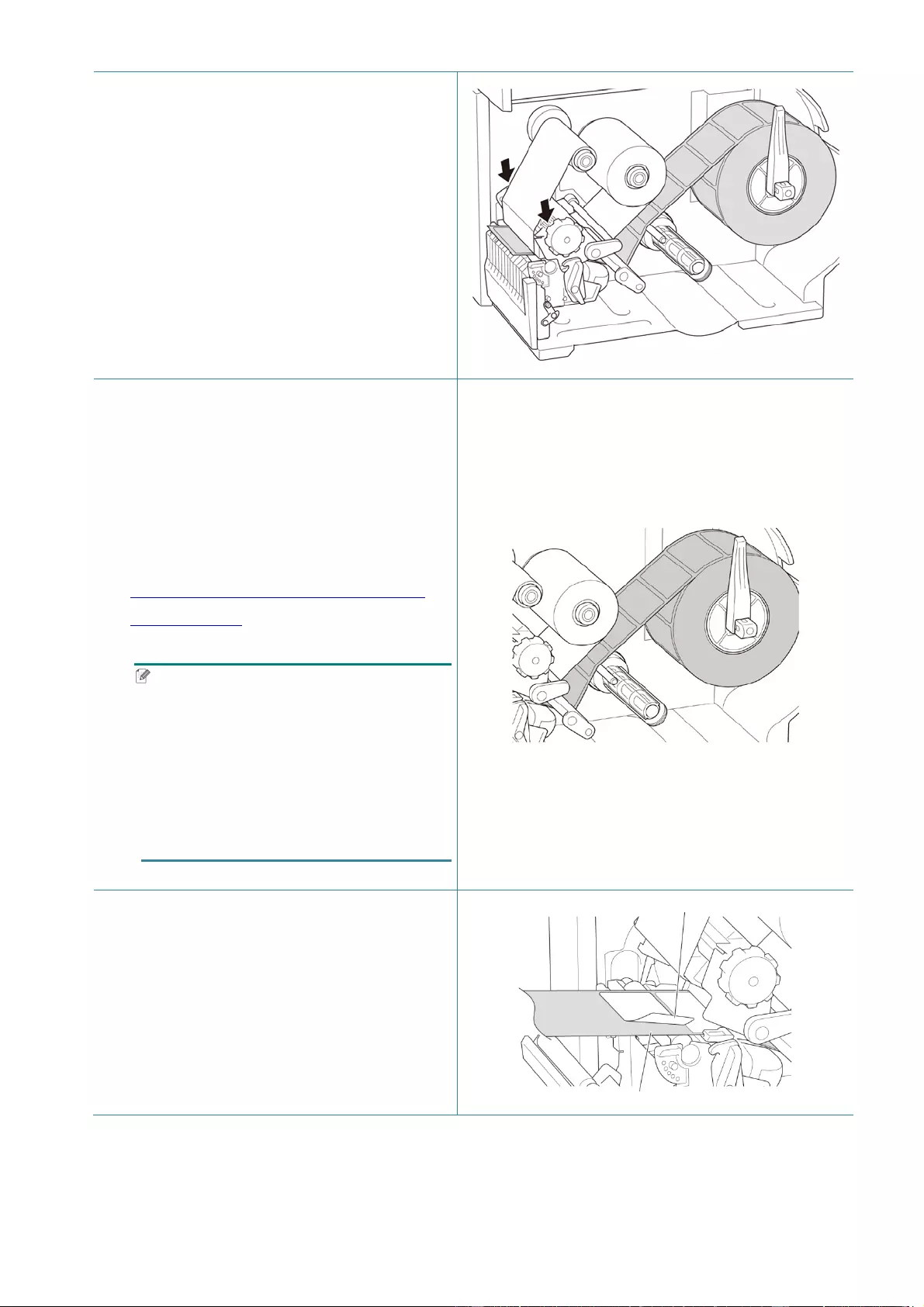

6. Adjust the Front Labe l Guide t o fix the

medi a po s it i o n.

Note

• Make sure you thread the media

through the Media Sensor.

• The sensor locations are marked by

the triang l e mark (Gap Sens or)

and the arrow mark (Black Mark

Sensor) at t he se ns or ho us ing.

• The Media Sensor position is

adjustable. Make sure the position of

the Gap or Black Ma rk Sensor

matches the pos ition of the

Gap/Black Mark on the label ro ll.

7. Close the Print Head on both sides and

make sure it locks into place.

8. Set the media sensor type and calibrate

the selected sensor.

Note

For RFID models, f eed the media through the Tear Cover Slot.

24

3.4.2 Load External Media

Fan-fold label loading path

1. Open the Media Cover.

2. Insert the media through the External

Label Ent r y Sl ot.

25

3. Push the Print Head Release Lever and

thread the label through the Damper,

Media Sensor, and Fr ont Labe l Guide to

install the media.

Align the Label Roll Guard with the label

width.

4. Move the Media Se ns or by adjusti ng t he Media Sensor Position Adjustment Knob. Make sure

the position of the Gap or Black Mark Sensor matches the position of the Gap/Black Mark on

the label.

5. Adjust the Front Labe l Guide t o fix the

medi a po s it i o n.

Note

• Make sure you thread the media

through the Media Sensor.

• The sensor locations are marked by

the triang l e mark (Gap Sensor)

and the arrow mark (Black Mark

Sen sor ) at the s e ns or ho us ing.

• The Media Sensor position is

adjustable. Make sure the position of

the Gap or Black Mark Sensor

matches the pos ition of the

Gap/Black Mark on the label.

Gap Sensor

(shown as )

Black Mark Sensor

(shown as )

26

6. Close the Print Head on both sides and

make sure it locks into place.

7. Set the media senso r type and calibrate

the selected sensor.

Note

Calibrate the Gap/Black Mark Sensor every time you change the media.

For m or e i n for m ation a bo ut se ns or cali brati o n, se e section 8.2 Auto-C al i br ating t h e Medi a

Sen sor us ing the BPM.

27

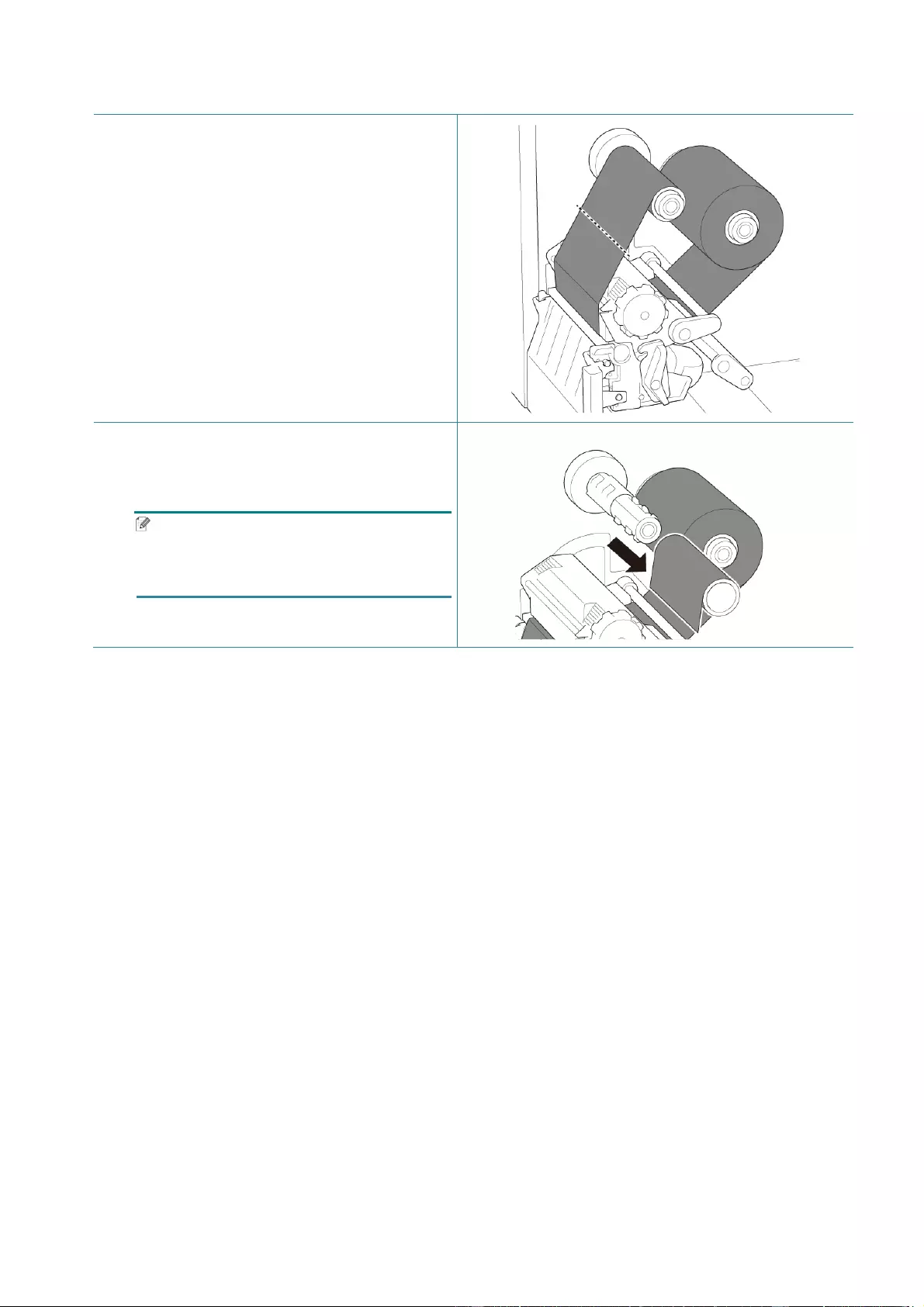

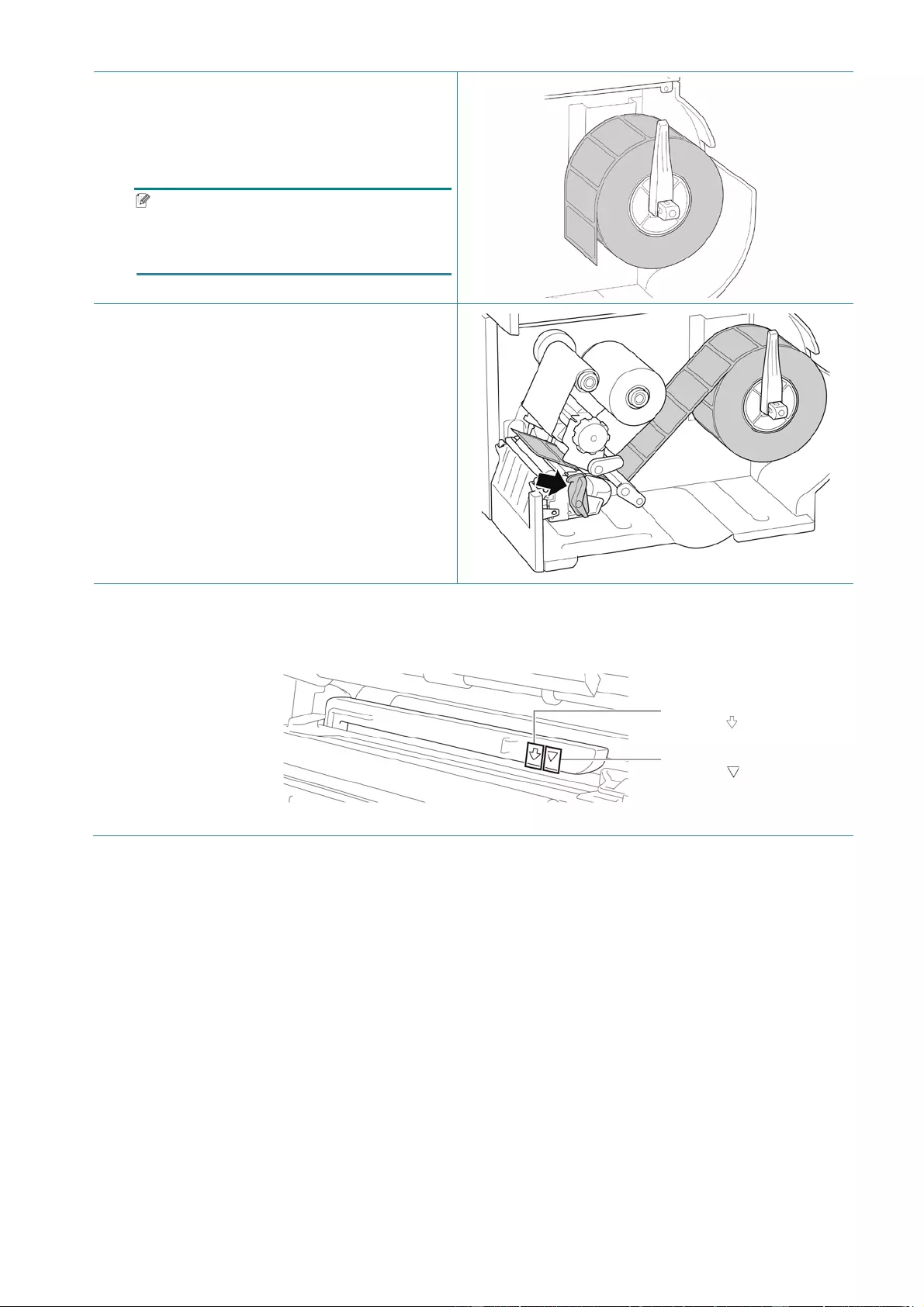

3.4.3 Load the Media in Peeler Mode (Optional)

1. Open the Media Cover.

2. Slide the Label Roll Guard horizontally to

the end of the Label Su ppl y Spindl e , and

the n flip d ow n the Label R oll Guard.

3. Place the label roll on the Label Supply

Spindle and then f lip the Label Roll Guard

upwards to hold it in place.

Note

M ak e sure the l a bel pr i nt si de is faci n g

up.

28

4. Push the Print Head Release Lever and

thread the label through the Damper,

Media Sensor, and Fr ont Labe l Guide to

install the media.

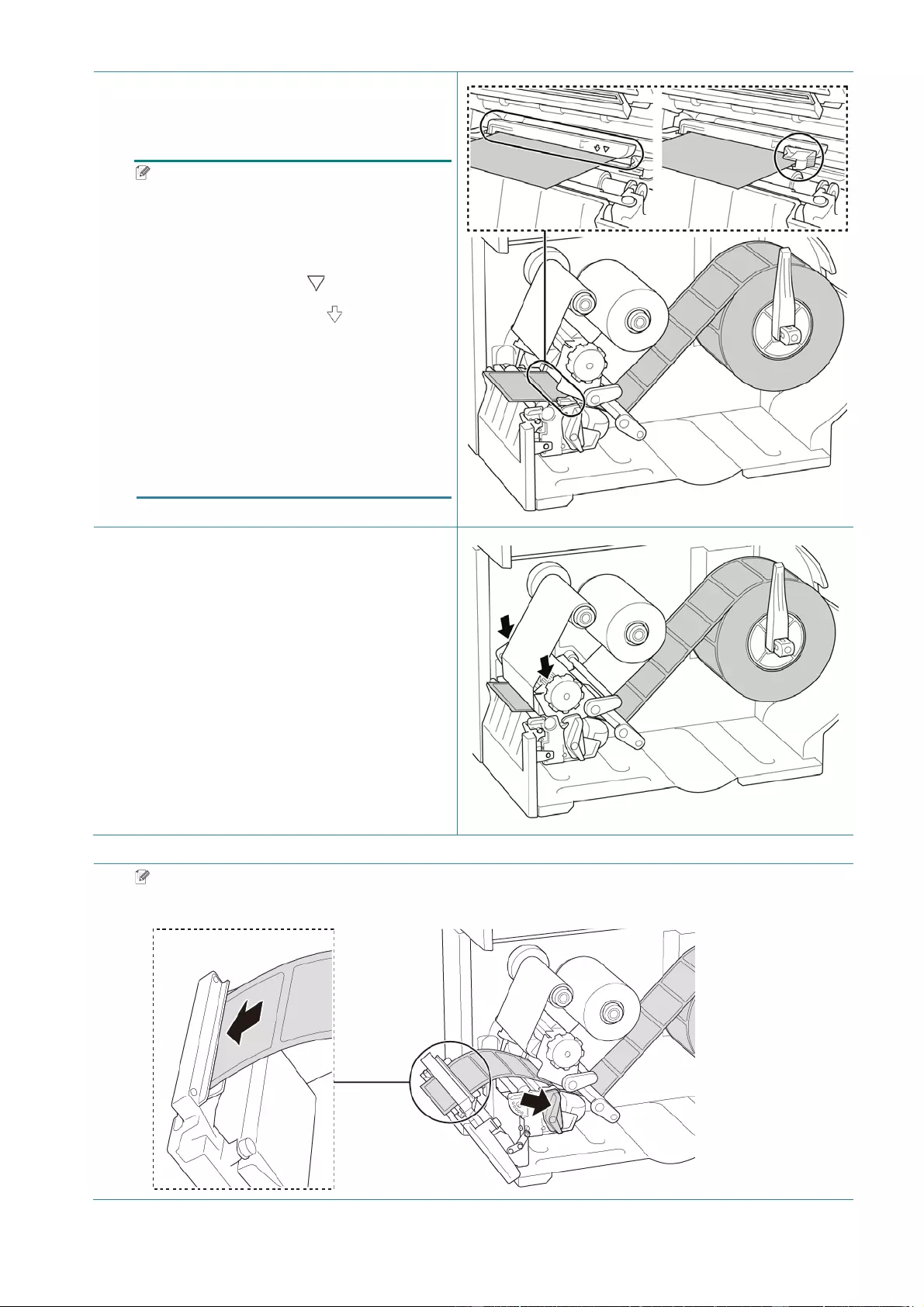

5. Move the Media Se ns or by adjusti ng t he Media Sensor Position Adjustment Knob. Make sure

the position of the Gap or Black Mark Sensor matches the position of the Gap/Black Mark on

th e la be l roll.

6. Adjust the Front Labe l Guide t o fix the

medi a po s it i o n.

Note

• Make sure you thread the media

through the Media Sensor.

• The sensor locations are marked by

the triangle mark (Gap S e nsor )

and the arrow mark (Black Mark

Sen sor ) at the s e ns or ho us ing.

• The Media Sensor position is

adjustable. Make sure the position of

the Gap or Black Mark Sensor

matches the pos ition of the

Gap/Black Mark on the label ro ll.

Black Mark Sensor

(shown as )

Gap Sensor

(shown as )

29

7. Close the Print Head on both sides and

make sure it locks into place.

8. Set the media sensor type and calibrate

the selected sensor.

9. Use the Touchscreen to perform the

cali br ation fir st, and set the printer mode

to Peeler Mode.

For models without a Touchscreen,

perform the calibration using the BPM.

For more information about sensor

calibration, see section

8.2 Auto-Calibr ati n g the M e di a Se ns or

using the BPM.

Note

1. Calibrate the Gap/Black Mark

Sensor before loading media in

Peeler Mode to avoi d pa per j am s.

2. Make sure you thread the label over

the Media Guide Bar and under the

Damper as shown.

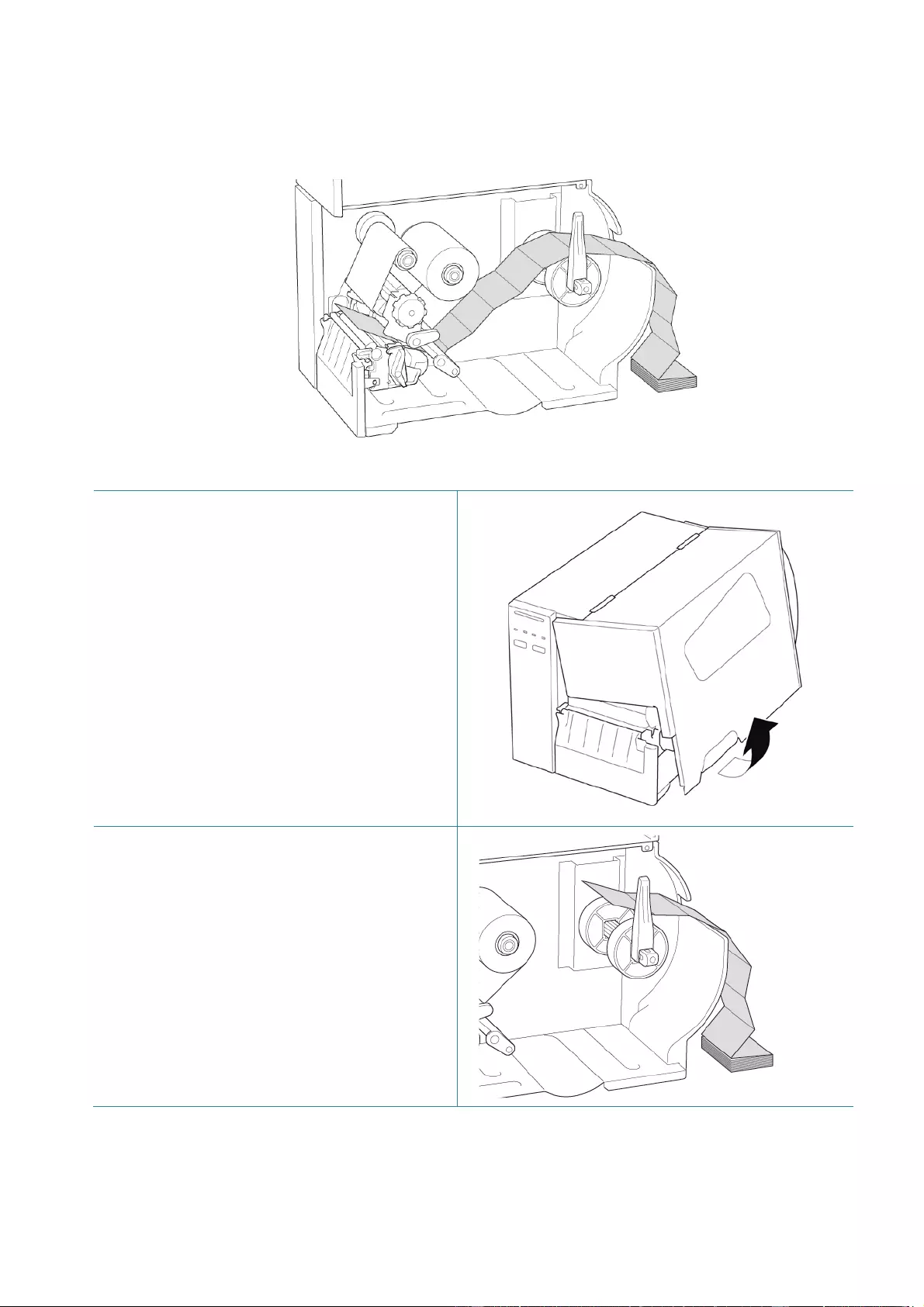

10. Turn the Print Head Release Lever, and

pull a ppr ox imatel y 650 m m o f th e l ab el roll

through the Media Output Slot.

11. Remove some labels leaving only the

liner.

Label

Liner

30

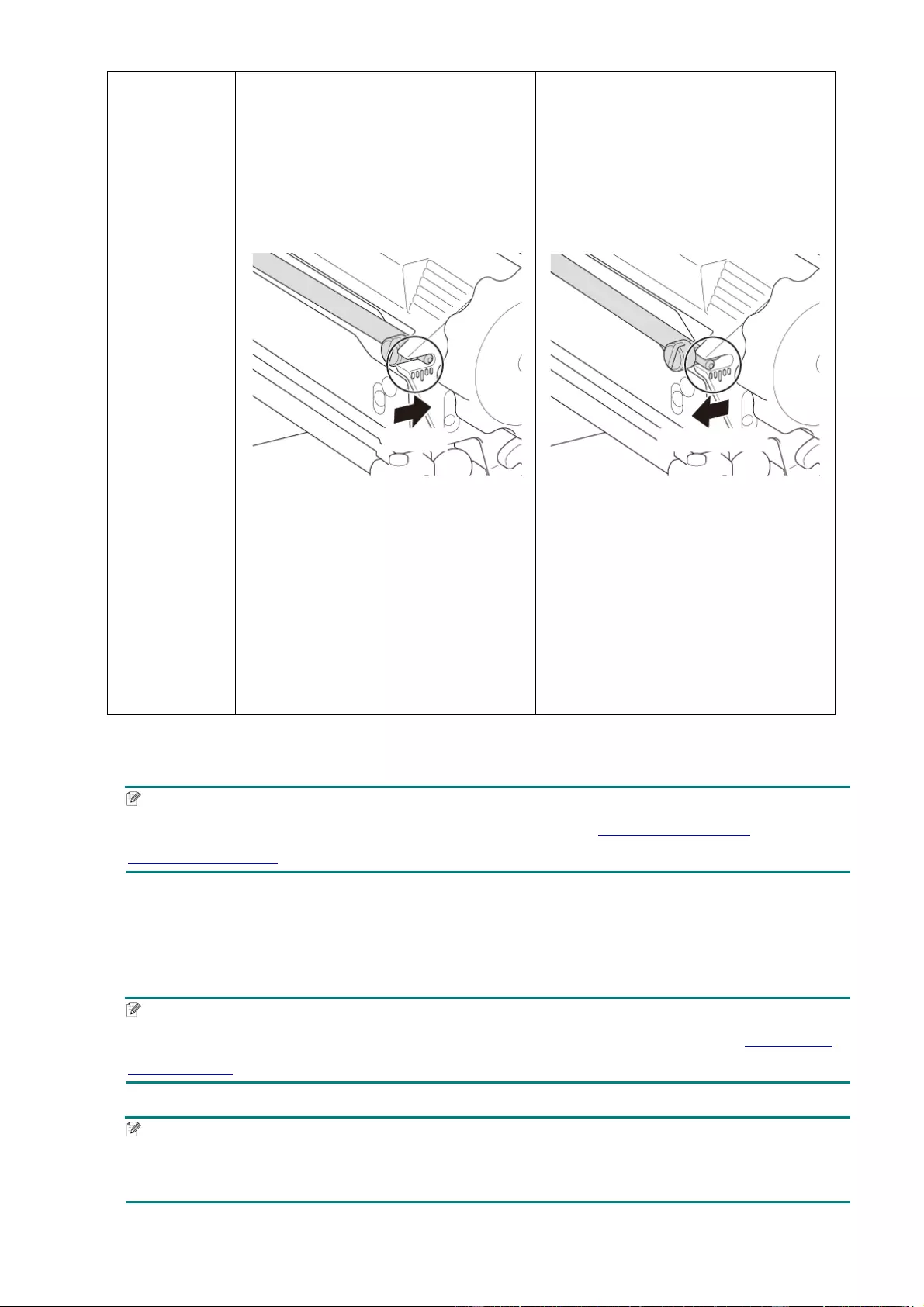

12. Thread the liner through the Label Peeler

Cover Slot.

13. Pull the Liner Securing Clip out from the

Liner Rewind Spindle, and wind the liner

on the Liner Rewind Spindle until the liner

is fu lly stretched.

14. Insert the Liner Securing Clip into the

Liner Rewind Spindle.

Note

You can also install a paper roll on the

Liner Rewind Spindle to wind the liner

around the paper roll.

15. Lock the Print Head Release Lever and

fee d on e la bel to test:

For touchs creen models: Tap the Feed

icon in the Main Menu.

For non-t ouchscr e en m odels: Pr ess th e

Feed button.

31

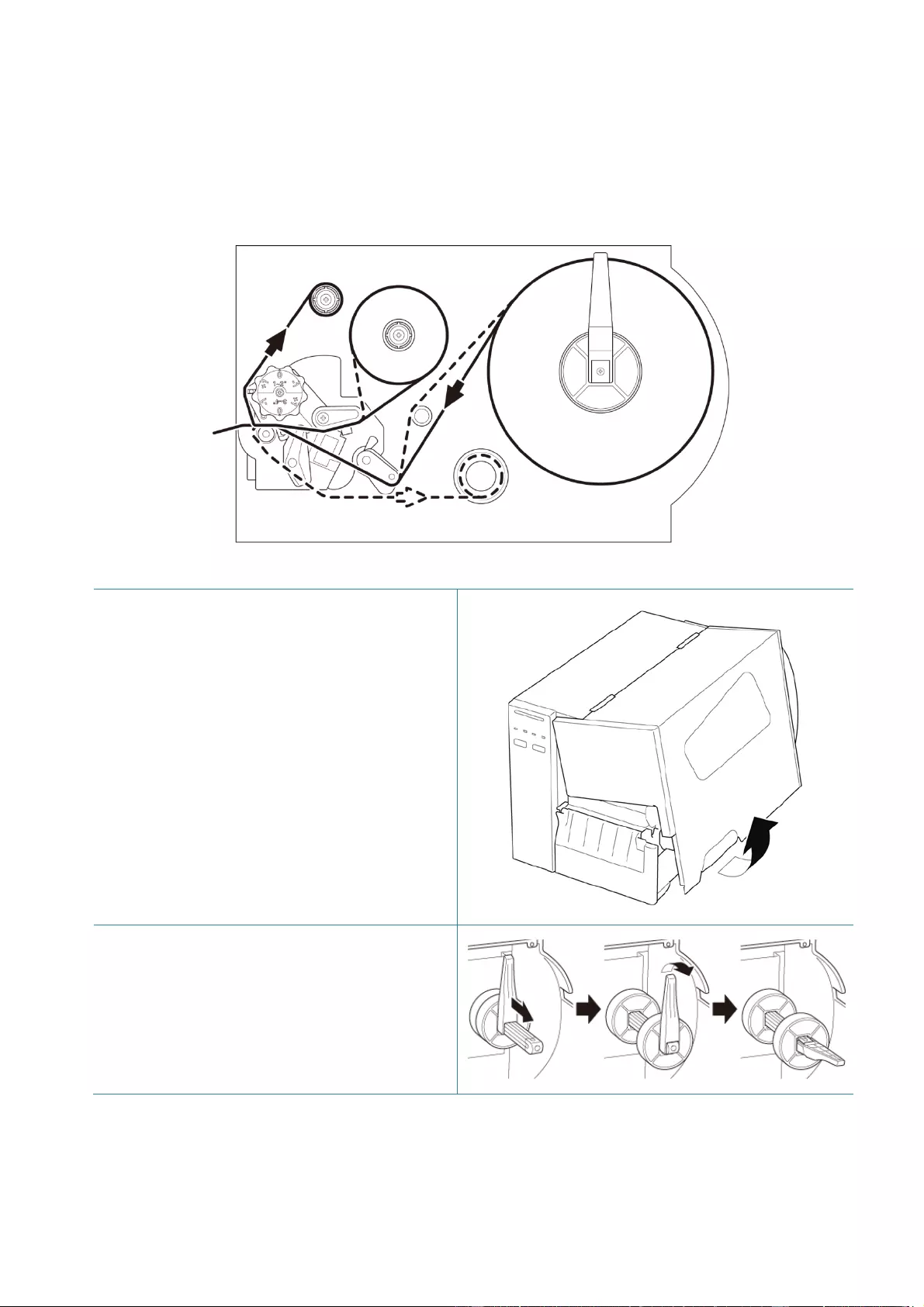

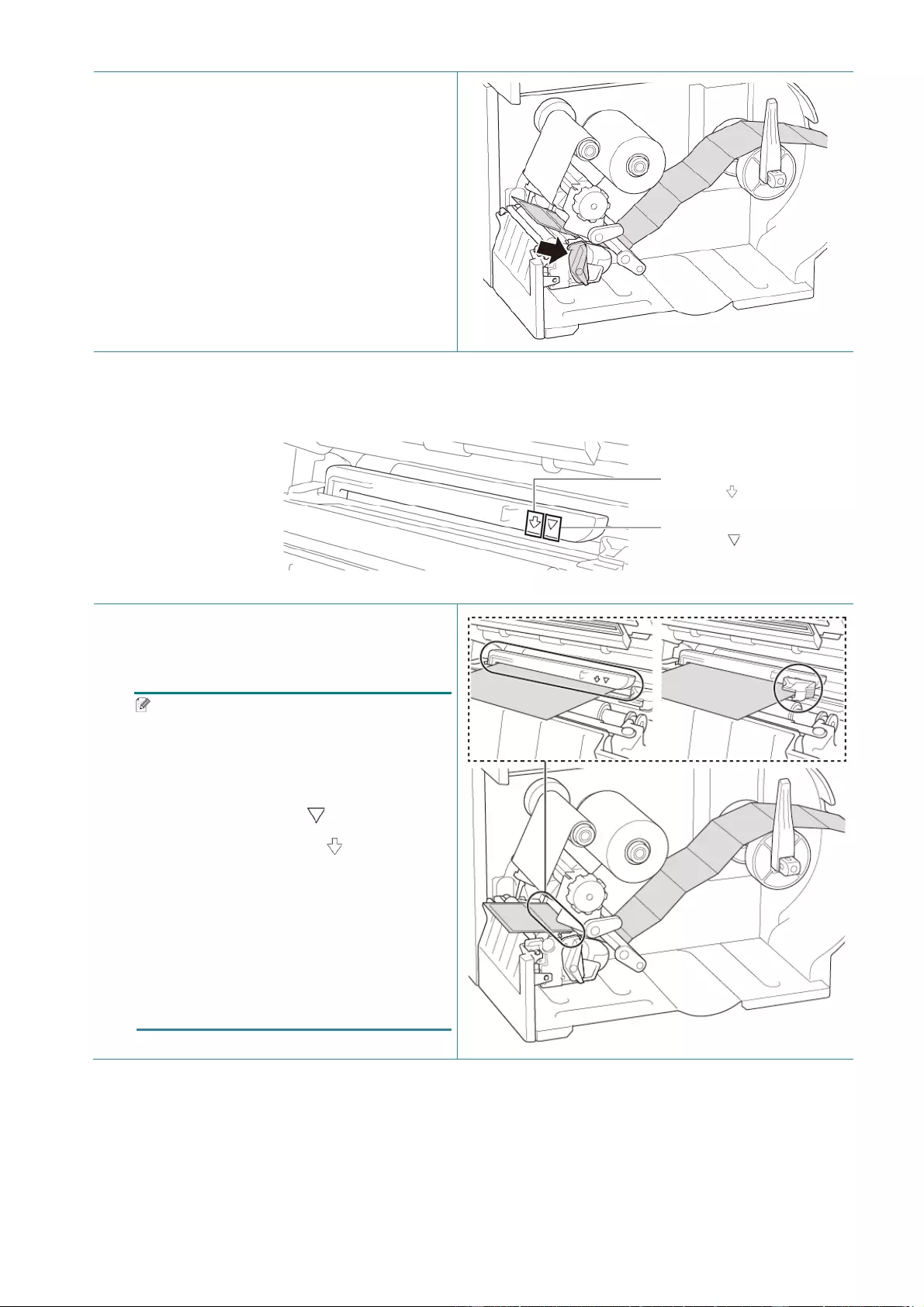

3.4.4 Load Media in Cutter Mode (Optional)

1. Open the Media Cover.

2. Slide the Label Roll Guard horizontally to

the end of the Label Supply Spindle, and

the n flip d ow n the Label R oll Guar d.

3. Place the label roll on the Label Supply

Spindle and then flip the Label Roll Guard

upwards to hold it in place.

Note

M ak e sure the l a bel pr i nt si de is faci n g

up.

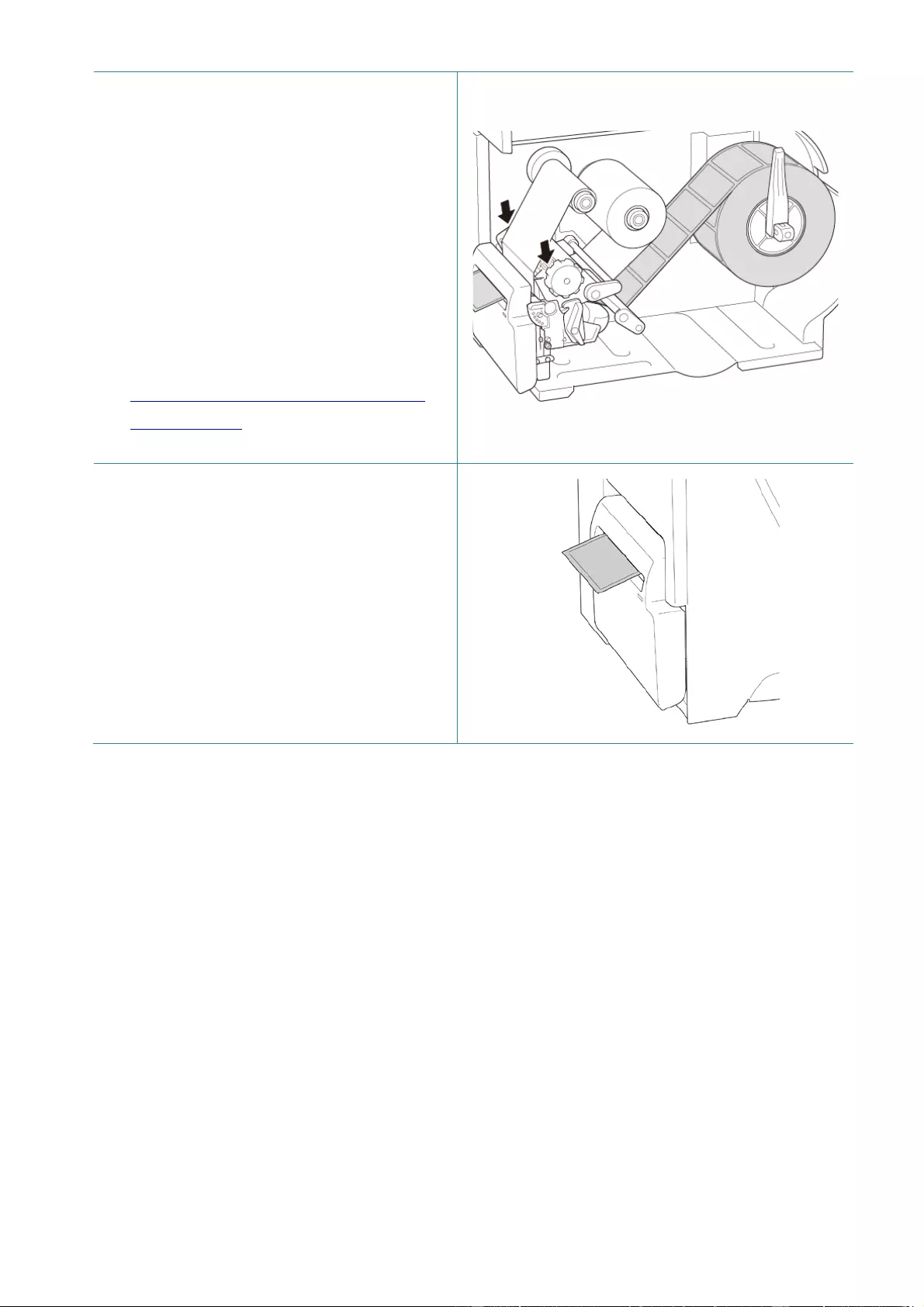

4. Push the Print Head Release Lever and

thread the label through the Damper,

Media Sensor, and Fr ont Labe l Guide to

install the media.

32

5. Feed the media through the Label Cutter

Cover Slot.

6. Move the Media Se ns or by adjusti ng t he Media Sensor Position Adjustment Knob. Make sure

the position of the Gap or Black Mark Sensor matches the position of the Gap/Black Mark on

th e la be l roll.

7. Adjust the Front Labe l Guide t o fix the

medi a po s it i o n.

Note

• Make sure you thread the media

through the Media Sensor.

• The sensor locations are marked by

the triangle mark (Gap Sensor)

and the arrow mark (Black Mark

Sen sor ) at the s e ns or ho us ing.

• The Media Sensor position is

adjustable. Make sure the position of

the Gap or Black Mark Sensor

matches the pos ition of the

Gap/Black Mark on the label ro ll.

Black Mark Sensor

(shown as )

Gap Sensor

(shown as )

33

8. Close the Print Head on both sides and

make sure it locks into place.

9. Set the media senso r type and calibrate

the selected sensor.

10. Use the Touchscreen to perform the

calibration first, and set the printer mode

to Cutter Mode.

For models without a Touchscreen,

perform the calibration using the BPM.

For more information about sensor

calibration, see section

8.2 Auto-Calibr ati n g the M e di a Se ns or

using the BPM.

11. Close t he Print H ead and feed on e l ab el to

test:

For touchs creen models: Tap the Feed

icon in the Main Menu.

For non-t ouchscr e en m odels: Pr ess th e

Feed button.

34

4. Impr o ve Print Quality

4.1 Ad just Print Head Tension to Improve Print Qualit y

For the best print quality, adjust the Print Head using the Print Head Tension Adjustment

Knob. Ch oose one o f si x l evels o f tension a dj us tment d ep endin g on the medi a w idth you use

(1” - 2” or 3” - 4”).

4.2 Avoid Wrinkled La bels

W rinkles can occur due to many factors, including media width and thickness, Print Head

pressure balance, ribbon film characteristics, and print density/darkness settings.

4.2.1 Adjust Ribbon Tension

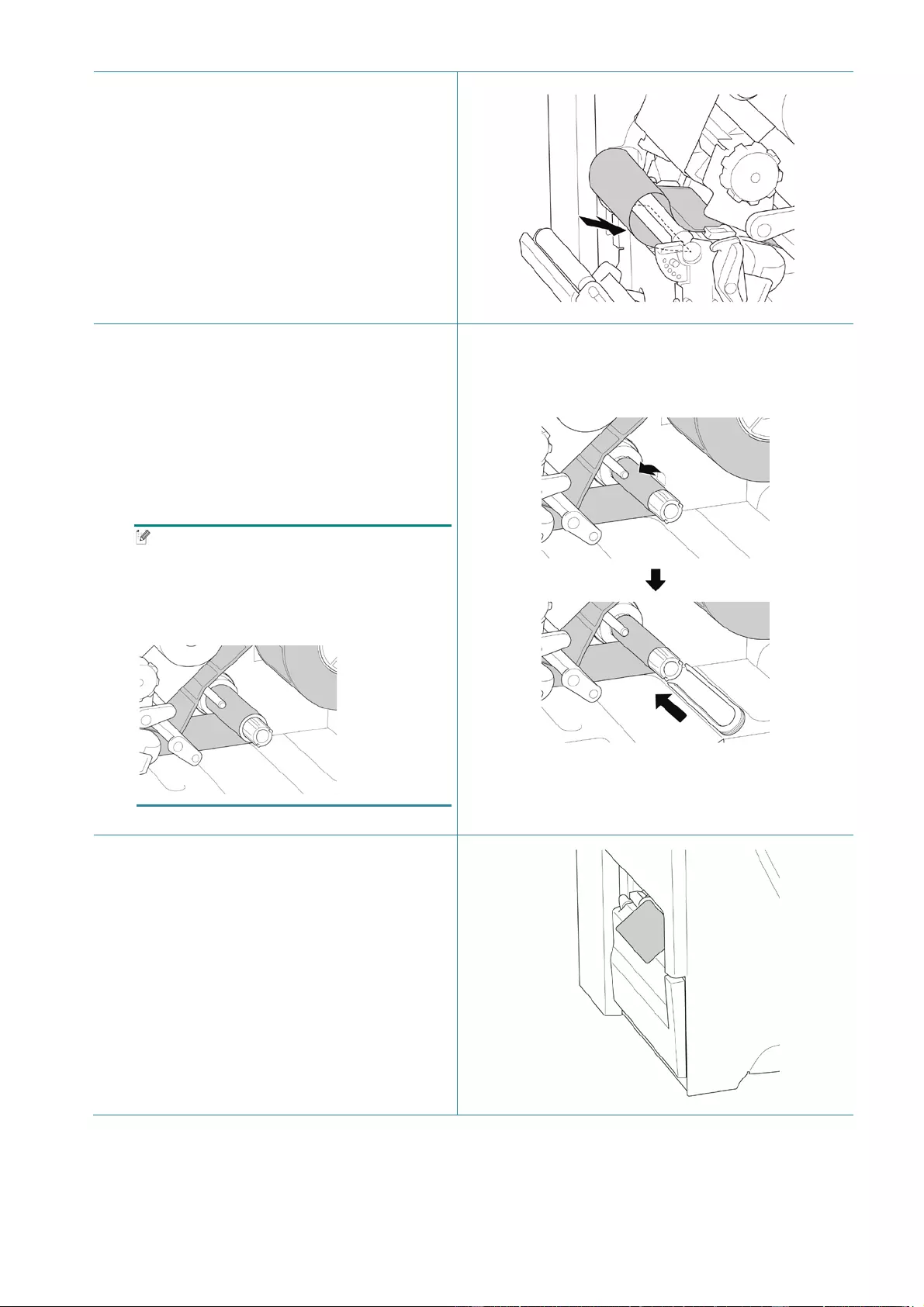

To avoid wrinkled labels, adjust the ribbon tension using the Ribbon Tension Adjustment

Screw. Choose one o f five l evel s o f te nsi o n adj ustm ent .

Suggested Print Head

Tension Values:

For 1" - 2" media width

For 3" - 4" media width

Ribbon Tensi on Adj ustment Screw

35

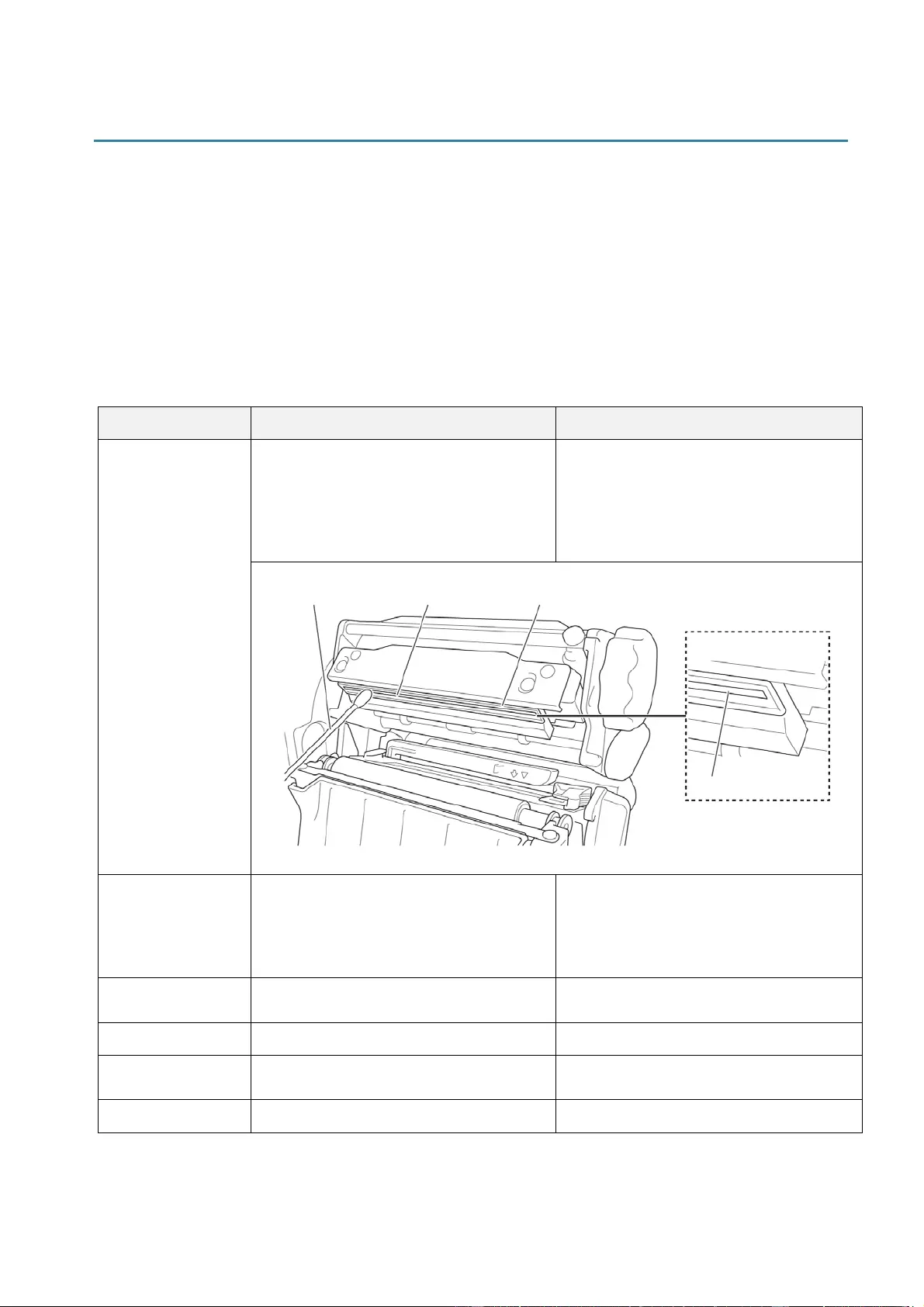

Description

The ribbon wrinkle occurs from the

lower right to the upper left of the

label.

The ribbon wrinkle occurs from the

lower left to the upper r ight of the

label.

Wrinkle

Example

Adjustable

Printer Parts

The Ribbon Tension Adjustment Screw has five levels for adjustment. Use a

flat bl ade screwdriver to change the ribbon tension level.

Ri bbo n T ension Adjustm e nt Screw

Ri bbo n T ension Adjustm e nt Scale

Feed

direction

36

1. Turn the Ribbon Tension

Adjustment Screw clockwise once

per level on the Ribbon Tension

Adjustment Scale and pri nt the

label again to check if the wrinkle is

gone.

2. If th e Ribbon Tension Adjustment

Screw is posi tion ed on the

innermost side but the ribbon

wr i nkl e has not improved, turn the

Print Head Tension Adjustment

Kno b onc e per l ev el at a time,

print

the label again, and check if the

wrinkle is gone.

1. Turn the Ribbon Tension

Adjustment Screw

counterclockwise

onc e per l evel on

the Ribbon Tension Adjustment

Scale and print the label again to

check if the wrinkle is gone.

2. If th e Ribbon Tension Adjustment

Screw is posi tion ed on the

outermost side but the ribbon

wrinkle has not improved, turn the

Print Head Tension Adjustment

Kno b onc e per l ev el at a time,

print

the label again, and check if the

wrinkle is gone.

4.2.2 Change the Print Density/Darkness Settings

Note

For information about the pr i nt density /dark ness, see sections 7.1.1 FBPL Settings and

7.1.2 ZPL2 Settings.

4.2.3 Try Different Media

Make sure you load the correct paper.

Note

For more information about the supported paper width and thickness, see section 10 Product

Specifications.

Note

If the wrinkles continue to occur, contact the product manufacturer's customer service or your

local dealer for servi ce.

Clockwise Counterclockwise

37

5. Printing

5.1 Printer Driver Installatio n

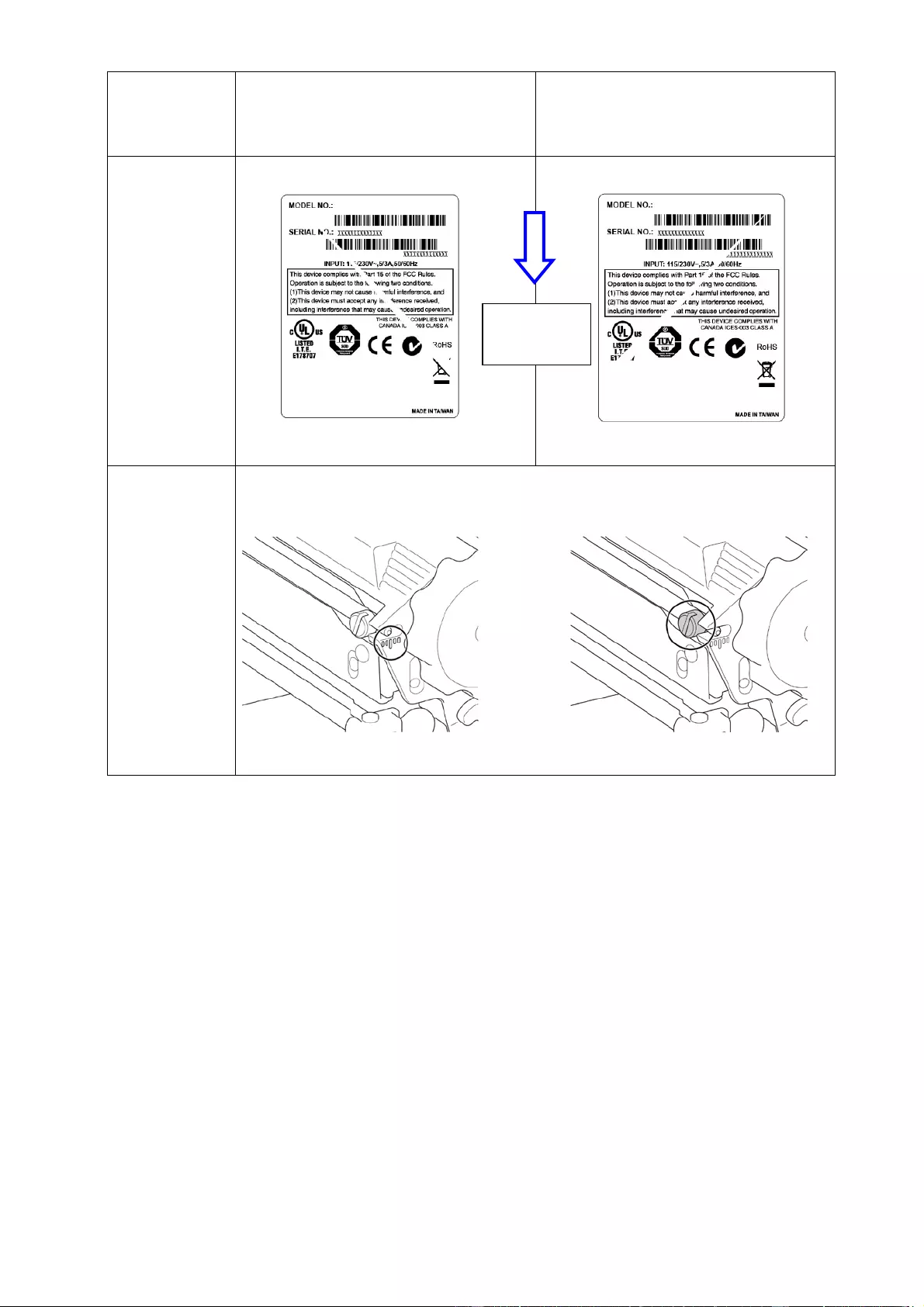

Note

The model name and serial number are located on the back of the printer.

Make sure you download the correct driver for your model:

• TJ-4020TN/TJ-4021TN/TJ-4021TNR: Brother TJ-40

• TJ-4120TN/TJ-4121TN/TJ-4121TNR: Brother TJ-41

The driver installation method de pe nds o n t he co nnection typ e:

USB Connection (Windows/Mac/Linux)

Wi-Fi Network Connection (Windows)

Wired Network Connection (Windows)

5.1.1 USB Connection (Wi ndows/Mac/Linux)

Note

Mac/Linux Users

For more information about driver installation, see the driver installation guide provided with the

driver.

1. Connect your printer to the computer using a USB cable.

2. Visit support.brother.com, go to yo ur mod el' s Downloads page, and download the latest

pri nter dr i ver and software.

3. Run the Seagull Driver Wizard application and select Install printer drivers and USB.

4. Follow the on-screen instructions.

Note

If you cannot install the printer driver:

Install the pri nter dr i ver m an ual l y :

In the Seagull Driver Wizard application, select Install printer drivers > Others.

Remove the printer drivers:

In the Seagull Driver W izard application, select Remove printer drivers > Automatically

remove all Drivers by Seagull or Use advanced printer driver re moval options.

Reset the pri nt er s etting s :

Start the BPM, and then click P r inter Func tion > Factory Default.

38

5.1.2 Wi-Fi Network Connection (Windows)

Note

To us e Wi -Fi, an option al WLAN Interface (PA-WI-002) is required.

Make sure both your wireless router/access point's and your printer's network settings are correctly

set up. F or m or e i n for m ation, s ee t h e documentat ion pr ov ided w i t h your w i r eless rout er /acces s point ,

or contact the router manuf acturer, your system administrator, or Internet service provider.

1. Configure the network settings:

- Using the BPM

a. Connect your printer to the computer using a USB cable.

b. Click Printer Configuration > Wi-Fi.

c. Specify SSID, Encryption, and Key (Network Password), and then click Set.

d. Click Get.

e. Click Printer Function > Configuration Page.

The network settings are printed. Confirm that the printer's IP address is correct.

- Using the Touchscreen

a. Select Interface > Wi-Fi.

b. Specify SSID, Security, and Password.

c. When finished, the Wi-Fi icon and printer's IP address appear on the Touchscreen.

2. Visit support.brother.com, go to yo ur mod el' s Downloads page, and download the latest printer

dri ver and s o ft war e.

3. Run the Seagull Driver Wizard application and select Ins tall printer drivers and Network.

4. Select your printer, and then click Next.

5. If your TCP/IP port does not appear in the list, click Create port and select Standard TCP/IP

port > New Po rt .

6. Type your printer’s IP address and port name, and then click Next.

7. Click Finish.

8. Return to the Specify P ort window and select the port you created.

9. Follow the on-screen instructions.

Note

If you cannot install the printer driver:

Remove the printer drivers:

In the Seagull Driver W izard application, select Remove printer drivers > Automatically

remove all Drivers by Seagull or Use advanced printer driver re moval options.

Reset the pri nt er s etting s :

Start the BPM, and then click P r inter Func tion > Factory Default.

39

5.1.3 Wired Network Connection (Windows)

1. Connec t bo t h t he pr i nter an d the c om p uter to yo ur rout er / access poin t us ing LAN c a bl es. The

printer automatically receives a default IP address and displays it on the Touchscreen. For

models without a Touchscreen, this can be confirmed using the BPM.

2. Visit support.brother.com, go to yo ur mod el' s Downloads page, and download the latest

pri nter dr i ver and software.

3. Run the Seagull Driver Wizard application and select Ins tall printer drivers and Network.

4. Select your printer, and then click Next.

5. If your TCP/IP port does not appear in the list, click Create port and select Standard TCP/IP

port > New Po rt .

6. Type your printer’s IP address and port name, and then click Next.

7. Click Finish.

8. Return to the Specify P ort window and select the port you created.

9. Follow the on-screen instructions.

Note

If you cannot install the printer driver:

Remove the printer drivers:

In the Seagull Driver W izard application, select Remove printer drivers > Automatically

remove all Drivers by Seagull or Use advanced printer driver re moval options.

Reset the pri nt er s etting s :

Start the BPM, and then click P r inter Func tion > Factory Default.

40

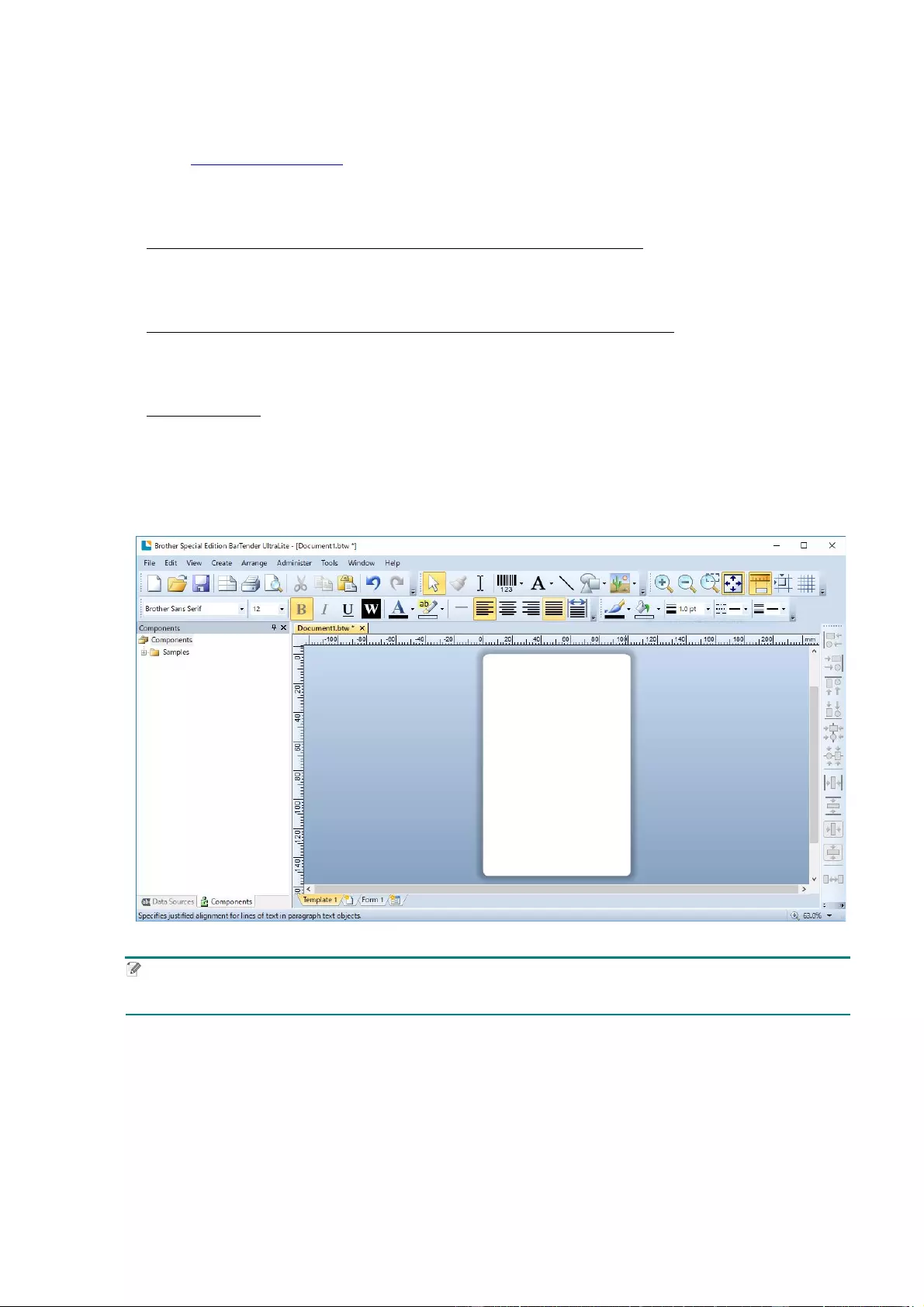

5.2 C reate and Print Labels Using BarTender

BarTender is a label creation tool, which can be downloaded for free from the product's

page at support.brother.com.

1. Launch BarTender.

• For Wi ndows 10, Wind ow s Ser ver 20 16, or Wind ows Ser v er 20 19:

Start > BarTender 2016 R7 UltraLite > click BarTende r Ultr aLite, or double-click th e

BarTender UltraLite icon on the desktop.

• For Wi ndows 8.1, Win dow s Ser ver 201 2, or Windows Server 2012 R2:

Click Ba rTende r UltraLite on the application screen, or double-click the BarTender UltraLite

icon on t h e des k t o p.

• For Wi ndows 7:

Start > All Progra ms > BarTender 2016 R7 UltraLite > click BarTender UltraLite, o r

double-click the BarTender Ultra Lite icon on the desktop.

2. Follow the on-screen steps to create a label.

Note

For more information on using BarTender, click Help.

3. Click File > Print to print the label.

41

6. Operation

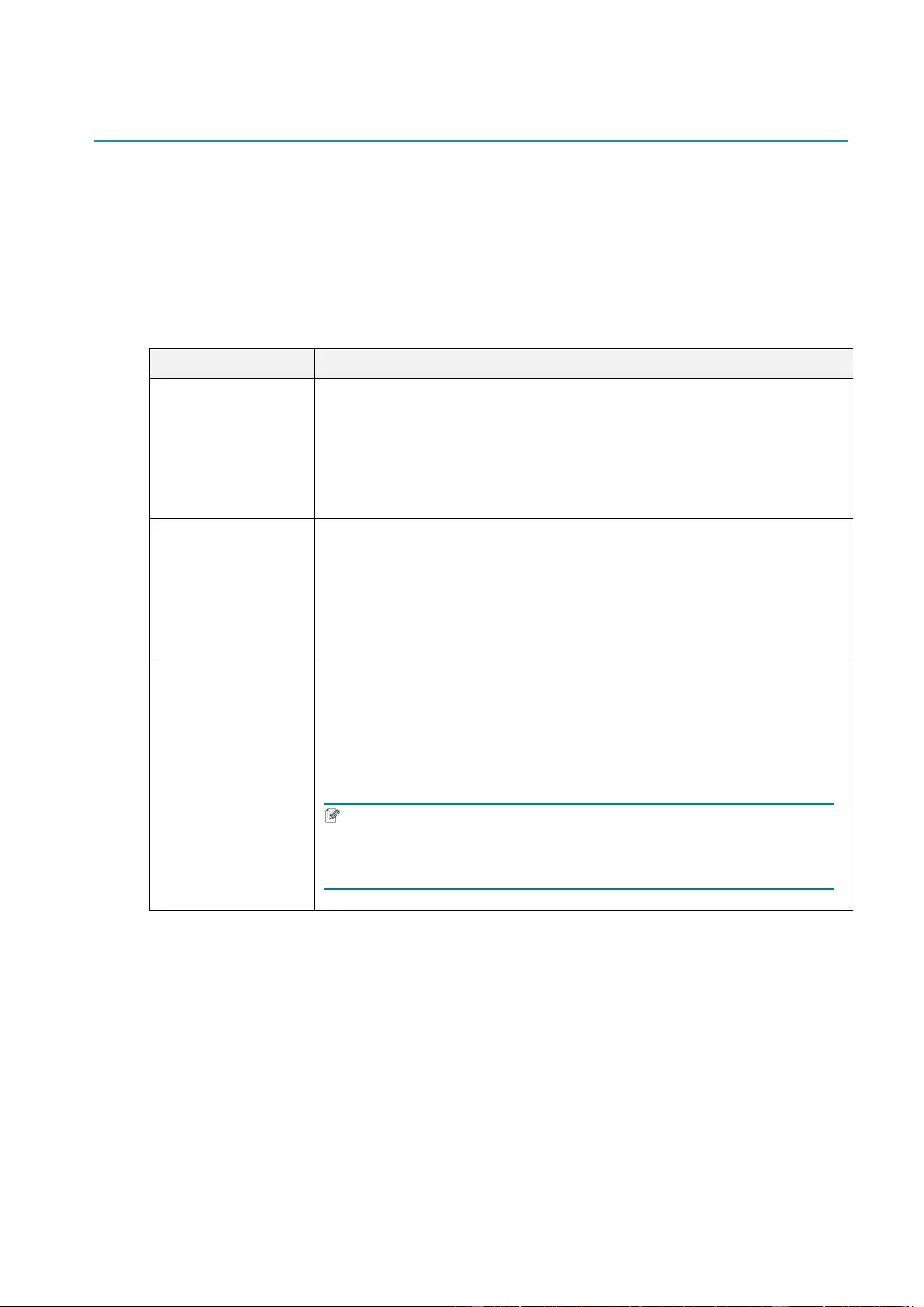

6.1 Power-on U tilities

There are various power-on utilities to set up and test the printer's functions.

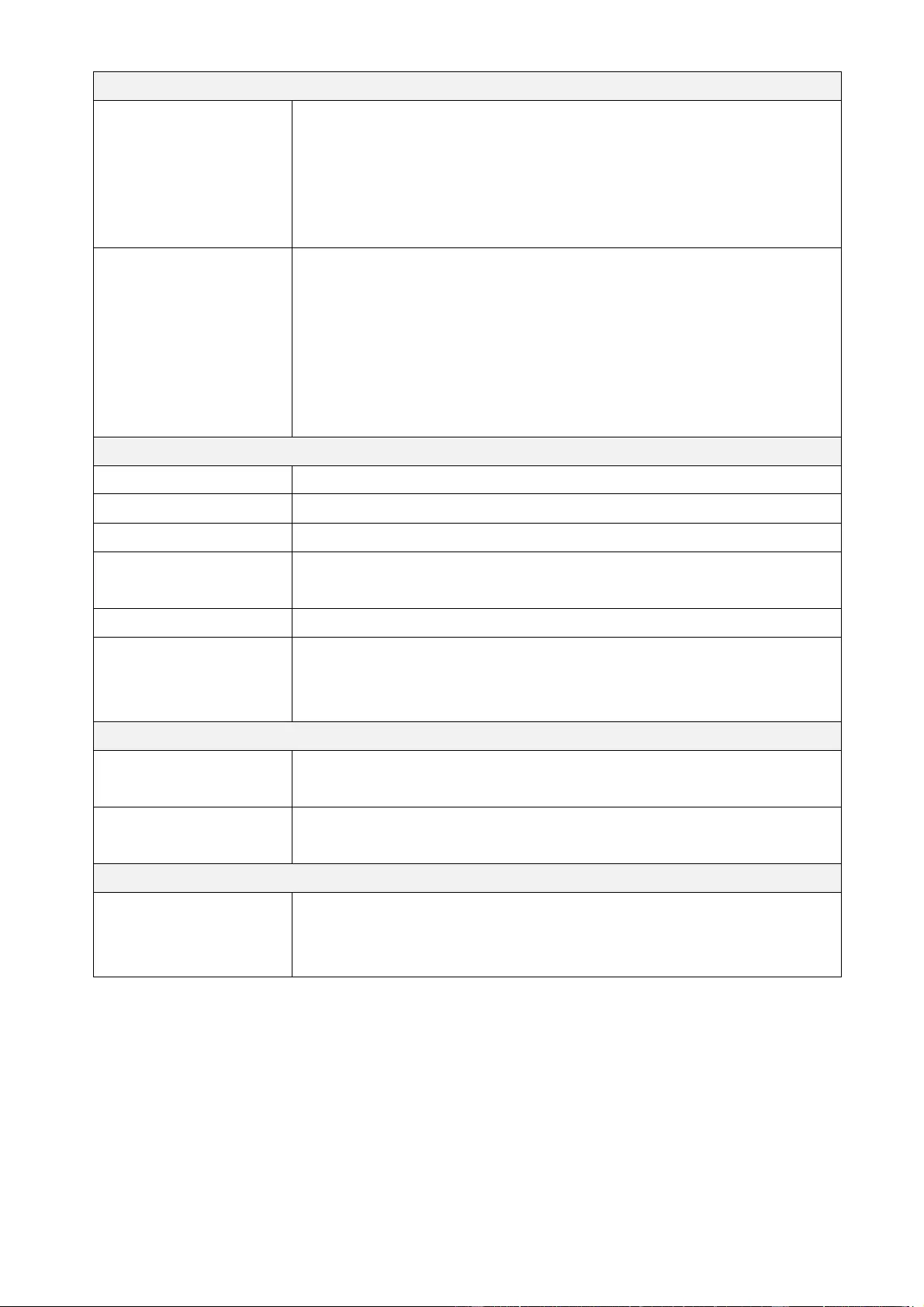

TJ-4020TN/TJ-4120TN

Use t he power-on utilities to calibrate sensors and initialize the hardware.

Function Instructions

Gap/Black Ma rk

Sensor Calibration

1. Turn o ff th e pri nt er .

2. Press an d hold the Pause Button, and th en t urn o n t he Power

Switch.

3. Releas e the butt on when the Power LED l i ght s, and t he pr inter

feed

the labels.

Self-test

1. Turn o ff th e pri nt er .

2. Press and hold the Feed Button, and then tur n on t he Pow er

Switch.

3. Release the button when the Power LED lights, and the printer

feeds the labels.

Prin ter initializat ion

1. Turn o ff th e pri nt er .

2. Press and h ol d b oth the Pause and Feed Buttons, a nd th en t ur n on

the P ow er S wi tc h.

3. Release the buttons when the Power LED lights.

Note

W hen printer initialization is complete, calibrate the Gap Sensor

again.

TJ-4021TN/TJ-4021TNR/TJ-4121TN/TJ-4121TNR

Use power-on utilities to set sensor calibration, self-test , and f ac t or y de f a ul t functions.

1. Turn o ff th e label printer.

2. Press and hold the right Selection button, and the n tur n on the Power Switch.

3. Release the button when the function you want to set or test appears on the

Touchscreen.

42

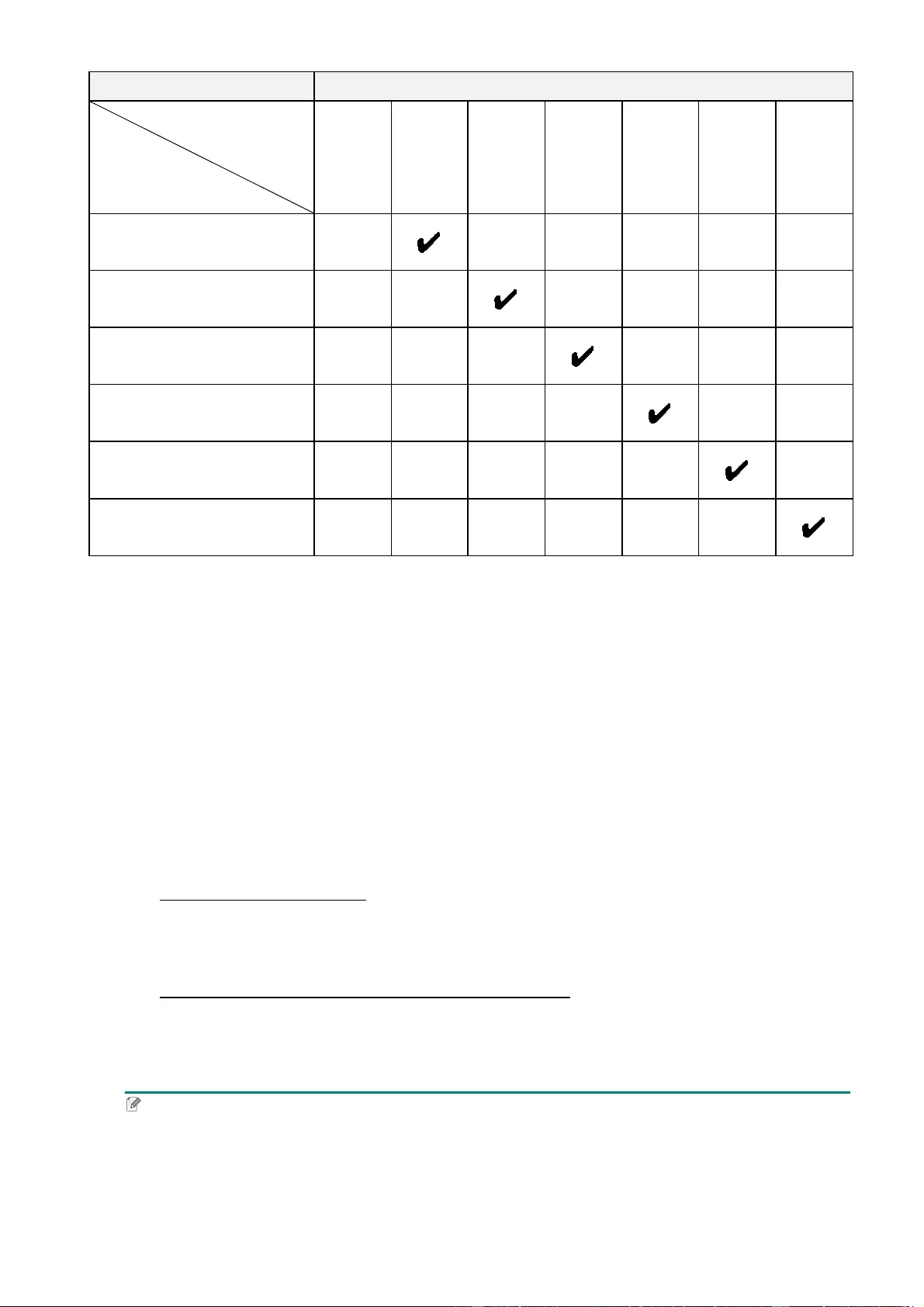

Power-On Utility Power LED Patterns

LED color

Function

Amber (Lit)

Red

(Blinks five

times)

Amber

(Blinks five

times)

Green

(Blinks five

times)

Green/

Amber

(Blinks five

times)

Red/Amber

(Blinks five

times)

Gr een ( Lit )

1. Sensor Calibration (Gap /

black mar k sensor)

2. Self-test (And enter Dump

Mode)

3. F actor y Default

4. Bline Calibrati on

5. G ap Calibr ation

6. READY (Skip AUTO.BAS)

6.1.1 Ribbon and Gap/Black Mark Sensor Calibration

Calibrate the Gap/Black Mark Sensor sensitivity when:

Y ou purc h as e a new pr inter.

You change label stock.

The label printer initializes.

To calibrate the Ribbon and Gap/Black Mark Sensors:

1. Turn o ff th e pri nt er .

2. Select the fu nct i o n you want:

- For TJ-4020TN/TJ-4120TN:

a. Press and hold the Pause button, a nd th en t urn o n t he Power Swit ch.

b. Release the button when the Power LED lights, and the pri n ter fe eds the labels.

- For TJ-4021TN/TJ-4021TNR/TJ-4121TN/TJ-4121TNR:

a. Press and hold the right Selection button, and then turn on the Power Switch.

b. Release the button when Sensor Ca libration appears on the Touchscreen.

Note

The LED color will change as fo llows:

Amber (lit) red (5 times) amber (5 times) green (5 t i mes) green/amber (5 times)

red/amber (5 times) green (lit)

43

To sel ec t th e sensor for calibration, send the correct command to the printer:

For the Gap Sensor: send the GAP command

For the Black Mark Sensor: send the BLINE command

For more information about the available commands, see the FBPL Command Reference

on your model's Manuals page at support.brother.com.

6.1.2 Gap/Black Mark Sensor Ca libra ti on , Self-Test, and Entering Dump

Mode

Calibrate the Gap or Black Mark Sensor if the sensor's settings used in the last print job are not

suit a bl e for the c ur r en t pr i n t job. Dur ing t he cal i brat i on o f the G a p/Black Mark Se ns or , the pr i nter

detects the la bel len gth, pr int s t h e i n ter nal c onfiguration (self-tes t), a nd th en enter s Dump Mode.

To calibrate the Gap/Black Mark Sensor:

1. Turn o ff th e pri nt er .

2. Select the function you want:

- For TJ-4020TN/TJ-4120TN:

a. Press and hol d the Feed bu t t on, a nd t h en tur n on t he printer.

b. Release the button when the Power LED lights, and the pri n ter feeds the labels.

- For TJ-4021TN/TJ-4021TNR/TJ-4121TN/TJ-4121TNR:

a. Press and hold the right Selection button, and then turn on th e Power Switch.

b. Release the button when Self-test appears on the Touchscreen.

Note

The LED col or wil l change as fol l ows :

Amber (lit) red (5 times) amber (5 times) green (5 time s) green/amb er (5 times)

red/amber (5 times) green (lit)

3. The printer calibrates the sensor and detects the label length, prints the internal settings,

and then enters Dump Mode.

44

Note

To select the sensor for calibration, send the correct command to the printer:

For the Gap Sensor: send the GAP command

For the Bl ack Mark Sensor: send the BLINE command

For more information about the available commands, see the FBPL Command Reference on

your model's Manuals page at support.brother.com.

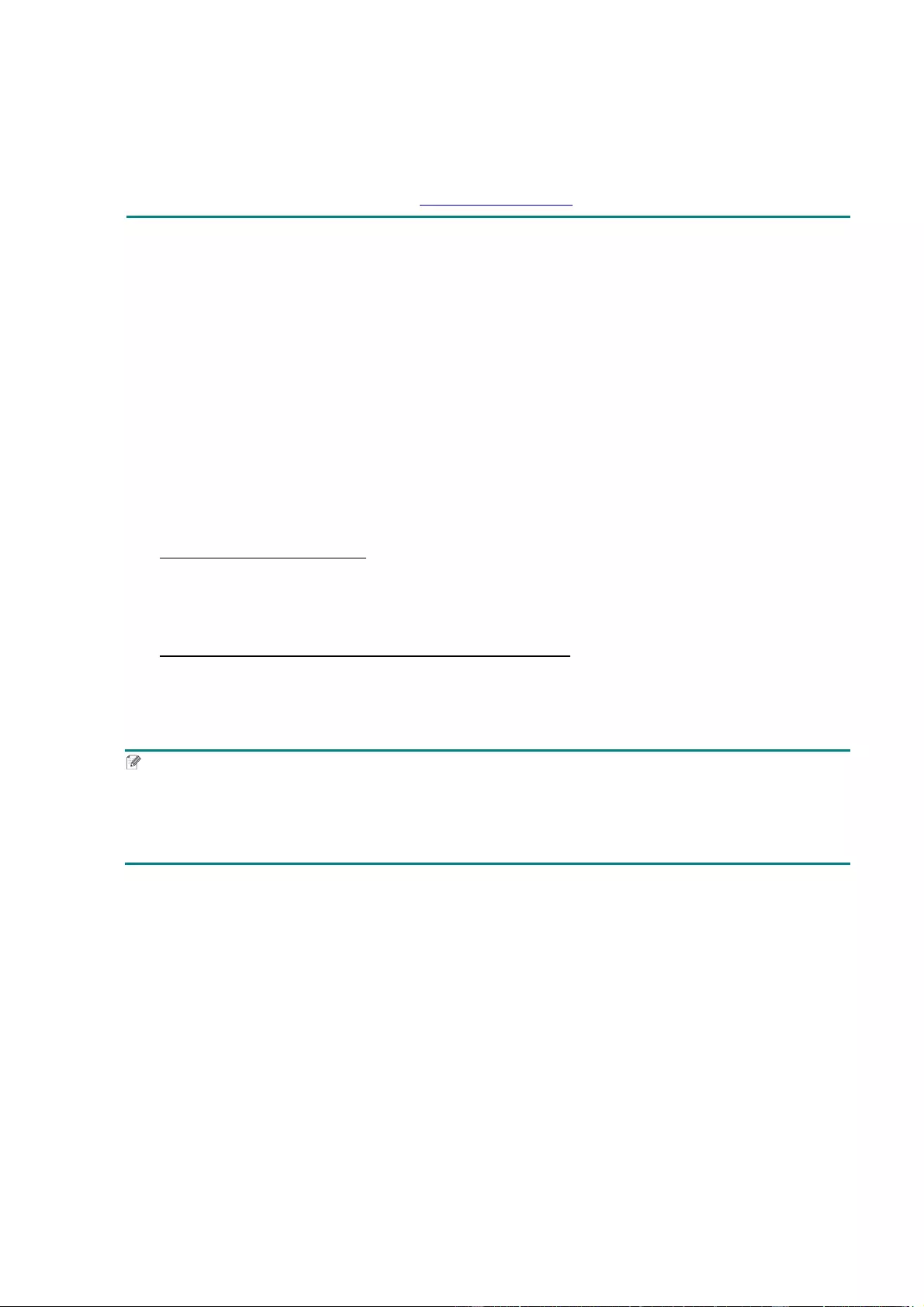

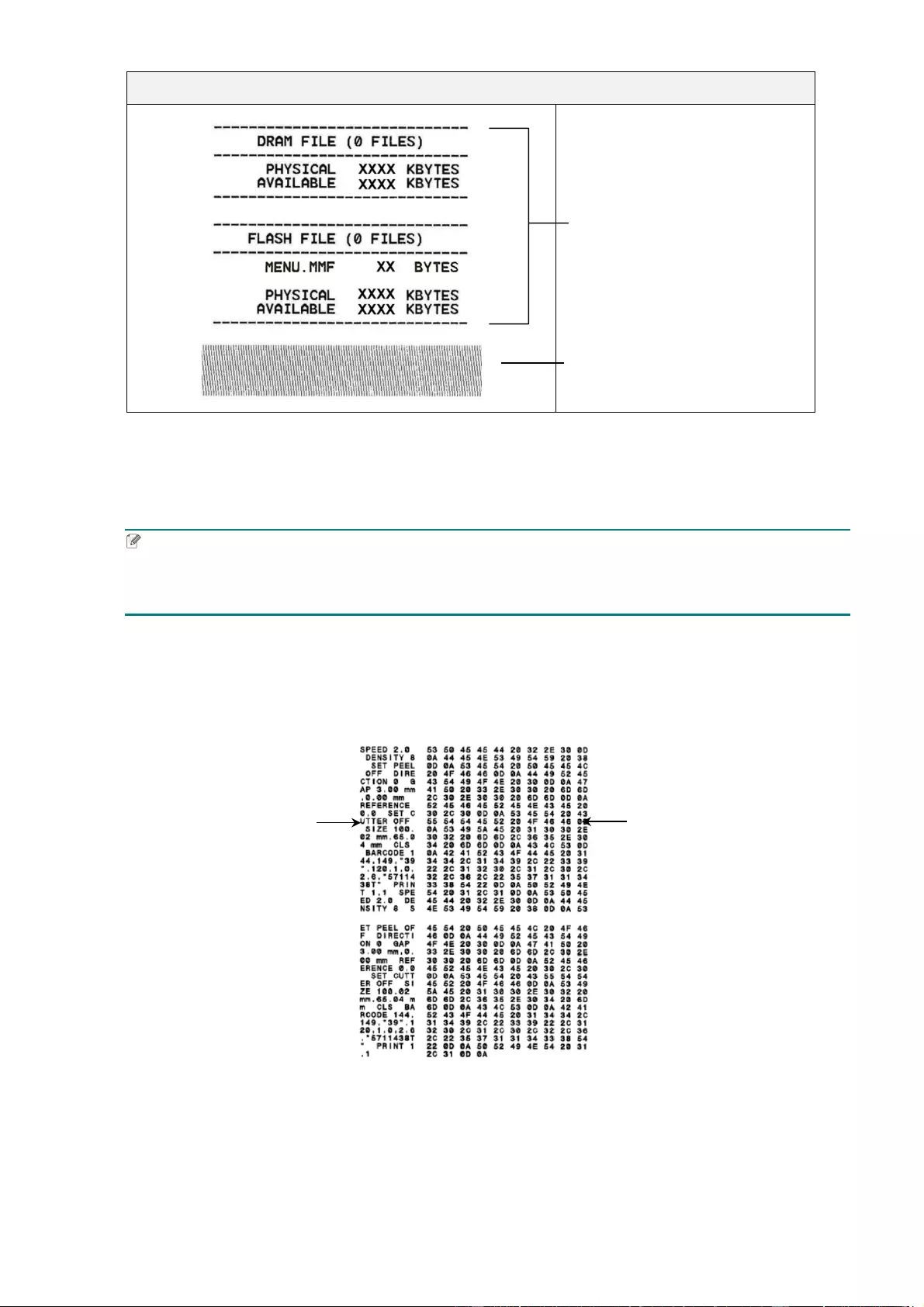

Self-test

Print the printer configuration after you run Gap/Black Mark Sensor calibration. T he self-test

prin tout lists the printer's conf iguration and available memory, and can indicate if th er e is a ny

dot dam ag e on the heater c om p on en t .

Self-test printout

Model name

Firmwa re vers i on

Firmware checksum

Pri nter s er ial num b er

Confi guration file

System date

System time

Printed mileage (meter)

Cutting counter

Print speed (inch/sec)

Pri nt density

Label size (inch)

Gap distance (inch)

Gap/Black Ma rk Senso r

sensitivity

Code page

Country code

45

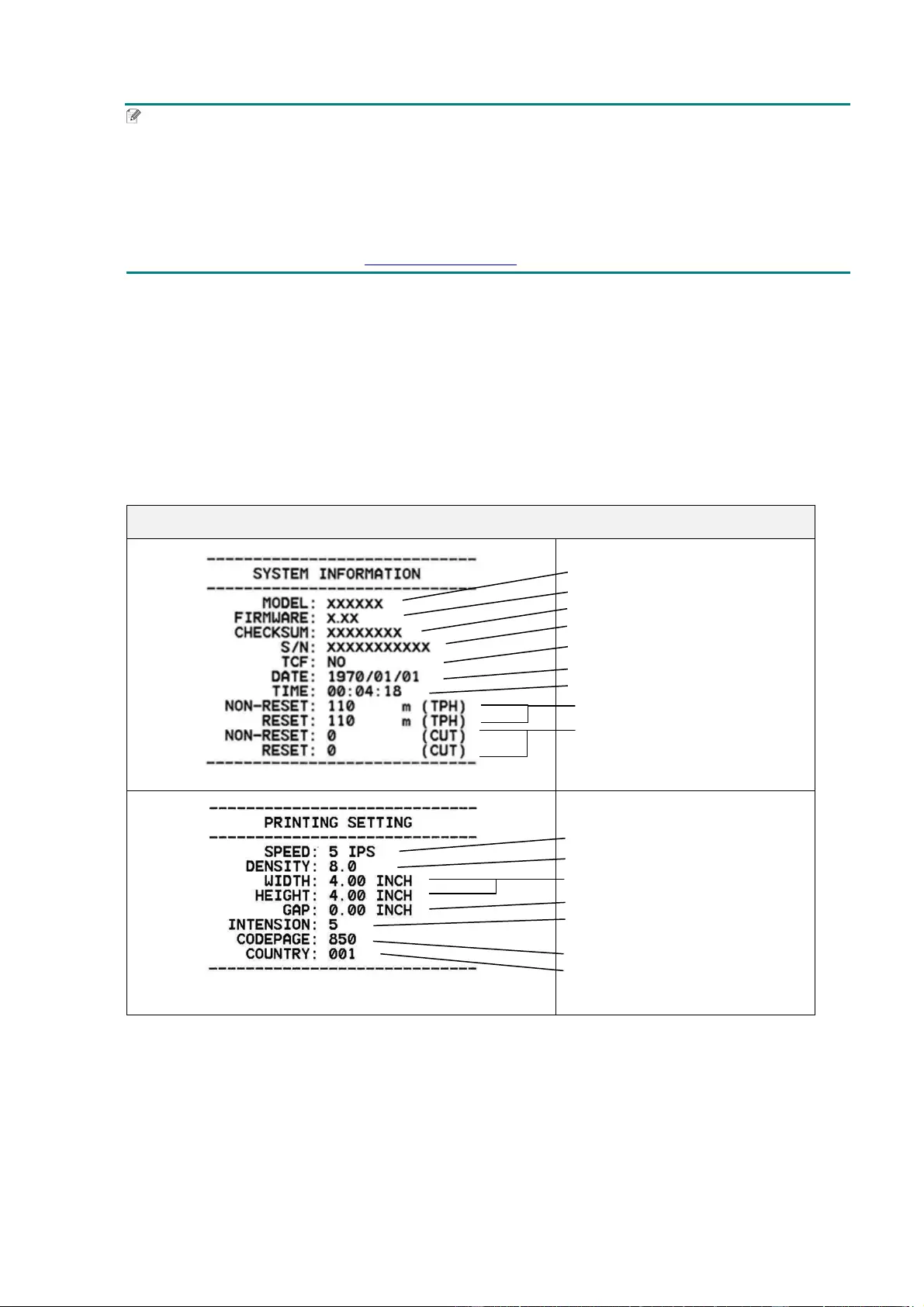

Self-test printout

Pri nt dar k n es s

Print speed (inch/sec)

Label size

Control prefix

Format prefix

Delimiter prefix

Printer power up motion

Print Head close motion

RS23 2 Ser i al Por t

configuration

RFID frequency band region

Pri nter name

Mac Address

DHCP

IP Address

Subnet Mask

Gateway

RAW Port

Wi-Fi configuration

46

Self-test printout

Num ber o f dow nl o ad ed f i les

Total an d av ail able memor y

space

Prin t Hea d check pattern

Dump Mode

Note

Dump Mode requires 101.5 mm wide paper.

To res um e nor m al pr i nting, tur n the printer off and then on again.

The pr i nt er enter s Dump Mode after printing the printer configuration. Dump Mode allows users

to verify and debug the printer's programs. The characters in the left column are received from

the printer's system and those in the right column are their hexadecimal representation.

ASCII data Hexadecimal

repr esent ation of th e

A SCII da ta

47

6.1.3 Printer Initialization

Printer initialization clears the printer's DRAM and restores its factory settings.

1. Turn o ff th e pri nt er .

2. Select the function you want:

- For TJ-4020TN/TJ-4120TN:

a. Press and hol d the Pause and Feed b utton, and then t ur n on th e printer.

b. Release the button when the Power LED lights on.

- For TJ-4021TN/TJ-4021TNR/TJ-4121TN/TJ-4121TNR:

a. Press and hold the right Selection button, and then turn on the Power Switch.

b. Release the button when Factory Default appears on the Touchscreen.

Note

The LED col or wil l change as fol l ows :

Amber (lit) red (5 times) amber (5 times) green (5 times) green/amber (5 times)

red/amber (5 times) green (lit)

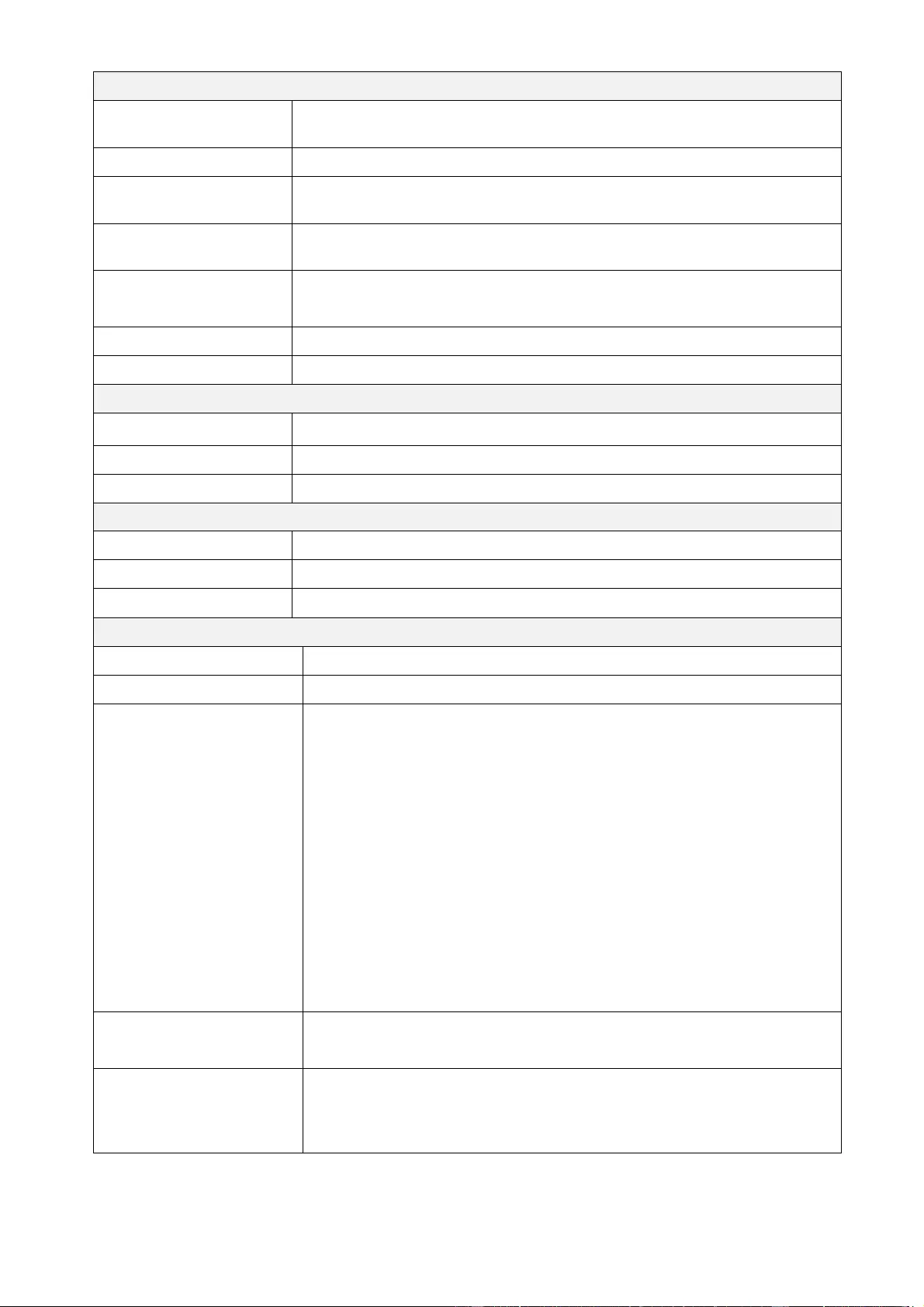

After th e initialization, the following factory settings will be restored:

Parameter Default setting

Speed 127 mm/sec (5 ips) (203 DPI)

76 mm/sec (3 ips) (300 DPI)

Density 8

Label Width 101.5 mm

Label Height 101.5 mm

Sensor Type Gap sensor: TJ-4020TN, TJ-4021TN, TJ-4120TN, TJ-4121TN

Black sensor: TJ-4021TNR, TJ-4121TNR

Gap Setting 3 mm

Prin t Directio n 0

Reference Point 0,0 (upper left corner)

Offset 0

Tear Mode On

Peeler Mode Off

Cutter Mode Off

Rewinder Mode Off

Code Page 850

Country Code 001

Clear Flash Memory No

48

6.1.4 Media Sensor Calibration (for the Black Mark Sensor)

1. Turn o ff th e pri nt er .

2. Select the function you want:

- For TJ-4020TN/TJ-4120TN:

The printer calibrates the Gap Sensor and the Black Mark Sensor simultaneously.

a. Press and hol d the Pause butto n, and then turn on t he pr inter.

b. Release the button when the Power LED lights, and the printer feeds the labels.

- For TJ-4021TN/TJ-4021TNR/TJ-4121TN/TJ-4121TNR:

a. Press and hold the right Selection button, and then turn on the Power Switch.

b. Release the button when Bline Calibra tion appears on the Touchscreen.

Note

The LED col or wil l change as fol l ows :

Amber (lit) red (5 times) amber (5 times) green (5 t imes) green/amber (5 times)

red/amber (5 times) green (lit)

6.1.5 Media Sensor Calibration (for the Gap Sensor)

1. Turn o ff th e pri nt er .

2. Select the function you want:

- For TJ-4020TN/TJ-4120TN:

The printer calibrates the Gap Sensor and the Black Mark Sensor simultaneously.

a. Press and hol d the Pause butto n, and then turn on t he pr inter.

b. Release the button when the Power LED lights, and the printer feeds the labels.

- For TJ-4021TN/TJ-4021TNR/TJ-4121TN/TJ-4121TNR:

a. Press and hold the right Selection button, and then turn on the Power Switch.

b. Release the button when Ga p Calib ra tion appears on the Touchscreen.

Note

The LED col or wil l change as fol l ows :

Amber (lit) red (5 times) amber (5 times) green (5 t imes) green/amber (5 times)

red/amber (5 times) green (lit)

49

6.1.6 S k i p t h e AUT O.BAS Program

You can upload the AUTO.BAS program to the printer's flash memory so that it runs

automatically at startup, but if you do not want it to run automatically, follow these steps:

1. Turn o ff th e pri nt er .

2. Select the function you want:

- For TJ-4020TN/TJ-4120TN:

Press and hold the Pause and Feed b uttons, and then turn on the pr i nter.

- For TJ-4021TN/TJ-4021TNR/TJ-4121TN/TJ-4121TNR:

a. Press and hold the right Selection button, and then turn on the Power Switch.

b. Release the button when READY (Skip AUTO.BAS) appears on t h e To uc hs cr een.

Note

The LED col or wil l change in the f oll ow i n g or der :

Amber (lit) red (5 times) amber (5 times) green (5 t imes) green/amber (5 times)

red/amber (5 times) green (lit)

3. The printer will start without running the AUTO.BAS program.

50

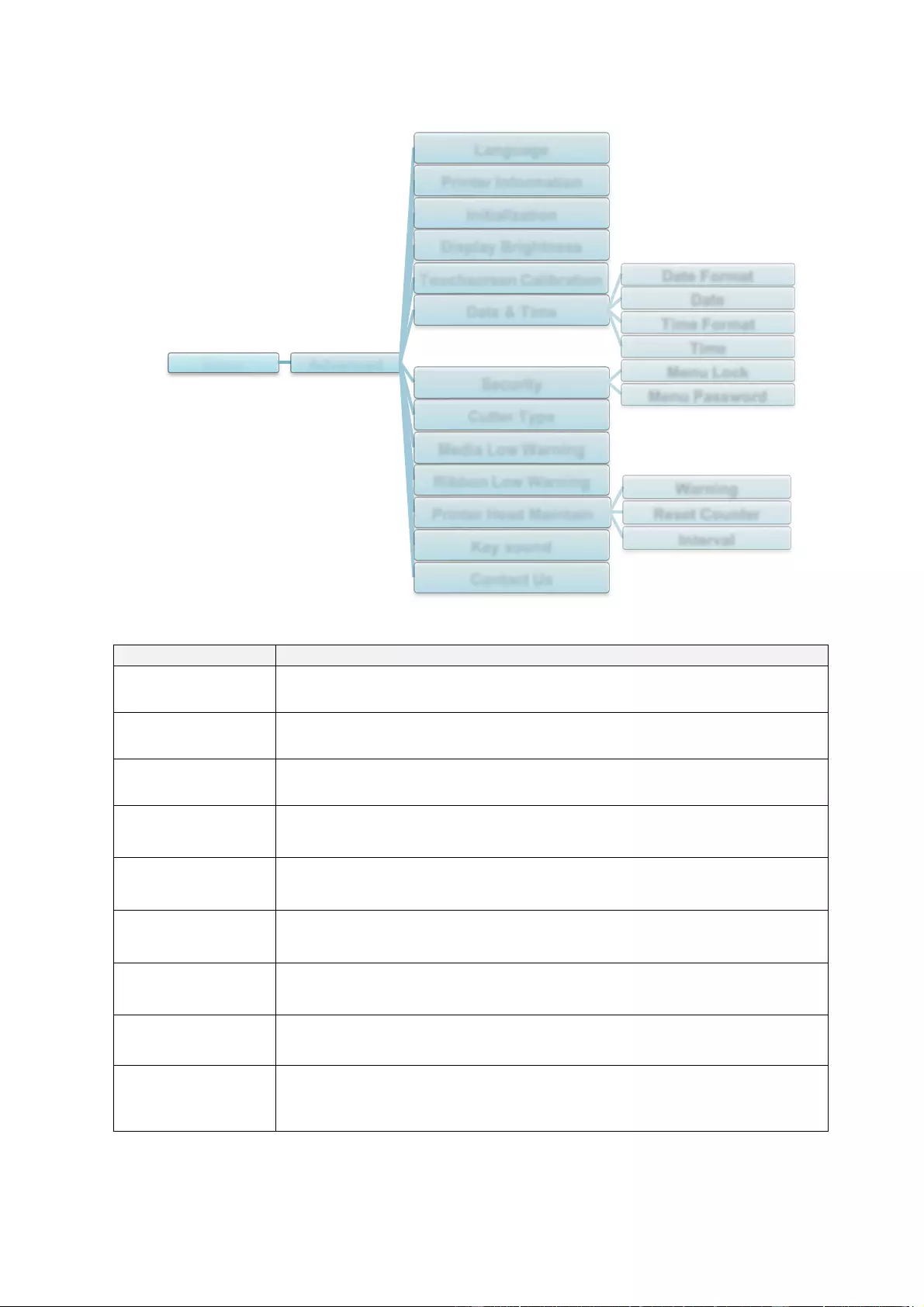

7. Change Printer Settings us ing the Touchscreen

(Avai l able for TJ-4021TN/4021TNR/4121TN/4121TNR only.)

7.1 Setting Menu

1. In the Main Menu, tap Setting.

2. Tap Comma nd S et, and then select the programming language you want.

3. Tap the icon.

7.1.1 FBPL Settings

Available FBPL settings:

Setting FBPL

Speed

Density

Direction

Print Mode

None

Batch Mode

Peeler M ode

Cutter Mode

Cutter Batch

Offset

Shift X

Shift Y

Reference X

Reference Y

Code Page

Country

51

Setting

Description

Speed Set up the pri nt s p eed. Setting s ra ng e from:

1 - 10 f or 203 dpi (Default: 5)

1 - 7 for 300 dpi (Defaul t : 3)

Density Adjust t he pr i nt darkness/lightness. Settings range from 0 to 15. You may

need t o adjust the print de ns i ty based on the media.

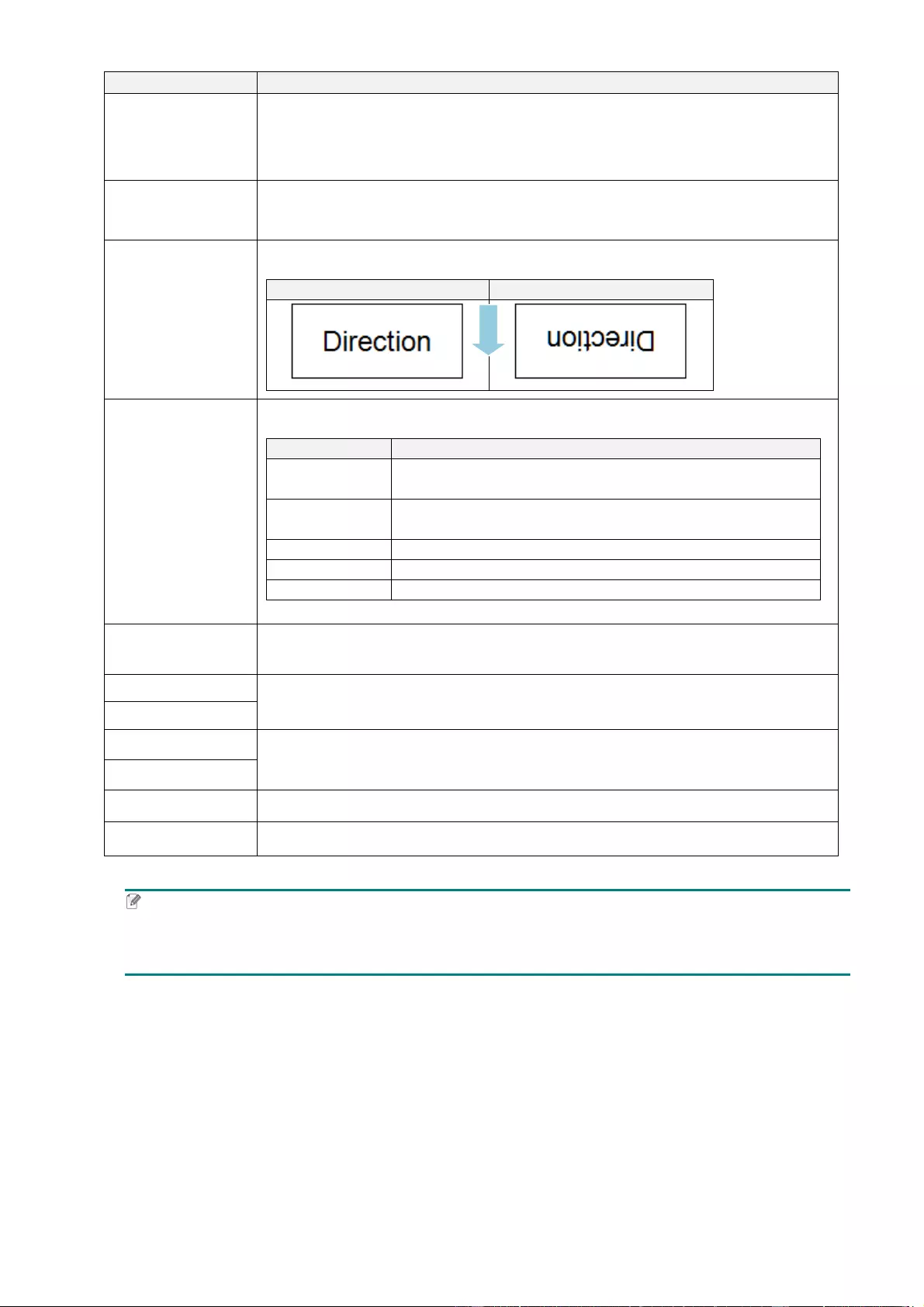

Direction

Spe cify pri nt di r ecti o n.

DIRECT ION 0

DIRECT ION 1

Print Mode

Set the Print Mode.

Print Mode

Description

None

The top of the next label is aligned with the Print Head

burn line ( Tear Off Mode) .

Batch Mode

When t he image is printed, the Ga p/Bl ack Mark is fed

through the t e ar pl ate for tear aw ay.

Peeler Mode

Enables label Peeler Mode.

Cutter Mode

Enables label Cutter Mode.

Cutter Ba tch

Cuts the label once at the end of the printing job.

Offset Fine-tune the media stop location. Settings range from -999 dots to 999

dots.

Shift X Fine-t une the pr i nt pos ition . Settings range from -999 do ts to 99 9 dot s.

Shift Y

Reference X Set the origin of the printer coordinate system horizontally and vertically.

Settings range from 0 dot s to 999 dot s.

Reference Y

Code Page Set the international character set code page .

Country Set th e cou nt r y code. Setting s range from 1 to 358.

Note

If printing from the downloaded software/driver, the software/driver commands will overwrite the

settings set from the Touchscreen.

FEED

52

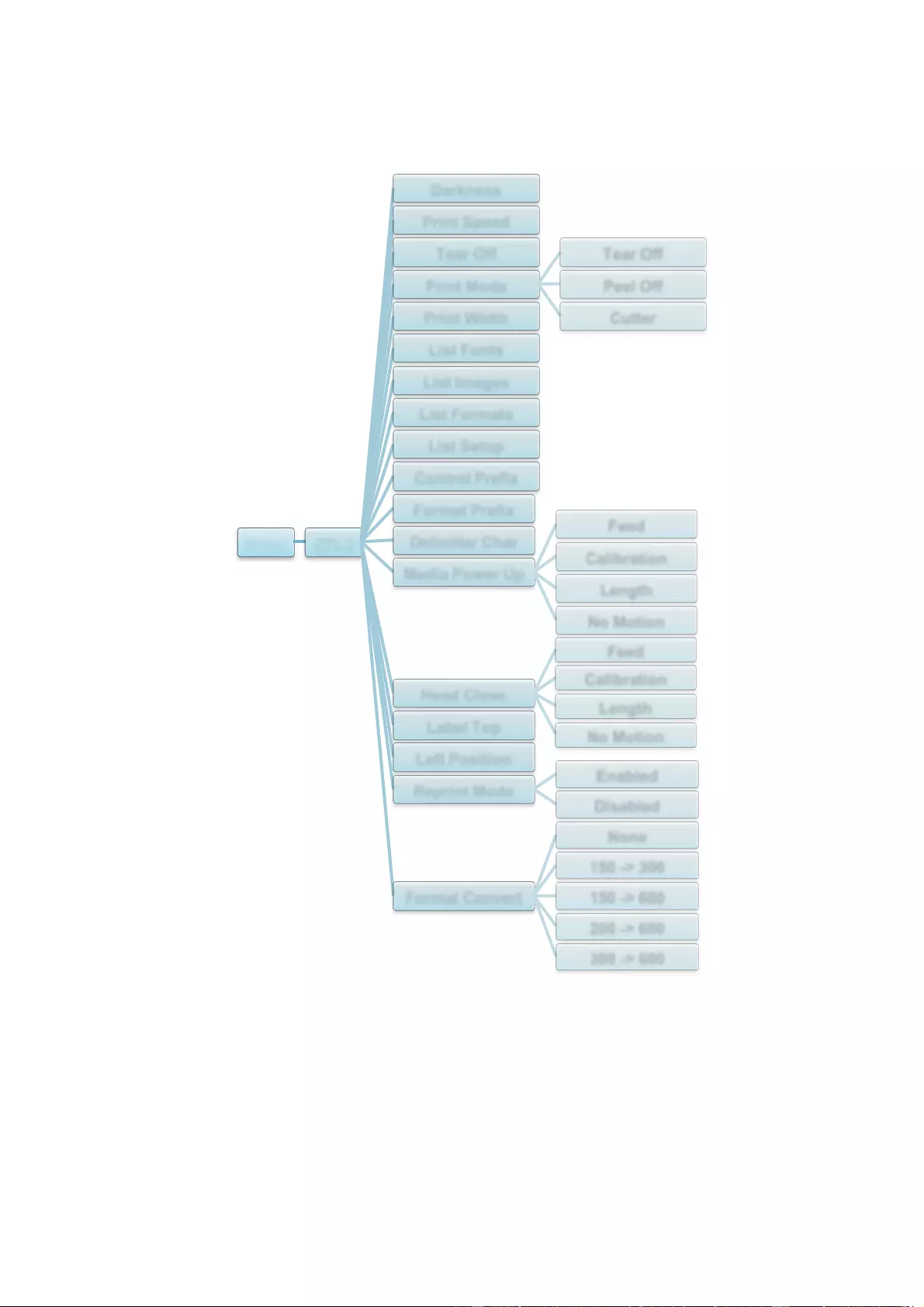

7.1.2 ZPL2 Settings

Available ZPL2 settings:

Menu ZPL2

Darkness

Print Speed

Tear Off

Print Mode

Tear Off

Peel Off

CutterPrint W idt h

List Font s

List Images

List Formats

List Setup

Contr ol Pre fix

Format Prefix

Delimiter Char

Media Power Up

Feed

Calibration

Length

No Mot ion

Head Close

Feed

Calibration

Length

No Mot ion

Labe l Top

Left Pos it ion

Re print Mode Enabled

Disabled

Format Convert

None

150 -> 300

150 -> 600

200 -> 600

300 -> 600

53

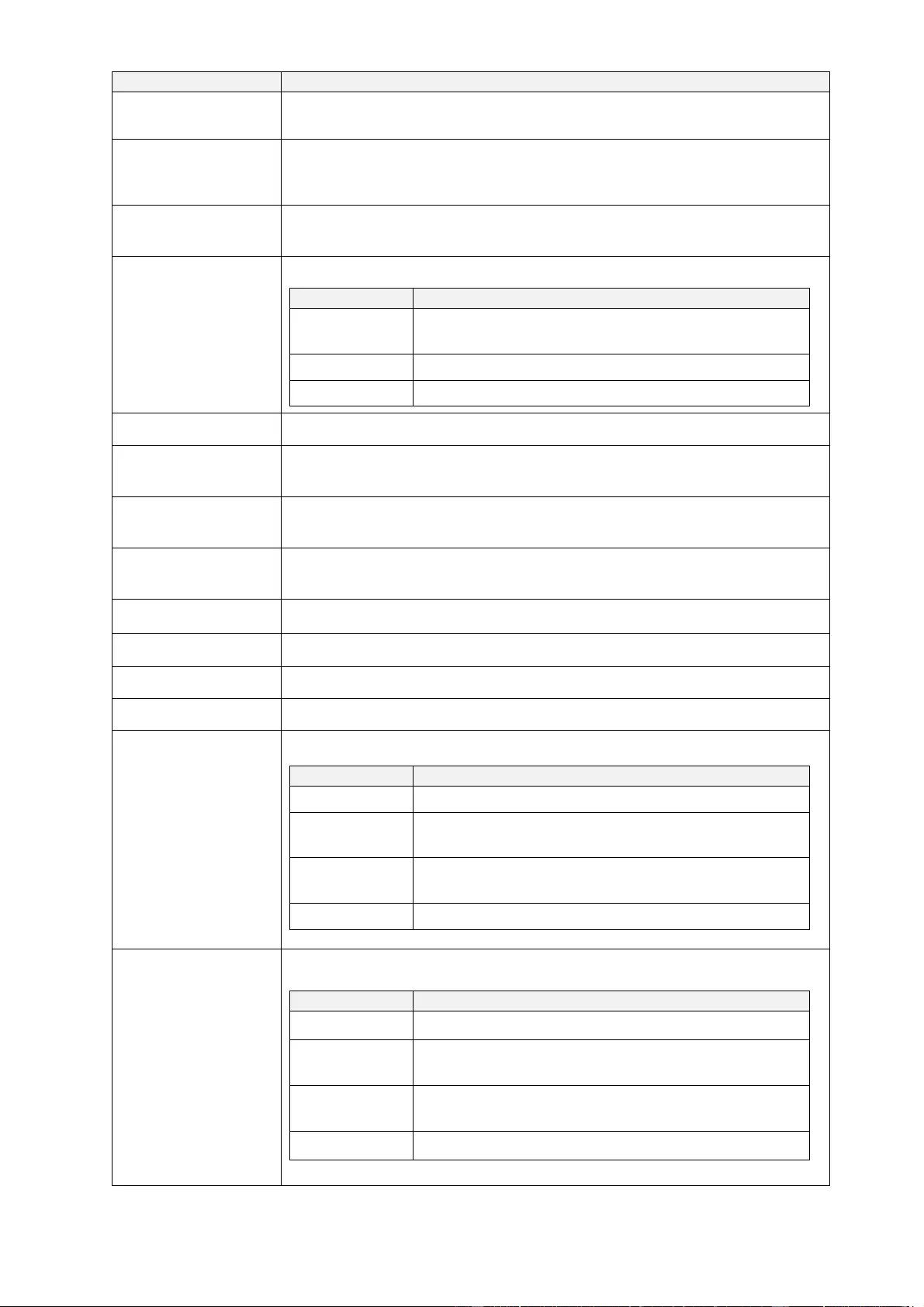

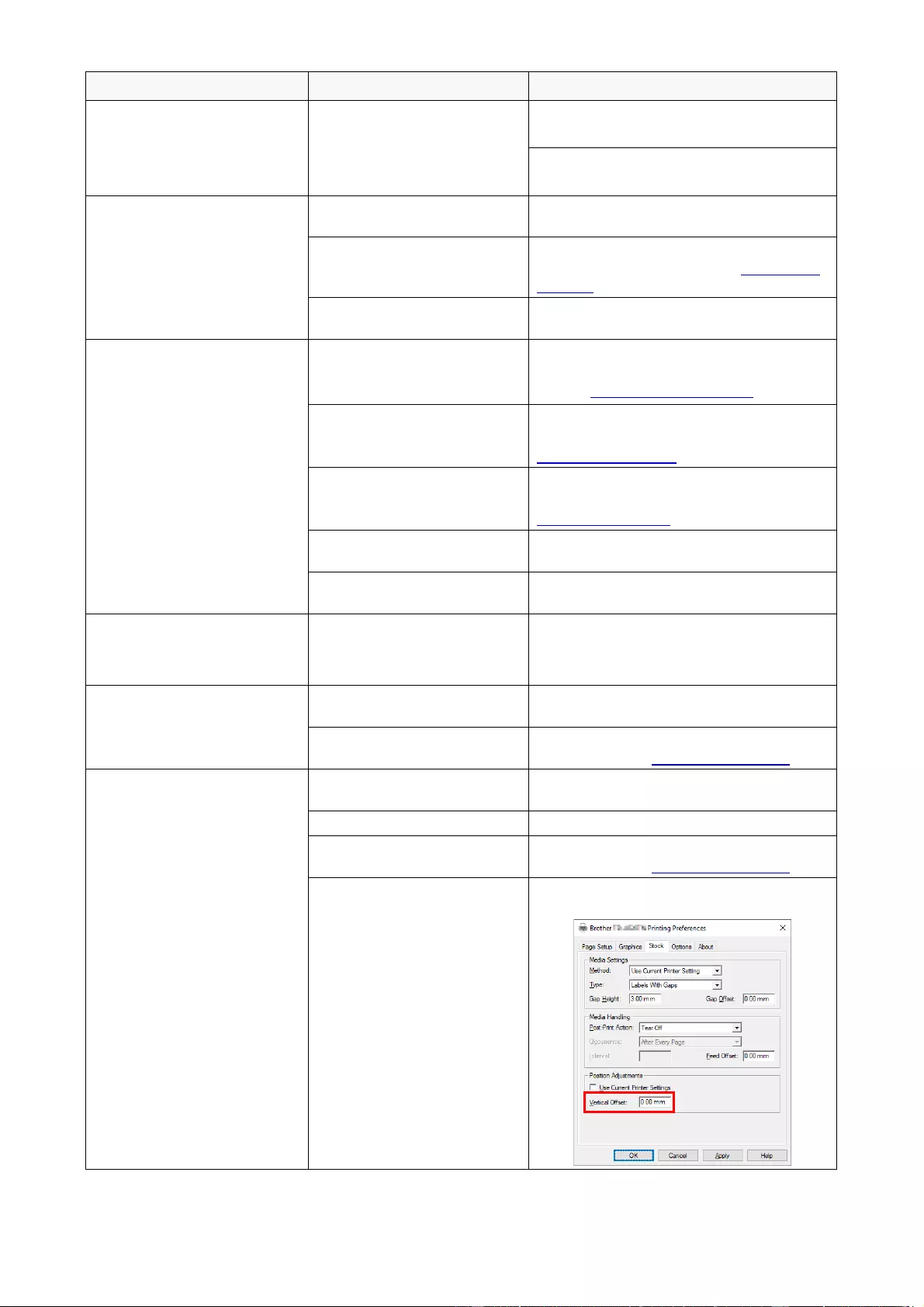

Setting

Description

Darkness Set up the print darkness. Settings range from 0 to 30. You may need

to adjust the print dens ity base d on the selected media.

Print Spee d

Set up the pri nt s p eed. Set ti ng s range from :

2 - 10 for 203 dpi (Default: 4)

2 - 7 for 300 dpi ( D e fa ul t: 3)

Tear Of f Fine-tune the media stop location. Settings range from -120 dots to

120 dots.

Print Mode

Set th e pr i nt m od e.

Print Mode

Description

Tear Off

The top of the next label is aligned with the Print

Head burn line.

Peel Off

Enable the label Peeler Mode.

Cutter

Enable the label Cutter Mode.

P rint Width Set the print width. S ettings r an ge fr om 2 dots to 9 99 do ts .

List Fonts Print the curr ent printer fo nt s l i st t o the l ab el . The f ont s can be stored in

th e p rinter’s DRAM, Flash, or optional memory card.

List Image s Print the curr e nt pr inter images list to the label. The images can be

stored in the printer’s DRAM, Flash, or optional memory card.

List Formats Print the current pri nt er form a t s li st t o th e la bel . Th e for m ats ca n be

stored in the printer’s DRAM, Flash, or optional memory card.

List Setu p Print the cur r e nt pri nter co n fig ur ation.

Control Prefix Set the control prefix character.

Format Prefix Set the format pr efi x c h ar acter.

Delimiter Char Set the delimiter character.

Media Power Up

Set the media action you want when you turn the printer on.

Action

Description

Feed

The pr i nt er ej ect s on e la bel .

Calibration

The printer calibrates the sensor levels,

determines the label length, and feeds one label.

Length

The printer determines the label length and feeds

the label.

No Motion

No action.

Head Close

Set the media action when you close the Print Head.

Action

Description

Feed The printer ejects one label.

Calibration The printer calibrates the sensor levels,

determines the label length, and feeds one label.

Length

The printer determines the label length and feeds

the label.

No Motion No action.

54

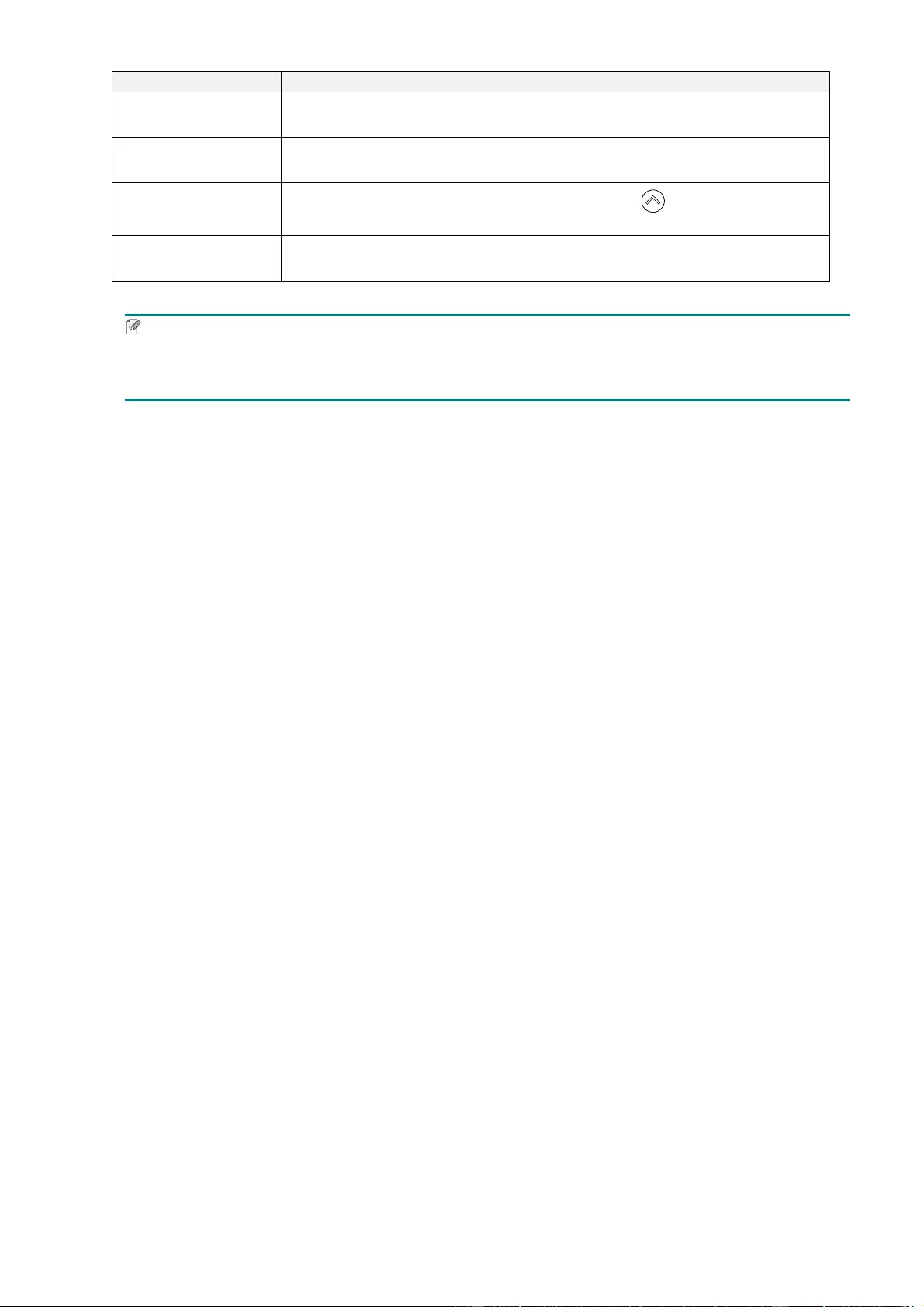

Setting

Description

Label Top

Adjust the print position vertically on the label. Settings range from

-120 dots to +120 dots.

Left Position Adjust the print position horizontally on the label. Settings range from

-999 9 dots to +99 99 do t s.

Reprint Mode Reprint the last label by tapping the Up arro w ( ) button on t he

Touchscreen.

Format Convert

Selects the bitmap scaling factor. The first number is the original DPI

value; the second num b er is the DPI setting you want.

Note

If printing from the downloaded software/driver, the software/driver commands will overwrite the

settings set from the Touchscreen.

55

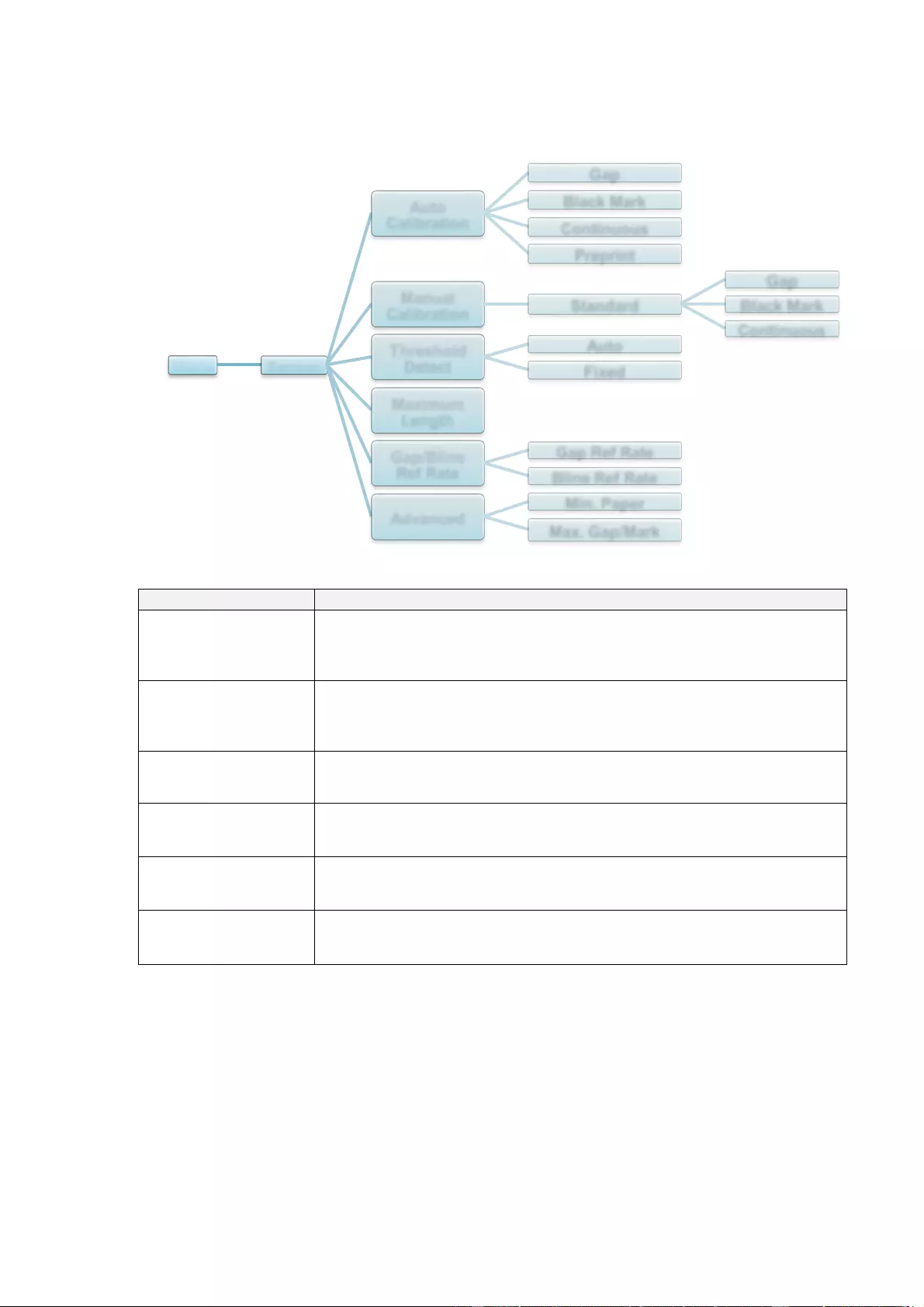

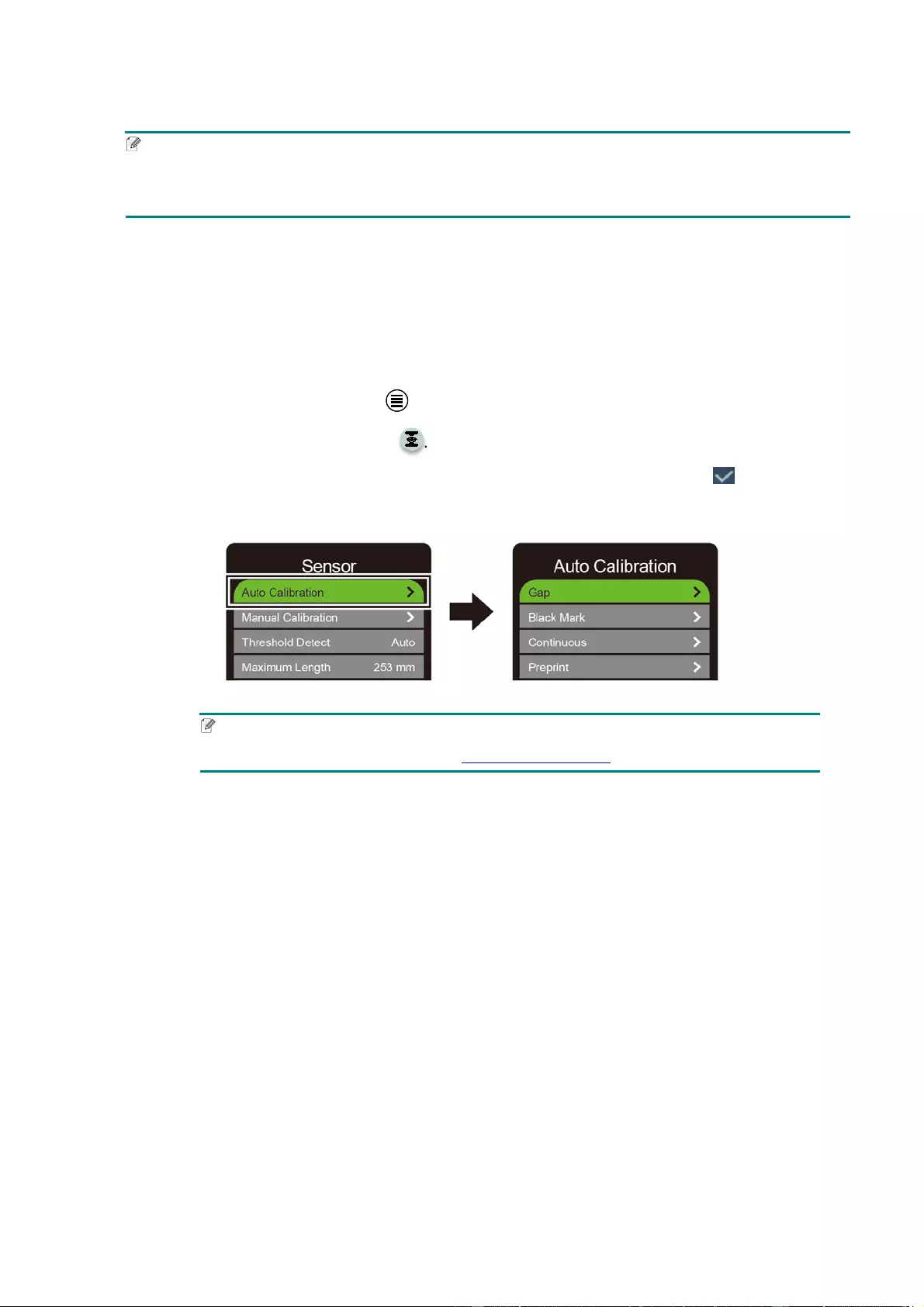

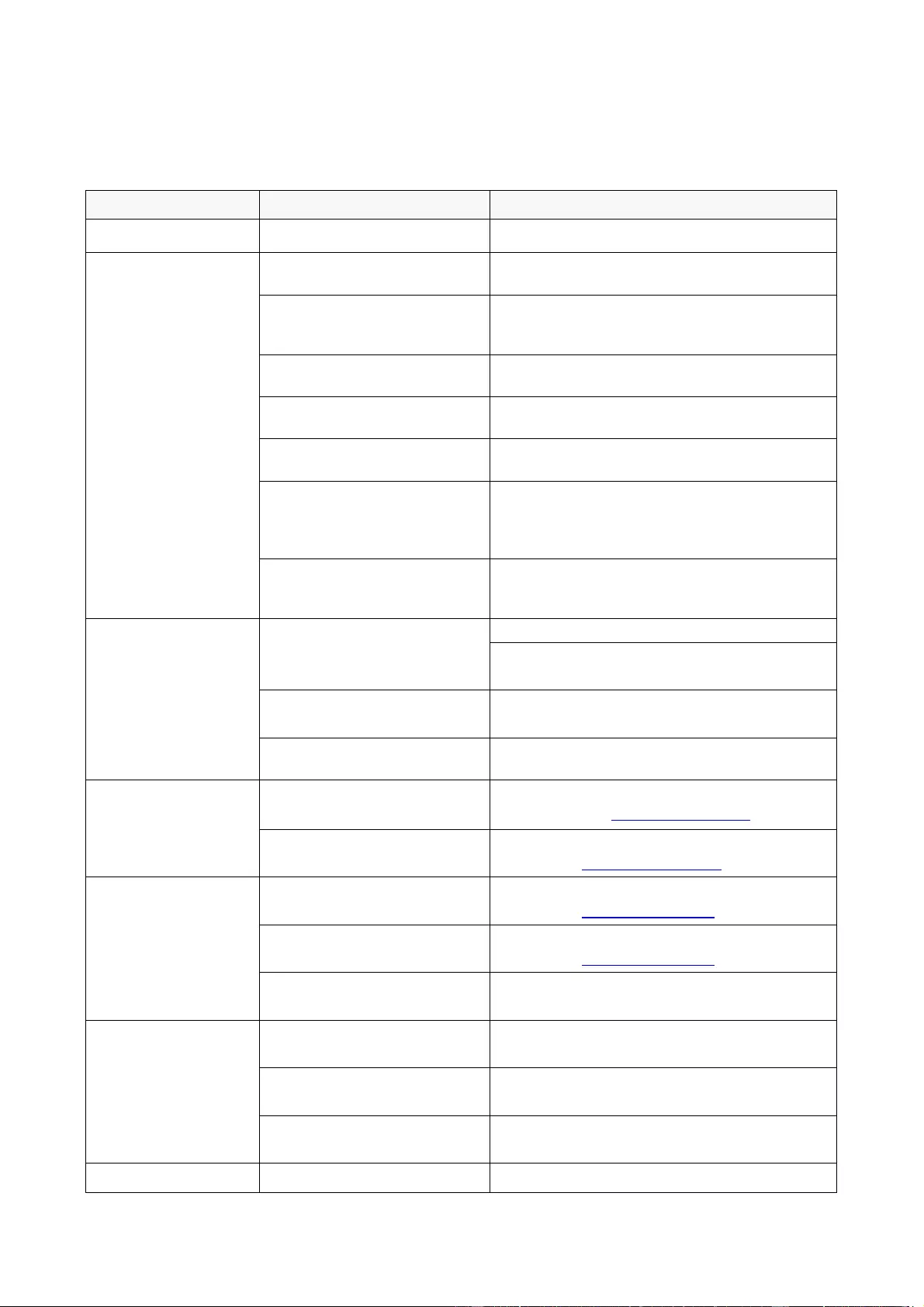

7.2 Sensor Settings

W e recommend calibrating the sensors every tim e you change the medi a.

Setting

Description

Auto Calibration Set the media sensor type and calibrate the selected sensor

automatically. The printer feeds u p to thr ee gap labels to calibrate

the sensor sensitivity automatically.

Manual Calibration If “Automatic” cannot apply to the media, use the “ Manual” funct ion

to set the pap er length and gap/BLINE size, and then s ca n t h e

backing/mark to calibrate the sensor sensitivity.

Threshold Detect Set the sensor sensitivity to Fix ed or Auto.

Maximum Length Set the maximum length for label calibration.

Gap/Bline Ref Rate Adj usts sens i ti vi ty for gap (spaci n g) det ec tion on die-cut labels or for

black mark detection.

Advanced Set th e mini m um paper length and maximum gap/BLINE length to

calibrate the sensor sensitivity automatically.

Menu Sensor

Auto

Calibration

Gap

Black Mark

Continuous

Preprint

Manual

Calibration Standard

Gap

Black Mark

Continuous

Threshold

Detect Auto

Fixed

Maximum

Length

Gap/Bline

Ref Rate Gap Ref Rate

Bline Ref Rate

Advanced Min. Pape r

Max. Gap/Mark

56

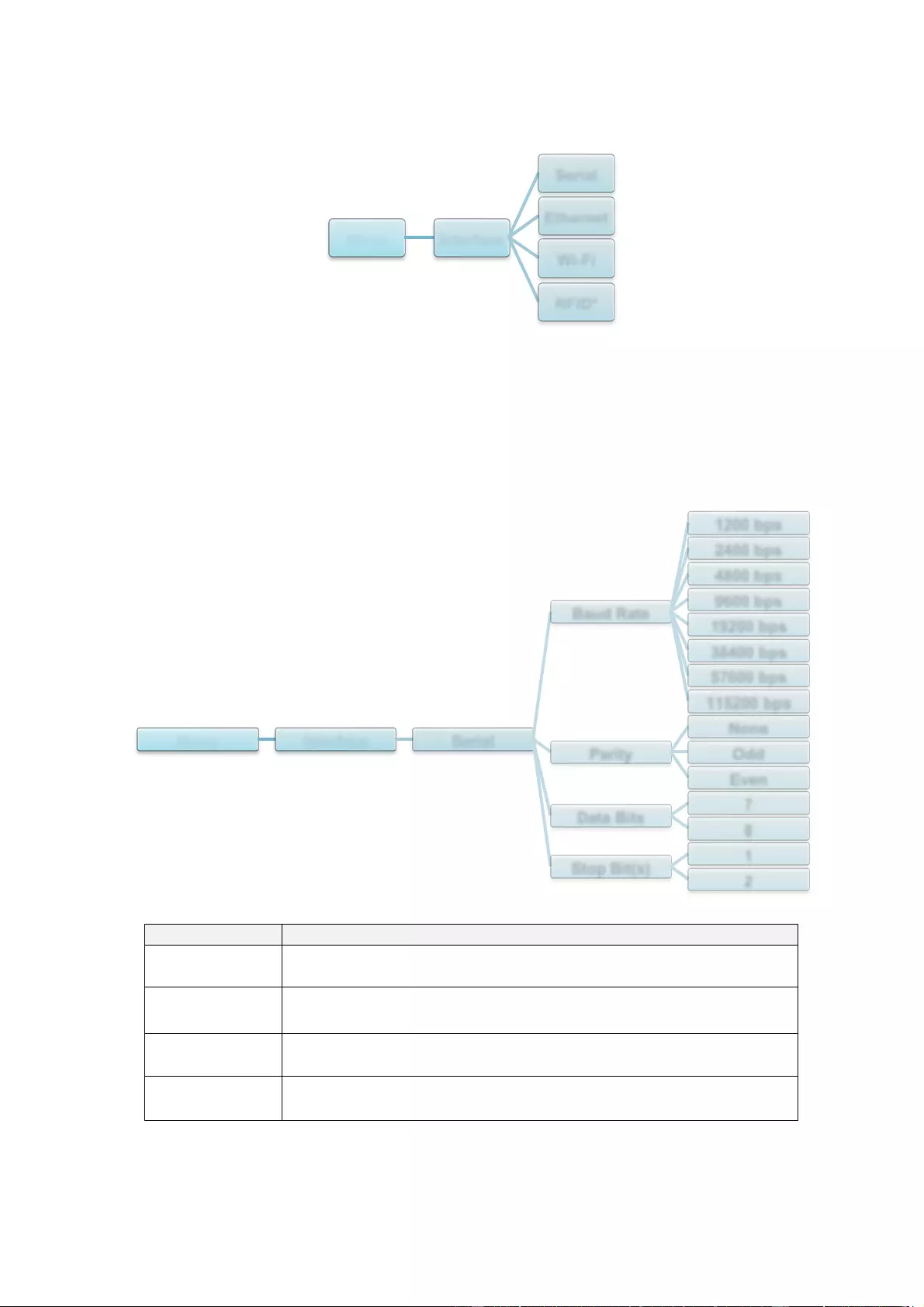

7.3 Interface Settings

Set th e pr i nter i nt erface s ett ings.

* Available for TJ-4021TNR a nd TJ-4121T N R only.

7.3.1 Serial Communication Settings

Set th e pr i nter R S-232 settings.

Setting

Description

Baud Rate Set the RS-232 Baud rate.

Parity Set the RS-232 Parity.

Data Bits Set the RS-232 Data bits.

Stop Bit(s ) Set the RS-232 Stop bits.

Menu Interface

Serial

Ethernet

RFID*

Wi-Fi

Menu Interface Serial

Baud Rate

1200 bps

2400 bps

4800 bps

9600 bps

19200 bps

38400 bps

57600 bps

115200 bps

Parity

None

Odd

Even

Data Bits 7

8

Stop Bit(s) 1

2

57

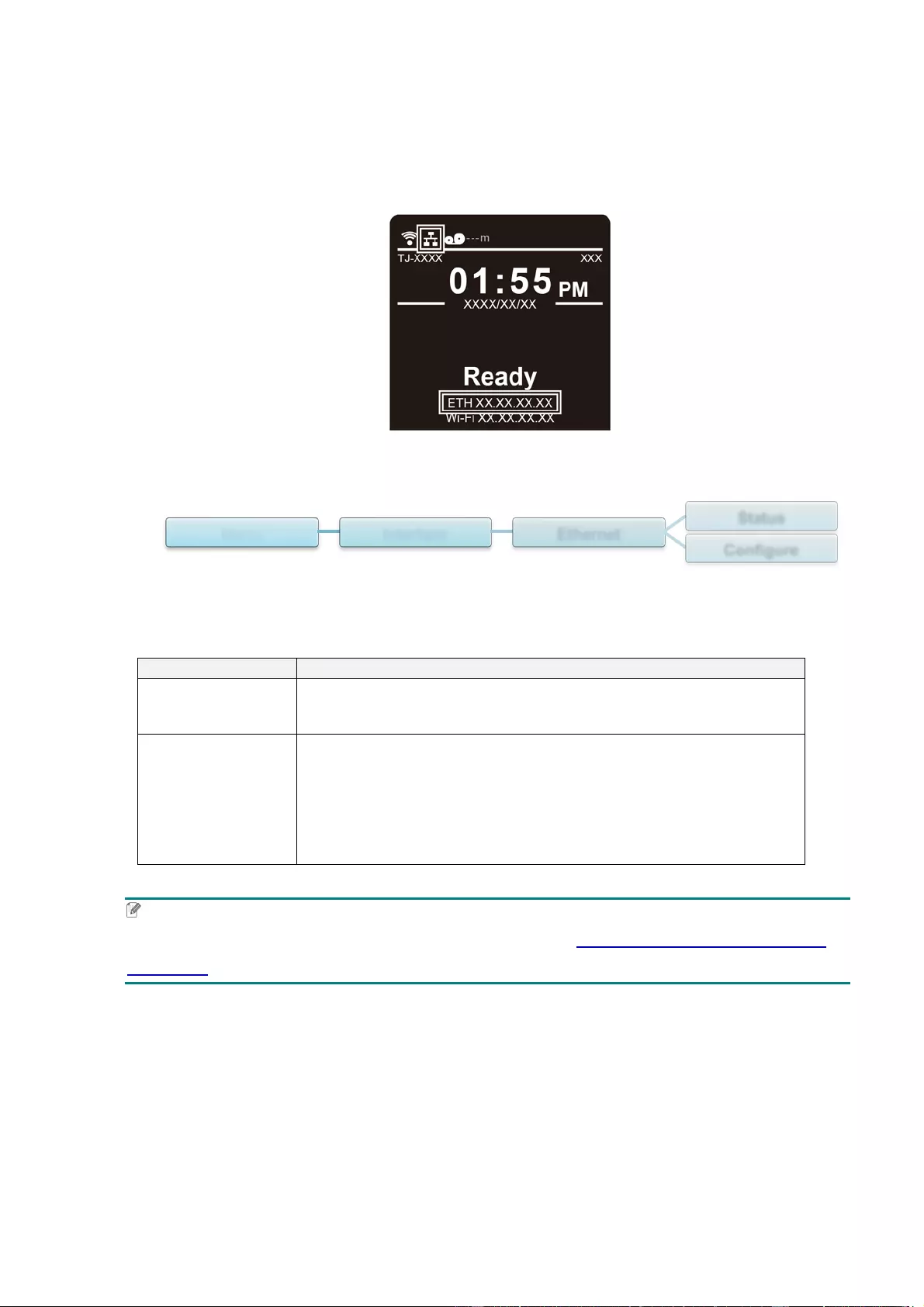

7.3.2 Ethernet Settings

Configure your printer's Ethernet (wired) connection and check its status.

When t he Etherne t is connec ted, the Ether net icon and IP address appear on the

Touchscreen as shown bel ow.

Item

Description

Status Chec k the Ether net IP address an d Mac address setting status.

Configure

DHCP:

Enable (On) or disable (Off) the Dynamic Host Configuration

Protocol (DHCP) network protocol.

S tat ic IP:

Set th e pr i nter ’ s IP ad dr ess, subn et m ask , and ga teway .

Note

For information about installing a printer driver, see section 5.1.3 Wired Network Connection

(Windows).

Menu Interface Ethernet Status

Configure

58

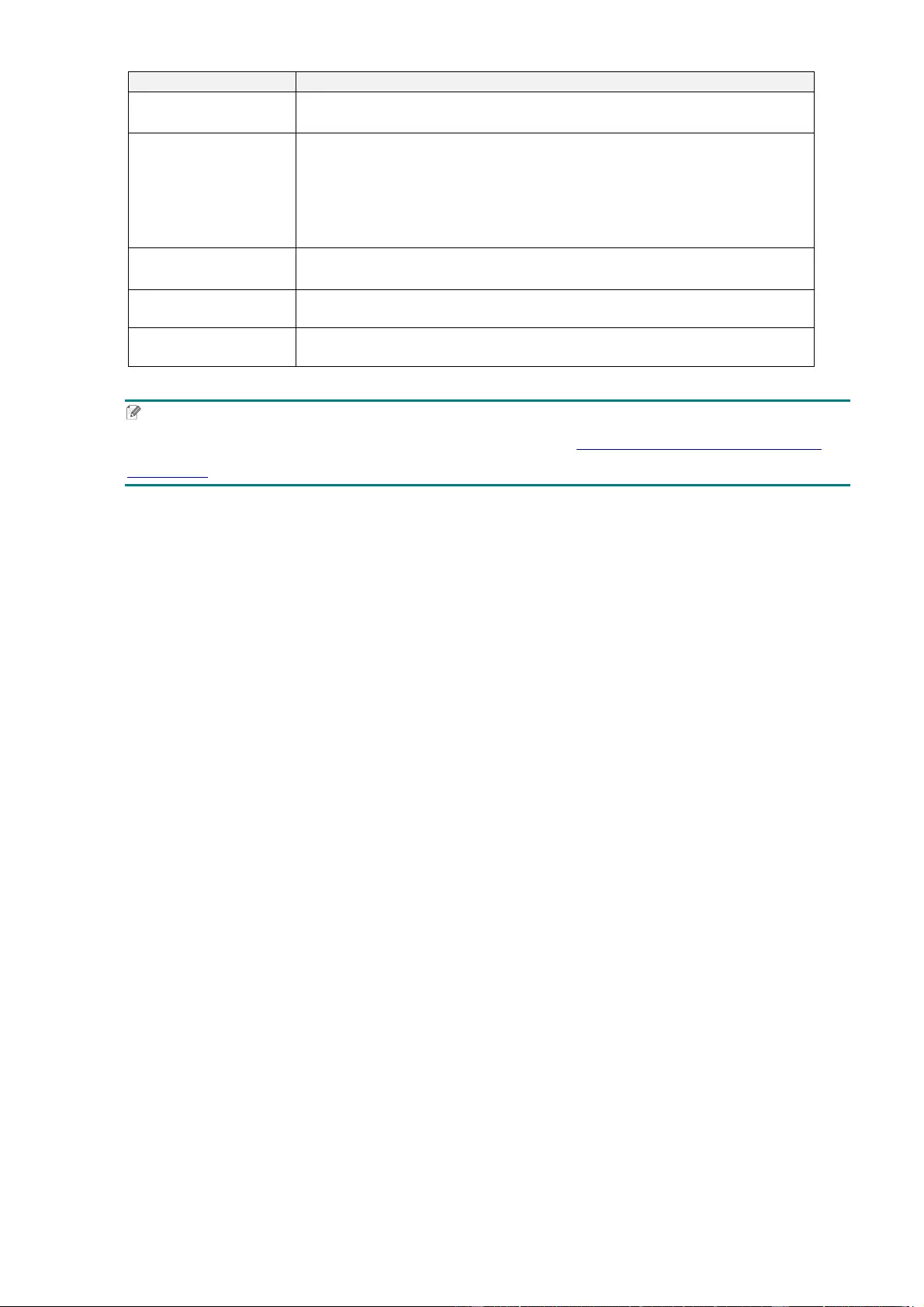

7.3.3 Wi-Fi Settings

Note

To us e Wi -Fi, the opt ional Wi -Fi Interface (PA-WI-002) is required.

Configure your printer's Wi-Fi connection and check its status.

To use t his fea t ur e , s et up the Enterprise configuration using th e B rother Printer

Management Tool (BPM). For more information on setting Wi-Fi using the BP M, see the

Brother Printer Management Tool Quick Start Guide on your model's Manuals page at

support.brother.com.

When the Wi-Fi Interface is connected, the Wi-Fi icon and IP ad dr ess appear on the

Touchscreen as shown bel ow.

Note

M ak e sure both your wireless router/access point's and your printer's network settings are

corr ectly se t u p. For more infor m ation, see the documentation pr ovided with your w ireles s

router/acces s p oi n t, or co ntac t t h e r o uter m a n u f actur er, y o ur sy stem admi nistrat or , or Inter net

servi ce provi d er.

Menu Interface Wi-Fi

Status

Configure

SSID

Security

Password

59

Item

Description

Status Check the Wi-Fi IP address and Mac address setting status.

Configure

DHCP:

Enable (On) or disable (Off) the Dynamic Host Configuration

Protocol (DHCP) network protocol.

S tat ic IP:

Set the printer’s IP address, subnet mask, a nd gatew ay .

SSID Set the SSID (Network Name).

Security Select the Wi-Fi encryption.

Password Set the pas sword (N e tw or k Key) .

Note

For information about installing a printer driver, see section 5.1.2 Wi-Fi Network Connection

(Windows).

60

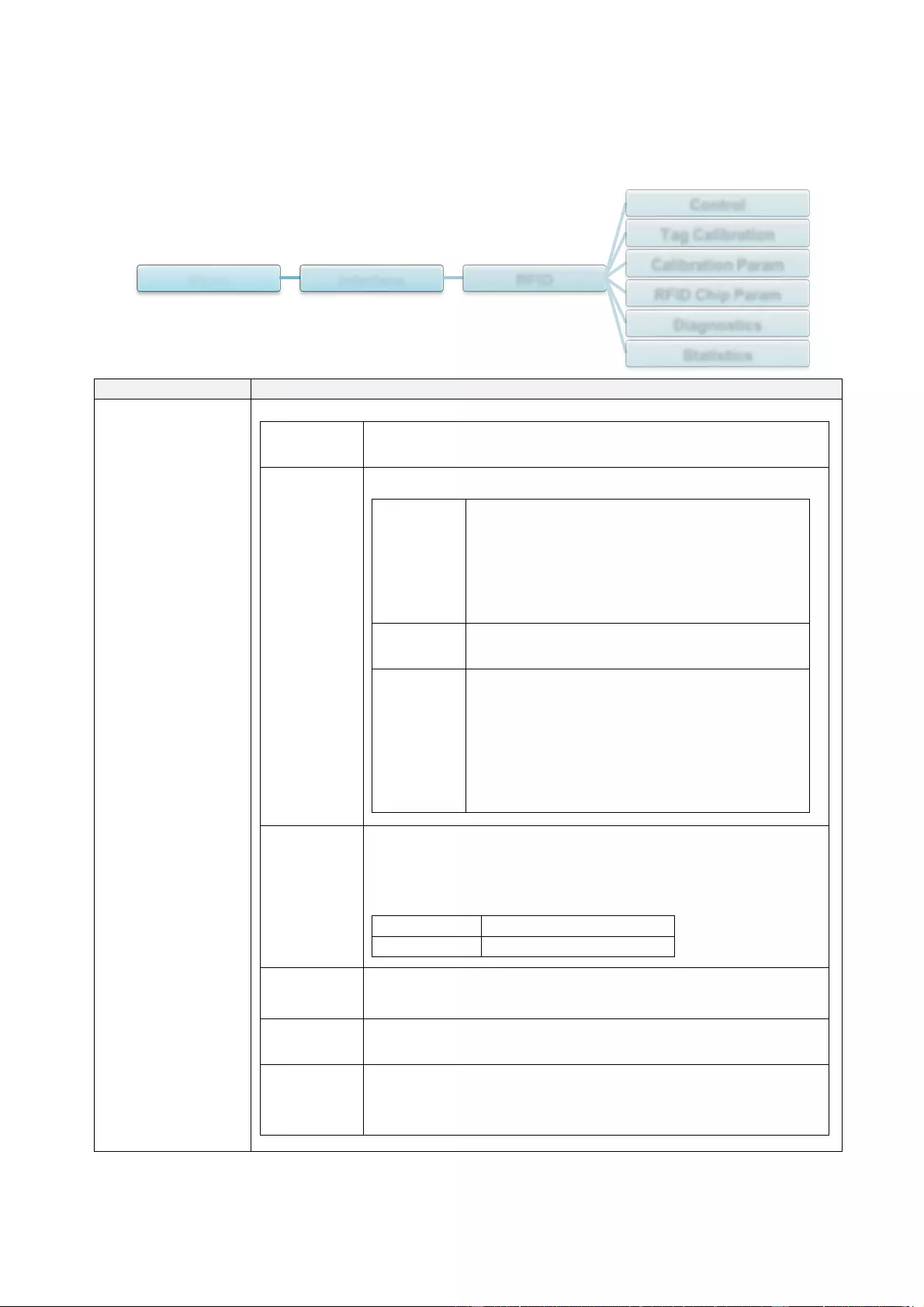

7.3.4 RFID (Radio Frequency Identification) Settings

(Av ai lable for TJ-4021 TNR and TJ-4121TNR only)

Set th e pr i nter RFID settings.

Item

Description

Control

RFID

Active

Select “Enable” to en abl e th e R F I D enco d er m o dule.

Error

Handling Select the error handling mode for RFID errors.

Overstrike

(Default) Each incor r ectly pr ocess ed label prints with

the Overstrike

pattern, and the form retries

on a new l a bel un t i l the Label R e tr y

cou nt i s

exh aust ed. Whet her an error mes s age

appears or the label gets reprinted

depends on the Max Ret ry Error

setting.

None No specific act i o n is taken whe n a tag fails

to be

programmed.

Stop

The pr i nt er wil l

halt and display the error

message “RFID Error: Check Media”. T he

label is di sc ar d ed a nd re pr i nti n g of t h e l a bel

must be

ini ti at ed from th e hos t . When th e

error is cleared, the label with the

incorrect

tag mov es for w ar d un ti l the nex t label is in

posit ion to be

printed.

Label

Retry Specifies the number of label retries that the RFID

encoder

will attempt before declaring a fault. This may indicate a

problem with the RFID encoder, the printer s etup, or th e

label st ock.

Minimum

1

Maximum

10 (Default)

Max Retry

Error Determines i f errors occur when the Label Retry count is

exceeded.

EPC Write

Ctrl

Controls how the printer encodes the RFID tag EPC

field.

Non-RFID

Warning Di s play s a war ni ng if the printer receives a print job that

does not contain any RFID commands when RFID media is

installed in the printer.

Menu Interface RFID

Control

Tag Calibr ation

Calibration Param

RFID Chip Param

Diagnostics

Statistics

61

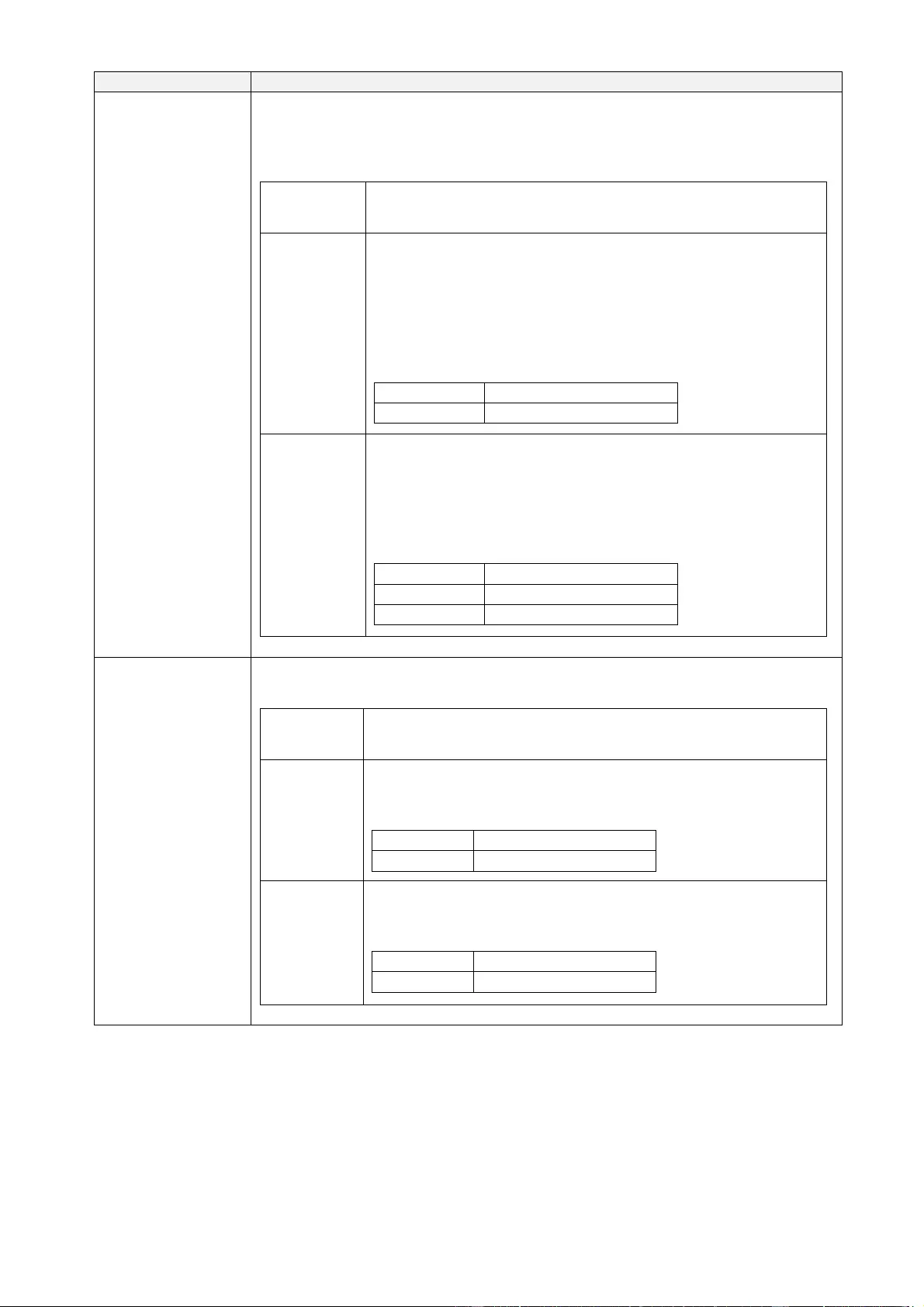

Item

Description

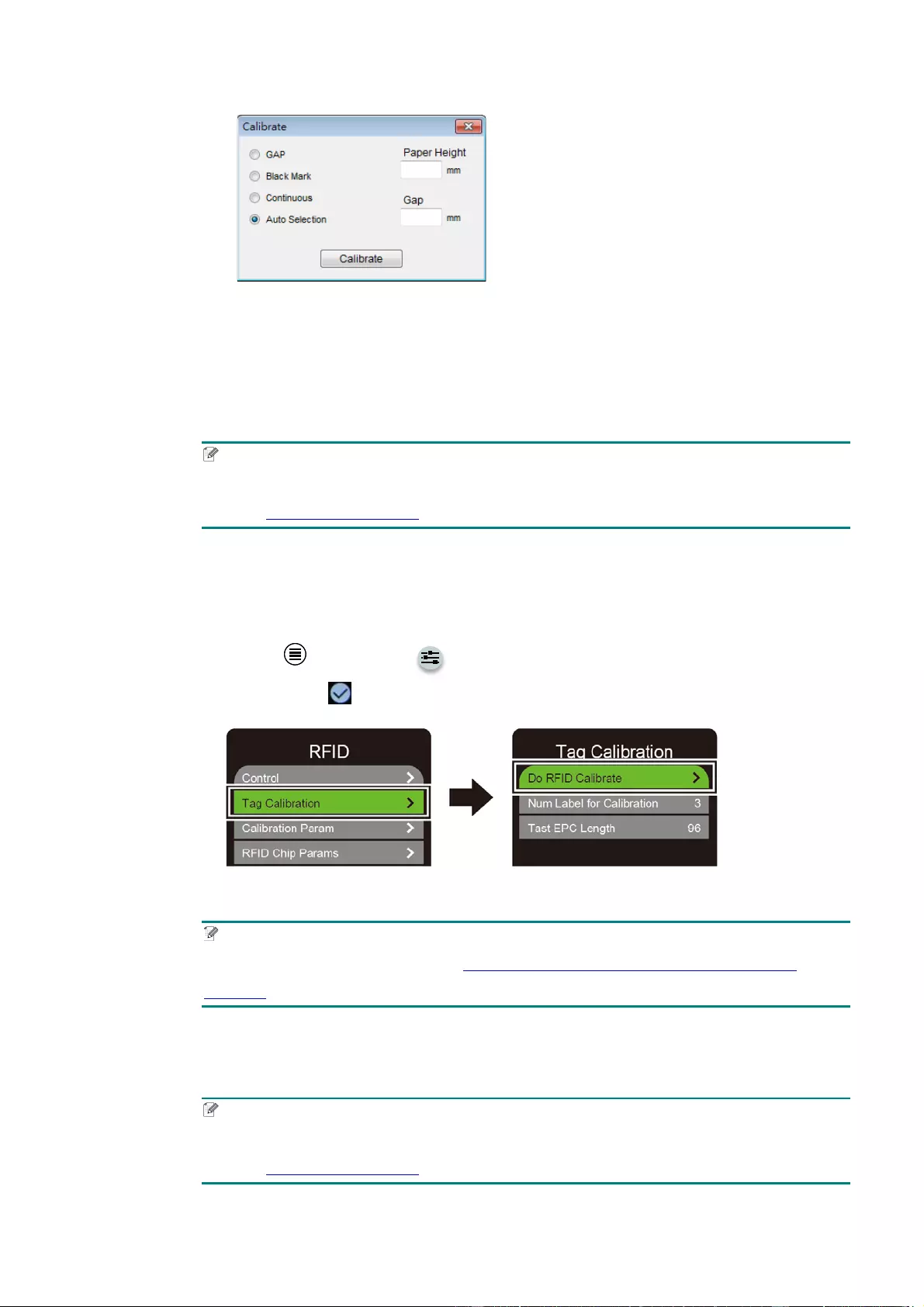

Tag Calibration

This submenu is used to perfor m an RFID calibration. You must perform a

tag calibration when installing a new tag in the printer. RFID calibration

determines the RFID chip type, the write/read power, program position, and

the length of the EPC/User field.

Do RFID

Calibrate Performs the RFID ca libration.

Execute it ev er y time you change the R FID tag type .

Num Labe l

for

Calibration

Determines the num ber o f tags to use for c ali br a t i on.

However, this value does not include tags moved when

seeking gaps during the calibration process. Depending on

the diffic ul ty in cal i brating t he install ed ta gs , t h e pr inter may

use more or fewer labels, but generally, the greater the

number selected in this menu, the more tags will be used

to determine the calibration result.

Minimum

3 (Default)

Maximum

7

Test EPC

Length Determines the size of the EPC data that will be used to

perform the RFID calibration. This length can be i ncr eased

to improve the accuracy of the RFID cali br at ion, but it

sho ul d no t be in c r eas ed to a val u e gr eater than the

maximum EPC length that the current Tag Type can

support.

Minimum

16

Maximum

256

Default

96

Calibration

Param

Contains the settings use d for opt im al tag encodi n g. T hese parameter s c a n

be obtained automatically through RFID calibration.

Tag

Position Determines how far the RFID tag encoding position of the

currently installed tag should be offset from Top of Form.

Write

Power Specifies the write power level to be used in the RFID

encoder. Normally, this value is set automatically by the

RFID calibration process and should not be changed.

Minimum

1

Maximum

30

Read

Power Specifies the read power level to be used in the RFID

encoder. Normally, this value is set automatically by the

RFID calibration process and should not be changed.

Minimum

1

Maximum

30

62

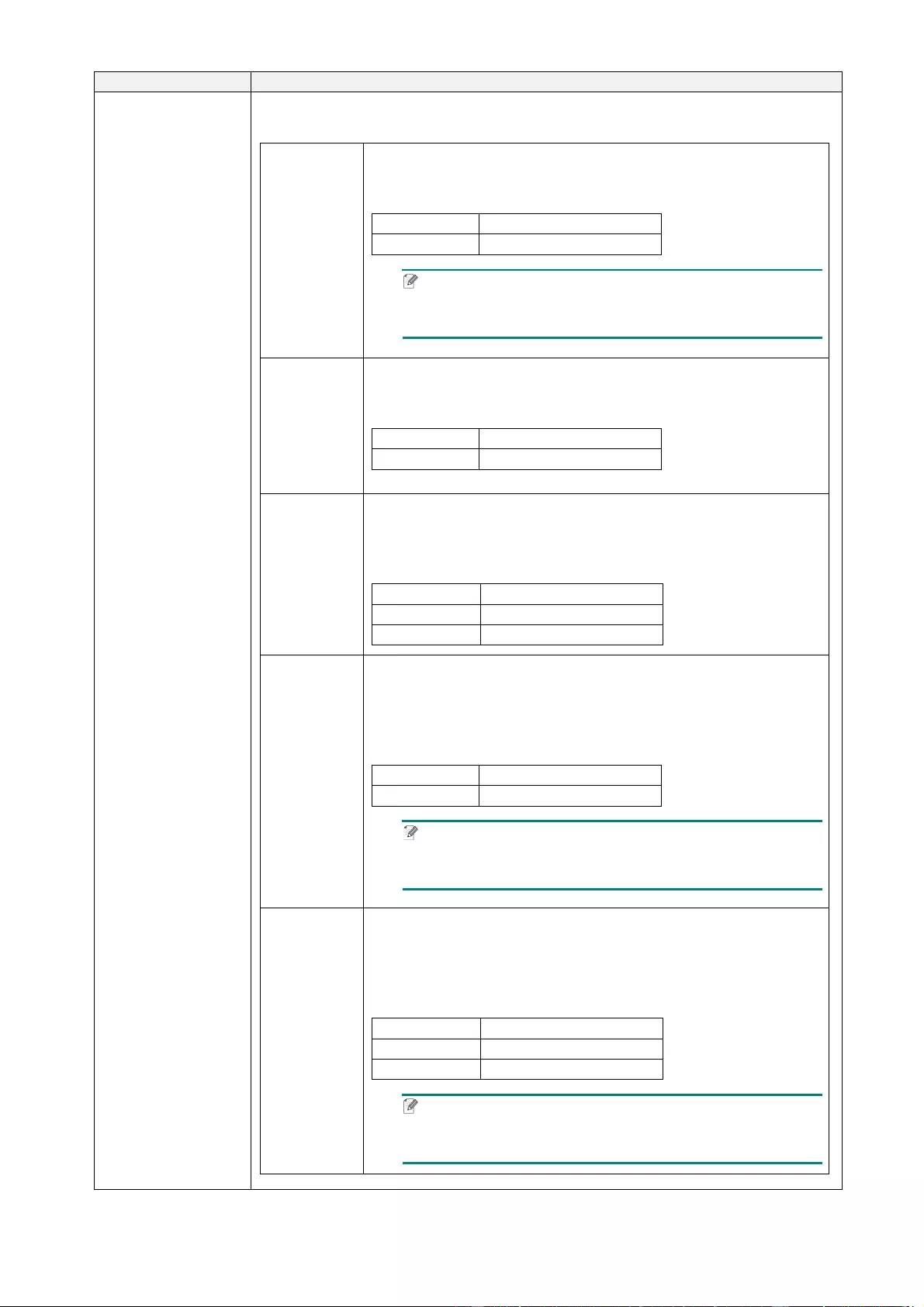

Item

Description

RFID Chip Param

These s ettings ar e us e d to c onfig ur e t h e sy stem whe n custom RF I D ta gs ar e

required.

USR Size Specifies t he U SR block b y t es siz e w i t hin th e R F I D ta g

memory. Normally, this value is set automatically by the

RF I D calibrati o n process an d sh oul d n ot be ch a n ged.

Minimum

0 (Default)

Maximum

256

Note

This value is hidden if Higgs 3 tags are detected , and

the Higgs 3 USR Len menu is shown instead.

USR

Address Specifies the starting location of the USR block wi thin the

RF ID tag memory. Normall y, t hi s v alue i s se t a ut omatical ly

by the R FID cali brati on pr ocess and should not be changed.

Minimum

0 (Default)

Maximum

32

TID Size Indicates the size of the memory block within the RFID tag

memory that contains the Tag ID. Normally, this value is set

automatically by the RFID cali bration process and shoul d

not be changed.

Minimum

0

Maximum

12

Default

8

Higgs 3

USR Len Hig gs 3 t ags dif fer fr om oth er R FI D t ag s i n th at their memory

bank size is not fixed. To accommodate EPC lengths longer

th a n 9 6 bi ts, Hig gs 3 b or r ows memory fr om the U S R ba nk.

This read-only menu indicates the size in bits of the USR

block within the RFID tag memory.

Minimum

128

Maximum

512 (Default)

Note

Thi s me nu wil l o nl y b e show n i f a H i g gs 3 ta g is

detected.

Higgs 3

EPC Len Hig gs 3 t ags di ffer fr om ot h er RF ID t ags i n th at their memory

bank size is not fixed. To accommodate EPC lengths longer

th a n 9 6 bi ts, Hig gs 3 b or r ows memory fr om the U S R ba nk.

This menu item allows you to select the numb er o f bi ts

dedicated to the EPC block w it hin the RF ID tag memo ry.

Minimum

96

Maximum

480

Default

96

Note

This menu will only be shown i f a H iggs 3 ta g i s

detected.

63

Item

Description

RFID Chip Param

Tag

Length Specifies the EPC block bytes size within the RFID tag

memory . This v alu e is set autom at icall y by t he R FID

calibration process and shoul d not be cha nged.

Minimum

8

Maximum

64

Default

12

Note

This value is hidden if Hi ggs 3 tags are detected, and

the Higgs 3 EPC Len menu is shown instead.

EPC

Address Specifies the st arting location of the EPC bloc k within the

RF ID tag memory. Normall y, t hi s v alue i s se t a ut omatical ly

by the R FID cali brati on pr ocess and s ho uld n ot be c h an ged.

Minimum

0 (Default)

Maximum

32

Blo ck Size Specifies the maximum number of bytes written to the USR

block within the RFID tag memory at one time. Normally,

this value is set automatically by the RFID calibration

process and should not be changed.

Minimum

0

Maximum

32

Default

8

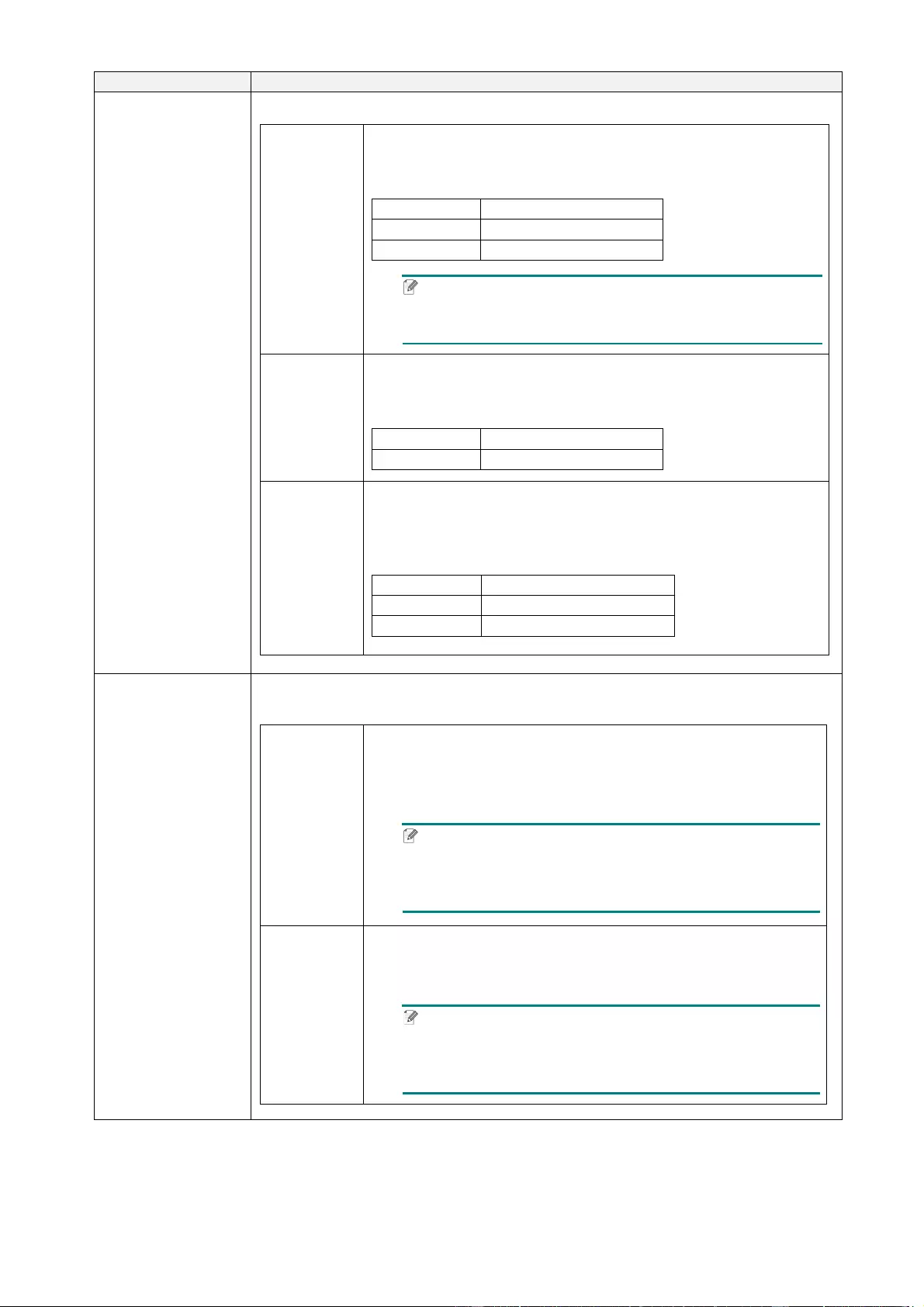

Diagnostics

These settings are used to run test procedures to help determine the

accuracy of the RFID system and troubleshoot it.

Read Tag Reads the tag in ra nge of the int ernal RFID coupler and

rep orts the t a g d ata to th e d ebug p or t and di spl ays it o n t he

Touchscreen. It is primarily intended for development

verification by checking that the system is working.

Note

This setting does not position the RFID tag over the

co upler . M ake sur e to pos it ion the t a g over t he coupl er

to re ceive an acc urat e r e adin g.

Read Tag

& Ejec t This setting wor k s e x a c tl y t h e s ame as Read Tag, exce pt

that after the printer reads the tag, it feeds the label to the

n e xt top -of-form.

Note

This setting does not position the RFID tag over the

co upler . M ake sur e to pos it ion the t a g over t he coupl er

to re ceive an acc urat e r e adin g.

64

Item

Description

Diagnostics

Read USR

Reads the User Memory bank of the tag in range of the

inter n al RFID cou pler and r e por ts the da ta to t h e d eb ug

port and displ ays it on th e Touchscreen. It is primarily

inte nded for develo pm ent verification by chec king that the

system is working.

Note

This setting does not pos ition the RFID tag ove r the

co upler . M ake sur e to pos it ion the t a g over t he coupl er

to re ceive an acc urat e r e adin g.

Read TI D Reads th e T ag I D ( T I D) from t he ta g i n r ang e o f the

internal

RF ID coupl er and dis plays the v alue read i n the Tag ID

menu.

Note

This setting does not position the RFID tag over the

co upler . M ake sur e to pos it ion the t a g over t he coupl er

to re ceive an acc urat e r e adin g.

Tag ID Displays the first Tag ID (TID) r ea d s inc e po w er -up, or if

using the Read TID menu, the most recently read TID. If no

tag is in range of the inter nal RFID coup ler, “Un known”

appears on the Touchscreen.

Read PC Re ad s t h e PC (Pr otoc ol Con t r ol) fi eld fr om an RFID t ag in

range of the internal RFID coupler and displays the value

read in the Tag PC menu.

Note

This setting does not position the RFID tag over the

co upler . M ake sur e to pos it ion the t a g over t he coupl er

to re ceive an acc urat e r e adin g.

Tag PC Displays the last PC (Protocol Control) field read from an

RFID tag. If no tag i s in range of the int ernal RFID couple r,

“U nknow n” ap p ears o n t h e Touchscreen.

Write EPC

with 1s Writes all ones to the tag in range of the in ternal RFID

coupler. It is primarily intended for development verification

by checking that the system is working.

Note

This setting does not position the RFID tag over the

co upler . M ake sur e to pos it ion the t a g over t he coupl er

to re ceive an acc urat e wr iti ng .

Write EPC

with 2s Writes all tw os to the tag in range of the internal RFID

coupler. It is primarily intended for development verification

by checking that the system is working.

Note

This setting does not position the RFID tag over the

co upler . M ake sur e to pos it ion the t a g over t he coupl er

to re ceive an acc urat e wr iti ng .

65

Item

Description

Statistics

These settings are gener al l y read-only and used to collect and report

statistics on how the RFID system is reporting on print jobs sent to the

printer.

Tag Write

Count Displays the number of tags attempted to be written since

the last Cl ear Tag Stat operation has been initiated.

Tag Failed

Count Di splays t h e numb er o f fai led RF ID t a gs sin c e t he l as t Clear

Tag Stat ope r ation ha s been initiated.

Tag Read

Count Displays the number of tags read since the last

Clear Tag

Stat operation.

Clear Tag

Stat Clears the Coun t me nu i tems in this submenu.

RFID

Reader

F/W

(Avail a ble for TJ-4021TNR and TJ-4121TNR only)

Di splays t h e R FID fir m ware v ers io n inst al led i n the enc o d er .

RFID

Reader

Hd/W

(Avail a ble for TJ-4021TNR and TJ-4121TNR only)

Displays the RFID hardware version installed in the

encoder.

66

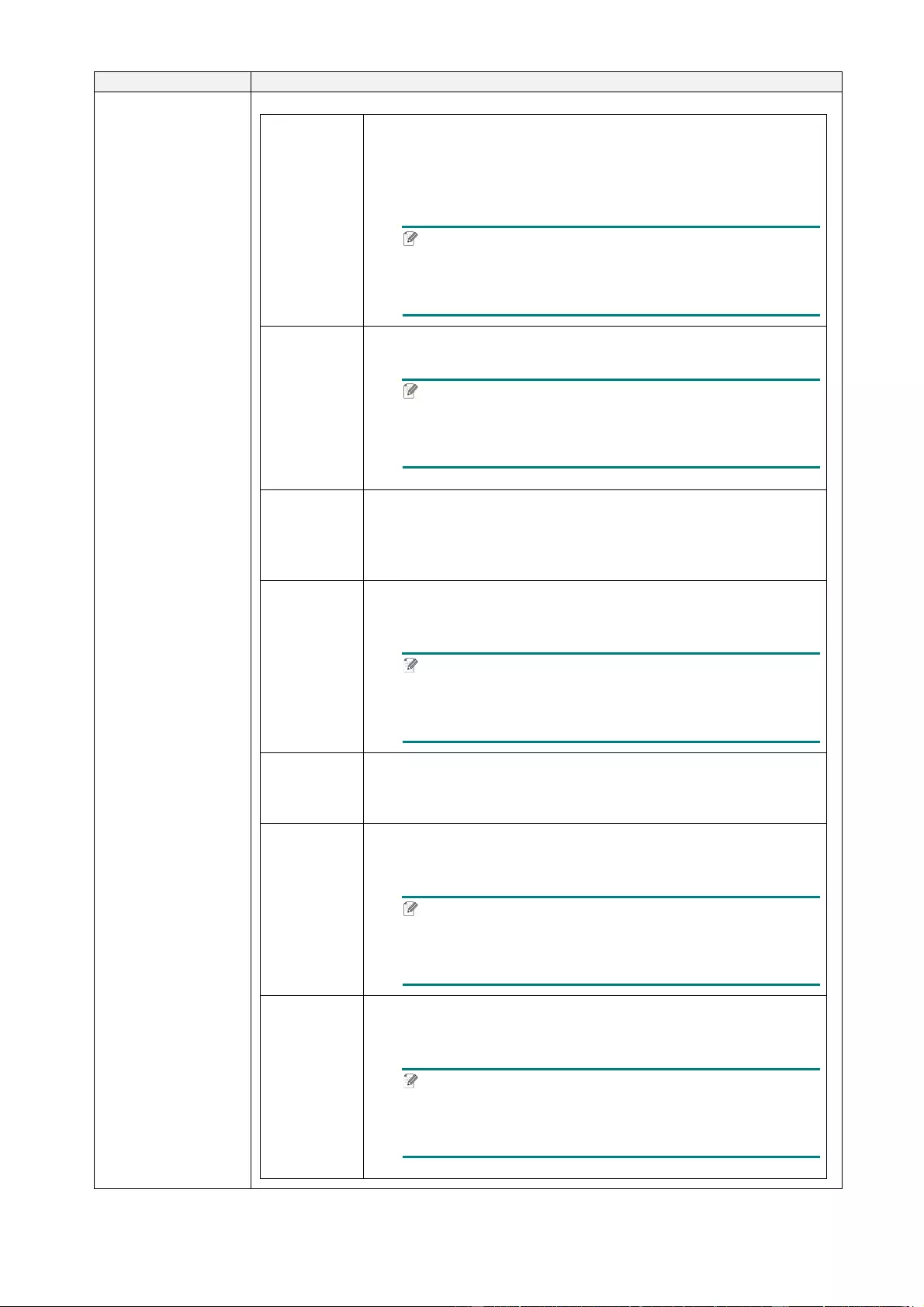

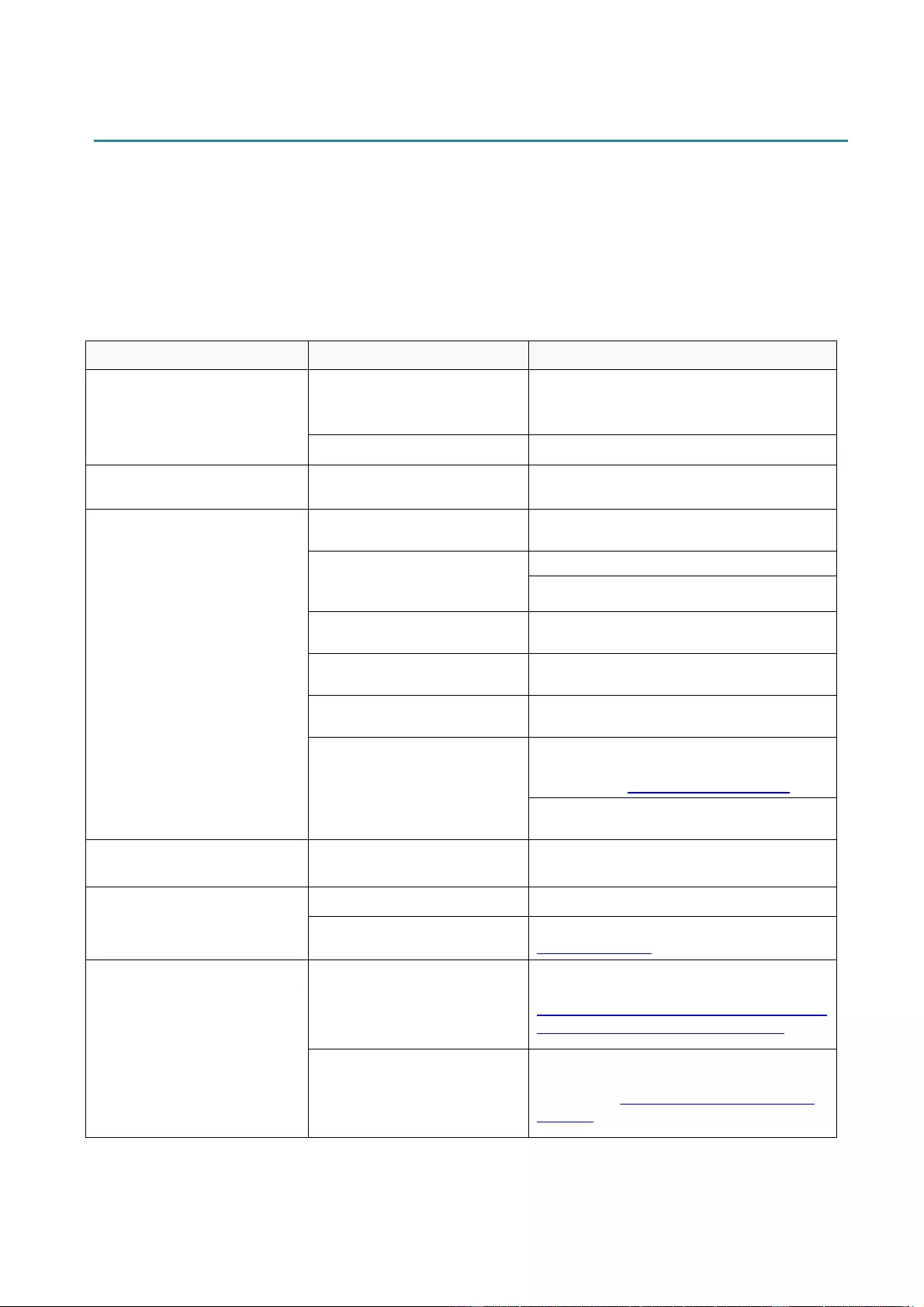

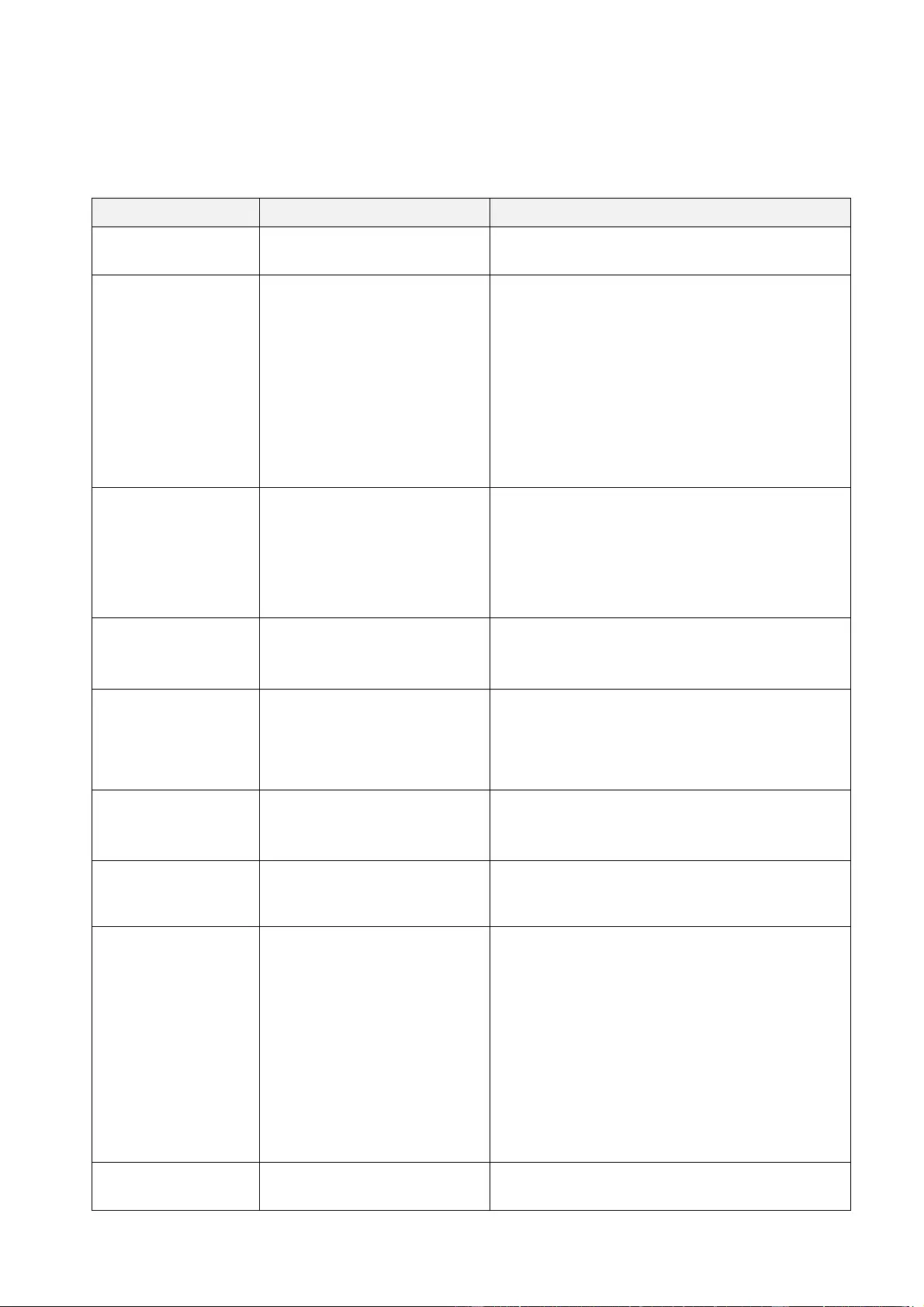

7.4 Advanced Settings

Item

Description

Language Specify the Touchscreen language.

Printer

Information

Check the printer serial number, printed mileage (in./m), number o f

printed labels (pcs), an d cut ting co unt er .

Initialization Restore the pr i nt er se tti n gs to the default settings.

Display

Brightness Adjust the Touchscreen brightness (setti ngs range fr om 0 t o 100 ).

Touchscreen

Calibration Calibrate the Touchscreen.

Date & Tim e Adjust the da te a nd t im e displayed on the Touchscreen.

Security Set the pas swor d for locking the m en u or favorites. The defau lt

password is 88 88 .

Cutte r Type Set the Cutter Type.

Media Low

Warning Set the M edi a Low War ning message.

Menu Advanced

Language

Print e r Infor m a t ion

Initialization

Display Brightness

Touchscreen Calibration

Date & Time

Date Format

Date

Time Format

Time

Security Menu Loc k

Menu Password

Cutter Type

Media Low W ar ning

Ribbon Low Warning

Printer Head Maintain

Warning

Reset Counter

Interval

Key sound

Contact Us

67

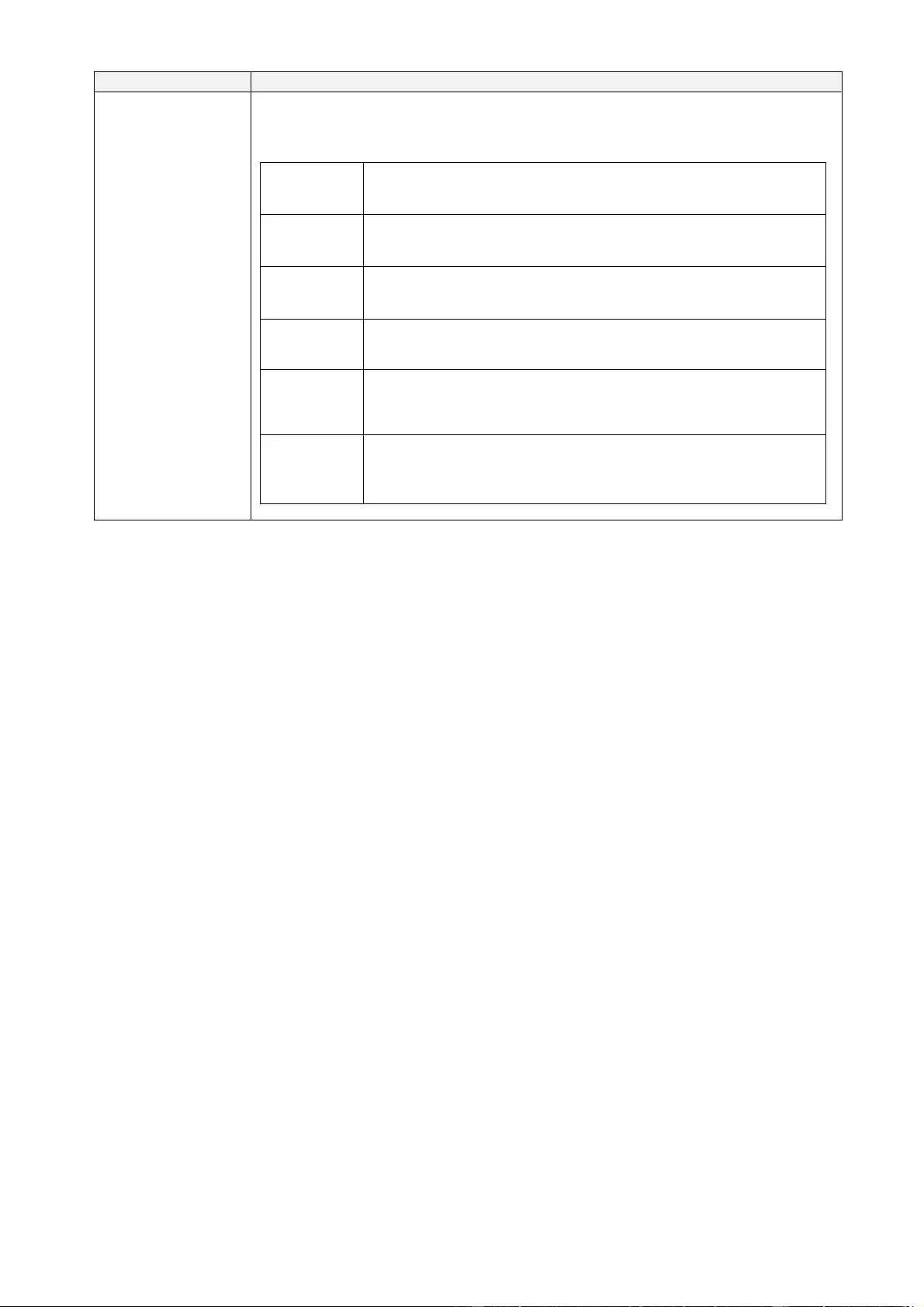

Item

Description

Ribbon Low

Warning

Set the Rib bon Low Warni ng message. For ex ample, if you set the

value at 30 m , when the ribbon capacity is less than 30 m, th e

icon appear s in red.

TJ-4020TN/TJ-4120TN: 30 m (Fixed)

TJ-4021TN/TJ-4021TNR/TJ-4121TN/TJ-4121T NR: 10 m - 10 0 m

(Customisable)

Printer Head

Maintain

Check the Pr int Head sta tus and maintenance notifications.

Item

Description

Warning

Ena ble or di sable the Print Head cleaning warning. If

this setting is enabled and the Print Head has

reached the setting mileage limit, a warning appears

on th e Touchscreen to remind you to clean the Print

Head. The default setting is "Disable".

Reset

Counter Reset the Print Head mileage warning after the Print

Head has be en c leaned.

Interval Set th e mil e age for wh en to di splay t he Print Head

cleaning warning. You must enable the “TPH

warning lock” to use it. The defaul t setting i s 1 km.

Key sound Enable or disable the button press sound.

Contact us Displays a QR code to access the Brother Support website at

support.brother.com using a mob ile device.

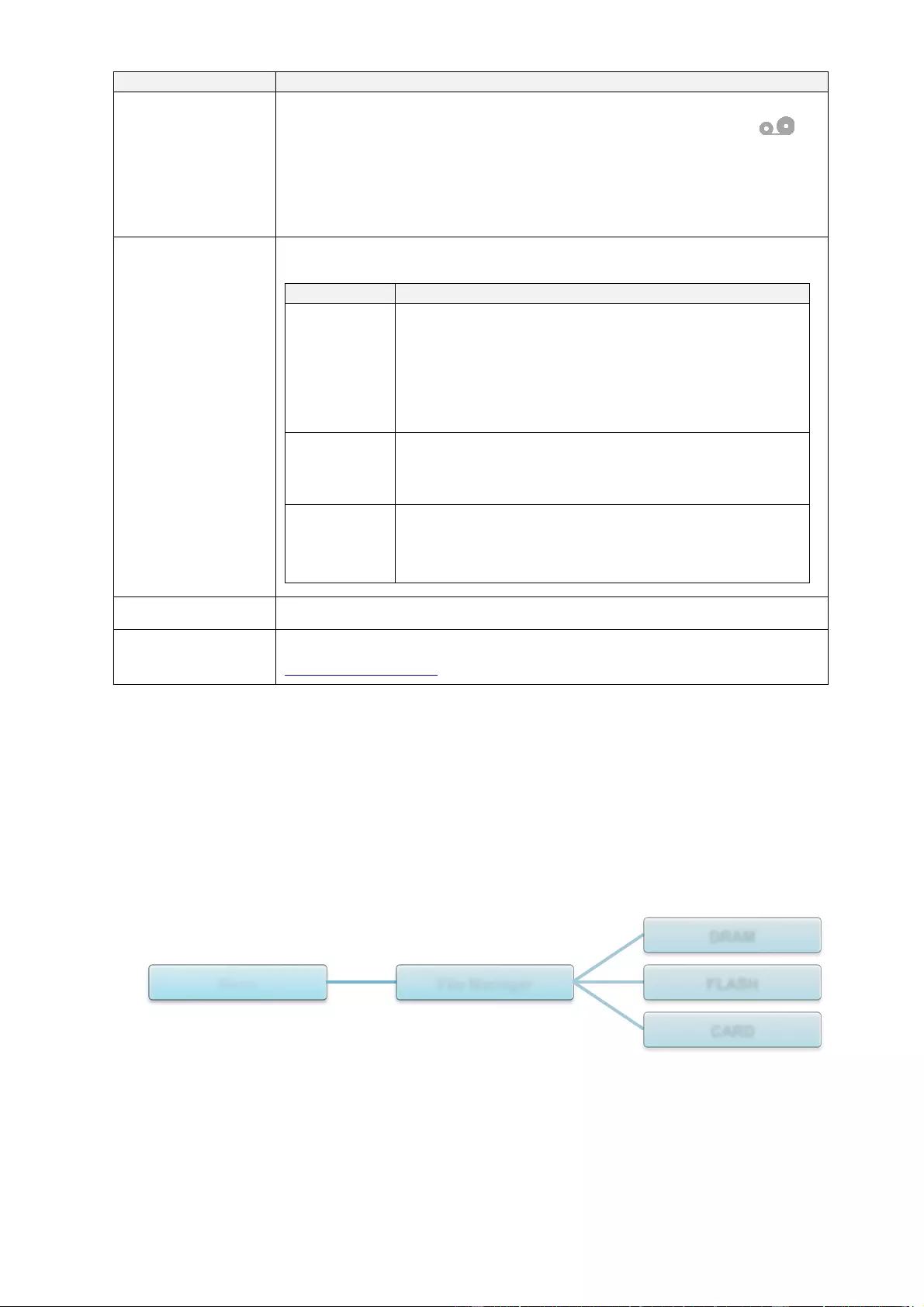

7.5 File Mana ge r

Check th e printer's available memory, show th e files list, delete t he files, or run t he fil es that

are saved in t he printer's DRAM/Flash/Card memory.

Menu File Mana ger

DRAM

FLASH

CARD

68

7.6 Diagnostic Functions

Item

Description

Print Config.

Print the current printer configuration. On t h e configuration printout, there is

a Print Head test p at tern , w hich is useful for checking if th ere is dot dam age

to the Print Head Heating Element.

For more information, see section 6.1.2 Gap/Black Mark Sensor

Cal i br ati o n, Self-Test, and Entering Dump Mode.

Dump Mode

Captures the data f rom the communications port and prints out th e data

rec eiv e d by the printer. In the Dump Mode, all characters will be printed in

two columns. The characters in the left column are received from the

printer's system and those in the rig ht col um n are thei r hexadec i m al

representation. It a llows you to verify and debug the program.

For more information, see section 6.1.2 Gap/Black Mark Sensor

Cal i br ati o n, Self-Test, and Entering Dump Mode.

Note

Dump Mode requires 101.6 mm paper width.

Print Head Check f or any visi bl e do ts an d the Print Head's temperature.

Display Check the Touchscreen color state.

Sensor Check the sensors’ intensity and reading state.

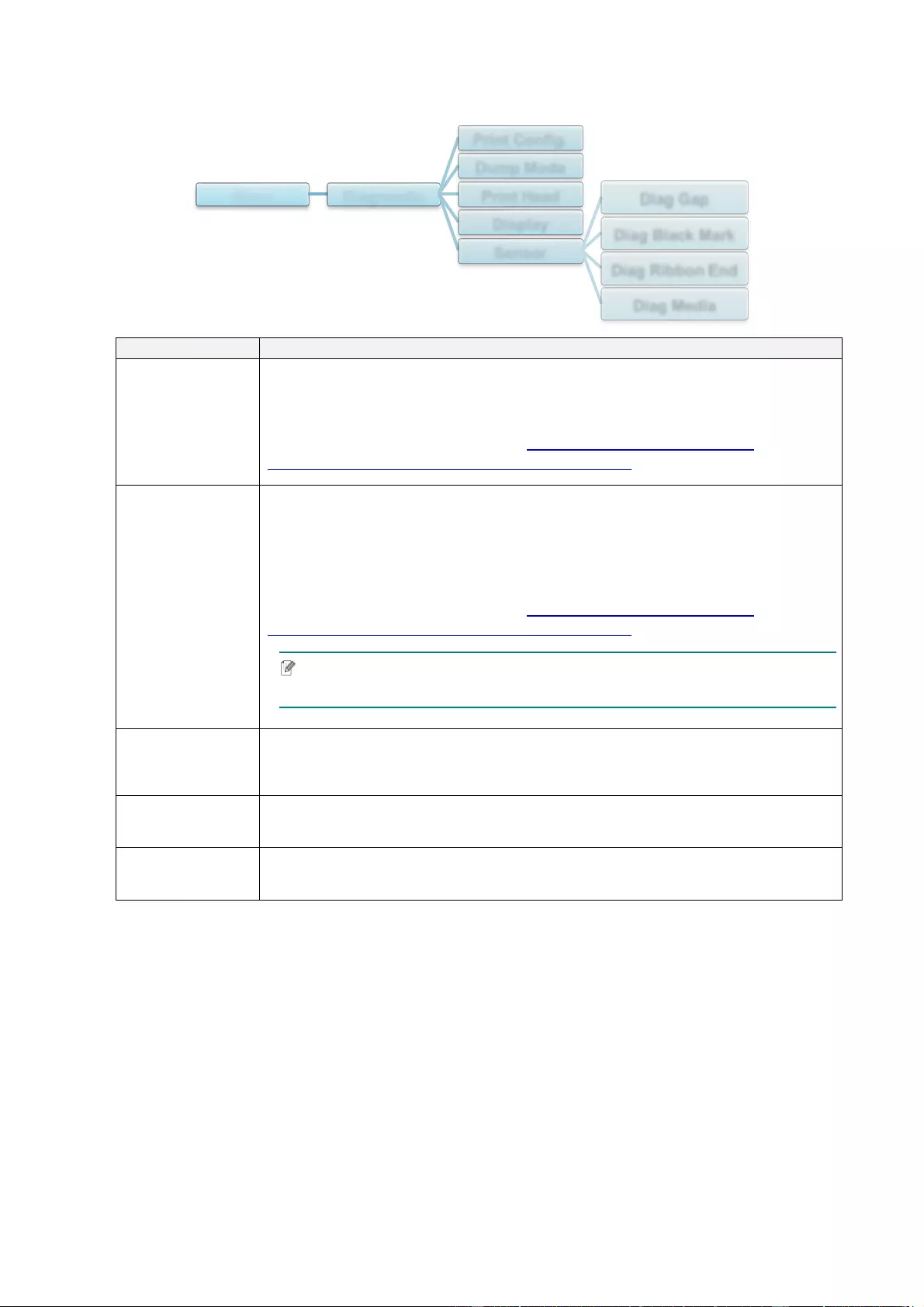

Menu Diagnostic

Print C onfig.

Dum p Mode

Print Head

Display

Sensor

Diag Gap

Diag Black Mark

Diag Ribbon End

Diag Media

69

8. Brother Printer Management Tool (BPM)

The Br ot her Pr i nter M anag em e nt Tool (BPM) is an integrated tool that lets you:

Check a pri nter’ s sta tus an d set tings

Change printer settings

Sen d ad di ti o nal com m a nds to a pri nt er

Dow nl o ad gr a phi cs and fo nts

Create a printer bitmap font

Dow nl o ad an d up date firm w are

Configure Wireless LAN (Wi-Fi)

Using this tool, you can also review your printer's status and settings to troubleshoot any

problems.

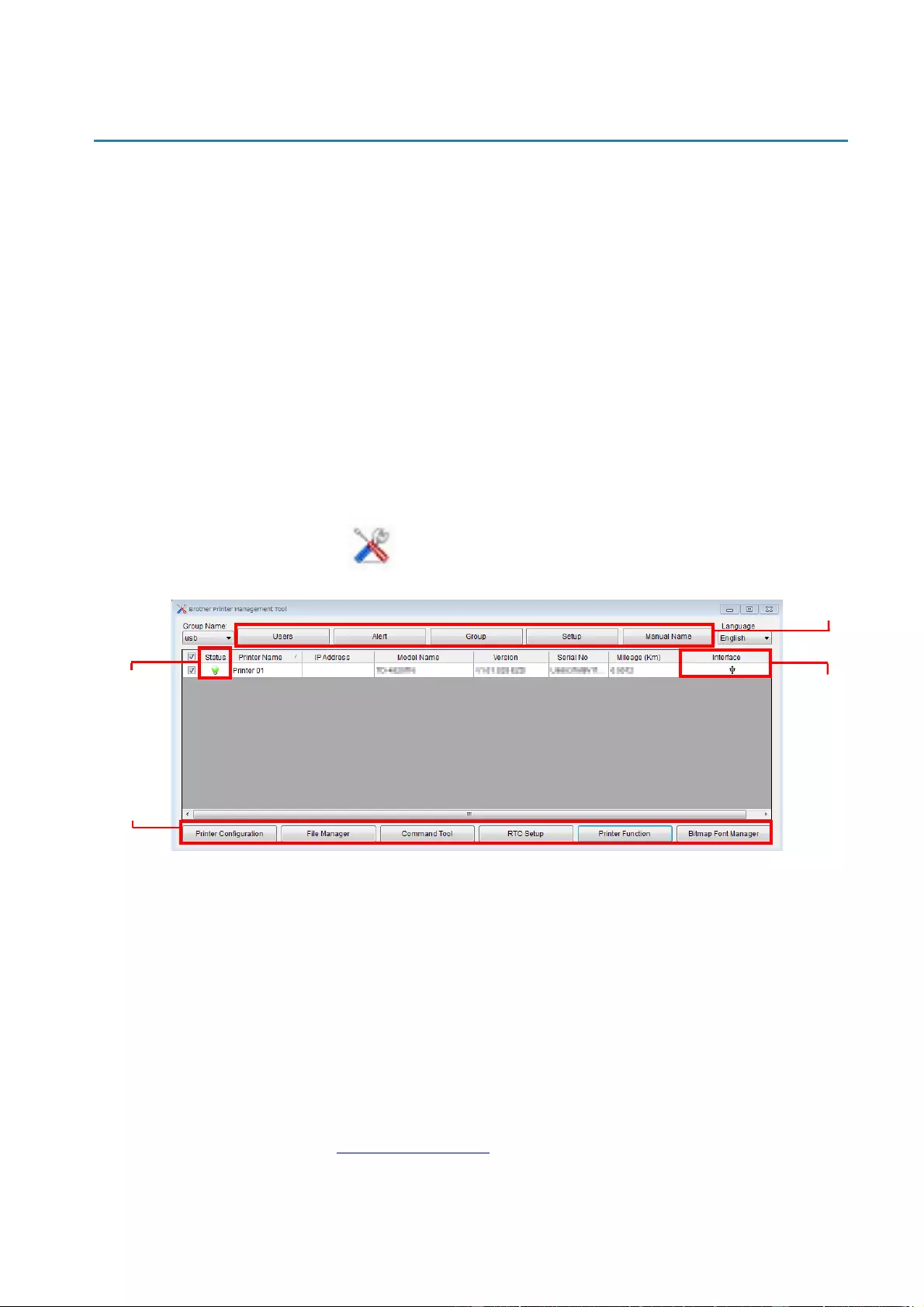

8.1 Start the BPM

Double-click the BPM icon to start the software.

The BPM's main screen allows you to access the following options:

Printer Configuration

File Manager

Command Tool

RTC Setup

Printer Function

Bitmap Font Manager

For more information, see the Br other Pr i nter M an ag em en t Tool Quick Start Guide on your

model's Manuals page at support.brother.com.

Features

Buttons

Interface

Type

Printer

Status

Configuration

Buttons

70

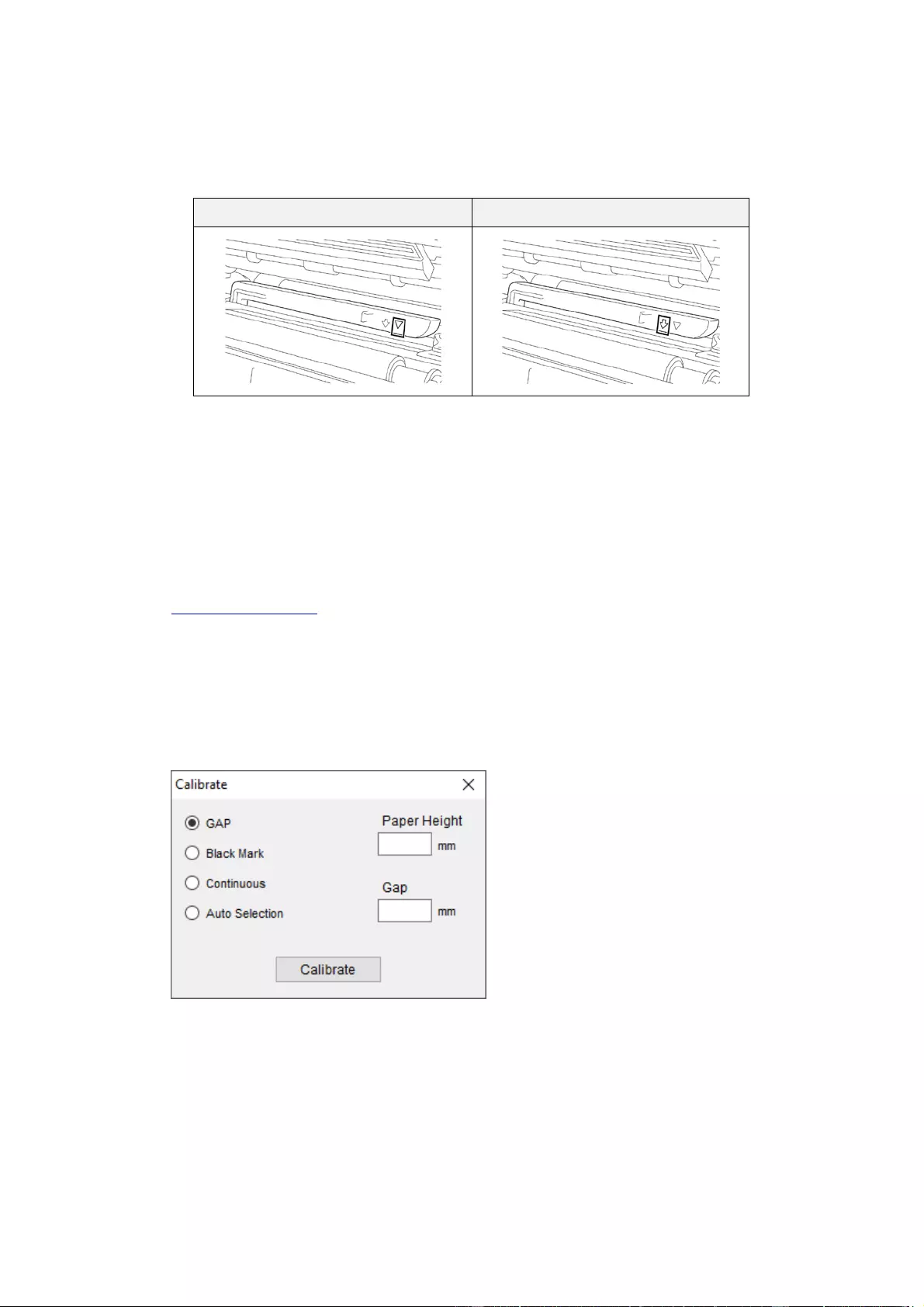

8.2 Auto-Calibrating the Media Sensor using the BPM

Use the BPM to set t he m edia se nsor ty p e ( Gap Sens or or B lack Mark Se nsor) an d c al ibrate the

selected sensor.

Gap Sensor B l ack M ar k Sen s or

The Gap Sensor (transmissive sensor) detects the beginning of the label and t h e pr i nt er feeds

the label to the correct position.

The Black Mark Sensor (reflective sensor) detects the mark and the printer feeds the media to

the correct position.

1. Make sure the media is already installed and the Print Head is closed. (See section

3.4 Load the Media.)

2. Turn on th e pri n ter .

3. Star t th e BPM .

4. Clic k the Printer Function button.

5. Click the Calibrate button.

6. Select the sensor media type and click Calibrate.

71

9. Setting Up the RFID

(Available for TJ-4021TNR and TJ-412 1TNR on ly)

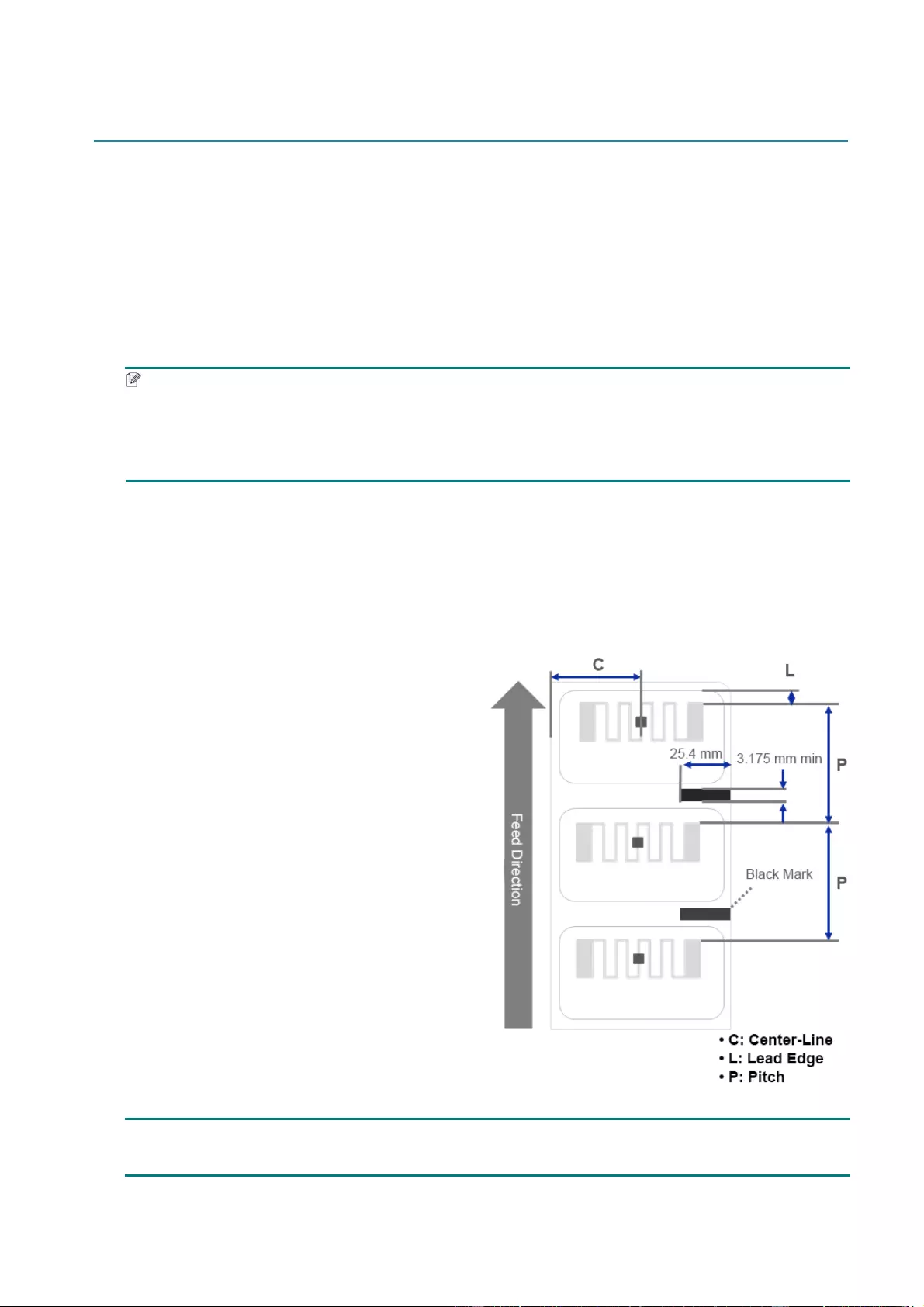

9.1 Introduction

W hen printing smart labels that use an EEPROM technology, the printer may need to write and

verify some RFID tags more than once before accepting them. This additional processing may

result in a short pause between each printed label, but is necessary to ensure consistent quality

and reliability.

Note

St atic electr ici ty can dama g e s m art label s. Be fore yo u h andl e sm art l abel s , op en the pr int er's

M edi a C over and touc h an un p aint e d m etal p ar t to discharge any static electricity that may have

built up on your hands.

This printer is equipped with an Auto-Calibration feature, which eliminates the need to specify

exact inlay placement or RFID power settings. The calibration routine is compatible with most

major inlays embedded in typical label sizes and will work with many oth er inlays as well .

For optimum performance:

Center inlays horizontally across the media

(dimension "C"). Consistent, ta g-to-tag

placement of the inlays is more important than

their proximity to the center.

The pitch is the overall distance from inlay to

inlay (dimension "P"). On-pitch ta gs an d tags

with a pitch less than 25.4 mm may require the

pri nter to back-fe ed dur ing th e encodin g and

printing process, thus slowing the throughput of

the printer. To avoid this, this pitch should be

greater than 25.4 mm.

Set the inlay back from the lead edge of the

media (dimension "L") at the same tag-to-tag

distance. To avoid back-fe edi n g, for l ab el s

longer than 25.4 mm, this di st a nce s h ould be

greater than 12.7 mm.

IMPORTANT

Always test RFID media on your printer before purchasing large quantities of media.

72

9.2 RFID Calibration

The TJ -4021TNR and TJ-4121T N R have a fixe d-position RFID antenna mounted at the Media

Output Slot, which supports a wide variety of tag types.

9.2.1 Load the RFID Media

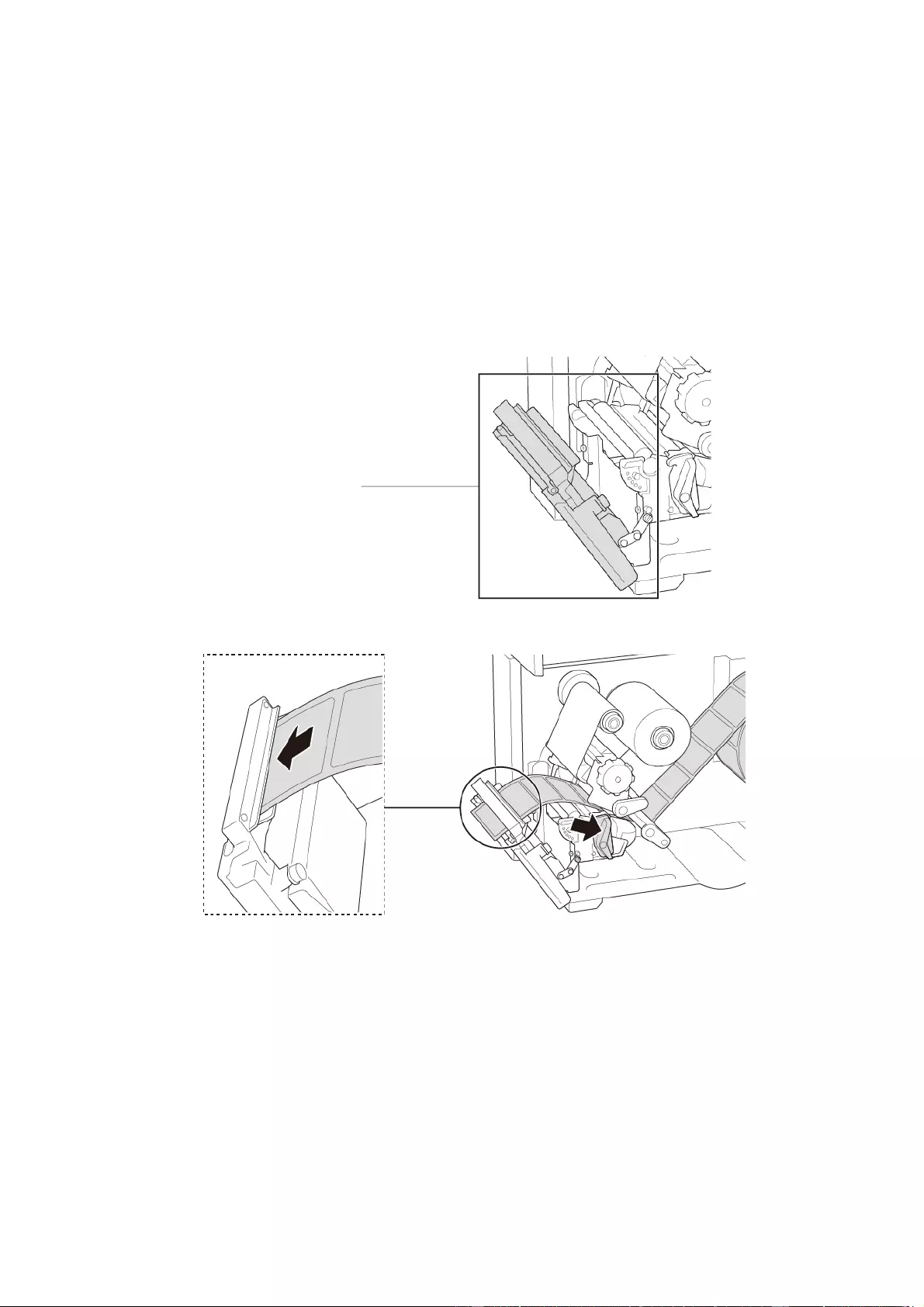

1. Load the RFID media onto the Label Su ppl y Spind l e.

2. Open the Print Head and RFID Tear Cover. Thread the media through the Damper, Media

Sensor, and Front Label Guide to install the media.

3. Feed the RFID media through the Tear Cover Slot.